Page 1

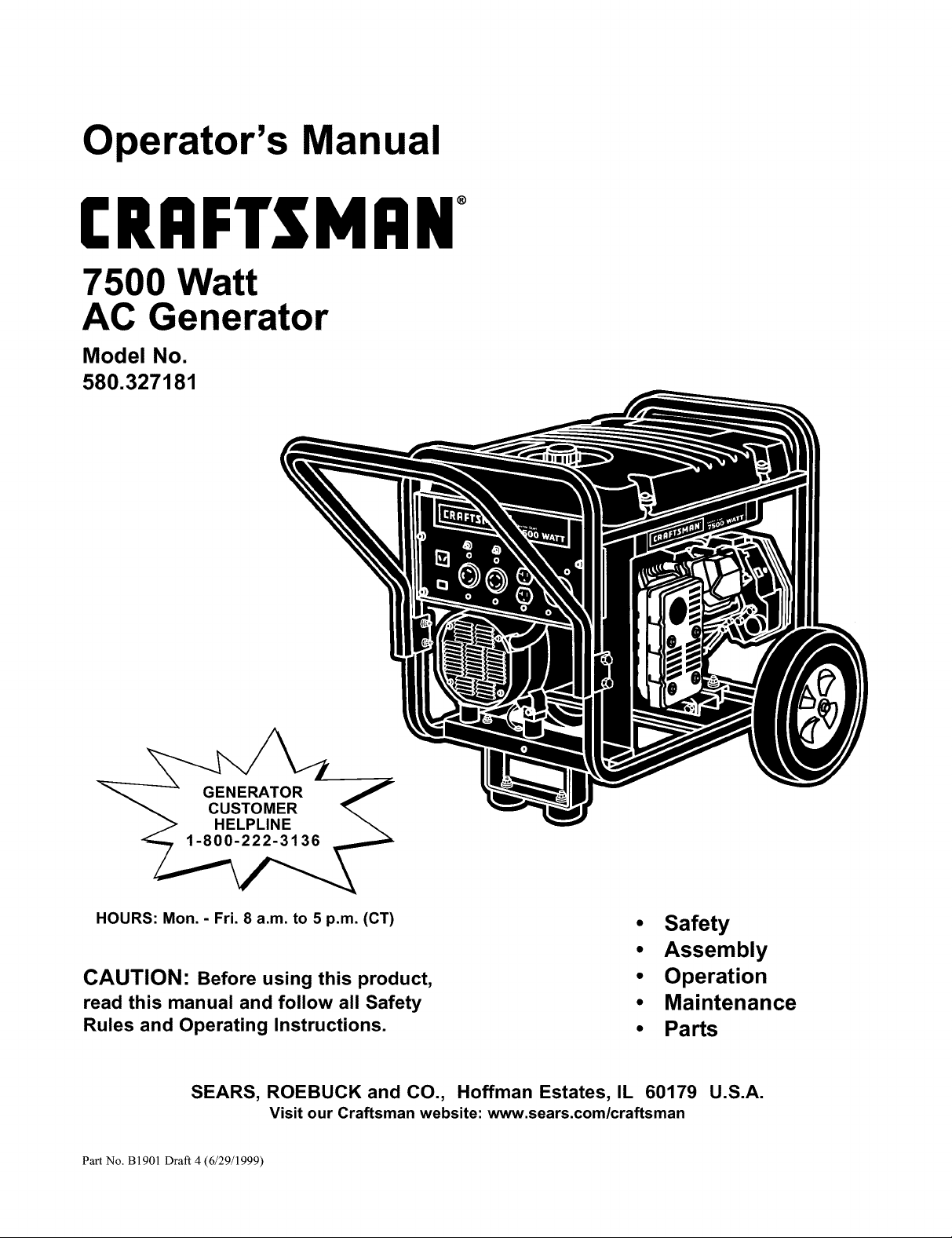

Operator's Manual

CRAFTSMAN°

7500 Watt

AC Generator

Model No.

580.327181

GENERATOR 7

CUSTOMER

HELPLINE

HOURS: Mon.- Fri. 8 a.m. to 5 p.m. (CT)

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

Part No, B1901 Draft 4 (6/29/1999)

• Safety

• Assembly

• Operation

• Maintenance

• Parts

Page 2

Safety Rules ........................... 2-3

Assembly .............................. 4-5

Operation ............................. 6-10

Maintenance ......................... 11-13

Storage ................................ 14

Troubleshooting ......................... 15

Replacement Parts .................... 17-27

HOW TO ORDER PARTS .......... BACK PAGE

Specifications ........................... 11

LIMITED WARRANTY FOR DELUXE PORTABLE GENERATORS

SEARS warrants to the original purchaser that the alternator and engine for its portable generator will be free from defects in

materials or workmanship for the items and period set forth below from the date of original purchase. This warranty is not

transferable and applies only to portable generators driven by the GN-Series Sears warranted engine.

Alternator 2 years (2nd year parts only) 1 year

Engine 2 years (2nd year parts only) 1 year

* NOTE: For the purpose of this warranty "Consumer Use" means personal residential household and emergency use by

original purchaser, not to be used as a primary source of power. "Commercial Use" means all other uses, including rental,

construction, commercial, and income producing purposes. Once a generator has experienced commercial use, it shall

thereafter be considered a commercial use generator for the purpose of this warranty.

During said warranty period, SEARS will, at its option, repair or replace any part which, upon examination by SEARS, is

found to be defective under normal use and service**. Starting batteries are not warranted by SEARS. All transportation

costs under warranty, including return to the factory if necessary, are to be borne by the purchaser and prepaid by him. This

warranty does not cover normal maintenance and service and does not apply to a generator set, alternator or engine, or

parts which have been subjected to improper or unauthorized installation or alteration, misuse, negligence, accident, over-

loading, overspeeding, improper maintenance, repair or storage so as, in SEARS's judgment, to adversely affect its perfor-

mance and reliability.

** NORMAL WEAR: As with all mechanical devices, engines need periodic parts service and replacement to perform well.

This warranty will not cover repair when normal use has exhausted the life of a part or engine.

THERE IS NO OTHER EXPRESS WARRANTY. SEARS HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE TO

THE EXTENT PERMITTED BY LAW. THE DURATION OF ANY IMPLIED WARRANTIES WHICH CANNOT BE DIS-

CLAIMED IS LIMITED TO THE TIME PERIOD AS SPECIFIED IN THE EXPRESS WARRANTY. LIABILITY FOR CONSE-

QUENTIAL, INCIDENTAL, OR SPECIAL DAMAGES UNDER ANY AND ALL WARRANTIES IS EXCLUDED. Some

provinces do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or conse-

quential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights

and you may also have other rights, which vary from state to state.

For service, see your nearest SEARS authorized warranty service facility. Warranty service can be performed only by a

SEARS authorized service facility. This warranty will not apply to service at any other facility. At the time of requesting war-

ranty service, evidence of original purchase date must be presented.

CONSUMER* COMMERCIAL*

SEARS, ROEBUCK and CO., D/817WA, Hoffman Estates, IL 60179 U.S.A.

CAUTION:Alwaysdisconnectspark plugwire and placethe wirewhereit cannotcontactthe spark plug.To

preventaccidentalstartingwhen setting up,transporting,adjustingor makingrepairsto yourgenerator.

DANGER:Thisgeneratoris designedfor outdooruse only.Do not usethis generatorinsideanybuildingor

enclosureincludingthe generatorcompartmentof a recreationalvehicle(RV). Fireoran explosionmayresult.No

userperformedmodifications, includingventingof exhaustand/orcoolingventilation,will eliminatethe danger.

Also,allowat least twofeet of clearanceon all sidesof the generatoreven whileoperatingthe unit outdoors.

1,_ CAUTION:Beforeusingthis product,read this

manualandfollowall Safety Rulesand

OperatingInstructions.

Page 3

• The generator produces dangerously high voltage

that can cause extremely hazardous electrical

shock. Avoid contact with bare wires, terminals,

etc. Never permit any unqualified person to

operate or service the generator.

• Never handle any kind of electrical cord or device

while standing in water, while barefoot or while

hands or feet are wet. Dangerous electrical shock

will result.

The National Electric Code requires the frame and

external electrically conductive parts of generator

be properly connected to an approved earth

ground. Local electrical codes may also require

proper grounding of the generator. Consult with a

local electrician for grounding requirements in your

area.

• Use a ground fault circuit interrupter in any damp

or highly conductive area (such as metal decking

or steel work).

• Do not use worn, bare, frayed or otherwise

damaged electrical cord sets with the generator.

Using any defective cord set may result in

electrical shock or damage to equipment and/or

property.

• Operate generator only on level surfaces and

where it will not be exposed to excessive moisture,

dirt, dust or corrosive vapors.

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames,

sparks or heat in the vicinity while handling

gasoline. Avoid spilling gasoline on a hot engine.

Comply with all laws regulating storage and

handling of gasoline.

• Never add fuel while unit is running.

• Do not overfill the fuel tank. Always allow room for

fuel expansion. If tank is overfilled, fuel can

overflow onto a hot engine and cause FIRE or an

EXPLOSION.

Allow at least 2 feet of clearance on all sides of

generator, even while operating unit outdoors, or

you could damage the unit.

Never store generator with fuel in tank where

gasoline vapors might reach an open flame or

spark or pilot light (as on a furnace, water heater

or clothes dryer). FIRE or an EXPLOSION might

result.

Generator exhaust gases contain DEADLY carbon

monoxide gas. This dangerous gas, if breathed in

sufficient concentrations, can cause

unconsciousness or even death. Operate this

equipment only in the open air where adequate

ventilation is available.

• The engine-generator requires an adequate flow of

cooling air for its continued proper operation.

Never operate the unit inside any room or

enclosure where the free flow of cooling air into

and out of the unit might be obstructed. Without

sufficient cooling air flow, the unit quickly

overheats, damaging the generator or nearby

property.

• Never start, or stop, the engine-generator with

electrical loads connected to receptacles with the

connected devices turned ON. Start the engine

and let it stabilize before connecting electrical

loads. Disconnect all electrical loads before

shutting down the generator.

• Do not insert any object through cooling slots of

the engine-generator. You could damage the unit

or injure yourself.

• Never operate generator (a) in rain; (b) in any

enclosed compartment; (c) if engine speed

changes; (d) if connected electrical devices

overheat; (e) if electrical output is lost; (f) if engine

or generator sparks; (g) if flames or smoke are

observed while unit is running; (h) if unit vibrates

excessively.

Note: Your generator is equipped with a spark

arrestor muffler, the spark arrestor must be

maintained in effective working order by the

owner/operator.

I,_ LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT I

MEANS "ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED."

Page 4

TO REMOVE GENERATOR FROM

CARTON

• Slice two corners at end of carton from top to

bottom so the panel can be folded down fiat.

• Remove all packing material, carton fillers, etc.

• Remove the generator from the shipping carton.

CARTON CONTENTS

• Generator

• Wheel Kit

• Locking Plugs

• Battery Tray components

• Manual

Check all contents. If any parts are missing or

damaged, call the Generator Helpline at

1-800-222-3136.

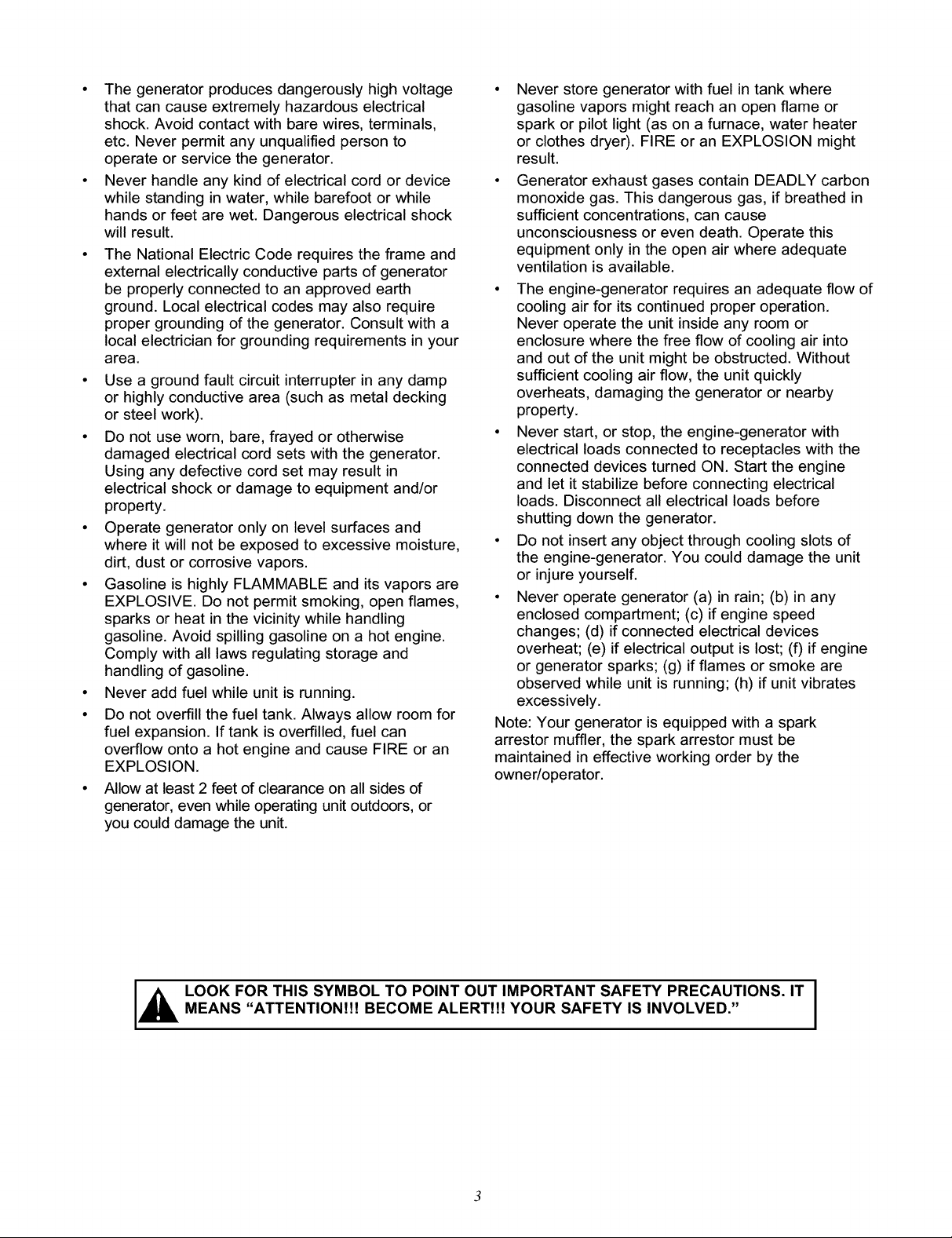

INSTALLING TRAY AND BATTERY

You must purchase and install a 12 Volt DC battery

(Sears DieHard Lawn & Garden Battery #28-27145).

The battery should be serviced with electrolyte fluid

and fully charged prior to installation. Install the battery

as follows:

• Find the battery tray and fasteners shipped loose in

the carton. You should have two 7" J bolts, two

lock washers,two flat washers and two hex nuts

• Remove the 4 battery tray screws from cradle

• Position the battery tray and install with supplied

hardware.

• Set battery onto tray

• Retain battery to tray with two J bolts, two lock

washers, two flat washers and two hex nuts.

• Connect the red battery cable from the engine

starter switch to positive (+) terminal on the

battery.

RED bNi_ery'_

• Connect the black battery cable to the negative (-)

terminal on the battery.

• Connect the other end of the black cable to the

engine, not the frame.

I,_ AUTION: Be sure the BLACKcableis

connectedto the enginemountandnotthe frame.

You could damagethegroundwire.

Page 5

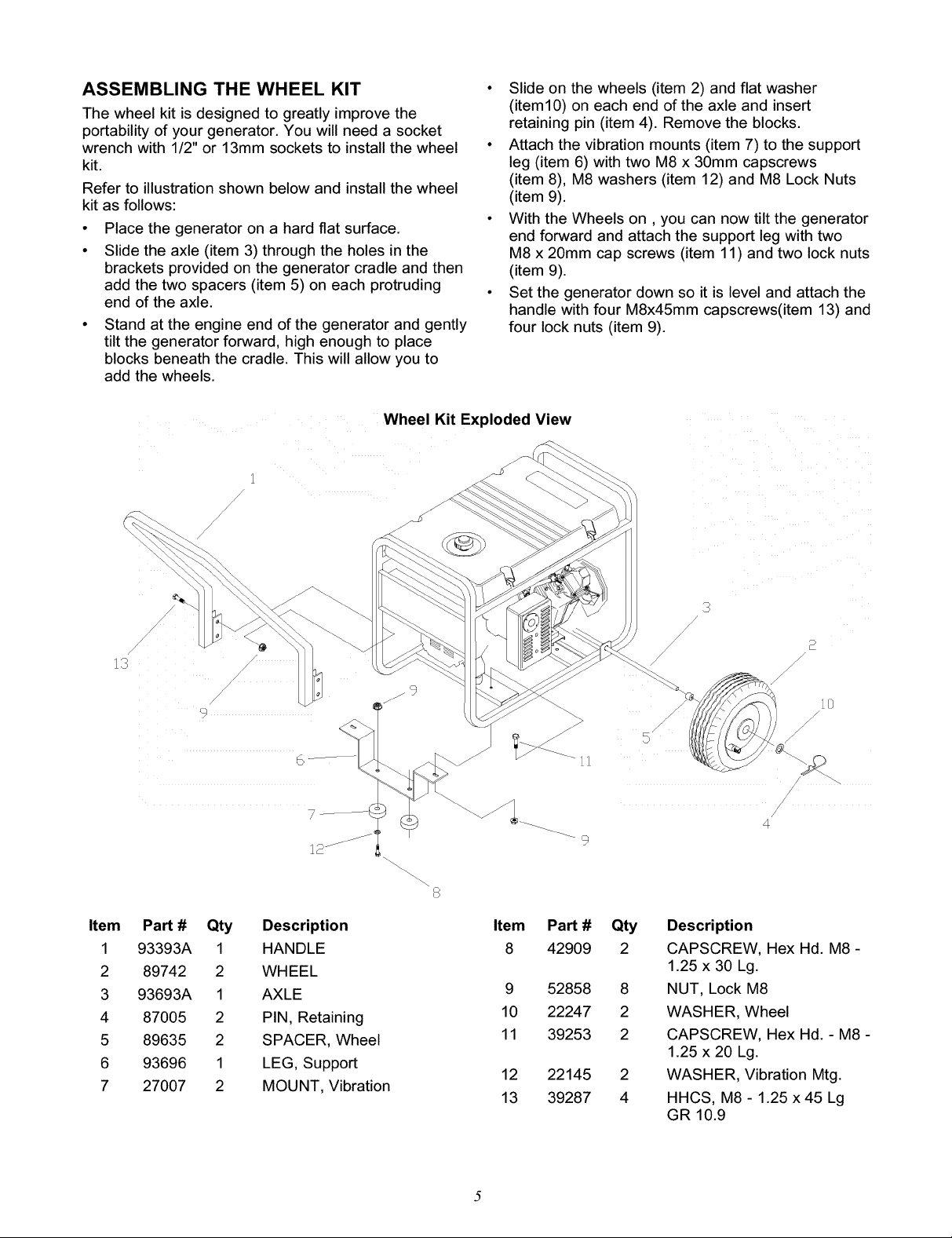

ASSEMBLING THE WHEEL KIT

The wheel kit is designed to greatly improve the

portability of your generator. You will need a socket

wrench with 1/2" or 13mm sockets to install the wheel

kit.

Refer to illustration shown below and install the wheel

kit as follows:

• Place the generator on a hard flat surface.

• Slide the axle (item 3) through the holes in the

brackets provided on the generator cradle and then

add the two spacers (item 5) on each protruding

end of the axle.

• Stand at the engine end of the generator and gently

tilt the generator forward, high enough to place

blocks beneath the cradle. This will allow you to

add the wheels.

Wheel Kit Exploded View

• Slide on the wheels (item 2) and flat washer

(item10) on each end of the axle and insert

retaining pin (item 4). Remove the blocks.

• Attach the vibration mounts (item 7) to the support

leg (item 6) with two M8 x 30mm capscrews

(item 8), M8 washers (item 12) and M8 Lock Nuts

(item 9).

• With the Wheels on, you can now tilt the generator

end forward and attach the support leg with two

M8 x 20mm cap screws (item 11) and two lock nuts

(item 9).

• Set the generator down so it is level and attach the

handle with four M8x45mm capscrews(item 13) and

four lock nuts (item 9).

Item

1

2

3

4

5

6

7

/

13

Pan # Qty

93393A 1

89742 2

93693A 1

87005 2

89635 2

93696 1

27007 2

/

/

/

9

6

Description

HANDLE

WHEEL

AXLE

PIN, Retaining

SPACER, Wheel

LEG, Support

MOUNT, Vibration

9

!

4

Item

Pan #

8

42909

Qty

2

Description

CAPSCREW, Hex Hd. M8 -

1.25 x 30 Lg.

9

10

11

52858

22247

39253

8

NUT, Lock M8

2

WASHER, Wheel

2

CAPSCREW, Hex Hd. - M8 -

1.25 x 20 Lg.

12

13

22145

39287

2

WASHER, Vibration Mtg.

4

HHCS, M8 - 1.25 x 45 Lg

GR 10.9

Page 6

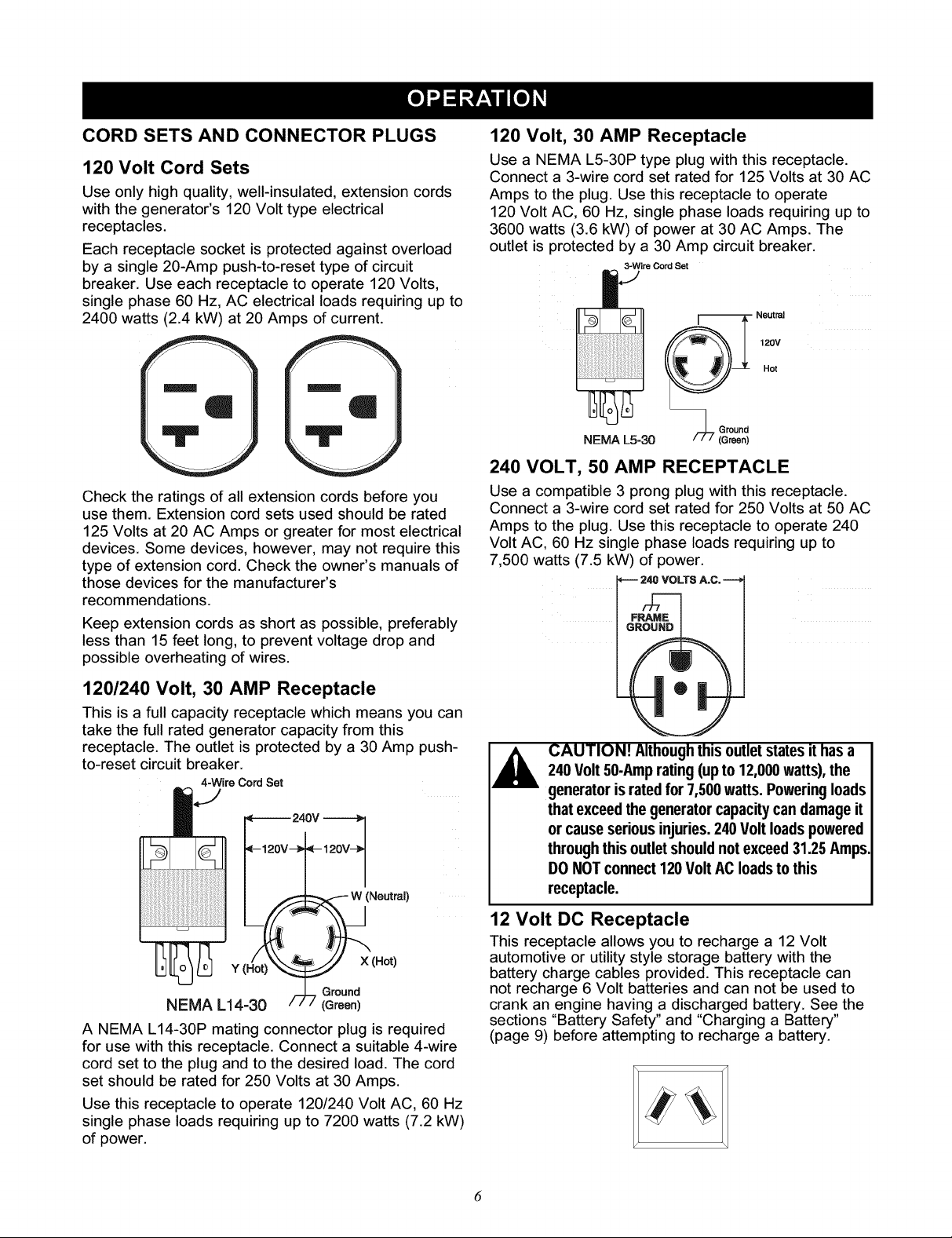

CORD SETS AND CONNECTOR PLUGS

120 Volt Cord Sets

Use only high quality, well-insulated, extension cords

with the generator's 120 Volt type electrical

receptacles.

Each receptacle socket is protected against overload

by a single 20-Amp push-to-reset type of circuit

breaker. Use each receptacle to operate 120 Volts,

single phase 60 Hz, AC electrical loads requiring up to

2400 watts (2.4 kW) at 20 Amps of current.

Check the ratings of all extension cords before you

use them. Extension cord sets used should be rated

125 Volts at 20 AC Amps or greater for most electrical

devices. Some devices, however, may not require this

type of extension cord. Check the owner's manuals of

those devices for the manufacturer's

recommendations.

Keep extension cords as short as possible, preferably

less than 15 feet long, to prevent voltage drop and

possible overheating of wires.

120 Volt, 30 AMP Receptacle

Use a NEMA L5-30P type plug with this receptacle.

Connect a 3-wire cord set rated for 125 Volts at 30 AC

Amps to the plug. Use this receptacle to operate

120 Volt AC, 60 Hz, single phase loads requiring up to

3600 watts (3.6 kW) of power at 30 AC Amps. The

outlet is protected by a 30 Amp circuit breaker.

3-Wira Cord Set

-- Neutral

120V

Hot

NEMA L5-30

240 VOLT, 50 AMP RECEPTACLE

Use a compatible 3 prong plug with this receptacle.

Connect a 3-wire cord set rated for 250 Volts at 50 AC

Amps to the plug. Use this receptacle to operate 240

Volt AC, 60 Hz single phase loads requiring up to

7,500 watts (7.5 kW) of power.

120/240 Volt, 30 AMP Receptacle

This is a full capacity receptacle which means you can

take the full rated generator capacity from this

receptacle. The outlet is protected by a 30 Amp push-

to-reset circuit breaker.

4-Wire Cord Set

240V

_- 120V_- 120V--_

Neutrai)

Y I P_ot)_ X (Hot)

NEMA L14-30 ,/-717 _rrOUenn_

A NEMA L14-30P mating connector plug is required

for use with this receptacle. Connect a suitable 4-wire

cord set to the plug and to the desired load. The cord

set should be rated for 250 Volts at 30 Amps.

Use this receptacle to operate 120/240 Volt AC, 60 Hz

single phase loads requiring up to 7200 watts (7.2 kW)

of power.

CAUTION! Althoughthis outlet states it has a

240 Volt50-Amprating(up to 12,000watts),the

generator is ratedfor 7,500watts. Powering loads

thatexceed thegeneratorcapacitycan damageit

or causeserious injuries.240Volt loadspowered

throughthis outletshould not exceed31.25Amps.

DO NOTconnect120 VoltAC loadstothis

receptacle.

2 Volt DC Receptacle

This receptacle allows you to recharge a 12 Volt

automotive or utilitystyle storage battery with the

battery charge cables provided. This receptacle can

not recharge 6 Volt batteries and can not be used to

crank an engine having a discharged battery. See the

sections "Battery Safety" and "Charging a Battery"

(page 9) before attempting to recharge a battery.

Page 7

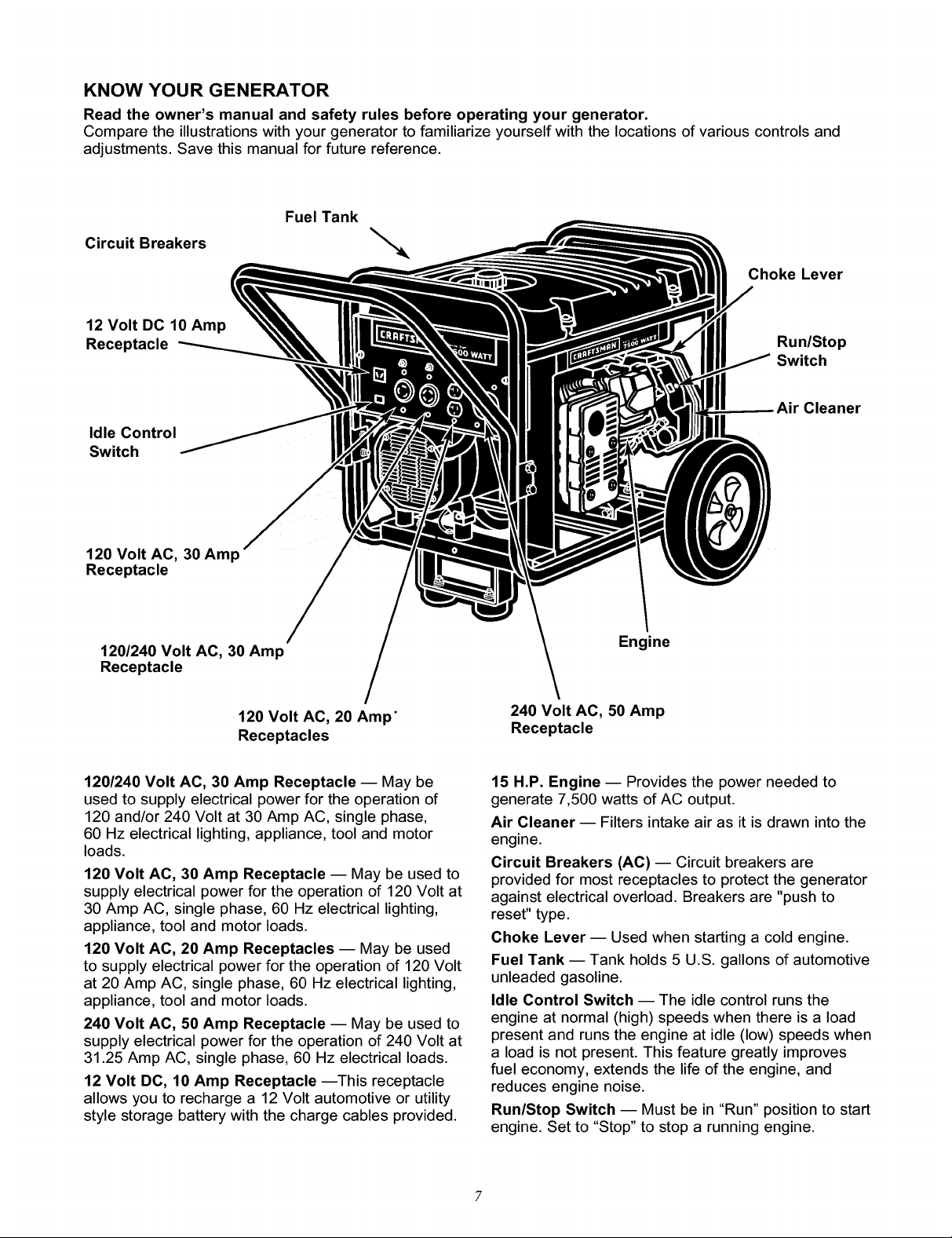

KNOW YOUR GENERATOR

Read the owner's manual and safety rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

FuelTank

Circuit Breakers "_

Choke Lever

12 Volt DC 10 Amp

Receptacle

Idle Control

Switch

Run/Stop

Switch

Cleaner

120 Volt AC, 30 Amp

Receptacle

120/240 Volt AC, 30 Amp

Receptacle

120 Volt AC, 20 Amp"

Receptacles

120/240 Volt AC, 30 Amp Receptacle -- May be

used to supply electrical power for the operation of

120 and/or 240 Volt at 30 Amp AC, single phase,

60 Hz electrical lighting, appliance, tool and motor

loads.

120 Volt AC, 30 Amp Receptacle -- May be used to

supply electrical power for the operation of 120 Volt at

30 Amp AC, single phase, 60 Hz electrical lighting,

appliance, tool and motor loads.

120 Volt AC, 20 Amp Receptacles -- May be used

to supply electrical power for the operation of 120 Volt

at 20 Amp AC, single phase, 60 Hz electrical lighting,

appliance, tool and motor loads.

240 Volt AC, 50 Amp Receptacle -- May be used to

supply electrical power for the operation of 240 Volt at

31.25 Amp AC, single phase, 60 Hz electrical loads.

12 Volt DC, 10 Amp Receptacle --This receptacle

allows you to recharge a 12 Volt automotive or utility

style storage battery with the charge cables provided.

Engine

240 Volt AC, 50 Amp

Receptacle

15 H.P. Engine -- Provides the power needed to

generate 7,500 watts of AC output.

Air Cleaner -- Filters intake air as it is drawn into the

engine.

Circuit Breakers (AC) -- Circuit breakers are

provided for most receptacles to protect the generator

against electrical overload. Breakers are "push to

reset" type.

Choke Lever- Used when starting a cold engine.

Fuel Tank -- Tank holds 5 U.S. gallons of automotive

unleaded gasoline.

Idle Control Switch -- The idle control runs the

engine at normal (high) speeds when there is a load

present and runs the engine at idle (low) speeds when

a load is not present. This feature greatly improves

fuel economy, extends the life of the engine, and

reduces engine noise.

Run/Stop Switch -- Must be in "Run" position to start

engine. Set to "Stop" to stop a running engine.

Page 8

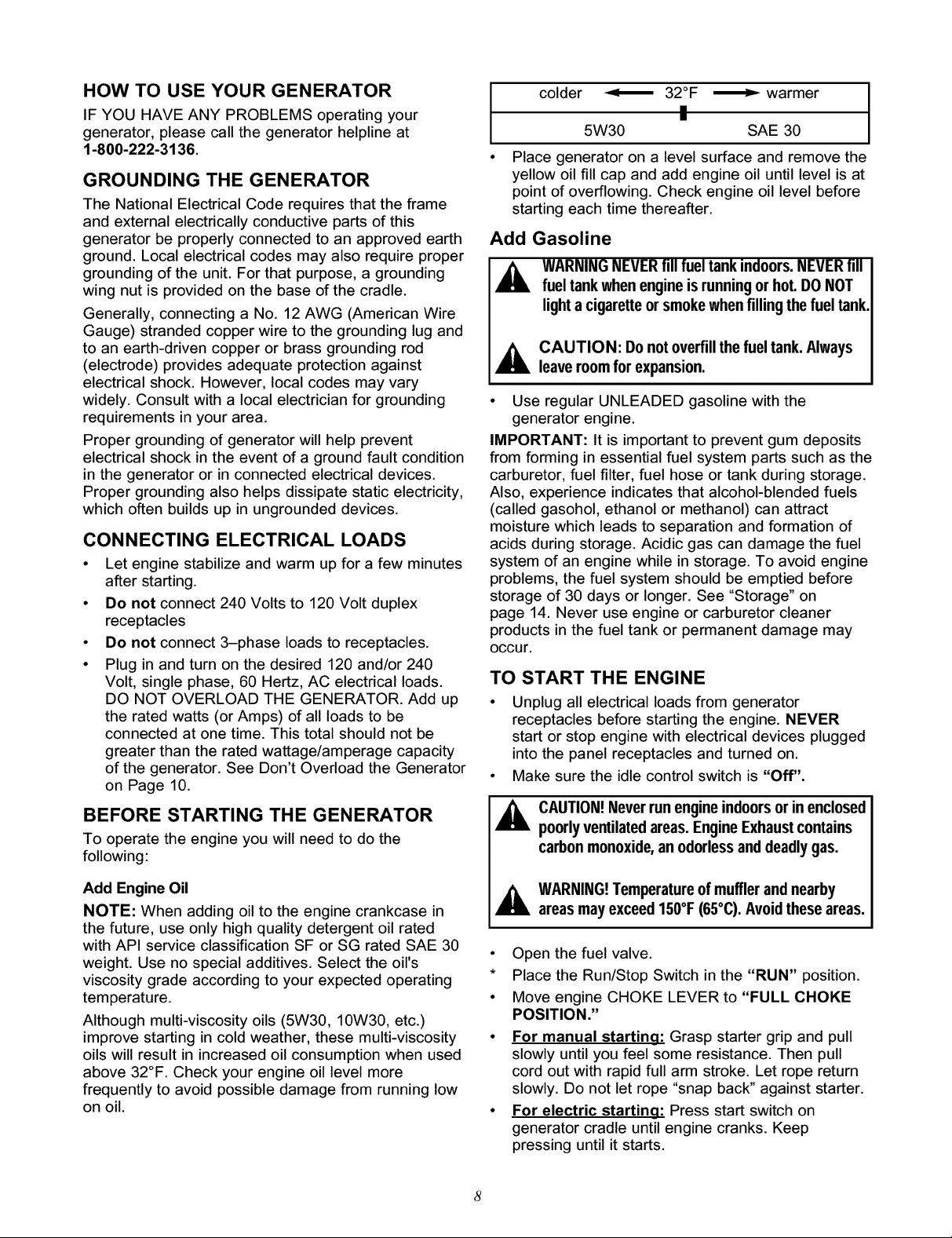

HOW TO USE YOUR GENERATOR

IF YOU HAVE ANY PROBLEMS operating your

generator, please call the generator helpline at

1-800-222-3136.

GROUNDING THE GENERATOR

The National Electrical Code requires that the frame

and external electrically conductive parts of this

generator be properly connected to an approved earth

ground. Local electrical codes may also require proper

grounding of the unit. For that purpose, a grounding

wing nut is provided on the base of the cradle.

Generally, connecting a No. 12 AWG (American Wire

Gauge) stranded copper wire to the grounding lug and

to an earth-driven copper or brass grounding rod

(electrode) provides adequate protection against

electrical shock. However, local codes may vary

widely. Consult with a local electrician for grounding

requirements in your area.

Proper grounding of generator will help prevent

electrical shock in the event of a ground fault condition

in the generator or in connected electrical devices.

Proper grounding also helps dissipate static electricity,

which often builds up in ungrounded devices.

CONNECTING ELECTRICAL LOADS

Let engine stabilize and warm up for a few minutes

after starting.

Do not connect 240 Volts to 120 Volt duplex

receptacles

Do not connect 3-phase loads to receptacles.

Plug in and turn on the desired 120 and/or 240

Volt, single phase, 60 Hertz, AC electrical loads.

DO NOT OVERLOAD THE GENERATOR. Add up

the rated watts (or Amps) of all loads to be

connected at one time. This total should not be

greater than the rated wattage/amperage capacity

of the generator. See Don't Overload the Generator

on Page 10.

colder _ 32°F _ warmer

!

I

Place generator on a level surface and remove the

yellow oil fill cap and add engine oil until level is at

point of overflowing. Check engine oil level before

starting each time thereafter.

Add Gasoline

_ AUTION: Donotoverfillthefueltank.Always

• Use regular UNLEADED gasoline with the

generator engine.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as the

carburetor, fuel filter, fuel hose or tank during storage.

Also, experience indicates that alcohol-blended fuels

(called gasohol, ethanol or methanol) can attract

moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage of 30 days or longer. See "Storage" on

page 14. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may

Occur.

TO START THE ENGINE

• Unplug all electrical loads from generator

receptacles before starting the engine. NEVER

start or stop engine with electrical devices plugged

into the panel receptacles and turned on.

• Make sure the idle control switch is "Off".

5W30 SAE 30

WARNINGNEVERfill fuel tank indoors.NEVERfill

fuel tank when engineisrunningor hot.DO NOT

lighta cigaretteor smokewhen filling the fuel tank.

leaveroomfor expansion.

BEFORE STARTING THE GENERATOR

To operate the engine you will need to do the

following:

Add Engine Oil

NOTE: When adding oil to the engine crankcase in

the future, use only high quality detergent oil rated

with API service classification SF or SG rated SAE 30

weight. Use no special additives. Select the oil's

viscosity grade according to your expected operating

temperature.

Although multi-viscosity oils (5W30, 10W30, etc.)

improve starting in cold weather, these multi-viscosity

oils will result in increased oil consumption when used

above 32°F. Check your engine oil level more

frequently to avoid possible damage from running low

on oil.

_ AUTION!Never runengineindoorsor in enclosed

poorlyventilatedareas. EngineExhaustcontains

carbonmonoxide,an odorlessanddeadlygas.

,_ WARNING!Temperatureof mufflerand nearby

areasmay exceed 150°F(65°C).Avoidtheseareas.

• Open the fuel valve.

* Place the Run/Stop Switch in the "RUN" position.

• Move engine CHOKE LEVER to "FULL CHOKE

POSITION."

• For manual starting: Grasp starter grip and pull

slowly until you feel some resistance. Then pull

cord out with rapid full arm stroke. Let rope return

slowly. Do not let rope "snap back" against starter.

• For electric starting: Press start switch on

generator cradle until engine cranks. Keep

pressing until it starts.

Page 9

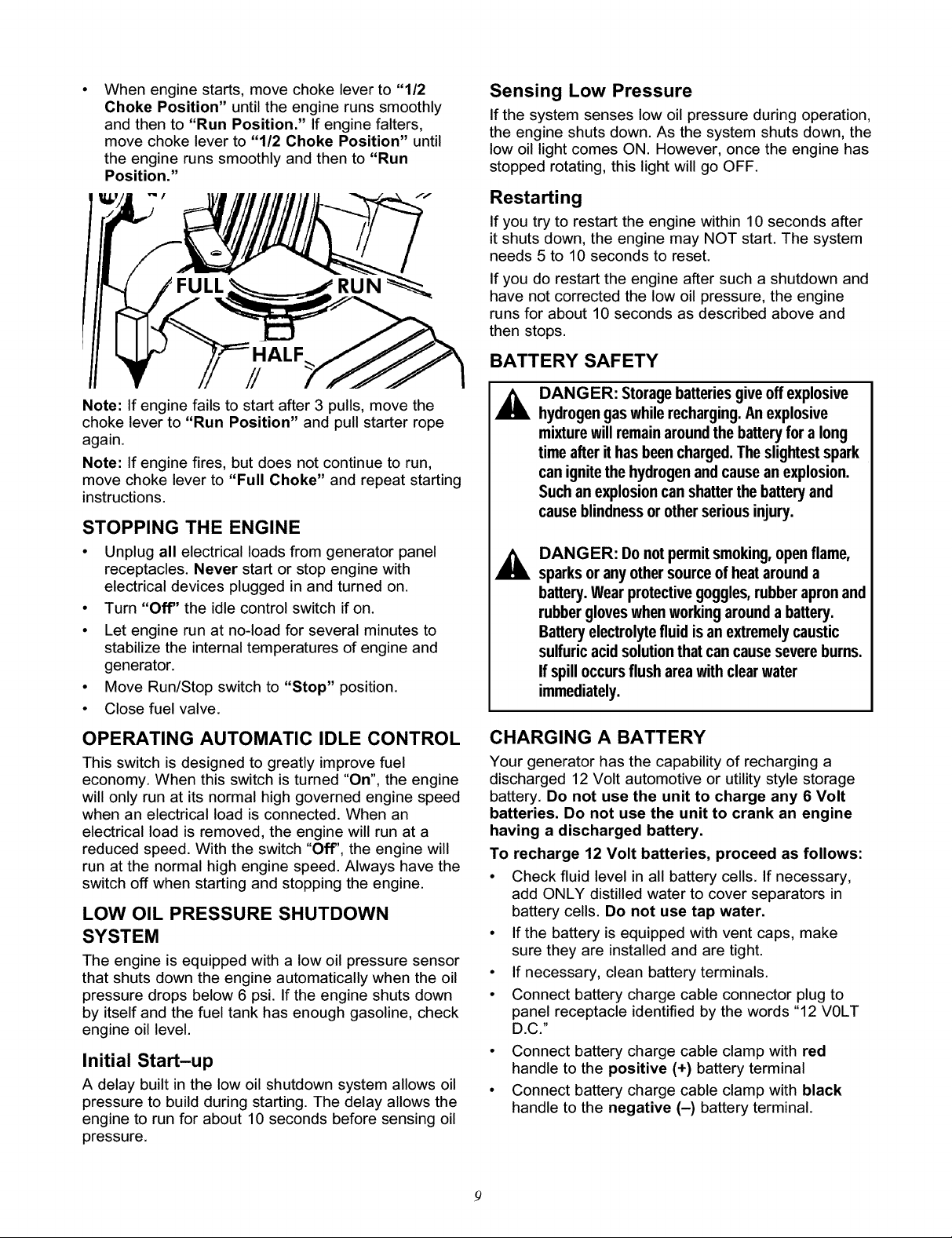

Whenenginestarts,movechokeleverto"1/2

ChokePosition"untiltheenginerunssmoothly

andthento"RunPosition."Ifenginefalters,

movechokeleverto"1/2ChokePosition"until

theenginerunssmoothlyandthento"Run

Position."

FULL RUN

HALF

//

Note: If engine fails to start after 3 pulls, move the

choke lever to "Run Position" and pull starter rope

again.

Note: If engine fires, but does not continue to run,

move choke lever to "Full Choke" and repeat starting

instructions.

STOPPING THE ENGINE

• Unplug all electrical loads from generator panel

receptacles. Never start or stop engine with

electrical devices plugged inand turned on.

• Turn "Off" the idle control switch if on.

• Let engine run at no-load for several minutes to

stabilize the internal temperatures of engine and

generator.

• Move Run/Stop switch to "Stop" position.

• Close fuel valve.

Sensing Low Pressure

If the system senses low oil pressure during operation,

the engine shuts down. As the system shuts down, the

low oil light comes ON. However, once the engine has

stopped rotating, this light will go OFF.

Restarting

If you try to restart the engine within 10 seconds after

it shuts down, the engine may NOT start. The system

needs 5 to 10 seconds to reset.

If you do restart the engine after such a shutdown and

have not corrected the low oil pressure, the engine

runs for about 10 seconds as described above and

then stops.

BATTERY SAFETY

DANGER: Storagebatteriesgive offexplosive

hydrogengas while recharging.Anexplosive

mixturewill remainaroundthe batteryfor a long

timeafter it has beencharged.The slightestspark

canignitethe hydrogenand causean explosion.

Suchan explosioncan shatterthe batteryand

causeblindnessor other seriousinjury.

DANGER: Donotpermitsmoking,openflame,

sparksoranyothersourceofheatarounda

battery.Wearprotectivegoggles,rubberapronand

rubbergloveswhenworkingaroundabattery.

Batteryelectrolytefluid isanextremelycaustic

sulfuricacidsolutionthatcancausesevereburns.

Ifspilloccursflushareawithclearwater

immediately.

OPERATING AUTOMATIC IDLE CONTROL

This switch is designed to greatly improve fuel

economy. When this switch is turned "On", the engine

will only run at its normal high governed engine speed

when an electrical load is connected. When an

electrical load is removed, the engine will run at a

reduced speed. With the switch "Off", the engine will

run at the normal high engine speed. Always have the

switch off when starting and stopping the engine.

LOW OIL PRESSURE SHUTDOWN

SYSTEM

The engine is equipped with a low oil pressure sensor

that shuts down the engine automatically when the oil

pressure drops below 6 psi. If the engine shuts down

by itself and the fuel tank has enough gasoline, check

engine oil level.

Initial Start-up

A delay built in the low oil shutdown system allows oil

pressure to build during starting. The delay allows the

engine to run for about 10 seconds before sensing oil

pressure.

CHARGING A BATTERY

Your generator has the capability of recharging a

discharged 12 Volt automotive or utility style storage

battery. Do not use the unit to charge any 6 Volt

batteries. Do not use the unit to crank an engine

having a discharged battery.

To recharge 12 Volt batteries, proceed as follows:

• Check fluid level in all battery cells. If necessary,

add ONLY distilled water to cover separators in

battery cells. Do not use tap water.

• If the battery is equipped with vent caps, make

sure they are installed and are tight.

• If necessary, clean battery terminals.

• Connect battery charge cable connector plug to

panel receptacle identified by the words "12 VOLT

D.C."

• Connect battery charge cable clamp with red

handle to the positive (+) battery terminal

• Connect battery charge cable clamp with black

handle to the negative (-) battery terminal.

Page 10

• Startengine.Lettheenginerunwhilebattery

recharges.

• Whenbatteryhascharged,shutdownengine

NOTE:Useanautomotivehydrometertotestbattery

stateofchargeandcondition.Followthehydrometer

manufacturer'sinstructionscarefully.Generally,a

batteryisconsideredto beat100%stateofcharge

whenspecificgravityofitsfluid(asmeasuredby

hydrometer)is1.260orhigher.

DON'T OVERLOAD THE GENERATOR

Overloading a generator in excess of its rated wattage

capacity can result in damage to the generator and to

connected electrical devices. Observe the following, to

prevent overloading the unit:

• Add up the total wattage of all electrical devices to

be connected at one time. This total should NOT be

greater than the generator's wattage capacity.

WATTAGE REFERENCE GUIDE

RUNNING

WATTS

*Air Conditioner (12,000 Btu) ........................................ 1700

Battery Charger (20 Amp) ............................................... 500

Belt Sander (3") ............................................................. 1000

Chain Saw ..................................................................... 1200

Circular Saw (6-1/2") .......................................... 800 to 1000

Coffee Maker ................................................................. 1000

*Compressor (1 HP) ...................................................... 2000

*Compressor (3/4 HP) ................................................... 1800

*Compressor (1/2 HP) ................................................... 1400

Curling Iron ...................................................................... 700

*Freezer .......................................................................... 500

Disc Sander (9") ............................................................ 1200

Edge Trimmer ................................................................. 500

Electric Nail Gun ........................................................... 1200

Electric Range (one element) ....................................... 1500

Electric Skillet ................................................................ 1250

*Furnace Fan (1/3 HP) .................................................. 1200

Hair Dryer ...................................................................... 1200

Hand Drill (1") ................................................................ 1100

Hand Drill (1/2") ................................................. 750 to 1000

Hand Drill (3/8") ............................................................... 500

Hand Drill (1/4") ............................................................... 250

Hedge Trimmer ............................................................... 450

The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can usually be found on a data plate or

decal affixed to the device.

If the appliance, tool or motor does not give

wattage, multiply volts times ampere rating to

determine watts (volts x amps = watts).

Some electric motors, such as induction types,

require about three times more watts of power for

starting than for running. This surge of power lasts

only a few seconds when starting such motors.

Make sure you allow for this high starting wattage

when selecting electrical devices to connect to your

generator. First, figure the watts needed to start the

largest motor. Add to that figure the running watts

of all other connected loads.

The Wattage Reference Guide below is provided to

assist you in determining how many items your

generator can operate at one time.

RUNNING

WATTS

Impact Wrench ................................................................ 500

*Jet Pump ........................................................................ 800

Lawn Mower .................................................................. 1200

Light Bulb ........................................................................ 100

Microwave Oven ............................................................. 700

*Milk Cooler ................................................................... 1100

Oil Burner on Furnace ..................................................... 300

Oil Fired Space Heater (140,000 Btu) ............................ 400

Oil Fired Space Heater (85,000 Btu) .............................. 225

Oil Fired Space Heater (30,000 Btu) .............................. 150

*Paint Sprayer, Airless (1/3 HP) ..................................... 600

Paint Sprayer, Airless (handheld) ................................... 150

Radio ...................................................................... 50 to 200

*Refrigerator .................................................................... 600

Slow Cooker .................................................................... 200

*Submersible Pump (1-1/2 HP) ..................................... 2800

*Submersible Pump (1 HP) ........................................... 2000

*Submersible Pump (1/2 HP)........................................ 1500

Sump Pump ................................................................... 600

*Table Saw (10") .............................................. 1750 to 2000

Television ............................................................. 200 to 500

Weed Trimmer ................................................................ 500

* Allow 3 times the listed watts for starting these devices.

/0

Page 11

MAINTENANCE SCHEDULE

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

Maintenance Operation

Check oil level

Change oil and oil filter-J:

Clean Spark Arrestor Screen

Service air cleaner

Service air cleaner cartridge

Adjust Valve Clearance

Replace spark plugs

Retorque head bolts

Every 8 Hours 25 Hours or 50 Hours or 100 Hours or Yearly

or Daily Every Season Every Season Every Season

X

Change oil after first 8 hours of operation then after every 50 hours or every season.

* Change oil and oil filter every 25 hours when operating under heavy load or in high

temperatures.

** Clean more often under dirty or dusty conditions. Replace Cleaner parts if very dirty.

*** Perform this task only after first 50 hours of operation. Head bolts will not need further

re-torquing.

PRODUCT SPECIFICATIONS

Generator Specifications

Rated Maximum Power ........ 7500 Watts (7.5kW)

Rated Voltage ............... 120/240 Volts AC

Rated Maximum Current

at 240 Volts ................ 31.2 AC Amperes

Rated Maximum Current

at 120 Volts ................ 62.5 AC Amperes

Rated Frequency ............ 60 Hz at 3600 rpm

Phase ..................... Single Phase

Engine Specifications

Rated Horsepower ........... 15 at 3600 rpm

Displacement ............... 410 cc

Spark Plug

Type: ................ Champion RC12YC or

Equivalent

Set Gap To: ........... 0.030inch (0.76mm)

Gasoline Capacity ............ 5 U.S. gallons

Oil

Summer ............. SAE 30 (10W-30)

Winter .............. SAE 5W-20 or 5W-30

GENERAL RECOMMENDATIONS

The warranty of the generator does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

operator must maintain generator as instructed in this

manual.

Some adjustments will need to be made periodically to

properly maintain your generator.

All adjustments in the Service and Adjustments

section of this manual should be made at least once

each season. Follow the requirements in the

"Maintenance Schedule" chart above.

Note: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit

clean and dry. Operate and store the unit in a clean

dry environment where it will not be exposed to

excessive dust, dirt, moisture or any corrosive vapors.

Cooling air slots in the generator must not become

clogged with snow, leaves,or any other foreign

material.

Check the cleanliness of the generator frequently and

clean when dust, dirt, oil, moisture or other foreign

substances are visible on its exterior surface.

Note: We DO NOT recommend using a garden hose

to clean generator. Water can enter the engine fuel

system and cause problems. In addition, if water

enters the generator through cooling air slots, some of

the water will be retained in voids and cracks of the

rotor and stator winding insulation. Water and dirt

buildup on the generator internal windings will

eventually decrease the insulation resistance of these

windings.

/1

Page 12

TO CLEAN THE GENERATOR:

IA CAUTION: Never Insertany objector tool

• Use a damp cloth to wipe exterior surfaces clean.

• A soft, bristle brush may be used to loosen caked

• A vacuum cleaner may be used to pick up loose

• Low pressure air (not to exceed 25 psi) may be

throughtheair coolingslots,even if theengine is

not running,

on dirt, oil, etc.

dirt and debris.

used to blow away dirt. Inspect cooling air slots

and openings on the generator. These openings

must be kept clean and unobstructed.

ENGINE MAINTENANCE

A ANGER: Whenworkingonthegenerator

alwaysdisconnectsparkplugwirefromsparkplug

andkeepitawayfromsparkplug.

CHECKING OIL LEVEL

Oil level should be checked prior to each use or at

least every 8 hours of operation. Keep oil level

maintained.

CHANGING ENGINE OIL AND OIL FILTER

Change oil after first 8 hours of operation. Change oil

and oil filter every 50 hours thereafter. If you are using

your generator under extremely dirty or dusty

conditions, or in extremely hot weather, change oil

more often.

Change oil while engine is still warm from running, as

follows:

• Clean area around oil drain plug.

• Remove oil drain plug and oil fill plug and drain oil

completely into a suitable container.

• When oil has completely drained, Install oil drain

plug and tighten securely.

• Place a suitable container beneath the oil filter and

turn filter counterclockwise to remove. Discard

according to local regulations.

• Coat gasket of new filter (p/n 70185) with engine

oil. turn filter clockwise until gasket contacts tightly

with filter adapter. Then tighten an additional 3/4

turn.

• Fill oil sump with recommended oil. (See "Before

Starting the Engine" on page 8 for oil

recommendations)

• Install the oil fill plug and tighten securely.

• Wipe up any spilled oil.

• Clean area around spark plug.

• Remove and inspect spark plug.

• Replace spark plug if electrodes are pitted, burned

or porcelain is cracked. For Replacement use

Champion RC12YC or equivalent.

• Check electrode gap with wire feeler gauge and set

spark plug gap to 0.030 inch (0.76mm) if

necessary.

RETORQUE HEAD BOLTS

After the first 50 hours of operation, you must retorque

the head bolts 6.9 kg.-m. (44 ft.-Ibs.)

Important: If you feel uncomfortable about doing this

procedure or you don't have the proper tools, please

take your generator in to the nearest service center to

have the head bolts re-torqued. This is a very

important step to insure the longest life for your

engine.

NOTE: Only perform this adjustment after the first 50

hours of operation. The head bolts will need no further

adjustment.

• Torque sequence is as follows: A, B, C, D,

(alternating pattern).

A

g

SERVICE AIR CLEANER

Your engine will not run properly and may be

damaged if you run it using a dirty air cleaner. Clean

or replace the air cleaner paper filter once every 50

hours of operation or once a year, whichever comes

first. Clean or replace more often if operating under

dusty conditions. Clean foam pre-cleaner every 25

hours of operation or sooner under dusty conditions.

PAPER

FILTER

CLEAN/REPLACE SPARK PLUG

Change the spark plug every 100 hours of operation

or once each year, whichever comes first. This will

help your engine to start easier and run better.

Replace with Champion RC12YC or equivalent.

FOAM

/2

PRE-FILTER

Page 13

To clean or replace foam pre-cleaner:

• Remove air cleaner cover, then foam pre-filter.

• Wash pre-cleaner in soapy water. Squeeze pre-

filter dry in clean cloth (DO NOT TWIST).

• Clean air cleaner cover before installing it.

To clean or replace paper air filter:

• Remove air cleaner cover; then remove foam pre-

filter (service if necessary) and remove paper filter.

• Clean paper filter by tapping it gently on a solid

surface. If the filter istoo dirty, replace it with a new

one. Dispose of the old filter properly.

• Clean air cleaner cover then insert pre-cleaner into

cover. Next insert new paper filter into cover to hold

pre-cleaner in place and assemble all of them to

the base of the air cleaner.

Note: If you need to order a new air filter, please call

1-800-366-PART.

CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor

screen. Inspect and clean the screen every 100 hours

of operation or once each year, whichever comes first.

NOTE: If you use your generator on any forest-

covered, brush-covered or grass-covered unimproved

land, it must have a spark arrestor. The spark arrestor

must be maintained in good condition by the

owner/operator.

Clean and inspect the spark arrestor as follows:

• To remove the muffler guard from the muffler,

remove the four screws that connect the guard to

the muffler bracket.

SPARKARRESTER

SCREEN

MUFFLER

HEAT SHIELD

To adjusting valve clearance:

• Make sure the engine is at room temperature

• Make sure that the spark plug wire is removed from

the spark plug and out of the way.

Remove the breather tube from the valve cover.

Remove the four screws attaching the valve cover

with a #2 or 3 phillips screwdriver.

Make sure the piston is at Top Dead Center (TDC)

of its compression stroke (both valves closed). To

get the piston at top dead center, pull on the recoil

handle slowly watching the piston trough the spark

plug hole. As you pull on the recoil handle the

piston should move up and down. The piston is put

Top Dead Center when it is up as high as it can go.

Feeler

Allen Wrench Gauge

Loosen

Jam Nut

• Loosen the rocker arm jam nut. Use an 8mm allen

wrench to turn the pivot ball stud while checking

clearance between the rocker arm and the valve

stem with a feeler gauge. Correct clearance is

0.002-0.004 inch (0.05-0.1mm). Note: You must

hold the rocker arm jam nut in place as you turn the

pivot ball stud.

• When valve clearance is correct, hold the pivot ball

stud in place with the allen wrench and tighten the

rocker arm jam nut. Tighten the jam nut to 165-183

inch-pounds torque. After tightening the jam nut,

recheck valve clearance to make sure it did not

change.

Remove four screws that attach the spark arrestor

screen.

Inspect screen and replace if torn, perforated or

otherwise damaged. DO NOT USE a defective

screen. If screen is not damaged, clean it with

commercial solvent.

Reattach the screen and the muffler guard.

ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should adjust

the valve clearance inthe engine.

Important: If you feel uncomfortable about doing this

procedure or you don't have the proper tools, please

take your generator in to the nearest service center to

have the valve clearance adjusted. This is a very

important step to insure longest life for your engine.

Tighten Jam Nut to 165

inch-pounds - 183

inch-pounds (19-21 N-m)

Reattach the valve cover. Note: Start all four

screws before tightening or you will not be able to

get all the screws in place. Note: Make sure the

gasket between the valve cover and cylinder head

is in place.

Reattach the breather tube.

Reattach the spark plug wire to the spark plug.

/3

Page 14

GENERAL

The generator should be started at least once every

seven days and allowed to run at least 30 minutes. If

this cannot be done and you must store the unit for

more than 30 days, use the following information as a

guide to prepare it for storage.

indoorsorinenclosed,poorlyventilatedareaswhere

fumesmayreachanopenflame,sparkorpilotlight

asona furnace,waterheater,clothesdryerorother

I_, WARNING: NEVERstoreenginewithfuelintank

gasappliance.

LONG TERM STORAGE INSTRUCTIONS

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasohol, ethanol or methanol) can attract moisture

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instructions:

outdoors,awayfromopen flame. Besureengineis

I_ WARNING:Drainfuel intoapprovedcontainer

cool.Do not smoke.

Protect Fuel System

• Remove all gasoline from the fuel tank to prevent

gum deposits from forming on these parts and

causing possible malfunction of engine.

• Run engine until engine stops from lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase.

Refill with recommended grade.

Oil Cylinder Bore

I_, CAUTION! Avoid sprayfromsparkplugholewhencrankingengineslowly.

• Remove spark plug and pour about 1/2 ounce

(15ml) of engine oil into the cylinder. Cover spark

plug hole with rag. Crank slowly to distribute oil.

• Install spark plug. Do not connect spark plug wire.

GENERATOR:

• Clean the generator as outlined on Page 11 ("To

Clean the Generator").

• Check that cooling air slots and openings on

generator are open and unobstructed.

OTHER STORAGE TIPS:

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause

problems.

• If possible, store your unit indoors and cover it to

give protection from dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

• Cover your unit with a suitable protective cover that

does not retain moisture.

• Store generator in clean, dry area.

IMPORTANT: NEVER cover your generator while

engine and exhaust area are warm.

14

Page 15

Problem

Engineisrunning,butno

ACoutputisavailable.

Cause

1.Oneof thecircuitbreakersisopen.

2.Faultin generator.

3.Poorconnectionordefective

cordset.

4. Connecteddeviceis bad.

Correction

1.Resetcircuitbreaker.

2.ContactSearsServiceFacility.

3.Checkandrepair.

4.Connectanotherdevicethat

isin goodcondition.

Enginerunsgoodat no-loadbut"bogs

down"whenloadsare connected

Enginewillnotstart;or starts

andrunsrough.

Engineshutsdownduringoperation

Enginelackspower.

1.Shortcircuitin a connectedload.

2.Enginespeedistoo slow.

3.Generatorisoverloaded.

4. Shortedgeneratorcircuit.

1.Run/StopSwitchsetto STOP.

2.Dirtyair cleaner

3.Out ofgasoline.

4. Stalegasoline.

5.Sparkplugwirenotconnected

tosparkplug.

6. Badsparkplug.

7. Waterin gasoline.

8. Overchoking.

9. Lowoil level 9.

10.Excessivelyrichfuelmixture.

11.Intakevalvestuckopenorclosed.

12.Enginehaslostcompression.

1.Out ofgasoline.

2.Lowoil level.

1.Loadistoo high.

2.Dirtyairfilter.

1.Disconnectshortedelectrical

load.

2.ContactSearsServiceFacility.

3.See"Don'tOverloadthe

Generator"

4.ContactSearsServiceFacility.

1.Setswitchto RUN.

2.Cleanor replaceaircleaner.

3.Fillfueltank.

4.Draingastank;fillwith freshfuel.

5.Connectwiretosparkplug.

6.Replacesparkplug.

7.Draingastank;fillwith freshfuel.

8.Openchokefullyandcrankengine.

Fillcrankcaseto properlevel.

10. ContactSearsServiceFacility.

11. ContactSearsServiceFacility.

12. ContactSearsServiceFacility.

1.Fillfueltank.

2.Fillcrankcaseto properlevel.

1.See"Don'tOverloadthe Generator"

2.Replaceairfilter.

Engine"hunts"orfalters.

NobatterychargeDCoutput

1.Chokeis openedtoosoon.

2.Carburetorisrunningtoorich

ortoo lean.

1.Batterypostsarecorroded.

2.Batteryfluidlevel islow.

3.Batterycableis bad.

4. Batteryisdefective.

5.Receptacleisbad.

15

1.Movechoketo halfwaypositionuntil

enginerunssmoothly.

2.ContactSearsServiceFacility.

1.Cleanbatteryposts

2.Adddistilledwaterto battery.

3.Replacecable.

4.Checkbatterycondition;replaceif

defective.

5.ContactSearsServiceFacility.

Page 16

16

Page 17

ill

CRAFTSMAN 7500 Watt AC Generator 580.327181

Wiring Diagram

1

1

17

Page 18

CRAFTSMAN 7500 Watt AC Generator 580.327181

Main Unit -- Exploded View

7O

51

66

65 67

DETAIL OF ELECTRIC

START SWITCH

J

TO + TERMINAL

ON BA]WERY

10

900.

TO STARTER

51

21

22

5O

72 \

27

'\

\

\

29

2O

9

58

17

/

/

7O

55

I

55

18

Page 19

CRAFTSMAN 7500 Watt AC Generator 580.327181

Main Unit -- Parts List

ITEM PART #. QTY.

1 92432 1

2 92531 1

3 92731 1

4 92247 1

5 B1342G 1

6 B1897G 1

7 65791 1

8 96796 1

9 22129 12

10 86307 4

11 47481 1

12 92609 2

13 82857 2

14 40976 2

15 66476 2

16 92532 1

17 22142 2

18 91153 1

19 90239 1

20 81917 1

21 81887J 1

22 52618 2

23 52856 2

25 66825C 1

26 74908 4

27 66449L 4

28 65795 2

29 66849C 1

30 67022 1

31 84132 1

32 66386 1

33 66849 2

34 78388 1

35 22769 1

36 86494 1

37 86292 1

38 77395 4

39 83465 4

40 78831B 4

41 80270 1

42 78299 1

43 94834 1

44 93595 1

45 92039 1

46 92665 1

DESCRIPTION

CRADLE

SUPPORT, Engine 48

SUPPORT, Engine & Muffler 49

HOUSING, Engine Adapter 50

ASSEMBLY, Rotor 51

ASSEMBLY, Stator 52

BEARING 53

WASHER, Special M8 Flat 55

WASHER, M8 Lock 57

HHMS, 5/16 - 24 x 3/4 Lg. Sems 58

HHCS, 5/16 - 24 x 10 - 5/8 Lg. 60

MOUNT, Vibration 62

MOUNT, Vibration

SCREW, M8 - 1.25 x 20mm

CAPSCREW, M6 - 1.0 x 12mm

BRACKET, Muffler

SCREW, 5/16 - 18 x 3/4"

MUFFLER

GASKET, Muffler

PIN, 4 mm x 10 Roll

WRAP, Stator

HHCS, M5 - 0.8 x12 Lg.

NUT, M5 Locking

CARRIER, Rear Bearing

TAPTITE, M5 - 0.8 x 10 Lg.

BOLT, M6 - 1 x 190 mm Stator

RECTIFIER, Battery Charge

TAPTITE, M5 - 0.8 x 30 Lg.

GROMMET, Rubber

ASSEMBLY, Power Regulator

ASSEMBLY, Brush Holder

TAPTITE, M5 - 0.8 x 16 Lg.

COVER, Bearing Carrier

WASHER, Shakeproof Int. #10

SCREW, M6 - 1.0 x 16 Lg. Wing

HHCS, #10 Self Driller

NUT, M6 Flange Lock

GROMMET, Tank

HHMS, M6 - 1.0 x 60 Black 96923 1 Battery Tray

VALVE, Tank

BUSHING, Plastic Tank 45771 2 Hex Nut

CAP, Fuel Gauge 96925 1 Battery Tie-down

TANK, Fuel 96924 2 J-Bolt

SHIELD, Heat 154-53621 1 Battery Cable Positive

INSULATION, #2 -1/4" Thick 155-53621 1 Battery Cable Negative

ITEM PART #. QTY. DESCRIPTION

47 85000 1 CLIP, Insulation

143-53621 1 WIRE, Ground

26850 2 LW, EXT, M6 Shakeproof

57593 1 MOUNT, Cable Tie

92982 1 DECAL, Danger

B1899 2 DECAL, Heat Shield

B4901 1 DECAL, 1-800-4MyHome

25244 12 NUT, Hex 5/16 - 18

B1898 1 DECAL, Control Panel

B1332A

22531

93826

63 77282 1 SWITCH, Starter

64 22287 2 SCREW, 1/4 - 20" x 3/4"

65 22097 2 WASHER, M6 Lock

66 22127 2 NUT, 1/4 - 20" Hex

67 77283 1 ASSY, Starter Switch

68 96068 1 SHIELD, Heat

69 56893 5 CRIMPTITE, 10 - 24 x 1/2

70 B2153

71 23762

72 22097

900 NSP

Parts Not Illustrated

B1901

AB3061

37806

43438

65787

84882

Optional Accessories Not Illustrated

09-32688 Cord Wrap Kit

09-32687 120V 30A Locking Plug

Battery Tray Kit Not Illustrated

22129 2 Lockwasher

22145 2 Flat Washer

1 ASSEMBLY, Control Box

2 HHCS, 5/16 - 18 x 1-3/4" Lg.

1 DECAL, Start Instructions

8 HHCS, 12 - 14 x 7/8 Self Driller

1 SHAKEPROOF, Ext #10

4 LOCKWASHER, 1/4 - M6

1 ENGINE, 15 HP, Generac Power

Systems, EHF 00935

1 Owner's Manual

2 28oz. Engine Oil

1 120V 30A Locking Plug

1 120/240V 30 A Locking Plug

1 Battery Charge Cables

1 Spark Plug Wrench/Driver

19

Page 20

CRAFTSMAN 7500 Watt AC Generator 580.327181

Control Panel -- Exploded View and Parts List

21

2O

19

\

10

6

10

11

13

17 18

16 /

I

11

_0

8

19

7

18 8

8

25

25

31

\

5

52

27

ITEM PART# QTY.

1 B1331 1

2 23897 4

3 49226 4

4 91526 4

5 82538 1

6 82881 4

7 43181 4

8 43182 4

10 75207A 2

11 75207 2

12 23365 10

13 68868 1

14 43437 1

15 68759 1

16 43180 10

I

17

16

DESCRIPTION ITEM PART # QTY.

PANEL, Control 17 22264 10

WASHER, #10 M5 Flat 18 51715 10

WASHER, M5 Lock 19 64526 8

SCREW, M5-0.8 x 12 mm 20 83970 1

SWITCH, Idle Control 21 64525 4

WASHER, 7/16" Int. Lock 22 87962 1

SCREW, M3- 0.5 x 10 mm

WASHER, M3 Lock 23 84335 1

CIRCUIT BREAKER, 30 AMP 24 84134 1

CIRCUIT BREAKER, 20 AMP 25 92069 1

WASHER, #8 Shakeproof 26 84028 1

OUTLET, 30A, 120V Locking Type 27 75475 9

OUTLET, 30A, 120V/240V Locking 30 74191 1

Type 31 90418 1

OUTLET, 20A,120V 32 75476 1

WASHER, M4 Flat

DESCRIPTION

WASHER, #8 M4 Lock

NUT, M4 - 0.7 Hex

SCREW, #6-32 x 3/8"

BOARD, System Control

3/4" Hex Standoff

CIRCUIT BREAKER, 10A

(automatic), 12V

ASSEMBLY, Wire Harness

GROMMET, Rubber Connector

BOX, Control Panel

TRANSFORMER, Idle Control

SCREW, M4- 0.7 x 10 mm

OUTLET, 50A, 240V

OUTLET, 10A, 12VDC

PPHMS, M4 - 0.7 x 16

2O

Page 21

CRAFTSMAN 7500 Watt AC Generator 580.327181

Wheel Kit -- Exploded View and Parts List

/

/

/

/

/

l/

13

/

/

/

9

6

/

/

/

/

/

5 I

3

/

10

/

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

PART NO.

93393A

89742

93693A

87005

89635

93696

27007

42909

52858

22247

39253

22145

39287

QTY.

1

2

1

2

2

1

2

2

8

2

2

2

4

DESCRIPTION

HANDLE

WHEEL

AXLE

PIN, Retaining

SPACER, Wheel

LEG, Support

MOUNT, Vibration

CAPSCREW, Hex Hd. M8 - 1.25 x 30 Lg.

NUT, Lock M8

WASHER, Wheel

CAPSCREW, Hex Hd. - M8 - 1.25 x 20 Lg.

WASHER, Vibration Mtg.

HHCS, M8 - 1.25 x 45 Lg GR 10.9

/

/

/

4

2!

Page 22

GENERAC Power Systems Engine, Model EHF 00935

Low Oil Shutdown And Governor- Exploded View

7 13

White

8

14

15

\

/

10

9

\15

/-25

21

\

24

\

\

\

29 28

\

\

5O

\

27

ITEM

7

8

9

10

12

13

14

15

16

PART NO. QTY. DESCRIPTION

78653 1 Run/Stop Switch

85272 1 Led Assembly

93104 1 L.O.S. Decal

93611 1 Black Sleeving

84329 1 3 Pin Male Hsg.

92981 1 Wire Asm.

22097 2 M6 Lockwasher

92079 2 M6 x 30 Taptite

84542 1 Ignition Coil

22

ITEM

20

21

23

24

25

27

28

29

30

PART NO. QTY. DESCRIPTION

72347 1 Sparkplug

72734 1 Governor Lever

83502 1 Adjust Screw

83512 2 M8 x 15 Taptite

73100 1 60Hz Gov. Spring

83503 1 M5 Lock Nut

73101 1 Governor Bracket

72735 1 Governor Rod

72789 1 Anti-Lash Spring

Page 23

GENERAC Power Systems Engine, Model EHF 00935

Low Oil Shutdown And Governor- Exploded View

91

92

ITEM

78

79

80

81

_79

/80

81 Z

PART NO. QTY. DESCRIPTION

82774 1 Woodruff Key

91222C 1 Flywheel w/Ring Gear

(410)

67198N 1 Conical Washer

67890 1 M20 Hex Nut

17.

93

22

ITEM

82

83

84

85

86

87

88

89

90

91

92

93

89

83

/

82

\

86 92

PART NO. QTY. DESCRIPTION

88433 1 Top Wrapper

45756 7 M6 x 10 Taptite

78609 2 Cover Bolt

73104A 1 Air Box Cover

92437 1 Blower Housing

88434 1 Lower Wrapper

66476 4 M6 x 12mm cap screw

96195 1 Recoil Assembly

96196 1 Recoil Cup

73116A 1 Back plate, E. SRT

81668 5 M6 x 10 HHCS

83512 1 M8 x 15 Taptite

ITEM

17

22

26

93

PART NO. QTY. DESCRIPTION

21544 1 Starter Motor

40976 2 SHCS M8-1.25 x 20

22129 2 Lock Washer M8

B2160 1 Rubber Spacer

23

ITEM

2

3

4

5

6

WITH OIL FILTER

PART NO. QTY. DESCRIPTION

86999 1 Oil Filter Gasket

94683 1 Oil Filter Adapter

49821 2 M8 x 30 SHCS

60108 1 Oil Press Switch

70185 1 Oil Filter

Page 24

GENERAC Power Systems Engine, Model EHF 00935

Carburetor, Air Cleaner, Oil Switch and Oil Blockoff-Exploded View and Parts List

34

33

/

43

38

46

48

5O

49

38

ITEM PART NO. QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

31 72745 1 Breather Hose 43 A4600 1 410 Nikki Carb.

32 91039 1 Head/Manifold Gasket 44 73108A 1 Air Cleaner Base

33 40945 2 M6 x 20 SHCS 45 49811 4 M6 Flatwasher

34 81647 2 Carb. Bolt 46 59635 1 #8 x 3/8 Plastite

35 66476 2 M6 x 12 HHCS 47 73111 1 Air Filter

36 91028 1 K Adapter 48 81646 1 Pre-cleaner

37 22097 3 M6 Lock Washer 49 83504 1 Choke Knob

38 49813 2 M6 Hex Nut 50 47411 2 M6 x 16 HHCS

39 90970 1 Carb./Airbox Gasket 51 90827 1 Brkt. Air Box

40 93873 2 M6 Ribbed Lockwasher 60 30340 12" 1/4" ID Hose

41 91204 1 Spitback Plate 61 48031C 1 Hose Clamp

42 89228 1 Carb/Manifold Gasket

37

24

Page 25

GENERAC Power Systems Engine, Model EHF 00935

Long Block - Exploded View and Parts List

1

25

46

14

48

43

5O

19

/ / \12

31

ITEM DESCRIPTION PART NO. QTY. ITEM DESCRIPTION PART NO. QTY.

1 Connecting Rod 71978 1 30 Balancer 84430 1

with Cap and Bolt 31 Cylinder Head With 21714 1

2 Piston Pin 71980 1 Valve Seats & Guides

3 Piston Ring Set (410) 21533 1 32 Exhaust Valve 86516 1

4 Piston (410) 96699 1 33 Intake Valve 86517 1

5 Piston Pin Retainer 71983 2 34 Push Rod 88396B 2

6 Crank Shaft Assembly 78666A 1 35 Tappet 83897 2

With Gears (Small Taper) 36 Oil Pick-Up Assembly 77158 1

7 Governor Arm 83948 1 37 Rocker Cover Gasket 71987 1

8 Governor Arm "R" Pin 78658 1 38 Pivot Ball Stud 72694 2

9 Governor Arm Washer 78659 2 39 Rocker Arm 83907 2

10 Crankcase H.S. W/Taper 88261E 1 40 Jam Nut (Rocker Arm) 72696 2

12 Crankshaft Seal 72655 2 42 M10 x 108 Head Bolt 21742 4

13 Gov. Gear Assembly 83912 1 43 Rocker Cover Breather 83938 1

14 Governor Retainer 78645 1 Assembly

15 Governor Spool 76365 1 46 O-ring 17.8 I.D. x 2.4 THK. 86254 1

19 Camshaft Assembly 83932 1 47 3/8" NPT Pipe Plug 26925 2

20 Crankcase Gasket 76701 1 48 M5-0.8 x 8mm Screw 74908 1

21 Cylinder Head Gasket (410) 21713B 1 (Thread Forming)

22 Oil Pressure Relief 78691 1 50 Valve Spring Keeper 86515 4

23

24

25

26

27

28

29

Plugs (410) 41 Push Rod Guide Plate 78694 1

("C" Ring) 44 Oil Fill Plug 76329 1

Cover 51 M6-1 x 12mm Pan Head 78606 4

Press. Relief Spring 83918

Press. Relief Ball 76362

Thrust Washer 76361

Gear Cover 88260B

Valve Spring Retainer 86514

Valve Spring 91308

Gerotor Set 86025

1

1

1

1

2

2

1

52

53

54

55

Screw and Lockwasher

Hex Head flange Bolt A1442 8

M8 1.25 x 42mm

Valve Stem Seal 78672 1

Valve Spring Washer 89673 2

Long Block Assm. A1044 0

47 10

F

25

Page 26

CALIFORNIA AND FEDERAL EMISSION

CONTROL WARRANTY STATEMENT

Your Warranty Rights and Obligations

The California Air Resources Board (CARB), United

States Environmental Protection Agency (EPA), and

Sears Roebuck and Co. USA (Sears) are pleased to

explain the emissions control system warranty on your

1997 and later utility and lawn and garden equipment

engine. New Utility and Lawn and Garden Equipment

(ULGE) engines must be designed, built, and

equipped to meet both the State of California and

Federal stringent anti-smog standards. Sears must

warrant the emission control system on your ULGE

engine for the periods of time listed below provided

there has been no abuse, neglect, or improper

maintenance of your ULGE engine.

The emissions control system may include parts such

as the carburetor, ignitionand exhaust systems. When

a warrantable condition occurs, Sears will repair your

lawn and garden equipment engine at no cost to you.

Expenses covered under warranty include diagnosis,

replacement parts and labor.

Manufacturer's Warranty Coverage

The 1997 and later ULGE engines are warranted for

two years. If any emission related component or

system on your engine (as listed below) is found to be

defective, repairs or replacement will be performed by

an authorized Sears service center.

Owner's Warranty Responsibilities

As the ULGE engine owner, you are responsible for

the completion of all required maintenance as listed in

your factory supplied Owner's Manual. For warranty

purposes Sears recommends that you retain all

receipts covering maintenance on your ULGE engine.

However, Sears cannot deny warranty solely because

of the lack of receipts or for your failure to ensure the

completion of all scheduled maintenance.

As the ULGE engine owner, you should be aware that

Sears may deny any and/or all warranty coverage or

responsibility if your ULGE engine or a

part/component of it has failed due to abuse, neglect,

improper maintenance, unapproved modifications, or

the use of counterfeit and/or 'grey-market' parts not

made, supplied or approved by the original equipment

manufacturer.

You are responsible for presenting your ULGE engine

to a Sears authorized service center as soon as a

problem occurs. Warranty repairs should be

completed in a reasonable amount of time, not to

exceed 30 days.

If you have any questions regarding your warranty

rights and responsibilities, you should contact your

nearest authorized service center or call Sears at

1-800-473-7247.

Warranty Commencement Date

The warranty period begins on the date the ULGE

engine isdelivered to the original, end-use purchaser.

Length of Coverage

Sears warrants to the initial owner and each

subsequent purchaser that the engine is free from

defects in materials and workmanship which cause the

failure of a warranted part for a period of two years.

What is Covered

Repair or Replacement of Parts

Repair or replacement of any warranted part will be

performed at no charge to the owner at an approved

Sears service center. If you have any questions

regarding your warranty rights and responsibilities, you

should contact your nearest authorized service center

or call Sears at 1-800-473-7247.

26

Page 27

Warranty Period

Any warranted part which is not scheduled for

replacement as required maintenance shall be

warranted for 2 years. Any warranted part which is

scheduled only for regular inspection and/or has

instructionsto the effect of "repair or replace as

necessary" shall also be warranted for 2 years. Any

warranted part which is scheduled for replacement as

required maintenance shall be warranted either for the

period of time up to its first scheduled replacement, or

for 2 years, whichever comes sooner.

Diagnosis

When the ULGE engine is inspected by an authorized

Sears service center, the owner shall not be held

responsible for diagnostic costs if the repair is deemed

warrantable.

Consequential Damages

Sears may be liable for damages to other engine

components caused by the failure of a warranted part

if the failed part was still under warranty.

What is not covered

Owner Responsibilities

Any failures caused by abuse, neglect, or improper

maintenance will not be covered.

Add-On or Modified Parts

The use of add-on, unauthorized or modified parts

constitutes sufficient reason for denial of submitted

warranty repairs. Sears will not be held liable for

repairs of this type.

How to File a Claim

If you have any questions regarding your warranty

rights and responsibilities, you should contact your

nearest authorized service center or call Sears at

1-800-473-7247.

Where to get Warranty Service

Warranty services or repairs shall be provided at all

Sears authorized service centers.

Maintenance, Replacement and Repair of

Emission Related Parts

Any Sears approved replacement part used in the

performance of any warranty maintenance or repair on

emission related parts will be provided without charge

to the owner if the part is under warranty.

Emission Control Warranty Parts List

1. Fuel Metering System:

a. Carburetor assembly

b. Fuel filter

2. Air Induction System:

a. Intake manifold

b. Air cleaner

3. Catalytic Muffler Assembly (if so equipped),

including:

a. Muffler gasket

b. Exhaust manifold

4. Ignition System

a. Spark plug

b. Ignition module

5. Crankcase Breather Tube

2?

Page 28

For in-home major brand repair service"

Call 24 hours a day, 7 days a week

1-800-4-MY-HOME sM(1-800-469-4663)

Para pedir servicio de reparacibn a domicilio - 1-800-676-5811

In Canada for all your service and parts needs call

Au Canada pour tout le service ou les pieces

For the repair or replacement parts you need:

Call 7 am - 7 pm, 7 days a week

- 1-800-665-4455

1-800-366-PART (1-800-366-7278)

Para ordenar piezas con entrega a domicilio - 1-800-659-7084

For the location of a Sears Parts and Repair Center in your area:

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears Maintenance Agreement

or to inquire about an existing Agreement:

Call 9 am - 5 pm, Monday- Saturday

1-800-827-6655

TheServiceSideof Sears"

Loading...

Loading...