Sears

OWNERS

MANUAL

MODEL NO.

572.36578

CAUTION:

115 VOLT A.C.

Read Rules for

Safe Operation

and Instructions

SAW CHAIN

SHARPENER

Carefully

Introduction

Assembly

Operation

Maintenance

Repair Parts

Sold by SE_RS, ROEBUCK AND CO_, Chicago, IL 60684 UoS A,

FORM NO 380223 PRINTED IN U,S A

FULL ONE YEAR WARRANTY ON CRAFTSMAN

SAW CHAIN SHARPENER _ --_._

For one year from the date of purchase, Sears will reptace this Crafts-

man Saw Chain Sharpener, free of charge, if it falls to work properly_

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE

CRAFTSMAN SAW CHAIN SHARPENER TO THE NEAREST SEARS

STORE IN THE UNITED STATES

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

SEARS, ROEBUCK & COo

SEARS TOWER

DEPT. 6981731A

CHICAGO, IL 60684

INTRODUCTION

WE SUGGEST YOU TAKE A FEW MINUTES TO READ THE INSTRUCTIONS CONTAINED IN THIS MANUAL

BEFORE USING YOUR CRAFTSMAN SAW CHAIN SHARPENER THIS WILL HELP YOU OBTAIN THE FULL

BENEFITS OF THE QUALITY AND CONVENIENCE BUILT INTO THE TOOL

RULES FOR SAFE OPERATION

WARNING

When using electric tools, basic safety precautions should always be followed to reduce the risk of fire, electric

shock, and personal injury, including the following:

READ AND SAVE ALL THE FOLLOWING INSTRUCTIONS

1_ KEEP WORK AREA CLEAN -- Cluttered areas

and benches invite injuries

2 AVOID DANGEROUS ENVIRONMENT -- Don't

expose tools to rain Don't use power tools in damp

or wet Iocations. Don't use power tools in the pres-

ence of flammable liquids or gases. Avoid chemical

or corrosive environments. Keep work area well lit.

3 GUARD AGAINST ELECTRIC SHOCK -- Prevent

body contact with grounded surfaces. For example;

pipes, radiators, ranges, refrigerator enclosures.

4. KEEP CHILDREN AWAY -- Do not let visitors

contact tool or extension cord All visitors should

be kept away from work area_

5. STORE IDLE TOOLS -- When not tn use, tools

should be stored in dry, and high or locked-up place-

out of reach of children_

6. DON'T FORCE TOOL _ it will do the job better

and safer at the rate for which it was intended.

7. USE RIGHT TOOL -_. Don't force small tool or

attachment to do the job of a heavy-duty tool Don't

use tool for purpose not intended - for example -

don't use circular saw for cutting tree limbs or logs.

8 DRESS PROPERLY _ Do not wear loose cloth-

ing or jewelry., They can be caught in moving parts.

Non-skid footwear is recommended when working

outdoors_ Wear gloves to prevent cutting your fingers

when ,touching or rotating chain. Wear protective

hair covering to contain long hair.

9. USE SAFETY GLASSES -- Also use face or dust

mask tf cutting operation is dusty.

10. DON'T ABUSE CORD -- Never carry tool by

cord or yank it to disconnect from receptacle Keep

cord from heat, oil, and sharp edges.

11_SECURE WORK _ Use clamps or a vise to hold

work., It's safer than using your hand and it frees both

hands to operate tool

12_ DON'T OVER-REACH -- Keep proper footing

and balance at all times.

13 MAINTAIN TOOLS WITH CARE _ Keep tools

sharp and clean for better and safer performance.

Fotlow instructions for lubricating and changing

accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service

facility. Inspect extension cords periodically and

replace if damaged_ Keep handles dry, clean, and

free from oil and grease

14. DISCONNECT TOOLS _ When not in use,

before servicing, and when changing accessories,

such as blades, bits, cutters.

15 REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and ad-

justing wrenches are removed from tool before

turning it on_

16. AVOID UNINTENTIONAL STARTING _ Don't

carry plugged-in tool with finger on switch_ Be sure

switch is off when plugging ino

17 OUTDOOR USE EXTENSION CORDS _ When

tool is used outdoors, use only extension cords

intended for use outdoors and so marked

18. STAY ALERT _ Watch what you are doing Use

common sense.. Do not operate tool when you are

tired Don't use power tools after taking drugs,

alcohol or medications..

!9,. CHECK FOR DAMAGED PARTS -- Before

further use of the tool, check for damaged parts,

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A part

that is damaged should be properly repaired or

replaced by an authorized service center before

further use of the tool Have defective switches

replaced by authorized service center. Do not use

tool if switch does not turn it on and off.

PAGE 2

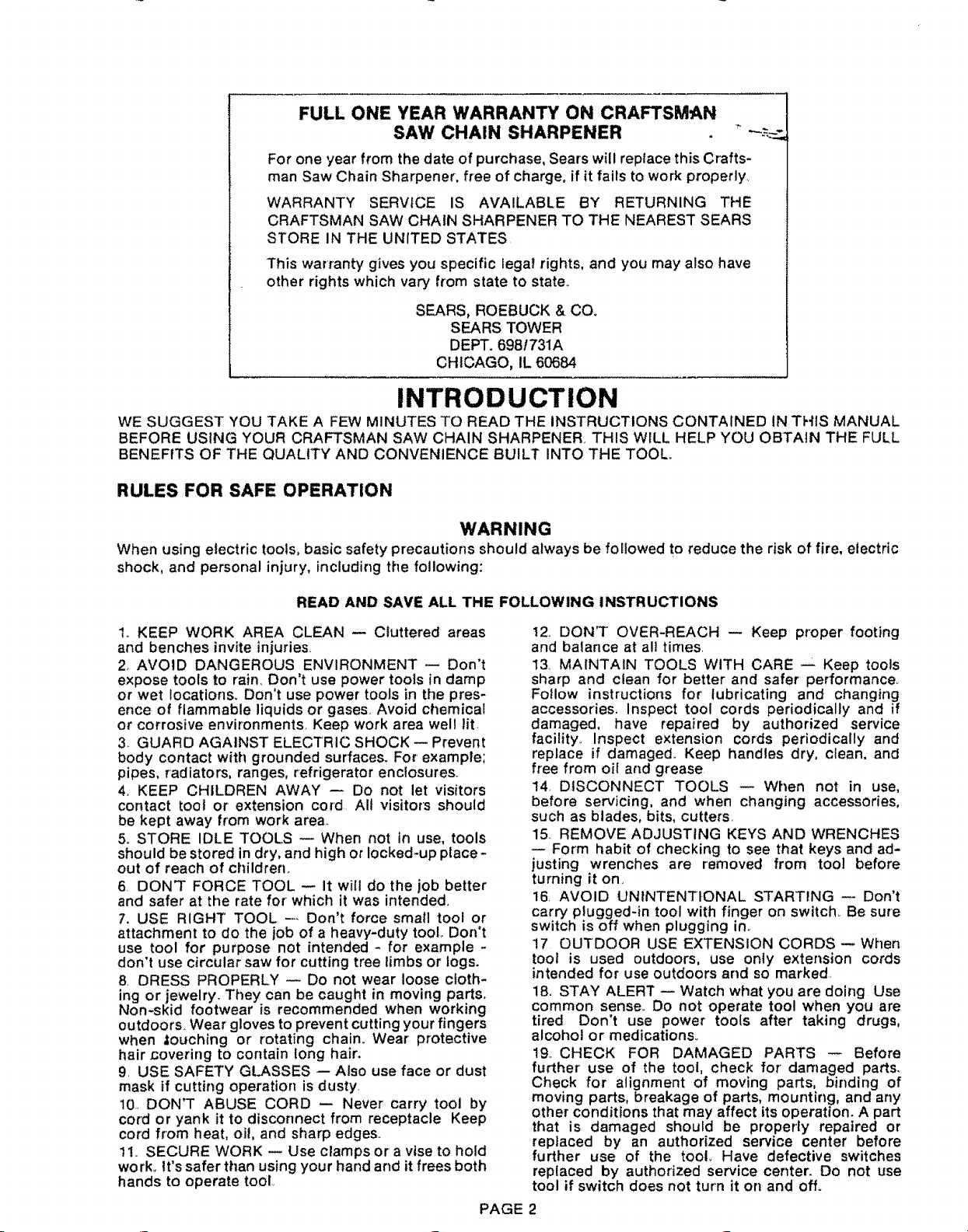

GROUNDING INSTRUCTIONS

This too! shou}d be grounded while in use to protect

the operator from electricshock, Thetool is equipped

with a three-conductor cord and three-prong

grounding type plug to fit the proper grounding type

receptacle. The green (or green and yellow) con-

ductor in the cord is the grounding wire, Never

connect the green (or green and yellow) wire to a

live terminal. Your unit is for use on less than 150

volts, and it has a plug like that shown in Figure A,,

An adapter, Figures B and C, is available for con_

necting Figure A plugs to two-prong receptacles°

The green-colored rigid ear, lug, etc,., must be con-

nected to a permanent ground such as a properly

grounded outlet box, Adapters are not allowed in

Canada by the Canadian electrical code..

Use only three-wire extension cords which have

three-prong grounding-type plugs and three-pole

receptacles which accept the toot's plugo Replace or

repair damaged or worn cords immediately_

READ AND SAVE ALL THE PRECEEDING INSTRUCTIONS

COVER OF GROUNDED

OUTLET BOX

GROUNDING _._ "',_ GROUNDING

BLADE _..f_ MEANS

TEMPORARY

ADAPTER I

Figure C

REPLACEMENT PARTS--When servicing use only

identica! replacement parts,

POWER SUPPLY_Tool operates on 115V, AC,

60-Hz,

TABLE OF CONTENTS

OPERATING INSTRUCTIONS ...................................................................................... 4

ADJUSTING SHARPENER ........................................................................................... 4-5_6

SHARPENING CHAIN .................................................................................. 6

SETTtNG DEPTH GAUGES ....................................................................................... 8

SHARPENED CUTTER EXAMPLES ..................................................................................... 9

TROUBLE SHOOTING ........................................................................................ 9

PARTS LIST AND ILLUSTRATION .................................................................................... 11

HOW TO ORDER REPAIR PARTS .............................................................................. 12

PAGE 3

IMPORTANT OPERATING INSTRUCTIONS -

Read before using.Chain Saw Sharpener

Check to see that the carton contains the following

items illustrated on pages 4 and 5.

One Chuck Cap - Part Number 660113

One Co!let - Part Number 480

One Chuck Wrench - Part Number 500045

Two Spacers

One Guide Gauge

Three Grinding Stones -

Part Numbers 36581, 82 & 83

Sharpener - Part Number 36578

IMPORTANT: If any of these parts are missing,

please IMMEDIATELY notify the Sears retail or

catalog store from which you purchased the sharp-

ener so corrective action can be taken as quickly as

possible,,

Read this manual carefully, It will help you use your

tool correctly and help you select the correct

accessory for your job

Your Craftsman Saw Chain Sharpener will sharpen

nearly all popular sizes of chain if you follow these

simple instructions

ALWAYS UNPLUG TOOL BEFORE CHANGING

GRINDING STONES OR SERVICING YOUR TOOL.

Just prior to the tool stopping it wdl start to run

sporadically, it will lose power and it may run at a

reduced speed and make unusual noises

BALANCING GRINDING STONES--It is important

that all grinding stones be in good balance (much

the same as the tires on your automobfle)_ To true

up or balance a grinding stone, slightly loosen chuck

cap and give the grinding stone or cotter a ¼ turn,

Retighten chuck cap and run the tool, You should

be able to tell by the sound and feel if your grinding

stone is running in balance.. Continue adjusting in

this fashion until best balance is achieved.

BEARINGS--Your tool is equipped with oil impreg-

nated sleeve bearings. Under normal use not more

than 2 drops of SAE No 5 or lighter, non-detergent

otl can be added to each oil hole for each 100 hours

of use,

STONE DIAMETER--Do not use grinding stones

other than the 3 listed in the chain identification

chart.

SAFETY--Protect your eyes when grinding with the

tool .... always wear an approved type of safety

glasses.

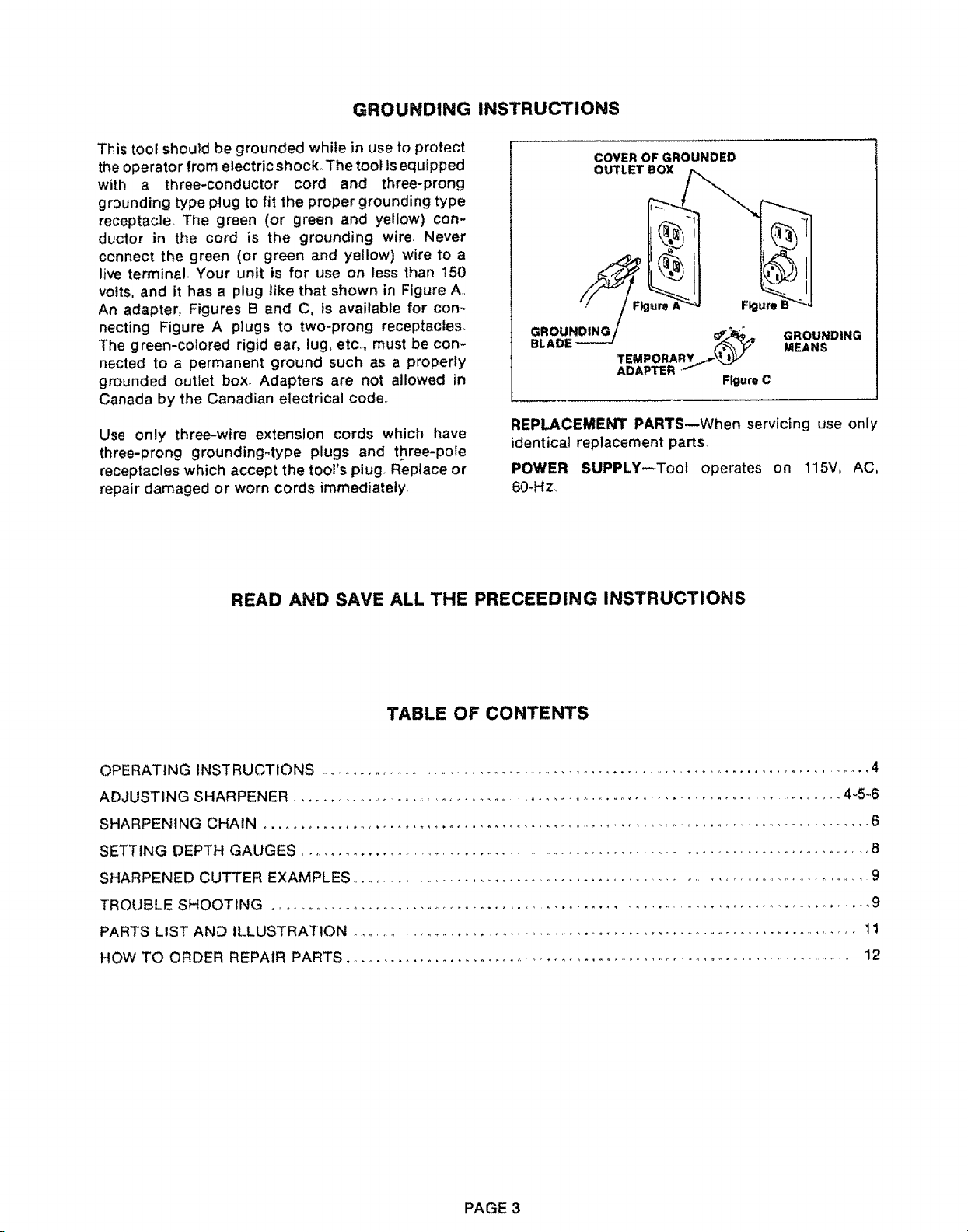

CHUCK--Consists of a chuck cap and collet. To

loosen, first unplug the sharpener from the power'

supply, then depress the chuck lock pin and rotate

the shaft by hand until the lock pin engages the shaft

preventing further rotation. NOTE: Do not depress

pin while the tool is running. With the lock pin

depressed, use the chuck wrench to loosen the chuck

cap Insert shank of grinding stone into colteL With

the lock pin depressed, tighten the chuck cap with

the wrench until the shank is gripped by the collet.

Avoid excessive tightening of the chuck cap.

CHUCK LOCK PIN -_J"

CHUCK j___j_-_,.,--_ _"_'_--- CAP

WRENCH / -- _

CAUTION--Any servicing of this tool (including

brush replacement) should be performed by an

authorized Sears service representative,

. I _'_ A'_ CHUCK

TO LOOSEN \COLLET

MAINTENANCE--The brushes in this tool are self-

limiting. This means that when the brushes are worn

out, they stop making contact with the commutator

and the toot wilt stop running This is done to

e_iminate the possibility of a piece of the brush

and/or the spring getting loose inside the toot when

the brushes are worn out.

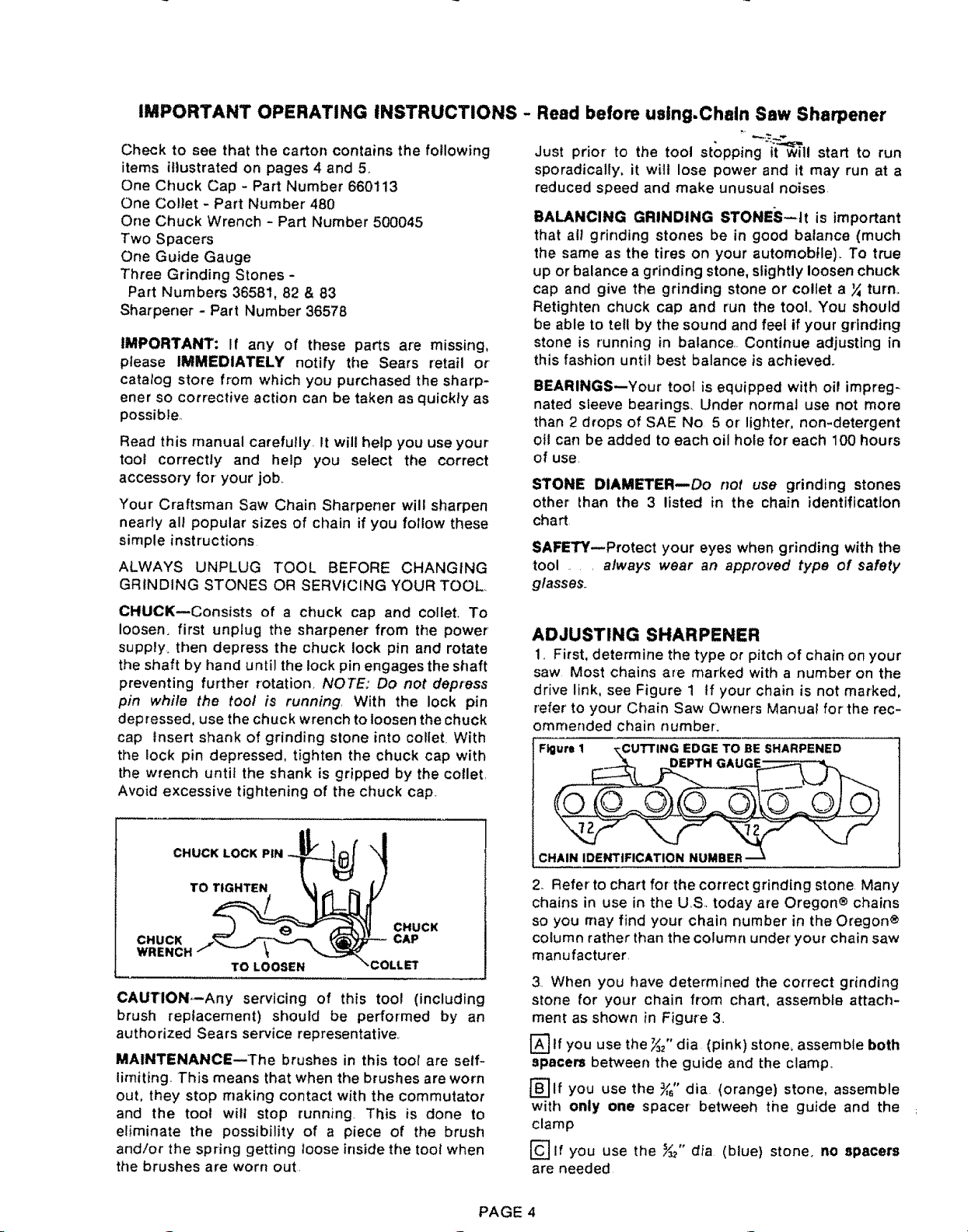

ADJUSTING SHARPENER

1, First, determine the type or pitch of chain on your

saw Most chains are marked with a number on the

drive link, see Figure 1 tf your chain is not marked,

refer to your Chain Saw Owners Manual for the rec-

ommended chain number.

Figure 1 _\CUTTING EDGE TO BE SHARPENED

© ©

c

2,, Refer to chart for the correct grinding stone Many

chains in use in the US,, today are Oregon® chains

so you may find your chain number in the Oregon®

column rather than the column under your chain saw

manufacturer,

3 When you have determined the correct grinding

stone for your chain from chart, assemble attach-

ment as shown in Figure 3,

If you use the _" dia (pink) stone, assembte both

spacers between the guide and the clamp.

rB]lf you use the ¾_"dia. (orange) stone, assemble

with only one spacer betweeh the guide and the

clamp

[_ If you use the _" alia (blue) stone, no spacers

are needed

PAGE 4

Loading...

Loading...