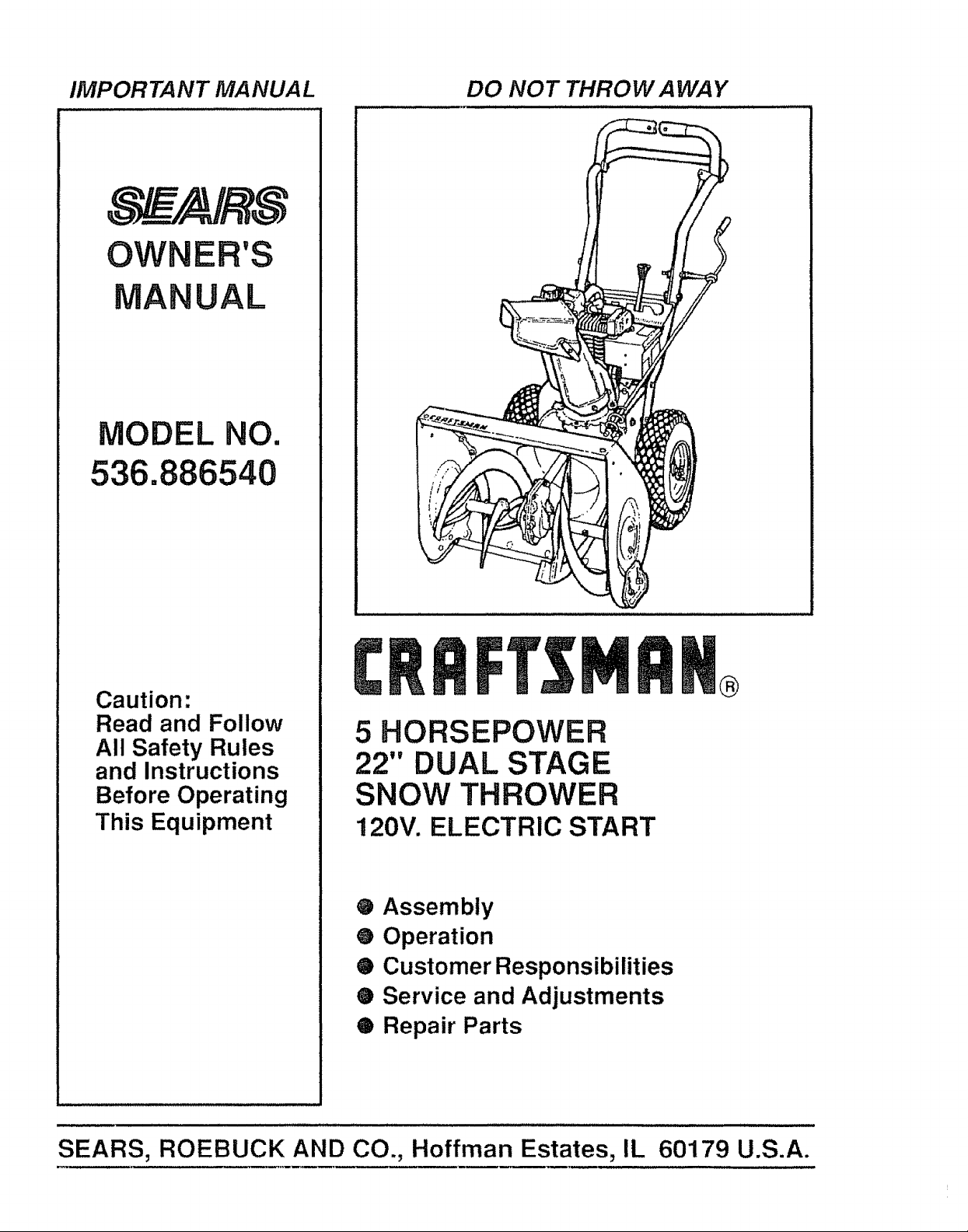

Craftsman 536886540 Owner’s Manual

IMPORTANT MANUAL DO NOT THROW AWAY

OWNER'S

MANUAL

MODEL NO.

536.886540

Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

®

5 HORSEPOWER

22" DUAL STAGE

SNOW THROWER

120V. ELECTRIC START

® Assembly

O Operation

O Customer Responsibilities

• Service and Adjustments

® Repair Parts

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

SAFETY RULES

& CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND &

PLACE WIRE WHERE IT CANNOT CONTACT SPARK PLUG

TO PREVENT ACCIDENTAL STARTING WHEN SETTING-UP,

TRANSPORTING, ADJUSTING OR MAKING REPAIRS.

IMPORTANT

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE

RISK OF INJURY.. YOUR SNOW THROWER IS EQUIPPED WITH SUCH CONTROLS. DO NOT

ATTEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER

ANY CIRCUMSTANCES.

TRAINING

1, Read the operator's manual carefully° Be

thoroughly familiar with the controls and the

proper use of the snow thrower. Know how to

stop the snow thrower and disengage the

controls quickly.

2o Never allowchildren to operate the snow thrower

and keep them away while it is operating Never

allow adults to operate the snow thrower without

proper instruction, Do not carry passengers.

3o Keep the area of operation clear of all persons,

particularly small children, and pets.

4_ Exercise caution to avoid slipping or falling,

especially when operating in reverse..

PREPARATION

1. Thoroughly inspect the area where the snow

thrower is to be used and remove all doormats,

sleds, boards, wires, and other foreign objects°

2. Disengage all clutches and shift into neutral

before starting the engine (motor).

3. Do not operate the snowthrower without wearing

adequate winter outer garments. Wear footwear

that will improve footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable,

(a) Use an approved fuel container..

(b) Never remove fuel tank cap or add fuel to a

running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care..

Never fill fuel tank indoor&

(d) Replace fuel tank cap securely and wipe up

spilled fuel.,

_e) Never store fuel or snow thrower with fuel in

the tank inside of a building where fumes may

reach an open flame or spark_

(f) Check fuel supply before each use, allowing

space for expansion as the heat of the engine

(motor) and/or sun can cause fuel to expand.

.

Use extension cords and receptacles as specified

by the manufacturer for all snow throwers with

electric drive motors or electric starting motors.

6. Adjust the snow thrower'height to clear gravel or

crushed rock surfaces.

7,, Never attempt to make any adjustments whilethe

engine (motor) is running (except when

specifically recommended bythe manufacturer)_

8. Let engine (motor) and snow thrower adjust to

outdoor temperatures before starting to clear

snow.

9. Always wear safety glasses or eye shields during

operation or while performing an adjustment or

repair to protect eyes from foreign objects that

may be thrown from the snow thrower.

OPERATION

1. Do not put hands or feet near' or under rotating

parts. Keep clear of the discharge opening at all

times_

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert

for hidden hazards or traffic.

After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

disconnect the cord on electric motors,

thoroughly inspect the snow thrower for any

damage, and repair the damage before restarting

and operating the snow thrower.

4_

If the snow thrower should start to vibrate

abnormally, stop the (motor) and check

immediately for the cause° Vibration is generally

a warning of trouble.

5._ Stop the engine (motor) whenever you leave the

operating position, before unclogging the auger/

impeller housing or discharge guide, and when

making any repairs, adjustments, or inspections.

6. When cleaning, repairing, or inspecting, make

certain the auger/impeller and all moving parts

have stopped_ Disconnect the spark plug wire

and keep the wire away from the plug to prevent

accidental starting.

7. Take all possible precautions when leaving the

snow thrower unattended. Disengage the auger/

impeller, shift to neutral, stop engine, and

remove key..

SAFETY RULES

8, DO not run the engine indoors, except when starting

the engine and for transporting the snow thrower in

or out of the building. Open the outside doors;

exhaust fumes are dangerous (containing CARBON

MONOXIDE, an ODORLESS and DEADLY GAS)°

9o Do not clear snow across the face of slopes.

Exercise caution when changing direction on

slopes. Do not attempt to clear steep slopes_

10. Never operate the snow thrower without proper

guards, plates or other safety protective devices

in place..

1t. Never operate the snow thrower near glass

enclosures, automobiles, window wells,

drop-offs, and the like wit hour proper adjustment

of the snow discharge angle Keep children and

pets away.

12o Do not overload the machine capacity by

attempting to clear snow at too fast a rate.

13. Neveroperate the snow thrower at high transport

speeds on slippery surlaces. Look behind and

use care when backing.

14.. Never direct discharge at bystanders or allow

anyone in front of the snow thrower..

15. Disengage power to the auger/impeller when

snow thrower is transported or not in use.

16. Use only attachments and accessories approved

by the manufacturer of the snow thrower (such

as tire chains, electric start kitS, etc )

'17. Never operate the snow thrower without good

visibility or light,. Always be sure ot your footing,

and keep a firm hold on the handles Walk; never

run..

MAINTENANCEAND STORAGE

1.. Check shear bolts and other boils frequently for

improper tightness to be sure the snow thrower

is in sate working condition_

2o Never store the snow thrower with tuel in the fuel

tank inside a building where ignition sources are

present such as hot water and space heaters,

clothes dryers, and the like.. Allow the engine to

coot before storing in any enclosure..

3 Always refer to operator's manual instructions

for important details if the snow thrower is to be

stored tor an extended period,

4o Maintain or replace safety and instruction labels,

as necessary.

5,. Run the snow thrower a tew minutes after

throwing snow to prevent freeze-up of the auger/

impeller°

WARNING

This snow thrower is for use on sidewalks,

driveways, and other ground level surfaces.

CAUTION should be exercised while using on

steep sloping surfaces. DO NOT USE SNOW

THROWER ON SURFACES ABOVE GROUND

LEVEL such as roofs of residences, garages,

porches or other such structures or bulldingso

LOOK FOR THIS SYMBOL TO POINT OUT---]

CAUTION:

ING AUGER,

_LOTH1NG AWAY!

DISCHARGE CHUTE!

_ IMPORTANT SAFETY PRECAUTIONS_ IT !

MEANS--ATTENTION!!! BECOME ALERT!!! _

YOUR SAFETY IS INVOLVED_ /

3

CONGRATULATIONS on your purchase of a Sears

Craftsman Snow Thrower It has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center/Department Sears has competent, wetHrained

technicians and the proper tools to service or repair this

unil

Please read and retain this manual The instruclions will

enable you Io assemble and maintain your snow thrower

]roperly, Always observe the "SAFETY RULES/

MODEL

NUMBER 536 886540

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE REAR

OF THE SNOW THROWER HOUSING

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE

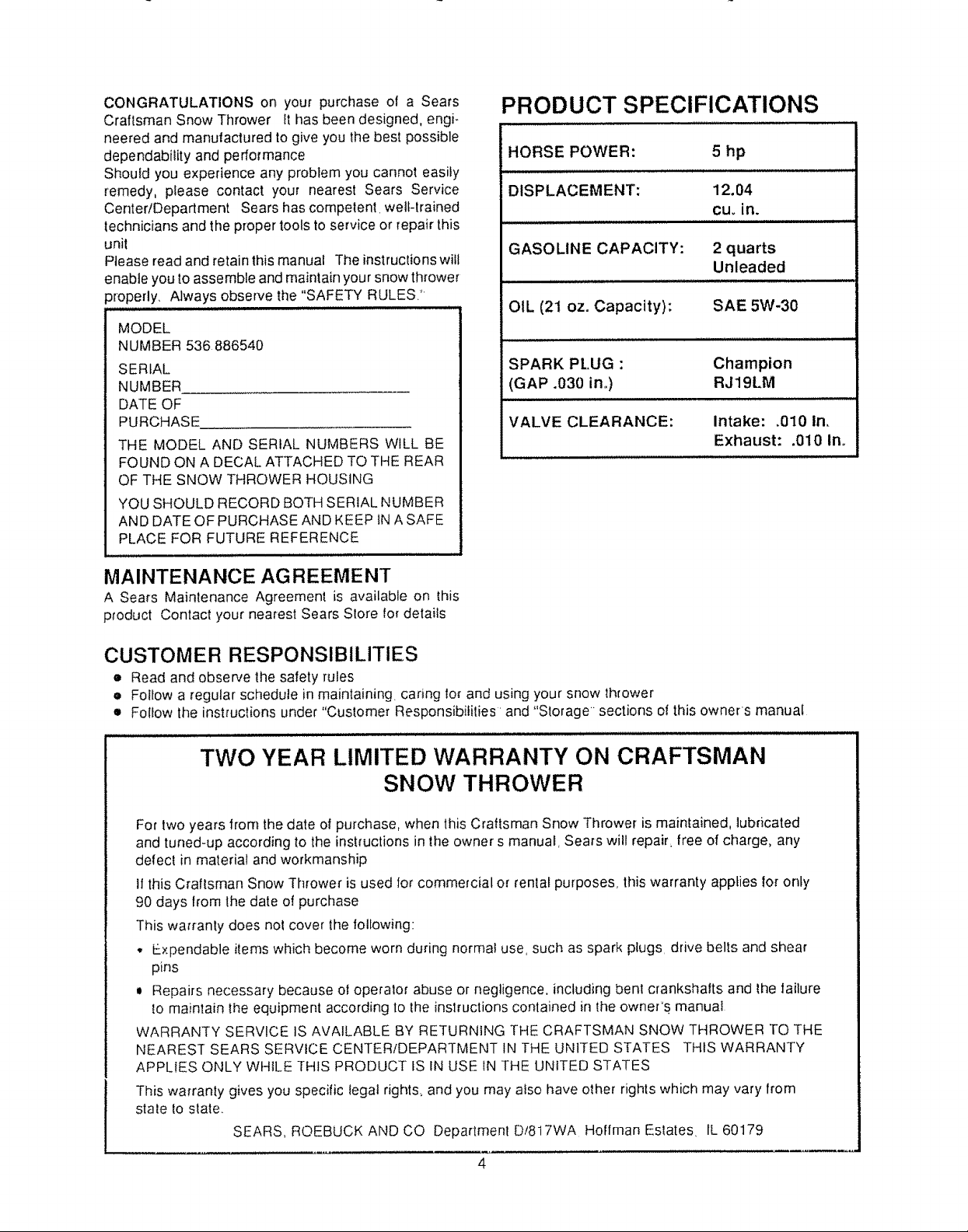

PRODUCT SPECIFICATIONS

HORSE POWER: 5 hp

DISPLACEMENT: 12.04

cu_ in.

GASOLINE CAPACITY: 2 quarts

Unleaded

OIL (21 oz. Capacity): SAE 5W-30

SPARK PL.UG :

(GAP .030 in.)

VALVE CLEARANCE: Intake: .010 In,

Champion

RJ19LM

Exhaust: .010 In.

MAINTENANCE AGREEMENT

A Sears Mainlenance Agreement is available on this

product Contact your nearest Sears Slore for details

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules

o Follow a regular schedule in maintaining, caring to_ and using your snow thrower

• Follow the instructions under "Customer Responsibilities and "Storage sections ot this owners manual

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

SNOW THROWER

For lwo years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated

and tuned-up according to the instructions in the owner s manual, Sears will repair, free of charge, any

detecl in material and workmanship

1Ithis Craftsman Snow Thrower is used Ior commercial or renlat purposes, this warranty applies !or only

90 days from the date of purchase

This warranty does not cover the following:

,, Expendable ilems which become worn during normal use, such as spark plugs, drive belts and shear

pins

t Repairs necessary because ol operator abuse or negligence, including benl crankshalts and lhe lailure

to maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES THIS WARRANTY

APPLIES ONLY WHtLE THIS PRODUCT IS IN USE IN THE UNITED STATES

This warranly gives you specific legal rights, and you may also have other rights which may vary from

state !o slate,

SEARS. ROEBUCK AND CO Department Di817WA Hoflman Estates_ IL 60179

4

TABLE OF CONTENTS

SAFETY RULES ....................................................2,3

PRODUCT SPECIFICATIONS ..............................4

CUSTOMER RESPONSIBILITIES .......4,15-!7

WARRANTY .......................................................................4

TABLE OF CONTENTS .............................................5

INDEX ........................................................................................5

ASSEMBLY .............................................................6-9

A

Adjustment:

Belt .....................................................................19,20

Belt Guide .................................................21

Cable .......................................................19

Carburetor ..............................................23

Friction Wheel ...............................2o,2I

Spark Plug .....:...........................................23

Traction and Auger ........................19,20

Assembly:

Crank Assembly .......................................8-9

Shifter Lever ............................................9

Skid Height Adjustment ................7, 19

Unpacking .................................................7

Belts:

Adjust Belts .....................................19,20

Bett Guide Adjustment ....................21

Replace Belts ..................................20

Cables, Ciutch ..................................7, 9, 19

Carburetor: ......................................................24

Choke .................................10, tl, 13,14

Clutch, Levers .........................................1O,11

Controls:

Engine ....................................10, 11, 13, 14

Snow Thrower .....................................t0

Crank:

Adjusting Rod ....................................8, 18

Assembly .....................................................................8

Operation .............................................................11

Customer Responsibilities ...........4,15-17

Agreement ....................................................4

Auger Gear Box .....................................17

Auger Shaft .........................................16

Engine ................................................t 7

General Recommendations ................16

Hex Shall and Gears ............................I7

Drive, Auger ....................................................1t

Drive, Traction ...........................................11

Deflector, Snow Chute .............................11

Engine:

Control ................................10, 11, I3, 14

Oil Cap ....................................................12, t7

Oil Change ..................._ ................16

Oil Level.......................:_....................12, 17

Oit Type .................................................4, 12, 17

Speed Governor ........................................26

Starling, Electrically .........................13

Starling, Manually ..................................t4

Storage ...................................................25

B

C

D

E

Fuel, Type ......................................................4, 12

Fuel, Storage .................................!2, 25

Friction Wheel:

Adjustment .............................................21

Replacement ........................................22

Gears:

Auger Gear Box ...............................I7

Hex Shaft ..................................................17

Handle, Upper and Lower ........................7

Height Adjust Skids ..........................7, 18

Hex Shaft ........................................................t7

Ignition, Key .................... 10, 11, I3, 14

Index .........................................................5

Levers:

Auger Drive Ctutch .............7, 10, tl, 19

Choke ................................!0, tl, 13, 14

Shifter ..............................................9, 10, 11

Throttle Control ..................I0, t 1, I3, t4

Traction Drive Clutch .... 7, 10, ! I, 19

Lubrication:

Auger Gear Box ......................................17

Auger Shaft ................................................16

Disc Drive Plate ...........................................16

Engine .......................................12,17,25

Hex Shaft and Gears ............................17

Oil:

Engine .........................................4, 12, 17

Extreme Cold Weather .................12,17

Storage ..........................................................25

Type .....................................................4, 12, 17

Operation:

Engine Controls ................10, 11, 13,14

Operating Snow Thrower.., tt, 12, 15

LockoutPin, Wheel ...............................12

Operating Tips .......................................14

Starling the Engine, Electric ...............t3

Starting the Engine, Recoil .................14

Snow Thrower Controls ....................10-12

Paris ..............................................................28-42

Primer Button .............................10, 1t, 13

Repair/Replacement Parts ............28-42

Recoil Starter .....................................13

Replacements:

INDEX

F

G

H

I

L

O

P

R

5

OPERATION ................................................... 10-14

SERVICE AND ADJUSTMENTS ..............18-24

STORAGE ..................................................... 25

TROUBLE SHOOTING ................................. 26

REPAIR PARTS (SNOW THROWER).,. 28-37

REPAIR PARTS (ENGINE) .................... 38-42

PARTS ORDERING/SERVICE ..........................44

Auger Shear Bolt ...................................23

Belts ..................................................19,20

Friction Wheel ................................21,22

S

Safety Rules.................................................2, 3

Service and Adjustments:

Auger Housing Height ..................7, 18

Auger Shear Bolt .......................................23

Belts .........................................................19-20

Belt Guide ..................................................21

Belt Replacements ...............................20

Cable ................................................... 7, 9, 19

Carburetor ...............................13,23, 25

Friction Wheel ............................21, 22

Spark Plug .......................................24

Service Recommendations .................25

Spark Plug ...........................................17, 24

Specifications ..................................................4

Speed Governor ............................. 23

Starting the Engine:

Recoil Start ...............................................13

Stopping the Engine ......................13, 14

Stopping the Snow Thrower ................11

Shipping Carton ............................ 6, 7

Skid Height ................................... 7, 18

Shifter Lever ...........................................9-11

Shear Bolts ...................................... 23

Storage .................................................25

T

Table of Contents ....................................5

Trouble Shooting Chart ..........................26

Toolsfor Assembly ...............................6

Traction Drive Belt .................. 19, 20

Tire Pressure ................................. 18

W

Warranty .........................................................4

Wheel, Lockout Pin ............................ t2

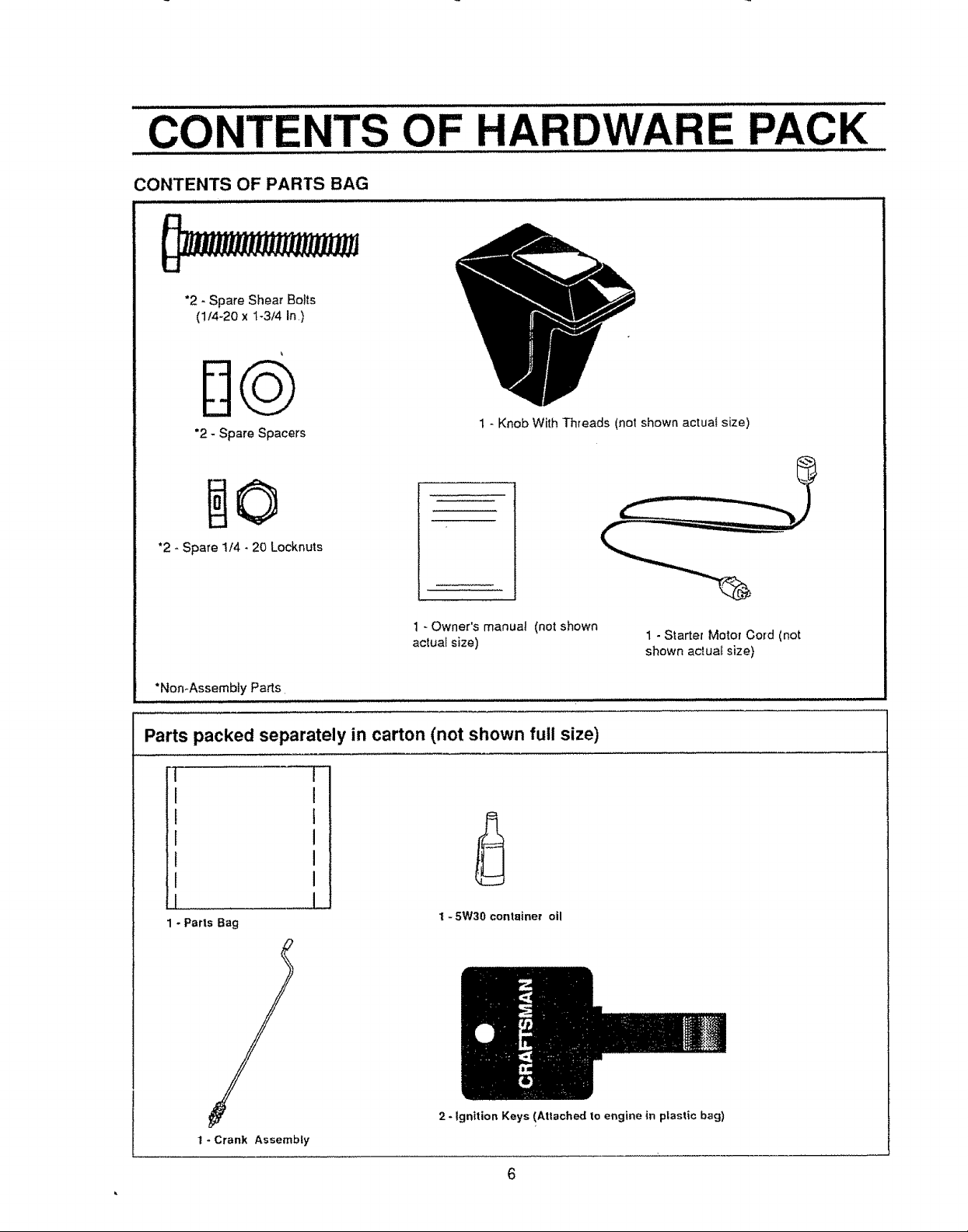

CONTEN rs OF HAR

CONTENTS OF PARTS BAG

*2 - Spare Shear Bolts

(1/4-20 x I-3/4 In)

D@

"2 - Spare Spacers

*2 - Spare 1/4 - 20 Locknuts

1 - Knob With Threads (not shown actua! size)

RE PACK

1 _ Owner's manua! (not shown

actual size)

"Non-Assembly Parts,

Parts packed separately in carton (not shown full size)

q

I

l

r

I

I

1 - Parts Bag

I - 5W30 container oil

1 - Starter Motor Cord (not

shown ac_ua_size)

t - Crank Assembly

2 - Ignition Keys (Attached to engine in plastic bag)

6

ASS

LY

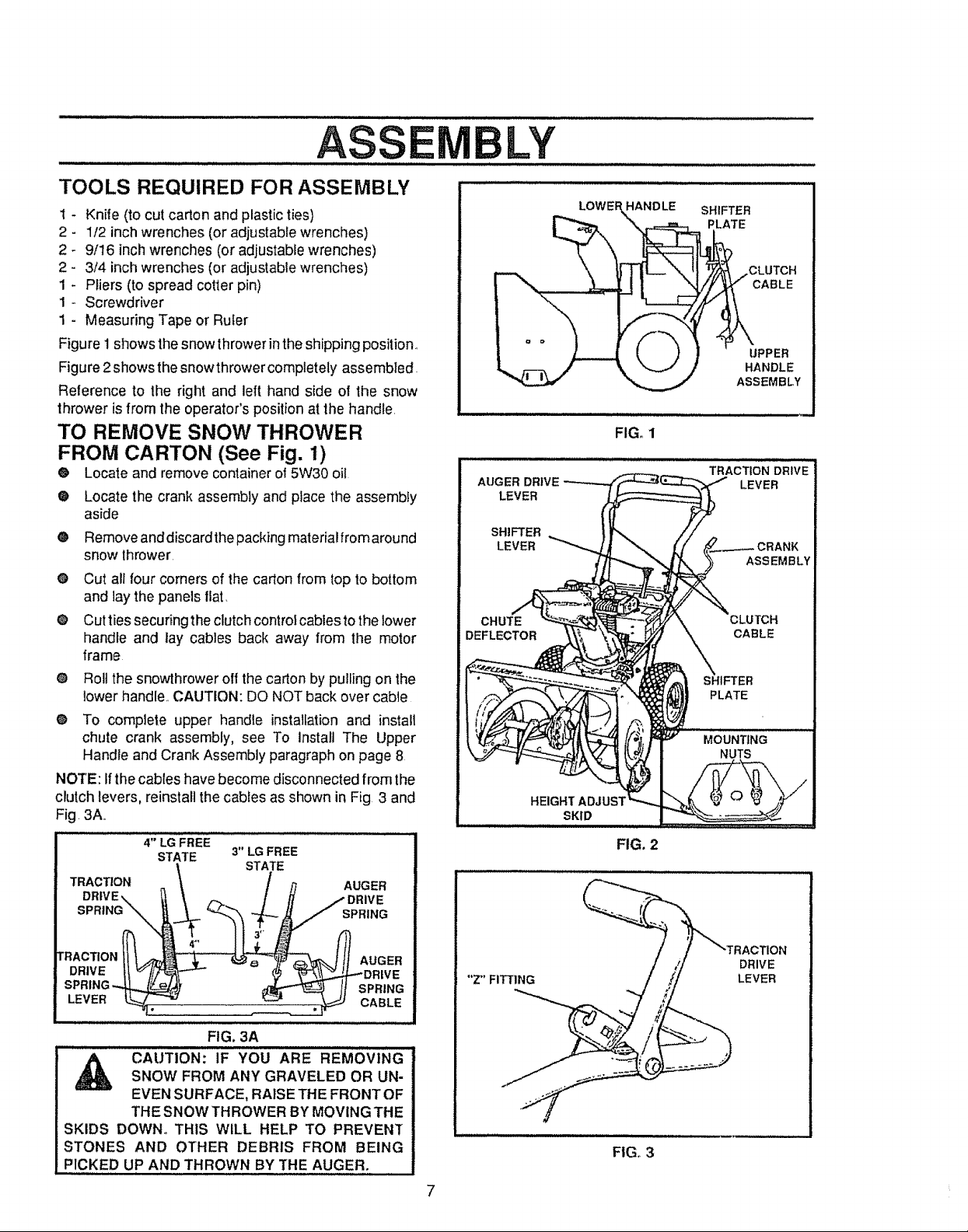

TOOLS REQUIRED FOR ASSEMBLY

1 - Knife (to cut carton and plastic ties)

2 - 1/2 inch wrenches (or adjustable wrenches)

2 - 9/16 inch wrenches (or adjustable wrenches)

2 - 3/4 inch wrenches (or adjustable wrenches)

1 - P_iers(to spread cotter pin)

1- Screwdriver

1 - Measuring Tape or Ruler

Figure 1 shows the snow throwerinthe shipping position.,

Figure 2showsthe snowthrower completely assembled.

Reference to the right and left hand side of the snow

thrower isfrom the operator's position at the handle,

TO REMOVE SNOW THROWER

FROM CARTON (See Fig. 1)

® Locate and remove container of 5W30 oil

®

Locate the crank assembly and place the assembly

aside

®

Remove anddiscardthe packing materialfrom around

snow thrower.

®

Cut all four corners of the carton from top to bottom

and lay the panels fiat,

®

Cutties securing the clutch control cables tothe lower

handle and lay cables back away from the motor

frame

® Roll the snowthrower off the carton by pulling on the

lower handle,,CAUTION: DO NOT back over cable

® To complete upper handle installationand install

chute crank assembly, see To Install The Upper

Handle and Crank Assembly paragraph on page 8

NOTE: Ifthe cables have become disconnected from the

clutch levers, reinstall the cables as shown in Fig 3 and

Fig, 3A,,

4" LG FREE

STATE 3" LG FREE

TRACTION _ / ,q AUGER

DRIVE,. "t_, / H -- DRIVE

STATE

i i iii,i i i

AUGER DRIVE

LEVER

SHIFTER

LEVER

CHUTE

DEFLECTOR

LOWEF

HEIGHT ADJUST

SKID

SHIFTER

PLATE

UPPER

HANDLE

ASSEMBLY

FIG. 1

TRACTION DRIVE

LEVER

FIG. 2

[ r%

DRIVEll _/_ ""- - $ '_L_.4"'DR_VE

SPRING_ _ If SPRING

LEVER °ABLE

FIG. 3A

,_ CAUTION: IF YOU ARE REMOVINGSNOW FROM ANY GRAVELED OR UN-

EVEN SURFACE, RAISETHE FRONTOF

THE SNOW THROWER BY MOVING THE

SKIDS DOWN° THIS WILL HELP TO PREVEN_

STONES AND OTHER DEBRIS FROM BEING

PICKED UP AND THROWN BY THE AUGER.

FION

DRIVE

"Z'FITTING

FIG. 3

7

LEVER

ASSEMBLV

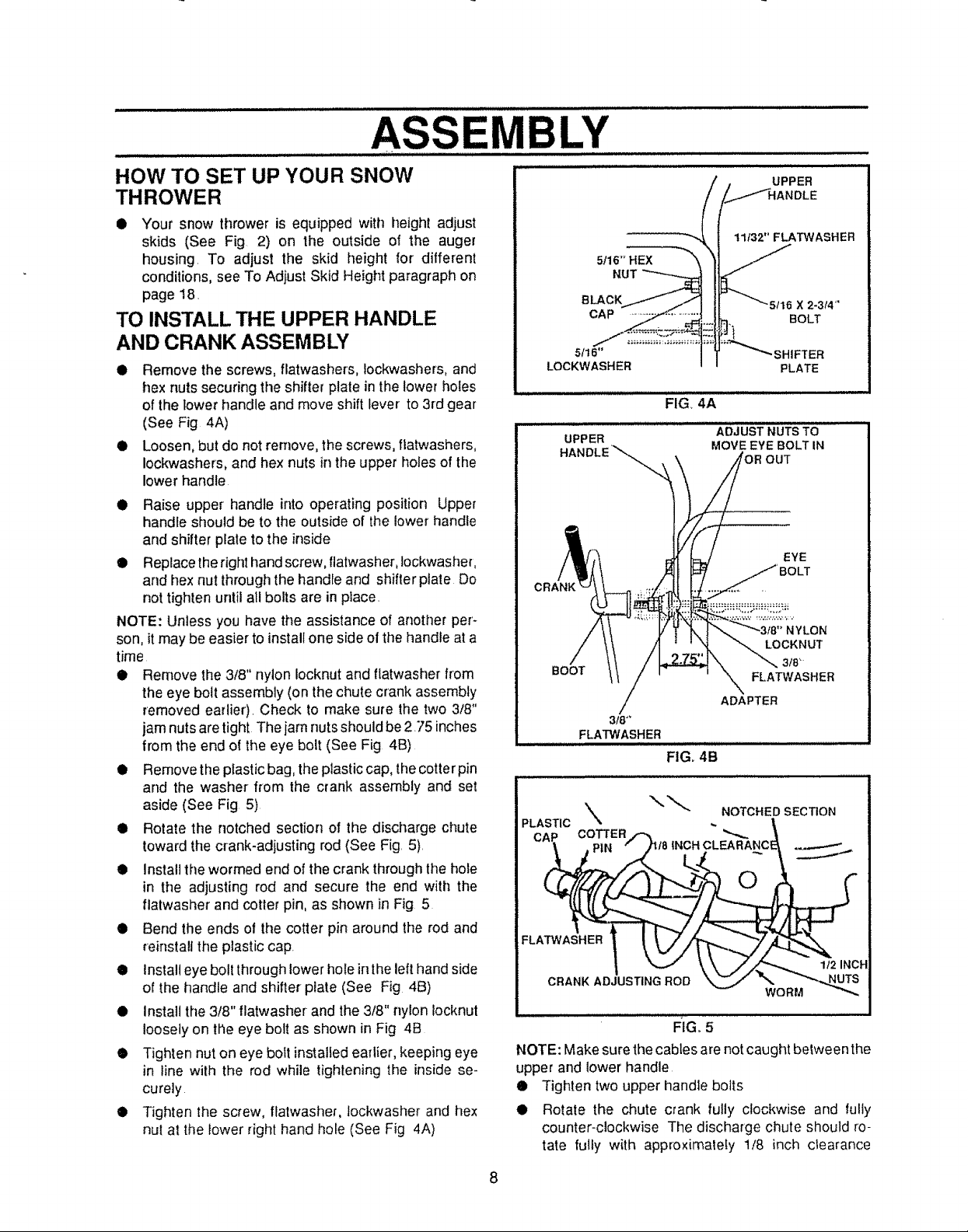

HOW TO SET UP YOUR SNOW

THROWER

@ Your snow thrower is equipped with height adjust

skids (See Fig 2) on the outside of the auger

housing, To adjust the skid height for different

conditions, see To Adjust Skid Height paragraph on

page 18,

TO INSTALL THE UPPER HANDLE

AND CRANK ASSEMBLY

• Remove the screws, flatwashers, Iockwashers, and

hex nuts securing the shifter plate in the lower holes

of the towerhandle and move shift lever to 3rd gear

(See Fig 4A)

• Loosen, but do not remove, the screws, flatwashers,

Iockwashers, and hex nuts in the upper holes of the

lower handle

I Raise upper handle intooperating position Upper

handle should be to the outside of the lower handle

and shifter plate to the inside

I Replacetheright hand screw, flatwasher,iockwasher,

and hexnut throughthe handle and shifter plate Do

not tighten until all bolts are in place.

NOTE: Unless you have the assistance of another per'-

son, itmay be easier to install one side of the handle at a

time

i Remove the 3/8" nylon Iocknut and flatwasher from

the eye bolt assembly (onthe chute crank assembly

removed earlier). Check to make sure the two 3/8"

jamnuts are tight The jam nuts should be 2 75 inches

from the end o{ the eye bolt (See Fig 4B)

• Remove the plastic bag,the plastic cap, the cotter pin

and the washer from the crank assembly and set

aside (See Fig 5)

I Rotate the notched section of the discharge chute

toward the crank-adjusting rod (See Fig, 5),

@ Install the wormed end of the crank throughthe hole

in the adjusting rod and secure the end with the

flatwasher and cotter pin, as shown in Fig 5

@ Bend the ends of the cotter pin around the rod and

reinstall the plastic cap.

• install eye bolt throughlower hole in thelefthand side

of the handle and shifter plate (See Fig 4B)

I install the 3/8" tlatwasher and the 3/8" nylon Iocknut

loosely on the eye bolt as shown in Fig 4B

I Tighten nut on eye boft installedearlier, keeping eye

in line with the rod while tighteningthe insidese-

curely

i Tighten the screw, flatwasher, lockwasher and hex

nut at the towerright hand hole (See Fig 4A)

UPPER

11f32" FLATWASHER

X 2-3/4'"

5/16"

LOCKWASHER

UPPER

HANDLE'_,

BOOT

318""

FLATWASHER

FIG 4A

ADJUST NUTS TO

MOVE EYE BOLT IN

ADAPTER

FIGo 4B

PLATE

OUT

EYE

BOLT

NYLON

LOCKNUT

3/84

FLATWASHER

PLAST,C\ \ .NOTC.E{ SECTiON

CAP COTTERtt,,,,'_ t18

FLA L<.

NOTE: Make sure the cabtes are notcaught between the

upper and lower handle

• Tighten two upper handle bolts

• Rotate the chute crank fully clockwise and tully

- PiN INCH CLEARANCE_ _,,_

i _ \,".. .//S"'._ _/zINCH

RG_ 5

counter-clockwise The discharge chute should ro-

tate futly with approximately 1/8 inch clearance

8

ASSE LY

@ Rotate the chute crank fully clockwise and fully

counter-clockwise. The discharge chute should ro-

tate fully with approximately 1/8 inch clearance be-

tweenthe worm and the bottomof the notch (See Fig.

5)

® If the chute crank needs to be adjusted, go to lhe

Service andAdjustments sectionon page 18.Screws

securing chute clips at the base of the chute should

be slightly loose for easy rotation.

NOTE: Be sure the crank does not touch the side of the

engine or the cover will be scratched

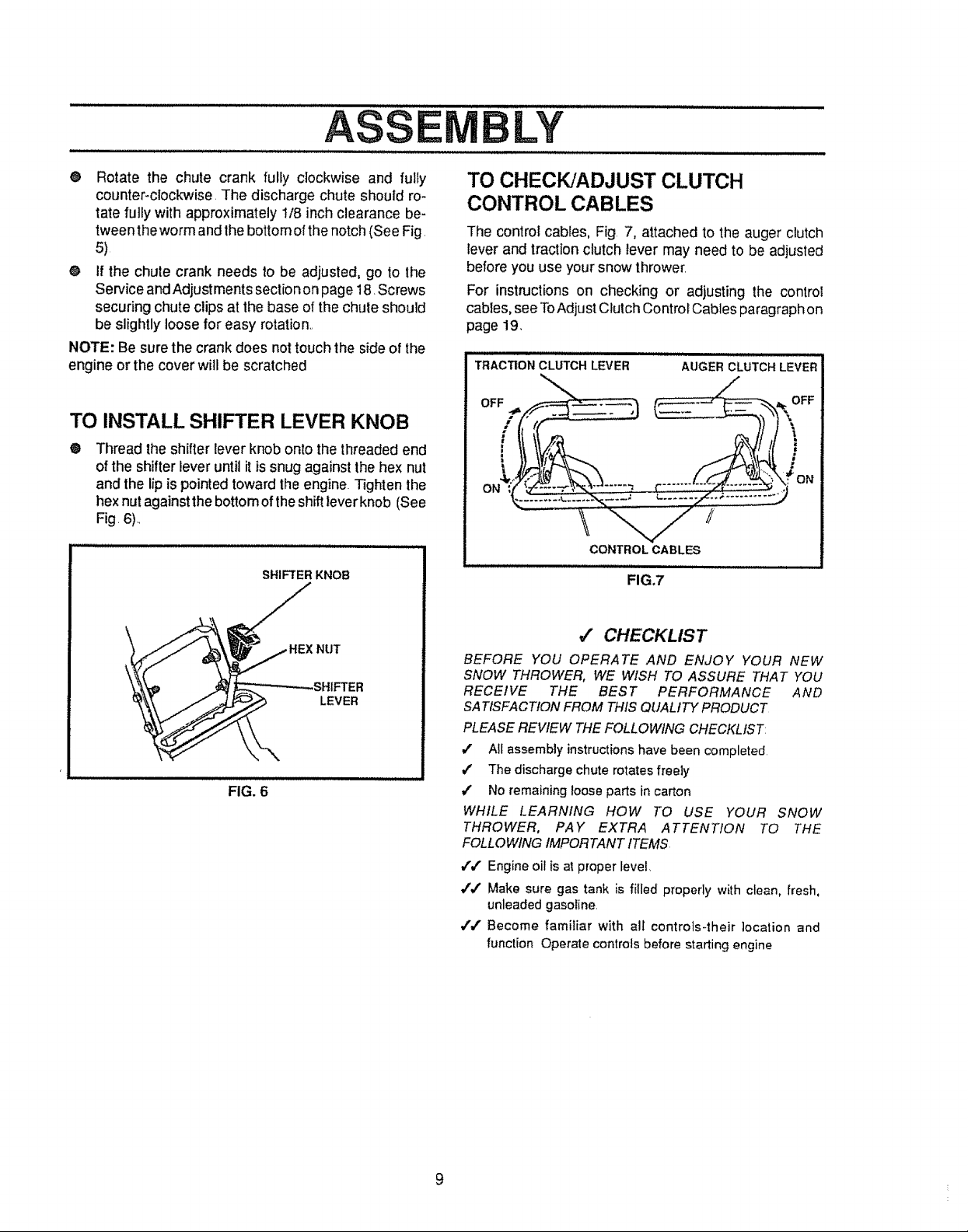

TO INSTALL SHIFTER LEVER KNOB

®

Thread the shifter lever knob ontothe threadedend

of the shifter lever until it issnug against the hex nut

and the lip is pointed toward Ihe engine. Tighten the

hex nutagainst the bottom ofthe shiftlever knob (See

Fig. 6)..

SHIFTER KNOB

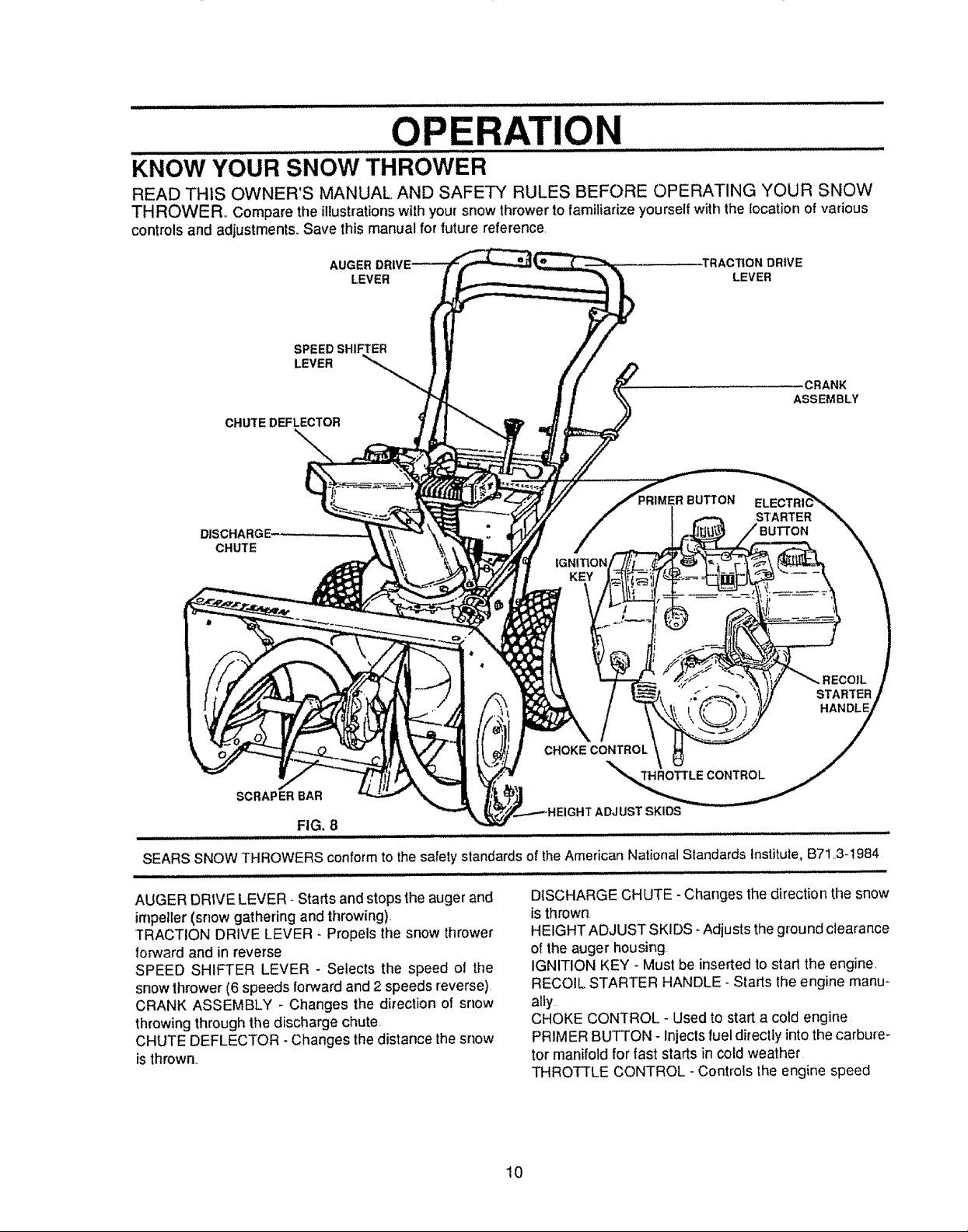

TO CHECK/ADJUST CLUTCH

CONTROL CABLES

The control cables, Fig. 7, attached to the auger clutch

lever and traction clutch lever may need to be adjusted

before you use your snow thrower.

For instructions on checking or adjusting the control

cabies, see ToAdjust Clutch Contro_Cables paragraph on

page 19.

TRACTION CLUTCH LEVER

CONTROLCABLES

FIG.7

AUGER CLUTCH LEVER

FIG. 6

LEVER

4' CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

SNOW THROWER, WE WISH TO ASSURE THAT YOU

RECEIVE THE BEST PERFORMANCE AND

SATISFACTIONFROMTHISQUALt7-YPRODUCT

PLEASEREVIEW THEFOLLOWINGCHECKLIST:

,l A_Iassemblyinstructionshave beencompleted

/ The discharge chute rotates freely

/ No remaining loose parts in carton

WHILE LEARNING HOW TO USE YOUR SNOW

THROWER, PAY EXTRA ATTENTION TO THE

FOLLOWINGIMPORTANTITEMS

/,/' Engineoilisatproperlevel

/4' Make sure gas tank is filled properly with clean, fresh,

unleaded gasoline,

v'/ Become familiar with all controls-their ]ocation and

function Operate controls before starting engine

9

u,l/,

OPERATION

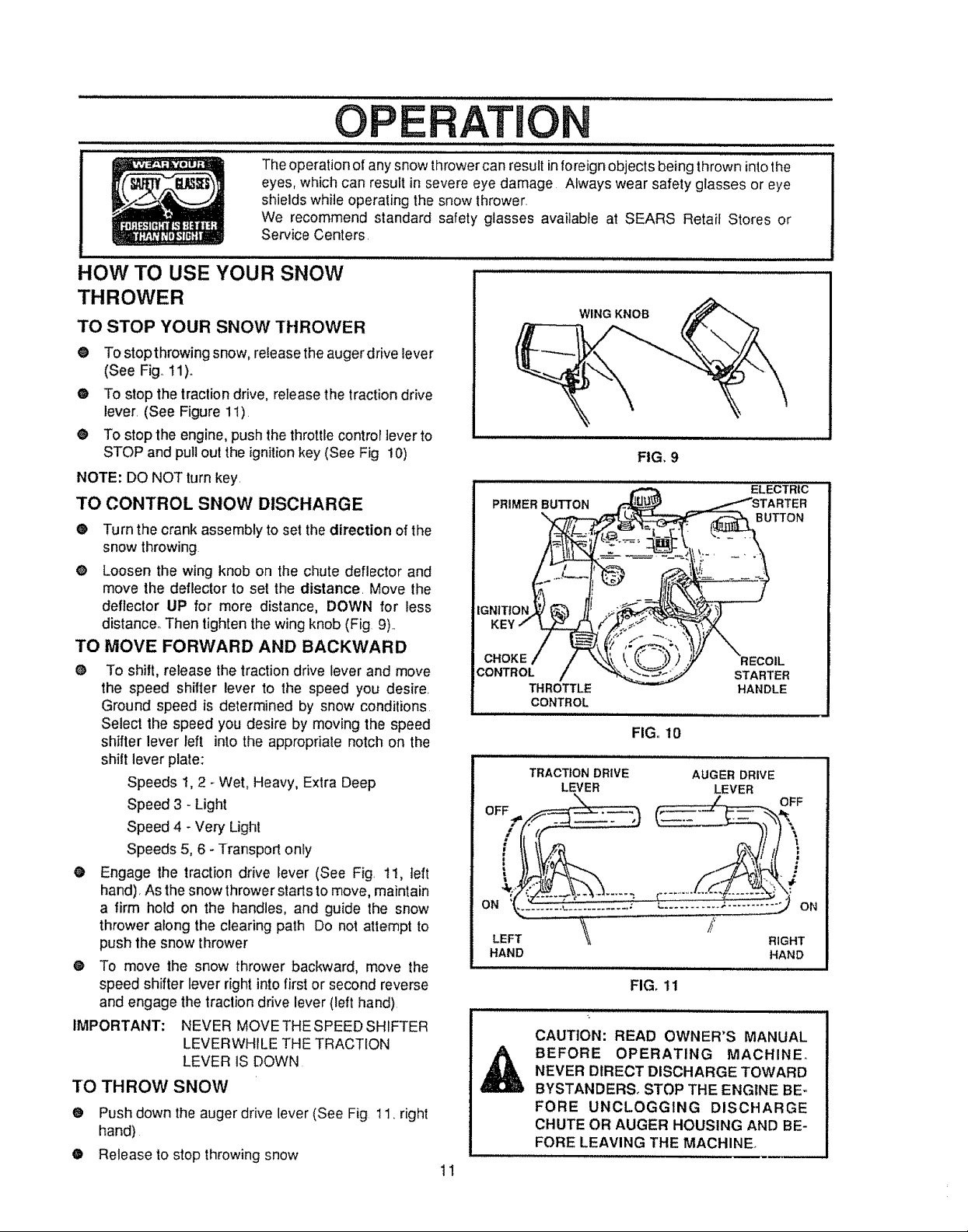

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR SNOW

THROWER_ Compare the illustrations with your snow thrower to familiarize yourself with the location of various

controls and adjustments. Save this manual for future reference,

TRACTION DRIVE

LEVER LEVER

SPEED SHIFTER

LEVER

CRANK

ASSEMBLY

CHUTE DEFLECTOR

--..

IMER BUTTON

STARTER

DISCHARGE,

CHUTE

KEY

STARTER

HANDLE

CHOKE CONTROL

THROTTLE CONTROL

SCRAP ER BAR

ADJUST SKIDS

FIG. 8

SEARS SNOW THROWERS conform to the safety standards of theAmerican National Standards Institute, B71,,3-1984

AUGER DRtVE LEVER * Starts and stops the auger and

impeller (snow gathering and throwing),

TRACTION DRIVE LEVER- Propels the snow thrower

forward and in reverse

SPEED SHIFTER LEVER - Selects the speed ol the

snow thrower (6 speeds forward and 2 speeds reverse).

CRANK ASSEMBLY - Changes the direction of snow

throwing through the discharge chute

CHUTE DEFLECTOR -Changes the distance thesnow

isthrown,_

DISCHARGE CHUTE - Changes the direction the snow

isthrown

HEIGHT ADJUST SKIDS- Adjusts the ground clearance

of the auger housing.

IGNITION KEY - Must be inserted to start the engine,

RECOIL STARTER HANDLE- Starts the engine manu-

ally

CHOKE CONTROL - Used to start a cold engine

PRIMER BUTTON - injeclsfuel directiy into the carbure-

tor manifold for fast starts in cold weather

THROTt-LE CONTROL -Controls the engine speed

10

OPE TlO

Theoperation of any snow thrower can result inforeign objects being thrown into the

eyes, which can result in severe eye damage Always wear safety glasses or eye

shields while operating the snow thrower.

We recommend standard safety glasses available at SEARS Retail Stores or

Service Centers.

HOW TO USE YOUR SNOW

THROWER

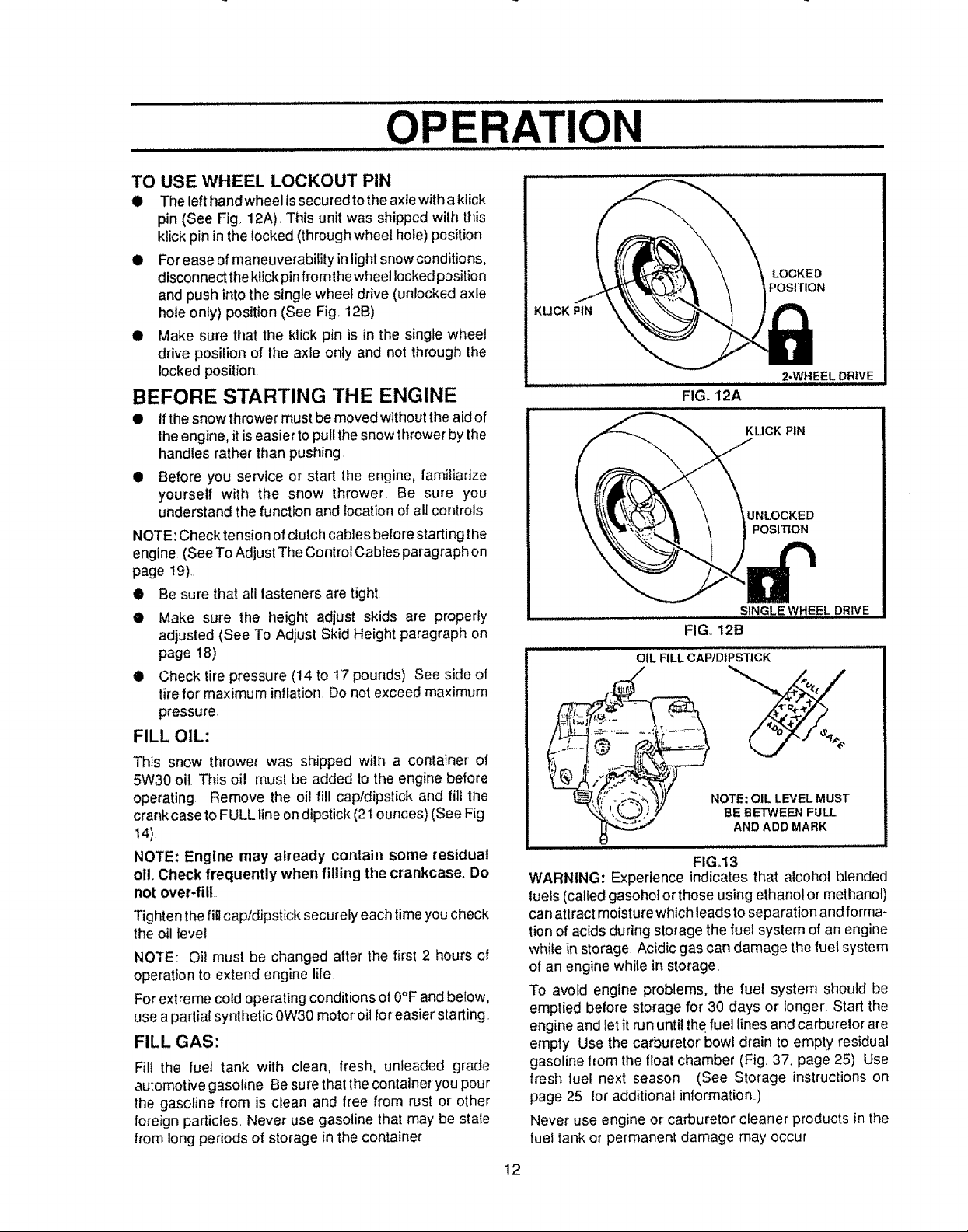

TO STOP YOUR SNOW THROWER

@ To stopthrowing snow, release theaugerdrive lever

(See Fig°11).

@ To stop the traction drive, release the traction drive

lever. (See Figure 1!)

® To stop the engine, push the throttle control lever to

STOP and pull out the ignition key (See Fig 10)

NOTE: DO NOT turnkey.

TO CONTROL SNOW DISCHARGE

• Turn the crank assembly to set thedirection of the

snow throwing

O Loosen the wing knob on the chute deflector and

move the deflector to set the distance. Move the

deflector UP for more distance, DOWN for less

distance° Then tighten thewing knob (Fig 9).

TO MOVE FORWARD AND BACKWARD

0 To shilt, release the traction drive lever and move

the speed shifter lever to the speed you desire.

Ground speed is determined by snow conditions.

Select the speed you desire by moving the speed

shifter lever left into the appropriate notch on the

shift lever plate:

Speeds 1,2 _Wet, Heavy, Extra Deep

Speed 3 - Light

Speed 4 - Very Light

Speeds 5, 6 - Transport only

O Engage the traction drive lever (See Fig. 11, teft

hand), Asthe snow thrower starts to move, maintain

a firm hold on the handles, and guide the snow

thrower along the clearing path Do not attempt to

push the snow thrower

® To move the snow thrower backward, move the

speed shifter lever right into first or second reverse

and engage the traction drive lever (left hand)

IMPORTANT: NEVER MOVE THE SPEED SHIFTER

LEVERWHILE THE TRACTION

LEVER IS DOWN

TO THROW SNOW

O Push down theauger drive lever (See Fig 11, right

hand)

O Release to stop throwingsnow

11

PRIMERBUTTON

\

CONTROL

THROTTLE

CONTROL

TRACTION DRIVE

ON

LEFT '_

HAND

CAUTION: READ OWNER'S MANUAL

BEFORE OPERATING MACHINE.

NEVER DIRECT DISCHARGE TOWARD

BYSTANDERS_ STOP THE ENGINE BE-,

FORE UNCLOGGING DISCHARGE

CHUTE OR AUGER HOUSING AND BE-

FORE LEAVING THE MACHINE,

WING KNOB

/

LEVER

FIG, 9

ELECTRIC

BUTTON

STARTER

HANDLE

FIG, 10

AUGER DRIVE

LEVER

FIG. 11

OPERATION

TO USE WHEEL LOCKOUT PIN

• The left hand wheel issecured tothe axlewith a klick

pin (See Fig., 12A), This unit was shipped with this

klick pin in the locked (through wheel hole) position

• Forease of maneuverability inlight snowconditions,

disconnect the klickpinfromthe wheel lockedposition

and push into the single wheel drive (unFockedaxle

hole only) position (See Fig, 12B)

• Make sure that the klick pin is in the single wheel

drive position of the axle only and not through the

lockedposition

BEFORE STARTING THE ENGINE

• Ifthe snow thrower must bemoved without the aid of

theengine, itis easier toputlthe snow thrower bythe

handles rather than pushing

II Before you service or start the engine, familiarize

yourself with the snow thrower, Be sure you

understand the function and location of all controls

NOTE: Check tension of clutch cables before starting the

engine (See To Adjust The Control Cables paragraph on

page 19),

• Be sure that all fasteners are tight

• Make sure the height adjust skids are properly

adjusted (See To Adjust Skid Height paragraph on

page 18),

• Check tire pressure (14 to 17 pounds) See side of

tirefor maximum inflation Do not exceed maximum

pressure

FILL OIL:

This snow thrower was shipped with a container of

5W30 oil This oil must be added to tile engine before

operating Remove the oil fill cap!dipstick and fill the

crankcase to FULL line ondipstick (21ounces) (SeeFig

14)

NOTE: Engine may already contain some residual

oil Check frequently when filling the crankcase, Do

not over.fill

Tightenthe fillcap/dipstick securely each time youcheck

the oil level

NOTE: Oil must be changed after the first 2 hours of

operation to extend engine life

For extreme cord operating conditions of 0°F and below,

use a partial synthetic 0W30 motor oil foreasier starting.

FILL GAS:

Fill the fuel tank with clean, fresh, unleaded grade

automotive gasoline Be surethat thecontainer you pour

the gasoline from is clean and free from rust or other

foreign particles, Never use gasoline that may be stale

from long periods of storage inthe container

LOCKED

POSITION

KLICK PIN

2-WHEEL DRIVE

FIG. 12A

KUCK PIN

UNLOCKED

POSITION

SINGLE WHEEL DRIVE

FIG+ 12B

OIL FILL CA'PID|PSTICK

NOTE: OIL LEVEL MUST

BE BETWEEN FULL

AND ADD MARK

FIG.13

WARNING: Experience indicates that alcohol blended

fuels (called gasohot or those using ethanol or methanol)

can attract moisture which leads toseparation and forma-

tion of acids during storage the fuel syslem of an engine

while in storage Acidic gas carl damage the fuel system

of an engine while in storage,

To avoid engine problems, the fuel system should be

emptied before storage for 30 days or longer, Start the

engine and letit run until the fuel lines and carburetor are

empty Use the carburetor bowl drain to empty residual

gasoline from the floatchamber (Fig, 37, page 25) Use

fresh fuel next season (See Storage instructions on

page 25 foradditional information,)

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur

12

O E

ATION

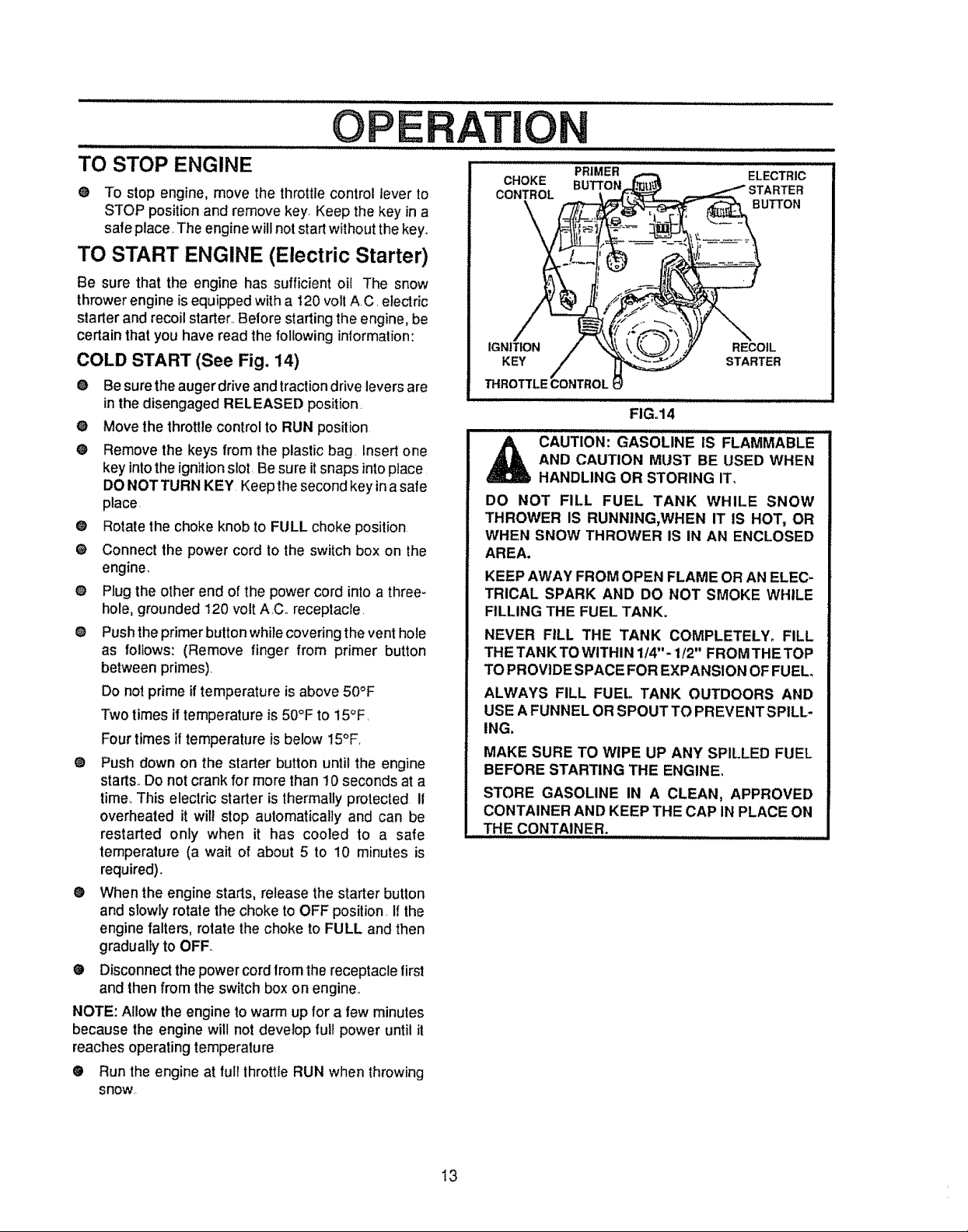

TO STOP ENGINE

O To stop engine, move the throttle control lever to

STOP position and remove key. Keep the key in a

safe place. The engine will notstart without the key.

TO START ENGINE (Electric Starter)

Be sure that the engine has sufficient oil The snow

thrower engine Jsequipped with a 120 voll AC. electric

starter and recoil starter_.Before starting the engine, be

certain that you have read the following intormatfon:

COLD START (See Fig. 14)

• Be sure the augerdrive and traction drive levers are

in the disengaged RELEASED position.

@ Move the throttle control to RUN position

O Remove the keys from the plastic bag. Insert one

key intothe ignition slot Be sure itsnaps into place

DO NOT TURN KEY Keep the second key in a safe

place

@ Rotate the choke knob to FULL choke position

O Connect the power cord to the switch box on the

engine.

O Plug the olher end of the power cord intoa three-

hole, grounded 120 volt A.C. receptacle.

O Push the primer button while covering the vent hole

as follows: (Remove finger from primer button

between primes).

Do not prime if temperature is above 50°F

Two times if temperature is 50°F to 15°F.

Four times if temperature is below 15°F.

@ Push down on the starter button until the engine

starts.. Do not crank for more than 10 seconds at a

time.,This electric starter is thermally protected I1

overheated it will stop aulomatically and can be

restarted only when it has cooled to a safe

temperature (a wait of about 5 to 10 minutes is

required).

O

When the engine starts, release the starter button

and slowly rotate the choke to OFF position. If the

engine falters, rotate the choke to FULL and then

gradually to OFF

• Disconnect the power cord fromthe receptacle first

and then from the switch box on engine,.

NOTE: Allow the engine to warm up for a few minutes

because the engine will not develop full power until il

reaches operating temperature

O Run the engine at fufithrottle RUN when throwing

snow,

CHOKE BUTTON

CONTROL

IGNITION RECOIL

KEY STARTER

THROTTLE CONTROL

_ AUTION: GASOLINE IS FLAMMABLE

DO NOT FILL FUEL TANK WHILE SNOW

THROWER IS RUNNING,WHEN IT IS HOT, OR

WHEN SNOW THROWER IS IN AN ENCLOSED

AREA,

KEEP AWAY FROM OPEN FLAME OR AN ELEC-

TRICAL SPARK AND DO NOT SMOKE WHILE

FILLING THE FUEL TANK,

NEVER FILL THE TANK COMPLETELY, FILL

THE TANKTOWlTHIN 1/4"-1f2" FROMTHETOP

TOPROVIDE SPACE FOR EXPANSION OF FUEL

ALWAYS FILL FUEL TANK OUTDOORS AND

USE AFUNNEL OR SPOUT TO PREVENTSPILL.

ING,

MAKE SURE TO WIPE UP ANY SPILLED FUEL

BEFORE STARTING THE ENGINE,

STORE GASOLINE IN A CLEAN, APPROVED

CONTAINER AND KEEP THE CAP IN PLACE ON

TH E CONTAINER.

PRIMER ELECTRIC

BUTTON

FIGo14

AND CAUTION MUST BE USED WHEN

HANDLING OR STORING IT,

13

iiiii,

OPERATION

CAUTION: NEVER RUN ENGINE

,_ INDOORS OR IN ENCLOSED,

CARBON MONOXIDE, AN ODORLESS AND

DEADLY GAS. KEEP HANDS, FEET, HAIR AND

LOOSE CLOTHING AWAY FROM ANY MOVING

PARTS ON ENGINE AND SNOW THROWER.

WARNING: TEMPERATURE OF MUFFLER AND

NEARBY AREAS MAY EXCEED 150° F. AVOID

THESE AREAS°

DO NOT ALLOW CHILDREN OR YOUNG TEEN-

AGERS TO OPERATE OR BE NEAR SNOW

THROWER WHILE IT IS OPERATING.

• RELEASE AUGER DRIVE AND TRACTION

DRIVE LEVERS.

• MOVE THROI3FLE LEVER TO STOP POSI-

TION,

• REMOVE (DO NOT TURN) IGNITION KEY,

• DISCONNECT SPARK PLUG WIRE.

• DO NOT PLACE YOUR HANDS IN THE

AUGER OR DISCHARGE CHUTE. USE A

PRY BAR°

TO START ENGINE (Recoil Starter)

Be sure that the engine has sufficient oil. Belore starting

the engine, be certain that you have read the following

information:

COLD START (See Fig. 14)

• Be sure the auger drive and the tractiondrive levers

are inthe disengaged RELEASED position

Move the throttlecontrolto RUN positionO

O

Pull thestarter handle rapidly Do not allow the handle

to snap back, but allow it to rewind slowly while

keeping a firm hold on the starter handle.

• Asthe engine warms up and begins to operate eve nly,

rotate the choke knob slowly to OFF position If the

engine falters, return to FULL choke, then slowly

move to OFF choke position

NOTE: Allow the engine to warm up for a few minutes

because the engine will not develop full power until it

reaches operating temperature

• Runthe engine ator neat thetop speed whenthrowing

snow

POORLY VENTILATED AREAS.

ENGINE EXHAUST CONTAINS

CAUTION: DO NOT ATTEMPT TO RE-

MOVE ANY ITEM THAT MAY BECOME

LODGED IN AUGER WITHOUT TAKING

THE FOLLOWING PRECAUTIONS:

WARM START

Ifrestarting awarmenginealter a short shutdown, rotate

choke to OFF instead of FULL and do not push the

primer button.

FROZEN STARTER

If the starter isfrozen and will not turn engine:

@ Pull as much rope out of the starter as possible.

@ Release the starter handle and let it snap back

against the starter.

If the engine still fails to start, push the primer buttontwo

or three timesagain and repeat the two previous sleps

until the engine starts Then continue with the directions

for cold start

To help prevent possible freeze-up of recoil starter and

engine controls, proceed as follows after each snow

removal job

• With the engine running, pull the starter rope hard

with acontinuous full arm stroke three or four times

Pulling of starter rope will produce a loud clattering

sound. This is not harmful to the engine or starter.

• With the engine not running, wipe all snow and

moisture from the carburetor cover in area of control

levers Also move throttle control choke control, and

starter handle several times.

SNOW THROWING TIPS

® For maximum snow thrower efficiency in removing

snow, adjust ground speed, NEVER the throttle=Go

slower in deep, freezing, or wet snow. If the track

slips,reduce forward speed The engine isdesigned

to deliver maximum pedormance at full throttle and

should be run at this power setting at aUtimes.

• Most elficient snow throwing is accomplished when

the snow is removed irnmediately after it falls..

• For complete snow removal, slightly overlap each

path previously taken

• Thesnow shouldbedischarged downwind whenever

possible.

• For normal usage, setthe skids so that the scraper

baris 1/8"above theskids. Forexlremely hardpacked

snow surfaces, adjust the skids upward so that the

scraper bar louches the ground

• On gravel or'crushed rock surfaces, set the skids at

1-1/4" below the scraper bar (see To Adjust Skid

Height paragraph on page 18) Stones and gravel

musl not be picked up and thrown by the machine.

• After the snow throw!ng job has been completed,

allow the engine toidle for a few minutes, which will

melt snow and accumulated ice off the engine.

® Clean the snow thrower thoroughly after' each use.

• Remove ice and snow accumulation and all debris

from the entire snow thrower, and flush with water (if

possible) to remove all salt or other chemicals Wipe

snow thrower dry

14

GUSTO E

ES PaN S B/IIII'IIIIIII/Ij1/11¸¸¸¸1111ii LmTm ES

iiiiiiiiiiiiii i iiiiiii

SERVICE RECORDS

Fill in dates as you complete

regular service

After Before As Every Every Every Each Before

SCHEDULE

iiiii IIHIL II II

First 2 Each Needed 5 t0 25 Season Storage

hours Use Hours Hours Hours

Check Engine Oi! Level ,_ _

Change Engine Oil ,I_ _

Tighten All Screws and Nuts _ V _'

Lubricate All Pivot Points

Lubricate Auger Shaft (See Shear

iBolt Replacement)

Lubricate Disc Drive PlateZerk (See

ICustomer Responsibilities}

Check Auger Clutch Cable

Adjustment (See Cable Adjustment)

Check Traction Clutch Cable

Adjustment (See CableAdjustment)

Adjust Drive Belts V 'I

Check Fuel

Drain Fuel V,#

It'

!.," v"

........ i.

SERVICE

DATES

, , = l_

Replace Spark Plug _

GENERAL RECOMMENDATIONS

LUBRICATION CHART

The warrantyonthis snow thrower does not cover items

that have been subjected to operator abuse or negli-

gence, To receive full value from the warranty, operator

must maintain snow thrower as instructed inthis manual,

Some adjustments will need to be made periodically to

properly maintain your snow thrower

All adjustments inthe Service and Adjustments section of

Lubricate auger shafL

Coat with a clinging type

grease such as Lubr|plate or

fiber impregnated grease.,

this manual should be checked at least once each

season

AFTER FIRST USE

o Check for any loose or damaged pads

® Tighten any loose fasteners

• Check and maintain the auger_

• After each use, remove all snow and slush off the

snowthrowerto prevent freezing of auger orcontrols

® Check controls to make sure they are functioning

properly,

• tf any parts are worn or damaged, replace

immediately

t5

CUSTOMER RESPONSIBILITIES

,JJl,i

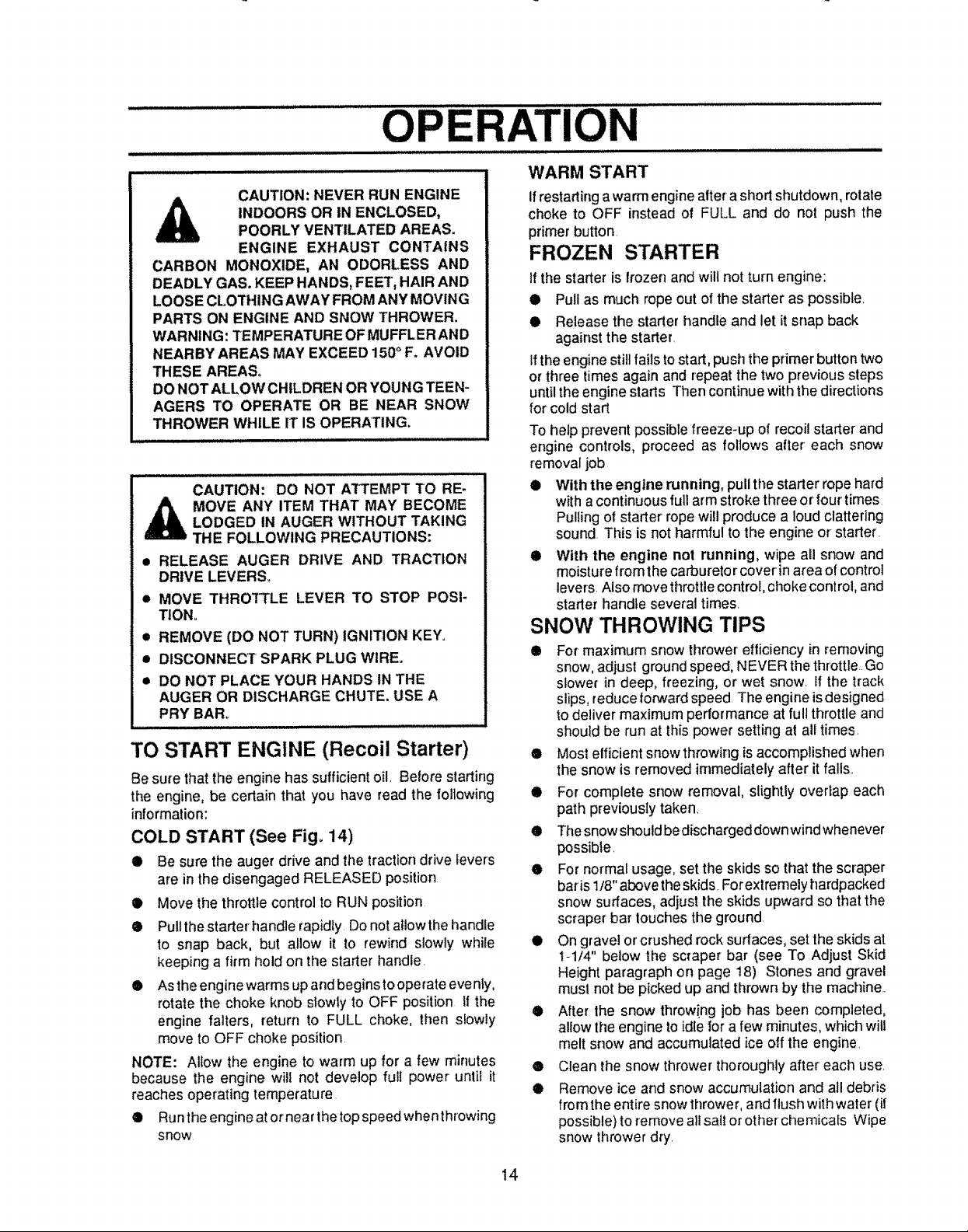

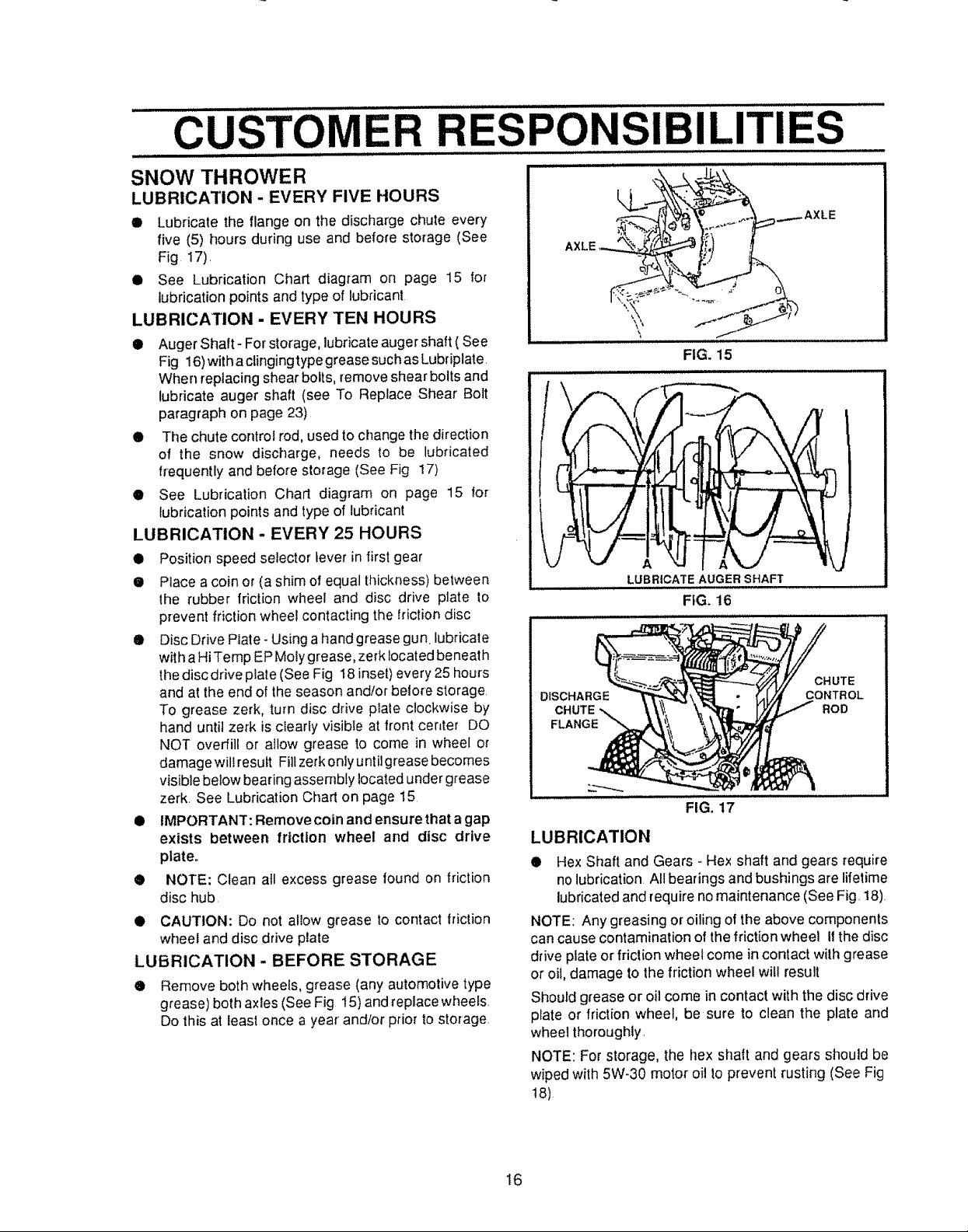

SNOW THROWER

LUBRICATION - EVERY FIVE HOURS

® Lubricate the flange on the discharge chute every

five (5) hours during use and before storage (See

Fig 17),

• See Lubrication Chart diagram on page 15 for

lubrication points and type of lubricant

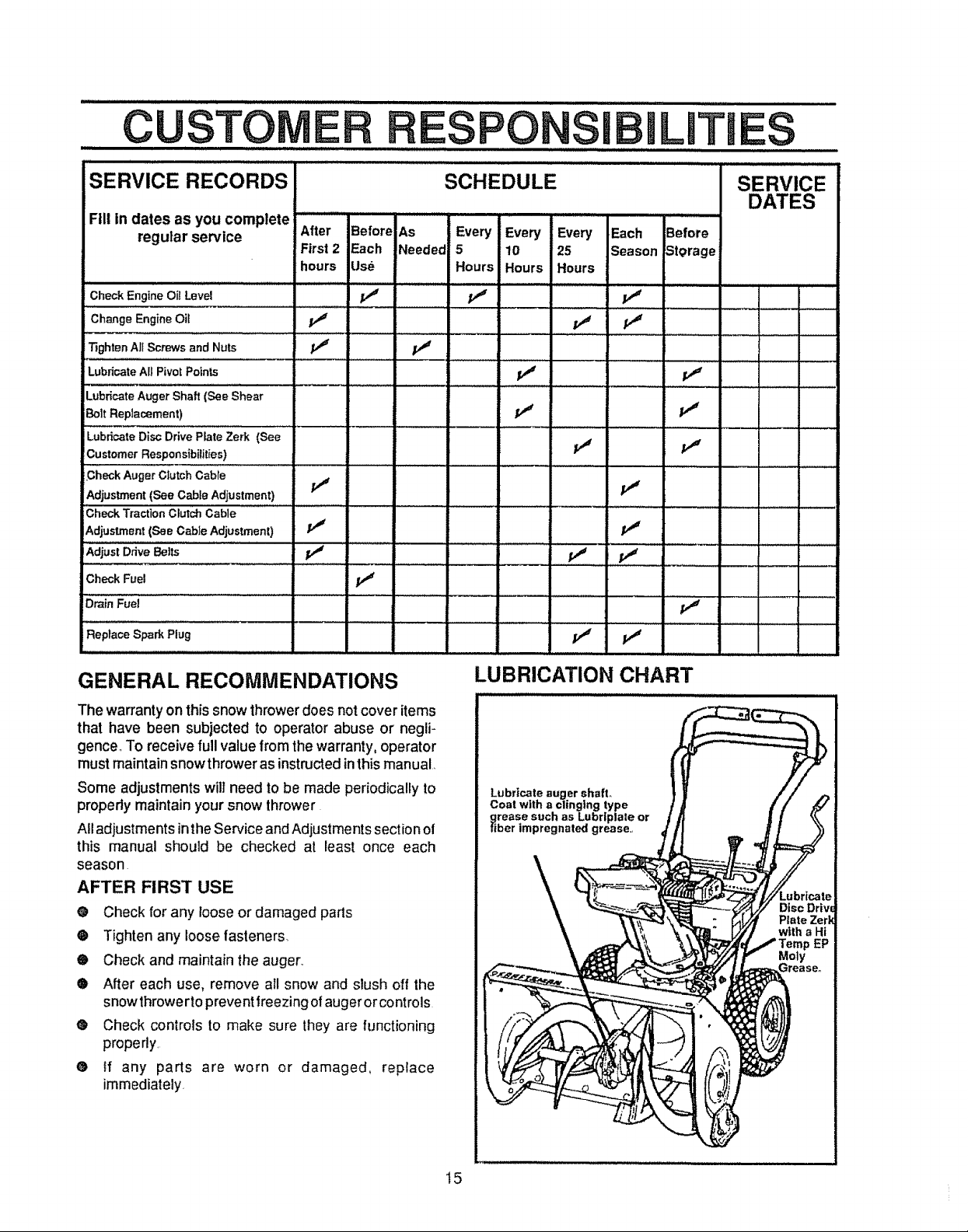

LUBRICATION - EVERY TEN HOURS

• Auger Shaft- For storage, lubricate auger shaft ( See

When replacingshear bolts, remove shear bolts and

• The chute control rod, used to change the direction

of the snow discharge, needs to be lubricated

• See Lubrication Chart diagram on page 15 for

LUBRICATION - EVERY 25 HOURS

• Position speed selector lever in first gear

• Place a coin or (a shim of equal thickness) between

• Disc Drive Plate- Using a hand grease gun lubricate

II IMPORTANT: Remove coin and ensure that a gap

® NOTE: Clean all excess grease lound on friction

t) CAUTION: Do not allow grease to contact friction

LUBRICATION - BEFORE STORAGE

® Remove both wheels, grease (any automotive type

lull

Fig 16)with aclinging type grease suchas Lubriplate,

lubricate auger shaft (see To Replace Shear Bolt

paragraph on page 23)

frequently and before storage (See Fig 17)

lubricationpoints and type of lubricant

the rubber friction wheel and disc drive plate to

prevent friction wheel contacting the friction disc

wit h a Hi Temp EP Moly grease, zerk iocated beneath

the disc drive plate (See Fig 18 inset) every 25 hours

and at the end of the season and/or before storage.

To grease zerk, turn disc drive plate clockwise by

hand until zerk is clearly visible at front cer_ter DO

NOT overfill or allow grease to come in wheel or

damagewill result Fill zerkontyuntiigrease becomes

visible below bearing assembly located under grease

zerk See Lubrication Chart on page 15

exists between friction wheel and disc drive

plate.

disc hub.

wheel and disc drive plate

grease) both axles (See Fig 15) and replacewheets.

Do this at least once a year and/or prior to storage,

i II i II i,illl i lll i _LL-

_ AXLE

AXLE _

FIG. 15

LUBRICATEAUGER'SHAFT

FIG. 16

DISCHARGE

CHUTE

FLANGE

FIG. 17

LUBRICATION

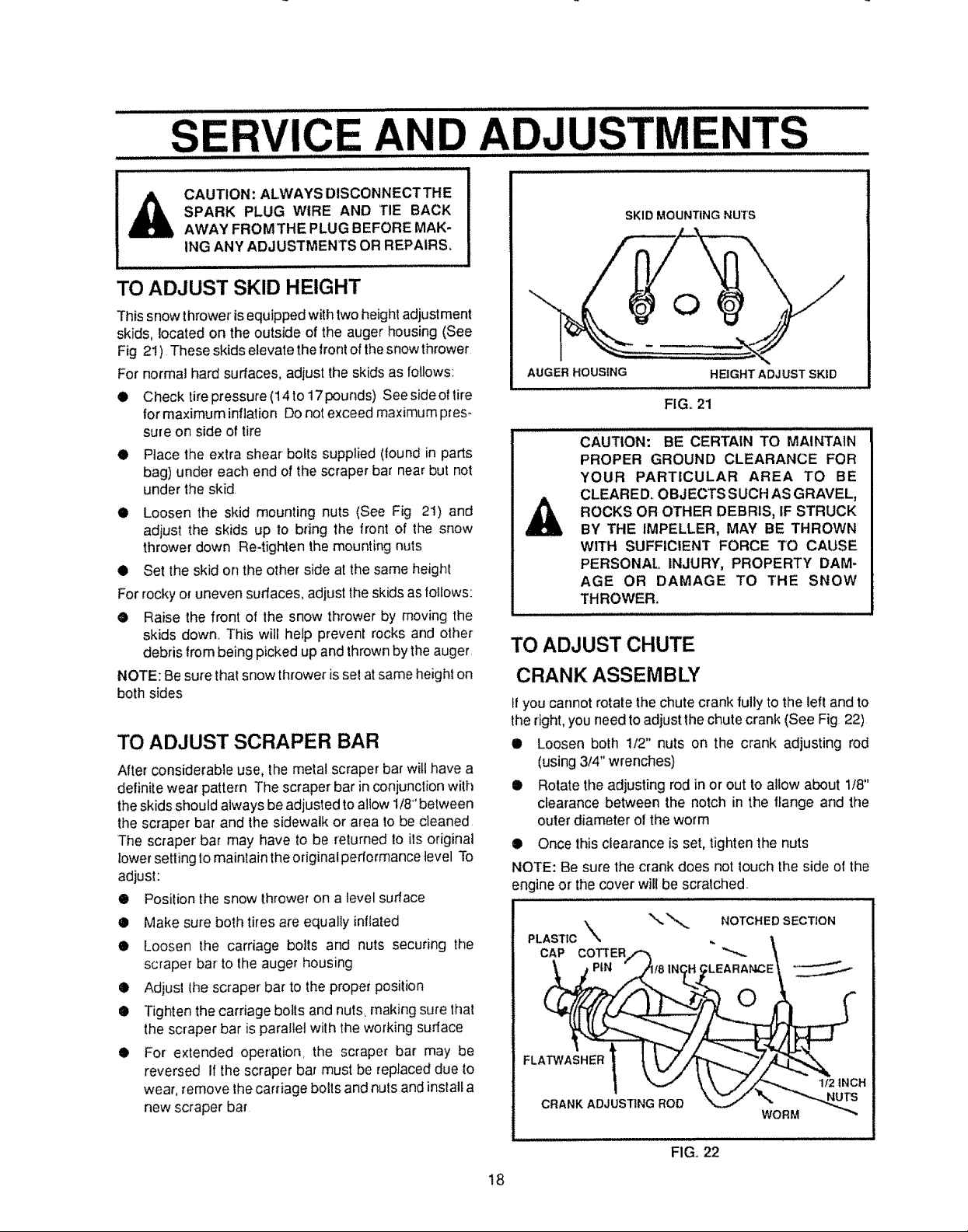

• Hex Shaft and Gears - Hex shaft and gears requ[re

no lubrication All bearings and bushings are lifetime

lubricated and requireno maintenance (See Fig, 18),

NOTE: Any greasing or oiling of the above components

can cause contamination of the friction wheel Ifthe disc

drive plate or friction wheel come in contact with grease

or oil, damage tothe friction wheel will result

Should grease or oil come in contact with the disc drive

plate or friction wheel, be sure to clean the plate and

wheel thoroughly.

NOTE: For storage, the hex shalt and gears should be

wiped with 5W-30 motor oil to prevent rusting (See Fig

18)

CHUTE

CONTROL

ROD

16

CUSTO E

PONSI LITI

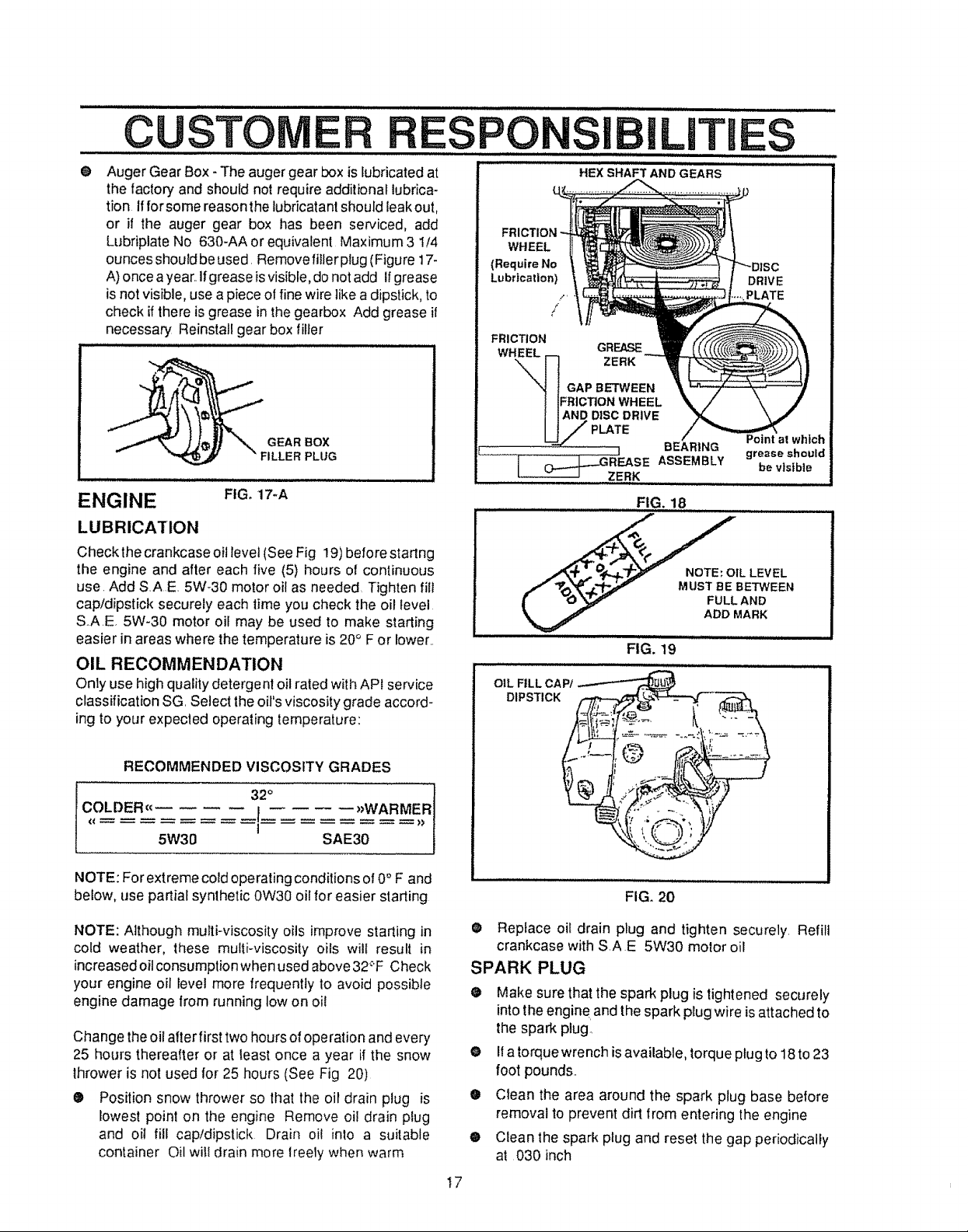

® Auger Gear Box - The auger gear box is lubricated at

the factory and should not require additional lubrica-

tion ifforsome reasonthe lubricatant should leakout,

or if the auger gear box has been serviced, add

Lubfiplate No 630-AA or equivalent Maximum 3 1/4

ounces shouldbeused, Removefillerplug (Figure 17-

A)once ayear,,Ifgrease is visible,do notadd Ifgrease

is notvisible, use a piece of fine wire like a dipstick, to

check if there is grease inthe gearbox Add grease if

necessary Reinstall gear box filler

GEAR BOX

° _ " FILLER PLUG

ENGINE FIG. 17-A

LUBRICATION

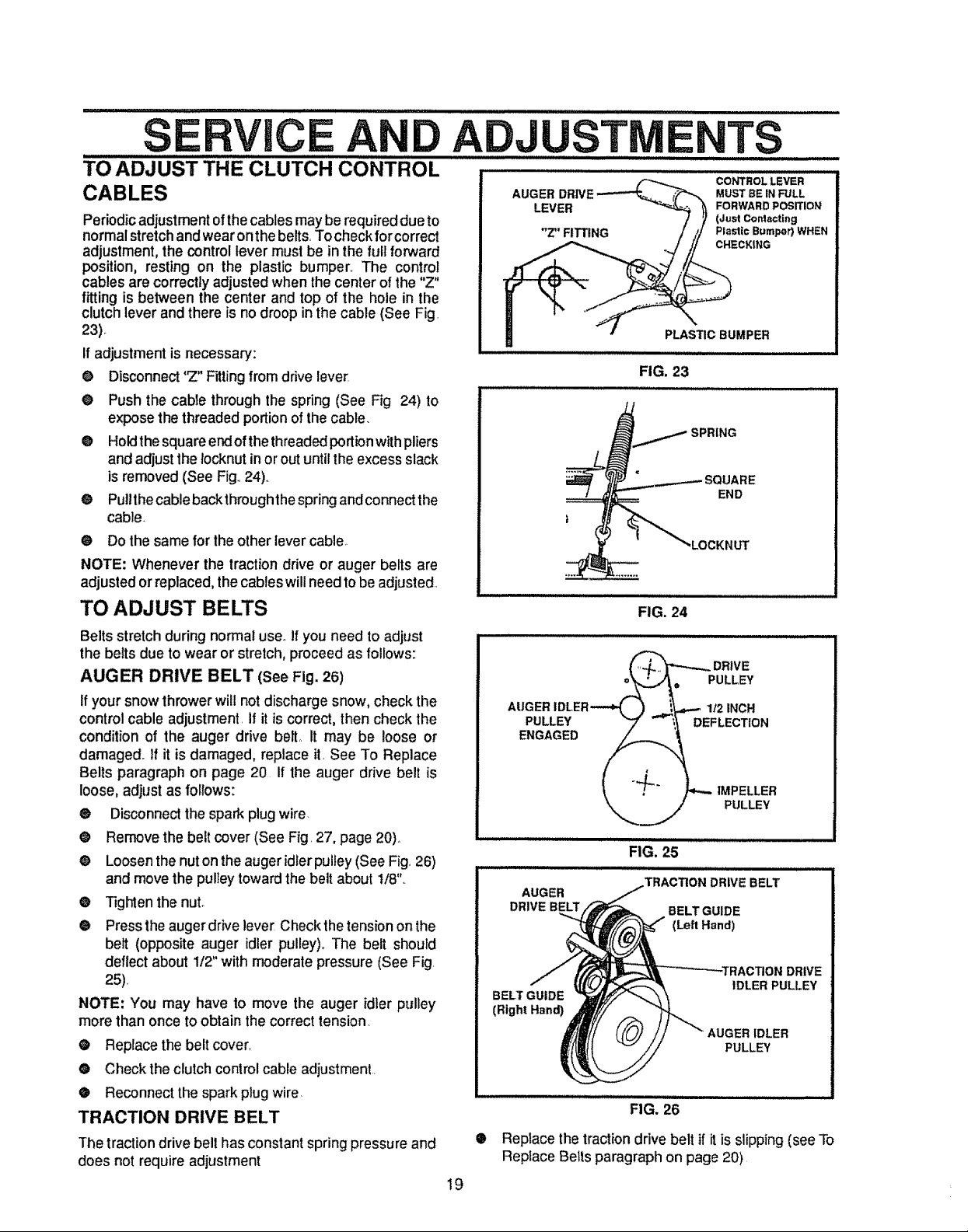

Check thecrankcase oil level (See Fig 19)before staring

the engine and after each five (5) hours o! continuous

USerAdd SAE. 5W-30 motor oil as needed Tighten lilt

cap/dipstick securely each time you check the oil level

S_A,E, 5W-30 motor oil may be used to make starting

easier in areas where the temperature is 20° For lower,,

OIL RECOMMENDATION

Only use high quality detergent oilrated with API service

classification SG Select theoil's viscosity grade accord-

ing to your expecled operating temperature:

HEX SHAFT AND GEARS

WHEEL

(Require No

Lubrication)

FRICTION

WHEEL

I -_'......... BEARING

i _GREASE ASSEMBLY

........ ZERK

GREASE

ZERK

GAP BETWEEN

=RICTtON WHEEL

AND DISC DRIVE

PLATE

........FIG. 18

_IL LEVEL

.,/ "1_'_'3_' "_eF" MUST BE BETWEEN

_" -0_ f" FULL AND

FIG. 19

OIL FILL CAP/

DIPSTICK

DRIVE

PLATE

Point at which

grease should

be visible

ADD MARK

RECOMMENDED VISCOSITY GRADES

32°

COLDER (€ I )_WARMER

5W30 SAE30

1

NOTE: For extreme cold operating conditions of0° F and

below, use partial synthetic 0W30 oil for easier starting

NOTE: Although multi-viscosity oils improve starting in

cold weather, these mufti-viscosity oils will result in

increased oil consumption when used above32_'FCheck

your engine oil level more frequently to avoid possible

engine damage from running low on oil

Change theoil afterfirst two hours ofoperation and every

25 hours thereafter or at least once a year if the snow

thrower is not used for 25 hours (See Fig 20)

• Position snow thrower so that the oil drain ptug is

_owestpoint on the engine Remove oHdrain plug

and oil fill cap/dipstick Drain oil into a suitable

container Oil will drain more lreely when warm

FIG. 20

O Replace oil drain plug and tighten securely, Refill

crankcase with S,A E 5W30 motor oil

SPARK PLUG

o

Make sure thatthe spark plug is tightened securely

into the engine,and the spark plug wire is attached to

the spark plug

o

Ifatorquewrench isavailable, torque plug to 18to 23

foot pounds..

O

Clean the area around the spark plug base before

removal to prevent dirt from entering the engine

0

Clean the spark plug and reset the gap periodically

at 030 inch

I7

SERVICE AND ADJUSTMENTS

CAUTION: ALWAYS DtSCONNECTTHE

SPARK PLUG WIRE AND TIE BACK

AWAY FROM THE PLUG BEFORE MAK-

ING ANY ADJUSTMENTS OR REPAIRS.

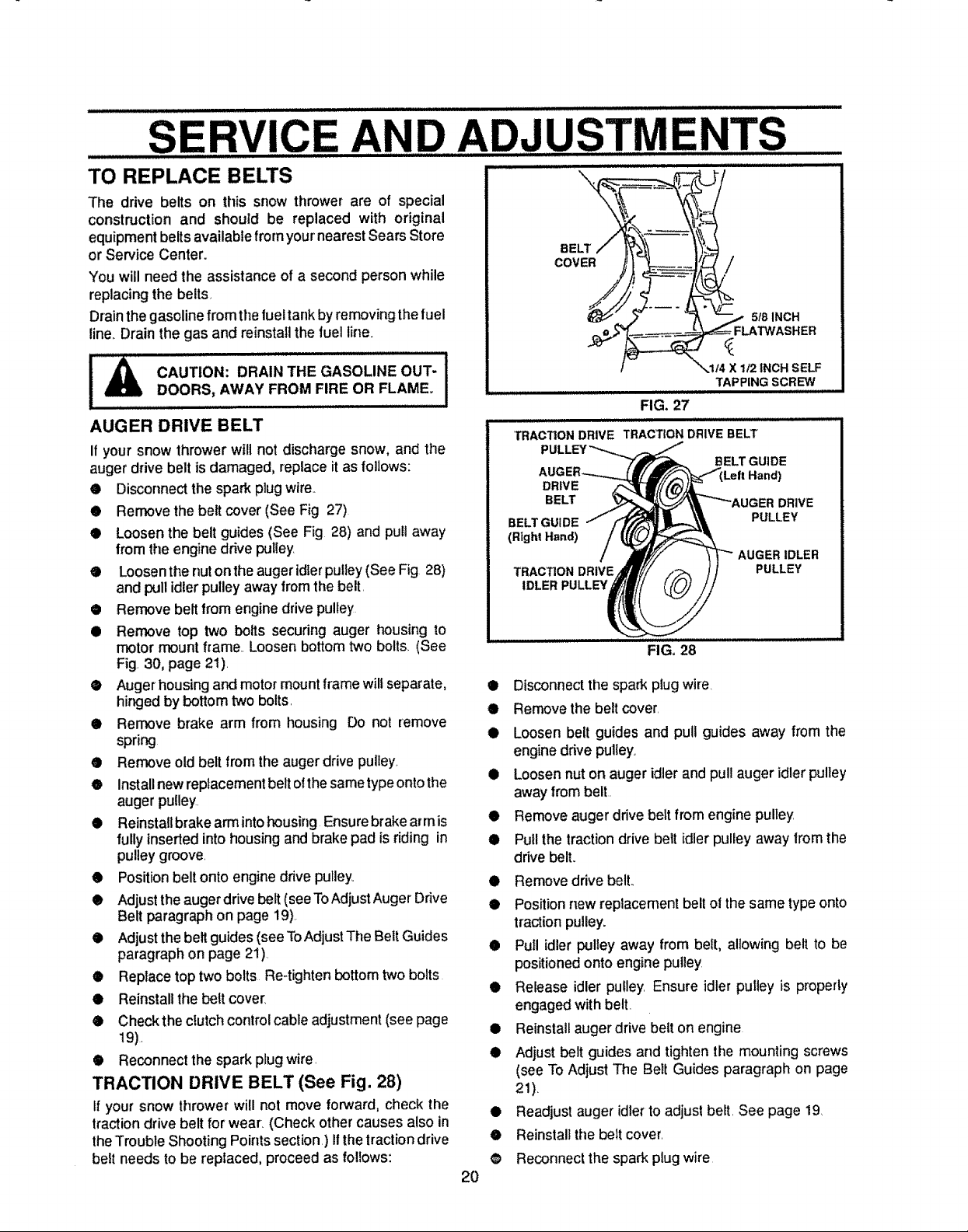

TO ADJUST SKID HEIGHT

This snow thrower isequipped with two height adjustment

skids, located on the outside of the auger housing (See

Fig 2!)These skids elevate the front of the snow thrower

For normal hard surfaces, adjust the skids as follows:

• Check tire pressure (14 to 17 pounds) See sicle of tire

for maximum inflation Do not exceed maximum pres-

sure on side of tire

• Place the extra shear bolts supplied (found in parts

bag) under each end of the scraper bar near but not

under' the skid

• Loosen the skid mounting nuts (See Fig 21) and

adjust the skids up to bring the front of the snow

thrower down Re-tighten the mounting nuts

Q Set the skid on the other side at the same height

For rocky or uneven surfaces, adjust the skids as follows:

• Raise the front of the snow thrower by moving the

skids down.. This will help prevent rocks and other

debris from being picked up and thrown by the auger

NOTE: Be sure that snow thrower is set at same height on

both sides

TO ADJUST SCRAPER BAR

After considerable use, the metal scraper bar will have a

definite wear pattern The scraper bar inconjunction with

the skidsshould always beadjusted toallow 1/8' between

the scraper bar and the sidewalk or area to be cleaned

The scraper bar may have to be returned to its original

lower settingto maintain the original performance level To

adjust:

• Position the snow throweron a level surface

• Make sure both tires are equally inflated

• Loosen the carriage bolts and nuts securing the

scraper bar to the augerhousing

i Adjust thescraper bar to the proper position

@ Tighten the carriage bolts and nuts, making sure that

the scraper bar is parallel with the working surface

• For extended operation, the scraper bar may be

reversed If the scraper bar must be replaceddue fo

wear, remove thecarriage bolts and nuts and install a

new scraper bar

SKID MOUNTING Nu_rs

AUGER HOUSING HEIGHT ADJ UST SKID

iii =l u=uu,

FIG. 21

CAUTION: BE CERTAIN TO MAINTAIN

PROPER GROUND CLEARANCE FOR

YOUR PARTICULAR AREA TO BE

CLEARED. OBJECTS S UCH AS GRAVEL,

ROCKS OR OTHER DEBRIS, IF STRUCK

BY THE IMPELLER, MAY BE THROWN

WiTH SUFFICIENT FORCE TO CAUSE

PERSONAL INJURY, PROPERTY DAM-

AGE OR DAMAGE TO THE SNOW

THROWER.

TO ADJUST CHUTE

CRANK ASSEMBLY

Ifyou cannot rotate the chute crank fully to the left and to

the right, you need to adjust the chute crank (See Fig 22)

• Loosen both 1/2" nuts on the crank adjusting rod

(using 314" wrenches)

• Rotate the adjusting rod in or out to allow about 1/8"

clearance between the notch in the flange and the

outer diameter of the worm

• Once this clearance is set, tighten the nuts

NOTE: Be sure the crank does not touch the side of the

engine or the cover will be scratched.

PLASTIC _ NOTCHEDSECTION

CAP COTTERJ'_ " "_,_ \

FL PIN 18IN_.. LEARANCE "_.

1 _J" \'k.J'_.._I'2',NCH

18

FIG. 22

TO ADJUST THE CLUTCH C6'N'TROL

CABLES

Periodic adjustment of the cables may be required due to

normal stretch and wear onthe belts, To check for correct

adjustment, the control lever must be in the full forward

position, resting on the plastic bumper,, The control

cables are correctly adjusted when the center of the "Z"

fitting is between the center and top of the hole in the

clutch lever and there is no droop in the cable (See Fig.

23)°

If adjustment is necessary:

O Disconnect '_" Fitting from drive lever

O

Push the cable through the spring (See Fig 24) to

expose the threaded portion of the cable.

®

Holdthe squareend ofthe threadedportionwith pliers

and adjust the Iocknut in or out untilthe excess slack

isremoved (See Fig,,24),,

®

Pullthecableback throughthespring andconnect the

cable.

O Do thesame for the other lever cable,

NOTE: Whenever the tractiondrive or auger belts are

adjustedorreplaced, thecableswillneed tobe adjusted.

TO ADJUST BELTS

Belts stretch duringnormaluser Ifyou need toadjust

the belts due to wear or stretch, proceed as follows:

AUGER DRIVE BELT (See Fig. 26)

If your snow thrower will not discharge snow, check the

control cable adjustment, If it is correct, then check the

condition of the auger drive bell it may be loose or

damaged° If it is damaged, replace it, See To Replace

Belts paragraph on page 20 If the auger drive belt is

loose, adjust as follows:

@ Disconnect the spark plug wire

@ Remove the belt cover (See Fig, 27, page 20)°

® Loosen the nuton the auger idlerpulley (See Fig, 26)

and move the pulley toward the belt about t/8'L

@ Tighten the nut.

@ Presstheauger drive lever Check the tension on the

belt (opposite auger idler pulley). The belt should

deflect about 1/2" with moderate pressure (See Fig.

25),

NOTE: You may have to move the auger idler pulley

more than once to obtain the correct tension.

@ Replace the belt cover,

@ Check theclutch control cable adjustment.

@ Reconnect the spark plug wire

TRACTION DRIVE BELT

The traction drive belt has constant spring pressure and

does not require adjustment

!9

AUGER MUST BE IN FULL

LEVER FORWARD POSITION

"Z" FITTING Plastic Bumpor) WHEN

PLASTICBUMPER

FIG. 23

CONTROL LEVER

(Just Contacting

CHECKING

SPRING

SQUARE

END

"LOCKNUT

FIG. 24

_ DRIVE

_,_. PULLEY

AUGER IDLER_ ) _._.,_',_._I/2INCH

., /.,--. IMPELLER

_,,,.J PLILLEY

illlllllll ii,,llll,i i ii i j i i

FIG. 25

AUGER

DRIVEBELT BELTGUIDE

BELTGUIDE

(Right Hand)

®

Replace thetractiondrive belt if it isslipping (see To

Replace Belts paragraphon page 20)

.TRACTIONDRIVEBELT

(Left Hand)

IDLER PULLEY

_ER IDLER

PULLEY

FIG. 26

DRIVE

TO REPLACE BELTS

The drive belts on this snow thrower are of special

construction and should be replaced with original

equipment beltsavailable from your'nearest Sears Store

or Service Center.

You will need the assistance of a second person while

replacing the belts,

Drainthe gasoline from the fueltank by removing the fuel

line..Drain the gas and reinstall the fuel line.

CAUTION: DRAIN THE GASOLINE OUT- 1

DOORS, AWAY FROM FIRE OR FLAME.

AUGER DRIVE BELT

If your snow thrower will not discharge snow, and the

auger drive belt is damaged, replace it as follows:

• Disconnect the spark plug wire._

• Remove the belt cover (See Fig 27)

® Loosen the belt guides (See Fig 28) and pull away

fromthe enginedrive pulley

® Loosen the nut on theauger idler pulley(See Fig 28)

and pull idler pulleyaway from the belt

• Remove belt from engine drive pulley

• Remove top two bolts securing auger housing to

motor mount frame. Loosen bottom two bolts, (See

Fig. 30, page 21).

• Auger housing and motor mount frame will separate,

hinged by bottom two bolts.

• Remove brake arm from housing Do not remove

spring

• Remove old belt from the auger drive pulley.

• Install newreplacement beltofthesame type onto the

auger pulley.

• Reinstall brake arm intohousing Ensurebrake arm is

fully insertedinto housing and brake pad isriding in

pulley groove.

• Position belt onto engine drive pulley°

® Adjust the augerdrive belt (see ToAdjustAuger Drive

Belt paragraph on page 19).

• Adjust the belt guides (see ToAdjustThe Belt Guides

paragraph on page 21)

® Replace top two bolts Re-tighten bottom two bolts

• Reinstall the belt cover,

• Checkthe clutch control cable adjustment (see page

19).

® Reconnect the spark plug wire.

TRACTION DRIVE BELT (See Fig. 28)

If your snow thrower will not move forward, check the

traction drive belt for wear, (Check other causes also in

theTrouble Shooting Points section.) 1Ithetractiondrive

belt needs to be replaced, proceed as follows:

BELT

COVER /

5/8 INCH

i

X 112 INCH SELF

TAPPING SCREW

I

TRACTION DRIVE TRACTION DRIVE BELT

DRIVE

BELT

BELT GUIDE

(Right Hand)

TRACTION DRIVE

IDLER PULLEY

0

Disconnect the spark plug wire.

O

Remove the beltcover

O

Loosen belt guides and pull guides away from the

FIG. 27

Hll j iji

BELT GUIDE

DRIVE

PULLEY

IDLER

PULLEY

FIGo 28

engine drive pulley.

0

Loosen nut on auger idler and pull auger idler pulley

away frombelt.

O

Remove auger drive belt from engine pulley

O

Pull the traction drive belt idler pulley away fromthe

drive belt.

O

Remove drive belt.,

0

Position new replacement belt ol thesame typeonto

traction pulley.

O

Pull idlerpulley away from belt, allowing belt to be

positioned onto engine pulley

O

Release idler pulley Ensure idler pulley is property

engaged with belt.

O

Reinstall auger drive belt on engine

O

Adjust belt guides and tighten the mounting screws

(see To Adiust The Belt Guides paragraph on page

2f).

O

Readjust auger idler to adjust beet.See page 19

0

Reinstall the belt cover.

@

Reconnect the spark plug wire

2O

S RVIC AN

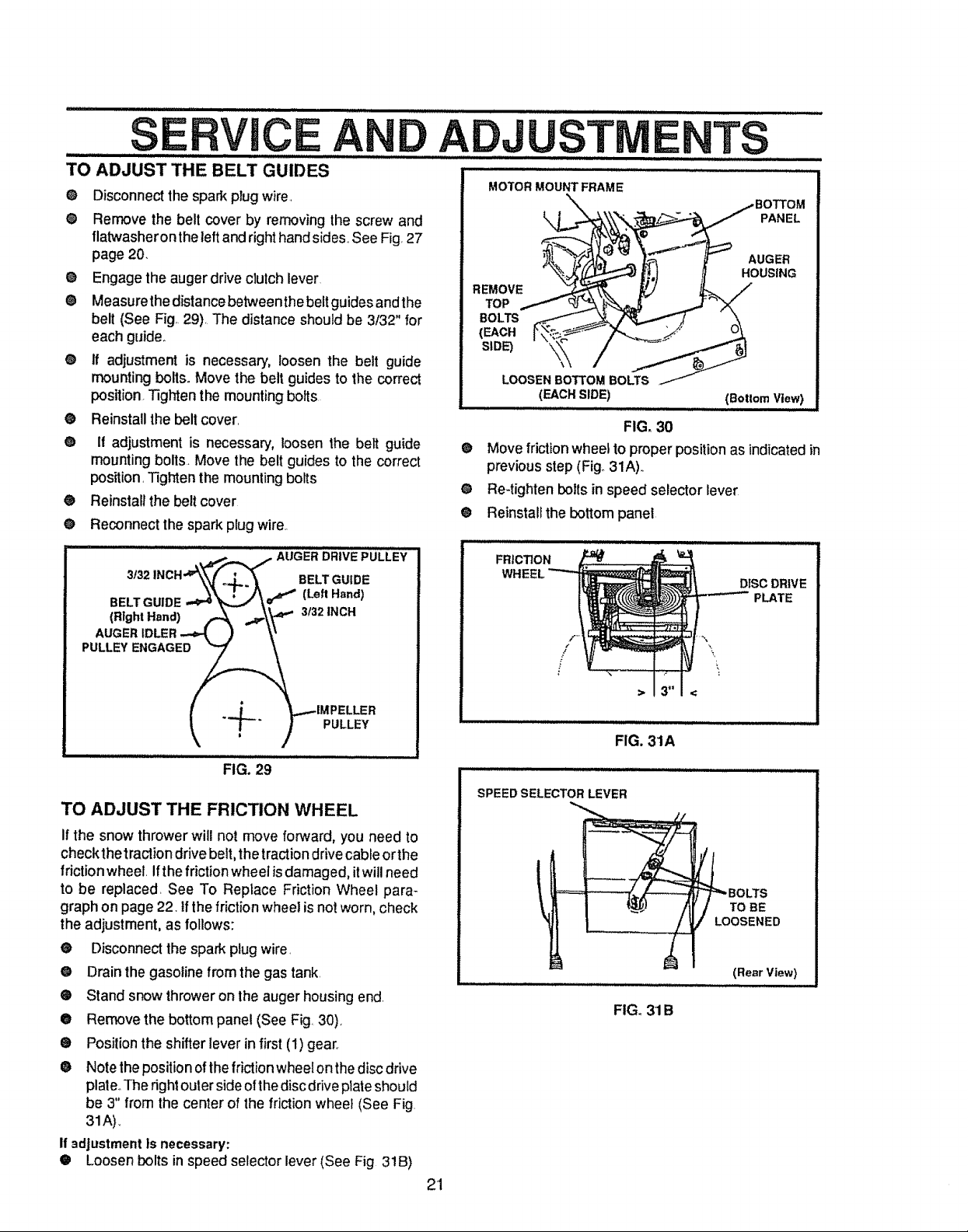

TO ADJUST THE BELT GUIDES

e

Disconnect the spark plug wire,

e

Remove the belt cover by removing the screw and

flatwasheron the leftandright handsides, See Fig,27

page 20,

e

Engage the auger drive clulch lever

e

Measurethe distance between the beltguides andthe

belt (See Fig. 29), The distance should be 3/32" for

each guide.,

@

if adjustment is necessary, loosen the belt guide

mounting bolts° Move the belt guides to the correct

position. Tighten the mounting bolts

@

Reinstall the bell cover,

o

If adjustment is necessary, loosen the belt guide

mounting bolts, Move the belt guides to the correct

position, Tighten the mounting bolts

®

Reinstall the belt cover

O

Reconnect the spark plug wire.,

ADJU TM

MOTOR MOUNT FRAME

k PANEL

REMOVE

TOP

BOLTS

(EACH

SIDE)

\

LOOSEN BOTTOM BOLTS

(EACH SIDE) (Botlom View)

®

Movefrictionwheeltoproperpositionas indicatedin

previousstep (Fig°31A).,

O

Re-tightenbelts in speed selector level

®

Reinstallthe bottom panel

,Lij /i / /J,. .................

FIG. 30

TS

AUGER

HOUSING

.... _ _,,_f..._./1 AUGER DRIVE PULLEY

BELTO0,D

wtg.,.o.,) ,=,NO.

if .._.L_.. _.._IMPELLER

It` {--" ) PULLEY

FIG. 29

TO ADJUST THE FRICTION WHEEL

If the snow thrower willnot move forward, you need to

check thetraction drive belt, the traction drive cableorthe

frictionwheel Ifthe friction wheeiis damaged, itwill need

to be replaced, See To Replace Friction Wheel para-

graph on page 22 tf the friction wheel is notworn, check

the adjustment, as follows:

@ Disconnect the spark plug wire,

@ Drain the gasoline from the gas tank,

• Stand snow throweron the auger housing end.

@ Remove the bottom panel (See Fig.,30).

• Position the shifter lever in first (1) gear.

• Note the position ofthe frictionwheel on thedisc drive

plate,.The rightouter sideofthe disc driveplateshould

be 3" from the center of the friction wheel (See Fig.

31A),

If 3dJustmentIs necessary:

• Loosen bolts in speed selector lever (See Fig 31B)

FRICTION

DISC DRIVE

PLATE

FIG. 31A

SPEEDSELECTOR LEVER

BOLTS

TO BE

OOSENED

(RearView t

FIG. 3'1B

21

.qFRVICF AND A_r}JUSTMENFS

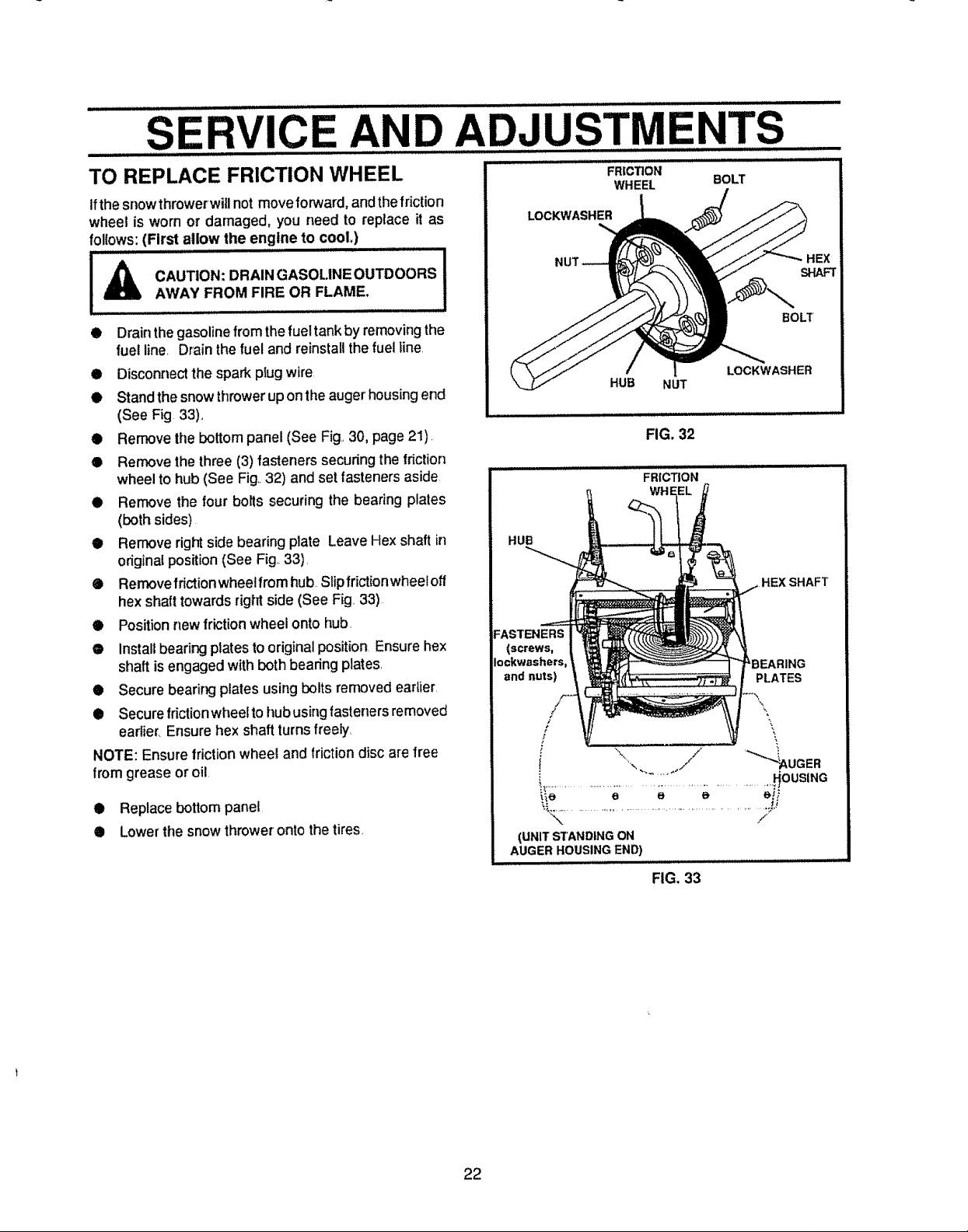

TO REPLACE FRICTION WHEEL

Ifthe snowthrower will notmoveforward,andthefriction

wheel is worn or damaged, you need to replace it as

follows: (First allow the engtne to cool.)

AWAY FROM FIRE OR FLAME, !

• Drainthe gasoline fromthefueltank by removing the

fuel line Drain the fuel and reinstall the fuel line.

• Disconnect the spark plug wire

• Stand the snow thrower up on the auger housing end

(See Fig 33).,

• Rerr_ve the bottom panel (See Fig,,30, page 21).

® Remove the three (3) fasteners securing the fnction

wheel to hub (See Fig..32) and set fasteners aside

• Remove the four bolts securing the bearing plates

(both sides)

• Remove right side bearing plate Leave Hex shaft in

original position (See Fig..33).

® Rernovefdction wheetfrom hub Slipfrictionwheel off

hex shaft towards right side (See Fig 33)

• Position new friction wheel onto hub,

• Install bearing plates to original position Ensure hex

shaft is engaged with both bearing plates,

• Secure bearing plates using bolts removed earlier.

• Secure frictionwheel to hub using fasteners removed

earlier. Ensure hex shaft turns freely,

NOTE: Ensure frictionwheel and friction disc are free

from grease or oil.

• Replace bottom panel

• Lowerthe snow throwerontothetires

FR|CTION

WHEEL BOLT

LOCKWABHER

BOLT

HUB NUT

LOCKWASHER

FIG. 32

FRICTION

HUB

HEX SHAFT

FASTENERS

(screws,

Iockwashers RING

and nuts) PLATES

; "\

0 • //

i,.................................................................... ous,NG

(UNIT STANDING ON

AUGER HOUSING END)

j Hi,ll ===ul,Jlu

FIG. 33

HEX

SHAFT

22

Loading...

Loading...