Page 1

120 VOLT

2500 WATT

Owner's

anuam

®

AC

MODEL NO.

580.327750

LU

a

0

0 8

_03

0

r_

o_

o_,_

z_- z

_=_ (.9LLI..... -4"--m

OOj_

,o

RATO

o

m

CAUTION: Before using this

product, read this manual and

follow all Safety Rules and

Operating Instructions.

HOURS: Mon. - Fri. 8 a.m. to 5 p.m. (CST)

SEARS. ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Partr',lo.B2418 REV._3/12/98

GENERATOR

CUSTOMER

HELPLINE

1_800-222-3136

Page 2

SERVICEANDADJUSTMENTS .......... 12-13

SAFETYRULES.............. INSIDECOVER

MAINTENANCEAGREEMENT................. 10

PRODUCTSPECIFICATIONS.............. 10

WARRANTY............................ 2

OPERATION......................... 4-9

MAINTENANCE........................ 9-12

LIMITED ONE YEAR WARRANTY CRAFTSMAN GENERATORS

SEARS warrants to the original purchaser that the alternator and engine for its portable generator will be free from

defects inmaterials or'workmanship for the items and period set forth below from the date of original purchase, this

warranty is not trasnferable.

Alternator 1 year' 90 Days

Engine 1 year 90 Days

NOTE: For the purpose of this warranty "Consumer Use" means personal residential household and emergency use

by original purchaser, not to be used as a primary source of power: "Commercial Use" means all other uses, includ-

ing rental, construction, commercial, primary source of residential household power and income producing purposes°

Once a generator has experienced commercial use, it shall thereafter be considered a commercial use generator for

the purpose of this warranty.

SERVICERECOMMENDATIONS........... 12

TROUBLESHOOTINGPOINTS ............. 14

WIRINGDIAGRAM...................... 15

REPAIRPARTS...................... 16-37

EMISSIONSWARRANTY................ 38-39

PARTSORDERING............. BACKCOVER

CONSUMER* COMMERCIAL*

During said warranty period, SEARS wit!, at its option, repair or replace any part which, upon examinations by

SEARS, is found to be defective under normal use and service_** Starting batteries and expendable items such as

spark plugs and air filters, which become worn during normal use are not warranted by SEARS. All transportation

costs under warranty, including return to the factory if necessary, are to be borne by the pruchaser and prepaid by

him° This warranty does not cover normal maintenance and service and does not apply to a generator set, alternator

or engine, or parts which have been subjected to improper or unauthorized installation or alteration, misuse, negli-

gence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in SEAR's judgment, to

adversely affect its performance and reliability°

**NORMAL WEAR: As with all mechanical devices, engines need periodic parts service and replacement to perform

well. This warranty will not cover repair when normal use has exhausted the life of a part or engine,.

THERE tS NO OTHER EXPRESS WARRANTY. SEARS HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRAN-

TIES, INCLUDING BUT NOT LIMITED TO THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE TO THE EXTENT PERMITTED BY LAW° THE DURATION OF ANY IMPLIED WARRANTIES WHICH

CANNOT BE DISCLAIMED IS LIMITED TO THE TIME PERIOD AS SPECIFIED IN THE EXPRESS WARRANTY.

LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, OR SPECIAL DAMAGES UNDER ANY AND ALL WARRANTIES

IS EXCLUDED° Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limita-

tion of incidental or'consequential damages, so the above limitations or' exclusions may not apply to you_ This war-

ranty gives you specific legal rights and you may also have other rights, which vary from state to state.

For service, see your nearest SEARS authorized warranty service facility. Warranty service can be performed only by

a SEARS authorized service facility° This warranty will not apply to service at any other facility° At the time of request-

ing warranty service, evidence of original purchase date must be presented.

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60719 U.S.A.

2

Page 3

CAUTION:ALWAYSDISCONNECTSPARKPLUGWIREANDPLACEWIREWHEREIT CAN- F_

NOTCONTACTSPARKPLUG,TO PREVENTACCIDENTALSTARTINGWHENSETTINGUP,

TRANSPORTING,ADJUSTING,ORMAKING REPAIRSTOYOURGENERATOR

IMPORTANT

THISGENERATORIS DESIGNEDFOROUTDOORUSEONLY.USINGTHIS GENERATORINSIDEANY BUILDINGORENCLOSURE,

INCLUDINGTHEGENERATORCOMPARTMENTOFA RECREATIONALVEHICLE(RV), IS DANGEROUS,FIREORANEXPLOSIONMAY

RESULT.NOUSERPERFORMEDMODIFICATIONS,INCLUDINGVENTINGOFEXHAUSTAND!ORCOOLINGVENTILATION,WILL ELiM-

INATETHE DANGER°

• If this unit isusedfor backup power in the event of a utility

powerfailure, takethefollowing steps: BEFORECONNECT-

INGTHEGENERATORTOAN ELECTRICALSYSTEM,OPEN

THEMAINCIRCUITBREAKERORMAIN SWITCHSERVIC-

INGTHESYSTEMTOISOLATETHEGENERATORFROM

THEELECTRICUTILITY.FAILURETOISOLATETHE GENER-

ATORANDUTILITYSYSTEMSMAY RESULTINDAMAGE

TOTHEGENERATORANDMAYALSO RESULTIN INJURY

ORDEATHTOELECTRICUTILITYWORKERSDUETO

BACKFEEDOFELECTRICALENERGY.

• This generator produces dangerously highvoltage that can

causeextremelyhazardouselectrical shock.. Avoid contact

with barewires,terminals, etc. Neverpermit any unqualified

personto operateor service the generator.

- DONOToperatethis equipmentin the rain, while standing

in water,while barefoot, or while hands or feet are wet..Dan-

gerous electricalshock will result.

, TheNational ElectricCode requires the frame and external

electrically conductive parts of the generator be properly

connectedto an approvedearth ground° Localelectrical

codesmay also requireproper grounding of the generator°

Consultwith a localelectricianfor grounding requirements

in your area.

Theengineexhaustfromthisproductcontainschemicals

knowntotheStateofCaliforniato causecancer,bidhdefects H

Gasolineis highly FLAMMABLEand its vaporsare EXPLO-

SIVE.Donot permit smoking, open flames, sparksor heat

in the vicinity while handling gasoline..Avoid spilling gaso-

line ona hot engine..Complywith alt lawsregulating storage

and handlingor gasoline_.

• Never addfuel whileunit is running

° Do not overfill thefuel tank.Always allow room for fuel

expansion. If tank is overfilled, fuel can overflow onto a hot

engine and cause FIREor an EXPLOSION..

• Drainall gasoline from tank before transporting yourgener-

ator insideyour car or other vehicle.

, Neverstore generator with fuel in tank where gasoline

vapors might reach an open flame orspark or pilot light (as

on afurnace, water heateror clothes dryer). FIREor AN

EXPLOSIONmight resulL

• Allow at least2 feet of clearanceon all sides of generator,

evenwhile operating unit outdoors, or you could damage

the unit..

• Generatorexhaustgases contain DEADLYcarbonmonoxide

gas_This dangerousgas, if breathed in sufficient concentra-

tions, can causeunconsciousness or evendeath_Operate

this equipment outdoors only in the open air whereade-

quate ventilation is available.

• Donot insert any object through cooling slots ofthe engine-

generator°You coulddamagethe unit or injure yourself.

• DONOTattempt to change the engine governed speed.Fac-

tory settings are correct when you receivethe unit..Exces-

sively high engine speeds may result ininjury or damageto

equipment.

o DONOT usethe unit if it has beendamaged..Repairor

replaceall damaged or defective components before you

run the unit.

• Do not permit childrento operate or servicethe unit..

= Readyour Owner'sManual carefully..Only personswho are

familiar with these safety rulesand havebeen properly

instructed inthe use of this product should be permittedto

usethe product.,

Note:Inthe Stateof Californiaasparkarrestorisrequiredbylaw(Sec-

tion4442oftheCaliforniaPublicResourcesCode).,Otherstatesmay

havesimilartaws_Federallawsapplyonfedera!lands,

,t_ LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.IT MEANS "ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED!!!"

3

Page 4

Your AC generator was completely assernsble at the fac-

tory. It is ready for use after it has been properly serviced

with the recommended lubricating oil and fuel.,

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR GENERATOR, PLEASE CALL THE GENERA-

TOR HELPLINE AT 1-800_222-3136.

IMPORTANT: ANY ATTEMPT TO RUN THE ENGINE

BEFORE tT HAS BEEN SERVICED WITH THE RECOM-

MENDED OIL WILL RESULT IN AN ENGINE FAILURE..

CORD SETS AND CONNECTOR PLUGS

TOQREMOVE GENERATOR FROM CARTON

Set the carton on a flat rigidsurface with "THIS SIDE

UP" arrows pointing upward.

° Carefully open the top flaps of shipping carton_

° Cut down corners at one end of shipping carton and

lay that side of carton down flat.

- Remove packing material, carton fillers, etc_.

° Remove the generator from the shipping carton°

TO ADJUST HANDLE GUIDE

Yourgenerator is equipped with a wheel kit for easy man-

ueveringo After' you remove the generator from the carton

Lifthandle into upright position and push the black slides

down to hold the handle in position. The handle may be

lowered for easier' storage.

120 VOLT CORD SETS

use only high quality, wefl-insutated, extension cords with

the generator's 120-volt type electrical receptacle&

Each receptacle of this pair is protected against overload

by a single 20-amp push-to-reset type of circuit breaker°

Use each receptacle to operate 120 volts, single phase

60 Hz, A C electrical loads requiring up to 2400 watts (2.4

kW) at 20 amps of current_

!

Figure-1

Check the ratings of all extension cords before you use

them Extension cord sets used should be rated 125 volts

at 20 AC amps or greater' for' most electrical devices..

Some devices, however, may not require this type of

extension cord° Check the owner's manual of those

devices for the manufacturer's recommendations.

CAUTION:Althougheachreceptacleis ratedfor120

voltsat 20 amps(2400 wattsor2A KW), the generator

israted for a totalof 2500 watts.Poweringloadsthat

exceedthewattagecapacityofthe generatorcandam-

age itor causeseriousinjuries.Thetotal loadswith

120 voltspoweredthoughthese receptaclesshouldnot

exceed20 amps.

Keep extension cords as short as possible, preferably

less than 15 feet long to prevent voltage drop and possi-

bly overheating of wires.

12 VOLTS DC 10 AMP BATTERY CHARGE OUTLET

Figure-2

The 12 VOLT DC outlet has a unique configuration that

will only allow the 12 volt wire harness to be inserted,

When the 12 volt harness is properly inserted the red wire

wil! be positive 12 volts and the blackwire will be negative_

DO NOT modify any plug to make it fit this outlet or dam-

age to the generator may result.

4

Page 5

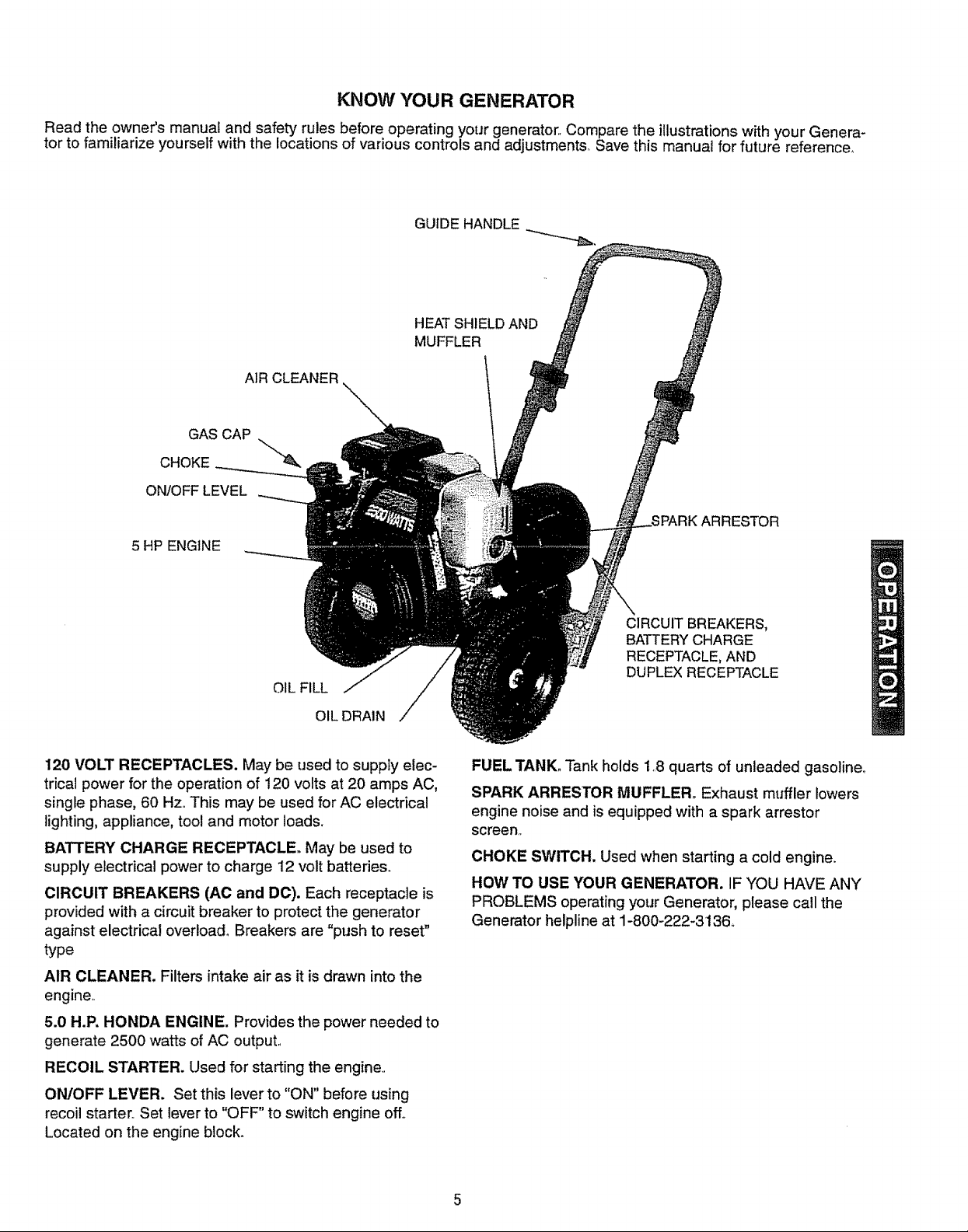

KNOW YOUR GENERATOR

Read the owner's manual and safety rules before operating your generator. Compare the illustrations with your Genera-

tor to familiarize yourself with the locations of various controls and adjustments. Save this manual for future reference_

GUIDE HANDLE

HEATSHIELD AND

MUFFLER

AIR CLEANER

GAS CAP

CHOKE

ON/OFFLEVEL

5 HP ENGINE

OIL FILL

OIL DRAIN

120 VOLT RECEPTACLES. May be used to supply elec-

trical power for the operation of 120 volts at 20 amps AC,

single phase, 60 Hz,.This may be used for AC electrical

lighting, appliance, tool and motor loads.

BATTERY CHARGE RECEPTACLE. May be used to

supply electrical power to charge 12 volt batteries.

CIRCUIT BREAKERS (AC and DC), Each receptacle is

provided with a circuit breaker to protect the generator

against electrical overload° Breakers are "push to reset"

type

AIR CLEANER. Filters intake air as it is drawn into the

engine

5.0 H.P. HONDA ENGINE. Provides the power needed to

generate 2500 watts of AC output,

RECOIL STARTER. Used for starting the engine,

ON/OFF LEVER. Set this lever to "ON" before using

recoil starter Set lever to "OFF" to switch engine off.

Located on the engine block.

CIRCUIT BREAKERS,

BATTERY CHARGE

RECEPTACLE, AND

DUPLEX RECEPTACLE

FUEL TANK. Tank holds 18 quarts of unleaded gasoline.

SPARK ARRESTOR MUFFLER. Exhaust muffler lowers

engine noise and is equipped with a spark arrestor

screen°

CHOKE SWITCH. Used when starting a cold engine.

HOW TO USE YOUR GENERATOR. IF YOU HAVE ANY

PROBLEMS operating your Generator, please call the

Generator helpline at 1-800-222-3136.

5

Page 6

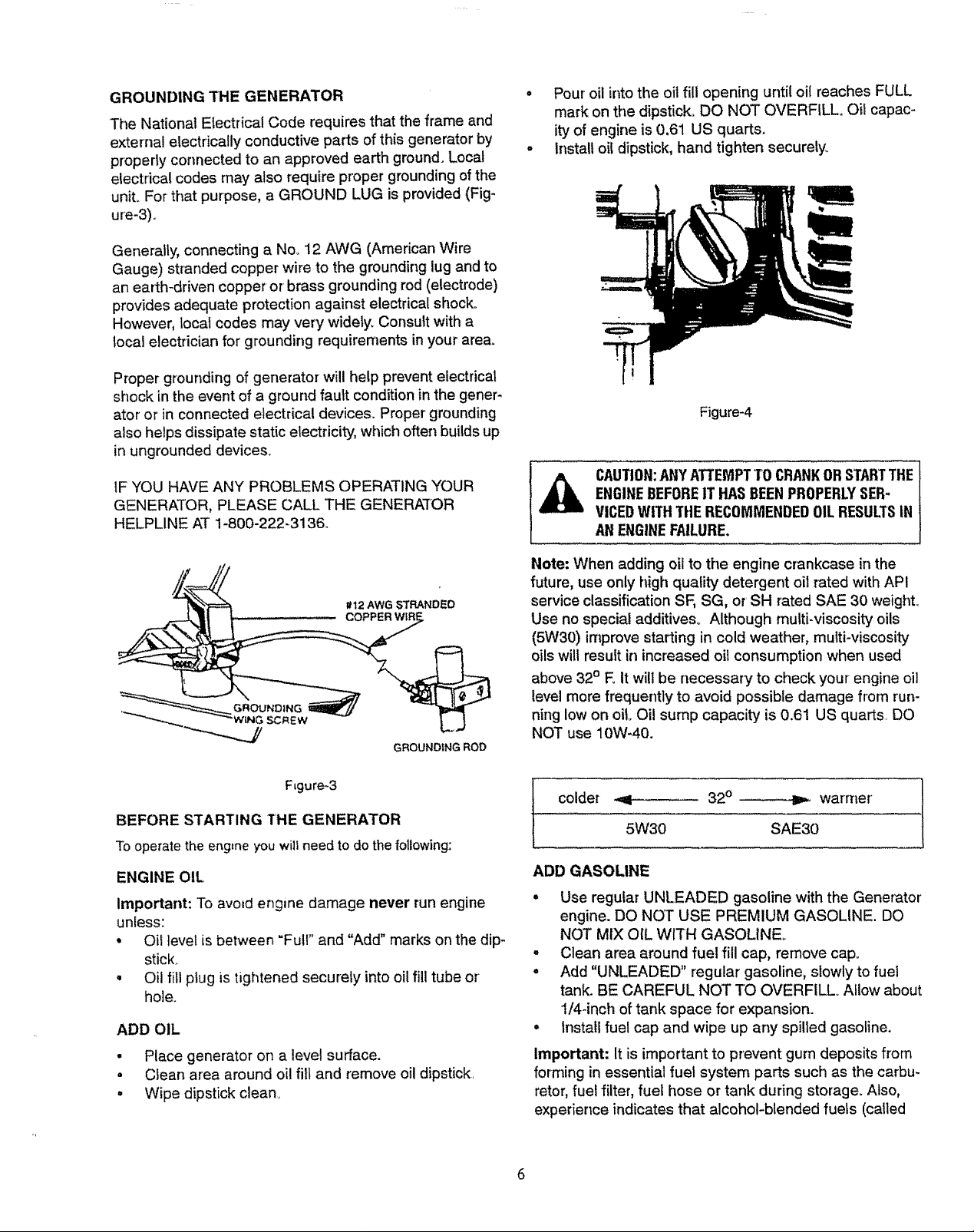

GROUNDING THE GENERATOR

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator by

properly connected to an approved earth ground. Local

electrical codes may also require proper grounding of the

unit. For that purpose, a GROUND LUG is provided (Fig-

ure-3).,

Generally, connecting a No. 12 AWG (American Wire

Gauge) stranded copper wire to the grounding lug and to

an earth-driven copper or brass grounding rod (electrode)

provides adequate protection against electrical shock.

However, tocaf codes may very widely. Consult with a

local electrician for grounding requirements in your area.

Proper grounding of generator will help prevent electricat

shock in the event of a ground fault condition in the gener-

ator or in connected electrical devices. Proper grounding

also helps dissipate static electricity, which often builds up

in ungrounded devices.,

IF YOU HAVE ANY PROBLEMS OPERATING YOUR

GENERATOR, PLEASE CALL THE GENERATOR

HELPLINE AT 1-800-222-3136.,

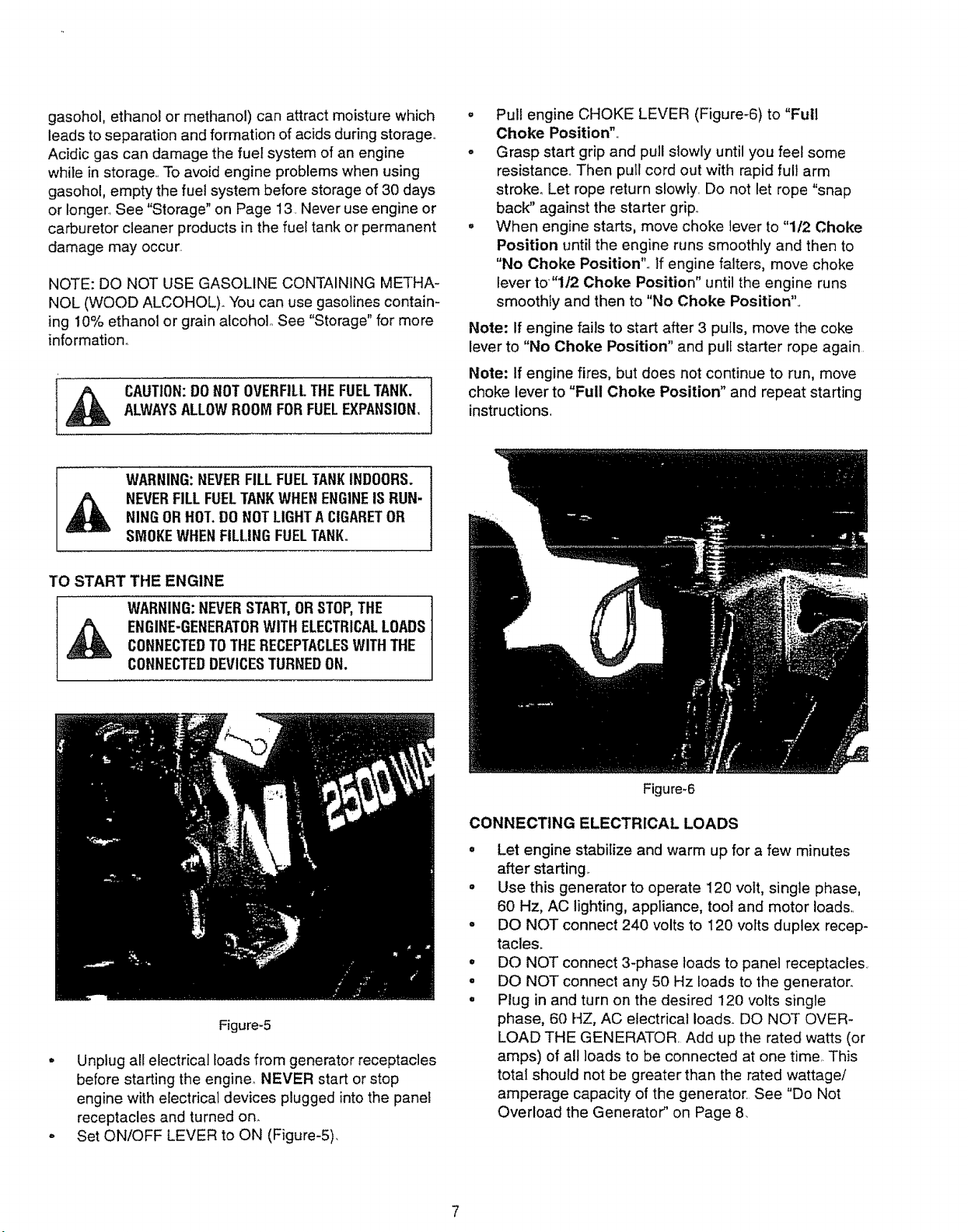

• Pour oilinto the oil fill opening until oil reaches FULL

mark on the dipstick. DO NOT OVERFILL. Oii capac-

ity of engine is 0.61 US quarts.

o Install oil dipstick, hand tighten securely

Figure-4

CAUTION:ANYATTEMPTTOCRANKORSTARTTHE

ENGINEBEFOREIT HASBEENPROPERLYSER-

VICEDWITHTHERECOMMENDEDOILRESULTSIN

ANENGINEFAILURE.

t_12 AWG STRANDEO

GROUNDING ROD

FLgure-3

BEFORE STARTING THE GENERATOR

Tooperatethe engtne youwill need todothe following:

ENGINE OIL,

Important: To avoid engine damage never run engine

unless:

• Oil level is between =Full" and "Add" marks on the dip-

stick,.

• Oil fillplug is tightened securely intooi! fill tube or

hole.

ADD OIL

• Place generator on a level surface.

• Clean area around oil fill and remove oildipstick.

• Wipe dipstick clean,.

Note: When adding oil to the engine crankcase in the

future, use only high quality detergent oit rated with API

service classification SF, SG, or SH rated SAE 30 weighL

Use no special additives. Although multi-viscosity oils

(5W30) improve starting in cold weather, multi-viscosity

oilswill result in increased oil consumption when used

above 32° E It will be necessary to check "yourengine oil

level more frequently to avoid possible damage from run-

ning low on oil Oil sump capacity is 0.61 US quarts. DO

NOT use 10W-40.

colder ._ 32° _LI=.- warmer

5W30 SAE30

ADD GASOLINE

• Use regular UNLEADED gasoline with the Generator

engine. DO NOT USE PREMIUM GASOLINE. DO

NOT MIX OIL WITH GASOLINE°

- Clean area around fuel fill cap, remove cap°

° Add "UNLEADED" regular gasoline, slowly to fuel

tank. BE CAREFUL NOT TO OVERFILL° Allow about

1/4-inch of tank space for expansion.

• tnstaflfuel cap and wipe up any spilted gasoline.

Important: It is important to prevent gum deposits from

forming in essential fuel system parts such as the carbu-

retor, fuel filter, fuei hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (catled

Page 7

gasohol,ethanolormethanol)canattractmoisturewhich

leadstoseparationandformationofacidsduringstorage..

Acidicgascandamagethefuelsystemofanengine

whileinstorage.Toavoidengineproblemswhenusing

gasohoI,emptythefuelsystembeforestorageof 30 days

or longer., See "Storage" on Page 13. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

NOTE: DO NOT USE GASOLINE CONTAINING METHA-

NOL (WOOD ALCOHOL). You can use gasolines contain-

ing 10% ethanol or grain alcohol See "Storage" for more

information°

CAUTION:DO NOTOVERFILLTHEFUELTANK.

ALWAYSALLOWROOMFORFUELEXPANSION.

WARNING:NEVERFILLFUELTANKINDOORS.

NEVERFILLFUELTANKWHENENGINEIS RUN-

NINGOR HOT,DONOTLIGHTA CIGARETOR

SMOKEWHENFILLINGFUELTANK.

o Pul! engine CHOKE LEVER (Figure-6) to "Full

Choke Position",.

o Grasp start grip and pull slowly until you feel some

resistance., Then pull cord out with rapid full arm

stroke. Let rope return slowly. Do not let rope "snap

back" against the starter grip.

. When engine starts, move choke lever to "1/2 Choke

Position until the engine runs smoothly and then to

"No Choke Position". if engine falters, move choke

lever to' "112 Choke Position" until the engine runs

smoothly and then to "No Choke Position"..

Note: If engine fails to start after 3 pulls, move the coke

lever to "No Choke Position" and pull starter rope again.

Note: If engine fires, but does not continue to run, move

choke lever to "Full Choke Position" and repeat starting

instructions..

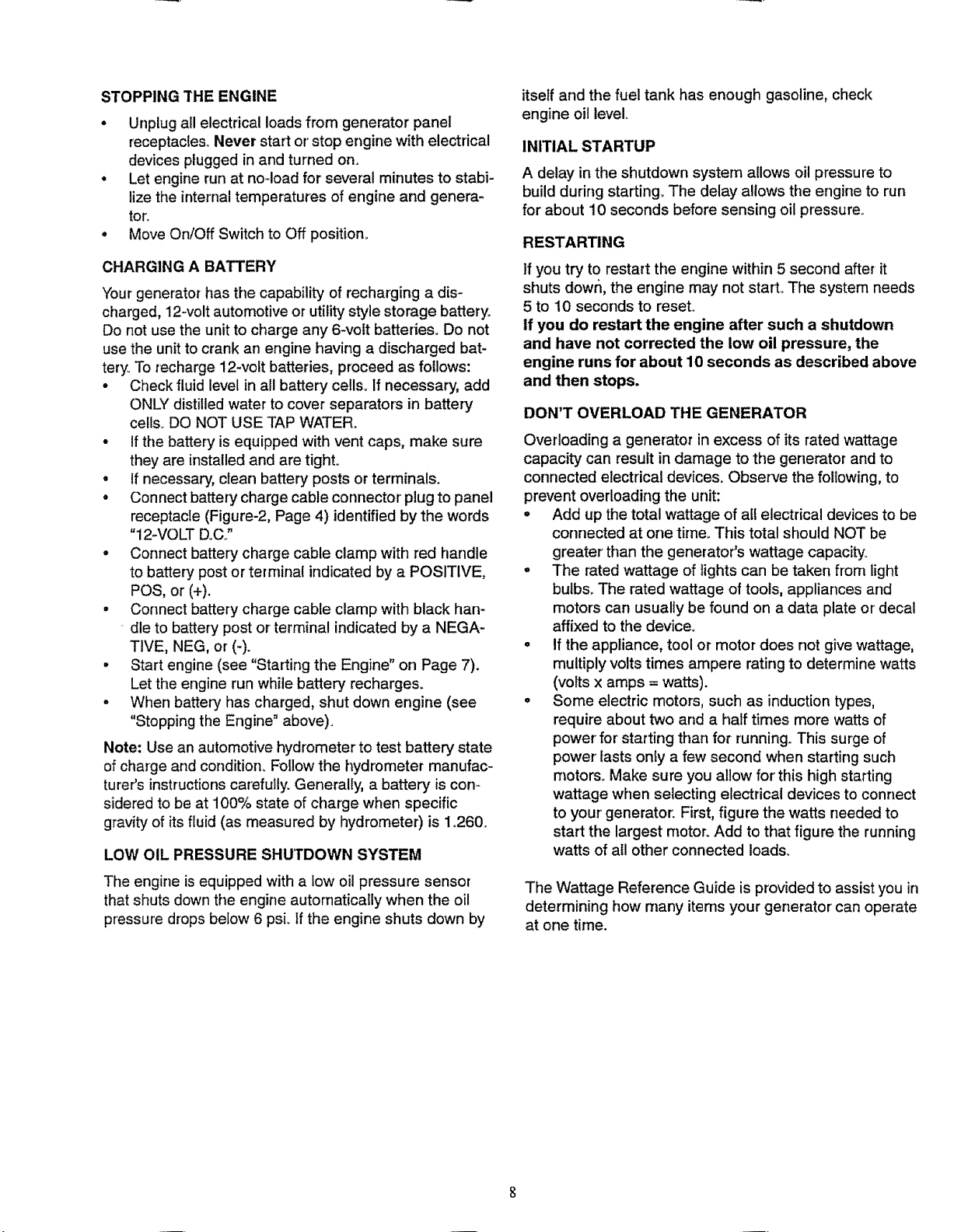

TO START THE ENGINE

WARNING:NEVERSTART,ORSTOP,THE

ENGINE-GENERATORWITHELECTRICALLOADS

CONNECTEDTOTHE RECEPTACLESWITHTHE

CONNECTEDDEVICESTURNEDON.

Figure-5

• Unplug all electrical loads from generator receptacles

before starting the engine_ NEVER start or stop

engine with electrical devices plugged into the panel

receptacles and turned on.

° Set ON/OFF LEVER to ON (Figure-5).

Figure-6

CONNECTING ELECTRICAL LOADS

o Let engine stabilize and warm up for a few minutes

after starting..

• Use this generator to operate 120 volt, single phase,

60 Hz, AC lighting, appliance, tool and motor loads,.

° DO NOT connect 240 volts to 120 voIts duplex recep-

tacles.

• DO NOT connect 3-phase loads to panel receptacles.

° DO NOT connect any 50 Hz loads to the generator.

o Plug in and turn on the desired 120 volts single

phase, 60 HZ, AC electrical loads. DO NOT OVER-

LOAD THE GENERATOR Add up the rated watts (or

amps) of all loads to be connected at one time.. This

total should not be greater than the rated wattage/

amperage capacity of the generator. See "Do Not

Overload the Generator" on Page 8.

Page 8

STOPPING THE ENGINE

° Unplug all electrical loads from generator panel

receptacles° Never start or"stop engine with electrical

devices plugged in and turned on.

• Let engine run at no-load for' several minutes to stabi-

lize the internal temperatures of engine and genera-

tort

• Move On/Off Switch to Off position.

CHARGING A BATTERY

Your generator has the capability of recharging a dis-

charged, 12-volt automotive or utility style storage battery°

Do not use the unit to charge any 6-volt batteries° Do not

use the unit to crank an engine having a discharged bat-

tery To recharge 12-volt batteries, proceed as follows:

° Check fluid level in all battery cells.. If necessary, add

ONLY distilled water to cover separators in battery

cells. DO NOT USE TAP WATER.

• if the battery is equipped with vent caps, make sure

they are installed and are tight.

° If necessary, clean battery posts or terminals°

° Connect battery charge cable connector' plug to panel

receptacle (Figure-2, Page 4) identified by the words

"12-VOLT DoC."

• Connect battery charge cable clamp with red handle

to battery post or terminal indicated by a POSITIVE,

POS,or (+).

° Connect battery charge cable clamp with black han-

" die to battery post or terminal indicated by a NEGA-

TIVE, NEG, or (-).

• Start engine (see "Starting the Engine" on Page 7).

Let the engine run while battery recharges.

, When battery has charged, shut down engine (see

"Stopping the Engine" above).

Note: Use an automotive hydrometer to test battery state

of charge and condition_ Follow the hydrometer manufac-

turer's instructions carefully. Generally, a battery is con*

sidered to be at 100% state of charge when specific

gravity of its fluid (as measured by hydrometer) is 1o260.

LOW OIL PRESSURE SHUTDOWN SYSTEM

itsetf and the fuel tank has enough gasoline, check

engine oil level.

INITIAL STARTUP

A delay in the shutdown system allows oil pressure to

build during starting., The delay allows the engine to run

for about 10 seconds before sensing oil pressure.

RESTARTING

If you try to restart the engine within 5 second after it

shuts dowrY,the engine may not start_ The system needs

5 to 10 seconds to reseL

If you do restart the engine after such a shutdown

and have not corrected the low oil pressure, the

engine runs for about 10 seconds as described above

and then stops.

DON'T OVERLOAD THE GENERATOR

Overloading a generator in excess of its rated wattage

capacity can result in damage to the generator and to

connected electrical devices. Observe the following, to

prevent overloading the unit:

= Add up the total 'wattage of afl electrical devices to be

connected at one time° This total should NOT be

greater than the generator's wattage capacity_

= The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can usually be found on a data plate or decal

affixed to the device°

° if the appliance, tool or motor does not give wattage,

multiply volts times ampere rating to determine watts

(volts x amps = watts).

, Some electric motors, such as induction types,

require about two and a half times more watts of

power' for starting than for running° This surge of

power lasts only a few second when starting such

motors. Make sure you allow for'this high starting

wattage when selecting electrical devices to connect

to your generator. First, figure the watts needed to

start the largest motor. Add to that figure the running

watts of all other connected loadso

The engine is equipped with a low oil pressure sensor

that shuts down the engine autornaticaIly when the oil

pressure drops below 6 psL If the engine shuts down by

The Wattage Reference Guide is provided to assist you in

determining how many items your generator' can operate

at one time.

Page 9

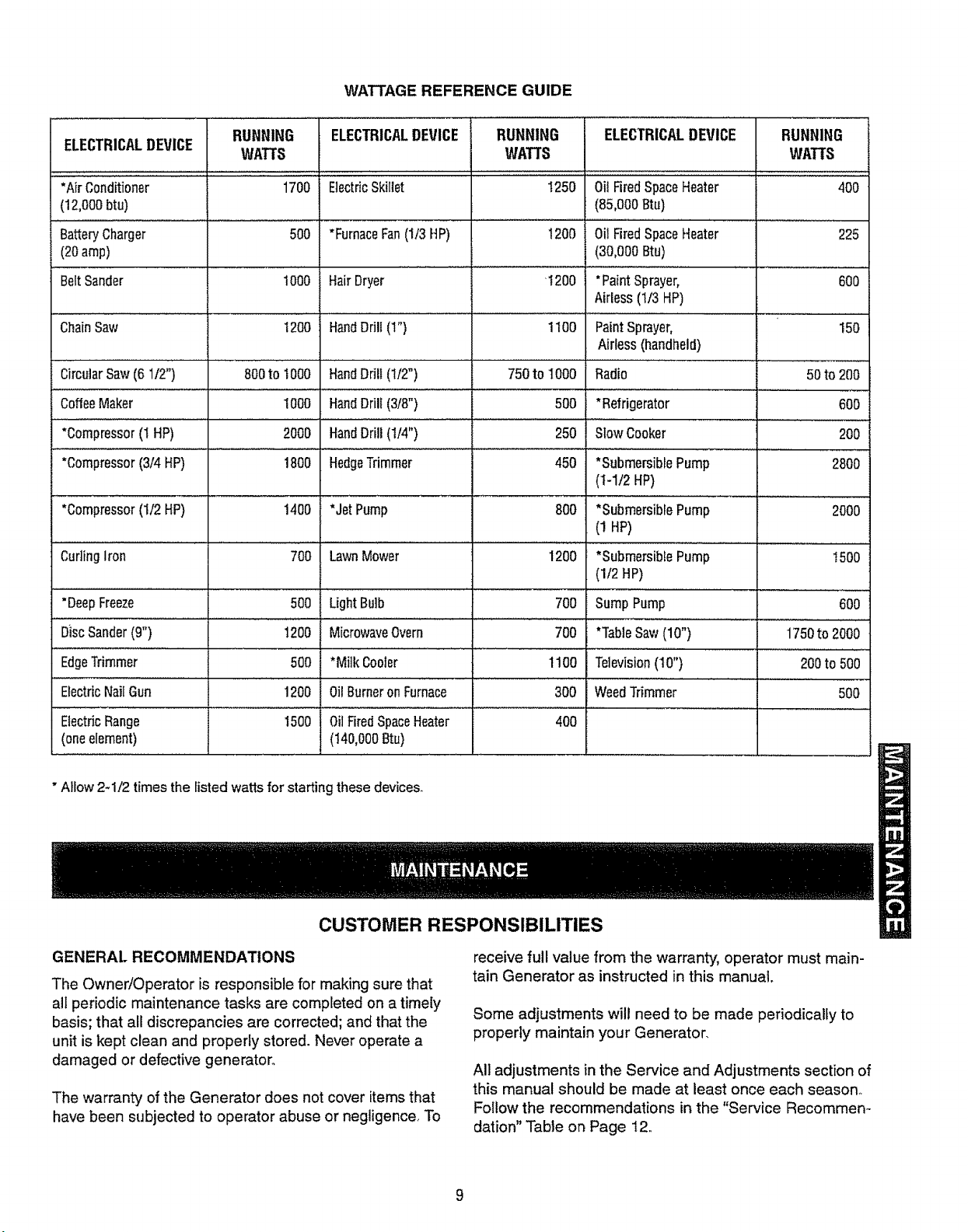

WATTAGE REFERENCE GUIDE

ELECTRICALDEVICE

RUNNING ELECTRICALDEVICE RUNNING ELECTRICALDEVICE RUNNING

WATTS WATTS WATTS

L_L ..._..... LLL _ :; :; :;:; :: ...................

*AirConditioner 1700 ElectricSkillet I250 OilFiredSpaceHeater 400

(12,000btu) (85,000Btu)

BatteryCharger 500 *FurnaceFan(113HP) 1200 OilFiredSpaceHeater 225

(20amp) (30,000Btu)

BeltSander t000 HairDryer 1200 *PaintSprayer, 600

Airless(1/3HP)

== ;,,. ..........

ChainSaw t200 HandDrill (1") 1100 PaintSprayer, 150

Airless(handheld)

CircularSaw(6112") 800to 1000 HandDdlf(1/2") 750to 1000 Radio 50to 200

CoffeeMaker 1000 HandDrill(3/8") 500 *Refrigerator 600

J r

*Compressor(I HP) 2000 HandDrill(1/4") 250 SlowCooker 200

*Compressor(3/4 HP) 1800 HedgeTrimmer 450 *SubmersiblePump 2800

(I-1/2 HP)

*Compressor(i/2 HP) 1400 *JetPomp 800 *SubmersiblePump 2000

(1 HP)

CurlingIron 700 LawnMower 1200 *SubmersiblePump t500

(1/2HP)

"DeepFreeze 500 LightBu]b 700 SumpPump 600

DiscSander(9") t200 MicrowaveOvern 700 *TableSaw(10") 1750to2000

EdgeTrimmer 500 *Milk Cooler 1100 Television(10") 200to 500

............................................................... , ....... i ............

ElectricNailGun 1200 OilBurneronFurnace 300 WeedTrimmer 500

.... ..... J , ..........,, ,

ElectricRange 1500 OilFiredSpaceHeater 400

(oneelement) (140,000Btu)

"Allow 2-1/2 times the Iisted watts for starting these device&

CUSTOMER RESPONSIBILITIES

GENERAL RECOMMENDATIONS

The Owner/Operator is responsible for making sure that

all periodic maintenance tasks are completed on a timely

basis; that all discrepancies are corrected; and that the

unit is kept clean and properly stored. Never operate a

damaged or defective generator°

The warranty of the Generator does not cover items that

have been subjected to operator abuse or negligence.. To

receive full value from the warranty, operator must main-

tain Generator as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your Generator.

All adjustments in the Service and Adjustments section of

this manual should be made at least once each season..

Follow the recommendations in the "Service Recommen-

dation" Table on Page 12..

Page 10

PRODUCT SPECIFICATIONS

Generator Specifications

Rated Maximum Power

Rated Voltage

Rated Maximum

Load Current

Rate Frequency

2500 (2.5 KW)

12 VDC and 120 Volts AC

20.8 AC amperes

60 Hz at 3600 rpm

Follow the instructions under "Maintenance" and "Stor-

age" sections of this Owner's Manual.

NOTE: Your generator is equipped with a spark arrestor

muffler: The spark arrestor must be maintained in effec-

tive working order by the owner/operator_ In the State of

California a spark arrestor is required by law (Section

4442 of the California Public Resources Code)_ Other

states may have similar' laws. Federal laws apply on fed-

eral lands°

Phase

Engine Specifications

Rated Horsepower 5,0 at 3600 rpm

Spark Plug NGK BPR6ES

Set Gap To: 0.030 inch (0.76mm)

Gasoline Capacity: 1.8 quarts

Oil (Q.61 US quarls capacity): SAE 30 weight

Solid State Ignition 0.0125 inch

Air Gap

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service Cen-

terJDepartment or call the 1-800 number listed on the

front of this manuat we have competent, well-trained

technicians and the proper toolsto service or repair' this

unit,.

Please read and retain tn_smanual, the instructions will

enable you to assemble and maintain your' generator

properly. Always observe the "SAFETY RULES'L

Once a year you should clean or'replace the spark plug

and replace the air filter A new spark plug and clean air

filter assure proper fuel-air mixture and help your engine

run better and last longer

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product,,

Single Phase

or equivalent

CAUTION:DISCONNECTSPARKPLUGWIRE

FROMSPARKPLUGANDPLACEWIREWHEREIT

CANNOT'COMEIN CONTACIWITHYOURSPARK

PLUGBEFOREWORKINGONYOURGENERATOR.

GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit clean

and dry Operate and store the unit in a clean, dry envi-

ronment where it wilt not be exposed to excessive dust,

dirt, moisture or any corrosive vapors,, Cooling air slots in

the generator must not become clogged with snow,

leaves, or any other foreign material.

Check the cleanliness of the generator frequently and

clean when dust, dirt, oi!, moisture or other foreign sub-

stances are visible on itsexterior surface,.

Note: We DO NOT recommend using a garden hose to

clean the generator_ Water can enter-the engine fuel sys-

tem and cause problems,, tn addition, ff water enters the

generator through cooling air slots, some of the water will

be retained in void and cracks of the rotor and stator

winding insulation, Water and dirt buildup on the genera-

tor internal windings will eventually decrease the insula-

tion resistance of these windings°

To clean the Generator:

* Use a damp cloth to wipe exterior surfaces cfean.

° A soft bristle brush may be used to loosen caked on

dirt, oil, etc.

. A vacuum cleaner may be used to pick up loose dirt

and debris.

° Low pressure air (not to exceed 25 psi) may be used

to blow away dirt,, inspect cooling air' slots and open-

ings on the generator,, These openings must be kept

clean and unobstructed.

CUSTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow regular schedule in maintaining, caring for and

using your generator.

CAUTION:NEVERINSERTANY OBJECTORTOOL1

THROUGHTHE AIRCOOLINGSLOTS,EVENIF !

THE ENGINEIS NOTRUNNING. DAMAGETOTHEi

UNITOR PERSONALINJURYMAYRESULT. J

10

Page 11

ENGINEMAINTENANCE

CHECKING OIL LEVEL

Oii levet should be checked prior to each use or at least

every 5 hours of operation, Keep oil level maintained.

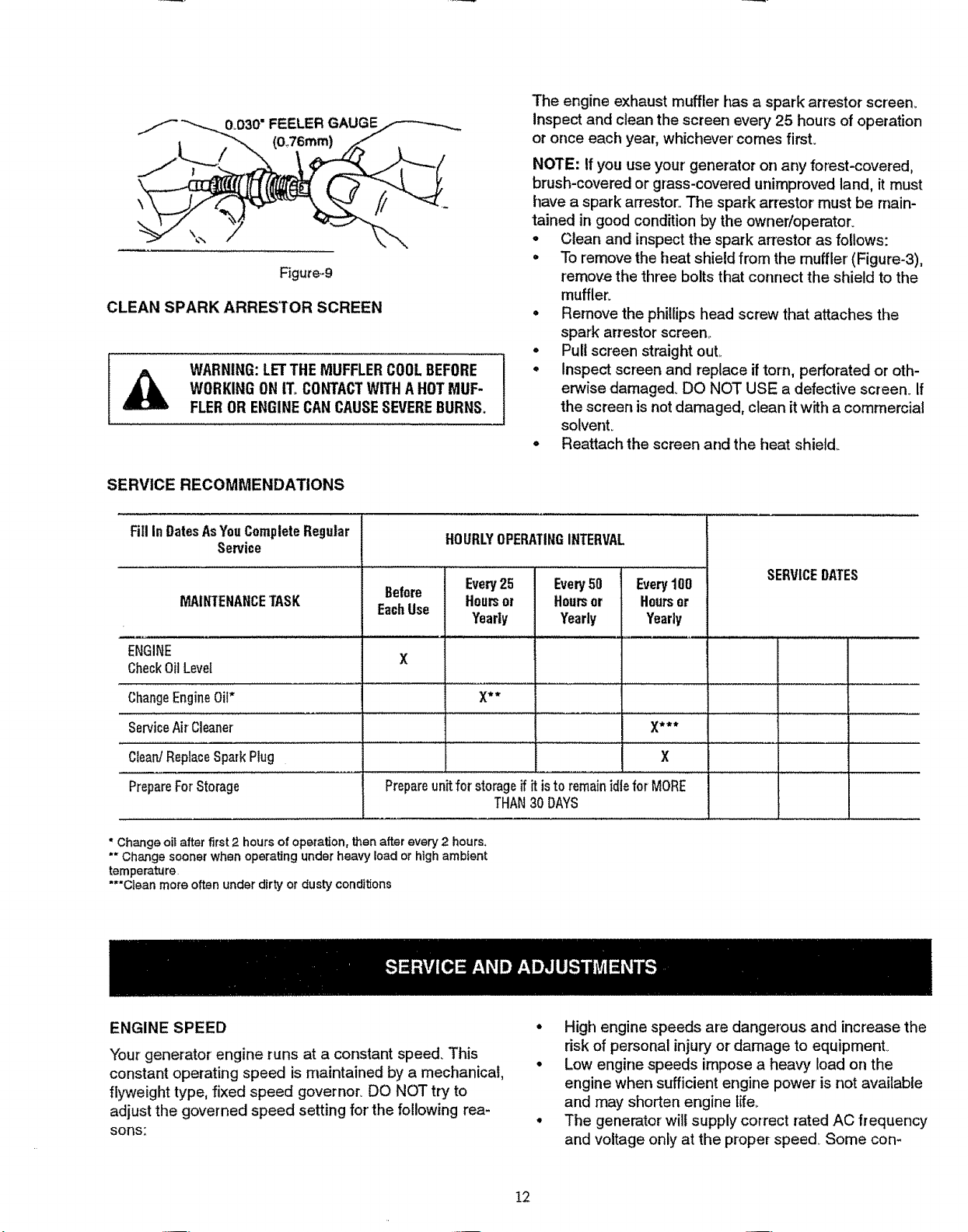

° Replace spark plug if electrodes are pitted, burned or

porcelain is cracked° For replacement use NGK

BPR6ES only,

o Check electrode gap with wire feeler gauge and set

spark plug gap to 0.030 inch (0.76 mm) if necessary

(Figure-9).

CHANGING ENGINE OIL

CAUTION:DISCONNECTSPARKPLUGWIRE

FROMSPARKPLUGAND KEEPITAWAYFROM

SPARKPLUG.DOTHIS EVERYTIME YOU PER-

FORMANYMAINTENANCEONTHEENGINEOR

GENERATOR

Change oil after first 2 hours of operation, Change oil

every 25 hours thereafter., tf you are using your generator

under extremely dirty or dusty conditions, or in extremely

hot weather, change oil more often,

Change oil while engine is still warm from running, as fol-

lows:

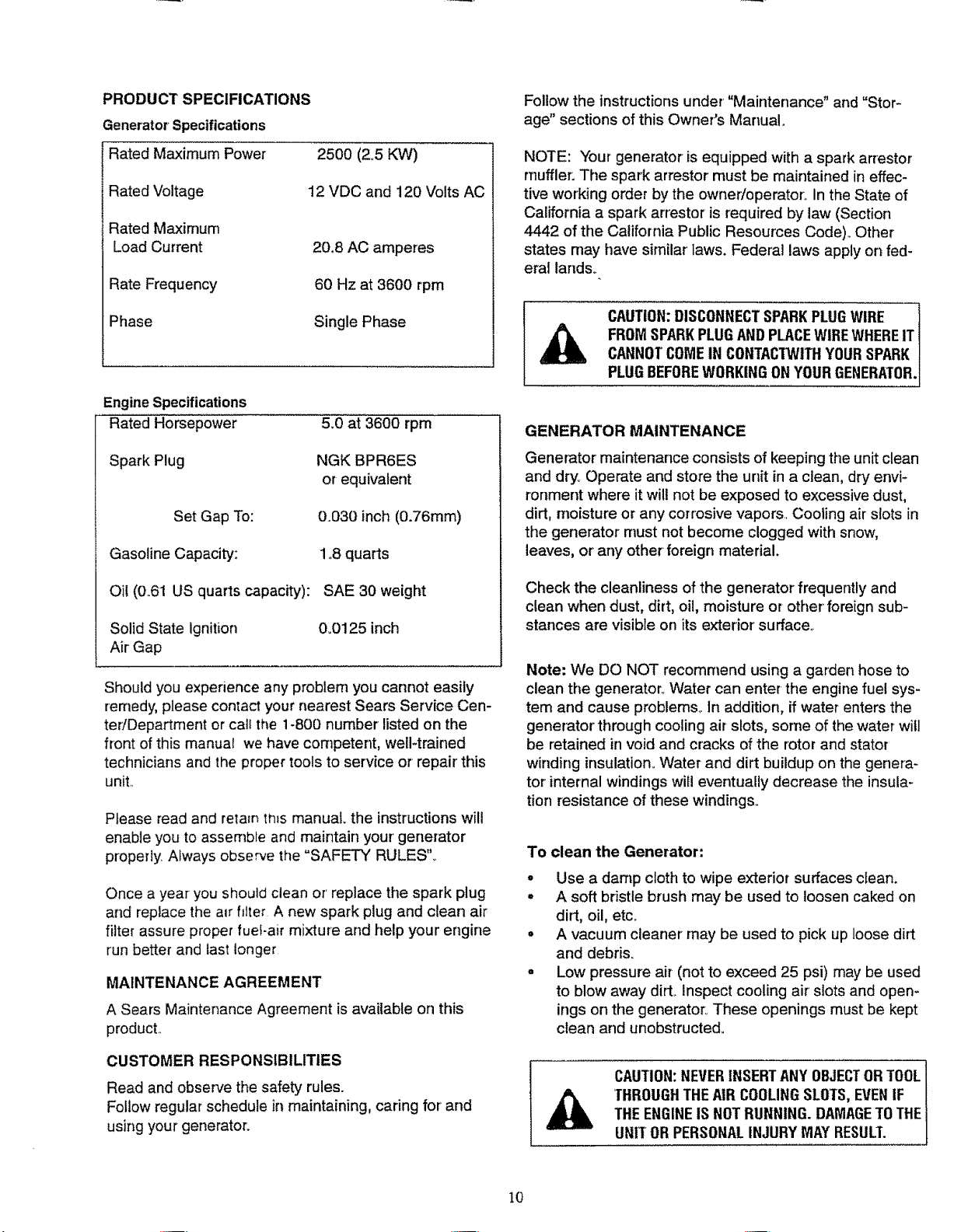

o Clean area around oil drain plug (Figure-7).

o Remove oil drain plug and oil fill plug to drain oil.

o When oil has drained, install oil drain plug and tighten

securely°

° Insert a clean fill funnel and fill oil sump with recom-

mended oil until oil level is at point of overflowing.

POUR SLOWLY. (See "Before Starting the Engine"

on Page 6 for oil recommendations).,

• Install the oil fill plug and tighten securely,

• Wipe up any spilled oilo

SERVICE AIR CLEANER

Your engine will not run properly and may be damaged if

you run it using a dirty" air cleaner,,

Clean or replace the air cleaner once every 125 hours of

operation or once each year, whichever comes first.

Replace more often if operating under dirty or dusty con-

ditionso Replacements are available at your local Sears

Authorized Service Center.

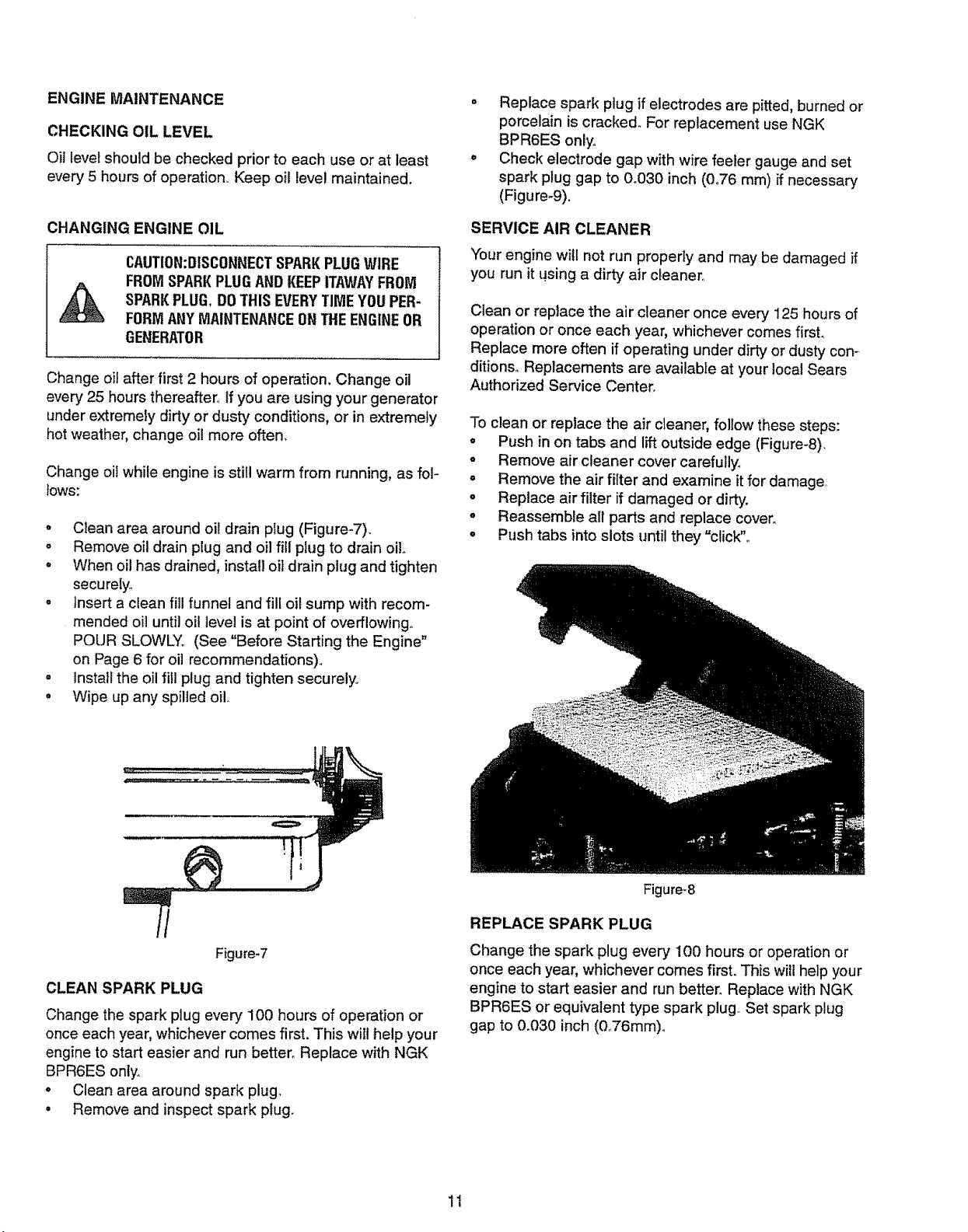

To clean or replace the air cleaner, follow these steps:

° Push in on tabs and lift outside edge (Figure-8),

= Remove air cleaner cover carefully°

° Remove the air filter and examine itfor damage,

= Replace air filter if damaged or dirty.

° Reassemble all parts and replace cover_,

o Push tabs into slots until they %lick"o

F}gure-7

CLEAN SPARK PLUG

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help your

engine to start easier and run better. Replace with NGK

BPR6ES only,

. Clean area around spark plug,

° Remove and inspect spark plug.

Figure_8

REPLACE SPARK PLUG

Change the spark plug every 100 hours or operation or

once each year, whichever comes first. This will help your

engine to start easier and run better° Replace with NGK

BPR6ES or equivalent type spark plug, Set spark plug

gap to 0.030 inch (0,76mm)_

11

Page 12

0030" FEELER GAUGE

(O,,76mm)

Figure-9

CLEAN SPARK ARRESTOR SCREEN

WARNING:LETTHEMUFFLERCOOLBEFORE

WORKINGON IT+CONTACTWITH AHOTMUF-

FLEROR ENGINECANCAUSESEVEREBURNS+

SERVICE RECOMMENDATIONS

The engine exhaust muffler has a spark arrestor screen+

Inspect and clean the screen every 25 hours of operation

or once each year, whichever' comes first.

NOTE: If you use your' generator on any forest-covered,

brush-covered or grass-covered unimproved land, it must

have a spark anestor.. The spark arrestor must be main-

tained in good condition by the ownedoperator+

• Clean and inspect the spark arrestor as follows:

• To remove the heat shield from the muffler (Figure-3),

remove the three bolts that connect the shield to the

muffler.

° Remove the phillips head screw that attaches the

spark arrestor screen.

• Pull screen straight ouL

° Inspect screen and replace if torn, perforated or oth-

erwise damaged+ DO NOT USE a defective screen. If

the screen is not damaged, clean it with a commercial

solvent.

° Reattach the screen and the heat shield.

Fillin DatesAsYouCompleteRegular HOURLYOPERATINGINTERVAL

Service

Before Every25 Every50 Every100

MAINTENANCETASK EachUse Hoursor Hoursor Hoursor

Yearly Yearly Yearly

ENGINE X

Check011Level

................................ , ............ : ............. i, ......... L L ....

ChangeEngineOil* X**

ServiceAir+Cleaner X***

C{eardReplaceSparkPlug X

PrepareForStorage Prepareunitfor storageif_tistoremainidleforMORE

THAN30 DAYS

"Change oil after first 2 hours of operation, then after every 2 hours,

** Change sooner when operating under heavy Goador high ambient

temperature

"*'Clean more often under dirty or dusty conditions

SERVICEDATES

ENGINE SPEED

Your generator engine runs at a constant speed+ This

constant operating speed is maintained by a mechanical,

flyweight type, fixed speed governor+ DO NOT try to

adjust the governed speed setting for' the following rea-

sons:

• High engine speeds are dangerous and increase the

risk of personal injury or damage to equipment+

° Low engine speeds impose a heavy load on the

engine when sufficient engine power' is not available

and may shorten engine f_fe+

• The generator will supply correct rated AC frequency

and voltage only at the proper speed+ Some con-

t2

Page 13

nectedelectricaldevicescouldbedamagedby incor-

rectfrequencyand/orvoltage

ADJUSTING THE CARBURETOR

Honda uses lean carburetor settings and other systems to

reduce the emissions of carbon monoxide, oxides of nitro-

gen, and hydrocarbons.

The carburetor of your generator is preset at the factory_

DO NOT TAMPER WITH THE CARBURETOR as this wilt

void the warranty for the emission control system. If you

think your carburetor needs adjusting, see your nearest

Sears Service dealer Ifyour generator is to be used at

an elevation above 5,000 feet in attitude, consult with a

Sears Authorized Service Facility regarding high altitude

jetting changes. To improve engine performance, see

your nearest Sears Service dealer_

EMISSION CONTROL SYSTEM INFORMATION

Sources of Emissions. The combustion process pro-

duces carbon monoxide, oxides of nitrogen, and hydro.

carbons Control of hydrocarbons and oxides of nitrogen

is very important because, under certain conditions, they

react to form photochemical smog when subjected to

sunlight. Carbon monoxide does not react inthe same

way but it is toxic°

The U.S. and California Clean Air Acts. EPA and Cali-

fornia regulations require all manufacturers to furnish writ-

ten instructions describing the operation and

maintenance of emission control systems,

Tampering and Altering. Tampering with or altering the

emission control system may increase emissions beyond

the legal limit. Among those acts that constitute tamper-

ingare:

o Removal or alteration of any part of the intake, fuel, or

exhaust systems

° Altering or defeating the governor linkage or speed

adjusting mechanism to cause to engine to operate

outside its design parameters.

Problems that may Affect Emissions. If you are aware

ofany of the following symptons, have your engine

inspected and repaired by you servicing dealer.

= Hard starting or stalling after starting

* Rough idle.

o Misfiring or backfiring under load

o Afterburning (backfidng)

GENERAL

The generator should be started at least once every

seven days and allowed to run at least 30 minutes_ If this

cannot be done and you must store the unit for more than

30 days, use the following information as a guide to pre-

pare itfor storage.

WARNING:NEVERSTOREENGINEWITH FUELiN

THETANKINDOORSOR IN ENCLOSED,POORLY

VEHTILATEDAREAS,WHEREFUMESCAN

REACHANOPENFLAMESPARKORPILOTLIGHT

ASON A FURNACE,WATERHEATER,CLOTHES

DRYEROROTHERGASFURNACE.

LONG TERM STORAGE INSTRUCTIONS

It is important to prevent gum deposffs from forming in

essential fuel system parts such as the carburetor, fuel fil-

ter, fuel hose or tank during storage Experience indicates

that alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture which leads to separation

and formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage_

To avoid engine problems, the fuel system should be

emptied before storage or 30 days or longer. Fo]low these

instructions

PROTECT FUEL SYSTEM:

Remove all gasoline from the fuel tank to prevent

gum deposits from forming on these parts and caus-

ing possible malfunction of engine

Run engine until engine stops from lack of fuel

WARNING:DRAINFUELINTO APPROVEDCON-

TAINEROUTDOORS,AWAYFROMOPENFLAME

BESUREENGINEIS COOL°

CHANGE OIL:

While engine is still warm, drain oil from crankcase. Refill

with recommended grade

OIL CYLINDER BORE:

• Remove spark plug and pour about 1/2 ounce (15 ml)

of engine oil into the cylinder Cover spark plug hote

with rag Crank slowly to distribute oil

- Install spark plugo Do not connect spark plug wire

13

Page 14

CAUTION:AVOIDSPRAYFROMSPARKPLUG

HOLEWHEN CRANKINGENGINESLOWLY,

GENERATOR:

o Clean the generator' as outlined on Page 11 to ("To

Clean the Generator'S,.

• Check that cooling air' slots and openings on genera-

tor are open and unobstructed,

OTHER STORAGE TIPS:

° Do not store gasoline from one season to another.

• Replace your gasoline can if it starts to rusL Rust

and/or dirt in you gasoline will cause problems, if pos-

J

sible, store your unit indoors and cover it to give pro-

tection from dust and dirt. BE SURE TO EMPTY THE

FUEL TANK.

°

Cover your unit with a suitable protective cover that

does not retain moisture°

o

Store generator' in a clean, dry area..

DANGER:STORAGECOVERIS FLAMMABLE,DO

NOT PLACETHE STORAGECOVEROVERA HOT

GENERATOR°LE'I"THEUNITCOOLFORASUFFI-

CIENTTIME BEFOREPLACINGTHECOVERON

THEUNIT. IFYOU PLACETHECOVERONTHE

UNIT BEFORETHE GENERATORIS COOL,THE

COVERCOULDSTARTFIRE,

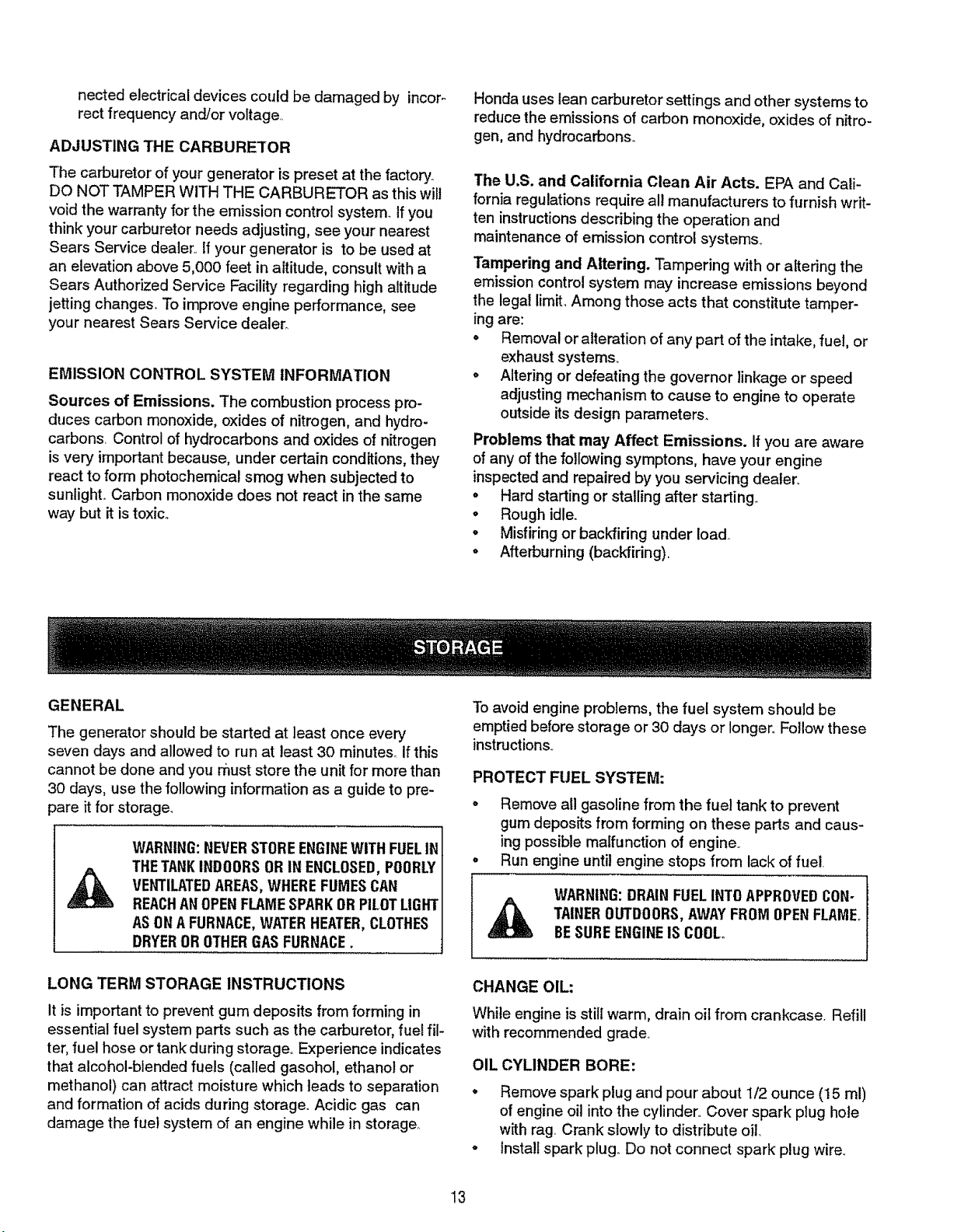

PROBLEM CAUSE

Engineis running,but I11 Oneof ille circuit breakersis open.

no AC output is available 2. Fault ingenerator:,

3_ Poorconnectionor defectivecord set_

4_ Connecteddeviceis bad,

Enginerunsgood at no-

load but "bogs down"

whenloads are con-

nectedo

Enginewill not start; or

starts and runs rough,

Engineshuts down dur-

ing operation_

1., Short circuit in a connectedload.

2. Enginespeed is too slow.

3. Generatoris overloaded,,

4. Shorted generatorcircuit,

1. On!OffSwitch set to Off.

2, Dirty air cleaner,

3. Outof gasoline,

4,, Stalegasoline,

5, Sparkplug wire not connectedto spark plug.

6. Badspark plug_

7, Waterin gasoline,,

8, Overchoking

9o Low oi! level.

10_ Excessivelyrich fuel mixture,

11, intake valvestuck open or closed,

12_ Enginehaslost compression.

1. Outof gasoline_ 1,, Fillfuel tank,

2,, Low oit level 2_ Fill crankcaseto proper level

CORRECTION

1_ Resetcircuitbreaker.

2. contactSearsService Facility.

3. Checkand repair:

4o Connect a device that is in good condition

1. Disconnect shorted electrical load_

2. Contact SearsService Facility,,

3, See"Don't Overloadthe Generator",

4. Contact SearsService Facility_

1o Setswitch to ON,

2.. Cleanor replaceair-cteaner:o

3. Fillfuel tank_

4. Drain gas tank; fill with fresh fuel.

5. Connectwire to spark plug,.

6. Replacespark plug.

7. Drain gas tank; fill with fresh fuel.

8, Open chokefully and crank engine.

9,. Fill crankcase to proper level

!0. Contact Sears ServiceFacility,

11_,Contact Sears ServiceFacility.

12. Contact Sears ServiceFacility,

Enginelacks power_ 1o Load is too high,, 1. See "Don't Overloadthe Generator"

2_ Dirty air filter,_ 2. Replaceair filter:

Engine"hunts" or falters 1,, Chokeis openedtoo soon, 1_, Move choke to halfway position until engine

2,. Carburetoris runningtoo rich or too lean, runs smoothly,,

2. Contact SearsService Facifity_

14

Page 15

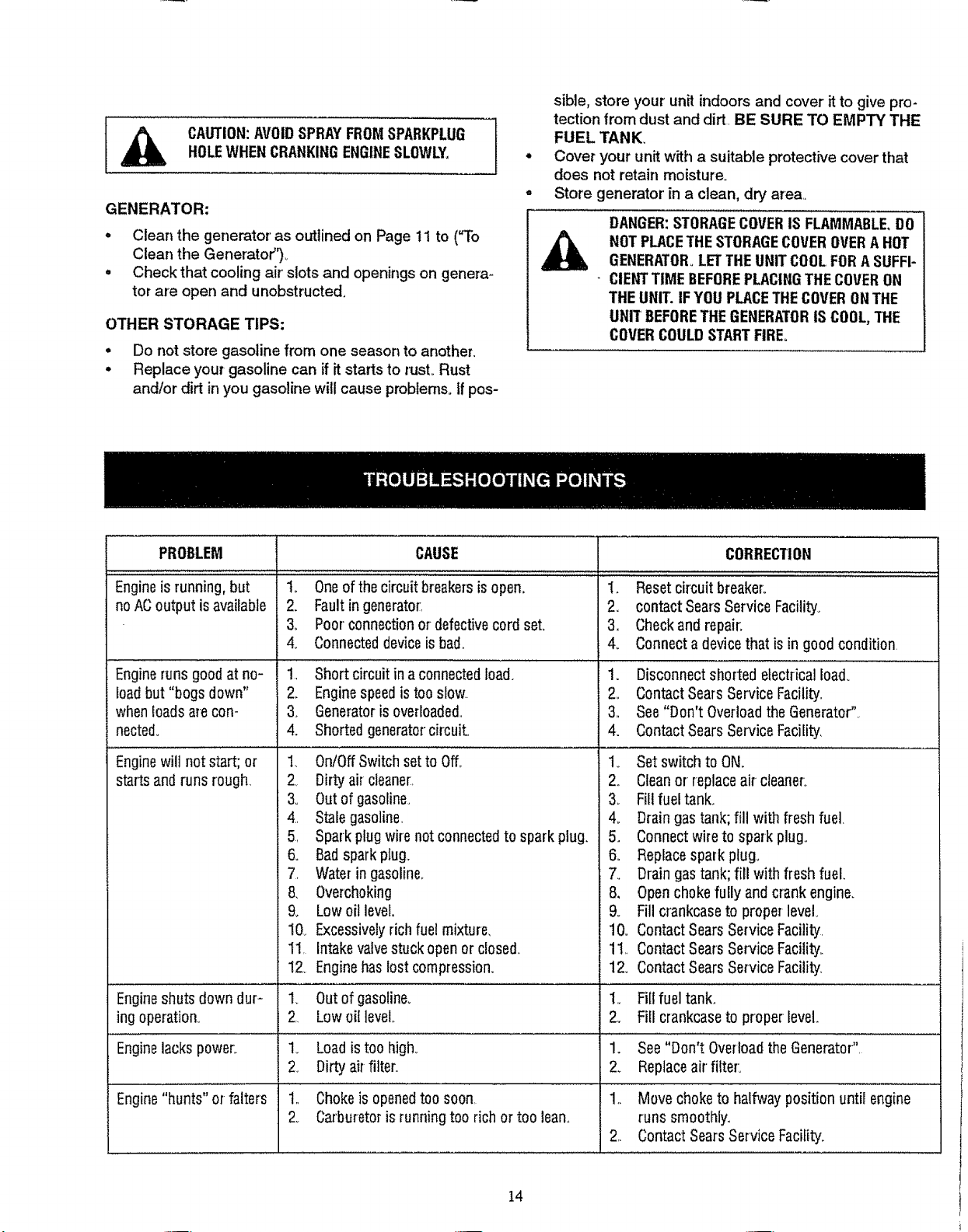

CRAFTSMAN 2500 WATT DELUXE AC GENERATOR 580.327750

<1:

u_

e,/

03

1

L;

O3

i

!=

q.

u

=i--k r=-t=_"l-=

15

Drawing No.,B2420

Page 16

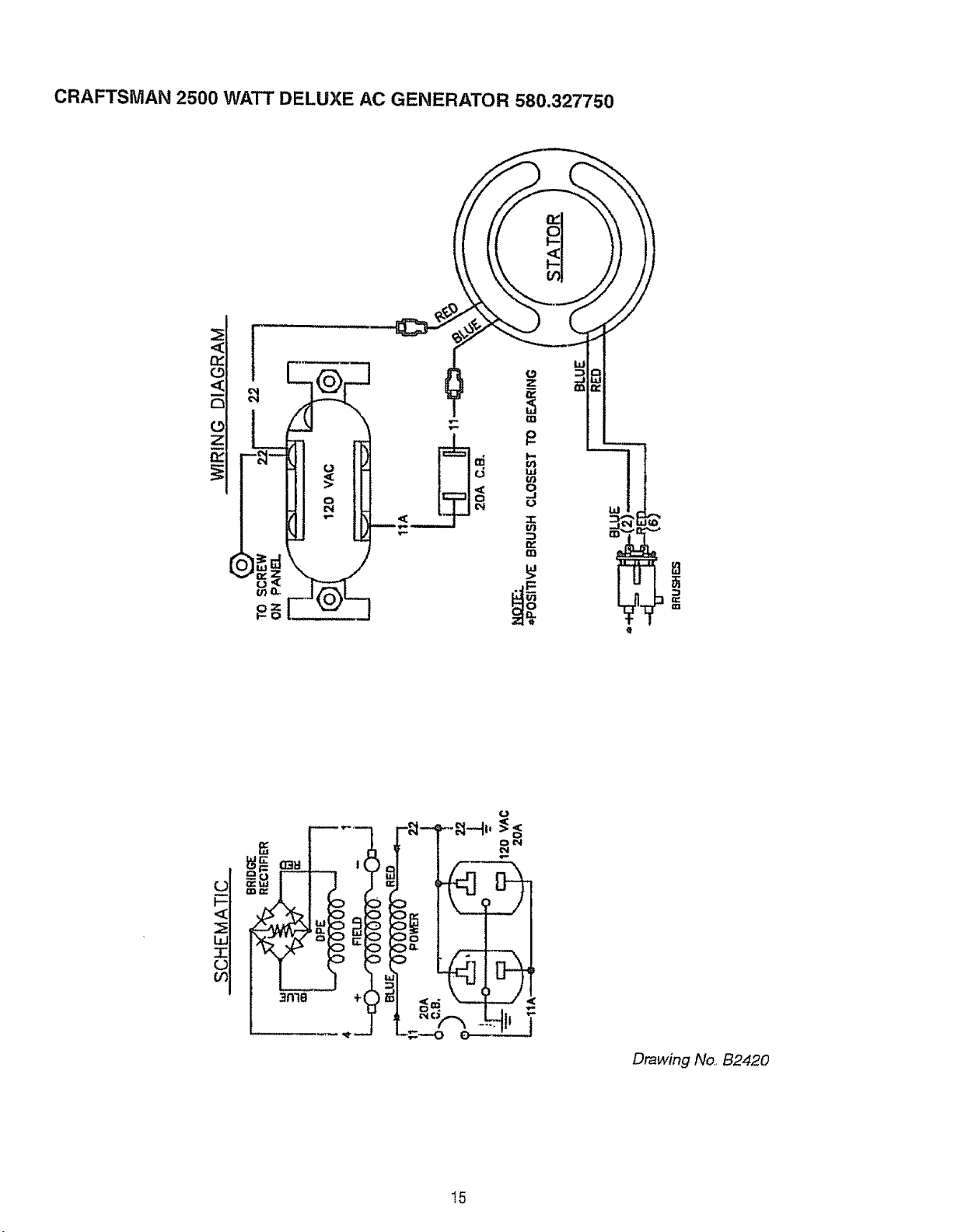

CRAFTSMAN 2500 WATT DELUXE AC GENERATOR 580.327750 REPAIR PARTS

.,,.o

o3

o3

o

O3

If)

_J

o3

L-- 7

\

!6

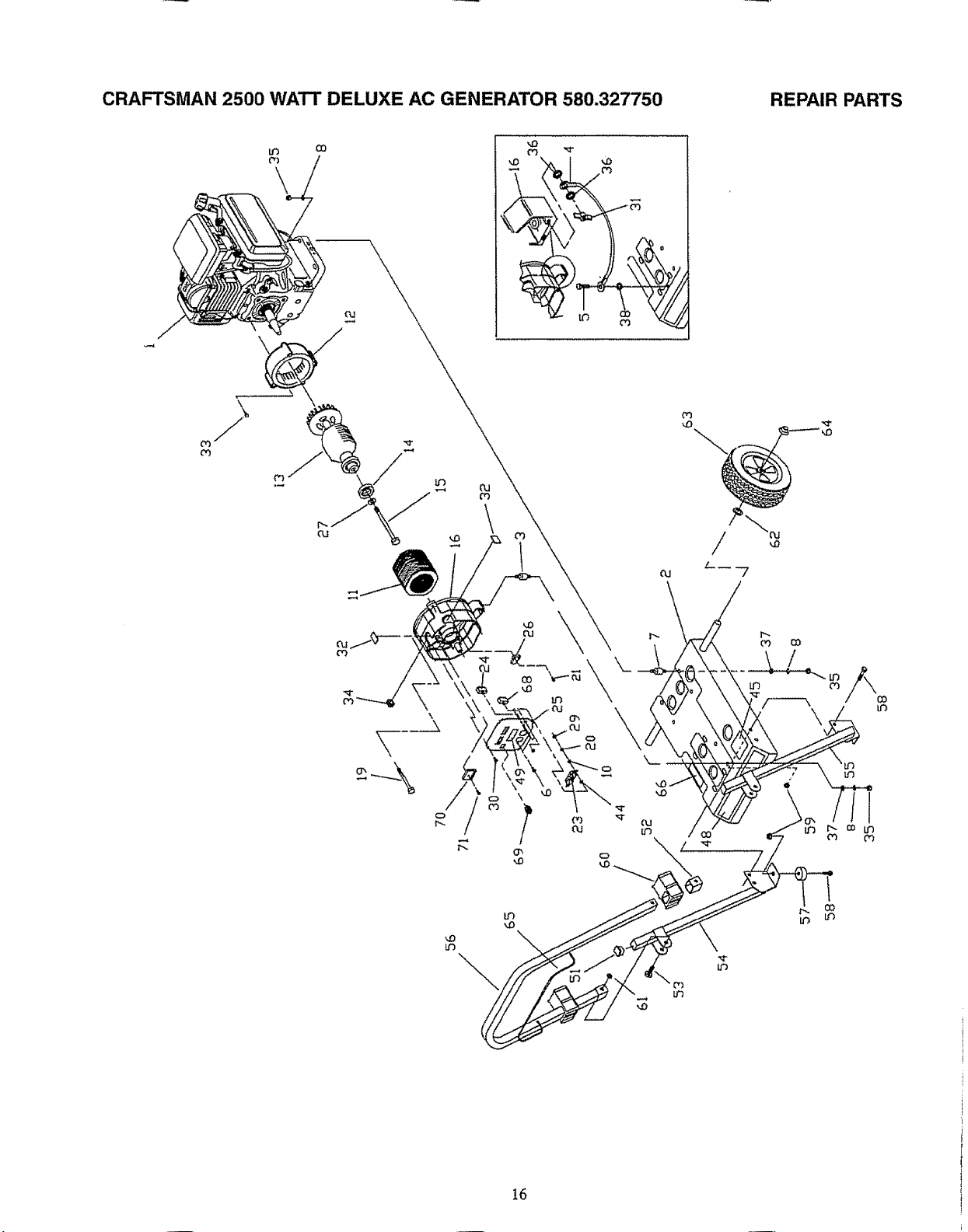

Page 17

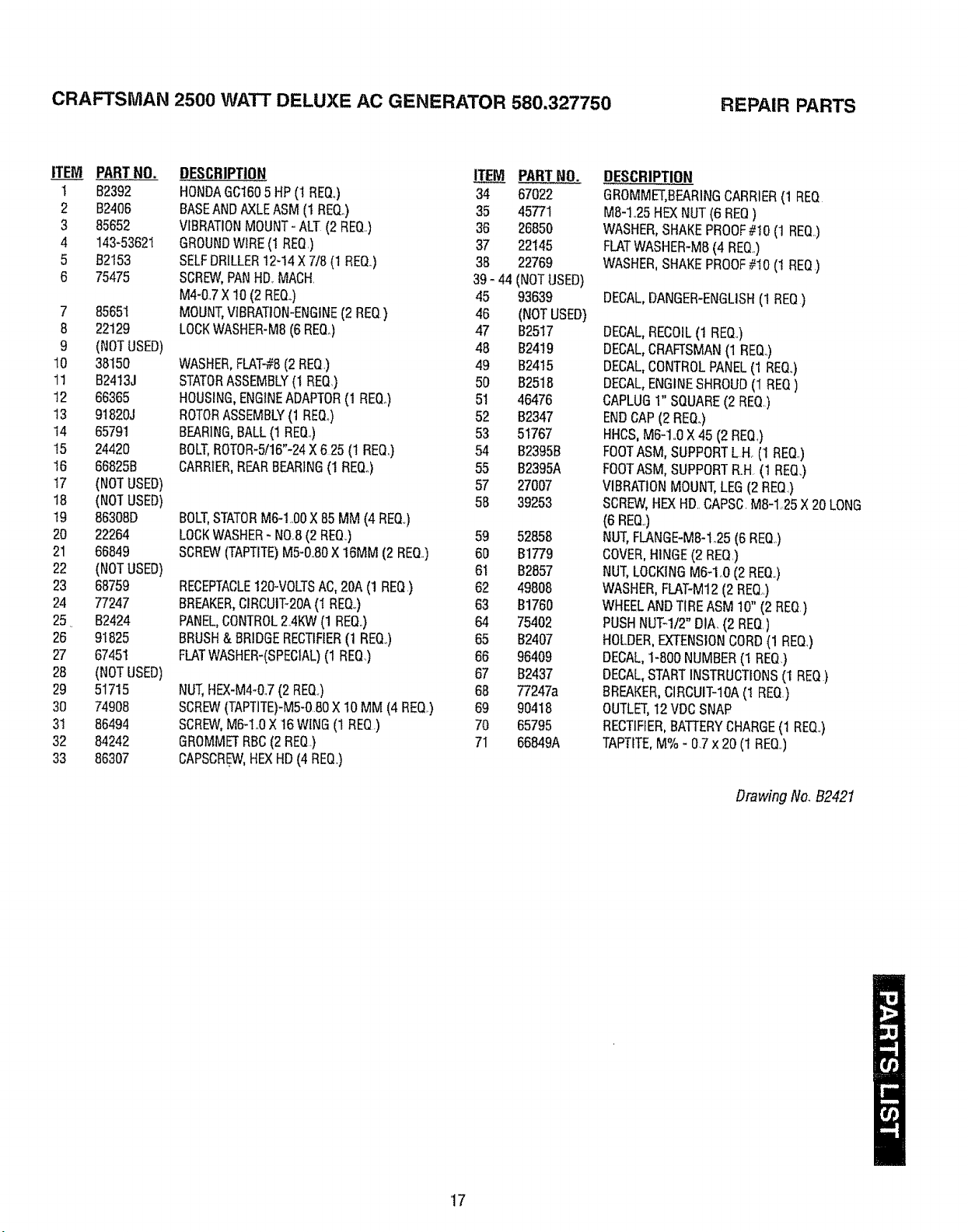

CRAFTSMAN 2500 WATT DELUXE AC GENERATOR 580.327750 REPAIR PARTS

t B2392

2 B2406

3 85652

4 143-5362I

5 B2153

6 75475

7 85651

8 22129

9 (NOTUSED)

10 38150

11 82413J

t2 66365

!3 91820J

14 65791

15 24420

16 668258

17 (NOTUSED)

18 (NOTUSED)

19 86308D

20 22264

21 66849

22 (NOTUSED)

23 68759

24 77247

25 B2424

26 91825

27 67451

28 (NOTUSED)

29 51715

30 74908

31 86494

32 84242

33 86307

_ESCRIPTION

HONDAGC1605 HP (t RE&)

BASEANDAXLEASM (1 REQ..)

VIBRATIONMOUNT- ALT (2 REQ)

GROUNDW1RE{I REQ.)

SELFDRILLER1244 X 7/8 {1 REQ.)

SCREW,PANHD. MACH

M4-&7 X 10 (2 REQ.)

MOUNT,VIBRATION-ENGINE(2 REQ)

LOCKWASHER-MS(6 REQo)

WASHER,FLAT_8 (2 REQ.)

STATORASSEMBLY(1 REQ.)

HOUSING,ENGINEADAPTOR(1 REQ)

ROTORASSEMBLY(t RE&)

BEARING,BALL(1 REQ.,)

BOLT,ROTOR-5116"-24X 6 25 (1 REQ,)

CARRIER,REARBEARING(i REQo)

BOLT,STATORM6-1.,00X 85MM(4 REQ,)

LOCKWASHER- NO8(2 REQ)

SCREW(TAPTITE)M5-&80X16MM(2REQ.,)

RECEPTACLE120-VOLTSAC, 20A (1 REQ.)

BREAKER,ClRCUIT-20A(i REQ.)

PANEL,CONTROL2AKW (1 REOo)

BRUSH& BRIDGERECTIFIER(1 REQ..)

FLATWASHER-(SPECIAL}(1 REQ)

NUT,HEX-M4-O..7(2 REQ,)

SCREW(TAPTITE)-M5-O.80X t0 MM (4 REQ.)

SCREW,M6-I nOX 16WING (1 REQ)

GROMMETRBC(2 REQ.)

CAPSCR_Ai,HE)(HD (4 REQ.)

ITEM PARTNO..

34 67022

35 45771

36 26850

37 22145

38 22769

39- 44 (NOTUSED)

45 93639

46 (NOT USED)

47 B2517

48 82419

49 B2415

50 B2518

51 46476

52 82347

53 51767

54 82395B

55 B2395A

57 27007

58 39253

59 52858

60 B1T/9

61 B2857

62 49808

63 81760

64 75402

65 B2407

66 96409

67 82437

68 77247a

69 90418

70 65795

7I 66849A

DESCRIPTION

GROMMET,BEARINGCARRIER(1 REQ

M8-125 HEX NUT (6 REQ)

WASHER,SHAKEPROOF#10 (1 REO.)

FLATWASHER-M8(4 REQ.)

WASHER,SHAKEPROOF#10 (1 REQ)

DECAL,DANGER-ENGLISH(1 REQ)

DECAL,RECOIL(1 REQ)

DECAL,CRAFTSMAN(1 REQ..)

DECAL,CONTROLPANEL(1 REQ_)

DECAL,ENGINESHROUD(I REQ)

CAPLUG1" SQUARE(2 REQ,)

ENDCAP(2 REQ,)

HHOS,M6-1,,0X 45 (2 REQ)

FOOTASM, SUPPORT LH (1 REQ,)

FOOTASM, SUPPORTR,H,.(t RE&)

VIBRATIONMOUNT,LEG(2 REQ,)

SCREW,HID{HD.CAPSC.M8-1,,25X 20 LONG

(6 REQo)

NUT,FLANGE-MS-125 (6 REQ..)

(;OVER,HINGE(2 REQ.)

NUT,LOCKINGM6-1o0 (2 REQ,,)

WASHER,FLAT-M12(2 REQ.)

WHEELANDTIRE ASM10" (2 REQ)

PUSH NUT-1t2" DIA. (2 REQ.)

HOLDER,EXTENSIONCORD(1 REQ..)

DECAL,1-800 NUMBER(1 REQ)

DECAL,STARTINSTRUCTIONS(1 REQ)

BREAKER,CIRCUIT-IOA(1 REQ.)

OUTLET,12VDC SNAP

RECTIFIER,BATTERYCHARGE(1 REQ.)

TAPTITE,M% - 0,7 x 20 (1 RE&)

Drawing No_[32421

17

Page 18

GG160

Ref.

No. DESCRIFr_N O

_ocK NO, E-6

1 COVERASSY.tCRANKCASE(Q-TYPE) • •

COVERASSY.,CRANKCASE(U-TYPE) . e!

COVERASSY.,CRANKCASE(UX-TYPE) •

2 GASKET,OIL FILLERCAP .......... ei

3 GAUSEASSY.,OILLEVEL.......... ei

4 GOVERNORASSY.................. •

5 WEIGHT,GOVERNOR............... •

6 HOLDER,GOVERNORWEIGH,......... =

7 PINt GOVERNORWEIGHT............ •

B SLIDER,GOVERNOR............... •

9 SHAFT,GOVERNORARM .............J

10BOLT,FLANGE(6X25).............•

11BOLT,DRAINPLUG ................•

BOLT DRAINPLUG

ZLe4EO600

, ,,,,,,,,,,

Q

T

G

0

U

ENGINE

SERIALP_'MBER R

............ _ E

FROM TO Q

Y

PARTNUMBER

1

11300-ZL8-600

1

111300-ZL8-660

1

11300"ZL8-670

1

1567.5-ZE1-003

1

15650-ZL8-003

1

16510-ZLE-000

,,,,,,,

16511-ZL8-000

1

16512-ZL8-000

2

16513-ZEI-000

1

16531rZE1-O00

1

16541-ZL8-000

8

90121-952--000

2

90131-883-000

1

o

0

m

..... I 't

90131-883-000

2

90131-896-650

90131-896-650

18

Page 19

CRANKCASE COVER

I0

E-17_,

10

11

GC!60

B

ZLB4EO600

ReL

BLOCKNO. E-6

No. DESCRIPTION

12WASHER,THRUST(6MR)............

13CLIP,GBVERNORHOLDER...........

14BEARING,RADIALBALL(67-128)....

15OILSEAL(28X41.25X6)...........

16WASHER,PLAIN(6MM).............

17WASHER,DRAINPLUG(12MR).......

IBPIN,LOCK(8MM).................

19PIN,DOWEL(8X20)...............

!G

!a

iei

o!

ENGINE

SERIALNUIVIBEB R

_ E

FROM TO Q

Q

T

Y

PARTNUMBER

,,,,,,,,,,,, ,,,,,,,, , .,,,

1 9045t-ZE1-000

1 90602-ZE1-000

1 91001-ZL8-003

1 91202-ZLB-003

2 94101-06800

94109-12000

94109-12000

94251-08000

I

94301-08200

2

19

Page 20

CRANKSHAFT

®

4

ZL34E0700

Ret,

No. DESCRIP3"r.JN

........... ,,,,,,,

1 CRANKSHAFTCOW,P, (_TYPE) .......

CRANKSHAFTC0RP............... •

2 CRANKSHAFT_0RP. (P-TYPE) ......,

CRANKSHAFT{OMP................

3 {RANKSHAFT{OMP. (V-TYPE) .......

CRANKSHAFTCOMP................

4 WASHER,IHR3ST

B.£)CKNO.

.,, ....... ........ e1

E-71

Q

T

r_

ENGINE

SERIALNUMI_

6

0

FROM TO

Y

R

E

Q PARTNUMBER

1 13310-ZLB-600

1 133I0-ZL9-600

1 13310-ZLB-650

I 13310-ZL9-650

1 13310-ZL8-670

I 13310-ZL9-670

1 90402-ZL8-000

20

Page 21

PISTON

G0!60

B

_4

6

5

ZI,,84EOBO0

ReL BLOC_NO. E--81

No. DESGRtFrfON 8

1 RINGSET, PISTON(RTKEN) ........

RINGSET,PISTON(TEIKDKU)......

2 PISTON...................... . . .

3 PINtPISTON ....................

4 RODASSY,,CONNECTING...........

RODASSY.,CONNECTING...........

5 BOLT,CONNECTINGROD ............

6 CLIP,PISTONPIN{13MM).........

Q

T

3

ENGINE

Y

SEPJALNUMBER R

FROM TO Q

PARTNLflVIBER

1

113010-ZL8-003

-- "",:....

13010-ZLB-004

1

13101"ZL8-000

1

13II!-ZE0-000

!13200-ZL8-000

I

t3200-ZL9-000

19000!-ZE1-000

2

90551-ZE0-000

2'1

= _ : _

Page 22

CAMSHAFT

GG160

2

3

)

2LB4E_900

G

Re[. 6

BLO('..,,,(NO. _ 1

No. DEBORIPTION O

C

m

i

1 PULLEY{0MP., CAMSHAFT.......... m

2 SHAFT,CAMPULLEY...............•

3 BELT,TIMING{84HL_G-200) ......•

BELT,TIMING(79H_G-200) ......

4 ARM,IN.VALVEROCKER...........•

5 ARM,EX.VALVEROCKER...........o!

6 SHAFT,ROCKERARM ...............e:

? VALVE,IN......................o_

8 VALVE,EX......................e

9 SPRING,VALVE ..................•

10RETAINER,IN.VALVESPRING ......•

11SCREW,TAPPETADJ...............ej

12NUT,TAPPETADJ.................•

13O-RING(6.8X1.9)...............o

ENGINE

SEP-.IALNUMBER R

FR_I TO Q

• I

q

T

Y

E

PP_TI_FAJ'wlBER

i

14320-ZL8-000

14324-ZL8-000

1

1_00-ZL8-'003

I

14400-ZL9-003

I

14431-ZL8-000

I

14441-ZL8-000

2

14461-ZL8-000

1

14711-ZL8-000

1

14721-ZL8-000

2

14751-ZL8-000

2

14711-ZEt-000

2

90012-333-000

90206-001-000

91306-PJ4-000

22

Page 23

RECOIL STARTER

GC160

9 8

1

i

ZLB4EI 100A

Ref, BLOCK NO. E-11

No. DESCRIPTION

1 STARTERASSY.,RECDIL*NRI*

(BLACK)......................o

8KNOB, RECOILSTARTER............e

9 ROPE,RECOILSTARTER............o

Q

T

S

C

1

6

o

ENGINE

SERIALNUMBER

FROM TO

Y

R

E

Q

PARTNUMBER

1

28400-ZLB-OO3ZA

1

28461-ZLB-O03

1

28462-ZL8-003

23

Page 24

FAN COVER

GC160

,2

2

ZL_E1290

_eL

No, DESCRIPTION

BLOCKNO,, E-12

1 COVER,FAN*NHI*

(BLACK) .. ,

(;OVER,FAN*flH1*

(BLACK)............... , ......

2 BOLT,STUD ......................

BOLT,STUD(FANIC) ..............

3 NUT.,FLANGE(6MR) ...............

ENGINE

SERtALNUME_ER

FROM "ffJ

Q

T

Y

R

E

Q

(PARTNUMBER

t

19611-ZL8-000ZA

1

19611-ZL9-OOOZA

3

90043-ZL8-000

3

90041-.ZL9-000

3

90303-MRt-000

24

Page 25

CARBURETOR

GCI60

12

11

I

t5

ZLB4E1400

Ref+

NO. DESGRIPTION

BLOCKNO. E-14

I GASKETSET .....................

2 FLOATSET ......................

3 C_MBERSET, FLOAT..............

4 SCREWSET ......................

5 _CREWSET,DRAIN................

6 SCREWSETB .....................

7 SCREWSET ......................

8 CARBURETORASSY.(BB61BB) ......

CARBURETORASSY.(BB63BA) ......

9 VALVECOMP.,FLOAT..............

10 NOZZLE,MAIN ...................

NOZZLE,NAIN ...................

11 INSULATOR,CARBURETOR..........

12 GASKET,INSULATOR..............

13 GASKET,CARBURETOR.............

14 BASKET,CARBURETOR(CHOKESIDE) .

Q

T

3

3

i

B

O

ENGINE

Sm LNUmBm

FROM TO

Y

R

E

O PARTNUMBER

+

1:16010-883-015

D

D

B

D

I=,

O

O

O

D

D

D

@

"1 16013"ZLI"003

1

16015-ZLB-O03

1

16016-ZGO-WO0

1

16024-124-760

1

16028-ZE0-005

1

16029-ZG0-901

I

16100-ZL8-801

i

16100-ZL9-801

+1

16155-ZL8-003

I

16166-ZL8-003

1

!6166-ZL9-003

1

16211-ZL8-000

1

!6212-ZL8-000

2

16221-883-BO0

i

1622B-ZLB-O00

25

Page 26

GC160

CARBURETORCont.

Re[.

No. DESCRIPTION

BLOCKNO. _14

(3

O

6

0

Q

T

ENGINE

1

SERIALNUMBER

FROM TO

Y

Ft

E

Q

_P_F_rNUMBEB

15 GUIDECOMP.tAIR ................

GUIDECDMP.,AIR ................

16 SCREW,PAN(5X6)................

17CLIP,TUBE(B6.5)...............

18BULKHOSE,VINYL(4X7X8000)

(4X7X150)....................

19 JET,MAIN(#60) ................

JET,MAIN(#62)

o_oi_woa_#wto_

JET,MAIN(#65)

JET,MAIN(#55)

JET,MAIN(#58)

e_mw_w_mam_o

wmwP m _a _wl

I

19650-ZL8-000

1

19650-ZL9"000

6

@

O

O

O

®

1

93500-05006-1H

1

95002-02650

1

95003-07008-60E

(I)

99101-124-0600

1

99101-124-0600

(I)

99101-124-0620

99101-124-0650

(I)

99101-124-0550

(I)

99101-124-0580

26

Page 27

AIR CLEANER

GC160

4

ZLB4Et 5OO

=._

Re[. BOOKNO. E-15

No. DESCRIPTION

1 TUBErBREATHER.................

TUBE,BREATHER.................

2 ELERENT,AIRCLEANER............

3 HOUSINGCORP.,AIRCLEANER......

4 GASKET,AIRCLEANER.............

5 COVER,AIR CLEANER..............

6 BOLT,FLANGE(6X112)(CT200)....

G

T

3

D

1

B

o

D

D

ENGINE

S_L_. NUMBER

FRO4VI TO

Y

R

E

Q

PARTt'&IMBER

1

!5721-Zt.8-000

1

15721-ZL9-000

t

17Zll-ZL8"000

1

17220"ZL8-000

1

17228-ZL8-000

1

17Z:31"ZLS-000

Z

90003-ZL8-000

27

E

Page 28

MUFFLER

2

9

GC160

Refo BLOCK NO. E_16

No. DESC_

1 MUFFLERCOHP...................

MUFFLERCQMP...................

2 PROTECTOR,RUFFLER.............

PROTECTOR,RUFFLER(CBJ) ........

3 ARRESTERCOMP.,SPARK...........

4 PLATE,ARRESTERNUMBER..........

5 SHROUD,MUFFLER................

6 BOLT,FLANGE(6X79) (CT200) .....

7 BOLT,FLANGE(6X12).............

8 SCREW,TAPPING(4X6)............

9 GASKET,MUFFLER................

7

3

7

;;_t,,,_]4.E!_A

Q

T

G

0

1

6

0

E_G_'qE

SEPJJU_NUMBER

r,

FROM TO

Y

R

E

Q PA.I:TTN_

1 i18310-ZL8-O10

1 18310-ZL9-000

1 18321-ZL8-000

1 18321-ZL8-000

1 18321-ZLS-A00

e

o

o

o

o

o

m

1 18350-ZL8-000

1 18356-ZL8-000

1 I%64-ZL8-000

Z 90004-ZL8-000

3 90013-883"000

2 90055-ZEI"_00

3 90055-ZE1400

(I) 18381-ZL8-305

28

Page 29

FUEL TANK

_;,..-20

6

6

!8

19

21

GC160

Ref_

No,

BLOCKNO, E-17 1

DESCRIPTION 0

1PUHPASSY., FUEL................ •

2 RUBBER,SUPPORTER(107MR).......o

RUBBER,SUPPORTER..............

3 TUBE,DIAPHRAGM................•

TUBE,DIAPHRAGM................

4 STRAINER,FUEL .................=

5 TANK,FUEL .....................D

TANK,FUEL ..................... •

TANK,FUEL .....................

TANK,FUEL .....................

6 RUBBERB,TANKMOUNTING.........D

7 JDINT,FUELTUBE................!o

8 COLLAR,FR.COVERSETTING .......Fo

9 STAYA, FUELTANK ...............ie

STAYA, FUELTANK ...............

10CAPASSY.,FUELTANK ............!e:

24

27

7

13

11

Q

T

G

6

ENGINE

SERIALNUMBER

FROM 10

,,,u, ,,

Y

R

E

Q PARTNUMBER

1 16700-ZLB-003

1 16854"ZHB-O00

1 168%'ZL9-800

1 16882-ZLB'O00

1 16882-ZL9-000

1 16952-ZAB-BO0

I 17511-ZLBoO00

I 17511-ZL8-800

mb m ,_ u

1 17511-ZL9-000

I 17511-ZL9-800

2 17516-ZV0-000

I 17519-ZL8-800

I 17535-166-000

I 17561-ZLB-O00

I 17561-ZL9-000

I 17620-ZL8-003

2g

Page 30

GG160

Re[ BLOCKNO. E-17

No, DESCRIFr_ION

11 TUBE,FUELTANK.................

12TUBE,FUEL .....................

13 TUBE,FUEL .....................

14TUBE,FUELRETURN...............

TUBE,FUELRETURN...............

15 RUBBER,RR.FENDER..............

16BOCT,STUD(FITANK).............

17WASHER(BMM)................._.

18COLLAR(14X6.1)................

19BOLT-WASHER(6X25).............

20 SCREW-WASHER(5X14} ............

21NUT,FLANGE(6_) ...............

23CLIP,TUBE(BS).................

24 CLIP,TUBE(BIO)................

25 CLIP,TUBE(C9).................

26 CLIP,TUBE{C11)................

27BULKHOSE,FUEL(5,5X8000)

(5.5)(33).....................

Q

T

G

C

1

6

0

,,,,,.,

o

0

0

6

®

0

0

0

®

0

®

I

0

®

ENGINE

SERIALNUMBER

FROM TO

N_a mmmm

Y

R

E

O

PART NUMBER

1

17701-ZL8-000

1

17?02-ZL8-000

1

17702-ZLB-800

1

17703-ZL8-800

1

17703-ZL9-801

1

80103-MG2-000

1

90041-ZL8-000

1

90473-896-000

2

90501-KA2-640

2

93404-06025-00

2

93894-05014-00

1

94050,06000

1

95002-02080

3

95002-02080

1

95002-02100

3

95002-02100

1

95002-50000

1

95002-70000

1

95001-55008-40M

30

Page 31

FLYWHEEL ® HGNR1ON COL

GC160

21..g_1tt_

Ref BLOCKNO. E-19

No. DESCRIP'TK_N

1 KEY,,SPECIAL_OODRUFF(25X18) ...

2 C0ILASSY.,IGNITION ............

3 CLAMP,STOPSWITIJHWIRE.........

4 CLAMP,WIRE ....................

5 FLYWHEELC0RP.......... . .......

6 WIRE,STOPSWITCH...............

7 WIRE,STOPSWITCH...............

8 PROTECTOR,SWITCH ..............

9 SWITCHCOMP.,DILLEVEL .........

10 HOLDER,STOPSWITCHWIRE ........

11 BOLT,FLANGE(6X12).............

12 BOLT,FLANGE(6X14)............;

13 BOLT,FLANGE(6X28).............

14 BOLT,FLANGE(6X20).............

15 NUT,SPECIAL(141_M).............

16 O'RING(11.8X2.4)..............

I? COLLAR(6.6X13.BX14.5).........

C

1

6

0

D

o

@

Ot

O

Ol

ot

o

O!"

O1'

@P

@l,

ENGINE

SERIALNUMBER

FROM TO

Q

T

Y

R

E

Q

PARTN_

13331-357-O00-

1

1

30500-Z_-004

1

30548-ZL8o000

1

30549"ZL8-000

1

3!110-ZL8-004

1

32195-ZL8-000

32195-ZL8-810

i

35419-ZL8-000

i!

35480-ZL8-811

1,

1

36103-ZE1-000

2

90013-883-000

1

90014-952-000

1

90015-883-000

1

90022-888-010

1

90201-878-_3

1

91320-MJ6-003

T

91501"ZL8-000

31

Page 32

CONTROL(I)

GG'160

2O

ZLB4F_._O0

Ref,, BLOCKNO. E_22

No. DEBORtPTION

1 CONTROLA$SY...................

2 ARM,GOVERNOR..................

ARM,,GOVERNOR..................

3 RO0,GOVERNOR..................

4 SPRING,GOVERNOR...............

5 SPRINGsTHROTTLERETURN.........

6 LEVERtCONTROL.................

7 SPRING,LEVER ..................

8 WASHER,CONTROLLLEVER..........

9 SPACER,CONTROLLEVER...........

10BASECOMP,,CONTROL.............

11 ROD,CHOKECONTROL..............

12 GRO_ET, CHOKEROD..............

13 PLATEsSIDE ....................

14 SWITCHASSY.,ENGINESTOP(N.O)..

15BOLT,FLANGE(6X12).............

O

T

G

C

I

6

o

o

o

0

o

o

o

o

o

o

o

I

J

o

ENGINE

SERIALNUMBER

FRr_ TO

N mwlN

u _

Y

R

E

Q

PAFTFNI/MBER

1

16500"ZL8-000

1

16551-ZL8-000

1

16551-ZL9-000

1

16555-ZL8-000

1

16561-ZL8-000

1

16562-ZL8-000

1

1657!-ZL8-000

1

16574-ZEI-000

1

16575"ZLB-O00

1

16578-ZEI-000

1

16580-ZL8-000

1

16611-Z_-000

1

16613-893-000

1

19612-ZL8-000

1

35120-ZL8-003

1

90013-883-000

32

Page 33

GC160

CONTROL1 Cont.

Ref., BLOCKNO, E-22

No. DESCRIPTION

16BOLT,FLANGE(6X14).............

17BOLT,GOVERNORARM ..............

18NUT,SELF-LOCK(6MM)............

19SCREW-WASHER(4X12)............

20NUT,FLANGE(6MM)...............

21WASHER,PLAIN(4_tM).............

GC160

CONTROL2 Cont.

Ref_ BLOCKNO, £_22_1

No. DESCRIPTION

C

i

6

0

o

O

oi

°i

Q

T

Y

ENGINE

SERIALNUMBER

FROM TO

R

E

Q

PARTNLrMBER

2

90014-952-000

90015-ZE5-010

90114-SA0"000

i

=

93892-04012-00

94050-06000

94103-04000

1i

!

Q

T

0

C

!

6

0

ENGINE

SERIALNUMBER

FROM 3"0

Y

R

E

O

P/U_TNUMBER

16 BOLT,FLANGE(6X14).............

17BOLT,GOVERNORARM ..............

18NUT,SELF-LOCK(6MR)............

19WASHER(12.5MH)................

20 SCREW,PAN(5X16)...............

o

D

o

O

O

21 SCREW-WASHER(4X12) ............

22NUT,FLANGE(6MR)...............

23WASHER,PLAZN(4MR).............

2

90014-952-000

90015-ZE5-010

i

I

90114-SA0-000

2

90452-KG8-000

I

93500-05016-0A

93892-04012-00

1

94050-06000

I

94103-04000

Ii

l

33

Page 34

CONTROL (2)

GC160

Re',

NO.

DES_JFTIOrq 0

17

G

C

BL( ;KNO E-22-I;1;

:6

ENGINE

SEPLr_t.NUMBER

FROM TO

21,B4E._01

Q

T

Y

R

E

Q PARTNUMBER

1 CONTROLASSY.

2 ARM,GOVERNOR

*. _.,...o._u=.., 10

eoe_oaa_mvoammeest

ARM,GOVERNOR

3 ROD,GOVERNOR.................. =

4 SPRING,GOVERNOR............... =

5 SPRING,THROTTLE)TURN ......... •

6 LEVER,CONTROL .................•

7 WASHER,COIt'TROLLVER ..........o

B HOLDER,{ABLE .................•

9 SPACER,ZONTRDLL VER ..........•

10 BASECDMP.,CONTROL.............•

11 ROD,CHOKECONTROL..............•

12 GROMMET,CHOKEROD ..............•

13 PLATE,SIDE ...................•

14 SWITCHASSY.,ENGINESTOP (N.B).. •

15 BOLT,FLANGE(6X12).............•

1 16500-ZL8-800

1 16551-ZL8-000

1 !6551-ZL9-000

1 16555-ZL8-000

1 16%1-ZL8-000

1 16562-ZL8-000

1 16571-ZL8-800

1 16575-ZL8-800

1 16576-891"000

1 16_8-ZL8-800

1 16580-ZL8-000

1 1661t-ZL8-000

1 16613-893-000

i ;19612-ZL8-000

1 35120-ZL8-003

1 90013-883-000

i

i

34

Page 35

CONTROL (3)

:\

19

GC160

R_I. BLOCKNO. E_,22-21

No. DESCRIPTION 0

1 CONTROL ASSY................... e

2 ARM, GOVERNOR .................. •

ARMtGOVERNOR..................

3 ROb, GOVERNOR .................. e

4 SPRING, GOVERNOR ...............e

5 SPRING,THROITLE RETURN ......... e

6 LEVER, {_ROL .................e

7 SPRING, LEVER ..................o

8 WASHER, CONTROLL LEVER .......... e

9 SPACER, CONTROL LEVER ........... e

10 BASE CORP., CON'IROL............. e

11 SPRING, CONTROLADJUSTING ....... o

12 ROD, CHOKECONTROL .............. e

13 GROMMET, CHOKE ROD .............. e

14 LEVER, STOP ....................e

15 PLATE, SIDE ....................e

%

I °B

6

_J34_2

Q

T

G

O

6

ENGINE

SERIALNUMBER R

-- :.... E

FROM TO Q PART NL_E_ ,,

Y

!16500"ZLB-BS0-

I

I

16551-ZL8-000

1 16551-ZL9-000

1 16555-ZL8-000

1 16561-ZL8-810

1 16562-ZL8'-000

1 i16571-ZL8-850

1 i16574-ZE1-000

1 [16575-ZL8-000

t 16578-ZE1-000

1 !165B0-ZL8-000

I 165B4-883-300

1 16611-ZL8-000

1 i16613-893-000

1 16631-ZL8-850

1 I%12-ZL8-000

35

Page 36

GC160

CONTROL 3 Cont.

Ref BLOCKNO. E_22-2

No. DESCRIFrRON

16 SWITCHASSY.,E_GINESTOP(N.O)..

17 BOLT,FLANGE(6X12).............

18 BOLT,FLANGE(6X14).............

19 BOLT,GOVERNORARM..............

20 SCREW,ADJUST........ ..........

21 NUT,SELF-LOCK(6HM)............

22 WASHER,WHEEL(6MM).............

23 SCREW-WASHER(4X12)............

24 NUT,FLANGE(6HE) ...............

25WASHER,PLAIN(4MM).............

E

E

;G

_C

11

16

0

ie

ie

io

o

Qi

Q

T

ENGINE

SERL,_LNLY_,IBER

FROM " TO

I

Y

R

E

Q

PARTNUMBE_

I

35120-ZL8-003

i

90013-883-000

Z

90014-952-000

I

90015-ZE5-010

1

90031-ZL8-85C

I

90114-SA0-000

1

90563-355-000

I

93892-04012-00

I

94050-06000

I

94103-04000

36

Page 37

MARK

GC160

Ref, 6

No. DESCPJPTION 0

BLOCKNO. E-2B I

1 MARK,EMBLEM(5.0) .............. e!

MARK,EMBLEM(GC1354.0) ........

2 MARK,ENGINESWITCHINDICATION.. :e

3 MARK,CHOKE ....................o

4 MARK,OILALERT(E) .............•

5 MARK,THRDTTLEINDICATION.......e

Gi

C

Q

T

Y

ENGINE

SERIAL_A.rMBER R

E

FROM TO Q PARTNUMBE_

i 87101-ZL8-000

1 87101-ZL9-000

1 8750t-ZL8-000

1 B?SZ8-ZLS-000

..... 1 87530-ZL8-850

1 87532-ZL8-800

37

Page 38

FOR CALIFORNIA RESIDENTS ONLY WHEN SEEKING SERVICE IN CALIFORNIA

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Sears Roebuck and Coo,USA (Sears), are please to explain the emissions

control system warranty on your 1995 and later lawn and garden equipment engine. In California new utility and lawn

and garden equipment engines must be designed, built, and equipped to meet the State's stringent ant-smog stan-

dards. Sears must warrant the emission contor! system on your lawn and garden equipment engine for' the periods of

time listed below provided there has been no abuse, neglect, or improper maintenance of your lawn and garden equip-

ment engine.

Your emission control system incluDed parts such as the carburetor and the ignition system. Where a warrantable con-

diton exists, Sears will repair your lawn and garden equipment engine at no cost to you. Expenses covered under war-

ranty include diagnosis, parts, and labor:

MANUFACTURER'S WARRANTY COVERAGE

The 1995 and later utilityand lawn and garden equipment engines are warranted for two years. If any emission related

part on you engine (as listed below) is defective, the part will be repaired or replaced by Sears.

OWNER'S WARRANTY' RESPONSIBLITIES

As the lawn and garden equipment engine owner; you are responsible for the performance of the required maintenance

listed in your Owner's Manual. Sears recommends that you retain all receipts covering maintenance on your lawn and

garden equipment engine, but Sears cannot deny warranty solely for*the lack of receipts or for your failure to ensure the

performance of all sceduled maintenance.

As the lawn arid garden equipment engine owner, you should be aware that Sears may deny you warTanty coverage if

your lawn and garden equipment engine or a part of it has failed due to abuse, neglect, improper maintenance, unap-

proved modifications, or the use of parts not made or*approved by the original equipment manufacturer.

You are responsible for presenting your lawn and garden equipment engine to a Sears authorized repair center as soon

as a problem exists Warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

if you have any questions regarding your' warranty rights and responsibfities, you should contact your nearest autho-

rized service center or call Sears at 1-800-473-7247.

WARRANTY COMMENCEMENT DATE

The warranty period begins on the date the lawn and garden equipment engine isdelivered to the original, end-use

purchaser.

LENGTH OF COVERAGE

Sears warrants to the initial owner and each subsequent purchaser that the engine is free from defects in materials and

workmanship which cause the failure of a warranted part for a period of two years..

WHATIS COVERED

REPAIROR REPLACEMENT OF PARTS

• Repair or replacement of any warranted part will be performed at no charge to the owner at an approved Sears

Servicing Center_

, If you have any questions regarding you warranty rights and responsibtities, you should contact your nearest

authorized service center or call Sears at 1-800-473-7247.

38

Page 39

WARRANTY PERIOD

Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled only for

regular inspection to the effect of =repair or replace as necessary" shall be warranted for 2 years.. Any warranted

part which is scheduled for replacement as required maintenances shall be warranted for the period of time up to

the first scheduled replacement point for that part..

DIAGNOSIS

The owner shall not be charged for diagnostic labor which leads to the determinations that a warranted part is

defective if the diagnostic work is performed at an approved Sears servicing center°

CONSEQUENTIAL DAMAGES

Sears may be liable for damages to other engine components caused by the failure of a warranted part still under

warranty°

WHAT IS NOT COVERED

All failures caused by abuse, neglect, or improper maintenance are not covered.

ADD -ON OR MODIFIED PARTS

The use of add-on or modified parts can be grounds for disallowing a warranty claim. Sears is not liable to cover

failures of warranted parts caused by the use of add-on or modified parts°

HOW TO FILE A CI.AIM

if you have any questions regarding your warranty rights and responsibilities, you should contact your nearest autho-

rized service center or call Sears at 1-800-473-7247o

WHERE TO GET WARRANTY SERVICE

Warranty services or repairs shall be provided at all Sears authorized service centers.

MAINTENANCE, REPLACEMENT AND REPAIR OR EMISSION RELATED PARTS

Any Sears approved replacement part used in the performance of any warranty maintenance or repair on emission

related parts will be provided without charge to the owner ifthe part is under warranty_

EMISSION CONTROL WARRANTY PARTS LiST

t. Carburetor Assembly

2 lgniti0nSystem

a. Spark Plug, covered up to maintenance schedule

b. Ignition Module

3. CrankcaseBreatherTube

4, ExhaustManifold

MAINTENANCE STATEMENT

The owner is responsible for the performance of all required maintenance as defined in the owners manual.

39

Page 40

For the repair or replacement parts you

need delivered directly to your home

Catt7 a.rn.-7 p.rn. 7 days a week

1=800-366=PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1=800=4=REPAIR

(1-800-473-7247)

For the location of a

Sears Parts and Repair Center

in your area

Call 24 hours a day, 7 days a week

1=800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing agreement

Call 9 a rn- 5 p.m. Monday-Saturday

1-800-827=6655

The model number of your product is on a

decal attached to the Generator.

The model number of the engine is located

on the blower housing of the engine,

When requesting service or ordering parts,

always provide the following information:

• Product Type , Part Number

• Model Number • Part Description

America's Repair Specialists

4O

Page 41

Manual del Propietario

Voltios 2500

Generador Portatil

Modelo Nro.

580.327750

PRECAUCION: Lea y Siga las

Reglas de Seguridad e

Instrucciones Antes de Operar

Este Equipo

HORAS: Lun. - Vie, 8 a.m. a 5 p.m. (TCE)

SEARS, ROEBUCK and

Nro,deParteB2418 Revisi6n0 (3112/98)

CO., Hoffman Estates, IL 60179 U.S.A.

Page 42

REGLES DE SEGURIDAD ...................................... 3

ENSAMBLE ............................................... 4

OPERACION .......................................... 4-9

MANTENIMIENTO ..................................... 9-t 2

SERVICIO Y ADJUSTES .................................... 12-13

ALMACENAJE ................................................... t2

DIAGNOSTICO DE AVERIAS ................................... 14

PARTES DE REEMPLAZO ............................... 16-37

GARANTIA LIMITADA DE UN ANO DE GENERADOR CRAFTSMAN

SEARS garantizaa! cornptadororiginalque el altemadory el motor para su generadorport&tilestar_nlibresde defectos

en los materialeso la mano de obrapara laspiezasy el periodo estabiecido a partir de la fecha de compraoriginal_Esta

gatantia no es ttansfetibley se apiica(_nicamentea losgeneradoresport,tiles impulsadospotel motor garantizado GN

seria de Sears

CONSUMIDOR* COMMERCIAL*

Attemador 1 afio 90 dias

Motor t aho 90 dias

"NOTA: Para el prop6sito de esta garantia "uso del consumidor" quiere decir uso dom_.stico de residencia personal yen el

caso de emergencia por el comprador original, pero, no debe set usada por la electr_cidad principal. "Uso Cornercial" quiere

:Iecir todos los otros uses, incluyendo alquiler, construcci6n, comercial, electricidad principal de potencia de ta domestico y

_rop6sitos que producen ganancia. Un vez que un genetrador ha experimentado uso comercial, de atli en adelente set_

:onsiderado como un generador de uso comercial pare los prop6sitos de esta garant[a.

_)urante dicho periodo de garantia, SEARS reparar& o reemplazar_ a su opci6 cualquier pieza la cual, at set examinada per

3EARS, se encuentre que est& defectuosa bajo uso y servicio normales** Las baterias de arranque y los arti'culos consumi-

:los, como las bujias y los filtros de aire quellos ponerse gastado o roto durante el uso normal, no est,_n garantizadas por

SEARS° Todos los cosotos de transporte bajo la garantia, inctuyendo la devofuci6n ala f_brica si fuera necesario, ser,_n car-

jades al comprador y prepagados po _L Esta garantia no incluye el mantenimento y servicio normal no se aplica a un can-

iunto de genetador, alternador o motor, o las piezas que hen sido sujetas a instalaci6n a alteracibn inadecuadadas o