Page 1

2610913327

Owner’s Manual

CRAFTSMAN.

ROTARY POWER TOOLS

Model Nos.

572.610830

572.610960

&

572.610950

Caution:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

« Safety

® Operation

* Maintenance

« Parts

® Español

2610913327

Page 2

Table of Contents Page

Warranty .................................................................................................... 2

Power Tool Safety Rules ........................................................................3-6

Symbols ....................................................................................................7

Functional Description and Specifications ............................................8-9

Assembly..............................................................................................10-II

Operating Instructions

Assembly & Operation of Attachments...............................................16-20

Maintenance .....................................................................................21-22

Accessories........................................................................................23-25

Operating Speeds for Accessories

Service Parts.....................................................................................28-31

Español .............................................................................................32-56

Sears Warranty

Full One Year Warranty on Craftsman Rotary Power Tool

.........'................................................................

...................................................

12-15

26-27

If this Craftsman Rotary Power Tool fails to give complete satisfaction within one

year from the date of purchase, Sears will replace it free of charge.

If this Rotary Power Tool is used for commercial or rental purposes, this warranty

applies for only one year from the date of purchase.

Warranty Service

Warranty service is available by returning this Craftsman Rotary Power Tool to your

nearest Sears Store in the United States.

This warranty applie's only while this Rotary Power Tool is used in the United

States.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 81 TWA, Hoffman Estates, IL 60179

Page 3

POWER TOOL SAFETY RULES

A WARNING

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with

a polarized piug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

stili does not fit, contact a qualified

electrician to instali a polarized outlet.

Do not change the plug in any way.

Double Insulation ^ eliminates the need

for the three wire grounded power cord and

grounded power supply system. Before

plugging in the tool, be certain the outlet

voltage supplied is within the voltage

marked on the nameplate. Do not use “AC

only” rated tools with a DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased

risk of electric shock if your body is

grounded. If operating the power tool in

damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to

supply the power to your tool. Electrician’s

rubber gloves and footwear will further

enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of electric

shock.

Read and understand all instructions. Failure to follow ail instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

When operating a power tool outside,

use an outdoor extension cord marked

"W-A” or “W.” These cords are rated for

outdoor use and reduce the risk of electric

shock. Refer to “Recommended sizes of

Extension Cords” in the Accessory section

of this manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves

away from moving parts. Loose clothes,

jewelry, or long hair can be caught in

moving parts. Keep handles dry, clean and

free from oil and grease.

Avoid accidental starting. Be sure switch

is “OFF” before piugging in. Carrying

tools with your finger on the switch or

plugging in tools that have the switch “ON”

invites accidents.

Remove adjusting keys or wrenches

before turning the tool “ON”. A wrench or

a key that is left attached to a rotating part

of the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do

the job better and safer at the rate for which

it is designed.

Page 4

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch Is dangerous and

must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the

tool. Such preventive safety measures

reduce the risk of starting the tool

accidentally.

of children and other untrained persons.

Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly

maintained tools, with sharp cutting edges

are less likely to bind and are easier to

control. Any alteration or modification is a

misuse and may result in a dangerous

condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

Store idle tools out of reach

SAFETY RULES FOR ROTARY TOOLS

caused by poorly maintained tools. Develop

a periodic maintenance schedule for your

tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become

hazardous when used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced

or pinched, safety guard return springs may

be improperly mounted.

When servicing a tool, use only Identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to

follow Maintenance Instructions may create

a risk of electric shock or injury. Certain

cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

Accessories must be rated for at ieast

the speed recommended on the tool

warning labei. Wheels and other

accessories running over rated speed can

fly apart and cause injury.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a “live" wire will

make exposed metal parts of the tool "live”

and shock the operator. If cutting into

existing wails or other blind areas where

electrical wiring may exist is unavoidable,

disconnect all fuses or circuit breakers

feeding this worksite.

The following warning is intended for flex

shaft tools and accessories: Do not

operate the flexible shaft with a sharp

bend. Over bending the shaft can generate

excessive heat on the jacket or hand piece.

The recommended minimum is 6" radius.

Always disconnect the power cord from

the power source before making any

adjustments or attaching any

accessories. You may unexpectedly cause

the tool to start leading to serious personal

injury.

Be aware of the switch location, when

placing the tool down or when picking

the tool up. You may accidentally activate

the switch. ,

The following warning is intended for flex

shaft tools and accessories: Always hold

the hand piece firmly in your hands

during the start-up. The reaction torque of

the motor, as it accelerates to full speed,

can cause the shaft to twist.

Always hold the tool with two hands

during start-up. The reaction torque of the

motor can cause the tool to twist.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working

in safe environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut

and any other adjustment devices are

securely tightened. Loose adjustment

device can unexpectedly shift, causing loss

of control, loose rotating components will

be violently thrown.

Do not reach in the area of the spinning

bit. The proximity of the spinning bit to your

hand may not always be obvious.

Page 5

Allow brushes to run at operating speed

for at least one minute before using

wheel. During this time no one is to stand

in front or in line with the brush. Loose

bristles or wires will be discharged during

the run-in time.

Wire and bristle brushes must never be

operated at speeds greater than

15,000/min. Direct the discharge of the

spinning wire brush away from you.

Small particles and tiny wire fragments may

be discharged at high velocity during the

“cleaning” action with these brushes and

may become imbedded in your skin.

Bristles or wires wiil be discharged from the

brush at high speeds.

Wear protective gloves and face shield

with wire or bristle brushes. Apply wire

or bristle brushes lightly to the work as

only the tips of the wire/bristles do the

work. “Heavy” pressure on bristles will

cause the wire or bristle to become

overstressed, resulting in a wiping action

and will cause the bristles/wire to be

discharged.

Carefully handle both the tool and

individual grinding wheels to avoid

chipping or cracking. Install a new wheel

if tool is dropped while grinding. Do not

use a wheel that may be damaged.

Fragments from a wheel that bursts during

operation will fly away at great velocity

possibly striking you or bystanders.

Never use dull or damaged bits. Sharp

bits must be handled with care.

Damaged bits can snap during use. Dull bits

require more force to push the tool,

possibly causing the bit to break.

Use clamps to support workpiece

whenever practical. Never hold a small

workpiece in one hand and the tool in the

other hand while in use. Allow for

sufficient space, at least 6", between

your hand and the spinning bit. Round

material such as dowel rods, pipes or

tubing have a tendency to roll while being

cut, and may cause the bit to “bite” or jump

toward you. Clamping a small workpiece

allows you to use both hands to control the

tool.

Inspect your workpiece before cutting.

When cutting irregularly shaped

workpieces, plan your work so it will not

slip and pinch the bit and be torn from

your hand. For example, if carving wood,

make sure there are no nails or foreign

objects in the workpiece. Nails or foreign

objects can cause the bit to jump.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter. ,

Avoid bouncing and snagging the wheel,

especially when working corners, sharp

edges etc. This can cause loss of control

and kick-back.

The direction of feed with the bit into the

material when carving, routing or cutting

is very important. Always feed the bit

into the material in the same direction as

the cutting edge is exiting from the

material (which is the same direction as

the chips are thrown). Feeding the tool in

the wrong direction, causes the cutting

edge of the bit to climb out of the work and

pull the tool in the direction of this feed.

If the workpiece or bit becomes jammed

or bogged down, turn the tool “OFF” by

the switch. Wait for all moving parts to

stop and unplug the tool, then work to

free the jammed material. If the switch to

the tool is left “ON” the tool could restart

unexpectedly causing serious personal

injury.

Do not leave a running tool unattended,

turn power off. Only when tool comes to a

complete stop it is safe to put it down.

Do not grind or sand near flammable

materials. Sparks from the wheel could

ignite these materials.

Do not touch the bit or collet after use.

After use the bit and collet are too hot to be

touched by bare hands.

Regularly clean the tool's air vents by

compressed air. Excessive accumulation

of powdered metal inside the motor housing

may cause electrical failures.

Do not allow familiarity gained from

frequent use of your rotary tool to

become commonplace. Always remember

that a careless fraction of a second is

sufficient to inflict severe injury.

Do not alter or misuse tool. Any alteration

or modification is a misuse and may result

in serious personal injury.

This product is not intended for use as a

dental drill, in human or veterinary

medical applications. Serious personal

injury may result.

Page 6

When using the steel saws, cutoff

wheels, high speed cutters or tungsten

carbide cutters, always have the work

securely clamped. Never attempt to hold

the work with one hand while using any

of these accessories. The reason is that

these wheels will grab if they become

slightly canted in the groove, and can kick

back causing loss of control resulting in

serious injury. Your second hand should be

used to steady and guide the hand holding

the tool. When a cutoff wheel grabs, the

wheel itself usually breaks. When the steel

saw, high speed cutters or tungsten carbide

cutter grab, it may jump from the groove

and you could lose control of the tool.

A WARNING

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are;

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicais: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

Some dust created by

power sanding, sawing,

Page 7

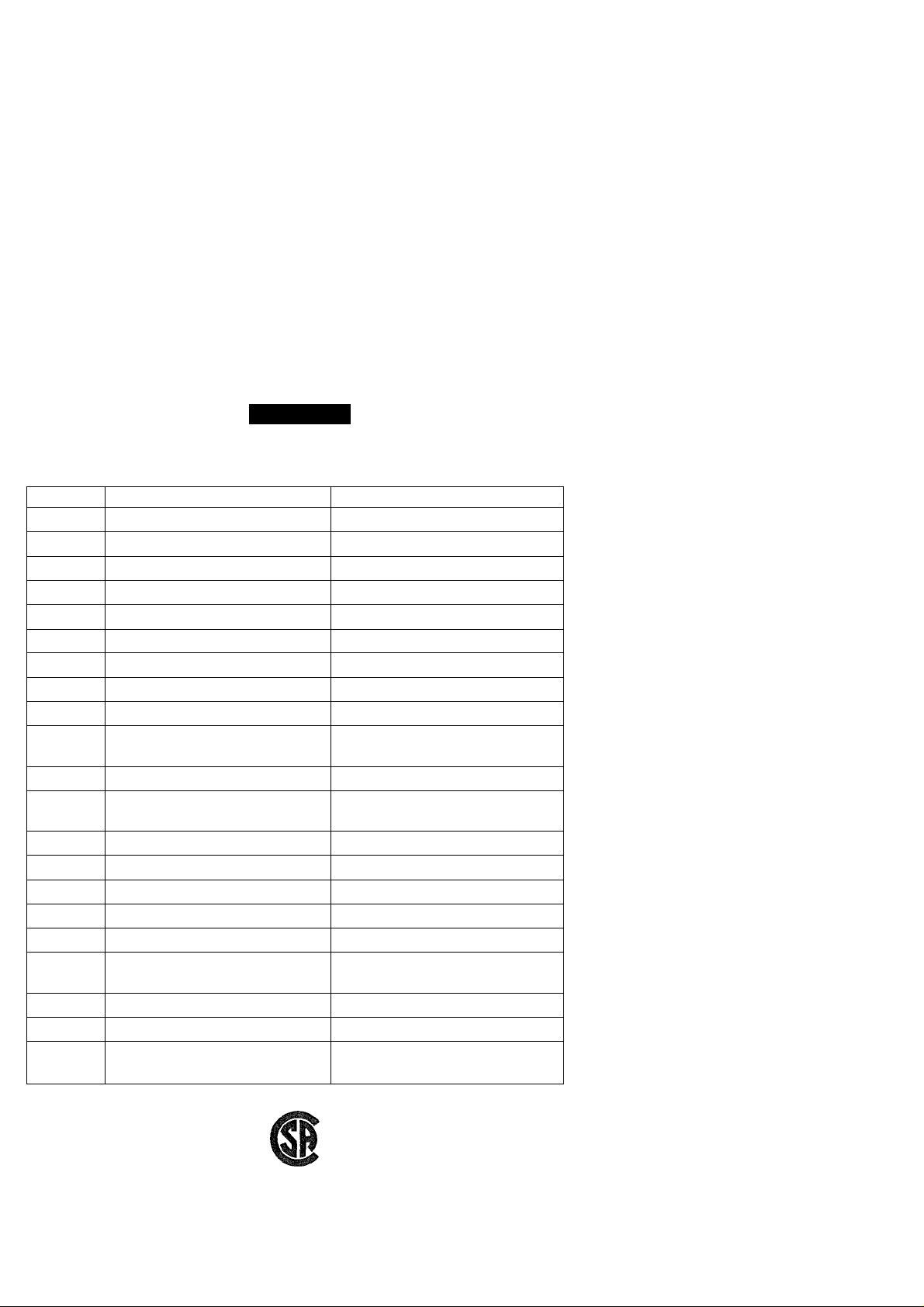

SYMBOLS

IMPORTANT; Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer. '

0

Name

Hertz

Watt

Kilograms Weight

Minutes Time

Seconds

Diameter

No load speed

Off position

Selector settings

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow

Alternating current

=

Direct current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double insulated

Earthing terminal Grounding terminal

©

Warning symbol

A

Ni-Cad RBRC™ seal Designates Ni-Cad battery recycling

Designatlon/Explanation

Voltage (potential)

Frequency (cycles per second)

Power

Time

Size of drill bits, grinding wheels, etc.

Rotational speed, at no load

orbits etc. per minute

Zero speed, zero torque... ,

Speed, torque or position settings.

Higher number means greater speed

Action in the direction of an'ow

Type or a characteristic of current

Type or a characteristic of current

Construction tools.

Alerts user to warning messages

program

Symbol

V Volts

A Amperes Current

Hz

W

kg

i min

s

no

.../min Revolutions or reciprocation per minuteRevolutions, strokes, surface speed,

0

1,2,3....

I, II, III,

-►

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symboi designates

that this tool is li,sted to

Canadian Standards by

Underwriters Laboratories.

Page 8

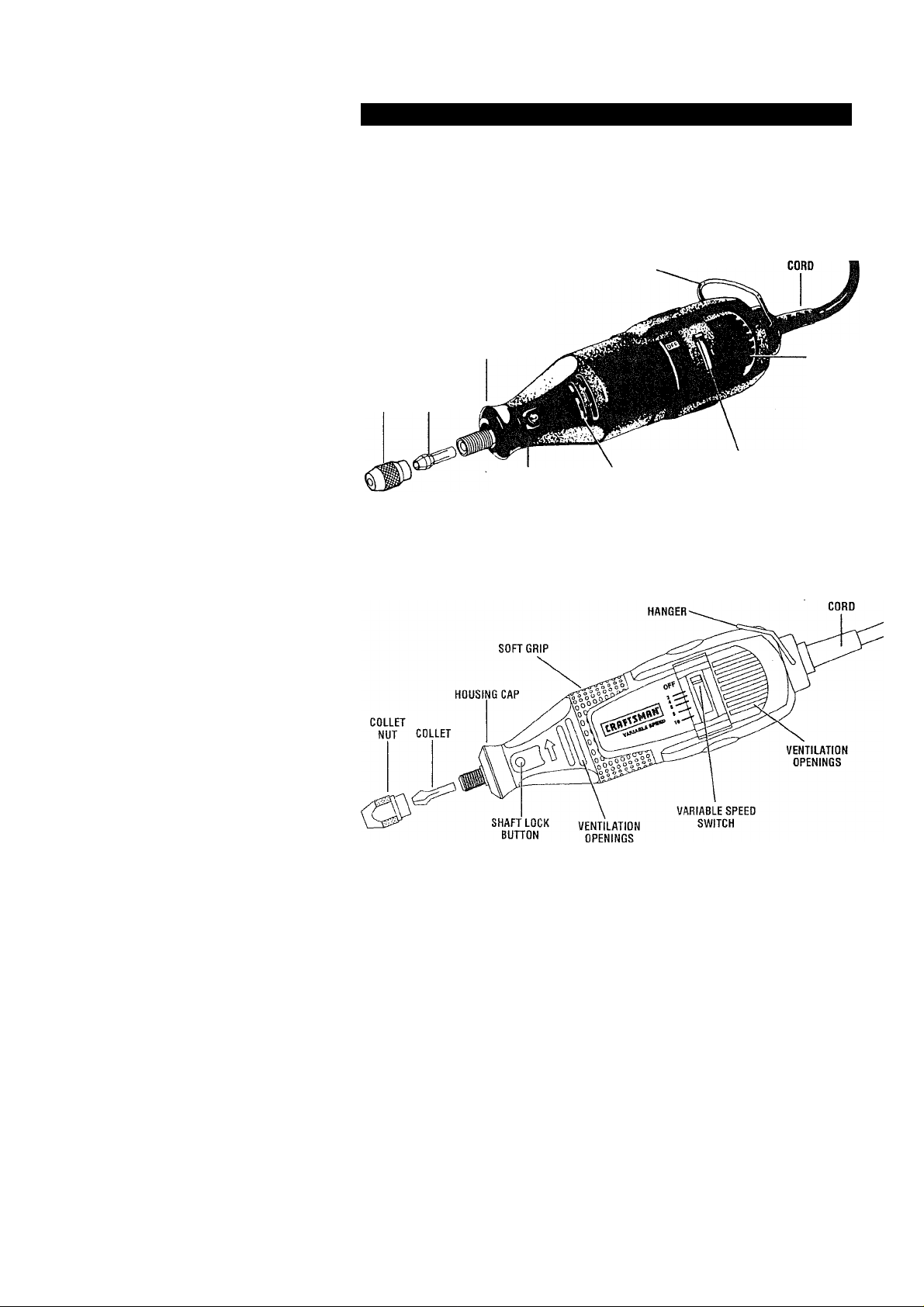

FUNCTIONAL DESCRIPTION AND SPECIFICATIONS

A WARNING

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive

safety measures reduce the risk of starting the tool accidentally.

Rotary Tool 610830 & 610960

HANGER-

HOUSING CAP

COLLET

NUT COLLET

SWITCH

SHAFT LOCK

BUnON

VENTILATION

OPENINGS

(610830 SINGLE SPEED)

(610060 TWO SPEED)

Rotary Tool 610950

VENTILATION

OPENINGS

NOTE; For tool specifications refer to the nameplate on your tool.

Page 9

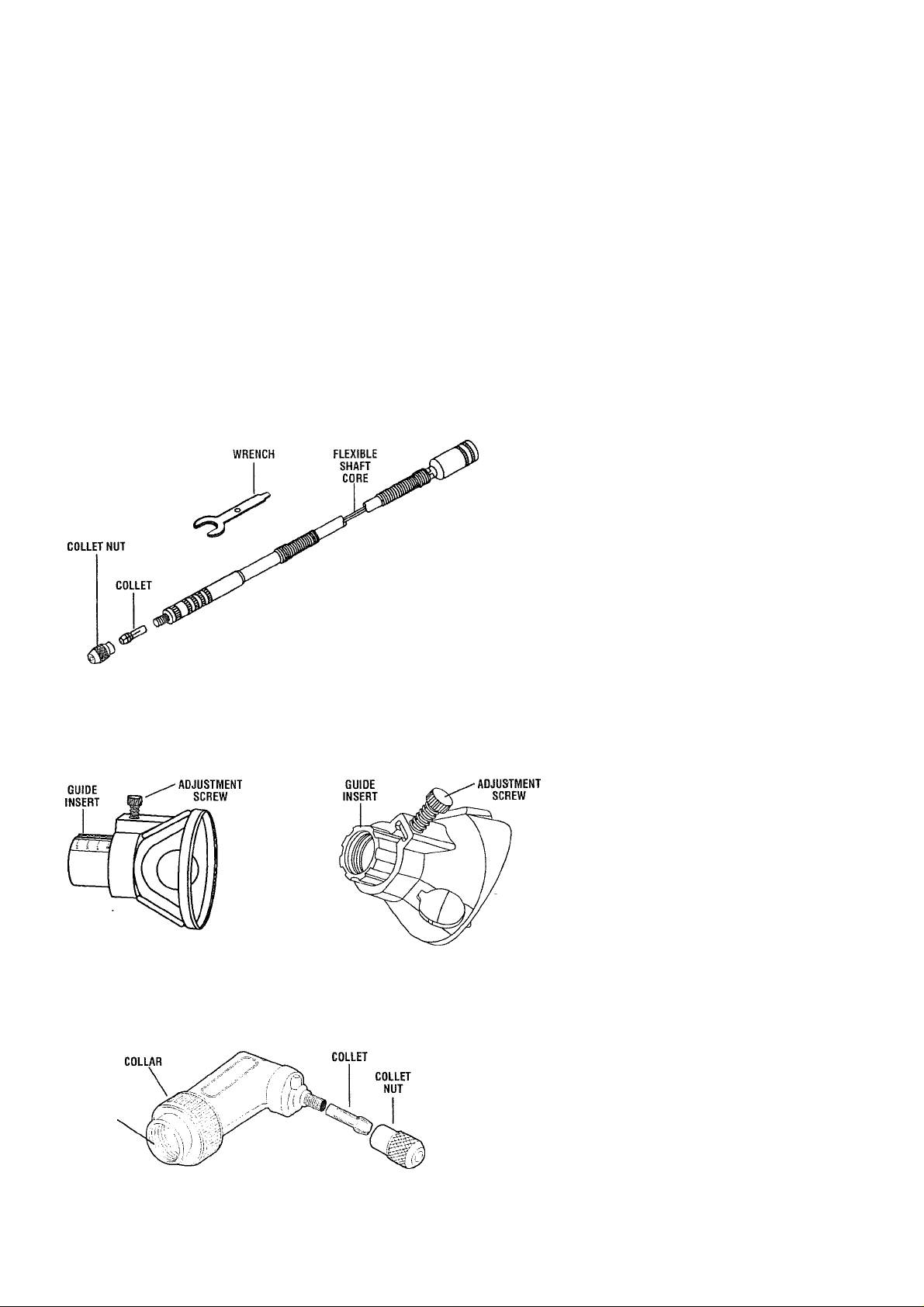

Flex-Shaft 53033

DRIVER

CAP

Cutting Guide 53141

DEPTH

Right Angie Attachment 53002

ADAPTER

Grout Removal Kit 53052

DEPTH

Page 10

ASSEMBLY

A WARNING

Always unplug rotary tool

before changing acces

sories, changing collets or servicing your

rotary tool.

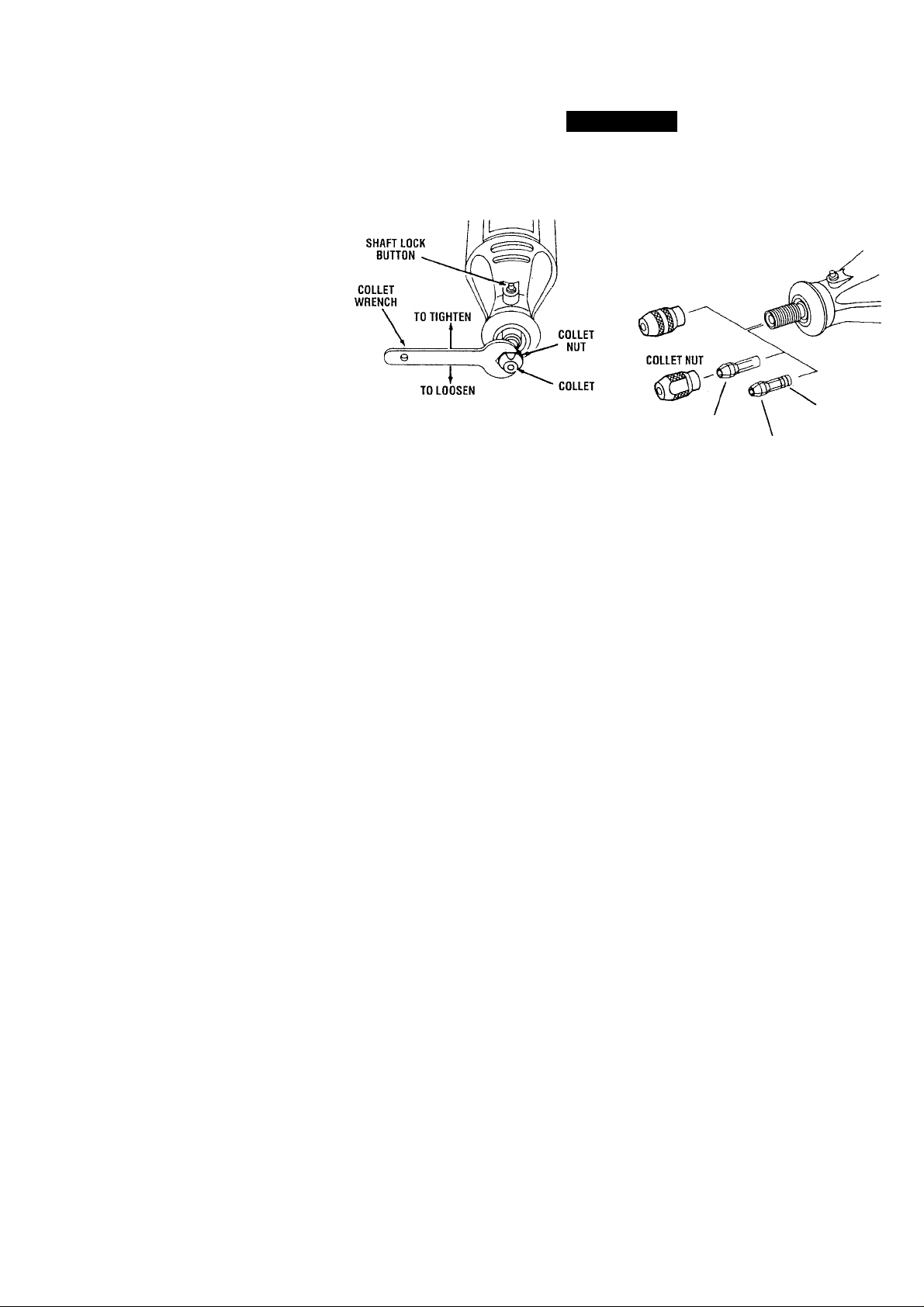

COLLET — To loosen, first press shaft lock

button and rotate the shaft by hand until the

lock engages the shaft preventing further

rotation.

A CAUTION

Do not engage lock while

the Rotary Tool is running.

With the shaft lock engaged use the collet

wrench to loosen the collet nut if necessary.

Change accessories by inserting the new

one into the collet as far as possible to

minimize runout and unbalance. With the

shaft lock engaged, finger tighten the collet

nut until the accessory shank is gripped by

the collet Avoid excessive tightening of the

collet nut. The collet system is a superior

method of securing accessories.

COLLETS — Two different size coilets (see

illustration), to accommodate different shank

sizes, are available for your Rotary Tool. To

install a different collet, remove the collet nut

and remove the old collet. Insert the

unslotted end of the collet in the hole in the

end of the tool shaft. Replace collet nut on

the shaft. Always use the collet which

matches the shank size of the accessory

you plan to use. Never force a larger

diameter shank into a collet.

BALANCING ACCESSORIES - For

precision work, it is important that all

accessories be in good balance (much the

same as the tires on your automobile). To

true up or balance an accessory, slightly

loosen collet nut and give the accessory Or

COLLET IDENTIFICATION CHART — Collet sizes can

be identified by the rings on the back end of collet.

1/32" Collet has one (1)ring.

1/16" Collet has two (2) rings.

3/32" Collet has three (3) rings.

1/8 " Collet has no rings.

KEYLESS CHUCK

IDENTIFICATION

1/8“ COLLET

3/32" COLLET

RINGS

collet a 1/4 turn. Retighten collet nut and run

the Rotary Tool. You should be able to tell

by the sound and feel if your accessory is

running in balance. Continue adjusting in this

fashion until best balance is achieved. To

maintain balance on abrasive wheel points,

before each use, with the wheel point

secured in the collet, turn on the Rotary Tool

and run the Dressing Stone lightly against

the revolving wheel point. This removes high

spots and trues up the wheel point for good

balance.

The hanger is provided for the use of

hanging your tool while using the flex-shaft

or for storage. If you do not use the hanger,

remove it from the tool and snap it back into

place underneath the cord so it will be out of

the way while the tool is in use.

Remember, your new Craftsman Rotary Tool

is the finest power tool of its kind. But its

performance is only as good as the

accessories with which it is used.

We recommend only Craftsman

accessories be used. Use of any other

accessories may create a hazard. We hope

you’ll enjoy many years of trouble free

pleasure from your Sears Craftsman Rotary

Power Tool.

10

Page 11

KEYLESS CHUCK - The keyless chuck

holds various accessories with shank sizes

1/32" to 1/8" and is intended for light duty

accessories such as drill bits, sanding

drums,

bristle brushes and cut-off wheels. The

keyless chuck allows you to change

accessories frequently, quickly and easily.

There are some applications which can

generate high forces on the bit or If you are

unable to generate finger tightening pressure

sufficient to secure the bit you must use the

supplied wrench to assist in securing the bit.

Attaching the Keyless Chuck and

Accessory Bit

keyless chuck with the tool. Insert and

securely tighten the shank of the

accessory well within the jaws of the

chuck. If an accessory is not properly

gripped within the jaws of a chuck it may

loosen and fly out during use possibly

striking you or bystanders.

To replace or attach the keyless chuck

accessory to your MultiPro rotary tool,

unplug the tool and engage the shaft lock

button then remove the collet and collet nut.

Thread the keyless chuck on the end of the

shaft. Engage the shaft lock button again.

polishing accessories, wire and

ik WARNING

Read and understand the

manual for use of the

insert the accessory shank into the chuck

and finger tighten until the shank is secure.

For small size drill bits, close the chuck to

the point where the bit will just fit in; then

tighten securely. This helps center the bit in

the keyless chuck correctly. In some high

force applications such as removing metal,

tile cutting or routing, the bit (tungsten

carbide cutters, high speed cutters, router

bits or tile cutters) and chuck will become

hot if overloaded for extended periods of

time. Overloading the chuck may cause the

bit to loosen and slip. It is recommended

that in these types of applications that the

bit be secured in the chuck with the supplied

wrench and work in intervals to allow cooling

of the bit and chuck. If the bit slips the tool

will begin to vibrate excessively, this is an

indication that you should shut the tool off,

re-position and tighten the bit then allow the

tool to run no-load for a few minutes to cool.

The chuck should be cleaned occasionally to

keep it functioning properly. Simply remove

the chuck from the tool and gently tap the

tip of the chuck on a fat surface to remove

any loose debris, in some applications the

keyless chuck may tighten up during use. If

this occurs, gently loosen using the wrench

included in your rotary tool kit.

11

Page 12

OPERATING INSTRUCTIONS

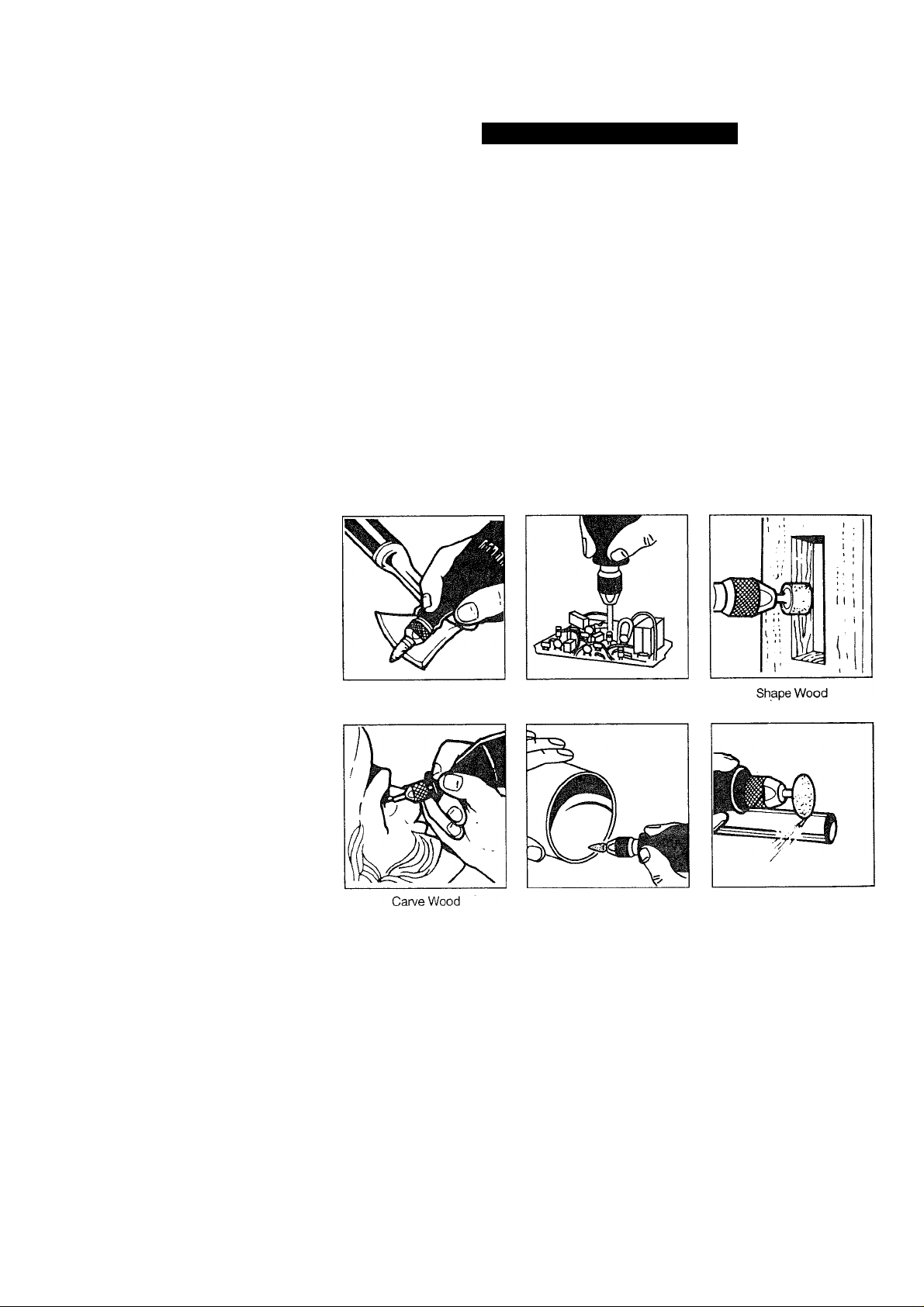

The Rotary Tool is a handful of high-speed

power. It serves as a carver, grinder,

polisher, Sander, cutter, power brush, drill

and more.

The Rotary Tool has a small, powerful

electric motor, is comfortable in the hand,

and is made to accept a large variety of

accessories including abrasive wheels, drill

bits, wire brushes, polishers, engraving

cutters, router bits, and cutting wheels.

Accessories come in a variety of shapes and

permit you to do a number of different jobs.

As you become familiar with the range of

accessories and their uses, you will learn just

how versatile the Rotary Tool is. You'll see

dozens of uses you hadn’t thought of before.

The real secret of the Rotary Tool is its

speed. To understand the advantages of its

high speed, you have to know that the

standard portable electric drill runs at

speeds up to 2,800 revolutions per minute.

The Rotary Tool operates at speeds up to .

35,000 revolutions per minute. The typical

electric drill is a low-speed, high torque tool;

the Rotary Tool is just the opposite - a high

speed, low torque tool. The chief difference

to the user is that in the high speed tools,

the speed combined with the accessory

mounted in the collet does the work. You

don’t apply pressure to the tool, but simply

hold and guide it. In the low speed tools, you

not only guide the tool, but also apply

pressure to it, as you do, for example, when

drilling a hole.

It is this high speed, along with its compact

size and wide variety of special accessories,

that makes the Rotary Tool different from

other power tools. The speed enables it to

do jobs low speed tools cannot do, such as

cutting hardened steel, engraving glass, etc.

Getting the most out of your Rotary Tooi is a

matter of learning how to let this speed work

for you.

Sharpen Tools

Precise Drilling

Deburr Metal

12

Cut Metal

Page 13

USING THE ROTARY POWER TOOL

The first step in learning to use the Rotary

Tool is to get the “feel” of it. Hold it in your

hand and feel its weight and balance. Feel

the taper of the housing. This taper permits

the Rotary Tool to be grasped much like a

pen or pencil. The Variable Speed tool has a

unique comfort grip on the nose and back

seating, which allows the user added

comfort and control during use. You can feel

the difference!

When you turn on the tool for the first time,

hold it away from your face. Accessories can

be damaged during handling, and can fly

apart as they come up to speed. This is not

common, but it may happen.

Practice on scrap materials first to see how

the Rotary Tooi cuts. Keep in mind that the

work is done by the speed of the tool and by

the accessory in the collet. You should not

‘ lean on or push the tool into the work.

Instead, lower the spinning accessory lightly

to the work and allow it to touch the point at

which you want cutting (or sanding or

etching, etc.) to begin. Concentrate on

guiding the tool over the work using veiy

little pressure from your hand. Allow the

accessory to do the work. •

Usually, it is best to make a series of passes

with the tooi rather than attempt to do all the

work in one pass. To make a cut, for

example, pass the tool back and forth over

the work, much as you would a small paint

brush. Cut a little material on each pass until

you reach the desired depth. For most work,

the gentle touch is best. With it, you have

the best control, are less likely to make

errors, and will get the most efficient work

out of the accessory.

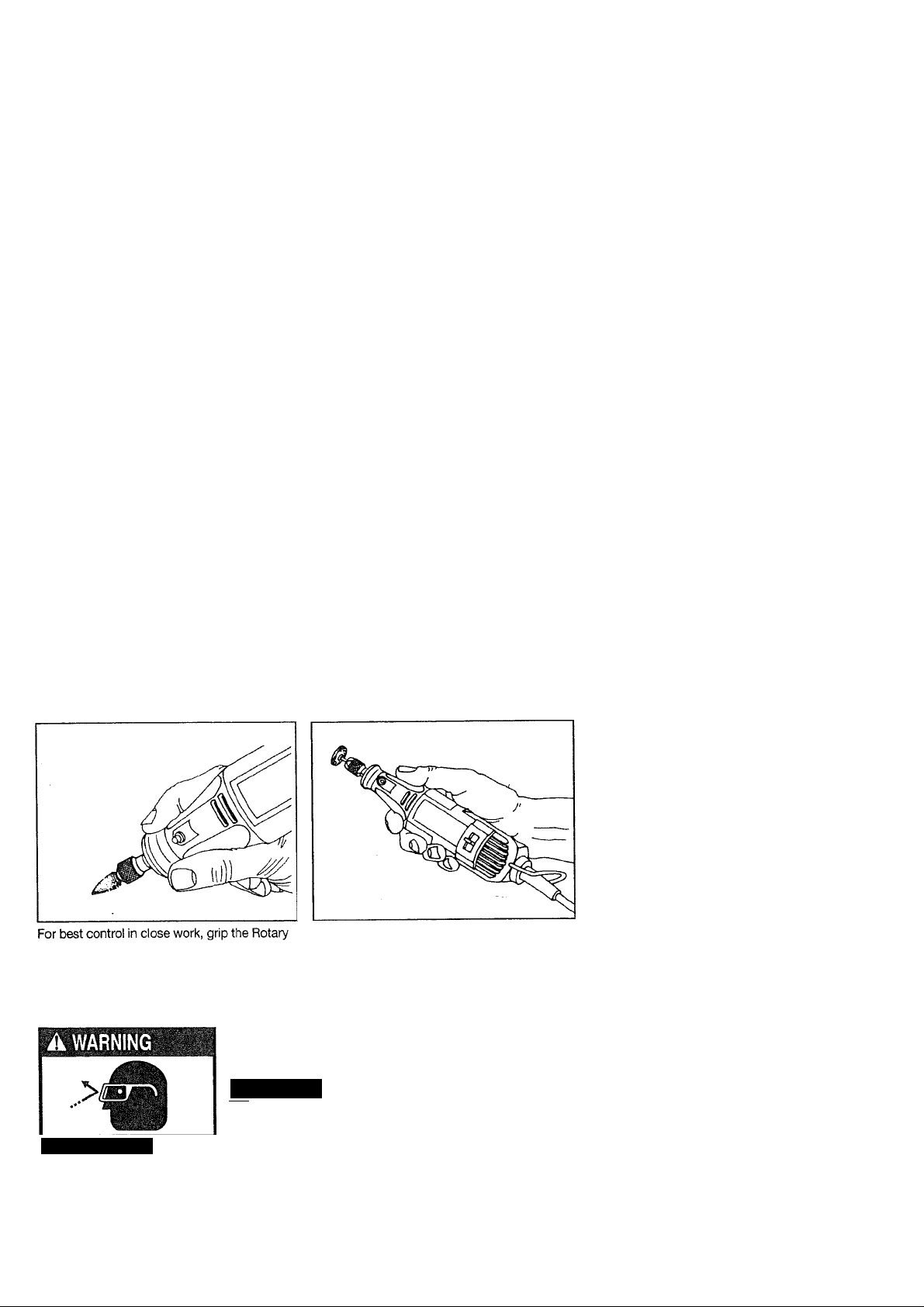

Tool like a pencil between your thumb and

forefinger.

A CAUTION

—..

.................

This blocks the air flow and causes the motor to overheat.

Wear Eye Protection

The “handgrip” method of holding the tool is

used for operations such as grinding a flat

surface or using cutoff wheels.

Whenever you hold the tool, be careful

not to cover the air vents with your hand.

13

Page 14

OPERATING SPEEDS

Set the speed indicator to fit the job; to achieve

the best job results when working with different

materials, the speed of the Rotary Tool should

be regulated.

A CAUTION

Models 610960 & 610950

Rotary Tools have an

integral speed control and an external

speed control should never be used with

these tools.

To select the right speed for each job, use a

practice piece of material. Vary speed to find

the best speed for the accessory you are using

and the job to be done.

NOTE: Speed is affected by voltage

changes. A reduced incoming voltage will

Slow speeds (15,000 RPM or less) usually are

best for polishing operations employing the felt

polishing accessories. They may also be best

for working on delicate projects as “eggery”

work, delicate wood carding and fragile model

parts. All brushing applications require lower

speeds to avoid wire discharge from the

holder.

Higher speeds are better for carving, cutting,

routing, shaping, cutting dadoes or rabbets in

wood.

Hardwoods, metals and glass require high

speed operation, and drilling should also be

done at high speeds.

The speed of the Rotary Tool is controlled

by setting this indicator on the housing.

slow the RPM of the tool, especially at the

lowest setting. If your tool appears to be

running slowly increase the speed setting

accordingly.

There are three basic types of Rotary Tools:

single speed, two-speed and variable speed

models.

• Single speed has one ON-OFF switch.

When the switch is on, the tool runs at

35,000 RPM.

• On the two-speed-model, there is a LO and

HI switch. When the switch indicator is on

the low setting, the tool runs at about 15,000

RPM. When the switch indicator is on the

high setting, the tool runs at about 35,000

RPM.

• On the variable speed model, there are

switch setting indicators marked with a

line. Slide to the number on the housing to

select the operating speed needed from

5,000-35,000 RPM.

You can refer to the charts on pages 26 & 27

to determine the proper speea, based on the

material being worked and the type o* cvstter o:

other accessory being used. These charts

enable you to select both the correct acces

sory and the optimum speed at

a glance,

if you have a single-speed or two-speed

model, you will be able to use many

accessories to do a wide assortment of jobs.

For the majority of applications, all models of

the Rotary Tool should be used at top speed.

NEEDS FOR SLOWER SPEEDS

Certain materials, however, (some plastics, for

example) require a relatively slow speed

because at high speed the friction of the

accessory generates heat and causes the '

plastic to melt.

The Settings for Approximate Revolutions

Per Minute Rotary Tool Variable Speed

Model 610950.

Switch Setting Speed Range

2

*4

g

s

1

'Model 6109b0 W:r-: Br

5,000- 8,000 RPM

9,000-11,000 RPM

12.000-17,000 RPM

18,000-24,000 RPM

25,000-35,000 RPM

sitina.

The point to re.member rs this: You can do the

great majority of work with the single speed at

its regular speed of 35.000 RPM. But for

certain materials and types of work, you need

slower speeds — which is the reason the

variable speed models were developed.

To aid you in determining the optimum

operational speed for different materials and

different accessories, we have constructed a

table that appears on pages 26 & 27. By

referring to this table, you can determine the

recommended speeds for each type of

Page 15

accessory. Look this table over and become

familiar with it.

Ultimately, the best way to determine the

correct speed for work on any material is to

practice for a few minutes on a piece of

scrap, even after referring to the chart. You

can quickly learn that a slower or faster

speed is more effective just by observing

what happens as you make a pass or two at

different speeds. When working with plastic,

for example, start at a slow rate of speed

and increase the speed until you observe

that the plastic is melting at the point of

contact. Then reduce the speed slightly to

get the optimum working speed.

Some rules of thumb in regard to speed:

1. Plastic and materials that melt at low

i temperatures should be cut at low

, speeds.

2. Polishing, buffing and cleaning with a wire

brush must be done at speeds not greater

than 15,000 RPM to prevent damage to

the brush.

3. Wood should be cut at high speed.

4. Iron or steel should be cut at high speed if

using tungsten carbide accessory, but at

slower speeds if using high speed steel

cutters. If a high speed steel cutter starts

to chatter — this normally means it is

running too slow.

5. Aluminum, copper alloys, lead alloys, zinc

alloys and tin may be cut at various

speeds, depending on the type of cutting

being done. Use paraffin or other suitable

lubricant on the cutter to prevent the cut

material from adhering to the cutter teeth.

Increasing the pressure on the tool is not the

answer when it is not cutting as you think it

should. Perhaps you should be using a

different cutter, and perhaps an adjustment

in speed would solve the problem. Leaning

on the tool does not help. The correct speed

will make using the rotary tool effortless.

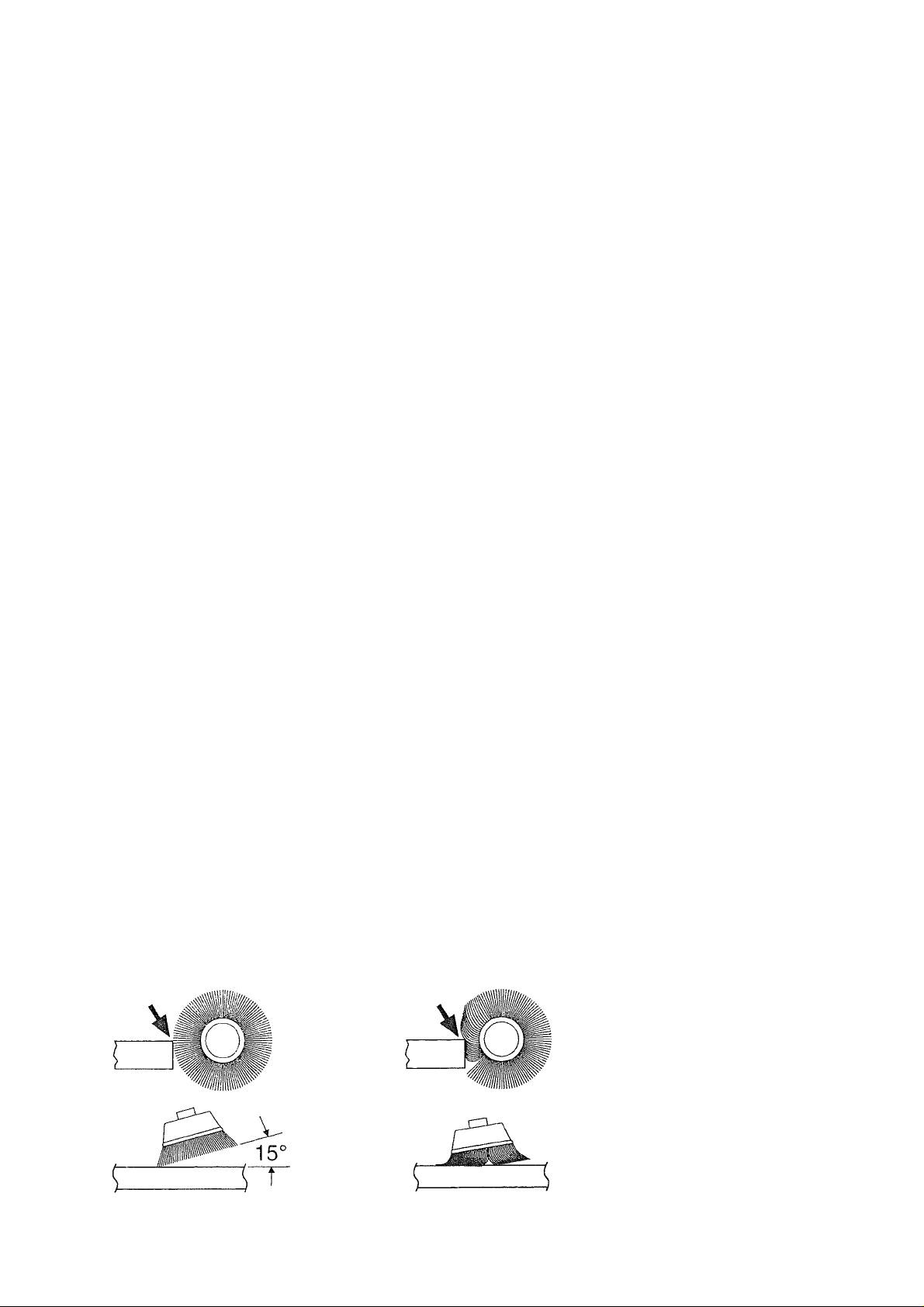

BRUSHING PRESSURE

1. Remember, the tips of a wire brush do the

work. Operate the brush with the lighte.st

pressure so only the tips of the wire come in

contact with the work.

2. If heavier pressures are used, the wires

will be overstressed, resulting in a wiping

action; and if this is continued, the life of the

CORRECT:

Wire tips

doing the

work.

15

brush will be shortened due to wire fatigue.

3. Apply the brush to the work in such a way

that as much of the brush face as possible is

in full contact with the work. Applying the

side or edge of the brush to the work will

result in wire breakage and shortened brush

life.

INCORRECT;

Excessive

pressure can

cause wire

breakage.

Page 16

ASSEMBLY & OPERATION OF ATTACHMENTS

AWARNING

will cause kickback.

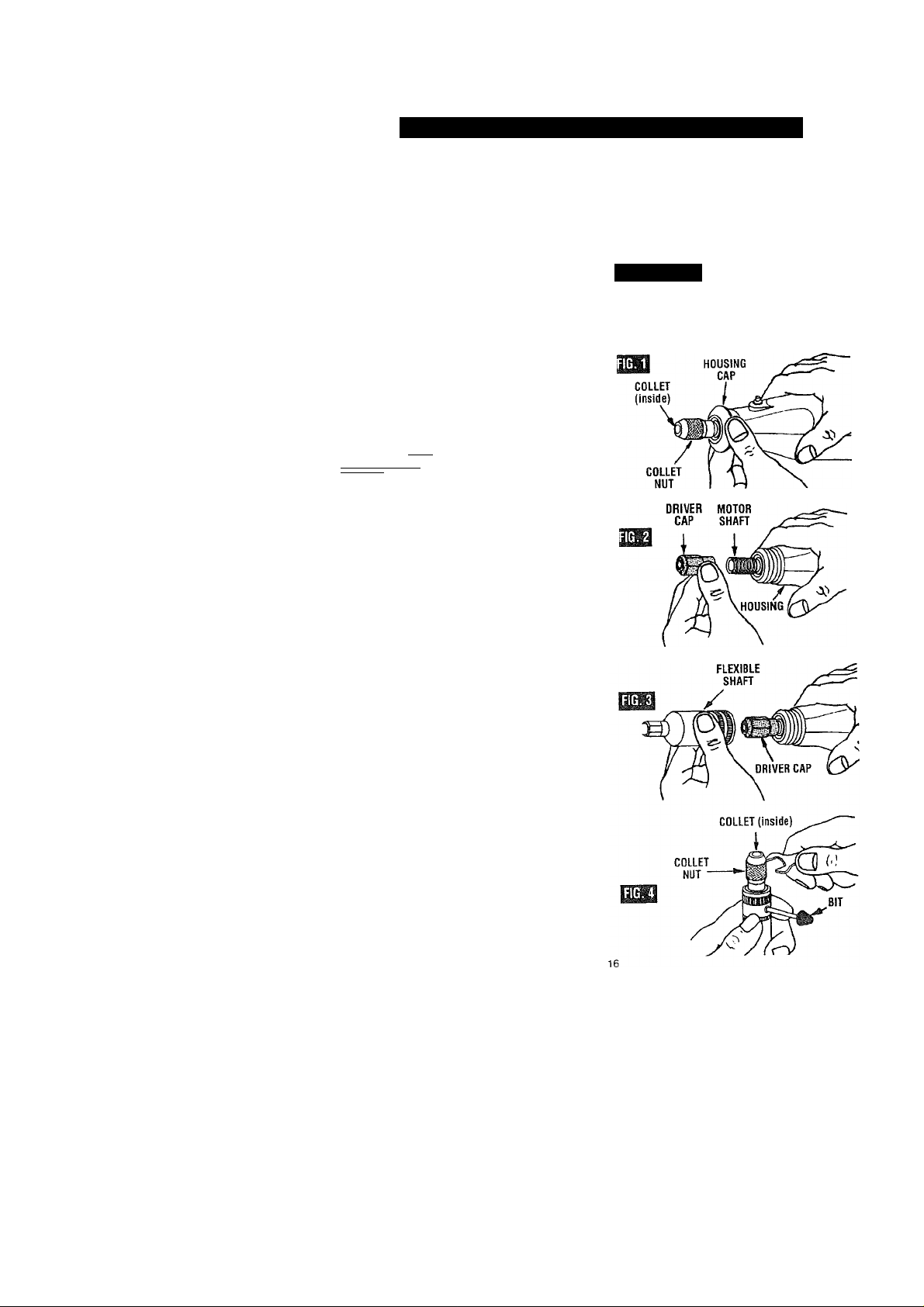

1, To attach the 53033 flex-shaft {sold

separately) to the Rotary Tool remove the

housing cap from the tool as shown in

Figure 1. Then press the shaft lock and

unscrew the collet nut and remove the

collet. Install the driver cap on the motor

shaft as shown in Figure 2 and tighten.

A CAUTION

driver cap. Tighten the driver cap finger

tight and then tighten an additional 1/3 turn

with the wrench. (Wrench included with your

Rotary Tool kit).

2. Screw the flexible shaft onto the Rotary

Tool housing being sure that the square

end of the center core engages the square

hole socket in the driver cap Figure 3.

■WMWItPjWM Do not pull out center

EjaflUliMkW core to engage into driver

cap. This could cause disengagement of

center core from handpiece. If tool stops

when shaft is bent, center core may be

lodged in driver cap. Loosen shaft and

remove core from driver cap. Then screw

flexible shaft onto rotary tool housing again.

Flex-Shaft Collet Assembly

The collet assembly consists of a collet nut

and collet. To change bits use the wrench

and a bit. Insert the shank portion of any bit

(1/8" shank recommended) through the

opening in the flex-shaft hand piece to lock

the shaft. With the shaft secured, use the

wrench to loosen or tighten the collet nut as

shown in Figure 4. With the collet nut loose,

insert an accessory or bit as deeply as

possible to avoid wobble during use.

Retighten the collet nut.

Collet Removal and Replacement

Four different size collets to accommodate

different shank sizes, are available for your

flex-shaft. To install a different collet, remove

the collet nut and remove the old collet.

Insert the unslotted end of the collet in the

hole in the end of the flex-shaft. Replace

collet nut on the shaft. Always use the

collet which matches the shank size of

the accessory you plan to use.

Never force a larger diameter shank into a

collet. -

Available Collets .

No. 53065 Collet Nut Kit -Includes one

1/8", 1/16", 1/32" & 3/32" collets and collet

nut.

Not for use with router

bits. Use with router bits

To prevent damage to

tool, do not overtighten

Flexible Shaft Lubrication

The flexible shaft should be lubricated after

every 25-30 hours of use. To lubricate,

unscrew the flexible shaft assembly from the

motor housing. Pull the center core out of

the flexible shaft assembly. Wipe a very thin

film of a good quality, high temperature

grease on to the center core.

A CAUTION

shaft. Too much grease will cause the unit

to overheat. Automotive wheel bearing

grease should be used.

Reattach the flex-shaft to the rotary tool.

To prevent damage to

tool do not over grease

Page 17

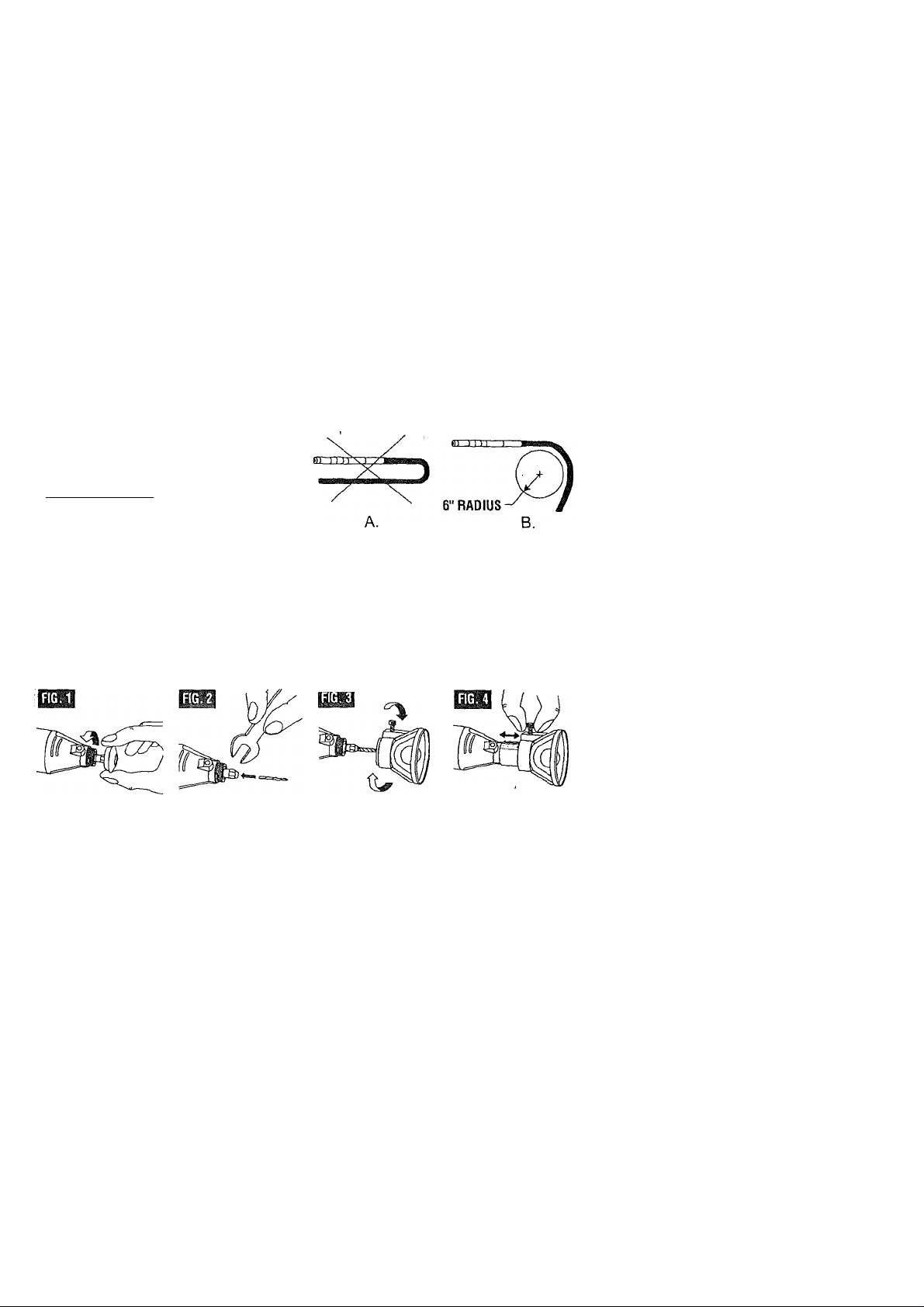

A WARNING

bend (A). This can generate excessive heat

and will reduce tool and flex-shaft life. The

recommended minimum is 6" radius (B).

Contents of 53033 Flex-shaft Attachment

Qtv. Description

1 Flex-Shaft Assembly (42" long)

1 Driver Cap

Do not operate the

flexible shaft with a sharp

Cutting Guide 53141

The cutting guide (sold separately) comes

completely assembled and ready to use. For

use in a variety of materials up to 3/4" thick.

Match the bit type to the material to be cut.

Always hold the tool firmly, using slow

53134

Drywall Cutting Bit

For use in drywall.

• When inserting the 53134 bit into your

Craftsman Rotary tool, make sure that the

bit has been inserted as far as possible.

• When making freehand cuts in drywall, ex., repairing a hole in drywall. When using

a template (outlet box) behind the drywall,

use the Drywall Cutting Bit 53134, cutting

in a counter-clockwise direction.

53135

Multipurpose Cutting Bit

For use in wood, plastics, drywaii,

fiberglass, vinyl or aluminum siding,

acoustical tile and laminates.

• When inserting the 53135 bit into your

Craftsman Rotary tool, make sure that the

bit has been inserted as far as possible.

• When making freehand cuts in use the

Multipurpose Cutting Bit 53135, cutting in a

clockwise direction.

c

T3

steady pressure to make cuts.

To attach, follow the four steps shown below.

Important: Always cut in a clockwise

direction, except when following a

template (outlet box), then cut in a

counterclockwise direction.

' When using 53135, Multipurpose Cutting

Bit, start the bit into the material at a 45

degree angle and then slowly bring it to a

90 degree angle to begin the cut.

53136

Tile Cutting Bit (Not Included)

For use on wall tile, cement board and

plaster

• When inserting the 53136 bit into your

Craftsman Rotary tool, it is very important

that 1/16”-1/8” of smooth shank remains

visible above the collet.

• When using 53136, Tile Cutting Bit, start

the bit into the material at a 45 degree

angle and then slowly bring it to a 90

degree angle to begin the cut.

• NOT FOR USE ON FLOOR TILE

17

Page 18

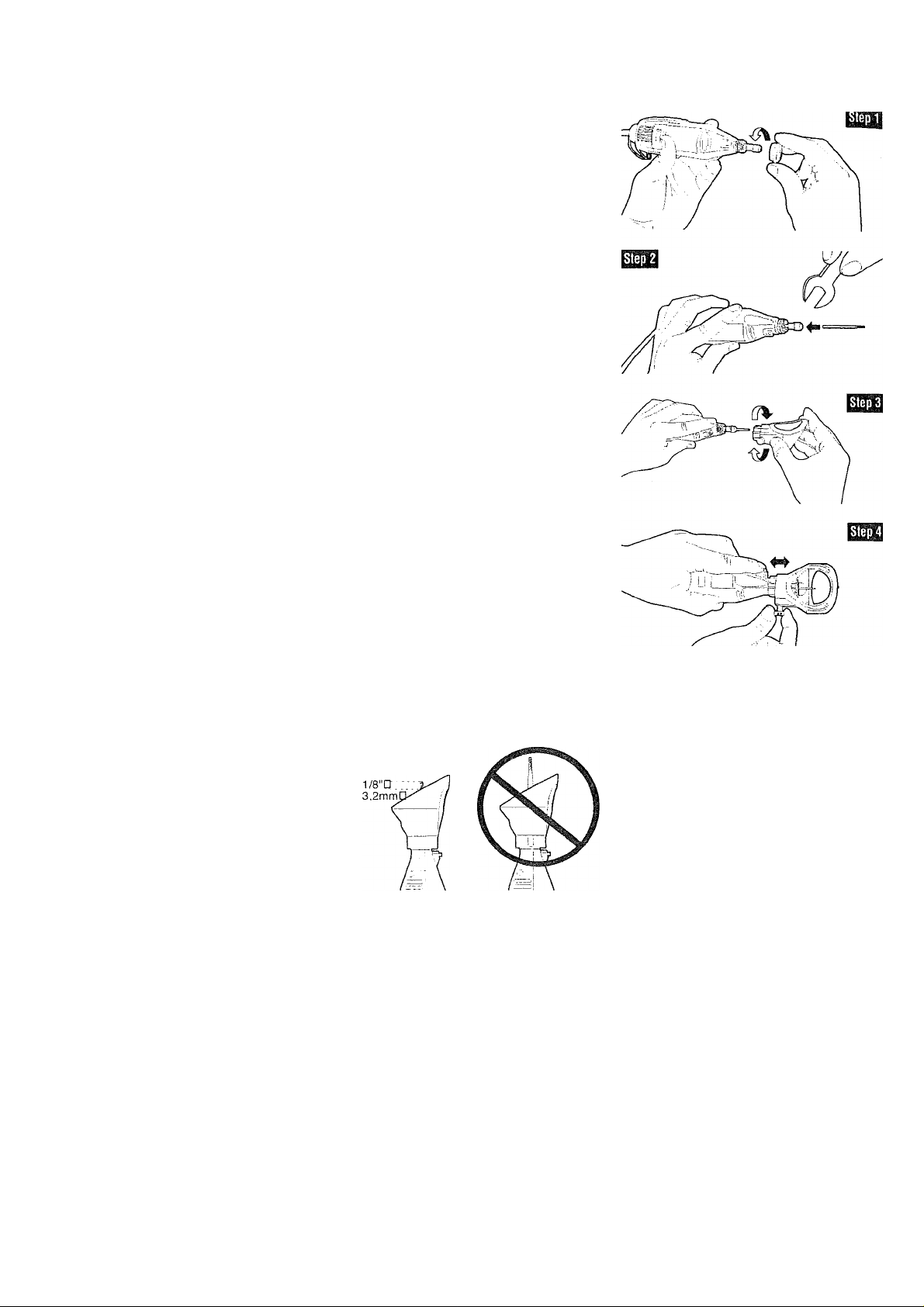

Grout Removal Kit 53052

The grout removal attachment comes completely

assembled and ready to use. Use the 1/16" bit that

comes with the grout removal kit for tiles spaced

more than 1/16" apart. If your tiles are spaced more

than 1/8" apart, it is recommended that you use the

53166 (1/8") bit (sold separately).

Note;

If the bit is too wide for the spacing between

your tiles, you may damage your tile or the grout

removal bit.

Step 1:

Remove the housing cap from the tool.

Step

2: Insert the grout removal bit into your rotary

tool.

A CAUTION

power tool, be sure that the bit is secure witbin tbe

“jaws" of the collet.

collet nut to prevent the bit from loosening within the

collet. Do not use your Craftsman Chuck, #53050,

with the grout removal bits.

Step 3:

Screw the grout removal attachment onto the

rotary tool.

Step 4:

Adjust the attachment and bit to the desired

cutting depth.

Grout Removal Attachment Cutting Depth

Adjustment

The Multi Slide Depth Adjustment has increment

markings of 1/8" (3,2 mm). These markings are for

reference only in identifying the depth of your desired

cut. The multiple channels of the depth adjustment let

you choose the orientation of the attachment to the

tool. Be sure to securely tighten the screw within one

of the multiple channel positions.

To set cutting depth:

Cleaning Grout:

Do not remove grout more than 1,''8“ below the face

surface of the tile. Adjust the Multi Slide Depth

Adjustment and bit so that no more than 1/8" of the

bit extends beyond the base of the attachment.

After removing 1,'8" of grout, regrout to tile level. Seal

the new grout. '

When inserting the #53166 grout

removai bit Into your rotary

Use the wrench to tighten the

Removing Grout to Replace A Broken Tile:

Remove all of the grout surrounding the broken tile.

Adjust the Multi Slide Depth Adjustment so that no

more than

the attachment. Remove grout at a depth no more

than 1,'8" at a time. You may need to adjust the Multi

Slide Depth Adjustment by 1/8" increments (reference

the 1/8" incremental white markings on the Multi Slide

Depth Adjustment) and make several passes until all

the grout is removed.

When removing grout deeper into the grout line, you

may strike hidden objects like screw heads, mortar,

tile cement or nails that may cause the bit to bind,

overheat or break. Reduce the tool speed and work

through it slowly, making several passes. In case of

screws or nails, remove the grout around the area as

the bit will not cut through them.

1/8"

of the bit extends beyond the base

of

Page 19

Operating Instructions

Awarning

may cause it to break.

with the tool positioned below the attachment and the

bit pointing upwards.

On your variable speed tool, recommended tool speed

is 15.000-20,000 RPM's or speed setting 6 to avoid

damage to the bit. On your two speed tool,

recommended tool speed is "Low" to avoid damage to

the bit. Do not force the bit or put pressure on the

back of the tool to remove the grout. Let the speed of

the rotating bit do the work.

Always pull the tool toward you!

Do

not push it! Pushing the bit

Hold the too! In a go!! grip

Grout Removal Safety Warnings

Wear

eye protection and dust mask. Inspect bit for

damage. When bit is installed, always run it at no-load

speed of the tool for one minute, as a damaged bit

will break apart. Do not stand in front of or in line

with bit.

Always use the tool with the depth guide positioned

flat against the material being cut.

The guide securely positioned on the material

improves stability and control of your tool.

The direction of feed with the bit info the grout is

important. Always drag or pull the bit through the

grout line. The grout bit is not intended for "plowing"

through the grout and feeding the tool in the wrong

direction will cause the bit to climb out of the work

possibly damaging the bit and/or causing loss of

control.

19

Page 20

Right Angle Attachment 53002

Before you begin, remove the black protective cap on

your attachment. If cap does not slide off easily, insert

the shank portion of any accessory through the

housing opening of the attachment to hold shaft from

rotating. Then twist off. Figure 1.

A CAUTION

accessories on the attachment. Internal damage to

the attachment may occur.

Remove the housing cap from your existing rotary

tool as shown in fig. 2. Then press the shaft lock

button on your rotary tool, unscrew the collet nut and

remove the collet.

Set your collet nut and collet aside it will be

reinstalled later in step 4.

install the drive adapter, inciuded with your right

angle attachment, on the motor shaft as shown in

fig.3 and tighten.

A CAUTION

finger tight and then tighten an additional 1/3 turn

with the wrench. {Wrench included with your rotary

tool kit) ■ .

Do not use the rotary tool shaft

lock button when changing

Do not overtighten drive

adapter.

Tighten the drive adapter

Screw the attachment onto your rotary tool. Hand

tighten only. Reassemble the collet and the collet nut

from step 2, on to the output shaft of the attachment.

Figure 4. '

The right angle attachment can be oriented on your

rotary tool in 12 different positions. The attachment

should be positioned so the on/off speed control

switch is easy to access.

To reposition, unscrew the collar from the attachment

until disengaged. Slide the attachment off. Then,

reposition, slide the attachment back on the tool and

retighten the collar. Figure 5.

To change an accessory, insert the shank portion of

any accessory {3,2 mm recommended) through the

housing opening of the attachment to hold the shaft

from rotating. With the shaft secured, loosen the

collet nut and insert an accessory as deeply as

possible to avoid wobble during use. You may need to

pull back the shank from the housing opening to

provide clearance while inserting the accessory.

Figure 6.

A WARNING

Attachment can become hot after prolong usage.

20

Page 21

MAINTENANCE

Ssrvice

A WARNING

personnel may result in misplacing of

internal wires and components which could

cause serious hazard. We recommend that all

tool service be performed by a Sears Service

Center.

CARBON BRUSHES

The brushes and commutator in your tool have

been engineered for many hours of dependable

service. To maintain peak efficiency of the

motor, we recommend every 50-60 hours the

brushes be examined. Only genuine Craftsman

replacement brushes specially designed for

your tool should be used.

i MAINTENANCE OF

REPLACEABLE BRUSHES

Models 610830,610960 & 610950.

The brushes should be inspected frequently

when tools are used continuously. If your tool

runs sporadically, loses power, makes unusual

noises or runs at a reduced speed, check the

brushes. To continue using the tool in this

condition will permanently damage your tool.

With the cord unplugged, remove the brush

caps one at a time with a small screwdriver by

rotating cap counterclockwise and check each

brush.

Preventive maintenance pe

rformed by unauthorized

If the brush is less than 1/8" long and the end

surface of the brush that contacts the _

commutator is rough and/or pitted, they should

be replaced. Check both brushes. Usually the

brushes will not wear out simultaneously. If one

brush is worn out, replace both brushes. Make

sure the brushes are installed as illustrated. The

curved surface of the brush must match the

curvature of the commutator.

After replacing brushes the tool should be run

at no-load; place on a clean surface and run

freely for 5 minutes before loading (or using) the

tool. This will allow the brushes to “seat"

properly and will give you more hours of life

from each set of brushes. This will also extend

the total life of your tool since the commutator

surface will “wear" longer.

BEARINGS

Rotary Tool Nos. 610830, 610960 & 610950 have

double ball bearing construction. Under normal

use neither type requires additional lubrication.

Cleaning

A WARNING

power supply before cleaning or performing

any maintenance. The tool may be cleaned

most effectively with compressed dry air.

Always wear safety goggles when cleaning

tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not at

tempt to clean by inserting pointed objects

through openings.

A CAUTION

parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that

contain ammonia.

To avoid accidents always

disconnect the topi from the

Certain cleaning agents and

solvents damage plastic

21

Page 22

A WARNING

tool must be used. This will prevent excessive voltage drop, loss of power or overheating.

Grounded tools must use 3-wire extension cords that have 3-prong plugs and receptacles.

If an extension cord is necessary, a cord with adequate size

conductors that is capable of carrying the current necessary for your

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

150

25 SO

18 16

18

18

16

14 12

1(H)

14

16

14 12 .75 1.0 2.5 4.0

16

16

16

12

14

14 12 1.0 2.5

—

—

Wire Sizes in mm^

15 30

60 120

.75 .75 1.5 2.5

—

2.5 4.0

—

4.0

—

—

.75 1.0

—

NOTE: The smaller the gauge number, the heavier the cord.

Extension Cords

22

Page 23

ACCESSORIES

A WARNING

property damage.

The number and variety of accessories for the

Rotary Tool are almost limitless. There is a

category suited to almost any job you might

have to do — and a variety of sizes and

shapes within each category which enables

you to get the perfect accessory for every

need.

Collets

If you expect to use a variety of accessories,

we recommend that in the beginning you

purchase a complete set of four collets. Store

these so that you will have the proper size of

collet for any accessory or drill bit you want to

use. Currently, the 1/8" and 3/32" collets

included with your tool accommodate all of

the available Craftsman accessories.

Mandrels

A mandrel is a shank with a threaded or screw

head, which are required when you use

polishing accessories, cutting wheels, sanding

discs, and polishing points. The reason

mandrels are used is that sanding discs,

cutting wheels and similar accessories must

be replaced frequently. The mandrel is a per

manent shank, allowing you to replace only

the worn head when necessary, thus saving

the expense of replacing the shaft.

Use only Craftsman Tested, High Performance Accessories. Other

accessories are not designed for this tool and may lead to personal injury or

High Speed Cutters

Available in many shapes, high speed cutters

are used in carving, cutting and slotting in

wood, plastics and soft metals such as

aluminum, copper and brass. These are the

accessories to use for freehand routing or

carving in wood or plastic, and for precision

cutting.

Tungsten Carbide Cutters

These are tough, long-lived cutters for use on

hardened steel, fired ceramics and other very

hard materials. They can be used for

engraving on tools and garden equipment.

Small Engraving Cutters

This group has a wide variety of sizes and

shapes, and are made for intricate work on

ceramics (greenware), wood carvings, jewelry

and scrimshaw. They often are used in

making complicated printed circuit boards.

They should not be used on steel and other

very hard materials but are excellent on wood,

plastic and soft metals. Needs 3/32" collet.

Screw Mandrel No. 53089

This is a screw mandrel used with the felt

polishing tip and felt polishing wheels.

Small Screw Mandrel No. 25028

This is a mandrel with a small screw at its tip,

and is used with emery cutting wheels,

sanding discs and polishing wheels.

23

Aluminum Oxide Grinding Stones

Round, pointed, flat — you name the shape

and there is one available in this category.

These are made of aluminum oxide and cover

virtually every possible kind of grinding

application. Use them for sharpening lawn

mower blades, screwdriver tips, knives,

scissors, chisels and other cutting tools. Use

to remove flash from metal castings,

deburring any metal after cutting, smoothing

welded joints, grinding off rivets and removing

rust. In machine shops, high speed drills and

cutters normally are ground with aluminum

oxide wheels.

Page 24

EZZZX3C:)

Silicon Carbide Grinding Stones

Tougher than aluminum oxide points, these

are made especially for use on hard materials

such as glass and ceramics. Typical uses

might be the removal of stilt marks and

excess glaze on ceramics and engraving on

glass.

Polishing Accessories

These include an impregnated polishing point

and an impregnated polishing wheel for

bringing metal surfaces to smooth finish; a felt

polishing tip and felt polishing wheel, and

cloth polishing wheel, all used for polishing

plastics, metals, jewelry and small parts.

Polishing points make a very smooth surface,

but a high luster is obtained using felt or cloth

wheels and polishing compound.

For best results polishing accessories

should be used at speeds not greater than

15,000 RPM. Refer to Operating Speeds

section for proper tool speed setting.

Wire Brushes

Three different shapes of wire brushes are

available. Never use wire brushes at

speeds greater than 15,000 RPM. Refer to

Operating Speeds section for proper tool

speed setting.

They remove rust from tools and other metal

surfaces, and clean and burnish metal parts.

Use for such jobs as cleaning electrical

connections to assure good conduction.

Bristle Brushes

This is an excellent cleaning tool on

silverware, jewelry and antiques. A bristle

brush can be used with polishing compound

for faster cleaning or polishing.

Aluminum Oxide Abrasive Wheels

Use to remove paint, deburr metai, polish

stainless steel and other metals. Available in

fine and medium grits.

Sanding Accessories

Sanding discs are made to fit mandrel No.

25028. They can be used for nearly any small

sanding job you might have, from model

making to fine furniturd finishing. In addition,

there is the drum sender, a tiny drum which fits

into the Rotary Tool and makes it possible to

shape wood, smooth fiberglass, sand inside

curves and other difficult places, and other

sanding jobs. You replace the sanding bands

on the drum as they become worn and lose

their grit. Bands corne in fine and coarse

grades.

24

Cutting Wheels

These thin discs of emery or fiberglass are

used for slicing, cutting off and similar

operations. Use them for cutting off frozen

bolt heads and nuts, or to reslot a screw head

which has become so damaged that the

screwdriver won’t work in it. Fine for cutting

BX cable, small rods, tubing, cable and

cutting rectangular holes in sheet metal.

U

High Speed Router Bits

For routing, inlaying, and mortising in wood

and other soft materials. Use with Craftsman

No. 53099 Router attachment and No. 53034

Shaper/Router table.

Page 25

Mandrel No. 53089 is used with the felt polishing tip and wheels. Thread the tip on to the

screw carefully. The felt tip must thread down straight on the screw Mandrel, and be turned all

the way to the collar.

Mandrel No. 25028 has a small screw at its tip, and is used with emery cutting wheels and

sanding discs. Higher speeds, usually maximum, are best for most work, including cutting

steel, which is shown here.

To replace a band on the drum sander, loosen the screw without removing it to contract the

drum, then slide the old band off. Slide the new sanding band on and then expand the drum by

tightening the screw once again.

Before each use, check to make certain that all components are

assembled to accessory shank and that the drum is sufficiently

expanded to secure the band during use. If sanding band is loose on the drum during

operation it may “fly" off and strike you or bystanders.

25

Page 26

* Speed for light cuts, caution burning on deep grooves.

SPEED SETTINGS

STOCK

NUMBER

25014

25012, 53070

25011. 53068

25008

53074

53112

53076

53137

■ " STRUCTURED TOOTH TUNGSTEN CARBIDE CUTTERS

■ 53106.53138

53071,52072,53104

53073, 53105

53107, 73096

53111. 53090, 53091

53092

53079. 25062, 25063 _ 6

25046, 25049, 25053

25057, 25058

36581. 36583

25024, 53114,53088

53165

53134

53134

53136

25016 -

SOFT

WOOD

10

10

10

10

10

10

10

10*

10

10

10

10*

10*

10'

10

10

6-10

10

For use on drvwall. For best results, use at setting 10. (Use with cutting guide)

6-10

■ Depending on cuttinq direction, relative to grain.

HARD

WOOD

6

10

6

10

8

10

10

10* 6*

8

8

8

HIGH SPEED ROUTER BITS (Use with cuttinq guide or shaper/router table)

8*-

10*-

8*-

10

10

CUTTING ACCESSORIES—SEE WARNING PAGE 6

6-10

8-10

6-10

LAMINATES

PLASTIC

HIGH SPEED CUTTERS

4

4

4

4

4

SMALL ENGRAVING CUTTERS

8

6

DIAMOND WHEEL POINTS

STEEL

6

6

6

6 6

6

8

8

8

.... _________

.4

TUNGSTEN CARBIDE CUTTERS

4

SILICON CARBIDE GRINDING STONES

ALUMINUM OXIDE GRINDING STONES

CHAIN SAW SHARPENING STONES

2-4

2-4

2-4

10

10

8

8

10

10

ALUMINUM,

BRASS, ETC.

6

10

6

6

6

6

3

6

6

4

4

4 6

10 10

10

SHELL/

STONE

10

8

8

6

6 10

CERAMIC

10

8-10

8-10

10

10

10

10

GLASS

10

8-10

8-10

10

Page 27

SPEED SETTINGS

STOCK SOFT HARD

NUMBER

53082

25033

53110 4

53120 4 4

25038, 25039, 53087

53131

53116, 53117, 53118

25042, 53083, 25043 2-10 2-10

53084

53136, 53162

53164

53166 For Use on Wall and Floor Grout (Use with grout removal cutting guide) 6-8

WOOD WOOD PLASTIC BRASS, ETC. STONE

6

4

2-10 2-10 2-6 10 10

8 8 2-4

______10_________

6 6

* Speed for light cuts, caution burning on deep grooves.

' Dependina on cuttinq direction, relative to grain.

LAMINATES

POLISHING ACCESSORIES

4 2-4 6 6

6

4

8

2

SANDING BANDS AND DISCS

2-6

FLAPWHEELS

2

FINISHING ABRASIVE BUFFS

4

GROUT REMOVAL BITS

STEEL

6

6-8

6

4

10

10 8-10

L 6 _

ALUMINUM,

6-8

2-4

SHELL/

6

6

4 4

10

6

CERAMIC GLASS

6 6 6

6-8 6-8

2-10

2-10 2-10

2-10

_________

_________

6-8

Page 28

CRAFTSMAN ROTARY POWER TOOLS

HERRAMIENTA MECÁNICAS GIRATORIAS CRAFTSMAN

MODEL NUMBERS

NÚMEROS DE MODELO

572.610830,572.610960 & 572.610950.

Page 29

CODE NO.

Э DE CODIGO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PART NO.

NUMERO DE PIEZA DESCRIPTION

2615990962

2615297355

•

*481

2615294028

2610912779

2610907324

2615297356

•

2615294043

2615302217

2615302695

•

2615294041

2615294035

2615297373

■ 3/32" Collet

Wrench

Collet Nut

1/8“ Collet (In Tool)

Housing Cap

Armature & Bearing Assembly

Field Assembly

Collet Lock & Spring

Housing Set

Hanger

Brush Cap (Pair)

Brush Spring (Pair)

Switch Assembly

Cord

Screws (Individual)

Isolator

DESCRIPCION

Llave de tuerca

Tuerca del portaherramienta

Portaherramienta de 3,2 mm (en la herramienta)

Portaherramienta de 2,4 mm

Tapa de la caja protectora

Ensamblaje de inducido y rodamientos

Ensamblaje de campo

Cierre y resorte de portaherramienta

Juego de caja protectora

Gancho

Tapa para escobillas (par)

Muelle para escobillas (par)

Ensamblaje del interruptor

Cordón

Tornillo

Aislante

CODE NO.

NUMERO DE CODIGO

3

8

12

MODEL

MODELO^

572.61083b

480

2615297374

2610912839

2610912840

2610912838

MODEL

MODELO

572.61096Ò

480

2615297374

2610912844

2610912845

2610912843

MODEL

MODELO

572.610950

480

2610912816

2610912832

2610912833

2610912831

DESCRIPTION

1/8" Collet (In Tool)

Housing Set

Switch Assembly

DESCRIPCION

Portaherramienta de 3,2 mm

(en la herramienta)

Juego de caja protectora

Ensamblaje del interruptor

Page 30

CRAFTSMAN CUTTING GUIDE

GUIA DE CORTE CRAFTSMAN

CODE NO.

NUMERO

DE CODIGO

1

2

3

4

5

6

7

8

PART NO.

NO. DE PIEZA

2615297355

529410970

2615990962

529417870

2615302049

2615302102

2615302103

DESCRIPTION

Collet Nut (Not included)

Collet (Not included)

Flexible Shaft Core

Wrench (Not included)

Driver Cap

Guide

Guide insert

Screw Spring & Nut

DESCRIPCION

Tuerca del portaherramienta (no incluida)

Portaherramienta (no incluida)

Núcleo del eje flexible

Llave de tuerca (no incluida)

Тара del impulsor

Guia

Guia para insertar

Destornillador, Muelle & Tuerca

Page 31

GROUT REMOVAL KIT

JUEGO PARA QUITAR LECHADA

CODE NO.

NUMERO DE CODIGO

NO. DE CODE

PART NO.

NUMERO DE PIEZA

NO. DE U PIECE

2615302691

2615302687

2615302688

2615302689

2615302690

DESCRIPTION

Angled Cone Housing

Multi Channel Slide

Thumbscrew

Square Nut

Compression Spring

Page 32

DESCRIPCION

DESCRIPTION

Cubierta Protectora en Forma de Angulos

Deslizamiento Multi-Canales

Tornillo de Apriete Manual

Tuerca Cuadrada

Resorte

Enveloppe angulaire conique

Glissière à cannelures

Vis à ailette

Écrou carré

Ressort

Page 33

Indice Página

Garantía..................................................................................................................................................32

Normas de seguridad para herramientas mecánicas........................................................................33-36

Simboios.................................................................................................................................................37

Descripción funcionai y especificaciones..........................................................................................38-39

Ensamblaje....................................................................................................................................... 40-41

Instrucciones de funcionamiento.......................................................................................................42-45

Velocidades de funcionamiento para los accesorios.........................................................................46-50

Mantenimiento...................................................................................................................................51-52

Accesorios.........................................................................................................................................53-57

Piezas de repuesto...........................................................................................................................28-31

Garantía de Sears

Garantía compieta de un año para la herramienta mecánicas giratorias Craftsman

Si no está completamente satisfecho con esfa herramienta mecánicas giratorias Craftsman

dentro del plazo de un año a partir de la fecha de compra, Sears la reemplazará gratuitamente.

Si esta herramienta mecánicas giratorias se utiliza con fines comerciales o de alquiler, esta

garantía solamente tiene una año de aplicación a partir de la fecha de compra.

Servicio de garantía

El servicio de garantía se encuentra disponible devolviendo esta herramienta mecánicas giratorias

Craftsman a la tienda Sears más próxima en los Estados Unidos.

Esta garantía tiene aplicación solamente mientras esta herramienta mecánicas giratorias se utilice

en los Estados Unidos.

Esta garantía le confiere a usted derechos legales específicos y es posible que también tenga

otros derechos que varían de un estado a otro.

Sears, Roebuck and Co., Depl. 817WA, Hoffman Estafes, IL 60179

32

Page 34

NORMAS DE SEGURIDAD PARA HERRAMIENTAS MECÁNICAS

A ADVERTENCIA

personales graves.

Lea y entienda todas las instrucciones.

indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones

CONSERVE ESTAS INSTRUCCIONES

Area de trabajo

Mantenga el área de trabajo limpia y bien

iluminada.

oscuras invitan a que se produzcan accidentes.

No Utilice herram ientas mecánicas en atmósferas

explosivas, tales como las existentes en presencia

de iíquidos, gases o polvos inflam ables. Las

herramientas mecánicas generan chispas y éstas

pueden dar lugar a la ignición del polvo o los vapores.

Mantenga a las personas que se encuentren

presentes, a ios niños y a los visitantes alejados al

utilizar una herramienta mecánica. Las

distracciones pueden hacer que usted pierda el

control.

Las mesas desordenadas y las áreas

Seguridad eléctrica

Las herramientas con aislamiento doble eslán

equipadas con un enchufe polarizado (un ferminal

es más ancho que el otro). Esle enchufe enfrará en

un tomacorriente polarizado solamente de una

manera. SI el enchute no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin entrar,

póngase en contacto con un eiectricista competente

para instaiar un tomacorriente poiarizado. No haga

ningúntmo de cambio en

doble

H elimina la necesidad del sistema de cordón

de

energía de tres hilos conectado a tierra y la fuente

de

energía conectada a tierra. Antes de enchufar la

herramienta, asegúrese de que la tensión del

tomacorriente suministrada se encuentre dentro del

margen de la tensión especificada en la placa del

fabricante. Nó utilice herramientas con capacidad

nominal "AC solamente" ("AC oniy") con una fuente de

energía DC.

Evite el contacto del cuerpo con las superficies

conectadas a tierra tales como tuberías,

radiadores, estufas de cocina y refrigeradores.

mayor riesgo de que se produzcan sacudidas

eléctricas si su cuerpo está conectado a tierra. Si la

utilización de la herramienta mecánica en lugares

húmedos es inevitable, se debe usar un interruptor de

circuito para fallos a tierra para suministrar la energía

a

la herramienta. Los guantes de goma para

eiectricista y el calzado antideslizante aumentarán

más la seguridad personal.

No exponga las herramientas mecánicas a

ni a situaciones húmedas.

herramienta mecánica aumentará ei riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar

las herramientas ni para sacar el enchufe de un

tomacorriente. Mantenga el cordón alejado del calor,

el aceite, los bordes afilados o ias piezas móviles.

Cambie los cordones dañados inmediatamente. Los

el

enchufe.

El aislamiento

Hay

la

La entrada de agua en una

lluvia

33

El incumplimiento de todas las instrucciones

cordones dañados aumentan ei riesgo de que se

produzcan sacudidas eléctricas.

Al utilizar una herramienla mecánica a la

intemperie, utilice un cordón de extensión para

intemperie marcado "W-A" o ”W".

tienen capacidad nominal para uso a ia intemperie y

reducen el riesgo de que se produzcan sacudidas

eléctricas. Consulte 'Tamaños recomendados de los

cordones de extensión' en la sección Accesorios de

este manual.

Estos cordones

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo y

use el sentido común cuando utilíce una

herramienta mecánica. No use la herramienta

cuando esté cansado o se encuentre bajo la

Influencia de drogas, afcohoi o medicamentos.

momento de distracción al utilizar herramientas

mecánicas puede dar lugar a lesiones personales

graves.

Un

Vístase adecuadamente. No se ponga ropa holgada

ni joyas. Sujétese el pelo. Mantenga el pelo, la

ropa y los guantes alejados de las piezas móviles.

La ropa holgada, ias joyas o el pelo largo pueden

quedar atrapados en las piezas móviles. Mantenga los

mangos secos, limpios y libres de aceite y grasa.

Evite el arranque accidental. Asegúrese de que ei

interruptor esté en la posición "OFP (apagado)

antes de enchufar la herramienta.

herramientas con el dedo en ei interruptor o el

enchufar herramientas que tengan el interruptor en la

posición "ON" (encendido) invita a que se produzcan

accidentes.

El llevar las

Quite las llaves de ajuste o de tuerca antes de

encender la herramienta.

tuerca que se deje puesta en una pieza giratoria de la

herramienta puede ocasionar lesiones personales.

Una llave de ajuste o de

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio adecuados en todo

momento.

adecuados permiten un mejor control de la

herramienta en situaciones inesperadas.

El apoyo de los pies y el equilibrio

Utilice equipo de seguridad. Use siempre

protección de los ojos.

antipolvo, zapatos de segundad antideslizantes, casco

o protección de los oídos según lo requieran las

condiciones.

Se debe utilizar una máscara

Utilización y cuidado de las herramientas

utilice abrazaderas u otro modo práctico de fijar y

soportar la pieza de trabajo a una plataforma

estable.

La sujeción de la pieza de trabajo con la

mano o contra el cuerpo resulta inestable y puede

ocasionar pérdida de control.

Page 35

No fuerce la herramienta. Use la herramienta

correcta para la aplicación que desea. La

herramienta correcta hará el trabajo mejor y con más

segundad a la capacidad nominal para la que está

diseñada.

No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no se

pueda controlar con el interruptor es peligrosa y debe

ser reparada.

Desconecte el enchufe de la fuente de energía

antes de hacer cualquier ajuste, cambiar

accesorios o guardar la herramienta. Estas medidas

de seguridad preventivas reducen el riesgo de

arrancar la herramienta accidentalmente.

Guarde las herramientas que no esté usando fuera

del alcance de los niños y otras personas no

capacitadas. Las herramientas son peligrosas en las

manos de los usuarios no capacitados.

Mantenga las herramientas con cuidado. Conserve

las herramientas de corte afiladas y limpias. Las

herramientas mantenidas adecuadamente, con bordes

de corte afilados, tienen menos probabilidades de

atascarse y son más fáciles de controlar. Toda

alteración o modificación constituye un uso

incorrecto y puede tener como resultado una

situación peligrosa.

Compruebe la desalineación o el atasco de las

piezas móviles, la ruptura de piezas y cualquier

otra situación que pueda afectar el funcionamiento

de las herramientas. Si la herramienta está

dañada, haga que realicen un servicio de ajustes y

reparaciones a la herramienta antes de usarla.