Page 1

&EAÑ&

owner’s

manual

WARNING:

For your own safety,

read your owner’s

manual before

operating your

rotary tool.

MODEL

NOS.

572.610520

572.610530

&

572.610720

FOFtM NO 2610911273 2/S6

CiiFTS^ii.

ROTARY POWER TOOLS

Refer to your service diagram for specific warranty

information on your Craftsman Rotary Power Tool.

Consulte el diagrama de servicio para obtener

información específica de garantía para su

herramienta mecánica giratoria Craftsman.

¿Habla español? Ver página 7

® assembly ® operation ® maintenance ® repair parts

Sears, Roebuck and Co., Hoffman Estates. IL 60179 U.S.A.

PRINTED IN U,S A

Page 2

READ AND SAVE ALL THE FOLLOWING INSTRUCTIONS:

1. Keep work area clean — Ciuitered areas

and benches Invite Injuries

2. Avoid dangerous environment — Don't

expose tools to rain,, Don’t use power tools in

damp or wet locations. Don’t use power tools

in the presence of llammable liquids or gases

Avoid chemica! or corrosive environments,

Keep work area welt llt-

3- Guard against electric shock — Prevent

body contact with grounded surfaces For

example: pipes, radiators, refrigerator

enclosures

4* Keep children away — Do not let visitors

contact tool or extension cord All visitors

should be kept away from work areas

5. Store idle tools — When noi in use, tools

should be stored in dry, and high or locked-up

place — oul of reach of children,

6. Don’t force tool — It will do the job better

and safer at the rate for which It was intended

7. Use right tool — Don’t force small too! or

attachment !o do the job of a heavy-duty tool.

Oon 1 use tool for purpose not intended —™ for

example — don’t use circular saw for cutting

tree limbs or logs

8. Dress properly — Do not wear loose

clothing or jewelry. They can be caught in

moving parts Rubber gloves and non-skid

footwear are recommended when working

outdoors Wear protective half covering to

contain tong hair

9.. Use safety glasses — Also use face or

dust mask if cutting operation is dusty

10- Don’t abuse cord — Never carry tool by

cord or yank it to disconnect from receptacle

Keep cord from heat, oil, and sharp edges.

When using electric tools, basic safety precautions

electric shock and personal Injury, Including the following:

11. Secure work — Use damps or vise to

hold work. It's safer than using your hand and

It frees both bands to operate tool.

12. Don't over-reach — Keep proper fooling

and balance at all times,

13. Maintain tools with care — Keep tools

sharp and clean for better and safer

performance. Follow instructions for lubricat

ing and changing accessories Inspect tool

cords periodically and. if damaged, have

repaired by authorized service facility. Inspect

extension cords periodically and replace if

damaged. Keep handies dry. clean and free

from oil and grease

14. Disconnect tools — When not in use,

before servicing, and when changing

accessories, such as blades, bits, cutters

15. Remove adjusting keys and wrenches

— Form habit of checking to see that keys

and adjusting wrenches are removed from

tool before turning it on

16. Avoid unintentional starting — Don’t

carry plugged-in tool with finger on switch. Be

sure switch is off when plugged in,

17. Outdoor use extension cords —^ When

tool Is used outdoors, use only extension

cords Intended for use outdoors and so

marked

18. Stay alert — Watch what you are doing.

Use common sense. Do noi operate tool

when you are tired. Don’t use power tools

after taking drugs, alcohol or medications

19. Do not alter or misuse tool — These

tools are precision built. Any alteration or

modification not specified Is misuse and may

result in a dangerous condition-

should always bs followed to raduce the risk of lire,

20. Avoid gaseous areas — Do not operate

portable electric tools in gaseous or explosive

atmospheres Motors in these tools normally

spark, and the sparks might ignite fumes

21. Check for damaged parts — Before

further use of the tool, check for damaged

parts Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect its Operation A part that is damaged

should be properly repaired or replaced by an

authorized service center before further use

of the toot Have defective switches replaced

by an authorized service center. Do not use

tool it switch does not turn it on and off,

22. Your tool Is double insulated — And no

grounding Is necessary The tool is equipped

with a two wire cord and two prong plug

which can be used in standard 120 volt

A.C. outlets- Use only identical

replacement parts when service is

required.

23. Polarized piugs ~ Your tool is equipped

with a polarized plug (one blade Is wider than

the other), this plug wilt fit in a polarized oultet

oniy one way If the plug does not fit fully in

the outlet, reverse the plug If it sti does not

fit, contact a qualified electrician to install the

proper outlet. To reduce the risk of electric

shock do not change the plug in any way,

24. Extension cords — An undersized cord

will cause a drop In line voltage, resulting in

loss of power and over-heating Use 18

gauge or heavier cord. NOTE: The smaller

the gauge number, the heavier the cord

(Extension cords are available)

25. WARNING: Use of damaged cords can

shock, bum or electrocute.

READ AND SAVE ALL THE PRECEDING INSTRUCTIONS

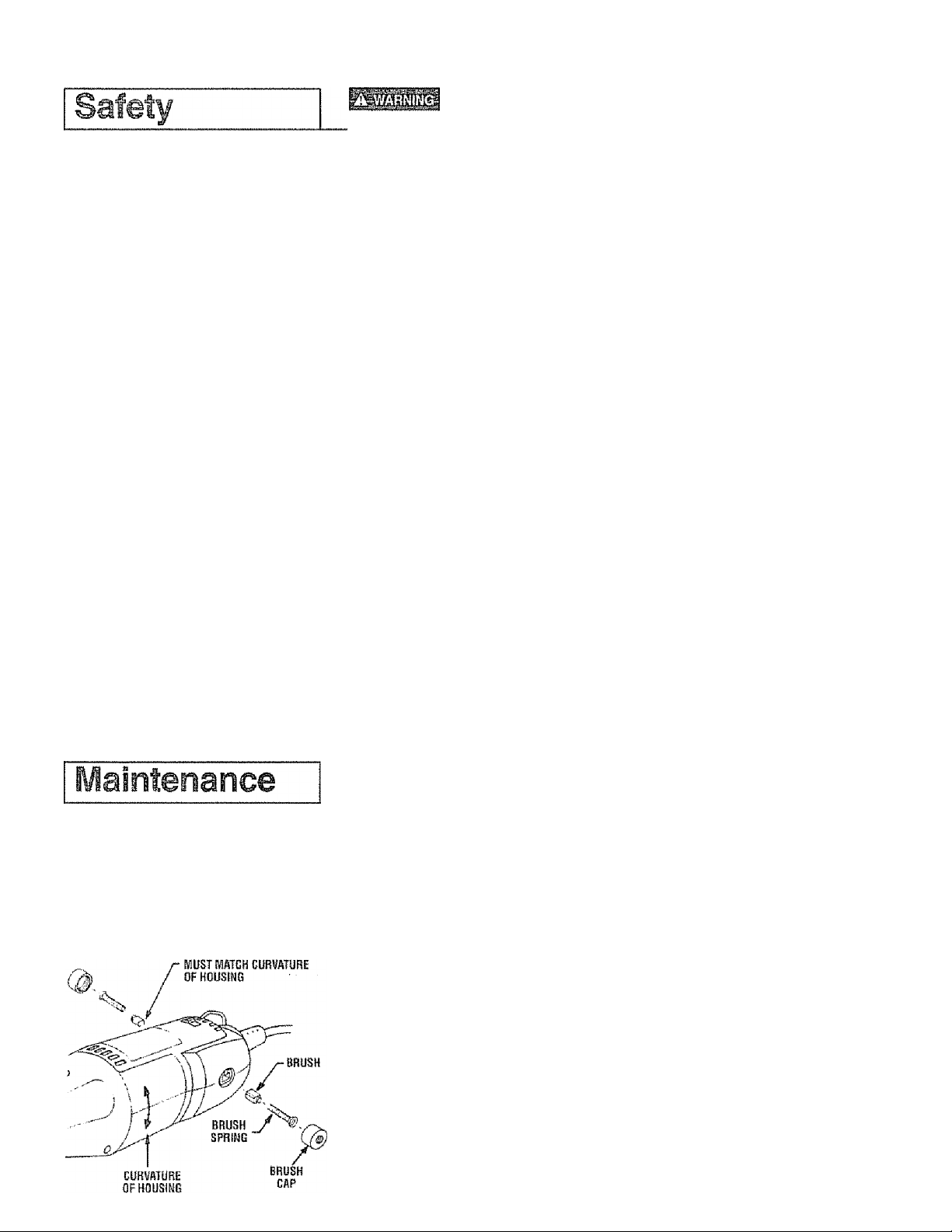

MAINTENANCE OF REPLACEABLE BRUSHES

Models 572 610520,572 610530 & 572 610720

The brushes should be Inspected frequently

when tools are used corttinuously. If your tool

runs sporadically, loses power, makes

unusual noises or runs at a reduced speed,

check the brushes To continue using the tool

in this condition will permanently damage

your tool

CURVED END OF BRUSH

With the cord unplugged, remove the brush

caps one at a time with a small screwdriver by

rotating cap counter-clockwise and check

each brush-

If the brush is less than 1/8" long and the end

surface of the brush that contacts the

commutator is rough and/or pitted, they

should be replaced Check both brushes

Usually the brushes will not wear out simul

taneously. If one brush is worn out, replace

both brushes Make sure the brushes are

installed as illustrated. The curved surface of

the brush must match the curvature of the

commutator,

After replacing brushes the tool should be run

at no-load; place it on a clean surface and run

it freely for 5 minutes before loading (or using)

the tool- This wi!i allow the brushes to “seaf

properly and will give you more hours of life

from each set of brushes. This will also

extend the total lite of your tool since the com

mutator surface will "wear" longer.

BEARINGS - Rotary Tool Nos,. 572.610520,

572.610530 & 572,610720 have double ball

bearing construction. Under normal use

neither type requires additional lubrication.

CAUTION:

Any servicing of this tool (Excluding brush re

placement for Models 572.610520,

572 510530 & 572 610720) should be

performed by an authorized service

representative

IMPORTANT!

Use of any accessories or attachments other

than those supplied by Sears may be

hazardous

Page 2

Page 3

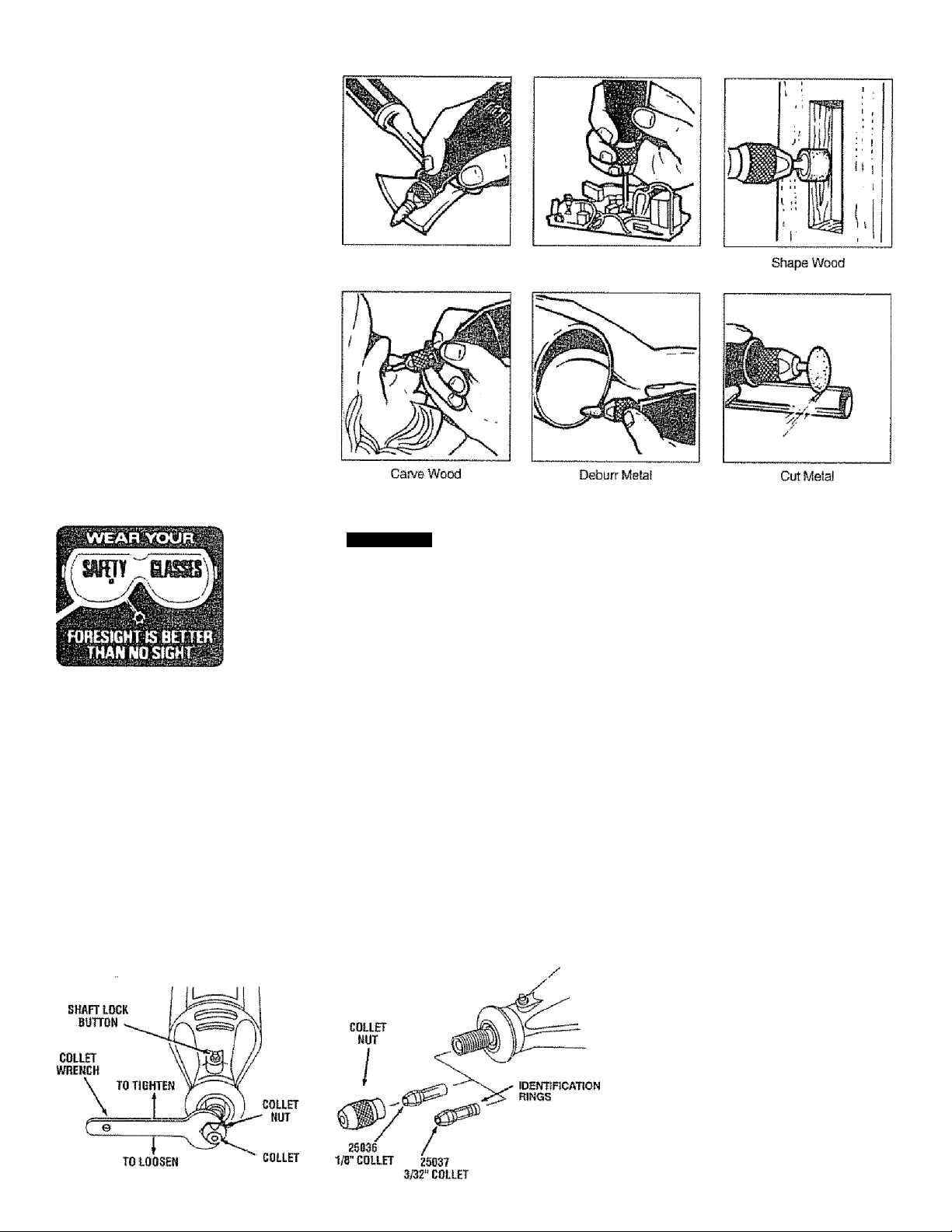

Here are examples

of what a SEARS

Craftsman tool can

do...

A, WARNING

objects being thrown Into the eyes, which can

result in severe eye damage. Always wear

safely glasses or eye shields before com

mencing power tool operation, We

recommend Wide Vision Safety Mask for use

over spectacles or standard safety glasses

Whenever you hoid the tool, be careful not to

cover the air vents with your hand. This blocks

the air flow and causes the motor to overheat

A WARNING

sories, changing collets or servicing your

rotary tool.

COLLET — To loosen, first press shaft iock

button and rotate the shaft by hand until the

lock engages the shaft preventing further

rotation.

The Operation of any power

tool can result in foreign

Always unplug rotary tool

before changing acces

Sharpen Tools

Do not engage (octc while the Rotary Tool Is running.

With the shaft lock engaged use the collet

wrench to toosen the collet nut if necessary.

Change accessories by inserting the new one

into the collet as far as possible to minimize

runout and unbalance. With the shaft lock

engaged, finger lighten the collet nut unlit the

accessory shank is gripped by the collet Avoid

excessive tightening of the collet nut. The

coliei system is a superior method of securing

accessories-

COLLETS " Two different size collets (see

illustration), to accommodate different shank

sizes, are available for your Rotary Tool,. To

Install a different collet, remove the coHel nut

and remove the old collet. Insert the unslotted

end of the collet in the hole in the end of tfje

tool shaft.. Replace collet nut on the shaft

Always use the coliet which matches the

shank size of the accessory you plan to

use. Never force a larger diameter shank into

a collet.

COLLCT iDENTIFlCATlON SMART — Collel sizes can

be identified by the rings on lha back end of collet

1/32' Collet has one (1) ririg

1/1B' Collet has two (2) rings

3/32’ Collet has threa (3) rings

1/8” Collet has no rifigs

Precise Drilling

BALANCING ACCESSORIES — For

precision work, it is important that all

accessories be in good balance (much the

same as the tires on your automobile), To true

up or balance an accessory, slightly loosen

collet nut and give the accessory or collet a 1/4

turn- Retighten collet nut and run the Rotary

Tool- You should be able to tell by the sound

and fee! If your accessory is running in

balance,. Continue adjusting in this fashion

until best balance is achieved To maintain

balance on abrasive wheel points, before each

use, with the wheel point secured in the collet,

turn on the Rotary too! and run the Dressing

Stone lighfiy against the revolving wheel point.

This removes high spots and trues up the

wheel point for good balance.

meter. Rotary Tool's high speed can cause

larger wheels to fly apart and could cause

injury.

SAFETY ^— Protect your eyes when grinding

or routing with the Rotary Tool .always wear

an approved type of safety glasses

Remember, your new Sears Rotary Tool is the

finest power tool of its kind. But its

performance is, .only as, good as the

accessories with which It is used- We

recommend only Sears accessories be used.

Use of any other accessories may create a

hazard. We hope you’ll enjoy many years of

trouble free pleasure from your Sears

Craftsman Rotary Power Too!

Do not Use grinding

wheels over 1" in dia

Pag© 3

USE ONLY RECOMMENDED

w Cw w'CJ w i* I

Page 4

Craftsman

Rotary Power

Tool

The Rotary Tooi is a handful of high-speed

power !t serves as a carver, a grinder,

polisher,

more

The Rotary Tool has a smali, poweriul elsclrfc

motor, is comfortable in the hand, and is

made to accept a large variety of accessories

including abrasive wheeis, drill bits, wire

brushes, polishers, engraving cutters, router

bits, and cutting wheels Accessories come irt

a variety of shapes and permit you to do a

number of different jobs. As you become

familiar with the range of accessories and

their uses, you will learn just how versatile the

Rotary Tool is. You'll see dozens of uses you

hadn't thought of before now

The real secret of the Rotary Tool is its speed.

To understand the advantages of Its high

speed, you have to know that the standard

portable electric driit runs at speeds up to

2,800 revolutions per minute. The Rotary Tool

operates at speeds up to 30,000 revolutions

per minute The typical eiectric drill is a iowspeed, high torque too!; the Rotary Tool is just

the opposite - a high-speed, low torque tool

The chief difference to the user is that in the

high speed tools, the speed combined with

the accessory mounted in the collet doss the

work. You don’t appiy pressure to the tool, but

simply hold and guide it In the iow speed

tools, you not only guide the toot, but also

apply pressure to it, as you do, for example,

when drilling a hole

It is this high speed, along with its compact

size and wide variety of special accessories,

that makes the Rotary Tool different from

other power tools The speed enables it to do

jobs low speed toots cannot do, such as

cutting hardened steel, engraving glass, etc.

Getting the most out of your Rotary Tod Is a

matter of learning how to let this speed work

for you

Using the

Rotary Power

Too!

Read the next seciions carefully They will

help you use your Rotary Tool correctly and

help you Select the correct accessory for your

job

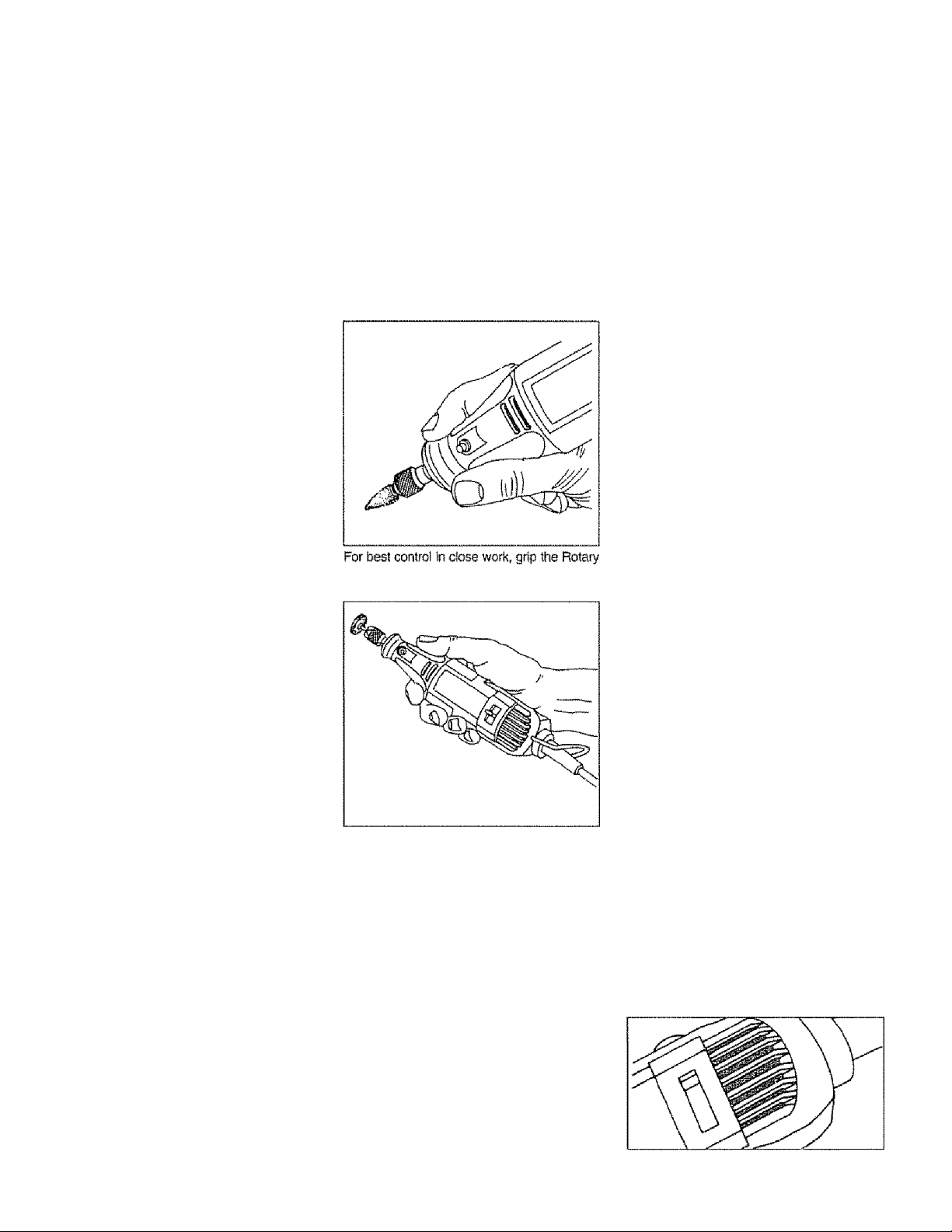

..The first step in learning to use the Rotary

Tool is to get the "feel" of it. Hold it in your

hand and feel Its weight and balance. Feet the

taper of the housing. This taper permits the

Rotary Tool to be grasped much like a pen or

pencil

When you turn on the tool for the first time,

hold it away from your lace. Accessories can

be damaged during handling, and can fly

apart as they come up to speed This is not

common, but it does happen

Practice on scrap materiats first to see how

the Rotary Tooi cuts. Keep in mind that the

work is done by the speed of the tool and by

the accessory in the coitet. You should not

lean on or push the tool into the work

Sander, cutter, power brush, dril! and

Instead, lower the spinning accessory lightly

to the work and allow it to touch the point at

which you want cutting (or sanding or etching,

etc) to begin. Concentrate on guiding the tool

over the work using very iittie pressure from

your hand- Allow the accessory to do the

work-

Usually, it is best to make a series of passes

with the tooi rather than attempt to do all the

work In one pass To make a cut, for example,

pass the tool back and forth over the work,

much as you would a smali paint brush Cut a

little materiai on each pass until you reach the

desired depth. For most work, the deft, gentle

touch is best With it, you have the best

control, are less likely to make errors, and will

get the most efficient work out of the

accessory.

Tooi like a pencil between your thumb and

forefinger.

This is the "handgrip" method of holding the

tool used for operations such as grinding a flat

surface or using cutoff wheels.

SitIWftHNJNGi

speed cutters or tungstett carbide cutters,

always have the work securely clamped.

Never attempt to hold the work with one

hand while using any of these

accessories. The reason is that these

wheels will grab if they become slightly

canted in the groove, and can kfckback

causing loss of control resoiting in

serious injury. Your second hand should

be used to steady and guide the hand

holding the took When a cutoff wheel

grabs, the wheel itself usually breaks.

When the steel saw, high speed cutters or

tungsten carbide cutter grab, it may Jump

from the groove and you could lose

control of the tool

When using the steel

saws, cutoff wheels, high

Page 4

Operating Speeds

& Accessories

Set the speed indicator to fit the job; to

achieve the best job results when working

with different materials, the speed of the

Rotary Toot should be regulated. Only a full

wave output speed control such as the Sears

Model 2514 {available from catalog only)

should be used with the Model 572.610520,

Models 572.610530 & 572.610720 Rotary

Tools have an integral speed control and an

external speed control should never be used

with these tools

Xa eibJjSir'i this AAHf ctAAisH fAf oqaK IaK fictA

I iw* It Iw sJyill WjFiiWww ICi? iJww CA

practice piece of material. Vary speed to find

the best speed for the accessory you are

using and the Job to be done

There are three basic types of Rotary Tools:

single speed, two-speed and variable speed

models On the single speed model, there is

an ON-OFF switch. When the switch is on,

the tool runs at 28,000 RPM On the twospeed-mode!, there Is a LO and H! switch.

When the switch indicator Is on the low

setting, the tool runs at about 20,000 RPM.

When the switch indicator is on the high

setting, the tool runs at about 30,000 RPM,

On the variable speed model, there is a

switch indicator with a white line on it. Slide to

the number on the housing to select the

operating speed needed from 5,000 - 30,000

RPM You can refer to the charts on page 5 to

determine the proper speed, based on the

material being worked and the type of cutter

Of other accessory being used These charts

enable you to select both the correct acces

sory and the optimum speed at a glance

If you have a single-speed or two-speed

model, you will be able to use many

accessories to do a wide assortment of Jobs.

For the majority of applications, ai) models of

the Rotary Tool should be used at top speed

Needs for Slower Speeds

Certain materials, however, (some plastics,

for example) require a retativeiy slow speed

because at nigh speed the friction of the tool

generates heat and causes the plastic to meit

Slow speeds (15,000 RPM or iess) usually

are best for polishing operations employing

the felt polishing accessories. They may also

be best for working on deticate projects as

"eggsry" work, delicate wood carving and

fragile model parts You should always do

polishing with wire brush accessories at

slower speeds and never higher than 15,000

RPM

Higher speeds are better for carving, cutting,

routing, shaping, cutting dadoes or rabbets In

wood

Hardwoods, metals and glass require high

speed operation, and drilling should also be

done at high speeds

The speed of the Rotary Tool is cortlrolled by

setting this indicator on the housing,

a

Page 5

The Settings for Approximate Revaiuiions Per

Minute Rotary Toof Variabie Speed Model

672610530

To aid you in determining the optimum

operational speed for different materials and

different accessories, we have constructed a

series of tables that appear on page 5 By

Switch Setting Speed Range

1

2

3 12,000-17,000 RPM

4

4,500- 8,000 RPM

9,000-11,000 RPM

18,000-24,000 RPM

5 25,000 - 30,000 RPM

referring to these tables, you can discover the

recommended speeds for each type of

accessory Look these tables over and

become familiar with them,

Ultimately, the best way to determine the

correct speed for work on any material is to

practice for a few minutes on a piece of scrap,

NOTE: Speed is affected by voltage

changes. A reduced incoming voltage wilt

slow the RPM of the tool, especially at the

lowest setting,. If your tool appears to be

running slowiy increase the speed setting

accordingly.

The point to remember is this; You can do the

great majority of work with the single speed at

its regular speed of 2S.OOO RPM But for

certain materials and types of work, you need

slower speeds ~ which Is the reason the

variable speed models were developed

QDIPC 111 QcTTIlk||^Q * Speed for light cuts, caution burning on deep grooves.

O» Cod»# OC 1 1 t Dependifig on cutting direction, relative to grain.

STOCK

NUMBER

SOFT

WOOD

evert after referring to the chart You can

quickly learn that a slower or faster speed is

more effective just by observing what happens

as you make a pass or two at different speeds.

When working with plastic, for example, start

at a slow rate of speed and increase the speed

until you observe that the plastic is melting at

the point of contact Then back the speed off

slightly to get the optimum working speed

Some nilfis of thumb in regard to speed:

1 Plastic and materials that melt at low

temperatures should be cut at low speeds.

HARD

WOOD

LAMINATES

PLASTIC

HIGH SPEED CUTTERS

53101 5 5 1 3

25014,53102 5

3 2

STEEL ALUMINUM,

SRASSi ВТО»

2 4

1-2 2

2, Polishing, buffing and cleaning with a wire

brush should be done at speeds below

15,000 RPM to prevent damage to the

brush,

3 Soft wood should be cut at high speed

4 Iron or steel should be cut at top speed il

using tungsten carbide accessory, but at

slower speeds if using high speed steel

cutters If a high speed steel cutter starts to

chatter — this normally means it is running

too slow

5 Aluminum, copper alloys, lead alloys, zinc

alloys and tin may be cut at any speed,

depending on the type of cutting being

done Use paraffin or other suitable

lubricant on the cutter to prevent the cut

material from adhering to the cutter teeth

Increasing the pressure on the tool is not the

answer when it is not cutting as you think It

should Perhaps you should be using a

different cutter, and perhaps art adjustment in

speed would solve the problem. But leaning on

the too! seldom helps

SHELU CERAMIC

CaLASS

STONE I

26012,53070 5

53103. 25011

2S008

2S0l8 4

53074,53075

53076

25034 1

.................................1..........

«íbU-cO

25Ô24, 53000

531 ОТ, 53100,

53111, 53095, 53096

53090, 63091 5

53092

53078

2504Э, 25046

26057

2S0S8

53079, 53080

25062

25063

S3071, 52072, 53104 4

5 3 2

5 2

5 5 2

2 I 1-2

SMALL ENGRAVING CUTTERS

5

5*

5* ! 3* i 4 i 2

RUBBER POLISHING POINT

1

......................t... 2..............

CUTTING ACCisSORIES—SEE WARNING PAGE 7

5 5

HIGH SPEED ROUTER BITS

3 3

3 2*

5*

5 2*

ALUMINUM OXIDE GRINDING STONES

SILICON CARBIDE GRINDING STONES

1

I

— —p 1 :¡ 1 i............................................................ 2

TUNGSTEN CARBIDE CUftERS

4 1

5 5 1

3 5

2 2

1-2 1-2

2

5 1 4 ! 4 I 3

1 1 i 1 ^

S

1

1

1

1-2 1-1

1

1 1

1-2121 1-2

2 3

2 3

2

3

1-2

1

I

i

j

1-3

1-1

1-1

1-1

j I 2 ! 1 j 2 I 2

...................1.......1..........

Page 5

Page 6

Rotary Tool Accessories

The number and variety of accessories for the

Rotary Tool are almost limitless. There is a

category suited to almost any job you might

have to do — and a variety of sizes and

shapes within each category which enables

you to get the perfect accessory for every

need

Collets

If you expect to use a variety of accessories,

we recommend that in the beginning you

purchase a complete set of four coliels. Store

these so that you will have the proper size of

coiiet for any accessory or drill bit you want to

use. Currently, the No. 25036 1/8" and No25037 3/32" collets accommodate all of the

available Sears accessories,

Mandrels

A mandrel is a shank with a threaded or

screw head, and mandrels are required when

you use polishing accessories, cutting

wheels, sanding discs, and polishing points

The reason mandrels are used is that sanding

discs, cutting wheels and similar accessories

must be replaced frequently The mandrel Is a

permanent shank, allowing you to replace

only the worn head when necessary, thus

saving the expense of replacing the shaft

each lime.

crr|iB>

Screw Mandrel No. 5308S

This Is a screw mandrel used with the felt

polishing tip and felt polishing wheels.

C

=o

Small Screw Mandrel No. 25028

This is a mandrel with a small screw at Its Up,

and is used with emery cutting wheels,

sanding discs and polishing wheels

High Speed Cutters

Available in many shapes, high speed cutters

are used in carving, cutting and slotting In

Wood, plastics and soft metals such as

aluminum, copper and brass. These are the

accessories to use for freehand routing or

carving in wood or plastic, and for precision

cutting

Tungsten Carbide Cutters

These are tough, tong-lived cutters for use on

hardened steel, Bred ceramics and other very

hard maferiais- They can be used for

engraving on tools and garden equipment

Smalt Engraving Cutters

This group has a wide variety of sizes and

shapes, and are mads for intricate work on

ceramics (greenware), wood carvings, jewelry

and scrimshaw They often are used in

making complicated printed circuit boards,

They should not be used on steel and other

very hard materials but are excellent on

wood, plastic and soft metals Needs 3/32"

collet.

Aluminum Oxide Grindirtg Stones

Round, pointed, fiat — you name the shape

and there is one available in this category.

These are made of aluminum oxide and

cover virtually every possible kind of grinding

application, Use them for sharpenirtg lawrt

mower blades, screwdriver tips, knives,

scissors, chisels and other cutting tools. Use

to remove flash from metal castings,

d8burring_ any metal after cutting, smoothing

welded joints, grinding off rivets and removing

oist, In machine shops, high speed drills and

cutters normally are ground with aluminum

oxide wheels

Silicon Carbide Grinding Stones

Tougher than aluminum oxide points, these

are made especially for use on hard materials

such as glass and ceramics. Typical uses

might be the removal of stilt marks and

excess glaze on ceramics and engraving on

glass

Polishing Accessories

These include an impregnated polishing point

and an impregnated poiishing wheel for

bringing metal surfaces to smooth finish; a felt

polishing tip and felt polishing wheel, and

cioth polishing wheel, all used (or polishing

plastics, metals, jewelry and small parts. Also

included in this group is a polishing

compound (No. 2S031) for use with the felt

and doth polishers

Polishing points make a very smooth surface,

but a high luster is obtained using felt or cloth

wheels and poiishing compound.

No polishing compound is needed when

using the 25034 Polishing Wheel

Aluminum Oxide Abrasive Wheels

Use to remove paint, deburr metal, polish

stainless steel and other metais Available in

fine and medium grtts

Sanding Accessories

Sanding discs in fine, medium and coarse

grades are made to fit mandrel No. 25028,

They can be used for nearly any small sanding

fob you might have, from mode! making .to, fine,

fumilure finishing. In addition, there is the drum

Sander, a tiny drum which fits Into the Rotary

Tool and makes It possible to shape wood,

smooth fiberglass, sand inside curves and

other difficult places, and other sanding Jobs

You replace the sanding bands on the drum as

they become worn and lose their grit Bands

come in fine and coarse grades

cn=c(^|

О

Wire Brushes

Three different shapes of wire brushes are

available For best results wire brushes

should be used at speeds not greater than

15,000 Rpy, They remove rust from tools

and other metal surfaces, and clean and

burnish metal parts Use for such jobs as

cleaning electrical connections to assure

good conduction

Bristle Brushes

These are excellent cleaning toots on

silverware, jewelry and antiques. The three

shapes make it possible to get Into tight

corners and other difficuit places. Bristle

brushes can be used with polishing

compound for faster cleaning or polishing

MWARNiNà

least one minute before using wheel.

During this time no one is to stand In front

or in line with the brush, do not run in

excess of 15,000 RPM.

Cutting Wheels

These thin discs of emery or fiberglass are

used for slicing, cutting off and similar

operations Use them for cutting off frozen

boll heads and nuts, or to resloi a screw head

which has become so damaged that the

screwdriver won’t work in It. Fine for cutting

8X cable, small rods, tubing, cable and

cutting rectangular holes In sheet metal.

ilïWARNIN,Gi

cutters or tungsten carbide cutters,

always have the work securely clamped.

Never attempt to hold the work with one

hand while using any of these

accessories. The reason is that these

wheels will grab if they become slightly

canted In the groove, and can kickback

causing loss of control resulting in

serious Injury. Your second hand should

be used to steady and guide the hand

holding the tool. When a cutoff wheel

grabs, the wheel Itself usually breaks.

When the steel saws, high speed cutter or

tungsten carbide cutter grab, it may Jump

from the groove and you could lose

control of the tool.

Allow brushes to run at

operating speed for at

When using steel saws,

cutoff wheels, high speed

Pages

Page 7

incendio, sacudidas eléctricas y lesiones personales, incluyendo las sigulentesí

LEA Y GUARDE TODAS LAS INSTRUCCIONES SIGUIENTES:

1. Mantenga limpia al ares de trabajo — Las áreas y me

sas desordenadas invitan a que se produzcan accidentes

2. EüüB ios sniamos peligrosos — Mo exponga las tioframientes a !a ¡iuvia No uliBcs herramientas mecánicas en

iugares húmedos o mojados. Mo utilice iiarramisntas me

cánicas en presencia de líquidos o gasas inflamables. Eviie

los entornos en que haya productos químicos o qua sean

corrosivos Mantenga eí área de trabajo bien Iluminada

3 Pfoíéjase contra ias sacinlifias eíéctricas ~ Evite si

contacio del cuerpo con tes superifcies conectadas a

tiería. Por ejemplo: tuberias. radiadores y refrigeradores

4, Mantenga alejados a ios niños — No permita que ios

visitantes toquen la herramienta o el cordón de extensión

Todos tos visitantes deban marslenersa alejados de tes

áreas de trabajo.

S- Buartle las herramleirtas qae no eslá usando—Cuan

do las herramientas no se estén utilizando, deberán

guardarse en un lugar seco, aito o cerrada — (gara del

slcanoB de los niños

B, No tuerce la herramleiiiB — La herramienta hará sí tra

bajo mejor y con más seguridad a la capacidad para te cual

lue diseñada

7. Uiflics la beframiepta adecauda — No iueree una lierramienia pequeña o un accesorio pequeño a realizar si

trabajo de una herramienta pesada No utilice te berramiente para funciones para ias cuales tro lue diseñada —por ejemplo, no usa una sierra clrcutar para cortar ramas o

troncos de árboles.

8.I Vrsiasi sdecuodamenie — No se ponga ropa suelte ni

joyas Pueden quedar atrapadas en las piezas móvites Se

recomienda utilizar guantes de caucho y calzado ani)deslizante cuando se trabaja a la inteinparfe. Use cubiertas

protectoras para el pelo a fin de sujetar el pelo largo

9,, Uss gafas de seguridad — Use también usm careta o

una máscara conlra el polvo si ia operación de corte gene

ra polvo

ia. Nfl abase de! cardón — Nunca lleve la herramienía por

el cordón ni tire de él para desconectarlo del lomacorfisnte

Proteja el cordón del calor, e! aceito y tos bordes afilados

11. Pije la pieza ds trabaja — Utilice abrazaderas a un

lomilio de carpintero para sujetar la pieza da trabajo Es

más seguro que utilizar 1a mano y libera ambas itiattos

para manejar la íterramlenía

12. No intente alcanzar demasiado Isjas Manlsnga

urra posición y un equfflhríQ adecuados ert todo momenlo

13 Mantenga las herraraletrías eqn suidado — Conserve

tes tierramtontas afiladas y limpias para que funcionen

mejor y con mas seguridad Sipa las mstrucciones de lubri

cación y de cambio de aoeesrrrios Inspeccione periotficamenía los cordones de la harrarnierste y si están dañados,

hágalos reparar par un centro de servicio autorizado, inspeceiorte periódlcamento tos cordones ds extensión y

sustiiúyalos si están dañados Mantenga los mangos

secos, ¡impíos y libres de aceite y grasa

14., Descongele tas heíramlenias — Cuantío no se estén

tiiszanda, antes del servicio de ajustes y reparaciones y aJ

cambiar accesorios taies como hojas, brocas y cortadores

15- Quite tas ttavas de ajuste y fas (laves de apriete —

Forme e! hábito de asegurarse de que ¡as lavas de ajuste y

de aprieto se han quitado de !a herramienta antes de

encenderla

16 Evtfe s| arranque no Intencionado — No fievs la

herrarniente enchufada con el dedo en si irtterruptor Ase

gúrese de que ei mlerruptor eslá apagada cuando (a

herramienta está enchutada

17 A ta intemperie, utilice cordortes de extensión —

Cuantío la herramienía se utiliza a la intemperte, use tmicamente cordones de extensión diseñados para la utili

zación a te tatotrrpetie y marcados para ese propósito

18. Marttsngase alerta — Fíjese en fo que está haciendo

Use 8! santido común No utilice la herramienta cuantío

esté cansado No utilice herramientas mecánicas después

de lomar drogas, aícohoi o medícaraenlos

19.. No altera nt haga usa Inoorrecto de ia harramierila

— Estas herramientas están fabricadas con precisión

Cualquier ailaración o modificadón no especificada consíiluve Ш1 uso incorrecto y puede dar lugar a una situación

peligrosa

Al tilílizar herramíenlas eléctricas, siempre se deberán tomar

precauciones de seguridad básicas para reducir el riesgo de

20. Evile las áreas de jases — No ulice herramientas

eléctricas portátiles en atmósferas gaseosas o explosivas

Los motores de estas herramientas normalfiiente produ

cen chispas y las chispas pueden dar lugar a la ignición de

vapores.

21, Camprnebe si hay piezas dañadas — Antes d® volver

a utilizar la herramienta, compruebe si hay piezas dañadas.

Veriíiqua la aiineaclón de las piezas móviles, ia sujeción de

las piezas móviies, la ruptura tí# pieas, e( móntele y cuai-

quier aira situación que pueda afectar su iuncianannfónto

Una pieza que presenta daños debe ser reparada o

sustituida adecuadamente en un centro de servicio auto

rizado antes de seguir utilizando ia herramienta Haga que

cambien los interruptores tíaISGtuosos ert un centro de

servicio autarizado No uíiiics !a herramienta si al interrup

tor no la enciende o apaga

22, La herramienta cuenta con alslamieiito dalle ■— Y

tro es necesario conectarla a tierra La henamienta está

equipada con un cordón de dos alambres y un enchufe de

dos terminales que se pueden ufitízar en iamacBrrfentBS

estándar de 120 vollfas A C Util tea únleamanfa plazas

da repuesto idártficas cuando se nacesife realizar

SBriílKio de raparaalones,

23, Enchutas polarizados — La (terramlenla está equi

pada con un enchufe polarizado {una tarmirsal es más

ancha qua la ofraj. Este enehufe entrará an un tomacorrleníe polarizado solamente tía una manera Si ei

enchufe no entra por completo eti eí tomacarrianle. déie la

vueiía. Si sigue sin entrar, póngase en contacto con un

electricista oompetenta para instalar el tomacorrienfe

adecuado Para reducif si riesgo de sacudidas eléctricas,

rio haga ningún cambio en ei enchufe

24. Cordones de exiansfón — Un cordón da tamaño

msuficianle causará una caída de tensión de linea, dando

lugar a pérdida de potencia y racalantamianto Utilice un

cordón ds calibro 18 o más grueso ROTA: Cuanto más

pequeño as el número da calibre, más grueso es a)

cordón {Hay cordones de extensión disponibles.)

25. ADVERTENCIA — La utilización de cordones dañados

puede producir sacudidas eléctricas, quemar o electro-

cu lar

LEA Y CONSERVE TODAS LAS INSTRUCCIONES ANTERIORES

MAHTIRHVflEKTO DE ESCOBILLAS REEMPLAZABLES

Modelos 572 610520,572 61053D y 572 610720

Sa deberán inspeccionar las escobillas frecueiuamente

cuando las herramientas se utilicen de manera continua. Si

ia herramienta es utilizada espafádícamente, pierde paten

cia, hace ruidos extraños o funciona a velocidad reducida,

revise las escobiltas. El seguir utilizando ia herramienta en

este estado la dañará de manera permanente

EL EXTREMO CUBWOOE

LAESCDaiLLADÉBECOINCIDiR

CONIACURUATURADELA

CAJAPRQTECTORA

ESGQBtUA

MUELLE OE

I iWr-f /

ESCOBILLA

CURVATURA DE LA

CAIA PROTECTORA

TAPA DE U

ESCOBílLA

Con e! cordón desenchufado, saque las tapas de escobilla

una a una con un destoffiillatíor pequeño girando la lapa

en sentido contrarío al de las agujas del reta} y revise cada

escobilla

Si la escobilla tiene una lonoítud inferior a 1/8' y la super(fctg del extremo de la escobilla que hace contacto con el

conmutador está ásjrera y/o corroída, se deberá cambiar

Revise ambas escobillas. Normalmente, las escobilías no

S8 desgastarán simultánsarnonte- S¡ una escobilla está

desgastada, cambie ambas escobiilas Asegúrese de que

las escobillas se instalan tal como se muestra en (a ilus

tración La superficie curva de !a escobilla debe coincidir

con la curvatura det conmutador.

Después de cambiar las escsblitas, se deberá hacer

íunctonar la herramienta sin carga; colóquda sobre una

superficie limpia y hágala funcionar tlbrernento durante

5 minutos antes ds someter a carga {o utiiizar) la herramíenta Esfo parmitirá que las escobifías se asienten

adecuadamente y haré que caria juego de escobillas pro

porcione muchas más horas de servició. Esto también

prolongará la vida total de la herramienta, ya que te super

ficie del conmutador lardará más en desgastarse

RODAMIENTOS — Las lisrramionlas mocánioas gira

torias Has. 572.610520 572.61053D y 572,.810720 tienen

una coRstrucctón da todamleníos de bolas dables. Con

una uttnzación normal, ninguno de estos tipos tsquiero

tubrisación aflistonsl-

Pàgina 7

PREGAÜCION;

Todo e! servicio do ajustes y reparaciones de esta herra-

mianta (excluyendo-e! cambio de-BSCoWílas paro-ios

modetos 572.610520 572 610530 y 572,610720} deberá

ssf realizado por un representante ¡fe servicio autorizado

jlMPORTANTEi

La utilteacióft da accesorios o aditamentos que no sean Sos

suministrados por Sears puede ser peligrosa

Page 8

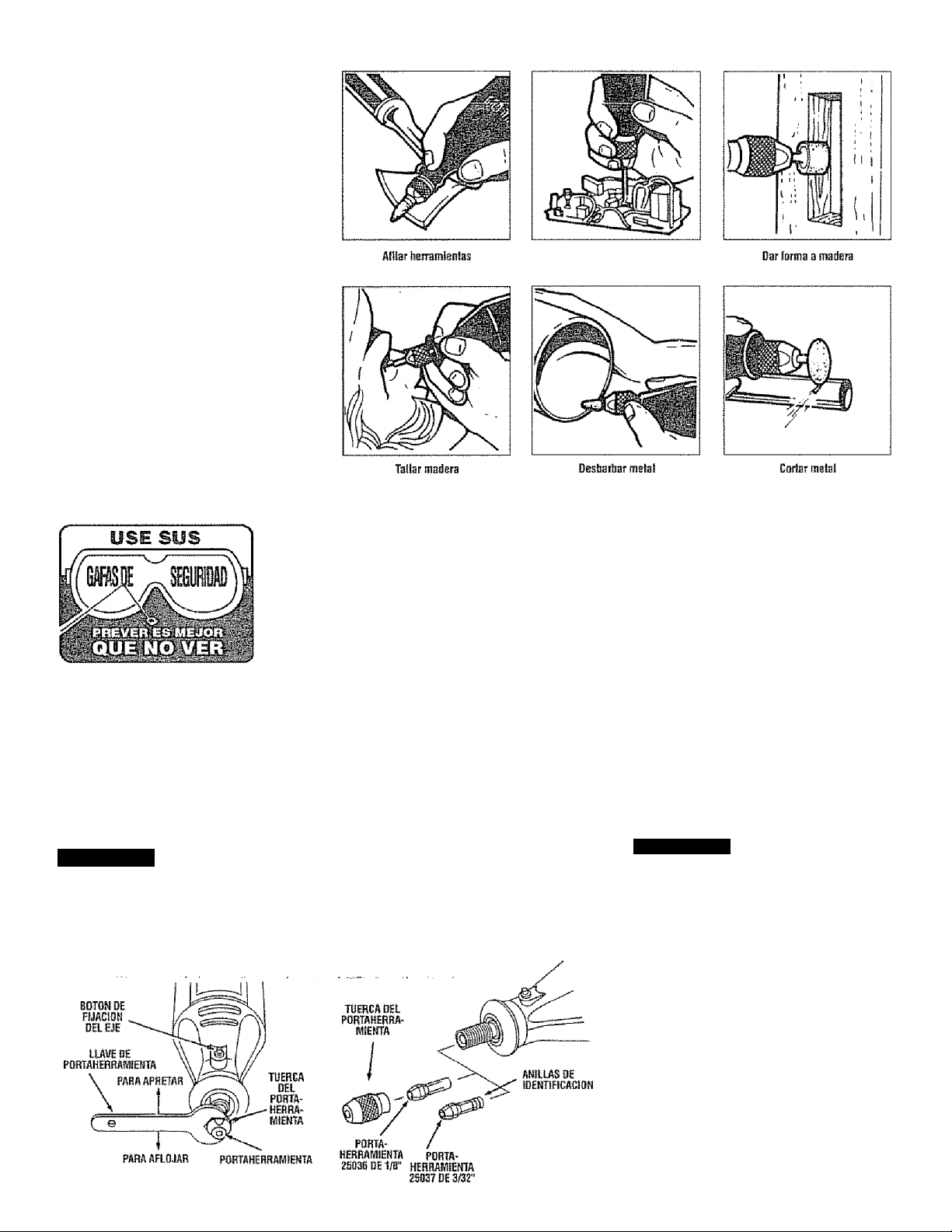

He aquí ejemplos

de lo que una

herramienta

Craftsman de

SEARS puede

hacer...

marcha,

Con b! cierre dei eje acoplado, utilice la liavi de poría-

herramlenta para aflojar te tuerca dei portatierramienta ert

caso de que sea necesario Cambie aGcesorJos iníroduDiendo el nuevo accesorio en e! portaherramienta hasta

donde se pueda para mlnlmHar el descefttrarnienlo y el

desequilibrlQ Con el cierre del eje acoplado, apriete la tuer

ca del portaherramienta con los dedos hasta que $1 porta-

»«ERItlíCIA

lugar a que objetos exlraños salgan riespadidos y caigan

en los ojos, lo cual puede tener como resuíladn lesiones

graves en los ojos, Use siempre gafas de seguridad o pro

tectores para los oíos antes de comenzar a hacer funcionar

la íierramienta mecánica RBComendaraos usar una más

cara de seguridad de amplia campa visual para utilización

sobre anteojos o galas de seguridad estándar.

Cuando aprre la berramienta, tenga cuidada de no cubrir

las aberturas de ventilación con la mano Esto bloquea el

flujo de aire y hace que el motor se recaüenie

i«6viai:ENil

cambiar accesorios, cambiar porlahcrramienlas o

Tsaliiar servicio de ajustes y reparaciones en ia

herramienta giratoria .

POflTAHERRAWÜENTA“ Para atlojarlo, Oprima primeto el

cierre det eje y gire el eje a mano hasta que el cierre acople

el eje. imptiendo así toda rotación posterior

Ei funcionamiento de cuaíquier

hetramieMa mecánica puede dar

Desenohufe siempre ia

herramienta giratoria antes de

herramienla agarre el cuerpo del accesorio Evite apretar

excesivamente ¡a tuerca del portaherramienta El sistema

de portaherramienta constituye un método excelente de

fijar accesorios

POBTAHERÍIAWHENTAS — Hay poflaherramíBntas de dos

tamaños distintos (vea la ilustración) disponibles para la

herraniienia giratoria con objeto de acomodar diíeremes

tamaños de cuerpo. Para instalar un portaherramienta dis

tinto, saque ia tuerca del portaherratrtienla y quite el portaherramiertla viejo Introduzca ei extremo no ranuratio dei

poítaherramienta en el agujero que se encuentra al final del

CUADRO DE iDENTIFICACiON DE RORTAHERRARliEMTAS — Los tamañas de portaherramienta se pue

den identificar por medio de las anillas que se encuentran

en e! extremo posterior del portaherramienta

a poilaherramísnta de 1/32' tiene (1) anilla

a portaherramienta tfa 1/1 S‘ tiene (2) anillas,

a portaherramienta de 3/32‘ tiene j3) anüias

Ei portaherramienta de 1/8' no tiene aniíiss

Taladrar ШП precisión

No acopie ol cierre misníras la

herramienta giratoria está en

eje dé ta herramienta Vuelva a colocar ia tuerca dei porta-

hBrramíerrta en el eje. Uülica siempre el partaherramianta

que correspanda ai lamais risi cuerpo del accesorio que

usted piensa utilizar. Nunca intente introducir a la tuerza

en un portaherramianta un cuerpo de diámetro más grande

que el que pueda aceptar dicho portaherramienta

EQUILIBRADO OE ACCESORIOS — Pata realizar trabaja de

precisión es importante que todos tos accesorios se sn-

cuertlren bien equibrados jde iranera muy parecida a tas

gofítas do su automóvi!) Para nivelar o equilibrar un acce

sorio. afloje iigerameníe la tuerca del portaherramienta y

haga girar el accssorio o el portaherramienta 1/4 de vuelta

Vuelva a apretar 1a tuerca dei portaherramienta y pDtsga en

marcha la herramierrla giratoria. Ei sonido y !a sensación

del accesorio deberán perniílírie saber si este está funcio

nando ds manera equiiibrada. Siga realizando ajustes de

esta manera hasta lograr el mejor equilibrio Para mantener

equilibradas tas fresas abrasivas, antes de cada ulilizadón.

can la fresa fijada de manera segura en el portaherrafflienta, encienda la herramienta giratoria y haga tuncionar

ia piedra de reacandlcionamiento apoyándola ligeramente

contra la fresa que gira Esto quita las partes que sobre

salen y niveia la fresa para que ésta queda bien equilibrada

Rd utlIíGs ruedas do amalar de

velocidad de ia herramienta giratoria puede hacer que

las ruedas mas grandes se rompan y salgan despedidas,

piídlendo causar lesiones.

SESUBIMD - Protéjase le$ ojos al amolar o fresar con la

herramierría giratoria . use siempre urras gafas de

seguridad de tipo aprobado

Recuerde, su nueva herramíenla giratoria de Sears es la

mejor herramienta mecánica de su dase Pero su rendi

miento sólo es tan bueno como los accesorios con íos que

se Utiliza, Recomendaffios que únicamertle se utilicen acce

sorios de Sears La utilización de cualquier otro accesorio

puede constituir on peligro. Esperarnos que ia herramienta

mecanioa giratoria Craftsman ds Sears le patitsita disfrutar

ds muchos años de saüsfacciótt sin problemas

mas da 1" de diametro. La alta

Página 8

USE UNICAMENTE

ACCESORIOS RECOMENDADOS

Page 9

no debe apoyarse sobre la hiframienta ni empujarla para

Herramienta

mecánica giratoria

Craftsman

La herraítiienla girasoria pone en la mano del usuario po

tencia a alta velocidad Sirve de (altadora- amoladora, puüdora. üladora, cortadora, capillo mecánico, taladro y más

La herramienta giratoria tiene un pequeño y potente motor

fliéctfico, se agarra cómodamente con ia mano y está he

cha para aceptar una amplia variedad de accesorios,

incluyendo ruedas abrasivas, brocas taladradoras, cepillos

de alafnbífl, pulidores, cortadores para grabar, brocas para

fresar y ruedas de corle Los accesorios vienen en íormas

diversas y te permiten a usted realizar varios trabafos diísrentes A medida que se vaya ísmillsrizando con la gama

de accesorios y sus usos, irá dándose cuenta de ta gran

versatilidad de ta herramienta giratoria Oescubrlfá dacenas de usos en los que no liabía pensado hasta ahora

El verdadero secreto de la herramienta gitaloria es su vetocidad Para entender las veníalas que ofrece su alta velo

cidad, usted te de saber que el taladro eléctrico portátil

estándar luncíona a velocidades de hasta 2,800 revolu

ciones por minuto. La herramiarita giratoria funcioria a

veiocidacles de hasta 30.000 revoluciones por minuto El

taladro eíéctrico típico es una herramienta de baja valocldad y par motor alto; la herramienta giratoria es justo lo

contrario •“ una herramienta de altó velocidad y par motor

baio La diferencia principal para el usuario es que en las

iierramierttas de alta velocidad, la vetocldad combinada

cotr el accesorio montado en el portaherramtenta realiza el

trabaio Usted no tiara que ejercer presión sobre la herra

mienta, sino simplemente sujetatla y guiarla En las herra

mientas de baja veiocidad, usted no soto lietie que guiar (a

herramienta, sino que además tiene que ejercer presión

sobre ella, tal como lo hace, por ejempio, al taladrar un

agujero

Esta alta velocidad, junto con su tamaño compacto y am

plia gama de accesorios especiales, es lo que hace que la

harramtebia giratoria sea distinta a otras herramientas me

cánicas La velocidad pertnile que la herramienta haga tra

bajos qua las herramientas de baja velocidad no pueden

hacer tales como corlar acero lemplado, grabar vidrio, etc

El sacar el mayor provecho a ta herramienta giratoria es

cussltón de aprender cómo dejar que la velocidad haga el

trabajo para ustsci

que entre an la pieza de trabajo

En vez de hacer esto, haga descender lentamente hasta la

pieza «e trabajo el accesorio mientras éste gira y deje que

toque e! punto en el cual usted quiere qua eotnienoe el

corte (o lijado o grabado, etc) Concéntrese en guiar te he

rramienta sobre la pieza de trabajo elsrdendo muy poca pre

sión con la mano De|0 que eí accesorio reaífco el trabajo

Normalmente, es mejor realizar una serie de pasadas con !a

herramienta en vez de intentar hacer todo eí trabajo en una

sola pasada Por ejemplo, para realizar un corte, pase la

hsrrafflíenta hacia adatante y hacia atrás sobre la pieza ds

Irabaj!) de manera muy parecida a eotriQ lo haría con una

brocha pequeña Corte un poco de material en cada pasada

hasta que llepue a (a prolutídldad deseada Para ia mayoría

de los trabajos, es mejor uiiitear un toque hábil y suave

Cofl éste, usted lagra el mejor control, reduce las posibili

dades de cometer errores y logrará que el accesorio realice

el trabajo de la manera más eíte posible

Para tener mejor control al realizar trabajo lino, agarre la

herramienta giratoria como un iápiz entre eS dedo pulgar y

g| dedo írtdice

Utilización de

la herramienta

Este as el método de “agarre'' para sujetar la lisíramíenla

mecánica giratoria

Lea las siguientes sBccíones cuidadosamente Le ayudarán

a utilizar la herramiertta giratoria correctamente y a seíecciemar el accesorio correcto para el trabajo que usted de

sea realizar

Erprimer psó para aprender a utilizar la herramienta gira

toria consiste en acostumbrase a la herramienta Téngala

an la mano y 8:<per¡meme la sensación que producen su

peso y equilibrio Toque la parte cónica de ta caja protec

tora Esta parle cónica permite agarrar la herramienta gira

toria de manera rauy parecida a como se agarra iwa pluma

o un lápiz

Cuando encienda la herramienla por primera vez. sostén

gala aisjada de la cara Los accBsortos pusdsn resultar

dafíactos durante el transporte o ef manejo y pueden salir

despedidos ai gattar velocidad Esto no es común, pero si

sucede

Practique primero en materiales da desecho para ver cómo

corta la herramienta giratoria Tenga en cuenta que el tra

bajo es realizado por la vatocidad de la herramienta y por ei

accesorio que se encuentra en el portaherramienla Usted

utilizado en operaciones talas como el amolado de una

superíicie plana o la utilización de ruedas de recortar

imOVERTEfieiAi

alta vsÍBsIdad o corladores de carburo de Sungsleno.

tenga siempre ta pieza de trabajo fija cen abrazaderas

Nunca intente sujetar ta pieza de trabajo can una mano

cuando este utilizando cualquiera de estos accesorios

La razón es que estas ruedas se atascaran si se ladean

ligeramente en la ranura y pueden experimentar retro

ceso, causando una perdida de control que tendrá como

resutíado lesiones grases La otra mano se debe utilisr

para afianzar y gufar ia mano que sujeta ta herramienta.

Cuando una rueda de rocetlar se atasca, normalmente la

propia rueda se rompe. Cuando la sierra de acero, los

coriadorís de alta velocidad a el cortador de carburo de

tungstene se atascan, es pasible que sallen y se salgan

de la ranura, con te que usted podría perder el cenirol de

la tierramisnla.

Al utilizar sierras de acero, rue

das de recortar, cortadores de

Página 9

Velocidades de

funcionamiento

y accesorios

Ajuste el intíicacior de velocidad de manera adecuada para

el trabajo que se va a realizar; para lograr tos mejores resul

tadas al trabajar con materiales diferentes, se deberá

regular la veiocidad de te herramienta giratoria Con el mo

delo 572 610520 sólo se debe usar un conimi de velocidad

de salida de onda completa tal como el rnodelo 2514 de

Sears (dispontbie a través del catalogo unicamente), Los

modelos 572 610530 y 572 610720 de ía herramienta

giratoria tlenert üti control de veiocidad integrai y nunca se

deberá Utilizar un control de veioctóatí externe con estas

herramientas

Can objeto de seisccionar la velocidad correcta para cada

trabajo, uticfl una pieza de maieriat de práctica Varíe ía

velocidad a fin de encontrar ia mejor velocidad para el

accesorio que usted está utilizando y el trabajo que va a

realizar.

Hay tres tipos básicos de herramientas giratorias; modelos

de una sola velocidad de dos vetocitísdes y de veiocidad

variable En los modelos de una sola velocidad hay un

interruptor "ON-ОЕГ (de eneendido y apagado). Cuantía й

interruptor está sncendido. la herramienta funciona a

28,000 RPM En el mortalo de dos velocidades hay un

interruptof de ALTA y BAJA velacidad Cuando ei indicador

del interruptor se encuentra en la posición baja, la

herramienta funciona a unas 20,000 RPM Cuando ei

indicatiQr dei interruptor se encuentra en la posición aba. la

herramienta funciona a unas 30,000 RPM En eS modelo de

velocidad variable hay un indicador dei interruptor que tiene

una línea blanca sobre ét Desticelo hasta ei número de ía

caja protectora para seleccionar ia velocidad de functana-

fíi lento que se necesita desde 5.000 hasta 30,000 RPM

Puede consultar ios cuadros de ia página 10 para

detorniinar la velocidad adecuada basándose en eí material

en el que se está írabajando y eí tipo de cortador и otro

accesorio que se está uliiízantío Estos cuadros ¡e permiten

seleccionar de un vistazo tanto el accesorio correcto como

ia veiocidad óptima

Si usted tiene un murielD de una sola veiocidad э de dos

velGCltíades, podrá utilizar muchos accesorios para realizar

una gran variedad de trabajos Para la mayoría de tas

aplicaciones, todos los modelos de la herramienta giratotia

ítebefán utitorse a máxima velocidad

Necesidades de yelocidades más lentas

Sin embargo, ciertos matertalss (algunos plásticos, por

ejempio) requieren una velocidad relativamente lenta

porque a alta velocidad ia fricción de ia herratnienta genera

cafar y hace que e! plástico se funda

Las veiocidades lentas (15CQ0 RPM o menos) norraal-

menls son mejores para operaciones de pulido utilizando

los accesorios de pulir de íieílro Puede que también sean

mejares para trabajar en proyectos delicados tales como

trabajo de tallado de ’cáscaras de huevo“, tallado de ma

dera delicada y trabaja con piezas frágiles de modelos

Slerapre debe pulir con accesorios de cepio de alambre a

velocidades más tenias y nunca superiores a 15,000 RPM

Las velocidades más altas son mejores para tallar, corlar,

íresar, dar forma y cortar esquinas o rebajos en madera

Las maderas duras, tos metales y si vidrio requieren un

ttmeionamienlo a alta velocidad, y el taladrado también

dóberá realizarse a atlas velocidades

La velocidad de te herramienta giratotia se controla ajus

tando este irrdicador en (a caja protectora

Page 10

Las posìctones correspondlerrtes a revoluciones por mi

nuto apfosiimadas para la lìerramienla giratoria tnodelo

572 610530 de veiocidad varìable son:

Posición del IntemiptorIntervalo de velocidad

1 4,500- 8,000 RPM

2 9,000-11.000 RPM

3 12.000-17.000 RPM

4 18.000 “24.000 RPM

S 25,000-30,000 RPM

KDTA; Las cambios de tonstün afeetan a ia vslocldad.

Una tansián de entmda laduclda hará bajar las RM de

la henamletilB, especialmente en la posioián más baja

Si parece que la herramienta íunciana déspoto, saieccione una posición de veluoidad más alia de manera

correspandienle.

a punto que hay que resordar es tí slquleníe: Usted puede

reatlar la mayor parte de los trabajos can e) moctelo de una

sola velocidad funcionando a su wlocidad norma! de 28,000

FIPM Pero para ciertos materiales y tipos de trabajo usted

rreceslla velocidades más lentas ~ esta es la rsén por ts

cual fueron desairoilados tos modelos de veloeiflad variabte-

Para ayudarle a deíBímiriar la velocidad de funcionamisfito

ópiima para diferentes msteriates y dlslintQS accesorioB,

hemos preparado una serie de tablas que aparecen en (a

página S Consultando dichas tablas usted puede deter

minar las velocidades recomendadas para cada tipo de ac

cesorio Eche un vistazo a esías tablas y familiarícese con

ellas

En üilima instancia, ia mejor maneta de determinar la velo

cidad correcta pata realizar trabajo en cualquier fTiaterW es

practicar durante unos minutos utilizando una pieza de

desecho. Inciuso después de consultar ai cuadro. Usted

puede descubrir rápidamente que una velocidad más lenta

o más rápida es mucho más eficaz sirapSemente obser

vando qué pasa cuando usted realiza una o dos pasadas a

diferentes velocidades Por ejemplo, al trabajar con plás

tico comience utilizando un régimen bajo de welociclacl y

aumente la velocidad hasta que observe que el plástica se

está fundiendo en s! punto de contacto Luego, reduzca (a

velocidad íigsrameníe para obtener la velocidad da trabajo

ópiimaAlgunas reglas prácticas en cuanto a velosidad:

t E) piásiico y los materiales que se funden a bajas tem

peraturas deberán cortarse a velocidades bajas

2 El pulido, el bruñido y !a limpieza con un cepillo de

alambre deberán reaíizarsa a velocidades Infefiores a

15,000 RPM para evitar que el cepillo sufra daños

3 La madera blanda se deberá cortar a ate velocidad

4 El hierro o el acero se deberán cortar a máxima veloci

dad si se utiliza eí accesorto de carburo de itmgsteno,

pero a velocidades más lemas si se utilizan cortadores

de acero da alta velocidad Si un cortador de acero de

alta velacidatí comienza a vibrar niidosaraente — nor

malmente esto síQtsffica que está íuncionando dema

siado despacio

5 El aluminio, las aleaciones de cobre, las ateacíones de

plomo, tes aleaclattes da slna y el estaño se podrán

cortar a cualquier velocidad, según el tipo de corte que

se está realizando Aplique al cortador parafina u otro

luWcants adecuado para evitar que el material cortado

se adhiera a tos dientes del cortador

El aumetitar la presión ejercida sobre la herramienta no es

ia solución cuando ésta no corta corno usted cree que

debería hacerlo, Tal vez usted deberla utilizar utt cortadar

diferente y quizás un ajuste de ia velocidad salucionarta el

problema Pero el apoyarse sobre te fierramlenta raramente

ayuda

POSICIONES DE V

NUMERO DE

ARTICULO

S i 1 Sk FTi ’ tleíacírlsá вага caries ligeros; precaución de no quemar en ranuras profundas

MADERA

BLANDA

MADERA

DURA

t Según Ib tlJreccIün de corte respecto a la veta.

MATEfiíALE S t

UKíMADOS MUÍSHU

PUS'RCO [

CORTADORES DE ALTA VELOCIDAD

53101 5 6 3 2

25014, 53102 5 3 2 1-2 2

25012, 53070 S s 2 3 5

53103,25011 5 3 2 2 2

25008 5 5 2 1-2 1-2

£5

líiOUlO 4 2 1-2 2 2

CORTADORES DE GRABAR PEQUEÑOS

53074, 53075

5

5 1 4 4 3

DoUíb 5* 5* i 3> 4 2

PUNTA DE PULIR DE CAUCHO

..............

2S534 ——] ^ ¡ ^ 1 ^ f 2 ! T 1 1 1

ACCESORIOS DE CORTE — VEA LA ADVERTENCIA DE LA PAGINA 7

25026 1 5 ! 5 !

25024,5308Б 1 i 1 5

SI>r»*%*'Ni'rT;í3 íJiC. vr^íittiiV M > AS “ АЛ ifislmwMkl*

Г4Л1ПДП fííaííClACi

53094 3 3 1

53107,53108, 53109,

3 2*

53111.53095, 63096

53090, 53091

53092

5

5

5»

2* I

PIEDRAS DE AMOLAR DE OXIDO DE ALUMINIO

53078 1

25053

r(-¡ti^4'%'*l 62 e (PÑi L7

1

1

25057 1 1 1-1

2505B

1

' PIEDRAS DE AMOLAR DE CARBURO DE SILICIO ' ............................................ ’ .........................................

5307Э, 53080

25062

25063

CORTADORES DE CARBURO DE TUNGSTENO

53071,52072, 53104 4 4 1 2

S3073, 53105 5 S 1 2

ALUMINO,

LATON, ETC.

CAPARAZON/

PIEDRA

4

1 1

1

1

3

1-2 1-1

1-2 1-1

1 1-1

[ 2 1

1-2

1

3

3

1-3

CERAiyilCA I VIDRIO

1

j

i

i 1

2 2

1 2

1 2 1

1-2

Págirra 1(3

Page 11

Accesorios para la herramienta giratoria

Et número y fa diversidad de accesorios para la herra

mienta giratoria sor casi iiimitados Hay una categoría

adecuada para casi lodos los trabajos qua usted tenga que

realizar — y una diversidad de tamaños y íormas dentro

de cada categoría que íe permiten a usted obtener e¡ acce

sorio perfecto para cada necesidad

Ports hBrrsntisniss

Si usted piensa utilizar diversos accesorios, !e recomen

damos que iiiicialinente compre uo juego compieto ds cua

tro partaterramlentas fiuórdetos con objalo de tener ei

tamaño adecuado de porlaherramienta para cualquier

accesolo o broca taladradora que quiera usar En la actua

lidad los portaberamientas No 25036 de 1/8", y No 25037

de 3/32" acomodan todos los accesorios Sears disponibles

Piedras de amolar de óxido de aluirtífiio

Redondas, puntiagudas, planas — diga qué forma quiere y

habrá alguna disponible en esta categoría Estas piedras

están hechas de ónldo de atuminio y cubrerr prácticamente

todos tos tipos posibles de aplicaciones de amolado üil*

celas para afilar hojas de cortadoras de césped, puntas

de deslorniliador, cuchillos. tijeBS, cinceles y oíros herra

mientas de corte ütiücslas para quitar rebabas de piezas

metálicas furttíitlas, desbarbar cualquier metal después da

cortarlo, alisar juntas soldadas, amolar remaches y quitar

herrumbre En los talleres de maquinaria, normalmente las

brocas y ios corladores de aita velocidad son amoladras con

muelas de óxido de aluminio

Cepilles de alambre

Hay tres formas ditereníss de cepillos da alambre dis

ponibles Para obtener mejores resultados, los cepillos ds

afambre se deberán utilizar a velocidades no superiores a

15,000 RPM Estos cepülos quitan herrumbre de las

herramientas y otras superficies msíálicas, y limpian y

bruñen piezas metálicas Ulllícelos para trabajos taies

como la limpieza de conexiones eléctricas para asegurarse

de que ía conducción es buena

VásISQOs

Un vastago es una espiga con una cabeza roscada o de

tornillo, y se requíBren vastagos cuando se utitan acce

sorios para piítir, ruedas de corle, discos de lijar y puntas

de pulir La razún por la cua! se utilizan vásíagos es que los

discos de lijar, ias ruedas de corte y accesorios similares

deber! ser sustituidos Irecuentemenís El vástago ss una

espiga permanente que permite que usted cambie

ünicaments la cabeza desgastada cuando sea necesario,

por lo que se ahorra ei costo de sustituir ei eje cada vez

Piedras de amolar de carburo de silicio

Más duras que las puntas de óxido de aluminio, estas pie

dras están hechas especialmente para la utilización sn

materiales duros tales como vidrio y cerámica, Algunos

usos típicos podrían ser la remoción de marcas que sobre

salgan y e! exceso de esmalte en cerámica, y si grabar en

vidrio

czzi:|»>

Vastago de tornillo No. 53089

Este es un vastago ds torniilo utilizado con la pimía de

pulir de fieltro y las ruedas da pulir de fieitro

O

Vastago de torniilo pequeño Ko. 25028

Este es uti vastago con un tomillo pequeño en la punta y

se utiliza cotí ruedas de corte de esmerit, discos de lijar y

ruedas de pulir

Cortadores de alta velocidad

Disponibles en muchas formas, los cortadores de alta veíDcMad se ufilizan para tallar, cortar y ranurar madera,

plásticos y metalas blandos tales como aiumlnio, cobre y

latón Estos son tos accesorios que se han de utilizar para

realizar a pulso fresado o tallado de madera o piástico y

para realizar cortes da precisión

Cortadores do carburo de tuogsteno

Estos son cortadores duros y de larga duración para utización en acero templado. Geramtsa cocida en horno y

otros materiales muy duros. Se pueden utilizar para grabar

en herramientas y equipos ¡tí iardin

Cortadores de grabar pequeños

Este grupa de corladores abarca una amplia gama da tama

ños y termas, y tos talladores están hechos para realizar

irabajo complicado en cerámica (del tipo no cosido e«

horno), tafiados ert madera, joyas y tallados en marfil, ca

parazones de moluscos o barbas de ballena Se uiizati

frecuenlements para hacer piacas de circuitos impresos

complicados Ns se debsrt utilizar en acero ni en otros mate-

riaies muy duros, paro son excelenles en madera, plástico y

malBles blandos Macesitan un portaherramíenta de 3/32‘

Accesorios para pulir

Entra estos accesorios se encuentran una punte de pulir

impregnada y una rueda de pulir Impregnada para dar un

acabado liso a las superficies metálicas; una punta de pulir

de fleliro y una rueda de pulir de fieltro, y una rueda de pulir

de tela Todos estos accesorios se utilizan para pulir plásti

cos, metales, joyería y pequeñas piezas También se en

cuentra en este grupo un compuesto para pulir (No 25031)

para utilizar con los pulidoras de tiellra y de tela

Íes puntas de pulir dejan una superticlB muy lisa, pero se

obtiene un brio mayor utiiizando ruedas de fieltrcr o de

tela y compuesto para puiir

No se necesita eompuesto para pulir cuando se utiliza la

rueda de pulir 2S034

Ruedas abrasivas de óxido de alumiuia

Se utilizan para quitar pintura, desbarbar metal y pulir

acero inoxidable y otros mslaíss Disponibles con grano

fino y mediano

Accesorios para lijar

Los discos tíe lijar da grado tino, mediano y gruesa están

hachos para acopiarse en e! vastago No 25028 Se

pueden utilizar para casi todos ios trabajos pequeños de

lijado que usted tenga que realizar, desde la fabricación de

modatos hasta el acabado de muebles finos. Además, está

e! lijador de tambor, un diminuto tambor que encaja en la

herramienta giratoria y que hace posible dar forma a

madera, alisar libra de vidrio, lijar sn ef interior de curvas y

otros lugares difíciles y realizar otras trabajas de lijado

Cambíe las bandas de lijar del tambor a medida que se

vayar! desgastando y pierdan el grano Las bandas vienen

en grados finos y gruesos

O

Cepilles áe cerda

Estos cepillos constituyen excetantes herrarnisnlas para la

limpieza da objetos da plata, joyas y anügflsdades. Las tres

íormas hacen posibíe tener acceso a rincones estrechos y

otros lugares dificiies Los cepilios de cerda se pueden

utilizar con compuesto para pulir con objeto de lograr una

limpieza o pulido más rápido

1йШ|СпТСНС1А

toíiOiDhSmiBnto durante a! menos un minuto antes de

utlilzar la rueda. Durante este Iferapo nadie debe

simarse detenie del cepillo o en Ипва con osle Para

obtener rnejores resultados, no haga lunefonar la

herramisnia a mas de 15,000 RPÜ

RuBClos ós corts

Estos delgados discos de esmeril o de fibra de vidrio se

utilizan para retranar, corlar y operBCiones simíteres Utilí

celos para cortar cabezas de perno y tuercas agarrotadas o

para volver a ranurar una cabeza de torniilo que esté tan

dañada que no permita usar un dastornltlador. Buenas para

cortar cable SX, varillas pequeñas, tubería, cable, y para

cortar agujeros rectanguiaras en chapa maláiiea

alta vslocídad o cortadores de carburo de tungsteno,

tenga siempre lo pieza de trabajo fijada can abrazaderas

de manera segura Nunca intente sujetar la pieza de tra

bajo con una mano cuando este utilizando cualquiera de

estos acossorÍDs . La razón es que estas ruedas se atas

caran si se tadean Ügeramenle en la ranura y pueden

experimeSlBr fólrooéso, cáusáñdó tina perdida de odn-

IfoJ que íerttfra como reauitado lesiones graves. La otra

mano S6 debe utilizar para afianzar y guiar la mano que

sujeta la hertatnSeríía. Cuaitíto una rueda de recorlar se

atasca, normaímsnie !a propia ruada se rompe. Cuando

las sierras do acero, el coriador de alia velocidad o el

cortadar de carburo de tungsteno se atascan, es posible

que sailBfl y se salgan de la ranura, con lo que usted po

dría perder ot control de !s herramiertta

Deje que ios sepíhos eslen en

marcha a la velocidad de

Ai utilizar sierras de acero,

ruedas do recortar, corladores de

Página i 1

Page 12

For the repair of replacement parts you need

delivered directly to your home

Call 7 ©in *** 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

Para ordenar piezas con entreQa a

domicilio -1-800-659-7084

For in-house major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1800-473-7247)

Para pedir servicio de reparación a

domicilio -1-800-676-5811

For the location of a Sears Parts and

Repair Center in your

Call 24 hours a day, 7 days a week

1-800-488-1222

When requesting service or

ordering parts, always provide

the following information:

• Product Type • Pari Number

* Model Number •» Part Description

Cuando solicite servicio o pida

piezas, dé siempre fa siguiente

información:

•Tipo de producto • Número de

«Número de modelo • Descripción de la pieza

America’s Repair Specialists

Loading...

Loading...