Page 1

Owner’s Manual

7.8 Horsepower 4200 Watt

AC GENERATOR

Model No. 580.327141

HOURS: Mon. - Fri. 8 a.m. to 5 p.m. (CT)

CAUTION:

Before using this product, read this

manual and follow all its Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

Part No. B2552 Draft 5 (6/27/2000) Printed in the U.S.A.

Safety

Assembly

Operation

Maintenance

Parts

Español

Page 2

TABLE OF CONTENTS

Warranty..................................................................2

Safety Rules............................................................3

Assembly ................................................................4

Operation ..........................................................5-10

Product Specifications..........................................11

Maintenance

Storage..................................................................15

...................................................

11-14

Troubleshooting

Schematic

Wiring Diagram

Replacement Parts

Emissions Warranty..............................................29

Español ...........................................................30-47

How to Order Parts

....................................................

.............................................................

.....................................................

..........................................

....................................

20-27

Back Page

16

18

19

WARRANTY

LIMITED WARRANTY FOR DELUXE PORTABLE GENERATORS

SEARS warrants to the original purchaser that the alternator and engine for its portable generator will be free

from defects in materials or workmanship for the items and period set forth below from the date of original pur

chase. This warranty is not transferable and applies only to portable generators driven by the GN-Series Sears

warranted engine.

CONSUMER*

Alternator 2 years (2nd year parts only)

Engine 2 years (2nd year parts only)

* NOTE: For the purpose of this warranty “Consumer Use” means personal residential household and emergency

use by original purchaser, not to be used as a primary source of power. “Commercial Use” means all other uses,

including rental, construction, commercial, and income producing purposes. Once a generator has experienced

commercial use, it shall thereafter be considered a commercial use generator for the purpose of this warranty.

During said warranty period, SEARS will, at its option, repair or replace any part which, upon examination by

SEARS, is found to be defective under normal use and service**. Starting batteries are not warranted by

SEARS. All transportation costs under warranty, including return to the factory if necessary, are to be borne by

the purchaser and prepaid by him. This warranty does not cover normal maintenance and service and does not

apply to a generator set, alternator or engine, or parts which have been subjected to improper or unauthorized

installation or alteration, misuse, negligence, accident, overloading, overspeeding, improper maintenance,

repair or storage so as, in SEARS’s judgment, to adversely affect its performance and reliability.

COMMERCIAL*

1 year

1 year

** NORMAL WEAR: As with all mechanical devices, engines need periodic parts service and replacement to

perform well. This warranty will not cover repair when normal use has exhausted the life of a part or engine.

THERE IS NO OTHER EXPRESS WARRANTY. SEARS HEREBY DISCLAIMS ANY AND ALL IMPLIED WAR

RANTIES, INCLUDING BUT NOT LIMITED TO THOSE OF MERCHANTABILITY AND FITNESS FOR A PAR

TICULAR PURPOSE TO THE EXTENT PERMITTED BY LAW. THE DURATION OF ANY IMPLIED WAR

RANTIES WHICH CANNOT BE DISCLAIMED IS LIMITED TO THE TIME PERIOD AS SPECIFIED IN THE

EXPRESS WARRANTY. LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, OR SPECIAL DAMAGES UNDER

ANY AND ALL WARRANTIES IS EXCLUDED. Some provinces do not allow limitations on how long an implied

warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the above limitations or

exclusions may not apply to you. This warranty gives you specific legal rights and you may also have other

rights, which vary from state to state.

For service, see your nearest SEARS authorized warranty service facility. Warranty service can be performed

only by a SEARS authorized service facility. This warranty will not apply to service at any other facility. At the

time of requesting warranty service, evidence of original purchase date must be presented.

SEARS, ROEBUCK and CO., D/817WA, Hoffman Estates, IL 60179 U.S.A.

Page 3

SAFETY RULES

CAUTION! Before using this product, read this

manual and follow all Safety Rules and

A

Operating Instructions.

WARNING:

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects, or

other reproductive harm.

DANGER! This generator is designed for

outdoor use only. Do Not use this generator

A

inside any building or enclosure including the

generator compartment of a recreational vehicle

(RV). Fire or an explosion may result. No user

performed modifications, including venting of

exhaust and/or cooling ventilation, will eliminate

the danger. Also, allow at least two feet of

clearance on all sides of the generator even

while operating the unit outdoors.

CAUTION! Always disconnect spark plug wire

and place the wire where it cannot contact the

A

spark plug. To prevent accidental starting when

setting up, transporting, adjusting or making

repairs to your generator.

The generator produces dangerously high voltage

that can cause extremely hazardous electrical

shock. Avoid contact with bare wires, terminals,

etc. Never permit any unqualified person to

operate or service the generator.

Never handle any kind of electrical cord or device

while standing in water, while barefoot or while

hands or feet are wet. Dangerous electrical shock

will result.

The National Electric Code requires the frame and

external electrically conductive parts of generators

to be properly connected to an approved earth

ground. Local electrical codes may also require

proper grounding of the generator. Consult with a

local electrician for grounding requirements in your

area.

Use a ground fault circuit interrupter in any damp

or highly conductive area (such as metal decking or

steel work).

Do Not use worn, bare, frayed or otherwise

damaged electrical cord sets with the generator.

Using a defective cord set may result in electrical

shock or damage to equipment and/or property.

Operate generator only on level surfaces and

where it will not be exposed to excessive moisture,

dirt, dust or corrosive vapors.

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do Not permit smoking, open flames,

sparks or heat in the vicinity while handling

gasoline. Avoid spilling gasoline on a hot engine.

Comply with all laws regulating storage and

handling of gasoline.

• Never add fuel while unit is running.

• Do Not overfill the fuel tank. Always allow room for

fuel expansion. If tank is overfilled, fuel can

overflow onto a hot engine and cause FIRE or an

EXPLOSION.

• Never store the generator with fuel in the tank

where gasoline vapors might reach an open flame,

spark, or pilot light (as on a furnace, water heater

or clothes dryer). FIRE or an EXPLOSION might

result.

• Generator exhaust gases contain DEADLY carbon

monoxide gas. This dangerous gas, if breathed in

sufficient concentrations, can cause

unconsciousness or even death. Operate this

equipment only in the open air where adequate

ventilation is available.

• Allow at least 2 feet of clearance on all sides of the

generator, even while operating unit outdoors, or

damage may occur. Never operate the unit inside

any room or enclosure where the free flow of

cooling air into and out of the unit might be

obstructed.

• Never start or stop the unit with electrical loads

connected to receptacles and with the connected

devices turned ON. Start the engine and let it

stabilize before connecting electrical loads.

Disconnect all electrical loads before shutting down

the generator. See page 9 for “Cold Weather

Operation”.

• Do Not insert any object through cooling slots of

the unit.

• Never operate the generator:

(a) in rain; (b) in any enclosed compartment; (c)

when connected electrical devices overheat; (d) if

electrical output is lost; (e) if engine or generator

sparks; (f) if flames or smoke are observed while

unit is running; (g) if unit vibrates excessively.

NOTE: The generator is equipped with a spark

arrester muffler that must be maintained in working

order by the owner/operator. In the State of California,

a spark arrester is required by law (Section 4442 of

the California Public Resources Code). Cther states

may have similar laws. Federal laws apply on federal

lands.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Cbey all safety

messages that follow this symbol to avoid possible injury or death.

A

Page 4

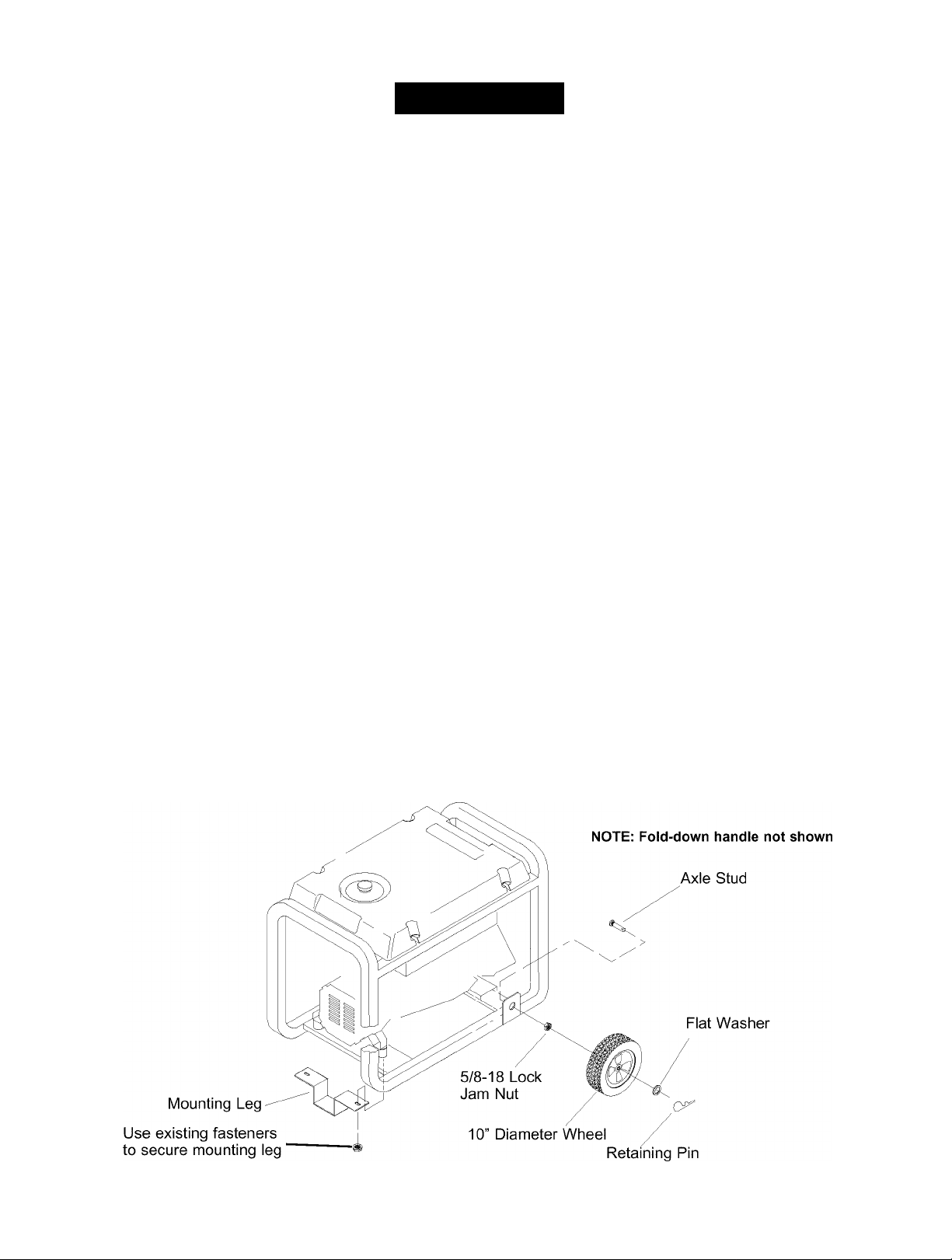

ASSEMBLY

Your Craftsman generator requires some assembly

and is ready for use after it has been properly serviced

with the recommended oil and fuel.

If you have any problems with the assembly of

your generator, please call the generator helpline

at 1-800-222-3136.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

TO REMOVE THE GENERATOR

FROM CARTON

• Set the carton on a rigid flat surface with “THIS

SIDE UP” arrows pointing upward. See “Cold

Weather Operation” on page 9 before cutting

carton.

• Carefully open the top flaps of the shipping carton.

• Cut down corners at one end of carton from top to

bottom and lay that side of carton down flat.

• Remove all packing material, carton filters, etc.

• Remove the generator from the shipping carton.

CARTON CONTENTS

Check all contents. If any parts are missing or

damaged, call the generator helpline at

1-800-222-3136.

The carton contains:

• The main unit

• Battery charge cables

• Spark plug

• Air filter

• Spark plug wrench

• Owner’s manual

• Engine oil

• Wheel kit

ASSEMBLING THE WHEEL KIT

The wheel kit is designed to improve the portability of

your generator.

To install the wheel kit, you need the following tools:

• 15/16" box, open end or socket wrench.

• (2) 13mm box, open end or socket wrenches.

Install wheel kit as follows (refer to illustration below):

• Place the bottom of the generator cradle on a flat,

even surface.

• Place axle stud through metal tab on cradle frame.

• Use a 15/16 inch wrench to secure the axle stud to

frame with 5/8-18 Jam nut.

• Install the other axle stud in the same manner.

NOTE: Be sure to install the wheel with raised hub

inboard.

• Tip unit and install wheel.

• Retain wheel on axle stud with retaining pin and

flat washer. Install other wheel on remaining axle

shaft In the same manner.

• Remove the two front nuts and lock washers from

vibration mounting with 13mm wrench. Use these

nuts to retain the mounting leg.

Wheel Kit

Page 5

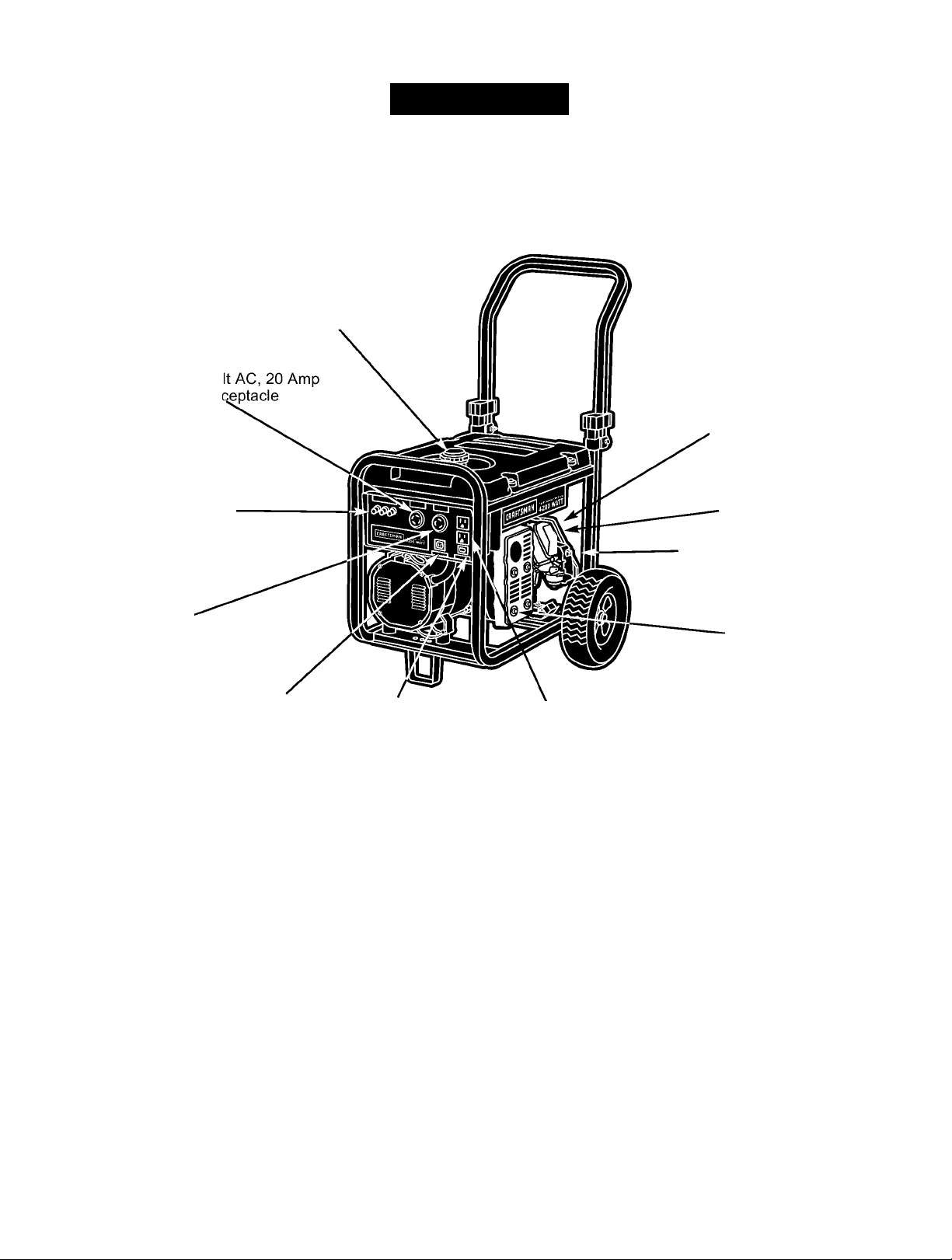

OPERATION

KNOW YOUR GENERATOR

Read the owner’s manual and safety rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

Fuel Tank

120/240 Vo

Locking Re*

Air Cleaner

Circuit Breakers

120 Volt AC, 30 Amp

Locking Receptacle

12 Volt DC

Receptacle

12 Volt DC Receptacle —This receptacle allows you

to recharge a 12 Volt automotive or utility style storage

battery with the battery charge cables provided.

120 Volt AC, 15 Amp, Duplex Receptacle — May be

used to supply electrical power for the operation of

120 Volt AC at 15 Amp, single phase, 60 Hz, electrical

lighting, appliance, tool and motor loads.

120 Volt AC, 30 Amp, Locking Receptacle — May

be used to supply electrical power for the operation of

120 Volt AC at 30 Amp, single phase, 60 Hz, electrical

lighting, appliance, tool and motor loads.

120/240 Volt AC, 20 Amp, Locking Receptacle —

May be used to supply electrical power to 120 and/or

240 Volt AC at 20 Amp, single phase, 60 Hz, electrical

lighting, appliance, tool and motor loads.

Air Cleaner — Filters intake air as it is drawn into the

engine.

Idle Control

Switch

Run/Stop Switch

Choke Lever

Spark Arrester Muffler

120 Volt AC, 15 Amp

Duplex Receptacle

Choke Lever — Used when starting a cold engine.

Circuit Breakers (AC) — Each receptacle is provided

with a push to reset circuit breaker to protect the

generator against electrical overload.

Fuel Tank — Tank holds 4 U.S. gallons of unleaded

gasoline.

Idle Control Switch — The idle control runs the

engine at normal (high) speeds when there is a load

present and runs the engine at idle (low) speeds when

a load is not present.

Run/Stop Switch — Must be in “Run” position to start

engine. Set to “Stop” to stop the unit.

Spark Arrester Muffler — Muffler lowers engine

noise and is equipped with a spark arrester screen.

Page 6

CORD SETS AND CONNECTOR

PLUGS

120 Volt AC Duplex Receptacle

Use only high quality, well-insulated, extension cords

with the generator’s 120 Volt electrical receptacles.

I

I I

I

4-Wire Cord Set

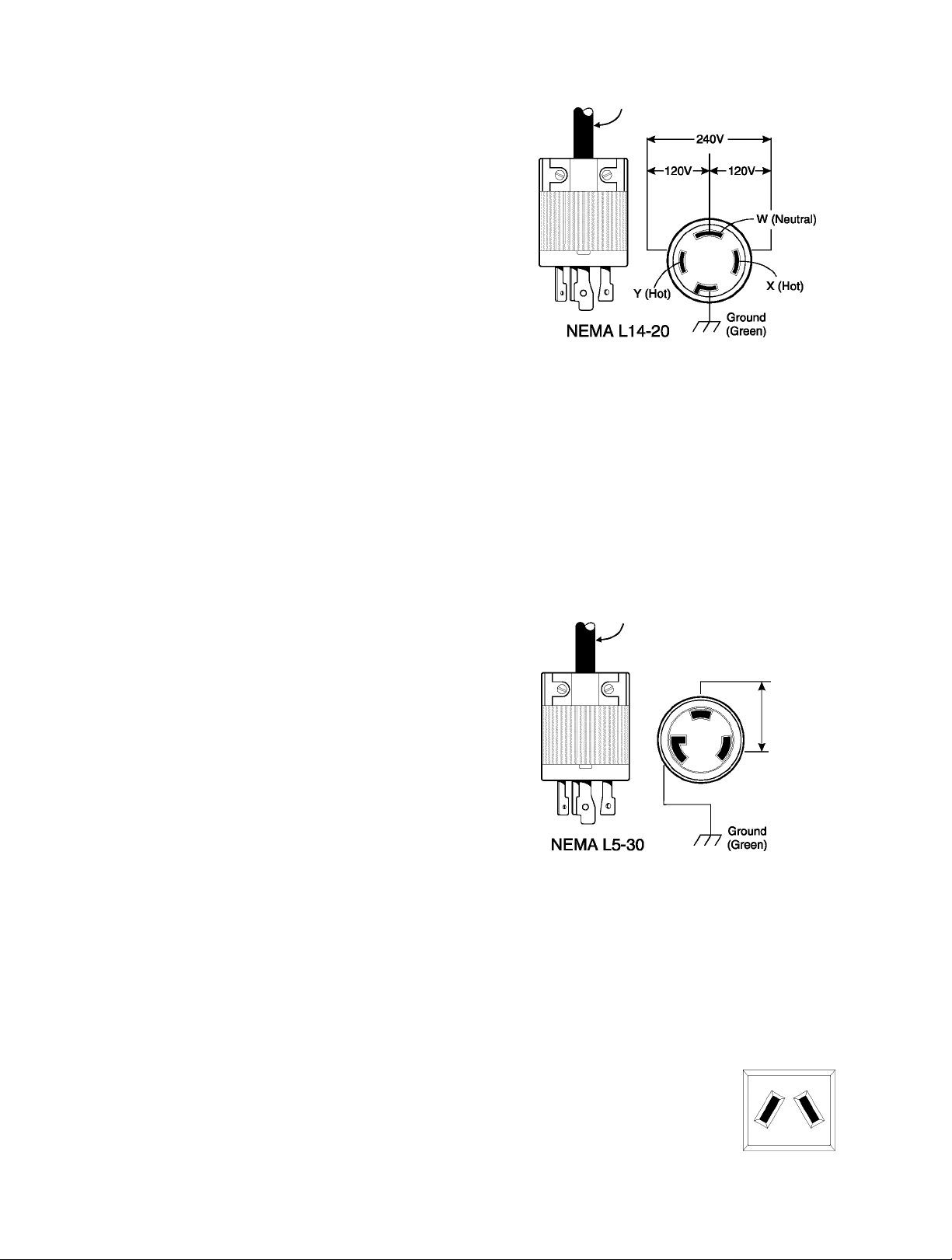

A NEMA L14-20 mating connector plug is required for

use with this 240 Volt receptacle. Connect a suitable

4-wire cord set to the plug and to the desired load.

The cord set should be rated for 250 Volt AC loads at

20 Amps.

Each receptacle is protected against overload by a

single push-to-reset circuit breaker. Use each

receptacle to operate 120 Volt AC, single phase,

60 Hz, electrical loads requiring up to 1,800 watts

(1.8 kW) at 15 Amps of current.

CAUTION! Although each receptacle is rated

for 120 Volts at 15 Amps (1,800 watts or

A

Check the ratings of all extension cords before you

use them. Extension cord sets used should be rated

electrical devices. Some devices, however, may not

require this type of extension cord. Check the owner’s

manuals of those devices for the manufacturer’s

recommendations.

Keep extension cords as short as possible, preferably

less than 15 feet long, to prevent voltage drop and

possible overheating of wires.

1.8 kW), the generator is rated for a total of

4,200 watts. Powering loads that exceed the

wattage capacity of the generator can damage it

or cause serious injuries. The total 120 Volt load

powered through these receptacles should not

exceed 15 Amps.

125 AC Volts at 15 Amps (or greater) for most

120/240 Volt AC, 20 Amp Receptacle

This is a full capacity receptacle which means you can

take the generator’s full rated wattage from this single

NEMA L14-20 receptacle. The outlet is protected by a

20 Amp push-to-reset circuit breaker.

CAUTION! Although this outlet is rated for

240 Volts AC at 20 Amps, the generator is

A

capable of producing only 17.5 Amps at

240 Volts AC.

120 Volt AC, 30 Amp Receptacle

Use a NEMA L5-30 plug with this receptacle. Connect

a 3-wire cord set rated for 125 Volts AC at 30 Amps to

the plug.

3-Wire Cord Set

Neutral

120V

Hot

Use this receptacle to operate 120 Volt AC, 60 Hz,

single phase loads requiring up to 3,600 watts

(3.6 kW) of power at 30 Amps. The outlet is protected

by a 30 Amp push-to-reset circuit breaker.

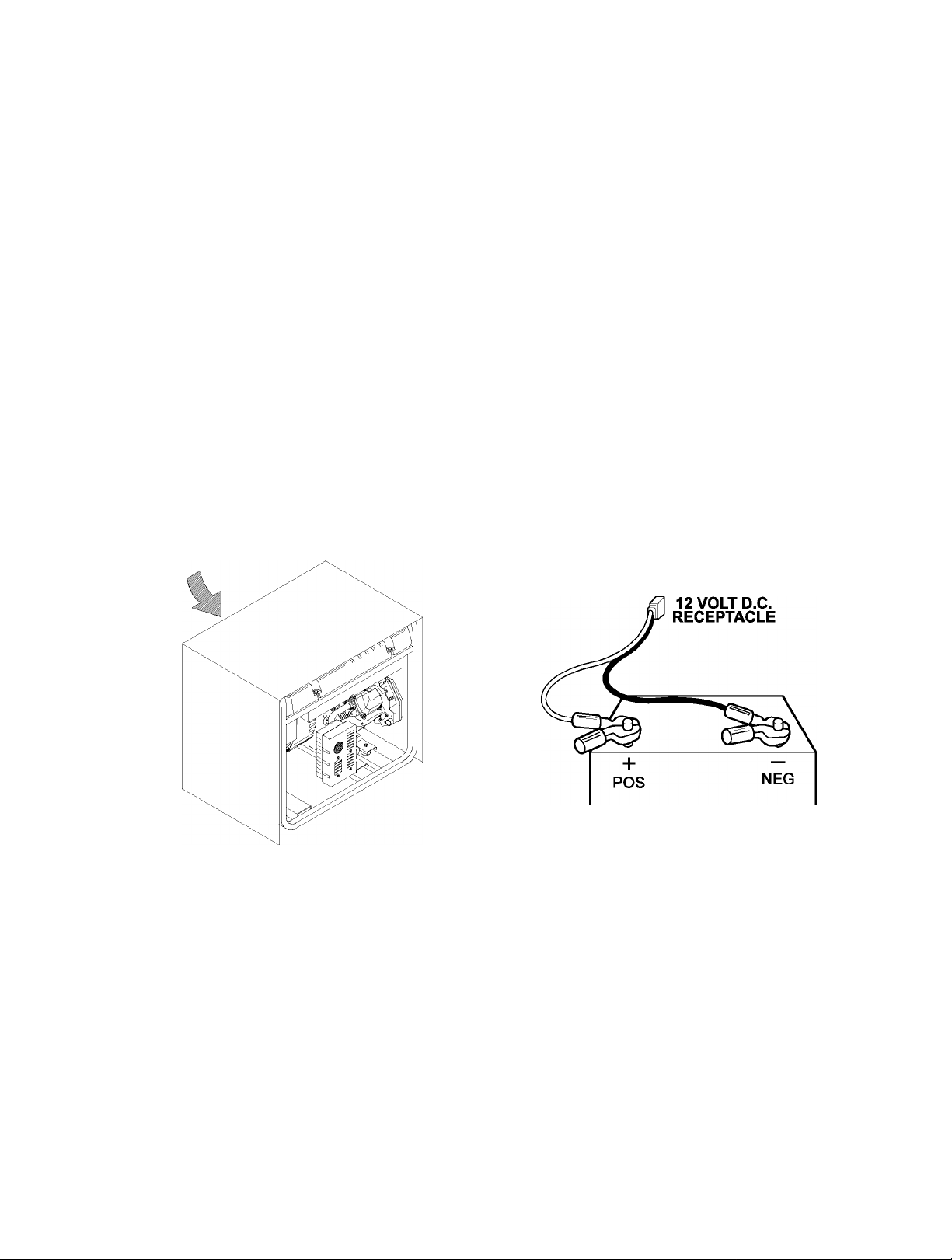

12 Volt DC Receptacle

This receptacle allows you to recharge a 12 Volt

automotive or utility style storage battery with the

battery charge cables provided. This receptacle can

not recharge 6 Volt batteries and can not be used to

crank an engine having a

discharged battery. See the

sections “Battery Safety” and

“Charging a Battery” (page 9)

before attempting to recharge a

battery.

Page 7

HOW TO USE YOUR GENERATOR

If you have any problems operating your generator,

please call the generator helpline at 1-800-222-3136.

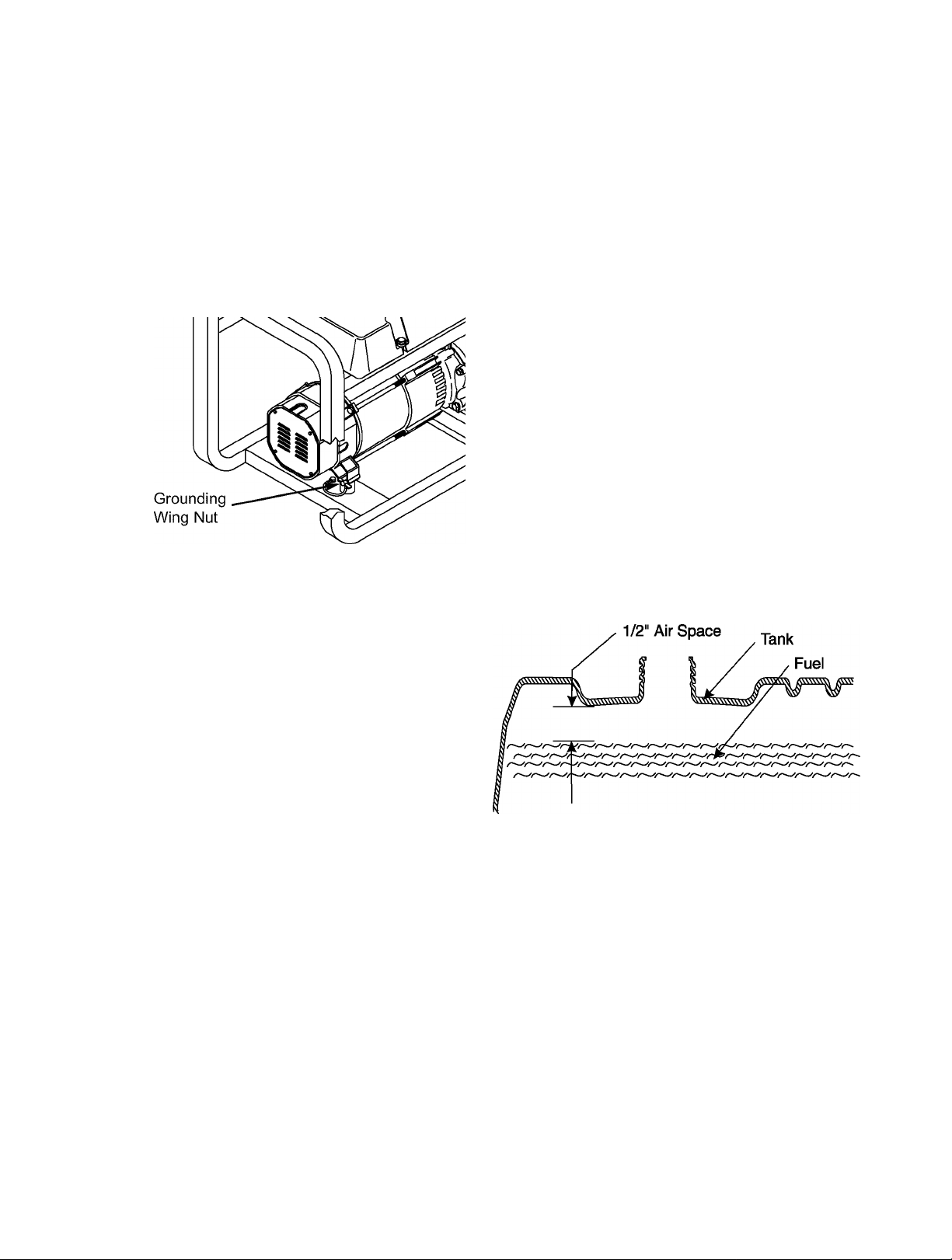

Grounding The Generator

The National Electrical Code requires that the frame

and external electrically conductive parts of this

generator be properly connected to an approved earth

ground. Local electrical codes may also require proper

grounding of the unit. For that purpose, a grounding

wing nut is provided on the base of the cradle.

Generally, connecting a No. 12 AWG (American Wire

Gauge) stranded copper wire to the grounding nut and

to an earth-driven copper or brass grounding rod

(electrode) provides adequate protection against

electrical shock. However, local codes may vary

widely. Consult with a local electrician for grounding

requirements in your area.

Proper grounding of the generator will help prevent

electrical shock in the event of a ground fault condition

in the generator or in connected electrical devices.

Proper grounding also helps dissipate static electricity,

which often builds up in ungrounded devices.

Although multi-viscosity oils (5W30, 10W30, etc.)

improve starting in cold weather, these multi-viscosity

oils will result in increased oil consumption when used

above 32°F. Check your engine oil level more

frequently to avoid possible damage from running low

on oil.

• Place generator on a level surface and remove the

yellow oil fill cap. Add engine oil until level is at

point of overflowing. Check engine oil level before

starting each time thereafter.

• Install oil fill plug, finger tighten securely.

Add Gasoline

WARNING! NEVER fill fuel tank indoors.

NEVER fill fuel tank when engine is running or

A

hot. DO NOT light a cigarette or smoke when

filling the fuel tank.

CAUTION! Do Not overfill the fuel tank.

Always leave room for expansion.

A

Use regular UNLEADED gasoline with the

generator engine. Do Not use premium gasoline.

Do Not mix oil with gasoline.

Clean area around fuel fill cap, remove cap.

Slowly add unleaded regular gasoline to fuel tank.

Be careful not to overfill. Allow about 1/2" of tank

space for fuel expansion, as shown here.

Before Starting The Generator

To operate the engine you will need to do the

following:

Add Engine Oil

NOTE: When adding oil to the engine crankcase in the

future, use only high quality detergent oil rated with API

service classification SF or SG rated SAE 30 weight. Use

no special additives. Select the oil's viscosity grade

according to your expected operating temperature:

colder

5W-30

32°F warmer

SAE 30 or 10W-30

• Install fuel cap and wipe up any spilled gasoline.

IMPORTANT: It is important to prevent gum deposits

from forming in fuel system parts such as the

carburetor, fuel hose or tank during storage. Alcohol-

blended fuels (called gasohol, ethanol or methanol)

can attract moisture, which leads to separation and

formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. See

“Storage” on page 15. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur.

Page 8

To Start The Engine

WARNING! Never start or stop engine with

electrical devices plugged into the panel

A

receptacles AND turned on.

• Unplug all electrical loads from generator

receptacles before starting the engine.

• Make sure the unit is in a level position.

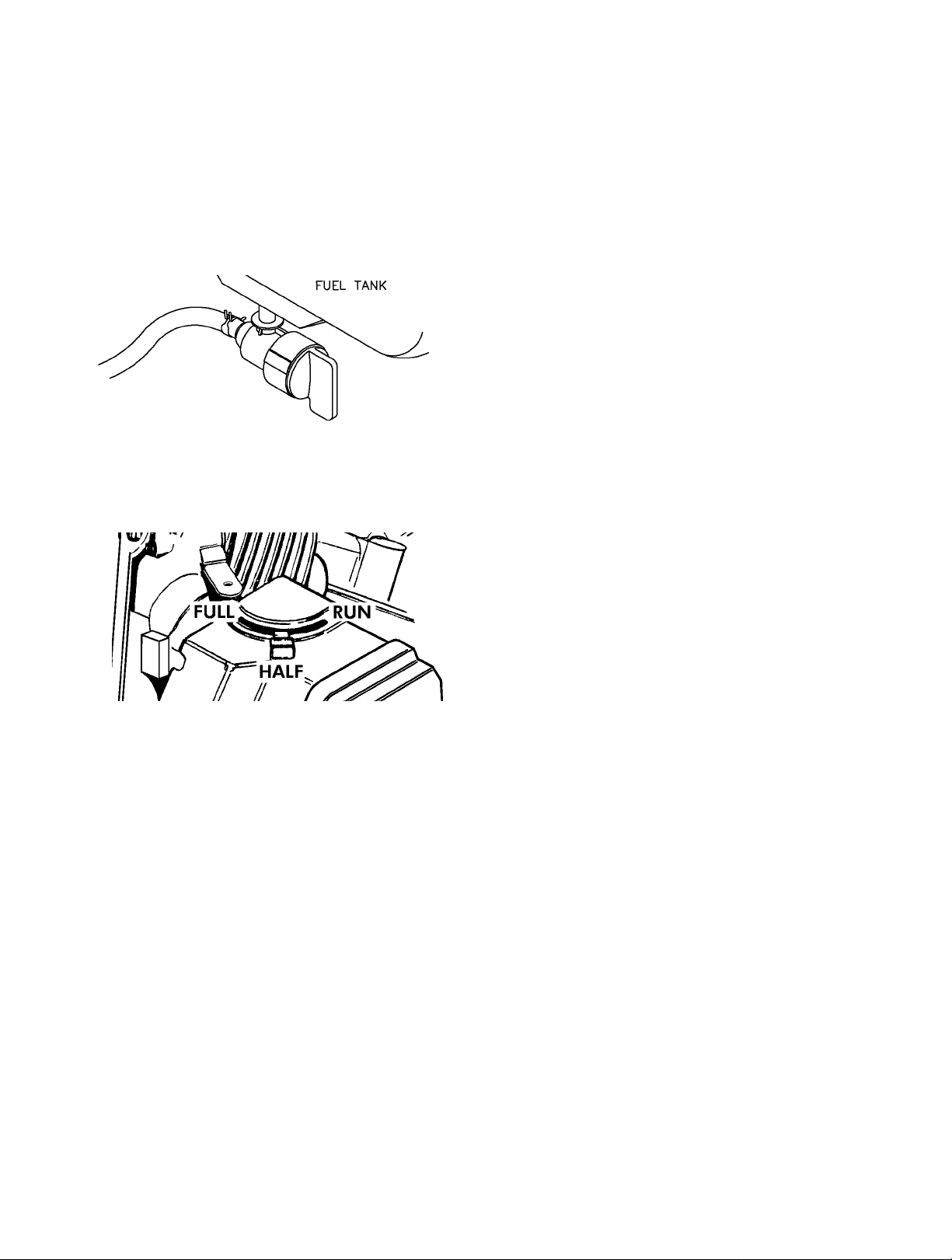

• Turn the fuel shut-off valve to ON position.

Locate the Idle Control On/Off switch on the control

panel and set it to the “Off position.

Place the Run/Stop switch in the “Run” position.

Move engine choke lever to the “Full” choke

position.

Connecting Electrical Loads

• Do Not connect 240 Volt loads to the 120 Volt

duplex receptacles.

• Do Not connect 3-phase loads to the generator.

• Do Not connect 50 Hz loads to the generator.

• Plug in and turn on the desired 120 and/or 240 Volt

AC, single phase, 60 Hertz, electrical loads. DC

NCT CVERLCAD THE GENERATCR. See “Don’t

Cverload the Generator” on page 10.

Stopping the Engine

• Unplug all electrical loads from generator panel

receptacles. Never start or stop engine with

electrical devices plugged in and turned on.

• Turn “Off” the Idle Control switch.

• Let engine run at no-load for several minutes to

stabilize the internal temperatures of engine and

generator.

• Move Run/Stop switch to the “Stop” position.

• Close the fuel valve.

Operating Automatic Idle Control

This switch is designed to greatly improve fuel

economy. When this switch is turned “On,” the engine

will only run at its normal high governed engine speed

while an electrical load is connected. When the

electrical load is removed, the engine will run at a

reduced speed. With the switch “Off,” the engine

always runs at the normal high engine speed. Always

have the switch Off when starting and stopping

the engine.

CAUTION! Never run engine indoors or in

enclosed poorly ventilated areas. Engine

A

exhaust contains carbon monoxide, an odorless

and deadly gas.

WARNING! Temperature of muffler and nearby

areas may exceed 150°F (65°C). Avoid these

A

areas.

• Grasp starter handle and pull slowly until you feel

some resistance. Then pull with one rapid full arm

stroke. Let rope return slowly. Do Not let rope

“snap back” against starter.

• If engine starts, move choke lever to “Run”

position. Allow engine to warm up for two minutes

before applying load to generator.

• If engine falters, move choke lever to “Half” choke

position and pull starter handle twice.

NOTE: If engine fails to start after 3 pulls, move the

choke lever to “Full” position and repeat starting

instructions.

• Set the Idle Control Cn/Cff switch to the “On”

position.

Low Oil Pressure Shutdown System

The engine is equipped with a low oil pressure sensor

that shuts down the engine automatically when the oil

pressure drops below 6 psi. If the engine shuts down

by itself and the fuel tank has enough gasoline, check

engine oil level.

Initial Start-up

A delay built in the low oil shutdown system allows oil

pressure to build during starting. The delay allows the

engine to run for about 10 seconds before sensing oil

pressure.

Sensing Low Pressure

If the system senses low oil pressure during operation,

the engine shuts down. As the system shuts down, the

low oil light comes CN. However, once the engine has

stopped rotating, this light will go CFF.

Restarting

If you try to restart the engine within 10 seconds after

it shuts down, the engine may NCT start. The system

needs 5 to 10 seconds to reset.

Page 9

If you do restart the engine after such a shutdown and

have not corrected the low oil pressure, the engine

runs for about 10 seconds as described above and

then stops.

COLD WEATHER OPERATION

Under certain weather conditions (temperatures below

40°F [4°C] and a high dew point), your generator may

experience icing of the carburetor and/or the

crankcase breather system. In an emergency, use the

original shipping box as a temporary shelter:

• Cut off all flaps and one of the long sides of the

box to expose exhaust side of unit. Cut appropriate

slots to access receptacles of unit.

• Start unit, then place box over it. Ensure a

minimum of two feet clearance between open side

of box and nearest object.

IMPORTANT: Remove shelter when temperature is

above 40T [4°C].

For a more permanent shelter, build a structure that

will enclose three sides and the top of the generator.

Make sure entire muffler-side of generator is exposed,

with two feet clearance between open side of box and

nearest object. Face exposed end away from wind

and elements.

Wind

DANGER! Do Not permit smoking, open

flame, sparks or any other source of heat

A

around a battery. Wear protective goggles,

rubber apron and rubber gloves when working

around a battery. Battery electrolyte fluid is an

extremely caustic sulfuric acid solution that can

cause severe burns. If spill occurs, flush area

with clear water immediately.

Your generator has the capability of recharging a

discharged 12 Volt automotive or utility style storage

battery. Do Not use the unit to charge any 6 Volt

batteries. Do Not use the unit to crank an engine

having a discharged battery.

To recharge 12 Volt batteries, proceed as follows:

• Check fluid level in all battery cells. If necessary,

add ONLY distilled water to cover separators in

battery cells. Do Not use tap water.

• If the battery is equipped with vent caps, make

sure they are installed and are tight.

• If necessary, clean battery terminals.

• Connect battery charge cable connector plug to

panel receptacle identified by the words

“12-VOLTS DC”

• Connect battery charge cable clamp with red

handle to the positive (+) battery terminal.

CHARGING A BATTERY

DANGER! Storage batteries give off explosive

hydrogen gas while recharging. An explosive

A

mixture will remain around the battery for a long

time after it has been charged. The slightest

spark can ignite the hydrogen and cause an

explosion. Such an explosion can shatter the

battery and cause blindness or other serious

injury.

• Connect battery charge cable clamp with black

handle to the negative (-) battery terminal.

• Start engine. Let the engine run while battery

recharges.

• When battery has charged, shut down engine.

NOTE: Use an automotive hydrometer to test battery

state of charge and condition. Follow the hydrometer

manufacturer’s instructions carefully. Generally, a

battery is considered to be at 100% state of charge

when specific gravity of its fluid (as measured by

hydrometer) is 1.260 or higher.

Page 10

DON’T OVERLOAD THE

GENERATOR

Overloading a generator in excess of its rated wattage

capacity can result in damage to the generator and to

connected electrical devices. Observe the following, to

prevent overloading the unit:

• Add up the total wattage of all electrical devices to

be connected at one time. This total should NOT

be greater than the generator’s wattage capacity.

• The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can usually be found on a data plate or

decal affixed to the device.

• If the appliance, tool or motor does not give

wattage, multiply volts times ampere rating to

determine watts (volts x amps = watts).

WATTAGE REFERENCE GUIDE

• Some electric motors, such as induction types,

require about three times more watts of power for

starting than for running. This surge of power lasts

only a few seconds when starting such motors.

Make sure you allow for this high starting wattage

when selecting electrical devices to connect to your

generator.

1. Figure the watts needed to start the largest

motor.

2. Add to that figure the running watts of all other

connected loads.

The Wattage Reference Guide below is provided to

assist you to determine how many items your

generator can operate at one time.

Device

*Air Conditioner (12,000 Btu)

*Air Conditioner (24,000 Btu)

*Air Conditioner (40,000 Btu)

Battery Charger (20 Amp)

Belt Sander (3")...................................................1000

Chain Saw...........................................................1200

Circular Saw (6-1/2")

‘Clothes Dryer (Electric)

‘Clothes Dryer (Gas)..............................................700

‘Clothes Washer

Coffee Maker.......................................................1750

‘Compressor (1 HP)............................................ 2000

‘Compressor (3/4 HP)..........................................1800

‘Compressor (1/2 HP)..........................................1400

Curling Iron............................................................700

‘Freezer

‘Dehumidifier..........................................................650

Disc Sander (9")..................................................1200

Edge Trimmer........................................................500

Electric Blanket......................................................400

Electric Nail Gun

Electric Range (per element)

Electric Skillet......................................................1250

‘Furnace Fan (3/5 HP)...........................................875

‘Garage Door Opener

Hair Dryer............................................................1200

Hand Drill

.....................................................

..............................

.............................

.............................

.....................................

...............................

.....................................

..................................................

.................................................................

.................................................

..............................

.................................

................................................

Load (watts)

800 to 1000

500 to 750

250 to 1100

1700

3800

6000

500

5750

1150

700

1200

1500

Device

Hedge Trimmer

Impact Wrench

Iron......................................................................1200

‘Jet Pump...............................................................800

Lawn Mower........................................................1200

Light Bulb

Microwave Oven........................................ 700 to 1000

‘Milk Cooler..........................................................1100

Oil Burner on Furnace.........................................300

Oil Fired Space Heater (140,000 Btu)...................400

Oil Fired Space Heater (85,000 Btu).....................225

Oil Fired Space Heater (30,000 Btu).....................150

‘Paint Sprayer, Airless (1/3 HP)

Paint Sprayer, Airless (handheld)

Radio...........................................................50 to 200

‘Refrigerator...........................................................700

Slow Cooker..........................................................200

‘Submersible Pump (1-1/2 HP)

‘Submersible Pump (1 HP)................................. 2000

‘Submersible Pump (1/2 HP)...............................1500

‘Sump Pump

‘Table Saw (10")

Television.................................................... 200 to 500

Toaster.................................................... 1000 to 1650

Weed Trimmer.......................................................500

....................................................

.....................................................

......................................................

..............................................................

............................

.........................

..........................

..............................................

.....................................

* Allow 3 times the listed watts for starting these devices.

Load (watts)

450

500

100

600

150

2800

800 to 1050

1750 to 2000

10

Page 11

MAINTENANCE

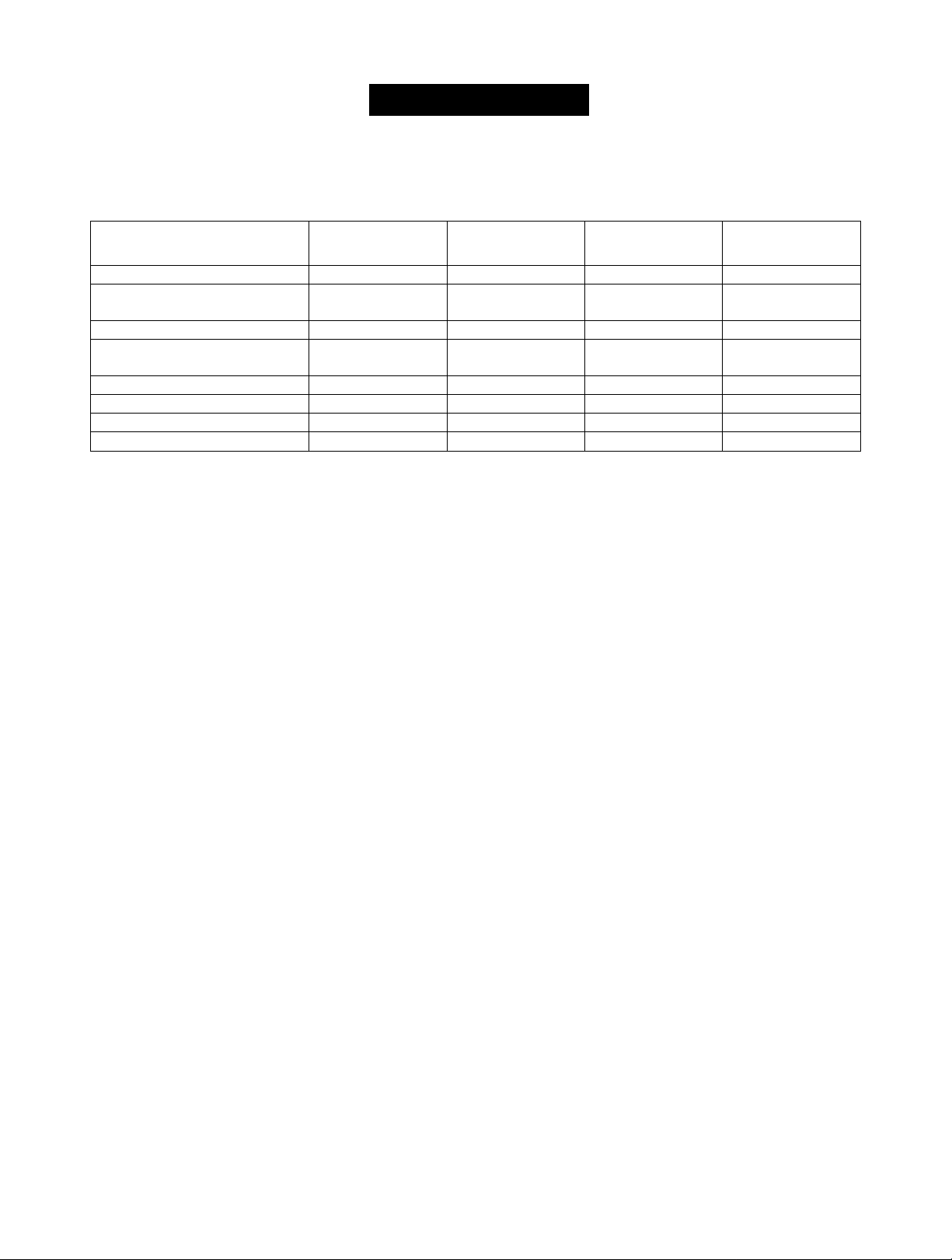

MAINTENANCE SCHEDULE

Follow the hourly or calendar Intervals, whichever occurs first.

More frequent service Is required when operating In adverse conditions noted below.

Maintenance

Operation

Check Oil Level

Service Air Cleaner Pre

Cleaner

Change Oil and Oil Filter^

Service Air Cleaner

Cartridge

Adjust valve Clearance

Retorque Head Bolts

Clean Spark Arrestor Screen

Replace Spark Plugs

Clean more often under dirty or dusty conditions. Replace air cleaner parts if very dirty.

■ Change oil after first 8 hours of operation then after every 50 hours or every season.

* Change oil and oil filter every 25 hours when operating under heavy load or in high temperatures.

‘ Perform this task only after first 50 hours of operation. Head bolts will not need further retorquing.

PRODUCT SPECIFICATIONS

Generator Specifications

Rated Maximum Power

Surge Power............................... 5,000 Watts (5.0 kW)

Rated AC Voltage

Rated Maximum Current

at 240 Volts

Rated Maximum Current

at 120 Volts

Rated Frequency

Phase

.........................................

.............................

.............................

Engine Specifications

Rated Horsepower

Displacement

Spark Plug Type:........................Champion RC12YC or

Set Gap To:

Gasoline Capacity

Oil

Summer

Winter

.............................

............................

...............................

..............

......................

......................

.....................

.....................

......................

Every 8 Hours 25 Hours or 50 Hours or 100 Hours or

or Daily

X

Every Season Every Season Every Season

X"

X^

X

X"

GENERAL RECOMMENDATIONS

The generator warranty does not cover items that

4,200 Watts (4.2 kW)

120/240 Volts

17.5 Amperes

35.0 Amperes

60 Hz at 3600 rpm

Single Phase

7.8 at 3600 rpm

220 cc

Equivalent

0.030inch (0.76mm)

4 U.S. gallons

Sae 30 or 10W-30

SAE 5W-30

have been subjected to operator abuse or negligence.

To receive full value from the warranty, the operator

must maintain the unit as instructed in this manual.

Some adjustments will need to be made periodically

to properly maintain the generator.

All adjustments in the Service and Adjustments

section of this manual should be made at least once

each season. Follow the requirements in the

“Maintenance Schedule” chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit

clean and dry. Operate and store the unit in a clean

dry environment where it will not be exposed to

excessive dust, dirt, moisture or any corrosive vapors.

Cooling air slots in the generator must not become

clogged with snow, leaves, or any other foreign

material.

X

X

11

Page 12

Check the cleanliness of the generator frequently and

clean when dust, dirt, oil, moisture or other foreign

substances are visible on its exterior surface.

CAUTION! Never insert any object or tool

through the air cooling slots, even if the engine

A

is not running.

NOTE: Do Not use a garden hose to clean generator.

Water can enter the engine fuel system and cause

problems. In addition, if water enters the generator

through cooling air slots, some of the water will be

retained in voids and cracks of the rotor and stator

winding insulation. Water and dirt buildup on the

generator internal windings will eventually decrease

the insulation resistance of these windings.

To clean the generator:

• Use a damp cloth to wipe exterior surfaces clean.

• A soft, bristle brush may be used to loosen caked

on dirt, oil, etc.

• A vacuum cleaner may be used to pick up loose

dirt and debris.

• Low pressure air (not to exceed 25 psi) may be

used to blow away dirt. Inspect cooling air slots

and openings on the generator. These openings

must be kept clean and unobstructed.

ENGINE MAINTENANCE

DANGER! When working on the generator,

always disconnect spark plug wire from spark

A

plug and keep it away from spark plug.

Change oil while engine is still warm from running, as

follows:

• Clean area around oil drain plug.

• Remove oil drain plug and oil fill plug. Drain oil

completely into a suitable container.

• When oil has completely drained, install oil drain

plug and tighten securely.

• Place a suitable container beneath the oil filter and

turn filter counterclockwise to remove. Discard oil

and filter according to local regulations.

• Coat gasket of new filter with engine oil. Turn filter

clockwise until gasket contacts tightly with filter

adapter, then tighten an additional 3/4 turn.

• Fill oil sump with recommended oil. See “Before

Starting the Generator” on page 7 for oil

recommendations.

• Install the oil fill plug and tighten securely.

• Wipe up any spilled oil.

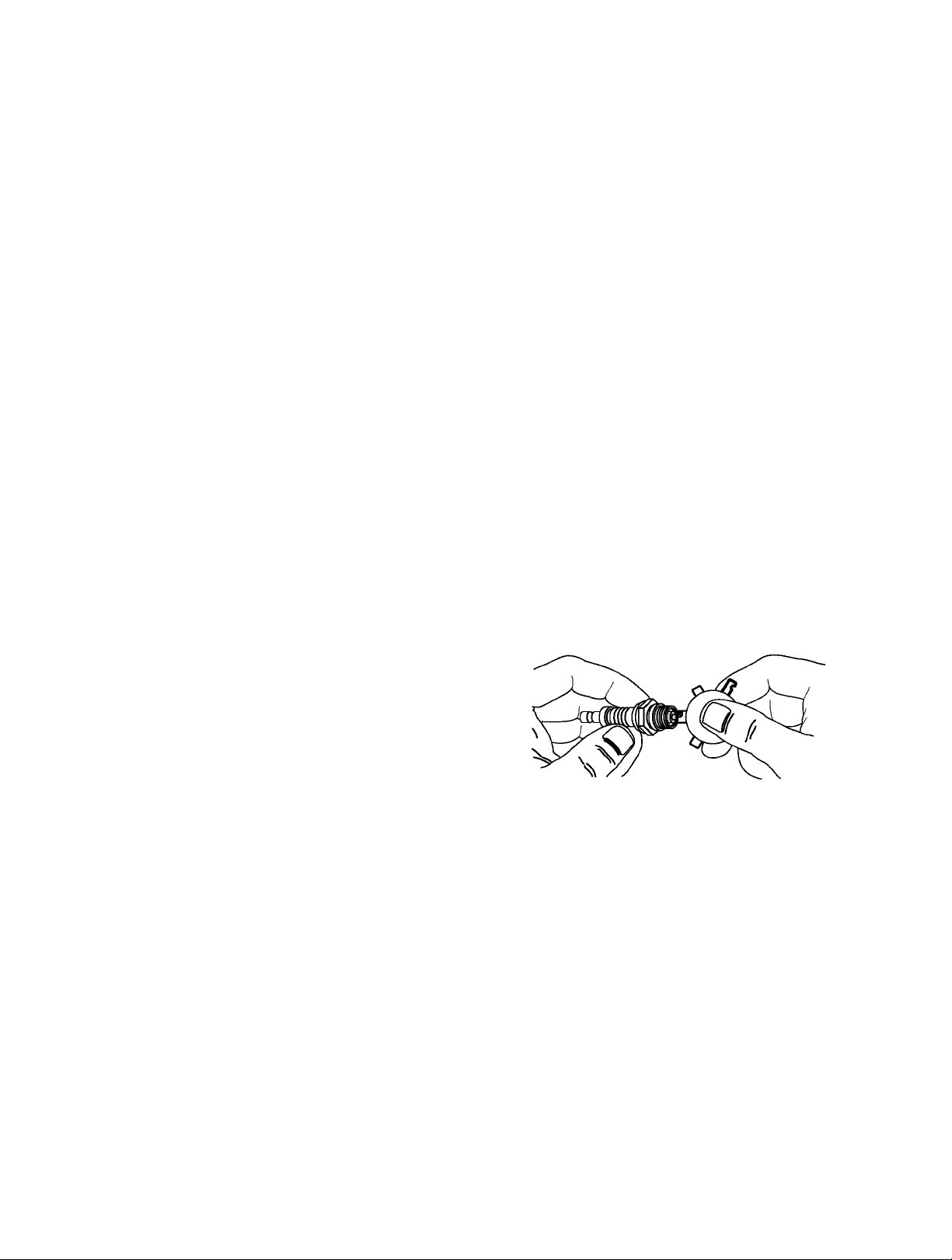

Clean/Replace Spark Plug

Change the spark plug every 100 hours of operation

or once each year, whichever comes first. This will

help your engine to start easier and run better.

Replace with recommended plug.

• Clean area around spark plug.

• Remove and inspect spark plug.

• Check electrode gap with wire feeler gauge and set

spark plug gap to 0.030 inch (0.76mm) if

necessary.

Checking Oil Level

Oil level should be checked prior to each use or at

least every 8 hours of operation. Keep oil level

maintained.

Changing Engine Oil and Oil Filter

Change oil after first 8 hours of operation. Change oil

and oil filter every 50 hours thereafter. If you are using

your generator under extremely dirty or dusty

conditions, or in extremely hot weather, change oil

more often.

Replace spark plug if electrodes are pitted, burned

or porcelain is cracked.

12

Page 13

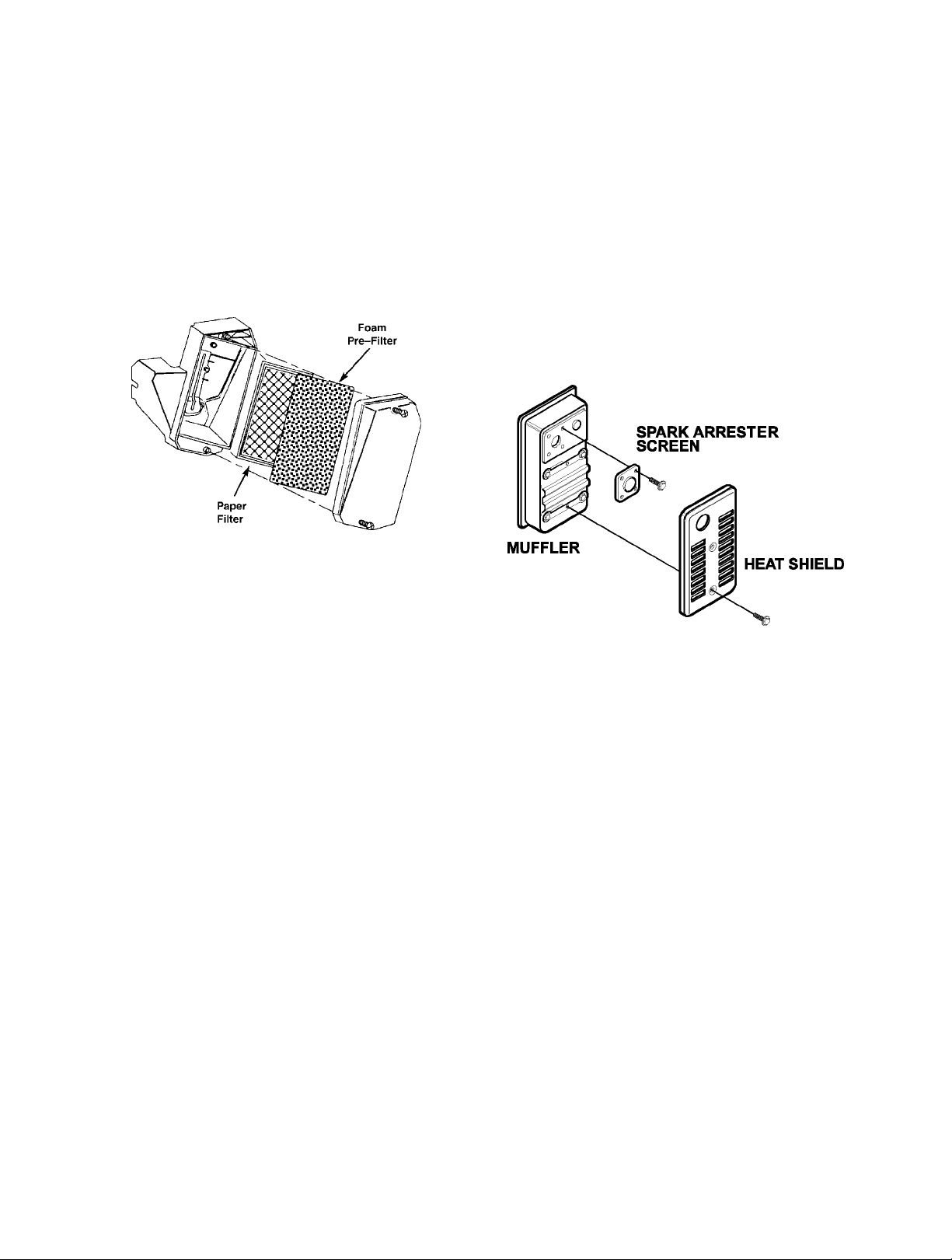

Service Air Cleaner

Your engine will not run properly and may be

damaged if you run it using a dirty air cleaner. Clean

or replace the air cleaner paper filter once every

50 hours of operation or once a year, whichever

comes first. Clean or replace more often if operating

under dusty or dirty conditions. Clean foam precleaner

every 25 hours of operation or sooner under dusty

conditions.

To clean or replace foam precleaner:

• Remove air cleaner cover, then the foam pre-filter.

• Wash precleaner in soapy water. Squeeze pre-filter

dry in the clean cloth. Do Not twist.

• Clean air cleaner cover before installing it.

Clean Spark Arrester Screen

The engine exhaust muffler includes a spark arrester

screen. Inspect and clean the screen every 100 hours

of operation or once each year, whichever comes first.

NOTE: If you use your generator on any forest-

covered, brush-covered or grass-covered unimproved

land, it must have a spark arrester. The spark arrester

must be maintained in good condition by the

owner/operator.

Clean and inspect the spark arrester screen as follows:

• To remove the heat shield from the muffler, remove

the screws that connect the shield to the muffler.

• Remove the screws that attach the spark arrester

screen.

To clean or replace paper air filter:

• Remove air cleaner cover; then remove foam pre

filter (service if necessary) and remove paper filter.

• Clean paper filter by tapping it gently on a solid

surface. If the filter is too dirty, replace it with a new

one. Dispose of the old filter properly.

• Clean air cleaner cover then insert precleaner into

cover. Next insert new paper filter into cover to

hold precleaner in place and assemble all of them

to the base of the air cleaner.

NOTE: If you need to order a new air filter, please call

1-800-366-PART.

Inspect screen and replace if torn, perforated or

otherwise damaged. Do Not use a defective

screen. If screen is not damaged, clean it with

commercial solvent.

Reattach the screen and the heat shield.

13

Page 14

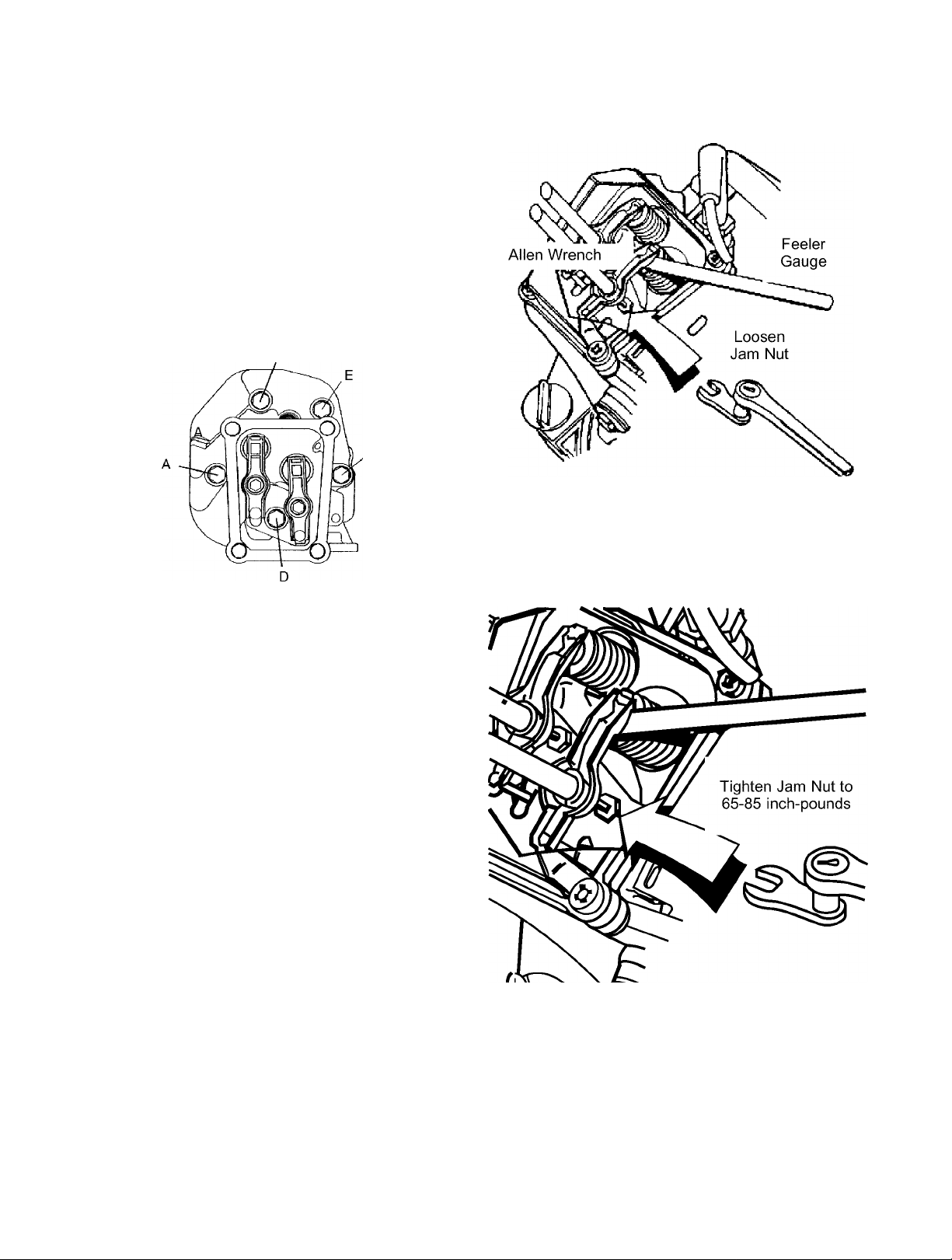

Retorque Head Bolts

After the first 50 hours of operation, you must retorque

the head bolts to 4.0 kg.-m. (22 ft.-lbs.)

IMPORTANT: If you feel uncomfortable about doing

this procedure or you don’t have the proper tools,

please take the unit to your nearest service center to

retorque the head bolts. This is a very important step

to insure the longest life for your engine.

NOTE: Only perform this adjustment after the first

50 hours of operation. The head bolts will need no

further adjustment.

• Torque sequence Is as follows: A, B, C, D, E (star

pattern).

C

Adjusting Valve Clearance

After the first 50 hours of operation, you should adjust

the valve clearance In the engine.

IMPORTANT: If you feel uncomfortable about doing

this procedure or you don’t have the proper tools,

please take the unit to your nearest service center to

have the valve clearance adjusted. This is a very

important step to insure the longest life for your

engine.

NOTE: You must hold the rocker arm jam nut In place

as you turn the pivot ball stud.

When valve clearance Is correct, hold the pivot ball

stud in place with the alien wrench and tighten the

rocker arm jam nut. Tighten the jam nut to

65-85 inch-pounds torque. After tightening the jam

nut, recheck valve clearance to make sure It did

not change.

To adjust valve clearance:

• Make sure the engine is at room temperature.

• Make sure that the spark plug wire is removed from

the spark plug and out of the way.

• Remove the breather tube from the valve cover.

• Remove the four screws attaching the valve cover

with a #2 or 3 phillips screwdriver.

• Make sure the piston is at Top Dead Center (TDC)

of its compression stroke (both valves closed). To

get the piston at TDC, pull on the recoil handle

slowly watching the piston through the spark plug

hole. As you pull on the recoil handle the piston

should move up and down. The piston is at TDC

when it is up as high as it can go.

• Using a 10mm wrench, loosen the rocker arm jam

nut. Use an 8mm alien wrench to turn the pivot ball

stud while checking clearance between the rocker

arm and the valve stem with a feeler gauge.

Correct clearance Is 0.002-0.004 Inch

(0.05-0.1mm).

Reattach the valve cover, making sure the gasket

between the valve cover and cylinder head is in

place. Start all four screws before tightening or you

will not be able to get all the screws In place.

Reattach the breather tube.

Reattach the spark plug wire to the spark plug.

14

Page 15

STORAGE

GENERAL

The generator should be started at least once every

seven days and allowed to run at least 30 minutes. If

this cannot be done and you must store the unit for

more than 30 days, use the following information as a

guide to prepare it for storage.

WARNING! NEVER store engine with fuel in

tank indoors or in enclosed, poorly ventilated

A

areas where fumes may reach an open flame,

spark or pilot light as on a furnace, water heater,

clothes dryer or other gas appliance.

LONG TERM STORAGE

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasohol, ethanol or methanol) can attract moisture,

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instructions:

Protect Fuel System

• Remove all gasoline from the fuel tank to prevent

gum deposits from forming on these parts and

causing possible malfunction of engine.

WARNING! Drain fuel into approved container

outdoors, away from open flame. Be sure

A

engine is cool. Do Not smoke.

Run engine until engine stops from lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase.

Refill with recommended grade.

Oil Cylinder Bore

• Remove spark plug and pour about 1/2 ounce

(15ml) of engine oil into the cylinder. Cover spark

plug hole with rag. Crank slowly to distribute oil.

CAUTION! Avoid spray from spark plug hole

when cranking engine slowly.

A

• Install spark plug. Do Not connect spark plug wire.

GENERATOR

• Clean the generator as outlined on page 12 (“To

Clean the Generator”).

• Check that cooling air slots and openings on

generator are open and unobstructed.

OTHER STORAGE TIPS

• Do Not store gasoline from one season to another.

• Replace the gasoline can if it starts to rust. Rust

and/or dirt in your gasoline will cause problems.

• If possible, store your unit indoors and cover it to

give protection from dust and dirt. BE SURE TO

EMPTY THE FUEL TANK.

• Cover your unit with a suitable protective cover that

does not retain moisture.

DANGER! NEVER cover your generator while

A

engine and exhaust area are warm.

Store generator in clean, dry area.

15

Page 16

TROUBLESHOOTING

Problem

Engine is running, but no

AC output is available.

Engine runs good at no

load but “bogs down"

when loads are connected.

Engine will not start; or

starts and runs rough.

Engine shuts down during

operation.

Engine lacks power.

Cause

1.

One of the circuit breakers is open.

2.

Connected device is bad.

Poor connection or defective cord

3.

set.

4. Fault in generator. 4. Contact Sears service facility.

1.

Short circuit in a connected load.

2.

Generator is overloaded.

3. Engine speed is too slow. 3.

4. Shorted generator circuit. 4. Contact Sears service facility.

1.

Run/Stop Switch set to “Stop”.

2. Dirty air cleaner. 2. Clean or replace air cleaner.

3. Out of gasoline. 3.

4.

Stale gasoline.

5. Spark plug wire not connected to

spark plug.

6. Bad spark plug. 6. Replace spark plug.

7.

Water in gasoline.

Overchoking.

8.

9. Low oil level. 9. Fill crankcase to proper level.

10. Excessively rich fuel mixture. 10.

11.

Intake valve stuck open or closed.

12. Engine has lost compression. 12. Contact Sears service facility.

1.

Out of gasoline.

2.

Low oil level.

1.

Load is too high.

2. Dirty air filter. 2. Replace air filter.

Correction

1. Reset circuit breaker.

2. Connect another device that is in

good condition.

Check and repair.

3.

1.

Disconnect shorted electrical load.

2.

See “Don't Cverload the

Generator” on page 10.

Contact Sears service facility.

1. Set switch to “Run”.

Fill gas tank.

4. Drain gas tank; fill with fresh fuel.

Connect wire to spark plug.

5.

7. Drain gas tank; fill with fresh fuel.

8. Cpen choke fully and crank

engine.

Contact Sears service facility.

11. Contact Sears service facility.

1. Fill fuel tank.

2.

Fill crankcase to proper level.

1.

See “Don't Cverload the

Generator” on page 10.

Engine “hunts” or falters.

No battery charge DC

output. 4.

2. Carburetor is running too rich or

2.

3. Battery cable is bad. 3. Replace cable.

5. Receptacle is bad. 5.

1.

Choke is opened too soon.

too lean.

1.

Battery posts are corroded.

Battery fluid level is low.

Battery is defective.

1.

Move choke to halfway position

until engine runs smoothly.

2. Contact Sears service facility.

1. Clean battery posts.

2.

Add distilled water to battery.

4. Check battery condition; replace if

defective.

Contact Sears service facility.

16

Page 17

NOTES

17

Page 18

SCHEMATIC

CRAFTSMAN 4200 Watt AC Generator 580.327141

18

Page 19

WIRING DIAGRAM

CRAFTSMAN 4200 Watt AC Generator 580.327141

CHARGE

RECTIFIER

19

Page 20

REPLACEMENT PARTS

CRAFTSMAN 4200 Watt AC Generator 580.327141

Main Unit — Exploded View

20

Page 21

CRAFTSMAN 4200 Watt AC Generator 580.327141

Main Unit — Parts List

Item

Part# Qty.

1

BB2551

2 B84021 1 SUPPORT, Engine

4

66365

84141J 1

5

83540A 1

6

7

65791

8 96796

86307 4 HHMS, 5/16-24x3/4 54 14353621 1

10

11

47480

12

84508

13 52858 8

14

83208

15 B4901

16 66476

17

89476

70644 1

18

19 84346 3 PPHMS, M8x35

20 40976

21

83083

22 83071 1 MUFFLER

81917 1

23

66825B 1 CARRIER, Rear Bearing 72

25

85652 2 MOUNT, Vibration

26

27

67989

28 B4986

30 74908

32

86308

33 65795

34 66849A 1

67022 1 GROMMET, Rubber B2552 1

35

84132 1 MODULE, Drive

36

37

66386

38 66849

B4871 1 COVER, Bearing Carrier

39

41 86494 1 SCREW, M6- I.Ox 16 Wing

42 86292 7 HHCS, 10- 16 X Self Drill

43 77395

44

83465

78831B 4

46

Description Item

1 CRADLE, 4200 W 47

1

HOUSING, Engine Adapter 49

ROTOR, Assembly 50 83311

STATOR, Assembly 51

1

BEARING

1 WASHER, M8 Flat

1 HHCS, 5/16-24x7"

2 MOUNT, Vibration 45°

NUT, M8 Locking

1 BRACKET, Muffler

1

DECAL, 1-800-4-MyHome

2 SCREW, M6- I.OOx 12 64

1 GASKET, Exhaust

PPHMS, M8- 1.25x20 66 93826

2

SCREW, M8- 1.25x20 68 77816

1 SCREEN, Spark Arrester

PIN, Roll M4x 10 71 B2347 2 END CAP, Tube

2

NUT, M8 Flange Serrated

1 DECAL, Ground

4

TAPTITE, M5-0.8X 10 900 NSP

4 BOLT, M6- 1.0 X 115 Stator

1 RECTIFIER, Battery Charge

TAPTITE, M5-0.8x20 Parts Not Illustrated

1 ASSY., Brush Holder 65787 1

2 TAPTITE, M5-0.7X 16 Long 84882 1 Spark Plug Wrench Driver

4

NUT, M6 Flange Lock 09-32686

4 GROMMET, Tank 09-32687 30 Amp Locking Plug

HHMS, M6- 1.0x60 (black) 09-32688 Cord Wrap Kit

Part# Qty.

80270

48 78299

85134 1 CAP, Fuel

B84042 1 SHIELD, Heat

52 84687 1 INSULATION, #2 1/4" Thick

53 85000

23762 1 SHAKEPROOF, #10

55

56 26850

60 B2550

61

Optional Accessories Not Illustrated

92982 1 DECAL, Danger

62

B2549

NSP

73054 1 DECAL, Fuel Shut Off

65

67

96409

B1432 1

69

70 B1779

BB2555

51767 2

73

74 52857 2 NUT, M6- 1.0 Locking

75 46476

AB3061

Description

1 VALVE, Tank

1

BUSHING, Plastic Tank

1 TANK, Fuel

1 CLIP, Insulation

WIRE, Ground

2 SHAKEPROOF, M6

1

DECAL, Control Panel

2 DECAL, Heat Shield

1 DECAL, Data

1 DECAL, Start Instructions

1 DECAL, 1-800#

1 DECAL, Muffler Warning

ASSEMBLY, Control Panel

2 COVER, Hinge

1 HANDLE

HHCS, M6- 1.0x45

2

CAP PLUG, 1" Square

1 ENGINE, 7.8 HP

Owner’s Manual

1

28oz Engine Oil

Battery Charge Cables

20 Amp Locking Plug

21

Page 22

CRAFTSMAN 4200 Watt AC Generator 580.327141

Control Panel — Exploded View and Parts List

14

Item

Part#

1

B1431

2

83975

3 66818

4 66821 1

5 68867C

6 68868C

7 75207A 1 CIRCUIT BREAKER, 30 Amp 21

8 75207G

9 82538

84134 1 GROMMET, Rubber 24 84543B

10

11 83514 1 CIRCUIT BREAKER, 10 Amp

12

83970

Description Item

Qty.

1

PANEL, Control 13 84028

1

BOX, Control

2

OUTLET, 120 Volt AC 15

OUTLET, 12 Volts DC 16

1 OUTLET, 120/240 Volt, 17

20 Amp Locking

1 OUTLET, 120 Volt, 30 Amp

Locking Retaining

2 CIRCUIT BREAKER, 18 Amp 22 22264 4 WASHER, M4 Lock

1 SWITCH, On/Off Rocker

1 CONTROL BOARD, System

22

Part# Qty.

14 67022 1 GROMMET, Rubber

85584 1 BAR, Bus

84543A 2 SCREW, 3.0 X 12mm

84543C 9

18 84198 3

84197 1 BAR, Circuit Breaker

19

75476

23 51715

25 84335

82542 1 BAR, DC Outlet Retaining

26

Description

1 TRANSFORMER, Idle Control

SCREW, 3.5 X 18mm

SHIELD, Circuit Breaker

2 SCREW, 4.15 X 16mm

4 NUT, M3 Hex

SCREW, 3.5 X 12mm

10

1

WIRE HARNESS

Page 23

CRAFTSMAN 4200 Watt AC Generator 580.327141 Wheel Kit — Exploded View and Parts List

Item

Part# Qty.

1 87005A 2 Retaining Pin

2

B1760

3 93728C

4 94222Q 2 5/8-18 Lock Jam Nut

5 49808

B1764 1 Mounting Leg

6

NOTE: Fold-down handle not shown

Description

2

10" Diameter Wheel

2

Axle Stud

2 Flat Washer

23

Page 24

Engine, 7.8 HP, Generac Power Systems, EHC 00952

101

Item

Part#

7

78653

85272 1

8

9 84195

10 85620

11 00285271 1

12

84329

00185271 1

13

14 22097 2 M6 Lock Washer

15 82981

16 81675

17 84274 1 Tinnerman Clamp

72347 1 Spark Plug

20

Description Item

Qty.

1

Run/Stop Switch

L.E.D. Assembly

1 Low Oil Shutdown Decal

1 Black Sleeving 24 83512 1 M8 X 15mm Taptite Screw

Black Wire Assembly 25

1 3-pin Male Connector Housing

White Wire Assembly

2 M6 X 30mm Screw

1 Ignition Coil

Part# Qty.

21 86962 1 Governor Lever

22

85953

83502 1 Adjust Screw

23

78604 1 60 Hz. Governor Spring

26 66476

27

83503

28 83781

86384 1 Governor Rod

29

86037 1 Anti-lash Spring

30

100

101 66311

24

83782 1

Description

1 Wear Washer

1 M6 X 12mm Capscrew

1 M5 Lock Nut

1 Governor Bracket

Idle Coil

1

M8-1.25 Jam Nut

Page 25

Engine, 7.8 HP, Generac Power Systems, EHC 00952

23 24

Item

Part# Qty.

1 78621 1

2

76389

88411 1 Piston Ring Set

3

4 A8897A 1 Gear Cover Assembly

5 77168 5

88057 1 Piston

6

7

76390

83337A 1 Tapered Crankshaft Assm.

8

9 78658

10 78659

11

89213J

12 A7637 1 Governor Arm

13 81695

14

A8929

15 78645

16 A7811

17

72683

98752 1 Camshaft Assembly 44

18

19 89096

20 88156

Description Item

Part#

Connecting Rod Assembly 26 78606

1 Piston Pin 27

76361

28 89230 6

99922 1 Spring Washer

29

M8 X 52mm Head Bolt

30 A1720

31 88401

2 Pin Retainer Ring 32

84186

83192 1 Geroter Set

33

1 Governor “R” Pin 34 86254 1

1 Governor Arm Thrust Washer

1

Crankcase Assm.

21705B 1

36

37 90082 1 Exhaust Valve

38 90081

2

Oil Seal

1 Governor Gear Assembly

1 Governor Gear C-Ring 41

88396A 2 Push Rod

39

40 83235

80336

1 Governor Spool 42 96362 1 Rocker Cover Gasket

1

1/8” NPT Pipe Plug 43 77161

77160

1

Crankcase Gasket

1

Valve Stem Seal 46 88403

76307 2 Rocker Arm Jam Nut

45

21 A8822 1 Cylinder Head Gasket 47 72657 2

22

78691

A5772 1

23

24

A5776

25 74908

1

Oil Pressure Relief Cover 48

Oil Pressure Spring 49 76329

1 11/32” Ball

50

1 M5 Form Screw

88412 1 Rocker Cover Assembly

21944E

Description

Qty.

4 M6-1.0X 12mm Screw

1 Governor Gear Thrust Washer

M8-1.25 X 35mm Screw

2 Valve Spring Retainer

2

Valve Spring

2 Valve Spring Wear Washer

“0” Ring

Cylinder Head Assembly

1

Intake Valve

2 Tappet

1

Oil Pick-up Assembly

2

Pivot Ball Stud

2

GN-190/220 Rocker Arm

1

Push Rod Guide Plate

1/4” NPT Pipe Plug

1

Plastic Oil Fill Plug

Complete Long Block

0

25

Page 26

Engine, 7.8 HP, Generac Power Systems, EHC 00952

Item

Part#

90947 1 Breather Hose

31

32

90051

35 80316

36 90948

39 91846

42

78631

97747 1 Dellorto Carburetor

43

44 78607 1 Air Cleaner Base

45 66476

46 59635

47

78601

78602 1 Precleaner

48

83504 1

49

50 78643

60 30340

61 48031C

Description

Qty.

1

Manifold Head Gasket

2 M6 X 30mm Screw

1

Intake Manifold

1 Carburetor/Air Box Gasket

1

Carburetor/Manifold Gasket

1 M6 X 12mm Capscrew

1

#8 X 3/8" Plastite Screw

1 Air Filter

Choke Knob

1

Curb Bolt

12” 1/4” ID Hose

2

Hose Clamp

26

Page 27

Engine, 7.8 HP, Generac Power Systems, EHC 00952

81

Item

Part# Qty

1

94820

2

91848

84982 1 Oil Filter Adapter

3

4

92978

5 99236

6 70185

82774 1

78

77182E 1

79

83312 1

80

81 81810

82 92984 1 Top Wrapper

83 45756

84

78609

78608A 1 Air Box Cover

85

90695A 1 Blower Flousing

86

87

89739

88 66476 9

89 A2799

A2842 1

90

91 78651C

Description

1 Expansion Plug

1 Oil Filter Gasket

2 M6 X 20mm Screw

1

Oil Pressure Switch

1 Oil Filter

Woodruff Key

Flywheel (220cc)

Conical Washer

1 M16HexNut

4 M6 X 10mm Screw

2 Cover Bolt

1 Lower Wrapper

M6 X 12mm Capscrew

1

Recoil Assembly

Recoil Cup

1

Backplate

27

Page 28

NOTES

28

Page 29

EMISSION CONTROL SYSTEM WARRANTY

Your Warranty Rights and Obligations

The California Air Resources Board ("CARB") and Sears

Roebuck and Co., USA, are pleased to explain the Emission

Control System Warranty on your model year 2000 and later

small off-road engine (engine). In California, new engines

must be designed, built and equipped to meet the State's

stringent anti-smog standards. Sears must warrant the

emission control system on your engine for the periods of

time listed below provided there has been no abuse,

neglect, or improper maintenance of your engine.

Your emission control system includes parts such as the

carburetor and the ignition system.

Where a warrantable condition exists. Sears will repair your

engine at no cost to you. Expenses covered under under

warranty include diagnosis, parts, and labor.

Manufacturer's Warranty Coverage

The model year 2000 and later engines are warranted for

two years. If any emission related part on your engine (as

listed below) is defective, the part will be repaired or

replaced by Sears.

Owner's Warranty Responsibilities

As the engine owner, you are responsible for the

performance of the required maintenance listed in this

owners manual. Sears recommends that you retain all

receipts covering maintenance on your engine, but Sears

cannot deny warranty solely due for the lack of receipts or

for your failure to ensure the performance of all scheduled

maintenance.

As the engine owner, you should be aware that Sears may

deny you warranty coverage if your engine or a part of it has

failed due to abuse, neglect, improper maintenance,

unapproved modifications, or the use of parts not made or

approved by the original equipment manufacturer.

You are responsible for presenting your engine to a Sears

authorized repair center as soon as a problem exists.

Warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact your nearest authorized

service center or call Sears at 1-800-473-7247.

Warranty Commencement Date

The warranty period begins on the date the engine is

delivered.

Length of Coverage

Sears warrants to the initial owner and each subsequent

purchaser that the engine is free from defects in materials

and workmanship which cause the failure of a warranted

part for a period of two years.

WHAT IS COVERED

Repair or Replacement of Parts

• Repair or replacement of any warranted part will be

performed at no charge to the owner at an

approved Sears service center.

• If you have any questions regarding your warranty

rights and responsibilities, your should contact your

nearest authorized service center or call Sears at

1-800-473-7247.

Warranty Period

Any warranted part which is not scheduled for replacement

as required maintenance, or which is scheduled only for

regular inspection to the effect of “repair or replace as

necessary” shall be warranted for 2 years. Any warranted

part which is scheduled for replacement as required

maintenance shall be warranted for the period of time up to

the first scheduled replacement point for that part.

Diagnosis

The owner shall not be charged for diagnostic labor which

leads to the determination that the warranted part is

defective if the diagnostic work is performed at an approved

Sears service center.

Consequential Damages

Sears may be liable for damages to other engine

components caused by the failure of a warranted part still

under warranty.

WHAT IS NOT COVERED

All failures caused by abuse, neglect, or improper

maintenance are not covered.

Add-on or Modified Parts

The use of add-on or modified parts can be grounds for

disallowing a warranty claim. Sears is not liable to cover

failures of warranted parts caused by the use of add-on or

modified parts.

How to File a Claim

If you have any questions regarding your warranty rights and

responsibilities, you should contact your nearest authorized

service center or call Sears at 1-800-473-7247.

Where to Get Warranty Service

Warranty services or repairs shall be provided at all Sears

authorized service centers.

Maintenance, Replacement and Repair of Emission Related Parts

Any Sears approved replacement part used in the

performance of any warranty maintenance or repair on

emission related parts will be provided without charge to the

owner if the part is under warranty.

Emission Control Warranty Parts List

1. Fuel Metering System:

a. Carburetor assembly

b. Fuel filter

2. Air Induction System:

a. Intake manifold

b. Air cleaner

3. Catalytic Muffler Assembly (if so equipped).

Including:

a. Muffler gasket

b. Exhaust manifold

4. Ignition System

a. Spark plug

b. Ignition module

5. Crankcase Breather Tube

29

Page 30

TABLA DE CONTENIDOS

Garantía .................................................................30

Reglas De Seguridad.............................................31

Montaje...................................................................32

Operación..........................................................33-38

Especificaciones del Producto

................................

39

Mantenimiento ..................................................39-42

Almacenamiento ....................................................43

Reparación de Averias

Garantía de Control de Emisiones

Cómo Ordenar Partes

...........................................

.........................

...........................

Ultima Página

GARANTIA

GARANTIA LIMITADA PARA GENERADORES PORTATILES DE LUJO

SEARS le garantiza al comprador original que el alternador y el motor de su generador portátil estará libre de defectos en

materiales y mano de obra en los componentes y por el periodo de tiempo establecido a continuación a partir de la fecha

de compra original. Esta garantía no es transferible y se aplica únicamente a los generadores portátiles accionados por el

motor garantizado Sears Serie GN.

CLIENTE* COMERCIAL*

Alternador 2 años (El 2o. año únicamente las partes) 1 Año

Motor 2 años (El 2o. año únicamente las partes) 1 Año

* NOTA: Para propósitos de esta garantía el término “Uso del Cliente” representa el uso doméstico residencial y de

emergencia por parte del comprador original, sin incluir aplicaciones donde la unidad sea usada como fuente de potencia

principal. El término “Uso Comercial” representa todos los otros usos, incluyendo alquiler, construcción, comercial y para

propósitos lucrativos. Una vez el generador haya tenido uso comercial, este será considerado como un generador para

uso comercial para los fines de esta garantía.

Durante dicho período de garantía, SEARS reparará o reemplazará, a su discreción, cualquier parte que haya sido

encontrada defectuosa, en examen previo realizado por SEARS, bajo uso y servicio normal**. Las baterías de arranque

no están garantizadas por SEARS. Todos los costos de transporte bajo garantía, incluyendo el envío a la fábrica, de ser

necesario, serán responsabilidad del comprador y deberán ser pagados por anticipado. Esta garantía no cubre el

mantenimiento y servicio normal y no se aplica a generadores, alternadores, motores o partes que hayan sido sujetos a

instalaciones o modificaciones incorrectas o no autorizadas, mal uso, negligencia, accidente, sobrecarga, exceso de

velocidad, mantenimiento, reparación o almacenamiento incorrecto que, ajuicio de SEARS, afecte negativamente su

funcionamiento y confiabilidad.

** DESGASTE NORMAL: Como con todos los dispositivos mecánicos, los motores necesitan el servicio y reemplazo

periódico de las partes para funcionar en buenas condiciones. Esta garantía no cubre reparaciones cuando el uso normal

haya sobrepasado la vida útil de una parte o motor.

NO EXISTEN OTRAS GARANTIAS EXPRESAS. SEARS POR MEDIO DE LA PRESENTE DESCONOCE TODAS LAS

GARANTIAS IMPLICITAS, INCLUYENDO, SIN LIMITARSE, A AQUELLAS DE COMERCIALIZACION Y ADAPTACION

PARA UN PROPOSITO PARTICULAR AL EXTREMO PERMITIDO POR LA LEY. LA DURACION DE CUALQUIER

GARANTIA IMPLICITA QUE NO PUEDA SER DESCONOCIDA, ESTA LIMITADA AL PERIODO DE TIEMPO

ESPECIFICADO EN LA GARANTIA EXPRESA. LA RESPONSABILIDAD LEGAL ES EXCLUIDA POR DAÑOS

CONSECUENCIALES, INCIDENTALES O ESPECIALES BAJO CUALQUIERA DE LAS GARANTIAS. Algunas provincias

no permiten limitaciones en la duración de las garantías implícitas, o la exclusión o limitación de daños incidentales o

consecuenciales, por tanto las limitaciones o exclusiones anteriormente mencionadas podrían no aplicarse a usted. Esta

garantía le otorga derechos legales específicos; usted podría tener otros derechos, los cuales cambian de estado a

estado.

Para servicio, visite su centro de servicio de garantía autorizado SEARS más cercano. El servicio de garantía puede ser

llevado a cabo únicamente por un centro de servicio autorizado SEARS. Esta garantía no se podrá aplicar para servicio

en otros centros de servicio. Evidencia de la fecha de compra original deberá ser presentada en el momento de solicitar el

servicio de garantía.

44

47

SEARS, ROEBUCK and CO., D/817WA, Hoffman Estates, IL 60179 U.S.A.

30

Page 31

REGLAS DE SEGURIDAD

¡PRECAUCION' Lea este manual y siga todas las

Reglas de Seguridad e Instrucciones de Operación

A

antes de usar este producto.

n ADVERTENCIA: 0

El escape del motor de este producto contiene

elementos químicos reconocidos en el Estado

de California por producir cáncer, defectos de

nacimiento u otros daños de tipo reproductivo.

¡PELIGRO! Este generador está diseñado para uso

en exteriores únicamente. No use este generador en

A

el interior de edificaciones o recintos cerrados,

incluyendo el compartimiento para generador de un

vehículo recreacional (VR). Podrían ocurrir incendios

o explosiones. Las modificaciones realizadas por el

usuario, incluyendo ventilación del escape y/o

ventilación de enfriamiento, no eliminarán el peligro.

También, permita que exista al menos dos pies de

distancia alrededor del generador, incluso cuando

esté operando la unidad en exteriores.

¡PRECAUCION! Siempre desconecte el alambre

de la bujía y colóquelo donde no pueda entrar en

A

contacto con la bujía, para evitar el arranque

accidental durante la instalación, transporte, ajuste o

reparación de su Generador.

El generador produce un voltaje bastante alto, el cual

puede ocasionar descargas eléctricas extremamente

peligrosas. Evite el contacto con terminales, alambres

pelados o sin recubrimiento, etc. Nunca permita que

personas no calificadas operen o proporcionen servicio al

generador.

Nunca manipule dispositivos o cordones eléctricos

cuando se encuentre parado en agua, descalzo o con los

pies o las manos mojadas. Ocurrirán descargas eléctricas

peligrosas.

El Código Eléctrico Nacional exige que el bastidor y las

partes externas conductoras de electricidad del

generador estén conectadas adecuadamente a una

conexión a tierra física. Los códigos eléctricos locales

también pueden exigir la conexión a tierra adecuada del

generador. Consulte a un electricista local para los

requisitos de conexión a tierra en su área.

Use un interruptor de circuito de falla a tierra en áreas

húmedas o de alta conductividad (como en pisos

metálicos o estructuras de acero).

No utilice en el generador juegos de cordones eléctricos

que estén desgastados, pelados, raídos o dañados de

cualquier manera. El uso de juegos de cordones

defectuosos puede resultar en descargas eléctricas o

daño al equipo y/o a la propiedad.

• Cpere el generador únicamente en superficies niveladas

y donde no se vaya a exponer a humedad excesiva,

suciedad, polvo o vapores corrosivos.

• La gasolina es altamente INFLAMABLE y sus vapores

son EXPLOSIVOS. No permita que fumen, que existan

llamas abiertas, chispas o calor a su alrededor cuando

manipule gasolina. Evite regar gasolina sobre un motor

caliente. Cumpla con todas las leyes que regulan el

almacenamiento y el manejo de gasolina.

• Nunca agregue combustibie cuando la unidad esté en

funcionamiento.

• No llene el tanque de combustible excesivamente.

Siempre permita que exista espacio para la expansión

del combustible. Si el tanque está demasiado lleno, el

combustible podría rebosarse y caer sobre el motor

caliente y ocasionar un INCENDIO o una EXPLOSION.

• Nunca almacene el generador con combustible en el

tanque, donde los vapores de la gasolina puedan entrar

en contacto con llamas abiertas, chispas o luces de piloto

(como en hornos, calentadores de agua o secadoras de

ropa). Podrían ocurrir INCENDIOS o EXPLOSIONES.

• Los gases de escape del generador contienen gas de

monóxido de carbono MORTAL. Si este gas peligroso se

inhala en concentraciones suficientes, puede ocurrir

pérdida de la consciencia e incluso la muerte.

Unicamente opere este equipo al aire libre donde exista

ventilación adecuada.

• Deje por lo menos 2 pies de distancia alrededor del

generador, incluso cuando la unidad esté funcionando en

exteriores, de otra forma podría dañar la unidad. Nunca

opere esta unidad dentro de un salón o recinto cerrado

donde el flujo libre de aire de enfriamiento, hacia el

interior y la parte externa de la unidad, pueda ser

obstruido.

• Nunca arranque o detenga el motor-generador cuando

tenga cargas eléctricas conectadas a los tomacorrientes

y los dispositivos conectados estén ENCENDIDOS.

Arranque el motor y permita que se estabilice antes de

conectar las cargas eléctricas. Desconecte todas las

cargas eléctricas antes de apagar el generador.

• No introduzca objetos a través de las ranuras de

enfriamiento del motor-generador. Usted podría dañar la

unidad o lesionarse a sí mismo.

• Nunca opere el generador (a) en la lluvia; (b) en espacios

encerrados; (c) si se recalientan los dispositivos

eléctricos conectados; (d) si se pierde la salida eléctrica;

(e) si se presentan chispas en el motor o generador; (f) si

se observan llamas o humo cuando la unidad está

funcionando; (g) si la unidad vibra demasiado.

NOTA: Su generador está equipado con un silenciador

apagachispas, el apagachispas deberá ser mantenido en

buenas condiciones de funcionamiento por parte del

propietario/operador. En el estado de California es

obligatorio, según ley, el uso de apagachispas

(Sección 4442 del Código de Recursos Públicos de

California). Otros estados pueden tener leyes similares. Las

leyes federales se aplican en tierras federales.

BUSQUE ESTE SIMBOLO PARA SEÑALAR PRECAUCIONES DE SEGURIDAD IMPORTANTES. ESTO SIGNIFICA “¡ATENCION!!! ¡ESTE ALERTA!!! SU SEGURIDAD ESTA EN PELIGRO.”

A

31

Page 32

MONTAJE

Su generador AC requiere de ciertos procedimientos de

armado y está listo para ser usado después de haberle

suministrado servicio adecuado con el aceite y combustible