Page 1

Operator'siVlanual

2550 PSi MAX

2.3 GPM MAX

CLEAN GSYSTEM

Model No. 580.676530

®

CUSTOMERHELPLINE

PRESSUREWASHER ,_

HOURS: Mon. - Fri. 8 a.m. to 5p.m. (CT)

WAReleG

Before usingthis product, readthis

manualand follow all SafetyRules

and Operating Instructions.

Sears Canada, Jnc,

Visit ourCraftsman website:www,sears,ca

Part No. 203800GS Draft - (07/26/2007)

AVERTJSSEMEHT

Avant d'utiliser ceproduit, veuillez lire le

manuelet suivre toutes les directives

relatives& la s6curit6 et &I'utilisation.

• Safety

• Assembly

• Operation

o Maintenance

• Parts

,, Fran_ais,p. 34

0

Page 2

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-14

SPECIFICATIONS..................................... 15

MAINTENANCE.................................... 16-20

STORAGE........................................... 21

TROUBLESHOOTING.................................. 22

NOTES ............................................. 23

REPLACEMENTPARTS.............................. 24-31

EMISSIONCONTROLWARRANTY ..................... 32-33

FRAN_AIS........................................ 34-59

HOWTO ORDERPARTS........................ BACKPAGE

ONE-YEARFULLWARRAHTYONCRAFTSMAHPRESSUREWASHER

If this pressurewasher fails dueto a defectin material or workmanship within one year from the dateof purchase, return it to

any Searsstore, other Craftsman outlet, or SearsParts & RepairCenterin the UnitedStates or Canadafor free repair (or

replacementif repair proves impossible).

All warranty coverageapplies for only 90 days from dateof purchaseif this pressure washer is ever usedfor commercial or

rentalpurposes.

This warranty gives you specific legal rights, and you mayalso haveother rights which vary from stateto state.

Sears, Roebuck and Co., Hoffman Estates, IL 60178

Sears Canada Inc., Toronto, Ontario, Canada M5B 288

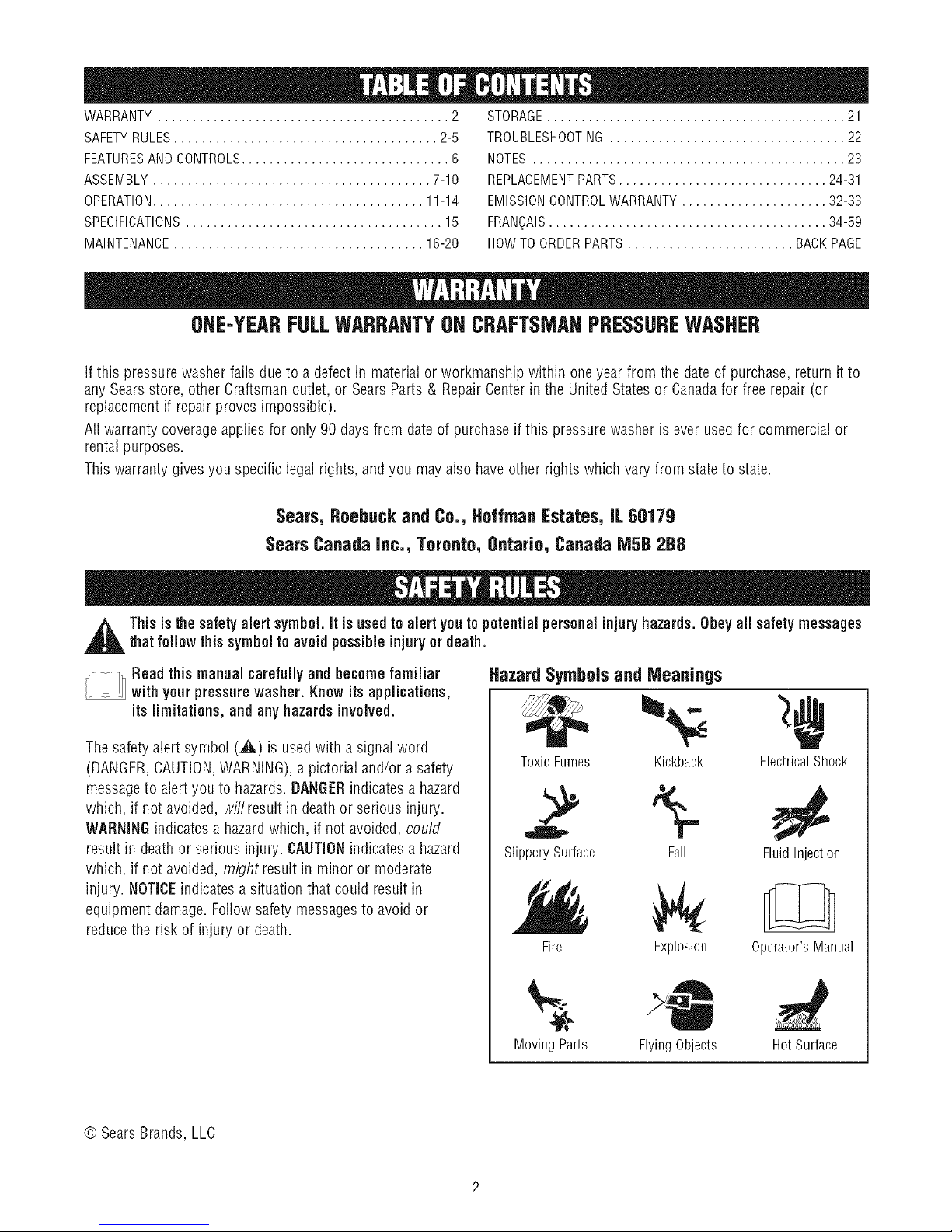

,_ Thisis the safetyalert symbol.It isusedto alert youtopotential personalinjuryhazards. Obey all safetymessages

thatfollow thissymboltoavoid possibleinjury or death.

_Read this manualcarefully and becomefamiliar

with your pressurewasher. Knowits applications,

its limitations, and any hazardsinvolved.

Thesafety alert symbol (_.) is usedwith a signal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert you to hazards.BANGERindicates a hazard

which, if not avoided, willresult in death or serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in death or serious injury. CAUTIONindicatesa hazard

which, if not avoided, might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage. Follow safety messagesto avoid or

reducethe risk of injury or death.

Hazard Symbolsand Meaninos

ToxicFumes Kickback

2 5-

SlipperySurface Fall

Fire

MovingParts FlyingObjects

Explosion

ElectricalShock

FluidInjection

Operator'sManual

HotSurface

© Sears Brands, LLC

Page 3

WARHJNG

Theengineexhaustfromthisproductcontains

chemicalsknownto the State of California tocause

cancer,birthdefects,or otherreproductiveharm.

WARHJHG

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathingcarbon monoxide can cause headache,

_ atigue, dizziness,vomiting, confusion, seizures,

* OperatepressurewasherONLYoutdoors.

Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,orotheropenings.

DONOTstartor runengineindoorsor in anenclosedarea,

evenif windowsanddoorsareopen.

Usea respiratoror maskwheneverthereisa chancethat

vaporsmaybeinhaled.

Readall instructionswith masksoyou arecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

nausea,fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting, or poisoning.

WARHIHG

_¢ isk of electrocution.

* NEVERspraynearpowersource.

Contactwith power source can causeelectric

shock or burn.

WARHIHG

Fueland its vapors are extremely flammable and

explosive.

death.

Fireor explosion cancause severe burns or

WHENADDINGORDRAININGFUEL

* TurnpressurewasherOFFandletit coolat least2 minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

Fillor drainfueltankoutdoors.

DONOToverfilltank.Allowspaceforfuelexpansion.

Iffuelspills,waituntil it evaporatesbeforestartingengine.

Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

DONOTlighta cigaretteorsmoke.

WHENSTARTIN6EQUIPMENT

* Ensuresparkplug,muffler,fuelcap,andair cleanerarein

place.

. DONOTcrankenginewith sparkplugremoved.

WHENOPERATINGEQUIPMENT

* DONOTtip engineor equipmentat anglewhichcausesfuelto

spill.

. DONOTsprayflammableliquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

* Transport/repairwithfueltank EMPTYor withfuel shutoffvalve

OFF.

. Disconnectsparkplugwire.

WHENSTORINGFUELOREQUIPMENTWITH FUELIN TANK

* Storeawayfromfurnaces,stoves,waterheaters,clothes

dryers,orotherappliancesthathavepilotlight or otherignition

sourcebecausetheycanignitefuelvapors.

Page 4

WARHJHG

Startercord kickback (rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

_,_.< toward engine faster than you can let go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spray gun

pressure.

. When starting engine, pull cord slowly until resistance is felt

andthen pull rapidly to avoid kickback.

• After eachstarting attempt, where enginefails to run, always

point spray gun in safe direction and squeezespray gun trigger

to releasehigh pressure. Engagespray guntrigger lock.

• Firmly grasp spray gun with both handswhen using high

pressure spray to avoid injury when spray gun kicks back.

WARHIHG

Useof pressure washer can create puddles and

slippery surfaces.

Kickbackfrom spray gun can cause you to fall.

%

. Operatepressure washer from astable surface.

• The cleaning area should haveadequateslopes and drainageto

reducethe possibility of afall due to slippery surfaces.

. Be extremelycareful if you must usethe pressure washer from

a ladder,scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARHIHG

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

• DONOTallow CHILDRENto operate pressure washer.

. NEVERrepair high pressure hose. Replaceit.

• NEVERrepair leaking connections with sealantof any kind.

Replaceo-ring or seal.

• NEVERconnect high pressure hoseto nozzle extension.

. Keep high pressure hose connectedto pump and spray gun

while system is pressurized.

• ALWAYSpoint spray gun in safe direction and squeezespray

gun trigger, to releasehigh pressure, every time you stop

engine. Engagetrigger lock when not in use.

• NEVERaim spray gun at people, animals, or plants.

. DONOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

. NEVERusea spray gun which does not have a trigger lock or

trigger guard in place and in working order.

. Always be certain spray gun, nozzlesand accessories are

correctly attached.

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

WARHIHG

_ Unintentionalsparking can result in fire or

WARHIHG

_ Contact with muffler result in serious

burns.

_ Exhaustheat/gases can ignite combustibles,structures or damagefuel tank causing a fire.

• DO NOTtouch hot parts and AVOID hot exhaust gases.

. Allow equipment to cool before touching.

• Keepat least 5feet (1.5 m) of clearanceon all sides of

pressure washer including overhead.

• Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have aspark arrester, maintained in

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may havesimilar laws.

area can

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTOYOUR

PRESSUREWASHER

. Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

. Use approved sparkplug tester.

• DONOTcheck for spark with spark plug removed.

Page 5

WARHJHG

Starter and other rotating parts canentangle

hands, hair, clothing, or accessories.

* NEVERoperate pressure washer without protective housing or

covers.

* DO NOTwear loose clothing, jewelry or anything that may be

caught in the starter or other rotating parts.

* Tie up long hair and remove jewelry.

WARNING

Risk of eye injury.

" _ JSpraycan splash back or propel objects.

Alwayswear safety goggles when using this equipment or in

vicinity of where equipment is in use.

Beforestarting the pressure washer, be sure you are wearing

adequatesafety goggles.

NEVERsubstitute safety glasses for safety goggles.

NOTICE

High pressure spray may damage fragile items including

lass.

DO NOTpoint spray gun at glass when using red (0°) spray tip.

NEVERaim spray gun at plants.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

Ifyou havequestions about intended use, ask dealer or contact

Sears.

NEVERoperate units with broken or missing parts, or without

protective housing or covers.

DONOT by-pass any safetydevice on this machine.

DONOTtamper with governed speed.

DONOToperate pressure washer above rated pressure.

DONOT modify pressure washer in any way.

Before starting pressure washer in cold weather, check all parts

of the equipment to besure ice has not formed there.

NEVERmove machine by pulling on hoses. Use handle

provided on unit.

Checkfuel system for leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects beforeoperating pressure

washer.

This equipment is designedto be used with Searsauthorized

parts ONLY.If equipment is usedwith parts that DO NOT

comply with minimum specifications, user assumes all risks

and liabilities.

Page 6

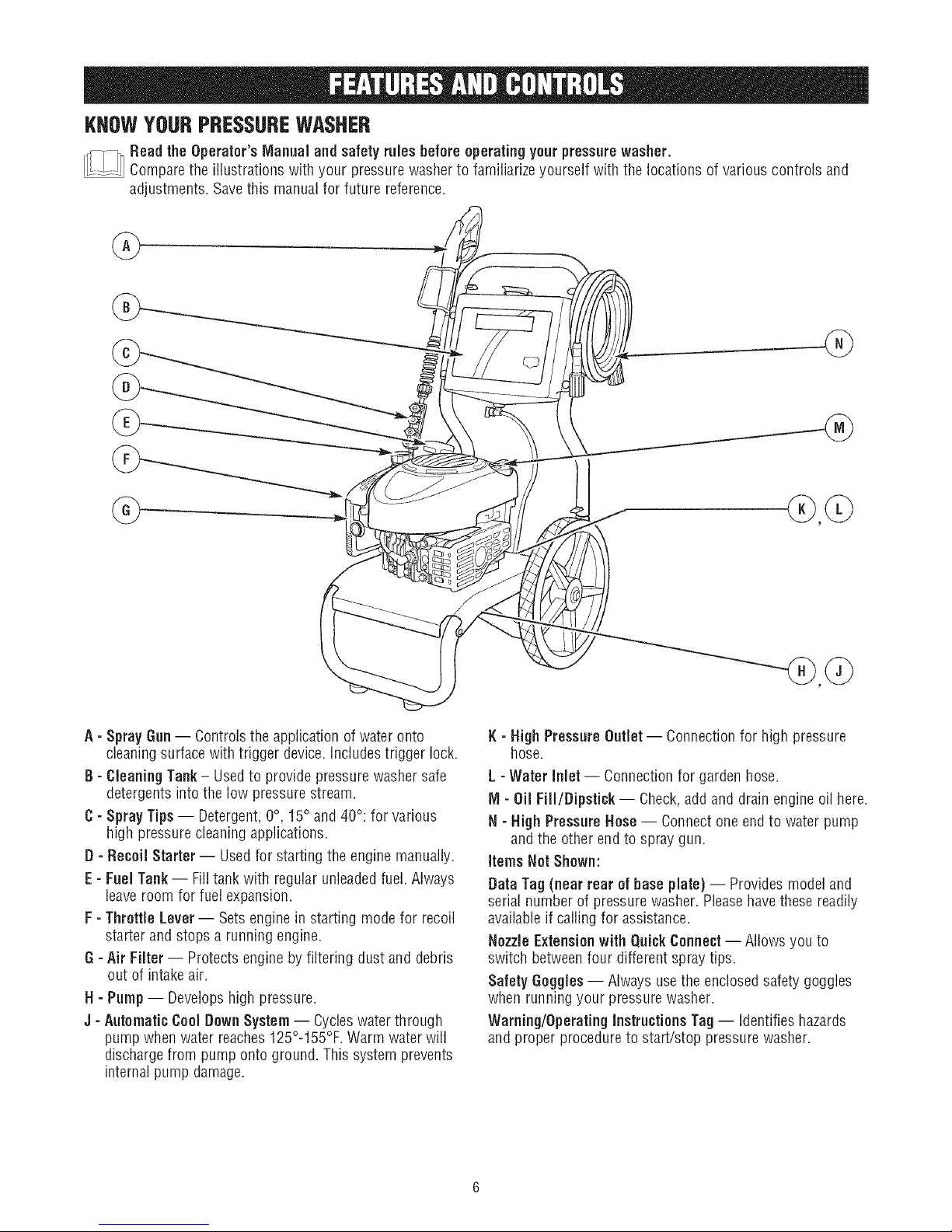

KNOWYOURPRESSUREWASHER

_Read the Operator'sManual and safety rules before operatingyourpressurewasher.

Comparethe illustrations with your pressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

A- Spray Gun-- Controls the application of water onto

cleaningsurface with trigger device,includes trigger lock.

B - Cleaning Tank - Usedto provide pressure washer safe

detergents into the low pressure stream.

C- Spray Tips -- Detergent,0°, 15° and 40°: for various

high pressure cleaning applications.

D - Recoil Starter -- Used for starting the engine manually.

E - Fuel Tank -- Filltank with regular unleadedfuel. Always

leaveroom for fuel expansion.

F - Throttle Lever -- Setsengine in starting mode for recoil

starter and stops a running engine.

G - Air Filter -- Protects engine by filtering dust and debris

out of intake air.

H - Pump -- Developshigh pressure.

J - AutomaticCoolDownSystem-- Cycleswaterthrough

pump when water reaches125°-155°F.Warm water will

dischargefrom pump onto ground. This system prevents

internal pump damage.

K- High Pressure Outlet -- Connection for high pressure

hose.

L - Water Inlet -- Connectionfor gardenhose.

IVl- Oil Fill/Dipstick -- Check,add and drain engine oil here.

N - High Pressure Hose-- Connectone end to water pump

and the other end to spray gun.

Items Not Shown:

Data Tag (near rear of base plate) -- Provides model and

serial number of pressure washer. Pleasehavethese readily

availableif calling for assistance.

NozzleExtensionwith QuickConnect -- Allows you to

switch betweenfour different spray tips.

Safety Goggles-- Always usethe enclosedsafety goggles

when running your pressure washer.

Warning/Operating instructionsTag-- identifies hazards

and proper procedure to start/stop pressure washer.

Page 7

Yourcleaningsystemrequiressomeassemblyandisready

foruseonlyafterit hasbeenproperlyservicedwiththe

recommendedoilandfuel.

If you have any problemswith the assemblyof your

pressurewasher, please call the pressurewasher heipline

at 1-800-222-3135.

UNPACKTHEPRESSUREWASHER

1. Removeeverything from carton exceptpressure washer.

2. Opencarton completely by cutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

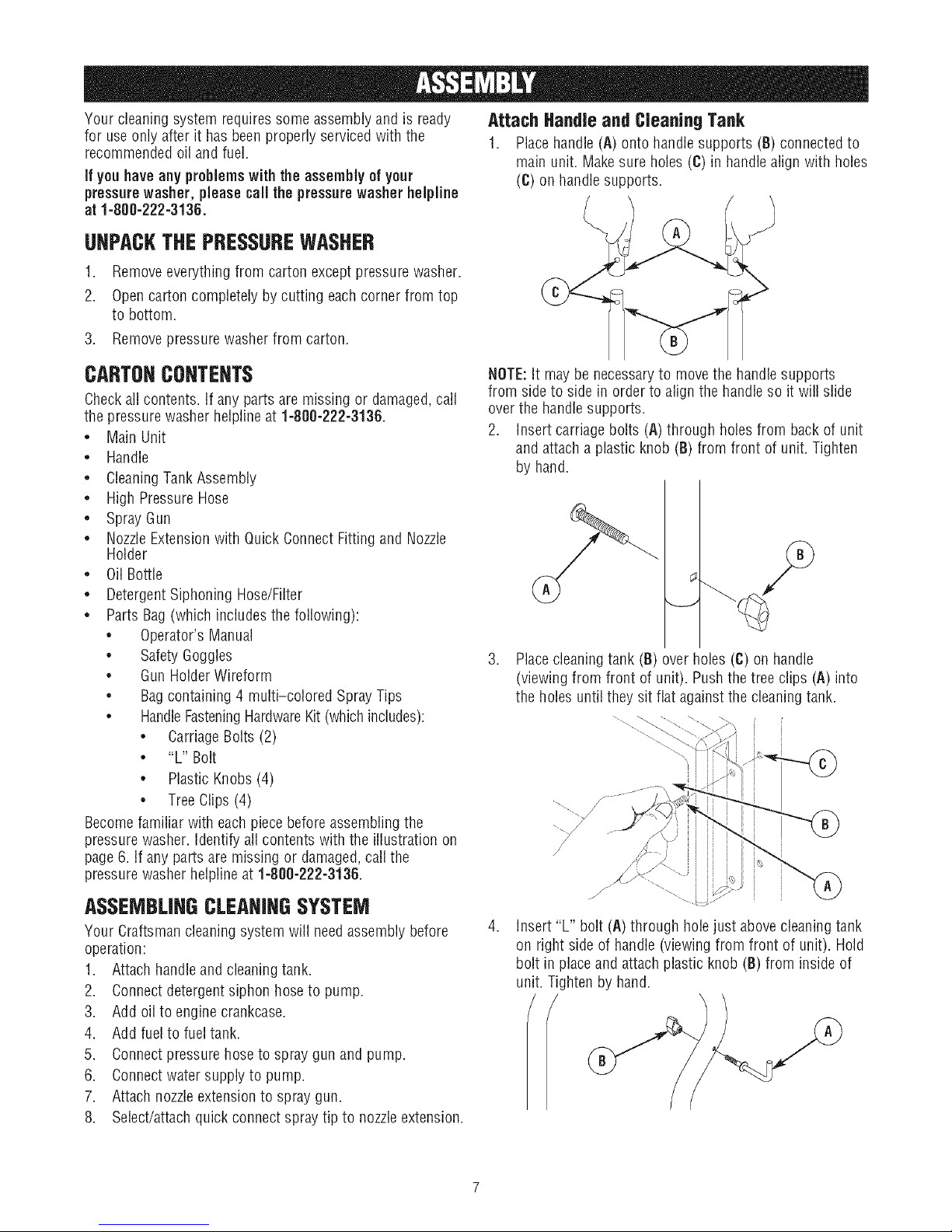

Attach Handle and Cleaning Tank

1. Placehandle (A) onto handlesupports (B) connectedto

main unit. Make sure holes (C) in handlealign with holes

(C) on handle supports.

CARTONCONTENTS

Checkall contents, if any parts are missing or damaged,call

the pressure washer helpline at 1-800=222=3136.

* Main Unit

* Handle

* CleaningTankAssembly

* High PressureHose

* Spray Gun

* NozzleExtensionwith Quick ConnectFitting and Nozzle

Holder

* Oil Bottle

* DetergentSiphoning Hose/Filter

* Parts Bag(which includes the following):

* Operator's Manual

* Safety Goggles

* Gun HolderWireform

* Bagcontaining 4 multi-colored Spray Tips

* HandleFasteningHardwareKit (whichincludes):

* CarriageBolts (2)

* "L" Bolt

* Plastic Knobs (4)

* TreeClips (4)

Becomefamiliar with eachpiece before assembling the

pressure washer, identify all contents with the illustration on

page 6. If any parts are missing or damaged,call the

pressure washer helpline at 1-800-222-3136.

ASSEMBLINGCLEAHIHGSYSTEM

Your Craftsman cleaning system will needassembly before

operation:

1. Attach handleand cleaningtank.

2. Connectdetergent siphon hoseto pump.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connectpressure hoseto spray gun and pump.

6. Connectwater supply to pump.

7. Attach nozzleextensionto spray gun.

8. Select/attachquick connect spray tip to nozzleextension.

NOTE:It may be necessaryto move the handle supports

from sideto side in order to align the handle so it will slide

overthe handlesupports.

2. Insert carriagebolts (A) through holesfrom back of unit

and attach a plastic knob (B) from front of unit. Tighten

by hand.

3. Placecleaningtank (B) over holes (C) on handle

(viewing from front of unit). Pushthe tree clips (A) into

the holes until they sit flat againstthe cleaningtank.

/J

Insert "L" bolt (A) through hole just abovecleaning tank

on right side of handle (viewing from front of unit). Hold

bolt in placeand attach plastic knob (B) from inside of

unit. Tighten by hand.

Page 8

,

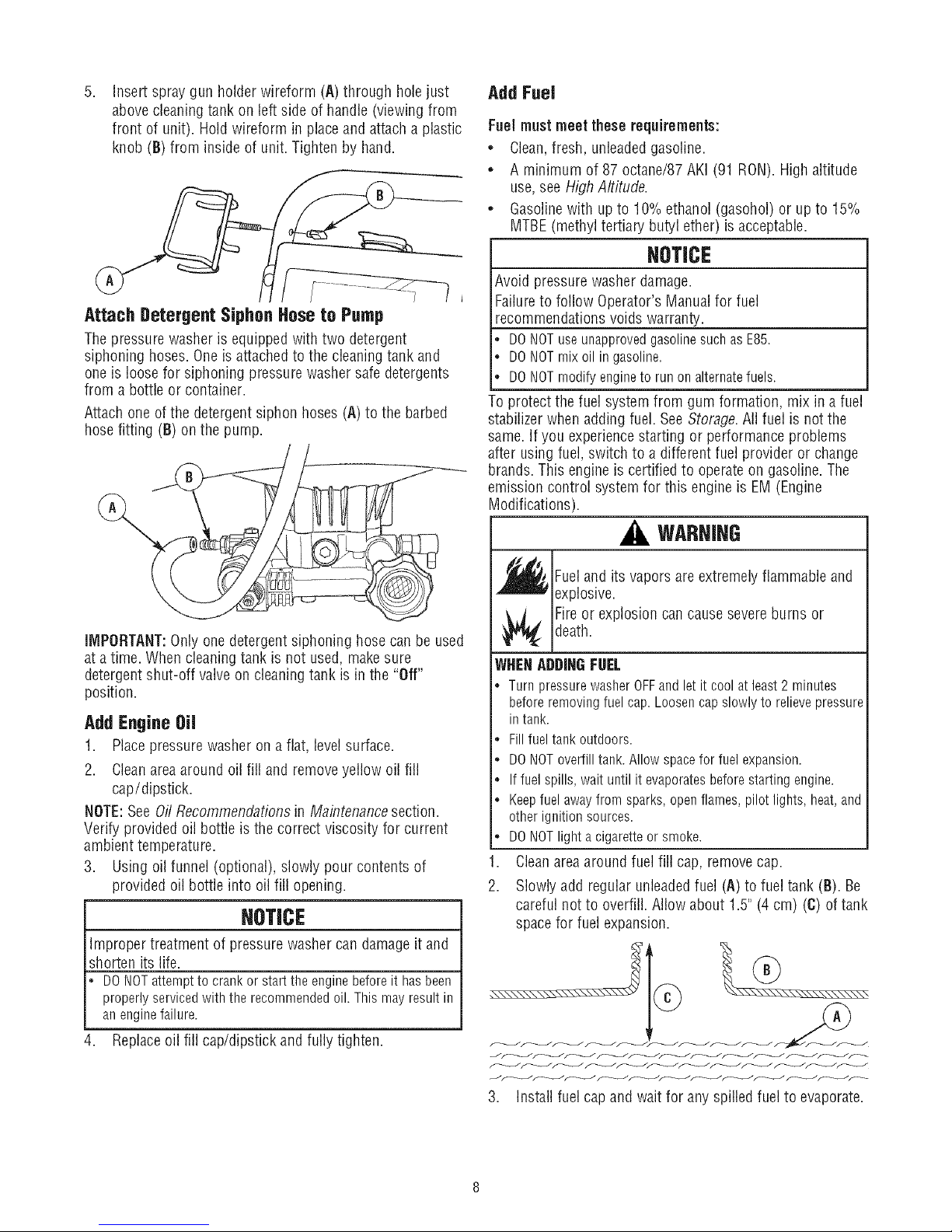

Insert spray gun holder wireform (h) through holejust

abovecleaning tank on left side of handle (viewing from

front of unit). Hold wireform in placeand attach a plastic

knob (B) from inside of unit. Tighten by hand.

Attach Detergent Siphon Hose to Pump

Thepressure washer is equipped with two detergent

siphoning hoses.One is attachedto the cleaningtank and

one is loosefor siphoning pressure washer safe detergents

from a bottle or container.

Attach one of the detergent siphon hoses (A) to the barbed

hose fitting (B) on the pump.

Add Fuel

Fuelmust meet theserequirements:

* Clean,fresh, unleadedgasoline.

* A minimum of 87 octane/87 AKI (91 RON).High altitude

use, see High Altitude.

* Gasolinewith up to 10% ethanol (gasohol) or up to 15%

MTBE(methyl tertiary butyl ether) is acceptable.

NOTICE

Avoid pressure washer damage.

Failureto follow Operator's Manualfor fuel

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchas E85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizer when adding fuel. See Storage.All fuel is not the

same. If you experiencestarting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operate on gasoline. The

emission control system for this engine is EM (Engine

Modifications).

WARHIHG

IMPORTANT:Only one detergent siphoning hosecan be used

at a time. When cleaningtank is not used, makesure

detergent shut-off valve on cleaning tank is in the "Off"

position.

Add Enoine OiJ

1. Placepressure washeron a flat, levelsurface.

2. Cleanarea around oil fill and remove yellow oil fill

cap/dipstick.

NOTE:See Oil Recommendationsin Maintenancesection.

Verify provided oil bottle is the correct viscosity for current

ambient temperature.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

HOTICE

Improper treatment of pressurewasher can damageit and

shorten its life.

DONOTattempttocrankor starttheenginebeforeit hasbeen

properlyservicedwith the recommendedoil. Thismayresultin

anenginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

FueIand its vapors are extremely flammable and

explosive.

death.

Fireor explosion can causesevere burns or

WHENADDINGFUEL

. TurnpressurewasherOFFandletit coolat least2 minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

. Fillfueltankoutdoors.

• DONOToverfilltank.Allowspacefor fuelexpansion.

. Iffuel spills,waituntilit evaporatesbeforestartingengine.

• Keepfuelawayfromsparks,openflames,pilot lights,heat,and

otherignitionsources.

• DONOTlight a cigaretteorsmoke.

1. Cleanareaaround fuel fill cap, removecap.

2. Slowly add regular unleadedfuel (A) to fuel tank (B). Be

careful not to overfill. Allow about 1.5" (4 cm) (C) oftank

space for fuel expansion.

3. Installfuel cap and wait for any spilled fuelto evaporate.

Page 9

CAUTION!Alcohol-blended fuels (called gasohoI, ethanol or

methanol) can attract moisture, which leads to separation and

formation of acids during storage. Acidic gas can damagethe

fuel system of an enginewhile in storage.

Toavoid engine problems, the fuel system should betreated

with a fuel preserver or emptied before storage of 30 days or

longer. If adding a fuel preserver, fill the fuel tank with fresh

fuel. if only partially filled, air in the tank will promote fuel

deterioration during storage, if fuel preserver is not used,

drain the fuel tank, start the engine and let it run until the fuel

lines and carburetor are empty. Usefresh fuel next season.

See Storagefor additional information.

NEVERuseengine or carburetor cleanerproducts in the fuel

tank as permanent damagemay occur.

HighAltitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remain emissions compliant, high altitude adjustment is

required. Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seea qualified Searsdealer for high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

Connect Hose and Water Supply to Pump

[ NOTICE

JDONOT the without the connected

and turned on.

L amageto equipmentresultingfromfailureto followthis

run

instructionwill void warranty.

pump

NOTE:Removeand discardthe shipping caps from the

pump's high pressure outlet and water inlet beforeattaching

hoses.

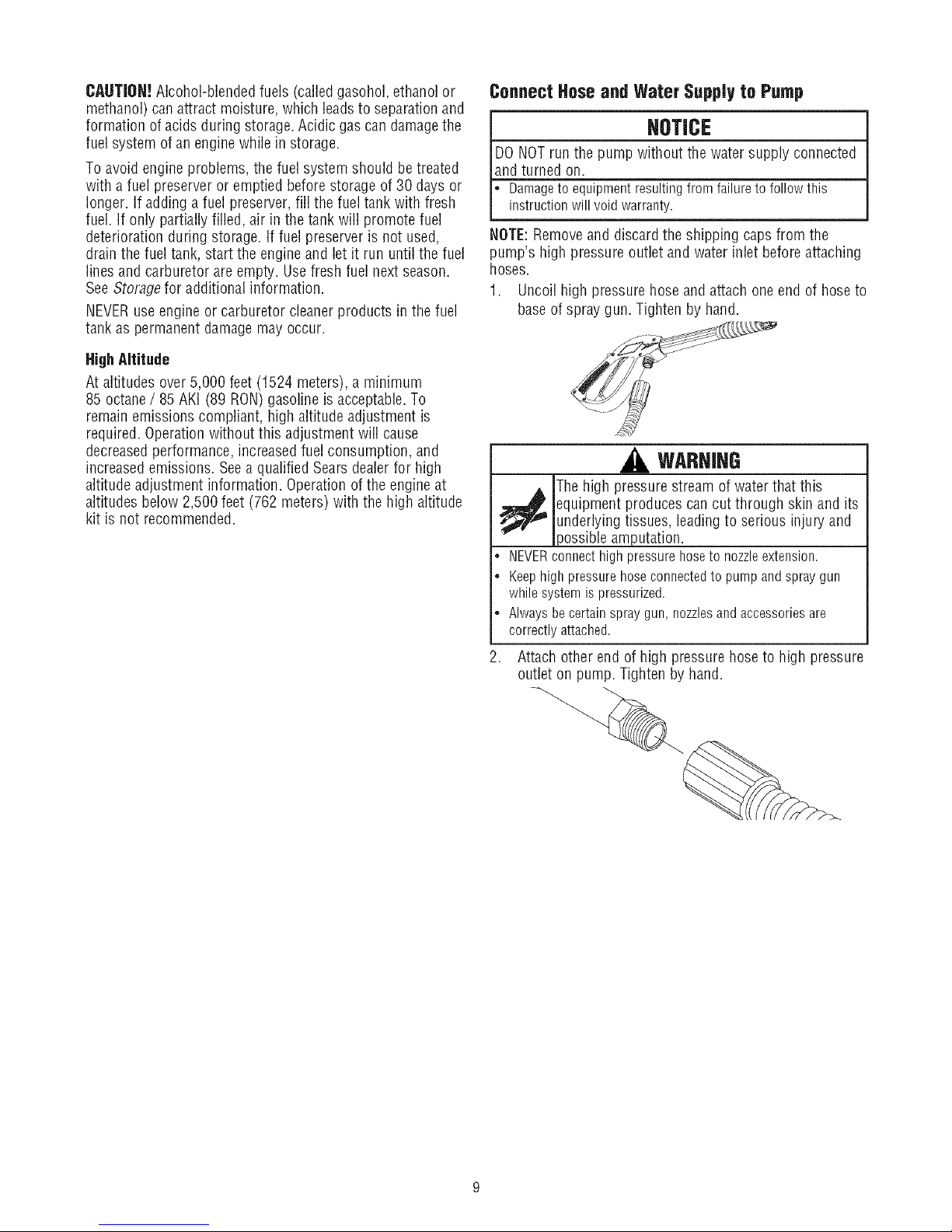

1. Uncoil high pressure hose and attach one end of hoseto

baseof spray gun. Tighten by hand.

water

supply

WARNING

Thehigh pressurestream of water that this

_ quipment produces can cut through skin and its

. NEVERconnecthighpressurehoseto nozzleextension.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

,

underlyingtissues, leadingto serious injury and

)ossible amputation.

Attach other end of high pressure hose to high pressure

outlet on pump. Tighten by hand.

Page 10

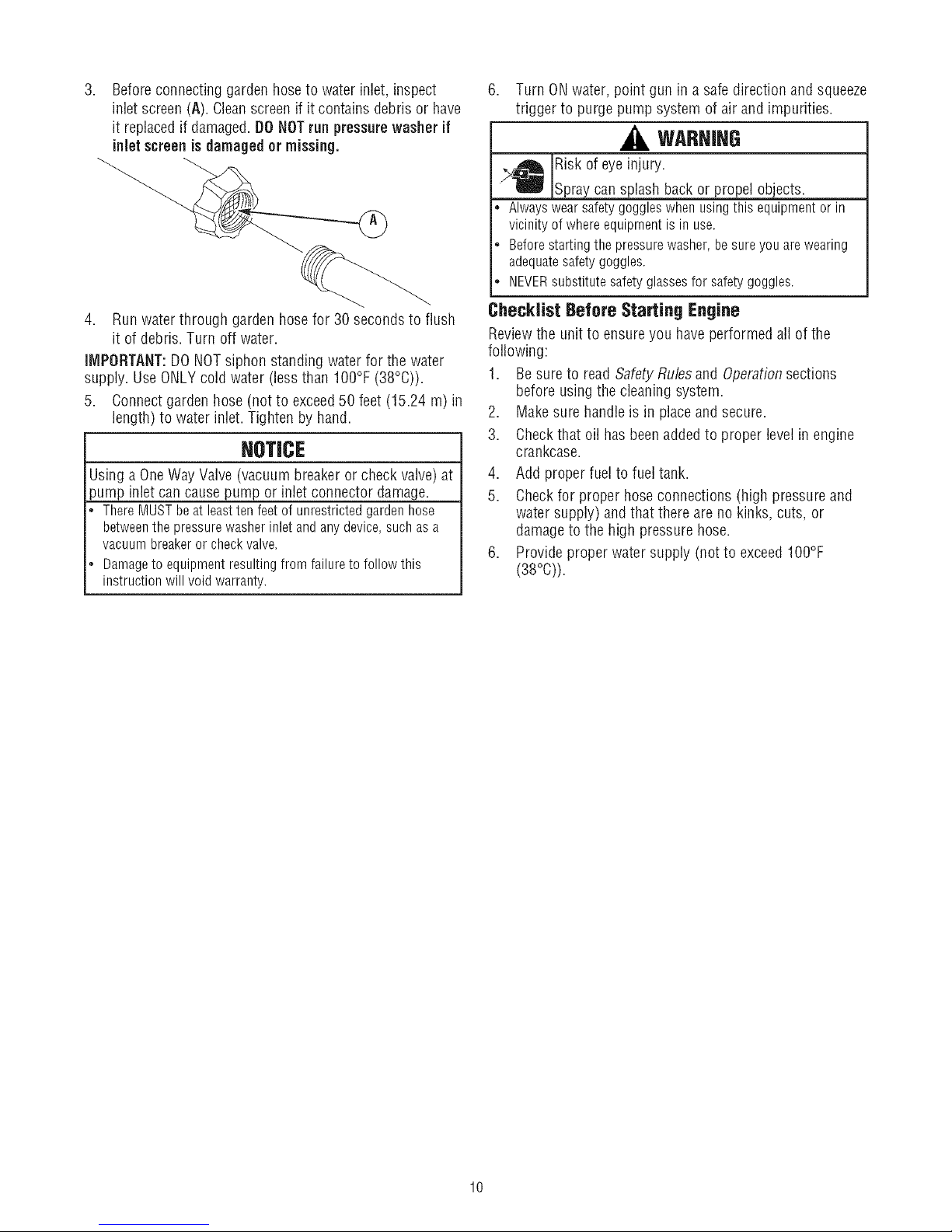

3. 6. TurnONwater,pointguninasafedirectionandsqueeze

Beforeconnectinggardenhosetowaterinlet,inspect

inletscreen(A).Cleanscreenifitcontainsdebrisorhave

triggertopurgepumpsystemofairandimpurities.

itreplacedifdamaged.DO NOTrun pressurewasher if

inlet screenis damagedor missing.

Riskof eyeinjury.

m_JSpray cansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentisin use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

WARHJHG

4. Run water through garden hose for 30 seconds to flush

it of debris. Turn off water.

IMPORTANT:DO NOTsiphon standing water for the water

supply. UseONLY cold water (less than IO0°F (38%)).

5. Connectgarden hose (not to exceed50 feet (15.24 m) in

length) to water inlet. Tighten by hand.

NOTICE

Using a OneWay Valve(vacuum breakeror check valve)at

pump inlet can cause pump or inlet connector damage.

ThereMUSTbeat leasttenfeetofunrestrictedgardenhose

betweenthe pressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

Damageto equipmentresultingfromfailuretofollowthis

instructionwill void warranty.

ChecklistBefore StartingEngine

Reviewthe unit to ensure you have performed all of the

following:

1. Besure to read Safety Rubs and Operationsections

before usingthe cleaning system.

2. Makesure handle is in placeand secure.

3. Checkthat oil has beenadded to proper levelin engine

crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor proper hoseconnections (high pressure and

water supply) and that there are no kinks, cuts, or

damageto the high pressure hose.

6. Provideproper water supply (not to exceedIO0°F

(38°C)).

10

Page 11

HOWTOUSEYOURCLEANJHGSYSTEM

If you haveany problems operating your pressure washer,

pleasecall the pressure washer helpline at 1-800-222-3136.

Pressure Washer Location

PressureWasherClearance

,_ WARNING

_ Exhaustheat/gases can ignitecombustibles,

* Keepatleast5ft. (152cm)clearanceonall sidesofpressure

Placepressure washer outdoors in an areathat will not

accumulate deadlyexhaustgas. DONOTplacepressure

washer where exhaust gas (A) could accumulateand enter

inside or be drawn into a potentially occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventilation intakes, or other openingsthat can allow exhaust

gasto collect in a confined area. Prevailingwinds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

structures or damagefuel tank causing a fire.

washerincludingoverhead.

,_ WARHJHG

Runningengine gives off carbon monoxide, an

To Start Your Cleanin8 System

To start your engine-powered cleaning system for the first

time, follow these instructions step-by-step. This information

also applies wheneveryou start the engine after you have let

the pressure washer sit idle for at least a day.

1. Placepressure washer outside near an water source

capableof supplying water at a flow rategreater than

3.3 gallons (12.5 I) per minute and no less than 20 PSI

(1.38 BARS)at pressure washer end of garden hose.

2. Checkthat high pressure hose istightly connectedto

spray gun and pump. SeeAssembyfor illustrations.

3. Makesure unit is in a levelposition.

4. Connectgarden hose to water inlet on pressure washer

pump.

5. Turn ONwater, point gun in a safedirection and squeeze

trigger to purge pump system of air and impurities.

{ NOTICE

% NOTrun the pump without the water supply connected

and turned on.

L amageto equipmentresultingfromfailureto followthis

instructionwill void warranty.

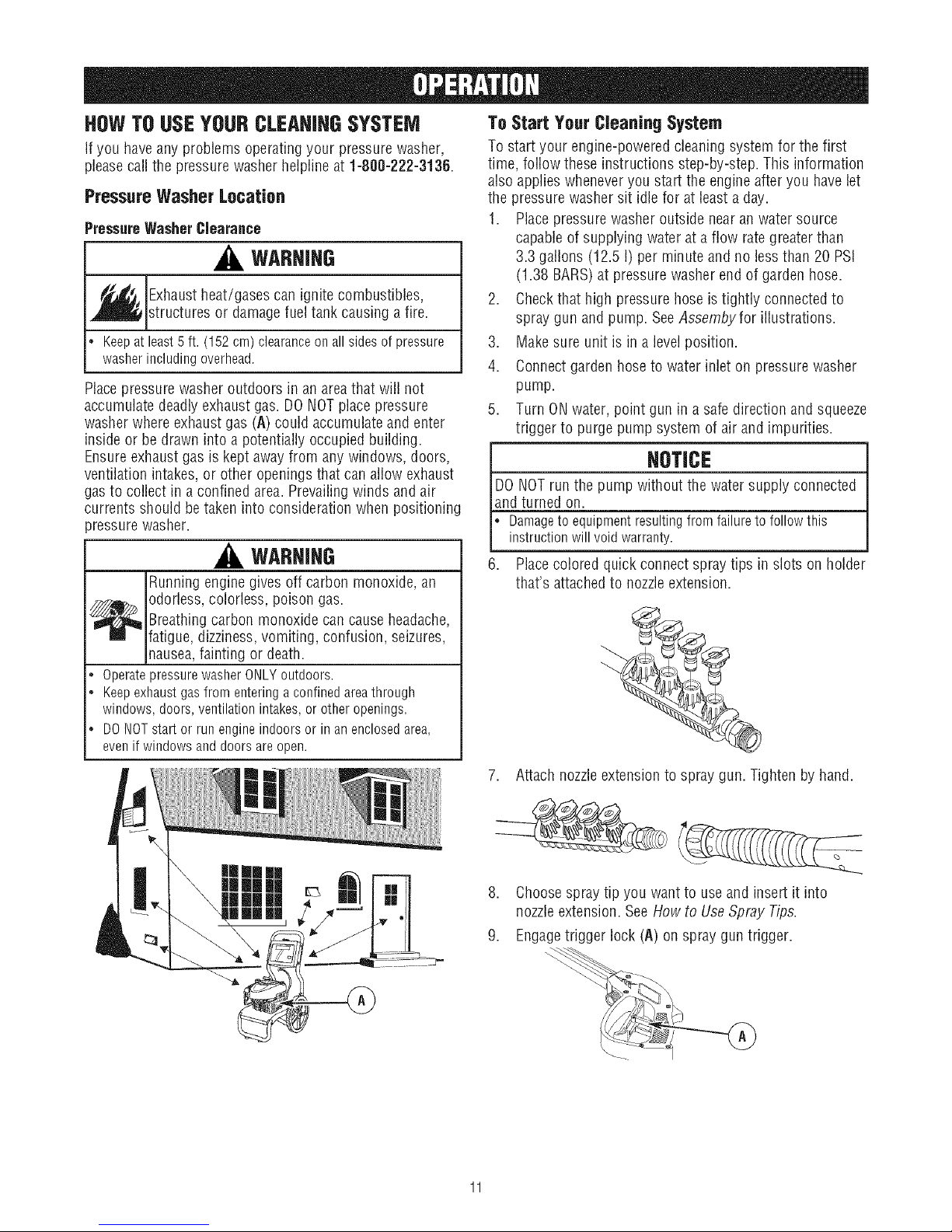

6. Placecolored quick connect spray tips in slots on holder

that's attachedto nozzleextension.

_ dorless, colorless, poison gas.

. OperatepressurewasherONLYoutdoors.

* Keepexhaustgasfromenteringaconfinedareathrough

. DONOTstartor runengineindoorsorin anenclosedarea,

Breathingcarbon monoxide can causeheadache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

windows,doors,ventilationintakes,or otheropenings.

evenif windowsanddoorsareopen.

\

7. Attach nozzleextension to spray gun. Tighten by hand.

B. Choose spray tipyou want to use and insert it into

nozzleextension. SeeHow to UseSpray Tips.

9. Engagetrigger lock (A) on spray gun trigger.

Page 12

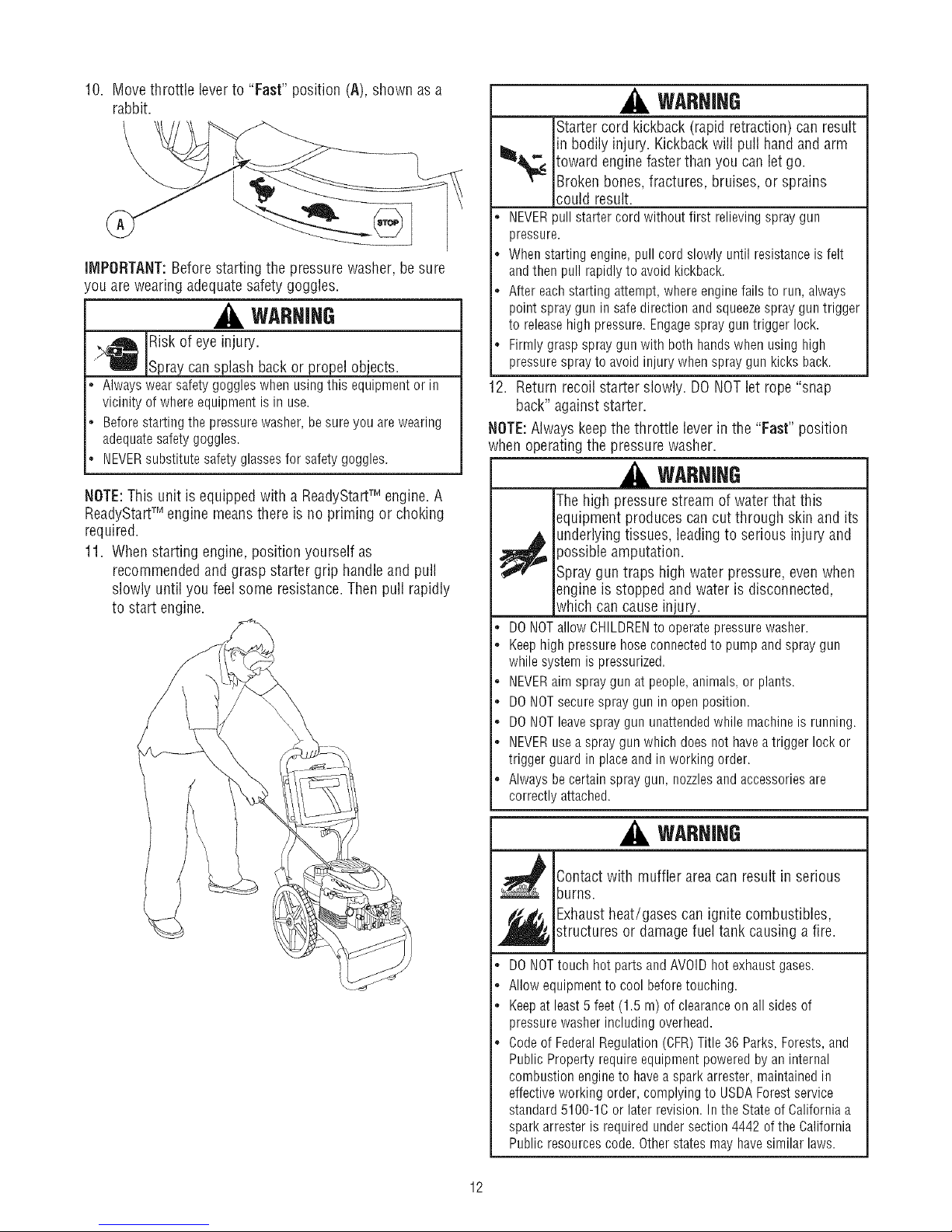

10. Move throttle lever to "Fast" position (A), shown as a

rabbit.

\

IMPORTANT: Before starting the pressure washer, be sure

7ou are wearing adequate safety goggles.

WARNING

Risk of eye injury.

_Spray can splash back or propel objects.

Alwayswear safety goggles when using this equipment or in

vicinity of where equipment is in use.

Beforestarting the pressure washer, be sure you are wearing

adequatesafety goggles.

NEVERsubstitute safety glasses for safety goggles.

NOTE:This unit is equipped with a ReadyStartTM engine. A

ReadyStartTM engine meansthere is no priming or choking

required.

11. When starting engine, position yourself as

recommendedand grasp starter grip handle and pull

slowly until you feelsome resistance. Then pull rapidly

to start engine.

WARHIHG

Starter cord kickback (rapid retraction) can result

in bodily injury. Kickback will pull hand and arm

_ toward engine faster than you can let go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance is felt

andthen pull rapidly to avoid kickback.

After eachstarting attempt, where enginefails to run, always

point spray gun in safe direction and squeezespray gun trigger

to releasehigh pressure. Engagespray gun trigger lock.

Firmly grasp spray gun with both handswhen using high

pressure spray to avoid injury when spray gun kicks back.

12. Return recoil starter slowly. DO NOT let rope "snap

back" against starter.

NOTE: Always keep the throttle lever in the "Fast" position

when operating the pressure washer.

WARHIHG

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

* DONOTallowCHILDRENtooperatepressurewasher.

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

. NEVERaimspraygunatpeople,animals,or plants.

* DONOTsecurespraygun inopenposition.

. DONOTleavespraygununattendedwhile machineis running.

* NEVERuseaspraygunwhichdoesnot haveatriggerlockor

triggerguardin placeandinworkingorder.

. Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

_ossibleamputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

WARHIHG

_ Contact with muffler result in serious

,_ Exhaustheat/gases can ignite combustibles,structures or damage fuel tank causing a fire.

* DONOTtouchhotpartsandAVOIDhotexhaustgases.

. Allowequipmenttocoolbeforetouching.

* Keepatleast5 feet(1.5m) ofclearanceonall sidesof

. Codeof FederalRegulation(CFR)Title36Parks,Forests,and

12

burns.

pressurewasherincludingoverhead.

PublicPropertyrequireequipmentpoweredbyaninternal

combustionengineto haveasparkarrester,maintainedin

effectiveworkingorder,complyingto USDAForestservice

standard51BB-1Cor later revision.IntheStateof Californiaa

sparkarresteris requiredundersection4442oftheCalifornia

Publicresourcescode.Otherstatesmayhavesimilarlaws.

area can

Page 13

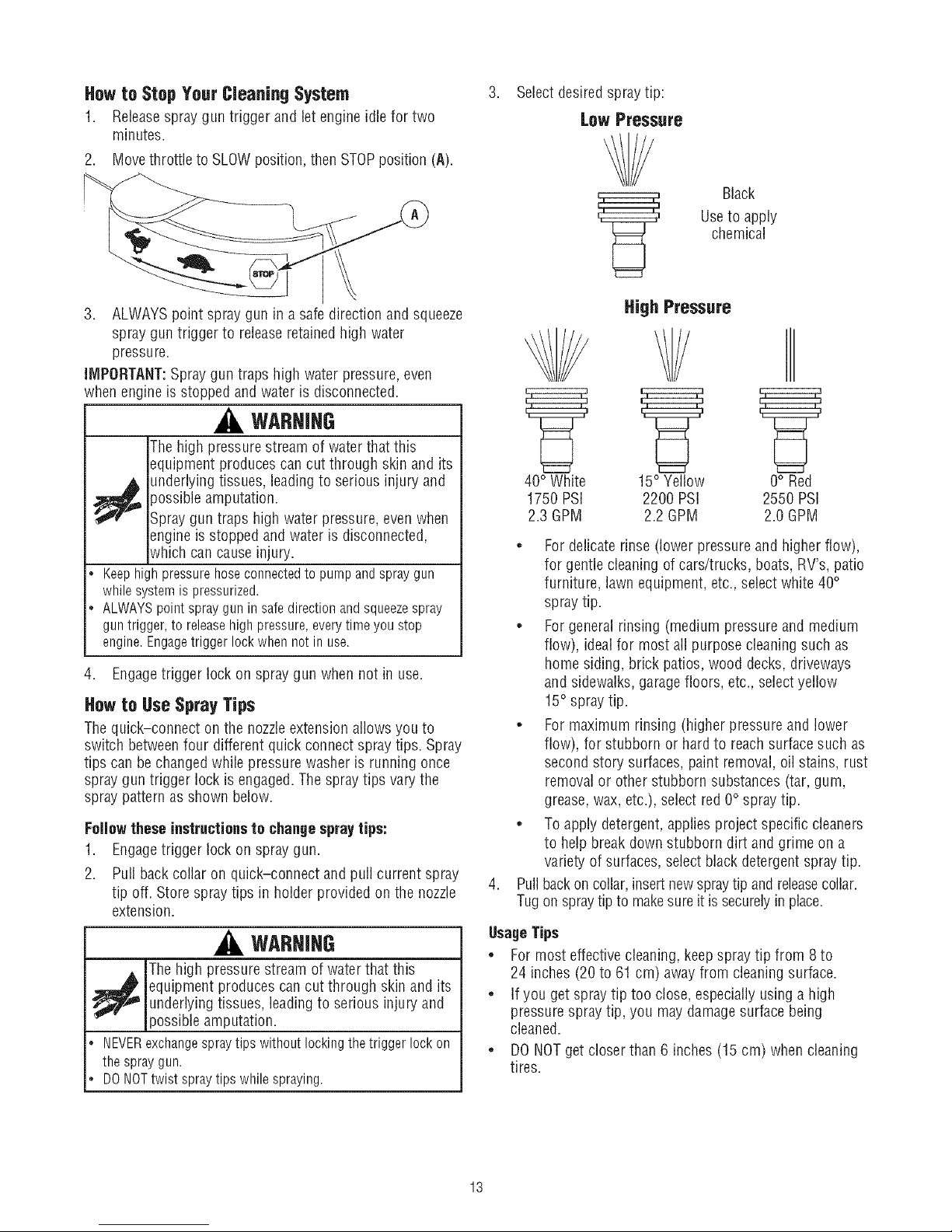

Howto StopYour CleaningSystem

1. Releasespray gun trigger and letengine idlefor two

minutes.

2. Movethrottle to SLOW position, then STOPposition (A).

,

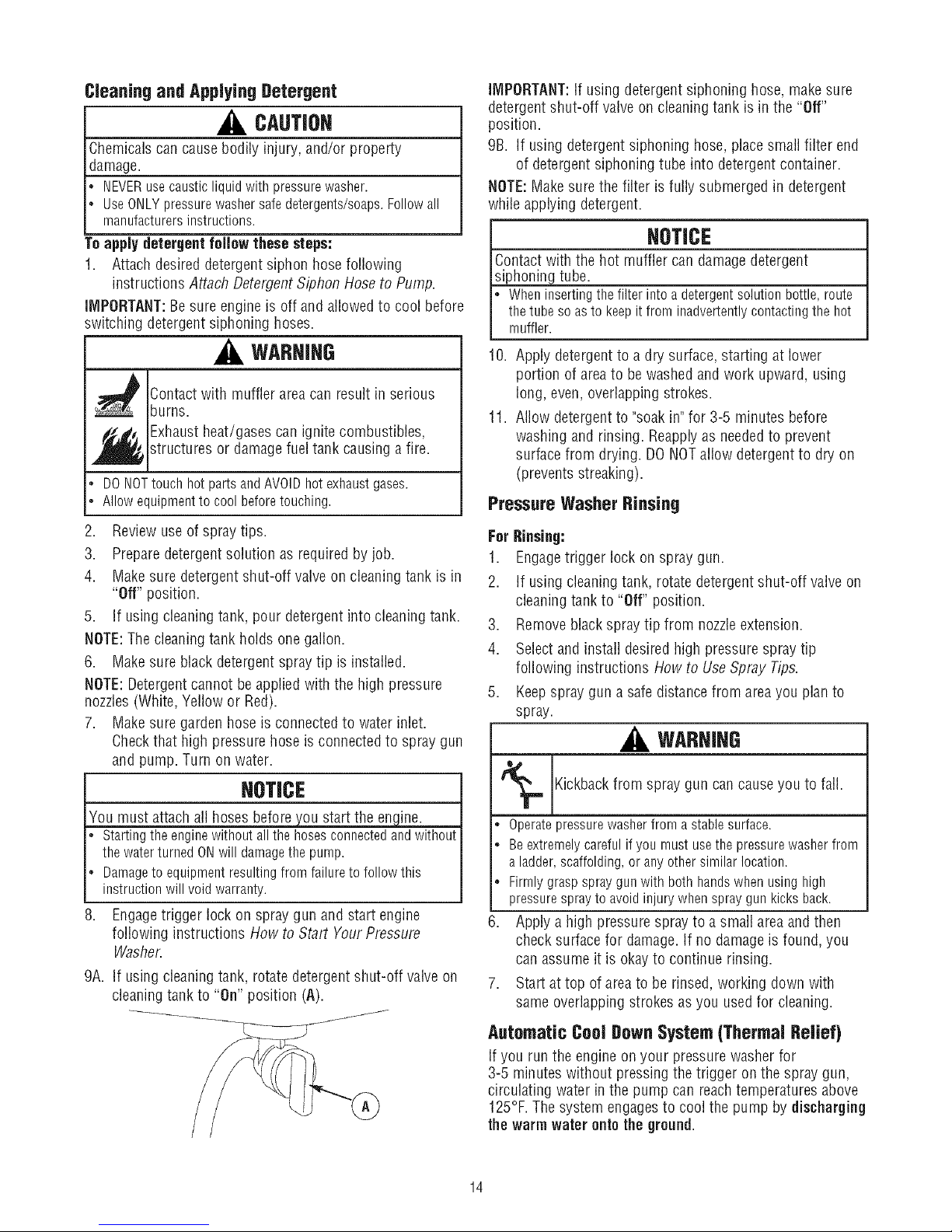

Select desiredspray tip:

Low Pressure

Black

Useto apply

chemical

3. ALWAYSpoint spray gun in a safe direction and squeeze

spray gun trigger to releaseretainedhigh water

pressure.

IMPORTANT:Spray gun traps high water pressure,even

when engine is stopped and water is disconnected.

WARHIHG

The high pressure stream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

. ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennotin use.

4. Engagetrigger lock on spray gun when not in use.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

How to Use Spray Tips

Thequick-connect on the nozzleextension allows you to

switch between four different quick connect spray tips. Spray

tips can be changedwhile pressure washer is running once

spray gun trigger lock is engaged. The spray tips vary the

spray pattern asshown below.

FolJowthese instructionsto changespraytips:

1. Engagetrigger lock on spray gun.

2. Pull back collar on quick-connect and pull current spray

tip off. Storespray tips in holder provided on the nozzle

extension.

WARHIHG

The high pressure stream of water that this

_ quipment produces can cut through skin and itsunderlyingtissues, leadingto serious injury and

possible amputation.

. NEVERexchangespraytips withoutlockingthetriggerlockon

the spraygun.

. DONOTtwist spraytips whilespraying.

High Pressure

40° White 15° Yellow

1750 PSi 2200 PSi

2.3 GPM 2.2 GPM

* For delicate rinse (lower pressure and higher flow),

for gentlecleaning of cars/trucks, boats, RV's,patio

furniture, lawn equipment, etc., select white 40°

spray tip.

. Forgeneral rinsing (medium pressure and medium

flow), ideal for most all purpose cleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garage floors, etc., selectyellow

15° spray tip.

. For maximum rinsing (higher pressure andlower

flow), for stubborn or hard to reachsurface such as

second story surfaces,paint removal,oil stains, rust

removal or other stubborn substances (tar, gum,

grease,wax, etc.), select red 0° spray tip.

. Toapply detergent,appliesproject specific cleaners

to help breakdown stubborn dirt andgrime on a

variety of surfaces, selectblack detergentspray tip.

,

Pull backon collar,insert new spraytip and releasecollar.

Tugon spraytip to makesure it is securelyin place.

UsageTips

• For most effective cleaning, keepspray tip from 8 to

24 inches (20 to 61 cm) awayfrom cleaningsurface.

• If you get spray tip too close, especially usinga high

pressure spray tip, you may damagesurface being

cleaned.

• DONOTget closer than 6 inches (15 cm) when cleaning

tires.

0° Red

255OPSi

2.0 GPM

13

Page 14

Cleaning and Applying Detergent

CAUTION

Chemicalscan causebodily injury, and/or property

damage.

NEVERusecausticliquidwithpressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

To apply detergent follow these steps:

1. Attach desired detergent siphon hosefollowing

instructions Attach DetergentSiphon Hose to Pump.

IMPORTANT:Besure engine is off and allowed to cool before

switching detergentsiphoning hoses.

IMPOFITANT:if using detergent siphoning hose, make sure

detergentshut-off valve on cleaning tank is in the ,Off,

position.

9B. If using detergent siphoning hose, place small filter end

of detergent siphoning tube into detergent container.

NOTE:Makesure the filter is fully submerged in detergent

while applying detergent.

NOTICE

Contact with the hot muffler can damagedetergent

siphoning tube.

Wheninsertingthefilterintoa detergentsolutionbottle,route

thetubesoasto keepit from inadvertentlycontactingthe hot

muffler.

WARNING

_ Contact with muffler result in serious

_ Exhaustheat/gases can ignite combustibles,

* DONOTtouchhotpartsandAVOIDhotexhaustgases.

* Allowequipmentto coolbeforetouching.

2. Reviewuse of spray tips.

3. Preparedetergent solution as required by job.

4. Make sure detergent shut-off valve on cleaningtank is in

5. If using cleaningtank, pour detergent into cleaningtank.

NOT[: Thecleaningtank holds one gallon.

6. Make sure black detergent spray tip is installed.

NOT[: Detergentcannot be applied with the high pressure

nozzles(White, Yellow or Red).

7. Make sure garden hoseis connectedto water inlet.

burns.

structures or damagefuel tank causing a fire.

"Off" position.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

area can

NOTICE

You must attacha]] hoses before ou start the en ine.

Startingthe enginewithoutallthehosesconnectedandwithout

thewaterturnedONwill damagethe pump.

Damageto equipmentresultingfromfailuretofollowthis

instructionwillvoidwarranty.

8. Engagetrigger lock on spray gun and start engine

following instructions How to Start Your Pressure

Washer.

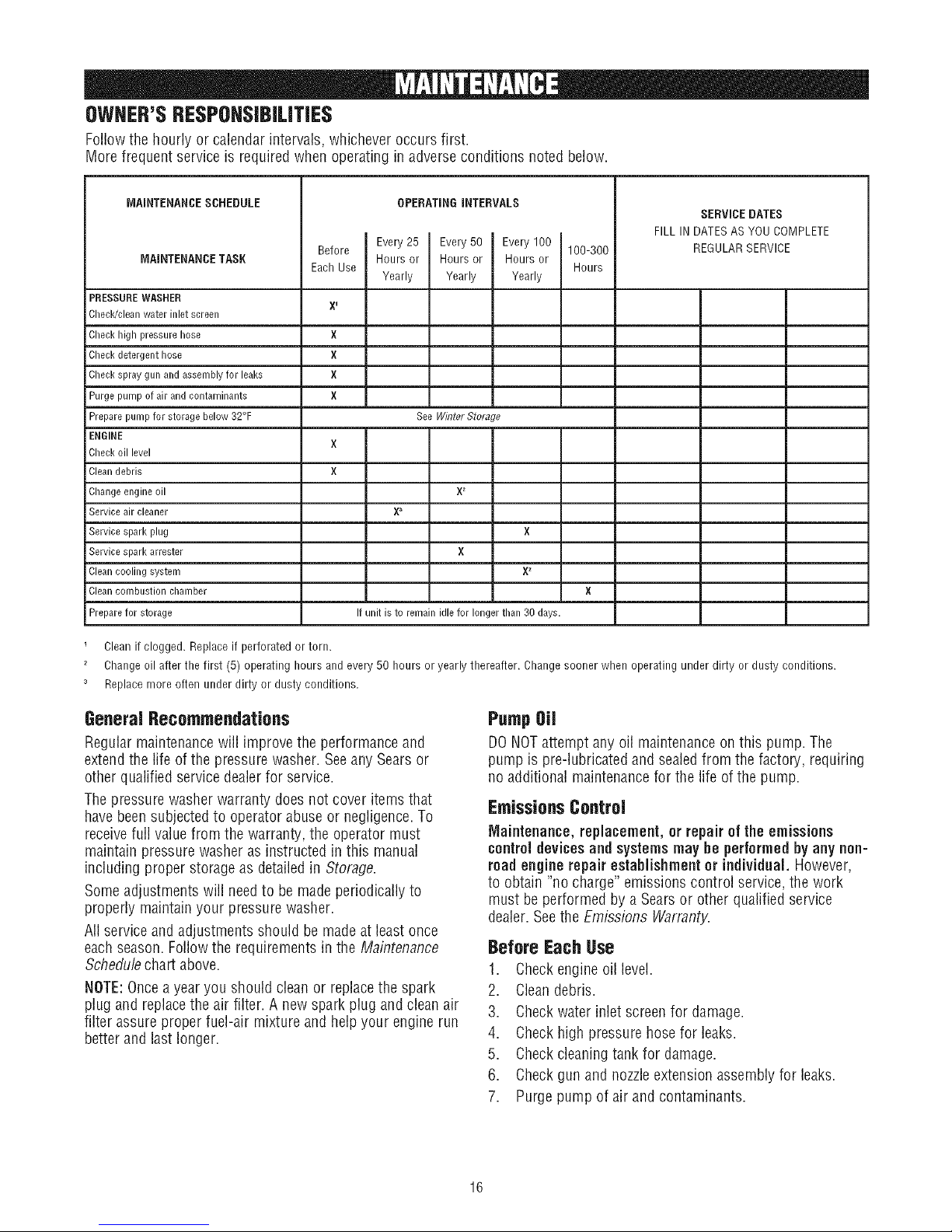

9A. If using cleaningtank, rotate detergentshut-off valve on

cleaningtank to "On" position (A).

10. Apply detergentto adry surface, starting at lower

portion of areato be washed and work upward, using

long, even, overlapping strokes.

11. Allow detergentto "soakin" for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surface from drying. DONOTallow detergent to dry on

(preventsstreaking).

Pressure Washer Rinsing

ForRinsing:

1. Engagetrigger lock on spray gun.

2. If using cleaningtank, rotate detergent shut-off valve on

cleaning tank to "Off" position.

3. Removeblackspray tip from nozzleextension.

4. Selectand install desiredhigh pressure spray tip

following instructions How to Use Spray Tips.

,

Keepspray gun a safe distance from areayou plan to

spray.

WARNING

Kickbackfrom to fall.

* Operatepressurewasherfrom astablesurface.

, Beextremelycarefulif you mustusethepressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

* Firmlygraspspraygunwith both handswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

6.

Apply a high pressure spray to a small areaand then

check surface for damage.If no damage is found, you

can assume it is okayto continue rinsing.

Start at top of areato be rinsed, working down with

same overlapping strokes asyou usedfor cleaning.

spray gun can causeyou

Automatic Cool Down System (Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures above

125°F.The system engagesto cool the pump by discharging

the warmwater onto the ground.

14

Page 15

EHGINETECHNICALINFORMATIOH PRODUCTSPECIFICATIOHS

This is a single cylinder, L-head,air cooled engine. It is a low

emissions engine.

Inthe Stateof California, Model 120000 engines are certified

by the California Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respectto the performance or

operational life of this engine.Theengine is warranted solely

according to the product and emissions warranties stated

elsewherein this manual.

Power Ratings

Thegross power rating for individual gas engine modelsis

labeledin accordancewith SAE(Society of Automotive

Engineers)code J1940 (Small EnginePower& Torque Rating

Procedure),and rating performance has been obtainedand

correctedin accordancewith SAEJ1995 (Revision 2002-05).

Torquevaluesare derivedat 3060 RPM;horsepower values

are derived at 3600 RPM.Actual gross engine powerwill be

lower and is affected by, among otherthings, ambient

operatingconditions and engine-to-enginevariability. Given

both the wide arrayof products on which enginesare placed

andthe variety of environmental issues applicableto

operatingthe equipment,the gas enginewill not developthe

ratedgross power when used in a givenpiece of power

equipment (actual "on-site"or net power). This differenceis

dueto a variety of factors including, but not limited to,

accessories(air cleaner,exhaust,charging, cooling,

carburetor,fuel pump, etc.), application limitations, ambient

operatingconditions (temperature,humidity, altitude), and

engine-to-enginevariability. Dueto manufacturingand

capacitylimitations, Briggs & Stratton maysubstitute an

engineof higher ratedpowerfor this Series engine.

Pressure Washer Specifications

Max Outlet Pressure............ 2,550 PSi (175.8 BARS)

Max Flow Rate........... 2.3 GPM (8.7 liters per minute)

ChemicalMix......................... Use as directed

Water Supply Temperature.... Notto exceedI O0°F(38° C)

Shipping Weight ..................... 72 Ibs. (32.7 kg)

Engine Specifications

Bore ................................. 2.69 in. (68mm)

Stroke ............................... 2.04 in. (52mm)

Displacement ........................ 11.57in. (190 cc)

SparkPlug

Type: ............. Briggs & Stratton 802592 or 5095D

SetGapTo: ...................... O.030inch(0.76ram)

ArmatureAir Gap: ........... 0.006-0.010in.(O.15-O.25mm)

Valveclearancewithvalvespringsinstalledand piston1/4in.

(6 ram)pasttopdeadcenter(checkwhenengineiscold).

Intake.................... 0.005-0.007in.(0.13-0.18ram)

Exhaust .................. 0.007-0.009in.(0.18-0.23mm)

FuelCapacity...................... 1.6 Quarts(1.5 liters)

OilCapacity........................ 18Ounces(0.5 liter)

NOTE:For practical operation, the engine load should not

exceed 85% of rated power. Enginepower will decrease

3-1/2% for each1,000 feet (300 meters) above sea level and

1% for each 10° F(5.6° C) above77° F (25° C).It should

operatesatisfactorily at an angle up to 15°.

15

Page 16

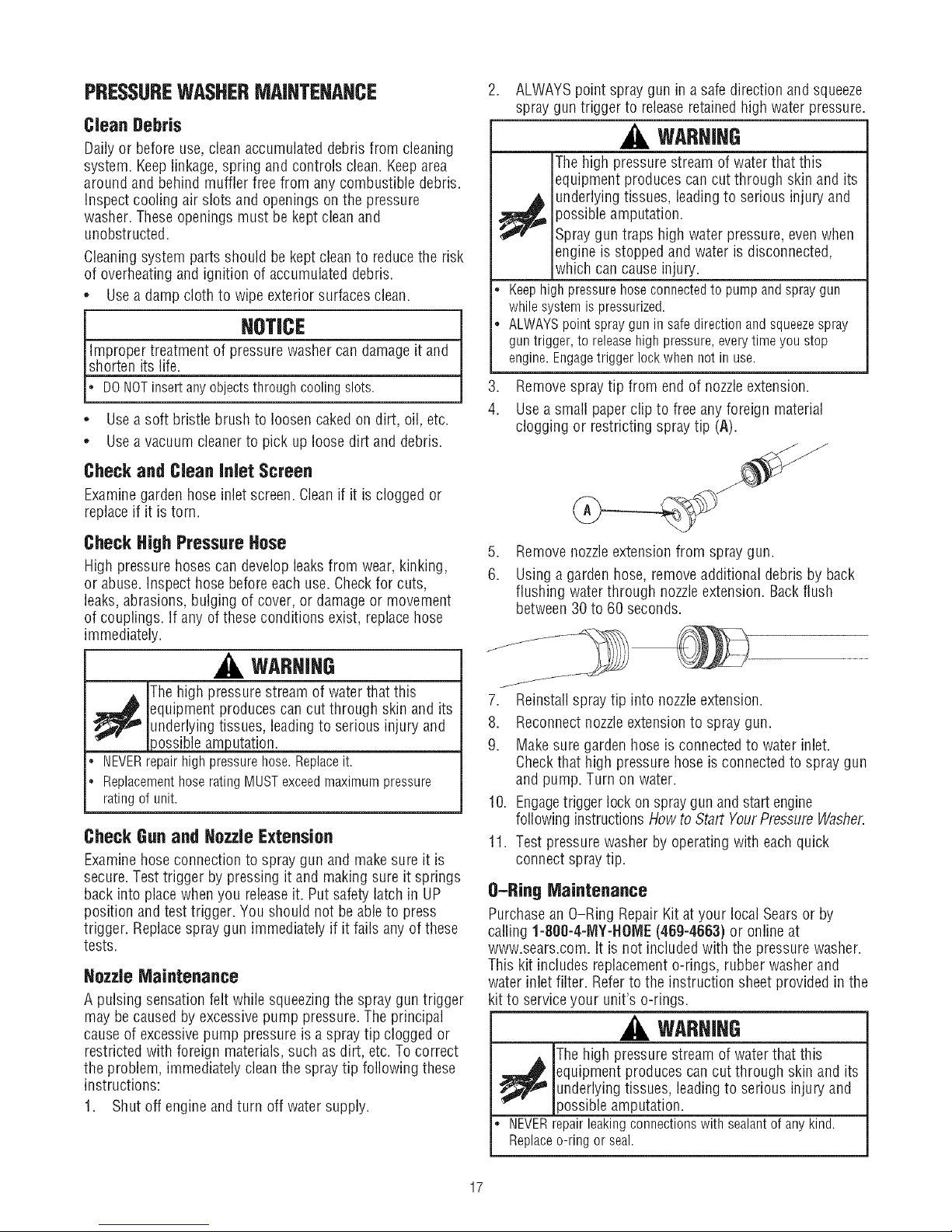

OWNER'SRESPONSIBILITIES

Followthe hourly or calendarintervals,whichever occurs first.

More frequent service is required when operating inadverse conditions noted below.

MAINTENANCESCHEDULE

MAINTENANCETASK

PRESSURE WASHER

Checldclean water inlet screen

Check high pressure hose

Check detergent hose

Check spray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Check oil level

Clean debris

Change engine oil

Service air cleaner

Service spark plug

Service spark arrester

Clean cooling system

Clean combustion chamber

Prepare for storage If unit is to remain idle for longer than 30 days.

Cleanif clogged. Replace if perforated or torn.

2 Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

3 Replace more often under dirty or dusty conditions.

Before

EachUse

X 1

X

X

X

X

X

X

OPERATINGiNTERVALS

Hours or Hours or Hours or

I Every 25 Every50 Every 100

Yearly Yearly Yearly

See Winter Storage

X_

X

X_

100-300

Hours

SERVICEDATES

FILL IN DATESASYOU COMPLETE

REGULARSERVICE

GeneraJRecommendations

Regularmaintenancewill improve the performance and

extendthe life of the pressure washer. Seeany Searsor

other qualified service dealerfor service.

Thepressure washer warranty doesnot cover items that

havebeen subjectedto operator abuse or negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressure washer as instructed in this manual

including proper storage as detailedin Storage.

Someadjustments will needto be madeperiodically to

properly maintain your pressure washer.

All service and adjustments should be madeat least once

eachseason. Follow the requirements in the Maintenance

Schedulechart above.

NOTE:Oncea year you should clean or replacethe spark

plug and replacethe air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

Pump Oil

DONOTattempt any oil maintenance on this pump. The

pump is pre-lubricated and sealed from the factory, requiring

no additional maintenancefor the life of the pump.

EmissionsControl

Maintenance, replacement, or repair of the emissions

control devices and systems may be performedby any non-

road engine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work

must be performed by a Searsor other qualified service

dealer.Seethe Emissions Warranty.

Before Each Use

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hose for leaks.

5. Checkcleaningtank for damage.

6. Checkgun and nozzleextension assembly for leaks.

7. Purge pump of air and contaminants.

16

Page 17

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use, cleanaccumulated debris from cleaning

system. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

Inspect cooling air slots and openings on the pressure

washer.These openings must be kept cleanand

unobstructed.

Cleaningsystem parts should be kept cleanto reducethe risk

of overheatingand ignition of accumulated debris.

• Usea damp cloth to wipe exterior surfaces clean.

NOTICE

Jlmproper treatment of pressurewasher can damage it and

_horten its life. _ ....

[, DONOTinsertanyobjectsthroughcoolingslots.

• Usea soft bristle brush to loosen cakedon dirt, oil, etc.

• Usea vacuum cleaner to pick up loose dirt and debris.

Check and Clean Inlet Screen

Examinegarden hose inlet screen.Clean if it is clogged or

replaceif it is torn.

2. ALWAYSpoint spray gun in a safe direction and squeeze

spray gun trigger to releaseretained high water pressure.

WARNING

Thehigh pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

, ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennot in use.

3. Removespraytip from end of nozzleextension.

4. Usea small paperclip to free any foreign material

)ossible amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which can cause injury.

clogging or restricting spray tip (A).

Check High Pressure Hose

High pressure hoses can developleaks from wear, kinking,

or abuse. Inspect hose beforeeach use. Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings. If any of these conditions exist, replace hose

immediately.

WARHIHG

The high pressure stream of water that this

_ quipment produces can cut through skin and its

• NEVERrepairhighpressurehose.Replaceit.

, ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

Check Gun and Hozzle Extension

Examinehose connectionto spray gun and makesure it is

secure.Test trigger by pressing it and making sure it springs

back into placewhen you releaseit. Put safety latch in UP

position and test trigger. You should not beable to press

trigger. Replacespray gun immediately if it fails any of these

tests.

HozzJeMaintenance

A pulsing sensationfelt while squeezingthe spray gun trigger

may becaused by excessive pump pressure. The principal

cause of excessive pump pressure is a spray tip clogged or

restricted with foreign materials, such as dirt, etc. To correct

the problem, immediately cleanthe spray tip following these

instructions:

1. Shut off engine and turn off water supply.

underlyingtissues, leadingto serious injury and

)ossible amputation.

5. Remove nozzleextension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush

between 30 to 60 seconds.

7. Reinstallspray tip into nozzleextension.

8. Reconnectnozzleextensionto spray gun.

9. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

10. Engagetrigger lock on spraygun andstart engine

following instructions How to Start YourPressure Washer.

11. Test pressure washer by operating with eachquick

connect spray tip.

O-Ring Maintenance

Purchasean O-Ring RepairKit atyour local Searsor by

calling 1-800-4-NIY-HOME(46g-4663) or online at

www.sears.com. It is not included with the pressure washer.

This kit includes replacemento-rings, rubber washer and

water inlet filter. Referto the instruction sheet provided in the

kit to serviceyour unit's o-rings.

WARHIHG

Thehigh pressurestream of water that this

_ quipment produces can cut through skin and its

, NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

underlyingtissues, leadingto serious injury and

)ossible amputation.

17

Page 18

ENGINEMAINTENANCE

,_ WARHIHG

,_ Unintentional sparking can result in fire or

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTOYOUR

PBESSUBEWASHER

* Disconnectthesparkplugwirefromthe sparkplugandplace

thewire whereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPAEE

* Useapprovedsparkplugtester.

* DONOTcheckfor sparkwith sparkplugremoved.

Oil

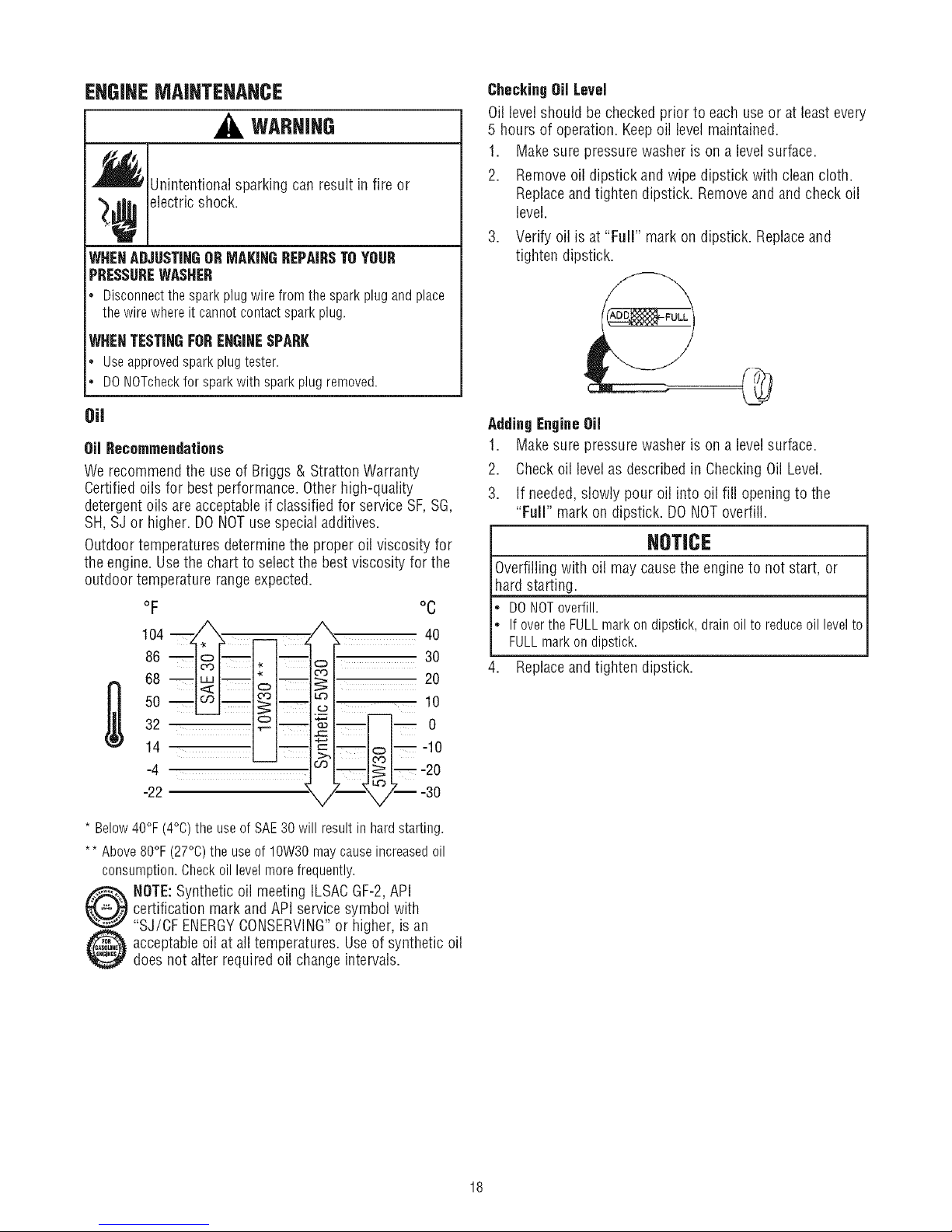

Oil Recommendations

We recommendthe use of Briggs & Stratton Warranty

Certified oils for best performance. Otherhigh-quality

detergent oils are acceptableif classified for service SF,SG,

SH, SJ or higher. DO NOTuse special additives.

Outdoortemperatures determine the proper oil viscosity for

the engine. Usethe chart to selectthe bestviscosity for the

outdoor temperature rangeexpected.

oF

86 w

104 Z_I_

68

%_ 40

| 30

°C

20

;_1-- to

5o _

32 _

14

-4

-22

__m mO

l-r =-10

oLIj LI-*o

,_--_-- -30

CheckingOil Level

Oil level should be checkedprior to each useor at least every

5 hours of operation. Keepoil level maintained.

1. Makesure pressure washer is on a levelsurface.

2. Removeoil dipstick and wipe dipstick with cleancloth.

Replaceand tighten dipstick. Removeand and check oil

level.

3. Verify oil is at "Full" mark on dipstick. Replaceand

tighten dipstick.

@

AddingEngineOil

1.

Makesure pressure washer is on a levelsurface.

2.

Checkoil level as described in CheckingOil Level.

3.

If needed,slowly pour oil into oil fill openingto the

"Full" mark on dipstick. DONOToverfill.

NOTICE

Overfilling with oil may causethe engineto not start, or

hard starting.

DONOToverfill.

Ifoverthe FULLmarkondipstick,drainoil to reduceoil levelto

FULLmarkon dipstick.

4. Replaceand tighten dipstick.

* Below40°F(4°C)theuseof SAE30will resultin hardstarting.

** Above80°F(27°0)the useof 10W30maycauseincreasedoil

consumption.Checkoil levelmorefrequently.

certification mark and API servicesymbol with

NOTE:Synthetic oil meeting ILSACGF-2,API

"SJ/CF ENERGYCONSERVING"or higher, is an

acceptableoil at all temperatures. Useof synthetic oil

doesnot alter required oil change intervals.

18

Page 19

ChangingEngineOil

Changeengine oil after the first 5 hours and every50 hours

thereafter. If you are usingyour pressure washer under

extremely dirty or dusty conditions, or in extremely hot

weather,change oil more often.

CAUTION

Avoid prolonged or repeatedskin contact with usedmotor

oil.

Usedmotoroil hasbeenshownto causeskincancerin certain

laboratoryanimals.

Thoroughlywashexposedareaswith soapandwater.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTO COLLECTIONCENTERS.

Changeoil while engine is still warmfrom running,as

follows:

1. Drain fuel tank by running pressure washer until fuel

tank is empty.

2. Disconnectspark plug wire and keepit away from spark

plug.

3. Cleanarea around oil fill, remove oil fill cap/dipstick.

Wipe dipstick clean.

4. Tipyour pressure washer to drain oil from oil fill into a

suitable container making sure you tip your unit away

from spark plug. When crankcaseis empty, return

pressure washer to upright position.

5. Slowly pour recommended oil (about 18 oz. (0.5 I))into

oil fill opening. Pauseto permit oil to settle. Fillto "Full"

mark on dipstick.

6. Wipe dipstick cleaneach time oil level is checked. DO

NOToverfill.

7. Replaceand tighten dipstick.

8. Wipe up any remaining oil.

9. Reconnectspark plug wire to spark plug.

Service Air Cleaner

Your engine will not run properly and may be damagedif you

run it with a dirty air cleaner.

Servicethe air cleaneronceevery 25 hours of operation or

onceeach year, whichever comesfirst. Servicemore often if

operating under dirty or dusty conditions. Replacementsare

availableat your local Searsservice center.

To service the air cleaner, follow these steps:

1. Loosenscrew (A) and tilt cover (B) down.

2. Carefullyremove cartridge (C)assembly.

3. To cleancartridge, gently tap pleatedpaper side on a flat

surface.

4. Reinstallcleanor newcartridge assembly inside cover.

5. Insert cover's tabs (8) into slots in bottom of base(E).

6. Tilt cover up and tighten screw securelyto base.

NOTE:You canpurchase new air filter elements bycalling

1-800-4-MY-HOIVlE(469-4663).

ServiceSparkPlug

Servicethe spark plug every 100 hours of operation or

yearly, whichever occurs first.

1. Cleanareaaround spark plug.

2. Removeand inspect spark plug.

3. Replacespark plug if electrodesare pitted, burned or

porcelainis cracked. Usethe recommended replacement

plug. See Specifications.

4. Checkelectrodegap with wire feelergauge and set spark

plug gap to 0.030 inch (0.76 ram) if necessary.

_. f_ ..........._

5. Install spark plug andtighten firmly.

NOTE:You canpurchase a new spark plug by calling

1-800-4-1VlY-HOIVlE(469-4663).

19

Page 20

Spark Arrester Service

Your engine is not factory-equipped with a spark arrester. In

some areas,it is illegal to operate an engine without a spark

arrester. Checklocal laws and regulations. A spark arrester is

availablefrom your nearest Sears servicecenter. Ifyou need

to order a sparkarrester, pleasecall 1-SOO-4-F,,IY-HOF,,IE

(46g-4663).

Thespark arrester must be serviced every 50 hours to keepit

functioning as designed.

If the engine has been running,the muffler will be very hot.

Allow the muffler to cool before servicing the spark arrester.

WARHIHG

s_ Contact with muffler area can result in serious

,_ Exhaustheat/gases can ignite combustibles,structures or damage fuel tank causing a fire.

* DO NOTtouch hot parts and AVOID hot exhaust gases.

. Allow equipment to cool before touching.

* Keep at least 5 feet (1.5 m) of clearanceon all sides of

* Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

* Remove spark arrester screen for cleaning and inspection.

* Replace if screen is damaged.

Air Cooling System

Overtime debris may accumulate in cylinder cooling fins and

cannot be observed without partial engine disassembly. For

this reason,we recommend you havea qualified Sears

servicedealer cleanthe cooling system per recommended

intervals (see MaintenanceSchedule). Equallyimportant is to

keeptop of engine freefrom debris. See CleanDebris.

burns.

pressure washer including overhead.

Public Property require equipment powered by an internal

combustion engine to have aspark arrester, maintained in

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may havesimilar laws.

Keepareaswithin heavyline clear of debris.

AFTEREACHUSE

Water should not remain in the unit for long periods oftime.

Sedimentsor mineralscan deposit on pump parts and

"freeze" pump action. Followthese proceduresafter every

use:

1. Flush detergentsystem byturning its detergent shut-off

valveto "Off" position and run pressure washer with

black detergent spray tip. Flushfor oneto two minutes.

2. Shut off engine,turn off water supply, point gun in a

safe direction and squeezetrigger to relievetrapped

pressure,engagetrigger lock on spray gun and let

engine cool.

WARHIHG

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennotin use.

3. Disconnect hosefrom spray gun and high pressure

4. Empty pump of all pumped liquids by pulling recoil

5. Coil high pressure hoseand properly hang it on hook

6. Store unit in a clean, dry area.

7. If storing for morethan 30 dayssee Long Term Storage

_ossibleamputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

outlet on pump. Drainwater from hose, gun, and nozzle

extension. Usea rag to wipe off the hose.

handle about6 times. This should remove most liquid in

pump.

provided on handle.

on next page.

WARHIHG

CleanCombustionChamber

Werecommendyou havea qualified Searsservicedealer

removecombustion depositsfrom the cylinder, cylinder head,

top of piston and around valvesper recommendedintervals

(seeMaintenance Schedule).

, uel and its vapors are extremely flammable and

explosive.

death.

Fireor explosion can cause severeburns or

WHENSTORINGFUELOREQUIPMENTWITH FUELIN TANK

* Storeawayfromfurnaces,stoves,waterheaters,clothes

dryers,orotherappliancesthathavepilotlight or otherignition

sourcebecausetheycanignitefuelvapors.

2O

Page 21

WINTERSTORAGE If gasoline in the engine has not beentreated with a fuel

stabilizer, it must be drained into an approved container. Run

NOTICE

You must protect your unit from freezing temperatures.

Failuretodo so will permanentlydamageyourpumpand

renderyour unit inoperable.

Freezedamageisnotcoveredunderwarranty.

To protect the unitfrom freezingtemperatures:

1. Emptycleaning tank as follows:

a. Disconnecthoseconnectedto injection fitting on

pump. Place end of hose into suitable container.

b. Rotatedetergent shut-off valveto "On" position and

open the tanks cover. Gravitywill empty tank

contents into container.

c. Reconnect hoseto injection fitting on pump. Add

0.5 quart (0.5 1)of cleanfresh water to cleaning

tank and closetanks cover.

2. Flush cleaning tank by turning its detergent shut-off

valveto "On" position and run pressure washerwith

black nozzle. Flush until tank is empty. Turn detergent

shut-off valveto "Off" position.

3. Follow steps 2-5 in the previous sectionAfter EachUse.

4. Use PumpSaver,availableat Searsto treat pump. This

minimizes freeze damageand lubricates pistons and

seals.

5. If PumpSaveris not available,connect a 3-foot (1 m)

section of garden hoseto water inlet adapter. Pour

RV-antifreeze (antifreezewithout alcohol) into hose. Pull

recoil handletwice. Disconnect3-foot (1 m) hose.

6. Store unit in a clean, dry area.

LONGTERM STORAGE

If you do not plan to usethe pressure washer for morethan

30 days, you must prepare the engine and pump for long

term storage.

Protect Fuel System

FuelAdditive:

Fuelcan becomestale when stored over 30 days.Stalefuel

causesacid and gum depositsto form in the fuel system or

on essential carburetor parts. To keep fuel fresh, use Briggs

& Stratton FRESHSTARTTM fuel stabilizer, availableas a

liquid additive or a drip concentrate cartridge.

Thereis no needto drain gasolinefrom the engine if a fuel

stabilizer is added according to instructions. Runthe engine

for 2 minutes to circulate the stabilizer throughout the fuel

system. The engineand fuel can then be stored up to

24 months.

the engine until it stops from lackof fuel.The use of a fuel

stabilizer in the storage container is recommended to

maintain freshness.

Change Engine Oil

While engine isstill warm, drain oil from crankcase. Refill

with recommendedgrade. See ChangingEngine Oil.

Oil Cylinder Bore

* Removespark plug and pour about 1/2 ounce (15 m]) of

cleanengine oil into the cylinder.

* Install spark plug and pull starter handle slowly to

distribute oil.

Protect Pump

To protect the pump from damagecausedby mineral

deposits or freezing, usePumpSaverto treat pump. This

preventsfreezedamageand lubricates pistons andseals.

NOTE:PumpSaveris availableas an optional accessory, it is

not included with the pressurewasher. Oontactyour local

Searsservice center to purchase PumpSaver.

NOTICE

You must protect your unit from freezingtemperatures.

Failuretodo so will permanentlydamageyourpumpand

renderyour unit inoperable.

Freezedamageisnotcoveredunderwarranty.

To usePumpSaver,makesure the pressurewasher is turned

off and disconnected from supplywater. Readand follow all

instructions and warnings given on the PumpSavercontainer.

Other Storage Tips

1. DONOTstore fuel from oneseasonto another unless it

hasbeentreated as described in Protect FuelSystem.

2.

Replacefuel container if it starts to rust. Rust and/or dirt

in fuel cancause problems if it's used with this unit.

Ooverunit with asuitable protective cover that does not

retain moisture.

WARHIHG

_ Storagecovers can be flammable.

* DONOTplacea storagecoveroverahot pressurewasher.

* Letequipmentcoolfora sufficienttime beforeplacingthe

coverontheequipment.

4. Store unit in a cleanand dry area.

Page 22

Problem Cause Correction

1. Low pressure spray tip installed.

2. Water inlet is blocked.

3. Inadequatewater supply.

4. Inlet hose is kinked or leaking.

Pumphasfollowing problems:

failure to producepressure,

erraticpressure, chattering,loss

ofpressure, low watervolume.

Detergentfails to mix with spray.

Engineruns geed at no-load but Enginespeed is too slow.

"begs" when lead is added.

Enginewill net start; or startsand

runsrough.

5. Cloggedinlet hosestrainer.

6. Water supply is over IO0°F.

7. High pressure hose is blocked or

leaks.

8. Gun leaks.

9. Nozzleis obstructed.

1

O. Pump is faulty. 10. ContactSearsservice facility

i.

Detergentshut-off valveis in the

"Off" position.

2.

High pressure spray tip installed.

1. Dirty air cleaner.

2. Out of fuel.

3. Stalefuel.

4. Sparkplug wire not connectedto

spark plug.

5. Badspark plug.

6. Water in fuel.

7. Excessivelyrich fuel mixture.

1. Replacewith high pressure spray tip.

2. Clearinlet.

3. Provideadequatewater flow.

4. Straighten inlet hose, patch leak.

5. Checkandclean inlet hose strainer.

6. Providecooler water supply.

7. Clearblocks in high pressure hoseor

replacehose.

8. Replacegun.

9. Cleannozzle.

1. Rotatedetergent shut-off valve to "On"

position.

2. Replacewith low pressure spray tip.

Movethrottle control to FASTposition. If

engine still "bogs down", contact Sears

service facility.

1. Cleanor replaceair cleaner.

2. Fillfuel tank.

3. Drainfuel tank; fill with fresh fuel.

4. Connectwire to spark plug.

5. Replacespark plug.

6. Drainfuel tank; fill with fresh fuel.

7. ContactSearsservice facility.

Engineshutsdownduring Out of fuel. Fillfuel tank.

operation.

Enginelacks power. Dirty air filter. Replaceair filter.

22

Page 23

23

Page 24

CRAFTSMAH2550 PSi CJeaning System 580.676630

Hettoyeur _ pression CRAFTSMAHde 2,550 psi 580°676630

Main Unit -- ExpJodedView

Unit_ principaJe - Vue 6clst6e

--3

--4

i3

11

14

\

\

\

©

w!5

24

Page 25

CRAFTSMAH2550 PSi Cleaning System 580.676630

Hettoyeur _ pression CRAFTSMAHde 2,550 psi 580.676630

Main Unit -- Parts List

Unit6 principale - Liste des pi_ces

Item h_#

A_icle Pi_ce .o.

1 200159GS

2 M202522GS

3 202364GS

195964GS

1929BOGS

4 202605GS

194298GS

23139GS

5 192529GS

6 201661GS

7 199955GS

8 194264GS

9 192198GS

10 193482GS

11 2BO557GS

195983AEGS

195983RGS

195983XGS

198841GS

12 192309GS

13 B2203GS

14 192310GS

15 196006GS

16 196439GS

192050GS

195454GS

900 NSP

DescrlpUon

Description

ASSY,Base(ENSEMBLE,base)

HANDLE(POIGNEE)

ASSY,Chem Tank w/Decal & Clips (ENSEMBLE,R_servoir chimiques a/D6calqueset Attache)

Clip (Attache)

Kit,Fuel Valve(ENSEMBLE,Robinet d'essence)

ASSY,Pump (seepage26-27) (ENSEMBLE,pompe(voir page26-27))

Valve,Thermal Relief(SOUPAPEDESURPRESSIONTHERMIQUE)

Key(CLE)

KIT,Pump Mounting Hardware(ENSEMBLE,quincailleriede montage de la pompe)

KIT,Gun HolderWeldment (ENSEMBLE,Support de pistolet, Assemblage soud_)

KIT,CapChem (ENSEMBLE,Bouchon produits chimiques)

KIT,Hook, Handle (ENSEMBLE,Crochet, Poign_e)

ASSY,Extensionw/Nozzle Holder(ENSEMBLE,Rallongea/Porte-buse)

GUN(PISTOLET)

KIT,Nozzles(ENSEMBLE,Buses)

Nozzle,QC,Red(BUSE, Raccordrapide, Rouge)

Nozzle,QC,White (BUSE,Raccord rapide, Blanche)

Nozzle,QC,Yellow (BUSE,Raccord rapide, Jaune)

Nozzle,Plastic, Soap(Buse, Plastique, Savon)

KIT,Hook (ENSEMBLE,Crochet)

KIT,HandleConnector (ENSEMBLE,Poign_e,Connecteur)

KIT,Vibration Mount (ENSEMBLE,Montant antivibratile)

HOSE(TUYAU)

KIT,Wheel (ENSEMBLE,Roue)

E-Ring(Anneauen E)

Axle (GLISSER)

ENGINE(seepages28-31) (MOTEUR(voirpages28_.31)) (126T02-0114-B1)

itemsNot illustrated

A_Jcles.on fl|us_

Pa_ #

Piece .o,

203354GS

AB3061BGS

87815GS

AIO4ORGS

203377GS

790701

794693

282846

195015GS

Optional Accessories NotIllustrated

Accessoires en optionnon illustr_s

191922GS KIT, Maintenance,O-Ring (ENSEMBLE,entretien, joint torique)

7167300GS HouseWashConcentrate (makes 4 gallons) (Concentr_ de nettoyant m_nager (produit 15 litres))

7167301GS DeckWash Concentrate (makes 2 gallons) (Concentr_de nettoyant de pont (produit 7,5 litres))

7167302GS Vehicle/BoatWash Concentrate(makes4 gallons) (Concentr6 de nettoyant de v_hicule/bateau (produit 15 litres))

7167303GS DegreaserConcentrate (makes4 gallons) (Concentr6 de d_graissant (produit 15 litres))

Descr|pUon

DescrlpUon

MANUAL,Operator's(MANUELd'utilisation)

OIL,Bottle,Engine(HUILE,bouteille,moteur)

GOGGLES(LUNETTESDESECURITt_)

HOSE,Chemical(TUBE,Chimique)

DECAL,Shroud(DECALQUE,TOledeprotection)

SHROUD(TOLLDEPROTECTION)

LABEL,Warning(DECALQUE,Avertissement)

COVER,Control(COUVERCLE,Commande)

KIT,Tag/WaringSrv(ENSEMBLE,Avertissement/Etiquettes_curitQ)

25

Page 26

CRAFTSMAH2550 PSi Cleaning System 580.676630

Hettoyeur _ pression CRAFTSMAHde 2,550 psi 580.676630

Pump-- ExplodedView

Pompe-- Vue _clat_e

@@

k

@

L

(_

$

o_

0

CO% C}

@@

L

%

0

26

Page 27

CRAFTSMAH2550 PSi CJeanJngSystem 580.676630

Hettoyeur _ pressJonCRAFTSMAHde 2,550 psi 580.676630

Pump -- Parts List

Pompe -- Liste des pi_ces

Item Part#

Article Pieceno.

19 190571GS

28 190627GS

45 190578GS

62 190581GS

76 194298GS

A 190594GS

B 190632GS

C 190634GS

D 203631GS

E 193806GS

F 190592GS

G 190593GS

H 193807GS

J 189971GS

K 193971GS

L 193972GS

Items Not Illustrated

Articles nonillustr_s

B2384GS

NOTE:Item letters A- L are service kits and include all parts shown within the box.

REMARQUE:Losarticles A _.L sont des ensemblesde remplacement et incluent toutes les pi_ces illustr_es clansI'encadr_ correspondant.

Description

Description

CAP,Oil (BOUCHON,Huile)

MANIFOLD(COLLECTEUR)

PIN(TIGE)

CAP,1/8 (BOUCHON,1/8)

THERMALRELIEF(SOUPAPEDESURPRESSIONTHERMIQUE)

KIT,UNLOADERSTEM (ENSEMBLE,TIGEDEDI_COMPRESSION)

KIT,WATERINLET,ALUM (ENSEMBLE,ENTREED'EAU,ALUMINIUM)

KIT,OUTLET,ALUMINIUM (ENSEMBLE,SORTIE,ALUMINIUM)

KIT,HEADALUMINIUM(ENSEMBLE,TETEDEPOMPE,ALUMINIUM)

KIT,CHECKVALVES(ENSEMBLE,CLAPETSDERETENUE)

KIT,INLETCHECK(ENSEMBLE,SOUPAPED'ENTREE)

KIT,CHEMICALINJECTION(ENSEMBLE,INJECTIONDEPRODUITSCHIMIQUES)

KIT,SEALSET(ENSEMBLE,ETANCHEITE)

KIT,CHEMICALHOSE(ENSEMBLE,TUYAUDEPRODUITSCHIMIQUES)

KIT,PIPEFITTING(ENSEMBLE,RACCORDDETUYAU)

KIT,UNLOADERSEAT(ENSEMBLE,SIEGEDEDECOMPRESSION)

FILTER,Inlet(Filtre,I'Arriv_e)

27

Page 28

EHGIHE,Brigss & Stratto., 126T02 - Exploded View

MOTEUR, Briggs & Stratton, 126T02 - Vue 6clarke

51

306

684 '_

87O 871

161

24 0

741

287

718

a

- 869

524 Q_

81

9

__ lO_b

158

209

615

404

616

20

613

28

Page 29

EHGIHE,Brigss & Stratto., 126T02 - ExpJodedView

MOTEUR, Briggs & Stratton, 126T02 - Vue 6cJat_e

843

188

19o

670 @

2271 II 3331

I_ 601

957

365 ':_

17

633

334

127 G 130

977CARBURETOR

GASKETSET 121CARBURETOR

1

3.0 276 0 633® 104 _ 617 633 ®

163 _ 617 127 _ 633A ®

633A ®

617

37

276 0

_ 276 Q

OVERHAULKIT

12t 1_

1210_

65 1_ 58

592

459 _

689 O

456

___ __ 633A _m 137 0 276 O

1386 1388_ 163_ _ ]

597

305

332

1005

29

Page 30

EHGIHE,Brigss & Stratton, 126T02 - Parts List

MOTEUR, Briggs & Stratton, 126TO2 - Homenclature de pi_ces

Item Part#

Article Piece no.

1 697322

2 399269

299819S

4

493279

691160

5

696125

7

8 695250

9 699472

10 691125

11 691781

12 692232

13 690912

15 691680

16 694849

20 399781S

22 691092

23 691992

24 222698S

25 791097

791326

26 791098

791324

27 691866

28 499423

29 499424

32 691664

32A 695759

33 262651S

34 262652S

35 691270

36 691270

37 694086

40 692194

43 691997

45 690548

46 691449

50 497465

51 272199S

54 691650

Description Item Part #

Description Article Piece no.

CylinderAssembly (Ensemblecylindre) 55 691421

Kit- Bushing/Seal (Magneto Side) (Ensemble-

Garnitured'6tanch_it_/Joint (c6t_ 58 697316

magneto)

Seal-Oil(Magneto Side) (Joint-Huile (c6t_ 60 281434S

magneto))

Surnp-Engine (Puisard-Moteur) 65 690837

Head-Cylinder (Culasse-Cylindre)

Gasket-CylinderHead(Joint statique-Oulassede 78 691108

cylindre) 81 691740

BreatherAssembly (Ensemblede reniflard) 97 696565

Gasket-Breather(Joint statique-Reniflard) 194 691242

Screw (Breather Assembly) (Vis (Ensemblede

reniflard)) 108 790844

Tube-Breather(Tube-Reniflard) 109 790843

Gasket-Crankcase(Joint statique-Carter) 117 697355

Screw (Cylinder Head) (Vis (Culasse de

cylindre)) 118 494879

Plug-Oil Drain (Bouchon-Vidange d'huile)

Crankshaft (Vilebrequin) 121 498260

Seal-Oil(PTOSide) (Joint-Huile (C6t_ prise de

force)) 125 790845

Screw (CrankcaseCover/Sump)(Vis (Couvercle- 127 694468

Carter/Puisard)) 130 696564

Flywheel(Volant-rnoteur) 133 398187

Key-Flywheel(Clavette-Volant-rnoteur) 134 398188

Piston Assembly (Standard) (Ensemblede

piston (Standard)) 137 693981

Piston Assembly (.020" Oversize)(Ensemble de 159 691753

piston (51 mm (0.920 pc)

Surdimensionn_)) 163 272653S

Ring Set (Standard) (Jeude bagues (Standard)) 187 791766

Ring Set (.020" Oversize)(Jeu de bagues (51

mm (0.020 pc) Surdimensionn6))

Lock-Piston Pin (Verrou-Axe de piston) 188 693399

Pin-Piston (Axe-Piston)

Rod-Connecting (Bielle) 190 690940

Screw (Connecting Rod) (Vis (Bielle)) 292 691829

Screw (Connecting Rod) !Vis (Bielle))

Valve-Exhaust(Soupape-Echappement) 299 691290

Valve-Intake(Soupape-Entr_e) 222 790143

Spring-Valve (Intake) (Ressort-Soupape 227 690783

(Entree))

Spring-Valve (Exhaust) (Ressort-Soupape 231 691636

(l'--chappernent))

Guard-Flywheel(Capot-Volant-rnoteur) 276 271716

Retainer-Valve(Dispositif de retenue-Soupape) 287 690940

Governor/OilSlinger(Bague d'6tanch_it_-

R_gulateur/Huile) 291 790830

Tappet-Valve(Poussoir-Soupape) 300 790828

Camshaft (Arbre _.cames) 304 791291

Manifold-Intake (Collecteur-Entr_e) 305 691108

Gasket-Intake(Joint statique-Entr_e)

Screw (Intake Manifold) (Vis (Collecteur 396 790836

d'entr_e))

Description

Description

Housing-RewindStarter(B_ti-D6rnarreur_.

cordon)

Rope-Starter(Cutto RequiredLength)(Cordon-

B_rnarreur)

Grip-StarterRope(Poign_e-Cordonde

d_marreur)

Screw(RewindStarterHousing)(Vis

(D_marreur_ cordon))

Screw(FlywheelGuard)(Vis(Ecrandevolant))

Lock-MufflerScrew(Verrou-Visdesilencieux)

Shaft-Throttle(Arbre-Pouss_e)

Pin-FloatHinge(Axe-Pivotd'articulation

flotteur)

Valve-Choke(Soupape-Etrangleur)

Shaft-Choke(Axe-I_trangleur)

Jet-Main(Standard)(Gicleur-Principal

(Standard))

Jet-Main(HighAltitude)(Gicleur-Principal

(Altitude_lev_e))

Kit-CarburetorOverhaul(Ensemble-Rernise

neufducarburateur)

Carburetor(Carburateur)

Plug-Welch(Pastille-Obturation)

Valve-Throttle(Soupape-Pouss_e)

Float-Carburetor(Flotteur-Carburateur

Valve-Needle(IncludesSeat)(Soupape-Pointeau

(incluantlesi_ge))

Gasket-FloatBowl(Jointd'_tanch_it_-Cuve)

Bracket-AirCleanerPrimer(Support-Pompe

d'arnorgagedu filtre_ air)

Gasket-AirCleaner(Jointstatique-Filtre&air)

Line-Fuel(Cutto RequiredLength)(Conduite-

Essence(CouperAlaIongueur

requise))

Screw(ControlBracket)(Vis(Supportde

contr61e))

Screw(FuelTank)(Vis(R6servoird'essence))

Link-MechanicalGovernor(Tringlerie-

R_gulateurm_canique)

Spring-Governor(Ressort-R_gulateur)

Bracket-Control(Support-ContrOle)

Lever-GovernorControl(Levier-Contr61edu

r_gulateur)

Screw(ChokeValve)(Vis(Soupape

d'6trangleur))

Washer-Sealing(Rondelle-I_tanch_it_)

Screw(OilFillTube)(Vis-(Jauge/Assernbl_ede

tube)

Thermostat(Thermostat)

Muffler(Silencieux)

Housing-Blower(B&ti-Soufflerie)

Screw(BlowerHousing)(Vis-(B&tide

soufflerie))

Shield-Cylinder(l'--cran-Cylindre)

39

Page 31

EHGIHE,Brigss & Stratton, 126T02 - Parts List

MGTEUR, Briggs & Stratton, 126TO2 - Homenclature de pi_ces

Item Part #

Article Piece no.

307 690345

332 690662

333 802574

334 691061

337 802592S

356 692390

358 497316

365 692524

494 690272

425 690670

443 692523

445 491588S

455 791960

456 692299

459 281505S

595 691251

523 499621

524 692296

525 495265

529 691923

562 691119

584 697734

585 691879

592 690800

597 691696

601 791850

608 497680

613 790833

615 690340

616 698801

617 270344S

621 692310

633 693867

633A 691321

635 66538S

Description 668 493823

Description

Screw (Cylinder Shield) (Vis (l_crande Item Part #

cylindre)) Article Piece no.

Nut (Flywheel) (l_crou-Volant-moteur) 670 692294

Armature-Magneto (Armature-lVlagn6to)

Screw (Magneto Armature) (Vis (Armature de 684 690345

magneto))

Plug-Spark (Bougie-Allumage) 689 691855

Wire-Stop (FiI-Arr_t) 718 690959

GasketSet-Engine (Jeude joints statiques- 741 790345

Moteur) 832 499034

Screw (Carburetor) (Vis (Carburateur)) 836 690664

Washer (Governor Crank) (Rondelle (Manivelle-

R_gulateur)) 842 691031