Page 1

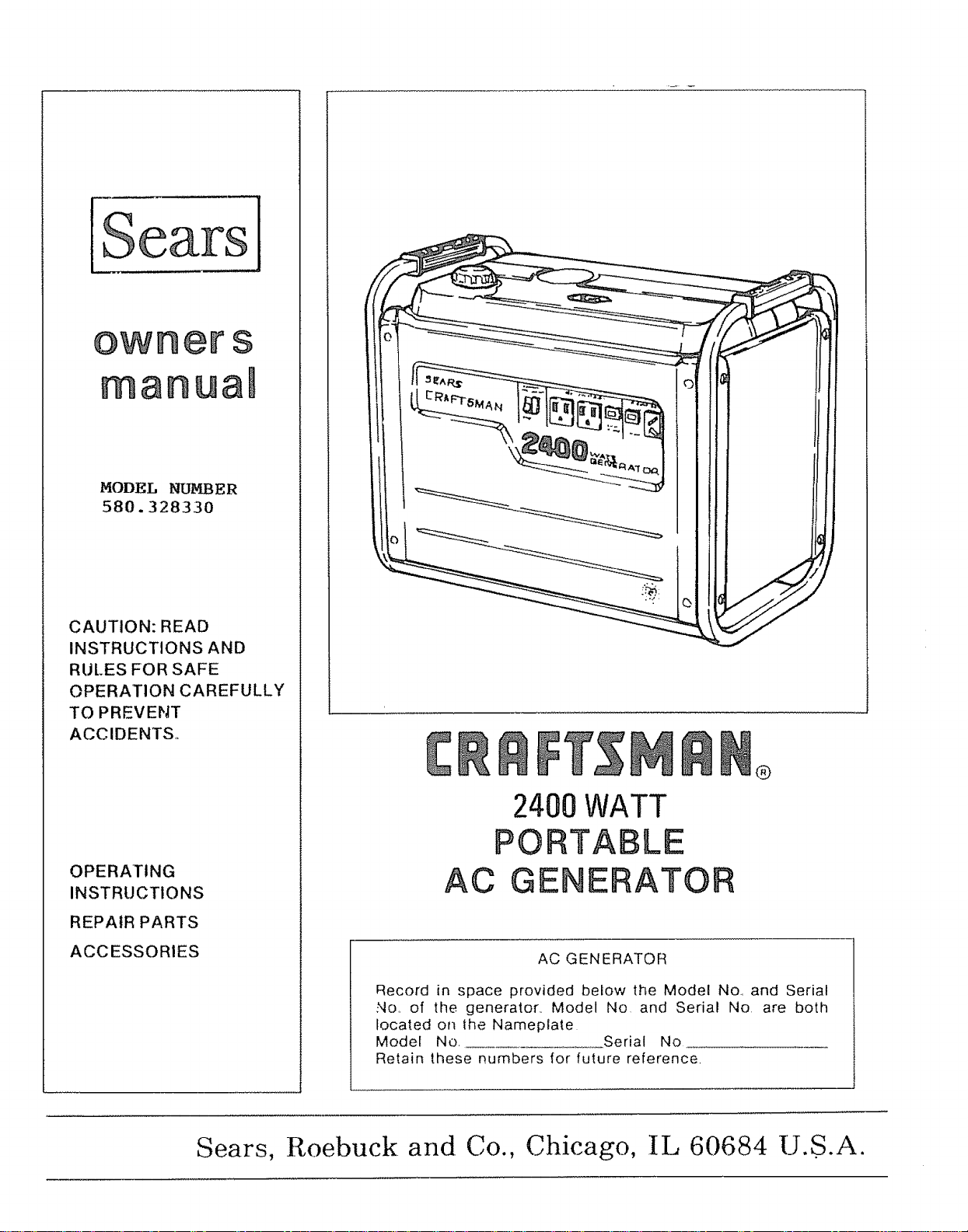

Sears

MODEL NUMBER

580.328330

CAUTION: READ

INSTRUCTIONS AND

RULES FOR SAFE

OPERATION CAREFULLY

TO PREVENT

ACCIDENTS,,

OPERATING

INSTRUCTIONS

REPAIR PARTS

ACCESSORIES

®

2400WATT

PORTABLE

AC GENERATOR

AC GENERATOR

Record in space provided below the Model No., and Serial

No, of the generator. Model No and Serial No are both

located on the Nameplate

Model No, Serial No

Retain these numbers for future reference.

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

Page 2

FULL ONE YEAR WARRANTY

For one year from the date of purchase, Sears will repair any defect in

material or workmanship in this Generator at no charge.

If the Generator is used for commercial or rental purposes, this warranty

applies for only ninety days from the date of purchase

Warranty service is available by RETURNING TO THE NEAREST SEARS

SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Sears, Roebuck and Co.

Dept. 698f731A

Chicago, tL 60684

RULES FOR SAFE OPERATION

i. Never permit any unqualified person- especially children- to oper-

ate this equipment. Equipment misuse, carelessness, improper

procedures, or incorrect application may result in personal injury or

damage to equipment and/or property.

2. Never handle any kind of electrical device while standing in water,

while barefoot, or while hands or feet are wet. Dangerous electrical

shock will result.

3. The engine that drives the generator consumes oxygen and gives off

deadly carbon monoxide gas through its exhaust system. This dangerous

gas, when breathed in sufficient concentrations, can cause unconsciou-

sness and even death, this equipment only in well ventilated

areas. Never operate this equipment in any room or enclosed space

where exhaust gases might accumulate and endanger people.

4. This equipment requires an adequate free flow of cooling air for

its operation. Without adequate cooling air flow, overheating and

resultant damage to equipment and/or property will result. Never

operate the generator inside any room or enclosure that might obstruct

the free flow of cooling air into and out of the unit.

5. Engines, engine exhaust mufflers and surrounding areas on this

equipment become extremely hot during operation and remain hot for

several minutes after shutdown. Avoid contact with these areas or

serious burns may result.

6. Gasoline is extremely flammable and its vapors are explosive. Do

not permit smoking, open flame, or sparks in the vicinity while

handling gasoline. Avoid spillage of gasoline on a hot engine. Never

fill the gas tank while the engine is running. Comply with all laws

regulating the storage and handling of gasoline.

'7. Never store this equipment indoors or in enclosed, poorly

ventilated enclosures with fuel in tank where gasoline fumes might

reach an open flame, spark or pilot light (as on a furnace, water

heater, clothes dryer, etc.).

8. In addition to these RULES FOR SAFE OPERATION, other SAFETY RULES

may apply. Practice safety at all times- by staying alert and by

reading the instructions in this Manual carefully.

Page 3

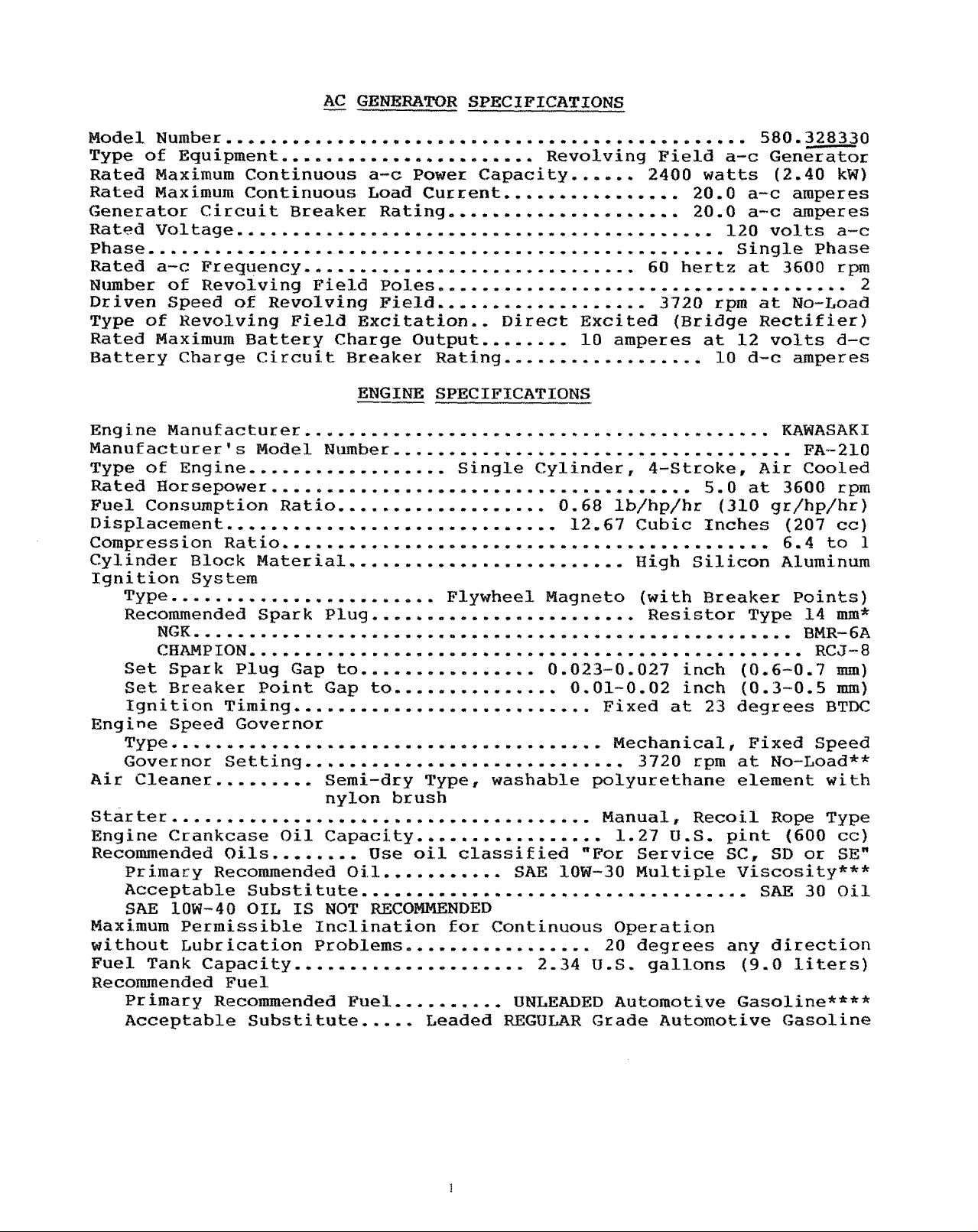

AC GENERATOR SPECIFICATIONS

Model Number ............................................... 580.328330

Type of Equipment ....................... Revolving Field a-c Generator

Rated Maximum Continuous a-c Power Capacity ...... 2400 watts (2.40 kW)

Rated Maximum Continuous Load Current ................ 20.0 a-c amperes

Generator Circuit Breaker Rating ..................... 20.0 a-c amperes

Rated Voltage ........................................... 120 volts a-c

Phase .................................................... Single Phase

Rated a-c Frequency .............................. 60 hertz at 3600 rpm

NL_ber of Revolving Field Poles ..................................... 2

Driven Speed of Revolving Field ................... 3720 rpm at No-Load

Type of Revolving Field Excitation.. Direct Excited (Bridge Rectifier)

Rated Maximum Battery Charge Output ........ i0 amperes at 12 volts d-c

Battery Charge Circuit Breaker Rating .................. 10 d-c amperes

ENGINE SPECIFICATIONS

Engine Manufacturer .......................................... KAWASAKI

Manufacturer's Model Number .................................... FA-210

Type of Engine .................. Single Cylinder, 4-Stroke, Air Cooled

Rated Horsepower ...................................... 5.0 at 3600 rpm

Fuel Consumption Ratio ................... 0.68 Ib/hp/hr (310 gr/hp/hr)

Displacement .............................. 12.67 Cubic Inches (207 cc)

Compression Ratio ............................................ 6.4 to 1

Cylinder Block Material ......................... High Silicon Aluminum

Ignition System

Type ........................ Flywheel Magneto (with Breaker Points)

Recommended Spark Plug ........................ Resistor Type 14 mm _

NGK ...................................................... BMR-6A

CHAMPION .................................................. RCJ-8

Set Spark Plug Gap to ................ 0.023-0.027 inch (0.6-0.7 mm)

Set Breaker Point Gap to ............... 0.01-0.02 inch (0.3-0.5 mm)

Ignition Timing ........................... Fixed at 23 degrees BTDC

Engine Speed Governor

Type ....................................... Mechanical, Fixed Speed

Governor Setting ............................. 3720 rpm at No-Load _

Air Cleaner ......... Semi-dry Type, washable polyurethane element with

ny!on brush

starter ...................................... Manual, Recoil Rope Type

Engine Crankcase Oil Capacity ................. 1.27 U.S. pint (600 cc)

Recommended Oils ........ Use oil classified "For Service SC, SD or SE"

Primary Recommended Oil ........... SAE 10W-30 Multiple Viscosity _

Acceptable Substitute ................................... SAE 30 Oil

SAE 10W-40 OIL IS NOT RECOMMENDED

Maximum Permissible Inclination for Continuous Operation

without Lubrication Problems ................. 20 degrees any direction

Fuel Tank Capacity ..................... 2.34 U.S. gallons (9.0 liters)

Recommended Fuel

Primary Recommended Fuel .......... UNLEADED Automotive Gasoline _e_

Acceptable Substitute ..... Leaded REGULAR Grade Automotive Gasoline

Page 4

Canada requires the use of RESISTOR spark plugs, in compliance

with the radio noise limitations (radio frequency interference)

order issued by the Ministry of Communications of the Canadian

Telecommunications Regulations Branch.

At 3720 rpm the generatorts a-c output will be 62 hertz. This

slightly high engine speed setting at no-load helps ensure that

engine speed (and a-c frequency) do not drop excessively when

heavier electrical loads are applied.

Use of a multiple viscosity oil will contribute to easier

starting in cold weather.

Use of UNLEADED gasoline in a 4-cycle engine contributes to in-

creased valve life by reducing lead and and carbon deposits. A

high quality REGULAR grade gasoline may be used, however, UN-

LEADED gasoline is the primary recommended fuel.

Page 5

SECTION 1 - GENERAL INFORMATION

1.1- INTRODUCTION

This OWNER'S _ANUAL has been prepared especially for the purpose of

familiarizing personnel with the handling, operation and servicing of

the applicable equipment. Study the Manual carefully and comply with

all instructions. This will help prevent possible injury or damage to

equipment and!or property, that might be caused by carelessness,

equipment misuse or abuse, improper procedures, or incorrect applica-

tion.

1.2- SAFETY

Prior to handling, operating or servicing this equipment, study the

ROLES FOR SAFE OPERATION at the front of this Manual carefully. All

ROLES must be complied with fully, to help avoid personal injury or

damage to equipment and/or property.

The following definitions apply to DANGER, CAUTION and NOTE blocks

found throuqhout this Manua!:-

DANGER!

Under this heading will be found handling, operating and servicing in-

structions that, if not complied with fully, may result in persona]

injury.

CAUTION!

Under this heading will be found handling, operating and servicing in-

structions that, if not complied with fully, may result in damage to

equipment.

NOTE

that require

Under this heading will

special emphasis.

be found explanatory statements

1.3- EQUIPMENT DESCRIPTION

This equipment is a gasoline engine-driven, revolving field a-c gener-

ator set. The generator may be used to operate 120 volts, single

phase, 60 hertz, a-c electrical devices requiring up to 2400 watts

(2.4 kW) of electrica! power or up to 20.0 a-c amperes of current. A

circuit breaker will open the unit's a-c output circuit if the current

requirements of connected electrical loads exceeds 20.0 a-c amperes.

The generator's revolving field (rotor) is directly attached to and

driven by a 4-cycle, air-cooled, gasoline engine. Engine speed with no

electrical loads connected to the generator is maintained at approxi-

mately 3720 rpm by a mechanical governor. Engine speed and generator

a-c output frequency are directly proportional. Thus, at 3600 rpm a-c

frequency will be 60 hertz; at 3720 rpm a-c frequency is 62 hertz. The

slightly high engine speed setting at no-load helps ensure that engine

speed (and a-c frequency) do not drop excessively under heavier elec-

trical loads.

Page 6

In addition to its a-c power capability, the generator may be used to

recharge a discharged 12 volts, automotive or utility type storage

battery. When properly connected to the discharged battery, an

operating generator will supply a maximum charge rate of approximately

i0 d-c amperes at 12 volts. The maximum rate of charge will gradually

decrease as the connected battery approaches a i00 percent state of

charge.

1.4- RECEIVING AND HANDLING

Upon receipt, completely remove the generator from its shipping carton

and from any shipping pallet to which it might be attached. Remove all

packing material from around the generator. Inspect the unit carefully

for any damage that might have occured during shipment.

In addition to this OWNERtS MANUAL a BATTERY CHARGE CABLE is shipped

with the generator. To order additional Manuals or Cables, refer to

the REPAIR PARTS section of the Manual.

CAUTION!

DO NOT to crank and start the generator engine until it has

been properly prepared for use, as outlined in Section 2 of this

Manual. Any attempt to crank or start the unit before it has been

properly serviced with the recommended oil will result in an engine

Page 7

SECTION 2 - OPERATING INSTRUCTIONS

DO AND DON'T CHART

i. DO comply with all SAFETY RULES.

i. DON'T operate the unit inside

any enclosure that might obstruct

the free flow of cooling air.

2. DO check oil level before start-

up or at least every 5 hours of op-

eration.

2. DON'T operate the unit inside

any room or enclosure where ex-

haust fumes might accumulate and

result in carbon monoxide poison-

iing.

3. DO disconnect electrical loads

from panel before

starting or stopping the engine.

3. DON'T overload the generator.

The total of all connected loads

should not exceed 2400 watts (2.4

kW), or 20.0 a-c amperes.

4. DO comply with instructions in

this Manual when charging a battery.

4. DON'T touch areas around the

engine exhaust muffler. These

areas are HOT.

5. DO operate the generator only on

surfaces that are as level as poss-

ible.

5. DON'T handle electrical

equipment while standing in

water, while barefoot, or while

hands or feet are wet.

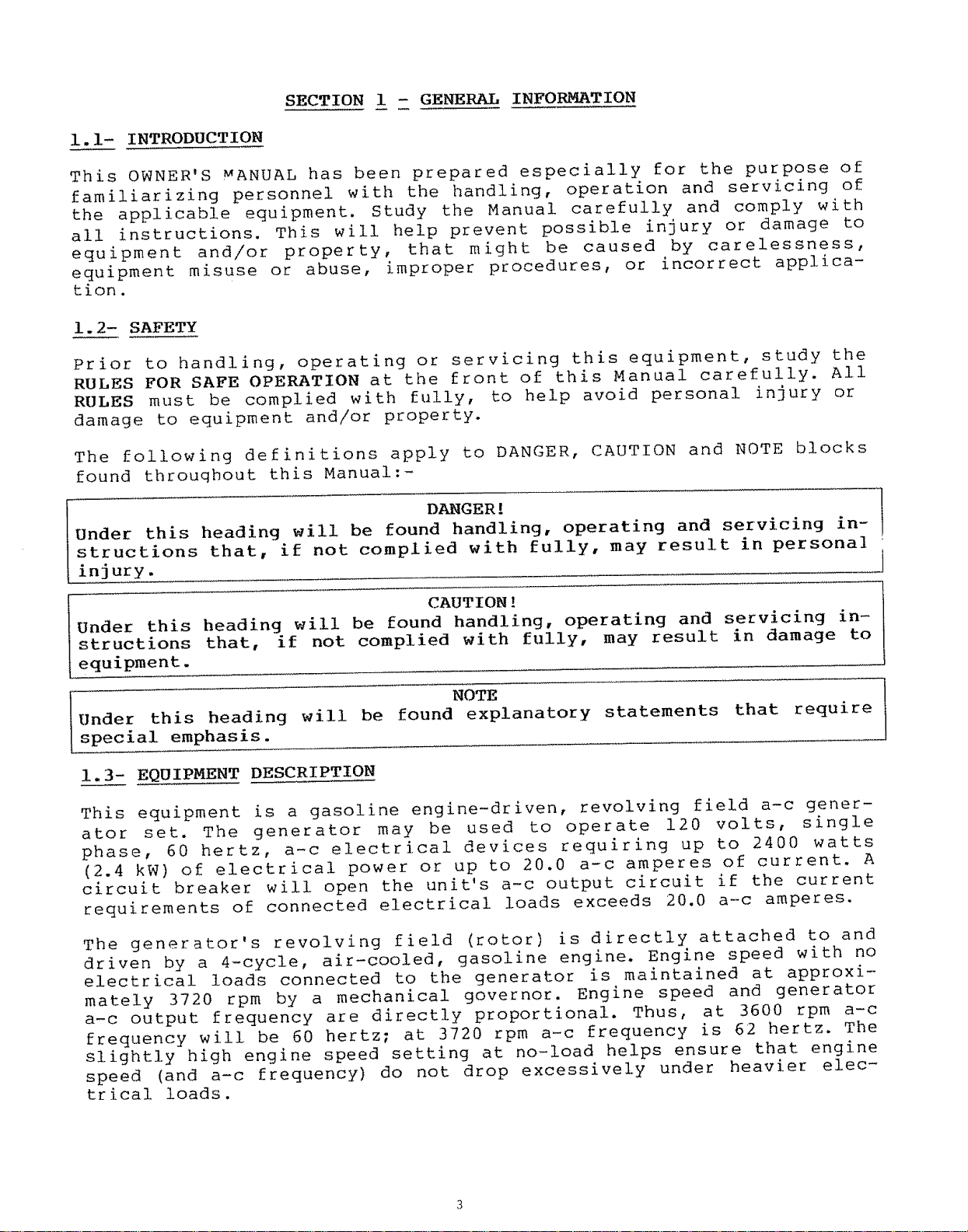

2.1- PI_PARATION BEFORE USE (Figure 2-1)

a. Check Enqine Oii Level (Figure 2-1):- Check oil level and (if

necessary) fill to proper level with the recommended oil as follows:-

(I) Place the generator on a level surface.

(2) Remove OIL FILL PLUG by turning counterclockwise.

(3) Check oil level. Oil should be at point of overflowing the 0IL

FILL PLUG opening. If necessary, add oil to that level. See

ENGINE SPECIFICATIONS CHART at front of Manual for recommended

oils and crankcase capacity.

(4) When oil is at proper level, install and tighten OIL FILL PLUG.

NOTE

The revolving field rotates on a pre-lubricated, sealed

bearing which requires no additional lubrication for the life of the

bearing.

OIL FIL_

PLUG _ _ _ _ .......... :_ ,

\

""_ OIL DRAIN

PLUG

Figure 2-1. Engine Oil Fill and Oil Drain Locations

Page 8

b. Fill Fuel Tank:- Remove Fuel Tank FILLER CAP by turning

counterclockwise. Fill Fuel Tank with clean, fresh gasoline as

recommended in the ENGINE SPECIFICATIONS CHART at front of Manua!.

Install and tighten FILLER CAP.

DANGER!

Gasoline is extremely FLAMMABLE and its vapors are EXPLOSIVE. DO NOT

permit smoking€ open flame or sparks in the vicinity while handling

gasoline. Avoid spillage of gasoline on a hot engine. Comply with all

laws regulating the storage and handling of gasoline. Never store the

generator with fuel in tank where gasoline vapors might reach an open

flame, spark or pilot light (such as on a furnace, water heater,

dryer, etc.)- FIRE or an EXPLOSION might result.

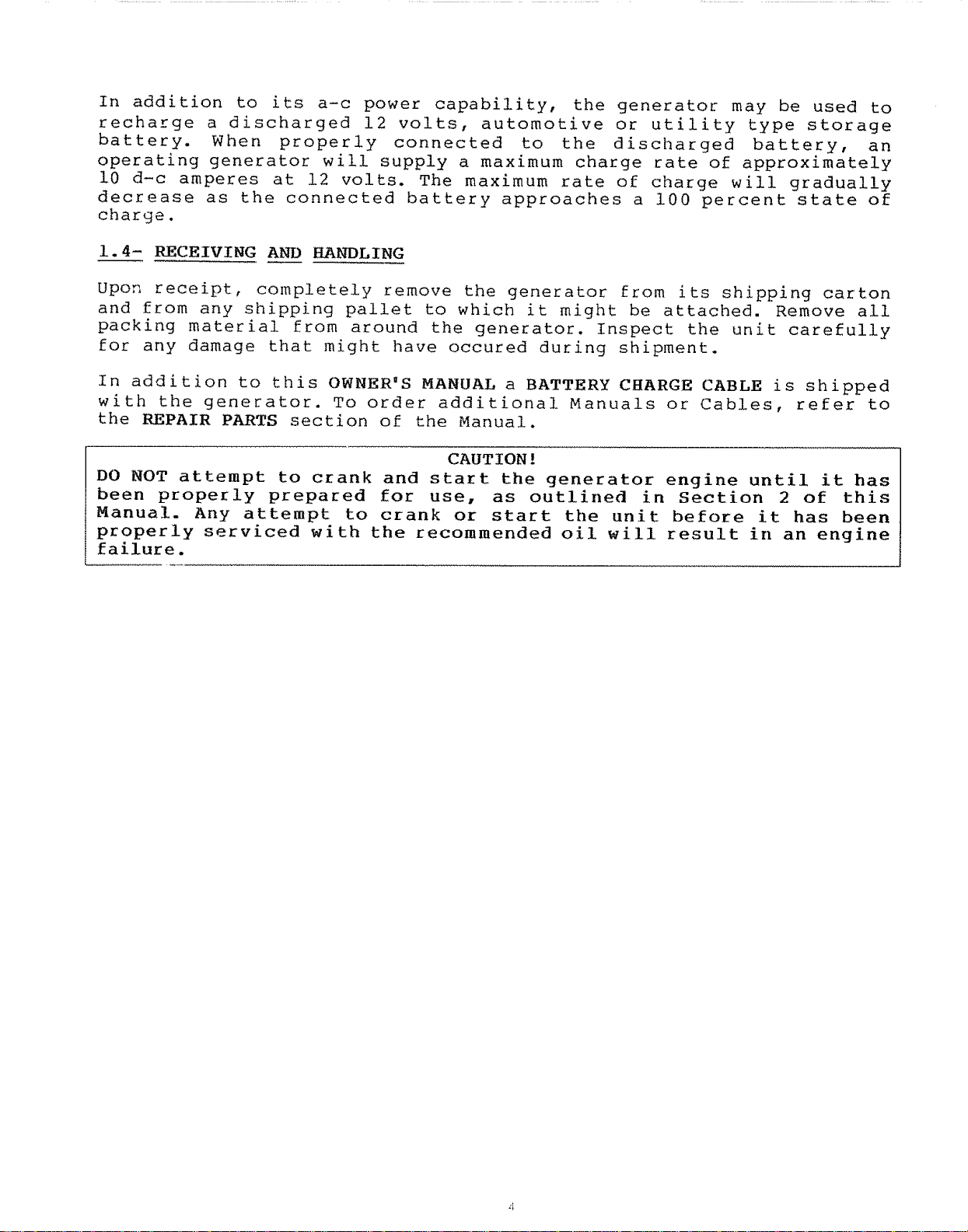

C. 120 Volts Cord Sets:- Use only high quality, well insulated,

grounded cord sets with the generator's 120 volts a-c receptacles.

Wire gauge of cord sets must be large enough to handle the maximum

anticipated current draw of connected electrical loads. Cord sets that

are excessively long or that are rated at too low an amperage will

cause a voltage drop and will overheat. Table 2-1 lists minimum

recommended wire gauges, based on the cord set length and the load

current draw in amperes.

COUNT

(AMPERES}

2-3

4-5

6

8

i0

12

14

16

18

2O

....LENGTH OF,,,..CORD SET IN FEET

0-50

18AWG ..........

16 AWG

16 AWG

16 AWG

16 AWG

14 AWG

14 AWG

12 AWG

12 AWG

I0 AWG

51-100

18 AWG

16 AWG

16 AWG

14 AWG

14 AWG

14 AWG

12 AWG

12 AWG

10 AWG

8 AWG

101-150

18 AWG

16 AWG

14 AWG

12 AWG

12 AWG

12 AWG

l0 AWG

l0 AWG

8 AWG

8 AWG

Table 2-1. Recommended Wire Gauges of 120 Volts Cord Sets

2.2- OPERATING LOCATION

Comply with the following rules pertaining to operating location of

the generator:-

a. Place the generator on a level surface. Maximum tilt of the engine

in any direction must not exceed 20 degrees, or engine lubricating

problems may result.

b. Never operate the generator where it will be exposed to flooding,

excessive moisture, dust, dirt or corrossive vapors.

c. Provide adequate ventilation. Never operate the generator inside

any room or enclosure where exhaust fumes might accumulate and

endanger people.

d. Never run the generator inside any room or enclosure that might ob-

struct the free flow of cooling air. Without adequate cooling air, the

unit will quickly overheat, causing serious operating problems and

possible damage to equipment and/or property.

Page 9

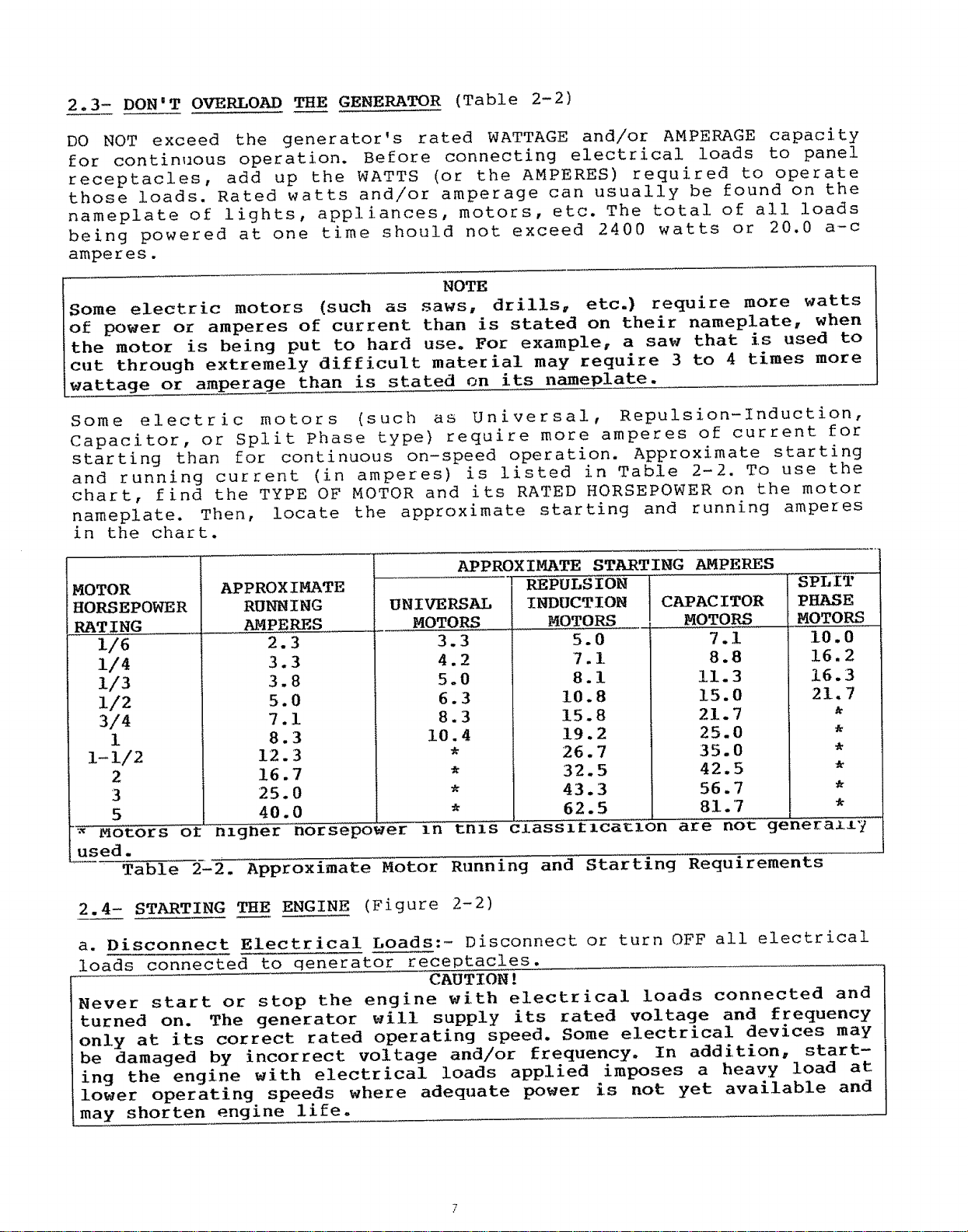

2.3- DON'T OVERLOAD THE GENERATOR (Table 2-2)

DO NOT exceed the generator's rated WATTAGE and/or AMPERAGE capacity

for continuous operation. Before connecting electrical loads to panel

receptacles, add up the WATTS (or the AMPERES) required to operate

those loads. Rated watts and/or amperage can usually be found on the

nameplate of lights, appliances, motors, etc. The total of all loads

being powered at one time should not exceed 2400 watts or 20.0 a-c

amperes.

NOTE

Some electric motors (such as saws, drills, etc.) require more watts

of power or amperes of current than is stated on their nameplate, when

the motor is being put to hard use. For example, a saw that is used to

cut through extremely difficult material may require 3 to 4 times more

wattage or amperage than is stated on its nameplate.

Some electric motors (such as Universal, Repulsion-Induction,

Capacitor, or Split Phase type) require more amperes of current for

starting than for continuous on-speed operation. Approximate starting

and running current (in amperes) is listed in Table 2-2. To use the

chart, find the TYPE OF MOTOR and its RATED HORSEPOWER on the motor

nameplate. Then, locate the approximate starting and running amperes

in the chart.

APPROXIMATE STARTING AMPERES

MOTOR

HORSEPOWER

RATING

1/6

1/4

1/3

1/2

3/4

1

i-1/2

2

3

5

APPROXIMATE

RUNNING

A_PERES

2.3

3.3

3.8

5.0

7.1

8.3

12.3

16.7

25.0

40.0

............ ,IREPULSION ......

UNIVERSAL I INDUCTION CAPACITOR

.........MOTORS I MOTORS ........._MOTORS

3.3

4.2

5_0

6.3

8.3

10.4

e

5.0

7.1

8.1

10.8

15.8

19.2

26.7

32.5

43.3

62.5

ii. 3

15.0

21.7

25.0

35.0

42.5

56.7

81.7

7.1

8.8

SPLIT

PHASE

MOTORS

I0.0

16.2

16.3

21.7

k

"_ Motors ot nlgner norsepower in tnls c±assltlcatlon are not generali?

used.

Table Approximate Motor Running and Starting Requirements

2.4- STARTING THE ENGINE (Figure 2-2)

a. Disconnect Electrical Loads:- Disconnect or turn OFF all electrical

loads connected to generator receptacles.

CAUTION!

Never start or stop the engine with electrical loads connected and

turned on. The generator will supply its rated voltage and frequency

only at its correct rated operating speed. Some electrical devices may

be damaged by incorrect voltage and/or frequency. In addition, start-

ing the engine with electrical loads applied imposes a heavy load at

lower operating speeds where adequate power is not yet available and

may shorten engine lifeo

Page 10

b. Close the Choke:- Rotate the CHOKE CONTROL to its FULL CHOKE posi-

tion. Lesser amounts of choking may be required when starting a warm

engine.

c. Set Switch to RUN:- Set the Engine-Run/Stop Switch to its RUN

position.

d. Crank Engine:- Grasp the recoil starter handle with one hand while

holding the generator carrying handle with other hand. Pull the

starter handle out rapidly to overcome compression and prevent

"kickback". Repeat, if necessary, with Choke opened slightly. When

engine starts, open the Choke gradually.

e. Let the engine stabilize and warm up for a few minutes.

f. Check that the AC ON light is illuminated. Then connect and turn ON

the desired electrica! load(s). DO NOT OVERLOAD THE GENERATOR- SEE

PARAGRAPH 2.3.

A. CLOSE THE CHOKE

ENGINE RUN/

B. SET ENGINE SWITCH TO "ON _

SWITCH

START£Ft HANDLE

C. CRANK ENGINE

Figure 2-2. Starting the Engine

2.5- STOPPING THE ENGINE

a. Disconnect (or turn OFF) all electrical loads connected to

generator receptacles.

b. Let the engine run for a minute or two at no-load, to cool.

c. Set the Engine-Run/Stop Switch to STOP position, wait for the

engine to come to a complete stop.

I

i

2.6- CHARGING A BATTERY (Figure 2-3)

This equipment has battery charging capability, may be used to

recharge a discharged 12 volts, automotive or utility type storage

battery. Te recharge a 12 volts battery, proceed as follows:-

CAOTION!

DO NOT attempt to recharge any 6 volts battery using the generatorWs

battery charge system. DO NOT attempt to crank an engine having a

discharged battery. Either of the preceding may result in damage to

equipment.

Page 11

a. Remove battery vent caps. Check that vent cap holes are not

clogged. If necessary, use a length of fine wire to open holes in

caps. Then, install vent caps onto battery.

DANGER!

Storage batteries give off EXPLOSIWE hydrogen gas while charging. DO

NOT permit smoking, open flames, sparks, or spark producing equipment

in the vicinity while charging a battery. NEVER use a match, lighter,

or any other source of heat to provide lighting while checking battery

fluid level. The danger of explosion is greatly diminished if battery

vent caps are installed while charging.

b. Check electrolyte fluid level in all battery cells, if necessary,

add DISTILLED WATER to bring fluid to the correct level. DO NOT OSE

TAP WATER.

DANGER!

Battery electrolyte fluid is an extremely caustic sulfuric acid

solution that can cause severe burns. DO NOT permit fluid to contact

eyes, skin, clothing, painted surfaces, wiring insulation, etc. If

spillage occurs, flush the affected area with clear water immediately.

c. Insert the 2-prong plug of the Battery Charge Cable (shipped with

unit) into the generator panel receptacle indicated by the words _12

VOLT D.C.".

d. Connect the Battery Charge Cable clamp with RED handle to the

battery post or terminal indicated by a POSITIVE, POS or "+".

e. Connect the Battery Charge Cable clamp with BLACK handle to the

battery post or terminal indicated by a NEGATIVE, NEG or "-".

f. Start the generator engine. The discharged battery will receive a

maximum charge of up to I0 d-c amperes. This maximum charge rate will

reduce as the battery approaches a i00 percent state of charge.

g. When the battery has recharged, shut the generator engine down.

Then, disconnect the Battery Charge cable from the panel receptacle

and from the battery posts or terminals.

t

_ RED

Figure 2-3. Charging a Battery

Page 12

2.7- DETERMINING BATTERY STATE OF CHARGE AND CONDITION

Use an automotive type BATTERY HYDROMETER to determine battery STATE

OF CHARGE and CONDITION. Follow the hydrometer manufacturer's instruc-

tions carefully.

Batter_rl State of Charge:- Check the specific gravity of electrolyte

fluid in al! battery cells. Write down the reading of each cell as it

is taken, then return the fluid to the cell from which it was

withdrawn. When the specific gravity of the fluid in all cells is

known, calculate the average specific gravity. If the hydrometer does

not have a percentage of charge scale, compare the average reading ob-

tained with the following:-

SPECIFIC GRAVITY PERCENT OF CHARGE

1.260 100%

1.230 75%

1.200 50%

1.170 25%

If necessary, recharge the battery to a 100% STATE OF CHARGE.

EXAMPLE:- Readings obtained are 1.230; 1.220; 1.230; 1.210; 1.225;

1.230. Sum of all readings is 7.345. Divide by 6 to obtain the average

of 1.224. The battery is less than 75% charged.

Determininq Battery Condition:- If the difference in specific gravity

_-etween the highest and lowest reading cell is 0.050 (50 points) or

more, the battery is nearing the end of its useful life and should be

replaced. However, if the specific gravity of the highest reading cell

is less than 1.200, the test for condition is questionable. Recharge

the battery and repeat the test.

EXAMPLE:- Specific gravity readings are 1.230; 1.220; 1.230; 1.210;

1.225; 1.230. Battery condition is good. If readings are 1.250; 1.180;

1.240; 1.240; 1.240; 1.210- battery is worn out.

10

Page 13

SECTION 3 - PERIODIC MAINTENANCE

HOU_Y OPERATING INTERVAL

BEFORE

MAINTENANCE TASK USE

AFTER FIRST EVERY EVERY EVERY

20 HOURS 50 _ i00 _ 200 .....OTHER ......

ii. check 0il level X

2. Change Enqine Oil

3. Service Air Cleaner _ _

14, Clean FuelIIIscreen .................

5. Decarbonize Muffler

i71DeC'arb0nize Engine*

8. Reface Valves*

:9. Check Valve

Clearance*

X X

X

x

X

X

x

X

X

I ....

10. Prepare for

Storage

x

Tasks indicated by a single asterisk (_) should be accomplished by

a qualified engine service technician.

** Prepare unit for storage if it is to remain idle longer than 30

days.

Table 3-1. Periodic Maintenance Chart

3.1- CHECK ENGINE OIL LEVEL

Check engine crankcase oil level prior to each use, or at least every

5 hours of operation. See Paragraph 2.1.

3.2- CHANGE ENGINE OIL (Figure 3-1)

Drain crankcase completely and refill with clean, fresh oil after the

first 20 hours of operation, every i00 operating hours thereafter, as

follows:-

a. Operate engine until thoroughly warmed up, then shut down

______ lllJ

il!/

OIL FILL--J)" _ 11II

--OIL DRAIN

PLUG

Figure 3-1. Engine OIL FILL and OIL DRAIN PLUGS

Page 14

b. Clean areas around O!L FILL and OIL DRAIN PLUGS, to prevent dirt

from entering engine.

c. Remove OIL FILL PLUG.

d. Remove OIL DRAIN PLUG and drain oil completely into a suitable

container.

e. When al! oil has drained, install OIL DRAIN PLUG. Tighten to !0

foot-pounds (1.4 kg-m).

f. Refill with recommended oi! through the OIL FILL PLUG opening. Pour

slowly. Oil level is correct when oil reaches point of overflowing the

OIL FILL PLUG opening. See ENGINE SPECIFICATIONS CHART at front of

Manual for recommended oils.

g. Install and tighten OIL FILL PLUG.

3.3- SERVICE AIR CLEANER (Figure 3-2, 3-3)

Service the engine air cleaner every 50 hours of operation, more

frequently if operating under extremely dirty or dusty conditions. To

service the air cleaner, proceed as follows:-

COVER

.................i

Fire 3-2. Remove End Panel

a. Remove 4 screws that retain END PANEL to cradle, then remove END

PANEL.

b. Unsnap the LATCH, then remove COVER, ELEMENT and PLATE.

c. Wash ELEMENT in kerosene. Squeeze dry.

d. Saturate ELEMENT in clean, fresh engine oil. Squeeze to distribute

oil and to remove excess oil.

e. Wash PLATE in kerosene, dry with a clean, lint-free cloth.

f. Install PLATE.

g. Install ELEMENT with nylon "brushes" facing outward.

h. Engage slot on COVER with tang on air cleaner CASE, install COVER

and retain with LATCH.

Figure 3-3. Air Cleaner Assembly

12

Page 15

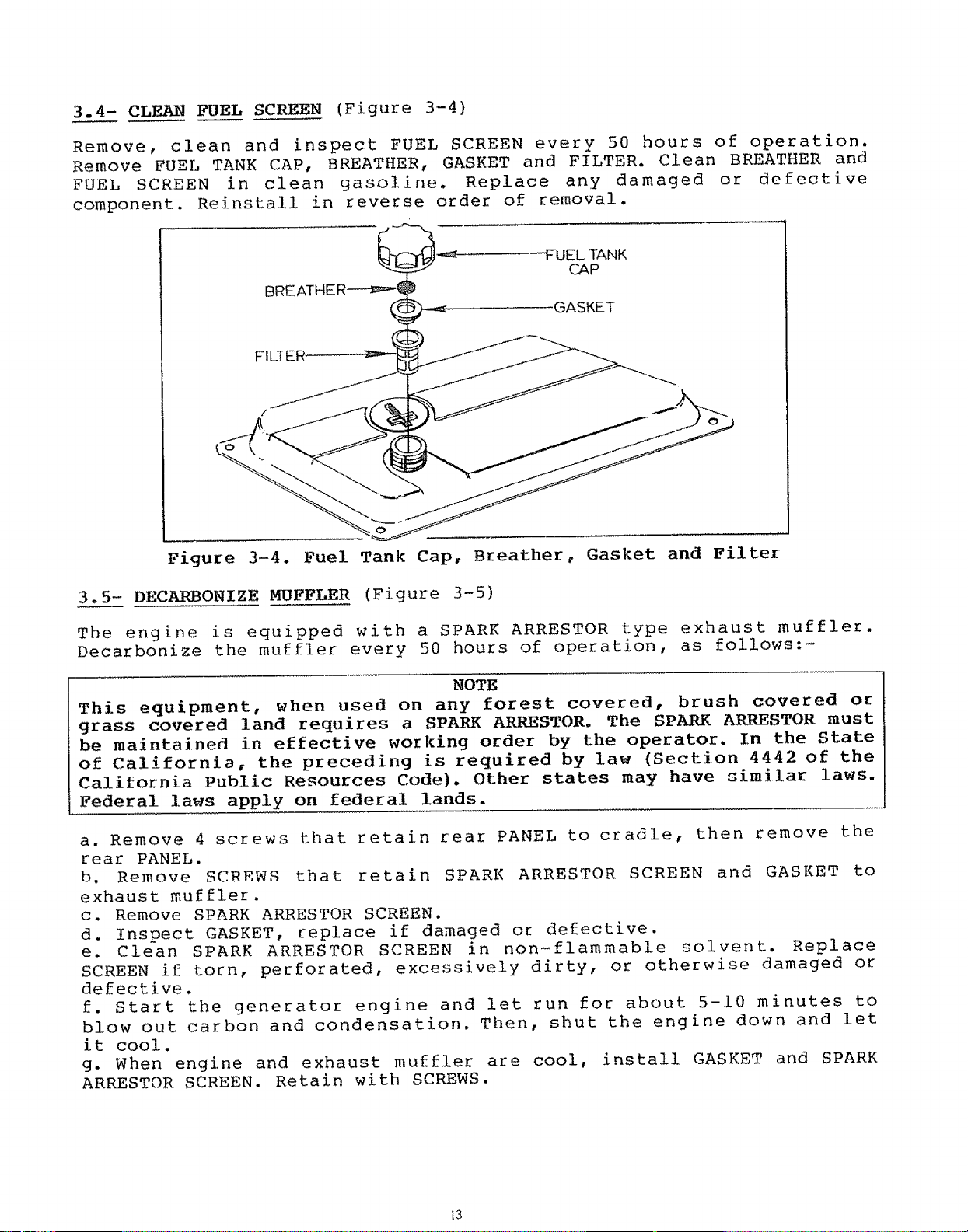

3.4- CLEAN FUEL SCREEN (F ig ur e 3- 4 )

Remove, clean and inspect FUEL SCREEN every 50 hours of operation.

Remove FUEL TANK CAP, BREATHER, GASKET and FILTER. Clean BREATHER and

FUEL SCREEN in clean gasoline. Replace any damaged or defective

component. Reinstall in reverse order of removal.

....... ----FUEL TANK

CAP

BREATHE

GASKET

FILTE

/

Figure 3-4. Fuel Tank Cap, Breather, Gasket and Filter

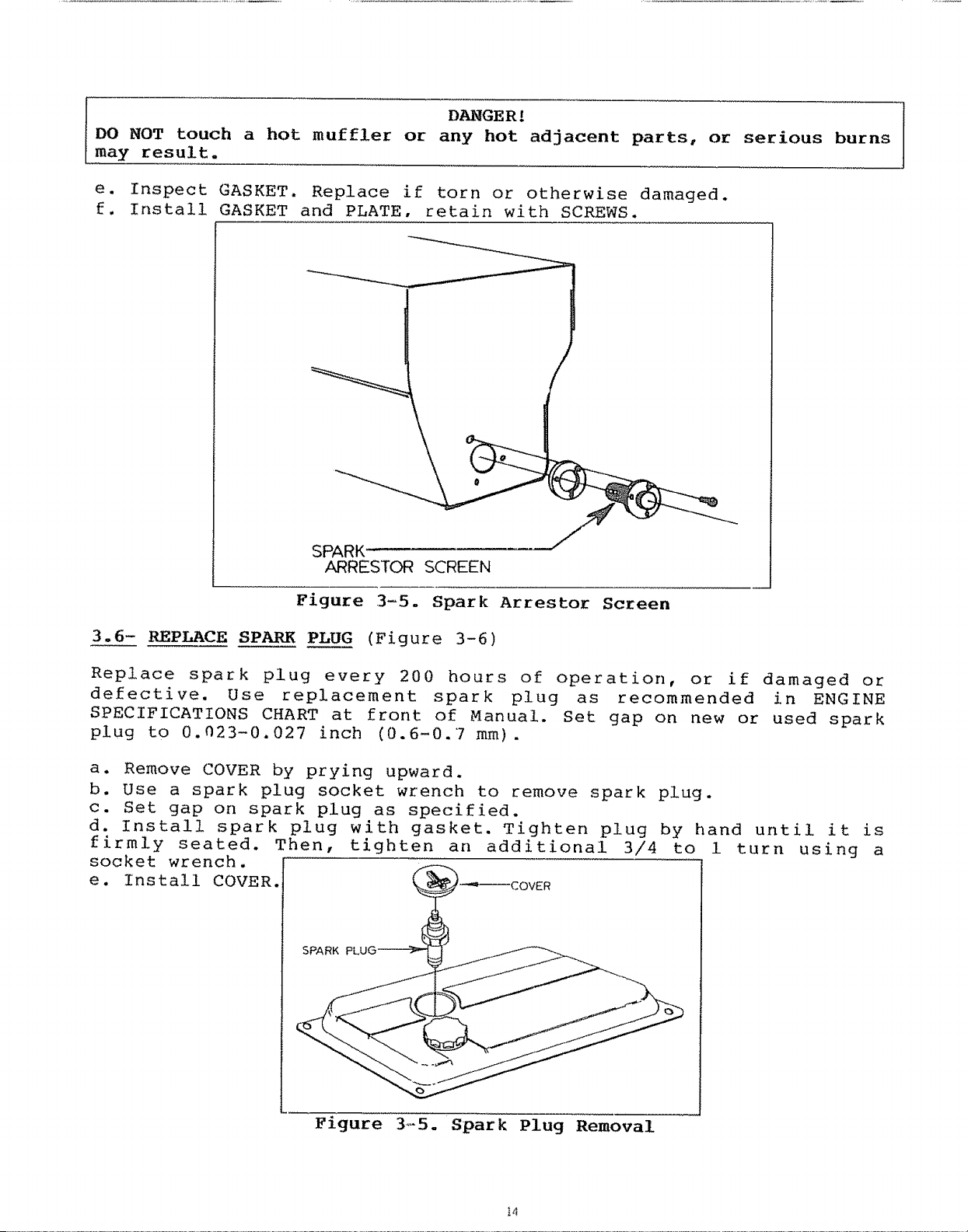

3.5- DECARBONIZE MUFFLER (Figure 3-5)

The engine is equipped with a SPARK ARRESTOR type exhaust muffler.

Decarbonize the muffler every 50 hours of operation, as follows:-

NOTE

This equipment, when used on any forest covered, brush covered or

grass covered land requires a SPARK ARRESTOR. The SPARK A_RESTOR must

be maintained in effective working order by the operator. In the State

of California, the preceding is required by law (Section 4442 of the

California Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

a. Remove 4 screws that retain rear PANEL to cradle, then remove the

rear PANEL.

b. Remove SCREWS that retain SPARK ARRESTOR SCREEN and GASKET to

exhaust muffler.

c. Remove SPARK ARRESTOR SCREEN.

d. Inspect GASKET, replace if damaged or defective.

e. Clean SPARK ARRESTOR SCREEN in non-flammable solvent. Replace

SCREEN if torn, perforated, excessively dirty, or otherwise damaged or

defective.

f. Start the generator engine and let run for about 5-10 minutes to

blow out carbon and condensation. Then, shut the engine down and let

it cool.

g. When engine and exhaust muffler are cool, install GASKET and SPARK

ARRESTOR SCREEN. Retain with SCREWS.

13

Page 16

DANGER!

DO NOT touch a hot muffler or any hot adjacent parts, or serious burns

may result.

e. Inspect GASKET. Replace if torn or otherwise damaged.

f. Install GASKET and PLATE, retain with SCREWS.

SPARK-

ARRESTOR SCREEN

Figure .3-5. Spark Arrestor Screen

3.6- REPLACE SPARK PLUG (Figure 3-6)

Replace spark plug every 200 hours of operation, or if damaged or

defective. Use replacement spark plug as recommended in ENGINE

SPECIFICATIONS CHART at front of Manual. Set gap on new or used spark

plug to 0.023-0.027 inch (0.6-0.7 mm).

a. Remove COVER by prying upward.

b. Use a spark plug socket wrench to remove spark plug.

c. Set gap on spark plug as specified.

d. Install spark plug with gasket. Tighten plug by hand until it is

firmly seated. Then, tighten an additional 3/4 to 1 turn using a

socket wrench.

e. Instal! COVER. __cov£R

S_RK

Figure 3-5. Spark Plug Removal

14

Page 17

3.7- DECARBONIZE ENGINE, REFACE VALVES, CHECK VALVE CLF/%RANCE

Have the carbon cleaned from the engine combustion area (cylinder

head, valves, piston) every i00 hours of operation. At the same time,

have the valves refaced and adjusted by an engine service technician.

3.8- PREPAP_ UNIT FOR STORAGE

If the unit is to be unused for longer than 30 days, prepare it for

storage as follows:-

a. Operate the engine until it runs out of gas.

b. Let the engine cool.

c. When engine has cooled, remove spark plug (see Paragraph 3.6).

Then, pour about 2 or 3 tablespoons of clean, fresh engine oil into

spark plug opening in engine cylinder head. Crank engine several times

to distribute oil.

d. Install spark plug and spark plug access cover.

e. Slowly pull starter handle out until resistance is felt, indicating

that engine is on its compression stroke. This will close both valves,

to prevent rusting of the cylinder interior.

f. Wipe exterior surface of engine and generator with an oil-soaked

cloth.

g. Cover the generator and store in a clean, dry place.

_5

Page 18

................_ BRIDGE

DIODEI

POWER _A,$ooYL

...... 1

WI_.ING DfAG RAiv_

T'3;, tG,,_..a_.mi C,'_.3

©

F.,,_

G_EEN ©

TO TANK. _.OUKt"_IA,fG

\

IGN._o--_ + _

@

BRIDGE

®

RECTIFIER

0

@

ba

Page 19

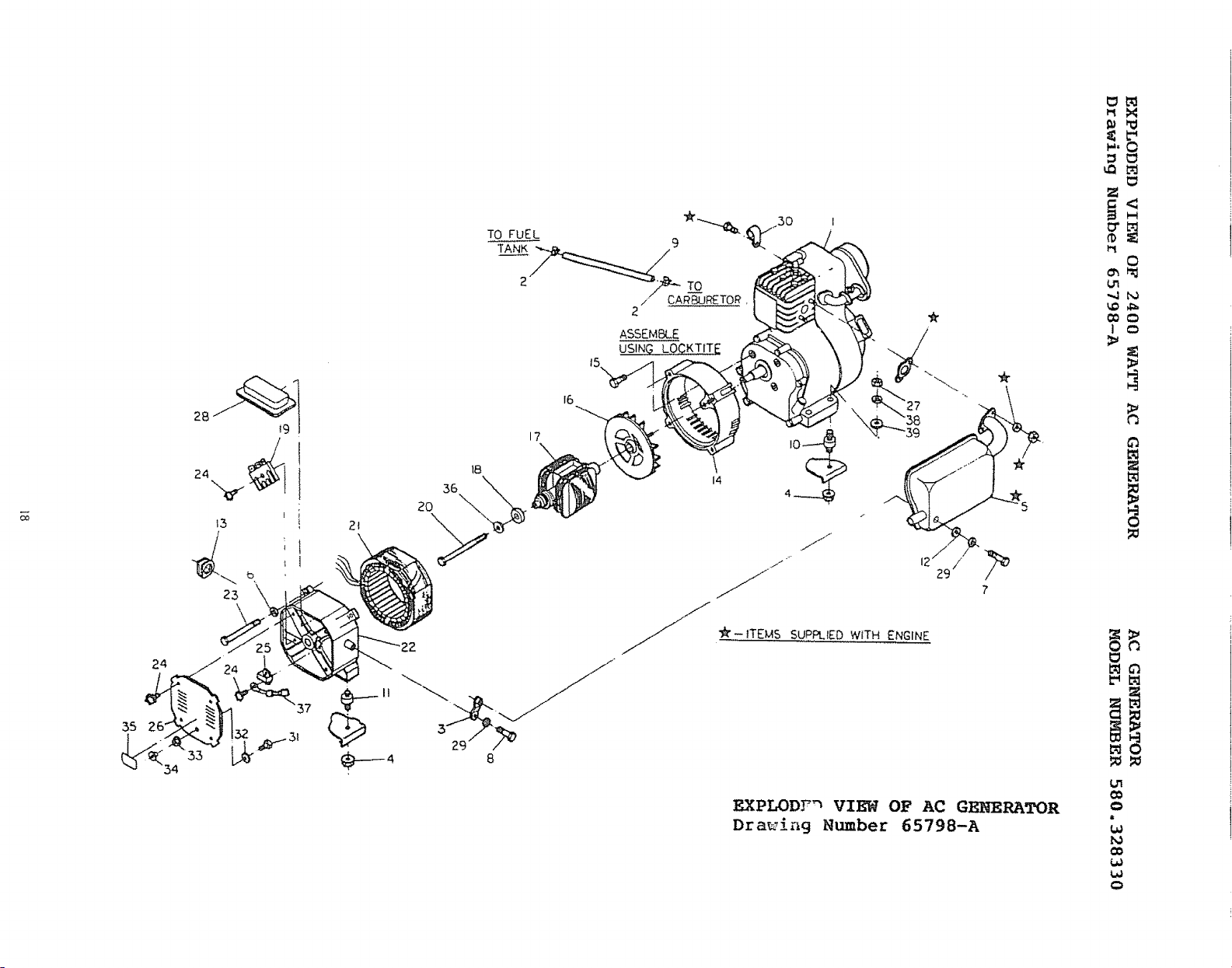

2400 WATT

PORTABLE

AC GENERATOR

MODEL NUMBER 580.328330

®

I7

Page 20

16

ASSEMBLE

USING LOCKT!TE

15\

-A"

u_

_N

tm

,_ItJ

X

H

o

17

2O

2t

f

J

?

_ 3_r-ITEMS SUPPLIED WITH ENGINE

8

EXPLODFn VIEW OF AC GENERATOR

Dra_ing Nnmber 65798-A

_n

O

i

w

_u

ffl

0

o

Page 21

EXPLODED VIEW OF AC GENERATOR

Drawing Numbe[ 65798-A

ITF_/_ PART NUMBER

1 65188

2 66836

3 66462

4 66834

5 66432

6 22097

7 52243

8 51755

9 66837

I0 66443A

ii 66443B

12 49809

13 67022

]4 66365

15 39253

16 66389

17 65785

18 65791

19 65795

20 66448B

21 66454

22 66825

23 66449B

24 66849

25 66386

26 67025

27 45771

28 66850

29 46526

30 66894

31 49815

32 67444

33 52856

34 67435

35 67210

36 67451

37 6'7462

38 22129

39 49810

DESCRIPTION

ENGINE- 5 Horsepower Kawasaki- FA210 (i Req'd)

CLAMP, Fuel Line (2 Req'd)

BRACKET, Muffler Support (I Req'd)

NUT, Flanged Lock- M8-!.25 (4 Req'd)

MUFFLER, Spark Arrest (i Req'd)

WASHER, Lock- M6 (4 Req'd)

CAPSCREW, Hex Head- MI0-1.50 x 60mm (I Req'd)

CAPSCREW, Hex Head- M10-1.50 x 16mm (I Req'd)

HOSE, Fuel- 300mm long (I Req'd)

MOUNT, Vibration- Engine (2 Req'd)

MOUNT, Vibration- Generator (2 Req'd)

WASHER, Flat- MI0 (i Req'd)

GROMMET, Lead Outlet (i Req'd)

HOUSING, Engine Adapter (i Req'd)

CAPSCREW, Hex Head- M8-1.25 x 20mm (4 Req'd)

FAN, Cooling (i Req'd)

ROTOR ASSEMBLY (! Req'd)

BEARING, Ball (i Req'd)

RECTIFIER, Battery Charge (i Req'd)

BOLT, Rotor- M8-!.25 x 190mm (i Req'd)

STATOR ASSEMBLY (i Req'd)

CARRIER, Rear Bearing (I Req'd)

BOLT, Stator- M6-1.00 x 90mm (4 Req'd)

SCREW (Taptite)- M5-0.80 x 15mm (7 Req'd)

ASSEMBLY, Brush (i Req'd)

COVER, Bearing Carrier (i Req'd)

NUT, Hex- M8-1.25 (2 Req'd)

BOARD, Bridge Rectifier (i Req'd)

WASHER, Lock- MI0 (2 Req'd)

CLAMP, Fuel Line Support (i Req'd)

SCREW, Machine- M5-0.80 (i Req'd)

WASHER, Serrated- M5 (I Req'd)

NUT, Flanged Lock- M5-0.80 (i Req'd)

NUT, Wing- M5-0.80 (i Req'd)

DECAL- Ground (i Req'd)

WASHER, Flat (Special)- M8 (i Req'd)

DIODE ASSEMBLY (i Req'd)

WASHER, Lock- M8 (2 Req'd)

WASHER, Flat- M8 (2 Req'd)

19

Page 22

26

28

_H

M

0

\

33

..4¢3

4O

3(

14

0

29

41

21

lm

o

i

w

Page 23

EXPLODED VIEW OF CRADLE- 2400 WATT GENERATORS (Sears 580.328330)

Drawing Number 65799-A

ITEM PART NUMBER

1 66394

2 66456

3 66457

4 66453

5 66455

6 66817

7 66818

8 66819

9 66820

i0 66821

ii 66822

12 66828

13 6682'7

14 66450

15 66368

16A 66802A

16B 66802B

16C 66802C

17 64680B

18 66391-B

19 65787

20 65788

21 66392

22 66393

23 66397D

24 66829

25 66823

26 66824

27 66398C

28 67103

29 67459

30 66831

31 66864

32 66838

33 66880

34 66839

35 52749

36 52619

37 67444

38 51716

39 66395-21

40*

41"

42*

++ 66832A

DESCRIPTION

BASE, Engine Cradle (i Req'd)

PANEL- Engine End (i Req'd)

PANEL, Muffler (i Req'd)

PANEL, Generator End (I Req'd)

PANEL, Receptacle and Control (i Req'd)

SWITCH, Engine-Run/Stop (i Req'd)

RECEPTACLE- 120 Volts a-c, 15 Ampere (2 Req'd)

BREAKER, Circuit- 20 a-c Amperes (i Req'd)

BREAKER, Circuit- i0 d-c Amperes (i Req'd)

RECEPTACLE- 12 Volts d-c (I Req'd)

RETAINER, 12 Volts d-c Receptacle (i Req'd)

SCREW, Machine- M3-0.50 x 5mm (2 Req'd)

SCREW, Machine (with Lock Washer)- M5-0.80 x 12mm

(25 Req'd)

COVER, Handle (4 Req'd)

TANK, Fuel- 2.34 U.S. Gallons (i Req'd)

CAP, Fuel Tank (i Req'd)

BREATHER, Fue! Tank (i Req'd)

GASKET, Fuel Tank Cap (i Req'd)

COVER, Spark Plug Access (i Req'd)

INDICATOR, Fuel Level (I Req'd)

CABLE, Battery Charge (i Req'd)

DECAL, Receptacle and Control Panel (i Req'd)

CRADLE, Engine End (i Req'd)

CRADLE, Generator End (I Req'd)

PLATE, Data (i Req'd)

RIVET- 3 mm (2 Req'd)

DECAL, Choke (I Req'd)

DECAL- Hot Caution (i Req'd)

DECAL- Starting Data (i Req'd)

DECAL- Warranty (i Req'd)

SCREW (Crimptite)- (8 Req'd)

RIVET, Black Anodized- 4mm (8 Req'd)

DECAL- U.S.D.A. (i Req'd)

FILTER, Fuel (I Req'd)

SHIELD, Fuel Tank Heat (l Req'd)

NUT, Hex Lock- M5-0.80 (6 Req'd)

SCREW, Machine- M5-0.80 x 12 mm (2 Req'd)

SCREW, Machine- M5-0.80 x 20mm (I Req'd)

WASHER, Serrated- M5 (i Req'd)

NUT, Hex - M5-0.80 (i Req'd)

WIRE, Ground (Green)- (i Req'd)

DECAL- Unleaded Fuel

DECAL- Air Cleaner

DECAL- Lubrication

MANUAL, Owner's (i Req'd)

* These Parts Supplied with Engine

++ NOT SHOWN

21

Page 24

55--_

57--_b

s6- D

64

6O

99

t05

103

I10

i'-

m

<

m

o

-1-t

m

x

78 77

76

8O

79 87

79 88

44

59

46

5O

t3 7

35

65

36

\

53

47

48

49

52

5i

22

21

I6

23

82

8!

74

I

i8

i7

2O

Page 25

EXPLODED VIEW OF KAWASAKI 5 HORSEPOWER

ENGINE

ITEM PART NUMBER DESCRIPTION

I 100-65188 HEAD,Cylinder

2 t01.65188 GASKET. Cylinder Head

3 102o65188 BOLT (8 x 56)

4 103-65188 COVE R .ValveC hamber

5 104-65188 GASKET

6 t05-65188 BOLT 16 x t2)

7 106-65188 CLEANER ASSEMBLY Air

8 t07,65188 COVE R, Air Cleaner

9 108.65188 ELEMENT

10 109-65 ] 8B PLATE Air Cleaner

t 1 110,65188 CASE. Air Cleaner

12 11 t_65188 BOLT (6 x 80)

13 112-65188 GASKET

14 ] t 3,65188 TUBE ,Rubber

15 114.65188 PIPE

16 66432 MUFF LE R. E×hau51. (Comptele)

17 116-65188 AR REST E R .SPark

18 116-65188 GASKET

19 117-65188 SCREW

20 118-65188 WASHER

2! t 19-65!88 GASKET

22 120-65188 STUD

23 121-65188 NUT (8 nlrn)

24 122-65188 WASHE R

25 t23-65188 VALVE Intakc _

26 124-65188 VALVE Exhaust

27 125-65188 SPRING.Valve

28 126-65188 SEAT Valve S!::,rir_!l

29 127-65188 TAPPET

30 128.65188 CAM SHA F T

31 129-65188 PISTON (Standard)

130,65188 PISTON 10 25ram OS)

131,65188 PISTON (0 50ram OS}

32 132-65 ! 88 SET. Piston Ring (Slandard)

133-65188 SET Piston Ring{O25mmOS)

134-65188 SET Piston Ring (0 50ram OS)

33 135_65 t 88 Pf N. P ist_m

34 136-65t88 RING Snap

35 137-65188 CR AN K SHAFT

36 138,65188 ROD ASSEMBL Y Connecting

37 !39-65188 BOLT Connecting Rod

38 140,65188 WASHER Lock

39 14 1-65188 ARM Splasher

40 142-65t88 CASE ASSEMBLY Connecting

41 143-65188 BEARING plain

42 144,65188 GASKET

43 t45,65188 BOLT (10 x t4}

44 !46-65188 SEAL.Oil

45 147.66188 Pt N.Dowel

46 148-65188 CA R BU R ETO R

47 149,65 _88 i NSU LATOR

48 150-65188 PIPE. Inlet

49 151-65t 88 GAS K E T

50 152-65188 GASK ET

51 153o65!88 NUT 16 ram)

52 154-65188 WASH E R

53 155.65188 STUD

54 66391B GAUGE. Fuel Level

55 66802A CAP Fuel Tank

ITEM

56

57

58

59

60

61

62

63

64

65

66

67

68

69

7O

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

t03

104

105

106

!07

108

t09

110

t11

1t2

t13

PART NUMBER

66802C

668028

156-65188

157-65188

!58-65188

159-65t88

160-65188

161-65188

t05,65188

162-65188

163-65188

t64-65!88

153-54188

154-65188

165,65188

!66-65188

167-65188

168_65!88

169-65188

t70-65188

171-65188

172-65188

173.65188

174-65188

t75-65188

176-65t88

177-65188

t78.65188

179-65188

t80.65188

18t-65188

182.65188

183-65188

184-65188

185,65188

t86-65188

187-65188

188.65188

189-65t88

190-65188

191-65t88

192-65188

193.65t88

194-65188

t95-65t88

196-65188

197-65t88

198.65188

t99,65188

200-65188

201-65t88

202-65188

20365188

204,65188

205-65188

206,65188

207-65188

208-65188

DESCRIPTION

GASKET

BREATHER

WIRE.

HOUSING Far_

CASE .Spiral

COVER Cyiinder Head

COVER Cylinder

BOLT 16 x i0)

BOLT (6 x 12_

SCREW (Sx IO}

ARM ,Governor

BOLT 16 x 25)

NUT (6 ram}

WASIHER

ROD .Governor

SPRING Link

SPRING .Governor

BRACKET

ADJUSTER Spring

NUT (6 ram)

BASE. Side

BEARING,Ball (6205)

GASKET

BOLT 16 x 30)

SEAL Oil

GOVERNOR

SLEEVE Governor

TIP.Governor

WASHER

PIN Snap

WASHER

GAUGE,Oil Level

O-RING

FLYWHEEL

COl L Ignilion.

BREAKER ASS'Y Contact

CONDENSER

BREAKER Contact

BRUSH

CLAMP

CLAMP

COVER

RING

BOLT (5 x 201

SCREW (4 x 8)

SCREW (4 x 20}

GROMMET

NUT 114 ram)

KEY

WASHE R

SPARK PLUG'

CAP. Plug

SPRING

STARTER ASSEMBLY Recoil

BOLT 16 x 10}

[DECA L

DECAL

DECAL

* UseNGK,BMR6A CHAMPION RCJ8 or equivalen! spark plug

23

Page 26

CARBURETOR

i0

3

2

4

\

12 ....

EXPLODED VIEW OF CARBURETOR

ITEM PART NUMBER

148-65188

] 209-65188

2 2t0-65188

3 2t1-65t88

4 212-65188

5 2t3-65t88

6 214-65188

7 225_65188

8 216-65188

9 217-65188

10 218,65!88

DESCRIPTION

CARBURETOR ASSEMBLY

SHAFTChoke

VALVEChoke

SCREW

JET Pilo; {#37 5)

SCREW. Pilol

SPF_fNG

SHAFT Throttte

VALVE _hrott_e

SCREW

SCREW Stop

ITEM

t2

13

14

15

16

I7

18

19

15

PART NUMBER

1I

2t9-65188

220-65t88

221-65188

222-65188

223-65188

224-65188

225-65188

226-65188

227-65188

DESCRIPTION ,.

JET, Main {#77 5)

NOZZLE Main(#5A)

VALVE Needle

FLOAT

PIN,Float

GASKET

CHAMBER Float

BOLT

GASKET

24

Page 27

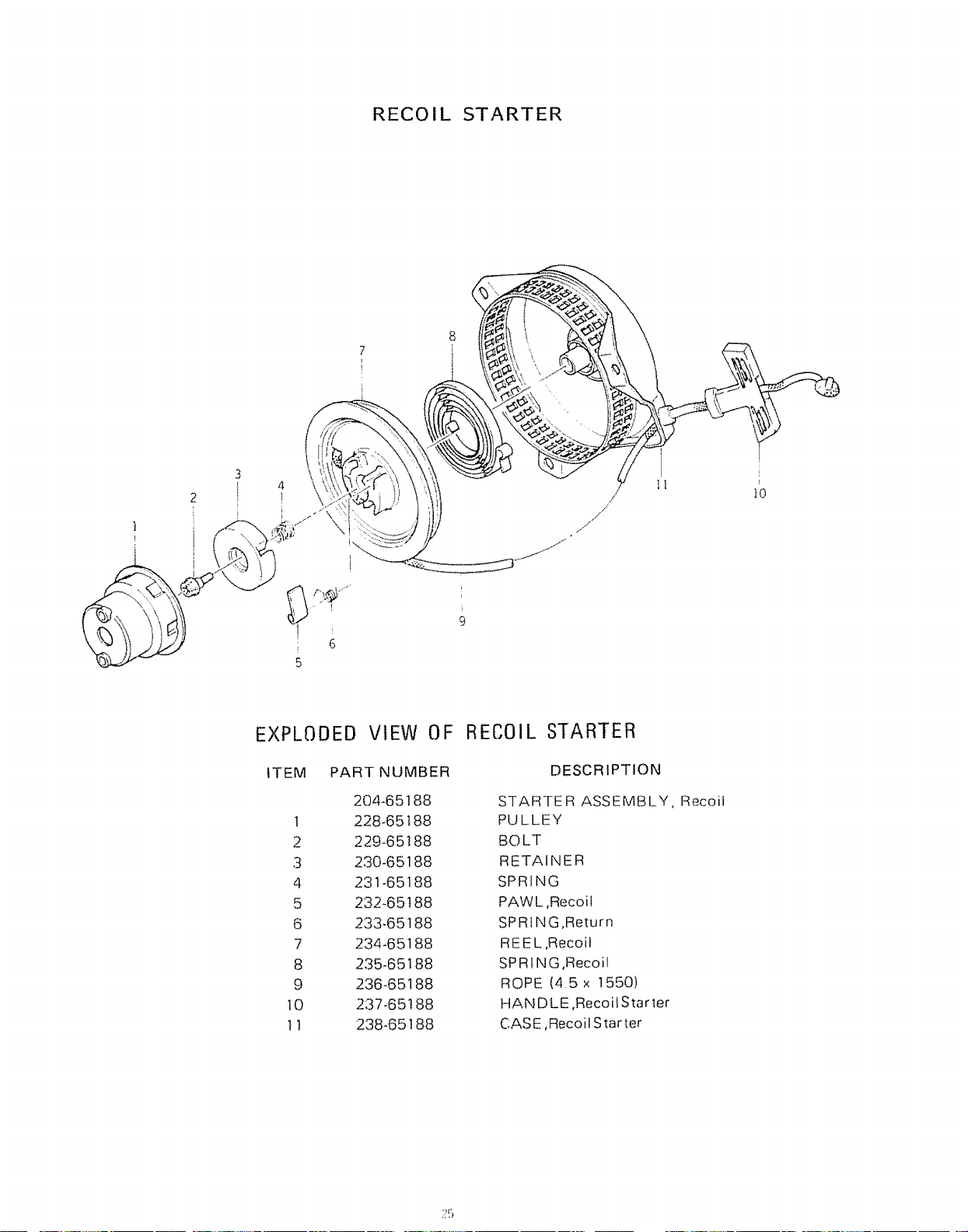

RECOIL STARTER

3

9

, 6

5

EXPLODED VIEW OF

ITEM PART NUMBER

204-65188 STARTER ASSEMBLY, Recoil

] 228-65188 PULLEY

2 229-65188 BOLT

3 230-65188 RETAI N ER

4 231-65188 SPRING

5 232-65188 PAWL ,Recoil

6 233-65188 SP R IN G ,Return

7 234-65188 RE E L ,Recoil

8 235-65188 SPRING,Recoil

9 236-65188 ROPE (4 5 x ]550)

] 0 237-65 ! 88 HAND L E ,RecoilS tar ter

] 1 238-65 ] 88 CASE ,Recoil Starter

RECOIL STARTER

DESCRIPTION

Page 28

Sears

MODEL NO. 580.328.330

SERVICE

HOW TO ORDER

PORTA LE

AC GE ERATO

Now that you have purchased your Alter-

nator, should a need ever exist for repair

parts or service, simply contact any Sears

Service Center and most Sears, Roebuck and

Co. stores. Be sure to provide all pertinent

facts when you call or visit.

The model number of you Alternator will be

listed on the data plate.

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFORMA-

TION:

REPAIR PARTS

o PART NUMBER o PART DESCRIPTION

° MODEL NUMBER ° NAME OF ITEM

All parts listed may be ordered from any

Sears Service Center and most Sears stores.

If the parts you need are not stocked locally,

your order will be electronically transmitted

to a Sears Repair Distribution center for

handling.

88-66855-t01 Ptlntod In U S.,/L

Haaual earl: t,lua_bez'66832-& Sears, Roebuck and Co., Chicago, IL 60684 U.S.A_

Loading...

Loading...