Page 1

JAN-30-2601 $2;48 706 651 7714 P.02/21

lSears I

owner's

manual

MODEL NO.

536.90515

CAUTION:

Re,ad SAFETY•

RULESand

INSTRUCTIONS

carefully

CRIIFTSMIIN_

24" SNOW:THROWER

• Assembly

• Operating

Pan Ne, 61172

• Maintenance

• Repair Parts

ii

Sold by S],ARS, ROI!,IJ't/C]_ AND CO., Chzcs,_u, IlL 60684 U.8.A.

' PS NS '_'AR' I T]',' ''o

andSIM 19 .-Sit, 8LMI iD, l vunto

w iii

4374

Page 2

7AN-_0-2001 12:48

706 651 7714 P,03/21

i

i ,,,

IMPORTANT

RULES FOR SAFE OPERATION

It is imperative in operating and handling the power snow thrower that certain nor-

mal precautions be observed to prevent 1he possiloility of injury or damage=

Please read the rates for sofa operation before you assemble or LJseyour powcr snow

thrower.

.

Read the Owner's Manual carefully. Familiarize yourself with the controls and use

of the snow thrower, Be prepared to stop in a moment's notice. Don't loon your

snow thrower to persons unfamiliar with its operation and use.

B

Do not allow minors to operate or to be near the snow thrower unless properly super-

vised.

3. Keep hands, feet and loose clothing clear of all moving parts. Do not ever piece

hands in discharge chutes or near an_y mov!ng part while eflgine ;s running.

4. Be sure of your footing at all times Io avoid sllpplng. Keep a firm hold on the

handle. Be careful when turning.

,5.

Check fuel before each using. Do nat fill gasoline tank when englna is running or

while engine is hot. Wipe off any spilled gasoline before starting engine. Gaso-

line iS highly flammable. Always handle with care.

.

Do not run engine indoors, exhaust gases contain carbon monoxide which ;s odor-

less and deadly poise.. If for some reason engine must be run indoors, open

all doors and windows to provide suffident ventilation,

7. Move speed control to the neutral position before starting engine. Keep gua_rds

in place,

g. Do not allow anyone in the area while using the snow thrower, A fore;an object

or piece of ice may be thrown through the discharge chute causing injuTy to person

or damage to property.

9, Stop the engine and be sure all moving parts have stopped turning. Remove the

spark p!ug,to prevent accidental slar_llngrbeforo €lea_ing the discharge chute on

Toter units; also before making any acl;ustments, mspechng or repairing, or cleaning.

10.

Keep all screws, nuts and bolts tight at all times.

11.

DanJt change governor settings, The governor controls the speed and protects the

engine from damagln9 excess;re speeds,

12.

Don't store snow thTower, with fuel In the tank,inside a building where fumes may

reach an open flame o¢ spark. Let the engine coal before storing in any enclosure.

13.

If your snow thrower should start vibrating, slop the englne and check for dam-

age or loose parts. Vibration generally is e warning of trouble.

14. For added safety, it is su9gasted that the operator wear safety glasses.

15. Never stand in front of the snow thrower or discharge chute.

JI

i,

-2--

Page 3

JAN-30-2001 12:48 906 651 9914 P.04/21

CRAFTSMAN POWER

SNOW REMOVAL EQUIPMENT

AFTSMAN GUARANTEE

CRAFTSMAN PRODUCT FAILS TO GIVE PROPER PERFORMANCE DUE _'_

WORKMANSHIP, W{_ WJLL MAKF ALL NECESSARY REPAIRS, FREE OP

__ CHARGE• ' _

THIS GUARANTEE SERVICE {S AVAILABLE IHROUGH ANY OF OUR STOR_S OR SERVIC_ C[;NTERS _

_ THROUGHOUT THE UNITEU STATES OR CANADA.

MAINTENANCE AGREEMENT

t!

TIIE SEARS GUARAN'IE_: PLUS A MAINTENANCE AGREEMENT PROVIDr, MAXIMUM VALUE FOR

SEARS PRODUCTS, CONTACT YOUI_ NEAREST S_ARS STORE Pr.JR DETAILS.

CUSTOMERS RESPONSIBILITIES

ALWAYS USE CARE WI4EN OPERA]ING THE SNOW 1HROWER. KEEP CLEAR OF MOVING PARTS. DO

NOT WORK ON SNOW THROWER WJlH ENGINE RUNNING. AVOID STRIKING OR RUNNING INTO

SOLID OBJECTS OR DEBRIS IN THE AR'EA 1'O BE WORKED, READ AND OBSP_RVEIHF RULES FOR SAFE

OPERAIION. KEEP THE SNOW THROWER CLEAN.' FOLLOW A REGULAR MAINlbNANCE AND CHECK

SCHEDULE TO PROVIDE EFFICIENT AND SAFE OPERATION. A WELt.CARED fOR SNOW THROWER

WILL LAST LONGER AND OPERATE MORE EFFICIENTLY. ALWAYS BE CAREFUL FOR YOURSELF AND FOR

01'HERS,

SET UP INSTRUCTIONS

II IS SUGGESTED THA! THIS MANUAL tip READ IN ITS EN?IR[TY BEFORE ATIEMPTING TO A$SEMBL[_

OR OPERATE THE SNOW IEHROWFR.

IH_ SEARS SNOW THROWER HAS BEEN COMPLIZTEY ASSEMBLED AT THE FACTORY, EXCEPT FOR THE

HANDLE AND OPERATING CONIROLS WHICH HAVE BI:EN LI_FTUNASSF,MBLED FOR _HIPPING PUR-

POSES. ALL PARTS SUCH AS NUTS, WASHERS. i_OLTS, E1C., NECESSARY 'tO COMPLETE AS,SEMDLY OF

THE HANDLE AND CONTROLS HAVE BEEN PRE-INSERTED IN IHE PLACES THEY ARE TO BE USED OR

PLACED JN A PLASTIC BAG.

ASSEMBLETHE UNIT AS OUTLINED. REFERTO ILLUSTRATIONS FOR A,T_EMBLY ASi_IMANCE.

, i

Page 4

JRN-30-2001 12:49 7B6 651 7714 P,05/21

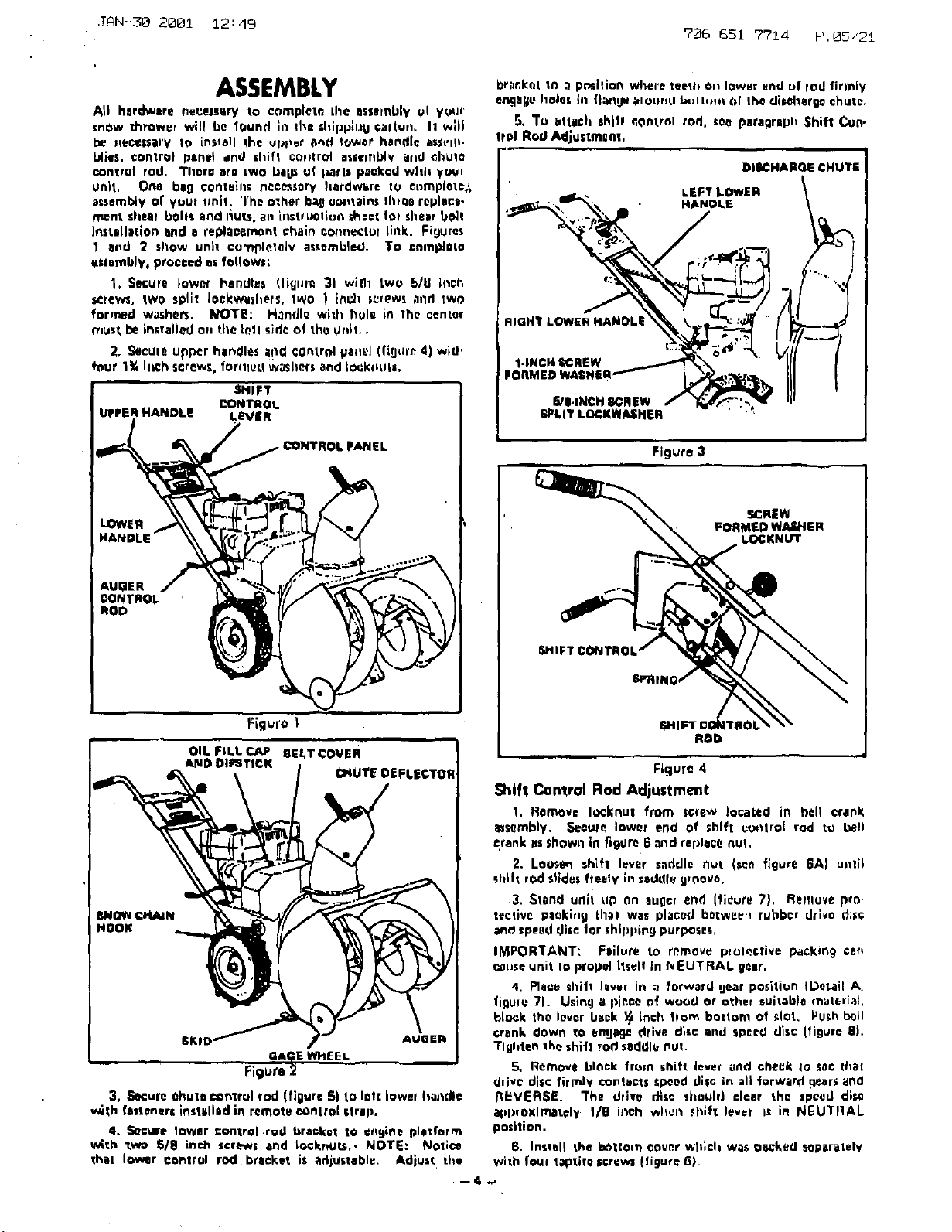

ASSEMBLY

All hardware neees;ary to completn Ihe asserllbl¥ _! yOUr

snow thrower wilt bc Iound in tl_a shippil.tg carton, II w;l!

be :lece_sary to install the upl)=r/rod tower handle assern.

bli0s, control pene_ and shift col)trol assembly arid nhutc

control rod. Tltoro ere two beLtSof parts packed wltll yoo_

unit, One beg contain; n_cL'Escryhardware to cl_mplolc,_

assembly of Vou_ trait. The other bagcontains three roplace.

ment sheet bolls end I_Uts,an irtstrzz_tlcmshoot lot' shear bolt

]nstatletlon end e replacement =ha;n €onnectul link. Figures

1 end 2 sltow unit €ompletely assembled. To ©omplnto

issambly, proceed as follows:

1, Secure Iownr handles Uig=Jm 31 with two 5/U Inch

screws, two split Ioekwesl_er;. two I {nd_ screws m_dtwo

formed washo_. NOTE: Hen(lie with I'wle in the center

must beir_talled o. tl_e 10It side of thu d.it..

2. SeCUle upper handles a!td control panel ((igtll',_ 4) with

fnur 1_ IltCh screws, fOrlll_(.! w_hnrs and I_knu|s,

I -- I

UPPER HANDLE I.EVER

COMTROL

pANEL

br,_r,k(_t tn ,1 petition where teeth o. lower end ul Iod firmly

engage holes igl flanLw ;=lou.d |J_ltt_!l_ of the disoharp chute,

r,, Tu attach shill ¢ontrfll rod, _oe para;Iriph Shift _n-

ttol Rod Adjustment,

i 1-1NCHECREW

! FORMED WAEHli

lUll.INCH ECREW

SPLIT LOCKWASHER

ml

DIECHARQE CHUTE

HANDLE

LEFT LOWER !

Figure 3

'='REW

FORMED WASHER

LOCKNUT

Figure I

3, ,_N:ure Chute €entral rod (figure Si to loll iowa, hw_dle

with fassenara instilled in remote control strap,

4. So=are lower control red bracket to engine platform

w|th two E/E inch scr_=ws and |ockng_,- NOTE: Notice

that lower control rod bracket is adjustable. Adjust the

SHIFT CONTRI

EeRll

Figure 4

,_hift Control Rod Adjustment

1. I;lemove lucknus front screw located in bell crank

astembly. Secure lower end of shift ca,tirol rod tu bell

crank as shown in figure 6 and replace nut.

'2. Loostm shift lever saddle nut (see f_gure 6AS until

shift rod stldas freely in saddle urnova.

3. Stand unit Ug on auge_ end (fib;are 7}, Remove prn.

tective pecking llt_t was placed betweer_ rubber drive d_sc

anr_ speed disc for shipping purposes,

IMPORTANT: Failure to rnmove p_ot_.ctive packing can

cause unit to propel ;tacit in NEUTRAL gear.

4, Place sltift lever let _ _orward gear position (Detail A.

figu_ 71. Using a isi_.ce of wood or other suitable material,

block the lover back _ inch Ilo='n bottom of slot, Push b011

crank down to engage drive dt_c a.d spccd dlsc _figure El.

Tighten th_ shill rod saddle mJr.

S, Remove bln_k from shift lever and check In sec ill,it

d,ive disc firmly contacts speed d;s_ in all forward gears and

REVERSE. The dFive disc should (:leer the speed dJs_

a!ip=oxlmetely 1/B in©h wi_el_ shift level ]_ tel NI;UTItAL

position.

8. Install the bottom Cover wtl_ch was p_;ked separately

with fou, taptire I;crewt {IJgufe 6}.

Page 5

e

JAN-30-2001 12:49 ?06 6_1 7714 P.06/21

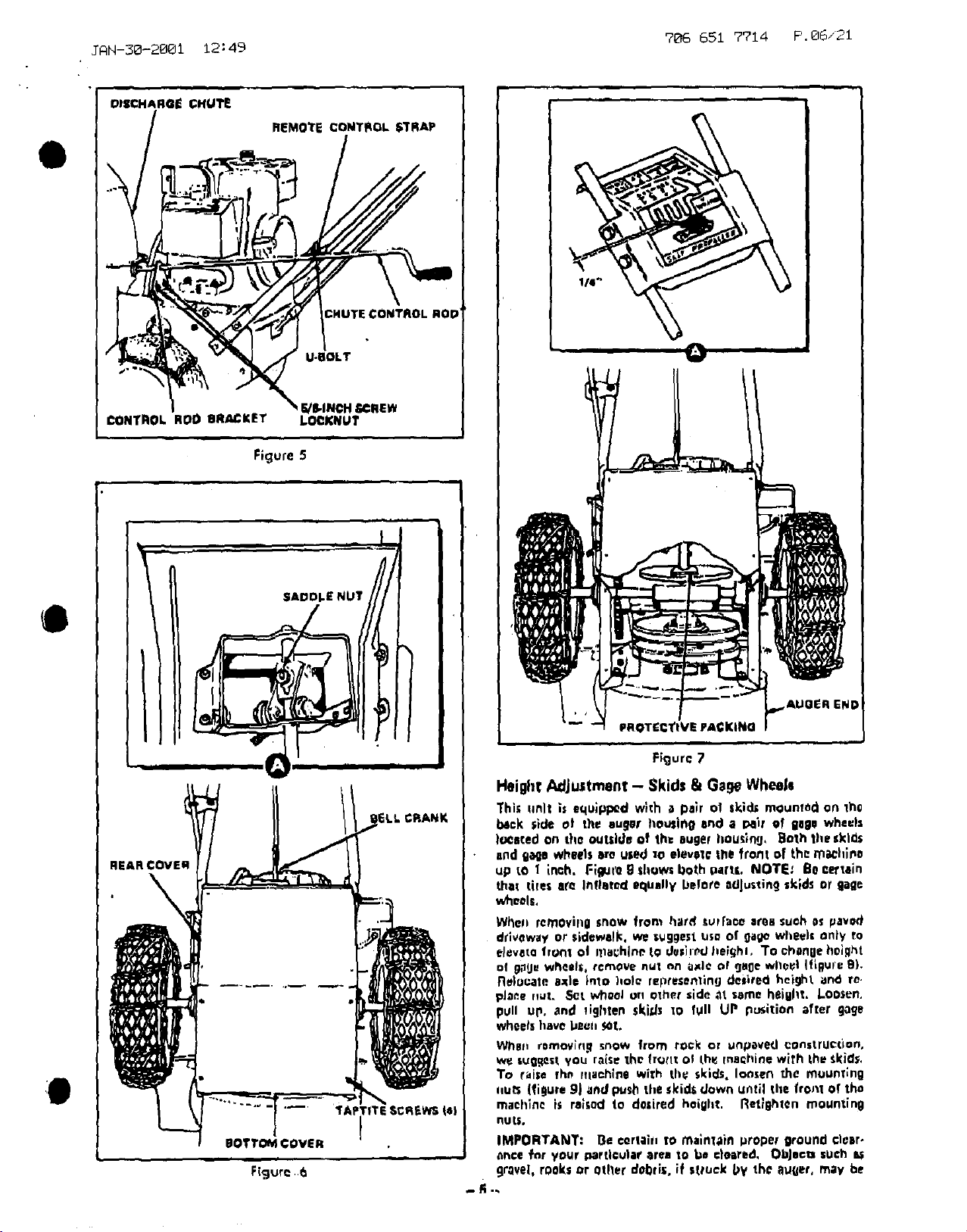

_'HUTE CONTROL ROP

U-BOLT

i

0

CONTROL ROD 8RACKET LOCKNUT

Figure 5

REARCOVER

r_IHNCH 8CREW

AUOER END

Height Adjustment - Skids & Gage Wheels

This ilnlt is equipped w_th a Daft ol ski_ mounted on th0

back side of the sugar ho_Jr_o and a pair of gega wheals

I(x_ated on the outside o! th= auger housin9, Both theskl_

cad gage wheels era used so eleveto the front of the machine

up to 1 inch. Figut'og shows both pattL NOTE,' Be certain

that tires -,re Inflated equally before -_dJussingskids or gage

wheels,

Wheu rcrnovino snow from !l'_r_ surface arab such Os paved

driveway or sidewalk, we suggest usa of gage wheels ontv to

elevctc front of machine to desired heighl. "1"ochange height

of gpt.lu wheals, remove nut on a_)e or rjeOe wllee| Ifigu)€ 9).

Relucate axle into hole representln9 desired he_ghL and re.

pJ_P.e r+uL Set wheel on other side ,lt same height, Loosen.

pull up. and tighten skids to full UP pu_ition after gage

wheels have bael_ r,ot.

Wha, romovinq snow from rock or unpaved constrUc_Lon,

v,m august you ra(se the frortz el th+ machine with the skids,

To raise the rnach;na wilrh the skids, loosen the muunzing

.uts (figure g) and push the skids down until tire front of the

math;he iS ra;sod to dosired height. Ret;ghtan moun_ing

nUtS,

IMPORTANT: Be corral, to mainlaie proper ground clear-

nnce for your particular area 1o be created, ObJecls such I_

gravel, rooks or otller debris, if slruck by the auger, may be

Page 6

-rAN-_O-2001 12:49

786 651 7714 P,07"21

d_rown w]tl) sufficient fume lo cause iniur ¥ to po_onnel o_

_mag# to property.

IMPORTANT: Chai1geer=nkca_€ oil after the first 2 hours

o1 opera,don and :,her each 25 hours uf ul)era_ionthereafter,

or st the beginning of eadr season, whichever come_ first,

're dtoin the oil, see poragmpl_I.ubriution.

2. Fill gas t,qnk with €lean re.qular grade eutUmoliva

gasoline, Lead.free or low,lead D_otitte is an acceptable

suhstlzute. Do not use E111ylor high o©_r_ gasoline. B_

ceq'tairl Cool,liner is clear_ and free _rofll rusl, or forcig_z

particles. Never LJSeg=lsoline thai may be stale tram long

p_riuds (Jrslola_ in the cotlta]ner.

CAUTION: Never fill the g_ tank while engine inrunning or

is hot° hxlmedi/toly wipe off any spilled gasoline before

attempting to start engine.

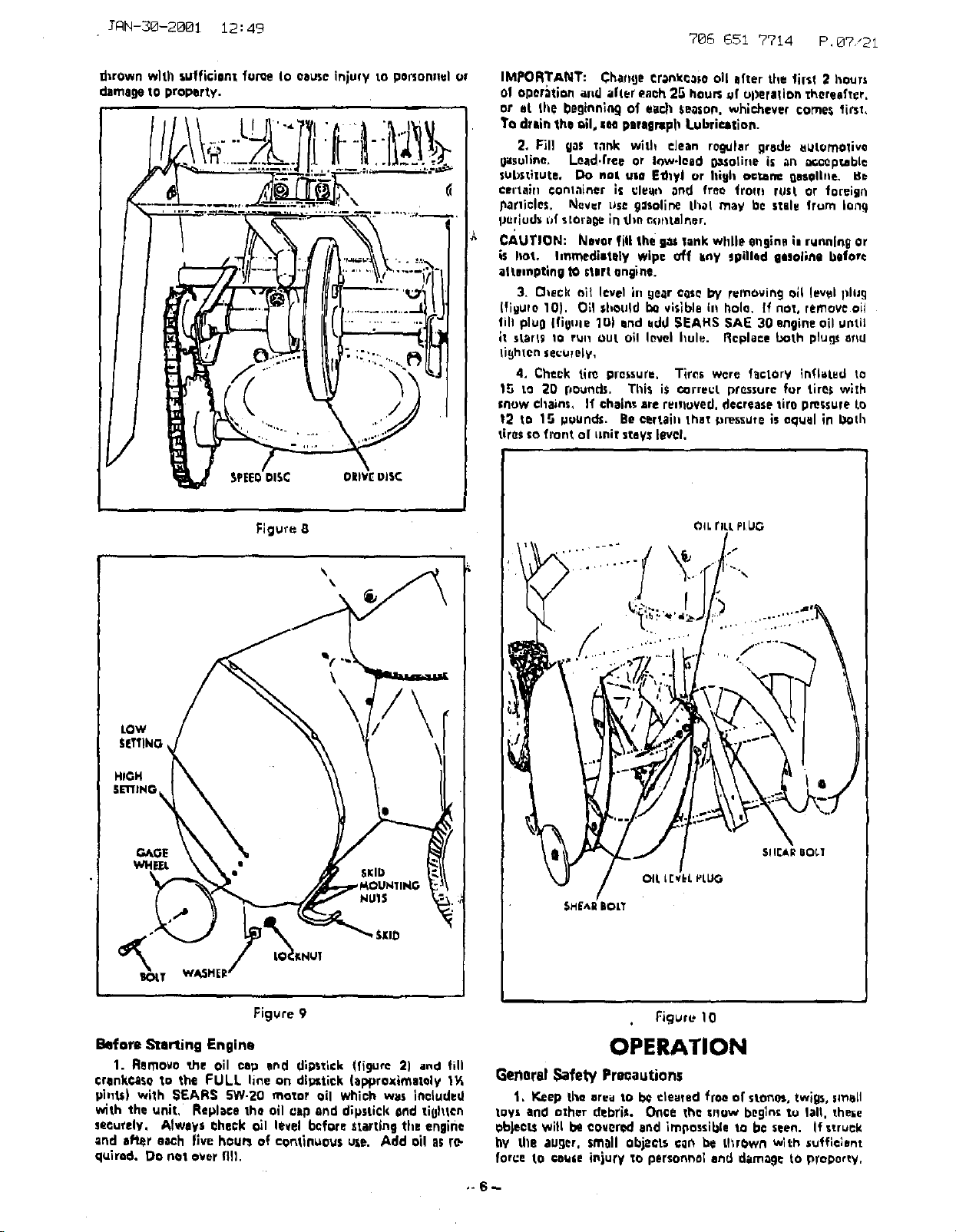

3. I_eck ell level i..Llear easelay removing ell level phJ9

(fiaule 10). 01! sl_otdd be visible I, hole, If not, remove oil

fill plug ifio.ie 1o) and add SEARS SAE 30 engine oil until

it stort_ Io rul_ out ell level hule. Replace both plu_ att_l

tighten securely,

4. Check ti_ pressure, Tires Were factory inflated to

15 to 20 pounds, This is oorrecL pressure for tires w;th

snow chains, If chaim ere relttuved, decrease tire pressureLo

t2 to 15 pounds. Be certain=that pressure is equal in both

tiros so front el trait stays level,

F;gure 8

OiLrILLPlUG

Figure 9

Before Starting Engine

I. Remove the oil cog end dipstick (figure 2) and fill

crank.s0 to the FULL line on dlpstiek (approximately t_A

pintS) with SEAR e: SW-20 motor oil which w_ included

with the unit, Replace the ell _op and dipstick €fld tighten

securely, Always check oil level before starting ti_e engine

and after each five hou_ of continuous ur,e. Add oil a; re'

quoted. Do not over fl11.

Figure 10

OPERATION

Genorel Safety Precautions

t, Keep the area to be cleated free of stones, twigs, small

toys and other debris. Once the uluw beglns tu 1all, these

objects will be covered end impossible to be seen. If struck

by the auger, small objects can be tlirown with suffie;ent

force tO cause injul'y to personnel and dam=9c to Pro_orw,

Page 7

3AN-30-2001 12:50

2, Stand clear of unit when starting engine. Nova( place

hands or feel ricer any movIIIg p:rlJ, Never dlrecI rite dis-

charge chute at byt;anders.

CAUTION: If the discharge chute should become blocked,

stop the onglne end remove the spark plug before attempting

to clear the obstruction.

3, Slap the engine and inspect uititfor damage imme-

diately after striking any foreign object. De not use the

maeh;ne until all damage has been rape[red,

4. Your snow thrower is shlpped with tlre chainsin.

stalled. For best traction, do riot operate the utow thrower

willlouz the tile chains.

6. When using the snow thrower, dresswarmly, If pest,

ible, use non*sliptype footwear te inure safe footing.

6, Keep a firm hold url zha handle. De careful when

turnlng to a_old slipplng,

7. Never leave the snOW throwel unattended while the

engine is running.

?06 651 7914 P.08/21

CHUTE DEFLECTOR

CHUTE NANDLE._

Figure 1 1

_. The operation of any powered outdoor uqulpmt_nt

can result in forei0n objects being thrown into Ihe eye_,

willeh can resul( in _evete eye (Jalnago. Always wear salary

glassesor eye shields before commencing powor toot Opera.

tion. We recommend Wide Vision Safety Mask for over

spectacles or _tendard safely glasses, available at SEARS

Retail or Catalog Stores.

9. Familiarize yourself wlth the cquJpme,t anti whh tile

Rules for Safe Operation. VER

Operating Controls - Unit

Operating controls (figure 11) and their lunutions are as

follows:

o Shift Control Lever - Used to select ded_ed trait

speed or direction, Choice of tour forward speeds,

NEUTRAL and REVERSE.

o Chutc Control Rod . Used to dlange directlnn of

anow discharge. Turn handle €loukw_se1o tUrrt chute

to left. Turn hondln counterclockwise to turn chule to

right. All snow can be discharged Lo one sid() l_y

changing direcUon of €ll=lte cad1 limo direction _f

trave_is changed.

= _ute Deflector - Tile dislance that the snow will be

discharged can be adjusted by moving the deller.l.al

chute up or dowrl using the chute handle inotiflted on

the deflector chute (figure 11).

CAUTION! Do not put hands in or near the dofJoctOi'

_hut_ while the engine isrunntng.

o Auger Clutch - Used to dise.geOOpnwer I.u auger.

Pull tip 1oengage. Pushdown to disengage.

To Star_Engi.e

CAUTION: Do not put |tends, feel Or loose oloshi.o in or

nell' the deflector ©bulc or auger housing while the Dnaiile Is

running.

Thr, snuw thrower e.gine is equipped wilh a ,ew instant

stin recoil starter. The operation of this engine is con-

trolled by the thlottie control (figure 13). Before starting

the en0ine, becertain that you have read and followed ell '.he

hlstruetions on the pleeeding pages.

1. FItl fuel t_nk with clean, fresh, regular gasoline,

CAUTION: Be eellain tiles the ahift lever is in NEUTRAL

position end tile auger control Jsin DISENGAGE pot,,Jtion

before starting engine_

2. Open ftJel shut.oil valve on fuel ta_k, if =;e©quipp,_d,

IMPORTANT: Before starting the et_gi=leon a unit tl_at has

been used. drain a Imall nmotJnt of gasoline from the car-

huletoI fuel bowl by f.ushin9 up o,: Shedump valve (figure

131. This will _emnv('. any cur:dens._tion which may have

accumulated si:_cethe snow II_luwer was last used.

Operating Controls -- Engine

Engine operating eonlrols (figure 12} and glair functions ere

asfollows:

o Primer Butch -.. Used Io InJent luel dlreedy into

carburetor manifold to insure fast starts.

O _oke Lever -- Set choke lever to FULL CItOKE posi-

tion to start engine.

• Throttle Level' -- Used to con[rot speed of engine.

Also used as kill switch whon pushed to PULL FOR_

WARD or STOP poshiol_s,

3. Maya throLtle layer tn RUN position.

4. Move chuke lever to FULL CHOKE position.

5. Pu,dl urimer bulb five times. NOTEs Do not prime a

warm engine.

6. Pull starter handle rapidly. NOTE: 0o riot ollow the

starter rope to snap beck but rewind slowly while keeping

hold 01 handle.

, 7. If cngine fails to star1 after three pulls, repeat :tap 5.

8. After engine stem. gradually return choke laver to

Figur_ 12

Page 8

JAN-_0-2001 12:50

706 651 7714 P,09/21

OFF CHOKE poshion. NOTE: Allow the engi.e tu walm

up for e few minutes es tire engine will not develop full

power until iTreaches operating lempvreture,

g. To stop engine, move throttle lever to STOP posll;o.,

To engage self-propelling all'ire nlndlenis_t and for thv most.

ef/eGtlve Useof your snow _llrower. refer to paragraph Snuw

Thrower Operalion.

P.AReUR_

m

l i°l 111 °t11

___ __

Figu,'a 14

FUEL 8OWL FUEL DUMP_:._..

VALVE "-:_._

F[gurn 1:3

Snow Tltrower Operation

The ra!! effective use ot the snow thrower w{ll be ostebtlsh.

ed by experience, taking into €or_slderatlon d_eterfairt, wiJld

conditlor_s, locaL|on of buildiltgs altd the depth anil weight

of the snow, It is the wind conditions and bu;Idlng Ioeallon

which will determine thn direction of Ihe discharge chute

((lgur0 111. Since the wind wil! rend lo blow rite dischargud

snow beck into the cleared area° it will be i_0cessary to

change the chute direction to offset this con_Jition ax shown

in figures 14 and 1S. De not dlscher.q0 snow toward e

building, is hidden ubJects uould b_ thtuwl_ whh sutflcjont

force to cause damage. To engage th© self-propelling dr;re

mechanism, pro_ed es follows:

1, StIR _he engine as described in paregral)h To Start

Engine,

2, UsirKj _he chute control rod (figure 111, positlon tile

discharge chute to dlscherge the snow with the wirid, u!

away from bu_idlngs.

3. Move auger control lever to ENGAG r: poe;flue, The

augerwill start turning (_iguro 11).

CAUTION: Keep hinds, feet end clothing away from the

auger while engine Is ronnhtg.

4. qnlect proper speed for s.ow conditions as outlined

below:

A, Number I p_itiun is tel e_lra deep, wet heavy

sinews.

B, Number ;_ position is lar similar conditlons, bLl[ nor

as llCVel _.

C. Number 3 position isfor light fluffy snow.

D, Number 4 position Is mainly for transportlng u.it

over bare or plowed areas, but may be usedfor very

light snow.

E. Run engine at or near top speed, regardless el which

' Figure 15

speed posilion you ere using.

E. To stop forward mmion, move shift ,lever t_ NEU-

TRAL posltion. Engine and augur will cuntinue to run. To

sIon ouger, move aL_ger control Io DIS_NGAG I= =oslti_n.

"J*nMOp engJnL', move li)rottle conBol IO STOP posir_un.

CAUTION: Oo not attempt 1o remove any item tiler may

become lodged in auger without laklng the following pre"

cautlom:

1. Move auger ©onttoi lever I0 DISENGAGF position,

2, Move shits lever lo NEUTRAL pillion,

3. Move tllmttll lever VOSTOP position.

4. Remove spark plug.

S, Do not place your hinds in tire auger. Use e pry bar,

CAUTION: Tl_e engine compression could cause the IKloer

to rotate sharply when lodged item Is removed, if above pre-

cautions are not followed.

IMPORTANT: At(or 0_ch use of the snow thrower, slog _hc

engine, remove the spark plug, remove ill ecoumulated snow

from the unit and wipe clean. EIore the snow thrower in ;_

p=otocted area.

SERVICE

CAUTION: Always remove the spark plug I_fore making

any repell_ or adjmtmenss.

Drive Belt Adjustment

This unit is equipped with two drive bolts located Just in

front O{ engine under belt cover {figure 111. Figures 16 and

17 show both bole; end Idler pulleys, Tensiun spring and

idler pulley should keep dr_ve mechanism belt {neeresl Io

nngine) firmly in corlrect with engine pulley at ell times.

-8.,.

Page 9

3RN-30-2001 12:5i 786 651 771a P.10/2i

If adiu_tmoot Ioocomcs necessarV due (o We_r or shetch of

bell, luos.i_l Iocknul idler pulley (figure 771 anti i;ush idlm

pulley toward I)€lt unlil SLllfJuiellt tel_Jiion is _i}ieved. Tigllt.

e!_ pulley securely, Auger drive buff (lerll_esl from e_igi.'ie)

is engng.id wlth engi,_e pl.illey o[dy when au0m venires luvel

Is ill ENGAGE po_illnn, Piece auuor cOmlol levee il, EN.

GAGE po._fflon gild adju:;I beff tcluion In _ame mam_=_ at

desnlibed lot tiriue meeha_lism bolt.

Dun to stiffness nf e _lew bell, II]e _,,igel may r;u_tinLm t.i

rotate attar auger cnntrol is moved to DISENGAGE posiliml.

When belt has seated itself, aLIgel should slop hlrtlhlll 10

to 20 seconds an,or _in 9 diset_g_d. If aug0l conllnues t.i

rotate fur mure than 20 seconds of let beillg disang;eJed, ad.

just auger belt ,is follows:

1, Stop englne and wait for nil Ino_i.g pans to slop.

2_ Remove _l)aJk plug,

3. I_emove belt €overt _see Drive Belt Adiuslment _ectiml

of Owner's ManualS.

d. Adjust b_lt guides I0 minimum €learances 1'€o111.iug0J'

drive belx with aug_r conical lever i,l ENGAfiE pnsizion.

(Clearances are: Left Guide , minimum, 1/16 ioch;

maximum, 118 inch; Right Guide - mlnlmtml, I/8 i.ich;

nlaxlmum, '4 Inch.)

S. Replace zpark plug and start engine, usinl! eztreoze

caution to avoid exposed bells,

6. Move auger €entre/lever to ENGAGE p_itioo.

7. Move throttle control lever to FAST po_ilion.

8. Allow engine to attain full speed, then move auuer

conlro) lever to DISENGAG_ pus)lion.

O. Check auger stoppinl_ Time. lir clopping time slill

exceeds 20 secondS,chock ddve belt leJtslon, _ deseHLmdin

Dries Ball Adjustment section of Owner's Manua!,

DRIVE CHAIN

\

10. Replace belt cover.

CAUTION; Never attempt to menually slop auger from

turning.

Figure 16

SLOT IN

|IDE FRAME

I_[Tetll line mASTER

(OPENtNP MU_TIlhULI liNK

i

Figure I0

Drive Chain Adjuslmenl

Ti_e drive chain {figure ZUJmust be checked p0lio,'iieally IO

ins_re correct chain tellsioI1, Prol)al' tef)lloo ez_Stswheo the

chain is tight enough to prevent any noticeable sag. To

ad._us¢,proceed _il follows:

1. _lartd Ul'_il U_ 011 01zoer ell(I,

-9-

Page 10

_AN-_0-2001 12:51

9_6 651 9714 P.11/21

2. Remove bottom end rmor coeoi; If=guru 61, NOTE:

Rear cover cannot bo mmowd onrlroly because shift COnlrOl

rod Is threaded through it.

3. Lo_en Idler sprocket (figure 18) alsd move if_ slut In

side frame until desired tension is achieved, Tighten spJock.

et Jeeumly.

Shift Red Length

For adjustment of shift rod lengdl, see paragraph Shift fled

Adjustment In assemblys0etiD1_uf thrs rnanuah

Shear Bolt Replacement

The auger M=ombly _s made up of e right end left ruder:

Each ir e_:ured with a special boll (figure 10J that acts as a

shear bolt. Those bolts am designed tn break if on o_ect

becomes lodged in the auger. Three sval'e shear boils silo

(zut=have becl_ furnished with your unit. If.additional bolts

are required, we suggest that you order genulno replacement

bolts. Use of a harder bolt will destroy the protection p)'o-

vided by tl_is spec;=l bolt, To mpleea e broken shear bell;;

prosed asfollows:

1, Remove d'mparas.Ofthe brckelt bolt.

2. Align tile hole ill the aurar with the hole if1 the _zJger

shaft, Install nawahesr bolt.

/:loller Chain Replacement

To remove a roller chain assembly ;t e simple pruuedgre

rvquiring that the ©hoin first be made slack {fur adjustable

chains) for ease of removal altd replacement, 3hen remove

the matter link and ehai_. To slacken t11ochain assemblyis

the reverse at the pfocedur_ described under pJ,regraphs

Drive P,Jlaln Adjustment. NOTE: Remairli,0chal_tsthat._re

not adjustable will have tO be replaced whllnUr being

slackened.

IMPORTANT: During insteltetlon of the regis=meet chain

e.embly, be certain to install the chain with the open end el

the minter link keeper =raiiing es shown in inset, fi_uJ'e18,

Drive Disc Replacement

'the repl_ement of the d;'lw disc on this unit is a major

se=viccoperation end should be do=)et_'. trained technician,

The entire drive r_setrod carriage a_embly must be removed.

The Repair Peru section Of rbls Inanual cuntaills e tist of

replecomont I_=rls elld illustration= to osslst the Ira=fred

technician in making rspoitr=alZ(J uldetirl u proper rerAeco-

=TINt1! p;Ir ts,

Snow Chai. Removal

To remove the mOWchains, release Useeltaln hook (figure 2,

pegs41 and die opposite fastener. Flesron the chain o_t o_t

the grou.d and push unit off the chain, h_stallatiun ;s ti_e

reverseof relrlOVal,

Drive Belt Replacement

The drive belt_ on th_s unit are of special construction and_

should be replaced with original equipment belts available

from your nearest _EARS StoI_ or Service C_.ter.

To replacedrive mechanism belt:

1, Remove belt cover {figure 21.

2. Releaseidler pulley l_nsion spring (figure 161.

3. Leben screw,; holding b_lt guldes end swing belt

guidesaway from belt.

4. Roll belt off en0ine pulley, NOTE: tt will be ne_s-

mary to roll e_ger drive belt off engine pulley to allow drive

m_olmnlsm belt to be _moved from en_ne pulley,

6, Remove belt by threading up between largo drive

Pulleys.

6. Install 1taw belt in revere order.

To replace auger drive belt:

1, Remove belt cover Ifigure 2).

2, Release tens;On on belt by placing eUger cootrol lever

In DISENGAGE p=itlo..

3, _'tand unit up on aU_lerand end remove bottom Cover

(figure lgJ.

4, I.OOSO_ screws hold;, g bait guides and swing oqides

away from belt.

K. Roll bolt oft = drive pulley and engine pulley and re.

move up between drive pulleys,

6. Install now belt in reverse u_dar,

Figure )9

THROTTLE L_VER

...........-............;:. e.DK ,EV,

•..... \

CARBURETOR

Figure 20

Carburetor Adjustment

Never make _meoessory adjustment=. Tl_e factory scrting_

-10-

Page 11

3RN-38-2001 12:51 906 BSI 9714 P112/21

ere correcl for most applications. The Ili.qhspeed neededis

not adjustable. II idte ad_ustmnnt become; nel;essaW,pro.

ceed as follows:

1, Start engl.e end allow to wasm up for a few minules,

2. Move Ulrottle laver tn SLOW position,

3. Turn idle adjusting screw (ligure 20) forwald or back-

ward 118 turn at a time ut)t_l cn_ine ruels smouthly, NOTE:

AJways allow several seconds between each adjtlstment Ior

the carburetu_ to react to tile new earth)g,

Never attempt to change mexlmum engirze speed as tl_is is

Preset at the foctury, Excessive speeds, housed by bv.p,'=Ssinfl

tile guy€roe!, can cause e_tonL_vc e.ltUille (Jilnlage,

Spark Plug Adjustment

(_leck tire sDark plug periodically end meet spark phlg gel)

to 0.030 inch us{rige wire feeler gauge,

The condition of Ihe spark plug may I_e detormhted by

Color. A carbonized plug is black and I)ttlltt plugs, are

greyish in culor, whereas a normal funeUonin 9 spark phlg._s

browlt, If a ne.w spark f_l_JUis required, refer to the Repair

Parts List for proper _t+plecm_ells sp<_rkplug,

Before ]nstalii.g spa,k phPj. Can! thre.lcls lightly with

graphite greaseto ;,_sureeasy removal.

For lubricatlon points, freqtlenev of lubricalio+l and type of

lubricant, see ligurcs 21 and 22.

1. Chock crankcase 011 level before starling engine en(l

after each 5 hours of _onti.uous use. Add SEARS 5W.20

motor oil or equivalco[ as required. (;hanga ©rankcaLeell

every 25 hours of operetiral) or aT Ueglnning of each seasoel.

NOTE: SEARS IO.W ut 5W-30 motor oil are aeee.ptabl0

substitutes.

To drain oil, prOCeed as fullowJ:

A. Remuv_ o_l fill cop and dip=tlck (figure 16, PelF:g).

B, Remove oil drain plug (_igure 17. page91.

C. Tip unl! toward oil droin I=lUg and drafn into ,

suitable €onlai.er. NOTE: Oil will drain more

freelv when warm.

D. Replace oil drai, plug securely a.d fill crankcaseto

proper level shown on dipstick (apptoximalery 1_

ph_ls).

ALL Fi, APIG|

BEARINGS

CHAIN

01L LEVEL PLUG

GAGE WHEEL

ADD SITARS S.A,I_, lOW Oil FY[RY 2 HOURS,

ANO AFT|II EACH USE.

ADD SEARS S.A,_, 3OW Oil AS REQUIIEO. CliECK kEFOa[:

EACH U$C.

(_ REMOVE AND f_OAf Wlltf CLINGING TYPE GREASE

SUCH AS LUBRIpLAII: ONCE $^CH SJ_ASON,

CHU/_

AUGER GEAR CAEE

Figure _P.

Lubrication

IMPORTANT: If oil or grcese gets on either the rubber drlve

dise or metal speed disc, is will hey0 !,o b_ removed or

_lippage will result. Use g_so];ne or other oil.cuttlng solvent

to remove. Wipe off exces_ oil or grease,

2. Cheek auger gear ease oil leuel before each use by

temovlng oil level plug (figure 22). Oil should be vislble in

hole. If ell la required, remove oll fill plug (figure 22) and

add SEARS SAE 30 ongl.e oil until ell beginsto run out ell

level hole. Heplece both plugs end tighten $eeurelyr

3. Remove discharge chute assembly and grease rim Of

chule opening wltlz a clJ_gin_type grease such as Lubrlplate.

-11-

Page 12

JAN-30-2801 12:52

786 651 7714 P.13/21

Storage Instructions

The snow thrower sllould be immediately prepared for

stores0 et the end of the season or if the unit is to be

Inoperotlvc for mo_ than 30 days,

1, Drain the gas tank,

2, Run the engine until carburetor is dry.

3. Drain d_e carburetor fuel bowl usln9 tho dump valve

shown in figure 13, page 8.

IMPORTANT: If not drained completely, gamllne will leave

gum deposits which will foul up the fuel system makh_gthe

engine hlrd zostart.

4, Clean the unit thuroughly; remove all debris and wipe

the unit dry.

5, inspect, the snow thrower for worn or damaged parts,

Tighten ell lOOSehardware.

6, Oil all I_In_ described in plragrapll Lubriultion,

7. Remove spade plug end pour a tablespoorr of o_1_nto

the opening. Cycle the engine bY pulling on the starter rope

IMPORTANT: A year1v checkup or tuneup by the SEARS

Service Oepartmmd is egood way of insuring that your snow

thrower will provide maximum performenoe for the next

s_ason.

'8, Store the snow thrower ;n e protected area end cover

the unit tar *Kldirio_el Woteetlon.

Engine Service

Unlesstim operator is fuily qualified to make engine adjusr-

rnontr and repairs, It is recommended that such work be

done by technieians trained to wnrk on snow thrower-type

easel;noengines,

The Repair Paras s_tioo pf this manuel contains e list of

engine replacement parts end illustrations to assist the

Uulned technician in making tepa]rs and ordering proper

replacement paris.

Service Helps

The following chert, Service Halos is provided as a guide

for correlhlg minor problcms when thc trouble Is known.

si0WIy severll flees to distribute the oil evenly on the piston

andoyllnder wall. Replaceeplrk plug,

SERV!,CE,HELPS

CAUTION: ALWAYS REMOVE SPARK PLUO BEFORE AT'TEMPTING ANY REMEDY

TROUBLE LOOK FOR REMEDY

Difficult a_lrtlng: Set choke lever to RUN position.

Engine runs erratic. ""

Enginestills;

Lossof power,

excessive vll_rarlon, Loose parts,

Unit fells to defective, Adjust dr!,v,,chain: repla_ ,ifdefective. _

propel ilseif. Drive I_h looseor ;Adjust drive belt: replace if defective.

Unit fails to Disch._rgachute dogged_, ,, Clean dlschsrgechute and inside of auger housing,

di_herge snow. Foreiwnobject lodged Remove object from auger. See CiLitJ,-n following seeD7 in pars-

i L J ml illl

Defective sperk.plu_.

Replace,defective plug.

Unlt running on Choke,

Obstruction in auger

houslng,jJ

BIm:ked lull line or'

empty Oilstank.

i , iii i

Water ;n fueJsystole,

Remove obstruction; clean auger housing.

Cleanfuel llne; thee fuel supply.

Reviewgo,seraphTost, F.gln.,

i i

Remove condensatefrom carburetor fuel bowl using clumprely0

(step 2 in .paragraphTo Stere ,,Engine).

Stop engine immJIdilitely;tighten ell bolts end make ell neceslery

repairs, If vibration continues, have the unit serviced by e com.

potent repai!'men.

Drive chain loose or

defective.

,. i m

Low transmission

fluid level. Fill re proper level.

Auger drive belt loose

or defective. Adjust auger drive ben; replace ;f dlOfect;Ve.

'Shear bolt broken, flep.ia_:e_'_'hearbolt; seepiregreph Shier Bolt RepJecan_ent.

in auger, graph Snow Tllfower adoration

.1 i.

I ii ill| i ,, i

C_eek augergear ease for broken or bound parts and for oil Leveh

Auger goat CBSOtrouble. See Repilr Parts section of this manual |oFcorrect order of parts.

• i . ,, i ,-I

-12--

Page 13

CRAFTSMAN 24" SNOW THROWER" MODE L NUMBER 536.90515

I

414

|

Q

U_

U_

U]

J_

Page 14

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.90515

Key

PareNo.

NO.

1

8240

2

40362

3

36602

D_crlf_ien

G_p, Hand

Hartdle, UpPer

Bolt, Carriage. Y.-2B Thd x

5/0 In. Lg

65724

4

5

22822

6

66739

7

41664

41666

8

9

122040

Oe_sJ.Sldfl Control

Knob. Handle

C_caf

Panel. Conxrol

Shih LeveeAx4eJ_bly

I "Screw. Hex Hd. 5/16-18 ll'hd x

1 Y,,tn. L9

IO 43484

11 41875

12 997314

13 4205O

14 42051

15 28149

16 996407

I

-_ "Standard ParisMay Be PurchasedLocally

O'l

Swing. Torsion

Cam PZale.Front

"LacJknut, 'h•2_0"ITnd

Shoulder Bolt

Bearing, Shift _-_nt_ot

Wave W;Kher

"Flatwashee, 5116 I0

I

KeY

No. Part No.

17 41924

18 9_13447

19 180816

20 43479

21 41874

22 t22052

23 121926

24 22025

25 41657

26 41658

27 122017

28 120638

29 120228

I Oem:HpUan

Shoulder 6o|1

"Lodknut, 5/18 x IB "rhd

"Screw, Hex Hd, 1_-20 Tlkd x

5 In, L9

Shift Rod UlCer

P_votBracket. Rear

"Screw, Nex Hd. 5/16- _6 Tt_dx

1Y. In, Lg

"Capscrew, He..( Hd, _-20 Thd x

1 • In. L9

Washu, Formed

Han_e, Lower,LH

Handle. Lower, RH

"Screw, Hex Hd, 5/16-18 Thd x

l lno L_

"LoqckwaSher,Split, 5116 In.

"Screw. Hex Hal. 5/16" I8 Thd x

5/8 !n. L9

;7

3O

31

32

33

34

35

36

37

38

39

4O

41

42

4,3

Pert No.

0196

23940

27325

41662

455481

27328

997319

9417373

27326

43428

9_!5

138538

998013

61028

Oe=€_on

Grip. Handle

U-Bo_t

Control Rod, Chu_

Bracket. Comr_ Rod, Lower

"flOII Pin. 5/16X 1 In.

Sprm:ket, 9 Te,e_

'Led(nut, 10-32 Thd, Hex

Type N

Sp_

Washer

Handle Strap. Remote

Saddle

Wmhez, 5/16 Ip.

Lod(washel, InfernO4Toolh

Bolt, Ca_ri_Je,5/16-18 x

In. Lg

O_mu's Manual (Not I{lustr_Zed)

3D

Z

L,J

rO

h2

Lq

PO

I

I

o_

Ln

k_

p_

Page 15

I

I

Page 16

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536,90515

K_

No. Pa_ No.

! 3057

2 12o228

0

7

8

9

10

I1

I

I

41689

40877

4T685

40885

4193S

435O4

Demiptian

Knob

"Scow,Hex Hd. 5/16-18 x 5/0 In.

"I.ad(r_t. 5/16-18 "rhd

"RollPin,1/8 x I (n.

U.ecket.Sb_port

1]lroymul Handte Assembly

SFrJng.Idler

M_un! Plate, Idler

Sceew, Talkie, Hex W_her Hd,

K-2Qx 3,/8 in,

Cover. Bell

Belt Guide, R.H.

Key

No, Parl No.

12 120_

13 120741

14 9G8503

15 41740

16 44917

17 20794

18 417Z6

19

41687

29

41727

21

3O466

22

9413534

Des_ptio_

"Loclo_v'_sher,Split, 5/16 1.0.

"ScTew, Hex H_, 5116.24 x % In.

"Set Scow, 511E-10 x Y4in,

V-Beh

Sheave, Engine

Key. _re, 3/36 X ]_ in,

Spacer, 11/32 I.D, x

I O.D.x 5/32 Tick

Idler A,,m, PrJma_f

Shoulder 6oh

Pulley Idter

• LoHmut, 3/_ t6 "l_d

Key

No.

23

24

25

26

27

26

29

3O

31

32

4:'_rlN_

12O9T8

41726

23589

41909

35144

41940

t38538

4350,1

3140

40e99

S_-w, Hex lid, 3/8-16 x 1); In.

Icier Arm, Sc,c_tdlu'y

Shoulder 0off

Mounting Brackel, Auxiliory

Screw, S_otled Flex Hd, Taplite

10-24 x 3/'8 in,

_h0n. _il Covet'

L_kwashey, Inlemal Taoth

5116 i.D.

Bell Guide. L.H.

Wi_k_, Wave

V-B_Jt

Z

L_J

(S)

ro

o,

L_

L,J

I

r

-.]

O_

(.q

Page 17

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536,90515

Page 18

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.90515

PartNo.

1

4O619

2

;9413534

3

4

9413447

;5

998503

417O4

120229

e

285_

9

25177

I0

43498

II

25O8O

12

I

18

I

2O

ZI

22

23

25

26

"Standard parts may be purchased locally.

435O1

43499

43502

15

Z73_

16

32398

17

32397

41702

19

30467

274517

36625

999314

25072

35345

41753

36602

435Q5

Om=ipfion

aearln9, Rotor

"L_knut, 3/I6-16 -I'nd

$p_'er, Pulley HIub

"Locknut, 5/16-16 11hal

'S_ Screw. 5/16.18 Thd x

Y,In.L 9

Hub. (_|ve

"5crew, Hu Hd, 5/16.18 Thd x

7/8 In. Lg

_eave B.4 ln. Die. OD

Wa_ner

_pporl _kBeateno AJsembly

8earing

Bearing,

Support Auembly

Sp_edShaft

Key, Hi ProNo. 606

Wmher

Thn;at 9earn 9

SPeed Disc

8eit Guide. I,ow_e

*Flasher, 3/8 ID

Ring, TTuafc

' Locknut. Y.-20 "rhd

Oi:r,c,Bearing Re_i_ne_,

9earing, SelI-,Alif_ing

5_de Fram_/_em_y. LH

Boll, C.a_ge. _.-20 Thd x

5/8 In. Lg

Chain Anembly

No, P_rt No.

2_ 25097

29 27189

30 454565

31 41995

32 41696

33 41743

34 41754

35 33154

_8 41849

39 4!707

49 41708

'- 120229

45 . 411593

49 271190

47 43495

48 43166

49 122188

50 4189Q

51 41991

62 406?7

53 136489

54 41711

24167

"169

41705

4170,6

36311

Oem'i_

Link Connector No. 40

Sprocke% 36 Tm.d_

"go_l Re, _; x 1'/, In. L9

Shall. Interrne_a_e

Sprocke% 9 Teeth

Chain A._eml_y

Side Frame _emt_y, RH

Q-,ai_, Snow l_n_

end Tire A._sembly

V_lve Stem

Screw, Special

OISCoBe,z_ng Retainer

Collar, Lock;_g

Shaft, Ax/e

Sprock_ 30 Teem

Pin. OHve-Lok, _ x 1½ in. Lg

"Scr_v_. Flex Hd, 5116-18Thd x

5/8 in. 1.9

_ f_K_e, Ffal_e

"Hut, KelP, 3/8-16 Thd

Sprocket, Id!.er

Bushing

*Screw, Hex Hd, 3_5- I9 Thd x

2 I.. Lg

Shoulder Bolt, Carriage

Wave Wesher

F1a'nveslter

Lockwasher: External Toolh,

5/16 fO

S_pporl A_,embiy, Ca_riege

Key

No. _ NO. Om©dpdon

55 465_9_

:56

57

68

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

43481

41865

44999

120834

4O632

25177

35703

35383-

180018

41922

36664

995338

35585

29162

4f716

41729

41/30

19196

180120

41871

42619

"Ball, Ca_H_ge,5/16-18 "rlkdx

5/8 In. Lg

6eli C_mk Assembly

Cramp, 9e_l@rink

S_rockm, 8 Teeth

'Screw, Hex Hd, 5116-t8 Thd: x

Bea_ing.St4f-Aligning

Flatv_er. 3/4 IO

Ring, TrJaec

Beadr'_

"Screw, Y,-20 Thd x 5/8 In. L9

Besrir.g Yoke and B_tlAzsemb_¥

Beating Yoke

"Screw. Tapdle, Hex Hd.

_-20 Tlhdx 5/8 !o. Lg

Castle. Retainer

Ois¢ A._e,mbly, Rubber

5p_er

Drive Shafl, Hex

Cower,Rear

Screw. Tip, re, Slotted, Hex Hd.

10-24 Thdx 3/6 In. IJj

Cover, I_om

Engine, Model No, 143.92692

*Screw, Hex Hd, 3t6.16 Thd x

_; In. Lg

PI_0 En_ne Mo_nl

"Screw, Tepdte, 3/8-16 x

H ln. Lg

z

I

I

I_,

B.)

ol

Ld

-a

O_

O_

-3

i_-

LO

\

r'O

Page 19

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER ,536,90515

Z

I

I

Q

_v 68 s 69

11

22

I'0

i

1

0

-,3

I

c.rl

-,3

\

f,O

Page 20

CRAFTSMAN 24" SNOW THROWER MODEL NUMBER 536.g0515

Key

No. PartNo.

I 122017

De*cdp5o.

"screw, Hex Hd, 5116.18 Tt_dx

1 In.L 8

2

3

4

9964O7

9413447

122_19

*Flatwasker. 5/16 ID

"Lockout, 5/16-1B Thd. Type N

+Screw. Hex Hal, 3/8-16 Thd x

ln. Lg

5

! 20382

6

36007

7

27324

8

986427

Lockw_hex, Solit, 3/8 10

Strap, Support

"Key, Hi Pro No. 606

"Washer, 13/16 ID • ! Y,OD x

16 Gause I

9 44979

10 25177

11 4|813

12 122052

Imp.:ll_" Assembly

•Ftatwasher, _ IO

Gear Case Alterably

"Screw, Hex Hd, 5/16-18 "l_d x

1-_, In. Lg

r13 21970

I

14 39119

d

I

15 274517

16 27318

17 271190

18 99801O

"Washer, 1 ID x _, OO x

.125Thk

Shoulder Bolt

•F/etwmher. 3/8 IO

Wheel, Gage Alsem_ty

°Nut. Keps. 3J8-16 Thd

"Bolt, CarriaBe. 5/16-16 "n-.d x

_ In. Lg

19 25091

20 446363

21 "271184

'Stancta,d parts may 1_ pu_cbiF.,ed locally

Skid

•Fla_va_her, 5/16 IO

"Nut, KeFs. 5116-18 Thd

Kay !

Mo. Pall No.

22 997314

23 180016

24 25840

25 16B39

26 8240

27 35137

28 122007

29 30480

30 28576

3t 4 1870

32 41868

33 120229

35 27368

36 41864

31 41852

38 39142

39 9413534

40 41863

41 110356

42 4_.851

43 41750

44 23700

41867

Oa=ultd[on

• Locknul, Hex '_-20 Thd, Type N

"Scr_'_v, He_ Hd. Y--__OThd x

y_In. Lg

Washer, Belleville, 5/16 ID

Oecal. Caullon

Grip. Hand

(_qute AJsernbly. Top

"._:rew, Hox Hd, 5/16-18 x

_..tn Lg

C!_u_eA_mbly, Bottom

Chute Q'ip

AUBeTBlade, RH

Auger A-_s_mbly.RH

"Screw. He.,( Hd. 5/16-19 Tlhd x

5/6 In. 14

Auger Assembly, LH

AIJger Blade. LH

Cover, Au_r

Auger Housing End, RH

Oeari_j. Auger

"Locknut. 318-16 Thd

Sr.Ia per 9{ _ie

"Bolt. Capriole, _-20 Thd x

Y-=In. L9

Auger Hot_ir_g End, LH

Cov_ _embly, Rot©_'

"Pipe Rug. Y. In.

Key

No. Pan No.

45 120854

46 120380

47 28568

46 29569

49 2iBBf

54} 8421

51 27117

52 8292

53 8290

54 28526

SS 28425

56 21684

57 21921

58 21686

59 119117

60 21922

61 21924

62 2E426

63 2503

64 28570

65 24274

68 3021

67 41725

68 35497

69 43490

Description

'Camcrew, Hex Hd. %-20 Thd_

516 I_l, Lq

*Lockwmher. V,ID

Plate, Cover

Gasket

RinB, Re_n_ng

Spring W_her

Worm Gear

5paoer

Bearing Ascembly

Gear C=_

Shaft, Gear Box, Sho(1

• Key. Hi JPro

"O*" Ring

Nut. Bea_,in9 Adj;_.,stin8

"Pin. Cotter, 3,13_ x Y=In. Lg=,-

Oil Seal

8earin 8 A_emb_y

Go=r, Bronze

"Pipe Plug, 319 In.

0earing

O31Seal

"Key. Woodruff No. 9

Shah, Gear Box. Lon 8

Sctl_w. Tzplife, 5/16-18 In. Lg

Rotor Shah

Z

I

UJ

I

-3

u]

-a

-.3

J_

-N

0

]_

[-

]3

k-=

Loading...

Loading...