Craftsman 580752040 Owner’s Manual

Operator'sManual

22{)0PSi MAX

2.2GPM MAX

Model No. 58{).752040

®

ADVERTE CIA

Before usingthis product, readthis

manuatandfoliow ali Safety RuIes

and Operating instructions=

Sears, Roebuck and Ca., Hoffman Estates, [L 68179 U.S.A.

Visit our Craftsman website: www.craftsman.eom

Part No. 203791GS Draft - (04/25/2007)

Antes de utiiizar ei producto, ieaeste

manuaiy siga todas las RegIasde

Seguridade instrucciones deUso=

®Safety

®Assembly

®Operation

,, Maintenance

,, Parts

,, Espa_oi,p. 34

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-14

SPECIFICATIONS..................................... 15

MAINTENANCE.................................... 16-20

STORAGE........................................... 21

TROUBLESHOOTING.................................. 22

NOTES......................................... 23 & 31

REPLACEMENTPARTS.............................. 24-30

EMISSIONCONTROLWARRANTY..................... 32-33

ESPANOL......................................... 34-59

HOWTO ORDERPARTS ........................ BACKPAGE

If this pressurewasher faiis dueto a defect in materiai or workmanship within one year from the dateof purchase,return it to

any Searsstore, other Craftsman outlet, or SearsParts & Repair Centerin the UnitedStates or Canadafor free repair (or

replacementif repair proves impossible).

Ali warranty coverageapplies for only 90 days from dateof purchaseif this pressure washer is ever usedfor commercial or

rentaipurposes.

This warranty gives you specific legal rights, and you mayalso have other rights which vary from stateto state.

Sears, Roebuck and Ce,, Heffman Estates, JL68179

Sears Canada Jnc,, Terente, 8ntarie, Canada MSB 2B8

Thisis the safety alert symbol, tt is used to alert yea to potentialpersenaminjary hazards. ObeyaHsafety messages

that fellow this symbemto avoid pessiNe injuryor death.

_Read this manual carefully andbecome familiar

..... with yourpressurewasher. Knew its applications,

Hazard $ymhomsand Meanings

itslimitations, and any hazardsinvolved.

Thesafety alert symboi (,_) is usedwith a signal word

(DAr/GER,CAUTION,WARNING),a pictorial and/or a safety

Toxic Furnes Kickback

ElectricalShock

messageto alert you to hazards. BANGERindicates a hazard

which, if not avoided, wi/'/resuIt in death or serious injury.

WARNINGindicates a hazard which, if not avoided, cou/d

result in deathor serious injury. CAUTtONindicatesa hazard

SlipperySurface

Fa_

which, if not avoided, might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage. Foiiow safety messagesto avoid or

reducethe risk of injury or death.

Fire

Moving Parts

Explosion

FlyingObiects

Operator's Manual

FluidInjection

HotSurface

© Sears Brands, LLC

WARNING

WARNING

Theengine exhaustfrom this productcontains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

Running engine gives off carbon monoxide, an

odoriess, coioriess, poison gas.

Breathingcarbon monoxide can cause headac!_e,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting, or poisoning.

* Operatepressure washer ONLYoutdoors.

, Keepexhaust gas from entering aconfined areathrough

windows, doors, ventilation intakes,or other openings.

o DO NOTstart or run engine indoors or in an enclosed area,

evenif windows and doors are open.

o Use a respirator or rnaskwhenever there isa chancethat

vapors rnay be inhaled.

, Readall instructions with mask so you are certain the mask will

provide the necessaryprotection against inhalingharmful

vapors.

WARNING

_iir Risk of electrocution.

• NEVER spraynearpowersource.

Contact with power source can cause electric

shock or burn.

Fueland its vapors are extremely flammable and

explosive.

death=

Fireor explosion can cause severe burns or

WidENA#UING8U URAiNIN6FUEL

* TurnpressurewasherOFFandletit coo[at least2 minutes

beforeremovingfuelcap.Loosencapslowly'to relievepressure

in tank.

* Fillor drainfueltankoutdoors.

o DONOToverfilltank.Allowspaceforfuelexpansion.

* Iffuelspi!ls,waituntilit evaporatesbeforestartingengine.

o Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

o DONOTlighta cigaretteorsmoke.

WidENSTARTINGEQUIPMENT

o Ensuresparkplug,muffler,fuel cap,andair cleanerarein

place.

, DONOTcrankenginewith sparkplugremoved.

WIDEN8PERATINGEQUIPMENT

* DONOTtip engineor equiprnentat anglewhichcausesfuelto

spill.

o DONOTsprayflamrnabieliquids.

WIDENTRANSPORTING8U REPAIRINGEQUIPMENT

, Transport/repairwithfue]tank EMPTYor withfuel shutoffvalve

OFF.

, Disconnectsparkplugwire.

WIDENSTOUINGFUEL8U EQUIP_dENTWiTidFUELIN TANE

* Storeawayfromfurnaces stoveswaterheaters,clothes

dryers,orotherappliancesthathavepilotlight or otherignition

sourcebecausetheycanignitefuelvapors.

WARNING

Starter cord kickback (rapid retraction) can result

in bodily injury, Kickback will pull hand and arm

toward enginefaster than you can iet go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spray gun

pressure.

o When starting engine pull cord slowly until resistance is felt

andthen pull rapidly to avoid kickback.

• After eachstarting attempt_where enginefails to run, always

point spray gun in safe direction andsqueezespray gLmtrigger

to releasehigh pressure. Engagespray gun trigger lock.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid iniury when spray gun kicks back.

WARNING

Useof pressure washer can create puddles and

slippery surfaces.

Kickbackfrom spray gun cancause you to fail.

• Operatepressure washer frorn astable surface.

• The cleaningarea should haveadequate slopes and drainageto

reducethe possibility of afall dueto slippery surfaces.

o Be extremelycareful if you rnust usethe pressure washer from

a ladder, scaf%ding_ or any other similar location.

• Firmly grasp spray gLmwith both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, ieading to serious injury and

_ossible amputation,

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• DONOTallow CHILDRENto operate pressure washer.

o NEVERrepair high pressure hose. Replaceit.

• NEVERrepair leaking connections with sealant of any kind.

Replaceo-ring or seal.

• NEVERconnect high pressure hoseto nozzle extension.

o Keephigh pressure hose connectedto purnp and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction and squeezespray

gun trigger to releasehigh pressure, every time you stop

engine. Engagetrigger lock when not in use.

• NEVERaim spray gun at people, animals, or plants.

o DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattended while rnachineis running.

o NEVERusea spray gun which does not have atrigger lock or

trigger guard in place and in working o!der.

o Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

WARNING

Unintentionalsparking can result in fire or

WARNING

Contact with muffler area can result in serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fueI tank causing a fire.

• DONOTtouchhot partsandAVOIDhotexhaustgases.

• Allowequipmentto cool beforetouching.

• Keepatleast5feet (152cm) ofclearanceonall sidesof

pressurewasherincludingoverhead.

• Codeof FederalRegulation(CFR)Title36 Parks,Forests,and

PublicPropertyrequireequipmentpoweredbyaninternal

combustionengineto haveasparkarrester rnaintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-1Corlaterrevision.Inthe Stateof Californiaa

sparkarresteris requiredundersection4442oftheCalifornia

Publicresourcescode.Otherstatesrnayhavesimilarlaws.

'_¢ electric shock,

WidENADJUSTINGGRJVIAKINGI_EPAIRSTGYGUR

PRESSIJi_EWASHER

o Disconnectthe sparkplugwirefromthesparkplugandplace

thewire whereit cannotcontactsparkplug.

WidENTESTINGFGRENGINESPARK

o Useapprovedsparkplugtester.

• DONOTcheckfor sparkwithsparkplugremoved.

WARNING

Starter and other rotating parts can entangle

qands, hair, clothing, or accessories.

• NEVERoperatepressure washer without protective housing or

covers.

• DO NOTwea! loose clothing jewelry or anything that may be

caught in the starter or other rotating parts.

, Tieup long hai! and remove jewelry.

WARNING

_Spray can sp ash back or propei objects.

vicinity of where equipment is in use.

Risk of eye injury=

Alwayswear safetygoggles when using this equipment or in

Beforestarting the pressure washer, be sureyou are wearing

adequatesafety goggles.

NEVERsubstitute safety glasses for safety goggles.

High pressure spray may damagefragiie items inciuding

iass.

DONOTpointspraygunatglasswhenusingred(0°) spraytip.

NEVERaimspraygunatplants.

Improper treatment of pressure washer can damageit and

shorten its life.

Ifyouhavequestionsaboutintendeduse,askdealerorcontact

Sears.

NEVERoperateunitswith brokenormissingpa!ts,or without

protectivehousingor covers.

DONOTby-passanysafetydeviceonthis rnachine.

DONOTtamperwithgovernedspeed.

DONOToperatepressurewasheraboveratedpressure.

DONOTmodifypressurewasherinanyway.

Beforestartingpressurewasherincoldweathercheckallparts

oftheequipmentto besureice hasnotformedthere.

NEVERrnovemachineby pulB_gon hoses.Usehandle

providedon unit.

Checkfuelsystemfor leaksor signs of deterioration,suchas

chafedor spongyhose,!ooseormissingclampsor damaged

tankorcap.Correctalldefectsbeforeoperatingpressure

washer.

Thisequipmentisdesignedto beusedwith Searsauthorized

partsONLY.If equipmentis usedwith partsthatDONOT

complywithrninimumspecifications,userassumesall risks

andliabilities.

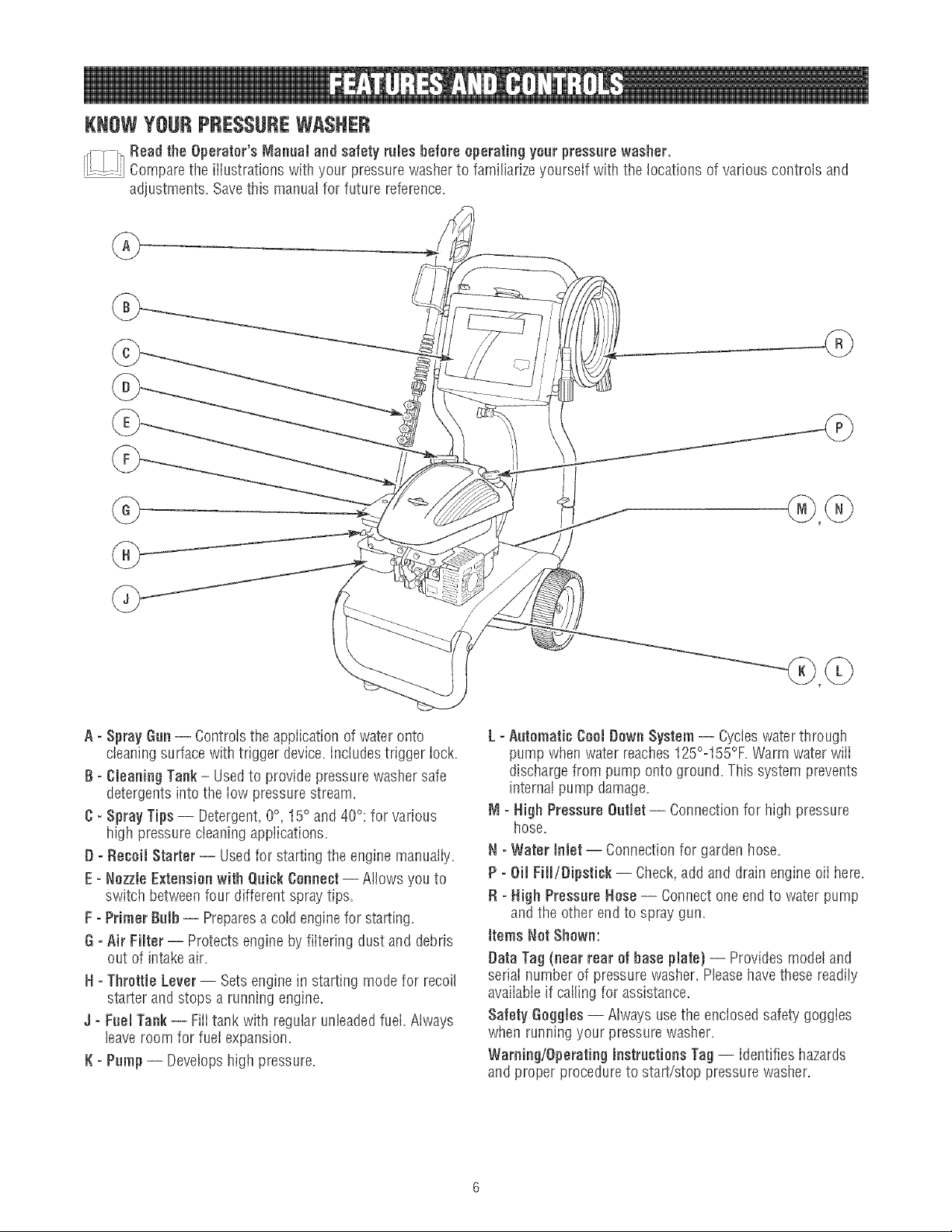

KNOWYOURPRESSUREWASHER

,r' F I-_Read the Operator's Manual and safety rubs before operating your pressure washer.

.... Comparethe illustrations with your pressurewasher to familiarize ,'ourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

- Spray Gun-- Controis the appiication of water onto

cleaningsurfacewith trigger device, includes trigger iock.

B - Charting Tank - Usedto provide pressure washer safe

detergents into the iow pressurestream.

C- Spray Tips -- Detergent,0°, 15° and 40°: for various

high pressure charting applications.

D - Reoeil Starter -- Used for starting the engine manuaIiy.

E =Nozzb Extensionwith Quick Connect-- Mows you to

switch betweenfour different spray tips.

F - PrimerBulb -- Preparesa cold enginefor starting.

6 - Air FiNer -- Protectsengine by fiitedng dust and debris

out of intake air.

N - Throttle Lever -- Setsengine in starting mode for recoil

starter and stops a running engine.

S- Fuel Tank -- Fiii tank with regular unleadedfuel. Aiways

leaveroom for fuei expansion.

K- Pamp-- Developshigh pressure.

{}

L=Automatic CoolDown System-- Cycleswaterthrough

pump when water reaches 125°o155°F.Warm water wiii

discharge from pump ontoground. This system prevents

internal pump damage.

M =High Pressure D}utJet-- Connectionfor high pressure

hose.

N =Water Inlet -- Connectionfor garden hose.

P =Oil FilliD}ipatick -- Check,add and drain engine eli here.

R =Nigh Pressure Hose -- Connectone end to water pump

and the other endto spray gun.

Items Net Shown:

Data Tag (near rear of base plate) -- Provides model and

seriai number of pressure washer. Pleasehavethese readily

avaiiabieif calling for assistance.

Safety Geggbs -- Always usethe enclosedsafety goggles

when running your pressure washer.

Warning/Operating Instructions Tag-- Identifieshazards

and proper procedureto start/stop pressure washer.

YourcleaningsystemrequiressomeassembIyandisready

foruseonlyafterit hasbeenproperiyservicedwiththe

recommendedoilandfuel.

Jfyouhaveany prohbmswith the assembly of your

pressurewasher, please call the pressurewasher hempJine

at 1o800o222o3136.

UNPACKTHEPRESSUREWASHER

1. Removeeverything from carton except pressure washer.

2. Opencarton completely bycutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

CARTONCONTENTS

Checkali contents, if any parts are missing or damaged,call

the pressure washer hetplineat 1o800o222o3136.

° Main Unit

° Handle

, 6baning TankAssembly

, High PressureHose

, Spray Gun

, Nozzb Extensionwith Quick ConnectFitting and Spray

TipHolder

, Oil Bottle

, Parts Bag (which includes the following):

, Operator's Manual

, Owner's Registration Card

, SafetyGoggles

, Gun Holder Wireform

, DetergentSiphoning Hose/Filter

° Bagcontaining 4 multi-coiored Spray Tips

, HandleFasteningHardwareKit (whichincludes):

, CarriageBolts (2)

, "L" Bolt

° Plastic Knobs (4)

, TreeClips (4}

Becomefamiliar with eachpiecebefore assemblingthe

pressure washer, identify ali contents with the iiiustrationon

page 6. if any parts are missing or damaged,calJthe

pressure washer helpline at 1o800o222o3136.

7. Connectwater supply to pump.

8. Attach nozzleextension to spray gun.

9. Select/attachquick connect spray tip to nozzb extension.

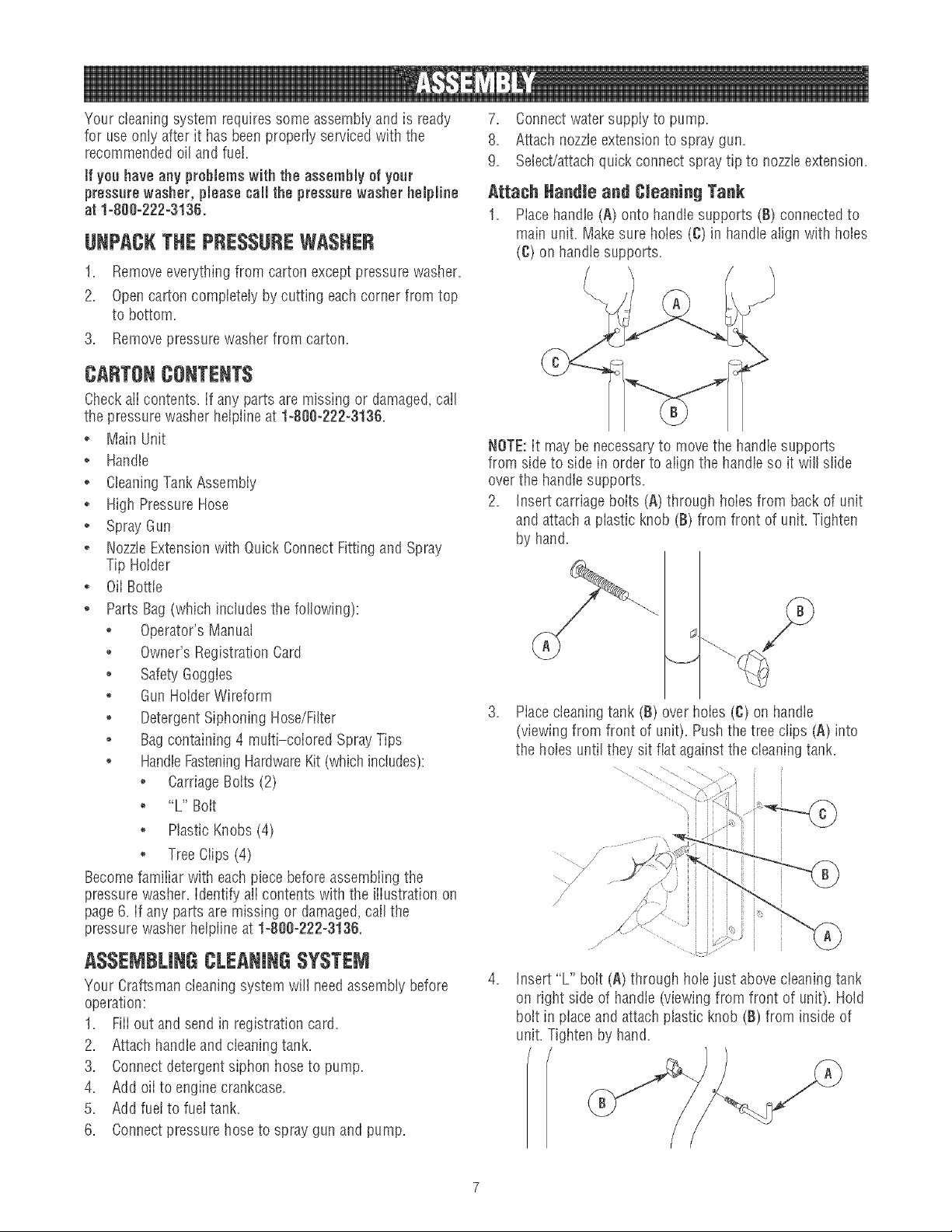

Attach Handle and Cleaning Tank

1. Placehandle (A) onto handlesupports (B) connectedto

main unit. Make sure holes (C) in handlealign with holes

(g) on handle supports.

NOTE:It may be necessaryto move the handle supports

from sideto side in order to align the handle so it will slide

overthe handb supports.

2. Insert carriagebolts (A) through holesfrom back of unit

and attacha plastic knob (B) from front of unit. Tighten

by hand.

3. Placecleaning tank (B} over holes (C}on handle

(viewing from front of unit). Pushthe tree clips (A) into

the holes until they sit fiat againstthe cieaningtank.

/

/

/

A$$EJVJBLJNGCLEANINGSYSTEJVJ

Your Craftsmancleaningsystem will needassembly before

operation:

1. Fill out and send in registration card.

2. Attach handleand cleaningtank.

3. Connectdetergent siphon hose to pump.

4. Add eli to engine crankcase.

5. Addfuei to fuel tank.

6. Connectpressure hoseto spray gun and pump.

Insert "L" bolt (A) througil hob just abovecleaning tank

on right side of handJe(viewingfrom front of unit). Hold

bolt in piaceand attachplastic knob (B) from inside of

unit. Tigilten by hand.

.

Insert spray gun holder wireform (A) through holejust

abovecleaningtank on left side of handle (viewing from

front of unit). Hold wireform in placeand attach a piastic

knob (B) from inside of unit. Tighten by hand.

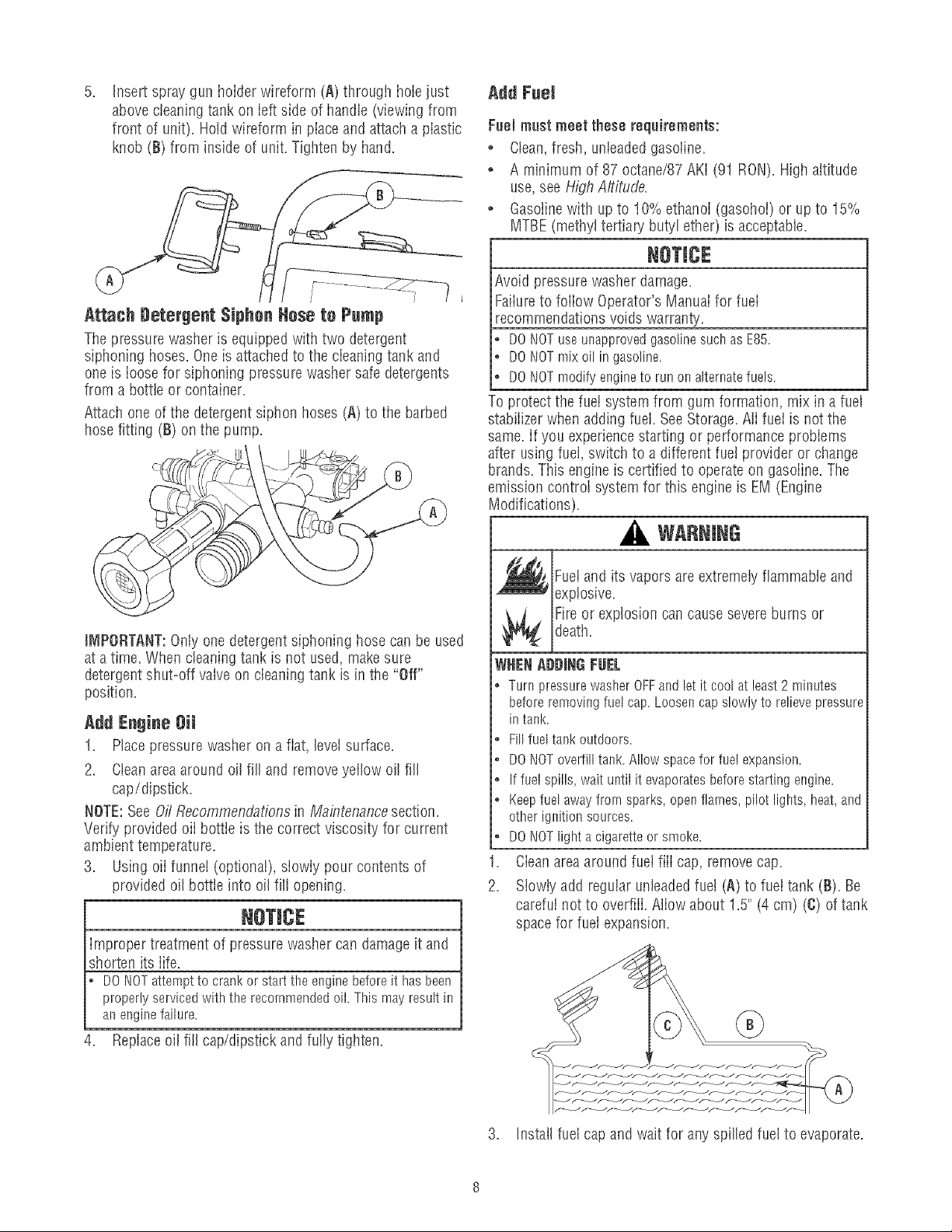

Add Fuel

Fuel must meet these requirements:

. Clean,fresh, unleadedgasoline.

o A minimum of 87 octane/87AKi (91 RON).High altitude

use, see High A/titude.

. Gasoiinewith up to 10% ethanoi (gas@@ or up to 15%

MTBE(methyl tertiary butyl ether) is acceptable.

l

Attach Detergent Siphon Hese to Pump

Thepressure washeris equipped with two detergent

siphoning hoses. One is attachedto the cleaning tank and

one is loosefor siphoning pressure washer safe detergents

from a bottle or container.

Attach one of the detergent siphon hoses (A) to the barbed

hose fitting (B) on the pump.

IMPORTANT:Only one detergent siphoning hosecan be used

at a time. When cteaningtank is not used, makesure

detergent shut=off valve oll cleaningtank is in the "Off"

position.

Add Engine Oil

1. Placepressure washer on a fiat, bvei surface.

2. Cleanarea around oil fill andremove yellow oil fill

cap/dipstick.

NOTE:See Oi/Recommendations in Ma,_otenancesection.

Verify provided oii bottle is the correct viscosity for current

ambient temperature.

3. Using oii funne! (optional), sIowiy pour contents of

provided oil bottle into oil fill opening.

improper treatment of pressurewasher can damageit and

shorten its iife.

DONOTattemptto crankor stat theenginebeforeit hasbeen

properlyservicedwiththerecommendedoil.Thismayresultin

anenginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

Avoid pressure washer damage.

Failureto follow Operator's Manual for fuei

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchasE85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabiiizer when adding fueI. See Storage.Ali fuei is notthe

same. if you experiencestarting or performance probiems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoiine. The

emission control system for this engine is EM (Engine

Modifications).

WARNING

Fueland its vapors are extremely flammable and

explosive.

death.

Fireor explosion can causesevere burns or

WNENADDINOFNEL

o TurnpressurewasherOFFandletit coolat least2 minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

o Fillfueltankoutdoors.

• DONOToverfilltank.Allowspaceforfue!expansion.

o Iffuelspills waituntil it evaporatesbeforestartingengine.

• Keepfuelawayfrornsparks,openflames,pilotlights,heat,and

otherignitionsources.

®

DONOTlight a cigaretteorsmoke.

1.

Cleanareaaround fuet fill cap, removecap.

2.

Siowiy add regular unleadedfuel (A) to fuet tank (B). Be

carefui not to overfiii. Aliow about 1.5" (4cm) (C) oftank

space for fuel expansion.

3. Install fuel cap and wait for any spilled fuelto evaporate.

CAUTISN! AlcohoI-btended fuels(called gasohoI, ethanol or

methanoi) can attract moisture, which ieads to separation and

formation of acids during storage. Acidic gas can damagethe

fuei system of an enginewhiie in storage.

Toavoid engine problems, the fuel system should betreated

with a fuei preserver or emptied before storage of 30 days or

longer, if adding a fuel preserver,fiii the fuel tankwith fresh

fuei. if only partialiy tiffed, air in the tank wiii promote fue!

deterioration during storage, if fuei preserver is not used,

drain the fueI tank, start the engine and iet it run untii the fuel

lines and carburetor are empty. Usefresh fueI next season.

See Storagefor additionai information.

NEVERuseengine or carburetor cleanerproducts in the fuel

tank as permanent damage may occur.

NighAltitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remain emissions compliant, high aititude adjustment is

required. Operationwithout this adjustment wiii cause

decreasedperformance, increasedfuet consumption, and

increasedemissions. Seea qualified Sears dealer for high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

Cenneet Hese and Water Supply te Pump

IDO NOT the without the connected

and turned on,

NOTE:Removeand discardthe shipping caps from the

pump's high pressure outtet and water inlet before attaching

hoses.

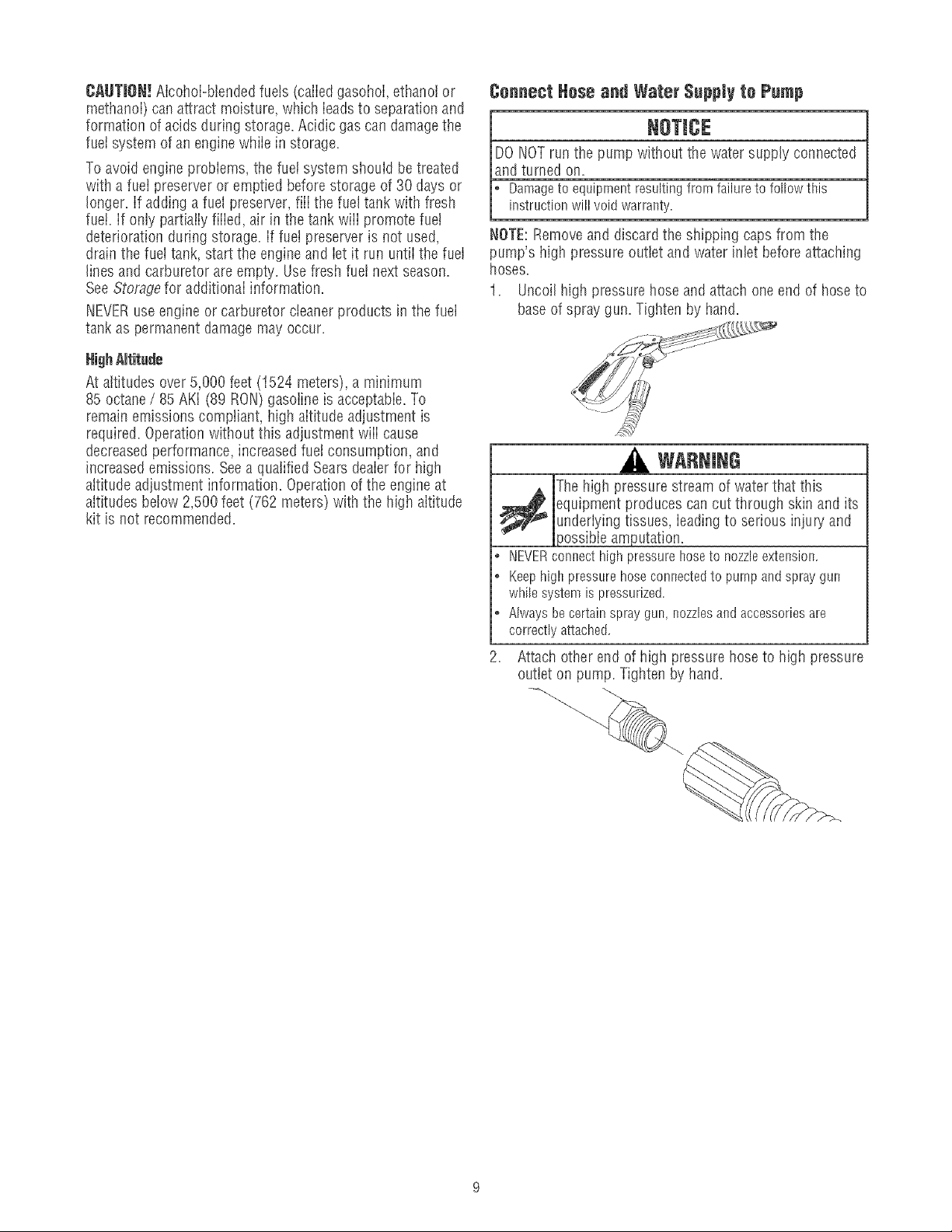

1. Uncoilhigil pressure hose and attach one end of hoseto

run

instructionwillvoidwarranty

Damageto equiprnentresultingfromfailureto followthis

baseof spray gun. Tigilten by hand.

pump

water

supply

WARNING

Thehigh pressurestream of waterthat this

1_ equipment produces cancut through skin and its

, NEVERconnecthighpressurehoseto nozzleextension.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

,', Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

underiyingtissues, ieadingto serious injury and

_ossibieamputation.

2. Attach other end of high pressure hoseto high pressure

outlet on pump. Tighten by hand.

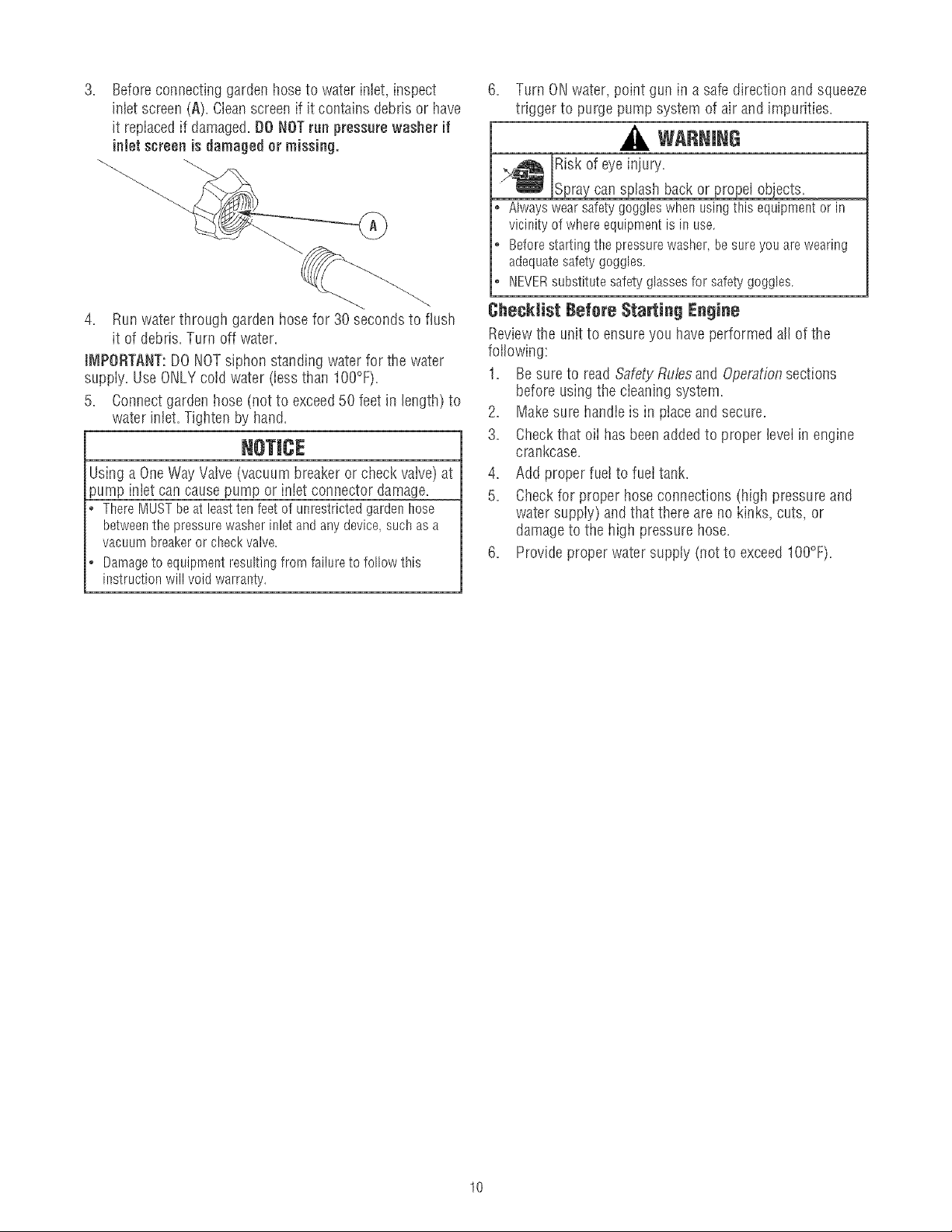

3. Beforeconnectinggardenhosetowaterinlet,inspect

inletscreen(A).Cleanscreenifitcontainsdebrisorhave

itreplacedif damaged=DONOTrunpressurewasher if

inlet screen is damaged or missing.

6. Turn ONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities.

WARNING

.

Run water through garden hose for 30 secondsto flush

it of debris. Turn off water.

IMPORTANT:DO NOTsiphon standing water for the water

supply. UseONLYcold water (less than 100%).

5. Connectgarden hose (not to exceed50 feet in length) to

water inlet. Tighten by hand.

Using a One Way Valve (vacuum breaker or check valve) at

pump inlet can cause pump or inlet connector damage.

There MUSTbe at least ten feet of unrestricted garden hose

betweenthe pressure washer inlet and any device, such as a

vacuum breakeror check valve.

Darnageto equipment resulting from failure to follow this

instruction will void warranty.

_Spray cansp ash backor propel objects.

Riskof eye injury.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentisin use

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles

NEVERsubstitutesafetyglassesfor safetygoggles

Checklist Before Starting Engine

Reviewthe unit to ensureyou have performed atl of the

following:

1. Besure to read SafetyRules and Operationsections

before usingthe cleaning system.

2. Makesure handle is in placeand secure,

3. Checkthat oii has beenadded to proper level in engine

crankcase.

4. Add proper fuetto fuet tank.

5. Checkfor proper hoseconnections (high pressure and

water suppiy) and that there are no kinks, cuts, or

damageto the high pressure hose.

6. Provideproper water supply (not to exceedIO0°F).

10

HOWTOUSEYOURCLEANINGSYSTEM

If you haveany probbms operatingyour pressure washer,

pleasecallthe pressure washer heJpfineat1-800-222-3136,

Pressure Washer Lecation

PressureWasherClearance

WANNING

Exhaustheat/gases can ignite combustibies,

structures or damage fuei tank causing a fire=

• Keepatleast5ft. (152cm)clearanceonall sidesofpressure

washerincludingoverhead.

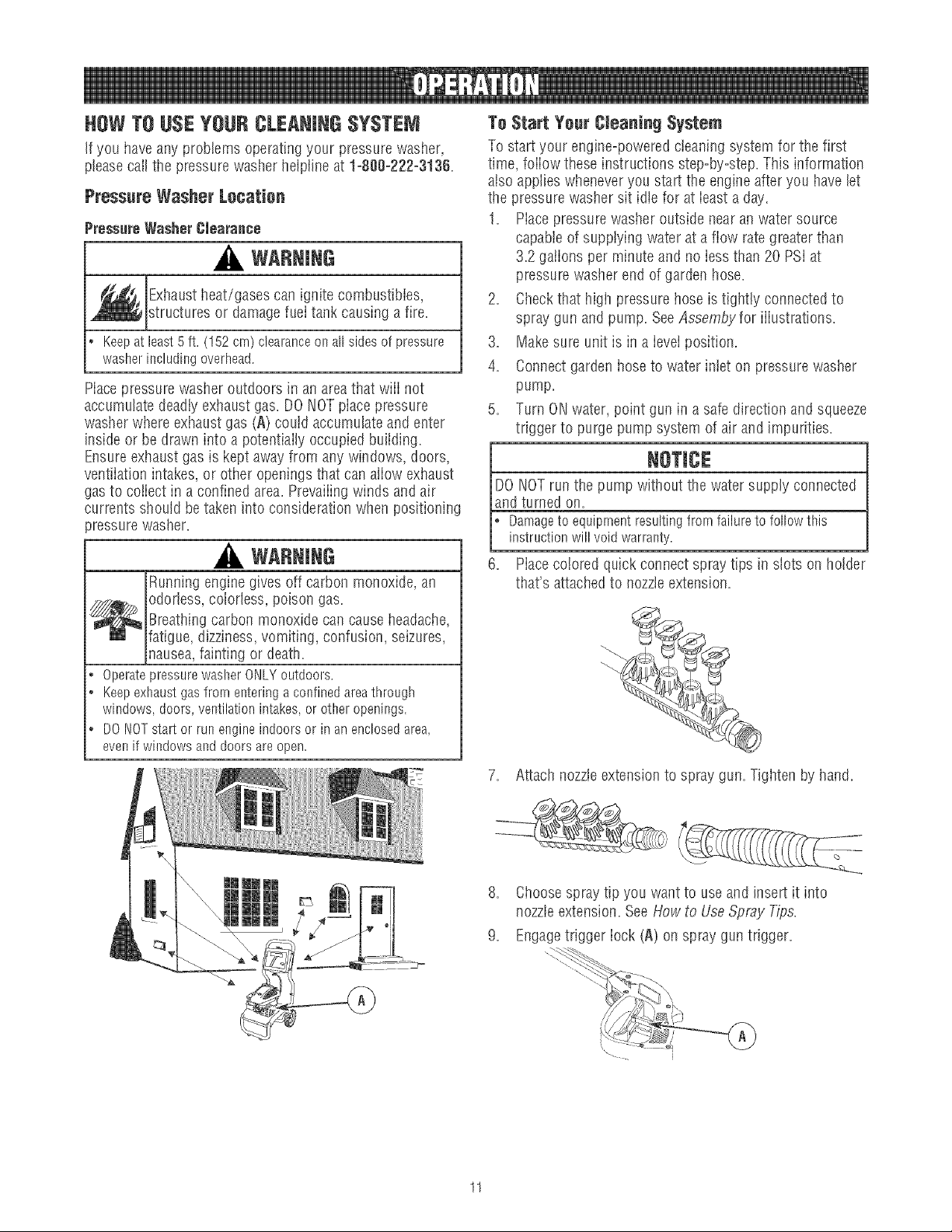

Macepressure washer outdoors in anareathat wiii not

accumulate deadtyexhaustgas. DONOTpiace pressure

washer where exhaustgas (A) could accumulateand enter

inside or be drawn into a potentiaily occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventiiation intakes, or other openings that can aliow exhaust

gasto coiiect in a confined area. Prevaiiingwinds and air

currents should be takeninto considerationwhen positioning

_ressurewasher.

WARNING

Runningengine gives off carbon monoxide, an

odorless, coiorbss, poison gas.

Breathingcarbon monoxide can causeheadache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death=

* OperatepressurewasherONLYoutdoors.

, Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,or otheropenings.

* DONOTstat or runengineindoorsorin anenclosedarea,

evenif windowsanddoorsareopen.

Te Start Yenr Cleaning System

To start your engine=poweredcleaning system for the first

time, foiiow these instructions step=by=step.This information

also applies wheneveryou start the engine after you havelet

the pressure wa@er sit idle for at bast a day.

1= Piacepressure washer outside near an water source

capabieof supplying water at a flow rategreater than

3=2galions per minute and no iess than 20 PSi at

pressurewasher end of garden hose.

2= Checkthat higil pressure hose istightly connectedto

spray gun and pump. SeeAssemby for iiiustrations.

3= Makesure unit is in a ieveiposition=

4= Connectgarden hoseto water intet on pressure washer

pump.

5. Turn ONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities.

NOTICE

DONOTrun the pump without the water supply connected

and turned on.

_ amageto equipmentresultingfrom failureto followthis

instructionwillvoidwarranty

6. Piacecolored quick connect spray tips in slots on holder

that's attachedto nozzleextension.

%

7. Attach nozzleextension to spray gun. Tightenby hand=

8. Choosespray tip you want to use and insert it into

nozzleextension=SeeHow to UseSpray Tips.

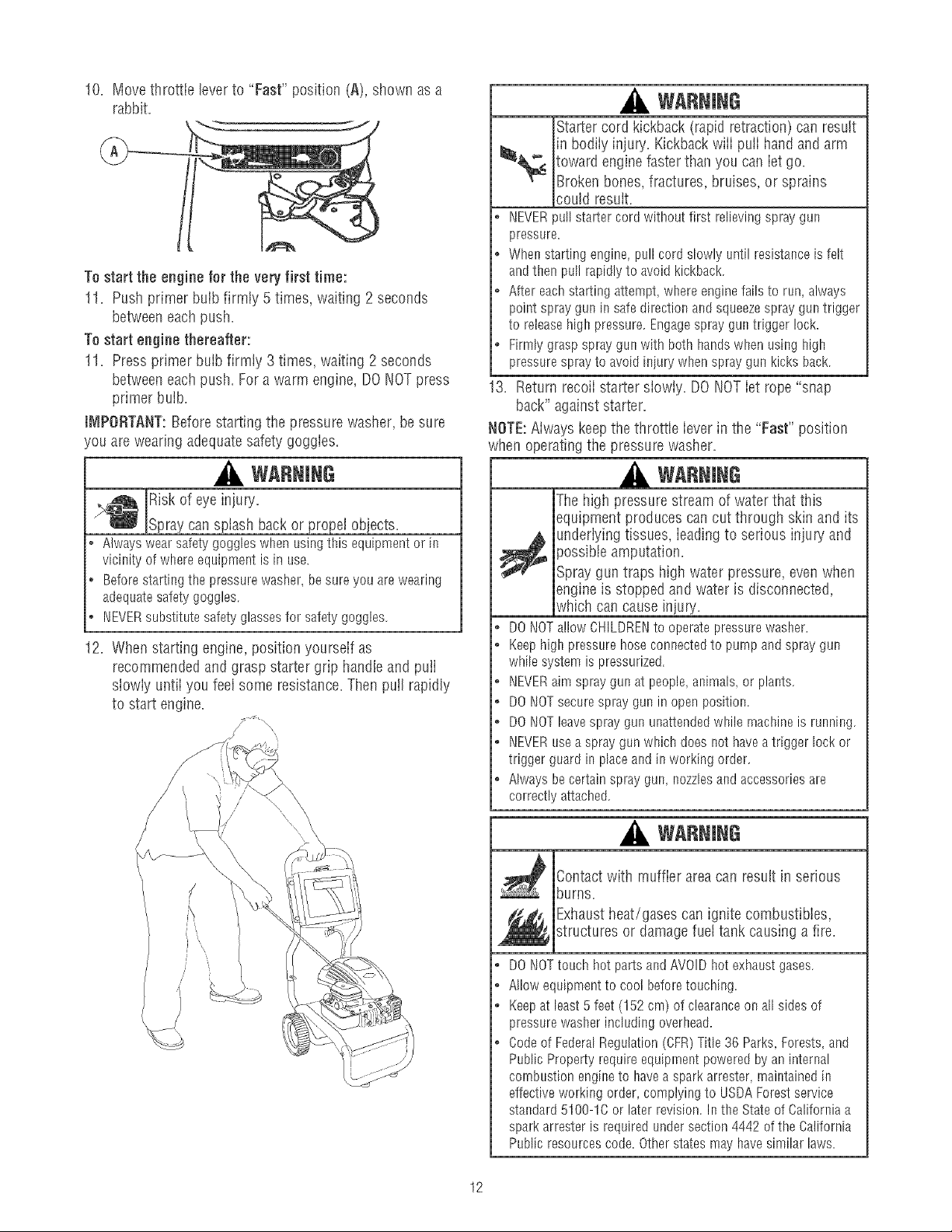

9. Engagetrigger iock (A) on spray gun trigger.

11

10. Move throttle leverto "Fast" position (A), shown as a

rabbit.

To start the engine for the veryfirst time:

11. Push primer buib firmly 5 times, waiting 2 seconds

betweeneach push.

To start engine thereafter:

11. Press primer buib firmty 3 times, waiting 2 seconds

betweeneach push. For awarm engine, DONOTpress

primer bulb.

t_IPORTANT:Before starting the pressure washer, be sure

'ou are wearing adequatesafety goggles.

WARNING

Starter cord kickback(rapid retraction) call result

in bodiiy injury. Kickbackwiii puIi handand arm

toward enginefaster than you can iet go.

Brokenbones, fractures, bruises, or sprains

could resuIt.

• NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

o Whenstartingengine,pullcordslowlyuntil resistanceisfelt

andthenpullrapidlyto avoidkickback

o Aftereachstartingattempt,whereenginefailsto run, always

pointspraygunin safedirectionandsqueezesprayguntrigger

to releasehighpressureEngagesprayguntrigger!ock.

o Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidiniurywhenspraygunkicksback

13. Return recoii starter siowiy. DONOTiet rope "snap

back"against starter.

t_OTE:Aiways keepthe throttle iever in the "Fast" position

when operating the pressure washer.

WARNING

v_ Riskof eye injury.

_Spray cansplash back or propel objects.

Alwayswea!safetygoggleswhenusingthisequipmentor in

vicinityof whereequipmentisin use.

Beforestartingthe pressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

12. Whenstarting engine, position yourseif as

recommendedand grasp starter grip handle and pulI

siowiy untii you feel some resistance. Then pull rapidly

to start engine.

WARNING

Thehigh pressurestream of waterthat this

equipment produces can cut through skin and its

_ nderlying tissues, ieadingto serious injury and

o DONOTallowCHLDREI',_to operatepressurewasher.

• Keephighpressurehoseconnectedto purnpandspraygun

whilesystemis pressurized.

• NEVERaim spraygunatpeople,animals_orplants.

o DONOTsecurespraygun inopenposition.

• DONOTleavespraygununattendedwhilernachineis running.

o [',]EVERusea spraygunwhichdoesnothaveatriggerlockor

triggerguardin placeandinworkingorder.

• Alwaysbecertainspraygun,nozzbsandaccessoriesare

correctlyattached.

}ossibte amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

WARNING

_, Contactwith muffler resultin serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

area can

o

DONOTtouchhotpartsandAVOIDhot exhaustgases.

®

Allowequipmentto cool beforetouching.

o

Keepatleast5 feet(152cm) ofclearanceonall sidesof

pressurewasherincludingoverhead.

Codeof FederalRegulation(CFR)Title36 Parks_Forests,and

PublicPropertyrequireequiprnentpoweredby aninternal

combustionengineto haveasparkarrester rnaintainedin

effectiveworkingorder,complyingto USDAForestservice

standard510B-1Cor laterrevision.IntheStateof6aliforniaa

sparkarresteris requiredundersection4442oftheCalifornia

Publicresourcescode.Otherstatesmayhavesimilarlaws.

12

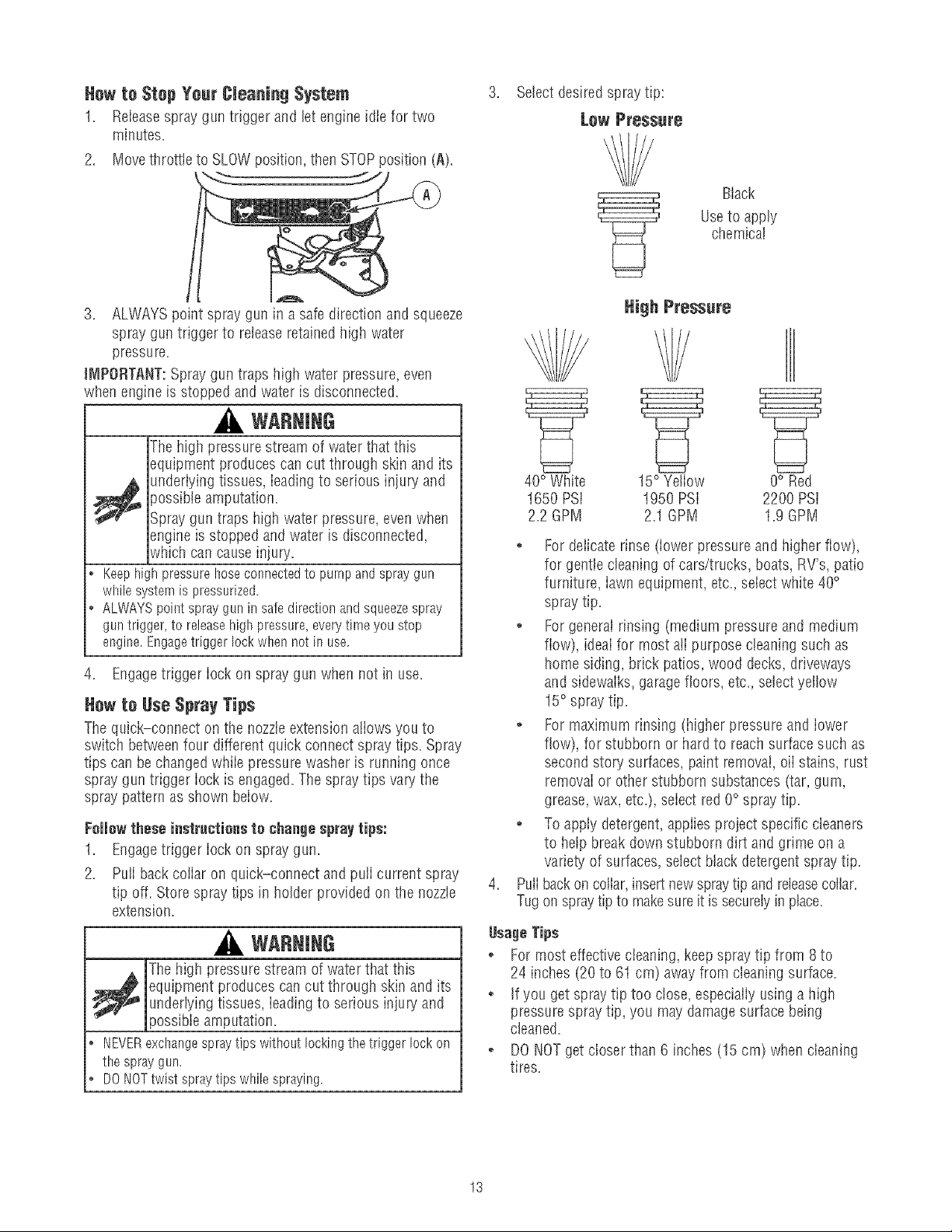

How to Stop Your Cleaning System

1. Reieasespray gun trigger and letengine idte for two

minutes.

2. Movethrottie to SLOWposition,then STOPposition (A).

3. ALWAYSpoint spray gun in a safe direction and squeeze

spray gun trigger to releaseretained high water

pressure,

iMPORTANT:Spraygun traps high water pressure,even

when engine is stopped and water is disconnected.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

,_ underiyingtissues, ieadingto serious injury and

• Keephighpressurehoseconnectedto purnpandspray'gun

whilesystemis pressurized.

, ALWAYSpointspray'gunin safedirectionandsqueezespray'

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetrigger lockwhennot inuse.

4. Engagetrigger lock on spray gun when not in use.

)ossibteamputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

Hewte UseSpray Tips

Thequick-connect on the nozzleextensionaliows you to

switch between four different quick connect spray tips. Spray

tips can be changedwhiie pressure washer is running once

spray gun trigger lock is engaged.The spray tips vary the

spray pattern as shown beiow.

F(_liawthese instructiansto changespraytips:

1= Engagetrigger lockon spray gun=

2. Puli back coliar on quick-connect and puli current spray

tip off. Storespray tips in holder provided on the nozzle

extension.

WARNING

The high pressure stream of water that this

_ quipment produces can cut through skin and itsunderlyingtissues, ieadingto serious injury and

possible amputation.

° NEVERexchangespraytips withoutlockingthetriggerlockon

the spraygun.

, DONOTtwist spraytips whilespraying.

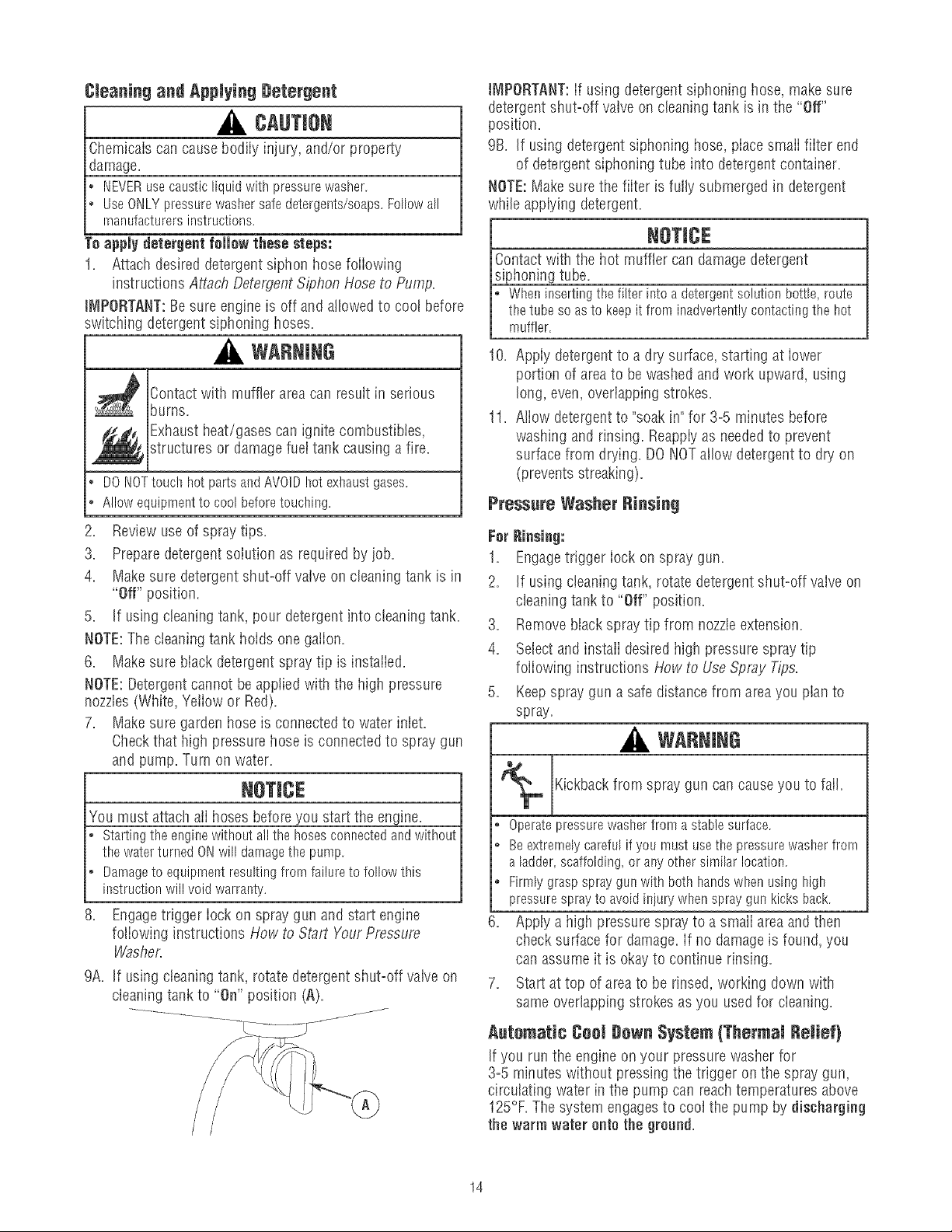

3. Selectdesiredspraytip:

Lew Pressure

Black

Useto apply

chemical

40° White 15°Yeliow 0° Red

1650 PSi 1950 PSi 2200 PSi

2.2 GPM 2.1 GPM 1.9 GPM

* For delicate rinse (lower pressure and higher flow),

for gentle cleaning of cars/trucks, boats, RV's, patio

furniture, lawn equipment, etc. select white 40°

spray tip.

, Forgeneral rinsing (medium pressure and medium

flow), ideal for most atIpurpose cleaning such as

home siding, brick patios, wood decks, driveways

and sidewaiks, garagefloors, etc., selectyellow

15° spray tip.

o For maximum rinsing (higher pressure and iower

flow), for stubborn or hard to reachsurfacesuch as

second story surfaces,paint removal,oii stains, rust

removai or other stubborn substances (tar, gum,

grease,wax, etc.), seiect red 0° spray tip.

, Toapply detergent, appiies project specific cleaners

to help breakdown stubborn dirt and grime on a

variety of surfaces, selectblack detergentspray tip.

.

Puffbackon coliar,insert new spraytip and releasecollar.

Tugon spraytip to makesureit is securelyin place.

UsableTips

o For most effective cleaning, keep spray tip from 8 to

24 inches (20 to 61 cm) awayfrom cleaningsurface.

, If you get spray tip too close, especialiy using a high

pressure spray tip, you may damagesurface being

cleaned.

, DONOTget closerthan 6 inches (15 cm) when cleaning

tires.

13

Cleaning and Applying Detergent

CAUTION

Chemicaiscan causebodiiy injury, and/or property

damage.

NEVERusecausticliquidwithpressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

rnanufacturersinstructions.

Te apply detergent feiiew these steps:

1. Attach desireddetergent siphon hosefoiiowing

instructions Attach DetergentSiphon Hose to Pump.

iMPORTANT:Be sure engine is off and allowed to cool before

switching detergentsiphoning hoses.

IMPORTANT:If using detergent siphoning hose, make sure

detergentshut=off valve on cleaningtank is in the "Off"

position.

9B. If using detergent siphoning hose, piace smaii fiiter end

of detergent siphoning tube into detergent container.

NOTE:Makesure the fiiter is fuily submerged in detergent

while applying detergent.

Contact with the hot muffler can damage detergent

siphoning tube.

When inserting the filter into a detergent solution bottle, route

the tube so as to keep it from inadvertently contacting the hot

muffler.

WANNING

;_ Contact with muffler result in serious

,', DONOTtouchhotpartsandAVOIDhotexhaustgases.

o Allowequipmentto coolbeforetouching.

2. Reviewuse of spray tips.

3. Preparedetergent soiution as required by job.

4. Makesure detergentshut-off valve on cleaningtank is in

5. If using cleaningtank, pour detergentinto cleaningtank.

NOTE:The cleaning tank hoids one galion.

6. Makesure blackdetergent spray tip is instalied.

NOTE:Detergentcannot be appiied with the higil pressure

nozzles(White, Yellow or Red).

7. Makesure gardenhose is connectedto water inlet.

You must attachaiJhoses beforeyou start the engine.

thewaterturnedONwill damagethepump.

8. Engagetrigger iock on spray gun and start engine

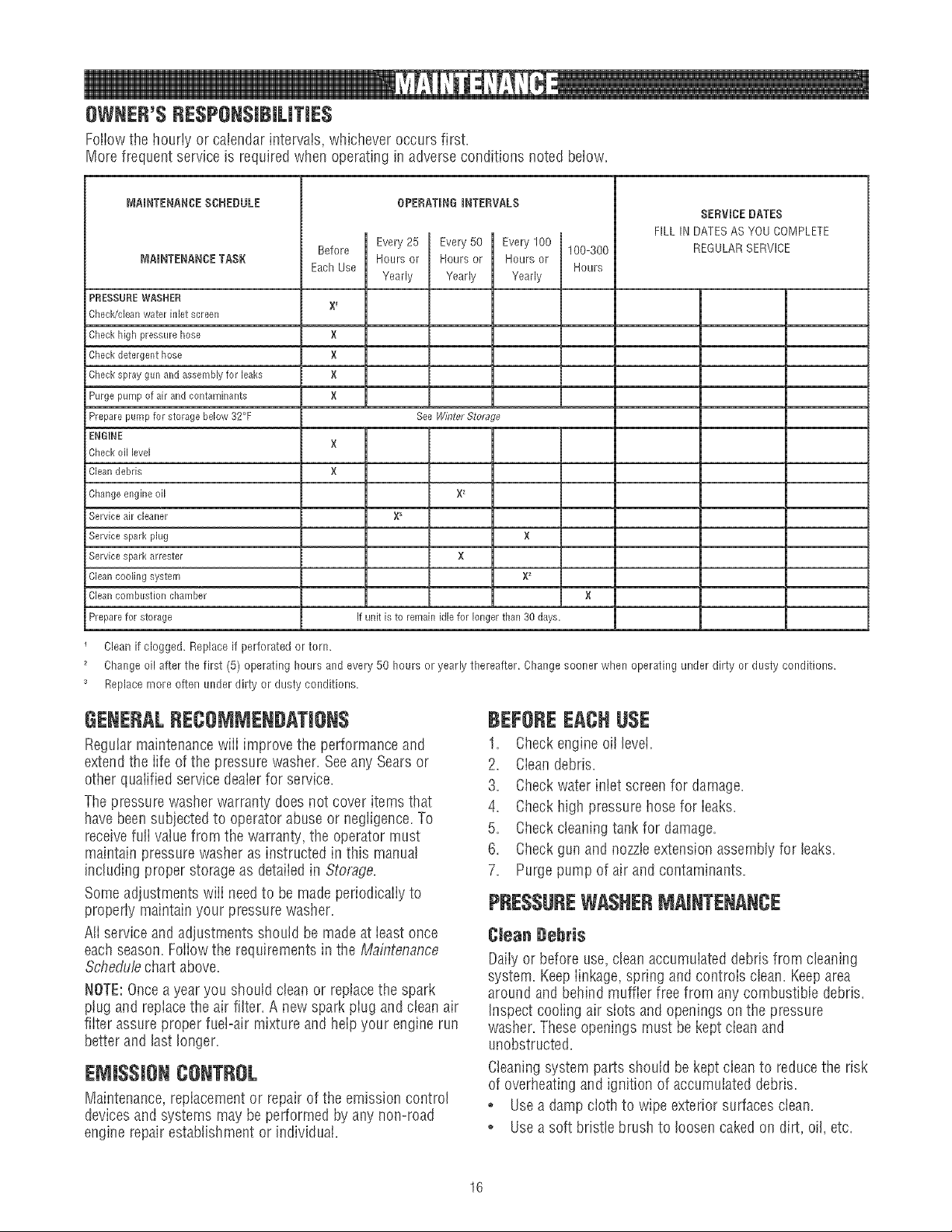

9A. If using cleaningtank, rotate detergentshut-off valve on

burns.

Exhaustheat/gases can ignite combustibies,

structures or damage fueI tank causing a fire.

"Off" position.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

Startingtheenginewithoutallthehosesconnectedandwithout

Darnageto equipmentresultingfrom failuretofollowthis

instructionwillvoidwarranty.

foliowing instructions How to Start Your Pressure

Washe,:

cleaningtank to "On" position (A).

area can

NOTICE

10. Appiy detergentto a dry surface, starting at iower

portion of areato be washed and work upward, using

long, even, overiappingstrokes.

11. Aliow detergentto "soak in" for 3-5 minutes before

washing and rinsing. Reappiyas neededto prevent

surface from drying. DO NOTallow detergent to dry on

(preventsstreaking).

Pressure Washer Rinsing

Fer Rieein_l;

1. Engagetrigger iock on spray gun.

2. If using cleaningtank, rotate detergent shut-off valve on

cleaning tank to "Off" position.

3. Removeblackspray tip from nozzteextension.

4. Selectand instaii desiredhigh pressure spray tip

following instructions How to UseSplay Tips.

5. Keepspray gun a safe distancefrom areayou plan to

spray.

WARNING

Kickbackfrom spray gun cancauseyou to fail.

,', Operatepressurewasherfromastablesurface.

o BeextrerneIycarefulifyou mustusethepressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

o Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

6.

Apply a higil pressure spray to a smali areaand then

check surface for damage,if no damage is found, you

can assume it is okayto continue rinsing.

Start at top of areato be rinsed, working down with

same overlapping strokes asyou used for cleaning.

Autemati¢ CeeJDewu System {Thermal Relief)

If you run the engineon your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circuiating water in the pump can reachtemperatures above

125%. Thesystem engagesto cool the pump by dischargieg

the warm water eete the greued.

14

ENGINETECHNICALiNFORMATiON

This is a single cylinder, L-head,air cooled engine. It is a low

emissions engine.

Intile Stateof California, Modei I00000 enginesare certified

by the California Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respectto the performance or

operational Iife of this engine.Theengine is warranted soiely

according to tile product and emissions warranties stated

elsewherein this manual.

Pewer Ratings

Thegross power rating for individual gas engine models is

labeledin accordancewith SAE(Societyof Automotive

Engineers)code J1940 (SmalI Engine Power & Torque

Rating Procedure),and rating performance hasbeen

obtained andcorrected in accordancewith SAEJ1995

(Revision2002-05). Torque values are derived at 3060 RPM;

horsepower vaiues are derivedat 3600 RPiVI.Actuai gross

engine power wiii be iower and is affected by, among other

things, ambient operating conditions and engine-to-engine

variabiiity. Givenboth the wide array of products on which

enginesare piacedand the variety of environmentai issues

appiicabteto operatingthe equipment, the gas engine wiii not

developthe rated gross power when used in a given pieceof

power equipment (actual "on-site"or net power). This

difference is due to a variety of factors including, but not

limited to, accessories (air cteaner,exhaust,charging,

cooiing, carburetor, fuel pump, etc.), appiication iimitations,

ambient operating conditions (temperature,humidity,

altitude), and engine-to-engine variabiiity. Due to

manufacturing and capacity iimitations, Briggs & Stratton

maysubstitute an engine of higher ratedpower for this

Seriesengine.

PRODUCTSPECiFiCATiONS

PressureWasherSpecifications

Max Outbt Pressure ....................... 2,200 PSi

Max Ftow Rate............................. 22 GPM

ChemicalMix......................... Use as directed

Water SupplyTemperature .......... Not to exceed IO0°F

Shipping Weight ............................. 63 Ibs.

EngineSpecificatiens

Bore............................... 256 in. (65A rnm)

Stroke ............................. 137 in. (47.6 turn)

Displacement........................ 9.67 in. (158.6 cc)

SparkPlug

Type: ............. Bfiggs & Stratton 802592 or 5095D

SetGapTo: ...................... O.030inch(O.76mm)

ArrnatureAir Gap: ........... 0.006-0.010in.(O.15=O.25mm)

Valveclearancewithvalvespringsinstalledand piston1/4in.

(6 turn)pasttopdeadcenter(checkwhenengineiscold).

Intake.................... 0.005-0.007in.(0.13-0.18rnrn)

Exhaust .................. 0.007-0.009in.(0.18=0.23turn)

FuelCapacity............................... 1.0Quarts

OilCapacity........................ 18Ounces(0.5 liter)

NOTE:For practicai operation, the engine ioad should not

exceed 85% of rated power. Enginepower will decrease

3-I/2% for each1,000 feet (300 meters) abovesea Ieveiand

1% for each 10° F(5.6° C) above 77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

15

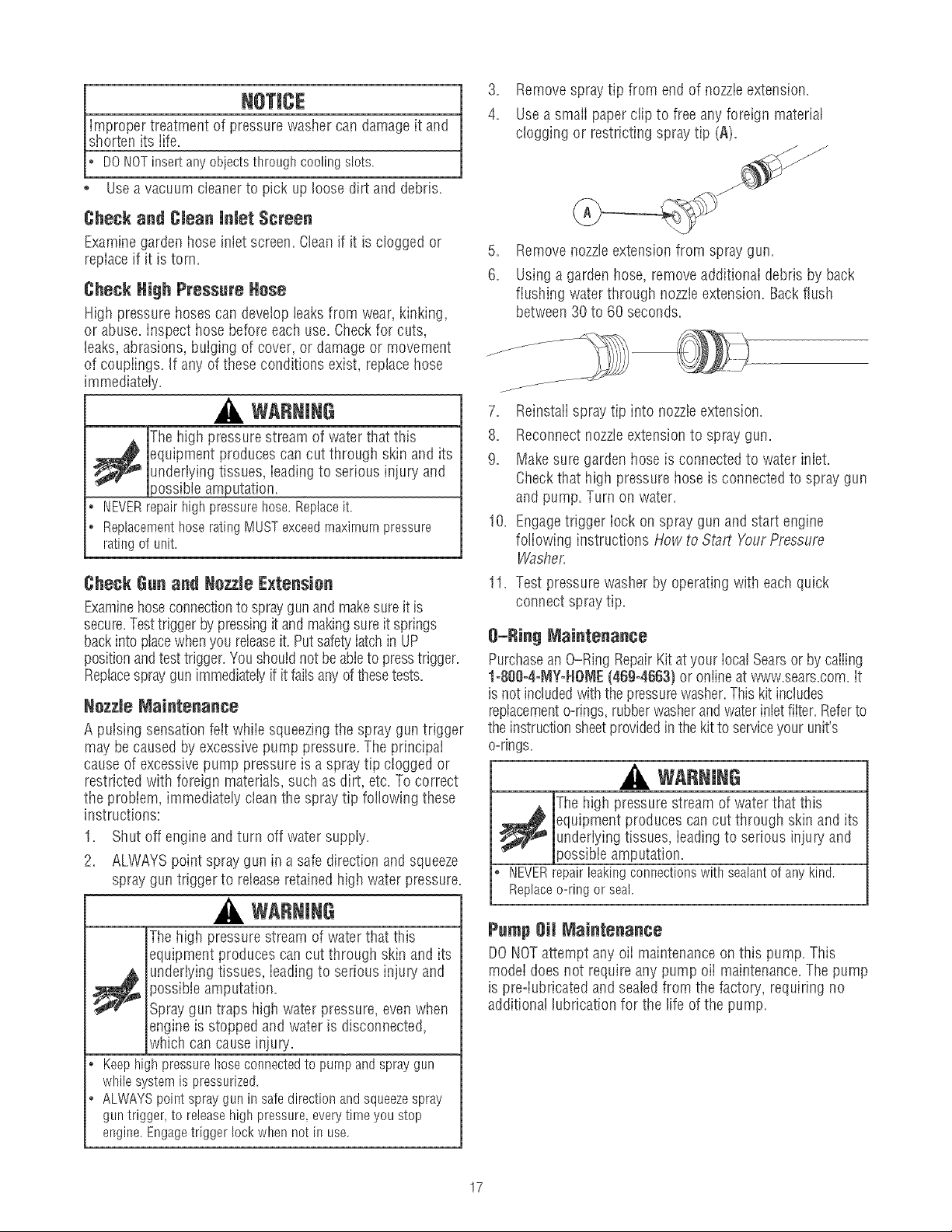

OWNER'SRESPONSiBiLiTIES

Followthe hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating inadverse conditions noted below.

MAINTENANCESCHEDULE

MAINTENANCETASK

PRESSUREWASHER

Chec_Ncieanwater inlet screen

Check high pressure hose

Check detergent hose

Checkspray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Check oil bye[

Clean debris

Changeengine oil

Service air cleaner

Service spark plug

Service spark arrester

Clean cooling system

Clean combustion chamber

Prepare for storage

Cleanif clogged. Replaceif perforated or torn.

Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

Replacemore often under dirty or dusty conditions,

Before

EachUse

X 1

}(

N

N

}(

X

X

OPERATINGiNTERVALS

Hours or Hours or Hours or

I Every25 Every50 Every 100

Yearly Yearly Yearly

See Winter Storz_ge

X _

X_

X

X

X_

If unit is to remain idle for longer than 30 days,

100-300

Hours

SERVICEDATES

FILL IN DATESAS YOU COMPLETE

REGULARSERVICE

GENERALRECO 'JMENDATION$

Regularmaintenancewill improve the performance and

extendthe iife of the pressure washer. Seeany Searsor

other quaiified service deaierfor service.

Thepressure washerwarranty doesnot cover items that

havebeen subjectedto operator abuseor negiigence.To

receivefurl vatuefrom the warranty, the operator must

maintain pressure washer as instructed in this manual

including proper storage as detaiied in Storage.

Someadjustments wiii needto be madeperiodicaliy to

properly maintain your pressure washer.

AtI service andadjustments should be madeat leastonce

eachseason.Follow the requirements in the Maintenance

Schedu/echart above.

NOTE:Oncea year you should clean or replace the spark

ptug and repiacethe air filter. A new spark piug and clean air

filter assure proper fuel-air mixture and helpyour engine run

better and last Ion@r.

ENIi$$i0N CONTROL

Maintenance,replacementor repair of the emission control

devicesand systems maybe performed by any non-road

engine repair establishment or individual.

BEFOREEACHUSE

1. Checkengine oil bvei.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hose for leaks.

5. Checkcteaningtank for damage.

6. Checkgun and nozzteextension assembly for leaks.

7. Purgepump of air and contaminants.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use,clean accumuiateddebris from cbaning

system. Keepiinkage, spring and controis cban. Keeparea

around and behind muffler free from any combustible debris.

Inspect cooiing air siots and openings onthe pressure

washer. Theseopenings must be kept cieanand

unobstructed.

Cleaningsystem parts should be kept cleanto reducethe risk

of overheating and ignition of accumuiated debris.

. Usea dampcioth to wipe exterior surfaces clean.

o Usea soft bdstte brush to loosencaked on dirt, oil, etc.

16

NOTICE

jImproper treatment of pressurewasher can damageit and

its fife,

_horten_ ....

L_ DONOTinsertany'objectsthroughcoolingslots.

° Usea vacuum cleanerto pick up loose dirt and debris.

Check and Cmean[n_etScreen

Examinegarden hose inbt screen. Cban if it is clogged or

repiaceif it is torn.

Check High Pressure Hese

High pressure hoses can developleaks from wear, kinking,

or abuse, inspect hose beforeeach use. Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of coupiings. If any of theseconditions exist, replacehose

immediately.

3. Removespray tip from end of nozzleextension.

4. Usea small paperctip to free any foreign material

clogging or restricting spray tip (A).

.

RemovenozzIeextension from spray gun.

6.

Using a garden hose, removeadditional debris by back

flushing water through nozzleextension. Backflush

between30 to 60 seconds.

j_J

WARNING

The high pressure stream of water that this

_ quipment produces cancut through skin and its

* NEVERrepairhighpressurehose.Replaceit.

, ReplacementhoseratingMUSTexceedrnaxhnurnpressure

ratingof unit.

underlyingtissues, ieadingto serious injury and

)ossibb amputation.

Check Gun and Nezzle Extensien

Examinehoseconnectionto spraygun and makesureit is

secure.Testtrigger bypressingit andmakingsure it springs

backinto placewhenyou releaseit.Putsafetylatchin UP

positionandtest trigger.You shouldnot beabb to presstrigger.

Replacespraygun immediatelyif it failsanyofthesetests.

Nezzle Maintenance

A pulsing sensationfelt whiie squeezingthe spray gun trigger

may becaused by excessivepump pressure. Theprincipal

cause of excessivepump pressure is a spray tip ctogged or

restricted with foreign materials, such asdirt, etc. Tocorrect

the problem, immediately cleanthe spray tip following these

instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction and squeeze

spray gun trigger to releaseretained high water pressure.

WARNING

Thehigh pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, ieading to serious injury and

• Keephighpressurehoseconnectedto purnpandspraygun

o ALWAYSpointspraygunin safedirectionandsqueezespray

possible amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which cancause injury.

whilesystemis pressurized.

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetrigger lockwhennot inuse.

7. Reinstatispray tip into nozzleextension.

8. Reconnectnozzleextensionto spray gun.

9. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

10. Engagetrigger Iock on spray gun and start engine

foflowing instructions How to Star Your Pressure

Washe,t

11. Test pressure washer by operating with eachquick

connect spray tip,

O-Ring Maintenance

Purchasean O-Ring RepairKitatyour iocatSearsor by caiiing

1-800-4-MY-HO_IE(469-4663)or online at _wvw.sears.com.it

isnot includedwiththe pressurewasher.Thiskit includes

replacemento=rings,rubberwasherandwater inletfilter. Referto

the instructionsheetprovidedin thekit to serviceyour unit's

o=fings.

WARNING

Thehigh pressurestream of waterthat this

_ quipment produces cancut through skin and itsunderlyingtissues, ieadingto serious injury and

}ossibie amputation.

• NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

Pump Oil Maintenance

DONOTattempt any oil maintenanceon this pump. This

model doesnot require any pump oii maintenance.Thepump

is pre-Iubricated and seaiedfrom the factory, requiring no

additional lubrication for the life of the pump.

17

ENGINEMAINTENANCE

WARNING

Unintentionalsparking can result in fire or

_¢ electric shock.

WidENADJUSTINGORMAKINGREPAIRSTOYOUR

PRESSUREWASHER

° Disconnectthe sparkplugwirefromthe sparkplugandplace

thewirewhereit cannotcontactsparkplug.

WidENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester.

. DONOTcheckfor sparkwith sparkplugremoved.

CheckingOil Level

OiIlevelshould be checked prior to each useor at least every

5 hours of operation. Keepoii ievei maintained.

1. Makesure pressure washer is on a ieveisurface=

2= Remove oii dipstick and wipe dipstick with cleancioth=

Reptaceandtigilten dipstick. Removeand and check oil

levei.

3. Verify oii is at "FuIF' mark on dipstick. Replaceand

tigilten dipstick.

Oil

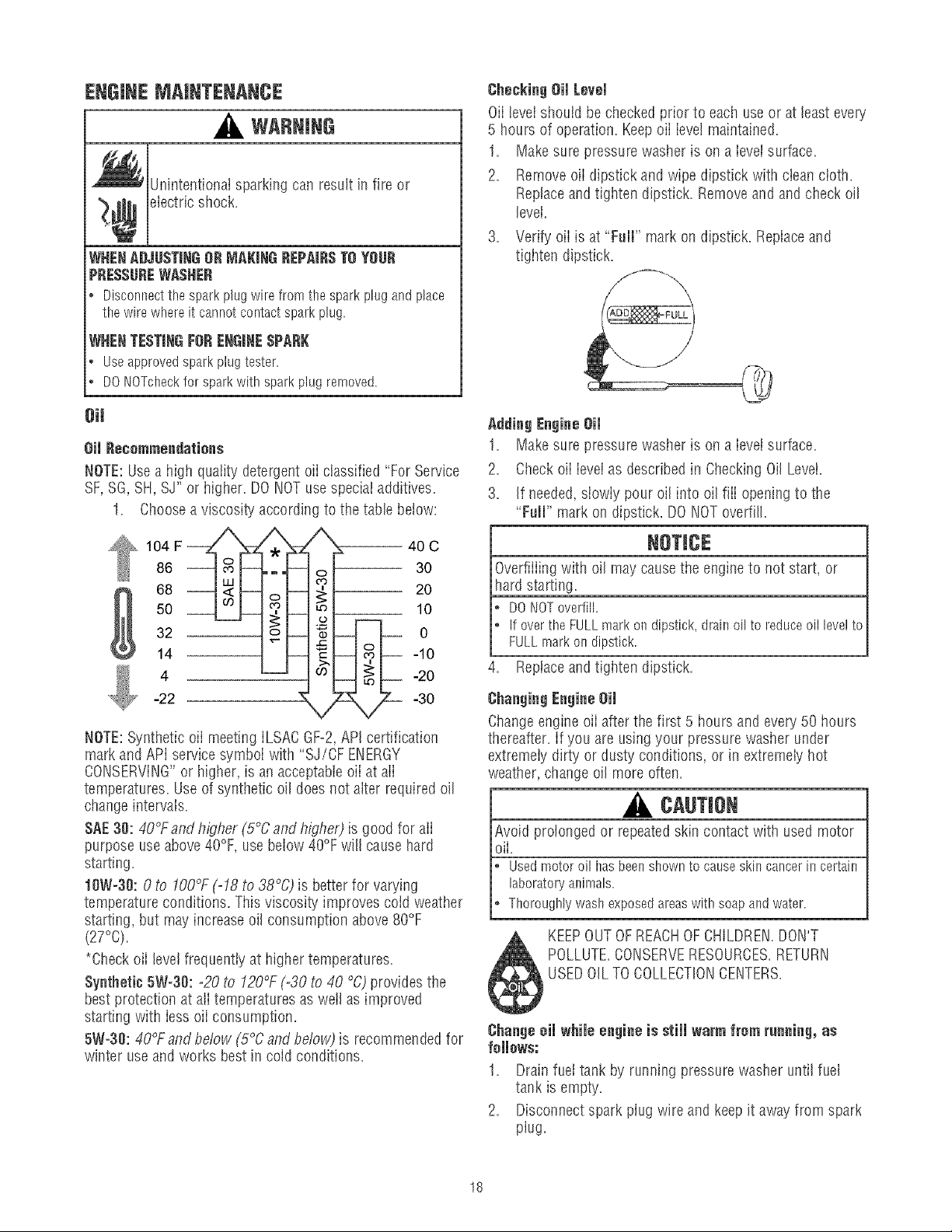

eli Recommendations

NOTE:Usea high quality detergent oiI classified "For Service

SF,SG,SH, SJ" or higher. DONOTusespecial additives.

1. Choosea viscosity according to the table below:

86

68

50

32

104F

14

4

-22

NOTE:Synthetic oii meeting iLSACGF=2,APIcertification

markand APi service symboi with "SJ/CF ENERGY

CONSERVING"or higher, is an acceptableoii at aii

temperatures. Useof synthetic oil does not alter required oil

changeintervals.

$AE 30: 40°Fand higher (5°C and higher) isgood for aii

purpose useabove40%, use below 40°F will cause hard

starting.

10W-30:0 to IO0°F(=18to 38°C) is better for varying

temperatureconditions. This viscosity improves cold weather

starting, but may increase oil consumption above80%

(27%).

*Check oii level frequently at higher temperatures.

Synthetic 5W=30:=20to 120°F(=30to 40 °C) provides the

best protection at ali temperatures as weil as improved

starting with iess oii consumption.

5W-30: 40°Fand below (5°Cand be/'ow)is recommendedfor

winter useand works best in cold conditions.

o 30

20

40 C

10

_ 0

-10

-20

-30

Adding EogineOil

1= Makesure pressure washer is ona Ieveisurface.

2. Checkoii ievei as described in Checking Oil Levei.

3. If needed,siowiy pour oil into oil fiii openingto the

"FolF' mark on dipstick. DONOToverfill.

Overfiiiing with oil may causethe engineto not start, or

hard starting.

DONOToverfill.

IfovertheFULLmarkon dipstick,drainoilto reduceoillevelto

FULLmarkon dipstick.

4. Reptaceandtigilten dipstick.

ChaogingEngineOil

Changeengine oii after the first 5 hours and every 50 hours

thereafter, if you are usingyour pressure washer under

extremeiy dirty or dusty conditions, or in extremely hot

weather, changeoil more often.

CAUTION

Avoid prolonged or repeatedskin contact with used motor

oil.

Usedmotoroil hasbeenshownto causeskincancerin certain

laboratoryanimals

Thoroughlywashexposedareaswith soapandwater

KEEPOUTOFREACHOF CHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTOCOLLECTIONCENTERS.

Chaogeoil while oogine is still warmfrom rooning, as

follows:

1. Drainfuel tank by running pressurewasher until fuel

tank is empty.

2. Disconnectspark plug wire and keepit awayfrom spark

plug.

18

Loading...

Loading...