Craftsman 580328301 Owner’s Manual

Owner's Manual

CRAFTSMAN+

120/240 Volt

Electric Start

10,000 Watt

AC GENERATOR

Model No 580.328301

CusGemn:/aHt°lpline_"

HOURS: Mon.- Fri. 8 a.m. to 5 p.m. (CT)

CAUTION:

Before using this product, read this

manual and follow all its Safety Rules

and Operating Instructions

Sears, Roebuck and Co, Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

Part No. 186942 Draft 3 (09/19/2002) Printed in the U.S.A.

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Espahol

Warranty .................................. 2

Safety Rules ............................... 3

Assembly ............................... 4-5

Operation .............................. 6-12

Maintenance ........................... 13-15

Product Specifications ....................... 14

Storage .................................. 16

Troubleshooting ............................ 17

Schematic ................................ 18

Wiring Diagram ............................ 19

Replacement Parts ...................... 20-37

Emissions Warranty ......................... 38

Notes ................................... 39

EspaSol ............................... 40-59

How to Order Parts .................. Back Cover

LIMITED WARRANTY FOR DELUXE PORTABLE GENERATORS

SEARS warrants to the original purchaser that the alternator and engine for its portable generator will be free

from defects in materials or workmanship for the items and period set forth below from the date of original

purchase. This warranty is not transferable and applies only to portable generators driven by the Sears

warranted engine.

CONSUMER* COMMERCIAL*

Alternator 2 years (2nd year parts only) 1 year

Engine 2 years (2nd year parts only) 1 year

* NOTE: For the purpose of this warranty "Consumer Use" means personal residential household and

emergency use by original purchaser, not to be used as a primary source of power. "Commercial Use" means all

other uses, including rental, construction, commercial, and income producing purposes. Once a generator has

experienced commercial use, it shall thereafter be considered a commercial use generator for the purpose of

this warranty.

During said warranty period, SEARS will, at its option, repair or replace any part which, upon examination by

SEARS, is found to be defective under normal use and service**. Starting batteries are not warranted by

SEARS. All transportation costs under warranty, including return to the factory if necessary, are to be borne by

the purchaser and prepaid by him. This warranty does not cover normal maintenance and service and does not

apply to a generator set, alternator or engine, or parts which have been subjected to improper or unauthorized

installation or alteration, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair

or storage so as, in SEARS's judgment, to adversely affect its performance and reliability.

** NORMAL WEAR: As with all mechanical devices, engines need periodic parts service and replacement to

perform well. This warranty will not cover repair when normal use has exhausted the life of a part or engine.

THERE IS NO OTHER EXPRESS WARRANTY. SEARS HEREBY DISCLAIMS ANY AND ALL

IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THOSE OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE TO THE EXTENT PERMITTED BY LAW. THE

DURATION OF ANY IMPLIED WARRANTIES WHICH CANNOT BE DISCLAIMED IS LIMITED TO

THE TIME PERIOD AS SPECIFIED IN THE EXPRESS WARRANTY. LIABILITY FOR

CONSEQUENTIAL, INCIDENTAL, OR SPECIAL DAMAGES UNDER ANY AND ALL WARRANTIES

IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights and you may also have other rights, which vary from state to state.

For service, see your nearest SEARS authorized warranty service facility. Warranty service can be performed

only by a SEARS authorized service facility. This warranty will not apply to service at any other facility. At the

time of requesting warranty service, evidence of original purchase date must be presented.

SEARS, ROEBUCK AND CO., D/817 WA, Hoffman Estates, IL 60179 U.S.A

CAUTION! Before using this product, read this

manual and follow all Safety Rules and

Operating Instructions.

WARNING! You must isolate the generator

from the electric utility by opening the electrical

system's main circuit breaker or main switch if

this unit is used for backup power. Failure to

isolate the generator from the power utility

may result in injury or death to electric utility

workers and damage to the generator due to

a backfeed of electrical energy. When used as

backup power, the local power utilitymust be

notified.

DANGER! Generator exhaust gases contain

DEADLY carbon monoxide gas. Carbon

monoxide, if breathed in sufficient

concentrations, will cause unconsciousness

or death. Operate this equipment outdoors

where adequate ventilation is available.

CAUTION! To prevent accidental starting when

setting up, transporting, adjusting or making

repairs to your generator, always disconnect

spark plug wire and place the wire where it

cannot contact the spark plug.

• The unit requires an adequate flow of cooling air

for its continued proper operation. Never operate

the unit inside any room or enclosure where the

free flow of cooling air into and out of the unit might

be obstructed. Allow at least 3 feet of clearance on

all sides of generator or you could damage the unit.

• The generator produces dangerously high voltage

that can cause extremely hazardous electrical

shock. Avoid contact with bare wires, terminals,

etc. Never permit any untrained person to operate

or service the generator.

• Do Not overfill the fuel tank. Always allow room for

fuel expansion. If tank is overfilled, fuel can

overflow onto a hot engine and cause FIRE or an

EXPLOSION.

• Never operate the generator:

in rain; in any enclosed compartment; when

connected electrical devices overheat; if electrical

output is lost; if engine or generator sparks; if flame

or smoke is observed while unit is running; if unit

vibrates excessively.

• Never handle any kind of electrical cord or device

while standing in water, while barefoot or while

hands or feet are wet. Dangerous electrical shock

will result.

• Use a ground fault circuit interrupter in any damp

or highly conductive area (such as metal decking or

steel work).

• Do Not use worn, bare, frayed or otherwise

damaged electrical cord sets with the generator.

Using any defective cord set may result in electrical

shock or damage to property.

• Operate generator only on level surfaces and

where it will not be exposed to excessive moisture,

dirt, dust or corrosive vapors.

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do Not permit smoking, open flames,

sparks or heat in the vicinity while handling

gasoline. Avoid spilling gasoline on a hot engine.

Comply with all laws regulating storage and

handling of gasoline.

• Never store generator with fuel in tank where

gasoline vapors might reach an open flame or

spark or pilot light (as on a furnace, water heater or

clothes dryer). FIRE or EXPLOSION may result.

• Never add fuel while unit is running.

• Never start or stop the unit with electrical loads

connected to receptacles AND with connected

devices turned ON. Start the engine and let it

stabilize before connecting electrical loads.

Disconnect all electrical loads before shutting down

the generator.

• Do Not insert any object through cooling slots of

the engine-generator.

NOTE: Your generator is equipped with a spark

arrester muffler. The spark arrester must be

maintained in effective working order by the owner/

operator. In the State of California, a spark arrester is

required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

,_ THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL

PERSONAL INJURY HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS

SYMBOL TO AVOID POSSIBLE INJURY OR DEATH.

Your generator requires some assembly and is ready

for use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of

your generator, please call the generator helpline

at 1-800-222-3136.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

TO REMOVE THE GENERATOR

FROM CARTON

• Set the palleted carton on a rigid flat surface.

• Carefully cut bands around the shipping carton.

• Lift carton off the generator.

• Remove all packing material, carton fillers, etc.

• Remove the generator from the shipping pallet.

CARTON CONTENTS

Check all contents. If any parts are missing or

damaged, call the generator helpline at

1-800-222-3136. Contents Include:

• 10,000 Watt generator

• Owner's manual

• 2 Bottles of engine oil (28 oz.)

• 125 Volt, 30 Amp plug

• 125 Volt, 20 Amp plug

• 240 Volt, 30 Amp plug

• Oil fill spout

• Wheel kit

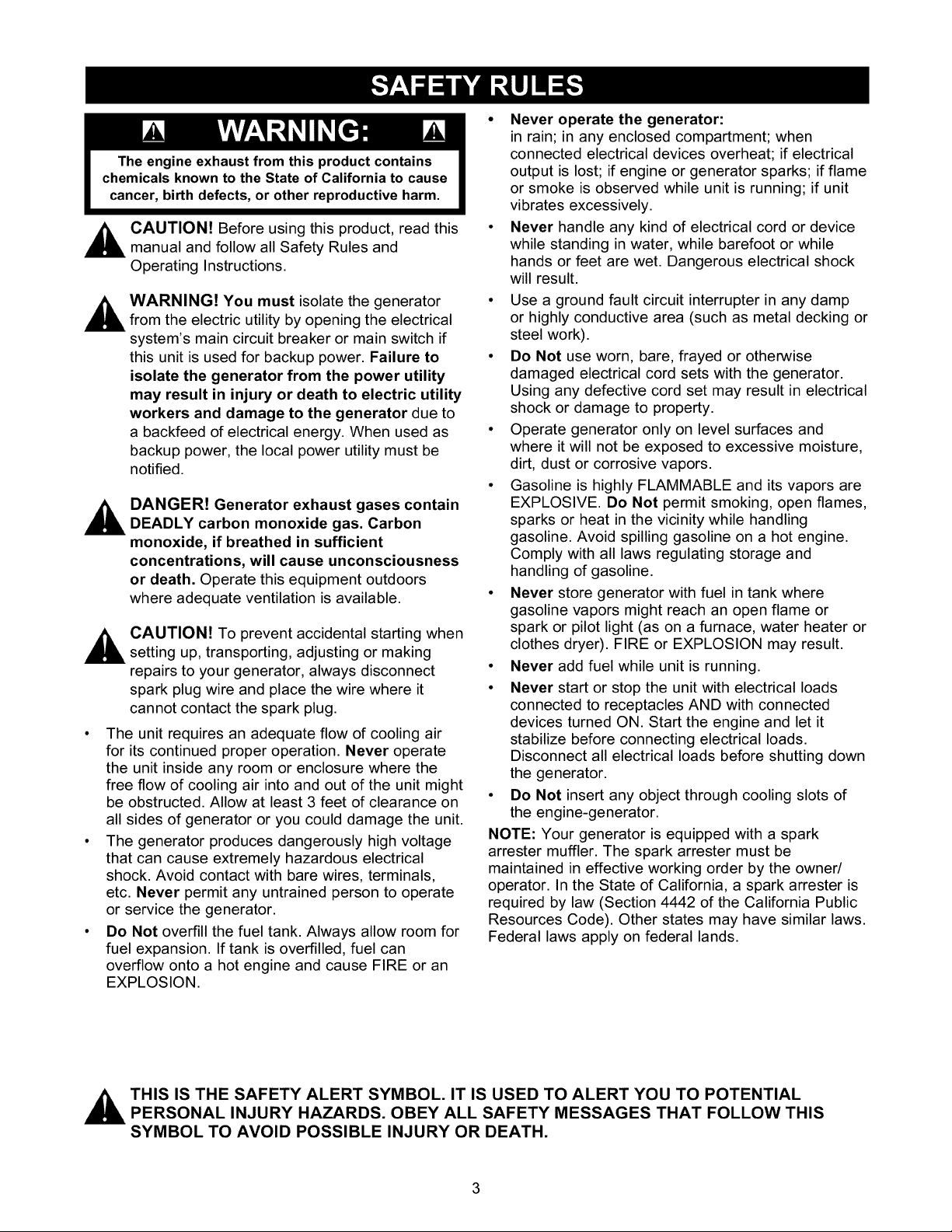

CHECK BATTERY / ATTACH

NEGATIVE BATTERY WIRE

The battery on the generator is fully charged, sealed

and pre-installed except for the negative (black)

battery cable.

To install:

• Place key switch in "Stop" position.

• Remove hardware on the negative battery terminal.

f

Neg_

• Align the negative battery cable with the terminal.

• Reattach hardware and tighten.

• Ensure the connections to the battery and

generator and tight and secure.

4

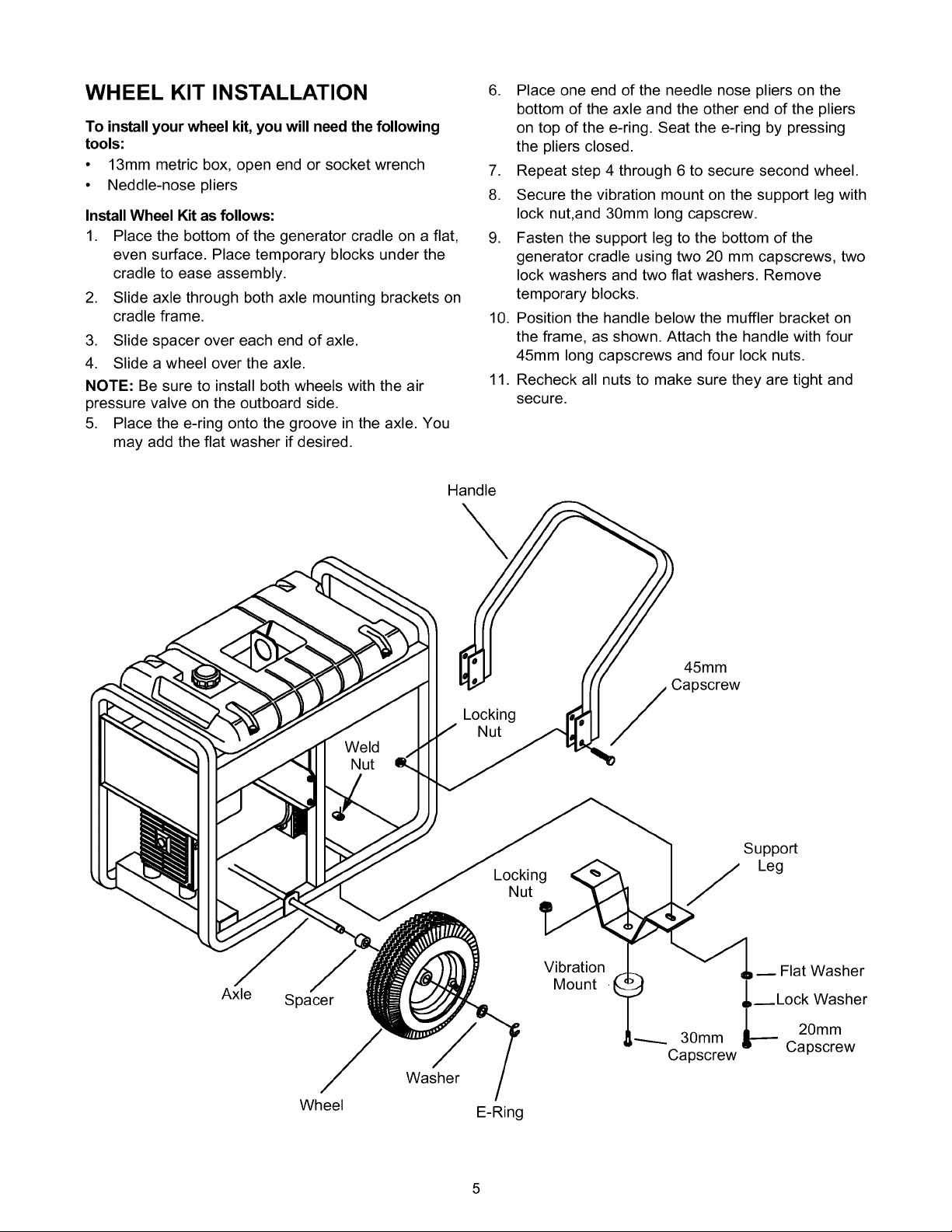

WHEEL KIT INSTALLATION

To install your wheel kit, you will need the following

tools:

• 13mm metric box, open end or socket wrench

• Neddle-nose pliers

Install Wheel Kit as follows:

1. Place the bottom of the generator cradle on a flat,

even surface. Place temporary blocks under the

cradle to ease assembly.

2. Slide axle through both axle mounting brackets on

cradle frame.

3. Slide spacer over each end of axle.

4. Slide a wheel over the axle.

NOTE: Be sure to install both wheels with the air

pressure valve on the outboard side.

5. Place the e-ring onto the groove in the axle. You

may add the flat washer if desired.

6. Place one end of the needle nose pliers on the

bottom of the axle and the other end of the pliers

on top of the e-ring. Seat the e-ring by pressing

the pliers closed.

7. Repeat step 4 through 6 to secure second wheel.

8. Secure the vibration mount on the support leg with

lock nut,and 30mm long capscrew.

9. Fasten the support leg to the bottom of the

generator cradle using two 20 mm capscrews, two

lock washers and two flat washers. Remove

temporary blocks.

10. Position the handle below the muffler bracket on

the frame, as shown. Attach the handle with four

45mm long capscrews and four lock nuts.

11. Recheck all nuts to make sure they are tight and

secure.

Handle

Axle

Spacer

Wheel

Weld

Nut

Washer

Locking

Nut

Locking

E-Ring

Nut

Vibration

Mount .

45mm

Capscrew

30mm

Capscrew

Support

Leg

Flat Washer

Washer

_ 20mm

Capscrew

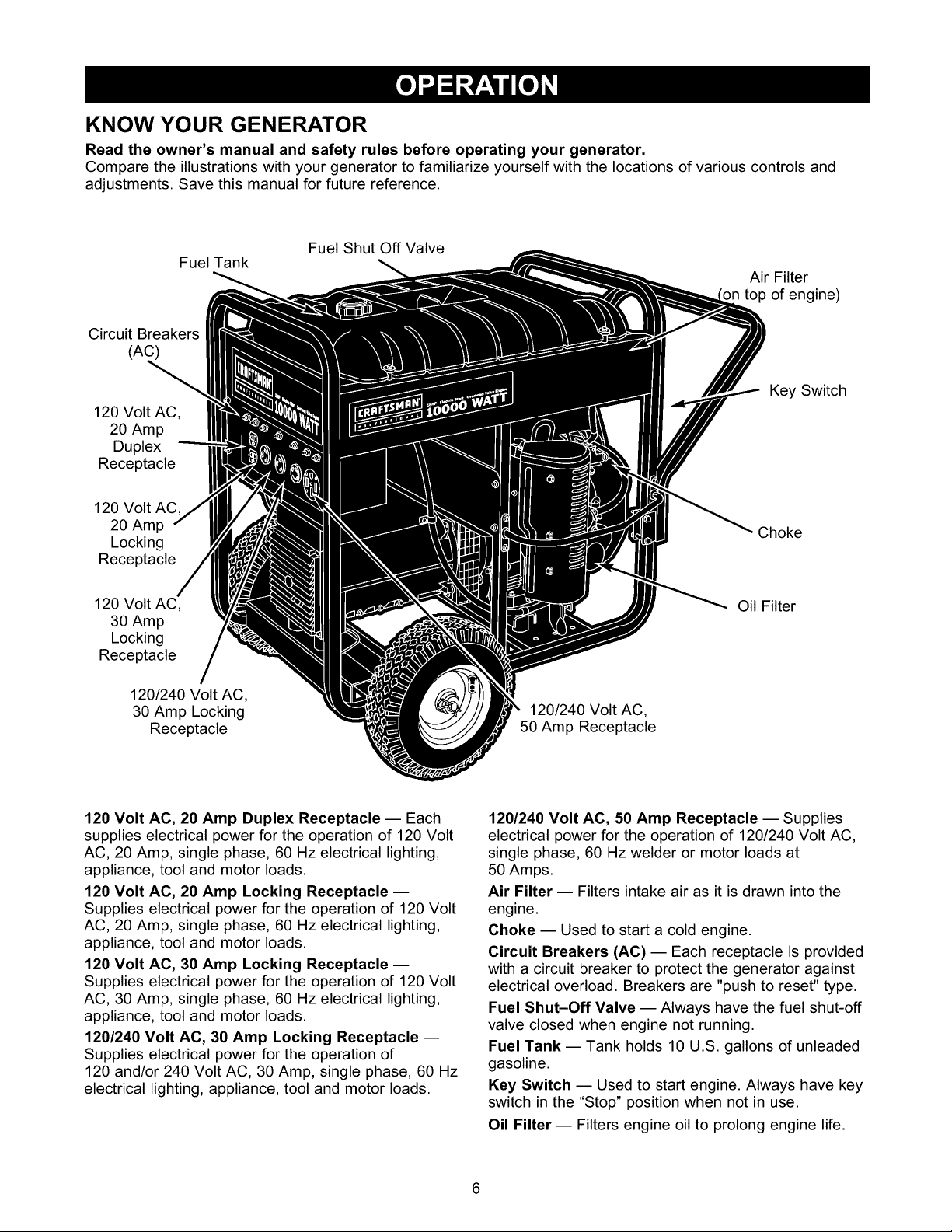

KNOW YOUR GENERATOR

Read the owner's manual and safety rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

FuelTank

Circuit Breakers

(AC)

120 Volt AC,

20 Amp

Duplex

Receptacle

120 Volt AC.

20 Amp

Locking

Receptacle

120 Volt AC,

30 Amp

Locking

Receptacle

120/240 Volt AC,

30 Amp Locking

Receptacle

Fuel Shut Off Valve

Air Filter

top of engine)

Key Switch

Choke

Oil Filter

120/240 Volt AC,

50 Amp Receptacle

120 Volt AC, 20 Amp Duplex Receptacle -- Each

supplies electrical power for the operation of 120 Volt

AC, 20 Amp, single phase, 60 Hz electrical lighting,

appliance, tool and motor loads.

120 Volt AC, 20 Amp Locking Receptacle --

Supplies electrical power for the operation of 120 Volt

AC, 20 Amp, single phase, 60 Hz electrical lighting,

appliance, tool and motor loads.

120 Volt AC, 30 Amp Locking Receptacle --

Supplies electrical power for the operation of 120 Volt

AC, 30 Amp, single phase, 60 Hz electrical lighting,

appliance, tool and motor loads.

120/240 Volt AC, 30 Amp Locking Receptacle --

Supplies electrical power for the operation of

120 and/or 240 Volt AC, 30 Amp, single phase, 60 Hz

electrical lighting, appliance, tool and motor loads.

120/240 Volt AC, 50 Amp Receptacle -- Supplies

electrical power for the operation of 120/240 Volt AC,

single phase, 60 Hz welder or motor loads at

50 Amps.

Air Filter -- Filters intake air as it is drawn into the

engine.

Choke -- Used to start a cold engine.

Circuit Breakers (AC) -- Each receptacle is provided

with a circuit breaker to protect the generator against

electrical overload. Breakers are "push to reset" type.

Fuel Shut-Off Valve -- Always have the fuel shut-off

valve closed when engine not running.

Fuel Tank -- Tank holds 10 U.S. gallons of unleaded

gasoline.

Key Switch -- Used to start engine. Always have key

switch in the "Stop" position when not in use.

Oil Filter- Filters engine oil to prolong engine life.

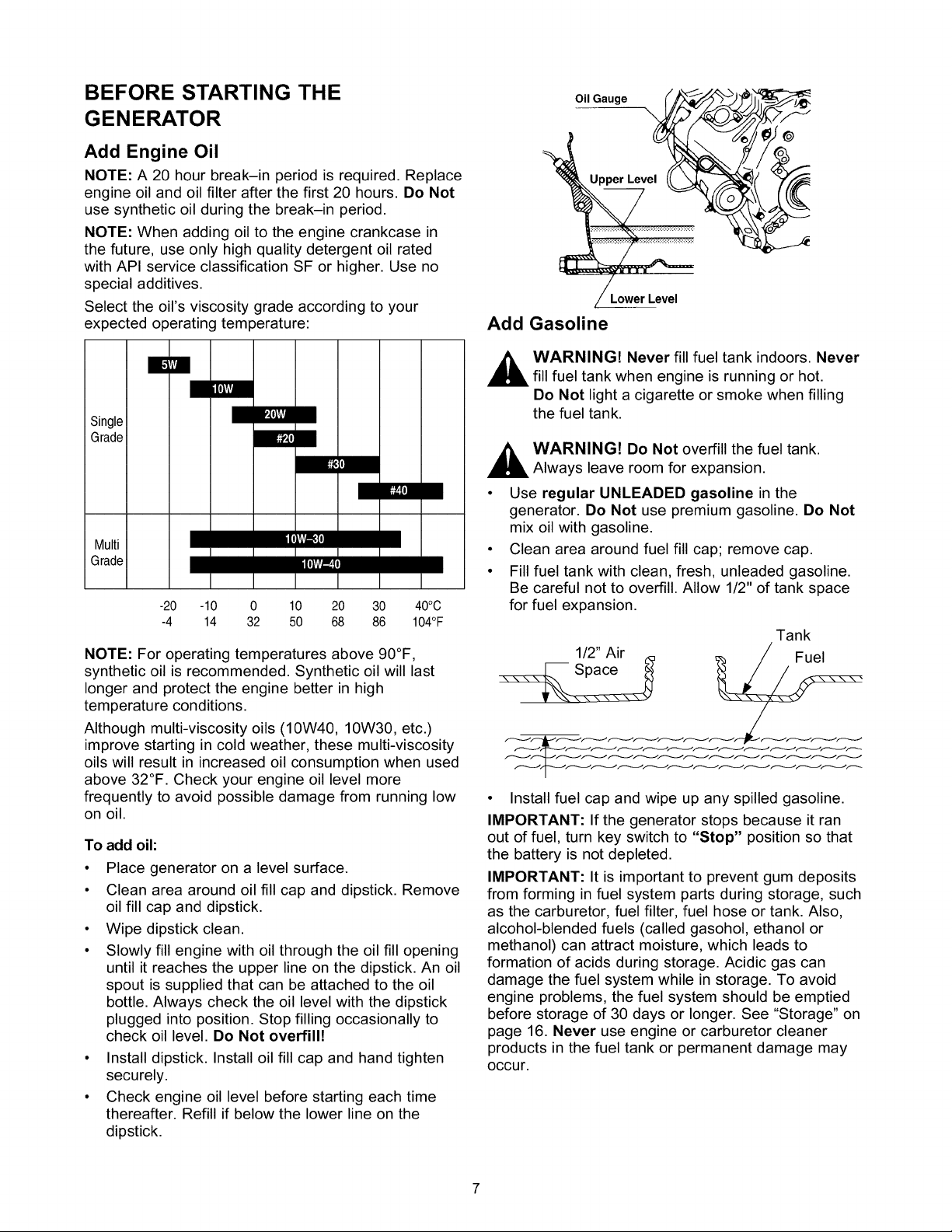

BEFORE STARTING THE

GENERATOR

Add Engine Oil

NOTE: A 20 hour break-in period is required. Replace

engine oil and oil filter after the first 20 hours. Do Not

use synthetic oil during the break-in period.

NOTE: When adding oil to the engine crankcase in

the future, use only high quality detergent oil rated

with API service classification SF or higher. Use no

special additives.

Select the oil's viscosity grade according to your

expected operating temperature:

i[tlYivj

Single

Grade

Multi • •

Grade • •

-20 -10 0 10 20 30 40°C

-4 14 32 50 68 86 104°F

NOTE: For operating temperatures above 90°F,

synthetic oil is recommended. Synthetic oil will last

longer and protect the engine better in high

temperature conditions.

Although multi-viscosity oils (10W40, 10W30, etc.)

improve starting in cold weather, these multi-viscosity

oils will result in increased oil consumption when used

above 32°F. Check your engine oil level more

frequently to avoid possible damage from running low

on oil.

To add oil:

• Place generator on a level surface.

• Clean area around oil fill cap and dipstick. Remove

oil fill cap and dipstick.

• Wipe dipstick clean.

• Slowly fill engine with oil through the oil fill opening

until it reaches the upper line on the dipstick. An oil

spout is supplied that can be attached to the oil

bottle. Always check the oil level with the dipstick

plugged into position. Stop filling occasionally to

check oil level. Do Not overfill!

• Install dipstick. Install oil fill cap and hand tighten

securely.

• Check engine oil level before starting each time

thereafter. Refill if below the lower line on the

dipstick.

PZ*IT_VJ

0,,Oau0e

Upper Level

Add Gasoline

A ARNING! Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot.

Do Not light a cigarette or smoke when filling

the fuel tank.

A ARNING! Do Not overfill the fuel tank.

Always leave room for expansion.

• Use regular UNLEADED gasoline in the

generator. Do Not use premium gasoline. Do Not

mix oil with gasoline.

• Clean area around fuel fill cap; remove cap.

• Fill fuel tank with clean, fresh, unleaded gasoline.

Be careful not to overfill. Allow 1/2" of tank space

for fuel expansion.

Tank

1/2" Air _ _ J Fuel

:___Space _ __ _:_zz_

• Install fuel cap and wipe up any spilled gasoline.

IMPORTANT: If the generator stops because it ran

out of fuel, turn key switch to "Stop" position so that

the battery is not depleted.

IMPORTANT: It is important to prevent gum deposits

from forming in fuel system parts during storage, such

as the carburetor, fuel filter, fuel hose or tank. Also,

alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leads to

formation of acids during storage. Acidic gas can

damage the fuel system while in storage. To avoid

engine problems, the fuel system should be emptied

before storage of 30 days or longer. See "Storage" on

page 16. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may

Occur.

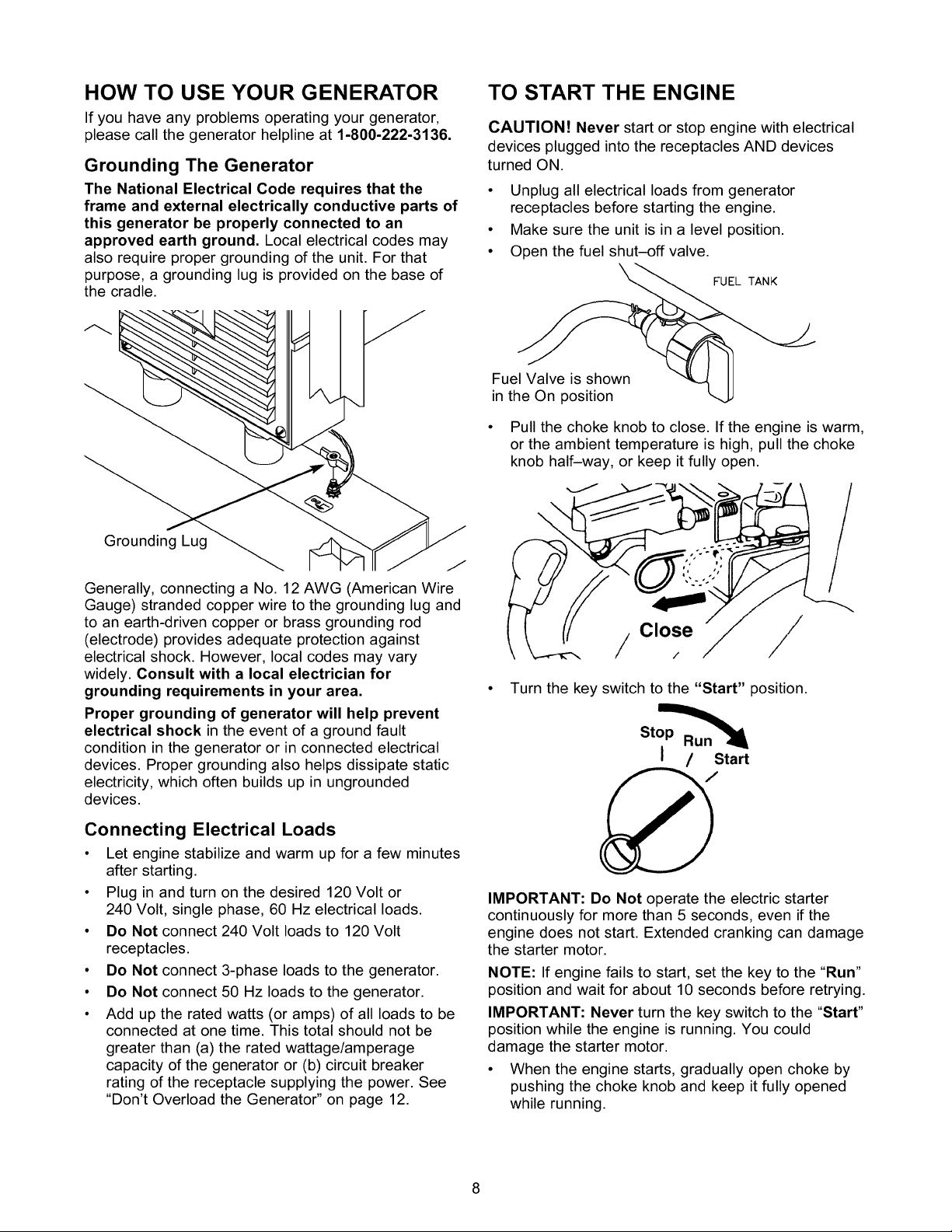

HOW TO USE YOUR GENERATOR

If you have any problems operating your generator,

please call the generator helpline at 1-800-222-3136.

Grounding The Generator

The National Electrical Code requires that the

frame and external electrically conductive parts of

this generator be properly connected to an

approved earth ground. Local electrical codes may

also require proper grounding of the unit. For that

purpose, a grounding lug is provided on the base of

the cradle.

TO START THE ENGINE

CAUTION! Never start or stop engine with electrical

devices plugged into the receptacles AND devices

turned ON.

• Unplug all electrical loads from generator

receptacles before starting the engine.

• Make sure the unit is in a level position.

• Open the fuel shut-off valve.

\

Fuel Valve is shown

in the On position

Pull the choke knob to close. If the engine is warm,

or the ambient temperature is high, pull the choke

knob half-way, or keep it fully open.

\

FUEL TANK

J

Generally, connecting a No. 12 AWG (American Wire

Gauge) stranded copper wire to the grounding lug and

to an earth-driven copper or brass grounding rod

(electrode) provides adequate protection against

electrical shock. However, local codes may vary

widely. Consult with a local electrician for

grounding requirements in your area.

Proper grounding of generator will help prevent

electrical shock in the event of a ground fault

condition in the generator or in connected electrical

devices. Proper grounding also helps dissipate static

electricity, which often builds up in ungrounded

devices.

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes

after starting.

• Plug in and turn on the desired 120 Volt or

240 Volt, single phase, 60 Hz electrical loads.

• Do Not connect 240 Volt loads to 120 Volt

receptacles.

• Do Not connect 3-phase loads to the generator.

• Do Not connect 50 Hz loads to the generator.

• Add up the rated watts (or amps) of all loads to be

connected at one time. This total should not be

greater than (a) the rated wattage/amperage

capacity of the generator or (b) circuit breaker

rating of the receptacle supplying the power. See

"Don't Overload the Generator" on page 12.

Close /

/

Turn the key switch to the "Start" position.

IMPORTANT: Do Not operate the electric starter

continuously for more than 5 seconds, even if the

engine does not start. Extended cranking can damage

the starter motor.

NOTE: If engine fails to start, set the key to the "Run"

position and wait for about 10 seconds before retrying.

IMPORTANT: Never turn the key switch to the "Start"

position while the engine is running. You could

damage the starter motor.

• When the engine starts, gradually open choke by

pushing the choke knob and keep it fully opened

while running.

IMPORTANT:DoNotoverloadthegenerator.Also,

DoNotoverloadindividualpanelreceptacles.These

outletsareprotectedagainstoverloadwithpush-to-

reset-typecircuitbreakers.Ifamperageratingofany

circuitbreakerisexceeded,thatbreakeropensand

electricaloutputtothatreceptacleislost.Read"Don't

OverloadtheGenerator"onpage12carefully.

STOPPING THE ENGINE

• Unplug (or turn OFF) all electrical loads connected

to generator panel receptacles. Never start or

stop engine with devices plugged in and turned

on.

• Let engine run at no-load for 30 seconds to

stabilize the internal temperatures of engine and

generator.

• Turn the key switch to the "Stop" position.

• Close the fuel valve.

STOPPING THE ENGINE WITH THE

FUEL VALVE

This procedure eliminates fuel from the carburetor.

Use this method to stop the generator if you plan to

store the generator over a long period. Fuel will clog

the internal passages of carburetor if allowed to

remain for an extended period.

• Unplug (or turn OFF) all electrical loads connected

to generator panel receptacles. Never start or

stop engine with devices plugged in and turned

on.

• Let engine run at no-load for 30 seconds to

stabilize the internal temperatures of engine and

generator.

• Close the fuel valve while the engine is running

and wait until the engine stops.

Set the key switch to the "Stop" position after

stopping the engine. Failure to put the key

switch into the "Stop" position will deplete the

battery.

If the Engine Will Not Start

Perform the following checks if your engine does not

start:

1. Do you have enough gasoline?

Check to make sure you have fuel in the gas tank.

2. Is the fuel valve open?

Check to make sure the fuel valve is open. If it is

closed, open it.

3. Is there enough compression?

Check to see if either spark plug is loose. Ifso,

tighten it.

4. Is there enough oil?

You unit comes equipped with a low oil pressure

shutdown system. If there is not enough oil in your

engine it will not start. Fill the engine with oil to the

proper level.

5. Is the spark plug wet with gasoline?

• Apply full choke and crank the engine for 2 or

3 seconds. Remove the plug and check to see if

the electrode is wet. If the electrode is wet, fuel is

well supplied to your engine.

• If the electrode is dry, check to find where the

fuel is restricted. (Check the fuel intake of the

carburetor and fuel strainer intake.)

• In case the engine does not start with well

supplied fuel, try using fresh fuel.

6. Is there a strong spark across the electrode?

,_ WARNING! Wipe off any spilled gasoline

before checking the spark plug. Place spark

plug as far away from the spark plug hole as

possible. Do Not hold spark plug by hand when

checking.

• Remove the spark plug and connect it to the

plug cap. Ground spark plug against engine

body. Turn key switch to "Start" position.

Observe strength of spark.

• Repeat above step with a new spark plug if

the spark is weak or there is no spark.

• The ignition system is faulty if there is no

spark with a new spark plug. Take your unit to

your nearest Sears service center.

7. Is your battery well charged?

• Check the battery as it may be discharged

and unable to operate the electric starter.

Consult your nearest Sears service center.

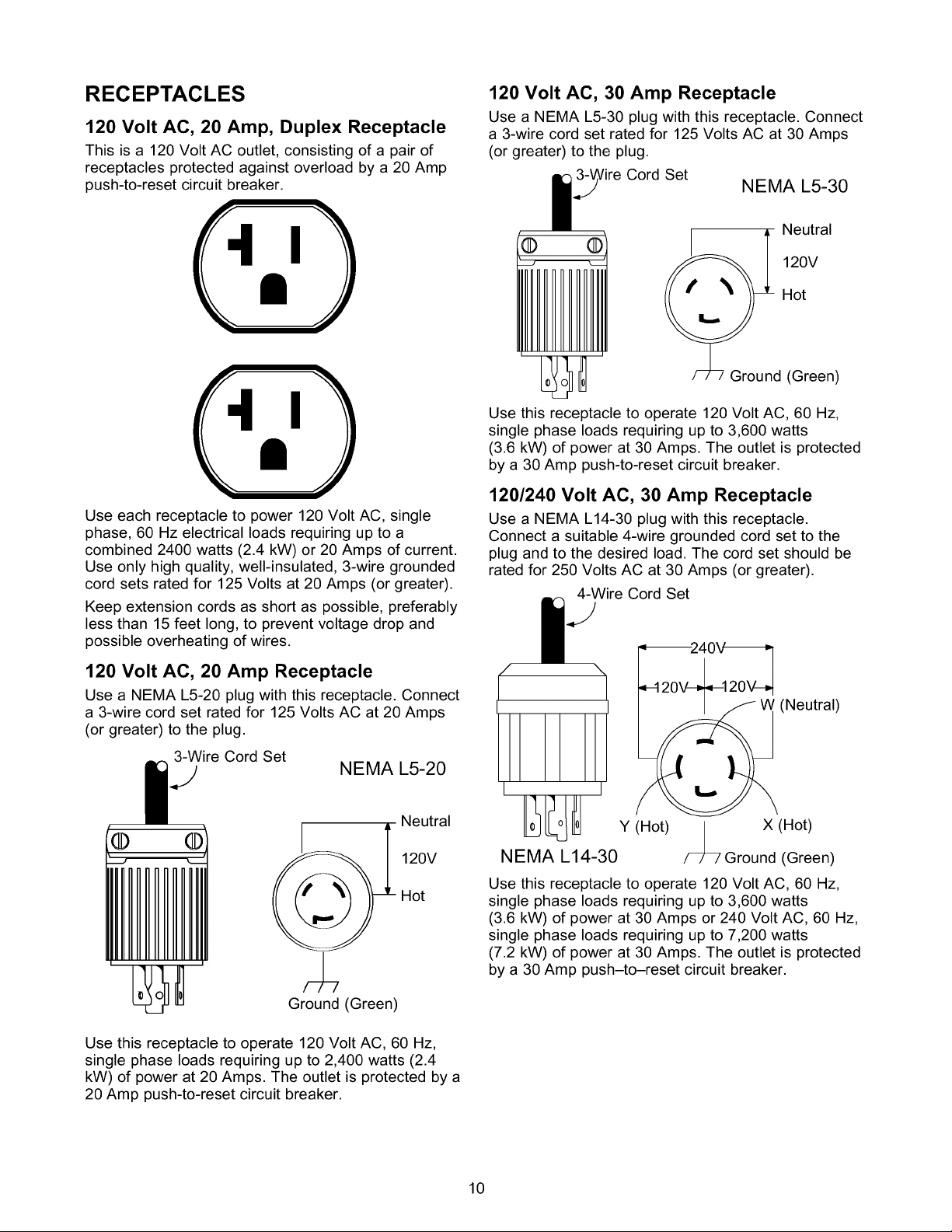

RECEPTACLES

120 Volt AC, 20 Amp, Duplex Receptacle

This is a 120 Volt AC outlet, consisting of a pair of

receptacles protected against overload by a 20 Amp

push-to-reset circuit breaker.

120 Volt AC, 30 Amp Receptacle

Use a NEMA L5-30 plug with this receptacle. Connect

a 3-wire cord set rated for 125 Volts AC at 30 Amps

(or greater) to the plug.

Cord Set

NEMA L5-30

Use each receptacle to power 120 Volt AC, single

phase, 60 Hz electrical loads requiring up to a

combined 2400 watts (2.4 kW) or 20 Amps of current.

Use only high quality, well-insulated, 3-wire grounded

cord sets rated for 125 Volts at 20 Amps (or greater).

Keep extension cords as short as possible, preferably

less than 15 feet long, to prevent voltage drop and

possible overheating of wires.

120 Volt AC, 20 Amp Receptacle

Use a NEMA L5-20 plug with this receptacle. Connect

a 3-wire cord set rated for 125 Volts AC at 20 Amps

(or greater) to the plug.

3-Wire Cord Set

©

Use this receptacle to operate 120 Volt AC, 60 Hz,

single phase loads requiring up to 3,600 watts

(3.6 kW) of power at 30 Amps. The outlet is protected

by a 30 Amp push-to-reset circuit breaker.

__r_nd eutral

120V

iltreen)

120/240 Volt AC, 30 Amp Receptacle

Use a NEMA L14-30 plug with this receptacle.

Connect a suitable 4-wire grounded cord set to the

plug and to the desired load. The cord set should be

rated for 250 Volts AC at 30 Amps (or greater).

4-Wire Cord Set

(Neutral)

__l.,.J NEMA L5-20

Neutral

Hot

Ground (Green)

Use this receptacle to operate 120 Volt AC, 60 Hz,

single phase loads requiring up to 2,400 watts (2.4

kW) of power at 20 Amps. The outlet is protected by a

20 Amp push-to-reset circuit breaker.

NEMA L14-30 /_ Ground (Green)

Use this receptacle to operate 120 Volt AC, 60 Hz,

single phase loads requiring up to 3,600 watts

(3.6 kW) of power at 30 Amps or 240 Volt AC, 60 Hz,

single phase loads requiring up to 7,200 watts

(7.2 kW) of power at 30 Amps. The outlet is protected

by a 30 Amp push-to-reset circuit breaker.

10

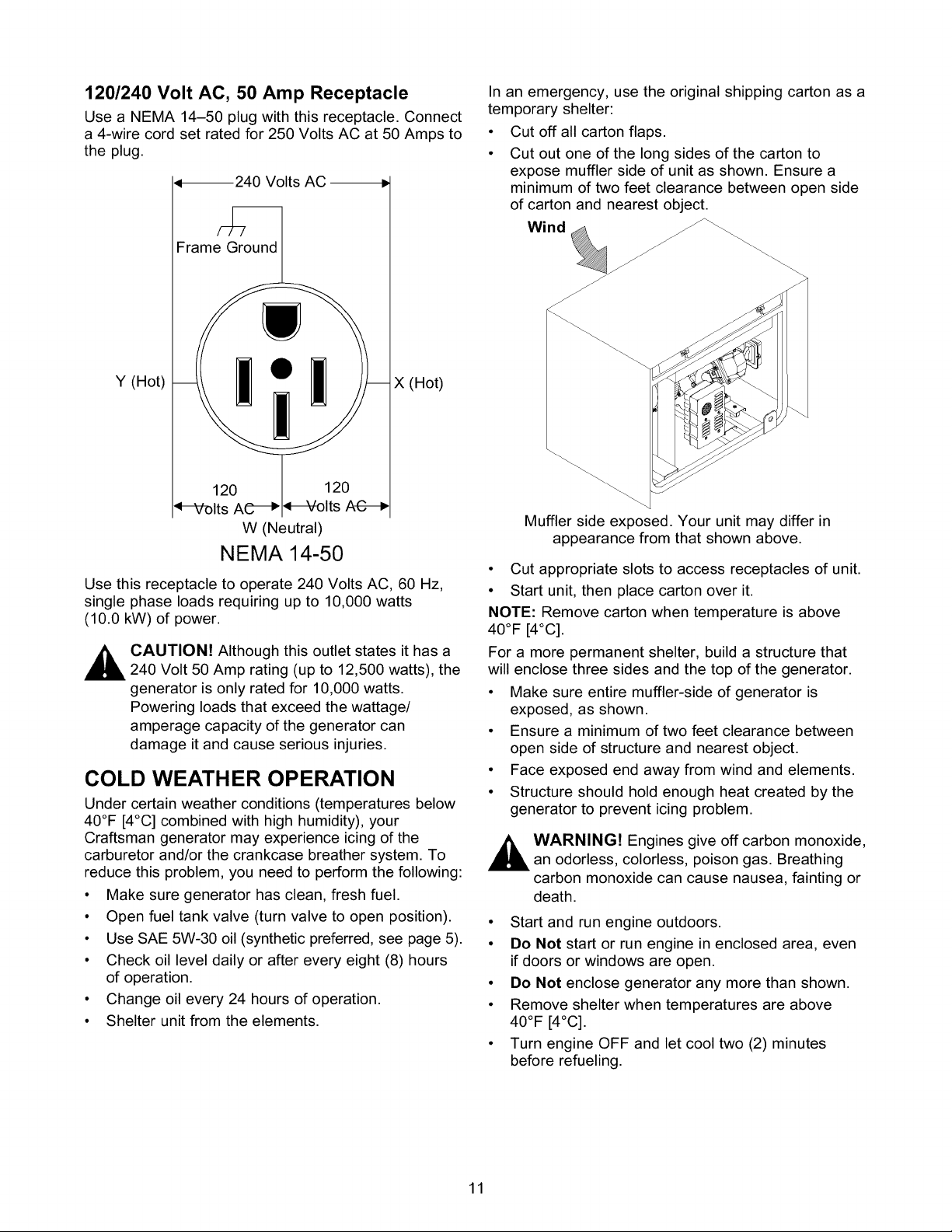

120/240 Volt AC, 50 Amp Receptacle

Use a NEMA 14-50 plug with this receptacle. Connect

a 4-wire cord set rated for 250 Volts AC at 50 Amps to

the plug.

240 Volts AC

r__m

Frame Ground

In an emergency, use the original shipping carton as a

temporary shelter:

• Cut off all carton flaps.

• Cut out one of the long sides of the carton to

expose muffler side of unit as shown. Ensure a

minimum of two feet clearance between open side

of carton and nearest object.

Wind

Y (Hot)

AC_

W (Neutral)

X (Hot)

NEMA 14-50

Use this receptacle to operate 240 Volts AC, 60 Hz,

single phase loads requiring up to 10,000 watts

(10.0 kW) of power.

_ CAUTION! Although this outlet states it has a

240 Volt 50 Amp rating (up to 12,500 watts), the

generator is only rated for 10,000 watts.

Powering loads that exceed the wattage/

amperage capacity of the generator can

damage it and cause serious injuries.

COLD WEATHER OPERATION

Under certain weather conditions (temperatures below

40°F [4°C] combined with high humidity), your

Craftsman generator may experience icing of the

carburetor and/or the crankcase breather system. To

reduce this problem, you need to perform the following:

• Make sure generator has clean, fresh fuel.

• Open fuel tank valve (turn valve to open position).

• Use SAE 5W-30 oil (synthetic preferred, see page 5).

• Check oil level daily or after every eight (8) hours

of operation.

• Change oil every 24 hours of operation.

• Shelter unit from the elements.

Muffler side exposed. Your unit may differ in

appearance from that shown above.

• Cut appropriate slots to access receptacles of unit.

• Start unit, then place carton over it.

NOTE: Remove carton when temperature is above

40°F [4°C].

For a more permanent shelter, build a structure that

will enclose three sides and the top of the generator.

• Make sure entire muffler-side of generator is

exposed, as shown.

• Ensure a minimum of two feet clearance between

open side of structure and nearest object.

• Face exposed end away from wind and elements.

• Structure should hold enough heat created by the

generator to prevent icing problem.

_ ARNING! Engines give off carbon monoxide,

an odorless, colorless, poison gas. Breathing

carbon monoxide can cause nausea, fainting or

death.

• Start and run engine outdoors.

• Do Not start or run engine in enclosed area, even

if doors or windows are open.

• Do Not enclose generator any more than shown.

• Remove shelter when temperatures are above

40°F [4°C].

• Turn engine OFF and let cool two (2) minutes

before refueling.

11

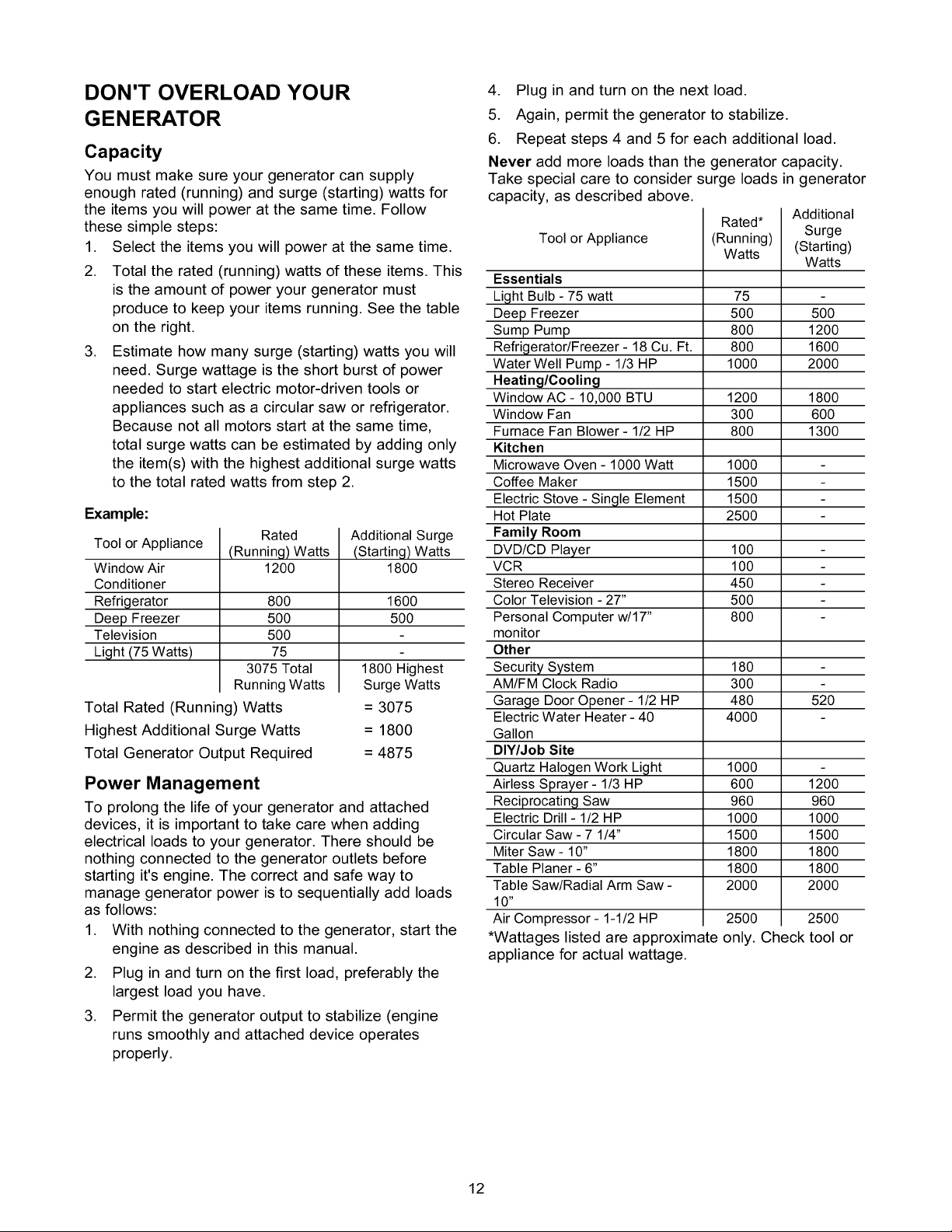

DON'T OVERLOAD YOUR

GENERATOR

Capacity

You must make sure your generator can supply

enough rated (running) and surge (starting) watts for

the items you will power at the same time. Follow

these simple steps:

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items. This

is the amount of power your generator must

produce to keep your items running. See the table

on the right.

3. Estimate how many surge (starting) watts you will

need. Surge wattage is the short burst of power

needed to start electric motor-driven tools or

appliances such as a circular saw or refrigerator.

Because not all motors start at the same time,

total surge watts can be estimated by adding only

the item(s) with the highest additional surge watts

to the total rated watts from step 2.

Example:

Tool or Appliance

Window Air

Conditioner

Refrigerator

Deep Freezer

Television

Light (75 Watts)

Rated

(Running) Watts

1200

800

500

500

75

3075 Total

Running Watts

Total Rated (Running) Watts

Highest Additional Surge Watts

Total Generator Output Required

Power Management

To prolong the life of your generator and attached

devices, it is important to take care when adding

electrical loads to your generator. There should be

nothing connected to the generator outlets before

starting it's engine. The correct and safe way to

manage generator power is to sequentially add loads

as follows:

1. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the

largest load you have.

3. Permit the generator output to stabilize (engine

runs smoothly and attached device operates

properly.

Additional Surge

(Starting) Watts

1800

1600

5OO

1800 Highest

Sure Watts

= 3075

= 1800

= 4875

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

Never add more loads than the generator capacity.

Take special care to consider surge loads in generator

capacity, as described above.

Additional

Watts

Tool or Appliance

Essentials

Light Bulb - 75 watt

Deep Freezer

Sump Pump

Refrigerator/Freezer- 18 Cu. Ft.

Water Well Pump- 1/3 HP

Heating/Cooling

Window AC - 10,000 BTU

Window Fan

Furnace Fan Blower- 1/2 HP

Kitchen

Microwave Oven - 1000 Watt

Coffee Maker

Electric Stove - Single Element

Hot Plate

Family Room

DVD/CD Player

VCR

Stereo Receiver

Color Television - 27"

Personal Computer w/17"

monitor

Other

Security System

AM/FM Clock Radio

Garage Door Opener- 1/2 HP

Electric Water Heater - 40

Gallon

DIY/Job Site

Quartz Halogen Work Light

Airless Sprayer- 1/3 HP

Reciprocating Saw

Electric Drill- 1/2 HP

Circular Saw - 7 1/4"

Miter Saw - 10"

Table Planer - 6"

Table Saw/Radial Arm Saw -

10"

Air Compressor - 1-1/2 HP

*Wattages listed are approximate

appliance for actual wattage.

Rated*

(Running) Surge

Watts (Starting)

75

500 500

800 1200

800 1600

1000 2000

1200 1800

300 600

800 1300

1000

1500

1500

2500

100

100

450

500

800

180

300

480 520

4000

1000

600 1200

960 960

1000 1000

1500 1500

1800 1800

1800 1800

2000 2000

2500 2500

only. Check tool or

12

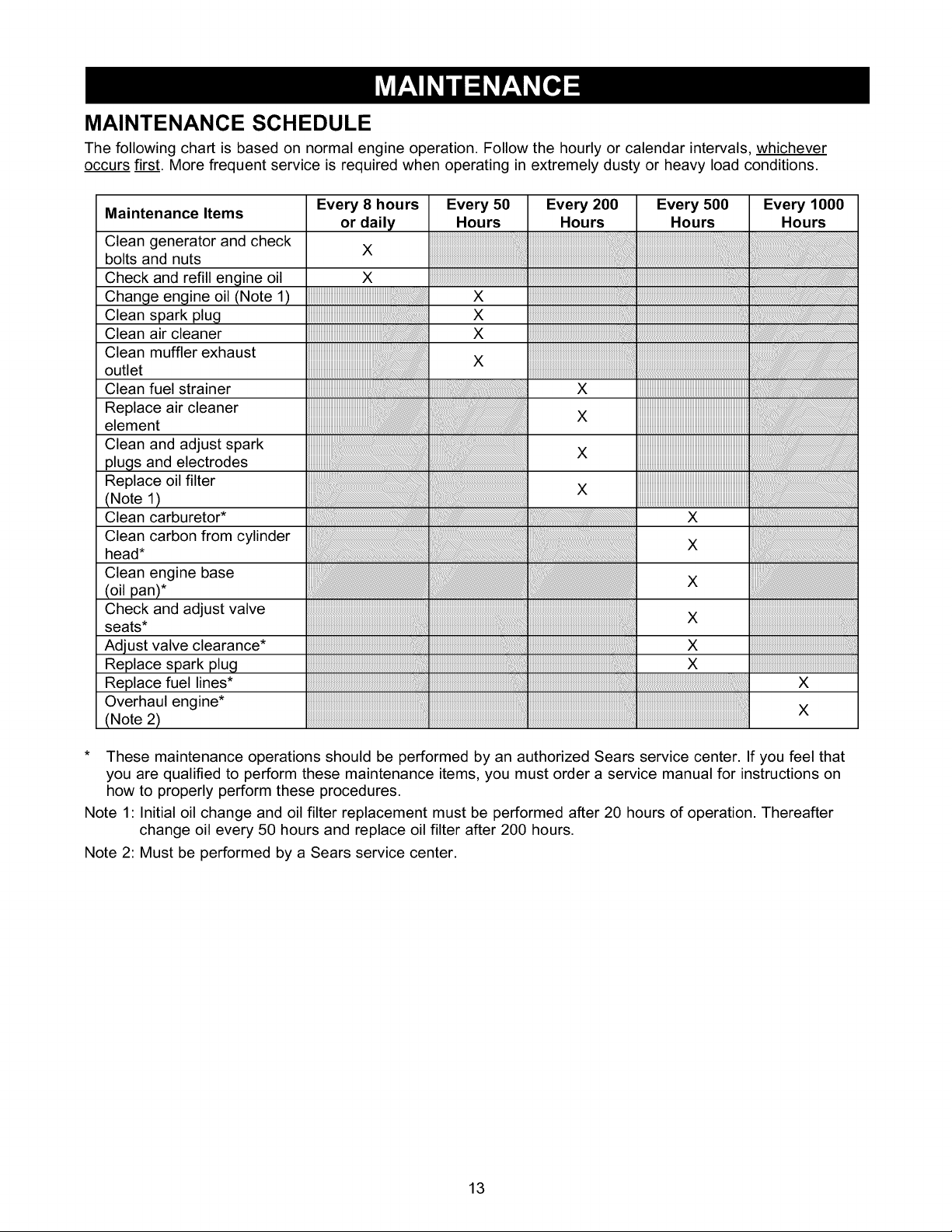

MAINTENANCE SCHEDULE

The following chart is based on normal engine operation. Follow the hourly or calendar intervals, whichever

occurs first. More frequent service is required when operating in extremely dusty or heavy load conditions.

Maintenance Items

Clean generator and check

bolts and nuts

Check and refill engine oil

Change engine oil (Note 1)

Clean spark plug

Clean air cleaner

Clean muffler exhaust

outlet

Clean fuel strainer

Replace air cleaner

element

Clean and adjust spark

plugs and electrodes

Replace oil filter

(Note 1)

Clean carburetor*

Clean carbon from cylinder

head*

Clean engine base

(oil pan)*

Check and adjust valve

seats*

Adjust valve clearance*

Replace spark plug

Replace fuel lines*

Overhaul engine*

(Note 2)

Every 8 hours

or daily

X

X

Every 50 Every 200

Hours Hours

X

X

X

X

X

X

X

X

Every 500

iHHHHHHHHHHHHHHHHHHHHHHHi

HHHHHHHHHHHHHHHHHHHHHHHH

HiHHHHHHHHHHHHHHHHHHHHHHii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii i i ! !iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii i i ! ii i'i'i i

Hours

X

X

X

X

X

X

Every 1000

Hours

ii!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i_ii_i_!__!_i_ii!ii!i__i!_i!_i!_i!_i!_i!_i___!_i_

_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i__,I_

__

X

X

* These maintenance operations should be performed by an authorized Sears service center. If you feel that

you are qualified to perform these maintenance items, you must order a service manual for instructions on

how to properly perform these procedures.

Note 1: Initial oil change and oil filter replacement must be performed after 20 hours of operation. Thereafter

change oil every 50 hours and replace oil filter after 200 hours.

Note 2: Must be performed by a Sears service center.

13

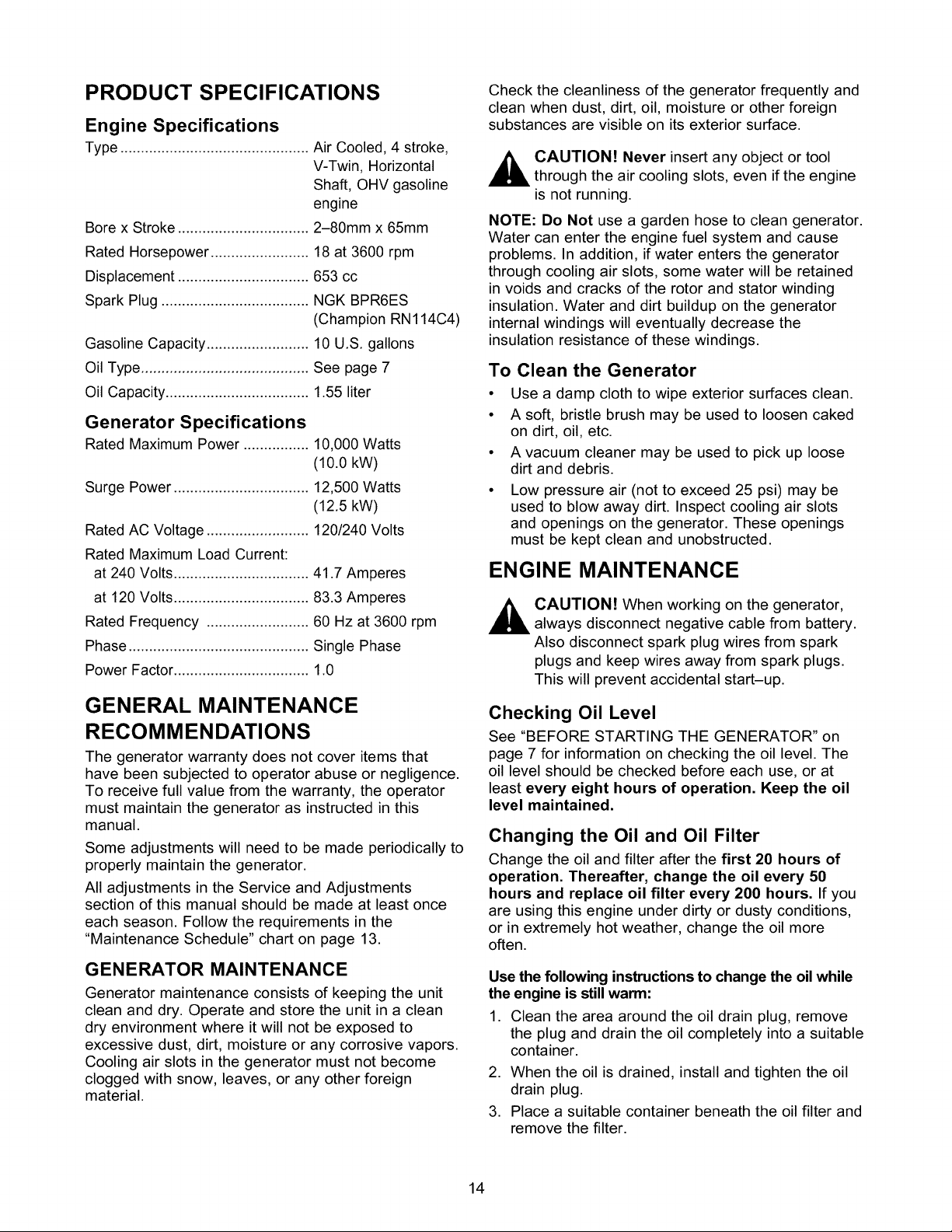

PRODUCT SPECIFICATIONS

Engine Specifications

Type .............................................. Air Cooled, 4 stroke,

V-Twin, Horizontal

Shaft, OHV gasoline

engine

Bore x Stroke ................................ 2-80mm x 65mm

Rated Horsepower ........................ 18 at 3600 rpm

Displacement ................................ 653 cc

Spark Plug .................................... NGK BPR6ES

(Champion RN114C4)

Gasoline Capacity ......................... 10 U.S. gallons

Oil Type......................................... See page 7

Oil Capacity ................................... 1.55 liter

Generator Specifications

Rated Maximum Power ................ 10,000 Watts

(10.0 kW)

Surge Power ................................. 12,500 Watts

(12.5 kW)

Rated AC Voltage ......................... 120/240 Volts

Rated Maximum Load Current:

at 240 Volts ................................. 41.7 Amperes

at 120 Volts ................................. 83.3 Amperes

Rated Frequency ......................... 60 Hz at 3600 rpm

Phase ............................................ Single Phase

Power Factor ................................. 1.0

GENERAL MAINTENANCE

RECOMMENDATIONS

The generator warranty does not cover items that

have been subjected to operator abuse or negligence.

To receive full value from the warranty, the operator

must maintain the generator as instructed in this

manual.

Some adjustments will need to be made periodically to

properly maintain the generator.

All adjustments in the Service and Adjustments

section of this manual should be made at least once

each season. Follow the requirements in the

"Maintenance Schedule" chart on page 13.

GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit

clean and dry. Operate and store the unit in a clean

dry environment where it will not be exposed to

excessive dust, dirt, moisture or any corrosive vapors.

Cooling air slots in the generator must not become

clogged with snow, leaves, or any other foreign

material.

Check the cleanliness of the generator frequently and

clean when dust, dirt, oil, moisture or other foreign

substances are visible on its exterior surface.

_ CAUTION! Never insert any object or tool

through the air cooling slots, even if the engine

is not running.

NOTE: Do Not use a garden hose to clean generator.

Water can enter the engine fuel system and cause

problems. In addition, if water enters the generator

through cooling air slots, some water will be retained

in voids and cracks of the rotor and stator winding

insulation. Water and dirt buildup on the generator

internal windings will eventually decrease the

insulation resistance of these windings.

To Clean the Generator

• Use a damp cloth to wipe exterior surfaces clean.

• A soft, bristle brush may be used to loosen caked

on dirt, oil, etc.

• A vacuum cleaner may be used to pick up loose

dirt and debris.

Low pressure air (not to exceed 25 psi) may be

used to blow away dirt. Inspect cooling air slots

and openings on the generator. These openings

must be kept clean and unobstructed.

ENGINE MAINTENANCE

_ AUTION! When working on the generator,

always disconnect negative cable from battery.

Also disconnect spark plug wires from spark

plugs and keep wires away from spark plugs.

This will prevent accidental start-up.

Checking Oil Level

See "BEFORE STARTING THE GENERATOR" on

page 7 for information on checking the oil level. The

oil level should be checked before each use, or at

least every eight hours of operation. Keep the oil

level maintained.

Changing the Oil and Oil Filter

Change the oil and filter after the first 20 hours of

operation. Thereafter, change the oil every 50

hours and replace oil filter every 200 hours. If you

are using this engine under dirty or dusty conditions,

or in extremely hot weather, change the oil more

often.

Use the following instructions to change the oilwhile

the engine is stillwarm:

1. Clean the area around the oil drain plug, remove

the plug and drain the oil completely into a suitable

container.

2. When the oil is drained, install and tighten the oil

drain plug.

3. Place a suitable container beneath the oil filter and

remove the filter.

14

4. Coattheo-ringofanewfilterwithengineoil.Turn

thenewfilterclockwiseuntilthegasketcontacts

thefilteradapter,thentightenanadditional

2/3turn.

5. Fillenginewithoilasdescribedonpage7.

6. Runtheengineforaminute;stoptheengineand

checkforoilleakagearoundtheoilfilter.Recheck

oillevel.

7. Whenthecrankcaseisfilledtotheproperlevel,

installandtightentheoilfillcap.

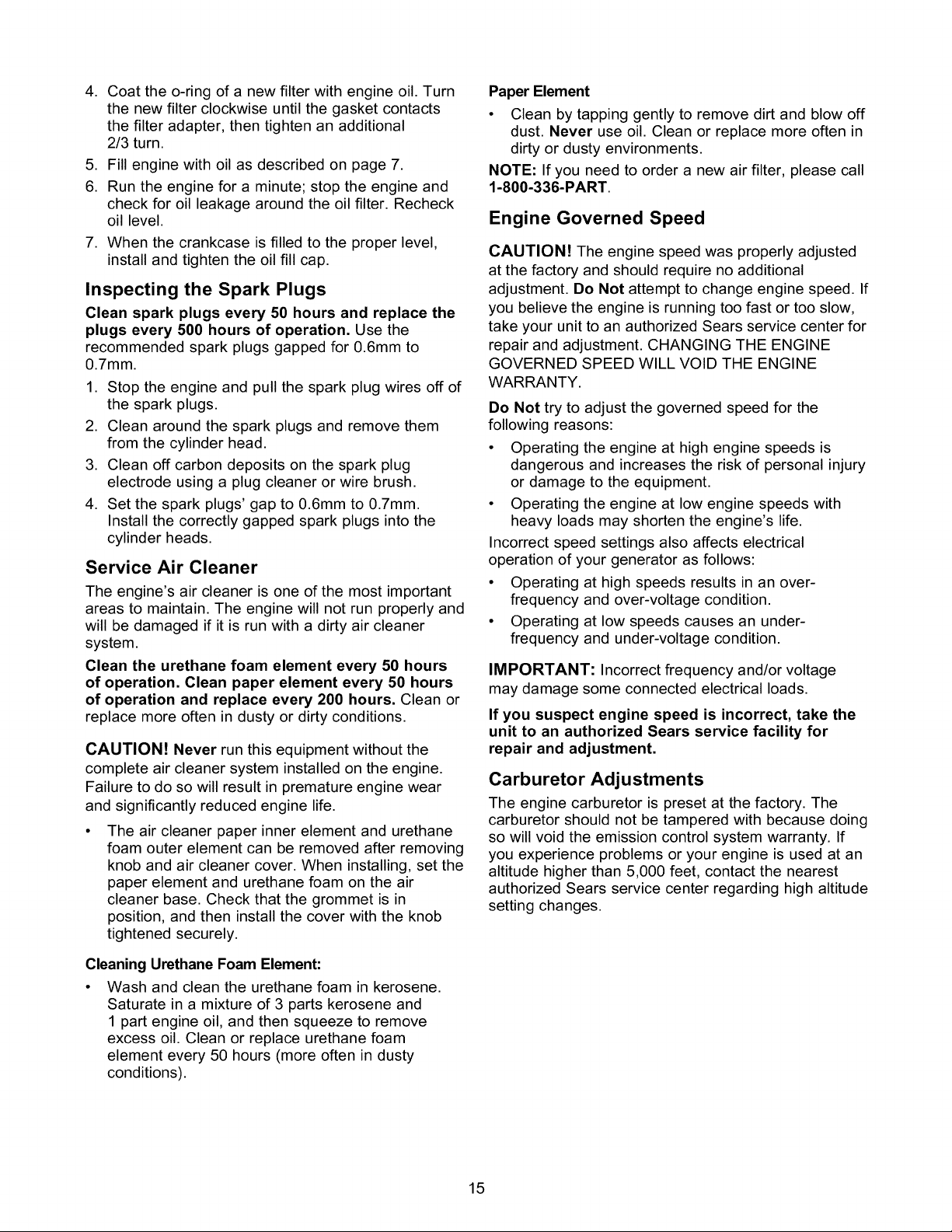

Inspecting the Spark Plugs

Clean spark plugs every 50 hours and replace the

plugs every 500 hours of operation. Use the

recommended spark plugs gapped for 0.6mm to

0.7mm.

1. Stop the engine and pull the spark plug wires off of

the spark plugs.

2. Clean around the spark plugs and remove them

from the cylinder head.

3. Clean off carbon deposits on the spark plug

electrode using a plug cleaner or wire brush.

4. Set the spark plugs' gap to 0.6mm to 0.7mm.

Install the correctly gapped spark plugs into the

cylinder heads.

Service Air Cleaner

The engine's air cleaner is one of the most important

areas to maintain. The engine will not run properly and

will be damaged if it is run with a dirty air cleaner

system.

Clean the urethane foam element every 50 hours

of operation. Clean paper element every 50 hours

of operation and replace every 200 hours. Clean or

replace more often in dusty or dirty conditions.

CAUTION! Never run this equipment without the

complete air cleaner system installed on the engine.

Failure to do so will result in premature engine wear

and significantly reduced engine life.

• The air cleaner paper inner element and urethane

foam outer element can be removed after removing

knob and air cleaner cover. When installing, set the

paper element and urethane foam on the air

cleaner base. Check that the grommet is in

position, and then install the cover with the knob

tightened securely.

Paper Element

• Clean by tapping gently to remove dirt and blow off

dust. Never use oil. Clean or replace more often in

dirty or dusty environments.

NOTE: If you need to order a new air filter, please call

1-800-336-PART.

Engine Governed Speed

CAUTION! The engine speed was properly adjusted

at the factory and should require no additional

adjustment. Do Not attempt to change engine speed. If

you believe the engine is running too fast or too slow,

take your unit to an authorized Sears service center for

repair and adjustment. CHANGING THE ENGINE

GOVERNED SPEED WILL VOID THE ENGINE

WARRANTY.

Do Not try to adjust the governed speed for the

following reasons:

• Operating the engine at high engine speeds is

dangerous and increases the risk of personal injury

or damage to the equipment.

• Operating the engine at low engine speeds with

heavy loads may shorten the engine's life.

Incorrect speed settings also affects electrical

operation of your generator as follows:

• Operating at high speeds results in an over-

frequency and over-voltage condition.

• Operating at low speeds causes an under-

frequency and under-voltage condition.

IMPORTANT: Incorrect frequency and/or voltage

may damage some connected electrical loads.

If you suspect engine speed is incorrect, take the

unit to an authorized Sears service facility for

repair and adjustment.

Carburetor Adjustments

The engine carburetor is preset at the factory. The

carburetor should not be tampered with because doing

so will void the emission control system warranty. If

you experience problems or your engine is used at an

altitude higher than 5,000 feet, contact the nearest

authorized Sears service center regarding high altitude

setting changes.

Cleaning Urethane Foam Element:

• Wash and clean the urethane foam in kerosene.

Saturate in a mixture of 3 parts kerosene and

1 part engine oil, and then squeeze to remove

excess oil. Clean or replace urethane foam

element every 50 hours (more often in dusty

conditions).

15

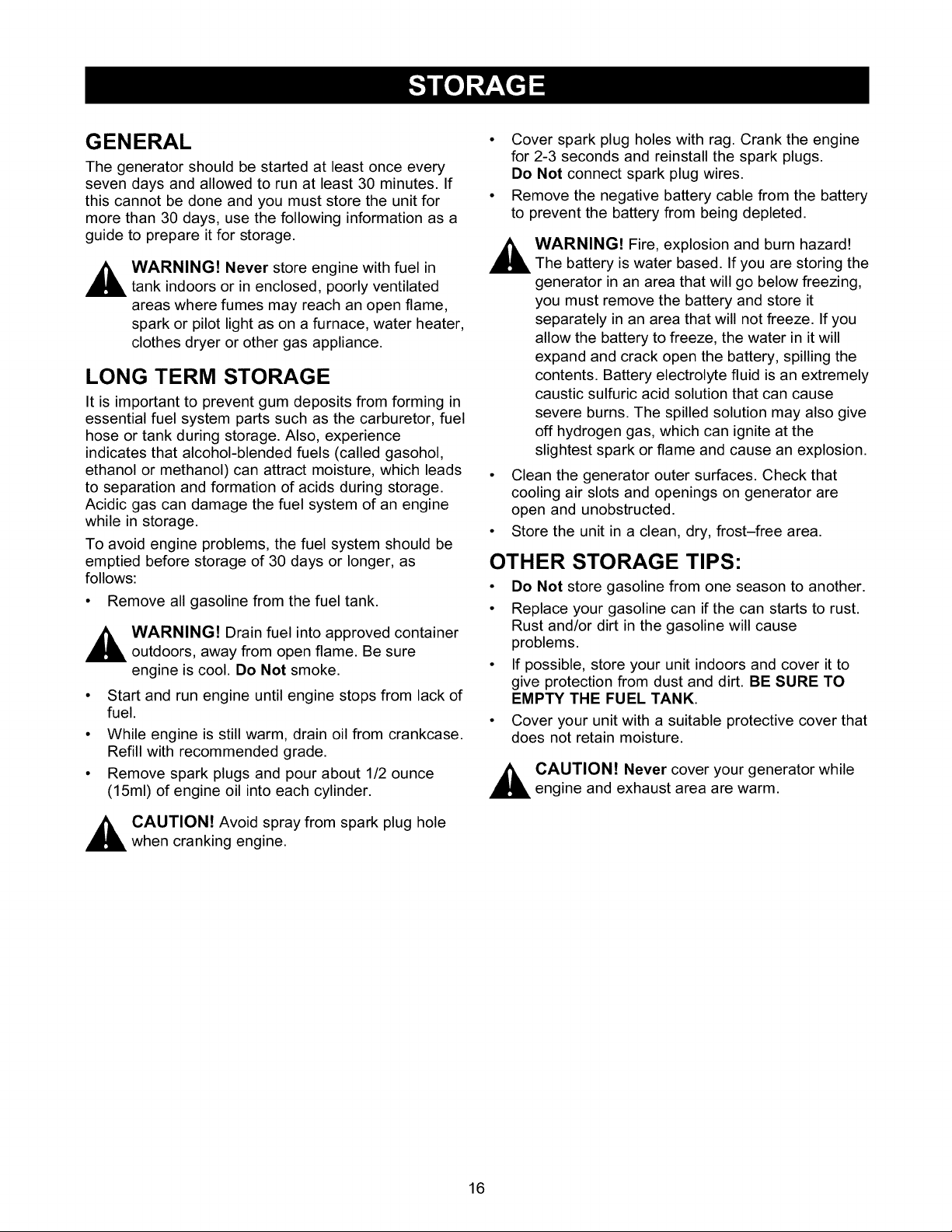

GENERAL

The generator should be started at least once every

seven days and allowed to run at least 30 minutes. If

this cannot be done and you must store the unit for

more than 30 days, use the following information as a

guide to prepare it for storage.

_ WARNING! Never store engine with fuel in

tank indoors or in enclosed, poorly ventilated

areas where fumes may reach an open flame,

spark or pilot light as on a furnace, water heater,

clothes dryer or other gas appliance.

LONG TERM STORAGE

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

hose or tank during storage. Also, experience

indicates that alcohol-blended fuels (called gasohol,

ethanol or methanol) can attract moisture, which leads

to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer, as

follows:

• Remove all gasoline from the fuel tank.

_ ARNING! Drain fuel into approved container

outdoors, away from open flame. Be sure

engine is cool. Do Not smoke.

• Start and run engine until engine stops from lack of

fuel.

• While engine is still warm, drain oil from crankcase.

Refill with recommended grade.

• Remove spark plugs and pour about 1/2 ounce

(15ml) of engine oil into each cylinder.

• Cover spark plug holes with rag. Crank the engine

for 2-3 seconds and reinstall the spark plugs.

Do Not connect spark plug wires.

• Remove the negative battery cable from the battery

to prevent the battery from being depleted.

WARNING! Fire, explosion and burn hazard!

The battery is water based. If you are storing the

generator in an area that will go below freezing,

you must remove the battery and store it

separately in an area that will not freeze. If you

allow the battery to freeze, the water in it will

expand and crack open the battery, spilling the

contents. Battery electrolyte fluid is an extremely

caustic sulfuric acid solution that can cause

severe burns. The spilled solution may also give

off hydrogen gas, which can ignite at the

slightest spark or flame and cause an explosion.

Clean the generator outer surfaces. Check that

cooling air slots and openings on generator are

open and unobstructed.

Store the unit in a clean, dry, frost-free area.

OTHER STORAGE TIPS:

• Do Not store gasoline from one season to another.

• Replace your gasoline can if the can starts to rust.

Rust and/or dirt in the gasoline will cause

problems.

• If possible, store your unit indoors and cover it to

give protection from dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

• Cover your unit with a suitable protective cover that

does not retain moisture.

_ AUTION! Never cover your generator while

engine and exhaust area are warm.

_ AUTION! Avoid spray from spark plug hole

when cranking engine.

16

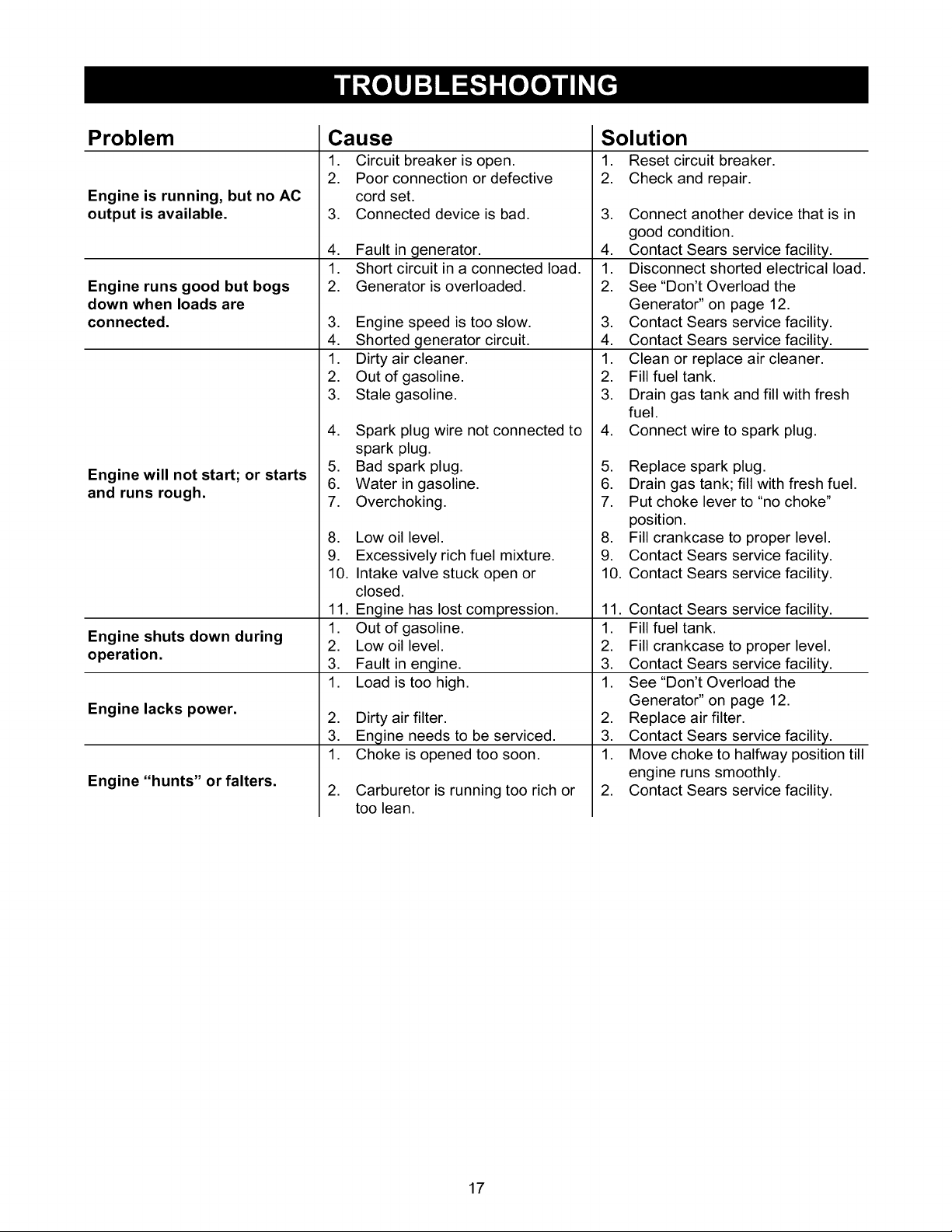

Problem

Engine is running, but no AC

output is available.

Engine runs good but bogs

down when loads are

connected.

Engine will not start; or starts

and runs rough.

Engine shuts down during

operation.

Engine lacks power.

Engine "hunts" or falters.

Cause

1. Circuit breaker is open.

2. Poor connection or defective

cord set.

3. Connected device is bad.

4. Fault in generator.

1. Short circuit in a connected load.

2. Generator is overloaded.

3. Engine speed is too slow.

4. Shorted generator circuit.

1. Dirty air cleaner.

2. Out of gasoline.

3. Stale gasoline.

4. Spark plug wire not connected to

spark plug.

5. Bad spark plug.

6. Water in gasoline.

7. Overchoking.

8. Low oil level.

9. Excessively rich fuel mixture.

10. Intake valve stuck open or

closed.

11. Engine has lost compression.

1. Out of gasoline.

2. Low oil level.

3. Fault in engine.

1. Load is too high.

2. Dirty air filter.

3. Engine needs to be serviced.

1. Choke is opened too soon.

.

Carburetor is running too rich or

too lean.

Solution

1. Reset circuit breaker.

2. Check and repair.

3. Connect another device that is in

good condition.

4. Contact Sears service facility.

1. Disconnect shorted electrical load.

2. See "Don't Overload the

Generator" on page 12.

3. Contact Sears service facility.

4. Contact Sears service facility.

1. Clean or replace air cleaner.

2. Fill fuel tank.

3. Drain gas tank and fill with fresh

fuel.

4. Connect wire to spark plug.

5. Replace spark plug.

6. Drain gas tank; fill with fresh fuel.

7. Put choke lever to "no choke"

position.

8. Fill crankcase to proper level.

9. Contact Sears service facility.

10. Contact Sears service facility.

11

Contact Sears service facility.

1.

Fill fuel tank.

2.

Fill crankcase to proper level.

3.

Contact Sears service facility.

1.

See "Don't Overload the

Generator" on page 12.

.

Replace air filter.

3.

Contact Sears service facility.

1.

Move choke to halfway position till

engine runs smoothly.

.

Contact Sears service facility.

17

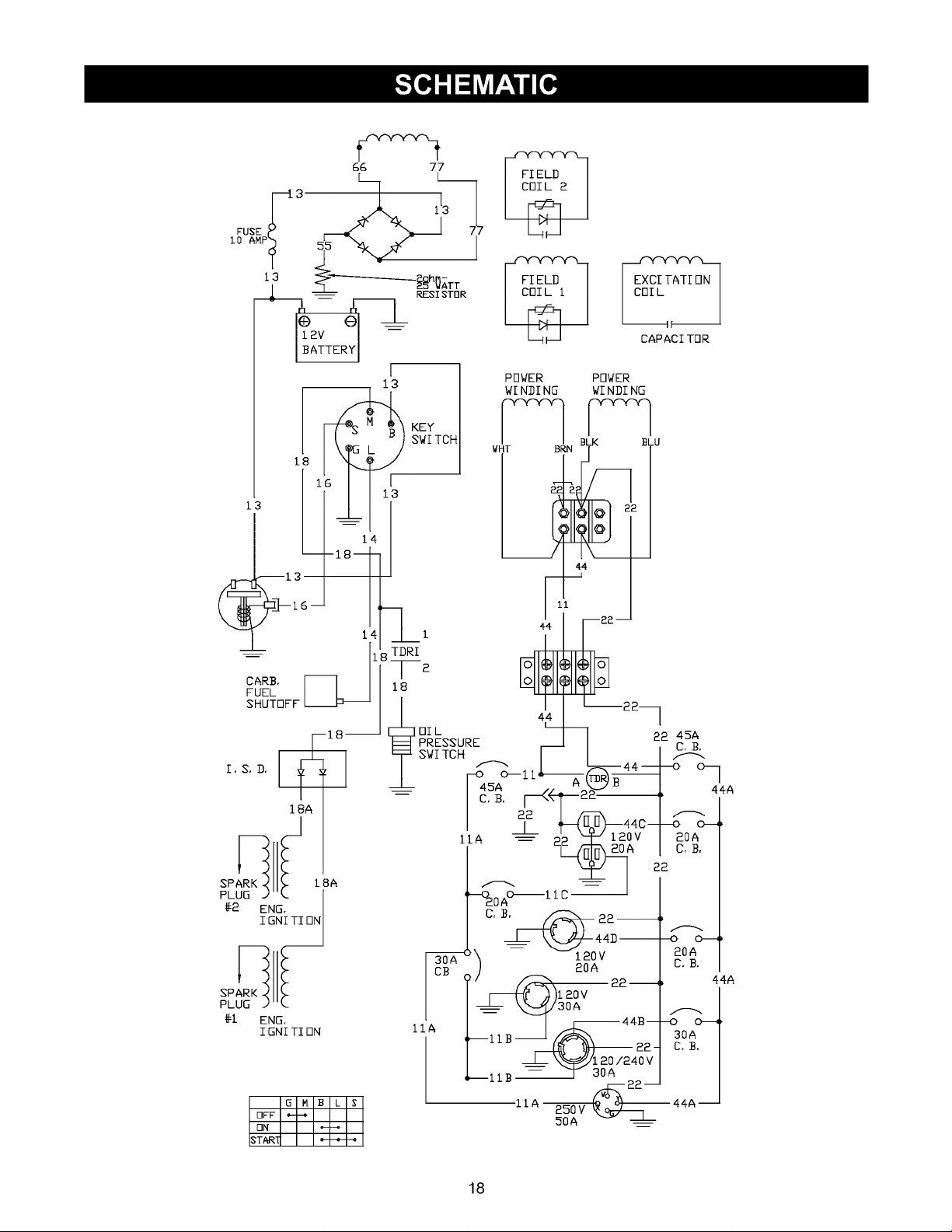

13

COILI_

CAPACI TOR

POWER

WI N]]I NG

KEY

SWZTCH

I

44

#2 ENG,

I GNZ TI ON

SPARK _A

#[ ENG,

I GNI TI ON ii A

G M B L S

OFF

ON

$TARG

_'_ 120V

_44D--

I) 20A

_.._'_-_J 30 A

I _44B- _'-"o--

_40V-

_IlB -- T 30A

IIA _44A--

50A

18

20A

C,B,

44A

Loading...

Loading...