Craftsman 580752090 Owner’s Manual

Operator'sManual

3408 PSi MAX

2.8 GPM MAX

Model No. 580.752090

®

CUSTOMERHELPUNE

PRESSUREWASHER

HOUriS: Non. - Fri. 8 a.m. to 5 p.m. (CT)

WARmeG

Before usingthis product, readthis

manualand follow atI Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, [L 68179 U.S.A.

Visit our Craftsman website: www.craftsman.eom

Part No. 203780GS Draft A (05/02/2007)

i ]

R, IADVERTENCJA

Antes de utiiizar el producto, iea este

manuaiy siga todas ias Reglasde

Seguridade Instrucciones de Use.

®Safety

®Assembly

®Operation

+ Maintenance

++Parts

+ Espa_oi, p. 36

0 4 } 5

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-11

OPERATION....................................... 12-16

SPECIFICATIONS..................................... 17

MAINTENANCE.................................... 18-22

STORAGE........................................... 23

TROUBLESHOOTING.................................. 24

NOTES............................................. 25

REPLACEMENTPARTS.............................. 26-33

EMISSIONCONTROLWARRANTY..................... 34-35

ESPA_!OL......................................... 36-63

HOWTO ORDERPARTS........................ BACKPAGE

If this pressurewasher faiis dueto a defectin materiai or workmanship within one year from the date of purchase,return it to

any Searsstore, other Craftsman outlet, or SearsParts & Repair Centerin the UnitedStates or Canadafor free repair (or

replacementif repair proves impossible).

Ali warranty coverageapplies for only 90 days from dateof purchaseif this pressure washer is ever usedfor commercial or

rentaipurposes.

This warranty gives you specific legal rights, and you mayalso haveother rights which vary from stateto state.

Sears, Roebuck and Ce,, Heffman Estates, JL6e179

Sears Canada Jnc,, Terente, entarie, Canada MSB 2B8

Thisis the safety alert symbol, tt is used to alert yea to potentialpersenaminjary hazards. ObeyaHsafety messages

that fellow this symbemto avoid pessiMe injury or death.

_Read this manual carefully and become familiar

..... with your pressurewasher. Knew its applications,

Hazard SymhoJsand Nteanings

itslimitations, and any hazardsinvolved.

Thesafety alert symbol (,_) is usedwith a signal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

ToxicFumes HazardousChemical

ElectricalShock

messageto alert you to hazards.BANGERindicatesa hazard

which, if not avoided, wi/'/resuIt in death or serious injury.

WARNINGindicates a hazard which, if not avoided, cou/d

result in deathor serious injury. CAUTIONindicatesa hazard

SlipperySurface

Fall FluidInjection

which, if not avoided, might resultin minor or moderate

injury. NOTIgEindicatesa situation that could result in

equipment damage. Foiiow safety messagesto avoid or

reducethe risk of injury or death.

Fire

Moving Parts

FlyingObjects Kickback Hot Surface

Explosion Operator'sManual

© SearsBrands, LLC

Contentsareharmfulorfatalifswailowed.Avoid

contacttoeyes,skinorclothing.DONOTtake

internaiiy.Avoidbreathingthemistorvapor.

Overexposuretoeyesorskincancauseirritation.

Keepstabilizeroutofthereachofchiidren.

Fueistabiiizerisahazardouschemical.**

", Fresh StartTM fuel cap is designedto hold a cartridge which

contains fuel stabilizer.

o If SWALLOWED,call physician immediately. DONOTinduce

vomiting. If inhaled, removeto fresh air. hscaseof eye or skin

contact, flush with water for 15 minutes.

o Store unopenedcartridges in a cool, dry, well ventilated area.

Keepopen cartridge in fuel cap, and fuel cap c!osed on fuel tank

when not in use.

o hsthe caseof an emergency,contact a physician immediately

and call 1-800-424-9300 for material safety inforrnation.

**Fuel stabilizer contains: 2,6-di-tret-butylphenol (128-39-2) and aliphatic petroleum

distillate (64742-47-8),

WARNING

Runningengine gives off carbon monoxide, an

odoriess, coloriess, poison gas.

Breathingcarbon monoxide can cause headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

Some chemicais or detergents may be harmful if

inhaied or ingested, causing severe nausea,

fainting, or poisoning.

• OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromelsteringaconfinedareathrough

windows,doors,ventilationintakes,or otheropenings.

o DONOTsta!t or runengineindoorsor in anenclosedarea,

evenif windowsanddoorsareopen.

o Usea respiratoror rnaskwheneverthereisa chancethat

vaporsrnaybeinhaled.

• Readall instructionswith masksoyouarecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

WARNING

Fuel and its vapors are extremely flammable and

explosive.

death.

Fire or explosion can cause severe burns or

WHENADDmNGORDRAiNiNG FUEL

• Turn pressure washer OFFand let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly' to relievepressure

in tank.

• Fillor drain fuel tank outdoors.

o DONOToverfill tank. Allow space for fuel expansion.

• Iffuel spills, wait until it evaporates before starting engine.

o Keepfuel away frorn sparks_openflames, pilot lights_heat,and

other ignition sources.

o DONOTlight a cigarette or smoke.

WHENSTARTINGEQUmP_dENT

• Ensurespark plug, muffler, fuet cap, and air cleaner are in

place.

• DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPI_IENT

o DONOTtip engine or equipment at anglewhich causes fuel to

spill.

• DONOTspray flammable liquids.

WRENTRANSPORTmNGOR REPAiRmNGEQUiPI'_IENT

• Transport/repair with fuet tank EMPTYor with fuel shutoff valve

OFF.

• Disconnect spark plug wire.

WHENSTORmNGFUELOR EQUiPIVlENTWiTH FUELmNTANK

o Store away from furnaces, stoves, water heaters,clothes

dryers, or other appliances that havepilot light or other ignition

source becausethey can ignite fuet vapors.

WARNING

Risk of electrocution=

Contact with power source can cause etectric

shock or burn,

• NEVERspray near power source.

WARNING

Starter cord kickback (rapid retraction) can result

in bodily injury. Kickback will pulI hand and arm

toward engine faster than you can Iet go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spray gun

pressure.

o When starting engine_pull cord slowly until resistance is felt

andthen pull rapidly to avoid kickback.

o After eachstarting atternpt where enginefails to run, always

point spray gun in safe direction press red button and squeeze

spray gun trigger to releasehigh pressure.

o Firmly grasp spray gun with both hands when using high

pressure spray to avoid iniury when spray gun kicks back.

WARNING

Useof pressure washer cancreate puddles and

slippery surfaces,

Kickbackfrom spray gun cancause you to fall,

* Operatepressure washer frorn a stable surface.

o The cleaningarea should haveadequateslopes and drainageto

reducethe possibility of a fall due to slippery surfaces.

o Be extremelycareful if you rnust usethe pressure washer from

a ladder, scaffolding, or any other similar location.

o Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARNING

The high pressure stream of water that thb

equipment produces can cut through skin and its

underlying tissues, ieading to serious injury and

_ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• DONOTallow CHILDRENto operate pressure washer.

o NEVERrepair high pressure hose. Replaceit.

• NEVERrepair leakingconnections with sealantof any kind

Replaceo-ring or seal

o NEVERconnect high pressure hoseto nozzle extension.

• Keephigh pressure hose connectedto purnp and spray gun

while system is pressurized.

• ALWAYSpoint spray gun in safe direction, press red button

and squeezespray gun trigger, to release high pressure, every

tirne you stop engine.

• NEVERaim spray gutsat people, animals, or plants.

o DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattended while rnacbineis running.

o NEVERusea spray gun wlsichdoes not have atrigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, nozzbs and accessories are

correctly attached.

WARNING

Unintentional sparking can result in fire or

WARNING

Contact with muffler area can result in serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

* DO NOTtouch hot parts and AVOID hot exlsaustgases.

* Allow equipment to cool before touching.

o Keepat least 5 feet (152 crn) of clearanceon all sides of

pressure washer including overhead.

o Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, rnaintainedin

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states rnay havesimilar laws.

'_¢ electric shock.

WHENADJUSTmNGORMAKING REPAIRSTOYOUR PRESSURE

WASHER

• Disconnectthe sparkplug wire frorn the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTmNGFORENGINESPARK

• Useapproved spark plug tester.

o DONOTcheck for spark with spark plug removed.

WARNING

Starter and other rotating parts canentangie

hands, hair, clothing, or accessories.

• NEVERoperatepressurewasherwithoutprotectivehousingor

covers.

• DONOTwea!looseclothingjewelryor anythingthat maybe

caughtinthestarterorotherrotati_gparts.

o Tieup longhai!andrernovejewelry.

WARNING

IRisk of eyeinjury=

..L..__jSpray cansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthisequipmentor in

vicinityof whereequipmentis in use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

High pressure spray may damagefragiie items inciuding

lass.

DONOTpointspraygunatglasswhenusingMAX(0°) nozzle.

NEVERaim spraygunatplants.

Improper treatment of pressure washer can damageit and

shorten its iife.

Ifyouhavequestionsaboutintendeduse,askdealeror contact

Sears.

NEVERoperateunitswith brokenormissingpa!rs,orwithout

protectivehousingor covers.

DONOTby-passanysafetydeviceonthis rnachine.

DONOTtamperwith governedspeed.

DONOToperatepressurewasheraboveratedpressure.

DONOTmodifypressurewasherinanyway.

Beforestartingpressurewasherincoldweathercheckallparts

oftheequiprner_tto besureicehasnot formedthere.

NEVERmovemachinebypullingon hoses.Usehandle

providedon unit.

Checkfuelsystemfor leaksorsignsofdeterioration,suchas

chafedor spongyhose,looseor missingclamps_or damaged

ta!_korcap.Correctalldefectsbeforeoperatingpressure

washer.

Thisequipmentisdesignedto beusedwith Searsauthorized

partsONLY.If equipmentis usedwithpartsthatDONOT

complywithminimumspecifications,userassumesall risks

andliabilities.

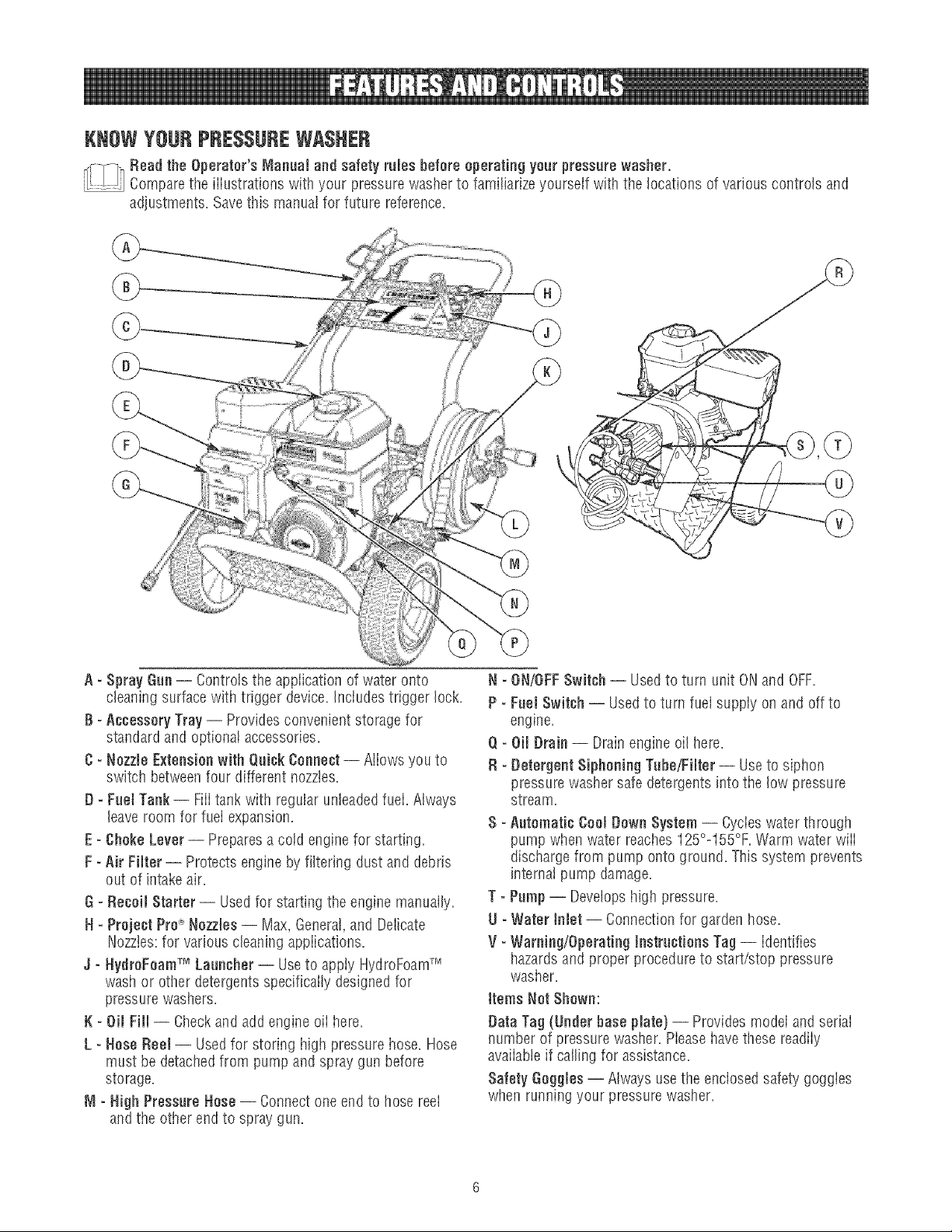

KNOWYOURPRESSUREWASHER

_Read the Operator'sManual and safety rules before operating your pressurewasher.

.... Comparethe iiiustrations with your pressurewasher to familiarizeyourself with the locationsof various controls and

adjustments. Savethis manualfor future reference.

A - Spray Can-- Controls the application of water onto

cleaning surfacewith trigger device.Inciudestrigger lock.

B - Accessory Tray -- Providesconvenient storage for

standard and optional accessories.

C=Nozzle Extensionwith Qaick Connect-- Allows you to

switch betweenfour different nozzles.

D =Fuel Tank-- Fill tank with regular unleadedfuel. Always

leaveroom for fuei expansion.

E =Choke Lever-- Preparesa coid engine for starting.

F - Air Filter -- Protectsengine by filtering dustand debris

out of intake air.

G - Recoil Starter -- Usedfor starting the enginemanually.

H =Project ProC_Nozzles -- Max, General,and Delicate

Nozztes:for various cleaning appiications.

J - HydroFoamTM Laancher -- Useto appiy HydroFoamTM

wash or other detergentsspecifically designed for

pressure washers.

K- Oil Fill -- Checkand add engine oil here.

L - Hose Reel -- Usedfor storing high pressure hose. Hose

must be detachedfrom pump and spray gun before

storage.

_1=High PressureHose -- Connectone end to hose reel

and the other end to spray gun.

N - ON/OFFSwitch -- Usedto turn unit ONand OFF.

P - Fael Switch -- Usedto turn fuel supply on and off to

engine,

Q =Oil Drain -- Drainengine oil here,

R =Detergent Siphoning Tahe/Filter-- Useto siphon

pressure washer safe detergentsinto the low pressure

stream,

S - Aatomatie Cool Down System-- Cycieswater through

pump when water reaches125°o155%. Warm water wiii

discharge from pump onto ground. This system prevents

internal pump damage,

T = Pump-- Developshigh pressure,

U - Water Inlet -- Connectionfor garden hose,

V =Warning/Operating tnetractions Tag -- Identifies

hazardsand proper procedureto start/stop pressure

washer.

ttems Not Shown:

Data Tag (Underbase plate) -- Providesmodel andserial

number of pressure washer. Pieasehavethese readiiy

avaiiabteif calling for assistance.

Safety Goggles-- Alwaysusethe enclosedsafety goggies

when running your pressure washer.

Your pressure washer requires some assembly and is ready

for use only after it has been properly serviced with the

recommendedoil and fuel.

If you haveany problems with the assembly ofyour pressure

washer, pleasecatl the pressure washer helplineat

1o800o222o3136.

UNPACKPRESSUREWASHER

1. Removeeverything from carton except pressure washer.

2. Opencarton completely bycutting eachcorner from top

to bottom.

3. Remove pressure washer from carton.

CARTONCONTENTS

CheckalI contents, if any parts are missing or damaged,calJ

the pressure washer hetpline at 1o808o222o3136.

* Main Unit

, Handle

, AccessoryTray

, High PressureHose

, Short High Pressure Hose

, Spray Gun

, NozzleExtensionwith Quick ConnectFitting

, HydroFoamTM Wash

. Oii Bottle

, HoseReelKit

, Parts Bag (which inciudes the foiiowJng):

, Operator's Manual

, Owner's Registration Card

, SafetyGoggles

, Bagcontaining 3 multi-colored ProjectPro_'Nozzies

, HydroFoamTM Launcher

, HydroFoamTM Launcher & Wash instruction Sheet

, FreshStart Fuel Cartridge

, HandieFasteningHardwareKit (which includes):

, Wireform (I}

° CarriageBolts (2)

, Plastic Knobs (3}

, TreeCiips (4)

Becomefamiiiar with eachpiecebefore assembiing the

pressure washer, identify aii contents with the iiiustration on

page 6. if any parts are missing or damaged,caiJthe

pressure washer helpJineat 1-880-222-3t36.

7. Connectwater supply to pump.

8. Attach nozzleextension to spray gun.

9. Select/attachquick connect ProjectPro_nozzleto nozzle

extension.

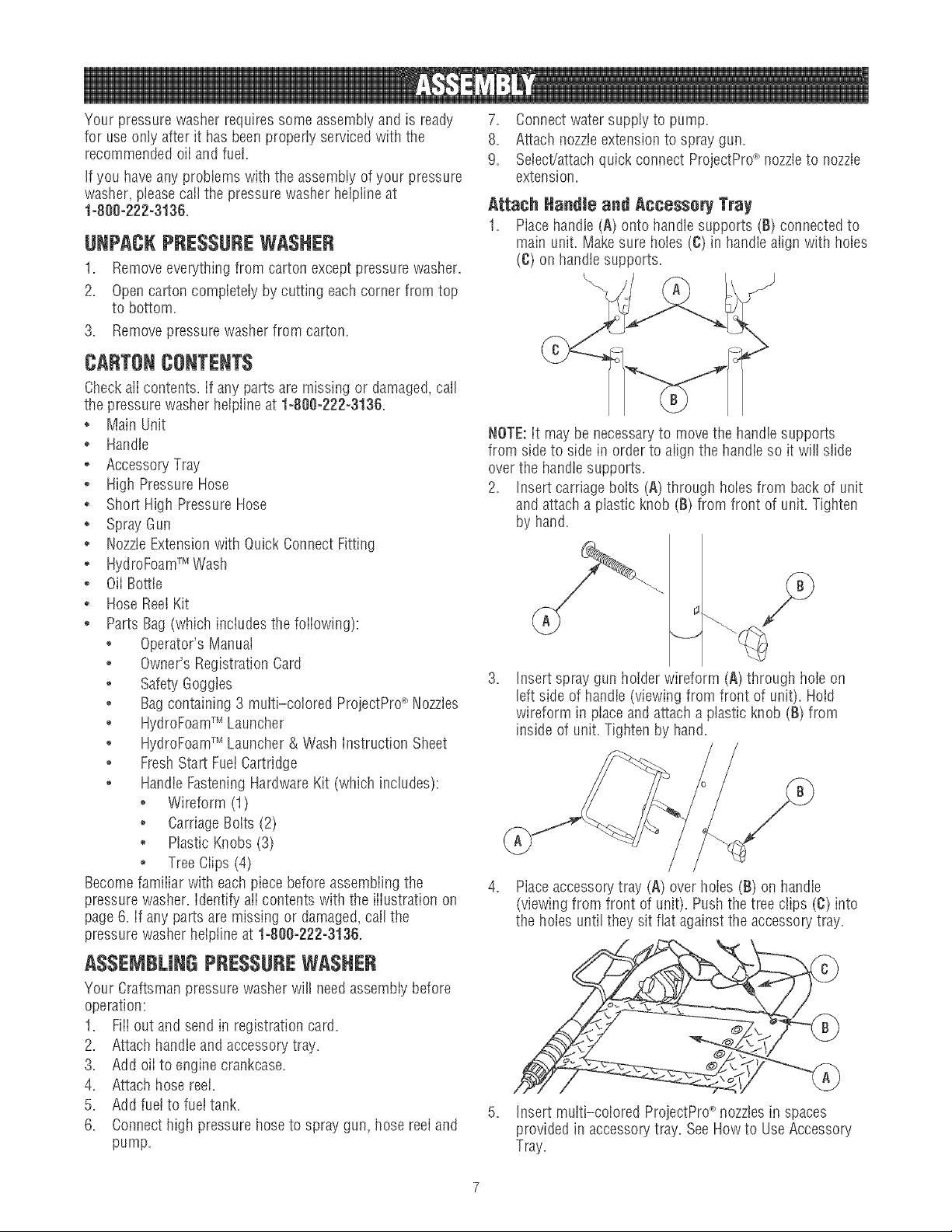

Attach ttandle and Accesso_ Tray

1. Placehandle (A) onto handlesupports (B) connected to

main unit. Make sure holes (C) in handlealign with holes

(C) on handle supports.

NOTE:it may be necessaryto move the handie supports

from sideto side in order to align the handle so it will slide

overthe handiesupports.

2. insert carriage bolts (A) througil holesfrom backof unit

and attacha plastic knob (B) from front of unit. Tighten

by hand.

Insert spray gun holder wireform (A} through hole on

left side of handle (viewing from front of unit). Hoid

wireform in piaceand attach a plastic knob (B) from

inside of unit. Tighten by hand.

4. Placeaccessory tray (A) over isoles(B) on handle

(viewing from front of unit). Pushthe tree clips (C} into

the holes until they sit fiat againstthe accessory tray.

ASSEMBLINGPRESSUREWASHER

Your Craftsmanpressure washer will need assembly before

operation:

1. FilI out and send in registration card.

2. Attach handleand accessorytray.

3. Add oii to engine crankcase.

4. Attach hose reel.

5. Add fuel to fuel tank.

6. Connect high pressure hoseto spray gun, hose reeland

pump.

5. Insert multi-colored ProjectPro_ nozzlesin spaces

provided in accessorytray. See Howto UseAccessory

Tray.

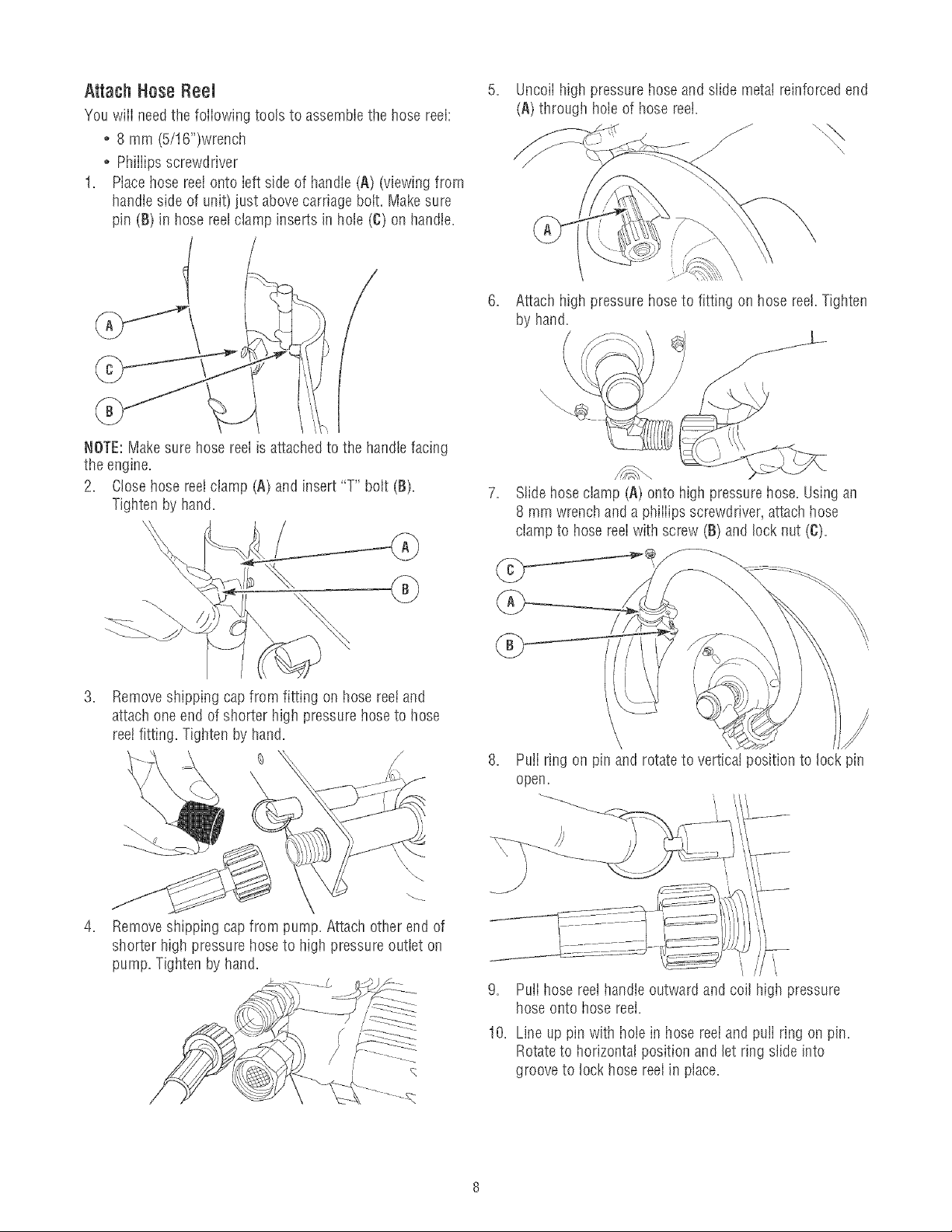

Attach Hose Reel

You wiii need the foiiowing tools to assemblethe hose reel:

o 8 mm (5/16")wrench

o Phiiiips screwdriver

1, Placehose reeI onto Ieft side of handle (A) (viewing from

handle side of unit) just abovecarriage bolt. Make sure

pin (B)in hose reelclamp inserts in hole (C)on handle,

I

NOTE:Makesure hose reel is attached to the handlefacing

the engine,

2, Close hosereeIciamp (A) and insert "T" bolt (B),

Tighten by hand,

Uncoil high pressure hose and slide metal reinforced end

(A) through hole of hose reel.

6, Attach high pressure hoseto fitting on hose reel.Tigilten

by hand.

7. Slidehosedamp (A) onto high pressure hose. Using an

8 mm wrench and a phiiiips screwdriver, attachhose

clamp to hose reeiwith screw (B) and lock nut (C).

.

Removeshipping cap from fitting on hose reetand

attach one end of shorter high pressure hoseto hose

reel fitting. Tighten by hand,

.

Removeshipping cap from pump. Attach other end of

shorter high pressure hose to high pressure outlet on

pump. Tighten by hand.

8. PulI ring on pin and rotate to vertical position to lock pin

open.

9, Puffhose reel handteoutward and coil higil pressure

hoseonto hose reei,

10, Line up pin with hote in hose reei and puii ring on pin,

Rotateto horizonta! position and let ring slide into

groove to lock hose reel in place,

Add Engine OiJ

1. Placepressure washer on a fiat, levelsurface.

2. Cleanarea around oii fiii and remove yeliow oii fiii cap.

NOTE:See Oil Recommendationsin Maintenancesection.

Verify provided oii bottie is the correct viscosity for current

ambient temperature.

3. Using oii funnel (optional), siowiy pour contents of

provided oil bottle into oil fill opening.

improper treatment of pressurewasher can damageit and

shorten its iife.

DONOTattempttocrankor startthe enginebeforeit hasbeen

properlyservicedwiththerecommendedoil.Thismayresultin

anenginefailure.

4. Replaceoil fill cap and fully tighten.

Add Fuel

Fuel must meet these requirements:

Clean,fresh, unleadedgasoline.

o A minimum of 87 octane/87 AKi (91 RON).Higil altitude

use, see High Altitude.

o Gasoiinewith upto 10% ethanol (gasohoi) or up to 15%

MTBE (methyl tertiary butyl ether) is acceptable.

WARNING

FueIand its vapors are extremely fiammabb and

explosive.

_l_ ire or explosion can causesevere burns or

WHENADDmNGFUEL

o TurnpressurewasherOFFandletit coolatleast2 minutes

o Fillfueltankoutdoors.

• DONOToverfilltank.Allowspaceforfue!expansion.

o Iffuelspills,waituntilit evaporatesbeforestartingengine.

• Keepfuelawayfromsparks,openflames,pilotlights,heat,and

o DONOTlight a cigaretteorsmoke.

1. Cieanareaaround fuel fiii cap, removecap.

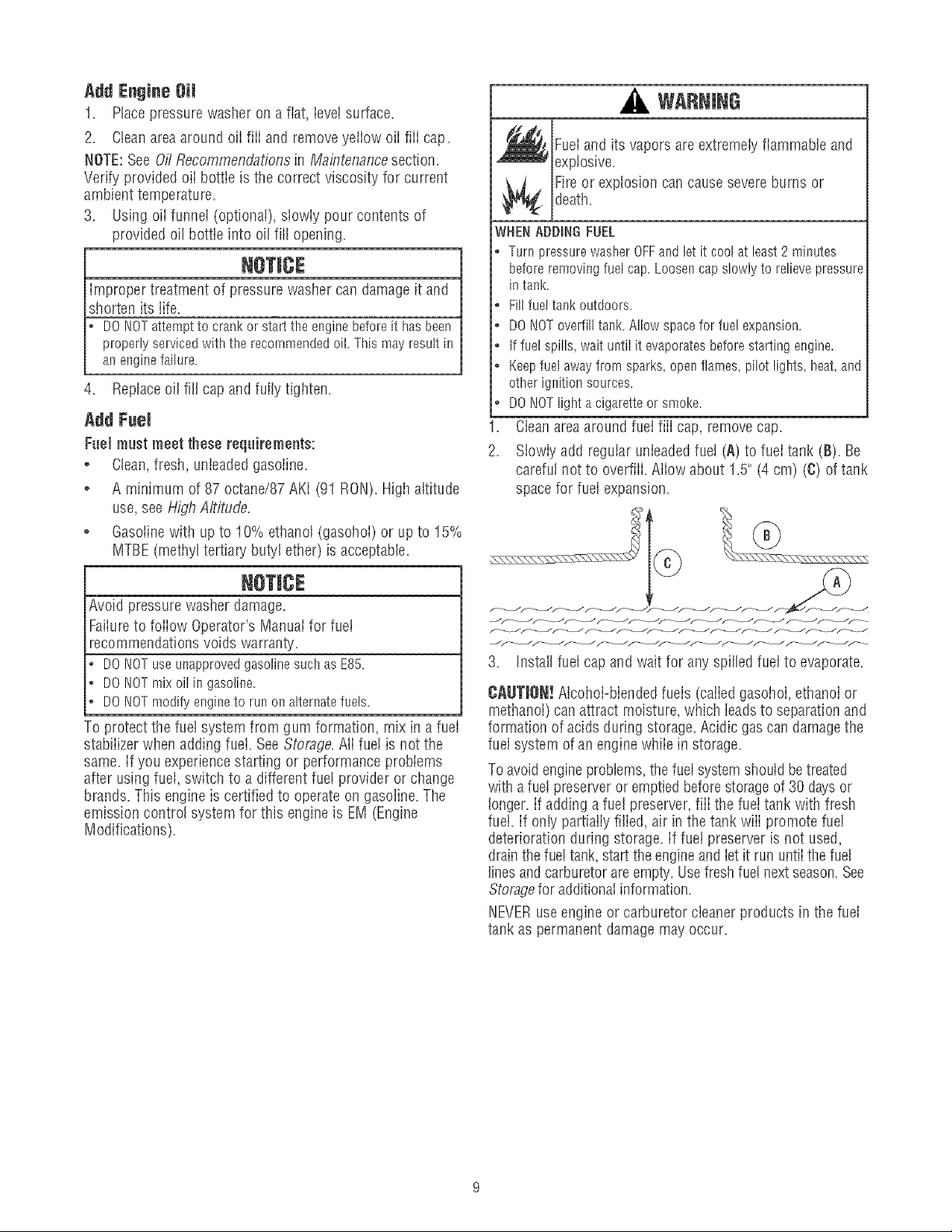

2. Siowiy add regular unleadedfuel (A) to fuei tank (B). Be

death.

beforeremovingfuelcap.Loosencapslowly'to relievepressure

in tank.

otherignitionsources.

carefui not to overfiii. Aiiow about 15" (4 cm) (C) oftank

space for fuel expansion.

NOTICE

Avoid pressure washer damage.

Faiiureto foiiow Operator's Manuaifor fuel

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchas E85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

To protect the fue! system from gum formation, mix in a fuel

stabiiizerwhen adding fuet. SeeStorage. Ali fuel is not the

same. if you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline. The

emission control system for this engine is EM(Engine

Modifications).

CAUTION! AIcohoI-blendedfuels (caiiedgasoiloI, ethanoi or

methanol) can attract moisture, which leadsto separationand

formation of acids during storage.Acidic gas candamagethe

fuel system ofan engine while in storage.

To avoidengineproblems,the fueIsystemshould betreated

with a fuel preserveror emptiedbefore storageof 30 days or

longer,if adding a fuel preserver, fiii the fuei tank with fresh

fuel. if oniy partiaiiy filied, air in the tank wiii promote rue!

deterioration during storage, if fuet preserver is not used,

drainthefuei tank, start the engineand ietit run untii the fuel

finesandcarburetorare empty. Usefreshfuel nextseason. See

Storagefor additionalinformation.

NEVERuseengine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

Fred1$tatlFuelCap

Adding fuel preserver helps keepfuet fresh and carburetors

cleanfor easier starting, aii season iong. This newfuei cap

automatically drips concentrated fuel preserver into your fuel

tank.

, DANGER

Contentsare harmful or fatal if swallowed. Avoid

contact to eyes,skin or clothing. DONOTtake

internaiiy.Avoid breathingthe mist or vapor.

Overexposureto eyesor skin can causeirritation.

KeepstabiIizerout of the reachof chiIdren.

Fuelstabilizer is a hazardouschemical.**

,* If SWALLOWED,callphysicianimmediately.

,, h_thecaseof anemergency,contacta physicianimmediately

andcall1-800-424-9300for materialsafetyirffonnation.

**Fuel stabilizer contains: 2,6-di-tret-butylphenol (128-39-2) and aliphatic petroleum

distillate (64742-47-8),

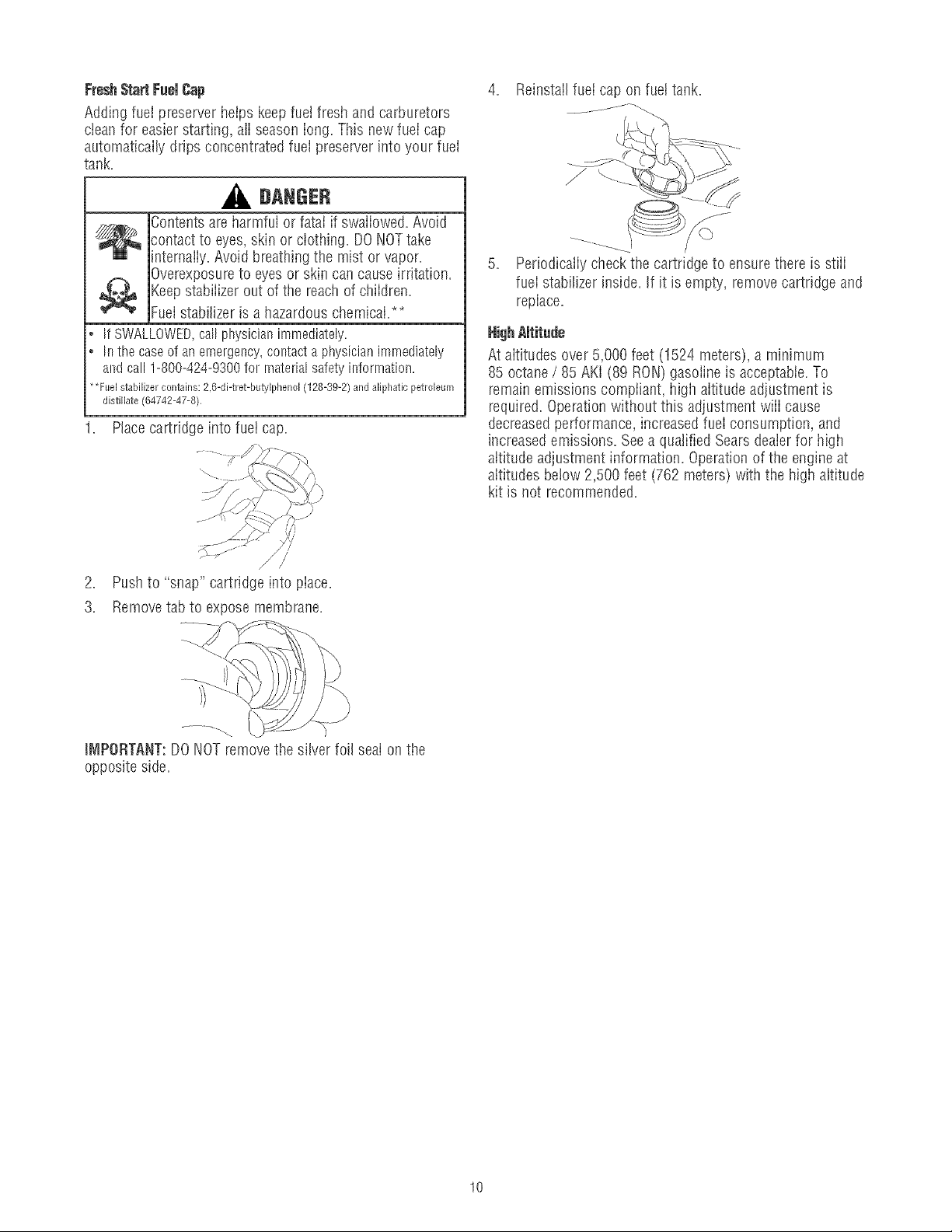

Placecartridge into fuel cap.

4. Reinstallfuel cap on fuettank.

J

Pedodicaiiy check the cartridge to ensurethere is stiii

fuei stabilizer inside. If it is empty, removecartridge and

replace.

At aititudes over 5,000 feet (1524 meters), a minimum

85 octane / 85 AKI (89 RON)gasoline is acceptable.To

remainemissions compiiant, higil aititude adjustment is

required. Operationwithout this adjustment wiii cause

decreasedperformance, increasedfueI consumption, and

increasedemissions. Seea qualified Searsdeaierfor higil

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters)with the high altitude

kit is not recommended.

2. Push to "snap" cartridge into piace.

3. Removetab to expose membrane.

IMPORTANT:DONOT removethe silver foil seal on the

opposite side.

10

ConnectHose and Water Supply to Pump

3. Runwater through your garden hose for 30 seconds to

clean out any debris.

iMPORTANT:DONOTsiphon standing water for the water

suppty. Use ONLYcoid water (less than I O0°F).

4. Connectthe garden hose (notto exceed50 feet in

bngth) to the water inlet. Tigistenby hand.

NOTE:Removeand discard the stlipping capfrom the

pump's water inlet beforeattaching hoses.

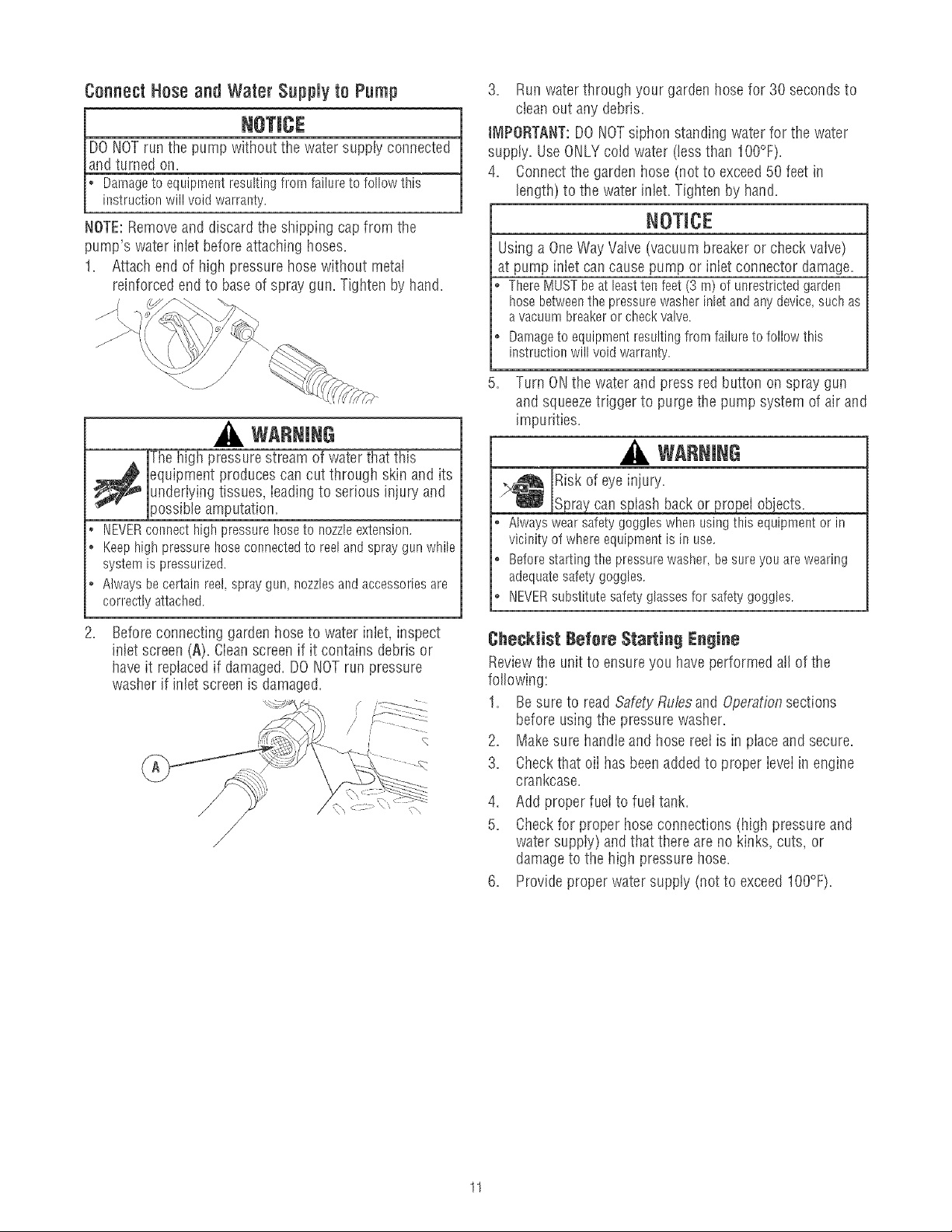

1. Attachend of higil pressure hosewithout metal

reinforced end to baseof spray gun. Tighten by hand.

WARNING

The high pressure stream of water that this

_ quipment produces can cut through skin and its

• NEVERconnect high pressure hoseto nozzleextension.

o Keephigh pressure hose cormectedto reel and spray gun while

system is pressurized.

o Always becertain reel, spray gun, nozzlesand accessories are

correctly attached.

.

underiying tissues, ieading to serious injury and

)ossibb amputation,

Beforeconnecting garden hoseto water inlet, inspect

inlet screen (A). Cleanscreen if it contains debris or

haveit replaced if damaged.DO NOTrun )ressure

washer if inlet screen is damaged.

/

?

NOTICE

Using a OneWay Vaive (vacuum breakeror checkvaive)

at pump inlet can cause pump or inlet connector damage.

ThereMUSTbeatleasttenfeet(3 m)ofunrestrictedgarden

hosebetweenthepressurewasherinletandan}/'device,suchas

avacuumbreakerorcheckvalve.

Darnageto equipmentresultingfromfailuretofollowthis

instructionwillvoidwarranty.

5. Turn ONthe water and press red button on spray gun

and squeezetrigger to purge the pump system of air and

impurities.

WARNING

,,_ Riskof eye injury.

_ jSpraycan splash back or propel objects.

Alwayswearsafetygoggleswhenusingthisequipmentor in

vicinityof whereequipmentisin use.

Beforestartingthe pressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

Checklist Before Starting Engine

Reviewthe unit to ensure you have performed atl of the

foflowing:

1. Besure to read Safety Rubs and Operationsections

before usingthe pressure washer.

2. Makesure handle and hose reetis in placeand secure.

3. Checkthat oii has beenadded to proper levelin engine

crankcase.

4. Add proper fuei to fuei tank.

5. Checkfor proper hoseconnections (high pressure and

water supply) and that there are no kinks, cuts, or

damageto the high pressure hose.

6. Provideproper water supply (not to exceedIO0°F).

11

HOWTOUSEYOURPRESSUREWASHER

If you haveany problems operatingyour pressure washer,

pleasecalIthe pressure washer heipline at 1-800-222-3136.

Pressure Washer Location

WANNING

Exhaustheat/gases can ignite combustibbs,

structures or damage fuei tank causing a fire.

o Keepatleast5ft. (152crn)clearanceonall sidesof pressure

washerincludingoverhead.

PressureWasherClearance

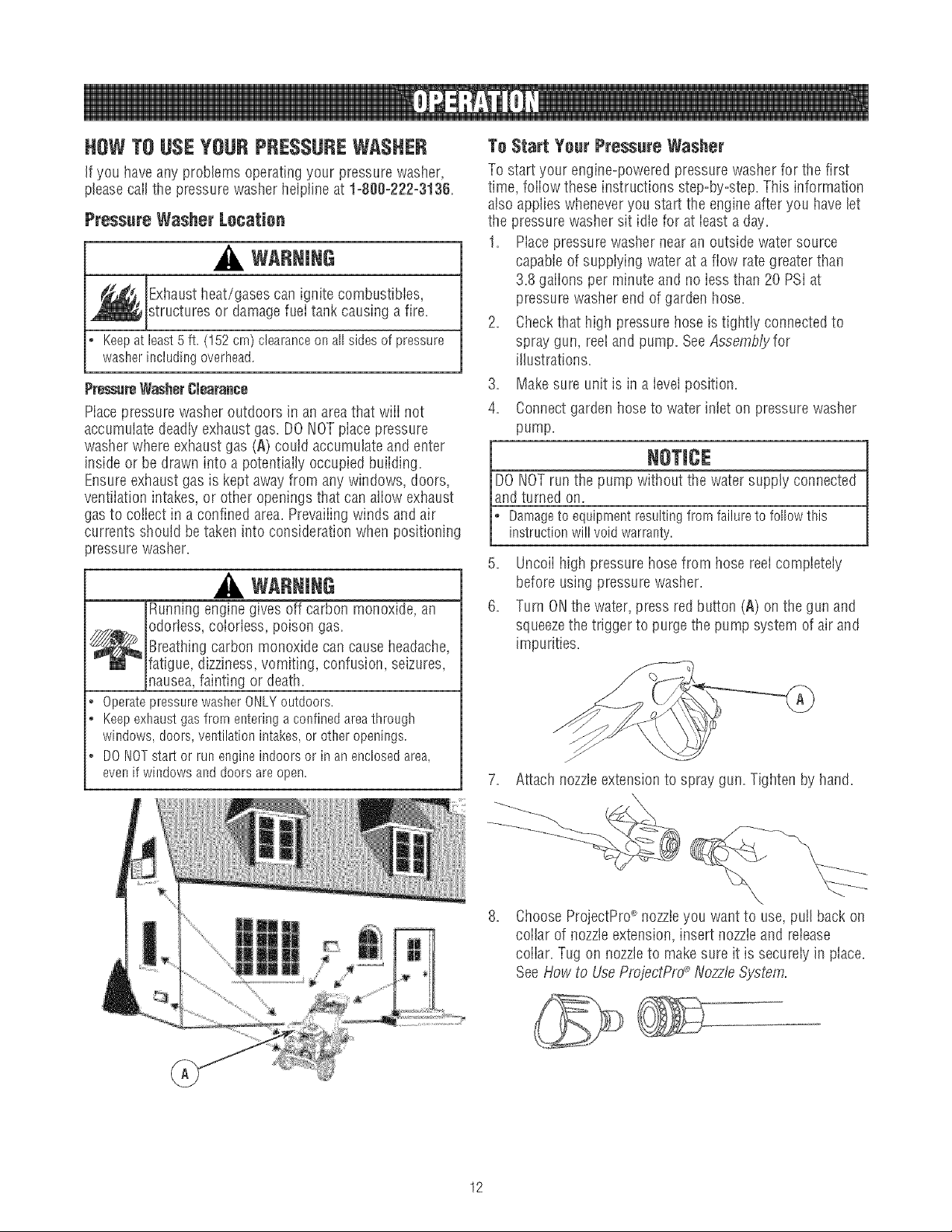

Macepressure wa@er outdoors in an areathat wiii not

accumulate deadiy exhaust gas. DO NOTpiacepressure

washer where exhaustgas (A) could accumulateand enter

inside or be drawn into a potentiaily occupied buiiding.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventiiation intakes, or other openings that can aliow exhaust

gasto coiiect in a confined area. Prevaiiingwinds and air

currents should be taken into considerationwhen positioning

pressure washer.

WARNING

Runningengine gives off carbon monoxide, an

odorless, coiorless, poison gas.

_ reathingcarbon monoxide can causeheadache,

* OperatepressurewasherONLYoutdoors.

o Keepexhaustgasfromenteringaconfinedareathrough

* DONOTeta1 or runengineindoorsor in anenclosedarea,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

windows,doors,ventilationintakes,or otheropenings.

evenif windowsanddoorsareopen.

To Start Yeur Pressure Washer

To start your engine-powered pressurewasher for the first

time, foiiow these instructions step-by-step. This information

also applies wheneveryou start the engine after you havelet

the pressure washer sit idle for at bast a day.

1. Piacepressure washer nearan outside water source

capableof supplying water at a flow rategreater than

3.8 gaiions per minute and no iess than 20 PSi at

pressurewasher end of garden hose.

2. Checkthat high pressure hose istightiy connectedto

spray gun, reel and pump. SeeAssemb_for

illustrations.

3. Makesure unit is in a ieveiposition.

4. Connectgarden hose to water intet on pressure washer

pump.

i NOTlC(

DONOTrun the pump without the water supply connected

and turned on.

L amageto equipmentresultingfrom failureto followthis

instructionwillvoidwarrasty

5. Uncoii high pressure hose from hose reelcompbteiy

before using pressure washer.

6. Turn ONthe water,press red button (A) on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

Attach nozzleextension to spray gun. Tigllten by hand.

ChooseProjectPro_ nozzleyou want to use, pull back on

coilar of nozzleextension, insert nozzleand release

coiiar. Tug on nozzleto makesure it is securely in place.

SeeHow to UseProjectPro_ NozzleSystem.

12

9. Rotatefueishut=offvalveto "On"position(A)(fully

counter=clockwise).

10.Movechokeleverto"Choke"position.

NOTE:For a warm engine, be sure the choke lever is in the

"Rue" position.

11. Move ON/OFFswitch (A) to ONposition.

iMPORTANT:Beforestarting the pressure washer, be sure

/ou are wearing adequatesafety goggles.

WARNING

_Spray cansp ash back or propel objects.

vicinityofwhereequipmentisinuse.

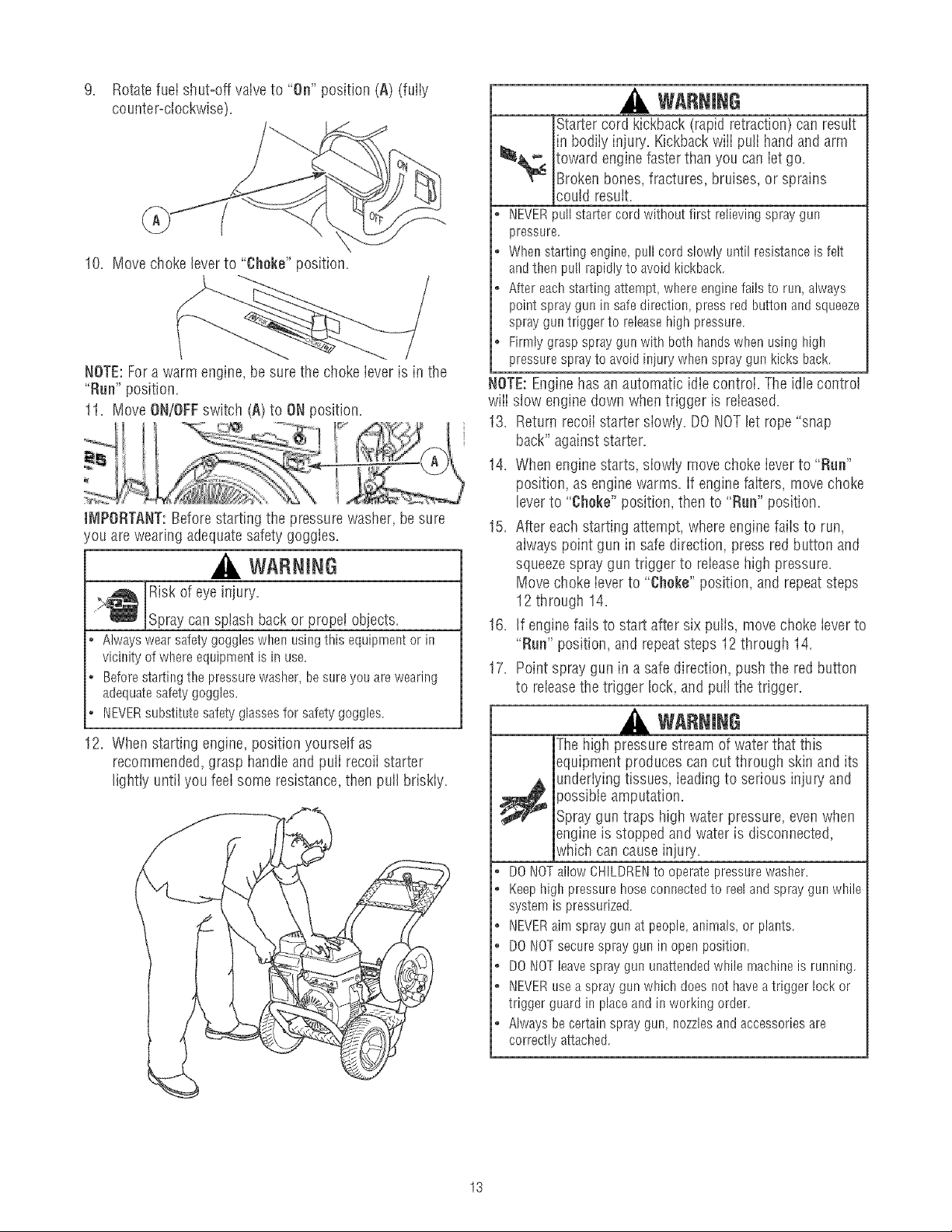

12. Whenstarting engine, position yourself as

Risk of eye injury.

Alwayswearsafetygoggleswhenusingthis equipmentor in

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesforsafetygoggles.

recommended, grasp handle and puff recoii starter

lightly until you feel some resistance, then pulI briskly.

WARNING

Starter cord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pu!I handand arm

toward enginefaster than you caniet go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpullstartercordwithoutfirst rdievingspraygun

pressure.

o Whenstartingengine,pullcordslowlyuntil resistanceisfelt

andthenpullrapidlyto avoidkickback.

o Aftereachstartingattempt,whereenginefailsto run, always

pointspraygunin safedirection,pressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

o Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidiniurywhenspraygunkicksback.

NOTE:Enginehas an automatic idle controi. The idle control

wiii slow engine down whentrigger is released.

13. Return recoii starter siowiy. DONOTlet rope "snap

back"against starter.

14. When engine starts, siowiy movechoke ieverto "Run"

position, as engine warms, if engine faiters, move choke

leverto "Choke" position, t!_ento "Rue" position.

15. After eachstarting attempt, w!_ereenginefaiis to run,

always point gun in safe direction, press red button and

squeezespray gun trigger to releasehigh pressure.

Move choke leverto "Choke" position, and repeatsteps

12 through 14.

16. If enginefaiis to start after six puffs, movechoke ieverto

"Run" position, and repeatsteps 12 througil 14.

17. Point spray gun in a safe direction, push the red button

to releasethe trigger lock, and pulI the trigger.

WARNING

Thehigh pressurestream of waterthat this

equipment produces can cut through skin and its

_ nderlying tissues, ieadingto serious injury and

• DONOTallowCHILDRENtooperatepressurewasher.

o Keephighpressurehoseconnectedto reelandspraygunwhile

systemis pressurized.

o NEVERaimspraygunatpeople,animals,or plants.

• DONOTsecurespraygun inopenposition.

o DONOTleavespraygununattendedwhilernachineis running.

• NEVERuseaspraygunwhichdoesnothaveatriggerlockor

triggerguardin placeandinworkingorder.

o Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

}ossibte amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

13

WARNING

Contact with muffler area can result in serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

* DONOTtouchhot partsandAVOIDhotexhaustgases.

* Allowequipmentto coolbeforetouching.

o Keepatleast5feet (152crn)ofclearanceonall sidesof

pressurewasherincludingoverhead.

, Codeof FederalRegulation(CFR)Title36 Parks,Forests,and

PublicPropertyrequireequipmentpoweredby aninternal

combustionengineto haveasparkarrester,rnaintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5!00-1C or laterrevision.Itsthe Stateof Californiaa

sparkarresteris requiredundersection4442of the California

Publicresourcescode.Otherstatesrnayhavesimilarlaws.

How to Stop Your Pressure Washer

1. Reieasespray gun trigger and let engine idte for two

minutes.

2. Move ON/OFFswitch to OFFposition.

WARNING

Backfire,fire or engine damagecould occur.

* DONOTstopenginebymovingchokeleverto "Choke"position.

3. ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, ieadingto serious injury and

• Keephighpressurehoseconnectedto reelandspraygunwhile

systemispressurized.

o ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntrigger,to rebasehighpressure,every

time youstopengine.

)ossibbamputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

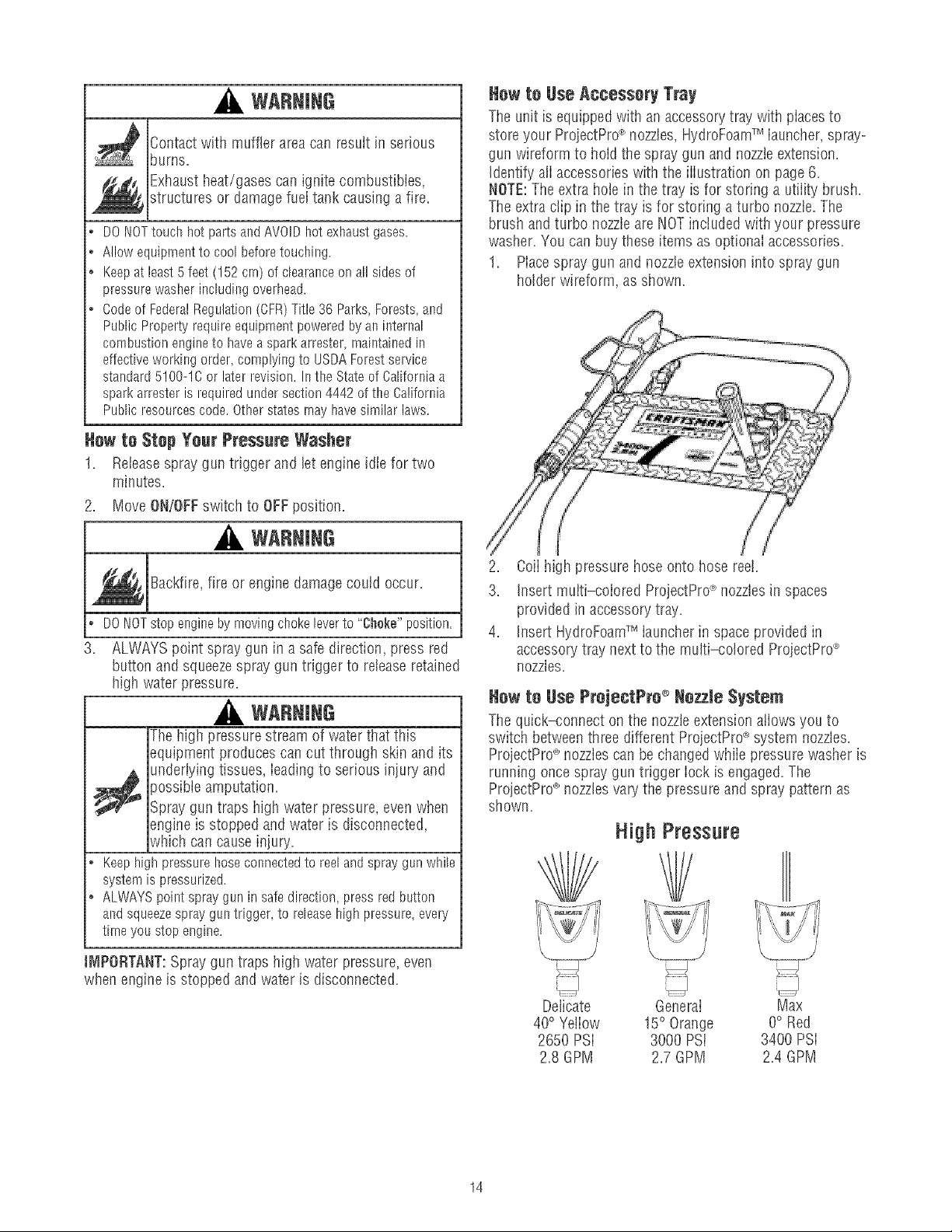

How to Use Accessory Tray

Theunit is equipped with an accessorytray with piacesto

store your ProjectPro_ nozzles,HydroFoamTM iauncher, spray-

gun wireform to hold the spray gun and nozzteextension.

identify ali accessorieswith the iiiustration on page6.

NOTE:The extra hob in the tray is for storing autiiity brush.

Theextra clip in the tray is for storing a turbo nozzle. The

brush and turbo nozzleare NOTincludedwith your pressure

washer.You can buythese items asoptionai accessories.

1. Piacespray gun and nozzleextension into spray gun

holder wireform, as shown.

2. Coii high pressure hose onto hose reel.

3. Insert muiti-colored ProjectPro_nozzlesin spaces

provided in accessorytray.

4. Insert HydroFoamTM iauncher in spaceprovided in

accessorytray next to the multi-colored ProjectPro_

nozzles.

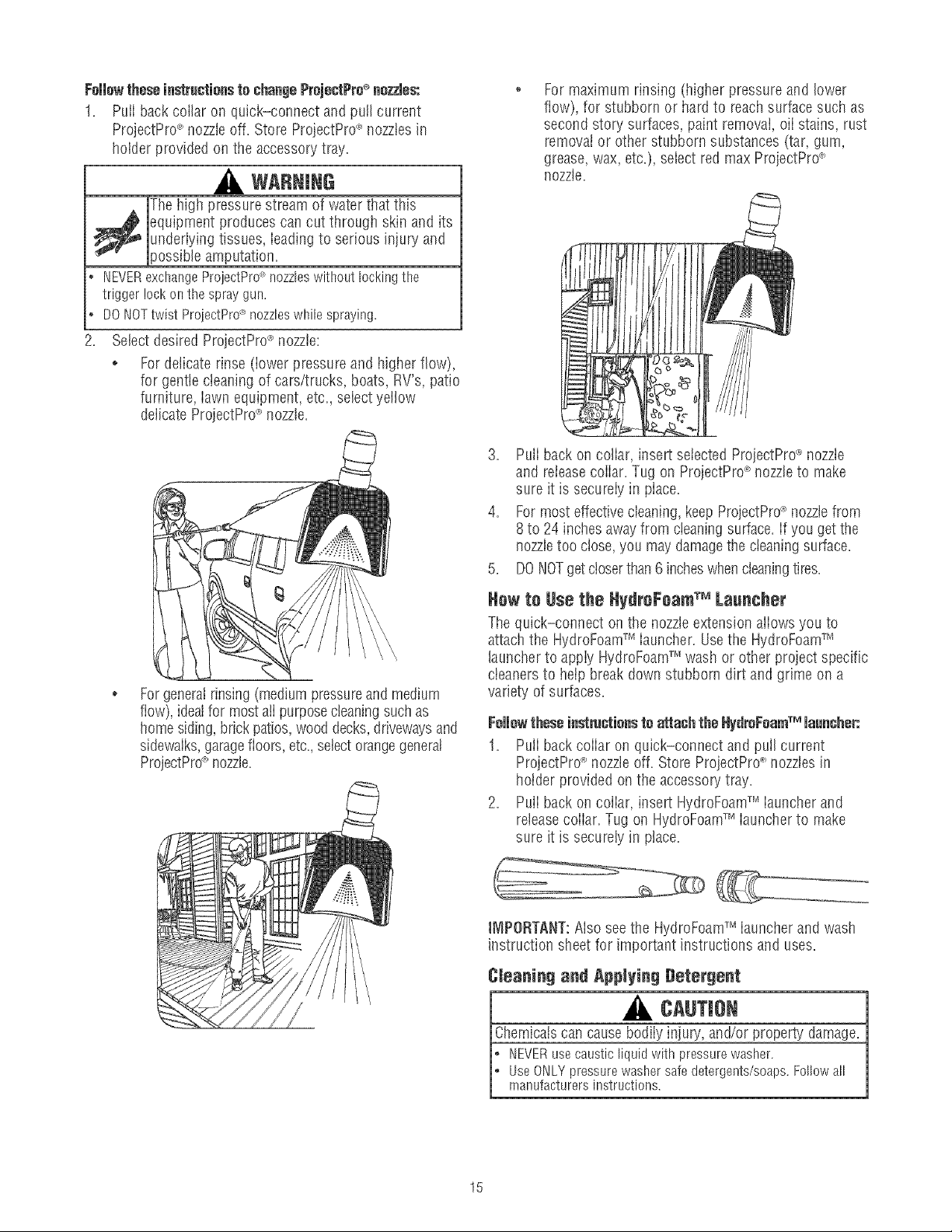

How to Hoe ProjectPro ®Hozzle System

Thequick-connect on the nozzleextension atiows you to

switch betweenthree different ProjectPro_system nozzles.

ProjectPrd_nozzlescan be changedwhile pressure washer is

running once spray gun trigger Iock is engaged.The

ProjectPrd_nozzlesvary the pressure and spray pattern as

shown.

High Pressure

JNIPORTANT:Spraygun traps high water pressure,even

when engine is stopped and water is disconnected.

14

Delicate General

40°Yeiiow 15° Orange

2650 PSi 3000 PSi

2.8 GPM 2.7 GPM

"--.i-.......l...J

Max

O° Red

3400 PSi

2.4 GPM

Fellowthese instructionsto shaegePrejestPro®nozzles:

1. PuiI back collar on quick-connect and pull current

ProjectPro_>nozzle off. Store ProjectPro_'nozzlesin

holder provided on the accessorytray.

WARNING

The high pressure stream of water that this

For maximum rinsing (higiler pressure and lower

flow), for stubborn or hard to reachsurface such as

second story surfaces, paint removal, eli stains, rust

removal or other stubborn substances (tar, gum,

grease, wax, etc.), select red max ProjectPro_'

nozzle,

_ quipment produces cancut through skin and its

* NEVERexchangeProjectPro__nozzleswithoutlockingthe

triggerlockonthe spraygun.

o DONOTtwist ProjectPro<'nozzleswhilespraying.

.

underiyingtissues, ieadingto serious injury and

)ossibleamputation.

Select desired ProjectPrd_nozzle:

o Fordelicate rinse (iower pressure and higher flow),

for genttecteaning of cars/trucks, boats, RV's, patio

furniture, iawn equipment, etc. selectyellow

delicate ProjectPro_nozzte.

Forgeneralrinsing(medium pressureand medium

flow), idealfor mostaiI purposecteaningsuch as

homesiding,brick patios,wooddecks,drivewaysand

sidewalks,garagefloors, etc.,selectorangegeneral

ProjectPro_>nozzte.

3. Pull back on collar, insert selectedProjectPro_nozzle

and releasecollar. Tug on ProjectPro_'nozzleto make

sure it is secureiy in piace.

4. Formost effectivecleaning,keepProjectPrd_nozzlefrom

8to 24 inchesawayfrom cleaningsurface. If you get the

nozzletoo close, you may damagethe cleaningsurface.

5. DONOTgetcloserthan6 incheswhencleaningtires.

Hew te 8se the HydreFeamTM Laancher

The quick-connect on the nozzleextension aliows you to

attach the HydroFoamTM iauncher. Usethe HydroFoamTM

launcherto appiy HydroFoamTM wash or other project specific

cteanersto heip break down stubborn dirt and grime on a

variety of surfaces.

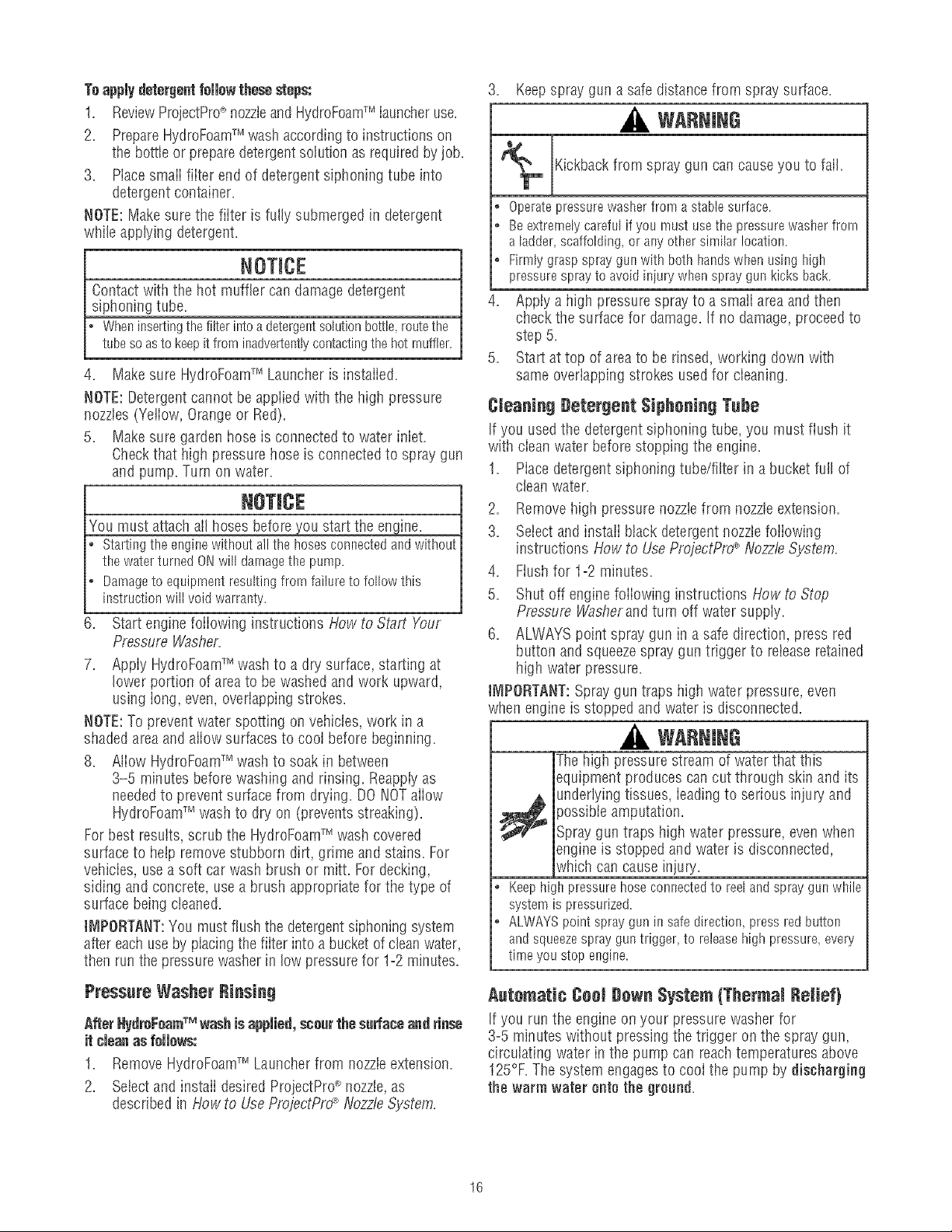

Followthese instructionsto attashthe HydreFearnTM lace€her:

1. Pull back collar on quick-connect and pull current

ProjectPrd_nozzleoff. Store ProjestPro_'nozzlesin

holder provided on the accessopj tray,

2. Pull back on collar, insert HydroFoamTM launcherand

releasecollar. Tug on HydroFoamTM launcherto make

sure it is securely in place.

IMPORTANT:Also see the HydroFoamTM launcher and wash

instruction sheet for important instructions and uses.

Cteaning and Applying Detergent

A CAUTJe

Chemicalscan causebodily injupj, and/or property damage.

UseONLYpressurewashersafedetergents/soaps.Followall

_ EVERusecausticliquidwithpressurewasher.

rnanufacturersinstructions.

15

Toapply detergentfellow these steps:

1. ReviewProjectPro_'nozzleand HydroFoamTM launcheruse.

2. PrepareHydroFoamTM wash accordingto instructions on

the bottle or preparedetergentsolution as requiredbyjob.

3. Mace smaii fiiter end of detergent siphoning tube into

detergent container=

NOTE:Makesure the fiiter is fully submerged in detergent

while applying detergent=

NOTICE

Contact with the hot muffler candamagedetergent

siphoning tube=

Wheninsertingthefilterintoadetergentsolutionbottle,routethe

tubesoastokeepitfrominadvertentlycontactingthehotrnuffler.

4. Make sure HydroFoamTM Launcheris installed.

NOTE:Detergentcannot be appiied with the high pressure

nozzles(Yeliow, Orange or Red).

5. Make sure garden hose is connectedto water iniet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

NOTICE

You must attachall hoses beforeyou start the engine=

Startingtheenginewithoutallthehosesconnectedandwithout

thewaterturnedONwill damagetbepump.

Darnageto equipmentresultingfrom failuretofollowthis

instructionwill void warranty.

6= Start engine foiiowing instructions How to Start Your

Pressure Washer=

7=

Appiy HydroFoamTM washto a dry surface, starting at

lower portion of areato be washed and work upward,

using iong, even, overlapping strokes=

NOTE:To prevent water spotting on vehicies,work in a

shadedareaand aliow surfacesto coot before beginning.

8= Aiiow HydroFoamTM wash to soak in between

3-5 minutes before washing and rinsing. Reappiyas

neededto prevent surface from drying. DONOTaiiow

HydroFoamTM wash to dry on (prevents streaking).

Forbest results, scrub the HydroFoamTM wash covered

surfaceto help remove stubborn dirt, grime and stains. For

vehicies, use a soft car wash brush or mitt. For decking,

siding and concrete, usea brush appropriate for the type of

surface being cleaned=

J_IPORTANT:You mustflush the detergentsiphoningsystem

after each use by piacingthe fiiter into a bucket of clean water,

then run the pressurewasherin low pressurefor 1-2 minutes.

3. Keepspray gun a safe distancefrom spray surface.

WARNING

Kickbackfrom spray gun cancauseyou to fail=

o Operatepressurewasherfrom astablesurface.

o Beextremelycarefulifyou mustusetbepressurewasberfrom

a ladder,scaffolding,or anyotbersimilarlocation.

* Firmlygraspspraygunwithboth handswbenusinghigh

pressuresprayto avoidiniurywhenspraygunkicksback.

4= Appty a high pressure spray to a smati areaand then

check the surface for damage=If no damage,proceedto

step 5=

Start at top of areato be rinsed, working down with

same overlapping strokes usedfor cleaning=

Cteauiug getergeut $ipheuiug Tube

If you usedthe detergentsiphoning tube, you must flush it

with cieanwater beforestopping the engine.

1= Piacedetergent siphoning tube/filter in a bucket full of

clean water.

.

Removehigh pressure nozziefrom nozzteextension.

3=

Selectand instaii btackdetergent nozzJefoiiowing

instructions How to UseProjectPrd_NozzleSystem.

,

Ftushfor 1-2 minutes.

5=

Shut off engine foiiowing instructions How to Stop

Pressure Washerand turn off water suppiy.

6= ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to reiease retained

high water pressure=

iMPORTANT:Spraygun traps high water pressure,even

when engine is stopped and water is disconnected.

WARNING

Thehigh pressurestream of waterthat this

equipment produces can cut through skin and its

underlyingtissues, ieadingto serious injupj and

}ossibie amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

o Keephighpressurehoseconnectedto reelandspraygunwhile

systemis pressurized.

• ALWAYSpointsprayguninsafedirection,pressredbutton

andsqueezesprayguntrigger,to releasehighpressure,every

timeyoustop engine.

Pressure Washer Rinsing

After NydroFoamTM washis applied, eceor the sorfaoeandrinoe

it cleanas fellows:

1. RemoveHydroFoamTM Launcherfrom nozzleextension.

2. Seiectand instaii desired ProjectPro_ nozzle,as

described in How to UseProjeotPrd"__NozzleSystem.

Automatic Cool gewu System {Thermal lielief}

If you run the engineon your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circuiating water in the pump can reachtemperatures above

125%=Thesystem engagesto cool the pump by discharging

the warm water onto the groond=

16

ENGINETECHNICALiNFORMATiON

This is a single cylinder, overheadvalve (OHV),air cooled

engine, it is a iow emissions engine.

Inthe Stateof California, Model 150000 enginesare certified

by the California Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respectto the performance or

operational iife of this engine. The engine is warranted solely

according to the product and emissions warranties stated

elsewherein this manual.

Power Ratings

Thegross power rating for individual gas engine models is

labeledin accordancewith SAE(Societyof Automotive

Engineers)code J1940 (Small Engine Power & Torque

Rating Procedure),and rating performance has been

obtained andcorrected in accordancewith SAEJ1995

(Revision2002=05).Torque values are derived at3060 RPM;

horsepower values are derivedat 3600 RPM. Actual gross

engine power wiii be lower and is affected by, among other

things, ambient operating conditions and engine-to-engine

variabiiity. Givenboth the wide array of products on which

enginesare piaced and the variety of environmentai issues

appiicabb to operatingthe equipment, the gas engine wiii not

developthe rated gross power when used ina given pieceof

power equipment (actual "on-site"or net power). This

difference is due to a variety of factors including, but not

limited to, accessories (air cleaner, exhaust,charging,

cooling, carburetor, fuel pump, etc.), appiication iimitations,

ambient operating conditions (temperature,humidity,

altitude), and engine-to-engine variabiiity. Due to

manufacturing and capacity iimitations, Briggs & Stratton

maysubstitute an engine of higher ratedpower for this

Seriesengine.

PRODUCTSPECiFiCATiONS

PressureWasherSpecifications

Max Outbt Pressure ....................... 3,400 PSi

Max Flow Rate............................. 2.8 GPM

ChemicalMix......................... Use as directed

Water SupplyTemperature .......... Not to exceed IO0°F

Shipping Weight ............................. 93 Ibs.

EngineSpecifications

Bore ............................. £970 in. (75.44turn)

Stroke .............................. 2.200 in. (56ram)

Displacement ........................ 15.22in. (249 cc)

SparkPlug

ResisterType: ............. Briggs & Stratton 491055S

Long Life Platinum: .......... Briggs & Stratton 5066D

SetGapTo: ...................... O.030inch(O.76mm)

ArrnatureAir Gap: ........... 0.010o0.014in.(O.25=O.36rnm)

Valveclearancewithvalvespringsinstalledand piston1/4in.

(6 rnrn)pasttop deadcenter(checkwhenengineiscold).

Intake.................... 0.004°0.006in.(0.10=0.15rnm)

Exhaust .................. 0.009o0.011in.(0.23=0.28rnrn)

Fue!Capacity............................... 1.6Quarts

OilCapacity........................ 20 Ounces(0.6 liter)

NOTE:For practical operation, the engine ioad should not

exceed 85% of rated power. Enginepower wiii decrease

3-1/2% for each 1,000 feet (300 meters) abovesea leveland

1% for each 10° F(5.6° C) above 77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

17

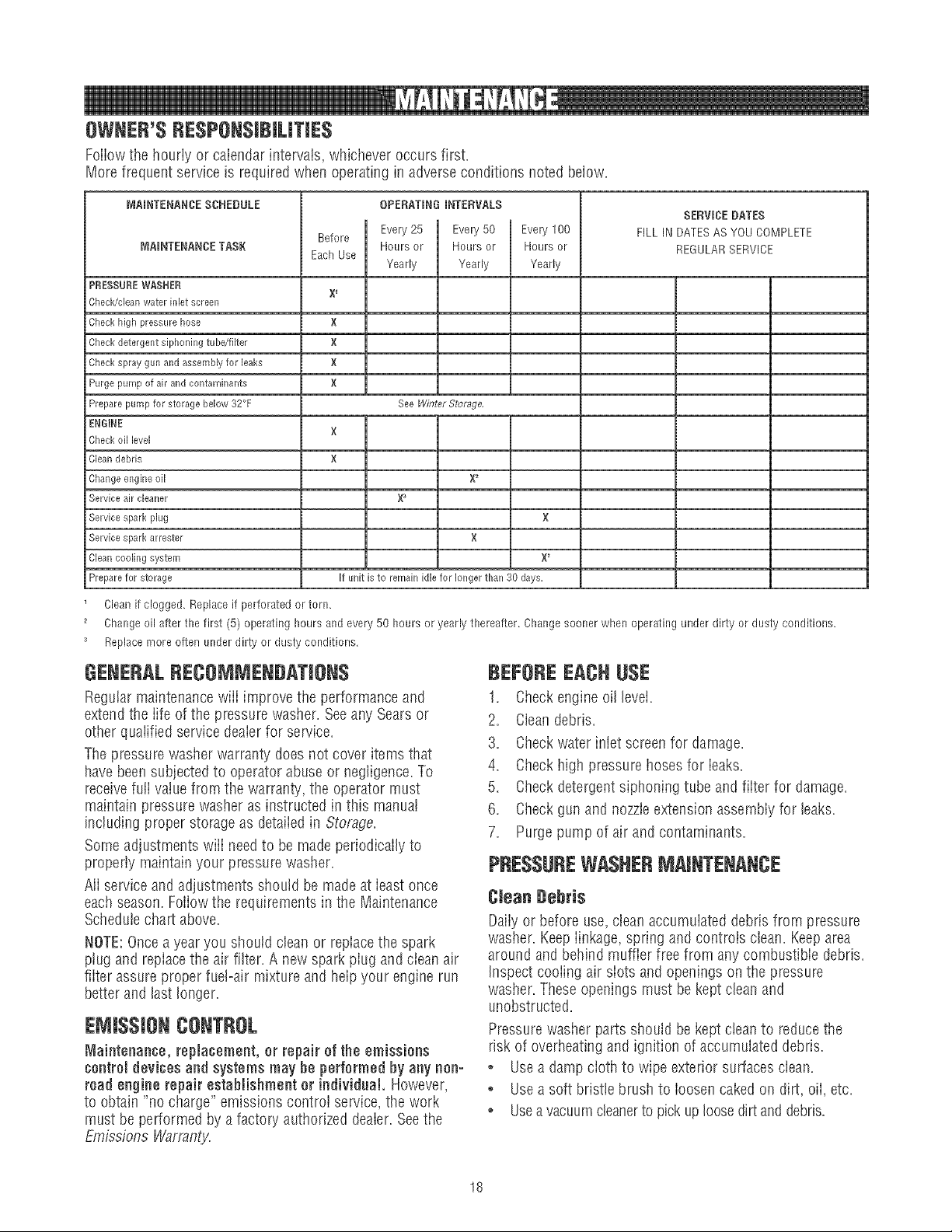

OWNER'SRESPONSiBiLiTiES

Foiiowthe hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MAINTENANCESCHEDULE

MNNTENANCETASK

PRESSUREW_,SHER

Check/clean water inlet screen

Check high pressure hose

Check detergent siphoning tube/filter

Checkspray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Check oil level

Clean debris

Changeengine oil

Service air cleaner

Service spark plug

Service spark arrestor

Clean cooling system

Prepare for storage

Cleanif clogged. Replaceif perforated or tern.

Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

Replacemore often under dirty or dusty conditions,

Before

EachUse

X 1

X

×

X

X

×

X

OPERATINGINTERVALS

Hours or Hoursor

Every 25 Evel_/50

Yearly Yearly

See Winter Stof_ge,

X_

×

if unit is to remain idle for longer than 30 days,

Evel_,lO0

Hours or

Yearly

SERVICEeATES

FILL IN DATESAS YOU COMPLETE

REGULARSERVICE

X

GENERALRECOMMENgATiON$

Regularmaintenancewiii improve the performance and

extendthe iife of the pressure washer. Seeany Searsor

other quaiified service deaierfor service.

Thepressure washer warranty doesnot cover items that

havebeen subjected to operator abuse or negligence.To

receivefuIi vatuefrom the warranty, the operator must

maintain pressure washer as instructed in this manual

including proper storage as detaiied in Storage.

Someadjustments wiii needto be madeperiodically to

properly maintain your pressure washer.

Ali serviceand adjustments should be madeat ieastonce

eachseason.Foliow the requirementsin the Maintenance

Scheduiechart above.

NOTE:Oncea year you should clean or replace the spark

ptug and repiacethe air filter. A new spark plug and ciean air

fiiter assure proper fuel-air mixture and helpyour engine run

better and last longer.

EJ J$$JONCONTROL

Maintenance, replacement, or repair of the emissions

¢ontromdevices and systemsmay heperformedby any non-

roadengine repairestablishment or individual.However,

to obtain "no charge" emissions controi service,the work

must be performed by a factory authorized dealer.Seethe

Emissions Warranty.

BEJ:OREEACHUSE

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hoses for leaks.

5. Checkdetergent siphoning tube and filter for damage.

6. Checkgun and nozzleextension assembly for leaks.

7. Purge pump of air and contaminants.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use,clean accumulated debris from pressure

washer. Keeplinkage, spring and controis clean. Keeparea

around and behind muffler free from any combustible debris.

inspect cooiing air siots and openings on the pressure

washer. Theseopenings must be kept cleanand

unobstructed.

Pressurewasher parts should be kept cieanto reducethe

risk of overheating and ignition of accumulated debris.

o Usea dampcloth to wipe exterior surfaces clean.

° Usea soft bristle brush to ioosencaked on dirt, oii, etc.

° Useavacuumcleanerto pick up loosedirt anddebris.

18

NOTICE

jImproper treatment of pressurewasher can damageit and

_tsq_fe,

W_orten _ ....

L: DONOTinsertanyobjectsthroughcoolingslots.

Check and (}mean JnJet Screen

Examinegarden hose inlet screen. Clean if it is clogged or

replaceif it is torn.

Check High Pressure Hnse

High pressure hoses can developleaks from wear, kinking,

or abuse. Inspect hose before each use. Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings. If any of these conditions exist, replacehose

immediately.

WARNING

Pressurestream

t produces cancut through skin and its

g tissues, ieadingto serious injury and

_"" jpossibleamputation.

NEVERrepairhighpressurehose.Replaceit.

ReplacementhoseratingMUSTexceedrnaxirnurnpressure

ratingof unit.

Check Detergent Siphoning Tube

Examinethe fiiter on the detergent tube and clean if ctogged.

Thetube should fit tightiy on the barbed fitting. Examinethe

tube for leaks or tears. Replacethe filter or tube if either is

damaged.

WARNING

Thehigh pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, ieading to serious injury and

° Keephighpressurehoseconnectedto reelandspraygunwhile

systemis pressurized.

o ALWAYSpointspraygeminsafedirection,pressredbutton

andsqueezesprayguntrigger,to releasehighpressure,every

timeyoustop engine.

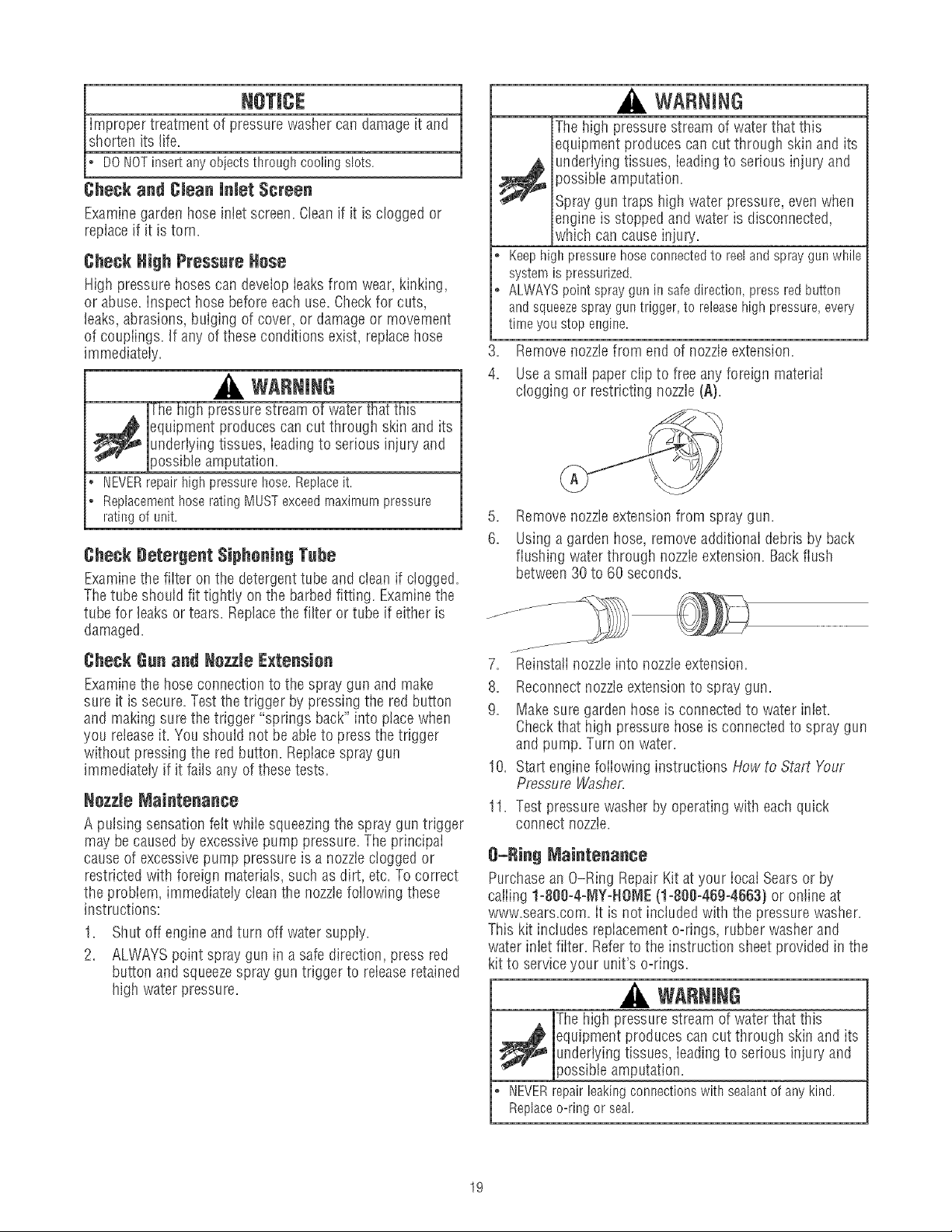

3= Remove nozzlefrom end of nozzleextension.

4. Usea smali paperclip to free any foreign material

B,

6.

jJ

)ossibie amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which cancause injury.

clogging or restricting nozzle(A).

Removenozzleextension from spray gun.

Using a garden hose, removeadditionai debris by back

flushing water through nozzleextension. Backflush

between30 to 60 seconds.

Check Gun and Nezzle Extensiun

Examinethe hose connectionto the spray gun and make

sure it is secure. Test the trigger by pressing the red button

and making sure the trigger "springs back" into placewhen

you releaseit. You should not be able to press the trigger

without pressing the red button. Repiacespray gun

immediately if it fails any of these tests.

Nezzle Maintenance

A pulsing sensationfelt whiie squeezingthe spray gun trigger

may becaused by excessivepump pressure. Theprincipal

cause of excessivepump pressure is a nozzleclogged or

restricted with foreign materials, such asdirt, etc. Tocorrect

the probiem, immediately cleanthe nozzlefollowing these

instructions:

,

Shut off engine and turn off water supply.

2.

ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

.

Reinstaiinozzleinto nozzleextension.

8.

Reconnectnozzleextensionto spray gun.

9.

Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

10.

Start engine foliowing instructions How to Start Your

Pressure Washe,_

11=

Test pressure washer by operating with eachquick

connect nozzle.

B-Ring Maintenance

Purchasean O-Ring RepairKit atyour iocaI Searsor by

caiiing 1-800-4-MY-NOME (1-800-469-4663) or oniine at

www=sears=com=it is not included with the pressure washer.

This kit includes repiacemento-rings, rubber washer and

water inlet fiiter. Referto the instruction sheet provided in the

kit to serviceyour unit's o-rings=

WARNING

Thehigh pressurestream of waterthat this

_ quipment produces cancut through skin and its

• NEVERrepairleakingconnectionswithsealantof anykind.

Replaceo-ringor seal.

underlyingtissues, ieadingto serious injury and

_ossibleamputation.

19

Pump OiJMaintenance

DONOTattempt any oil maintenanceon this pump. This

modeldoes not require any pump oii maintenance.The pump

is pre=iubricatedand sealedfrom the factory, requiring no

additional lubrication for the life of the pump.

ENGINEMAINTENANCE

WARNING

Checkingeli Level

Oil Ieveishould be checkedprior to each use or at least every

5 hours of operation. Keepeli ieve! maintained.

1= Makesure pressure washer is on a ieveisurface.

2= Cleanareaaround eli fiii and remove eli fiil cap=

3= Verify eli is atthe point of overflowing at oil fill opening.

4. Replaceand tighten oil fill cap.

Unintentionalsparking can result in fire or

_¢ electric shock.

WHENAD3USTmNGOR_IAKmNGREPAmRSTOYOURPRESSURE

WASHER

o Disconnectthe sparkplugwirefromthesparkplugandplace

thewirewhereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester.

. DONOTcheckfor sparkwith sparkplugremoved.

Oil

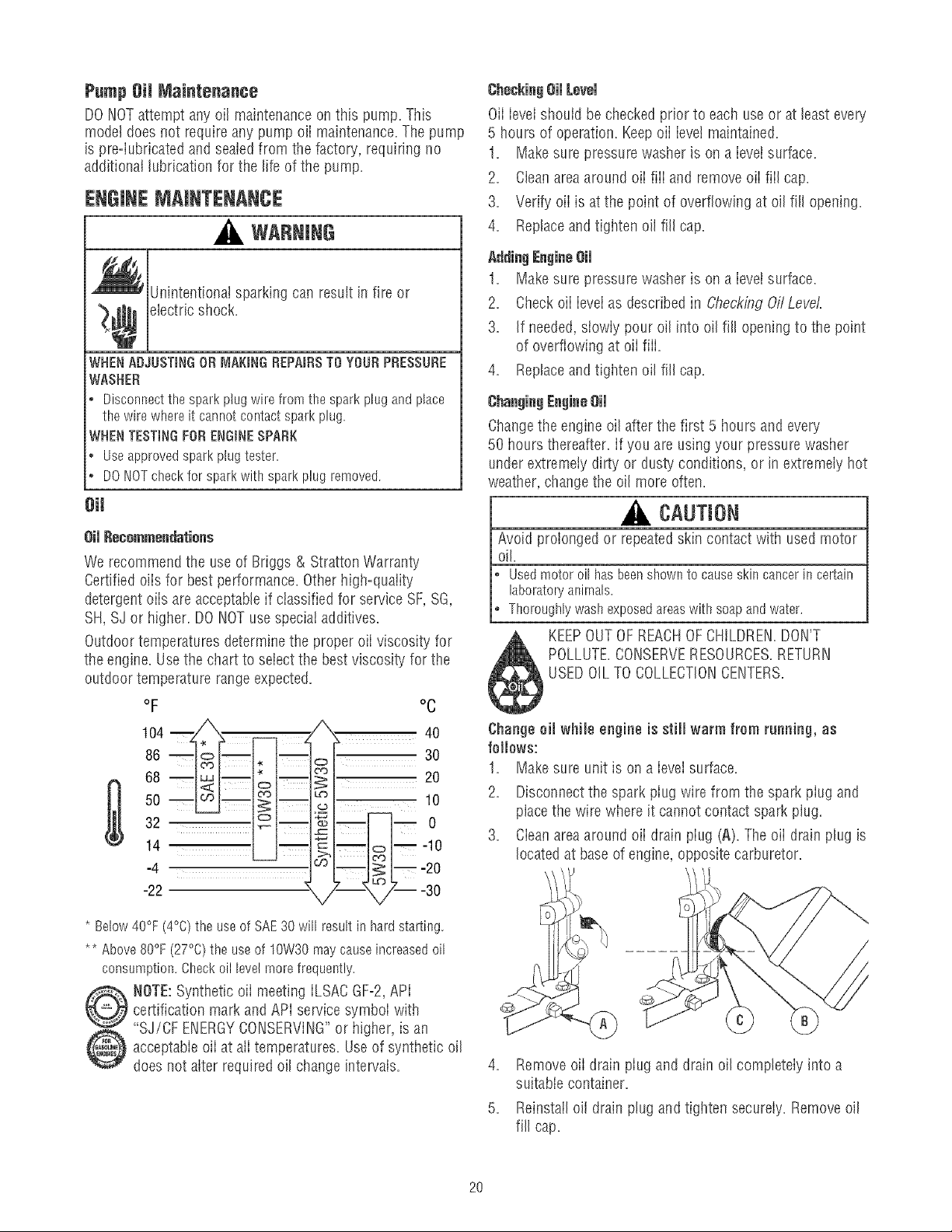

eli Becemmendatiens

We recommendtile useof Briggs & Stratton Warranty

Certified otis for best performance. Other high=quality

detergent oiis are acceptable if ciassified for service SF,SG,

SH, SJ or higher. DONOTuse speciai additives.

Outdoortemperatures determine the proper eli viscosity for

the engine. Usethe chart to selectthe best viscosity for the

outdoor temperature rangeexpected.

oF

oc

'X 4o

86 _

104 ZIX'X

68

5o

32 _

14

-4

-22

| 30

:_ 0

_m _0

- -lO

oh--j k-- o

1, Makesure pressure washer is on a Ieveisurface.

2= Checkeli ievei as described in CheckLogOffLevel

3= If needed,slowly pour oil into oil fill openingto the point

of overflowing at eli fiii.

4= Replaceand tigilten oil fill cap=

Changethe engine oil after the first 5 hours and every

50 hours thereafter, if you are using your pressure washer

under extremely dirty or dusty conditions, or in extremely hot

weather, changethe oil more often.

CAUTION

Avoid prolonged or repeatedskin contact with usedmotor

oil.

Usedmotoroil hasbeenshownto causeskincancerincertain

laboratoryanimals.

Thoroughlywashexposedareaswithsoapandwater.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTOCOLLECTIONCENTERS.

Changeoil while engine is still warm frem running,as

feiJows:

1. Makesure unit is on a ieveisurface.

2. Disconnect the spark piug wire from the spark piug and

placethe wire where it cannot contact spark plug.

3. Cleanareaaround oil drain plug (A). Theoil drainplug is

locatedat baseof engine, oppositecarburetor.

* Below40°F(4°C)theuseof SAE30will resultin hardstarting.

** Above80%(27%) theuseof 10W30maycauseincreasedoil

consumption.Checkoillevelmorefrequently.

certification mark and APi servicesymboi with

NOTE:Synthetic eli meeting ILSACGF=2,API

"SJ/CF ErIERGYCONSERVING"or higiler, is an

acceptabieeli at aii temperatures. Useof synthetic oil

doesnot alter required oil change intervals.

4. Removeeli drain piug and drain oil completely into a

suitable container.

5. Reinstalloil drain plug and tigilten securely. Removeoil

fill cap,

2O

Loading...

Loading...