Page 1

Owner's Manual

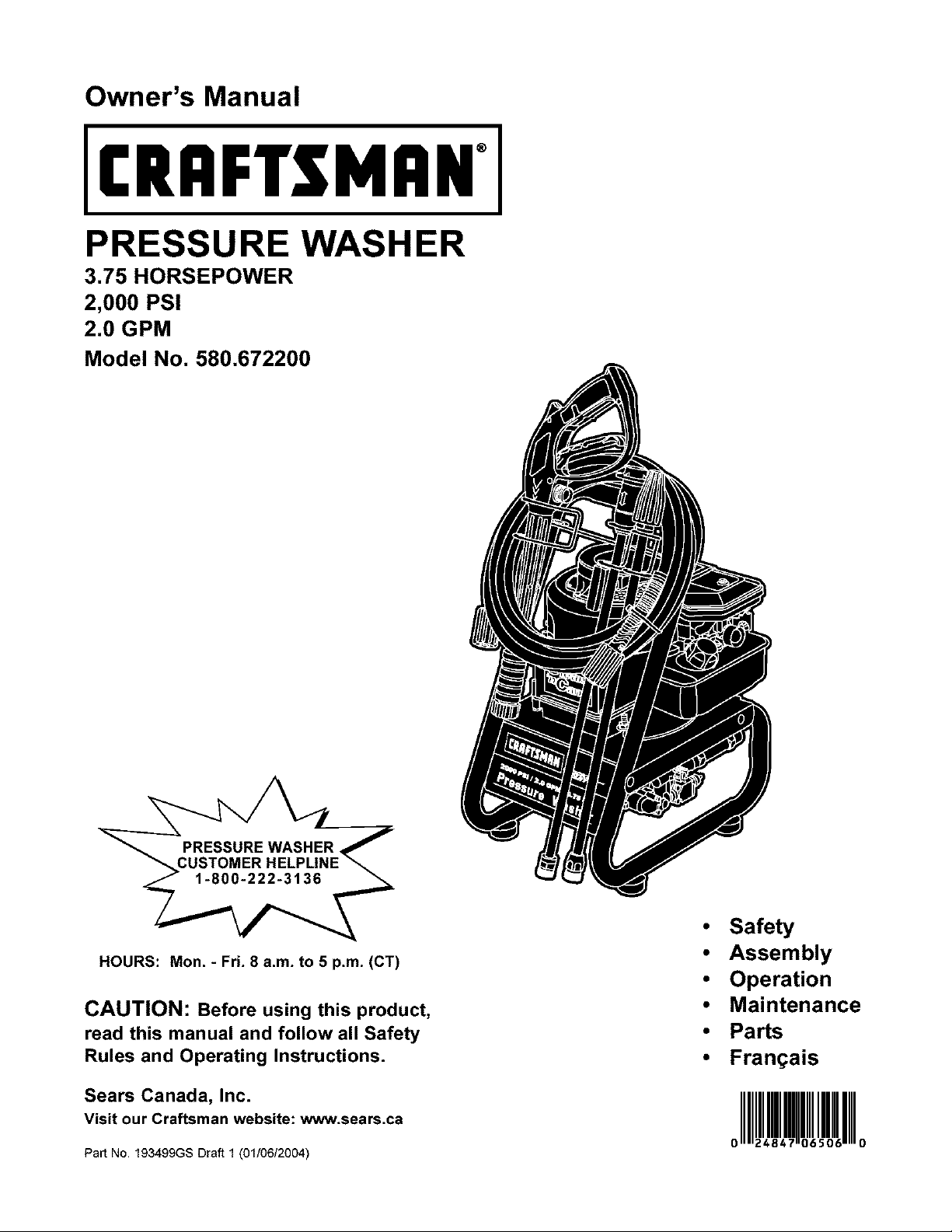

II:RRFTSMRNI

PRESSURE WASHER

3.75 HORSEPOWER

2,000 PSI

2.0 GPM

Model No. 580.672200

HOURS: Mon. - FrL 8 a.m. to 5 p.m. (CT)

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears Canada, Inc.

Visit our Craftsman website: www.sears.ca

Part No. 193499GS Draft 1 (01/06/2004)

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Fran(;ais

Page 2

WARRANTY .................................... 2

SAFETY RULES ............................... 2-4

ASSEMBLY ................................... 6-7

OPERATION ................................. 8-10

MAINTENANCE .............................. 11-14

SPECIFICATIONS ............................... 11

STORAGE ..................................... 15

TROUBLESHOOTING ............................ 16

HOW TO ORDER PARTS ......................... 17

REPLACEMENT PARTS ....................... 18-22

EMISSION CONTROL WARRANTY ................. 23

FRAN(,?,AIS .................................. 24-40

UMITED ONE YEAR WARRANTY ON CRAFTSMAN PRESSURE WASHER

For one year from the date of purchase, when this CRAFTSMAN@ Pressure Washer is maintained and operated

according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

If this pressure washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase.

If this pressure washer is used for rental purposes, this warranty applies for only 30 days after date of purchase.

This warranty does not cover:

Expendable items such as spark plugs and air filters, which become worn during normal use.

Repairs necessary because of operator abuse or negligence, including damage resulting from no water being

supplied to pump or failure to maintain the equipment according to the instructions contained in the owner's

manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE PRESSURE WASHER TO THE NEAREST

SEARS SERVICE CENTER OR DEALER IN CANADA.

This warranty gives you specific legal rights and you may also have other rights, which vary from province to

province.

Sears Canada, Inc.

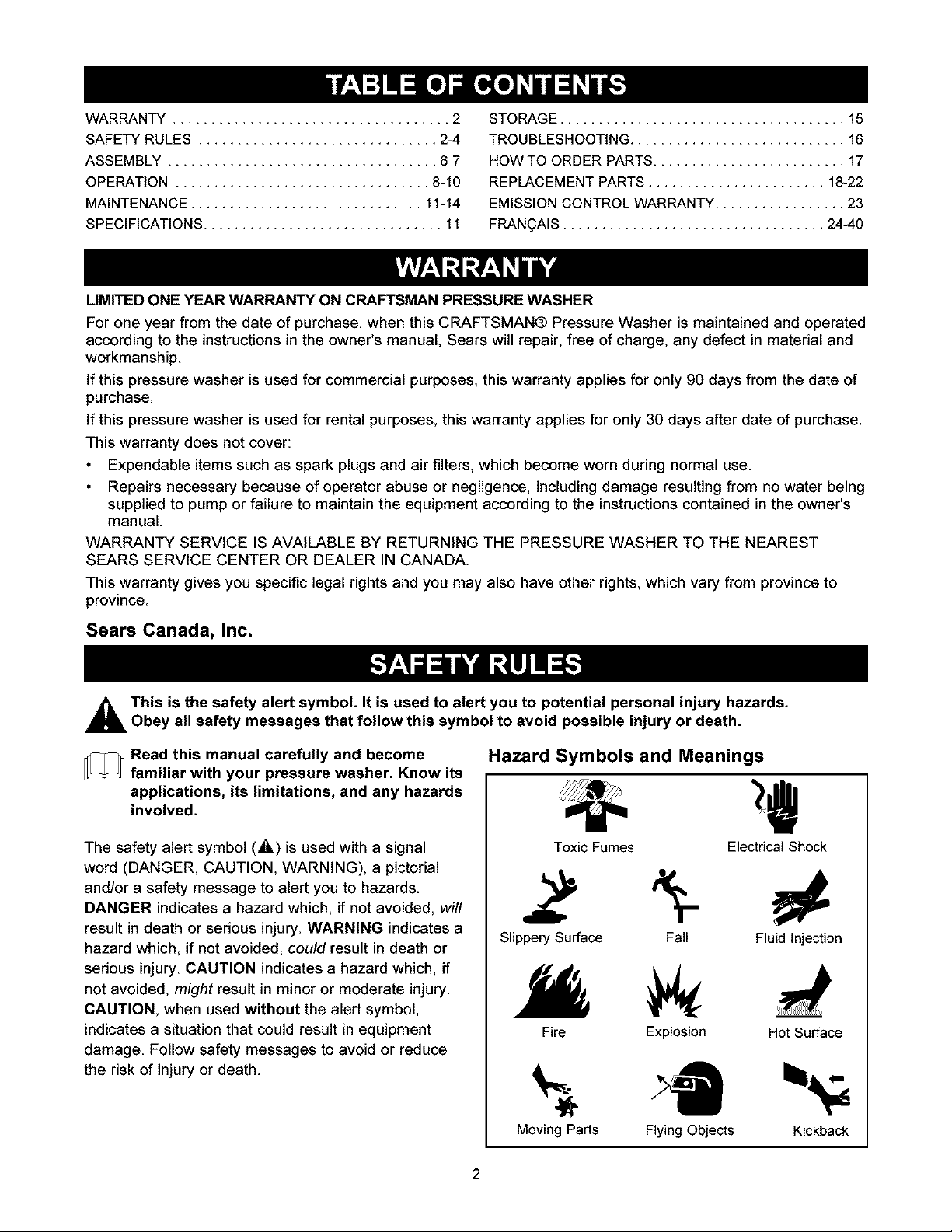

,_ This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

_Read this manual carefully and become

familiar with your pressure washer. Know its

applications, its limitations, and any hazards

involved.

The safety alert symbol (_,) is used with a signal

word (DANGER, CAUTION, WARNING), a pictorial

and/or a safety message to alert you to hazards.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury. WARNING indicates a

hazard which, if not avoided, could result in death or

serious injury. CAUTION indicates a hazard which, if

not avoided, might result in minor or moderate injury.

CAUTION, when used without the alert symbol,

indicates a situation that could result in equipment

damage. Follow safety messages to avoid or reduce

the risk of injury or death.

Hazard Symbols and Meanings

Toxic Fumes

Slippery Surface Fall Fluid Injection

Fire Explosion Hot Surface

Electrical Shock

Moving Parts Flying Objects

2

Kickback

Page 3

IntheStateof California a spark arrester is required

_y law (Section 4442 of the California Public

Resources Code). Other states may have similar laws.

Federal laws apply on federal lands. If you equip the

"nuffler with a spark arrester, it must be maintained in

_=ffectiveworking order.You can order a spark arrester

_hrough your authorized Sears service dealer.

WARNING I

The engine exhaust from this product contains I

chemicals known to the State of California to cause

cancer, b rth defects, or other reproduct ve harm,

DANGER

Operate pressure washer ONLY outdoors.

Use a respirator or mask whenever there is a chance

that vapors may be inhaled.

Read all instructions packed with mask so you are certain

mask will provide necessary protection against inhaling

harmful vapors.

WARNING

WHEN ADDING FUEL

Turn pressure washer OFF and let it cool at least

2 minutes before removing gas cap.

Fill fuel tank outdoors.

DO NOT overfill tank. Allow space for fuel expansion.

Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

DO NOT light a cigarette or smoke.

VHEN OPERATING EQUIPMENT

DO NOT tip engine or equipment at angle which causes

fuel to spill.

DO NOT spray flammable liquids.

VHEN TRANSPORTING OR REPAIRING EQUIPMENT

Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

VHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

WARNING

Keep water spray away from electric wiring or fatal

electric shock may result.

WANNING

Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

Operate this unit on a stable surface.

Cleaning area should have adequate slopes and

drainage to reduce possibility of fails due to slippery

surfaces.

Be extremely careful if you must use pressure washer

from a ladder, scaffolding or any other relatively unstable

location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

WARNING

NEVER aim spray gun at people, animals or plants.

DO NOT allow CHILDREN to operate pressure washer.

NEVER repair high pressure hose. Replace it.

Keep high pressure hose connected to pump and spray

gun while system is pressurized.

WARNING

DO NOT touch hot surfaces.

Stay clear of exhaust gases.

NEVER move equipment while operating.

Allow equipment to cool before touching.

3

Page 4

WARNING

DO NOT wear loose clothing, jewelry or anything that

may be caught in starter or other rotating parts.

Tie up long hair and remove jewelry.

WARNING

Disconnect spark plug wire from spark plug and place

wire where it cannot contact spark plug.

WARNING

Always wear eye protectionwhen using equipment orwhen

in vicinity of equipment in use.

CAUTION

DO NOT tamper with governed speed.

DO NOT operate pressure washer above rated pressure.

CAUTION

DO NOT secure spray gun in open position.

DO NOT leave spray gun unattended while machine is

running.

NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

Always be certain spray gun, nozzles and accessories

are correctly attached.

CAUTION

DO NOT point spray gun at glass when in jet spray mode,

NEVER aim spray gun at plants,

CAUTION

If you have questions about intended use, ask dealer or

contact Sears.

NEVER operate units with broken or missing parts, or

without protective housing or covers.

DO NOT by-pass any safety device on this machine.

Before starting pressure washer in cold weather, check

all parts of the equipment to be sure ice has not formed

there.

NEVER move machine by pulling on high pressure hose.

Use handle provided on unit.

Check fuel system for leaks or signs of deterioration,

such as chafed or spongy hose, loose or missing

clamps, or damaged tank or cap. Correct all defects

before operating pressure washer.

This equipment is designed to be used with Sears

authorized parts ONLY. If equipment is used with parts

that DO NOT comply with minimum specifications, user

assumes all risks and liabilities.

4

Page 5

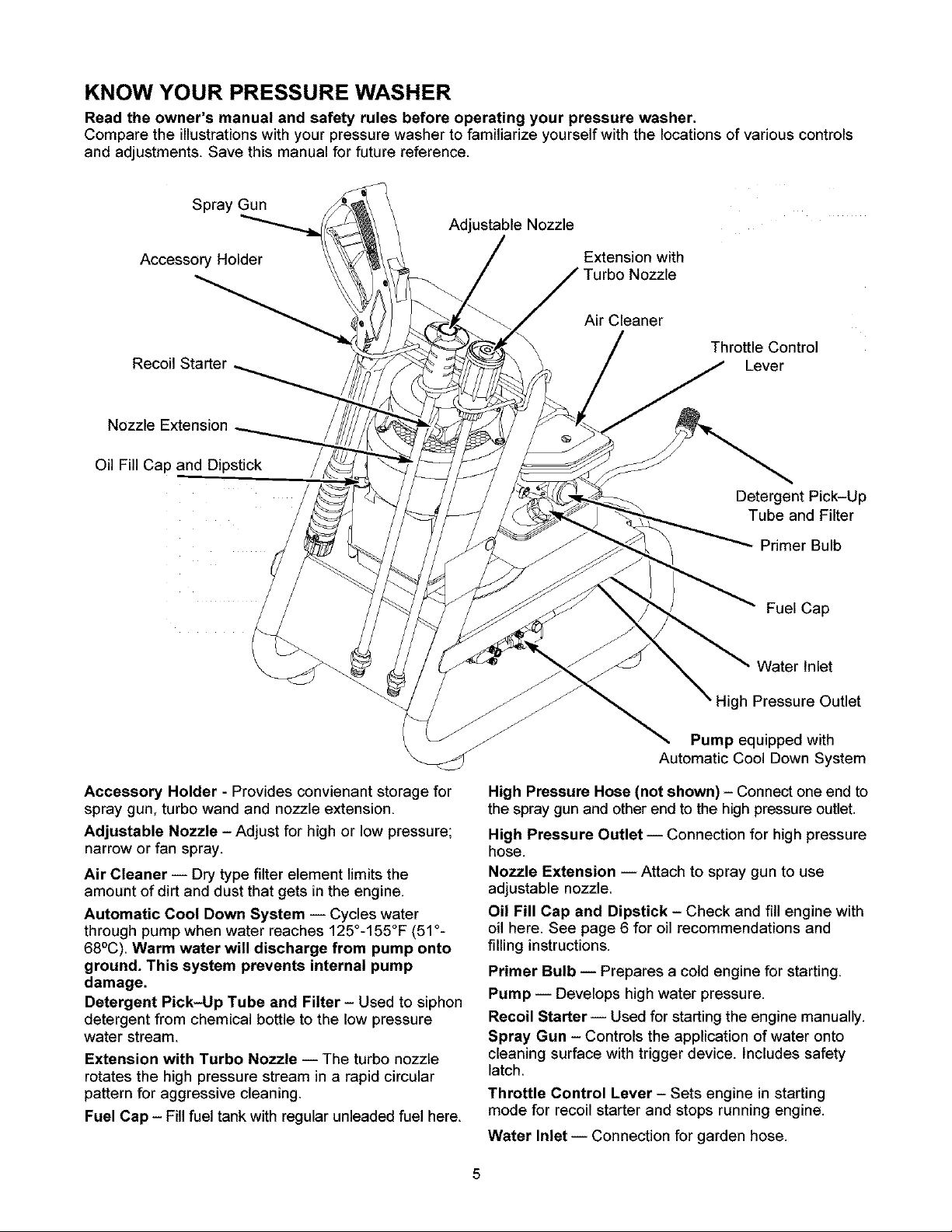

KNOW YOUR PRESSURE WASHER

Read the owner's manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Spray Gun

Adjustable Nozzle

Accessory Holder

Recoil Starter

Nozzle Extension

Oil Fill Cap and Dipstick

Extension with

Air Cleaner

Throttle Control

Lever

Detergent Pick-Up

Tube and Filter

Primer Bulb

Fuel Cap

Water Inlet

High Pressure Outlet

Accessory Holder - Provides convienant storage for

spray gun, turbo wand and nozzle extension.

Adjustable Nozzle -Adjust for high or low pressure;

narrow or fan spray.

Air Cleaner -- Dry type filter element limits the

amount of dirt and dust that gets in the engine.

Automatic Cool Down System -- Cycles water

through pump when water reaches 125°-155°F (51°-

68°C). Warm water will discharge from pump onto

ground. This system prevents internal pump

damage.

Detergent Pick-Up Tube and Filter - Used to siphon

detergent from chemical bottle to the low pressure

water stream.

Extension with Turbo Nozzle -- The turbo nozzle

rotates the high pressure stream in a rapid circular

pattern for aggressive cleaning.

Fuel Cap - Fill fuel tank with regular unleaded fuel here.

Pump equipped with

Automatic Cool Down System

High Pressure Hose (not shown) - Connect one end to

the spray gun and other end tothe high pressure outlet.

High Pressure Outlet -- Connection for high pressure

hose.

Nozzle Extension --Attach to spray gun to use

adjustable nozzle.

Oil Fill Cap and Dipstick - Check and fill engine with

oil here. See page 6 for oil recommendations and

filling instructions.

Primer Bulb -- Prepares a cold engine for starting.

Pump -- Develops high water pressure.

Recoil Starter-- Used for starting the engine manually.

Spray Gun - Controls the application of water onto

cleaning surface with trigger device. Includes safety

latch.

Throttle Control Lever - Sets engine in starting

mode for recoil starter and stops running engine.

Water Inlet i Connection for garden hose.

5

Page 6

Yourpressurewasherrequires some assembly and is

ready for use only after it has been properly serviced

with the recommended oil and fuel.

If you have any problems with the assembly of

your pressure washer, please call the pressure

washer helpline at 1-800-222-3136.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

REMOVE PRESSURE WASHER

FROM CARTON

Open carton and slice two corners opposite guide

handle from top to bottom so the panel can be

folded down flat.

Remove fillers, accessories and parts bag shipped

with your pressure washer.

Remove the pressure washer out the open end of

the carton.

Check carton for additional loose parts.

CARTON CONTENTS

Check all contents. If any parts are missing or damaged,

call the pressure washer helpline at 1-800-222-3136.

The main unit

High pressure hose

Spray gun

Nozzle extension with adjustable nozzle

Turbo wand

Accessory holder

Engine oil

Parts bag (which includes items listed below)

Owner's manual

Registration card

Become familiar with each piece before assembling

the pressure washer Compare contents against the

view on page 5. If any parts are missing or damaged,

call the pressure washer helpline at 1-800-222-3136

ASSEMBLING YOUR PRESSURE

WASHER

Your Craftsman pressure washer was mostly

assembled at the factory. However, you will need to

perform these tasks before you can operate your

pressure washer:

1. Add oil to engine crankcase.

2. Add fuel to fuel tank.

3. Connect high pressure hose to spray gun and

pump.

4. Connect water supply to pump.

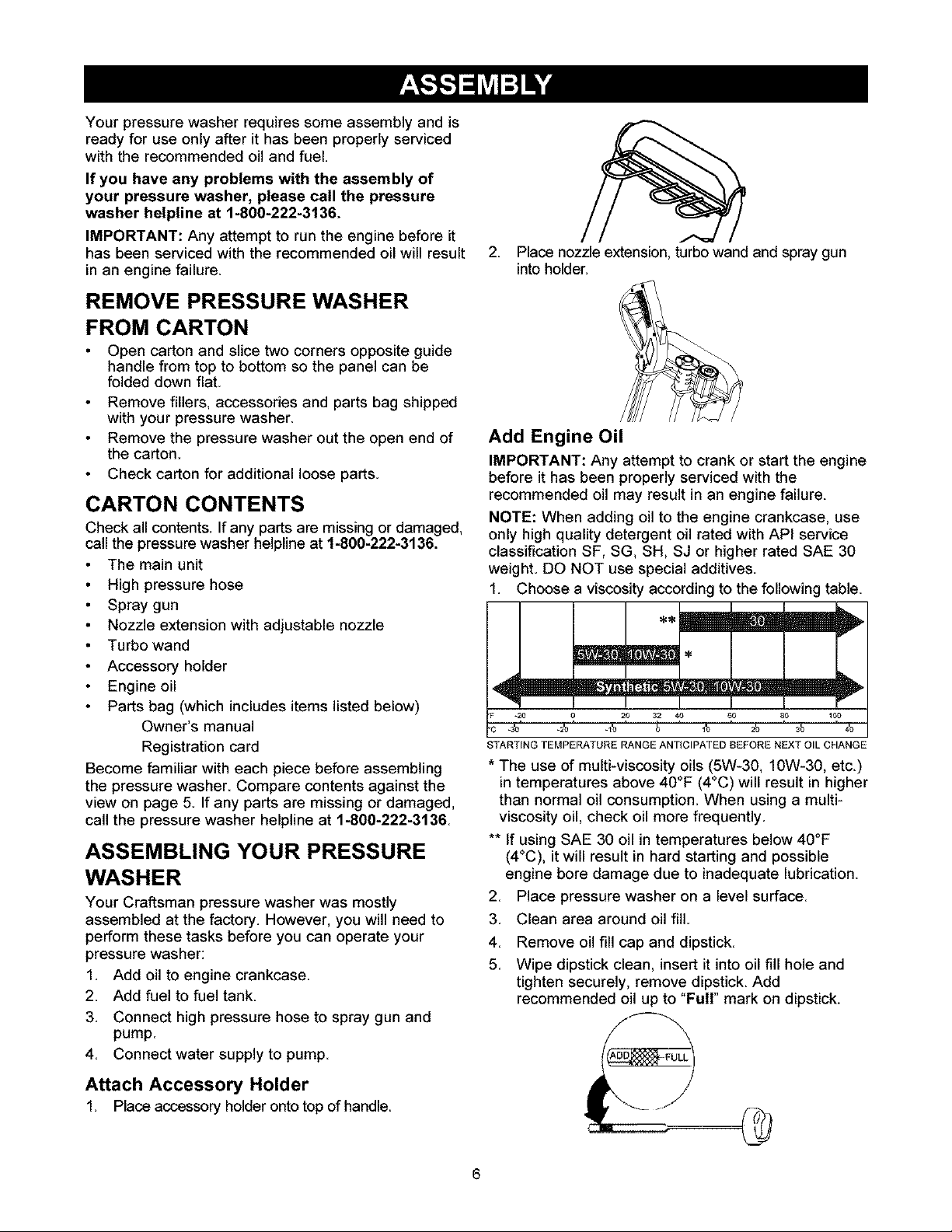

2 Place nozzle extension, turbo wand and spray gun

intoholder.

Add Engine Oil

IMPORTANT: Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure

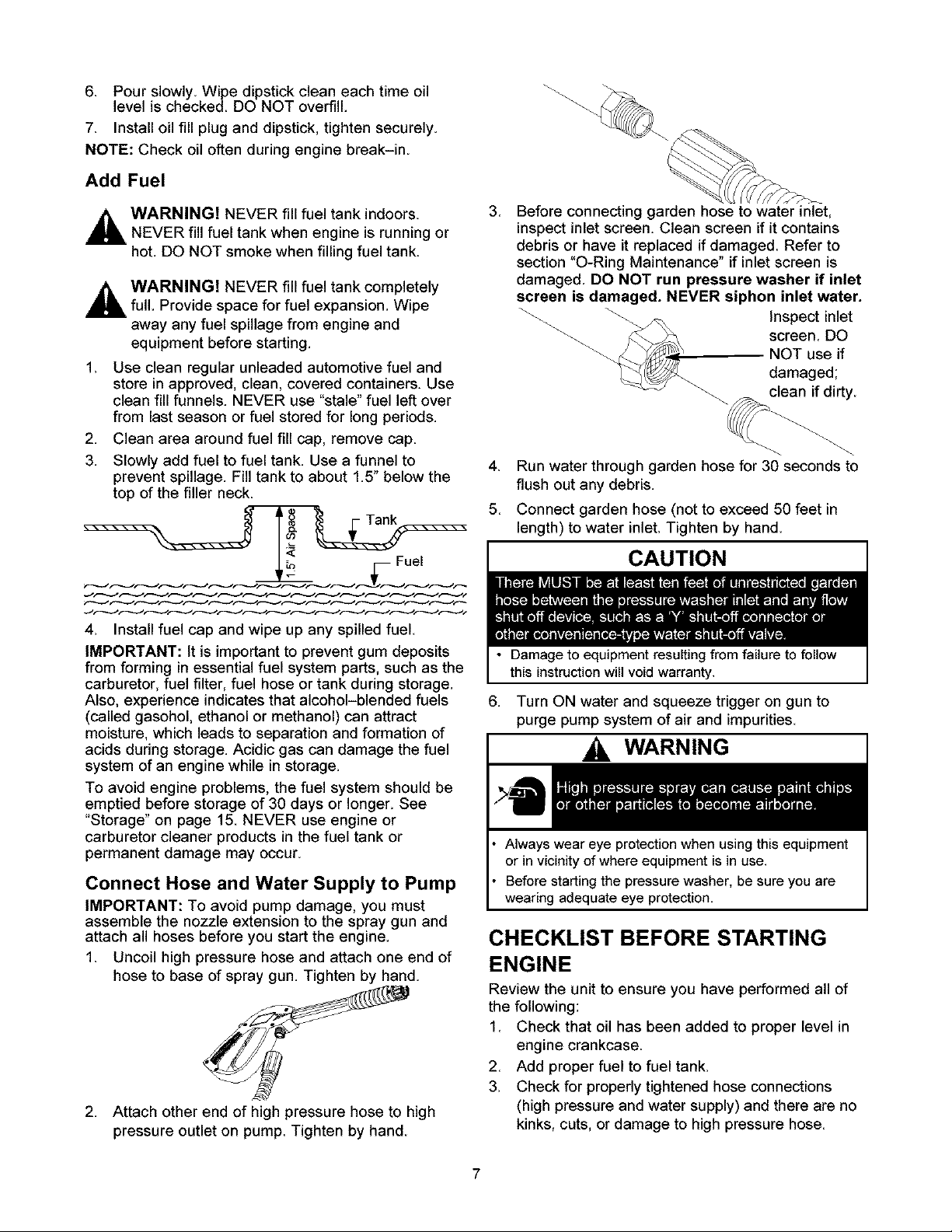

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SG, SH, SJ or higher rated SAE 30

weight DO NOT use special additives

1. Choose a viscosityaccording to the following table

._o o, =o = ,o ,o _,o _oo

'c =so =2b 4b _ 1'o 2b 3b ' 4'o

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

* The use of multi-viscosity oils (5W-30, 10W-30, etc.)

in temperatures above 40°F (4°C) will result in higher

than normal oil consumption. When using a multi-

viscosity oil, check oil more frequently.

** If using SAE 30 oil in temperatures below 40°F

(4°C), itwill result in hard starting and possible

engine bore damage due to inadequate lubrication.

2. Place pressure washer on a level surface.

3. Clean area around oil fill.

4.

Remove oil fill cap and dipstick

5.

Wipe dipstick clean, insert it into oil fill hole and

tighten securely, remove dipstick. Add

recommended oil up to "Full" mark on dipstick.

Attach Accessory Holder

1. Place accessory holderontotop of handle

6

Page 7

6. Pourslowly.Wipedipstickcleaneachtimeoil

levelischecked.DONOToverfill.

7. Installoilfillpluganddipstick,tightensecurely.

NOTE:Checkoiloftenduringenginebreak-in.

Add Fuel

,_ WARNING! NEVER fill fuel tank indoors

NEVER fill fuel tank when engine is running or

hot. DO NOT smoke when filling fuel tank.

_ WARNING! NEVER fill fuel tank completely

full. Provide space for fuel expansion. Wipe

away any fuel spillage from engine and

equipment before starting.

1. Use clean regular unleaded automotive fuel and

store in approved, clean, covered containers. Use

clean fill funnels. NEVER use "stale" fuel left over

from last season or fuel stored for long periods.

2. Clean area around fuel fill cap, remove cap.

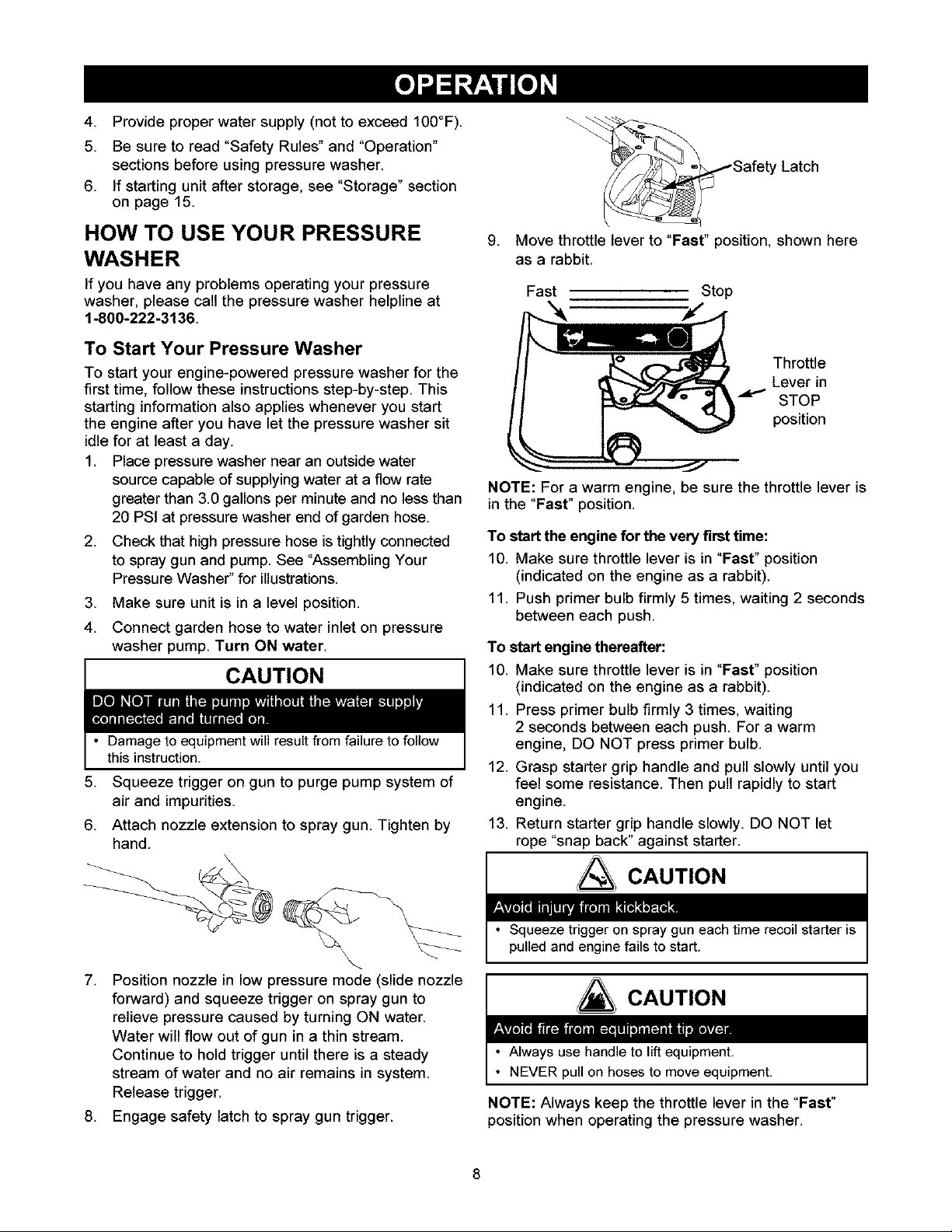

3. Slowly add fuel to fuel tank. Use a funnel to

prevent spillage. Fill tank to about 1.5" below the

top of the filler neck.

,

Before connecting garden hose to water inlet,

inspect inlet screen. Clean screen if it contains

debris or have it replaced if damaged. Refer to

section "O-Ring Maintenance" if inlet screen is

damaged. DO NOT run pressure washer if inlet

screen is damaged. NEVER siphon inlet water.

screen. DO

"_._ Inspect inlet

- clean if dirty.

4, Run water through garden hose for 30 seconds to

flush out any debris.

5, Connect garden hose (not to exceed 50 feet in

length) to water inlet. Tighten by hand.

NOT use if

damaged;

Fuel

4. Install fuel cap and wipe up any spilled fuel

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts, such as the

carburetor, fuel filter, fuel hose or tank during storage.

Also, experience indicates that alcohol-blended fuels

(called gasohol, ethanol or methanol) can attract

moisture, which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. See

"Storage" on page 15. NEVER use engine or

carburetor cleaner products in the fuel tank or

permanent damage may occur.

Connect Hose and Water Supply to Pump

IMPORTANT: To avoid pump damage, you must

assemble the nozzle extension to the spray gun and

attach all hoses before you start the engine.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

2. Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

CAUTION

• Damage to equipment resulting from failure to fellow

this instruction will void warranty,

6, Turn ON water and squeeze trigger on gun to

purge pump system of air and impurities.

WARNING

Always wear eye protection when using this equipment

or in vicinity of where equipment is in use,

Before starting the pressure washer, be sure you are

wearing adequate eye protection,

CHECKLIST BEFORE STARTING

ENGINE

Review the unitto ensure you have performed all of

the following:

1 Check that oil has been added to proper level in

engine crankcase

2 Add proper fuel to fuel tank.

3. Check for properly tightened hose connections

(high pressure and water supply) and there are no

kinks, cuts, ordamage to high pressure hose

7

Page 8

4 Provideproperwatersupply(nottoexceed100°F)

5. Besuretoread"SafetyRules"and"Operation"

sectionsbeforeusingpressurewasher.

6. Ifstartingunitafterstorage,see"Storage"section

onpage15.

_Safety Latch

HOW TO USE YOUR PRESSURE

WASHER

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

starting information also applies whenever you start

the engine after you have let the pressure washer sit

idle for at least a day.

1. Place pressure washer near an outside water

source capable of supplying water at a flow rate

greater than 3.0 gallons per minute and no less than

20 PSI at pressure washer end of garden hose.

2.

Check that high pressure hose is tightly connected

to spray gun and pump. See "Assembling Your

Pressure Washer _for illustrations.

.

Make sure unit is in a level position.

4.

Connect garden hose to water inlet on pressure

washer pump. Turn ON water.

CAUTION

• Damage to equipment will result from failure to follow

this instruction,

5. Squeeze trigger on gun to purge pump system of

air and impurities.

.

Attach nozzle extension to spray gun. Tighten by

hand.

\\

.

Move throttle lever to "Fast" position, shown here

as a rabbit.

Fast Stop

f

Throttle

Lever in

STOP

position

NOTE: For a warm engine, be sure the throttle lever is

in the "Fast" position.

To start the engine for the very first time:

10. Make sure throttle lever is in "Fast" position

(indicated on the engine as a rabbit).

11. Push primer bulb firmly 5 times, waiting 2 seconds

between each push.

To start engine thereafter:

10. Make sure throttle lever is in "Fast" position

(indicated on the engine as a rabbit).

11. Press primer bulb firmly 3 times, waiting

2 seconds between each push. For a warm

engine, DO NOT press primer bulb.

12. Grasp starter grip handle and pull slowly until you

feel some resistance. Then pull rapidly to start

engine.

13. Return starter grip handle slowly. DO NOT let

rope "snap back" against starter.

A CAUTION

7.

Position nozzle in low pressure mode (slide nozzle

forward) and squeeze trigger on spray gun to

relieve pressure caused by turning ON water.

Water will flow out of gun in a thin stream.

Continue to hold trigger until there is a steady

stream of water and no air remains in system.

Release trigger.

8 Engage safety latch to spray gun trigger

\

• Squeeze trigger on spray gun each time recoil starter is

pulled and engine fails to start.

CAUTION

• Always use handle to lift equipment,

• NEVER pull on hoses to move equipment,

NOTE: Always keep the throttle lever in the "Fast"

position when operating the pressure washer.

8

Page 9

How to Stop Your Pressure Washer

1 Move throttle lever to "Stop" position

2. Squeeze trigger on spray gun to relieve

pressure in hose.

NOTE: A small amount of water will squirt out when

you release the pressure.

How To Use the Adjustable Nozzle

You now should know how to START your pressure

washer and how to STOP it. The information in this

section will tell you how to adjust the spray pattern

and apply detergent or other cleaning chemicals.

CAUTION

NEVER adjust spray pattern when spraying.

NEVER put handsin front of nozzleto adjustspray pattern.

On the end of your spray gun is a nozzle handle that

can adjust the spray pressure and the spray pattern.

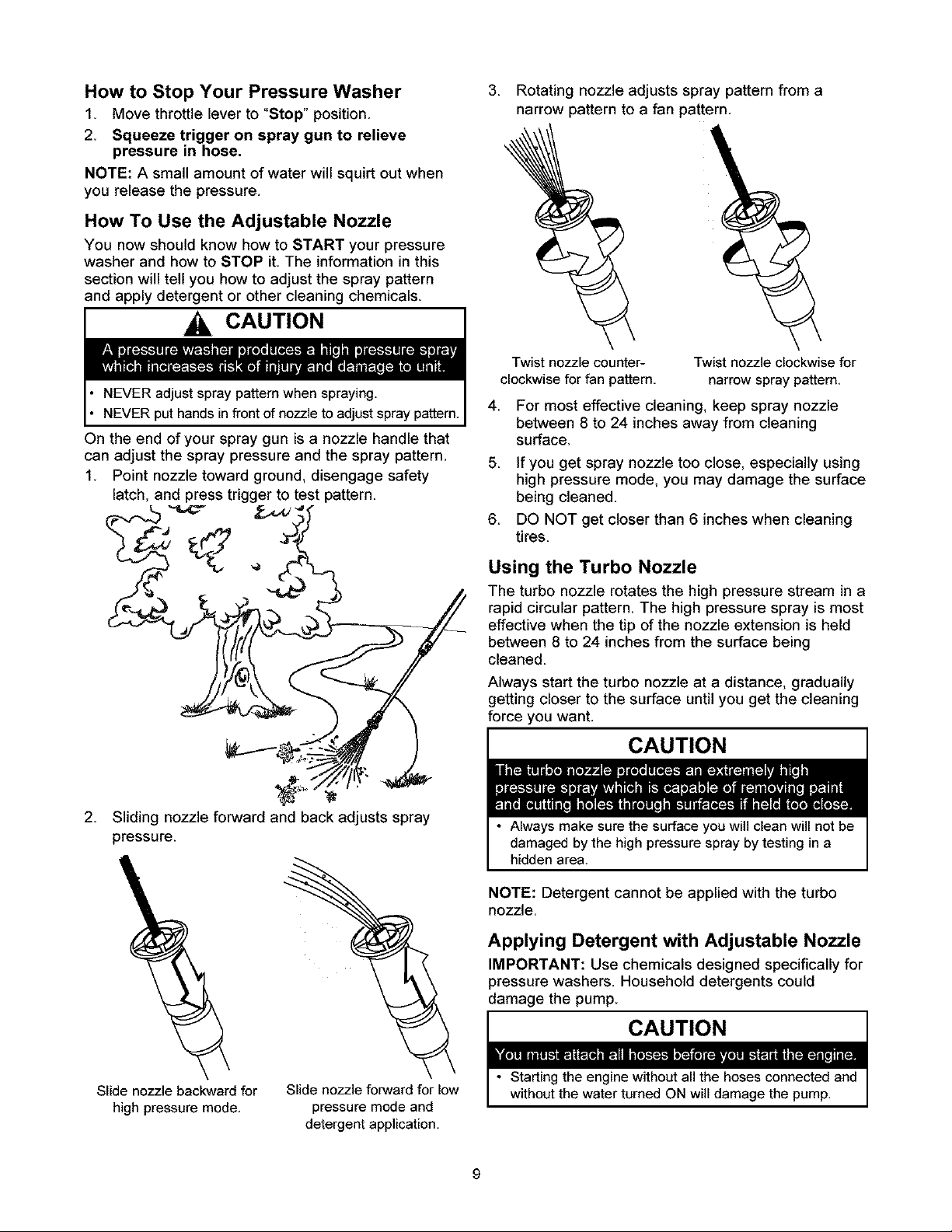

1. Point nozzle toward ground, disengage safety

latch, and press trigger to test pattern.

3 Rotating nozzle adjusts spray pattern from a

narrow pattern to a fan pattern

Twist nozzle counter- Twist nozzle clockwise for

clockwise for fan pattern, narrow spray pattern,

4. For most effective cleaning, keep spray nozzle

between 8 to 24 inches away from cleaning

surface.

5. If you get spray nozzle too close, especially using

high pressure mode, you may damage the surface

being cleaned.

6. DO NOT get closer than 6 inches when cleaning

tires.

2.

Sliding nozzle forward and back adjusts spray

pressure.

Using the Turbo Nozzle

The turbo nozzle rotates the high pressure stream in a

rapid circular pattern. The high pressure spray is most

effective when the tip of the nozzle extension is held

between 8 to 24 inches from the surface being

cleaned.

Always start the turbo nozzle at a distance, gradually

getting closer to the surface until you get the cleaning

force you want.

CAUTION

• Always make surethe surface you will clean will not be

damaged by the high pressure spray bytesting in a

hidden area.

NOTE: Detergent cannot be applied with the turbo

nozzle.

Applying Detergent with Adjustable Nozzle

IMPORTANT: Use chemicals designed specifically for

pressure washers. Household detergents could

damage the pump.

Slide nozzle backward for

high pressure mode,

CAUTION

• Starting the engine without all the hoses connected and

Slide nozzle forward for low without the water turned ON will damage the pump.

pressure mode and

detergent application,

9

Page 10

To apply detergent, follow these steps:

1 Review use of adjustable nozzle.

2

Prepare detergent solution as required by job

.

Place filter end of detergent siphoning tube into

detergent container.

CAUTION

Pressure Washer Rinsing

For Rinsing:

1 Slide nozzle backward to high pressure, press

trigger and wait for detergent to clear.

NOTE: You can also stop detergent flow by removing

detergent siphoning tube from container.

2. Keep spray gun a safe distance from area you

plan to spray.

• When insertingthe filter into a detergentsolution bottle,

route the tube so as to keep itfrom inadvertently

contacting the hot muffler.

4. Slide adjustable nozzle forward to low pressure

mode. Detergent cannot be applied with nozzle in

high pressure position.

5. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump. Start engine.

6. Apply detergent to a dry surface, starting from

bottom and working up.

7. Allow detergent to "soak in"for 3-5 minutes before

rinsing. Reapply as needed to prevent surface

from drying.

8. For washing, start at lower portion of area to be

washed and work upward, using long, even,

overlapping strokes.

IMPORTANT: You must flush the chemical injection

system after each use by placing the filter into a clean

bucket of water and running the pressure washer in

low pressure for 1-2 minutes.

WARNING

Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

Operate this unit on a stable surface.

Be extremely careful if you must use the pressure

washer from a ladder, scaffolding or any other relatively

unstable location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

.

Apply a high pressure spray to a small area, then

check surface for damage, if no damage is found,

it is okay to continue cleaning.

4.

Start at top of area to be rinsed, working down

with same overlapping strokes as you used for

washing and applying detergent.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach

temperatures above 125°F (51°C). The system

engages to cool the pump by discharging the warm

water onto the ground

10

Page 11

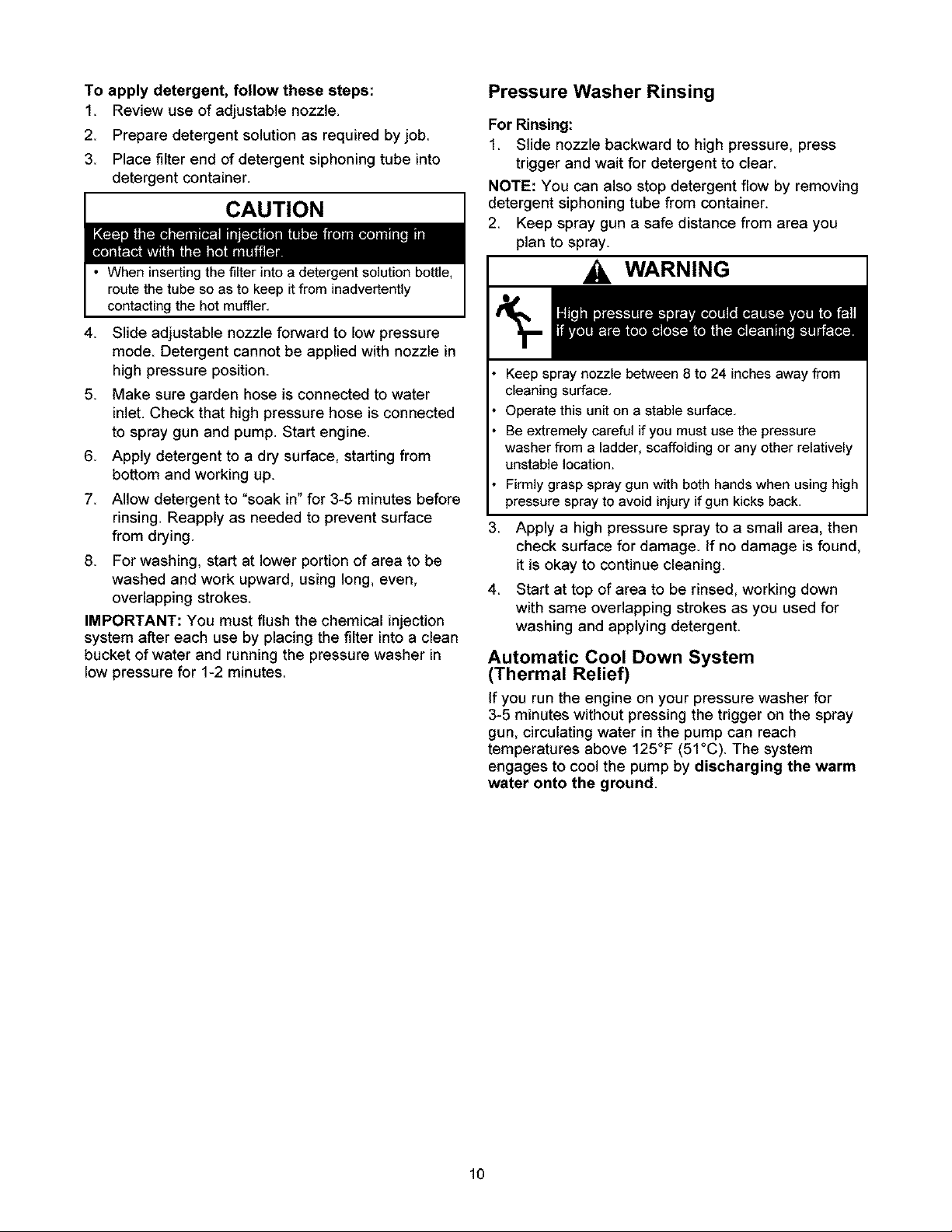

OWNER'S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first

More frequent service is required when operating in adverse conditions noted below

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

HOURLY OPERATING INTERVAL SERVICE DATES

MAINTENANCETASK

PRESSURE WASHER

Check/clean water inlet screen

Check high pressure hose

Check detergent hose

Check spray gun and assembly for leaks

Purge pump of air and contaminants

Change pump oil

Prepare pump for storage below 32°F (0°C)

ENGINE

Check oil level

Change engine oil

Service air cleaner

Service spark plug

Service spark attester

Prepare for storage

Clean if clogged. Replace if perforated or torn.

Change oil after the first (5) operating hours and every 50 hours or yearly thereafter.

Change sooner when operating under dirty or dusty conditions.

Replace more often under dirty or dusty conditions.

Before

Each Use

X 1

I x I_'f_l__]

I x I_//_i

I x I_&___i!_2;I

I x I__/_?,1

I__/l//////////////I x I_;I

X

I__ x= l_IIIIIIIIIIIIIIIIIIll

l_ifIIIIIIIIIIIIIII _:_ x I

U_IIIIIITIIIIIIIIII| x _IIIIIIIIIIIITIIII|

I If unit is to remain idle for longer than 30 days. I

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Pressure.................. 2,000 PSI (137.9 BAR)

Flow Rate ................. 2.0 GPM (7.6 L/MIN)

Chemical Mix .............. Use as directed

WaterSupplyTemperature..... Nottoexceed 100°F(38°C)

ShippingWeight............ 48 Ibs. (21.8 kg)

Engine Specifications

Rated Horsepower........... 3.75 HP (2.8 kW)

Spark PlugType:

Resistor ................ Champion RJ-19LM

Set GapTo: .............. 0,030 inches (0.76mm)

Fuel Capacity .............. 1.0 Quarts (.95 I)

Oil

Above 40°F (4°C) .......... SAE 30

0°F - 40°F (-18°C-4°C ....... SAE 5W-30 or 10W-30

GENERAL RECOMMENDATIONS

The pressure washer warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual including proper storage as

detailed in "Storage" on page 15.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

"Maintenance Schedule" chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

If equipped with inflatable tires, keep the air pressure

at the value marked on the tire or within 15 and 40 psi.

BEFORE EACH USE

1. Check engine oil level.

2. Check water inlet screen for damage.

3. Check in-line filter for debris.

4. Check high pressure hose for leaks.

5. Check chemical filters for damage.

6. Check gun and nozzle extension assembly for

leaks.

7. Purge pump of air and contaminants.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inlet screen Clean if it is

clogged or replace if it is torn

11

Page 12

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse Inspect hose before each use

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

WARNING

NEVER repair high pressure hose. Replace it,

Replacement hose rating MUST exceed maximum

pressure rating of unit,

Check Gun and Nozzle Extension

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back into place when you release it. Engage

safety latch and test trigger. You should not be able to

press trigger. Replace gun immediately if it fails any of

these tests.

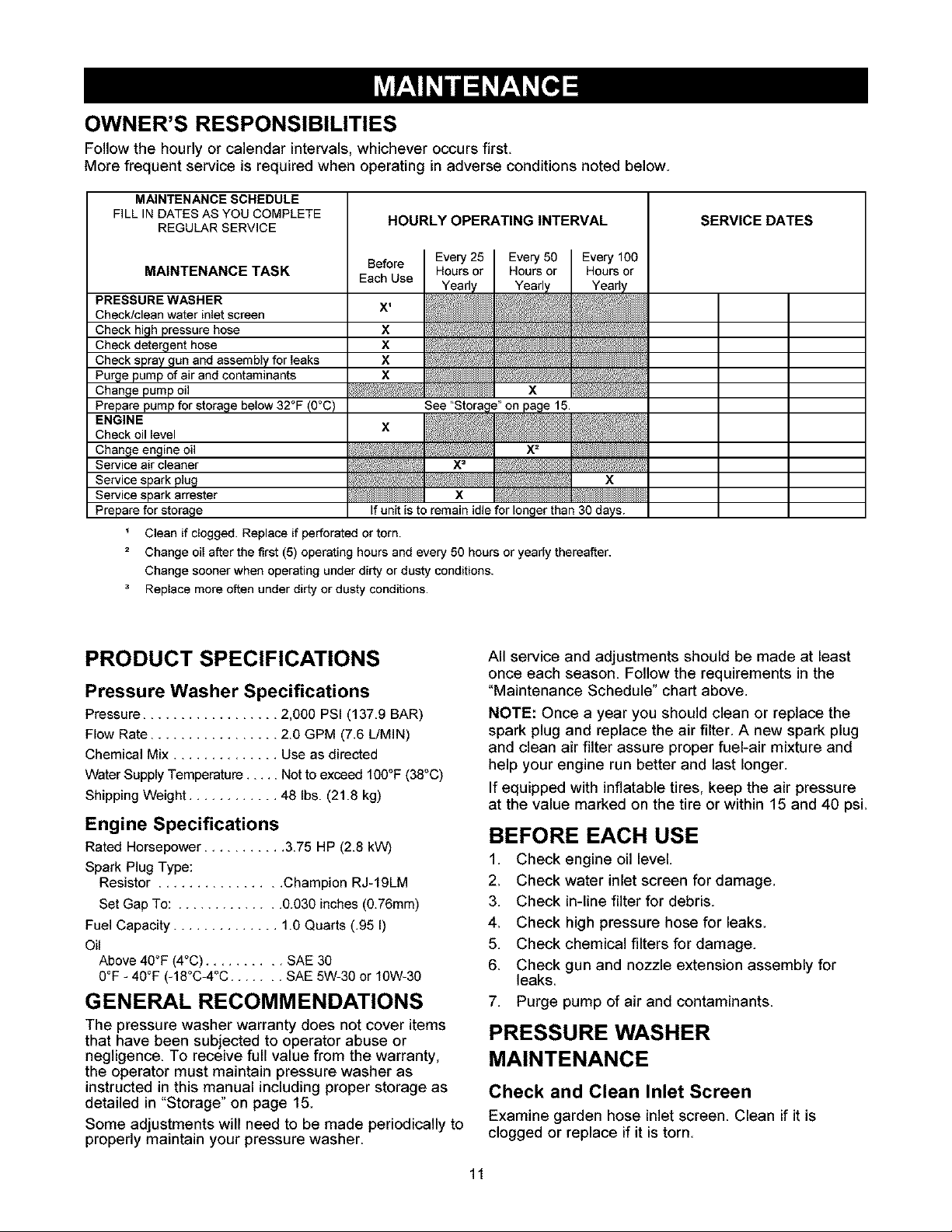

Check In-Line Filter

Refer to the illustrationand service the in-line filter if it

becomes clogged, as follows:

To remove contaminants from the pump, follow these

steps:

1 Set up pressure washer as described in

"Assembling Your Pressure Washer" section, and

connect water supply

2 Remove nozzle extension from gun

3 Start engine according to instructions in"How To

Use Your Pressure Washer _ section.

4 Pull trigger on gun and hold

5 When water supply issteady and constant, engage

safety latch and refasten nozzle extension

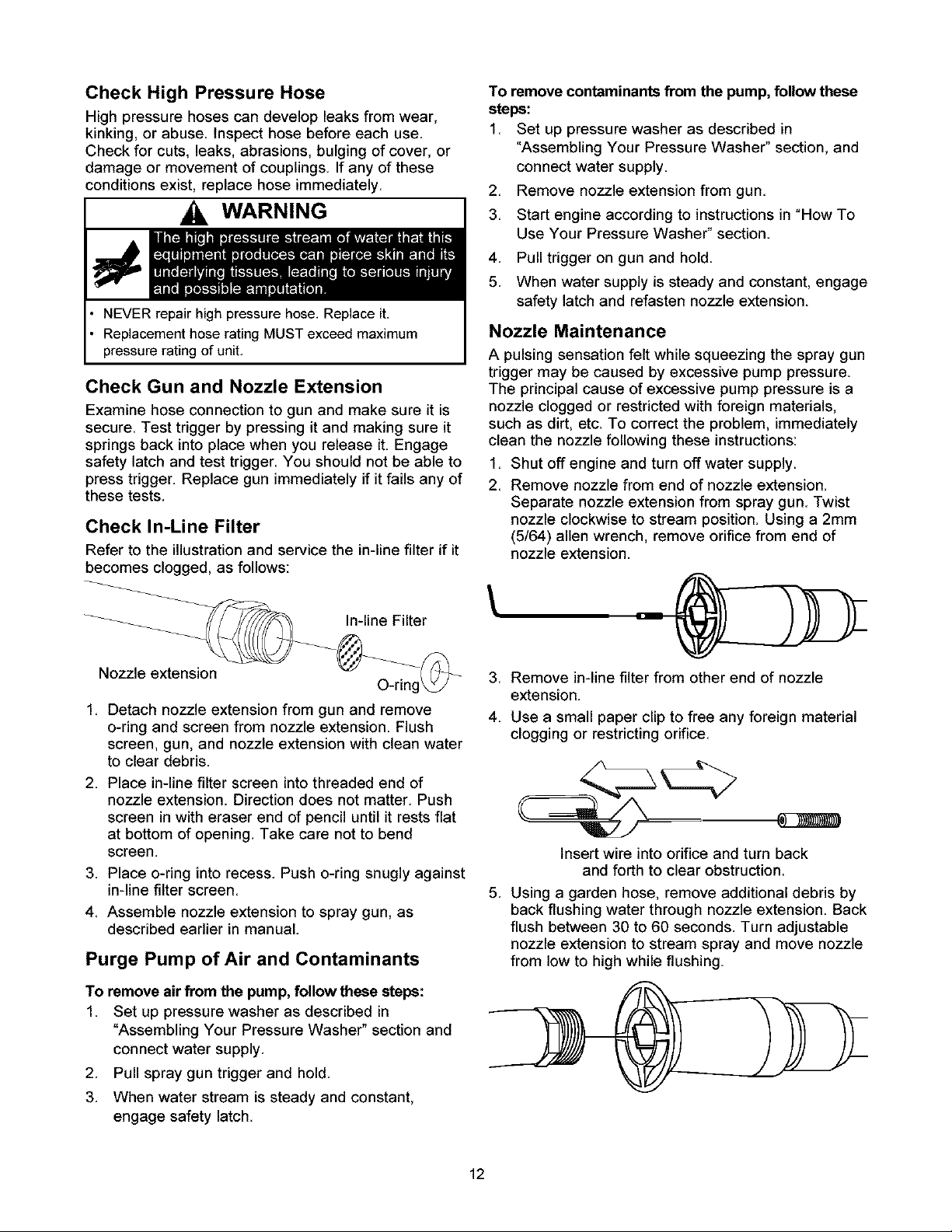

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

nozzle clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the nozzle following these instructions:

1. Shut off engine and turn off water supply.

2. Remove nozzle from end of nozzle extension.

Separate nozzle extension from spray gun. Twist

nozzle clockwise to stream position. Using a 2mm

(5/64) allen wrench, remove orifice from end of

nozzle extension.

In-line Filter

Nozzle extension O_ring=

1 Detach nozzle extension from gun and remove

o-ring and screen from nozzle extension Flush

screen, gun, and nozzle extension with clean water

to clear debris.

2 Place in-line filter screen intothreaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests flat

at bottom of opening. Take care not to bend

screen.

3 Place o-ring into recess. Push o-ring snugly against

in-line filter screen.

4 Assemble nozzle extension to spray gun, as

described earlier in manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps:

1 Set up pressure washer as described in

"Assembling Your Pressure Washer" section and

connect water supply.

2. Pull spray gun trigger and hold.

3. When water stream is steady and constant,

engage safety latch.

3 Remove in-line filter from other end of nozzle

extension.

4. Use a small paper clip to free any foreign material

clogging or restricting orifice.

Insert wire into orifice and turn back

and forth to clear obstruction

.

Using a garden hose, remove additional debris by

back flushing water through nozzle extension. Back

flush between 30 to 60 seconds. Turn adjustable

nozzle extension to stream spray and move nozzle

from low to high while flushing.

12

Page 13

6. Reinstallorificeandin-linefilterintonozzle

extension.DONOTovertightanorificewithallen

wrench.

7. Reconnectnozzleextensiontospraygun.

8. Reconnectwatersupply,turnonwater,andstart

engine.

9. Testpressurewasherbyoperatingnozzleinhigh

andlowpositions.

O-Ring Maintenance

Purchase an O-Ring Repair Kit, item number

191922GS, at your local Sears sevica center. It is not

included with the pressure washer. This kit includes

replacement o-rings, rubber washer and water inlet filter.

Refer to the instruction sheet provided in the kit to

service your unit's o-rings.

ENGINE MAINTENANCE

Checking Oil Level

Oil level should be checked prior to each use or at least

every 8 hours of operation, Keep oil level maintained,

Changing Oil

Change engine oil after the first 5 hours and every

50 hours thereafter. If you are using your pressure

washer under extremely dirty or dusty conditions, or in

extremely hot weather, change oil more often.

CAUTION

Pump Maintenance

Changing Pump Oil

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE: You must purchase a premeasured bottle of

pump oil, item number 190586GS at your local Sears

sevice canter.

Change pump oil as follows:

1. Drain engine oil and fuel from pressure washer.

2. Use a 8mm allen wrench to remove black pump

oil cap between high pressure outlet and garden

hose inlet.

J

3. Tilt pressure washer to drain oil into an approved

container until it drips slowly from pump.

4. Tilt pressure washer in opposite direction and

empty premeasured pump oil bottle into same

opening (a small funnel may be helpful).

5. Install black pump oil cap and tighten firmly.

6. Set pressure washer in upright position.Add fuel

and engine oil.

certain laboratory an!reals.

• Thoroughly wash exposed areas with soap and water.

DON'T POLLUTE. CONSERVE

RESOURCES. RETURN USED OIL TO

KEEP OUT OF REACH OF CHILDREN.

)COLLECTION CENTERS.

Change oil while engine is still warm from running,

as follows:

1. Drain fuel tank by running pressure washer until

fuel tank is empty.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Clean area around oil fill, remove oil fill

cap/dipstick. Wipe dipstick clean.

4. Tip your pressure washer to drain oil from oil fill

into a suitable container making sure you tip your

unit away from spark plug and air cleaner. When

crankcase is empty, return pressure washer to

upright position.

5. Wipe dipstick clean, insert it into oil fill hole and

tighten securely, remove dipstick. Add

recommended oil up to "Full" mark on dipstick.

Pour slowly. Wipe dipstick clean each time oil

level is checked. DO NOT overfill.

6. Install oil fill plug and dipstick, tighten securely.

7. Wipe up any remaining oil.

8. Reconnect spark plug wire to spark plug.

13

Page 14

Service Air Cleaner

Your engine will not run properly and may be

damaged if you run it with a dirty air cleaner.

Service the air cleaner once every 25 hours of

operation or once each year, whichever comes first.

Service more often if operating under dirty or dusty

conditions. Replacements are available at your local

Sears service center.

To service the air cleaner, follow these steps:

1 Remove screw

2 Carefully remove air cleaner assembly to prevent

debris from falling intocarburetor.

3. Take air cleaner assembly apart and clean all

parts. Wash foam air cleaner in liquid detergent

and water. Squeeze dry in a clean cloth.

4. SATURATE foam air cleaner in engine oil and

squeeze in a clean cloth to remove excess oil.

5. Reinstall clean or new foam air cleaner in body.

6. Install air cleaner securely on carburetor with

screw.

Service Spark Plug

Service the spark plug every 100 hours of operation or

yearly, whichever occurs first.

WARNING

1 Clean area around spark plug.

2 Remove and inspect spark plug.

3. Replace spark plug with recommended plug if

electrodes are worn or if insulator is cracked or

chipped.

4. Check electrode gap with wire feeler gauge and

set gap at 0.030 inches (0.76mm), if necessary.

\

\

5 Install spark plug, tighten securely

AFTER EACH USE

Water should not remain in the unit for long periods of

time Sediments or minerals can deposit on pump

parts and "freeze" pump action Follow these

procedures after every use:

1 Flush detergent siphoning tube by placing filter

into a pail of clean water while running pressure

washer in low pressure mode (adjustable nozzle in

forward position). Flush for one to two minutes.

2 Shut off engine and let it cool, then remove all

hoses.

3. Disconnect spark plug wire from spark plug.

4. Empty pump of all liquids by pulling recoil handle

about 6 times. This should remove most of the

liquid in pump.

5. If storing for more than 30 days see "Long Term

Storage" on page 15.

Disconnect spark plug wire from spark plug and place

wire where itcannot contact spark plug.

14

Page 15

GENERAL

Inspect high pressure hose for damage. Cuts in

hose or fraying could result in leaks and loss of

pressure. Should any damage be found, replace

hose. DO NOT attempt to repair a damaged hose.

Replace hose with genuine Craftsman part.

Drain water from hose, gun, and nozzle extension

and properly coil it on attached wireform.

Reconnect spark plug wire to spark plug.

Store unit in a clean, dry area.

_k ARNING1 NEVER store the engine with fuel

in the gas tank indoors or in enclosed, poorly

ventilated areas where fumes may reach an

open flame, a spark, or pilot light.

WINTER STORAGE

CAUTION

and render your unit inoperable.

• Freeze damage is not covered Under warrar4y.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also,

experience indicates that alcehol-blended fuels (called

gasohol, ethanol or methanol) can attract moisture,

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage.

Protect Fuel System

Draining Fuel Tank:

_hL ARNING1 Drain fuel, using a funnel, into

approved container outdoors, away from open

flame. Be sure engine is cool. DO NOT smoke.

Remove all fuel from carburetor and fuel tank to

prevent gum deposits from forming on these parts

and causing possible malfunction of engine.

Run engine until fuel tank is empty and engine

stops due to lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase.

Refill with recommended grade. See "Changing Oil"

on page 13.

To protect the unit from freezing temperatures:

1. Flush detergent siphoning tube by placing filter

into a pail of clean water while running pressure

washer in low pressure mode (adjustable nozzle in

forward position). Flush for one to two minutes.

2. Empty pump of all pumped liquids by pulling recoil

handle about 6 times. This should remove most

liquid in pump.

4. Connect a 3-foot section of garden hose to water

inlet adapter. Pour RV-antifreeze (antifreeze

without alcohol) into hose. Pull recoil handle twice.

Disconnect 3-foot hose.

LONG TERM STORAGE

If you do not plan to use the pressure washer for more

than 30 days, you must prepare the engine for long

term storage.

Oil Cylinder Bore

Remove spark plug, Squirt about 1 ounce of clean

engine oil into the cylinder. Cover spark plug hole

with rag. Pull recoil handle slowly to distribute oil.

Avoid spray from spark plug hole.

Install spark plug. DO NOT connect spark plug wire.

OTHER

DO NOT store fuel from one season to another.

If possible, store your unit indoors and cover it to

give protection from dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

IMPORTANT: NEVER cover your pressure washer

while engine and exhaust area are warm.

15

Page 16

Problem

Pump has following problems:

failure to produce pressure,

erratic pressure, chattering, loss

of pressure, low water volume.

Detergent fails to mix with

spray.

Engine runs good at no-load but

"bogs" when load is added.

Engine will not start; or starts

and runs rough.

Engine shuts down during Out of fuel. Fill fuel tank.

operation.

Engine lacks power. Dirty air filter. Replace air filter.

Cause

1. Nozzle in low pressure mode.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5, Clogged inlet hose strainer.

6. Water supply is over 100°F.

7. High pressure hose is blocked

or leaks.

8. Gun leaks.

9. Nozzle is obstructed.

10. Pump is faulty.

1. Detergent siphoning tube is not

submerged.

2. Chemical filter is clogged.

3, Dirty in-line filter.

4, Nozzle is in high pressure

mode,

Engine speed is too slow.

1. Dirty air cleaner.

2. Out of fuel.

3. Stale fuel.

4. Spark plug wire not connected

to spark plug.

5. Bad spark plug.

6. Water in fuel.

7. Excessively rich fuel mixture.

8. Intake valve stuck open or

closed.

9. Engine has lost compression. 9. Contact Sears service facility.

Correction

1. Pull nozzle backward for high

pressure mode.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch

leak.

5. Check and clean inlet hose

strainer.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace gun.

9. Clean nozzle.

10. Contact Sears service facility.

1. Insert detergent siphoning tube

into detergent.

2. Clean or replace

filter/detergent siphoning tube.

3. See "Check In-Line Filter".

4. Push nozzle forward for low

pressure mode.

Move throttle control to FAST

position. If engine still "bogs down",

contact Sears service facility.

1. Clean or replace air cleaner.

2. Fill fuel tank.

3. Drain gas tank; fill with fresh

fuel,

4, Connect wire to spark plug,

5. Replace spark plug.

6. Drain gas tank; fill with fresh

fuel,

7, Contact Sears service facility,

8, Contact Sears service facility,

16

Page 17

1-800-4-MY-HOME ®

..... (1'800-469-4663)

For the repair of major brand appliances in your own home .i.

no matter who made it, no matter who sold it!

For your nearest Sears Parts & Service location,

to bring in products like vacuums, lawn equipment and electronics.

For Sears Parts & Service, to order the replacement parts,

accessories and owner's manuals that you need to do-it-yourself,

To purchase or inquire about a Sears Maintenance Agreement, call:

1'800'361'6665

i(1,800,533-6937)

iiiiiiiiiiiiiiiii iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii i

i!ii!iliiiliiiii!iiiiii!iiiiiiiiiiiiiiiiiiiiiiii!

errMTrademarks of Sears, Roebuck and Co. used under license by Sears Canada

• MC i

Marque depos_e/ Marque de commerce de Sears, Roebuck and Co. utJlis6ean vertu dune licence de Sears Canada

17

Page 18

CRAFTSMAN 2,000 PSI Pressure Washer 580.672200

Nettoyeur & haute pression CRAFTSMAN de 2 000 psi 580.672200

Main Unit -- Exploded View and Parts List

Unitd principale - Vue dclatde et liste des pi_ces

Item Part # Description Item Part #

Article Pi6ce no. Description Article Pi6ce no.

1 190906GS BASE (BASE) 8 188792HGS

2 192162GS VvIREFORM (FORME EN BROCHE)

3 190249GS HOSE (TUYAU) 9 B2335GS

4 192649GS KIT, Pump/Engine Mounting 10 23139GS

Hardware (ENSEMBLE, 11 194216GS

quincaillerie de montage de la 900 NSP

pompeimoteur)

5 190132GS GUN (PISTOLET)

7 21760GS ORIFICE (ORIFICE)

Items Not Illustrated

Ar_cles non illustr6s

Part #

Piece no.

t93499GS MANUAL Owner's ',MANUEL d'utilisa_ion)

"93608GS ,(IT. Decals (ENSEMBLE. decalques._

AB3061BGS OIL. Bottle (HUILE, bouteille)

190586GS OIL. Pump (HUILE, pompe)

Optional Accessories Not Illustrated

Accessoires en option non illustrbs

191922GS ,(IT. Maintenance, O-Ring (ENSEMBLE, entretien, joint torique)

7167300GS House Wash Concentrate (makes 4 gallons) (Concentr6 de nettoyant manager (produit 15 litres))

7167301GS Deck Wash Concentrate (makes 2 gallons) (Concentr6 de netioyant de pot4 (produit 7.5 litres))

7167302GS VehMe/Boat Wash Concentrate (makes 4 gallons) (Concentre de nettoyar_ de v6hiculelbateau

7167303GS Degreaser Concentrate (makes 4 gallons) (Concentre de degraiasant (#roduit 15 litres))

Description

Description

(produit 15 litres))

Description

Description

WAND, Adjustable Nozzle (LANCE,

buse r_glable)

WAND, Turbo (LANCE, turbo)

KEY (CLE)

ASSY, Pump (ENSEMBLE, pompe)

ENGINE (see pages 20-22)

(MOTEUR (voir pages 20 _ 22))

18

Page 19

CRAFTSMAN 2,000 PSI Pressure Washer 580.672200

Nettoyeur & haute pression CRAFTSMAN de 2 000 psi 580.672200

Pump -- Exploded View and Parts List

Pompe -- Vue dclatde et liste des pi_ces

C

Item Part #

Article Pi6ee no.

19 190571GS

28 190627GS

29 190575GS

30 190576GS

34 190577GS

45 I90578GS

46 190629GS

47 190630GS

62 190581GS

68 190582GS

69 190584GS

76 194298GS

A NSP

Description Item Part #

Description Article Pif_ce no.

CAP, Oil (BOUCHON, huile) B 190632GS

MANIFOLD (COLLECTEUR)

O-RING (JOINT TORIQUE)

SCREW (VIS) C 190634GS

CONNECTION, Chemical Inlet

(CONNECTEUR, Entree de E 190591GS

pmduits chimiques)

PIN (TIGE) F 190592GS

VALVE, Seat Plate, Plastic

(SOUPAPE, Assise du siege de, G 190593GS

en plastique)

VALVE, Seat, Plastic (SOUPAPE,

Siege de, en plastique) H 190628GS

CAP (BOUCHON)

BALL, SS (BILLE, Acier inoxydable)

O-RING (JOINT TORIQUE) J 189971GS

THERMO RELIEF (SOUPAPE DE

SURPRESSION THERMIQUE)

ASSY, CASE, PISTON (order K 190636GS

complete pump assy, 191693GS)

(ENSEMBLE, BO|TIER, PISTON

(no. de commande de I'ensemble

pompe complet, 191693GS))

NOTE: Item letters B - K are service kits and include all

parts shown within the box.

REMARQUE: Les articles B _ K sont des ensembles de

remplacement et incluer4 toutes les pieces illustrees dens

I'encadre correspondent.

H

Description

Description

KIT, WATER INLET, ALUM

(ENSEMBLE, ARRIVEE D'EAU,

ALUMINIUM)

KIT, OUTLET, ALUM (ENSEMBLE,

SORTIE, ALUMINIUM)

KIT,CHECK VALVES (ENSEMBLE,

CLAPETS DE RETENUE)

KIT, INLET CHECK (ENSEMBLE,

RETENUE D'ENTREE)

KIT, CHEMICAL INJECTION

(ENSEMBLE, INJECTION DE

PRODUITS CHIMIQUES)

KIT, UNLOADER STEM

(ENSEMBLE, TIGE DE

DECHARGE)

KIT, CHEMICAL HOSE

(ENSEMBLE, TUYAU DE

PRODUITS CHIMIQUES)

KIT, SEAL SET (ENSEMBLE, JEU

DE JOINTS)

19

Page 20

ENGINE, 3.75 HP, Briggs and Stratton, 10D902 - Exploded View

MOTEUR, 3,75 HP, Briggs & Stratton, t0D902 - Vue dclatde

842_

1211_

1210_

5s

592_ 60

459_ _

689_

456@

597g

2O

Page 21

ENGINE, 3.75 HP, Briggs and Stratton, 10D902 - Exploded View

MOTEUR, 3,75 HP, Briggs & Stratton, 10D902 - Vue dclat_e

365

_o_

163

633_ -

1218 _ 130_

334_

20}.

356_

190_ 832_

_836 _

ENGINE GASKET SET

670

300

536_ 5341

535_

1630

21

Page 22

ENGINE, 3.75 HP, Briggs and Stratton, 10D902 - Parts List

MOTEUR, 3,75 HP, Briggs & Stratton, 10D902 - Nomenclature de pi_ces

Item Part #

Article Pl&ce no,

1 399164

2 399269

3 299819

4 698691

5 890396

7 692289

8 495785

9 895890

10 691666

11 691245

12 692219

270895

270896

13 691697

15 691690

16 692999

19 293709

20 391483

22 691662

23 690843

24 222999

25 498669

498669

498670

498671

26 498680

498681

498682

498683

27 691589

28 298909

299908

29 496792

32 691664

33 296676

34 296677

35 690520

36 690520

37 691289

40 692194

43 698690

45 691792

46 691999

50 693446

51 270345

54 691111

55 692144

58 692259

80 691915

85 690837

73 691235

90 498811

97 691931

106 691901

130 691190

163 271139

190 494406

Oesctl_lon

Oesctl_lon

CylinderAssembly (Ensemble#ylindre)

Kit-Bushing/_eal (Magneto Side) (Ensemble-Garniture

d'_ncheit_JJatnt (c5t_ magn_))

SeaFOil (Magne_eSide) (Joird-Huile(_e magn_ta))

Sump-Engi_e (Fuisar_l-Mate_r)

Head-Cylinder (C_l_sse-Cylindre)

Gasket-Cylinder Head (Joint s_ique-Oul_,_e de

eylindre)

BreatherAssemb_ (Ensemble de reniflard)

Gasket-Breather (Joint ata0que-Ren_rd)

Screw (Breather Assembly) (',/is(En_mbJe de

renifl_rd))

Tube-Breather (Tuee-Reniflard)

Gasket-Crankcase (.919", Sland_rd) (Joint statique-

Carter (0,036 mmou 0,015 po,S_andard))

Gasket-Crankcase (.005") (Joint statique-Car_er

(0,013mm o2 0,005pe))

Gasket-Crankcase (.009") (Joint statique-Car_er

(0,023mm ou 0,009pe))

Screw (Cylinder Head)(Vi_ (Cata_e de eylindre))

Plug-Oil Drain (BouchomVid_nge fflh_ile)

Crankehaff (Vilebrequin)

Kit-Bushing/Side (PTO Side) (E_semble-G_miture

d'Ciancheit_CCCe(C¢¢€prise de force))

Seat-Oil (PTO Side) (jatnt-H_ile (C_ pdse de force))

Screw (Engine Sump) (vis (Fuisard de moteu_)

Flywheel(Vatant-moteu_

Key-Flywheel (Clavette-Volard-mate_r)

Piston AssembJy(Standar_l)(Ensemble de piston

(Standard))

Piston Assembly ( 010" Oversize) (Ensemble de piston

(surdimensionnede 0_25mmou 0_01pe))

Piston Assembly ( 020" Oversize) (Ensemble de piston

(surdimensionnede 0_51mmou 0_020po)_

Piston Assembly ( 030" Oversize) (Ensemble de piston

(surdimensionnede 9_79mmou 9_030ee)_

Rin9 Sat (Sland_rd) (jew de bagues (Standard))

RingSet (.010"Oversize)(Jeude _gue_

(s_rdime_sionn_e_de0,25 mm ou 0,919po))

RingSet (.020"Oversize)(Jeude _gue_

(s_rdime_sionn_e_de0,91 mm ou 0,920po))

RingSet (.030"Oversize)(Jeude _gue_

(s_rdime_sionn_e_de0_76mmou 0,930pc))

Loc_Piaton Pin (Verrou-Axe de piaton)

PimPiaton (Sland_rd) (Axe-Piaton(Standar_l))

Pin_Piaton(09_' Undersize)(Axe-Pith

(_u_imensionne de 0,13 mm ou 0,095ee))

Rod-Conneating(Bielle)

Screw (Connecting Rod) 0/is (Bielle))

Vfflve-Exhau_ (Soupape-_chappemerd)

Valve-intake (Soup_i:_-Erdree)

Spring-valve (Jn_ke) (Re_ort-Soup_ (Entree))

Spring-Valve (Exhaust) (Res,_ort-Soupape

(_chappemerd))

Guard-Fl_,_1_eei(Capot-Vatant-mate_r)

Ret_iner-Vfflve (DisposiSf de ratenue-Soupa_e)

SIinger-Govemor,'Oil(Bague d'ata_ch_ite_

RegulateuriHuile)

Tappat_Vfflve(Po_ssatr-Sou_ee)

Camshaft (Arbr_ _ came_)

M_nifatd-tntake _Coll_x_teur-E_r_e)

Gasket-ln_ke (Joint atatique-Entr_e)

Screw (_rdakeManifold)(Vis (Colleuteur d'erdree))

Housing-ReWindStair (B_8-D_m_rreur _ cordon)

Roee-St_rter (Cordon-DCmarreu0

Grip-Star_erRope (Poignee-Cordon de demarreur)

Screw (Rewind Star_er)0/is (D_marreur _ cordon))

Scr_n-Rotating (Cr_pine_Rot_

Carburetor (Carbur_te_0

Shaft-Throttle (Arbre-Pou_e)

Seat4nJet(Si_ge-Admissioe)

Valve-Throttle(_oupeee-Pouss_)

Gasket-Air Cleaner (joint _ati_ue-Fiitre _ ai0

Tank-Fuat(R_rvoir-Combuatible)

Part#

Item Description

Pl_ceno,

Article Description

691697

190 Screw (FuelTank) _'VJS(R6seP#oird'essence))

692199

190A Screw (FuelTank) 0/is (R_servoir d'essence))

691912

209 Bleee-Govemor (Pffle-R_9_late_r)

690347

201 Link-Air V_ne (Lier_-Voietd'air mobile)

691862

209 Spring-Governor (Resso_Regulateur)

691859

211 Spring-Govemee Idle (Ressort-Regulataur de ralen0)

691445

222 Bracket_OordroJ(Suppo_Con_le)

394569

300 M_ffler (Silencieux)

692536

304 Housing-Blower (B_0-Souffleee)

692199

305 Screw (BJowerHousing)(Vis-(B_8 de soufflede))

690400

306 Shield-Cylinder (_cren-Cylindre)

690345

307 Screw (Cylinder Shield) (Vis (_cran decylindre))

690662

332 Nut (Flywhee0 (_crouWatant_mateu0

496914

333 Armature-Magneto (Am_ature_Mag_ete)

691061

334 Screw (vis (Armaturede m_gn_e))

902592

337 Plug-S_,_rk(Bougie-Allumage)

692390

356 Wire-Step (FiFArr6t)

398809

356A Wire-Step (FiFArr6t)

298989

359 Gasket Set-Engine(Jeu de jointsstatique_-Moteur)

692280

368 Screw (Garburato0 ('#is(Carburateu0)

691839

390 Spring-Choke Diaphragm (Res_o_Membrane de

I'etrengle_0

393 691837 Screen-Carburetor (Cr6_ine_Carburataur)

394 495770 Gasket-Carburetor Pum_ (Joint statique-Pomee du

carburate_0

426 691197 Screw (Governor Blade) ('#is (P_leduregulataur))

458 691236 Cup-Flywheel (Cou_elle-Volant_moteur)

456 692299 Plate_F_av,,lFsctio_ (Rieeue-Cliquat _friction)

469 694420 Ring_Rofatin9 Trim (Annea_-Compensateur rotatif)

523 691913 Dipstick (Jauge)

529 692199 Grommet (Geill_t)

534 691417 Screw (Air Cleaner)('#is(Flirts _ _i_)

535 698369 Fi_er-Air Cleaner Foam (Filtre-Mou&sedu filtre _air)

536 698472 Cle_ner_Air(Filtre-Air)

592 690800 Nut (Rewind Sterte0 (_crou (D_marre_r _ cordon))

597 691696 Screw (F_awlFsction F'lata)('#is (Plaquede cliquet

fiic0on))

909 499796 St_Ier-Rewind (D#_marreur-Rebobinage)

912 496046 TueeW_ickUp (Tube-Ramassage)

917 270344 SeaI-O Ring (Ird_ke M_nifold)(Joirtt_JointtoSque

(Catleateurd'eutree))

921 692310 Sw_ch-Stap (IntemJpteur_Arr¢t)

933 691321 SeaFOheeeYThrottleShaft (Joir_t-_trangleuriArbrede

eeussCe)

635 68538 Boot_Sp_rkPlug(Couvre-bome-Bougie d'_llumage)

669 692899 Spacer (Bu_e d'espacement)

970 691633 Spacer-Fuel T_nk (Butte d'espacemertt_Reeervatrde

c_mbusSble)

999 691855 Spring-Friction (Resso_Fdation)

719 690959 Pin_Locatir_9 (Det_mpeur)

718A 499047 PimLocatin9 (Det_mpeur)

741 691895 Gear-Timin9 (Pignon de distribution)

932 691443 Guard-Mufger(CapuchomSilencieuk)

936 691443 Screw (Muffler Guard) (vis (Capuceen du silencieuk))

942 691876 Seat-O Ring (Dipstick) (joint-Jatnt toSque(J_uge))

951 493890 Tarminat-Spark Plu9 (Borne_Bougied'atlumage)

969 691791 Seat_vaive(Intake) (Si_ge-So_eepe (Erdr_e))

970 691702 Seat_Vaive(Exha_at) (Si¢ge-Sou_ee (_chappemerd))

971 231349 Bushing-Guide (Exhaust)(G_mSure d'et_nch_,Se-Gatde

(_chappemerd))

63709 Bushing-Guide (intake)(Garniture d'C'tanch_ite-Guide

(Entree))

913 494499 Seat_CheckValve (Si¢ge-CJap_ de %'tenue)

957 497929 Cap-Fuel T_nk (Bo_cho_-Reservoir de comb_s0bte)

976 694394 Primer-Carburetor (Amorceu_C_rburateur)

1095 498526 Gasket Set-Valve (Jeu dejoints statiq_e_-Soupffl_e)

1219 499901 Pulle¥iS_ring Assemb_ (Pulley) (Po_lie/Ensemble de

re&sorts(Poulie))

1211 499901 PulleyiS_ring Assembly (Spring) (PoatieiEnsembie de

re&sorts(Poulie))

1219 695866 SeaI-O Ring (Carburato0 (Joint_Jointtosque

(Carburataur))

22

Page 23

Sears, Roebuck and Co. U.S.A. (Sears), the California Air Resources Board (GARB) and

the United States Environmental Protection Agency (U.S.EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE iS a. Fuel Metering System

APPLICABLE TO CERTIFIED ENGINES PURCHASED iN

CALIFORNIA IN 1995 AND THEREAFTER WHICH ARE

USED iN CALIFORNIA, AND TO CERTIFIED MODEL

YEAR 1997 AND LATER ENGINES WHICH ARE

PURCHASED AND USED ELSEWHERE IN THE UNITED

STATES (AND AFTER JANUARY 1, 2001 IN CANADA).

California and U.S. EPA Emission Control Warranty

Statement Your Warranty Rights and Obligations

The California Air Resources Board (CARB), U.S.EPA and

Sears are pleased to explain the Emission Control System

Warranty on your model year 2000 and later small off-road

engine (SORE). In California, new small off*road engines

must be designed, built and equipped to meet the State's

stringent anti-smog standards. Elsewhere in the United

States, new non-road, spark-ignition engines certified for

model year I997 and later, must meet similar standards set

forth by the U.S.EPA. Sears must warrant the emission

control system on your engine for the periods of time listed

below, provided there has been no abuse, neglect, or

improper maintenance of your small off-read engine.

Your emission control system may include parts such as the

carburetor or fuel-injection system, the ignition system, and

catalytic converter. Also included may be hoses, belts,

connectors and other emission related assemblies.

Where a warrantable condition exists, Sears will repair your

small off-road engine at no cost to you including diagnosis,

parts and labor.

Sears Emission Control Defects Warranty Coverage

The 1995 and later small off-road engines are warrar_ed for

two years. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Sears.

Owner's Warranty Responsibilities

As the small off-read engine owner, you are responsible for

the performance of the required maintenance listed in this

owner's manual. Sears recommends that you retain all your

receipts covering maintenance on your small off-reed

engine, but Sears cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the small off-read engine owner, you should however be

aware that Sears may deny you warranty coverage if your

small off-road engine or a part has failed due to abuse,

neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-read

engine to an approved Sears Service Center as soon as a

problem exists. The warranty repairs should be completed in

a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a Sears Service

Representative at 1-800,469-4663.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your

Emission Control Defects Warranty Coverage.

1. Warranted Parts

Coverage under this warranty extends only to the parts

listed below (the emission control systems parts) to the

extent these parts were present on the engine purchased.

Inthe USA and Caned& a 24-hour hotline 1-800-469-466& has a menu of pre-recorded messages offering you product

maintenance information:

Cold start enrichment system

Carburetor and internal parts

Fuel Pump

b. Air Induction System

Air cleaner

Intake manifold

c. Ignition System

Spark plug(s)

Magneto ignition system

d. Catalyst System

Catalytic converter

Exhaust manifold

Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

Vacuum, temperature, position, time sensitive valves

and switches

Connectors and assemblies

2. Length of Coverage

Sears warrants to the initial owner and each subsequent

owner that the Warranted Parts shall be free from

defects in materials and workmanship which caused the

failure of the Warranted Parts for a period of two years

from the date the engine is delivered to a retail

purchaser.

3. No Charge

Repair or replacemer4 of any Warrar4ed Part will be

performed at no cha_je to the owner, including

diagnostic labor which leads to the determination that a

Warranted Part is defective, if the diagnostic work is

performed at an approved Sears Service Center.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the

previsions of the Sears Warranty Policy. Warranty

coverage shall be excluded for failures of Warranted

Parts which are not original Sears parts or because of

abuse, neglect or improper maintenance as set forth in

the Sears Engine Warranty Policy. Sears is not liable to

cover failures of Warranted Parts caused by the use of

add-on, non-original, or modified parts.

5. Maintenance

Any Warrar4ed Part which is not scheduled for

replacement as required maintenance or which is

scheduled only for regular inspection to the effect of

"repair or replace as necessary" shall be warranted as to

defects for the warranty period. Any Warrar_ed Part

which is scheduled for replacement as required

maintenance shall be warrar4ed as to defects only for

the period of time up to the first scheduled replacement

for that part Any replacement part that is equivalent in

performance and durability may be used in the

performance of any maintenance or repairs. The owner

is responsible for the performance of all required

maintenance, as defined in this owner's manual.

6. Consequential Coverage

Coverage hereunder shall extend to the faiJure of any

engine components caused by the failure of any

Warranty Part still under warranty.

23

Page 24

GARANTIE ..................................... 24

REGLES DE SECURITE ....................... 24-26

ASSEMBLAGE ............................... 28-29

OPERATION ................................. 30-32

CARACTERISTIQUES DU PRODUIT ................ 33

ENTRETIEN ................................. 33-36

RANGEMENT .................................. 37

DEPANNAGE .................................. 38

GARANTIE DU DISPOSITIF ANTIPOLLUTION ........ 39

COMMENT COMMANDER LES PARTIES ........ PAGE

POSTERIEURE

GARANTIE LIMITI_E SUR LE NETTOYEUR ._, HAUTE PRESSION CRAFTSMAN

Pour une periode d'un an _ partir de la date d'achat, Sears reparera, sans frais, taut defaut de materiel ou de fabrication si

ce nettoyeur _ haute pression CRAFTSMAN® est entretenu et utilis6 conformement aux directives du manuel d'utilisation.

Sice nettoyeur est utilise _ des fins commerciales, la garantie s'appliquera pendar_ seulement 90 jours _ compter de la date

d'achat.

Sice nettoyeur _ haute pression est Iou6, carte garar_ie s'appliquera pendant seulemer_ 30 jours _ compter de la date

d'achat

La presente garar_ie ne couvre pas:

Les pieces non recuperables somme les bougies d'allumage ou les filtres _ air, lesquelles s'usent durant I'utilisation

normale de I'appareil.

Les reparations rendues necessaires en raison de I'abus ou de la negligence de I'operateur, y compris les dommages

causes par un manque d'eau dons la pampa ou le defaut d'entretenir Pappareil conformement aux directives du guide

d'utilisation.

LES SERVICES EN VERTU DE LA GARANTIE SERONT RENDUS EN RETOURNANT LE NETTOYEUR ,& HAUTE

PRESStON AU CENTRE DE SERVICE SEARS OU AU DETAILLANT SEARS CANADA.

La presente garar_ie vous accerde certains dreits I_jaux specifiques et il se peut qua vous ayez 6galement d'autres droits,

lesquels varient d'un l_tat _ I'autre ou d'une province _ Pautre.

Sears Canada, Inc.

_k eci est Ia sQret6 Ie symbole vif. II est utilis_ pour vous alerter aux dangers de blessure personnels potentiels,

Ob6ir tous messages de sQret_ qui suivent ce symbole _viter la blessure ou Ia mort possibles.

_ Lisez avec soin ce manuel et familiarisez-vous

avec votre pulv6risateur _ pression, Connaissez

ses applications, ses limitations et les dangers

qu'il implique.

Le symbole indiquant un message de secudte (,l&) est

accempagne d'un mot indicateur (DANGER, ATTENTION,

AVERTISSEMENT), d'un message iflustre eVou d'un

message de secudte visant _ vous avertir des dangers.

DANGER indique un danger qui, s'il n'est pas evite,

provoquera des blessures graves, voire fatales.

AMERTISSEMENT indique un danger qui, s'il n'est pas evite,

peut provoquer des blessures graves, voire fatales.

ATTENTION indique un danger qui, s'il n'est pas evite, peut

prevoquer des blessures mineures ou legates. Le mot

ATTENTION, Iorsqu'il est utilise sans le symbole d'alerte,

indique une situation pouvant endommager I'equipement.

Suivez les messages de securite pour eviter ou reduire les

risques de blessures ou de mort.

Symboles de Danger et Moyens

Emanations Toxiques

Surface Glissante Chute

Choc E_lectdque

injection Fluide

J

Feu Explosion Surface Chaude

Parties en mouvement Objets volant Effet de Recul

24

Page 25

3ans P_tat de Caiifornie un pare-_tincelles est requis par la

oi (section 4442 du Code des ressources publiques de

3alifornie). D'autres _tats ont des lois similaires. Les lois

'_d_raies s'appliquer_ aux terres f6d_rales. Si vous _quipez

e silencieux d'un pare-_tincelles, il doit _tre en bon _tat de

'onctionnement. Vous pouvez commander un

_are-_tincelles aupr_s de votre distdbuteur de service

Sears autoris&

AVERTISSEMENT

L'6chappement du moteur do ce produit eontient des produits I

ehimiques que I'Etat do Californie eonsid_re comme causant I

le cancer, des d_formations _ la naiseence ou d'autres

dangers conesrnant a reproduet on.

DANGER

I'inhalati0n des vapeurs nocives.

AVERTISSEMENI

LORSQUE VOUS AJOUTEZ DU CARBURANT

• Eteignez le pulveriseT:eur et laissez-le refreidir au moins

2 minutes avant de retirer le caouchon du reservoir do carburant.

• Remplissez toujours le reservoir _ essence _ I'exterieur.

• Ne remp_ssez pas trep le reesrvo_r Laissez esr_aco r_our

expansion de ressence.

• Eloigcez _essence oss _t_nceiles. des fiammes des ve_lleusss.

de la chaleur et de toute autrs source d'inflammetion.

• N'ailumez pss oe c_£arette ou ne fumez pas _ proximit_ de

apDarell.

LORSQUE L'EQUIPEMENT FONCTIONNE

• Ne peFiohez pas le motet_r OU I_cJIDemeTit vous £1scuerlez de

reNvet_er _e ['essence.

• Ne vapedesz pse de liquidss inflammables.

LORSQUE VOUS TRANSPORTEZ OU RtePAREZ

L'I_QUtPEMENT

• TransDortez ou reparez I'appare_l/orsque le reservoir d'essence

est VIDE ou Iors_ue _a seupape d'arr6t d'essence est FER_IEE

LORSQUE VOUS ENTREPOSEZ L'ESSENCE OU UN

_eQUIPEMENT AVEC UN R_eSERVOIR A ESSENCE

• Entrsposes-le Iota des a_oareils de chauffage, des fours, des

chauffeeau, des s6cheuses ou de tout autre appare_l

electremenager o_spose_t oune ve{_euse ou oe route autre

source d'inf_ammation risouant d'enfiammer tes vapeurs

d'essenoe

AVERTISSEMENT

provoquerdes ele_rocutions.

AVERTISSEMENT

• Pour nettoyer de fa_on plus eff_cacel tenez ie gicleur _ une

distance de 8 _ 24 pouces dela surface &nettoyer.

• Faitesfon_ionceretrar_:jezcetepparsitsurunesurfacestabfe.

• La surface _ nettoyer doit etre inolin6e et equipee

d'ecou_emer_ts afin de reduire la possibi_it_ de chutes dues aux

sprfa_S £1issantes.

• Soyez extr_mement pruderff si vous devez utJliser _

pulwrisateur Bur une 6che!le, un echafaudage ou tout autre

endroit reiativement instable:

• FermemenUe fusil de pulv_risation de comprehension aveo tes

deux mains en utitisent I!haute pulver_sation depression pour

eviter la blessure si le fusil donne un coup de pied le dos.

AVERTISSEMENT

• N visez jamais des personnes, des animaux ou des plantes

ave¢ le pistoiet puiv_riseteu_.

• N'aut0nsez jamai s des ENFANTS _ se servir du p_lverfseteU [.

, Ne reparez jamais les tuYaux & haute pres$ion Remplacez

• Gardez toujours le tuyau flexible & haute pression rass0rdea la

pompe et au pistolet de pS!verisatied torsque le sys_eme est

seus pression:

AVERTISSEMENT

• Laissez I%_uipement refroidir avarff de le toucher:

25

Page 26

AVERTISSEMEN1

rotative.

• Embouteiller des cheveux iOngs et enleve la bijouterM

AVERTISSEMEN1

ATTENTION

" NE verreuillez PAS le pistolet de pulv@risation dabs la position

ouverte.

* NE laiesez PAS le pistolet de pulverisation sans surveillance

alors que I!apparei[ e_: en marc.he.

" N'utilisez JAMAIS un pistolet de pulverisatJon qui n'est pes muni

d'un verrou d'arme ou d'un pontet installe et en ordre de

marehe.

* Aesurez-vous toujours que ie pistolet de pulverisaT:ion:los buses

et los acceesoires sor_ bieb fixes.

ATTENTION

• Protegez toujours Vos yeux toreque veus Otflisez Cot equipement

Ou Iorsque vous etes a proximite de quelqu'un qui I'utilise

AVERTISSEMENT

ce qu'il ne salt bes en contac_ avec la bougie:

ATTENTION

superieure & la pression nominate.

" Ne pointez pus le pistolet pulvensateur sur du verre Iorsquil est

en mode pulverisation.

* N vise.z jamais des blantes aveo le pistolet pulvenestePr

ATTENTION

• Si vous avez des questions e pro#as de {'utilisation or_vue de

Cot apparel] consultez votre d_taillaNt ou o'ommuni_usz avec

Sears

• N'utilisez JAMAIS un apparell ayant _les pieces bnsees ou

manauantes ou sans b_ti ou couverctes protecreurs.

• NE neutralisez AUCUN dispesitif de securite de cette machine

• Par tomes froid avant de demurrer le nettoyeur t_haute

oressmn verlfiez-en tous los elements pour vous assurer

qu'aucune £_ace ne s_yest formee

• N'ut;lisez JAMAIS te tuyau a haute aress_on oomme _oignee

oour de#later ra#parei! Utilisez touJours la po_gnee _e

aDearelL

• Verif_z ta eresence de fuites ou los slgnes de deterioration au

s¥_me de com_ustt_le, comme un tuyau use ou spong_eux.

des brides de esrrage desserrees ou manquantes ou un

r_ervo_r ou un bouchon endommag& Reparez routes los

defectuosites avant d'ubliesr le nett_yeur & haute o_on

• Cot apparett est con_u pour 6tre utilise uniquement avec des

eces Sears approuvees. Si I'aooareil est utilise avec des

recess oui NE sent PAS conformes aux carac_eristioues

mm_male_ tousles nsques et responesbilites incomberont &

utllmateur.

26

Page 27

CONNAiTRE VOTRE PULVERISATEUR .&.PRESSION

Lisez ce manuel d'utilisetion ainsi que les regles de s_curit6 avant de faire fonctionner votre pulverisateur b pression.

Comparez lee illustrations avec votre pulverisateur _ haute pression pour vous familiadser avec {'emplacement des differents

boutons et reglages. Conservez ce manuel pour reference ulterieure.

Pistolet de pulverisation

Buse reqlabte

/

/

/

Por_e-aocassolres

/

Rallonge de buse

Bouchon de rempliesage

et jaug _

Rallonge avec

air

lre

f Manette de pouesee

#

Chimique Injection

Pomce

d'amor_age

:_ese_oir

d'eesence

Prise d'eab

"Prise haute #ression

Pompe equip6 aveo

Systeme de refroidiesement automatiaue

Bouchon de remplissege et jauge d'huile - Verifiez le Porte-acceseoires - Le porte-aceessoires vous foumit un

niveau d'huile et remoliesez le moteur d'huile ici. Consultez la espace rJe rangement pratique pour le pistolet de

page 29 au sujet des recommandations relatives & I'huile et

des directives de rempliesage.

Buse reglable * reglage & haute ou baese press_on;jet etroit

ou en ever_ail.

Injection Chimique Usage &siphon ou autre oression

chimioue daes le bas uresslon

Demarreur & reoul - Util}se oour demarrer le moteur

manuellement,

Filtre & air - Filtre de type sac qui limite la quantite de

oouesieres et de saletes dane te moteur.

Marietta de pouseee -Cette manege [_lace le moteur en

mode demarrage pour ie lanceur et eteint le moteur en

marcne.

Pistolet de pulverisetion - un dispositif de detente oermet

pulverisatior la turbo-lance et la rallonge de buse.

Prise d'eau - Branchement oour le tuyau d'arresage.

Prise haute pression *Vous permet de brancher le tuyau &

haute _rese_on,

Rallonge aveo turbo-lance - La turboqance oroduit un

mouvement rapide et circulaire du jet _ haute oressJon afin

de procurer un nettoyage efficace.

Rallonge de buse - Pour utiliser la buse reglable, fixez la

rallonge au p_stolet de pulverisation.

Reservoir d'essence - Remoliesez le reservoir avec de

I'essence ordinaire sans plumb. Laissez toujours de la olace

pour I'expansion de I'eesence.

Systeme de refroidiseement automatique - Fait circuler

I'eau dans la pompe Iorsqu'elle atteir4 51_ & 68°C (125 °

de contrSler le jet d'eau sur la surface _ nettoyer. Le oistolet 155_FJ. L'eau chaude s'eeoulora de la pompe sur le sol.

est muni d'un verrou de securit& Ce systeme empeche la pompe interne de s'abfmer.

Pompe - Developpe une pression 6levee Tuyau & haute pression (non illustr6) - Raccerdez une

Pompe d*amorqage - Prepare un moteur froid pour _e extremite du tuyau au pistolet de eulv_risation et I'autre &la

demarrage

sortie du netloyeur _ haute press_on.

27

Page 28

Vc_re nettoyeur _ haute pression exJge que quelque _mblee

et soit pt_,t pour I'usage apr_s il a et6 convenablemer_ entretenu

avec le petrole et le carburant recommandes.

Si vous avez des problf_*mes au cours de I'assemblage

de votre nettoyeur & haute pression ou si certaines

pi_ces sont manquantes ou endommagL_es, appelez la

ligne d'assistance pour les nettoyeur & haute pression

au 1-800-222-3136,

IMPORTANT: Tout essai de demarrer le moteur avant qu'il

ne soit correctement ravitaille en huile risque de provoquer

une panne de moteur.

DI BALLER LE NETTOYEUR A

HAUTE PRESSION DU CARTON

Ouvrez le carton et deceupez de haut en bas les deux

angles opposes _ la poignee, afin que le panneau se

replie _ plat.

Enlevez la sac de pieces, accessoires et insertions qui

accempagne le nettoyeur _ haute pression.

Faites rouler le nettoyeur _ haute pression par le c6te

ouvert du carton.

Verifiez si vous n'avez pas oublie de pieces

supplementaires dans le carton

CONTENU DU CARTON

Verifiez routes les pieces et accessoires du nettoyeur ,_haute

prassion. Si certaines des pieces enumerees ci-dessus sont

manquantes ou endommagees, appelez la ligne d'assistance

pour les nettoyeur _ haute pression au 1-800-222-3136.

Appareil principal

Tuyau _ haute pression

Pistolet pulverisateur

Rallonge de buse avec buse reglable

Turbo-lance

Por|e-accessolres

Huile & moteur

Sac de pieces (cempr_nant les pieces enumerees

ci-dessous)

Manuel d'utilisation

Fiche d'enregistrement

Familiarisez-vous avec chaque piece avant d'assembler le