Craftsman 572.61000, 572.61002 Owner's Manual

owners

manual

CAUTION:

Read SAFETY

RULES and

INSTRUCTIONS

carefully

CRAFTSMAN

MODEL

NOS.

572.61000

&

572.61002

MADE

IN

U.S.A.

SEARS,

ROTARY POWER

assembly • operation

ROEBUCK

AND CO., Chicago, Ill. 60684 U.S.A.

TOOLS

- ---

---

--

------

Safety

READ AND SAVE ALL THE FOLLOWING INSTRUCTIONS:

1.

Keep

work

and benches invite injuries.

2.

Avoid

expose tools to rain. Don't use

damp

or

in the presence of flammable liquids or gases.

Avoid chemical or corrosive environments.

work

Keep

Guard

3.

body contact with

example: pipes, radiators, ranges, refrigerator enclosures.

4. Keep

contact tool or extension cord. All visitors

should be kept away from work areas.

5. Store

should

up place - out of reach of children.

Don't

6.

and safer at the rate for which it was intended.

7. Use

attachment to

Don't use tool for

example tree limbs or logs.

8. Dress

clothing

moving parts. Rubber gloves and

area clean - Cluttered areas

dangerous

wet

locat

area well lit.

against

children

idle

tools

be stored

force

right

tool -

don't

properly

or

jewelry. They can be

environment - Don't

ions. Don't use

electric

grounded

away

- Do

- When not

in

dry, and high or

tool

- It will do the

Don't

do

use

the

purpose

force small tool or

job

of a heavy-duty tool.

circular

- Do

shock

not intended - for

not

power

tools in

power

tools

- Prevent

surfaces. For

not

let visitors

in

use, tools

locked-

job

better

saw for cutting

wear loose

caught

in

non-skid

---------------

When

using

always

personal injury,

footwear are recommended when working

outdoors. Wear protective hair covering to

contain long hair.

9. Use safety

mask if cutting operation is dusty.

10.

Don't

cord

or yank it to

Keep cord from heat, oil and sharp edges.

11. Secure

hold work. It's safer than using your hand and

it frees both hands to operate tool.

12.

Don't

and balance at all times.

13. Maintain tools

sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords

periodically and if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged.

Keep handles dry, clean, and free from oil and

grease.

14.

Disconnect

before servicing, and when changing

sories, such as blades, bits, cutters.

15. Remove

-Form

adjusting wrenches are removed from tool

before turning it on.

glasses-Also

abuse

cord

- Never carry tool by

disconnect

work

- Use clamps or a vise to

over-reach - Keep

with

tools - When

adjusting

habit

of

checking

electric

be

followed

use face or dust

from receptacle.

proper

care

- Keep tools

keys and wrenches

to see that keys and

tools, basic safety precautions

to

reduce

including

footing

not

in use,

acces-

-

-------------------

the risk

of

lire,

the

following:

16.

Avoid

carry

plugged-in

Be sure switch is off when plugging in.

17.

Outdoor

tool is used outdoors, use only extension

cords

marked.

18

. Stay alert - Watch what you are doing .

Use

common

when you are tired. Don't use

after taking drugs, alcohol or medications.

19.

Check

further use of the

parts. Check the alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any

affect its operation. A part that is damaged

should be properly repaired or replaced by an

authorized service center before further use

of the tool. Have defective

by authorized service center. Do no t use tool

if switch does not turn it on and off.

REPLACEMENTS - When servicing use

only

identical

POWER SUPPLY AC,

50-60

electric

unintentional

tool with finger on switch.

use extension

intended for use outdoors and so

sense. Do

for

damaged

replacement parts.

Hz.

should

shock, and

starting -Don't

cords

not

too

other

parts

l,

check

conditions

switches

Tool

operates on 115V.,

- When

operate tool

power

- Before

tor damaged

that may

replaced

·

tools

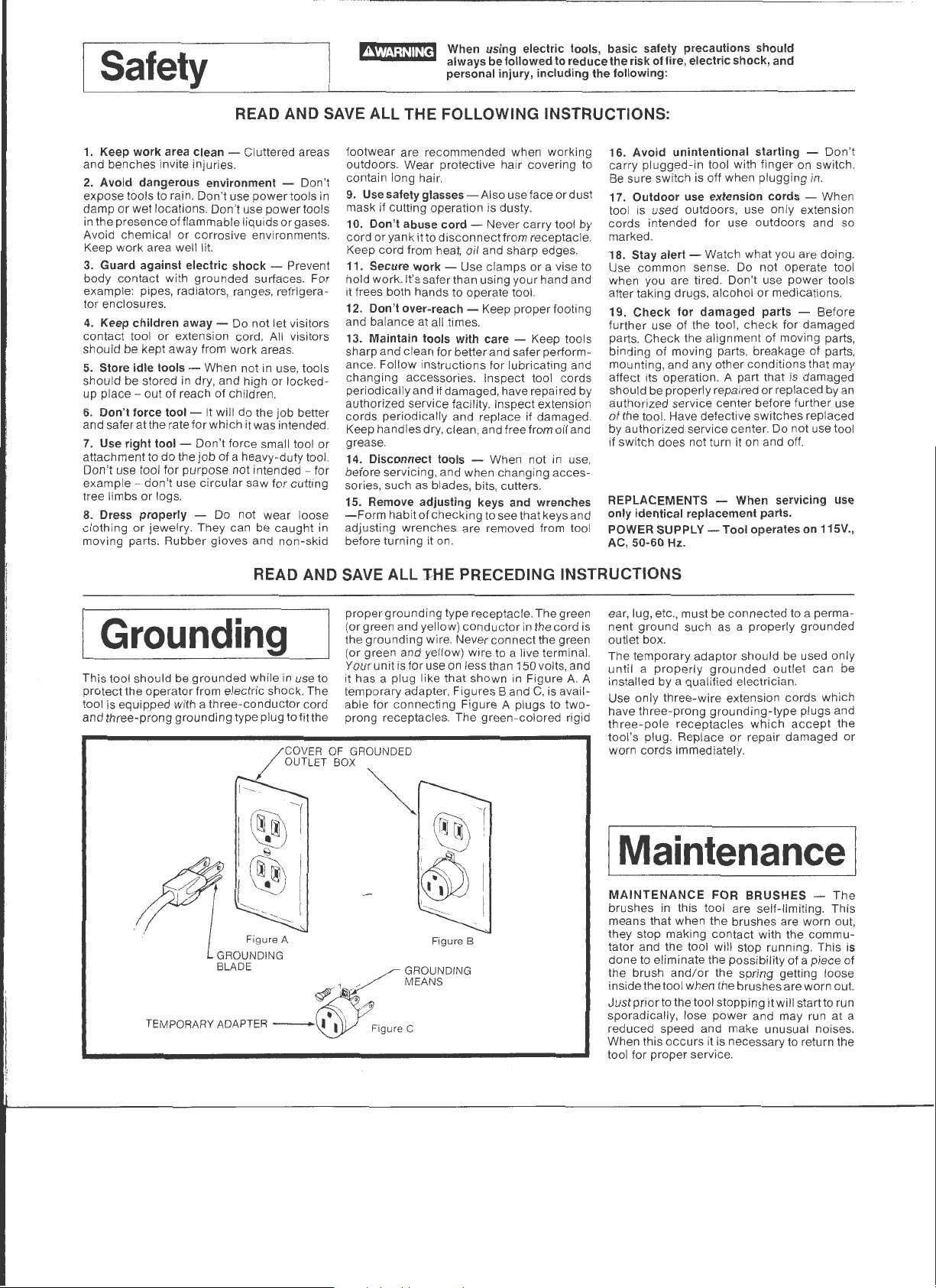

Grounding

This tool should be

protect

the operator from electric shock. The

tool is equipped with a threeand

three-prong

A1

grounded

grounding

GROUNDING

BLADE

while in use to

conductor

type plug to

I~

~

I~

READ AND SAVE ALL THE PRECEDING INSTRUCTIONS

proper

fitthe

/COVER

OUTLET BOX

-I

grounding

(or green and ye

the

grounding

(or green and yel low) wire to a live terminal.

Your

unit

it has a plug like that shown in Figure

temporary adapter, Figures

cord

able for

prong receptacles. The

OF

GROUNDED

is for use on less than 150 volts, and

connecting

~

type receptacle. The green

ll

ow)

conductor

wire. Never

Figure A plugs to

,

@!)

-I

in

connect

Band

green-colored

the cord is

the green

A. A

C,

is avail-

two-

rigid

ear, lug, etc., must be

ground

nent

outlet box .

The temporary adaptor should be used only

until a proper

installed by a qualified electrician.

Use only

have three -prong

three-pole

tool's pl u

worn cords immediately.

three-wire

g.

I Maintenance ]

MAINTENANCE

brushes in this tool are self-limiting. This

-

~B

GROUND/NG

MEANS

means that when the brushes are worn out,

they stop making

tator and the tool wi ll stop running. This is

done

to eliminate the possibility of a piece of

the brush

inside the too l when the brushes are worn out.

Just

sporadically, lose

reduced speed and make unusual noises.

When this

tool for

and/or

prior

to the tool stopping it will start to run

occurs

proper

connected

such

as a properly

ly

grounded

extension cords which

grounding-type

receptac

Replace

les

FOR

contact

the spr ing getting loose

power

it is necessary to return the

service.

outlet

which

or

repair damaged or

BRUSHES -The

with the

and may run at a

to a perma-

grounded

can

be

plugs and

accept

the

commu-

----------------------------------------------

For

example, if you

square hole in a furnace duct, the Rotary Tool

will

do

the

in

your home is slightly misaligned because

the house has settled, the latch bolt may no

longer

enter the strike plate properly, making

door

the

Rotary Tool to cut

strike plate so the latch bolt operates properly.

You can

hundreds

these for the Rotary Tool in every home.

In

addition to these special applications,

of

your

Rotary Tool for shaping or removing

wood, metal and plastics. This is

carvers use the tool, and while you may

interested in wood carving, there are many

times when you

sharp corner, or enlarge

And then there are the

jobs

done

sharpen tools, scissors and cutlery, get rid

burrs and unwanted sharp edges,

lated rust, grind

The

point

jobs

many

properties and capabilities. When you have a

job

to do, think of the Rotary Tool as one

possible solution.

t,Yl?J;@W1

jects being

result in severe eye damage. Always wear

safety glasses or eye shields before

mencing

mend Wide Vision Safety Mask for use

spectacles,

available at Sears retail or catalog stores.

j

Operation

The operation

tool can result

thrown

into the eyes, which can

power

tool operation. We recom-

or

standard safety glasses ...

_of

in

any

power

foreign ob -

com-

over

t•W4iM@eJ

METER OTHER THAN THE NO. 53088 CUTOFF

WHEEL

CAN CAUSE LARGER WHEELS TO FLY

APART AND CAUSE INJURY.

BALANCING ACCESSORIES

sion work, it is important that all accessories

be in

good

tires on

balance an accessory, slightly loosen collet

cap and give the accessory or collet a

turn. Retighten col let cap and run the Rotary

Tool. You

and feel if

balance. Continue adjusting

best balance is achieved. To maintain

until

balance on abrasive wheel points, before

each use, with the wheel point secured

chuck, turn on the Rotary Tool and run a

Dressing Stone lightly against the revolving

wheel point. This removes high spots and

trues up the wheel point for good balance.

~~E~~~

ROTARY TOOL'S HIGH SPEED

balance

your

automobile). To true up or

should

your

ci'iEER

-

(much the same as

be

able

to tell by the sound

accessory

is running in

in

~~11~D~~A~

For preci-

this fashion

the

1/4

in

the

USE ONLY RECOMMENDED

ACCESSORIES

want

to

cut

a neat

2-inch

job

quickly

and easily.

difficult to close or lock. Use the

do

of special

is to

it can

away

it

in

minutes. There are literally

applications

want

to

cut

an

by

grinding

the

Rotary

new

shapes, etc.

think

of the Rotary Tool for the

do

because of its

Or

if a

door

just enough of the

such as

think

how

wood

not

a recess, round a

opening.

and polishing

Tool. You

accumu-

own

can

unique

be

of

r•W/]jkjj~[Cj

--·····,,··-

COLLETS OR INSERTING ACCESSORIES

trVlf.!·W@ij

• " ERATE CHUCK LOCK PIN

WHILE (ROTARY TOOL) IS RUNNING.

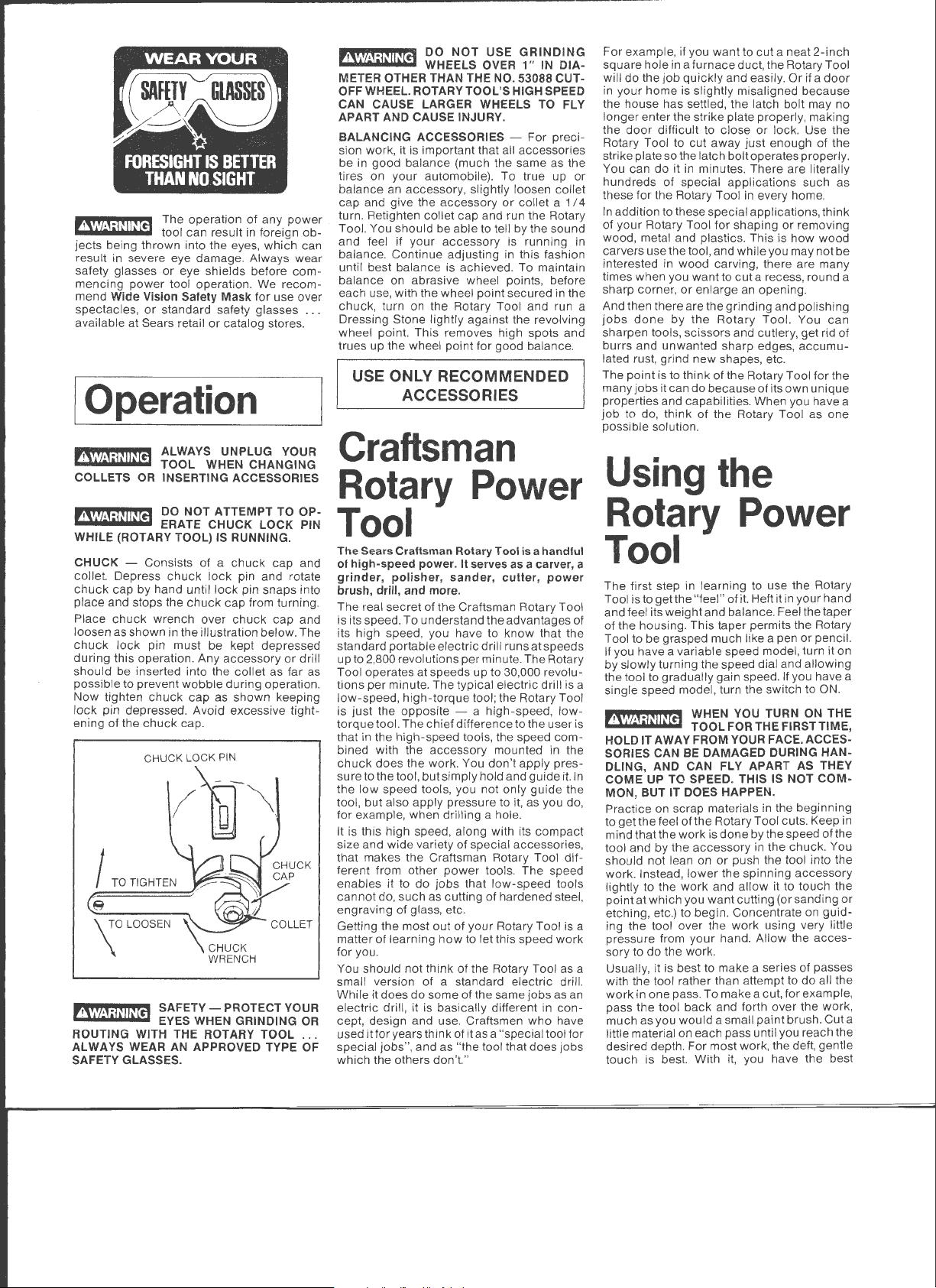

CHUCK

collet. Depress

chuck

cap by hand until

place and stops the

Place

chuck

loosen as shown in the illustration below. The

chuck

during

this operation . Any

should be inserted into the collet as far as

possible to prevent

Now

tighten

lock

pin depressed. Avoid excessive tight-

ening of the

ALWAYS UNPLUG YOUR

TOOL

WHEN CHANGING

DO

NOT

ATTEMPT

Consists of a

-

chuck

wrench

lock

pin must be kept depressed

wobble

chuck

chuck

cap.

chuck

lock

pin and rotate

lock

chuck

cap

pin snaps into

cap from turning.

over

chuck

accessory

during

as shown keeping

TO

OP-

cap and

cap

and

or

drill

operation.

I

\0

LOO

SEN

f•f@·

W@ij

b ' EYES WHEN GRINDING OR

ROUTING WITH

ALWAYS WEAR AN APPROVED TYPE OF

SAFETY GLASSES.

SAFETY - PROTECT YOUR

THE ROTARY TOOL

..

Craftsman

Rotary

Power

Tool

The

Sears

of

grinder, polisher, sander, cutter,

brush, drill, and more.

The real

is its speed. To understand the advantages of

its high speed , you have to

standard portable electric drill runs at speeds

up to 2,800 revolutions per minute. The Rotary

Tool operates at speeds up to 30,000 revolutions

low-speed,

is

torquetool.

that in the high-speed tools, the speed

bined with the accessory mounted in the

chuck

sure to the tool, but simply hold and guide

the low speed tools, you

too l, but also apply pressure to

for example, when drill ing a hole.

It is this high speed, along with its

size and wi

that makes the Craftsman Rotary Tool

ferent from

enables it to

cannot

engraving of glass, etc.

Getting the most

matter of le

for you.

You should

small version of a standard electric drill.

While it does

electric

cept, design and use. Craftsmen

used it for years

.

special jobs", and as "the tool that does jobs

which the others don't."

Craftsman Rotary Tool is a handful

high-speed power. II serves as a carveT,a

secret

of the Craftsman Rotary Tool

know

per

minute. The typical electric drill is a

just

high-torque

the opposite - a high-speed,

The

chief

does the

de

variety of

other

do

do, such as cutting of hardened steel,

arning

not think of the Rotary Tool as a

do

dr

ill, it is basically different in

th

tool; the Rotary Tool

difference to the user is

work

. You

don't

apply

not

only

it,

as you do,

spec

ial accessories,

power

jobs

out

how

some

ink of it as a "special tool for

tools. The speed

that

low-speed

of

your

Rotary Tool is a

to let this speed

of

the same

jobs

who

power

that the

lowcompres-

it.

guide

the

compact

dif-

tools

work

as an

conhave

Using

Rotary

the

Power

Tool

The first step in learning to use the Rotary

Tool is to

and feel its weight and balance. Feel the taper

of

Tool to be grasped much like a pen or pencil.

If you have a variable speed model, turn it on

by slowly turning the speed dial and allowing

the tool to gradually gain speed. If you have a

single speed model, turn the switch to ON.

,.

HOLD IT AWAY FROM YOUR FACE. ACCESSORIES CAN

DUNG,

In

COME

MON, BUT IT DOES HAPPEN.

Practice on scrap materials

to get the feel of the Rotary Too l cuts. Keep in

mind

tool and by

should

work. Instead,

lightly to the

point

etching, etc .) to begin. Concentrate on

ing the tool over the

pressure from

sory to

Usually, it is best to make a series of passes

with the tool rather than attempt to

work

pass the tool

much

little material on each pass until you reach the

desired depth. For most work, the deft, gentle

touch

getthe

"feel"

of

it.

Heft it in your hand

the housing. This taper permits the Rotary

,,n,c.i'11'rS

J'ur\

thatthe

at

in one pass. To make a cut, for example,

as you

WHEN YOU TURN ON THE

VJ

TOOL

FOR THE FIRST TIME,

BE

AND CAN FLY APART

UP TO SPEED. THIS IS

not

which

do

is best. With it, you have the best

DAMAGED DURING

in

the beginning

work

is

done

the

accessory

lean on or push the tool into the

lower

work

you

your

the work.

back

would

by the speed of the

in the chuck. You

the spinning

and

allow

want

hand.

and forth

a small

it to

cutting (or sanding or

work

using very little

Allow

over

paint

HAN·

AS

THEY

NOT

COM·

accessory

touch

the

guid-

the acces -

do

all the

the work,

brush. Cut a

control, are less likely to make errors, and will

get

the

most

accessory.

For best control

Rotary Tool like a pencil between your thumb

and forefinger.

The pencil grip we described is one way to

hold the Rotary Tool. A second way is to grip

the tool

bicycle, with your hand wrapped around the

housing and the

your

thumb and forefinger. This

used for cutoff wheels and saws for maximum

control and is often used with polishing ,

brushing, and

This

is

tool used

the

brushing.

f1\hf.i.mi~tij

-

lA'

......

TO COVER THE AIR VENTS WITH YOUR

HAND. THIS BLOCKS THE AIR FLOW AND

CAUSES THE MOTOR TO OVERHEAT.

f1\fQ.i·i@[ij

--1--'

......

WHILE USING EITHER OF THESE ACCESSORIES. WHEN USING THE SAW WHEEL

OR

CUTOFF WHEELS ALWAYS HAVE THE

WORK SECURELY CLAMPED.

The reason

they become slightly angled

and can kickback causing

resulting

should be used to steady and guide the hand

holding the tool. When a cutoff wheel grabs,

the wheel itself usually breaks. When the

steel saw wheel grabs, it may jump from the

groove

and you

efficient

much

as you

chuc

grinding

the "handgrip" method

for

WHENEVER YOU HOLD THE

_ TOOL,

NEVER ATTEMPT TO HOLD

_ THEWORKWITHONEHAND

is

that these wheels

in

serious injury.

could

work

out

of

the

in

close work, grip the

would

the

handgrip

k extending just beyond

accessories.

operations such as wire

BE

CAREFUL NOT

in

loss

Your

second hand

lose control of

on a

grip

must be

of

holding

will

grab

the groove,

of

control

the

too

Operating

Speeds

&

Accessories

There are two basic types of Rotary Tools:

Single speed and Variable speed. On the

si

ngle

speed model (572.61000), there is an

ON

-OFF switch. When the switch is on, the

P.M

tool runs at 30,000 R.

speed model (572.61002), there is a small

numbered dial

the operating speed needed. You can refer to

the dial setting chart to determine

mate revolutions per minute for each setting.

If you have the single speed model, you will

be able to use many

assortment of jobs. For the majority of jobs

top speed should be used.

which

. On the variable

you can turn to select

accessories

to

do a wide

Needs for slower speeds:

To achieve the best results when

with different materials, the speed of your

Rotary

Tool should be regulated.

For the single-speed model (572.61000) only

a full wave output speed control should be

used . Sears

(Model 572.61002) has an integral speed

control.

CONTROL SHOULD NEVER

Certain materials (some plastics, for example)

require a relatively slow speed because at

high speeds the friction of the tool generates

heat and causes the plastic to melt.

Slow

speeds {15,000 R.P.M.

are best for polishing operations employing

the felt polishing accessories. They may also

be best for working on delicate projects such

"eggery"

as

and fragile model parts. You should always

do

polishing with

slower

R.P.M.

Higher

routing, shaping, cutting dadoes or rabbets in

wood.

Hardwoods, metals, and glass require high

speed operation , and drilling should also be

done

at high speeds.

if

The speed

Tool

is

housing.

Dial Settings

l.

Per Minute, Craftsman Variable

Rotary Tool (No. 572.61002).

Dial Setting

(Note: You can dial intermediate settings. For

example, a dial setting

duce a motor

RPM.)

Variable

THEREFORE,

work, delicate wood carvings,

speeds, and never higher than 15,000

speeds are better for carving, cutting,

of

variable speed model Rotary To help

controlled

for

1

2

3

4

5

6

7

speed

Speed Rotary

AN

EXTERNAL SPEED

BE

USED.

or

less) usually

wire

brush accessories at

by

setting this dial

Approximate Revolutions

·Motor Speed

4,000 RPM

5,000 RPM

6,500 RPM

8,000 RPM

11,000 RPM

16,500 RPM

25,000 RPM

of

1-112 would

of

approximately 4,500

Ultimately, the best way to determine the

correct

speed for

practice for a few minutes on a piece of scrap,

approxi-

working

on

Speed

even after referring to the chart. You can

quickly

learn that a

more effective just by observing what

pens as you make a pass or

speeds. When

ple, start at a

speed until you observe that the plastic is

melting at the point of contact. Then

speed off slightly to get the optimum

speed.

Some rules of thumb in regard to speed:

1.

Plastics and materials that melt at

temperatures

2.

Polishing, buffing and cleaning with a wire

Tool

the Rotary Tool, dial the speed

wheel should be done at speeds below

15,000 RPM to prevent damage to the

wheel.

3.

Soft

4. Iron

using a tungsten

slower

cutters. If a high speed steel cutter starts to

chatter - this normally means it is running

too slow.

5.

Aluminum,

alloys, and tin may be

depending

done. Use paraffin or other suitable lubr

cant on the cutter to prevent the

material from adhering to the cutter teeth.

Increasing the pressure on the tool is

answer when it is

should. Perhaps

ferent cutter, and perhaps an adjustment

speed

on the tool seldom helps.

this

Sears Table Top Speed Control.

Dial settings

minute, using the Sears Model 572.25144

Manually Operated Speed Control

single speed Rotary Tool No. 572.61000.

Dial Selling

working

slow

wood

should be

or

steel should be

speeds if using high speed steel

copper

on the type of cutting being

would

solve the problem. But leaning

you

do

more with your single speed

for

approximate revolutions per

1

2

3

4

5

(Note: You can dial intermediate settings. For

example, a dial setting

pro-

duce a motor

RPM)

speed

work

on any material is to

slower

or faster speed is

two

with plastic, for exam-

rate and increase the

should

be

cut

at

cut

at high speeds.

cut

carbide

alloys, lead alloys, zinc

not

you should be using a dif-

of

at top speed if

accessory, but at

cut

at any speed,

cutting as you think it

you

Motor Speed

500 RPM

4,000 RPM

12,000 RPM

22,000 RPM

28,000 RPM

of

2-112 would

approximately 8,000

hap-

at different

back

wo

rking

low

speeds.

not

need

with

with

pro-

the

low

i-

cut

the

in

the

Loading...

Loading...