Craftsman 536889252 Owner’s Manual

ICRRFTSMRN°I

Operator's Manual

Snow Thrower

13 Horsepower

Electric Start

33-inch Dual Stage

Model 536.889252

CAUTION: Before using this product,

read this manual and follow all of its

Safety Rules and Operating Instructions

Manual del usario

Quitanieves

de 33 pulgadas

13 caballos de fuerza (hp)

Bietapico

Arranque electrico

Modelo 536.889252

PRECAUCION: Antes de usar este producto,

lea este manual y siga todas las reglas de

seguridad e instrucciones de operaci6n.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

F-041074L www.sears.com/craftsman

i('-I:]I=IEe]_[_e_'_

WARRANTY STATEMENT ...... 2

SAFETY RULES ............... 2

INTERNATIONAL SYMBOLS .... 4

ASSEMBLY ................... 6

OPERATION .................. 13

MAINTENANCE ............... 21

SERVICE AND ADJUSTMENT .. 24

|V/:I,|;r:1_iIi'd[-"_

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow thrower is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner's manual, Sears will repair, free of charge, any defect in material or workmanship.

If this Craftsman Snow thrower is used for commercial or rental purposes, this warranty ap-

plies for only 90 days from the date of purchase.

This warranty does not cover the following:

Items which become worn during normal use, such as spark plugs, drive belts and shear

pins.

Repair necessary because of operator abuse or negligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained in the

owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW

THROWER TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates. IL 60179

STORAGE .................... 34

TROUBLESHOOTING TABLE . ,. 35

REPAIR PARTS ............... 41

ENGINE REPAIR PARTS ....... 61

SPANISH (ESPAI_IOL) .......... 75

PARTS ORDERING/SERVICE ..

BACK COVER

_IL OOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other repro-

ductive harm.

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

F-O41074L 2

IT MEANS-- ATTENTION!!! BECOME ALERTt!! YOUR SAFETY IS INVOLVED.

,_ WARNING: Always discon-

IMPORTANT: Safety standards re-

quire operator presence controls to

minimize the risk of injury. Your snow

thrower is equipped with such controls.

Do not attempt to defeat the function of

the operator presence control under any

circumstances.

nect the spark plug wire

and place it where it cannot

make contact with spark plug to

prevent accidental starting during:

Preparation, Maintenance, or Stor-

age of your snow thrower.

TRAINING

1. Read this operating and service instruction

manual carefully. Be thoroughly familiar

with the controls and the proper use of the

snow thrower. Know how to stop the snow

thrower and disengage the controls quick-

ly.

2. Never allow children to operate the snow

thrower. Never allow adults to operate the

snow thrower without proper instruction.

3. Keep the area of operation clear of all per-

sons, particularly small children and pets.

4. Exercise caution to avoid slipping or falling

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

snow thrower is to be used and remove all

doormats, sleds, boards, wires, and other

foreign objects.

2. Disengage all clutches before starting the

engine (motor).

3. Do not operate the snow thrower without

wearing adequate winter outer garments.

Wear footwear that will improve footing on

slippery surfaces.

4. Handle fuel with care; it is highly flam-

mable.

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel

to a running engine (motor) or hot en-

gine (motor).

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

d. Replace fuel cap securely and wipe up

spilled fuel.

e. Never store fuel or snow thrower with

fuel in the tank inside of a building

where fumes may reach an open flame

or spark.

f. Check fuel supply before each use, al-

lowing space for expansion as the heat

of the engine (motor) and/or sun can

cause fuel to expand.

5. For all snow throwers with electric starting

motors use electric starting extension

cords certified CSA/UL. Use only with a re-

ceptacle that has been installed in accord-

ance with local inspection authorities.

6. Let engine (motor) and snow thrower ad-

just to outdoor temperatures before starting

to clear snow.

7. Always wear safety glasses or eye shields

during operation or while performing an ad-

justment or repair to protect eyes from

foreign objects that may be thrown from the

snow thrower.

F-041074L

OPERATION

1. Do not operate this snow thrower if you are

taking drugs or other medication which can

cause drowsiness or affect your ability to

operate this snow thrower.

2. Do not use the snow thrower if you are

mentally or physically unable to operate the

snow thrower safely.

3. Do not put hands or feet near or under ro-

tating parts. Keep clear of the discharge

opening at all times.

4. Exercise extreme caution when operating

on or crossing gravel drives, walks or

roads. Stay alert for hidden hazards or

traffic.

5. After striking a foreign object, stop the en-

gine (motor), remove the wire from the

spark plug, thoroughly inspect snow

thrower for any damage, and repair the

damage before restarting and operating

the snow thrower.

6. If the snow thrower should start to vibrate

abnormally, stop the engine (motor) and

check immediately for the cause. Vibration

is generally a warning of trouble.

7. Stop the engine (motor) whenever you

leave the operating position, before un-

clogging the auger/impeller housing or dis-

charge chute and when making any

repairs, adjustments, or inspections.

8. When cleaning, repairing, or inspecting,

make certain the auger/impeller and all

moving parts have stopped and all controls

are disengaged. Disconnect the spark plug

wire and keep the wire away from the spark

plug to prevent accidental starting.

9. Take all possible precautions when leaving

the snow thrower unattended. Disengage

the auger/ impeller, stop engine (motor),

and remove key.

10. Do not start or run engine in enclosed area,

even if doors or windows are open. Ex-

haust fumes are dangerous (containing

CARBON MONOXIDE, an ODORLESS

and DEADLY GAS).

11. Do not clear snow across the face of

slopes. Exercise extreme caution when

changing direction on slopes. Do not at-

tempt to clear steep slopes.

12. Never operate the snow thrower without

proper guards, plates or other safety pro-

tective devices in place.

13. Never operate the snow thrower near en-

closures, automobiles, window wells, drop-

offs, and the like without proper adjustment

of the snow discharge angle. Keep children

and pets away.

14.Donotover!cadthesnowthrowercapacity

byattemptingtoclearsnowattoofasta

rate.

2. Store the snowthrower away from ignition

15.Neveroperatethesnowthrowerathigh

transportspeedsonslipperysurfaces.

Lookbehindandusecarewhenbacking

up.

3. Always refer to operator's guide instruc-

16.Neverdirectdischargeatbystandersor

allowanyoneinfrontofthesnowthrower.

17.Disengagepowertothecollector/impeller

whensnowthroweristransportedornotin

use.

18.Useonlyattachmentsandaccessoriesap-

provedbythemanufacturerofthesnow

4. Maintain or replace safety and instruction

5. Run the snow thrower a few minutes after

thrower(suchastirechains,electricstart

kits,ect.).

19,Neveroperatethesnowthrowerwithout

goodvisibilityorlight,Alwaysbesureof

_lb WARNING: This snow thrower isfor use on sidewalks, driveways

yourfootingandkeepafirmholdonthe

handles.Walk;neverrun.

20,Donotover-reach.Keepproperfooting

andbalanceatalltimes,

21.Donotattempttousesnowthrowerona

roof.

MAINTENANCE AND STORAGE

1. Check shear bolts and other bolts at fre-

quent intervals for proper tightness to be

sure the snow thrower is in safe working

condition.

_"_"_'_o_l_..-_

Caution should be exercised while using on

steep sloping surfaces. DO NOT USE

SNOW THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of resi-

dences, garages, porches or other such

structures or buildings.

sources or appliances that have a pilot

light, such as hot water and space heaters,

clothes dryers, etc.... Allow the engine

(motor) to cool before storing in any enclos-

ure.

tions for important details if the snow

thrower is to be stored for an extended

period.

labels, as necessary.

throwing snow to prevent freeze-up of the

auger/impeller.

and other ground level surfaces.

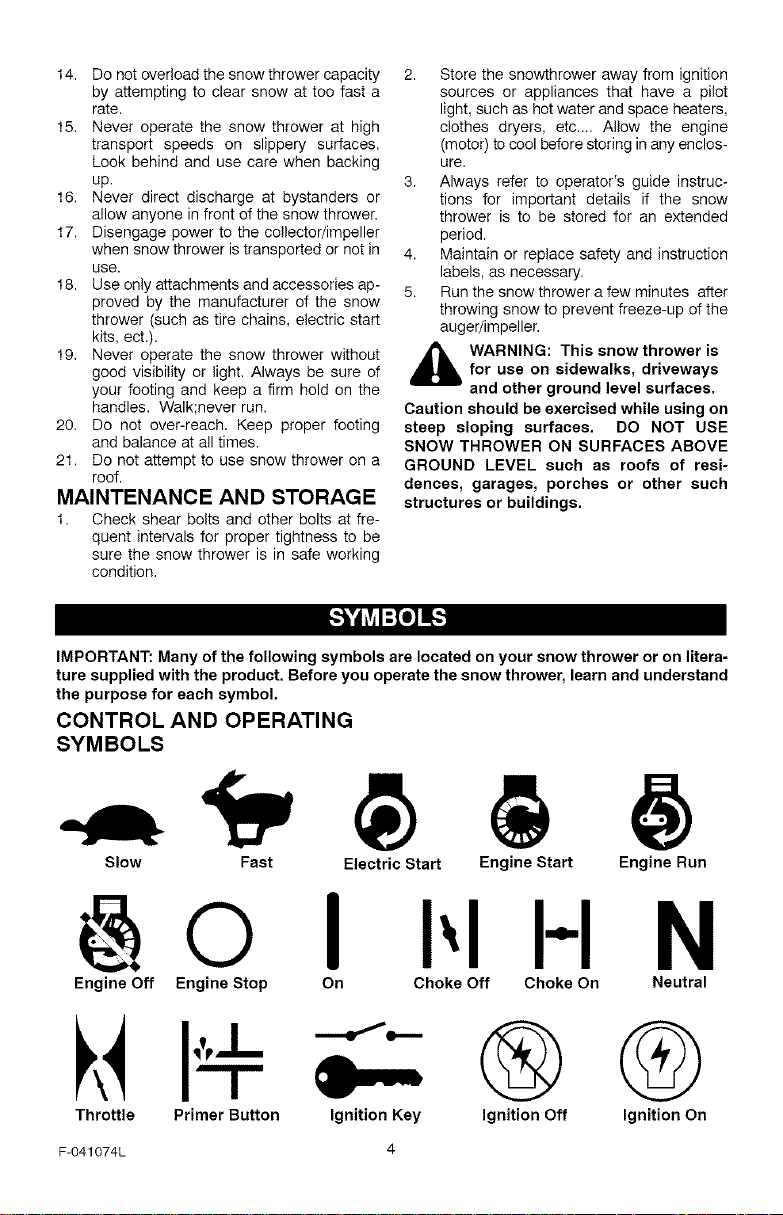

IMPORTANT: Many of the following symbols are located on your snow thrower or on litera-

ture supplied with the product. Before you operate the snow thrower, learn and understand

the purpose for each symbol.

CONTROL AND OPERATING

SYMBOLS

Slow Fast Electric Start Engine Start Engine Run

I H N

Engine Off Engine Stop On Choke Off Choke On Neutral

I''J-

Throttle Primer Button Ignition Key

F-041074L 4

®@

Ignition Off Ignition On

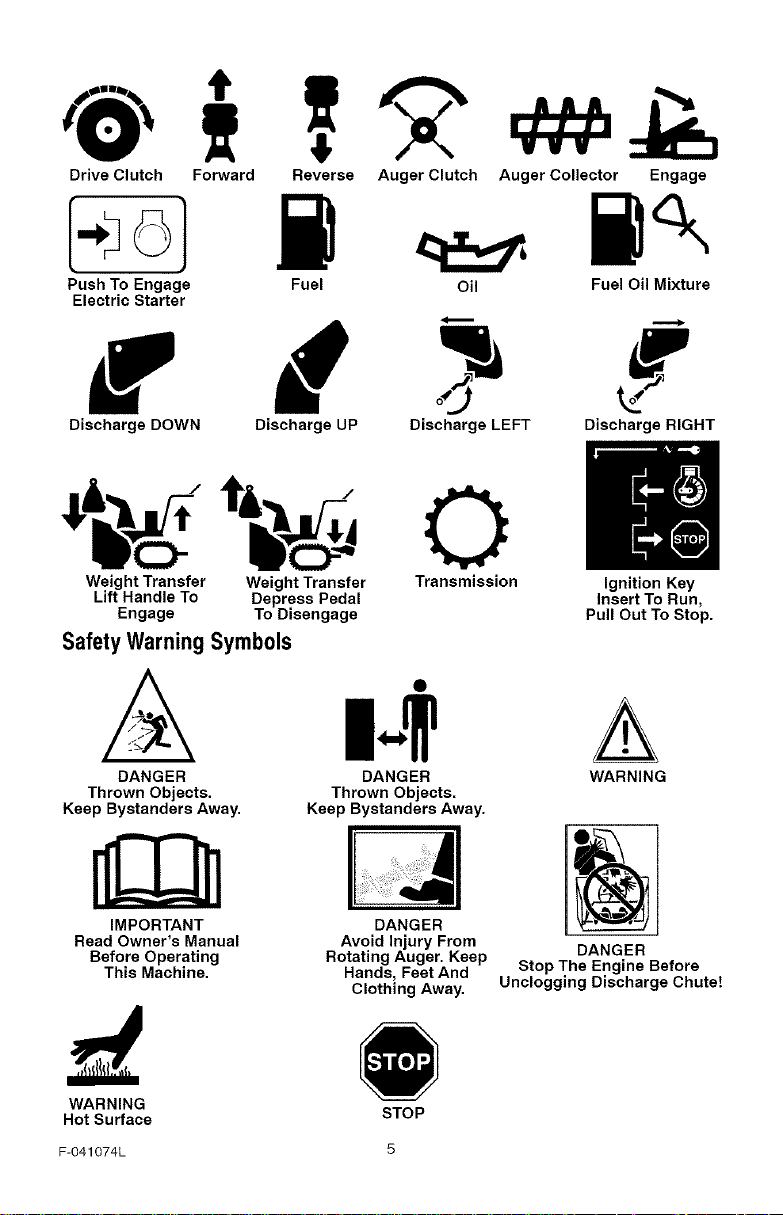

Drive Clutch Forward

Reverse Auger Clutch Auger Collector Engage

Push To Engage

Electric Starter

Discharge DOWN

Fuel Oil Fuel Oil Mixture

Discharge UP Discharge LEFT Discharge RIGHT

(.m

Weight Transfer Weight Transfer Transmission Ignition Key

Lift Handle To Depress Pedal Insert To Run,

Engage To Disengage Pull Out To Stop.

Safety WarningSymbols

DANGER DANGER WARNING

Thrown Objects. Thrown Objects.

Keep Bystanders Away. Keep Bystanders Away.

L_3

IMPORTANT DANGER

Read Owner's Manual

Before Operating

This Machine.

WARNING

Hot Surface

F-O41074L 5

Avoid Injury From

Rotating Auger. Keep

Hands, Feet And

Clothing Away.

DANGER

Stop The Engine Before

Unclogging Discharge Chute!

STOP

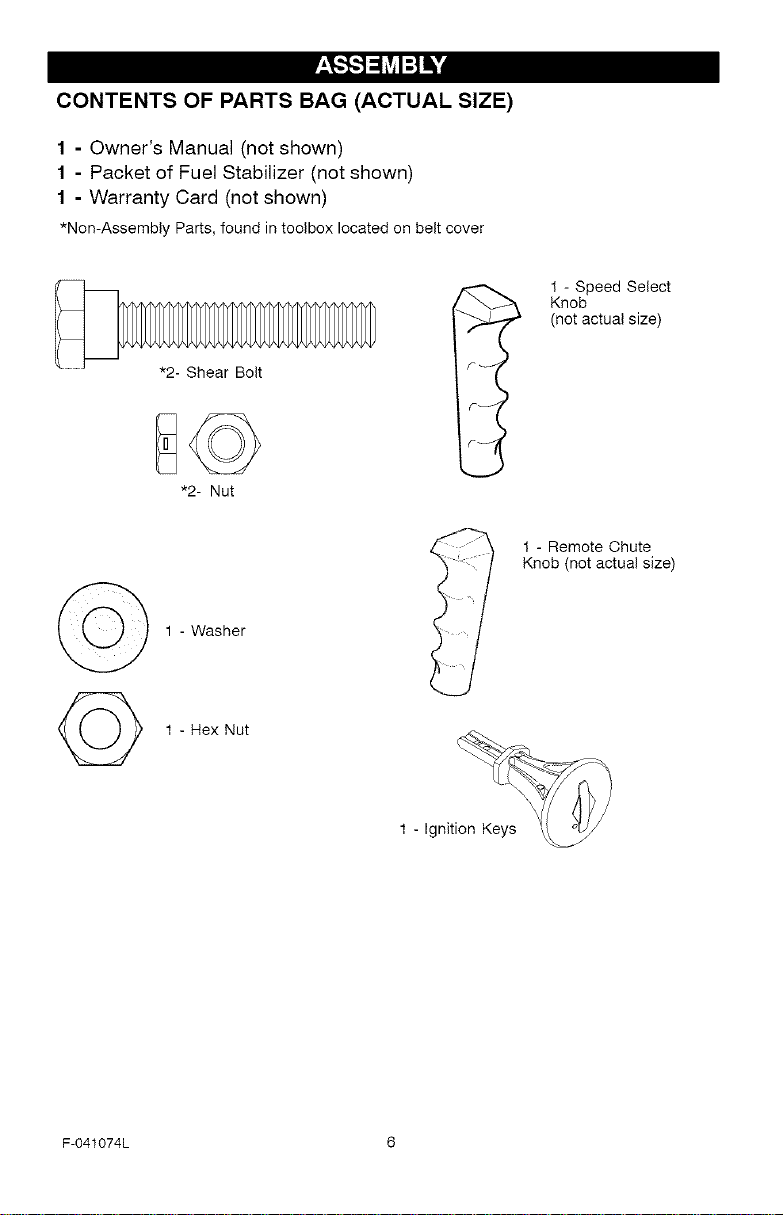

CONTENTS OF PARTS BAG (ACTUAL SIZE)

1 - Owner's Manual (not shown)

1 - Packet of Fuel Stabilizer (not shown)

1 - Warranty Card (not shown)

*Non-Assembly Parts, foundintoolboxlocatedon beltcover

1 - Washer

1 - Speed Select

_ Knob

(not actual size)

1 - Remote Chute

Knob (not actual size)

©

F-041074L 6

1 - Hex Nut

_hb ARNING: Always wear

thrower.

TOOLS REQUIRED FOR

ASSEMBLY

1 - Knife to cut carton

2 - 1/2 inch wrenches

2 - 9/16 inch wrenches

2 - 3/4 inch wrenches

1 - Pliers (to spread cotter pin)

1 - Screwdriver

1 - Measuring tape or ruler

safety glasses or eye shields

while assembling snow

(or adjustable wrenches)

(or adjustable wrenches)

(or adjustable wrenches)

/'-"-4

o

Figure 1

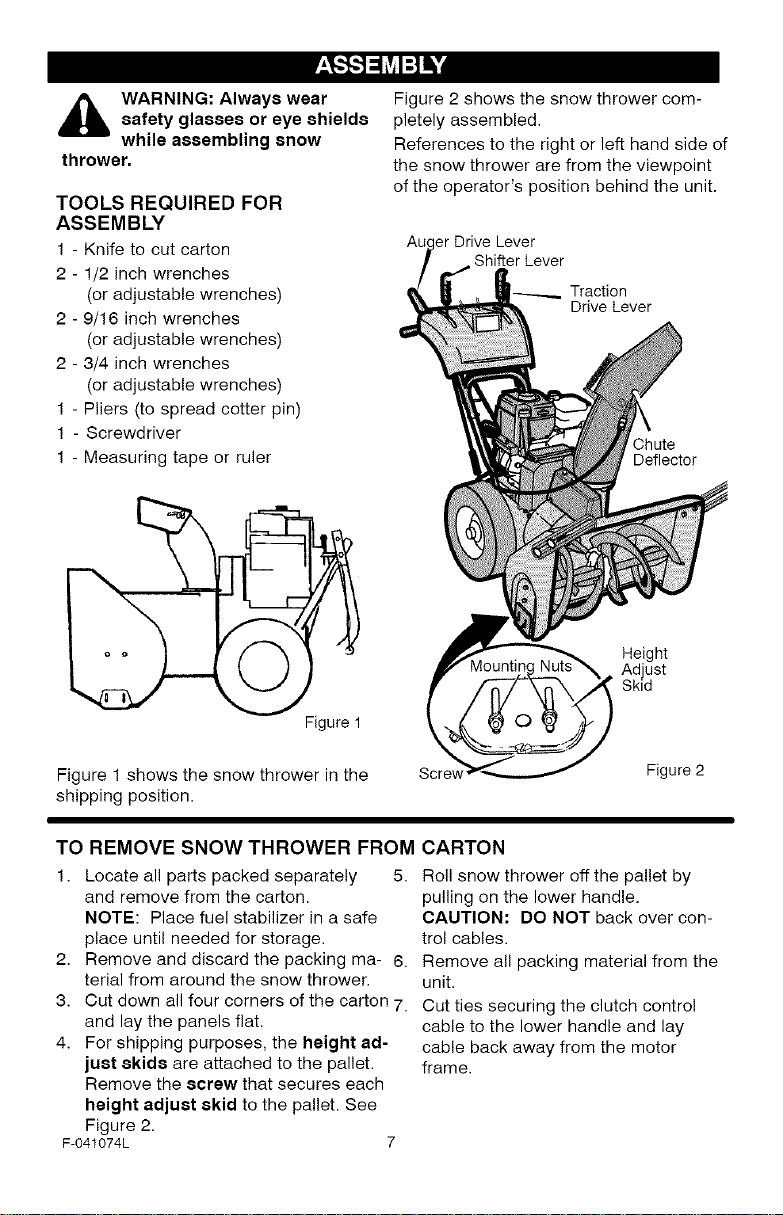

Figure 2 shows the snow thrower com-

pletely assembled.

References to the right or left hand side of

the snow thrower are from the viewpoint

of the operator's position behind the unit.

_r Drive Lever

Shifter Lever

Traction

Drive Lever

Chute

Deflector

Height

Adjust

Skid

Figure 1 shows the snow thrower in the

shipping position.

TO REMOVE SNOW THROWER FROM

1. Locate all parts packed separately 5.

and remove from the carton.

NOTE: Place fuel stabilizer in a safe

place until needed for storage.

2. Remove and discard the packing ma- 6.

terial from around the snow thrower.

3. Cut down all four corners of the carton 7.

and lay the panels flat.

4. For shipping purposes, the height ad-

just skids are attached to the pallet.

Remove the screw that secures each

height adjust skid to the pallet. See

Figure 2.

F-O41074L 7

Figure 2

CARTON

Roll snow thrower off the pallet by

pulling on the lower handle.

CAUTION: DO NOT back over con-

trol cables.

Remove all packing material from the

unit.

Cut ties securing the clutch control

cable to the lower handle and lay

cable back away from the motor

frame.

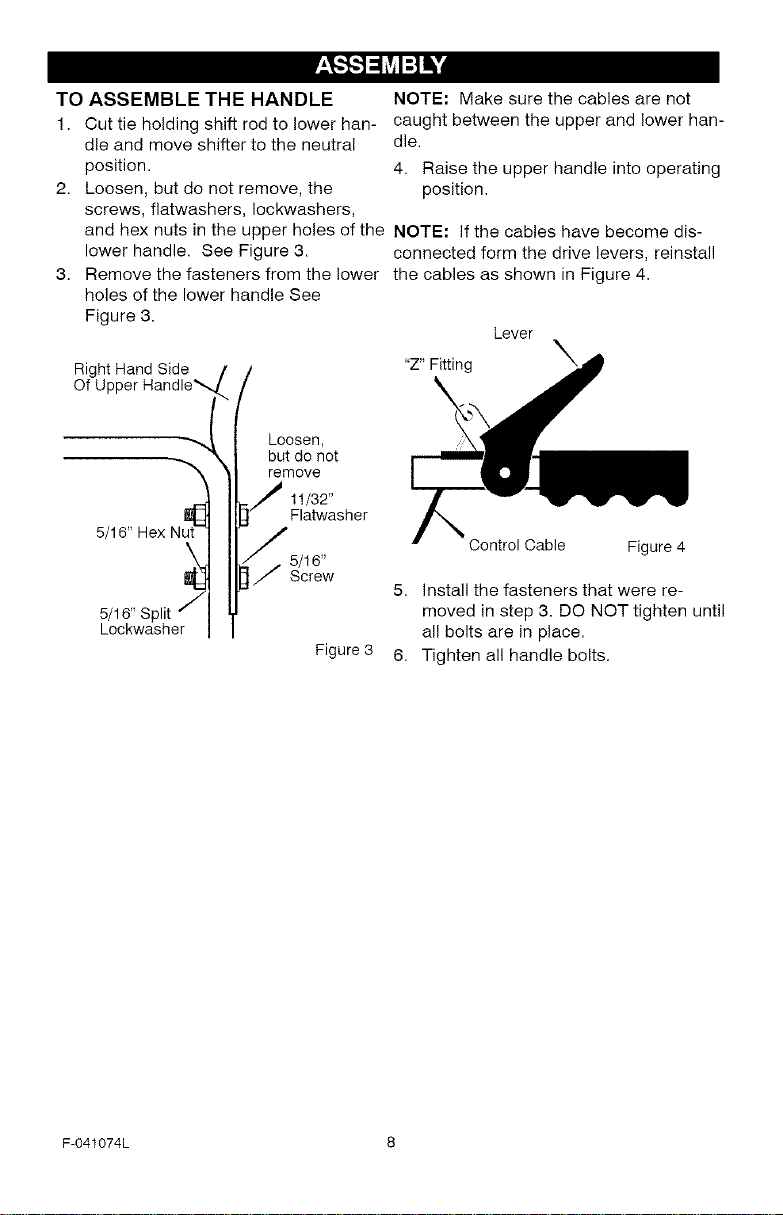

TOASSEMBLETHEHANDLE

1. Cuttieholdingshiftrodtolowerhan-

dleandmoveshiftertotheneutral

position.

2. Loosen,butdonotremove,the

NOTE:Makesurethecablesarenot

caughtbetweentheupperandlowerhan-

dle.

4. Raisetheupperhandleintooperating

position.

screws,flatwashers,Iockwashers,

and hex nuts in the upper holes of the NOTE: If the cables have become dis-

lower handle. See Figure 3. connected form the drive levers, reinstall

Remove the fasteners from the lower the cables as shown in Figure 4.

holes of the lower handle See

Figure 3.

Right Hand Side

Of Upper Handle_

"Z" Fitting X

Lever

//

but do not

t Loosen,

-h

5/16" Hex Nut_

remove

/ 111/a3t2"asher

Control Cable Figure 4

5/16" Split _

Lockwasher

Figure 3

F-O41074L 8

5. install the fasteners that were re-

moved in step 3. DO NOT tighten until

all bolts are in place.

6. Tighten all handle bolts.

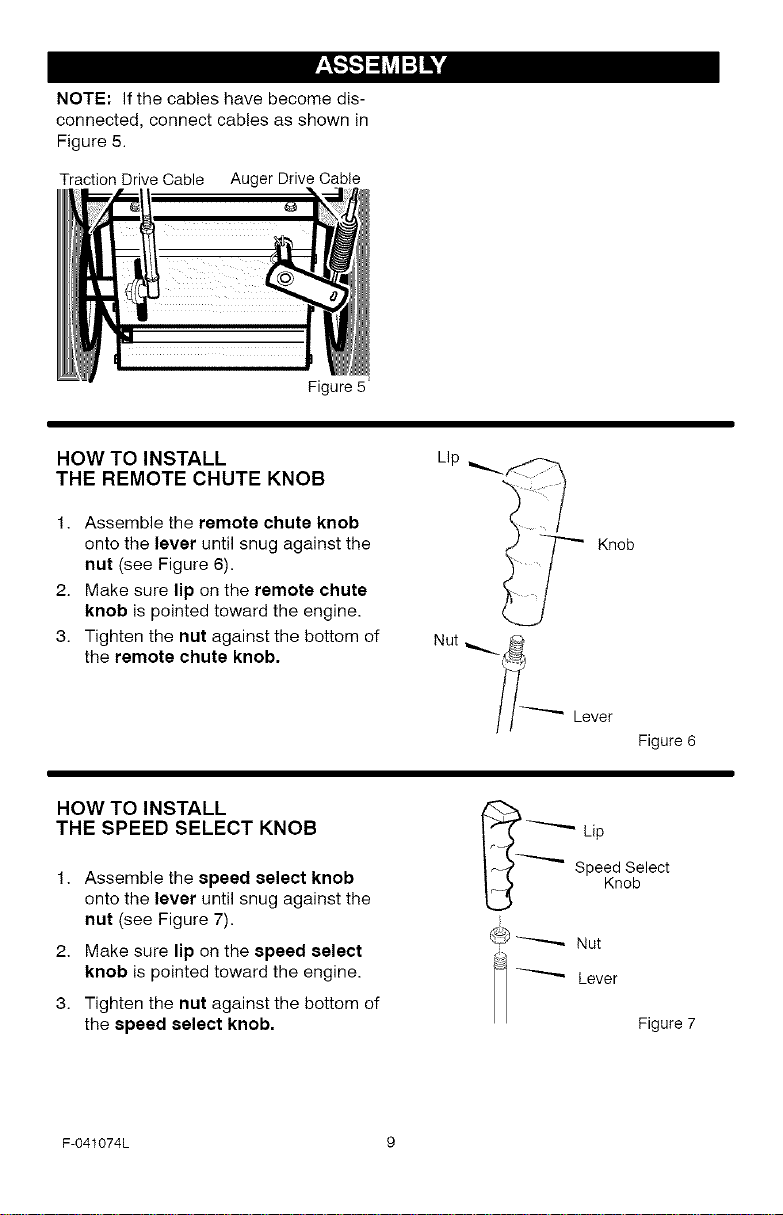

NOTE: If the cables have become dis-

connected, connect cables as shown in

Figure 5.

Traction Drive Cable Auger Drive Cable

Figure 5 =

HOW TO INSTALL

THE REMOTE CHUTE KNOB

1. Assemble the remote chute knob

onto the lever until snug against the

nut (see Figure 6).

2. Make sure lip on the remote chute

knob is pointed toward the engine.

3. Tighten the nut against the bottom of

the remote chute knob.

HOW TO INSTALL

THE SPEED SELECT KNOB

1. Assemble the speed select knob

onto the lever until snug against the

nut (see Figure 7).

2. Make sure lip on the speed select

knob is pointed toward the engine.

3. Tighten the nut against the bottom of

the speed select knob.

Lip _.

Nut

i1--'-----_ Lever

_ Lip

@ _ Nut

i

_ Figure 7

Knob

Figure 6

Speed Select

Knob

Lever

F-041074L 9

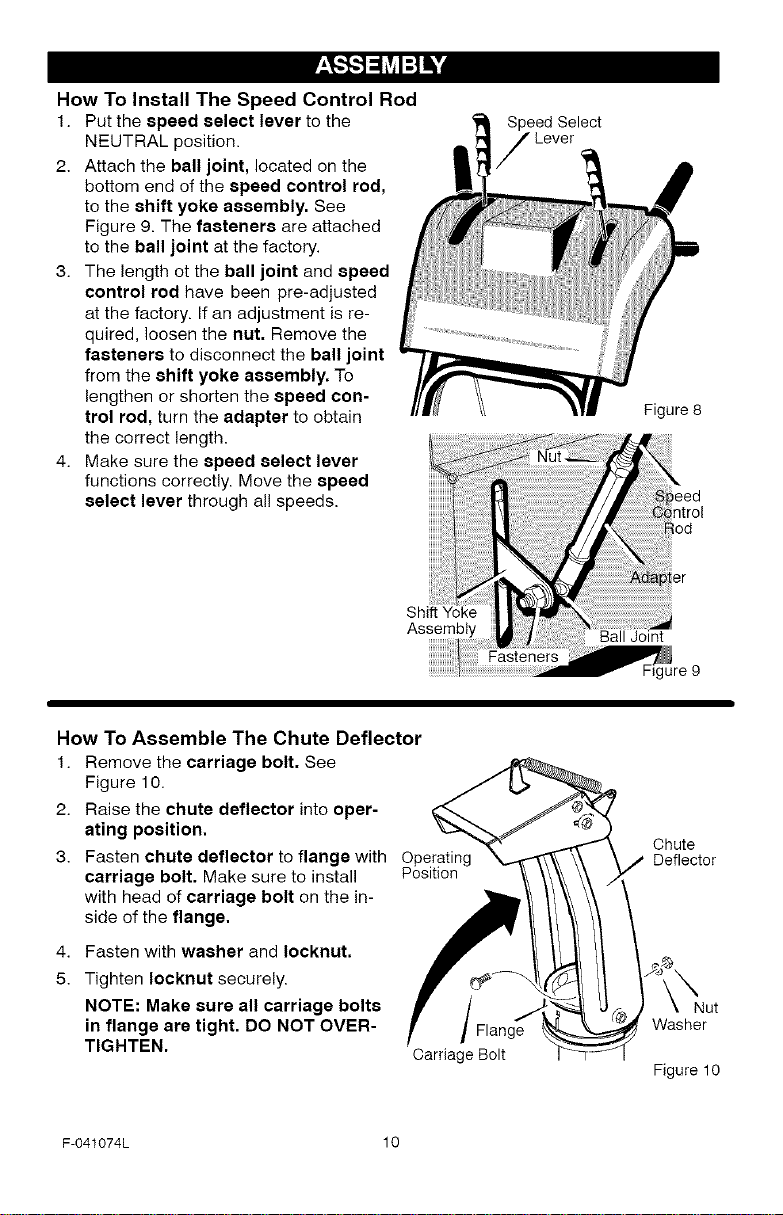

How To Install The Speed Control Rod

1. Put the speed select lever to the

NEUTRAL position.

2. Attach the ball joint, located on the

bottom end of the speed control rod,

to the shift yoke assembly, See

Figure 9. The fasteners are attached

to the ball joint at the factory.

3. The length ot the ball joint and speed

control rod have been pre-adjusted

at the factory. If an adjustment is re-

quired, loosen the nut. Remove the

fasteners to disconnect the ball joint

from the shift yoke assembly. To

lengthen or shorten the speed con-

trol rod, turn the adapter to obtain

the correct length.

4. Make sure the speed select lever

functions correctly. Move the speed

select lever through all speeds.

Shift

Assembly

Speed Select

Lever

Figure 8

Ball Joint

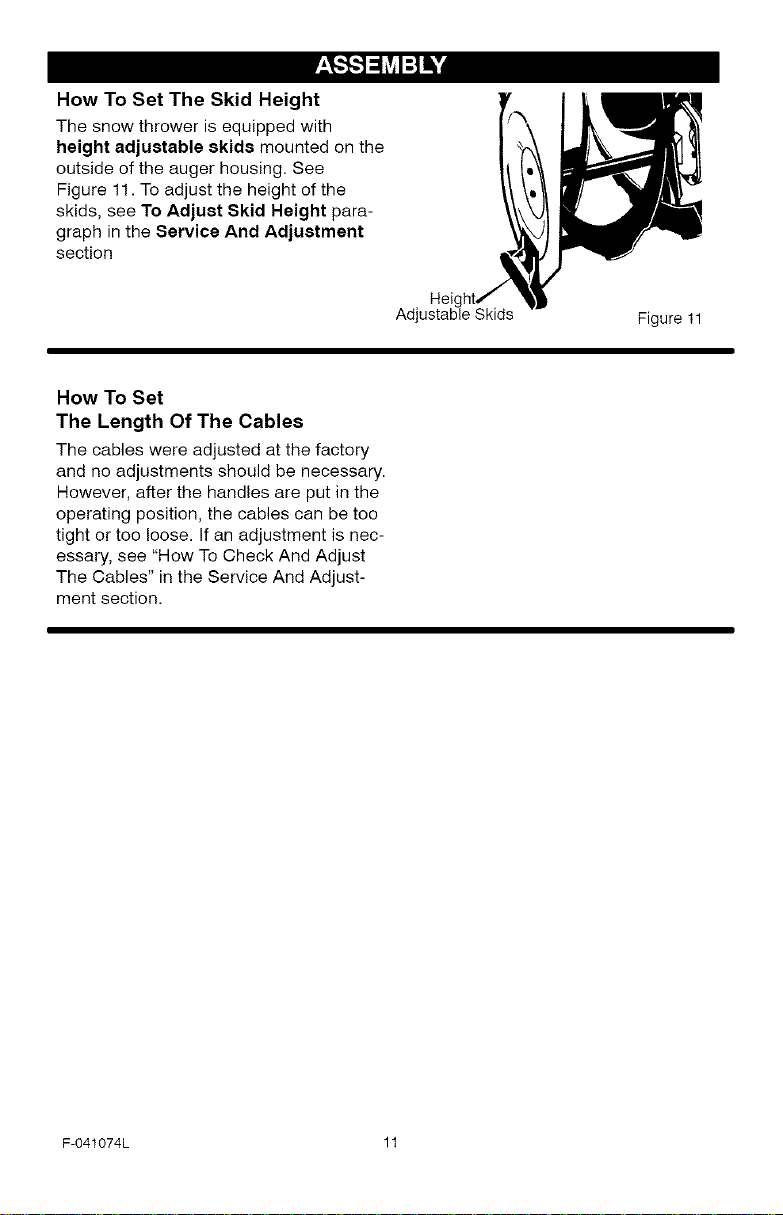

How To Assemble The Chute Deflector

1. Remove the carriage bolt. See

Figure 10.

2. Raise the chute deflector into oper-

ating position.

3. Fasten chute deflector to flange with Operating

carriage bolt. Make sure to install Position

with head of carriage bolt on the in-

side of the flange.

4.

Fasten with washer and Iocknut.

5.

Tighten Iocknut securely.

NOTE: Make sure all carriage bolts

in flange are tight. DO NOT OVER-

TIGHTEN.

F-041074L 10

Carriage Bolt

Chute

Deflector

Nut

Washer

Figure 10

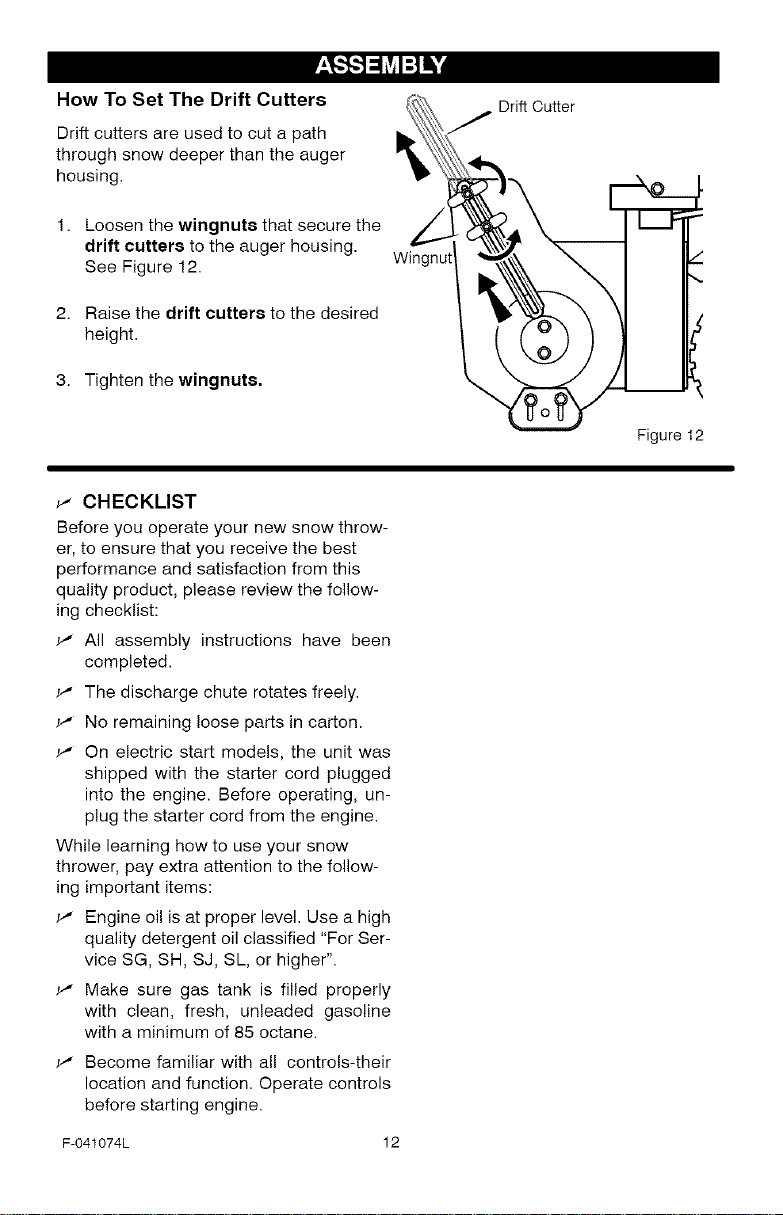

How To Set The Skid Height

The snow thrower is equipped with

height adjustable skids mounted on the

outside of the auger housing. See

Figure 11. To adjust the height of the

skids, see To Adjust Skid Height para-

graph in the Service And Adjustment

section

How To Set

The Length Of The Cables

The cables were adjusted at the factory

and no adjustments should be necessary.

However, after the handles are put in the

operating position, the cables can be too

tight or too loose. If an adjustment is nec-

essary, see "How To Check And Adjust

The Cables" in the Service And Adjust-

ment section.

Adj

Heie

Figure 11

F-O41074L 11

How To Set The Drift Cutters

Drift cutters are used to cut a path

through snow deeper than the auger

housing.

1. Loosen the wingnuts that secure the

drift cutters to the auger housing.

See Figure 12.

2. Raise the drift cutters to the desired

height.

3. Tighten the wingnuts.

_" CHECKLIST

Before you operate your new snow throw-

er, to ensure that you receive the best

performance and satisfaction from this

quality product, please review the follow-

ing checklist:

_' All assembly instructions have been

completed.

v' The discharge chute rotates freely.

v' No remaining loose parts in carton.

v' On electric start models, the unit was

shipped with the starter cord plugged

into the engine. Before operating, un-

plug the starter cord from the engine.

While learning how to use your snow

thrower, pay extra attention to the follow-

ing important items:

_' Engine oil is at proper level. Use a high

quality detergent oil classified "For Ser-

vice SG, SH, SJ, SL, or higher".

_' Make sure gas tank is filled properly

with clean, fresh, unleaded gasoline

with a minimum of 85 octane.

_' Become familiar with all controls-their

location and function. Operate controls

before starting engine.

F-041074L 12

Drift Cutter

Wingnut

Figure 12

[o_o)_

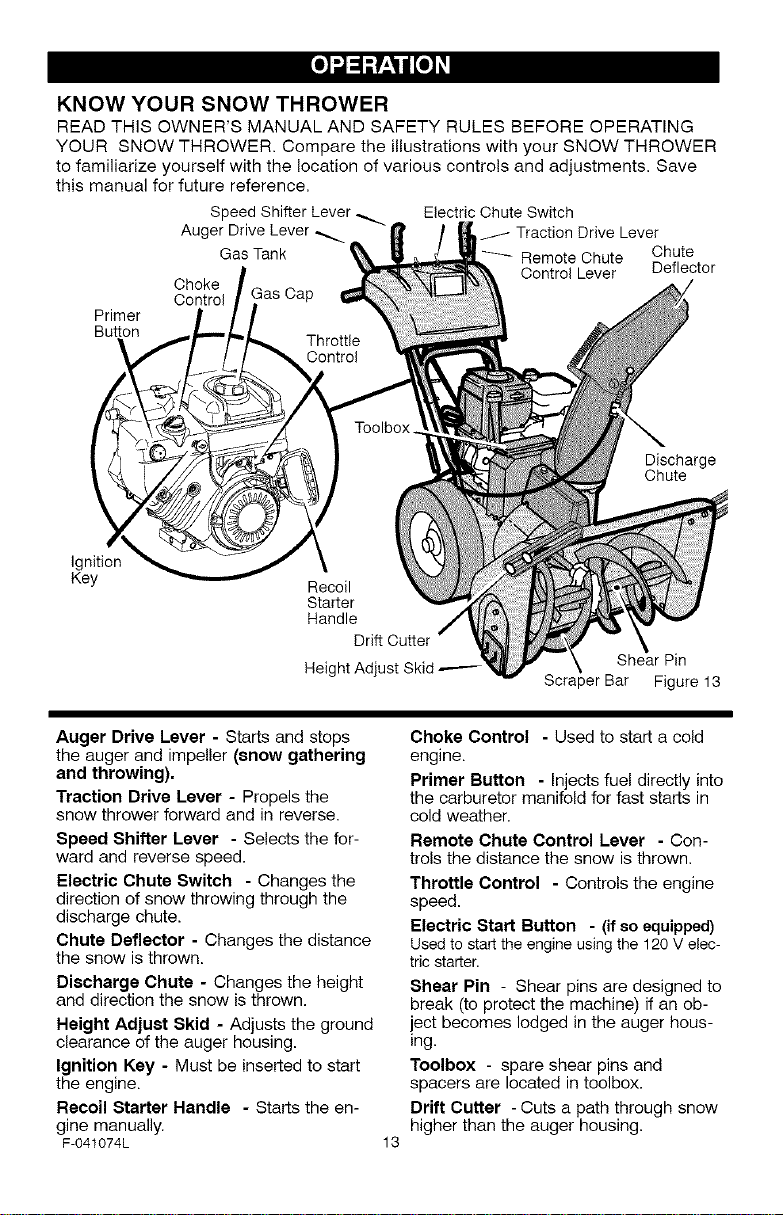

KNOW YOUR SNOW THROWER

READ THiS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR SNOW THROWER. Compare the illustrations with your SNOW THROWER

to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

Electric Chute Switch

Traction Drive Lever

Remote Chute Chute

Control Lever Deflector

Scraper Bar Figure 13

Discharge

Chute

Shear Pin

Primer

Button

Ignition

Key

Speed Shifter Lever.

Auger Drive Lever _.

Gas Tank

Choke

Control Cap

Recoil

Starter

Handle

Drift Cutter

Height Adjust Skid _--

Auger Drive Lever - Starts and stops

the auger and impeller (snow gathering

and throwing).

Traction Drive Lever - Propels the

snow thrower forward and in reverse.

Speed Shifter Lever - Selects the for-

ward and reverse speed.

Electric Chute Switch - Changes the

direction of snow throwing through the

discharge chute.

Chute Deflector - Changes the distance

the snow is thrown.

Discharge Chute - Changes the height

and direction the snow isthrown,

Height Adjust Skid - Adjusts the ground

clearance of the auger housing.

Ignition Key - Must be inserted to start

the engine.

Recoil Starter Handle - Starts the en-

gine manually.

F-041074L

Choke Control - Used to start a cold

engine.

Primer Button - Injects fuel directly into

the carburetor manifold for fast starts in

cold weather,

Remote Chute Control Lever - Con-

trols the distance the snow is thrown,

Throttle Control - Controls the engine

speed.

Electric Start Button - (if so equipped)

Usedto startthe engineusingthe 120V elec-

tricstarter.

Shear Pin - Shear pins are designed to

break (to protect the machine) if an ob-

iect becomes lodged in the auger hous-

ing.

Toolbox - spare shear pins and

spacers are located in toolbox.

Drift Cutter -Cuts a path through snow

higher than the auger housing.

13

[o_o)_

The operation of any snow thrower can

result in foreign objects being thrown

into the eyes, which can result in se-

vere eye damage. Always wear safety

glasses or eye shields while operating

the snow thrower.

We recommend standard safety

glasses or a wide vision safety mask for

over your glasses.

_b ARNING: Read Owner's

charge toward bystanders. Stop the

engine before unclogging discharge

chute or auger housing and before

leaving the machine.

TO STOP YOUR

SNOW THROWER

1. To stop throwing snow, release the

2. To stop the wheels, release the

3. To stop the engine, push the

Manual before operating

machine. Never direct dis-

auger drive lever. See Figure 14.

traction drive lever.

throttle control lever to off and pull

out the safety/ignition key.

TO CONTROL SNOW DISCHARGE

1. Move the electric chute switch to

set the direction (left to right) of the

snow throwing.

2. Push the remote chute lever for-

ward to discharge the snow down.

Pull the remote chute lever back to

discharge the snow high and far.

HOW TO MOVE

FORWARD AND BACKWARD

1. To move the snow thrower forward,

engage the traction drive lever

(left hand). As the snow thrower

starts to move forward, push the

8hift lever to the desired speed.

Maintain a firm hold on the handles

and guide the snow thrower along

the clearing path. Do not attempt to

push the snow thrower.

2. To move the snow thrower back-

ward, pull the shift lever to the re-

verse position.

TO THROW SNOW

1. Push down the auger driver lever

(right hand). See Figure 14.

2. Release to stop throwing snow.

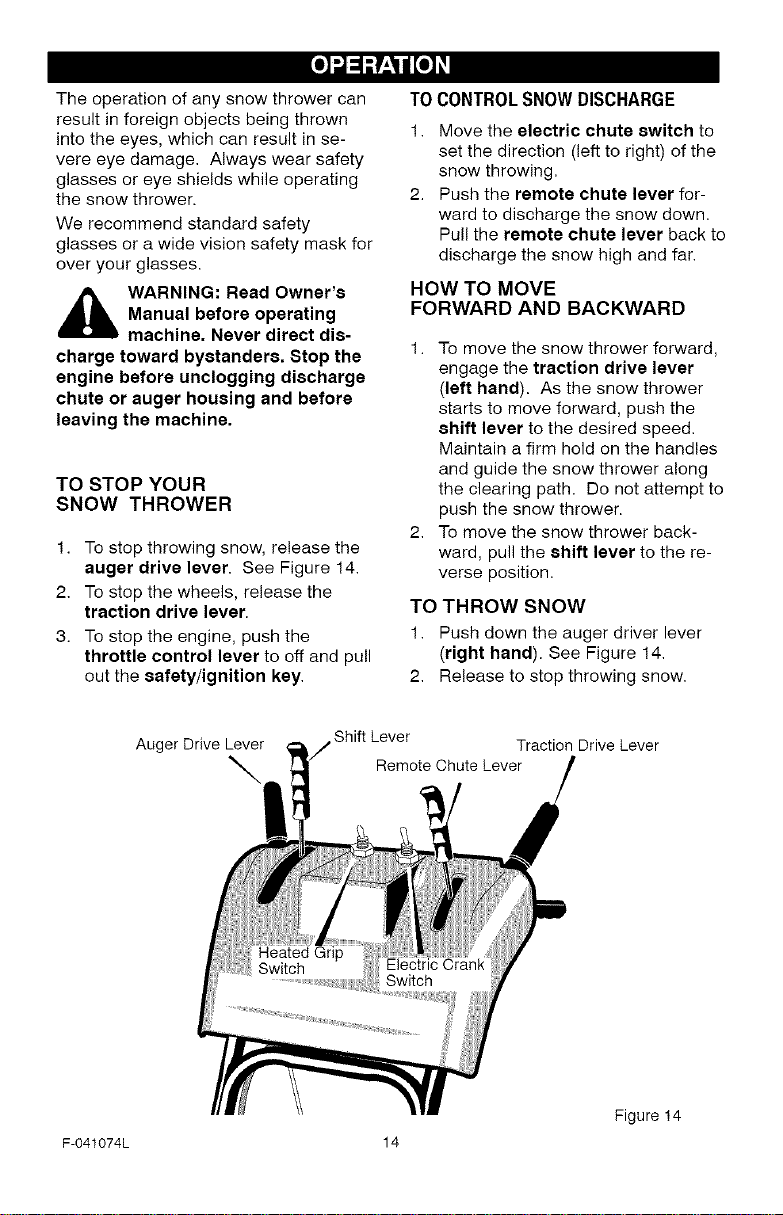

Auger Drive Lever

\

F-041074L 14

Shift Lever

Remote Chute Lever

Traction Drive Lever

Figure 14

[o_o)_

HOW TO USE

THE WHEEL LOCKOUT

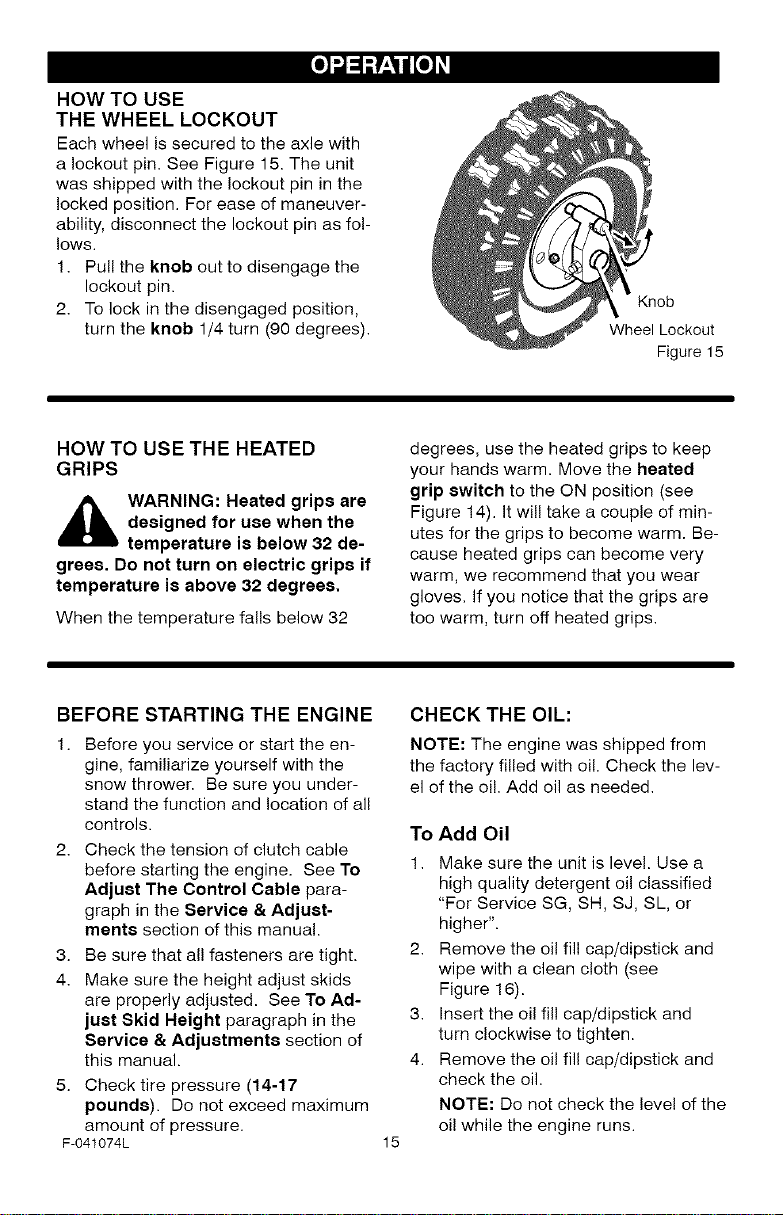

Each wheel is secured to the axle with

a lockout pin. See Figure 15. The unit

was shipped with the lockout pin in the

locked position. For ease of maneuver-

ability, disconnect the lockout pin as fo!-

lows.

1. Pull the knob out to disengage the

lockout pin.

2. To lock in the disengaged position,

turn the knob 1/4 turn (90 degrees).

Knob

Wheel Lockout

Figure 15

HOW TO USE THE HEATED

GRIPS

,_ WARNING: Heated grips are

grees. Do not turn on electric grips if

temperature is above 32 degrees.

When the temperature falls below 32

designed for use when the

temperature is below 32 de-

BEFORE STARTING THE ENGINE

1. Before you service or start the en-

gine, familiarize yourself with the

snow thrower. Be sure you under-

stand the function and location of all

controls.

2. Check the tension of clutch cable

before starting the engine. See To

Adjust The Control Cable para-

graph in the Service & Adjust-

ments section of this manual.

3. Be sure that all fasteners are tight.

4. Make sure the height adjust skids

are properly adjusted. See To Ad-

just Skid Height paragraph in the

Service & Adjustments section of

this manual.

5. Check tire pressure (14-17

pounds). Do not exceed maximum

amount of pressure.

F-041074L

degrees, use the heated grips to keep

your hands warm. Move the heated

grip switch to the ON position (see

Figure 14). It will take a couple of min-

utes for the grips to become warm. Be-

cause heated grips can become very

warm, we recommend that you wear

gloves. If you notice that the grips are

too warm, turn off heated grips.

CHECK THE OIL:

NOTE: The engine was shipped from

the factory filled with oil. Check the lev-

el of the oi!. Add oil as needed.

To Add Oil

1.

Make sure the unit is level. Use a

high quality detergent oil classified

"For Service SG, SH, SJ, SL, or

higher".

Remove the oil fill cap/dipstick and

wipe with a clean cloth (see

Figure 16).

3.

Insert the oil fill cap/dipstick and

turn clockwise to tighten.

4.

Remove the oil fill cap/dipstick and

check the oil.

NOTE: Do not check the level of the

oi! while the engine runs.

15

[o_o)_

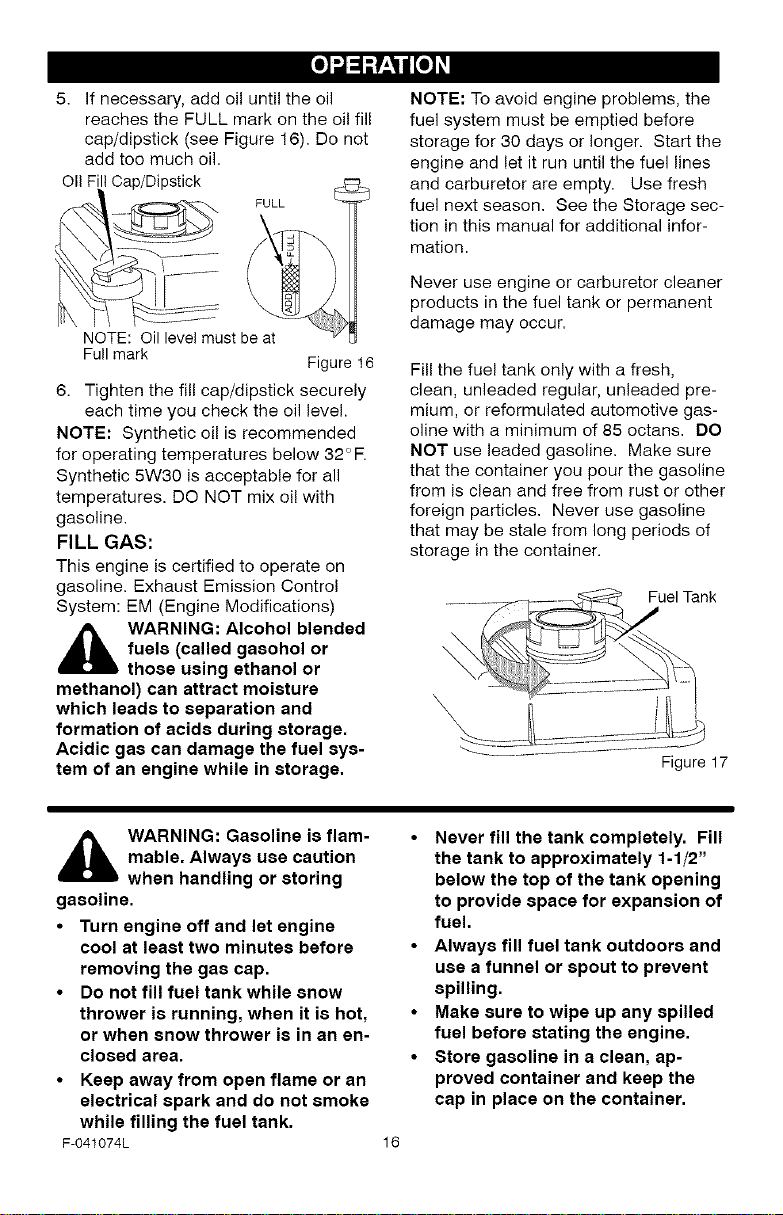

5. If necessary, add oil until the oil

reaches the FULL mark on the oil fill

cap/dipstick (see Figure 16). Do not

add too much oil.

OIIFIllCap/Dipstick

NOTE: Oil level must be at

Fullmark Figure 16

6. Tighten the fill cap/dipstick securely

each time you check the oil level.

NOTE; Synthetic oil is recommended

for operating temperatures below 32 °R

Synthetic 5W30 is acceptable for all

temperatures. DO NOT mix oi! with

gasoline.

FILL GAS:

This engine is certified to operate on

gasoline. Exhaust Emission Control

System: EM (Engine Modifications)

,_ WARNING: Alcohol blended

fuels (called gasohol or

those using ethanol or

methanol) can attract moisture

which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage.

NOTE: To avoid engine problems, the

fuel system must be emptied before

storage for 30 days or longer. Start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh

fuel next season. See the Storage sec-

tion in this manual for additional infor-

mation.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

Fill the fuel tank only with a fresh,

clean, unleaded regular, unleaded pre-

mium, or reformulated automotive gas-

oline with a minimum of 85 octans. DO

NOT use leaded gasoline. Make sure

that the container you pour the gasoline

from is clean and free from rust or other

foreign particles. Never use gasoline

that may be stale from long periods of

storage in the container.

Fuel Tank

\

,_ WARNING: Gasoline is flam-

mable. Always use caution

when handling or storing

gasoline.

• Turn engine off and let engine

cool at least two minutes before

removing the gas cap.

• Do not fill fuel tank while snow

thrower is running, when it is hot,

or when snow thrower is in an en-

closed area.

• Keep away from open flame or an

electrical spark and do not smoke

while filling the fuel tank.

F-041074L

• Never fill the tank completely. Fill

the tank to approximately 1-1/2"

below the top of the tank opening

to provide space for expansion of

fuel.

• Always fill fuel tank outdoors and

use a funnel or spout to prevent

spilling.

• Make sure to wipe up any spilled

fuel before stating the engine.

• Store gasoline in a clean, ap-

proved container and keep the

cap in place on the container.

16

[o_o)_

HOW TO STOP THE ENGINE

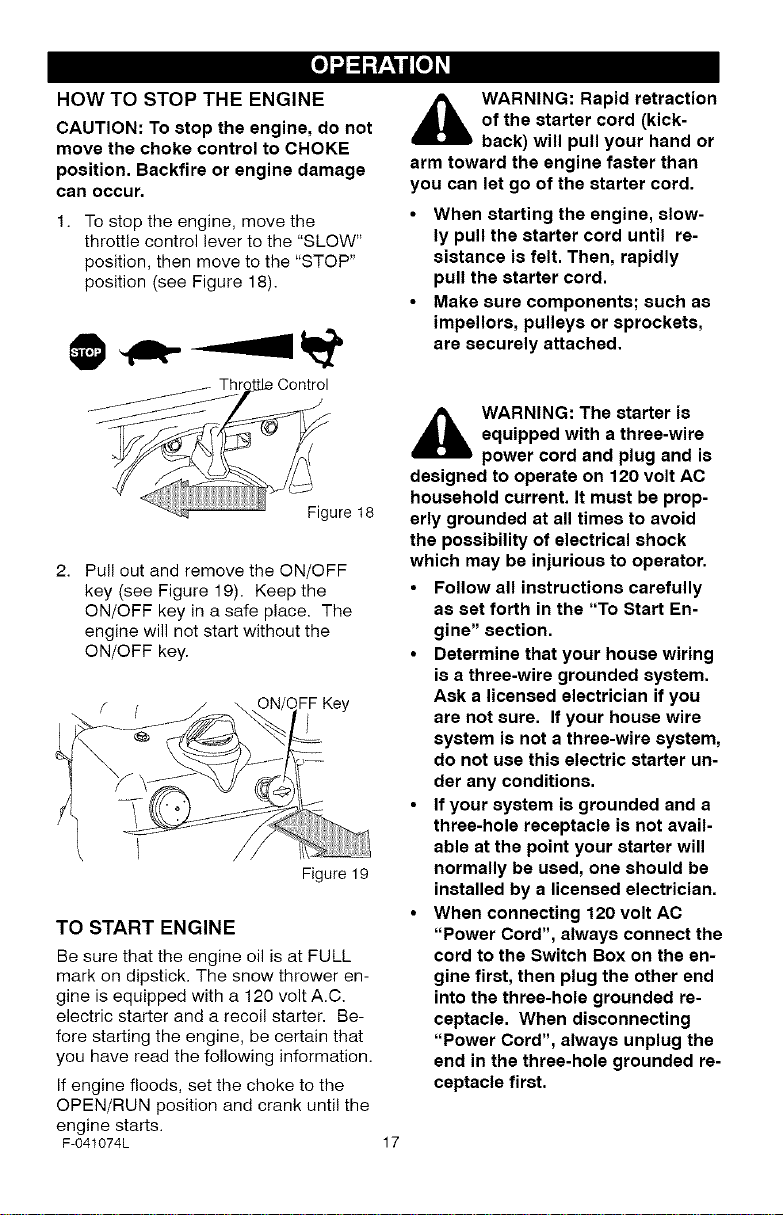

CAUTION: To stop the engine, do not

move the choke control to CHOKE

position. Backfire or engine damage

can occur.

1. To stop the engine, move the

throttle control lever to the "SLOW"

position, then move to the "STOP"

position (see Figure 18).

A ARNING: Rapid retraction

of the starter cord (kick-

back) will pull your hand or

arm toward the engine faster than

you can let go of the starter cord.

• When starting the engine, slow-

ly pull the starter cord until re-

sistance is felt. Then, rapidly

pull the starter cord.

• Make sure components; such as

impellors, pulleys or sprockets,

are securely attached.

Figure 18

Pull out and remove the ON/OFF

key (see Figure 19). Keep the

ON/OFF key in a safe place. The

engine will not start without the

ON/OFF key.

FF Key

Figure 19

TO START ENGINE

Be sure that the engine oil is at FULL

mark on dipstick. The snow thrower en-

gine is equipped with a 120 volt A.C.

electric starter and a recoil starter. Be-

fore starting the engine, be certain that

you have read the following information.

If engine floods, set the choke to the

OPEN/RUN position and crank until the

engine starts.

F-041074L

A ARNING: The starter is

equipped with a three-wire

power cord and plug and is

designed to operate on 120 volt AC

household current. It must be prop-

erly grounded at all times to avoid

the possibility of electrical shock

which may be injurious to operator.

• Follow all instructions carefully

as set forth in the "To Start En-

gine" section.

• Determine that your house wiring

is a three-wire grounded system.

Ask a licensed electrician if you

are not sure. If your house wire

system is not a three-wire system,

do not use this electric starter un-

der any conditions.

• If your system is grounded and a

three-hole receptacle is not avail-

able at the point your starter will

normally be used, one should be

installed by a licensed electrician.

• When connecting 120 volt AC

"Power Cord", always connect the

cord to the Switch Box on the en-

gine first, then plug the other end

into the three-hole grounded re-

ceptacle. When disconnecting

"Power Cord", always unplug the

end in the three-hole grounded re-

ceptacle first.

17

[o_o)_

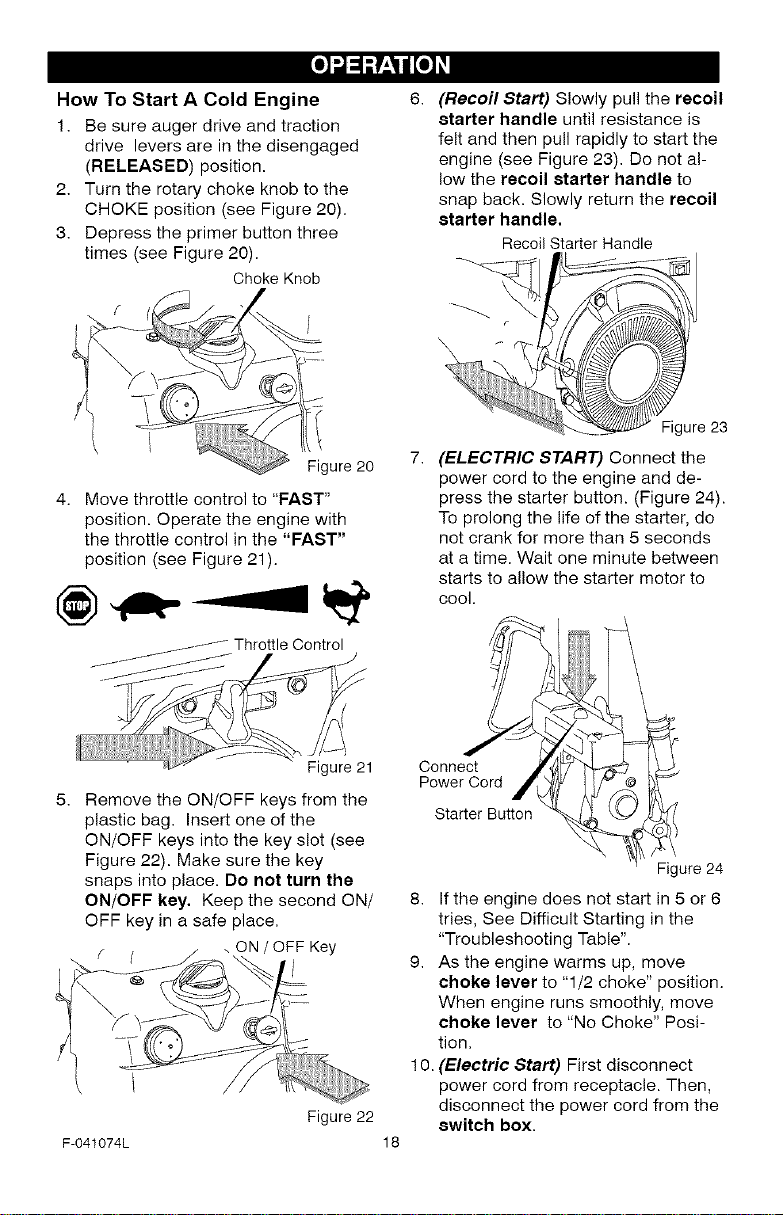

How To Start A Cold Engine

1. Be sure auger drive and traction

drive levers are in the disengaged

(RELEASED) position.

2. Turn the rotary choke knob to the

CHOKE position (see Figure 20).

3. Depress the primer button three

times (see Figure 20). _______

Choke Knob

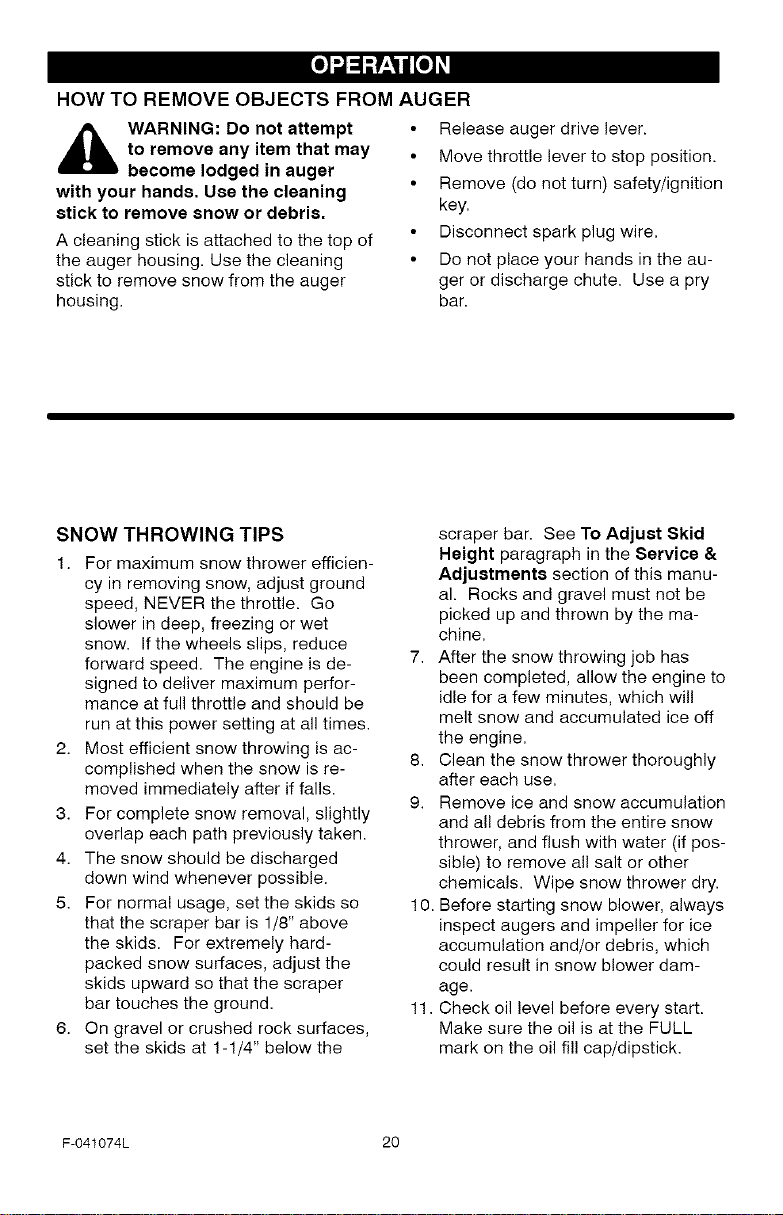

ure 20 7. (ELECTRIC START) Connect the

4. Move throttle control to "FAST"

position. Operate the engine with

the throttle control in the "FAST"

position (see Figure 21).

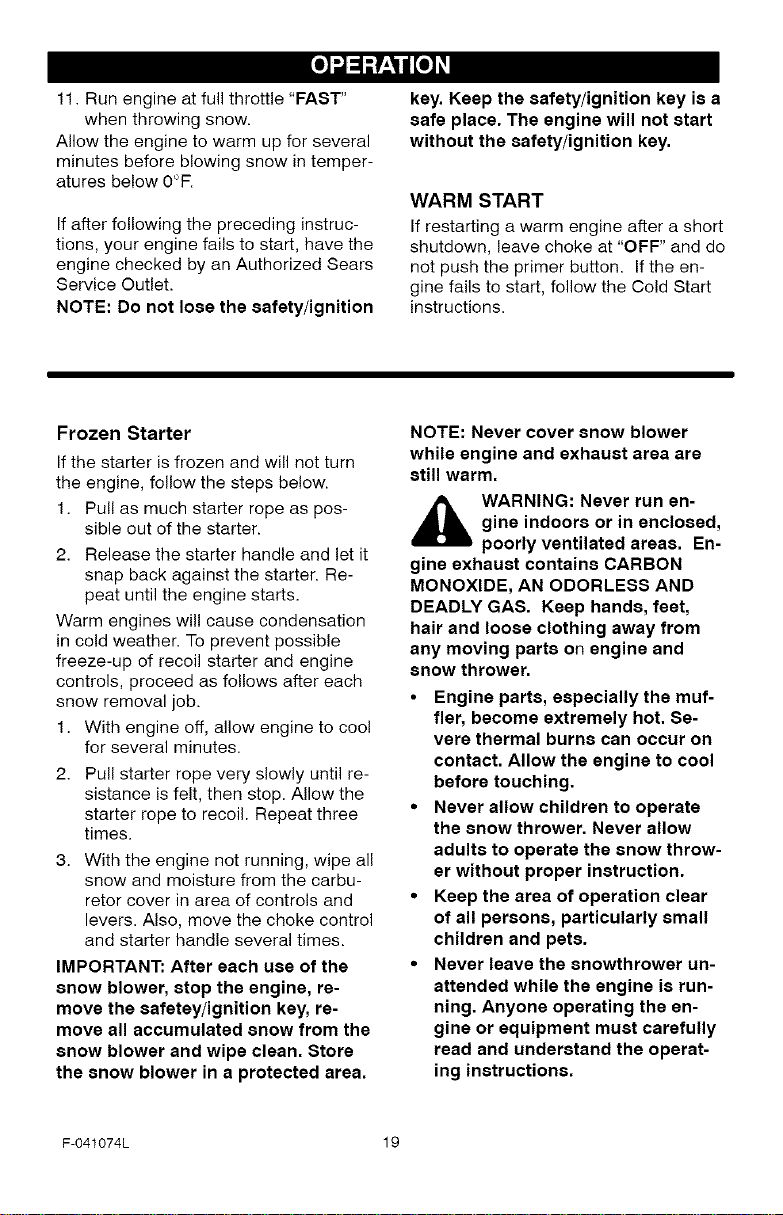

(Recoil Start) Slowly pull the recoil

starter handle until resistance is

felt and then pull rapidly to start the

engine (see Figure 23). Do not al-

low the recoil starter handle to

snap back. Slowly return the recoil

starter handle.

Recoil StarterHandle

Figure 23

power cord to the engine and de-

press the starter button. (Figure 24).

To prolong the life of the starter, do

not crank for more than 5 seconds

at a time. Wait one minute between

starts to allow the starter motor to

cool.

Remove the ON/OFF keys from the

plastic bag. Insert one of the

ON/OFF keys into the key slot (see

Figure 22). Make sure the key

snaps into place. Do not turn the

ON/OFF key, Keep the second ON/

OFF key in a safe place.

ON / OFF Key

\\

F-041074L

Figure 21

Figure 22

Connect

Power Cord

Starter Button

Figure 24

8. If the engine does not start in 5 or 6

tries, See Difficult Starting in the

"Troubleshooting Table".

9. As the engine warms up, move

choke lever to "1/2 choke" position.

When engine runs smoothly, move

choke lever to "No Choke" Posi-

tion.

10. (Electric Start) First disconnect

power cord from receptacle. Then,

disconnect the power cord from the

switch box.

18

[o_o)_

11. Run engine at full throttle "FAST"

when throwing snow.

Allow the engine to warm up for several

minutes before blowing snow in temper-

atures below 0°R

If after following the preceding instruc-

tions, your engine fails to start, have the

engine checked by an Authorized Sears

Service Outlet.

NOTE: Do not lose the safety/ignition

Frozen Starter

If the starter is frozen and will not turn

the engine, follow the steps below.

1. Pull as much starter rope as pos-

sible out of the starter.

2. Release the starter handle and let it

snap back against the starter. Re-

peat until the engine starts.

Warm engines will cause condensation

in cold weather. To prevent possible

freeze-up of recoil starter and engine

controls, proceed as follows after each

snow removal job.

1. With engine off, allow engine to coo!

for several minutes.

Pull starter rope very slowly until re-

sistance is felt, then stop. Allow the

starter rope to recoil. Repeat three

times.

With the engine not running, wipe all

snow and moisture from the carbu-

retor cover in area of controls and

levers. Also, move the choke control

and starter handle several times.

IMPORTANT: After each use of the

snow blower, stop the engine, re-

move the safeteyiignition key, re-

move all accumulated snow from the

snow blower and wipe clean. Store

the snow blower in a protected area.

key. Keep the safety/ignition key is a

safe place. The engine will not start

without the safety/ignition key.

WARM START

If restarting a warm engine after a short

shutdown, leave choke at "OFF" and do

not push the primer button. Ifthe en-

gine fails to start, follow the Cold Start

instructions.

NOTE: Never cover snow blower

while engine and exhaust area are

still warm.

_ WARNING: Never run en-

gine indoors or in enclosed,

poorly ventilated areas. En-

gine exhaust contains CARBON

MONOXIDE, AN ODORLESS AND

DEADLY GAS. Keep hands, feet,

hair and loose clothing away from

any moving parts on engine and

snow thrower.

• Engine parts, especially the muf-

fler, become extremely hot. Se-

vere thermal burns can occur on

contact. Allow the engine to cool

before touching.

• Never allow children to operate

the snow thrower. Never allow

adults to operate the snow throw-

er without proper instruction.

• Keep the area of operation clear

of all persons, particularly small

children and pets.

• Never leave the snowthrower un-

attended while the engine is run-

ning. Anyone operating the en-

gine or equipment must carefully

read and understand the operat-

ing instructions.

F-041074L 19

[o_o)_

HOW TO REMOVE OBJECTS FROM AUGER

• Release auger drive lever.

_ ARNING: Do not attempt

with your hands. Use the cleaning

stick to remove snow or debris.

A cleaning stick is attached to the top of

the auger housing. Use the cleaning

stick to remove snow from the auger

housing.

to remove any item that may

become lodged in auger

• Move throttle lever to stop position.

• Remove (do not turn) safety/ignition

key.

• Disconnect spark plug wire.

• Do not place your hands in the au-

ger or discharge chute. Use a pry

bar.

SNOW THROWING TIPS

1. For maximum snow thrower efficien-

cy in removing snow, adjust ground

speed, NEVER the throttle. Go

slower in deep, freezing or wet

snow. If the wheels slips, reduce

forward speed. The engine is de-

signed to deliver maximum perfor-

mance at full throttle and should be

run at this power setting at all times.

2. Most efficient snow throwing is ac-

complished when the snow is re-

moved immediately after if falls.

3. For complete snow removal, slightly

overlap each path previously taken.

4. The snow should be discharged

down wind whenever possible.

5. For normal usage, set the skids so

that the scraper bar is 1/8" above

the skids. For extremely hard-

packed snow surfaces, adjust the

skids upward so that the scraper

bar touches the ground.

6. On gravel or crushed rock surfaces,

set the skids at 1-1/4" below the

scraper bar. See To Adjust Skid

Height paragraph in the Service &

Adjustments section of this manu-

al. Rocks and gravel must not be

picked up and thrown by the ma-

chine.

7. After the snow throwing job has

been completed, allow the engine to

idle for a few minutes, which will

melt snow and accumulated ice off

the engine.

8. Clean the snow thrower thoroughly

after each use.

9. Remove ice and snow accumulation

and all debris from the entire snow

thrower, and flush with water (if pos-

sible) to remove all salt or other

chemicals. Wipe snow thrower dry.

10. Before starting snow blower, always

inspect augers and impeller for ice

accumulation and/or debris, which

could result in snow blower dam-

age.

11. Check oil level before every start.

Make sure the oil is at the FULL

mark on the oil fil! cap/dipstick.

F-041074L 20

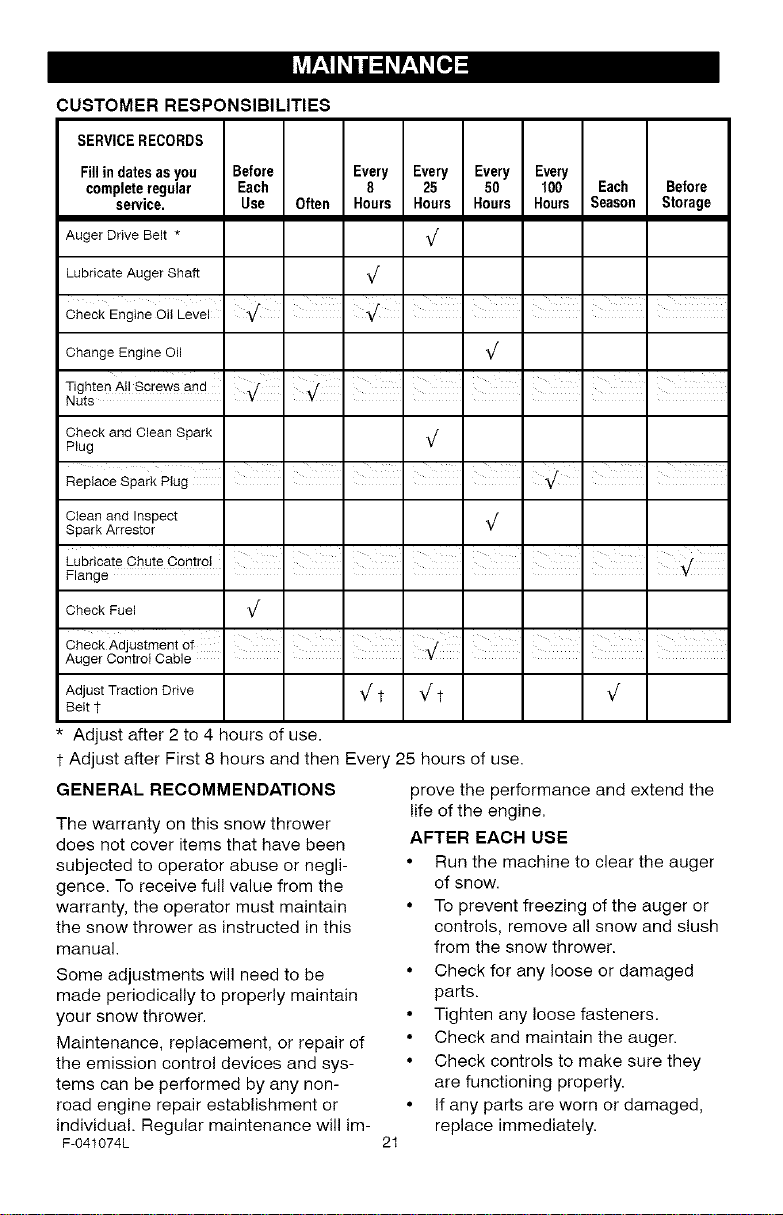

CUSTOMERRESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you Before

complete regular Each

service. Use Often

Auger Drive Belt *

Lubricate Auger Shaft

Check Engine Oil Level

Change Engine Oil

Tighten A!! Screws and

Nuts

Check and Clean Spark

Plug

Clean and Inspect

Spark Arrestor

Check Fuel

Check Adjustment of I I I I I I

Auger Contro Cab e -

Every Every Every Every

8 25 50 100 Each Before

Hours Hours Hours Hours Season Storage

V

Adjust Traction Drive _ t _ t

Belt

* Adjust after 2 to 4 hours of use.

t Adjust after First 8 hours and then Every 25 hours of use.

GENERAL RECOMMENDATIONS

The warranty on this snow thrower

does not cover items that have been

subjected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the snow thrower as instructed in this

manual.

Some adjustments will need to be

made periodically to properly maintain

your snow thrower.

Maintenance, replacement, or repair of

the emission control devices and sys-

tems can be performed by any non-

road engine repair establishment or

individual. Regular maintenance will im-

F-041074L

prove the performance and extend the

life of the engine.

AFTER EACH USE

• Run the machine to clear the auger

of snow.

• To prevent freezing of the auger or

controls, remove all snow and slush

from the snow thrower.

• Check for any loose or damaged

parts.

• Tighten any loose fasteners.

• Check and maintain the auger.

• Check controls to make sure they

are functioning properly.

• If any parts are worn or damaged,

replace immediately.

21

PRODUCT SPECIFICATIONS

HORSEPOWER 13 HP

DISPLACEMENT 20.85 cu. in.

BORE 83.82mm (3.300 in.)

STROKE 61.67mm (2.438 in.)

GASOLINE 4 quarts

CAPACITY (unleaded)

OIL CAPACITY

(28oz capacity)

5W30

SPARK PLUG: Gap0.030 in.

VALVE Intake: 0.004-0.006 in.

CLEARANCE: Exhaust: 0.009-0.011 in.

ARMATURE

AIR GAP: 0.010-0.014 in.

POWER RATINGS

The power ratings for an individual

engine model are initially developed by

starting with SAE (Society of Automo-

tive Engineers) code J1940 (Small

Engine Power & Torque Rating Proce-

dure) (Revision 2002-05). Given both

the wide array of products on which our

engines are placed, and the variety of

environmental issues applicable to

operating the equipment, it may be that

the engine you have purchased will not

develop the rated horsepower when

used in a piece of power equipment

(actual "on-site"power). This difference

is due to a variety of factors including,

but not limited to, the following: differ-

ences in altitude, temperature, baro-

metric pressure, humidity, fuel, engine

lubrication, maximum governed engine

speed, individual engine to engine

variability, design of the particular piece

of power equipment, the manner in

which the engine is operated, engine

run-in to reduce friction and clean out of

combustion chambers, adjustments to

the valves and carburetor, and other

factors. The power ratings may also be

adjusted based on comparisons to

other similar engines utilized in similar

applications, and will therefore not

necessarily match the values derived

using the foregoing codes.

SNOW THROWER

AUGER DRIVE BELT

Adjust the auger drive belt after the first

2 to 4 hours of use, again about mid-

season and twice each season thereaf-

ter (See "Belt Adjustment" in the

Service and Adjustment section).

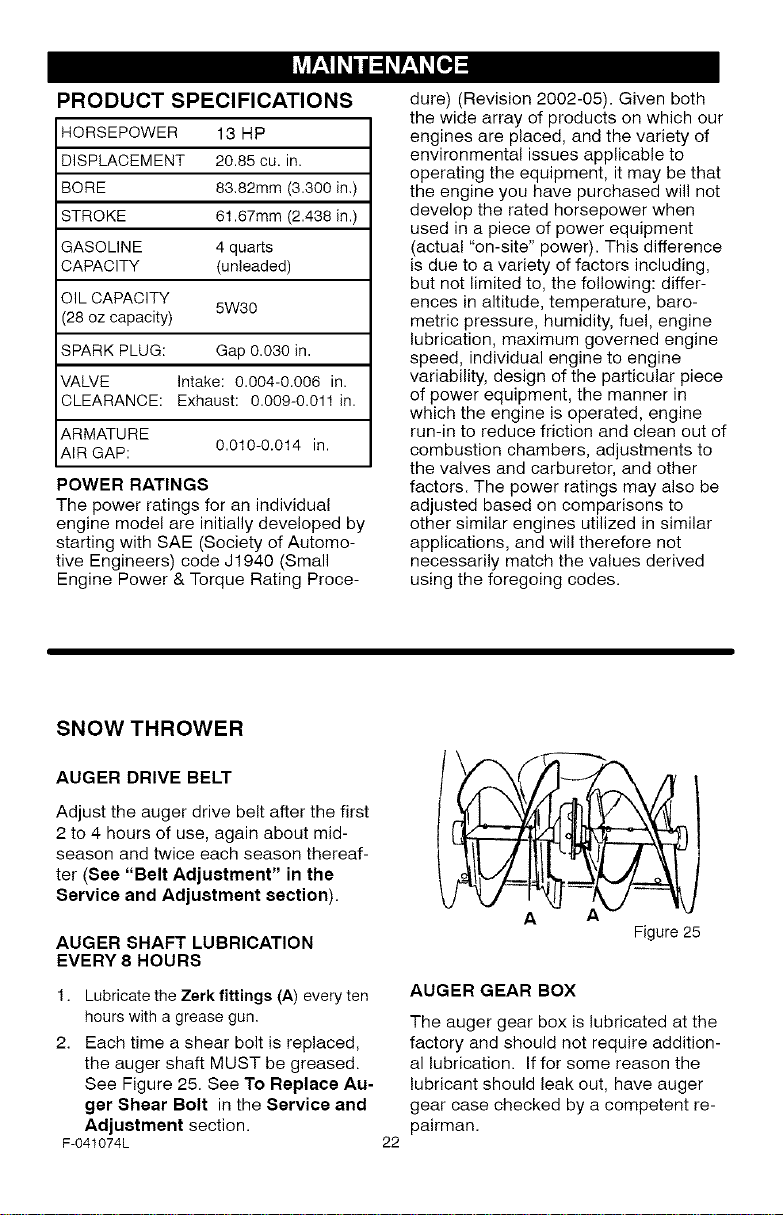

AUGER SHAFT LUBRICATION

EVERY 8 HOURS

1. Lubricate the Zerk fittings (A) every ten

hours with a grease gun.

2. Each time a shear bolt is replaced,

the auger shaft MUST be greased.

See Figure 25. See To Replace Au-

ger Shear Bolt in the Service and

Adjuetment section.

F-041074L

A

Figure 25

AUGER GEAR BOX

The auger gear box is lubricated at the

factory and should not require addition-

al lubrication. If for some reason the

lubricant should leak out, have auger

gear case checked by a competent re-

pairman.

22

ENGINE

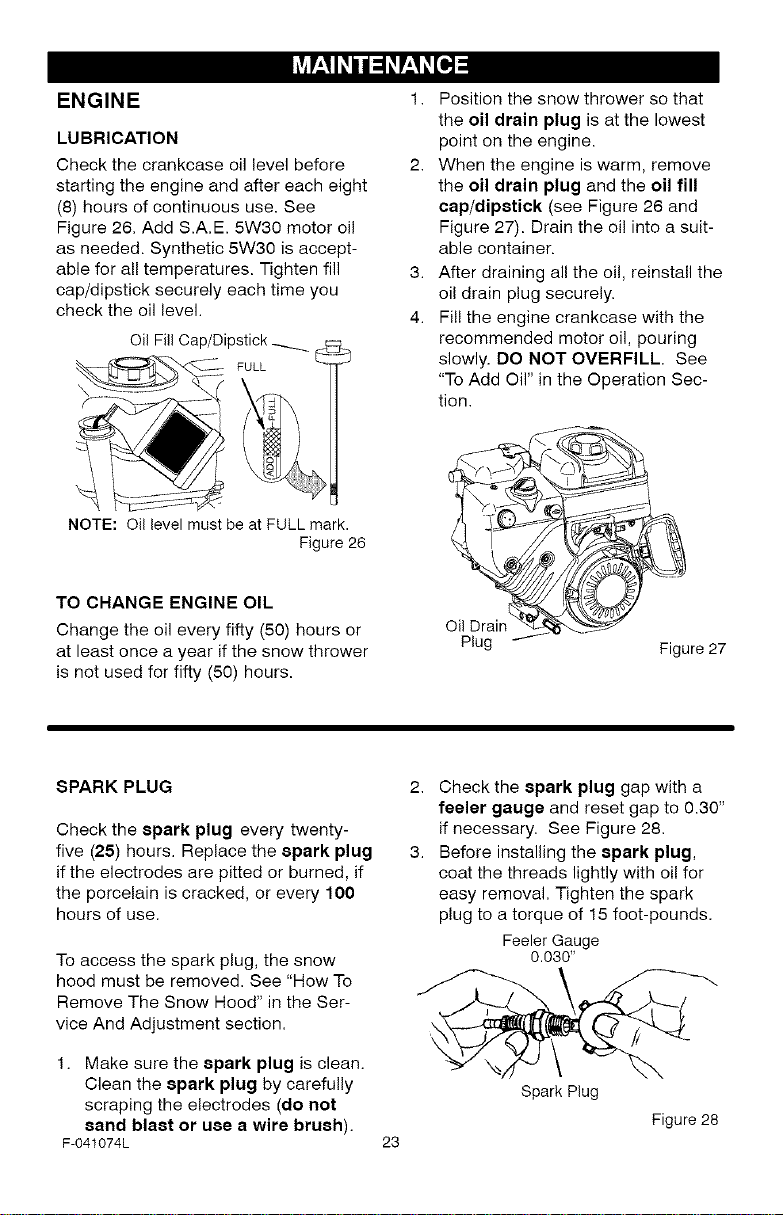

LUBRICATION

Check the crankcase oil level before

starting the engine and after each eight

(8) hours of continuous use. See

Figure 26. Add S.A.E. 5W30 motor oil

as needed. Synthetic 5W30 is accept-

able for all temperatures. Tighten fill

cap/dipstick securely each time you

check the oil level.

Oil Fill Cap/Dipstick_

FULL

NOTE: Oil level must be at FULL mark.

Figure 26

TO CHANGE ENGINE OIL

Change the oil every fifty (50) hours or

at least once a year if the snow thrower

is not used for fifty (50) hours.

1. Position the snow thrower so that

the oil drain plug is at the lowest

point on the engine.

2. When the engine is warm, remove

the oil drain plug and the oil fill

cap/dipstick (see Figure 26 and

Figure 27). Drain the oi! into a suit-

able container.

3. After draining all the oil, reinstall the

oil drain plug securely.

4. Fil! the engine crankcase with the

recommended motor oil, pouring

slowly. DO NOT OVERFILL. See

"To Add Oil" in the Operation Sec-

tion.

Oil Drain

Plug

Figure27

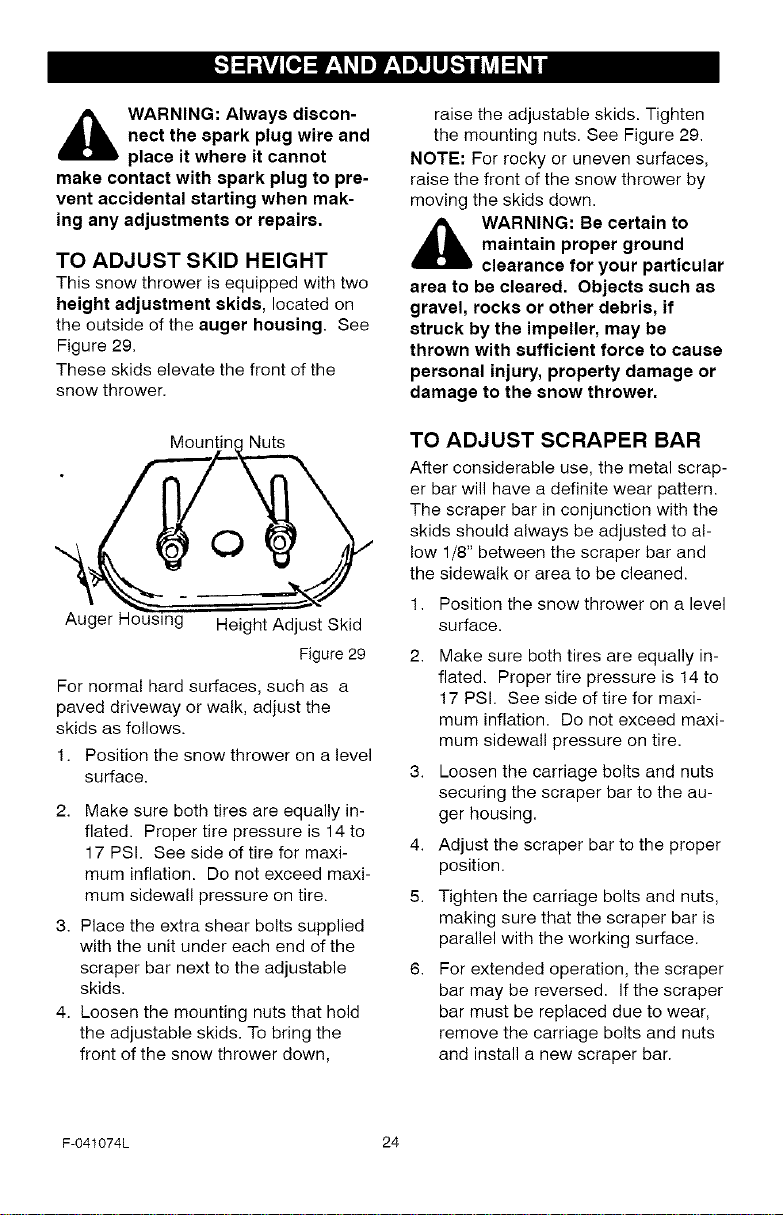

SPARK PLUG

Check the spark plug every twenty-

five (25) hours. Replace the spark plug

if the electrodes are pitted or burned, if

the porcelain is cracked, or every 100

hours of use.

To access the spark plug, the snow

hood must be removed. See "How To

Remove The Snow Hood" in the Ser-

vice And Adjustment section.

1. Make sure the spark plug is clean.

Clean the spark plug by carefully

scraping the electrodes (do not

sand blast or use a wire brush).

F-041074L

2. Check the spark plug gap with a

feeler gauge and reset gap to 0.30"

if necessary. See Figure 28.

3. Before installing the spark plug,

coat the threads lightly with oil for

easy removal. Tighten the spark

plug to a torque of 15 foot-pounds.

Feeler Gauge

0.030"

Spark Plug

23

Figure 28

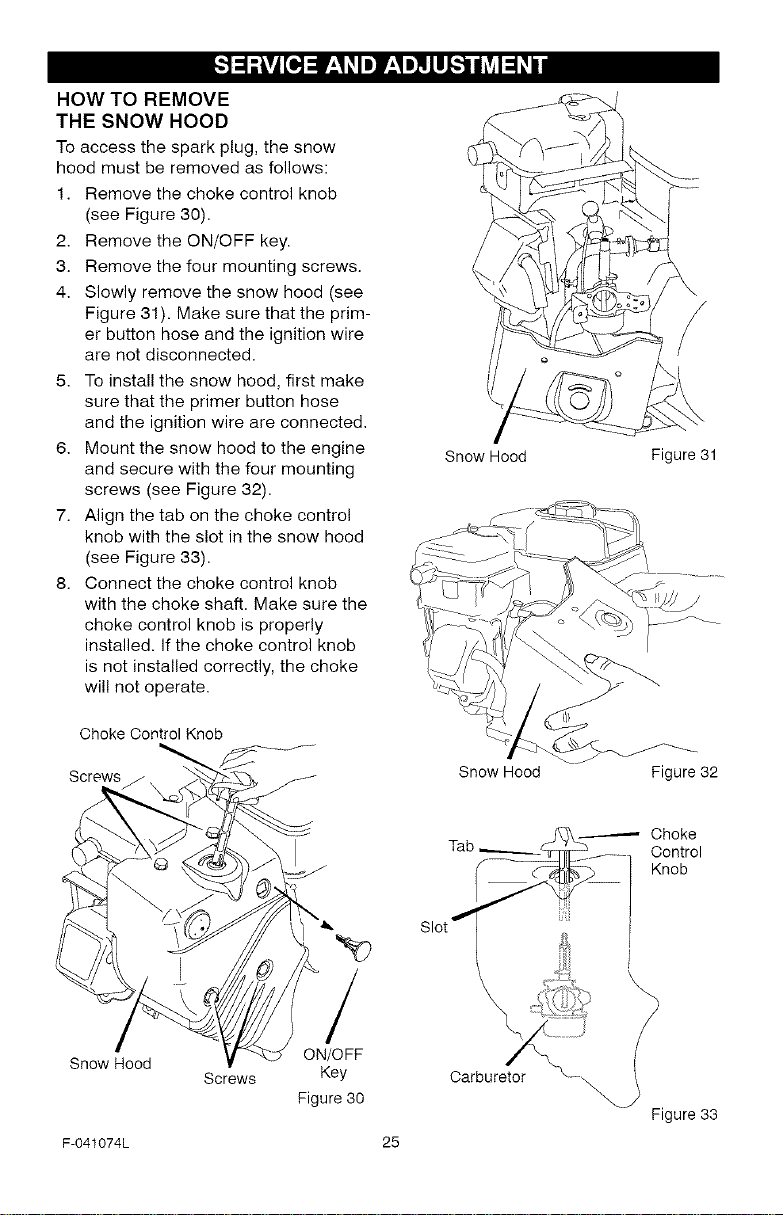

_b ARNING: Always discon-

nect the spark plug wire and

place it where it cannot

make contact with spark plug to pre-

vent accidental starting when mak-

ing any adjustments or repairs.

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two

height adjustment skids, located on

the outside of the auger housing. See

Figure 29.

These skids elevate the front of the

snow thrower.

raise the adjustable skids. Tighten

the mounting nuts. See Figure 29.

NOTE: For rocky or uneven surfaces,

raise the front of the snow thrower by

moving the skids down.

_k WARNING: Be certain to

maintain proper ground

clearance for your particular

area to be cleared. Objects such as

gravel, rocks or other debris, if

struck by the impeller, may be

thrown with sufficient force to cause

personal injury, property damage or

damage to the snow thrower.

Mountinc Nuts

0

Au( g Height Adjust Skid

Figure 29

For normal hard surfaces, such as a

paved driveway or walk, adjust the

skids as follows.

1. Position the snow thrower on a level

surface.

2. Make sure both tires are equally in-

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3. Place the extra shear bolts supplied

with the unit under each end of the

scraper bar next to the adjustable

skids.

4. Loosen the mounting nuts that hold

the adjustable skids. To bring the

front of the snow thrower down,

TO ADJUST SCRAPER BAR

After considerable use, the metal scrap-

er bar will have a definite wear pattern.

The scraper bar in conjunction with the

skids should always be adjusted to al-

low 1/8" between the scraper bar and

the sidewalk or area to be cleaned.

1. Position the snow thrower on a level

surface,

2. Make sure both tires are equally in-

flated. Proper tire pressure is 14 to

17 PSI. See side of tire for maxi-

mum inflation. Do not exceed maxi-

mum sidewall pressure on tire.

3. Loosen the carriage bolts and nuts

securing the scraper bar to the au-

ger housing.

4. Adjust the scraper bar to the proper

position.

5. Tighten the carriage bolts and nuts,

making sure that the scraper bar is

parallel with the working surface.

6. For extended operation, the scraper

bar may be reversed. If the scraper

bar must be replaced due to wear,

remove the carriage bolts and nuts

and install a new scraper bar.

F-041074L 24

HOW TO REMOVE

THE SNOW HOOD

To access the spark plug, the snow

hood must be removed as follows:

1. Remove the choke control knob

(see Figure 30).

2. Remove the ON/OFF key.

3. Remove the four mounting screws.

4. Slowly remove the snow hood (see

Figure 31). Make sure that the prim-

er button hose and the ignition wire

are not disconnected.

5. To install the snow hood, first make

sure that the primer button hose

and the ignition wire are connected.

6. Mount the snow hood to the engine

and secure with the four mounting

screws (see Figure 32).

7. Align the tab on the choke control

knob with the slot in the snow hood

(see Figure 33).

8. Connect the choke control knob

with the choke shaft. Make sure the

choke control knob is properly

installed, if the choke control knob

is not installed correctly, the choke

will not operate.

, 4s

Snow Hood

/

\E

Figure31

Choke Control Knob

Screws

Snow Hood

F-041074L

Screws

/

ON/OFF

Key

Figure30

Snow Hood

Carburetor

25

Figure 32

Choke

Control

Knob

Figure33

BELT ADJUSTMENT

Traction Drive Belt

After approximately ten hours of opera-

tion, a new belt will stretch and require

an adjustment of the belt tension. Also,

if your snow thrower experiences a loss

of power under heavy load, check the

condition of the traction drive belt. If it is

damaged or loose, replace it (see "How

To Replace The Belts" in this section of

the manual).

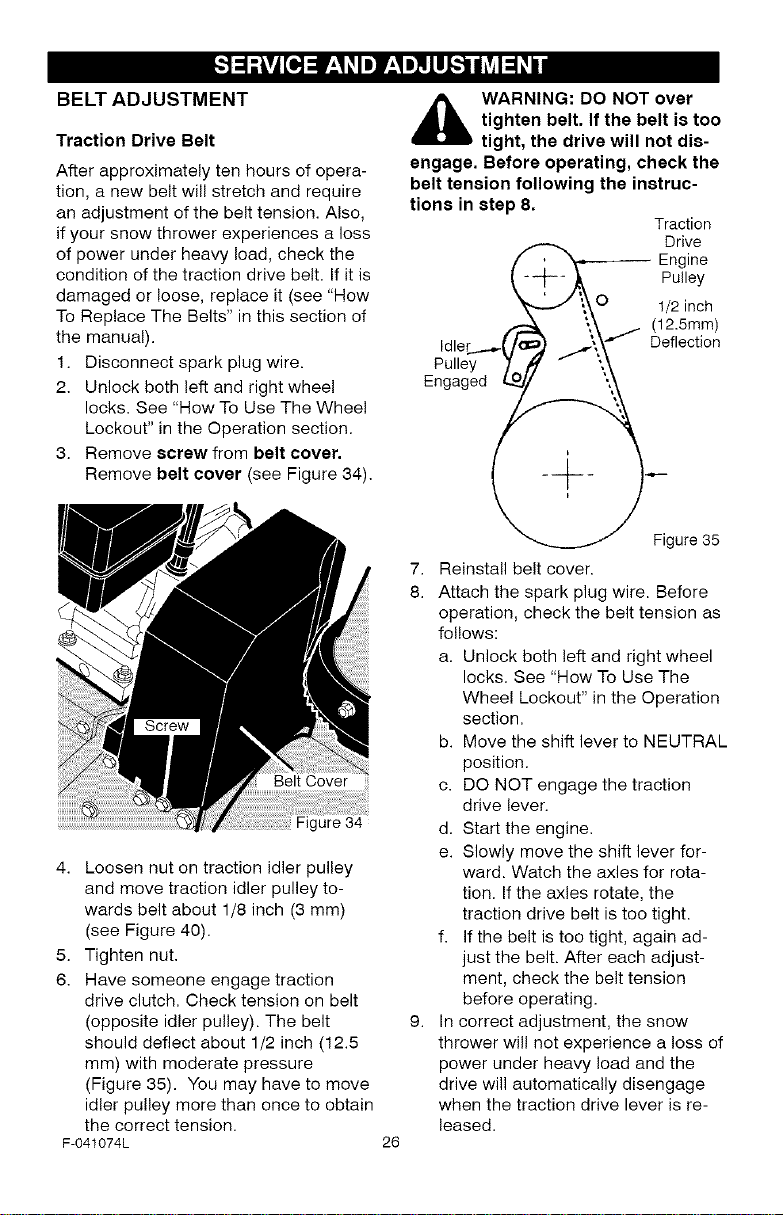

1. Disconnect spark plug wire.

2. Unlock both left and right wheel

locks. See "How To Use The Wheel

Lockout" in the Operation section.

3. Remove screw from belt cover.

Remove belt cover (see Figure 34).

gure 34

4. Loosen nut on traction idler pulley

and move traction idler pulley to-

wards belt about 1/8 inch (3 mm)

(see Figure 40).

5. Tighten nut.

6. Have someone engage traction

drive clutch. Check tension on belt

(opposite idler pulley). The belt

should deflect about 1/2 inch (12.5

mm) with moderate pressure

(Figure 35). You may have to move

idler pulley more than once to obtain

the correct tension.

F-041074L

,_ WARNING: DO NOT over

engage. Before operating, check the

belt tension following the instruc-

tions in step 8.

7. Reinstall belt cover.

8. Attach the spark plug wire. Before

9. In correct adjustment, the snow

26

tighten belt. If the belt i8 too

tight, the drive will not dis-

f _ Engine

-/_1_ ,_ Pulley

, ./\\O 1/2 inch

/- ';,_ j (12.5mm)

Idler ...__/c ..._\\f"J Deflection

Pulley 7 " ',\

Engaged/._i __

_Figure 35

operation, check the belt tension as

follows:

a. Unlock both left and right wheel

locks. See "How To Use The

Wheel Lockout" in the Operation

section.

b. Move the shift lever to NEUTRAL

position.

c. DO NOT engage the traction

drive lever.

d. Start the engine.

e. Slowly move the shift lever for-

ward. Watch the axles for rota-

tion. If the axles rotate, the

traction drive belt is too tight.

f. If the belt is too tight, again ad-

just the belt. After each adjust-

ment, check the belt tension

before operating.

thrower will not experience a loss of

power under heavy load and the

drive will automatically disengage

when the traction drive lever is re-

leased.

Traction

Drive

[.,,."]_e,,_ r*..1ZIB]I'_"_

Auger Drive Belt

If your snow blower will not discharge

snow, check the control cable adjust-

ment. If it is correct, then check the

condition of the auger drive belt. If it is

damaged or loose, replace it (see "How

To Replace The Belts" in this section of

the manual).

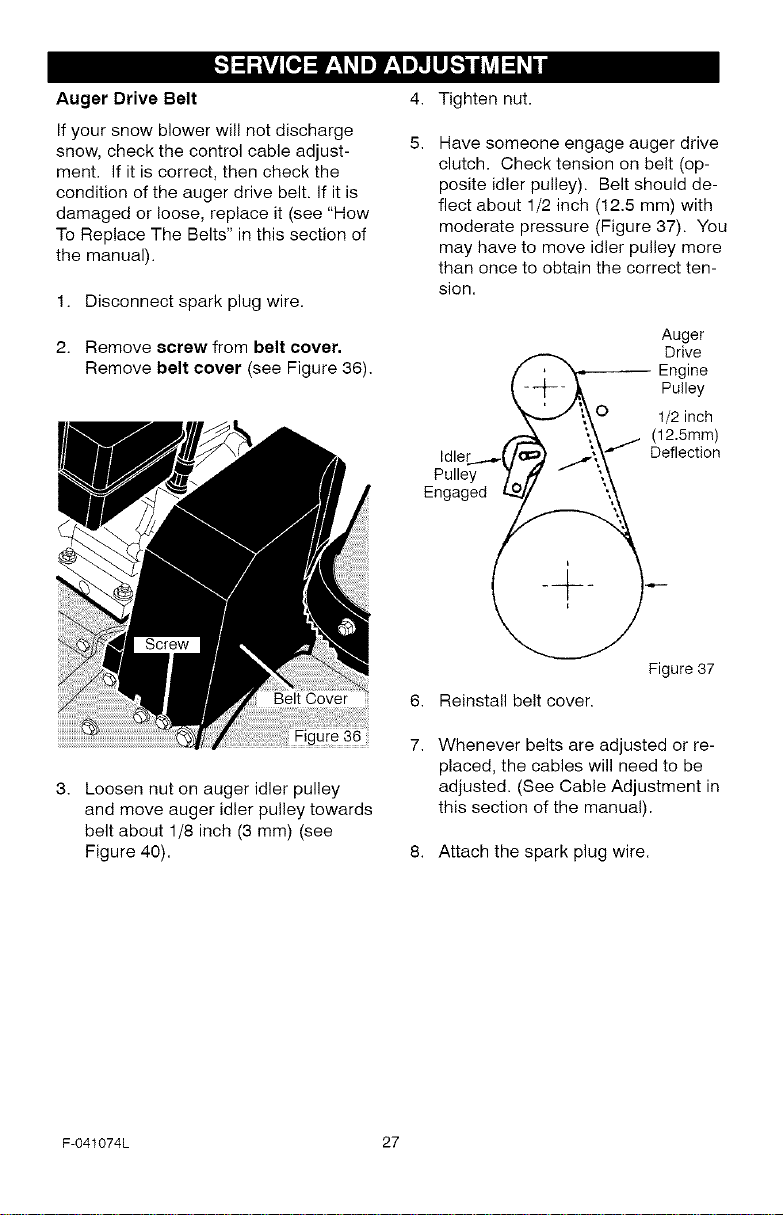

1. Disconnect spark plug wire.

2. Remove screw from belt cover,

Remove belt cover (see Figure 36).

4.

Tighten nut.

5.

Have someone engage auger drive

clutch. Check tension on belt (op-

posite idler pulley). Belt should de-

flect about 1/2 inch (12.5 mm) with

moderate pressure (Figure 37). You

may have to move idler pulley more

than once to obtain the correct ten-

sion.

f _ Engine

k A Pu,ey

, J \\O 1/2 inch

idler_..._C F ..7\\f'f" Deflection

Pulley 70, " "_

Engaged _ ",,_

';,_ _ (12.5mm)

Auger

Drive

Belt Cover

ure 36

Loosen nut on auger idler pulley

and move auger idler pulley towards

belt about 1/8 inch (3 mm) (see

Figure 40).

F-041074L 27

6.

Reinstall belt cover.

7.

Whenever belts are adjusted or re-

placed, the cables will need to be

adjusted. (See Cable Adjustment in

this section of the manual).

8. Attach the spark plug wire.

Figure 37

HOW TO REPLACE THE BELTS

The drive belts are of special construc-

tion and must be replaced with original

equipment replacement belts available

from your nearest Sears service center.

Some steps require the assistance of a

second person.

How To Remove the Auger Drive Belt

If the auger drive belt is damaged, the

snow thrower will not discharge snow.

Replace the damaged belt as follows.

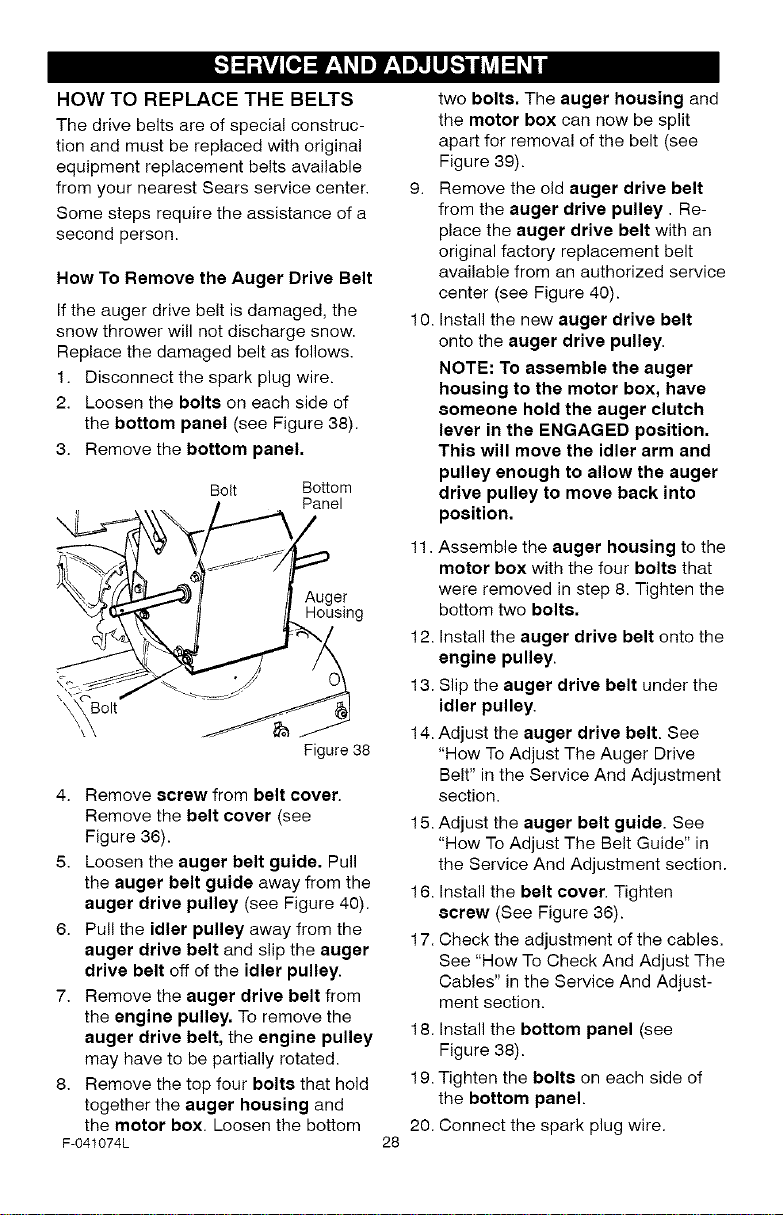

1. Disconnect the spark plug wire.

2. Loosen the bolte on each side of

the bottom panel (see Figure 38).

3. Remove the bottom panel.

Bolt Bottom

Panel

Auger

Housing

olt

Figure38

4. Remove screw from belt cover.

Remove the belt cover (see

Figure 36).

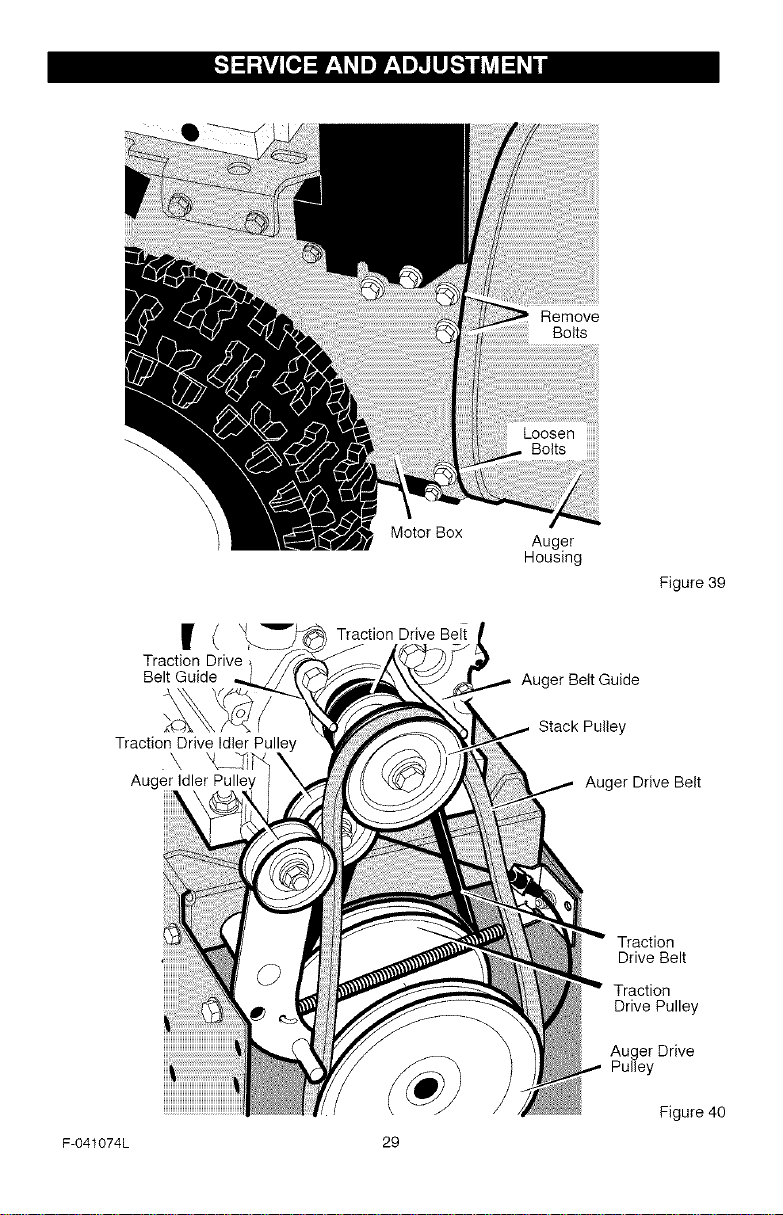

5. Loosen the auger belt guide. Pull

the auger belt guide away from the

auger drive pulley (see Figure 40).

6. Pull the idler pulley away from the

auger drive belt and slip the auger

drive belt off of the idler pulley.

7. Remove the auger drive belt from

the engine pulley. To remove the

auger drive belt, the engine pulley

may have to be partially rotated.

8. Remove the top four bolts that hold

together the auger housing and

the motor box. Loosen the bottom

F-041074L

two bolts. The auger housing and

the motor box can now be split

apart for removal of the belt (see

Figure 39).

9. Remove the old auger drive belt

from the auger drive pulley. Re-

place the auger drive belt with an

original factory replacement belt

available from an authorized service

center (see Figure 40).

10. Install the new auger drive belt

onto the auger drive pulley.

NOTE: To assemble the auger

housing to the motor box, have

someone hold the auger clutch

lever in the ENGAGED position.

This will move the idler arm and

pulley enough to allow the auger

drive pulley to move back into

position.

11. Assemble the auger housing to the

motor box with the four bolts that

were removed in step 8. Tighten the

bottom two bolts.

12. Install the auger drive belt onto the

engine pulley.

13. Slip the auger drive belt under the

idler pulley.

14. Adjust the auger drive belt. See

"How ToAdjust The Auger Drive

Belt" in the Service And Adjustment

section.

15. Adjust the auger belt guide. See

"How ToAdjust The Belt Guide" in

the Service And Adjustment section.

16. Install the belt cover. Tighten

ecrew (See Figure 36).

17. Check the adjustment of the cables.

See "How To Check And Adjust The

Cables" in the Service And Adjust-

ment section.

18. Install the bottom panel (see

Figure 38).

19. Tighten the bolts on each side of

the bottom panel.

20. Connect the spark plug wire.

28

Remove

Bolts

Traction Drive

Belt Guide

Traction Drive Idler Pulley

Auger Idler Pulley

Motor Box

Auger

Housing

Figure 39

Auger Belt Guide

Stack Pulley

Auger Drive Belt

Traction

Drive Belt

Traction

Drive Pulley

Auger Drive

Pulley

F-041074L 29

Figure 40

How To Remove

The Traction Drive Belt

If the snow thrower will not move for-

ward, check the traction drive belt for

wear or damage, if the traction drive

belt is worn or damaged, replace the

belt as follows.

stack pulley. Tighten the stack

pulley securely to the engine shaft.

Adjust the traction drive belt

guide(s). See "Traction Drive Belt

Guide Adjustment" in the Service

And Adjustment section.

1. Disconnect the spark plug wire.

Remove the auger drive belt. See

"How To Remove The Auger Drive

Belt" in the Service And Adjustment

section.

3. Loosen the traction drive belt

guide(s). Pull the belt guide(s)

away from the traction drive belt.

Loosen the nut on the drive idler

pulley (see Figure 40). Move the

pulley the maximum distance away

from the traction drive belt and

then tighten the nut on the pulley.

Remove the old traction drive belt

from the smaller stack pulley.

Then, remove the stack pulley and

old traction drive belt. Replace the

traction drive belt with an original

equipment replacement belt avail-

able from a Sears service center.

6. Install the new traction drive belt

onto the traction drive pulley and

onto the engine shaft..

7. Install the stack pulley onto the en-

gine shaft. Then, mount the trac-

tion drive belt onto the smaller

Install and adjust the auger drive

belt. See "How To Remove The Au-

ger Drive Belt" in the Service And

Adjustment section.

10. Adjust the auger belt guide. See

"Auger Belt Guide Adjustment" in

the Service And Adjustment section.

11. Install the bottom panel (see

Figure 38).

12. Tighten the bolts on each side of

the bottom panel.

13. Install the belt cover. Tighten

screw (see Figure 36).

14. Check the adjustment of the cables.

See "How To Check And Adjust The

Cables" in the Service And Adjust-

ment section.

15. Connect the spark plug wire.

IMPORTANT: After approximately ten

hours of operation, a new belt will

stretch and require an adjustment of

the belt tension. See "Belt Adjust-

ment" in the Service And Adjustment

section.

F-041074L 30

Loading...

Loading...