Craftsman 536886331 Owner’s Manual

OWNER'S

CRAFTSMAN®

10 HORSEPOWER

29" DUAL STAGE

MANUAL

MODEL NO.

536.886331

HOW TO ORDER

REPAIR PARTS

120V. ELECTRIC START

SNOW THROWER

WHEN ORDERING REPAIR PARTS, ALWAYS

Each SNOW THROWER has its own MODEL

NUMBER found on the engine mount frame.

Each ENGINE has its own MODEL NUMBER

found on the BLOWER HOUSING.

Always mention these MODEL NUMBERS when

requesting service or Repair Parts for your SNOW

THROWER.

All parts may be orderedthrough Sears, Roebuck

and Company Service Centers and most Retail

Stores,

GIVE THE FOLLOWING INFORMATION:

* PRODUCT - "SNOW THROWER"

* MODEL NUMBER - 536.886331

* ENGINE MODEL NUMBER - 143.941001

* PART NUMBER

* PART DESCRIPTION

"Your Sears merchandise has added value when you

consider that Sears has service units nationwide staffed

with Sears trained technicians...Professional lechnicians

specifically trained on Sears products, having the parts,

tools and equipment to ensure that we meet our pledge

to you...we service what we sell."

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179

334224 07/28/94 Printed In U.S.A.

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND A

&

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE

RISK OF INJURY. YOUR SNOW THROWER IS EQUIPPED WITH SUCH CONTROLS. DO NOT

ATTEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER

ANY CIRCUMSTANCES.

PLACE WIRE WHERE IT CANNOT CONTACT SPARK PLUG

TO PREVENT ACCIDENTAL STARTING WHEN SETTING-UP

TRANSPORTING, ADJUSTING OR MAKING REPAIRS.

IMPORTANT

BEFORE USE

• Read the Owner's Manual carefully. Be thor-

oughly familiar with the controls and the proper

use of the snow thrower. Know how to stop the

snow thrower and disengage the controls

quickly.

• Do not operate the snow thrower without

wearing adequate winter outer garments.

Wear footwear that will improve footing on

slippery surfaces.

• Keep the area of operation clear of all persons,

particularly small children, and pets.

• Thoroughly inspect the area where the snow

thrower is to be used and remove all doormats,

sleds, boards, wires, and other foreign objects.

• Use extension cords and receptacles as

specified by the manufacturer for all snow

throwers with electric drive motors or with

factory-installed or optional starting motors.

• Use only attachments and accessories ap-

proved by the manufacturer of the snow thrower

(such as electric starter kits, etc.).

• Never operate the snow thrower without good

visibility or light. Always be sure of your footing,

and keep a firm hold on the handles. Walk;

never run.

• This snow thrower is for use on sidewalks,

driveways, and other ground level surfaces.

CAUTION should be exercised while using on

steep stoping surfaces. DO NOT USE SNOW

THROWER ON SURFACES ABOVE

GROUND LEVEL such as roofs of residences,

garages, porches or other such structures or

buildings.

• Check all bolts at frequent intervals for proper

tightness to be sure the snow thrower is in safe

working condition.

• Disengage clutch before starting the engine.

• Let engine and snow thrower adjust to outdoor

temperatures before starting to clear snow.

FUEL SAFETY

• Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Check fuel supply before each use, allowing

space for expansion as the heat of the engine

and/or sun can cause fuel to expand.

• Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

• Replace fuel tank cap securely and wipe up

spilled fuel.

• Never remove fuel tank cap or add fuel to a

running engine or hot engine.

• Never store fuel or snow thrower with fuel in the

tank inside a building where fumes may reach

an open flame or spark.

OPERATING SAFETY

• Never allow children or young teenagers to

operate the snow thrower and keep them away

while it is operating. Never allow adults to

operate the snow thrower without proper in-

struction. Do not carry passengers.

• Always wear safety glasses or eye shields

during operation or white performing an

adjustment or repair to protect eyes from for-

eign objects that may be thrown from the snow

thrower.

• Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay

alert for hidden hazards or traffic.

• Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at

all times.

• Exercise caution to avoid slipping or falling,

especially when operating in reverse or back-

ing up.

• Do not clear snow across the face of slopes.

Exercise caution when changing direction on

slopes. Do not attempt to clear steep slopes.

• Never operate the snow thrower without

proper guards, plates or other safety protective

devices in place.

SAFETY RULES

• Never operate the snow thrower near glass

enclosures, automobiles, window wells drop-

offs, and the like without proper adjustment of

the snow discharge angle. Keep children and

pets away.

• Never operate the snow thrower at high

transport speeds on slippery surfaces. Look

behind and use care when backing.

• Never direct discharge at bystanders or allow

anyone in front of the snow thrower.

• Do not run the engine indoors, except when

starting the engine and for transporting the

snow thrower in or out of the building. Open

the outside doors; exhaust fumes are dangerous

(containing CARBON MONOXIDE, an

ODORLESS and DEADLY GAS).

• Take all possible precautions when leaving the

snow thrower unattended. Disengage the auger/

impeller, stop engine, and remove key.

• Do not overload the machine capacity by

attempting to clear snow at too fast a rate.

SAFE STORAGE

• Always refer to Owner's Manual instructions

for important details if the snow thrower is to be

stored for an extended period.

• Disengage power to the auger/impeller when

snow thrower is transported or not in use.

• Never store the snow thrower with fuel in the

fuel tank inside a building where ignition sources

are present such as hot water and space

heaters, clothes dryers, and the like. Allow the

engine to cool before storing in any enclosure.

REPAIR/ADJUSTMENTS SAFETY

• After striking a foreign object, stop the engine

and remove the wire from the spark plug, or

disconnect the cord from electric motor.

Thoroughly inspect the snow thrower for any

damage, and repair the damage before

restarting and operating the snow thrower.

• If the snow thrower should start to vibrate

abnormally, stop the engine (or electric motor)

and check immediately for the cause. Vibration

is generally a warning of trouble.

• Stop the engine (or electric motor) whenever

you leave the operating position, before un-

clogging the auger/impeller housing or dis-

charge guide, and when making any repairs,

adjustments, or inspections. Remove wire from

spark plug or disconnect cord from electric

motor.

• When cleaning, repairing, or inspecting, make

certain the auger/impeller and all moving parts

have stopped. Disconnect the spark plug wire

and keep the wire away from the plug to prevent

accidental starting.

• Never attempt to make any adjustments while

the engine is running (except when specifically

recommended in this manual).

• Maintain or replace safety and instruction

labels, as necessary.

• Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the

auger/impeller.

CONGRATULATIONS on your purchase of a Sears

_rattsman Snow Thrower. It has been designed, engi-

neered a_d manufactured to give you the best poss;ble

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center/Department. Sears has competent, well-trained

technicians and the proper tools to service or repair this

unit.

Please read and retain this manual. The instructionswill

enab(e you to assemble and maintain your snow thrower

oropedy. Always observe the "SAFETY RULES."

MODEL

NUMBER 536.886331

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE REAR

OF THE SNOW THROWER HOUSING.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

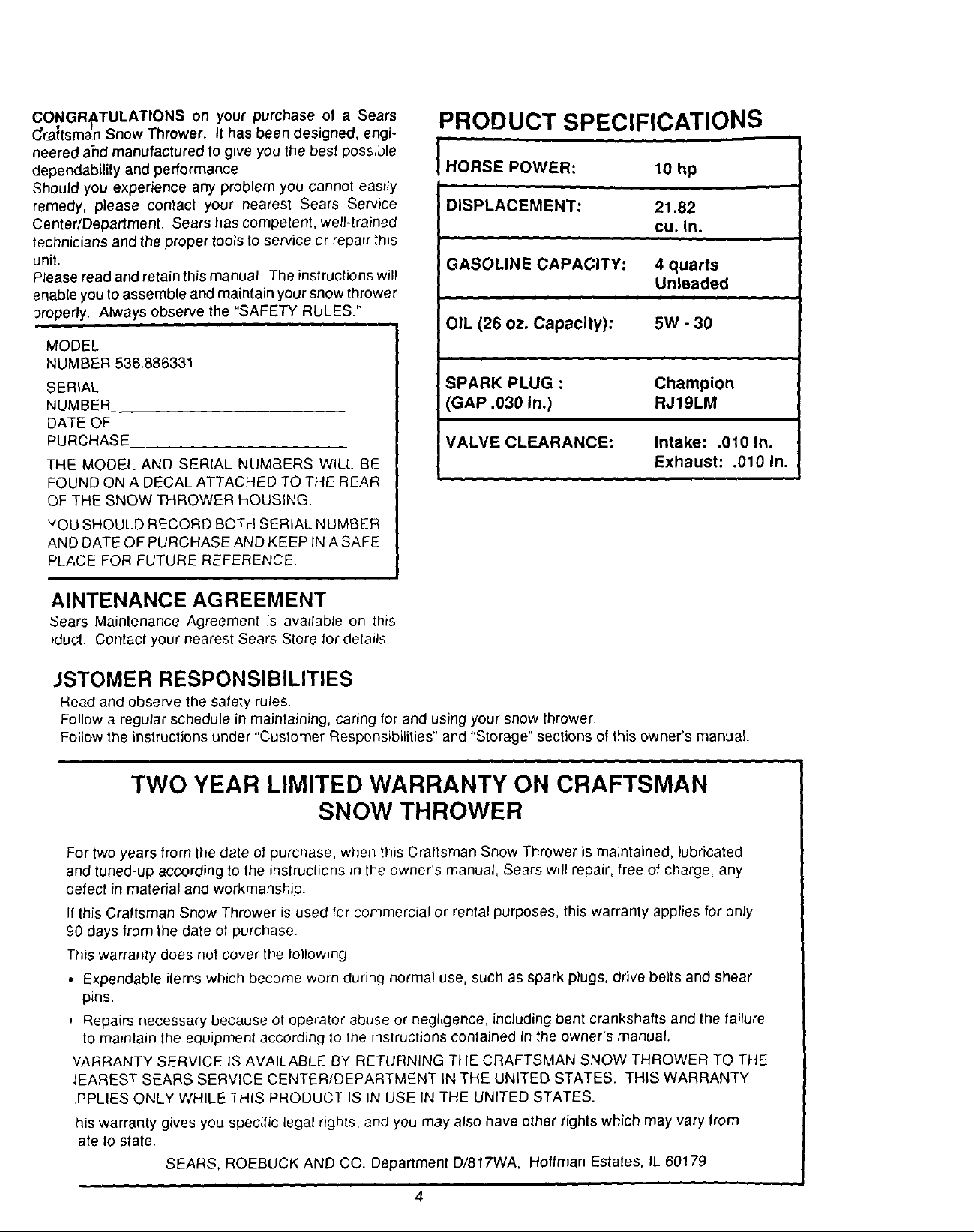

PRODUCT SPECIFICATIONS

i =

HORSE POWER: 10 hp

DISPLACEMENT: 21.82

cu, in.

GASOLINE CAPACITY:

OIL (26 oz. Capacity): 5W - 30

SPARK PLUG :

(GAP .030 In.)

VALVE CLEARANCE:

4 quarts

Unleaded

Champion

RJ19LM

Intake: .010 In.

Exhaust: .010 In.

AINTENANCE AGREEMENT

Sears Maintenance Agreement is available on this

)duct. Contact your nearest Sears Store for details.

JSTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for and using your snow thrower.

Follow the instructions under "Customer Responsibilities" and "Storage" sections of this owner's manual.

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

SNOW THROWER

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated

and tuned-up according to the instructions in the owner's manual, Sears will repair, free of charge, any

defect in material and workmanship.

If this Craftsman Snow Thrower is used for commercial or rental purposes, this warranty applies for only

90 days from the date of purchase.

This warranty does not cover the following:

• Expendable items which become worn during normal use, such as spark plugs, drive belts and shear

pins.

Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure

to maintain the equipment according to the instructions contained in the owner's manual.

VARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE

_EAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY

,PPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

his warranty gives you specific legal rights, and you may also have other rights which may vary from

ate to state.

SEARS, ROEBUCK AND CO. Department D/817WA, Hoffman Estates, IL 60179

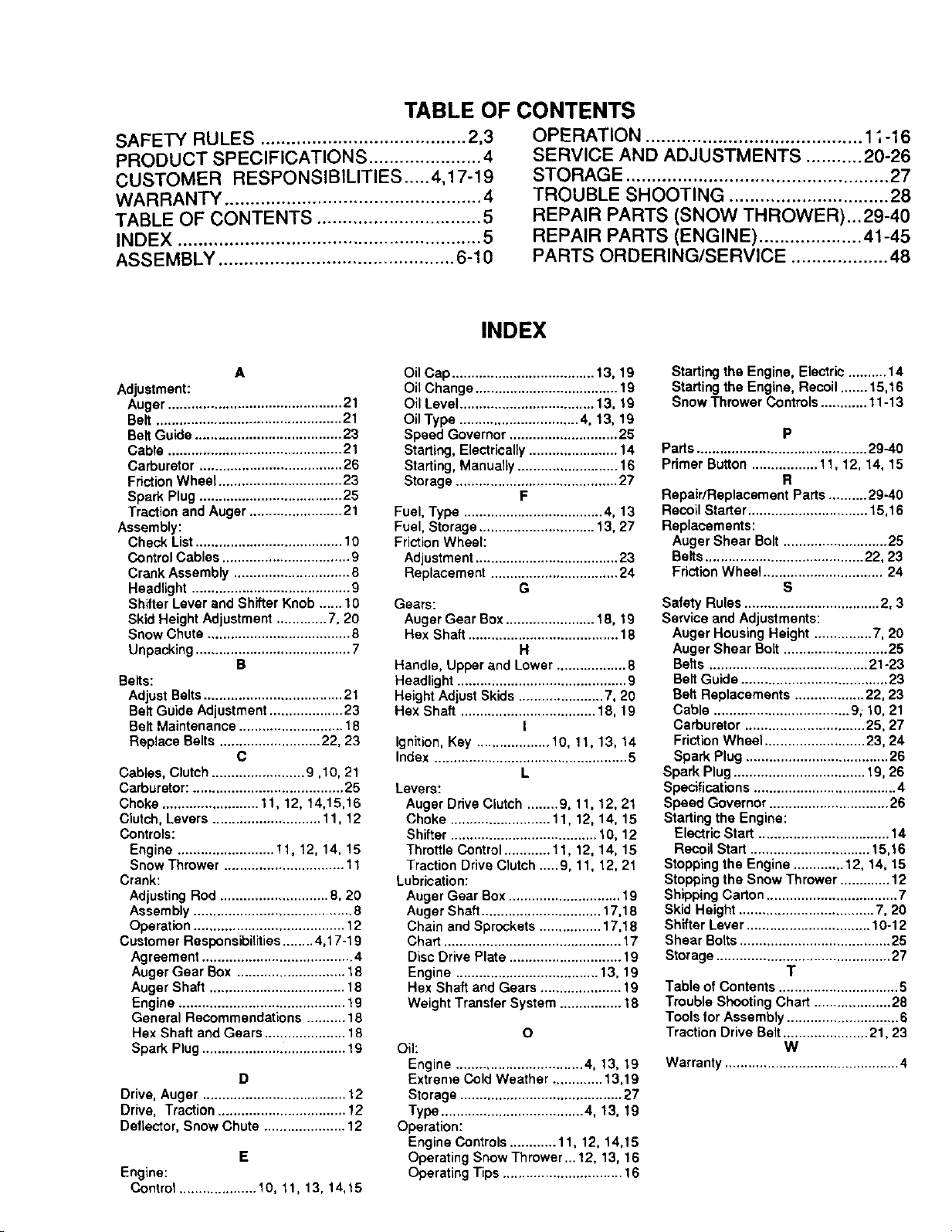

TABLE OF CONTENTS

SAFETY RULES ........................................ 2,3

PRODUCT SPECIFICATIONS ...................... 4

CUSTOMER RESPONSIBILITIES ..... 4,17-19

WARRANTY .................................................. 4

TABLE OF CONTENTS ................................ 5

INDEX ........................................................... 5

ASSEMBLY .............................................. 6-10

OPERATION .......................................... 1;-16

SERVICE AND ADJUSTMENTS ........... 20-26

STORAGE ................................................... 27

TROUBLE SHOOTING ............................... 28

REPAIR PARTS (SNOW THROWER)...29-40

REPAIR PARTS (ENGINE) .................... 41-45

PARTS ORDERING/SERVICE ................... 48

INDEX

A

Adjustment:

Auger ............................................. 21

Belt ................................................ 21

Belt Guide ...................................... 23

Cable ............................................. 21

Carburetor ..................................... 26

Friction Wheel ................................ 23

Spark Plug ..................................... 25

Traction and Auger ........................ 21

Assembly:

Check List ...................................... 10

Control Cables ................................. 9

Crank Assembly .............................. 8

Headlight ......................................... 9

Shifter Lever and Shifter Knob ...... 10

Skid Height Adjustment ............. 7, 20

Snow Chute ..................................... 8

Unpacking ........................................ 7

B

Belts:

Adjust Belts.................................... 21

Belt Guide Adjustment ................... 23

Belt Maintenance ........................... 18

Replace Belts .......................... 22, 23

C

CabLes,Clutch ........................ 9,10, 21

Carburetor: ....................................... 25

Choke ......................... 11, 12, 14,15,16

Clutch, Levers ............................ 11, 12

Controls:

Engine ......................... 11, 12, 14, 15

Snow Thrower ............................... 11

Crank:

Adjusting Rod ............................ 8, 20

Assembly ......................................... 8

Operation ....................................... 12

Customer Responsibilities ........ 4,17-19

Agreement ....................................... 4

Auger Gear Box ............................ 18

Auger Shaft ................................... 18

Engine ........................................... 19

General Recommendations .......... 18

Hex Shaft and Gears ..................... t 8

Spark Plug ..................................... 19

D

Drive,Auger.....................................12

Drive, Traction .................................12

Deflector, Snow Chute ..................... 12

E

Engine:

Control .................... 10, 11, 13, 14,15

Oil Cap ..................................... 13, 19

Oil Change ..................................... 19

Oil Level ................................... 13, 19

Oil Type ............................... 4, 13, 19

Speed Governor ............................ 25

Starting, Electrically ....................... 14

Starting, Manually .......................... 16

Storage .......................................... 27

F

Fuel, Type .................................... 4, 13

Fuel, Storage .............................. 13, 27

Friction Wheel:

Adjustment ..................................... 23

Replacement ................................. 24

G

Gears:

Auger Gear Box ....................... 18, 19

Hex Shaft ....................................... 18

H

Handle, Upper and Lower .................. 8

Headlight ............................................ 9

Height Adjust Skids ...................... 7, 20

Hex Shaft ................................... 18, 19

I

Ignition, Key ................... 10, 11, 13, 14

Index .................................................. 5

L

Levers:

Auger Drive Clutch ........ 9, 11, 12, 21

Choke .......................... 11, 12, 14, 15

Shifter ...................................... 10, 12

Throttle Control ............ 11, 12, 14, 15

Traction Drive Clutch ..... 9, 11, 12, 21

Lubrication:

Auger Gear Box ............................. 19

Auger Shaft ............................... 17,18

Chain and Sprockets ................ 17,18

Chart .............................................. 17

Disc Drive Plate ............................. 19

Engine ..................................... 13, 19

Hex Shaft and Gears ..................... 19

Weight Transfer System ................ 18

O

Oil:

Engine ................................. 4, 13, 19

Extreme Cold Weather ............. 13,19

Storage .......................................... 27

Type ..................................... 4, 13, 19

Operation:

Engine Controls ............ 11, 12, 14,15

Operating Snow Th rower... 12, 13, 16

Operating Tips ............................... 16

Starting the Engine, Electric .......... 14

Starting the Engine, Recoil ....... 15,16

Snow Thrower Controls ............ 11-13

P

Parts ............................................ 29-40

Primer Button ................. 11, 12, 14, 15

R

Repair/Replacement Parts .......... 29-40

Recoil Starter ............................... 15,16

Replacements:

Auger Shear Bolt ........................... 25

Belts ......................................... 22, 23

Friction Wheel ............................... 24

S

Safety Rules ................................... 2, 3

Service and Adjustments:

Auger Housing Height ............... 7, 20

Auger Shear Bolt ........................... 25

Belts ......................................... 21-23

Belt Guide ...................................... 23

Belt Replacements .................. 22, 23

Cable ................................... 9; 10, 21

Carburetor ............................... 25, 27

Friction Wheel .......................... 23, 24

Spark Plug ..................................... 26

Spark Plug .................................. 19, 26

Specifications ..................................... 4

Speed Governor ............................... 26

Starting the Engine:

Electric Start .................................. 14

Recoil Start ............................... 15,16

Stopping the Engine ............. 12, 14, 15

Stopping the Snow Thrower ............. 12

Shipping Carton .................................. 7

Skid Height ................................... 7, 20

Shifter Lever ................................ 10-12

Shear Bolts ....................................... 25

Storage ............................................. 27

T

Table of Contents ............................... 5

Trouble Shooting Chart .................... 28

Tools for Assembly ............................. 6

Traction Drive Belt ...................... 21, 23

W

Warranty ............................................. 4

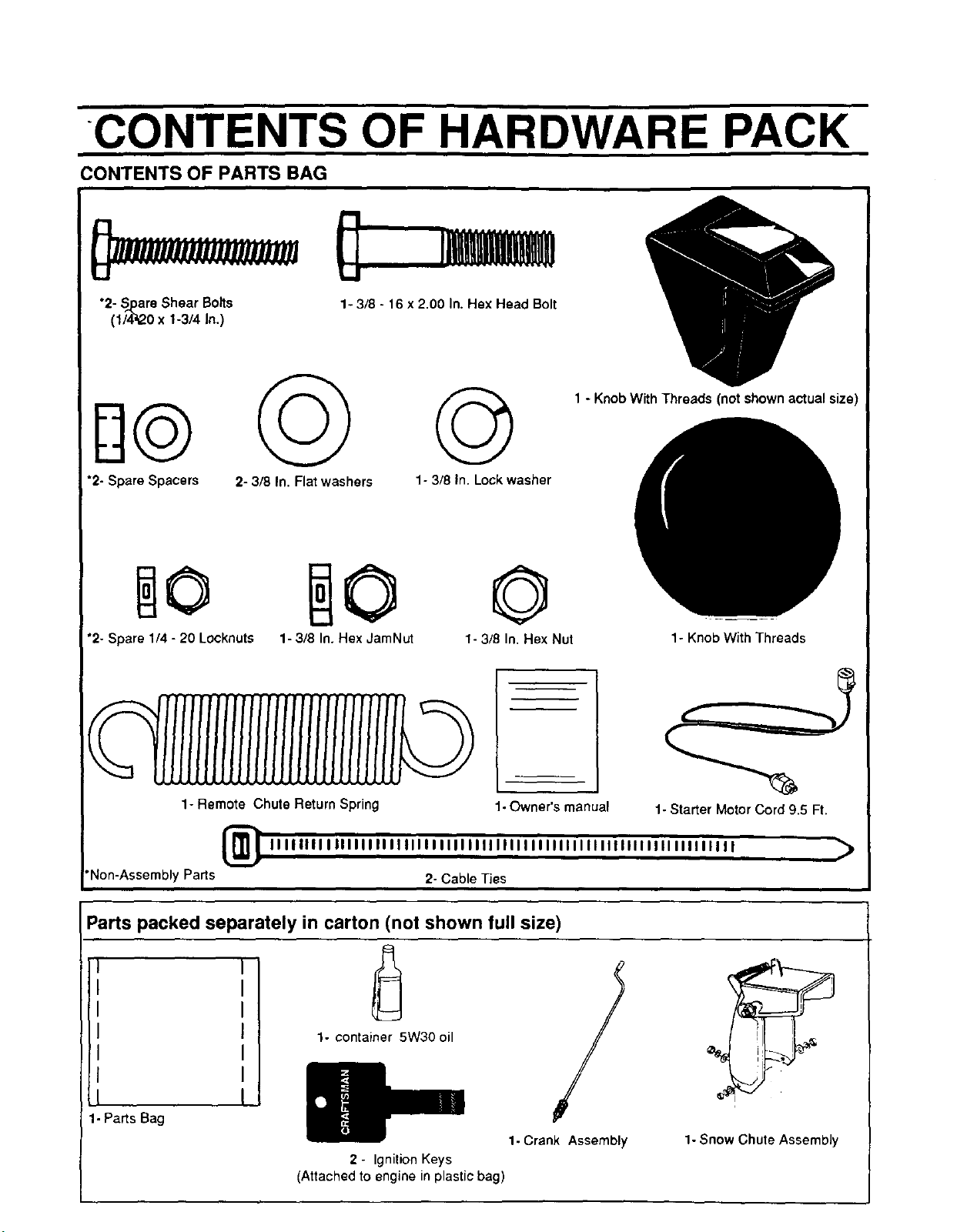

CONTENTS OF HARDWARE PACK

CONTENTS OF PARTS BAG

"2- Spare Shear Bolts 1- 3/8 - 16 x 2.00 In. Hex Head Bolt

(1/4_0 x 1-3/4 In.)

1 - Knob With Threads (not shown actual size)

©

*2- Spare Spacers 2- 3/8 In. Flat washers

1- 3/8 In. Lock washer

©

"2- Spare 1/4 - 20 Locknuts 1- 3/8 In. Hex JamNut

1- Remote Chute Return Spring 1- Owner's manual

_ IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII )

"Non-AssemblyParts 2- Cable Ties

Parts packed separately in carton (not shown full size)

1- 3/8 In. Hex Nut

1- Knob With Threads

1- Starter Motor Cord 9.5 Ft.

I

1-Parts Bag

1. container 5W30 oil

2 - IgnitionKeys

(Attached to engine in plastic bag)

1- Crank Assembly

1- Snow Chute Assembly

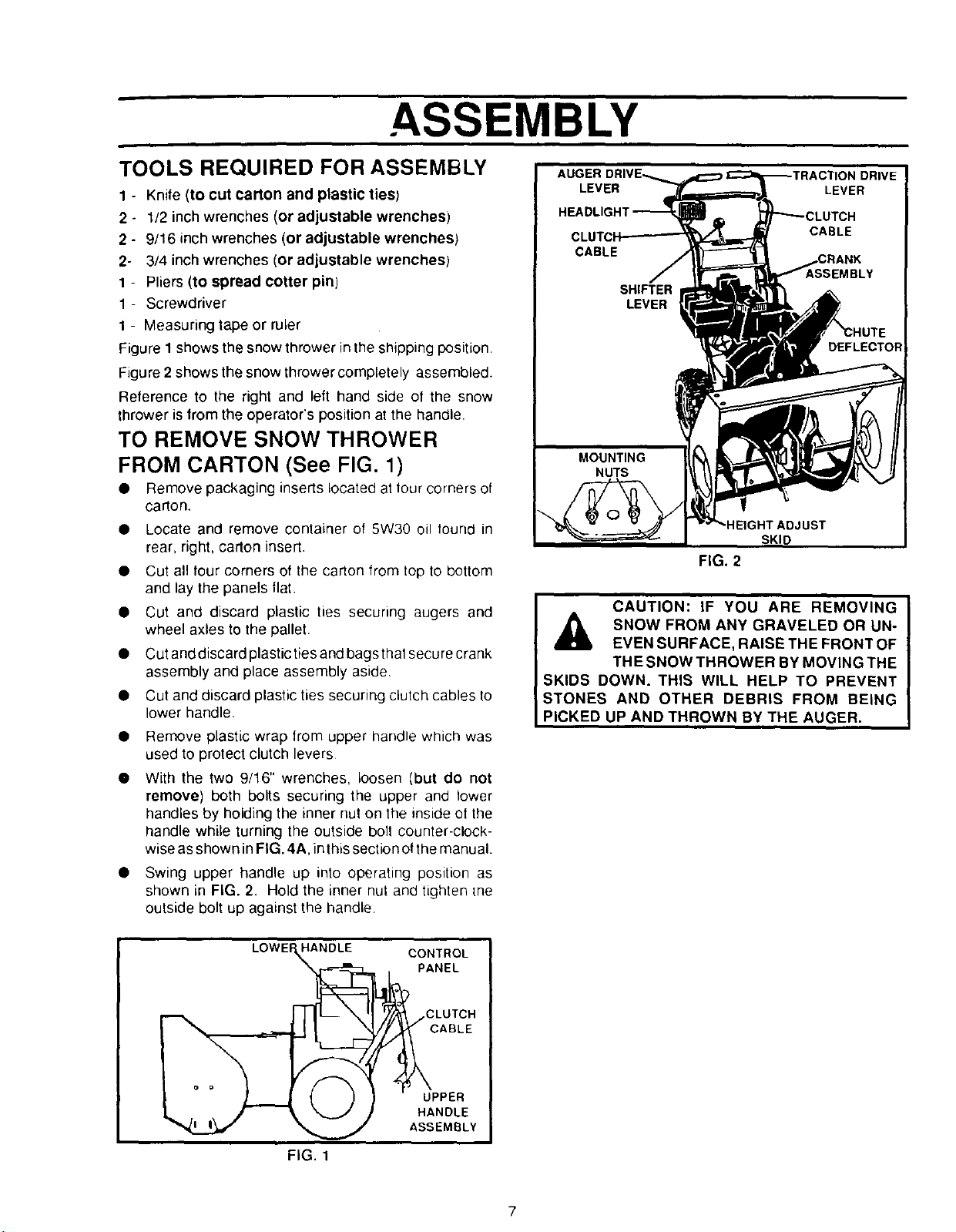

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

1 - Knife (to cut carton and plastic ties/

2 - 1/2 inch wrenches (or adjustable wrenches)

2 - 9/16 inch wrenches (or adjustable wrenches}

2- 3/4 inch wrenches (or adjustable wrenchesl

1 - Pliers (to spread cotter pin)

1- Screwdriver

1 - Measuring tape or ruLer

Figure 1 shows the snow thrower inthe shipping position

Figure 2 shows the snow thrower completely assembled.

Reference to the right and left hand side of the snow

thrower is from the operator's position at the handle.

TO REMOVE SNOW THROWER

FROM CARTON (See FIG. 1)

• Remove packaging inserts located at lour corners of

carton.

• Locate and remove container o! 5W30 oil found in

rear, right, carton insert.

• Cut all four corners of the carton from top to bottom

and lay the panels llat.

• Cut and discard plastic ties securing augers and

wheel axles to the pallet.

• Cutand discard plasticties and bagsthat secure crank

assembly and place assembly aside

• Cut and discard plastic ties securing clutch cables to

lower handle.

• Remove plastic wrap from upper handle which was

used to protect clutch levers

• With the two 9/16" wrenches, loosen (but do not

remove) both bolts securing the upper and lower

handles by holding the inner nut on the inside ot the

handle while turning the outside boll counter-clock-

wise as shown in FIG. 4A, in this section of the manual.

• Swing upper handle up into operating position as

shown in FIG. 2. Hold the inner nut and tighten [ne

outside bolt up against the handle

LEVER LEVER

CABLE

CABLE

MBLY

SHIFTER

LEVER

DEFLECTOR

FIG. 2

CAUTION: IF YOU ARE REMOVING

SNOW FROM ANY GRAVELED OR UN-

EVEN SURFACE, RAISE THE FRONT OF

THE SNOW THROWER BY MOVING THE

SKIDS DOWN. THIS WILL HELP TO PREVENT

STONES AND OTHER DEBRIS FROM BEING

PICKED UP AND THROWN BY THE AUGER.

LOWEr HANDLE

FIG. 1

CONTROL

PANEL

CLUTCH

UPPER

HANDLE

ASSEMBLY

7

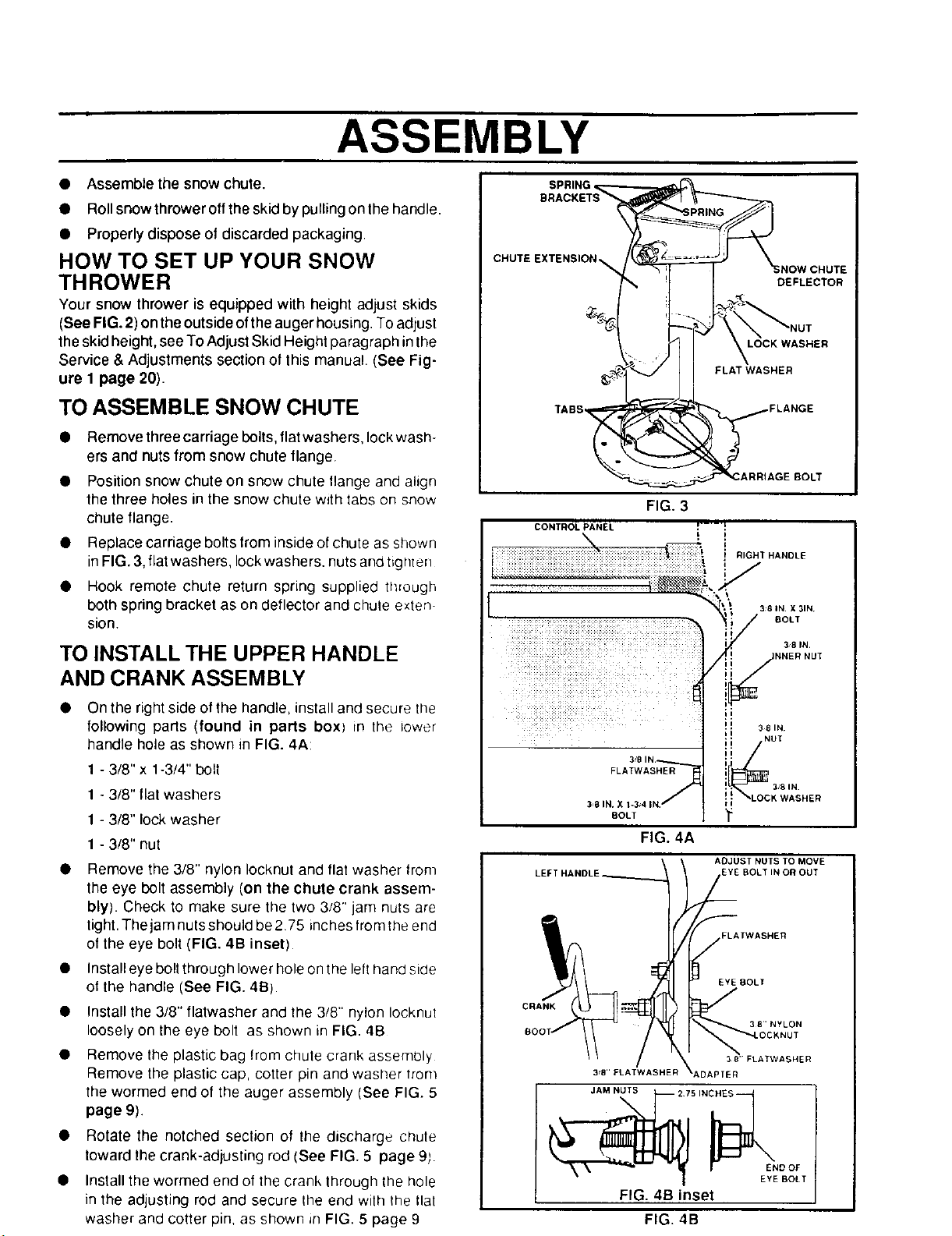

ASSEMBLY

• Assemble the snow chute.

• Rollsnow throweroff the skid by pulling on the handle.

• Properly dispose of discarded packaging.

HOW TO SET UP YOUR SNOW

THROWER

Your snow thrower is equipped with height adjust skids

(See FIG. 2) on the outside of the auger housing. To adjust

the skid height, see To Adjust Skid Height paragraph inthe

Service & Adjustments section of this manual. (See Fig-

ure 1 page 20).

TO ASSEMBLE SNOW CHUTE

• Remove three carriage bolts, flat washers, lock wash-

ers and nuts from snow chute flange.

• Position snow chute on snow chute llange and align

the three holes in the snow chute with tabs on snow

chute flange.

• Replace carriage bolts from inside of chute as shown

in FIG. 3, flat washers, lock washers, nuts and tighter]

• Hook remote chute return spring supplied through

both spring bracket as on deflector and chute exten

sion.

TO INSTALL THE UPPER HANDLE

AND CRANK ASSEMBLY

• On the right side of the handle, install and secure tile

following pads (found in parts boxl in the lower

handle hole as shown in FIG. 4A:

1 - 3/8" x 1-3/4" bolt

1 - 3/8" flat washers

1 - 3/8" lockwasher

1 - 3/8" nut

Remove the 3/8" nylon Iocknut and flat washer from

the eye bolt assembly (on the chute crank assem-

bly). Check to make sure the two 3/8" jam nuts are

tight. The jam nuts should be275 inches from _heend

of the eye bolt (FIG. 4B inset)

Install eye bolt through lower hole on the left hand side

ot the handle (See FIG. 4B)

Install the 3/8" flatwasher and the 3/8" nylon Iocknul

loosely on the eye bolt as shown in FIG. 4B

Remove the plastic bag lrom chute crank assembly

Remove the plastic cap, cotter pin and washer trom

the wormed end of the auger assembly (See FIG. 5

page 9).

Rotate the notched seclion of the discharge chute

toward the crank-adjusting rod (See FIG. 5 page 9;

Install the wormed end of the crank through the hole

in the adjusting rod and secure the end with the tlat

washer and cotter pin, as shown in FIG. 5 page 9

BRACKETS

SPRING _

CHUTE EXTENSION _ #L ......

TABS ., FLANGE

_ARRIAGE BOLT

FIG. 3

CONTROL PANEL _'-'-'!

" " _ : : ." • " " "_'_" _ R GHT HANDLE

• .... l

_ BOLT

/

d

3s8 IN.

CRANK

FLATWAS_

3_8 IN. X 1-3_4 IN.

BOLT

FIG. 4A

3sB"ELATWASHER

JAM NUTS

\

FIG. 4B inset

FIG. 4B

_LOCK WASHER

¥

ADJUST NUTS TO MOVE

.EYE BOLT IN OR OUT

;LAfWASHER

EYE BOLl

38'FLATWASHER

DAPTER

NOW

DEFLECTOR

3 8 IN. X 3IN+

381N.

,_NNER NUT

381N.

38"NYLON

END OF

EYE BOLT

CHUTE

ASSEMBLY

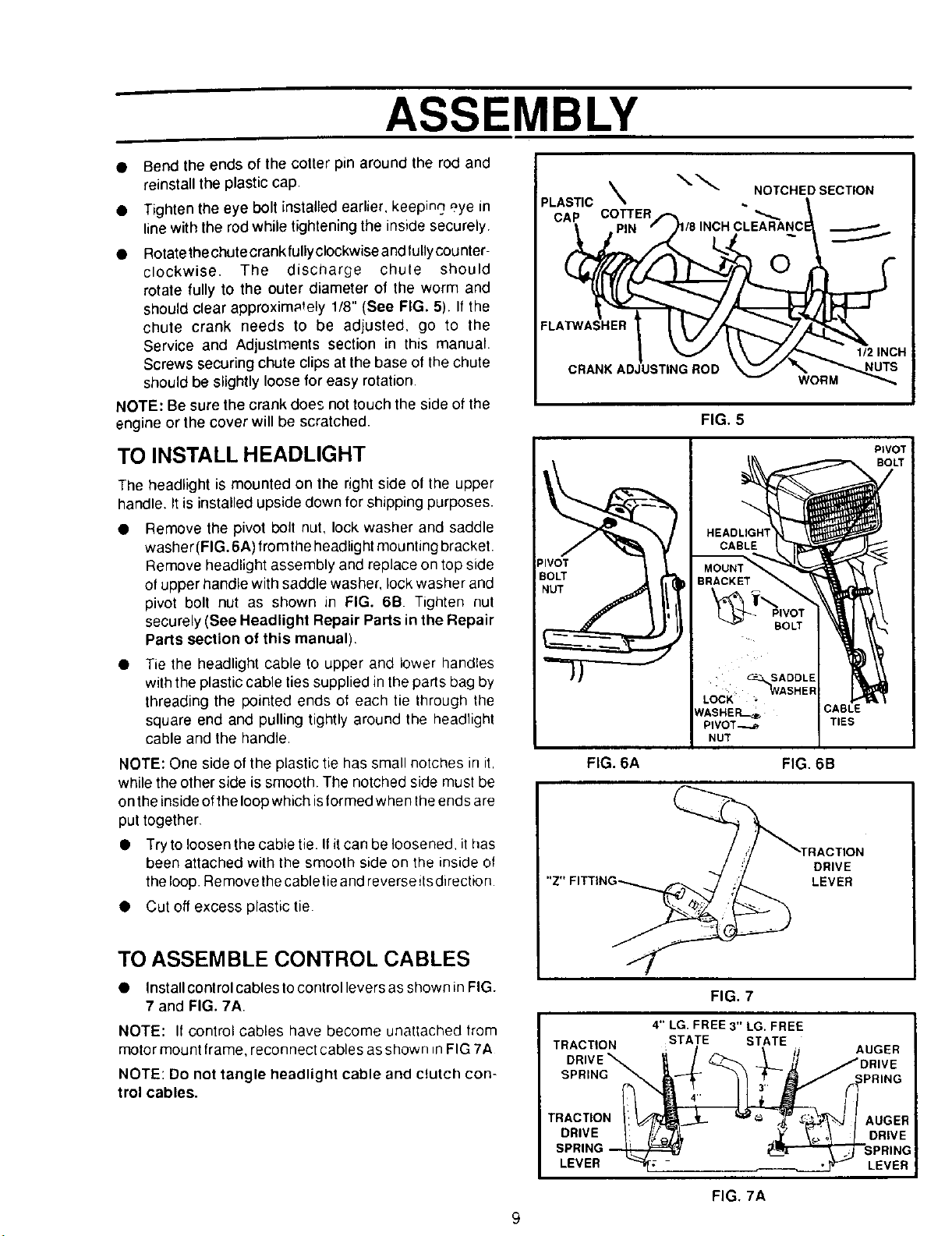

Bend the ends of the cotter pin around the rod and

reinstall the plastic cap.

Tighten the eye bolt installed earlier, keeping eye in

line with the rod while tightening the inside securely

Rotatethe chute crank fully clockwise and tullycounter-

clockwise. The discharge chule should

rotate fully to the outer diameter of the worm and

should clear approximately 1/8" (See FIG. 5). If the

chute crank needs to be adjusted, go to the

Service and Adjustments section in this manual•

Screws securing chute clips at the base of the chute

should be slightly loose for easy rotation

NOTE: Be sure the crank does not touch the side of the

engine or the cover will be scratched.

TO INSTALL HEADLIGHT

The headlight is mounted on the right side of the upper

handle. It is installed upside down for shipping purposes•

Remove the pivot bolt nut, lock washer and saddle

washer (FIG.6A) from the headlight mounting bracket•

Remove headlight assembly and replace ontop side

of upper handle with saddle washer, lock washer and

pivot bolt nut as shown in FIG. 6B Tighten nut

securely (See Headlight Repair Parts in the Repair

Parts section of this manual).

Tie the headlight cable to upper and lower handles

with the plastic cable ties supplied in the parts bag by

threading the pointed ends ot each tie through the

square end and pulling tightly around the headlight

cable and the handle.

NOTE: One side of the plastic tie has small notches in it,

while the other side is smooth. The notched side must be

on the inside of the loop which isformed when the ends are

put together,

• Try to loosen the cable tie. Ifit can be loosened, it has

been attached with the smooth side on the inside ol

the loop• Remove the cable tieand reverse itsdirection

• Cut off excess plastic tie.

PLASTIC\ . NOTCHEDSECTION

CAP COTTER _.

FLATWASHER 1

CRANK ADJUSTING ROD

FIG. 6A FIG. 6B

_1/8INCH CLEARANC

WORM

FIG. 5

BOLT

• C-= SADDLE

• ='_ASH ER

LOCK -

NASHER--_, CABLE

PIVOT--._ TIES

NUT

1/2 INCH

PtVOT;

DRIVE

LEVER

i

TO ASSEMBLE CONTROL CABLES

• Install control cables tocontrol levers as shown in FIG.

7 and FIG. 7A.

NOTE: If control cables have become unattached from

motor mount frame, reconnect cables asshown _nFIG 7A

NOTE: Do not tangle headlight cable and clutch con-

trol cables.

FIG. 7

4" LG. FREE 3" LG. FREE

TRACTION STATE STATE

DRIVE_ _/ _ _L__ /DRIVE

SPRING m,,_)_J_- _! :' A_""_ R PRING

DRIVE I: [_'Q"[J_, ,.¥ _;o\ I DRWE

SPRING _ I___I!I"_"--"_'_,T-S p RING

LEVER ""_ • _ LEVER

: / t iJ AUGER

4,,

FIG. 7A

9

Loading...

Loading...