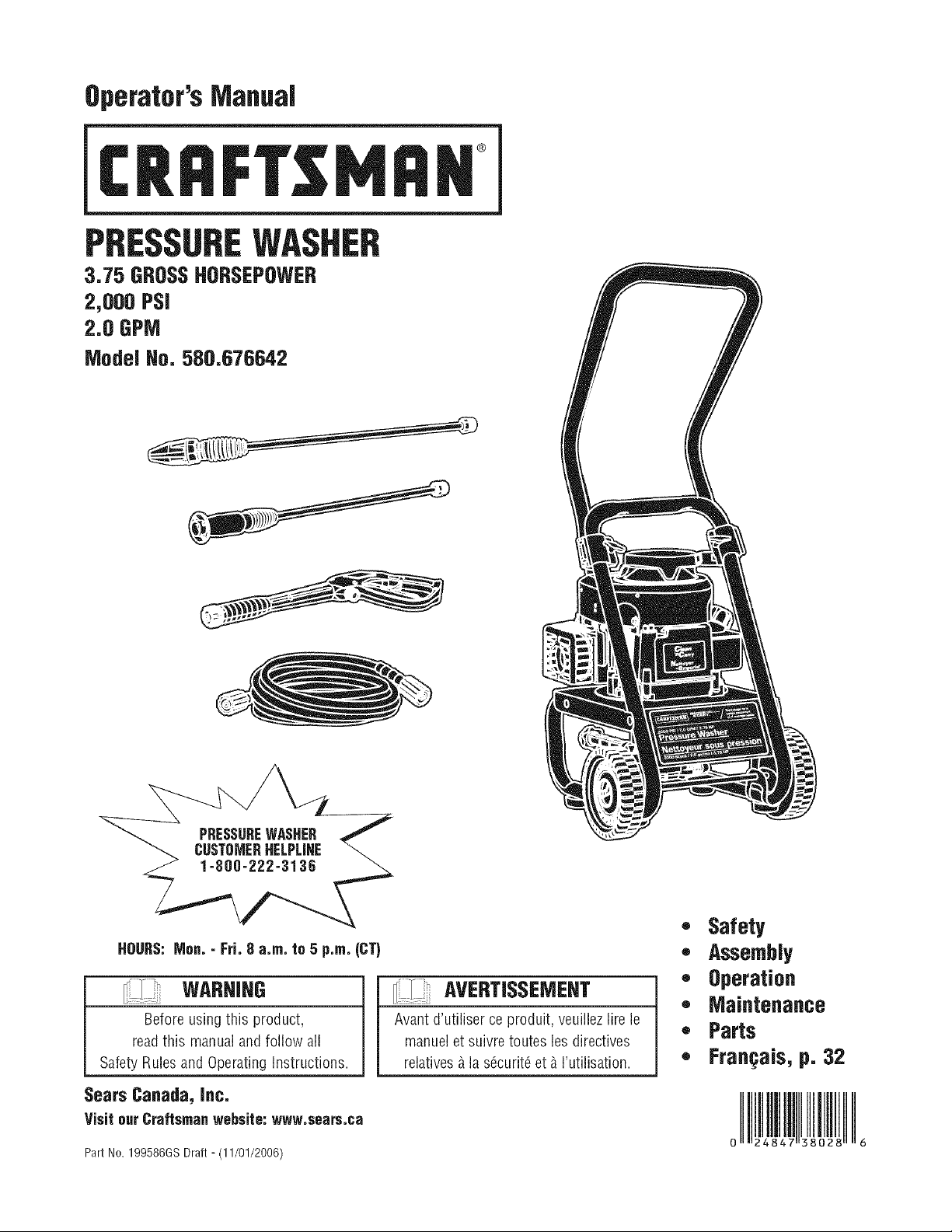

Craftsman 580676642 Owner’s Manual

Operator'sManual

PRESSURE

3.75 GROSSHORSEPOWER

2,000 PSi

2.0 GPM

ModeJ Ho. 580.676642

®

CUSTOMERHELPLIHE

PRESSUREWASHER

HOURS:Non. - Frio8 aomoto 5 p.m. (CT)

WAReING

Beforeusing this product,

readthis manualand follow all

SafetyRules and Operating Instructions.

Sears Canada, Inc.

Visit ourCraftsmanwebsite:wwwosearsoca

Part No. 199586GS Draft - (11/01/2006)

AVERTiSSEMENT

Avant d'utiliser ce produit, veuillezlire le

manuelet suivre toutes les directives

relatives&la s6curit6et& I'utilisation.

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Fran_ais, p. 32

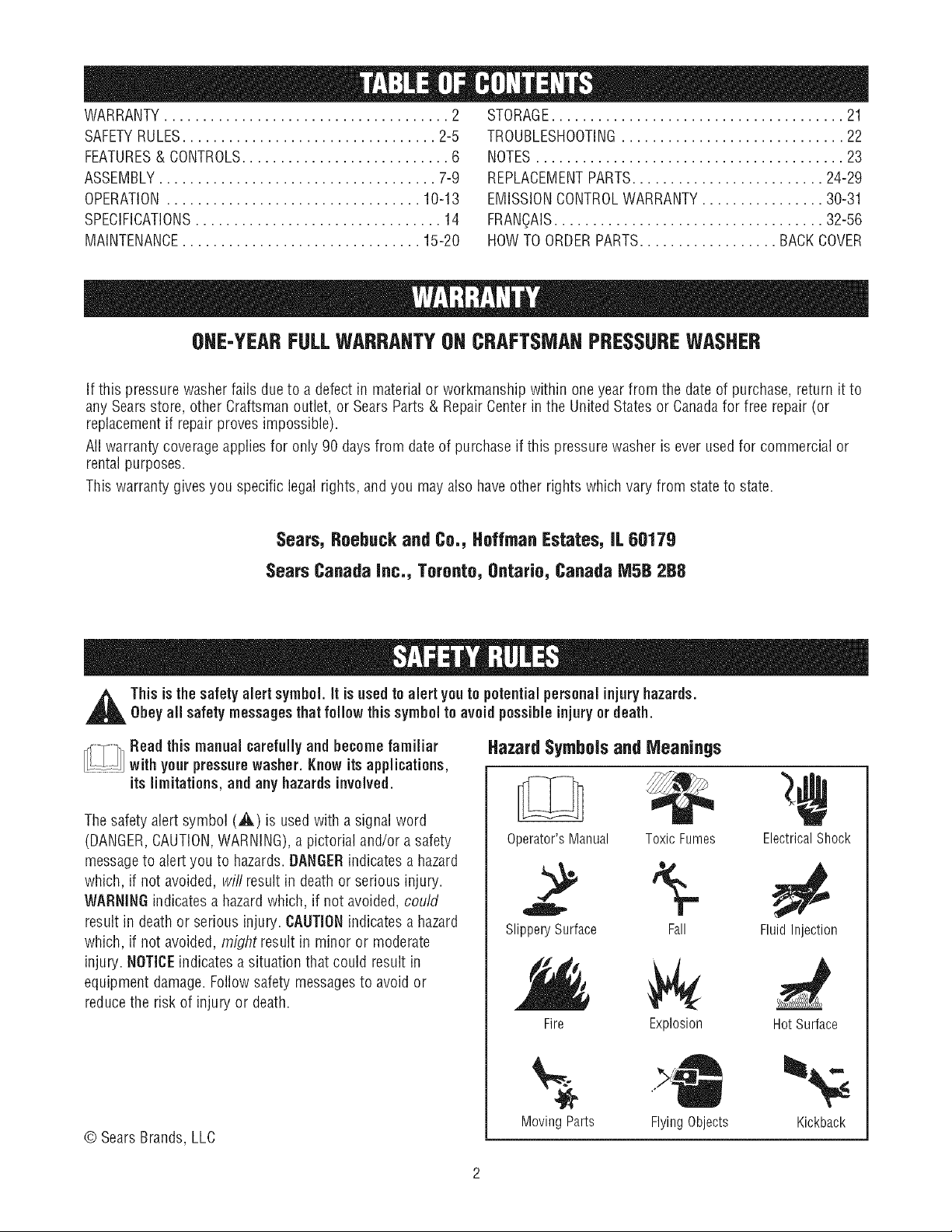

WARRANTY..................................... 2

SAFETYRULES................................. 2-5

FEATURES& CONTROLS........................... 6

ASSEMBLY.................................... 7-9

OPERATION................................. 10-13

SPECIFICATIONS................................ 14

MAINTENANCE............................... 15-20

STORAGE...................................... 21

TROUBLESHOOTING............................. 22

NOTES........................................ 23

REPLACEMENTPARTS......................... 24-29

EMISSIONCONTROLWARRANTY................ 30-31

FRAN_AIS................................... 32-56

HOWTOORDERPARTS.................. BACKCOVER

ONE-YEARFULLWARRAHTYOHCRAFTSMAHPRESSUREWASHER

If this pressure washerfails dueto a defect in material or workmanship within one year from the date of purchase, return it to

any Searsstore, other Craftsmanoutlet, or Sears Parts & Repair Centerin the United States or Canadafor free repair (or

replacementif repair proves impossible).

All warranty coverageappliesfor only 90 days from date of purchase if this pressure washer is everused for commercial or

rental purposes.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Sears Canada Inc., Toronto, Ontario, Canada MSB 288

,_ Thisis thesafety alert symbol,it is used toalert youto potentialpersonal injuryhazards.

Obeyall safetymessagesthatfollow thissymbol to avoid possibleinjuryor death.

_] Read this manual carefully and becomefamiliar

with yourpressurewasher. Know its applications,

its limitations, and any hazardsinvolved.

Thesafety alert symbol (_) is usedwith a signal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert you to hazards. DANGERindicatesa hazard

which, if not avoided, will result in deathor serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in death or serious injury. CAUTIONindicatesa hazard

which, if not avoided, might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage.Follow safety messagesto avoid or

reducethe risk of injury or death.

Hazard Symbols and Meanings

Operator'sManual ToxicFumes

Z 5-

SlipperySurface Fall

Fire

Explosion

ElectricalShock

FluidInjection

HotSurface

© SearsBrands, LLC

MovingParts

FlyingObjects

Kickback

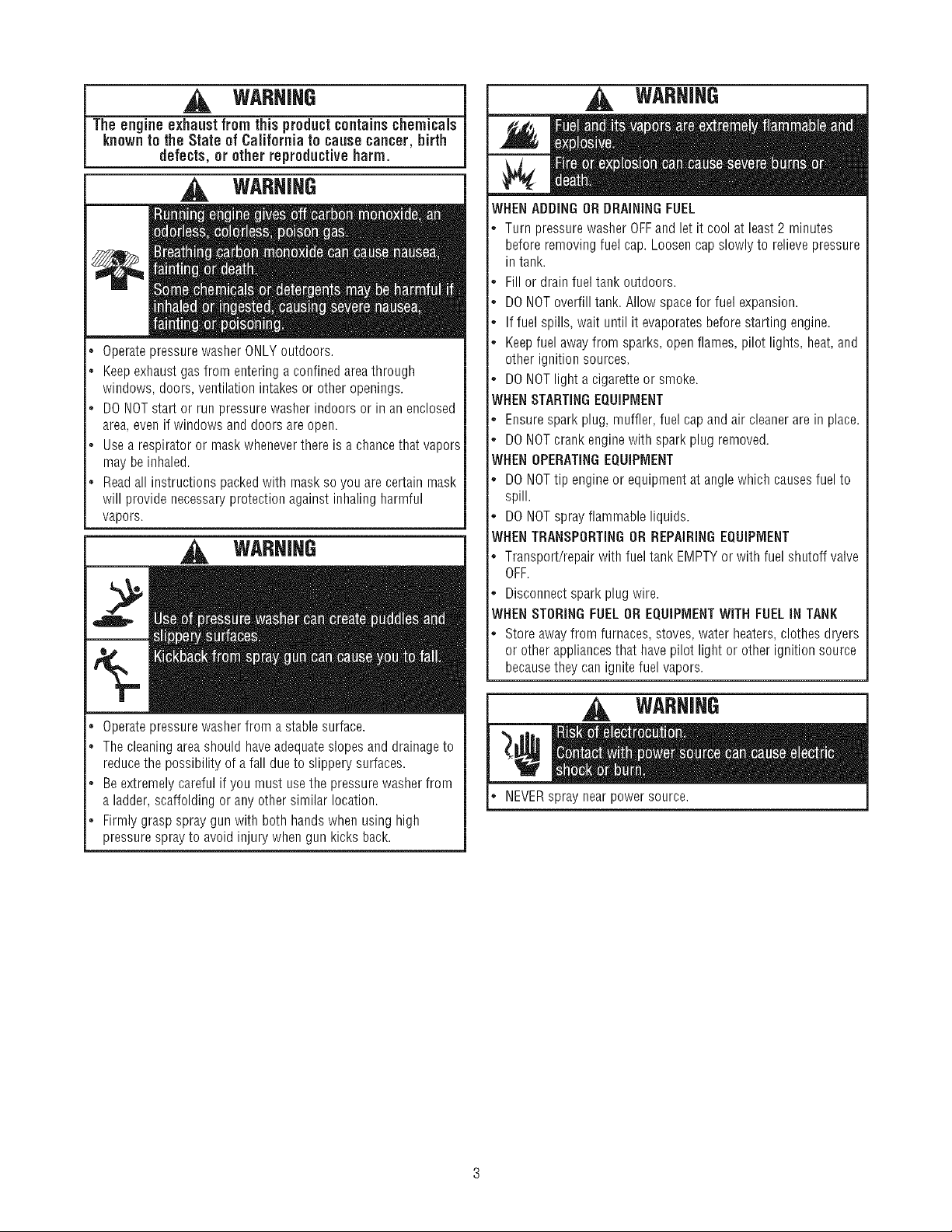

WARHJHG

The engine exhaustfrom this productcontainschemicals

knownto the State of California to causecancer,birth

defects, or other reproductiveharm.

WARHJHG

Operatepressure washer ONLY outdoors.

Keepexhaust gas from entering a confined areathrough

windows, doors, ventilation intakes or other openings.

DO NOTstart or run pressure washer indoors or in an enclosed

area, evenif windows and doors areopen.

Use a respirator or maskwhenever there is a chance that vapors

may be inhaled.

Readall instructions packed with mask so you are certain mask

will provide necessary protection against inhaling harmful

vapors.

WARNING

WARHING

WHENADDING OR DRAININGFUEL

Turn pressure washer OFFand let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

Fill or drain fuel tank outdoors.

DONOToverfill tank. Allow space for fuel expansion.

If fuel spills, wait until it evaporates before starting engine.

Keepfuel away from sparks, open flames, pilot lights, heat,and

other ignition sources.

DONOTlight a cigaretteor smoke.

JHENSTARTINGEQUIPMENT

. Ensure spark plug, muffler, fuel capand air cleaner are in place.

. DONOTcrank engine with spark plug removed.

WHENOPERATINGEQUIPMENT

. DONOTtip engineor equipment at angle which causes fuel to

spill.

. DONOTspray flammable liquids.

WHENTRANSPORTINGOR REPAIRINGEQUIPMENT

. Transport/repair with fuel tank EMPTYor with fuel shutoff valve

OFF.

. Disconnect spark plug wire.

WHENSTORINGFUELOR EQUIPMENTWiTH FUELIN TANK

Store awayfrom furnaces, stoves, water heaters, clothes dryers

or other appliances that have pilot light or other ignition source

becausethey can ignite fuel vapors.

Operatepressure washer from a stable surface.

The cleaningarea should haveadequateslopes and drainageto

reducethe possibility of a fall due to slippery surfaces.

Be extremely careful if you must usethe pressure washer from

a ladder,scaffolding or any other similar location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when gun kicks back.

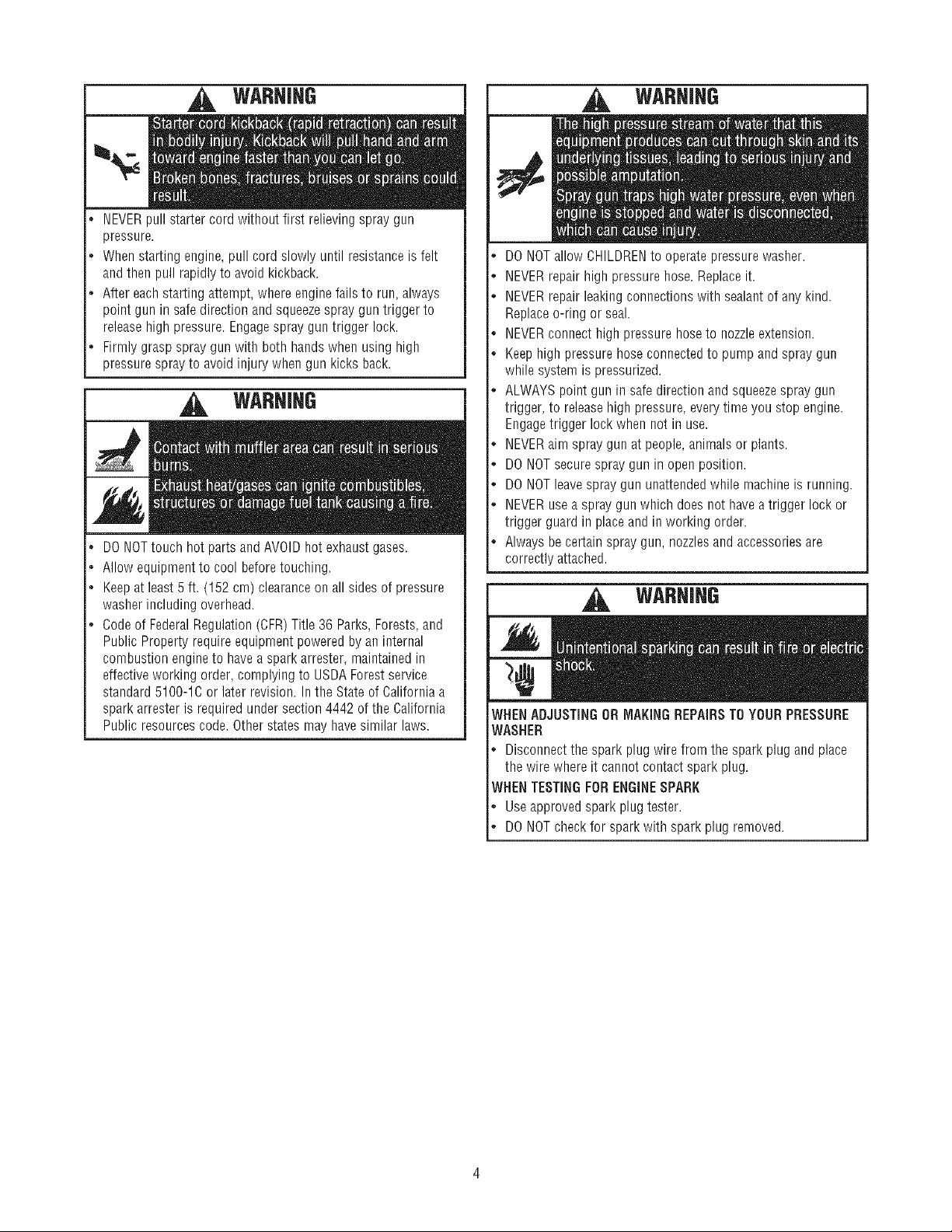

WARHIHG

NEVERpull starter cord without first relieving spray gun

pressure.

When starting engine, pull cord slowly until resistanceis felt

andthen pull rapidly to avoid kickback.

After eachstarting attempt, where enginefails to run, always

point gun in safedirection and squeezespray gun trigger to

release high pressure. Engagespray guntrigger lock.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when gun kicks back.

WARHIHG

DO NOTtouch hot parts and AVOID hot exhaust gases.

Allow equipment to cool before touching.

Keepat least 5 ft. (152 cm) clearanceon all sides of pressure

washer including overhead.

Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have aspark arrester, maintained in

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. Inthe State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may havesimilar laws.

WARHIHG

DONOTallow CHILDRENto operate pressure washer.

NEVERrepair high pressure hose.Replace it.

NEVERrepair leaking connections with sealant of any kind.

Replaceo-ring or seal.

NEVERconnect high pressure hose to nozzleextension.

Keephigh pressure hose connectedto pump andspray gun

while system is pressurized.

ALWAYS point gun in safe direction and squeezespray gun

trigger, to releasehigh pressure, every time you stop engine.

Engagetrigger lock when not in use.

NEVERaim spray gun at people, animals or plants.

DONOTsecure spray gun in open position.

DONOTleave spray gun unattendedwhile machine is running.

NEVERusea spray gun which does not haveatrigger lock or

trigger guard in place andin working order.

Always becertain spray gun, nozzlesand accessories are

correctly attached.

WARHIHG

WHENADJUSTINGORMAKINGREPAIRSTO YOURPRESSURE

WASHER

o Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

Useapproved spark plug tester.

DONOTcheck for sparkwith spark plug removed.

WARHIHG

NEVERoperatepressure washer without protective housing or

covers.

DO NOTwear looseclothing, jewelryor anythingthat may be

caught instarter or other rotating parts.

Tie up long hair and remove jewelry.

WARHIHG

Alwayswear safety goggles when using this equipment or in

vicinity of where equipment is in use.

Beforestarting the pressure washer, be sure you are wearing

adequatesafety goggles.

NEVERsubstitute safetyglasses for safety goggles.

CAUTION

DO NOTsecure spray gun in open position.

DO NOTleavespray gun unattendedwhile machine is running.

NEVERusea spray gun which does not havea trigger lock or

trigger guard in place andin working order.

Always becertain spray gun, nozzlesand accessories are

correctly attached.

HOTICE

DONOTpoint spray gun at glass when in jet spray mode.

NEVERaim spray gun at plants.

If you have questions about intended use, ask dealer or contact

Sears.

NEVERoperateunits with broken or missing parts, or without

protective housing or covers.

DONOT by-pass any safety device on this machine.

DONOTtamper with governed speed.

DONOToperate pressure washer above rated pressure.

DONOT modify pressure washer in any way.

Beforestarting pressure washer in cold weather, check all parts

of the equipment to besure ice has not formed there.

NEVERmove machine by pulling on high pressure hose. Use

handle provided on unit.

Checkfuel system for leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washer.

This equipment is designed to be used with Sears authorized

parts ONLY. If equipment is used with parts that DO NOT

comply with minimum specifications, userassumes all risks

andliabilities.

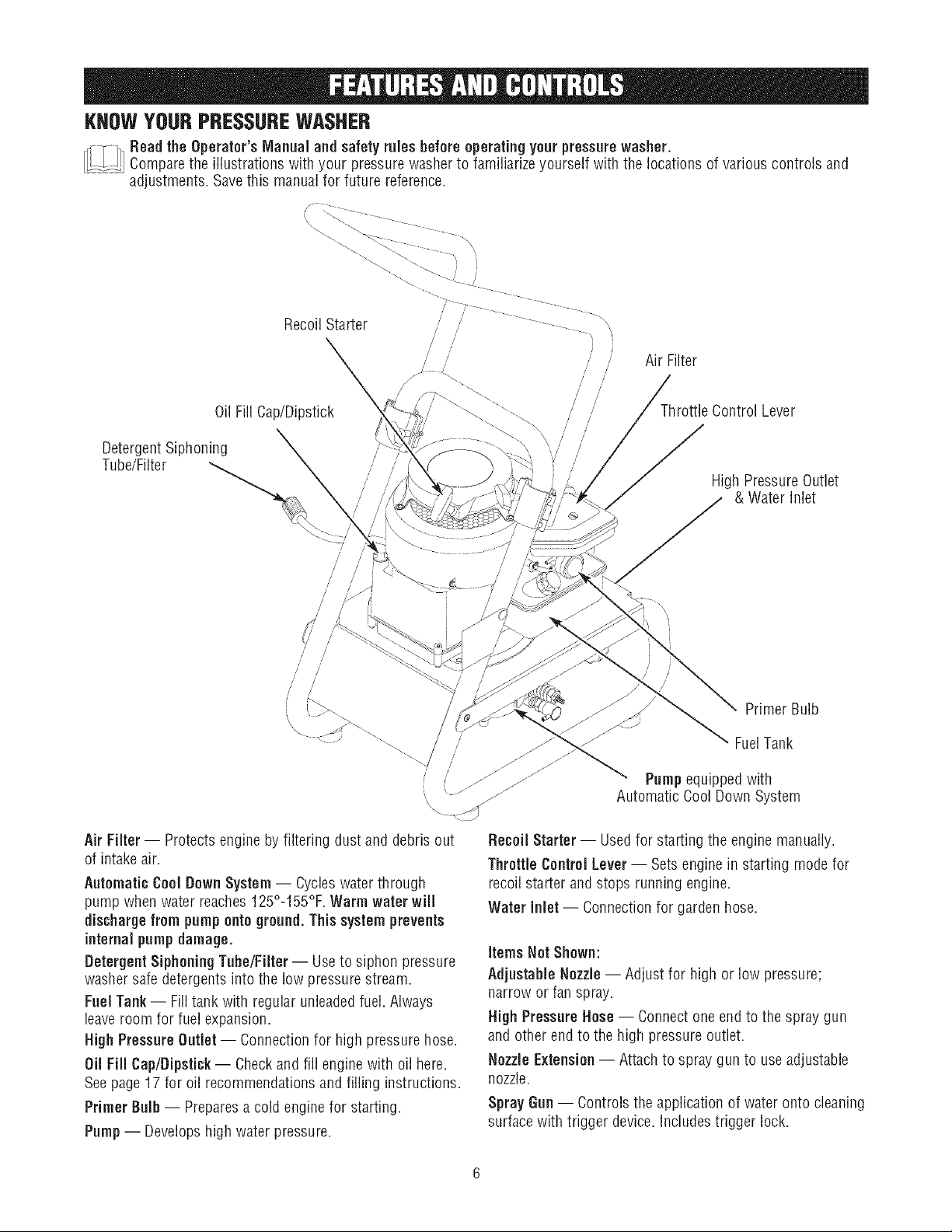

KNOWYOURPRESSUREWASHER

i[_-_ i Read the Operator'sManual and safety rulesbefore operatingyour pressurewasher.

.....................I Comparethe illustrations with your )ressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manual for future reference.

RecoilStarter _ , ',

/

DetergentSiphoning

Tube/Filter

Oil Fill Cap/Dipstick_

/

/

/

/

/ /

/ /

/ /

/ /

/ /

/ /

/

//

//

/

Air Filter

Throttle Control Lever

High Pressure Outlet

& Water Inlet

//' //

/' /'

/ /'

/ //

/

Air Filter-- Protects engine by filtering dust and debris out

of intake air.

Automatic Cool Down System -- Cycleswater through

pump when water reaches125°-155°F. Warm water will

dischargefrompump onto ground. This systemprevents

internalpump damage.

DetergentSiphoning Tube/Filter-- Useto siphon pressure

washer safe detergentsinto the low pressure stream.

FuelTank-- Filltank with regular unleadedfuel. Always

leaveroom for fuel expansion.

High Pressure Outlet -- Connectionfor high pressure hose.

Oil Fill Cap/Dipstick -- Checkand fill engine with oil here.

Seepage 17 for oil recommendations and filling instructions.

Primer Bulb -- Preparesa cold engine for starting.

Pump-- Developshigh water pressure.

Primer Bulb

FuelTank

//

Pump equipped with

Automatic Cool Down System

Recoil Starter -- Usedfor starting the engine manually.

ThrottleControl Lever-- Setsenginein starting mode for

recoil starter and stops running engine.

Water Inlet -- Connectionfor garden hose.

Items Hot Shown:

AdjustableNozzle-- Adjust for high or low pressure;

narrow or fan spray.

HighPressureHose-- Connectone end to the spray gun

and other end to the high pressure outlet.

NozzleExtension-- Attachto spray gun to useadjustable

nozzle.

Spray Gun-- Controls the application of water onto cleaning

surface with trigger device. Includes trigger lock.

Your pressure washer requires some assembly and is ready

for useonly after it has been properly serviced with the

recommendedoil and fuel.

If you haveany problemswith the assembly of your

pressurewasher, please call the pressurewasher helpline

at 1-800-222-3136.

IMPORTANT:Any attempt to run the engine before it has

been servicedwith the recommended oil will result in an

engine failure.

Unpack the Pressure Washer

1. Removeeverything from carton except pressure washer.

2. Opencarton completely by cutting each corner from top

to bottom.

3. Removepressurewasher from carton.

CARTONCONTENTS

Checkall contents. If any parts are missing or damaged,call

thepressurewasherhelplineat 1-800-222-3136.

* Themain unit

* Handle

* Highpressure hose

* Spraygun

* Nozzleextension with adjustable nozzle

* Turbonozzle

* Wheelkit

* Engineoil

* Parts bag (which includes items listed below)

Operator's manual

Safetygoggles

Becomefamiliar with each piecebefore assembling the

pressure washer. Comparecontents against the view on page

6. if any parts are missing or damaged,call the pressure

washer helpline at 1-800-222-3136.

ASSEMBLINGYOURPRESSUREWASHER

Your Craftsman pressure washer was mostly assembledat

the factory. However,you wiil needto perform these tasks

beforeyou can operateyour pressure washer:

1. Attach handleto main unit.

2. Installwheel kit.

3. Add oil to engine crankcase.

4. Addfuel to fuel tank.

5. Connecthighpressurehoseto spraygun and pump.

6. Connectwatersupply to pump.

Attach Handle

1. Placeplastic adapters in hinges on handleextension as

shown.

NOTE:Make sure lip on plastic adapters is facing up in

hinges.

2. Clamphandleextension onto pressure washer handle

and insert T-bolts into holes of clamp. Tighten by hand.

Install Wheel Kit

Thewheel kit is designedto greatly improve the portability of

your pressure washer.

NOTE:Wheel kit is not intended for over-the-road use.

installthewheelkit asfollows:

1. Placethebottom of the pressurewasherframe ona flat,

evensurface,such as blocksto easeassembly.

2. Spreadaxlebrackets apartand placeover front vibration

mounts on the pressure washer frame as shown.

\

\

\

Squeezeaxle brackets back to original shape.

\

,

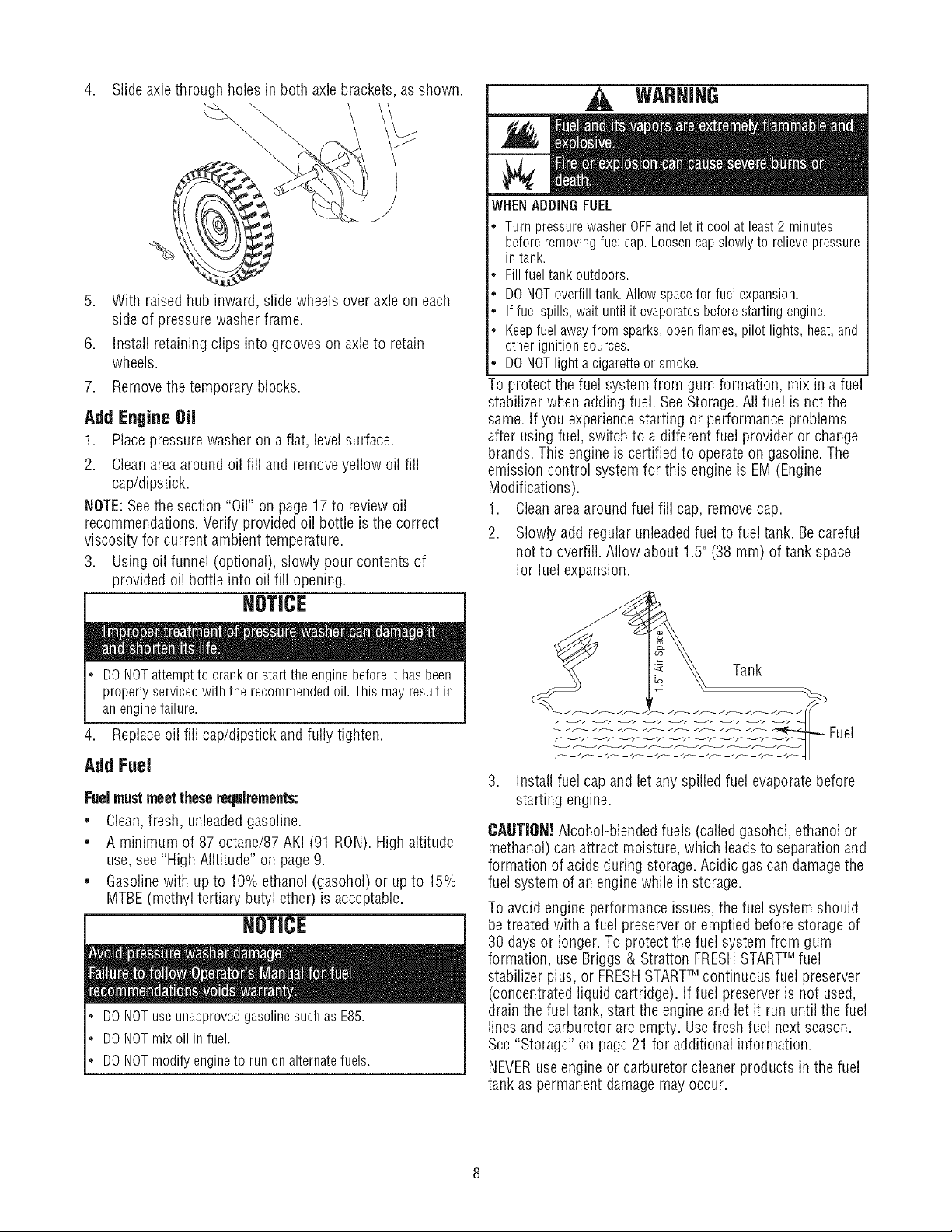

Slide axlethrough holes in both axlebrackets, as shown.

%

5. With raised hub inward, slide wheels over axle on each

side of pressure washer frame.

6. Install retainingclips into grooves on axleto retain

wheels.

7. Removethe temporary blocks.

Add Engine Oil

1. Placepressure washer on a flat, levelsurface.

2. Cleanareaaround oil fill and remove yellow oil fill

cap/dipstick.

NOTE:Seethe section "Oil" on page 17 to review oil

recommendations.Verify provided oil bottle is the correct

viscosity for current ambient temperature.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

WARHING

WHENADDINGFUEL

TurnpressurewasherOFFandlet it coolat least2 minutes

beforeremovingfuel cap.Loosencapslowlyto relievepressure

intank.

Fillfueltankoutdoors.

DONOToverfilltank.Allowspaceforfuelexpansion.

If fuelspills,waituntilitevaporatesbeforestartingengine.

Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

DONOTlighta cigaretteorsmoke.

To protect the fuel system from gum formation, mix in a fuel

stabilizer when adding fuel. See Storage.All fuel is notthe

same. If you experiencestarting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline. The

emission control system for this engine is EM (Engine

Modifications).

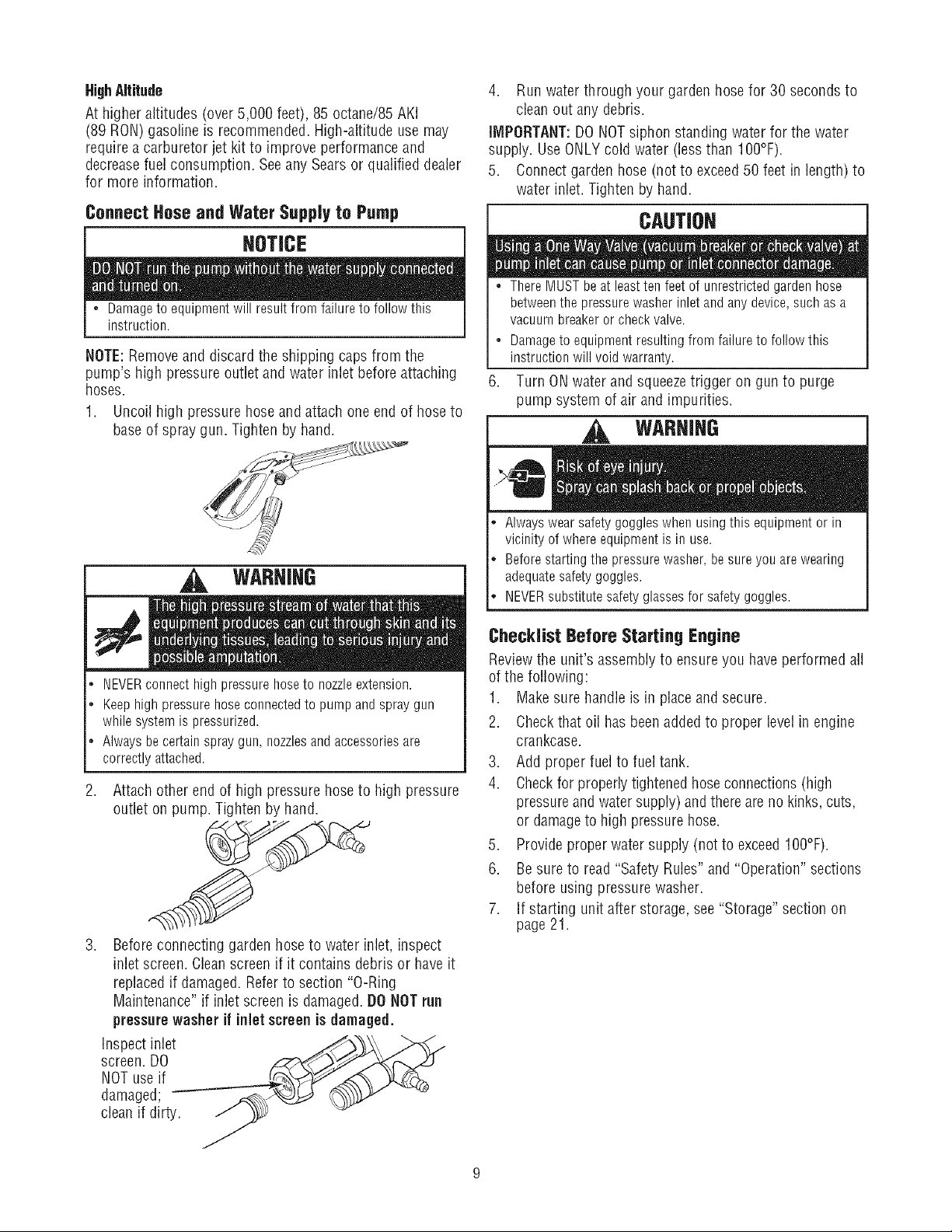

1. Cleanareaaround fuel fill cap, removecap.

2. Slowlyadd regular unleadedfuel to fuel tank. Becareful

not to overfill. Allow about 1.5" (38 mm) of tank space

for fuel expansion.

I NOTICE 1

DO NOTattempt to crank or start the engine before it has been

properly serviced with the recommended oil. This may result in

an engine failure.

,

Replace oil fill cap/dipstick and fully tighten.

Add Fuel

Fuelmust meettheserequirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87 AKI (91 RON). Highaltitude

use,see"High AIItitude" on page9.

• Gasolinewith up to 10% ethanol (gasohol) or up to 15%

MTBE(methyl tertiary butyl ether) is acceptable.

I NOTICE 1

DO NOTuse unapproved gasoline such as E85.

DO NOTmix oil in fuel.

DO NOTmodify engine to run on alternatefuels.

Tank

3. Install fuel cap and let any spilled fuel evaporate before

starting engine.

CAUTION! Alcohol-blendedfuels (calledgasohol, ethanol or

methanol) canattract moisture, which leadsto separationand

formation of acids during storage.Acidic gas candamagethe

fuel system ofanengine while in storage.

To avoid engine performance issues,the fuel system should

betreated with a fuel preserver or emptied before storage of

30 days or longer. To protect the fuel system from gum

formation, use Briggs & Stratton FRESHSTARTTM fuel

stabilizer plus, or FRESHSTARTTM continuous fuel preserver

(concentrated liquid cartridge). If fuel preserver is not used,

drain the fuel tank, start the engine and let it run until the fuel

linesand carburetor are empty. Usefresh fuel next season.

See"Storage" on page21 for additional information.

NEVERuseengine or carburetor cleaner products in the fuel

tank as permanent damage may occur.

HighAltitude

At higher altitudes (over5,000 feet), 85 octane/85 AKI

(89 RON)gasoline is recommended. High-altitude usemay

require a carburetor jet kit to improve performance and

decreasefuel consumption. Seeany Sears or qualified dealer

for more information.

Connect Hose and Water Supplyto Pump

* Damageto equipmentwill resultfrom failureto followthis

instruction.

NOTE:Removeand discard the shipping caps from the

pump's high pressure outlet and water inlet beforeattaching

hoses.

1. Uncoilhigh pressure hose and attach one end of hoseto

baseof spray gun. Tighten by hand.

WARHJHG

4. Runwater through your garden hose for 30 seconds to

cleanout any debris.

IMPORTANT:DO NOTsiphon standing water for the water

supply. UseONLYcold water (lessthan I O0°F).

5. Connectgardenhose (not to exceed50 feet in length) to

water inlet. Tighten by hand.

CAUTJOH

* ThereMUSTbeatleasttenfeetof unrestrictedgardenhose

betweenthepressurewasherinletandany device,suchasa

vacuumbreakeror checkvalve.

. Damageto equipmentresultingfromfailuretofollowthis

instructionwillvoid warranty.

6. TurnONwater and squeezetrigger on gun to purge

pump system of air and impurities.

A WARNING

Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

Beforestarting the pressure washer, be sure you are wearing

adequatesafety goggles.

NEVERsubstitute safetyglasses for safety goggles.

NEVERconnect high pressure hoseto nozzleextension.

Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

Always becertain spray gun, nozzlesand accessories are

correctly attached.

Attach other end of high pressure hose to high pressure

outlet on pump. Tighten by hand.

S

,

Beforeconnecting garden hose to water inlet, inspect

inlet screen. Cleanscreen if it contains debris or have it

replacedif damaged. Referto section "O-Ring

Maintenance"if inlet screen is damaged.DONOTrun

pressurewasher if inlet screen isdamaged.

Inspect inlet

screen. DO

NOTuseif

ChecMist Before Starting Enoine

Reviewthe unit's assembly to ensureyou have performed all

of the following:

1. Makesure handle is in place and secure.

2. Checkthat oil hasbeenadded to proper levelin engine

crankcase.

3. Addproper fuel to fuel tank.

4. Checkfor properly tightenedhose connections (high

pressureand watersupply) andthere are no kinks, cuts,

or damageto high pressurehose.

5. Provideproperwater supply (notto exceedIO0°F).

6. Besureto read "Safety Rules" and "Operation" sections

before using pressure washer.

7. If starting unit after storage, see "Storage" section on

page21.

cleanif dirty.

damaged;

HOWTOUSEYOURPRESSUREWASHER

If you haveany problems operatingyour pressure washer,

pleasecall the pressure washer helpline at 1-800-222-3136.

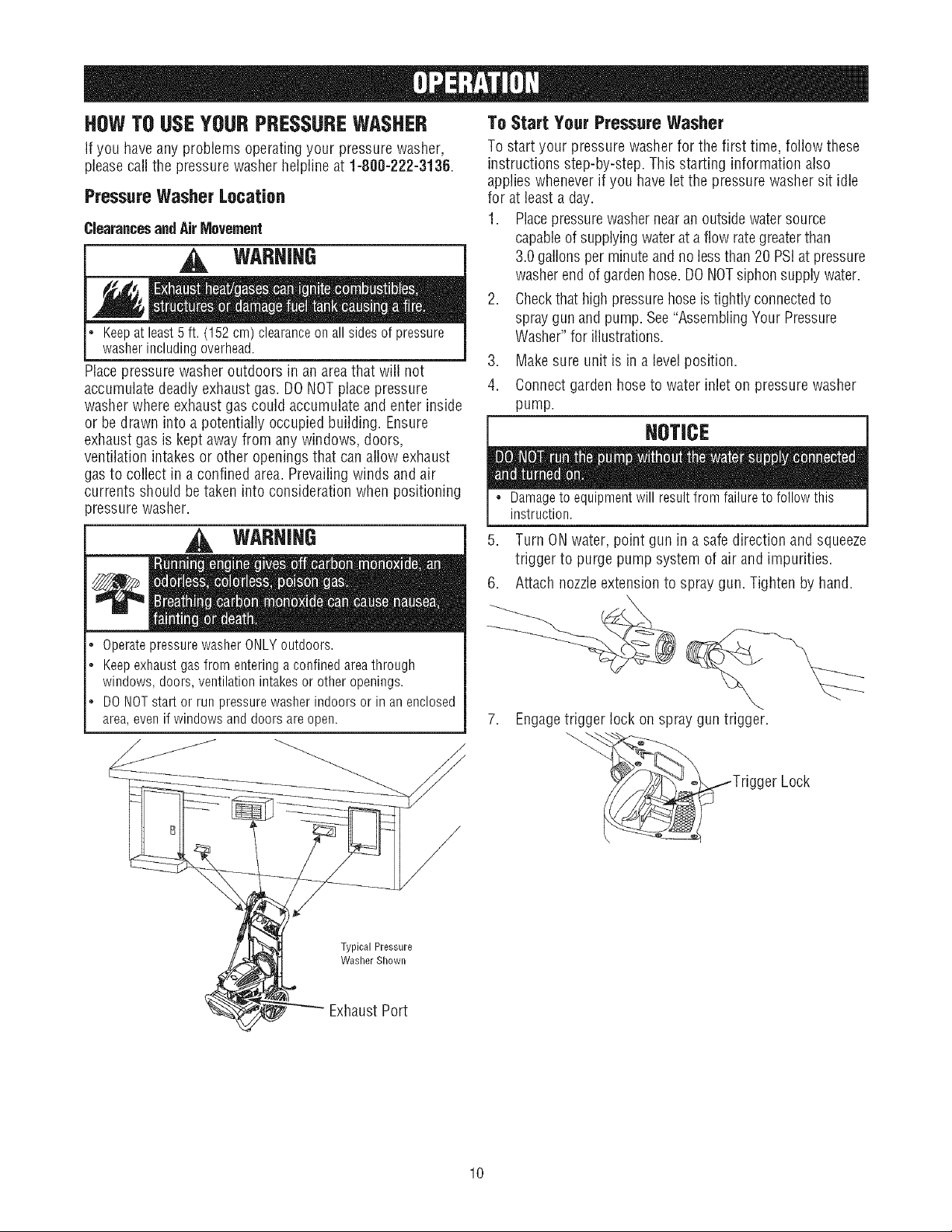

Pressure Washer Location

ClearancesandAirMovement

I A WARNING 1

Keepatleast5ft. (152cm)clearanceonall sidesofpressure

washerincludingoverhead.

Placepressure washer outdoors in an areathat will not

accumulate deadlyexhaust gas. DONOTplace pressure

washer where exhaustgas could accumulate and enter inside

or be drawn into a potentially occupied building. Ensure

exhaustgas is kept awayfrom any windows, doors,

ventilation intakes or other openings that canallow exhaust

gasto collect in a confined area. Prevailingwinds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

To Start Your Pressure Washer

To start your pressure washer for the first time, follow these

instructions step-by-step. This starting information also

applies wheneverif you havelet the pressure washer sit idle

for at least a day.

1. Placepressurewashernearanoutsidewater source

capableof supplyingwater at a flow rategreaterthan

3.0gallons per minuteand no lessthan 20 PSiat pressure

washerend of gardenhose.DONOTsiphonsupply water.

2. Checkthathigh pressurehoseis tightly connectedto

spray gun and pump. See"Assembling Your Pressure

Washer"for illustrations.

3. Makesure unit is in a level position.

4. Connectgardenhoseto water inlet on pressure washer

pump.

NOTICE

o Damageto equipmentwill resultfrom failureto followthis

instruction.

_, WARHIHG

OperatepressurewasherONLYoutdoors.

Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakesor otheropenings.

DONOTstartor runpressurewasherindoorsor in anenclosed

area,evenifwindowsanddoorsareopen.

5. TurnONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities.

6. Attachnozzleextensionto spray gun. Tighten by hand.

7. Engagetrigger lock on spray gun trigger.

Trigger Lock

_ '7"_-- ExhaustPort

10

,

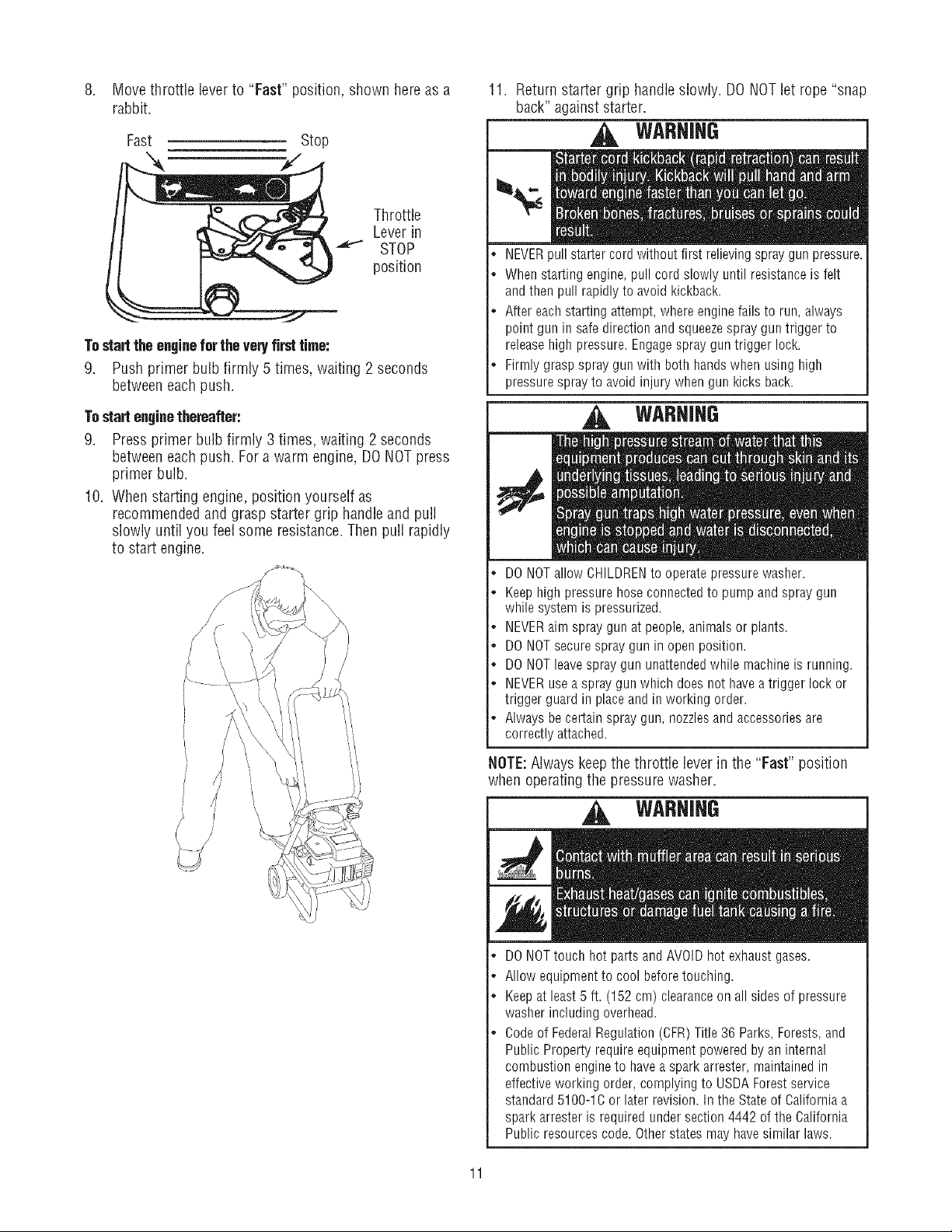

Move throttle lever to "Fast" position, shown here as a

rabbit.

11. Returnstarter grip handleslowly. DONOTlet rope "snap

back"against starter.

Fast

Stop

J

Throttle

Leverin

STOP

position

Testart the enginefor the veryfirsttime:

9. Pushprimer bulb firmly 5 times, waiting 2 seconds

betweeneach push.

Tostartenginethereafter:

9. Pressprimer bulb firmly 3 times, waiting 2 seconds

betweeneach push. Fora warm engine, DONOTpress

primer bulb.

10. When starting engine, position yourself as

recommendedand grasp starter grip handle and pull

slowly until you feelsome resistance. Thenpull rapidly

to start engine.

A WARNING

NEVERpullstartercordwithoutfirst relievingspraygunpressure.

Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpull rapidlytoavoidkickback.

Aftereachstartingattempt,whereenginefailsto run,always

pointgunin safedirectionandsqueezesprayguntrigger to

releasehighpressure.Engagesprayguntriggerlock.

Firmlygraspspraygunwith bothhandswhenusinghigh

pressurespraytoavoidinjurywhengunkicksback.

WARHIHG

DONOTallow CHILDRENto operate pressure washer.

Keephigh pressure hose connectedto pump andspray gun

while system is pressurized.

NEVERaim spray gun at people, animals or plants.

DONOTsecure spray gun in open position.

DONOTleave spray gun unattendedwhile machine is running.

NEVERusea spray gun which does not haveatrigger lock or

trigger guard in place andin working order.

Always becertain spray gun, nozzlesand accessories are

correctly attached.

NOTE:Always keepthe throttle lever in the "Fast" position

when operatingthe pressure washer.

A WARNING

DONOTtouch hot parts and AVOID hot exhaust gases.

Allow equipment to cool before touching.

Keepat least5 ft. (152 cm) clearance on all sidesof pressure

washer including overhead.

Codeof FederalRegulation(CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to havea spark arrester, maintained in

effectiveworking order, complying to USDAForestservice

standard 5100-1C or later revision. In the Stateof Californiaa

spark arrester is required under section 4442 of the California

Public resources code.Other states may havesimilar laws.

11

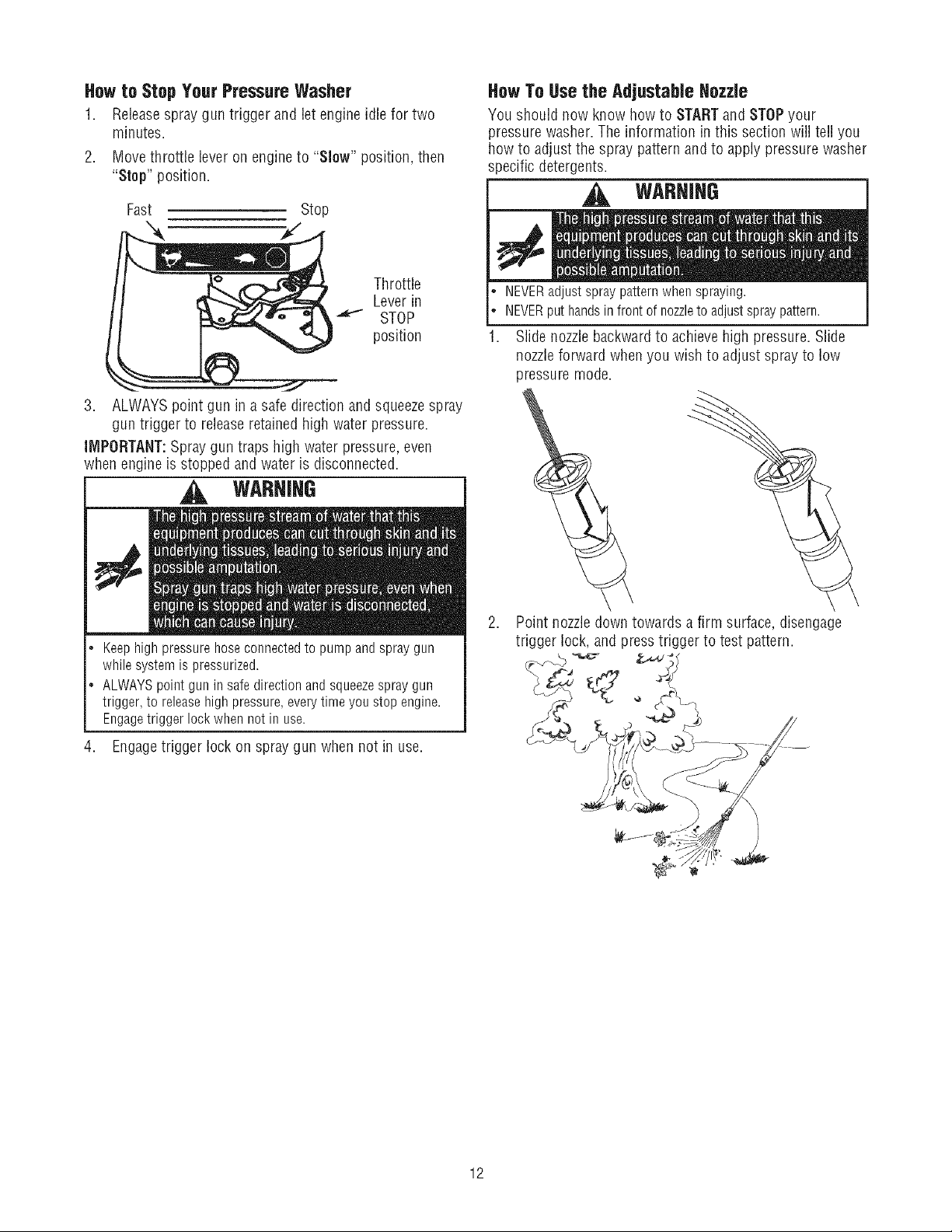

How to Stop Your Pressure Washer

1. Releasespray gun trigger and let engine idle for two

minutes.

2. Movethrottle leveron engineto "Slow" position, then

"Stop" position.

Fast

Stop

J

HowTo Use the Adjustable Hozzle

You should now know howto STARTand STOPyour

pressure washer.The information in this section will tell you

howto adjust the spray pattern and to apply pressure washer

specific detergents.

A WARNING

Throttle

Leverin

STOP

position

3. ALWAYSpoint gun in a safe direction and squeezespray

gun trigger to release retainedhigh water pressure.

INIPORTANT:Spraygun traps high water pressure, even

when engine is stopped and water is disconnected.

,A WARNING

Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

ALWAYSpoint gun in safe direction and squeezespray gun

trigger, to releasehigh pressure, every time you stop engine.

Engagetrigger lock when not in use.

,

Engage trigger lock on spray gun when not in use.

NEVERadjustspraypatternwhenspraying.

NEVERputhandsinfrontof nozzleto adjustspraypattern.

Slide nozzlebackwardto achievehigh pressure. Slide

nozzleforward when you wish to adjust spray to low

pressure mode.

Point nozzledown towards a firm surface, disengage

trigger lock, and press trigger to test pattern.

12

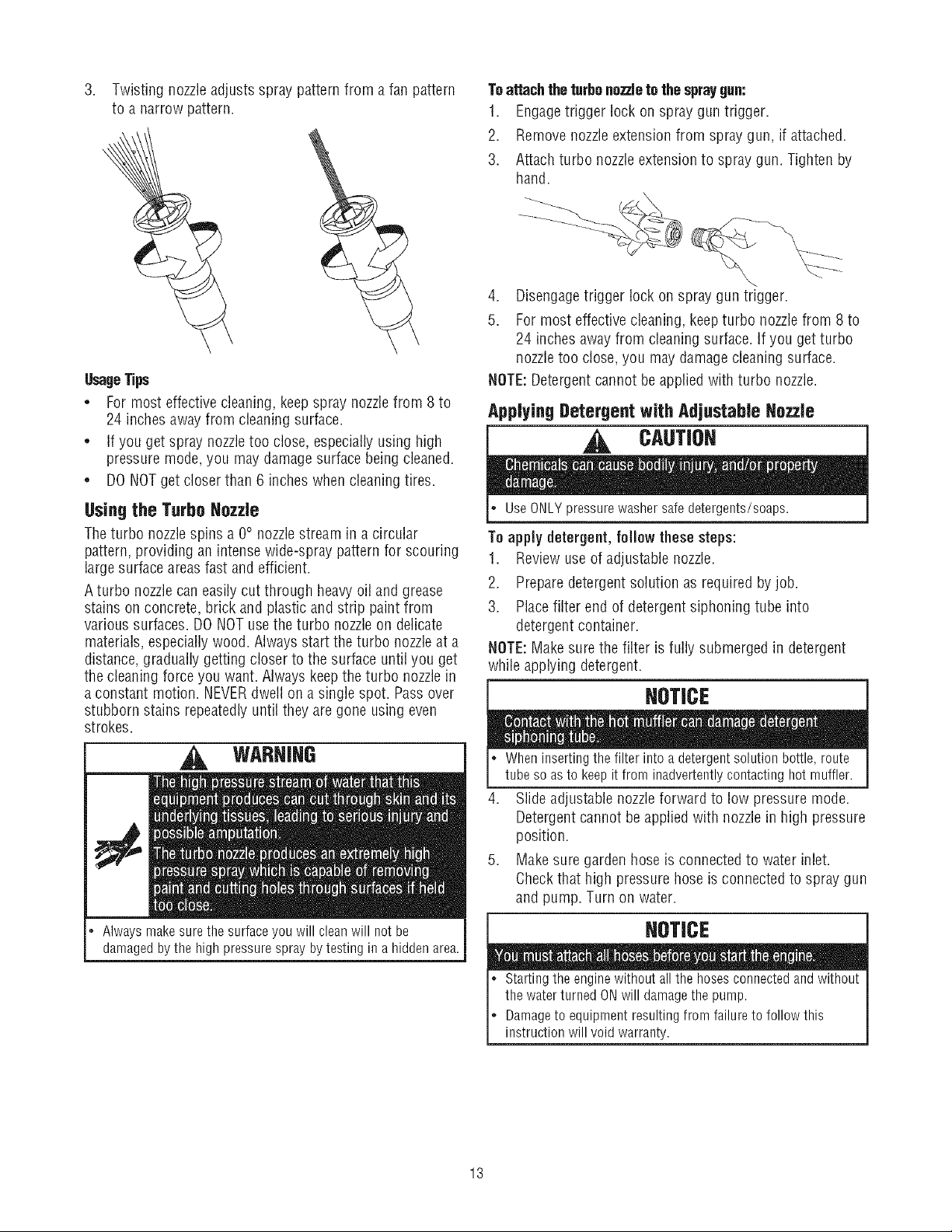

3. Twistingnozzleadjustsspraypatternfromafanpattern

toanarrowpattern.

UsageTips

• Formost effective cleaning, keepspray nozzlefrom 8 to

24 inches away from cleaning surface.

• Ifyou get spray nozzletoo close, especially using high

pressure mode,you may damagesurface being cleaned.

• DONOTget closer than 6 inches when cleaning tires.

Toattachtheturbonozzletothe spraygun:

1. Engagetrigger lock on spray gun trigger.

2. Removenozzleextension from spray gun, if attached.

3. Attachturbo nozzleextensionto spray gun. Tighten by

hand.

4. Disengagetrigger lock on spray gun trigger.

5. Formost effectivecleaning,keepturbo nozzlefrom 8 to

24 inchesaway from cleaning surface. If you get turbo

nozzletoo close, you may damagecleaning surface.

NOTE:Detergentcannot be applied with turbo nozzle.

Applying Detergent with Adjustable Nozzle

A CnUTlOe

Using the Turbo Hozzle

Theturbo nozzlespins a 0° nozzlestream in a circular

pattern, providing an intense wide-spray pattern for scouring

large surfaceareas fast and efficient.

A turbo nozzlecan easily cut through heavyoil and grease

stains on concrete, brick and plastic and strip paint from

various surfaces. DONOTuse the turbo nozzleon delicate

materials,especiallywood. Always start the turbo nozzleat a

distance, gradually getting closer to the surface until you get

the cleaning force you want. Always keep the turbo nozzlein

a constant motion. NEVERdwell on a single spot. Passover

stubborn stains repeatedlyuntil they are gone usingeven

strokes.

I wAR.I.G

Always makesure the surface you will cleanwill not be

damagedby the high pressure spray by testing in a hidden area.

UseONLYpressurewashersafedetergents/soaps.

To apply detergent, fellow thesesteps:

1. Reviewuseof adjustable nozzle.

2. Preparedetergent solution as required by job.

3. Placefilter end of detergentsiphoning tube into

detergentcontainer.

NOTE:Makesure the filter is fully submerged in detergent

while applying detergent.

NOTICE

j Wheninsertingthefilterintoa detergentsolutionbottle,route

tubeso asto keepit frominadvertentlycontactinghotmuffler.

4. Slideadjustable nozzleforward to low pressure mode.

Detergentcannot be applied with nozzlein high pressure

position.

5. Makesure garden hose is connected to water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

NOTICE

Starting the engine without all the hoses connected and without

the water turned ONwill damagethe pump.

Damageto equipment resulting from failure to follow this

instruction will void warranty.

13

6. Engagetrigger lock on spray gun andstart engine

following instructions "How to Start Your Pressure

Washer".

7. Applydetergentto a dry surface, starting at lower

portion of area to be washedand work upward, using

long, even, overlapping strokes.

8. Allow detergentto "soak in" for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surfacefrom drying. DO NOTallow detergentto dry on

(prevents streaking).

IMPORTANT:You must flush the detergent siphoning system

after each useby placing the filter into a bucket of clean

water,then run the pressure washer in low pressure for

1-2 minutes.

Pressure Washer Rinsing

FerRinsing:

1. Slide nozzlebackwardto high pressure, press trigger

and wait for detergentto clear.

NOTE:You can also stop detergentflow by removing

detergent siphoning tube from container.

2. Keepspray gun a safe distancefrom areayou plan to

spray.

WARNING

Operatepressurewasherfromastablesurface.

Beextremelycarefulif youmust usethepressurewasherfrom

a ladder,scaffoldingorany othersimilarlocation.

Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhengunkicksback.

3. Applya high pressure spray to a small area,then check

surfacefor damage.If no damage is found, it is okay to

continue cleaning.

4. Startat top of area to be rinsed, working down with

same overlappingstrokes asyou usedfor washing and

applying detergent.

Cleaning Detergent Siphoning Tube

If you usedthe detergentsiphoning tube, you must flush it

with cleanwater beforestopping the engine.

1. Placedetergentsiphoning tube/filter ina bucket full of

clean water.

2. Engagetrigger lock on spray gun.

3. Slideadjustable nozzleforward to low pressure position.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions "How to Stop

PressureWasher" and turn off water supply.

A WARNING

Keephigh pressure hose connectedto pump andspray gun

while system is pressurized.

ALWAYS point gun in safe direction and squeezespray gun

trigger, to releasehigh pressure, every time you stop engine.

Engagetrigger lock when not in use.

6. ALWAYSpoint gun in asafe direction and squeezespray

gun trigger to releaseretained high water pressure.

iMPORTANT:Spraygun traps high water pressure,evenwhen

engineis stoppedand water is disconnected.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water inthe pump can reachtemperaturesabove

125°F(51°C). The system engagesto cool the pump by

dischargingthewarm water ontothe ground.

14

ENGINETECHNICALINFORMATION

This is a single cylinder, L-head,air cooled engine. It is a low

emissions engine.

Inthe Stateof California, ModelSeries90000 engines are

certified by the CaliforniaAir ResourcesBoardto meet

emissions standards for 125 hours. Such certification does

not grant the purchaser,owner or operator of this engine any

additional warranties with respectto the performance or

operational life of this engine. Theengineis warranted solely

according to the product and emissions warranties stated

elsewherein this manual.

Power Ratings

* The gross power rating for individual gasengine models is

labeledin accordance with SAE(Societyof Automotive

Engineers)code J1940 (Small Engine Power & Torque

Rating Procedure),and rating performance has been

obtained andcorrected in accordancewith SAEJ1995

(Revision2002-05). Actual gross engine power will be lower

and is affected by, among other things, ambient operating

conditions and engine-to-enginevariability. Givenboth the

wide array of products on which enginesare placedand the

variety of environmental issues applicable to operating the

equipment,the gasengine will not developthe rated gross

power when used in a given piece of powerequipment

(actual"on-site"or net horsepower). This difference is due to

a variety of factors including, but not limited to, accessories

(air cleaner,exhaust, charging, cooling, carburetor, fuel

pump, etc.), application limitations, ambient operating

conditions (temperature, humidity, altitude), and engine-to-

engine variability. Due to manufacturing and capacity

limitations, Briggs & Stratton may substitute an engine of

higher rated power for this Seriesengine.

PRODUCTSPECIFICATIONS

Pressure Washer Specifications

Pressure ................................. 2,000 PSI

Flow Rate ................................. 2.0 GPM

Detergent............................ Use asdirected

Water Supply Temperature .......... Not to exceed IO0°F

Shipping Weight ............................. 48 Ibs.

Engine Specifications

Gross* Horsepower ................. 3.75 at 3600 rpm

Bore .......................... 2.562 in. (65.09 ram)

Stroke .......................... 1.75 in. (44.45 ram)

Displacement ..................... 9.02 in. (147.8 cc)

SparkPlug

Type: ............ Briggs & Stratton 802592 or 5095D

SetGapTo: ................... O.030inch(0.76mm)

Armature Air Gap: ........ 0.006-0.010 in. (0.15-0.25mm)

Valveclearancewith valvesprings installed and piston 1/4 in.

(6 mm) past top dead center (check whenengine is cold).

Intake ................. 0.005-0.007 in. (0.13-0.18 ram)

Exhaust ............... 0.007-0.009 in. (0.18-0.23 mm)

FuelCapacity .................. 1.0 Quarts (0.95 Liters)

Oil Capacity .................... 20 Ounces(0.6 Liters)

NOTE:For practical operation, the horsepower loading should

not exceed85% of rated horsepower. Engine power will

decrease3-1/2% for each 1,000feet (300 meters) abovesea

leveland 1% for each 10° F (5.6° C)above 77° F (25° C). It

will operate satisfactorily at an angle up to 15°.

15

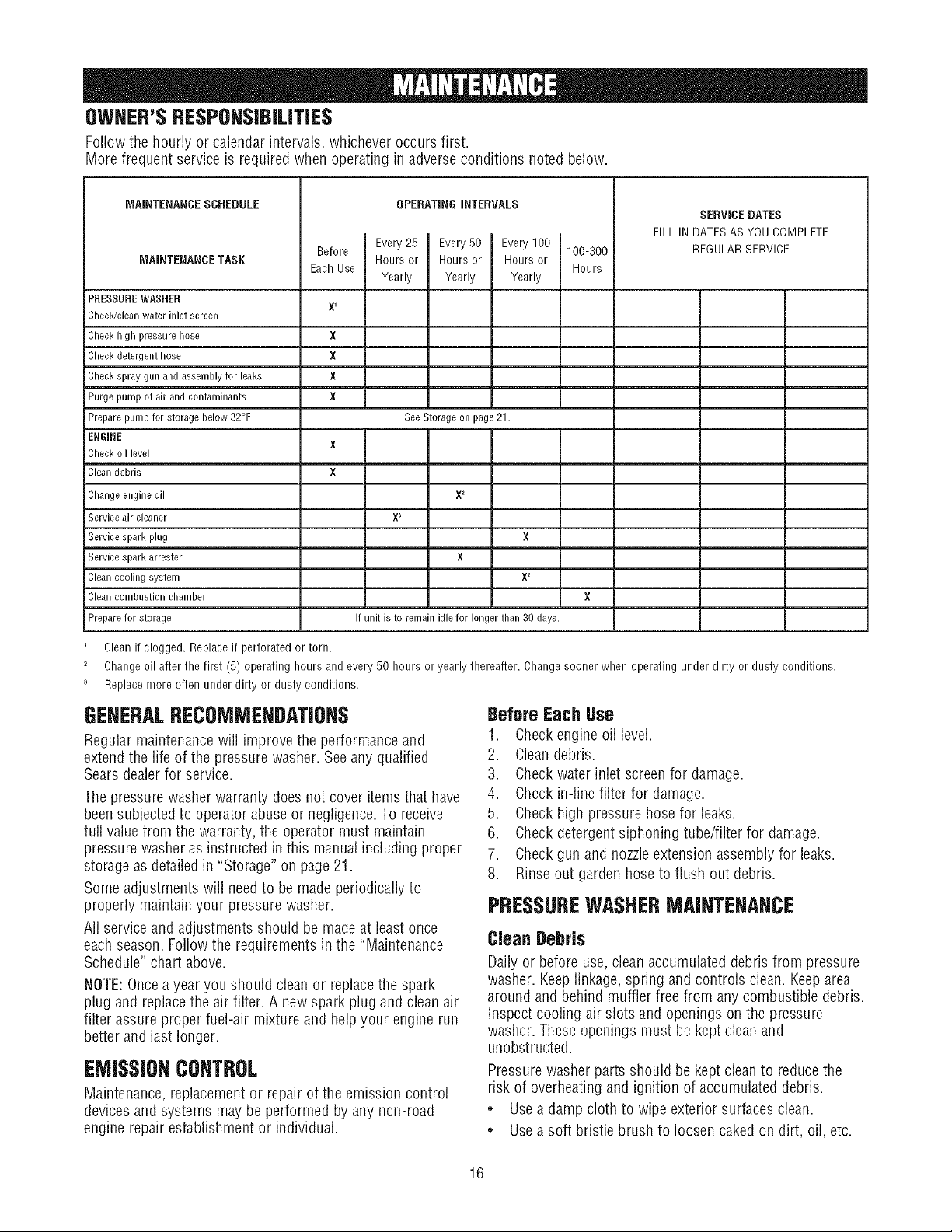

OWNER'SRESPONSIBILITIES

Followthe hourly or calendarintervals,whichever occurs first.

More frequent service is required when operating inadverse conditions noted below.

MAINTENANCESCHEDULE

MAINTENANCETASK

PRESSUREWASHER

ChecWcleanwater inlet screen

Cheek high pressure bose

Check detergent hose

Check spray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Check oil level

Clean debris

Change engine oil

Service air cleaner

Service spark plug

Service spark attester

Clean cooling system

Clean combustion chamber

Preparefor storage

Cleanif clogged. Replace if perforated or torn.

2 Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

3 Replace more often under dirty or dusty conditions.

Before

Each Use

X1

X

X

X

X

X

X

OPERATINGiNTERVALS

Every25

Hours or

I

Yearly

If unit is to remain idle for longer than 30 days.

Every50

Hours or

Yearly

See Storage on page 21.

X2

X_

X

Hours or

I very 100

Yearly

X

X_

100-300

Hours

SERVICEDATES

FILL IN DATESAS YOU COMPLETE

REGULARSERVICE

GENERALRECOMMENDATIONS

Regular maintenancewill improve the performanceand

extendthe life of the pressure washer. Seeany qualified

Searsdealerfor service.

Thepressurewasher warranty does not cover items that have

beensubjectedto operatorabuse or negligence.To receive

full valuefrom the warranty, the operator must maintain

pressure washeras instructed in this manualincluding proper

storage asdetailed in "Storage" on page21.

Someadjustments will needto be madeperiodically to

properly maintain your pressure washer.

All service and adjustments should be made at least once

eachseason. Follow the requirements in the "Maintenance

Schedule" chart above.

NOTE:Oncea year you should clean or replace the spark

plug and replace the air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and helpyour engine run

better and last longer.

EMiSSiONCONTROL

Maintenance, replacementor repair of the emission control

devicesand systems may be performed by any non-road

engine repair establishment or individual.

Before Each Use

1. Checkengine oil level.

2. Cleandebris.

3. Checkwaterinlet screenfor damage.

4. Checkin-line filter for damage.

5. Checkhigh pressure hose for leaks.

6. Checkdetergentsiphoning tube/filter for damage.

7. Checkgunand nozzleextension assembly for leaks.

8. Rinseout garden hoseto flush out debris.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use, clean accumulated debris from pressure

washer. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from anycombustible debris.

Inspect cooling air slots and openings on the pressure

washer. Theseopenings must be kept clean and

unobstructed.

Pressurewasher parts should be kept clean to reducethe

risk of overheatingand ignition of accumulated debris.

• Useadamp cloth to wipe exterior surfaces clean.

• Useasoft bristle brush to loosen caked on dirt, oil, etc.

16

DONOTinsertanyobjectsthroughcoolingslots.

* Useavacuumcleanertopick up loosedirt anddebris.

Check and Clean Inlet Screen

Examinethe screen on the pump's water inlet. Cleanif it is

clogged or replaceif it is torn.

Check High Pressure Hose

High pressure hoses can developleaksfrom wear, kinking,

or abuse, inspect hose before each use.Checkfor cuts,

leaks,abrasions, bulging of cover, or damage or movement

of couplings. If any of these conditions exist, replacehose

immediately.

4. Assemblenozzleextensionto spray gun, as described

earlier in manual.

Hozzle Maintenance

A pulsing sensationfelt while squeezingthe spray gun

trigger may be caused by excessivepump pressure. The

principal cause of excessivepump pressure is a orifice

clogged or restricted with foreign materials, such asdirt, etc.

Tocorrect the problem, immediately clean the orifice

following these instructions:

1. Shutoff engine and turn off water supply.

2. ALWAYSpoint gun in a safe direction and squeezespray

gun trigger to release retainedhigh water pressure.

WARHIHG

I A WARNING

NEVERrepair high pressure hose. Replaceit.

Replacement hose rating MUSTexceedmaximum pressure

rating of unit.

Check Detergent Siphoning Tube

Examinethe filter on the detergenttube and cleanif clogged.

Thetube should fit tightly on the barbedfitting. Examinethe

tube for leaks or tears. Replacethe filter or tube if either is

damaged.

Check Gunand Hozzle Extension

Examinehoseconnection to gun and make sure it is secure.

Testtrigger by pressing it and making sure it springs back

into placewhen you releaseit. Engagesafety latch andtest

trigger. You should not be able to press trigger. Replacegun

immediately if it fails any of these tests.

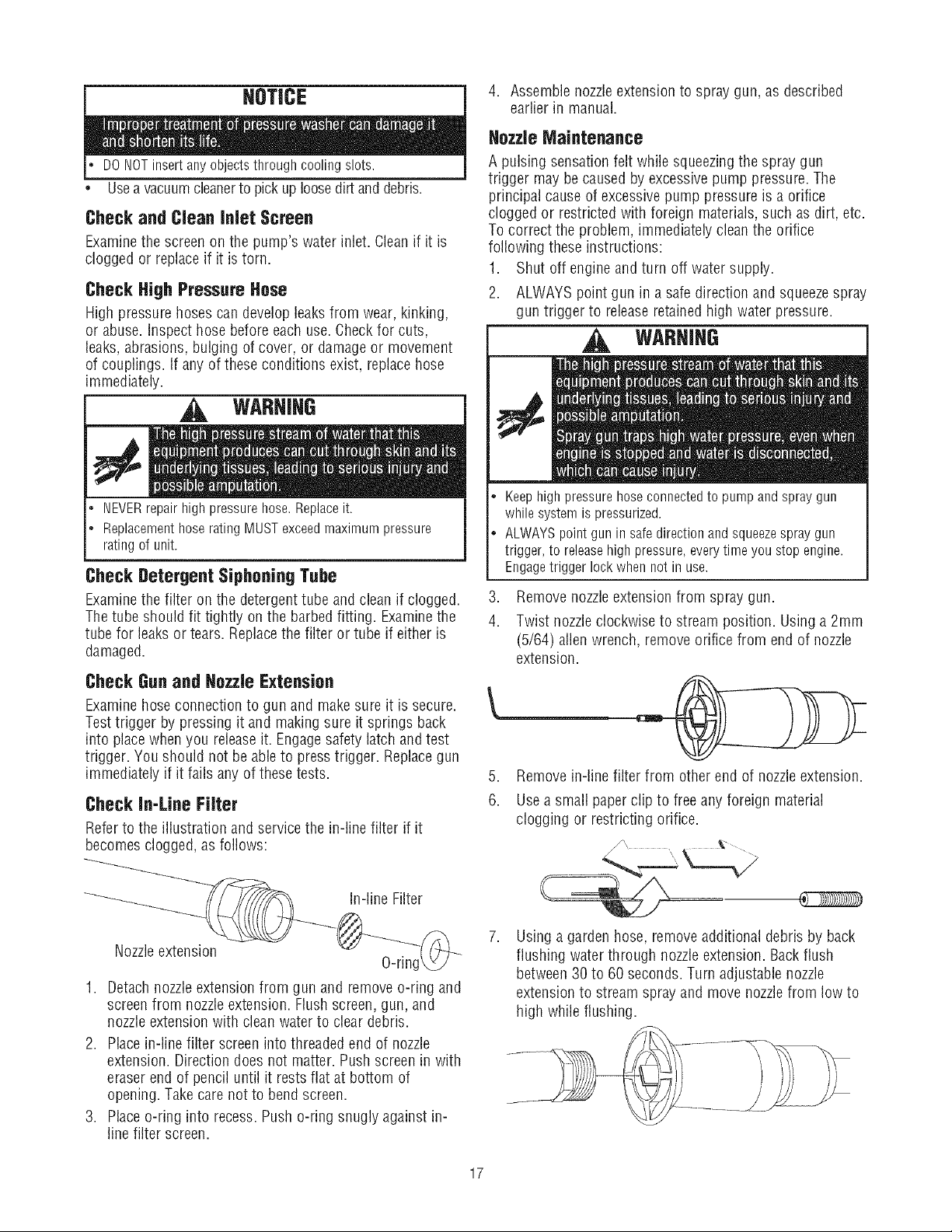

Check In-Line Filter

Referto the illustration and service the in-line filter if it

becomesclogged, as follows:

I

Keephigh pressure hose connectedto pump andspray gun

while system is pressurized.

ALWAYS point gun in safe direction and squeezespray gun

trigger, to releasehigh pressure, every time you stop engine.

Engagetrigger lock when not in use.

,

Removenozzleextension from spray gun.

4.

Twist nozzleclockwise to stream position. Using a 2ram

(5/64) allen wrench, removeorifice from end of nozzle

extension.

,

Removein-line filter from other end of nozzleextension.

6.

Usea small paperclip to free any foreign material

clogging or restricting orifice.

in-line Filter

Nozzleextension

1. Detachnozzleextensionfrom gun and removeo-ring and

screenfrom nozzleextension. Flushscreen, gun, and

nozzleextensionwith clean water to clear debris.

2. Placein-line filter screen into threaded end of nozzle

extension. Direction does not matter. Push screen in with

eraserend of pencil until it rests fiat at bottom of

opening.Take care not to bend screen.

3. Placeo-ring into recess. Push o-ring snugly against in-

line filter screen.

17

,

Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush

between 30 to 60 seconds. Turn adjustable nozzle

extension to stream spray and move nozzle from low to

high while flushing.

Loading...

Loading...