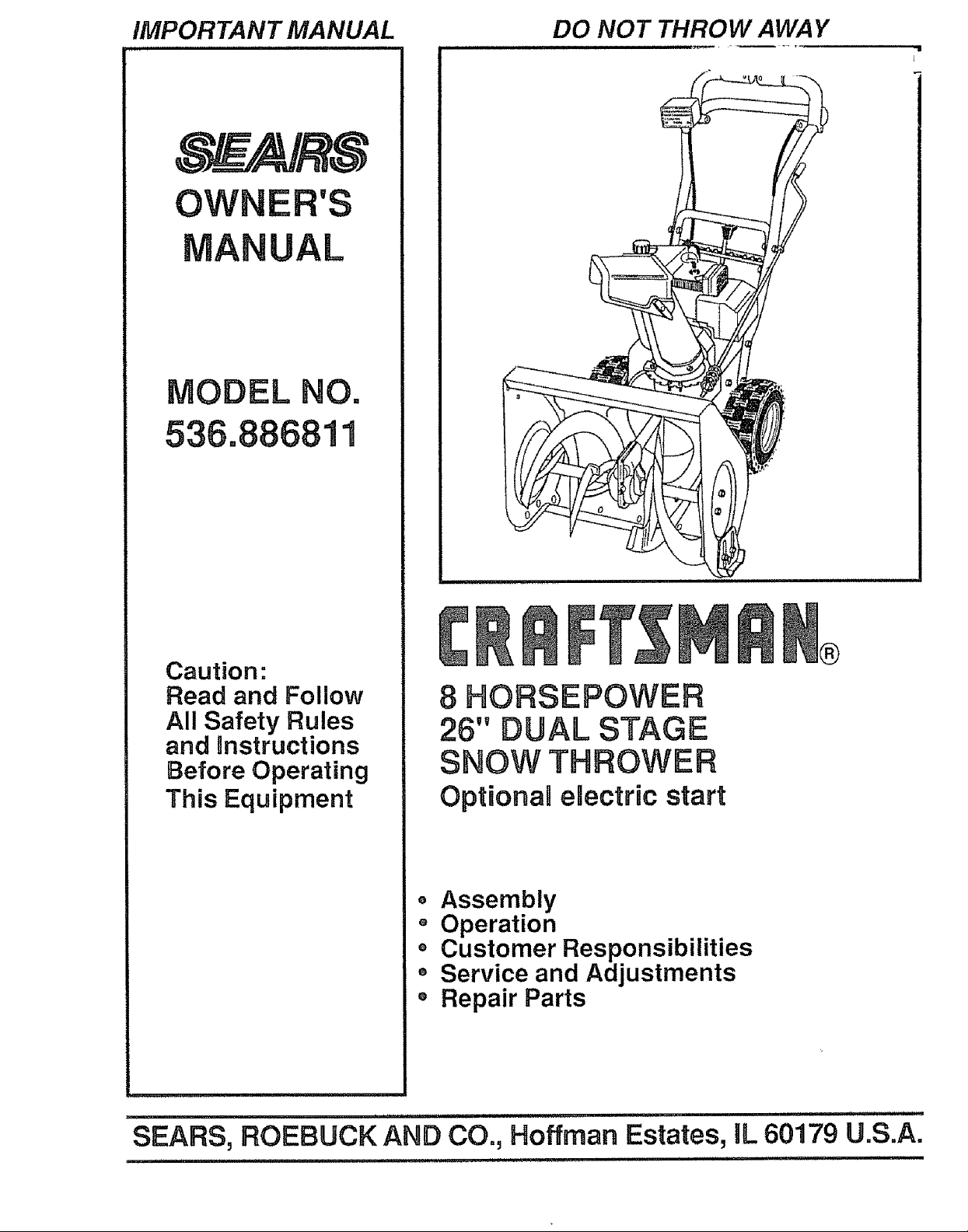

Craftsman 536886811 Owner’s Manual

IMPORTANT MANUAL DO NOT THROW AWAY

OWN R'S

UAL

Caution:

Read and Follow

All Safety Rules

and Rnstructions

Before Operating

This Equipment

8 HORSEPOWER

26" DUAL STAGE

SNOW THROWER

OptionaU enectric start

o Assembly

, Operation

o Customer Responsibilities

o Service and Adjustments

o Repair Parts

i, iii ii iiii ,11. ii iiill ii,llllll

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

.................... i ii ii iil,ll,ll,

SAFETY RULES

& CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND _

PLACE WIRE WHERE IT CANNOT CONTACT SPARK PLUG

IMPORTANT

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE

RISK OF INJURY.. YOUR SNOW THROWER IS EQUIPPED WITH SUCH CONTROLS. DO NOT

ATTEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER

ANY CIRCUMSTANCE&

TRAINING

1. Read the operator's manual carefully. Be

thoroughly familiar with the controls and the

proper use of the snow thrower. Know how to

stop the snow thrower and disengage the

controls quickly.

2. Never allow children to operate the snow thrower

and keep them away while it is operating, Never

allow adults to operate the snow th rower without

proper instruction. DOnot carry passengers.

3. Keep the area of operation clear of all persons,

particularly small children, and pets.

4. Exercise caution to avoid slipping or falling,

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the snow

thrower is to be used and remove all doormats,

sleds, boards, wires, and other foreign objects.

2. Disengage all clutches and shift into neutral

before starting the engine (motor).

3. Do not operate the snow thrower without wearing

adequate winter outer garments. Wear footwear

that will improve tooting on slippery surfaces.

4. Handle fuel with care; it is highly flammable.

(a) Use an approved fuel container.

(b) Never remove fuel tank cap or add fuel to a

running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

(d) Replace fuel tank cap securely and wipe up

spilled fuel.

(e) Never store fuel or snow thrower with fuel in

the tank inside of a building where fumes may

reach an open flame or spark.

(f) Check fuel supply before each use, allowing

space for expansion as the heat of the engine

(motor) and/or sun can cause fuel to expand,

.

Use extension cords and receptacles as specified

by the manufacturer for all snow throwers with

electric drive motors or electric starting motors.

6. Adjust the snow thrower height to clear gravel or

crushed rock surfaces.

7o Never attempt to make any adjustments while the

engine (motor) is running (except when

specifically recommended by the manufacturer).

8. Let engine (motor) and snow thrower adjust to

outdoor temperatures before starting to clear

SnOW_

9. Always wear safety glasses or eye shields during

operation or while performing an adjustment or

repair to protect eyes from foreign objects that

may be thrown from the snow thrower.

OPERATION

1, Do not put hands or feet near or under rotating

parts, Keep clear of the discharge opening at all

times,

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads° Stay alert

for hidden hazards or traffic.

3o After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

disconnect the cord on electric motors,

thoroughly inspect the snow thrower for any

damage, and repair thedamagebefore restarting

and operating the snow thrower.

4_ If the snow thrower should start to vibrate

abnormally, stop the (motor) and check

immediately forthe cause, Vibration is generally

a warning of trouble,

& Stoptheengine (motor) wheneveryou leavethe

operating position, before unclogging the auger/

impeller housing or discharge guide, and when

making any repairs, adjustments, orinspectionso

6. When cleaning, repairing, or inspecting, make

certain the auger/impeller and all moving parts

have stopped. Disconnect the spark plug wire

and keep the wire away from the plug to prevent

accidental starting.

7o Take all possible precautions when leaving the

snow thrower unattended. Disengage the auger/

impeller, shift to neutral, stop engine, and

remove key.

SAFETY RULES

8. Do not runthe engine indoors, except when starting

the engine and for transporting the snow thrower in

or out of the building. Open the outside doors;

exhaust fumes aredangerous (containing CARBON

MONOXIDE, an ODORLESS and DEADLY GAS),

9. Do not clear snow across the face of slopes.

Exercise caution when changing direction on

slopes. Do not attempt to clear steep slopes.

10. Never operate the snow thrower without proper

guards, plates or other safety protective devices

in place.

11. Never operate the snow thrower near glass

enclosures, automobiles, window wells,

drop-offs, and the like without proper adjustment

of the snow discharge angle. Keep children and

pets away°

12. Do not overload the machine capacity by

attempting to clear snow at too fast a rate.

13. Never operate the snow thrower at high transport

speeds on slippery surfaces_ Look behind and

use care when backing.

14. Never direct discharge at bystanders or allow

anyone in front of the snow thrower°

15. Disengage power to the auger/impeller when

snow thrower is transported or not in use.

16. Use only attachments and accessories approved

by the manufacturer of the snow thrower (such

as tire chains, electric start kits, etc.)°

17o Never operate the snow thrower without good

visibility or light. Always be sure of your footing,

and keep a firm hold on the handles. Walk; never

run.

MAINTENANCE AND STORAGE

1. Check shear botts and other bolts at frequent

improper tightness to be sure the snow thrower

is in safe working condition.

2. Never store the snow thrower with fueiin the fuel

tank inside a building where ignition sources are

present such as hot water and space heaters,

clothes dryers, and the like. Allow the engine to

cool before storing in any enclosure.

3. Always refer to operator's manual instructions

for important details if the snow thrower is to be

stored for an extended period.

4o Maintain or replace safety and instruction labels,

as necessary.

5. Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the auger/

impeller.

i,,11,,,11111iii iii

WARNING

This snow thrower is for use on sidewalks,

driveways, and other ground level surfaces.

CAUTION should be exercised while using on

steep sloping surfaces. DO NOT USE SNOW

THROWER ON SURFACES ABOVE GROUND

LEVEL such as roofs of residences, garages,

porches or other such structures or buildings.

LOOK FOR THIS SYMBOL TO POINT OUT

fMPORTANT SAFETY PRECAUTIONS. IT

MEANS--ATTENTION!!! BECOME ALERT!!!

YOUR SAFETY IS INVOLVED°

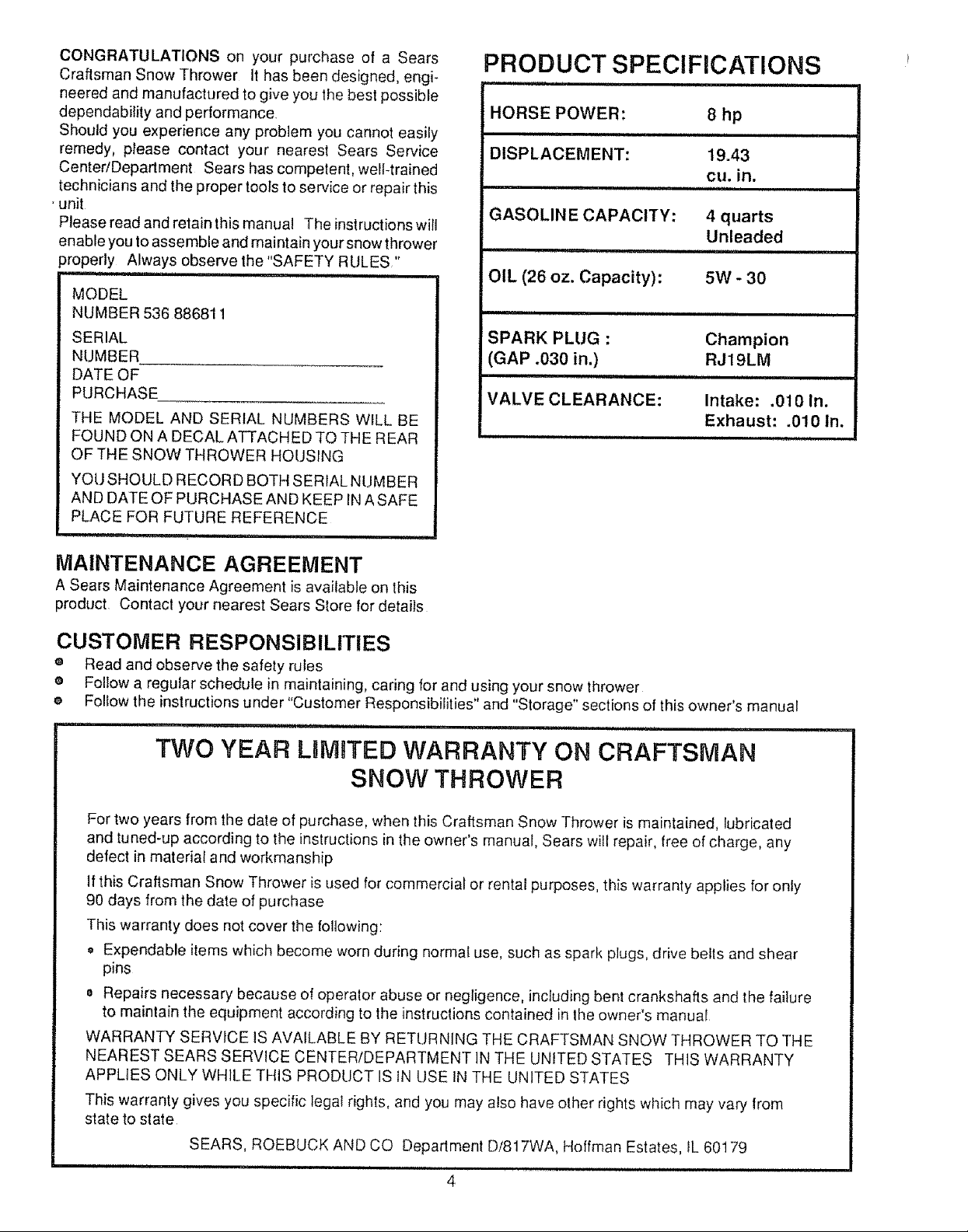

CONGRATULATIONS on your purchase of a Sears

Craftsman Snow Thrower It has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center/Department Sears has competent, well-trained

technicians and the proper tools to service or repair this

•unit

Please read and retain this manual The instructions wiIi

enable you to assemble and maintain your snow thrower

properly A! ays observethe SAFETY RULES"

W _E

,i iii ii 1,1,1,1

MODEL

NUMBER 536 886811

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACH ED TO THE REAR

OF THE SNOW THROWER HOUSING

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN ASAFE

PLACE FOR FUTURE REFERENCE

PRODUCT SPECIFICATIONS i

HORSE POWER: 8 hp

,.I,HHIIHI, I' I1' '11 II

DISPLACEMENT: 19.43

cu. in.

GASOLINE CAPACITY:

OIL (26 oz. Capacity):

SPARK PLUG : Champion

(GAP .030 in.) RJ19LM

i1,1111i Hll II ' Ill III

VALVE CLEARANCE: Intake: .010 In.

4 quarts

Unleaded

IIIII,rlH'l'll'I

5W - 30

IIIIH I'111

Exhaust: .010 In.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product Contacl your nearest Sears Store for details

CUSTOMER RESPONSIBILITIES

® Read and observethe safety rules

® Follow a regular schedule in maintaining, caring for and using your snow thrower

® Follow h " " "

,111,11111,,i

t e fnstruct_ons under Customer Responsibilities" and "Storage" sections of this owner's manual

TWO YEAR LnMnTED WARRANTY ON CRAFTSMAN

SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated

and tuned-up according to the instructions in the owner's manual, Sears will repair, free of charge, any

defect in material and workmanship

If this Craftsman Snow Thrower is used for commercial or rental purposes, this warranty applies for only

90 days from the date of purchase

This warranty does not cover the following:

o Expendable items which become worn during normal use, such as spark plugs, drive belts and shear

pins

0 Repairs necessary because of operalor abuse or negligence, including bent crankshafts and the failure

to maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT 1NTHE UNITED STATES THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN USE iN THE UNITED STATES

This warranty gives you specific legat rights, and you may also have other rights which may vary from

state to state

SEARS, ROEBUCK AND CO Department Di817WA, Hoffman Estates, IL 60179

TABLE OF CONTENTS

SAFETY RULES ....................................... 2,3

PRODUCT SPECIFICATIONS ........................ 4

CUSTOMER RESPONSIBILITIES .....4,15,16

WARRANTY ............................................................4

TABLE OF CONTENTS ...................................... 5

INDEX ................................................................. 5

ASSEMBLY ................................................... 6-9

OPERATION ................................................ 10-14

SERVICE AND ADJUSTMENTS ............. 17-23

STO RAG E ........................................................ 24

SERVICE RECOMMENDATIONS ..................25

........................ •TROUBLE SHOOTING ............. 6

REPAIR PARTS (SNOW THROWER). :.27-36

REPAIR PARTS (ENGINE) ...................... 37-40

PARTS ORDERINGISERVlCE .... Back Cover

INDEX

A

Adjustment:

Auger ......................... 22

Belts ......................... 18, 19

Belt Guide ............................. 20

Cable .................................. t8

Carburetor .......................... 22

Friction Wheel ....................... 20

Spark Plug ............ 23

Traction and Auger .............. 19

Assembly:

Crank Assembly ....................... 8

Headlight ................................... 9

Shilter Lever. .................................. 9

Skid Height Adjustment .......... 7, 17

Unpacking ................................ 7

B

Belts:

Adjust Belts ............................. 18

Belt Guide Adjustment ............... 20

Belt Maintenance ............. t8, 19

Replace Belts ....................... t 9

C

Cables, Ctutch ....................... 7, 9, 18

Carburetor: ............................ 22, 24

Choke .................................. 10, 1t, 13

Clutch, Auger ................... t0, 1t, !4

Clutch, Traction ............... 10, ! 1,14

Controls:

Engine .......................... t0, 11,13

Snow Thrower ............... 7, 10, 11, 14

Crank:

Adjusting Rod .................. 8, 17

Assembly ....................................... 8

Operation ................................... 10

Customer Responsibilities ..... 4,15,16

Agreement ....................................... 4

Auger Gear Box ................. 16

Auger Shaft ............................... 15

Engine ............................... 16

General Recommendations ..... 15

Hex Shaft and Gears ............. 16

Spark Plug ....................................... l 6

D

Deflector, Snow Chute ....... 10, 11, 14

E

Engine:

Control ......................... !0, 11, 13, 14

Oil Cap .................... 12, 16

Oil Change ........................... 16

Oil Level ...................... 12, 16

Oil Type ......................... 4, t2, 16

Speed Governor ............. 22

Stading the Engine ............. 13

Storage ................................... 24

F

Fuel, Type .............. 4, 12

Fuel, Storage .............. 13,24

Friction Wheel:

Adjustment ............ 20

Replacement ..... 21

G

Gears:

Auger Gear Box 16

Hex Shaft ............ 16

H

Handle, Upper and Lower ..... 7

Headlight .......................... 9

Height Adjust Skids .......... 7, 17

Hex Shaft ............... 16

1

Ignition, Key ........ 10, 13, 14

index ................. 5

L

Levers:

Auger Ddve Clutch 7 10 11. 14

Choke ......... 10 1!, 13

Shifter .......... 9, 10, 11

Throttle Control ........ t 1,13, 14

Traction Drive Clutch 7, t 0, 11, 14

Lubrication:

Auger Gear Box .... 16

Auger Shaft ................. 15

Ctlart ................. 25

Disc Ddve Plate 15

Engine .......... 16

Hex Shaft and Gears ......... 16

O

Oil:

Engine .................. 4, t2, 16

Extreme Cold Weather 12,t6

Storage ....................... 24

Type ........................ t 6

Operation:

EngineContro]s . . 10, 11,13

Lockout Pin, Wheel ............ 12

Operating Snow Thrower t0, 11, 14

Snow Throwing Tips .......... 14

Starting the Engine ............ !3

Snow Thrower Conlrols ..... 10, 11

P

Parts ................. 28-38

Primer Button ....... 10, 11,13

R

Repair/Replace ment Part s 28-38

Recoil Starter ...... 13

Replacements:

Auger Shear Bolt 22

Belts .... t9

Friction Wheel ...................... 21

S

Safety Rules ................... 2, 3

Service and Adjustments:

Auger Housing Height ....... 7, t7

Auger Shear Bolt ...................... 22

Belts .................. 18, 19

Belt Guide ........................... 20

Belt Replacement ................... 19

Cable .................. 7, 9, 18

Carburetor .............................. 22, 24

Chute Crank ............................ 17

Friction Wheel ..................... 20, 21

Scraper Bar ................ 17

Spark Plug ....................... 23

Service Recommendations ........... 25

Spark Plug ............................ 16, 23

Specifications .................................... 4

Speed Govern or ....................... 22

Starting the Engine .................. 13

Stopping the Engine ................ 11, !3

Stopping the Snow Thrower ...............11

Shipping Carton .................... 6, 7

Skid Height ................. 7, 17

Shifter Lever ...................... 9-11

Shear Bolts ................................. 22

Storage ............................. 24

T

Table of Contents ............................ 5

Tire Pressure ............................. 17

Trouble Shooting Chart ................. 26

Tools for Assembly .............................. 6

Traction Drive Belt ........................... 19

W

Warranty ............................ 4

Wheel, Lockout Pin ............ 12

i ii .

ASSEMBLY

H"HI ,H, ,I,'m,, H Hl',lI "H I

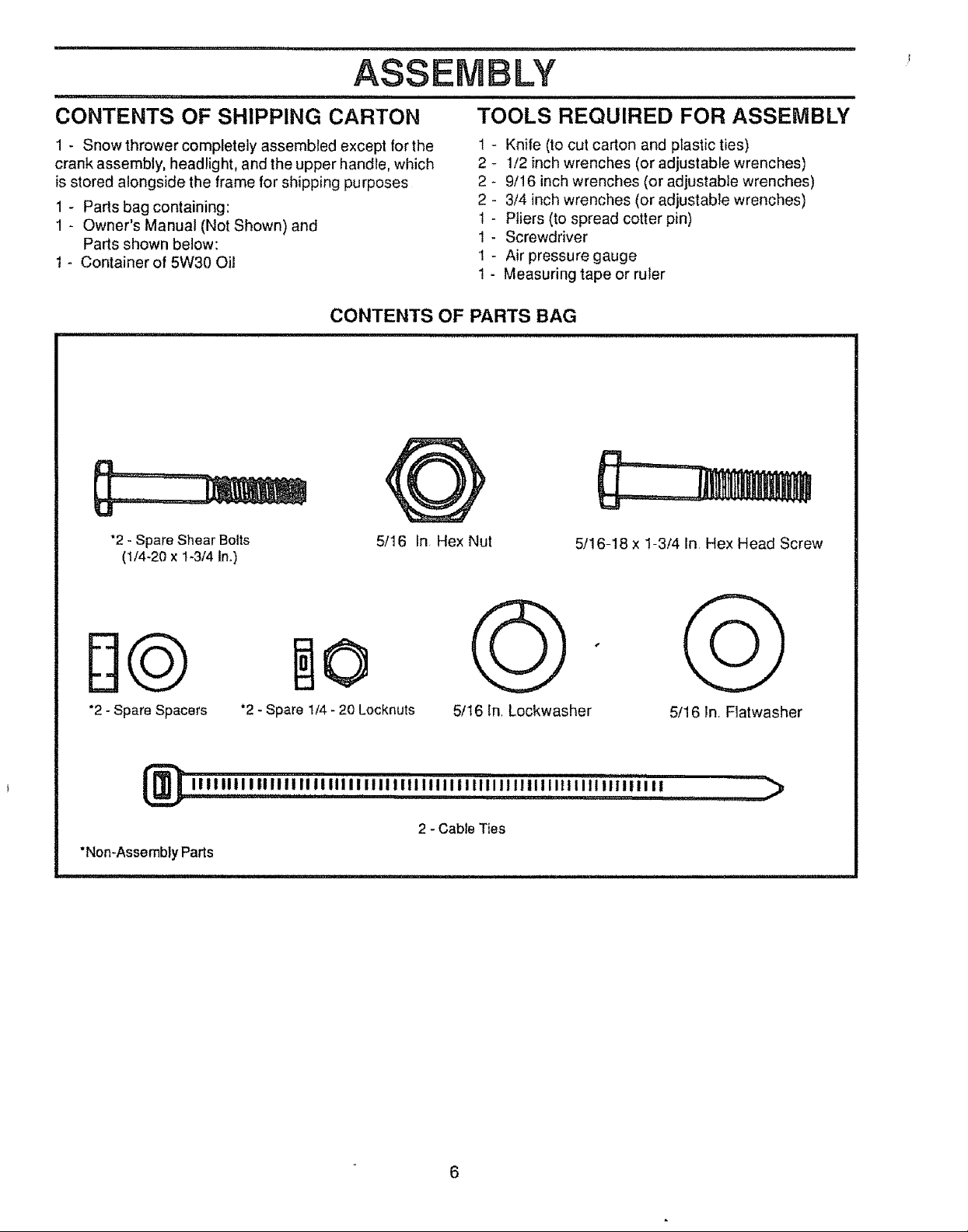

CONTENTS OF SHIPPING CARTON TOOLS REQUIRED FOR ASSEMBLY

1 - Snow thrower completely assembled except for the

crank assembly, headlight, and the upper handle, which

is stored alongside the frame for shipping purposes

1 - Paris bag containing:

1 - Owner's Manual (Not Shown) and

Parts shown below:

t - Container of 5W30 Oil

CONTENTS OF PARTS BAG

"2- Spare ShearBolts

(1/4-20 x t-3/4 lno)

5/16 in Hex Nut

1 - Knife (to cut carton and plastic ties)

2 _ 1/2 inch wrenches (or adjustable wrenches)

2 - 9/16 inch wrenches (or adjustable wrenches)

2 - 3/4 inch wrenches (or adjustable wrenches)

1 - Pliers (to spread cotter pin)

1- Screwdriver

! - Air pressure gauge

1 - Measuring tape or ruler

5/16-18 x 1-3/4 In Hex Head Screw

D@

*2- SpareSpacers *2 - Spare 1/4-20 Locknuts

_ II II IIII I II I!11 II II III I I IIIi I IIIIIIII! IIIIIll'llillllllllll li'i'i'i"i'iII

"Non-AssemblyParts

G

5/t6 In, Lockwasher

2 -Cable Ties

5/16 In, Flatwasher

' i i..i. >

ASS

l= m m ,,,, ,uH,,

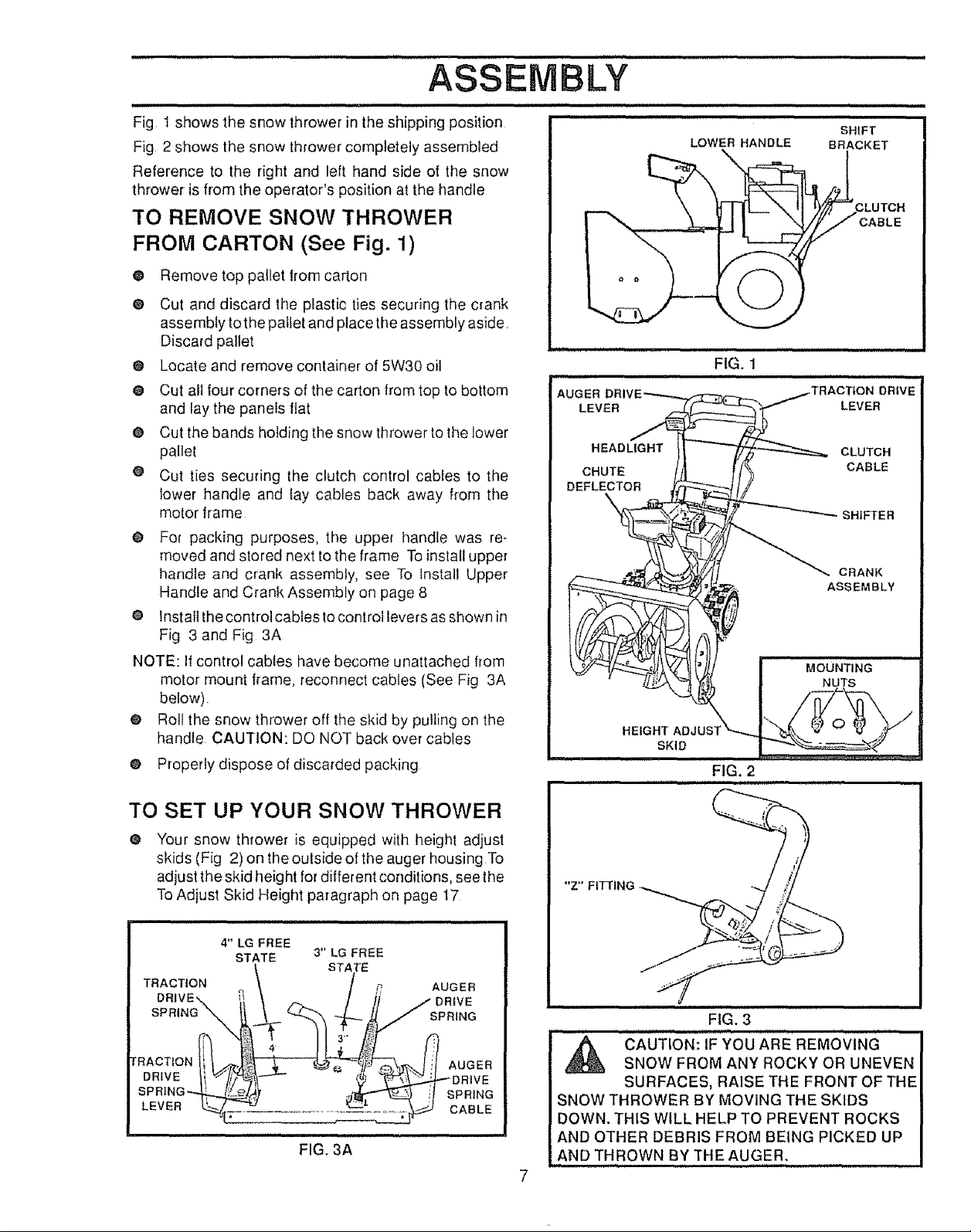

Fig 1 shows the snow thrower in the shipping position

Fig 2 shows the snow thrower completely assembled

Reference to the right and left hand side of the snow

thrower is from the operator's position at the handle

TO REMOVE SNOW THROWER

FROM CARTON (See Fig. 1)

® Remove top pallet from carton

® Cut and discard the plastic ties secunng the crank

assembly to the pallet and place the assembly aside

Discard pallet

@ Locate and remove container of 5W30 oil

,8 Cut all four corners of the carton from top to bottom

and lay the panels flat

,8 Cut the bands holding the snow thrower to the lower

pallet

,8 Cut ties securing the clutch control cables to the

lower handle and lay cables back away from the

motor frame

,8 For packing purposes, the upper handle was re-

moved and stored next to the frame Toinstall upper

handle and crank assembly, see To Install Upper

Handle and Crank Assembly on page 8

'8 Install the control cables to control levers as shown in

Fig 3 and Fig 3A

NOTE: If control cables have become unattached Irom

motor mount frame, reconnect cables (See Fig 3A

below)

,8 Roll the snow thrower off the skid by pulling on the

handle CAUTION: DO NOT back over cables

,8 Properly dispose of discarded packing

HEADLIGHT

CHUTE

DEFLECTOR

HEIGHT AI

SKID

LOWER HANDLE

,(D

FIG. 1

FIG. 2

i

SHIFT

BRACKET

/_CLUTCH

CABLE

LEVER

CLUTCH

CABLE

SHIFTER

CRANK

ASSEMBLY

TO SET UP YOUR SNOW THROWER

®

Your snow thrower is equipped with height adjust

skids (Fig 2) on the outside of the auger housing To

adjust the skid height for different conditions, see the

To Adjust Skid Height paragraph on page 17

TRACTION

fRACTION

DRIVE

LEVER

in

FIG. 3A

AUGER

SPRING

CABLE

"Z" FITTING

..................... Fi&3

.....,_ ' CAUTION:iFYOU ARE REMOVING

SNOW THROWER BY MOVING THE SKIDS

DOWN. THIS WILL HELP TO PREVENT ROCKS

AND OTHER DEBRIS FROM BEING PICKED UP

ANDTHROWNBYTHEAUeER.

7

SNOWFROMANYROCKYORUNEVEN

SURFACES, RAISE THE FRONT OF THE

........................... ijtt ii

,i,,,i,=,,=

ASS

....... U"Hli I'L '.i..,...lli.Hi II

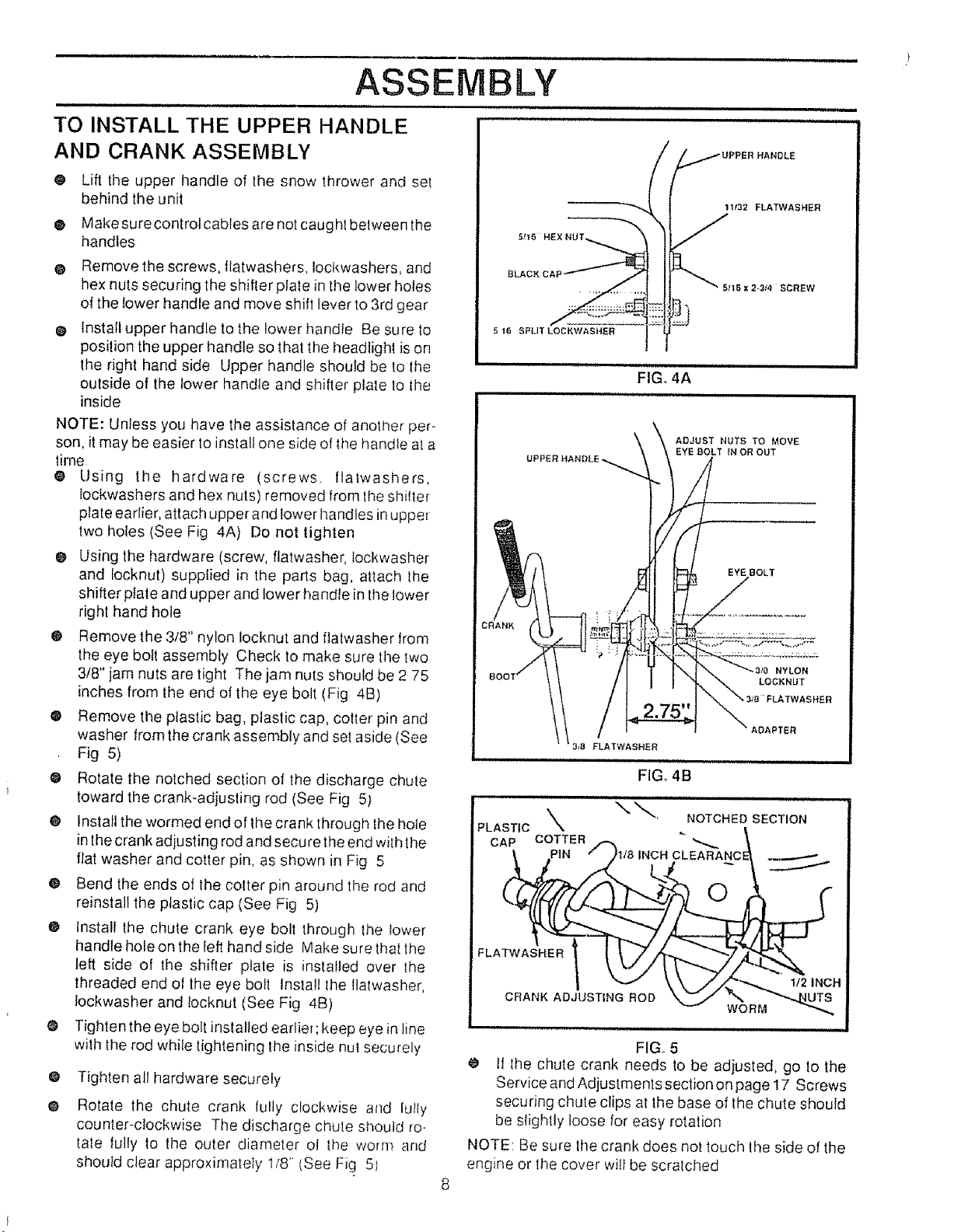

TO INSTALL THE UPPER HANDLE

AND CRANK ASSEMBLY

O Lift the upper handle of the snow thrower and set

behind the unit

@ Make surecontrotcabfes are not caught between the

handles

O Remove the screws, llatwashers, Iockwashers, and

hex nuts securing the shifter piale in the lower holes

of the lower handle and move shift lever to 3rd gear

@ Install upper handle to the lower handle Be sure to

position the upper handle so that the headlight is on

the right hand side Upper handle should be to the

outside of the lower handle and shifter plate to the

inside

NOTE: Unless you have the assistance of another per-

son, itmay be easier to install one side of the handle at a

time

• Using the hardware (screws. flatwashers,

tockwashers and hex nuts) removed from _heshilter

plate earlier, attach upper and lower handles in upper

two holes (See Fig 4A) Do not tighten

O Using the hardware (screw, ftatwasher, Iockwasher

and locknut) supplied in the parts bag, attach the

shifter plale and upper and lower handle inthe lower

right hand hole

• Remove the 3/8" nylon Iocknut and flatwasher trom

the eye boll assembly Check to make sure the two

318"jam nuts are tight The jam nuts should be 2 75

inches from the end of the eye bolt (Fig 4B)

Remove the plastic bag, plastic cap, cotter pin and

washer from the crank assembly and set aside (See

Fig 5)

O Rotate the notched section of the discharge chute

toward the crank-adjusting rod (See Fig 5}

® Install the wormed end of the crank through the hole

in the crank adjusting rod and secure the end with the

flat washer and cotter pin, as shown in Fig 5

® Bend the ends of the cotter pin around the rod and

reinstall the plastic cap (See Fig 5)

€, Install the chute crank eye bolt through the lower

handle hole on the left hand side Make sure that the

left side of the shifter plate is installed over the

threaded end ot the eye boft install the llatwasher,

lockwasher and tocknut (See Fig 4B)

@ Tighten the eye bolt installed earlieT; keep eye in line

with the rod while tightening lhe inside nut securely

@

Tighten all hardware securely

O

Rotate the chute crank fully clockwise and luily

counter-clockwise The discharge chute should _o-

tale fully to the outer diameter ot the wom_ and

should clear approximately 1/8 (See Fig 5t

m"H' =

11t32 FLATWASHER

5 16 SPLIT LOCKWASH_

FIG. 4A

ADJUST NUTS TO MOVE

EYE BOLT rN OR OUT

EYE BOLT

N',tLON

LOCKNUT

= '=HHH

PLASTIC X "% _', NOTCHED

CAP COTTER-- " "_,,.

"_ _P)N-''''/ )t/8 IN_ CLEARANCE_ _

SECTION

LATWASNER/

CRANK ADJUSTING ROD _..__/'_,___TS

!! Ihe chute crank needs to be adjusted, go to the

Service and Adjustments section on page 17 Screws

securing chute clips at the base of the chute should

be slightly loose for easy rotation

NOTE: Be sure the crank does not touch the side of the

engine or the cover will be scratched

| v \ \ /"/_'_.. I/2 INCH

WORM

FIGo5

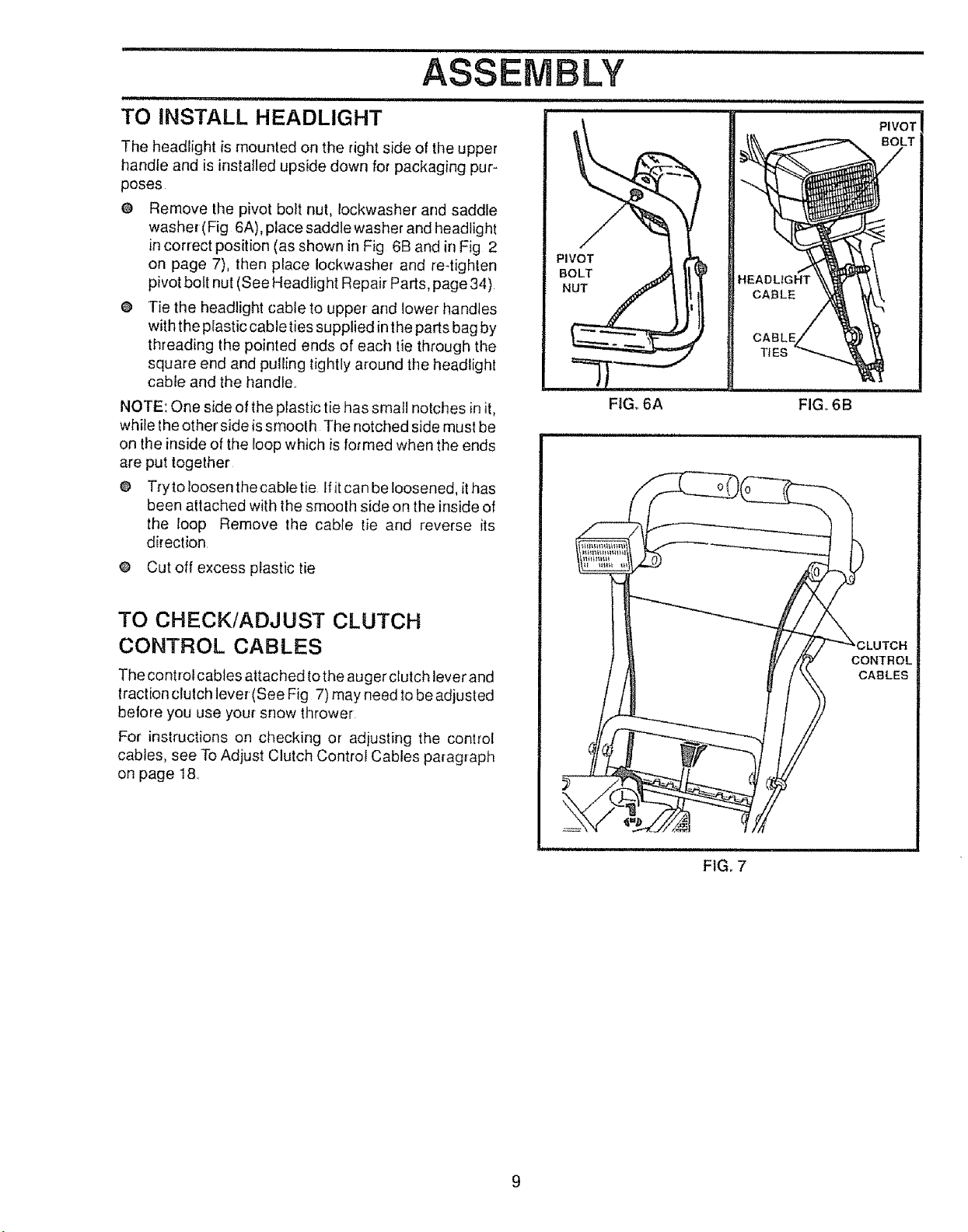

Theheadlightismountedontheright side of the upper

handle and is installed upside down for packaging pur-

poses

O Remove the pivot bolt nut, lockwasher and saddle

washer (Fig 6A), place saddle washer and headlight

in correct position (as shown in Fig 6B and in Fig 2

on page 7), then place Iockwasher and re-tighten

pivot bolt nut (See Headlight Repair Parts, page 34)

O Tie the headlight cable to upper and lower handles

with the plastic cable ties supplied inthe parts bag by

threading the pointed ends of each tie through the

square end and pulling tightly around the headlight

cable and the handle,

NOTE: One side of the plastic tie has small notches in it,

while the other side is smooth The notched side must be

on the inside of the loop which is formed when the ends

are put together

Q Trytoloosenthecabletie tfitcanbeloosened, ithas

been attached with the smooth side on the inside of

the loop Remove the cable tie and reverse its

direction

@ Cut off excess plastic Iie

FtG,, 6A

FIGo6B

TO CHECK/ADJUST CLUTCH

CONTROL CABLES

The control cables attached to the auger clutch lever and

traction clutch lever (See Fig 7) may need to be adjusted

before you use your snow thrower

For instructions on checking or adjusting the control

cables, see ToAdjust Clutch Controt Cables paragraph

on page 18,

CONTROL

CABLES

FIG, 7

OPERATION

m,, n i

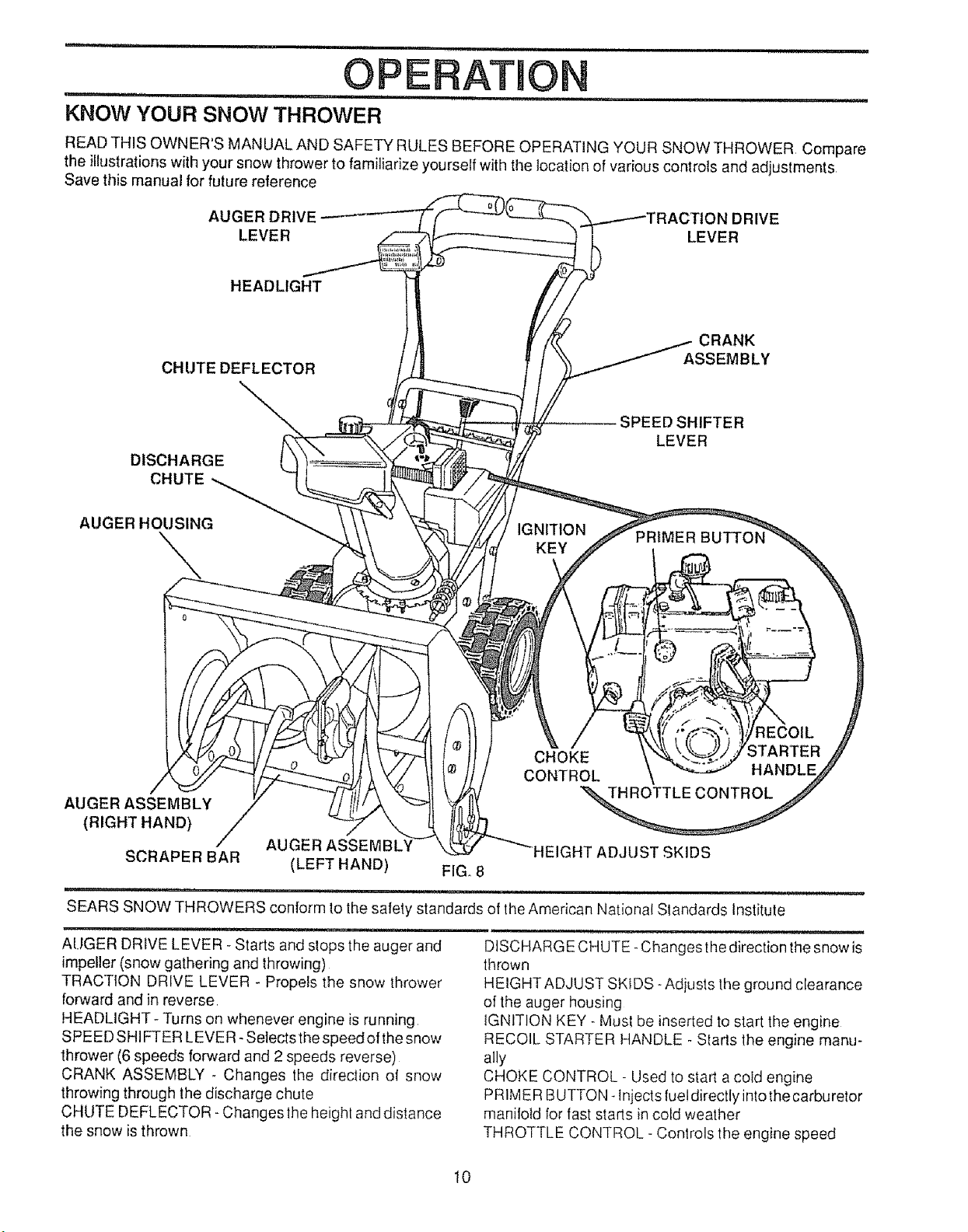

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR SNOWTHROWER Compare

the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments

Save this manual for future reference

AUGER DRIVE 3TtON DRIVE

LEVER LEVER

HEADLIGHT

CRANK

CHUTE DEFLECTOR

SPEED SHIFTER

DISCHARGE

CHUTE

ASSEMBLY

LEVER

AUGER HOUSING

AUGER ASSEMBLY

(RIGHT HAND)

AUGER

SCRAPERBAR

(LEFT HAND) FIG, 8

hi,, ,,n ,,,

SEARS SNOW THROWERS contorm to the safety standards of the American National Standards Institute

AUGER DRIVE LEVER - Starts and stops the auger and

impeller (snow gathering and throwing)

TRACTION DRIVE LEVER - Propels the snow thrower

forward and in reverse

HEADLIGHT - Turns on whenever engine is running

SPEED SHIFTER LEVER - Selects the speed of the snow

thrower (6 speeds forward and 2 speeds reverse)

CRANK ASSEMBLY * Changes the direction o! snow

throwing through the discharge chute

CHUTE DEFLECTOR -Changes the height and distance

the snow is thrown

IGNITION I BUTTON

KEY

RECOIL

CHOKE STARTER

CONTROL HANDLE

THROTTLECONTROL

ADJUST SKIDS

DISCHARGE CHUTE- Changes the direction the snow is

thrown

HEIGHT ADJUST SKIDS _Adjusts the ground clearance

of the auger housing

IGNITION KEY - Mus_ be inserted to start the engine

RECOIL STARTER HANDLE - Starts the engine manu-

ally

CHOKE CONTROL- Used to stad a cold engine

PRIMER BUTTON-Injects fuel directly into the carbu retor

manilold for fast starts in cold weather

THROTTLE CONTROL - Controls the engine speed

10

OPERATmON

,,111 , ,,i i HN,, I I I1,,1, roll,

The operation of any snow thrower can result in foreign objects being thrown intothe eyes,

which can result in severe eye damage AIways wear safety glasses or eye shields while oper-

ating the snow thrower.

We recommend standard safety glasses, available at SEARS Retail or Catalog Stores, or a

wide vision safety mask for over your glasses

HOW TO USE YOUR SNOW

THROWER

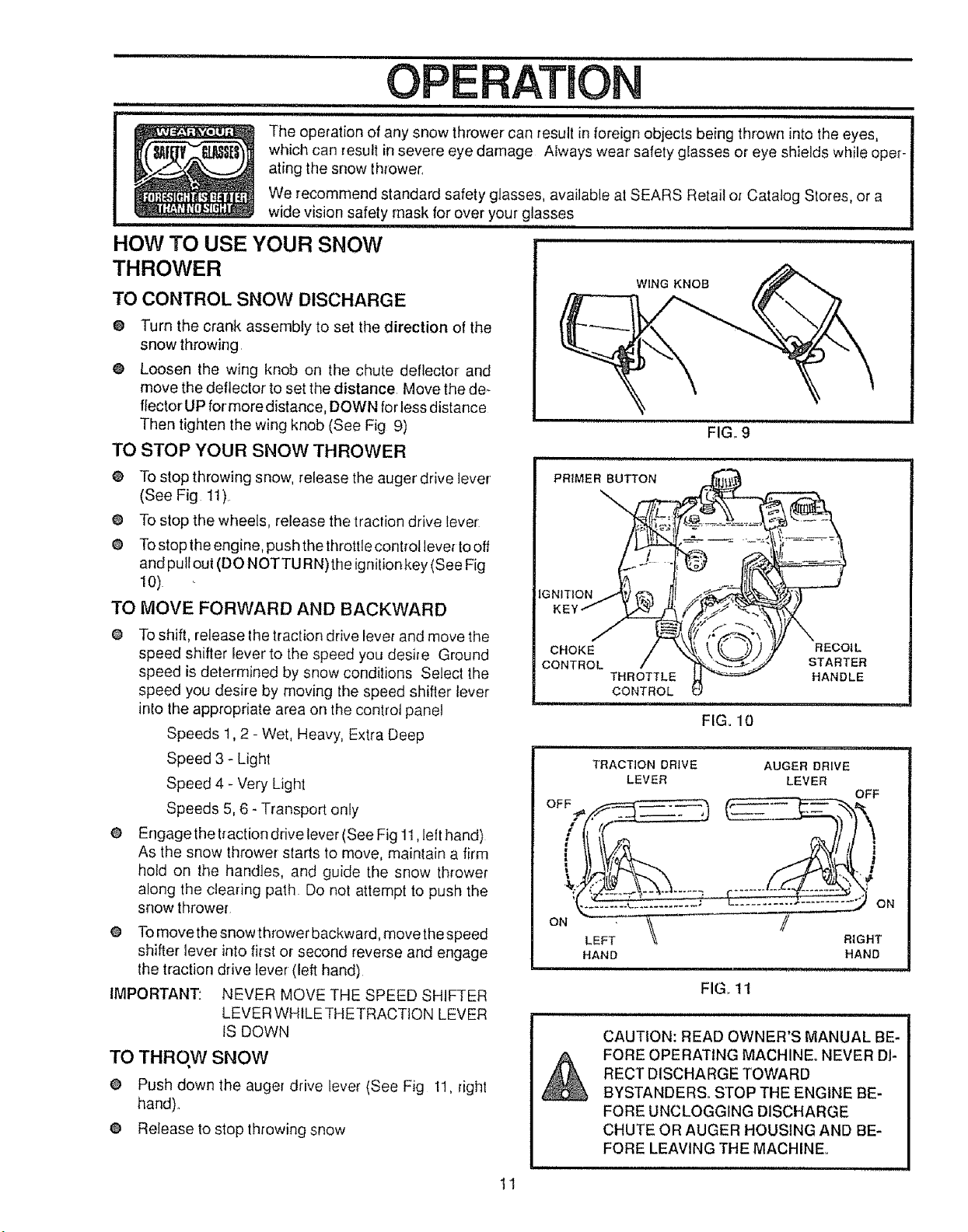

TO CONTROL SNOW DISCHARGE

@ Turn the crank assembly to set the direction of the

snow throwing

e Loosen the wing knob on the chute deflector and

move the deflector to set the distance Move the de_

flector UP for more distance, DOWN for less distance

Then tighten the wing knob (See Fig 9)

TO STOP YOUR SNOW THROWER

,,,mini ,1111 II1, II I, ,mH,,H,H, mmH'

,ll,m,,mll

Nil,, I,] III II

'HHI

FIG. 9

@ To stop throwing snow, release the augerdrive lever

(See Fig I1),

@ To stop the wheels, release the traction drive lever:

@ Tostop the engine, push the throttlecontrol lever to off

and pull out (DO NOTTU RN) the ignition key (See Fig

10)

TO MOVE FORWARD AND BACKWARD

@ To shift, release the traction drive level and move the

speed shifter lever to the speed you desire Ground

speed is determined by snow conditions Select the

speed you desire by moving the speed shifter lever

into the appropriate area on the control panel

Speeds 1,2 - Wet, Heavy, Extra Deep

Speed 3 - Light

Speed 4 - Very Light

Speeds 5, 6 - Transport only

@ Engage the traction drive lever (See Fig 11,lett hand)

As the snow thrower starts to move, maintain a firm

hold on the handles, and guide the snow throwe_

along the clearing path Do not attempt to push the

snow thrower

PRIMER BUTTON

\

CHOKE RECOIL

CONTROL STARTER

THROTTLE HANDLE

CONTROL

FIGo 10

TRACTION DRIVE AUGER DRIVE

LEVER LEVER

OFF

_N

@ To movethe snow thrower backward, move the speed

shifter lever into first or second reverse and engage

the traction drive lever (left hand)

IMPORTANT: NEVER MOVE THE SPEED SHIFTER

LEVER WHILE THETRACT1ON LEVER

tS DOWN

TO THROW SNOW

@ Push down the auger drive lever (See Fig 11, right

hand),

@ Release to stop throwing snow

11

LEFT

HAND

RIGHT'

HAND

FIG. 11

LLJJL'...................

CAUTION: READ OWNER'S MANUAL BE-

FORE OPERATING MACHINE° NEVER DI-

RECT DISCHARGE TOWARD

BYSTANDERS. STOP THE ENGINE BE-

FORE UNCLOGGING DISCHARGE

CHUTE OR AUGER HOUSING AND BE-

FORE LEAVING THE MACHINE°

................opE.....R o........

:_ ir,,,rrr,, , I i, i ],,,m,,, Jl,nu Hm u i i, JU m l,n

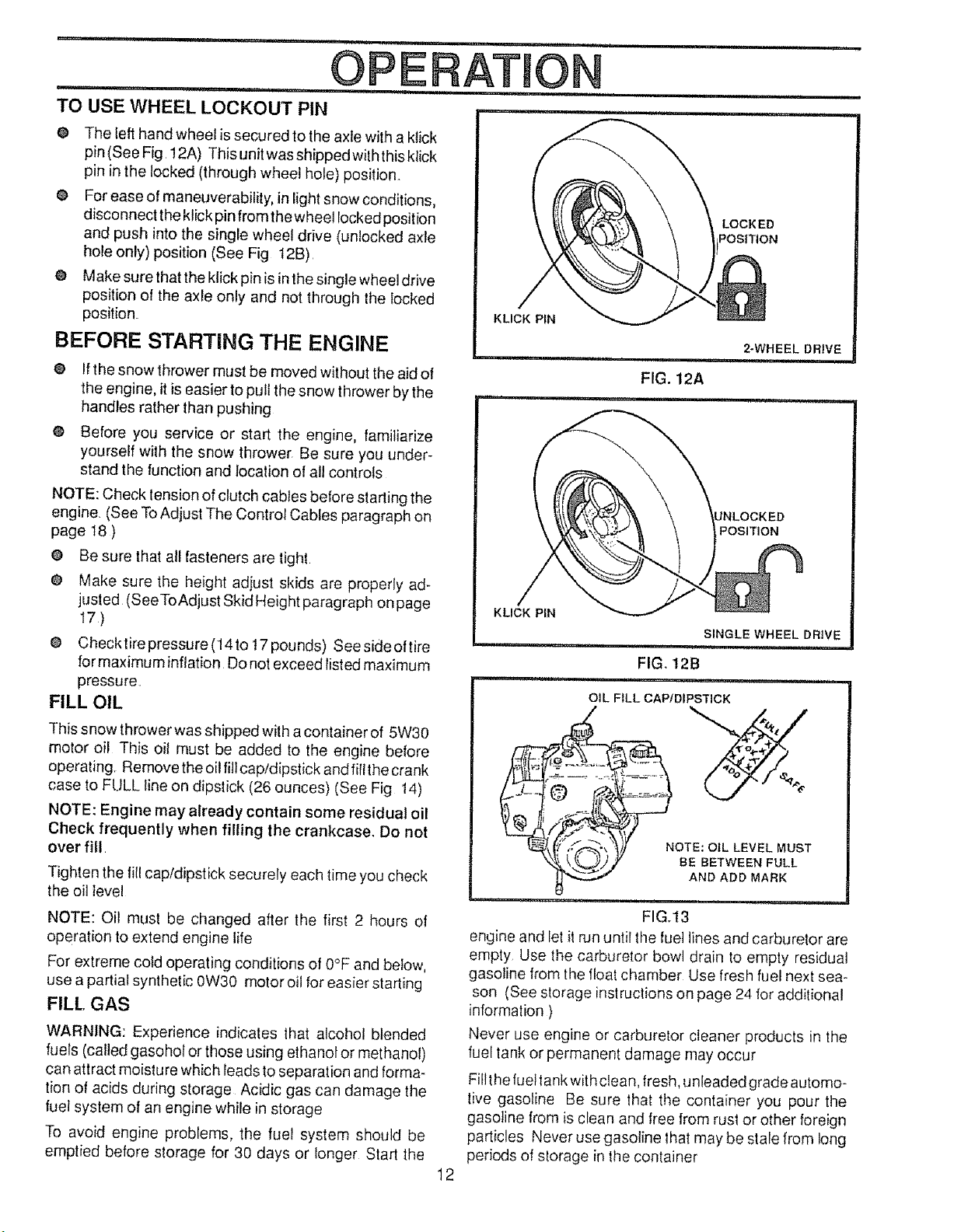

TO USE WHEEL LOCKOUT PIN ....... ,.................................

@ The left hand wheel is secured to the axle with a klick

pin(SeeFig 12A) Thisunitwasshippedwiththiskiick

pin in the locked (through wheel hole) position

@ For ease of maneuverability, in light snow conditions,

disconnect the ktick pin from the wheel locked posit ion

and push into the single wheel drive (unlocked axle

hole only) position (See Fig 12B)

@ Make surethat the klick pin is in the single wheel drive

position of the axle only and not through the locked

position

BEFORE STARTING THE ENGINE

® Ifthe snow thrower must be moved without the aid of

the engine, it is easier to pull the snow thrower by the

handles rather than pushing

® Before you service or start the engine, familiarize

yourself wilh the snow thrower Be sure you under-

stand the function and location ot all controls

NOTE: Check lension of clutch cables before starling the

engine, (See ToAdjust The Control Cables paragraph on

page 18 )

® Be sure that all lasteners are tighl

@ Make sure the height adjust skids are properly ad-

justed (SeeToAdjust Skid Height paragraph on page

17)

® Checkfire pressure (14to 17 pounds) See side oftire

for maximum inflation Do not exceed listed maximum

pressure.

FILL OIL

KLICK PIN

J.rl..i.. ii '

FIG. 12A

............ ulmrl"_'' I,,,n,' I

/

KLICK PIN

FIG, 12B

hill

OIL FILL CAP/DIPSTICK

LOCK ED

2-WHEEL DRIVE

_CKED

POSITION

SINGLE WHEEL DRIVE

This snow thrower was shipped with a container of 5W30

motor oil This oil must be added to the engine before

operating. Removethe oil fi]lcap/dipstick and fillthe crank

case to FULL line on dipstick (26 ounces) (See Fig 14)

NOTE: Engine may already contain some residual oil

Check frequently when filling the crankcase, Do not

over fill

Tighten the till cap!dipstick securely each time you check

the oil level

NOTE: Oil must be changed after the first 2 hours of

operation to extend engine life

For extreme cold operating conditions of 0°F and below,

use a partial synthetic 0W30 motor oil for easier starting

FILL GAS

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or those using ethanol or methanol)

can attract moisture which leads to separation and forma-

tion of acids during storage Acidic gas can damage the

fuel system of an engine while in storage

To avoid engine problems, the fuel system should be

emptied before storage for 30 days or longer Start the

%

NOTE: OIL LEVEL MUST

BE BETWEEN FULL

AND ADD MARK

., ,,,, .................... j,

FIG13

engine and let it run until the fuel lines and carburetor are

empty, Use the carburetor bowl drain to empty residual

gasoline from the float chamber Use fresh fuel next sea-

son (See storage instructions on page 24 for additional

information )

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur

Fittthe fuellank withclean, fresh, unleaded grade automo-

tive gasoline Be sure lhat the container you pour the

gasoline from is clean and free from rust or other foreign

particles Never use gasoline that may be stale from long

periods of s_orage in the container

12

,,,nnl ii i ,,,,ll,,i, i,ii, i,l,,l,l,lll,

OP RAON

TO STOP ENGINE

@ To stop engine, move the throltle control lever to

STOP position and remove key. Keep the key inasafe

place The engine will not start without the key_

NOTE: DO NOT turn key

CARBURETOR

The factory settings for the carburetor are for most

conditions ]fthe engine is operaled under the following

conditions, you can adjust carburetor mixture See "How

To Adjust The Carburetor"(See Service and Adjust-

ments, page 22)

e The engine has a loss of power or does not run

smooth

e The engine's operated above 4,000 feet

TO START ENGINE

Be sure that the engine has sufficient oit Thesnowthrower

engine isequipped with a recoil starter: Before starting the

engine, be certain that you have read the following infor-

mation:

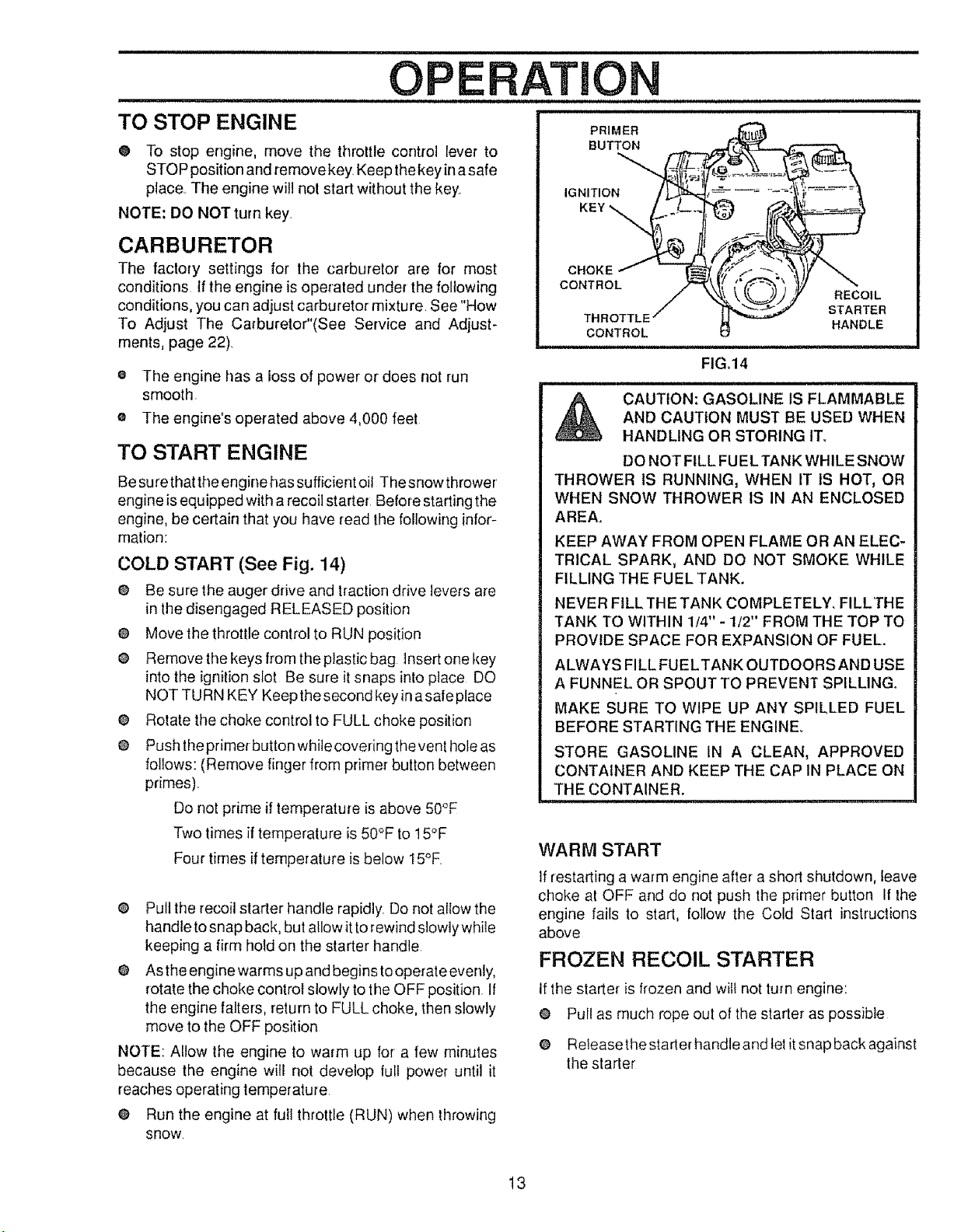

COLD START (See Fig. 14)

@ Be sure the auger drive and traction drive levers are

in the disengaged RELEASED position

@ Move the throttle control to RUN position

@ Remove the keys from the ptastic bag Insert one key

into the ignition slot Be sure it snaps into place DO

NOT TURN KEY Keep the second key in a safeplace

@ Rotate the choke control to FULL choke position

O Pushtheprimerbuttonwhilecoveringthevenl holeas

follows: (Remove finger from primer button between

primes),

Do not prime if temperature is above 50°F

Two times if temperature is 50°F to 15°F

Four times if temperature is below 15°F

@ Pull the recoil starter handle rapidly Do not allow the

handle to snap back, but allow itto rewind slowly while

keeping a firm hold on the starter handle

@ As the engine warms up and begins tooperateevenly,

rotate the choke control slowly to the OFF position. If

the engine falters, return to FULL choke, then slowly

move to the OFF position

NOTE: Allow the engine to warm up for a few minutes

because the engine will not develop full power until it

reaches operating temperature

@ Run the engine at full throttle (RUN) when throwing

SnOW

PRIMER

BUTTON

IGNITION

CHOKE _

CONTROL

THROTTLE HANDLE

CONTROL

ULUUL'LULI'I

i RECOIL

STARTER

FIG.14

, inl, ii nn n,,n,,,nl,nln,,n

AND CAUTION MUST BE USED WHEN

CAUTION: GASOLINE IS FLAMMABLE

HANDLING OR STORING IT_

DO NOT FILL FUEL TANK WHILE SNOW

THROWER IS RUNNING, WHEN IT IS HOT, OR

WHEN SNOW THROWER IS IN AN ENCLOSED

AREA.

KEEP AWAY FROM OPEN FLAME OR AN ELEC-

TRICAL SPARK, AND DO NOT SMOKE WHILE

FILLING THE FUEL TANK.

NEVER FILL THE TANK COMPLETELY. FILLTHE

TANK TO WITHIN 1/4" - 1/2" FROM THE TOP TO

PROVIDE SPACE FOR EXPANSION OF FUEL.

ALWAYS FILL FUELTANK OUTDOORSAND USE

A FUNNEL OR SPOUT TO PREVENT SPILLING.

MAKE SURE TO WIPE UP ANY SPILLED FUEL

BEFORE STARTING THE ENGINE.

STORE GASOLINE IN A CLEAN, APPROVED

CONTAINER AND KEEP THE CAP IN PLACE ON

THE CONTAINER.

WARM START

If restarting a warm engine after a short shutdown, leave

choke at OFF and do not push the primer button If the

engine fails to start, follow the Cold Start instructions

above

FROZEN RECOIL STARTER

If the starter is frozen and will not turn engine:

@ Pull as much rope out of the starter as possible

@ Releasethe starter handle and let itsnap back against

the starter

13

i,_,l,i,, ,i,,,11,,,,i,ii, ii, i ,

iii

OPE

Ifthe engine still fails to start, repeat the two previous step s

untilthe engin estarts Then continue with the directions for

cold start

To help prevent possible freeze-up of recoil starter and

engine controls, proceed as follows after each snow

removal job

e With the engine running, pull the slarter rope hard

with a continuous full arm stroke three or four times

Pulling of starter rope will produce a loud claltering

sound This is not harmful to the engine or starter.

@ With the engine not running, wipe a!l snow and

moisture from the carburetor cover in area of control

levers Also move throttle control, choke control, and

starter handle several times

CAUTION: NEVER RuN"ENGINE IN-

DOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EX-

HAUST CONTAINS CARBON MONOX-

IDE,AN ODORLESS AND DEADLY

GAS. KEEP HANDS_ FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ANY MOVING PARTS ON

ENGINE AND SNOW THROWER°

WARNING: TEMPERATURE OF MUFFLER AND

NEARBY AREAS MAY EXCEED 150 ° R AVOID

THESE AREAS.

DO NOT ALLOW CHILDREN OR YOUNG TEENAG-

ERS TO OPERATE OR BE NEAR SNOW

THROWER WHILE IT IS OPERATING°

CAUTION: DO NOT ATTEMPT TO RE-

MOVE ANY ITEM THAT MAY BECOME

LODGED 1NAUGER WITHOUT TAKING

THE FOLLOWING PRECAUTIONS:

e RELEASE AUGER DRIVE AND TRACTION

DRIVE LEVERS.

e MOVE THROTTLE LEVER TO STOP POSI-

TION_

ATION

SNOW THROWING TIPS

@ For maximum snow thrower efficiency in removing

snow, adjust ground speed, NEVER the throttle Go

slower in deep, freezing, or wet snow. If the wheels

slip, reduce forward speed The engine is designed to

deliver maximum performance at full throttle and

should be run at this power setting at all times Most

efficient snow blowing is accomplished when the

snow is removed immediately after it falls

@ For complete snow removal, slightly overlap each

path previously taken Use more overlap indeep snow

to prevent overloading.

@ The snow should bedischarged down wind whenever

possible Inwindy conditions, lowerthe chute deflector

to direct discharged snow close to the ground, where

it is less likely to Mow into unwanted areas

@ For normal usage, set the skids sothat the scraper bar

is 1/8" above the skids For extremely hard-packed

snow surfaces, adjust the skids upward so that the

scraper bar touches the ground

O On gravel orcrushed rock surfaces, set the skids at 1-

I/4" below the scraper bar (see ToAdju st Skids Height

paragraph on page 17) Stones and gravel must not

be picked up and thrown by the machine

e Ongravel orcrushed rock surfaces, set the skids at 1

t/4" belowthe scraper bar(see ToAdjust Skids Height

paragraph on page !7) Stones and gravel must not

be picked up and thrown by the machine

e After the snow throwing job has been completed,

allow lhe engine to idle for a few minutes, which will

melt snow and accumulated ice off the engine

@ Clean the snow thrower thoroughly after each use

Remove ice and snow accumulation and all debris

from the entire snow thrower, and flush with water (if

possible) to remove all sall or other chemicals Wipe

snow thrower dry

e REMOVE (DO NOT TURN) IGNITION KEY.

e DISCONNECT SPARK PLUG WIRE.

DO NOT PLACE YOUR HANDS IN THE AU-

GER OR DISCHARGE CHUTE, USE A PRY

BAR.

14

Loading...

Loading...