Craftsman 536886121 Owner’s Manual

OWN

R'S

UAL

MODEL NO.

536.886121

Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

®

5 HORSEPOWER

22" DUAL STAGE

SNOW THROWER

120V. ELECTRIC START

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

Q Repair Parts

SEARS, ROEBUCK AND CO., Hoffman Estates, IL

337440 05/17/95

60179 U.S.A.

SAFETY RULES

PLACE WIRE WHERE IT CANNOT CONTACT SPARK PLUG

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND

TO PREVENT ACCIDENTAL STARTING WHEN SETTING-UP,

TRANSPORTING, ADJUSTING OR MAKING REPAIRS.

IMPORTANT

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE

RISK OF INJURY. YOUR SNOW THROWER IS EQUIPPED WITH SUCH CONTROLS, DO NOT

ATTEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER

ANY CIRCUMSTANCES.

TRAINING 6,

1. Read the operator's manual carefully_ Be

thoroughly familiar with the controls and the 7,

proper use of the snow thrower. Know how to

stop the snow thrower and disengage the

controls quickly.

2_ Never allow chUdren to operate the snow thrower

and keep them away while it is operating. Never

allow adults to operate the snow thrower without

proper instruction, Do not carry passengers., 9

3. Keep the area of operation clear of all persons,

particularly small children, and pets..

4. Exercise caution to avoid slipping or falling,

especially when operating in reverse

PREPARATION

1. Thoroughly inspect the area where the snow

thrower is to be used and remove all doormats,

sleds, boards, wires, and other foreign objects.

2. Disengage all clutches and shift into neutral

before starting the engine (motor).

3. Do not operate the snow thrower without wearing

adequate winter outer garments Wear footwear

that will improve footing on slippery surfaces.

4 Handle fuel with care; _tis highly flammable.

(a) Use an approved fuel container,

(b) Never remove fuel tank cap or add fuel to a

runningengineor hot engine°

(c) Fill fuel tank outdoors with extreme care

Never fill fuel tank indoors_

(d) Replace fuel tank cap securely and wipe up

spilled fuel

(e) Never store fuel or snow thrower with fuel in

the tank inside of a building where fumes may

reach an open flame or spark.

(f) Check fuel supply before each use, allowing

space for expansion as the heat of the engine

(motor) and/or sun can cause fuel to expand.

5_

Use extension cords and receptacles as specified

by the manufacturer for all snow throwers with

electric drive motors or electric starting motors.

Adjust the snow thrower height to clear gravel or

crushed rock surfaces.

Never attempt to make any adjustments while the

engine (motor) is running (except when

specifically recommended by the manufacturer)

8-

Let engine (motor) and snow thrower adjust to

outdoor temperatures before starting to clear

snow,,

Always wear safety glasses or eye shieEdsduring

operation or while performing an adjustment or

repair to protect eyes from foreign objects that

may be thrown from the snow thrower-

OPERATION

1.. Do not put hands or feet near or under rotating

parts Keep clear of the discharge opening at all

times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads Stay alert

for hidden hazards or traffic.

3. After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

disconnect the cord on electric motors,

thoroughly inspect the snow thrower for any

damage, and repair the damage before restarting

and operating the snow thrower.

zl_ If the snow thrower should start to vibrate

abnormally, stop the (motor) and check

immediately for the cause Vibration is generally

a warning of trouble..

5. Stop the engine (motor') whenever you leave the

operating position, before unclogging the auger/

impeller housing or discharge guide, and when

making any repairs, adjustments, or inspections

6 When cleaning, repairing, or inspecting, make

certain the augedimpeHer and all moving parts

have stopped. Disconnect the spark plug wire

and keep the wire away from the plug to prevent

accidental starting.

7. Take all possible precautions when leaving the

snow thrower unattended Disengage the auger/

impeller, shift to neutral, stop engine, and

remove key.

,l_lJIl_ II'l ......

SAFETY RULES

8. Do not tun the engine indoors, except when starting

the engine and for transporting the snow thrower in

or out of the building. Open the outside doors;

exhaust fumesare dangerous(containing CARBON

MONOXIDE,an ODORLESS and DEADLYGAS)

9° Do not clear snow across the face of slopes

Exercise caution when changing direction on

slopes_Do not attempt to clearsteep slopes

10. Never operate the snow thrower without proper

guards, platesor othersafety protectivedevices

in place.

11o Never operate the snow thrower near glass

enclosures, automobiles, window wells,

drop-otis, and the like without proper adjustment

of the snow discharge angle. Keep children and

pets away.

12. Do not overload the machine capacity by

attempting to clear snow at too fast a rater

13. Never operate the snow thrower at high transport

speeds on slippery surfaces. Look behind and

use care when backing

14 Never direct discharge at bystanders or allow

anyone in front of the snow thrower.

15. Disengage power to the auger/impeller when

snow thrower is transported or not in use..

16 Llse only attachments and accessories approved

by the manufacturer of the snow thrower (such

as tire chains, electric start kits, etc.),,

17_ Never operate the snow thrower without good

visibilityor light. Always be sure of your footing,

and keep a firm hold on the handles, Walk; never

run.

MAINTENANCE AND STORAGE

1. Check shear bolts and other bolts frequently for

proper tightness to be sure the snow thrower

is in safe working condition

2. Never store the snow thrower with fuel in the fuel

tank inside a building where ignitionsources are

present such as hot water and space heaters,

clothes dryers, and the like,. Allow the engine to

cool before storing in any enclosure,

3o Always refer to operator's manual instructions

for important details if the snow thrower is to be

stored for an extended period

4 Maintain or replace safety and instruclion labels,

as necessary..

5. Run the snow thrower a few minutes after

throwing snow to prevent freeze-up of the auger/

impeller.

WARNING

This snow thrower Is for use on sidewalks,

driveways, and other ground level surfaces°

CAUTION should be exercised while using on

steep sloping surfaces. DO NOT USE SNOW

THROWER ON SURFACES ABOVE GROUND

LEVEL such as roofs of residences, garages,

porches or other such structures or buildings.

LOOK FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS. IT

MEANS--ATTENTION!!! BECOME

ALERTI!! YOUR SAFETY IS INVOLVED.

......c=.0r,ia o s.io,,65WA""i.G!

_i The engine exhaust from this product

3

contains chemicals known to the State

of California to cause cancer, birth de-

fects or other reproductive harm.

CONGRATULATIONS on your purchase of a Sears

Craftsman Snow Thrower it has been designed, engi-

neered and manufacturedtogive youthe best possible

dependability and performance

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

CenterlDepartmenL Sears hascompetent, well-trained

techniciansand the proper toolsto service or repairthis

unity

Please read and retainthismanual The instructions will

enableyoutoassembleandmaintainyoursnowthrower

properly. Always observe the "SAFETY RULES:

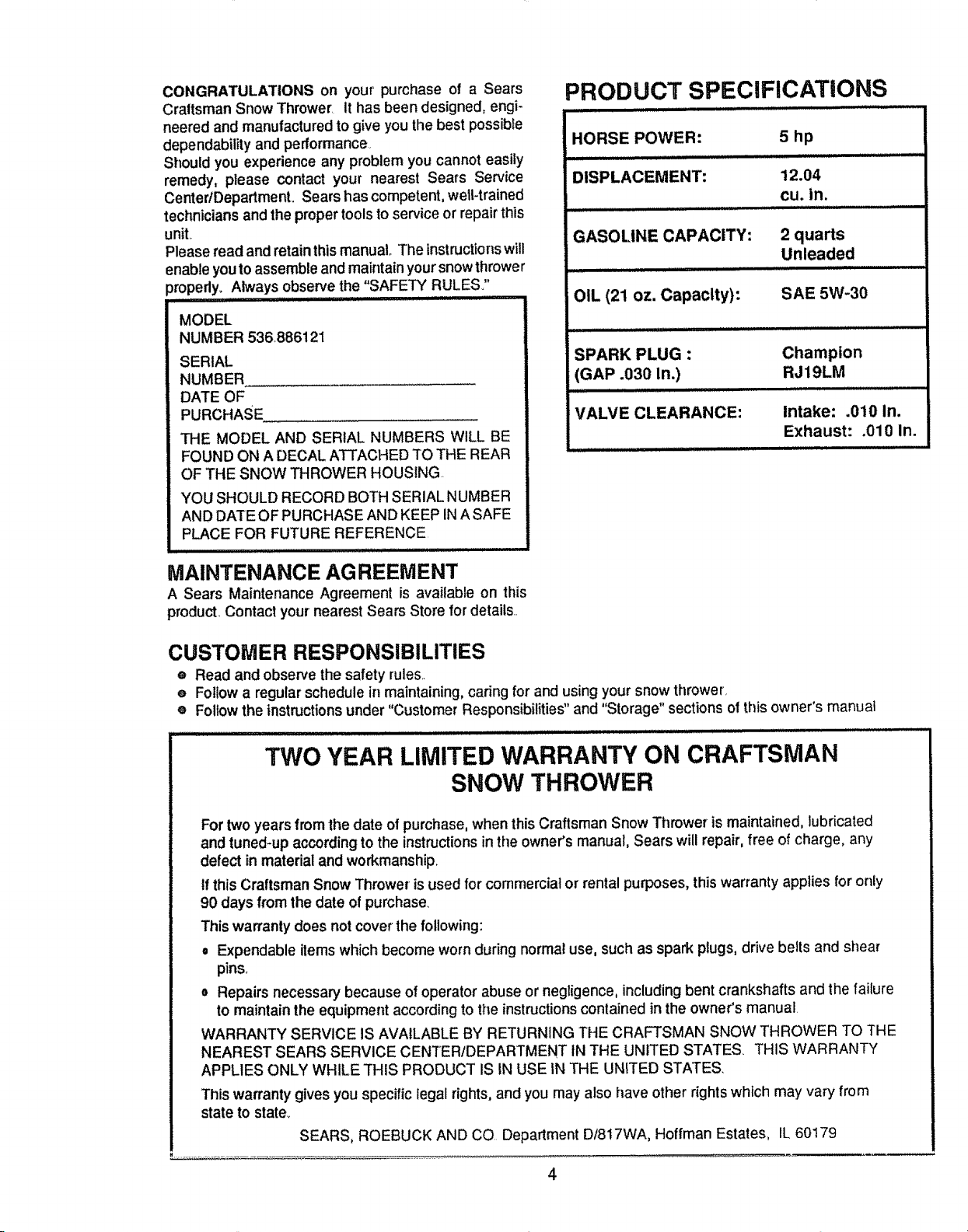

: RODUCT SPECIFICATIONS

llll i

HORSE POWER: 5 hp

DISPLACEMENT: 12.04

cu. in.

GASOLINE CAPACITY: 2 quarts

Unleaded

OIL (21 oz. Capacity): SAE 5W-30

SPARK PLUG : Champion

(GAP .030 in.) RJ19LM

VALVE CLEARANCE: Intake: .010 In.

Exhaust: .010 In.

MAINTENANCE AG REEMENT

A Sears Maintenance Agreement is available on this

product Contact yournearest Sears Store for details

CUSTOMER RESPONSIBILITIES

® Read and observethe safety rules

e Followa regularschedule in maintaining,caring for and using your snow thrower

e Followthe instructions under "Customer Responsibilities" and "Storage" sections of thisowner's manual

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

SNOW THROWER

For two years fromthe date of purchase,when this Craftsman Snow Thrower is maintained, lubricated

and tuned-up according to the instructions in the owner's manual, Sears will repair, free of charge, any

defect in material and workmanship_

If this Craftsman Snow Thrower is used for commercial or'rental purposes, this warranty applies for only

90 days from the date of purchase.

This warranty does not cover the following:

e Expendable items which become worn during normal use, such as spark plugs, drive belts and shear

pins.

o Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure

to maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE

NEAREST SEARS SERVICE CENTERIDEPARTMENT tNTHE UNITED STATES THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which may vary from

state to state_

SEARS, ROEBUCK AND CO Department DI817WA, Hoffman Estates, IL 60179

4

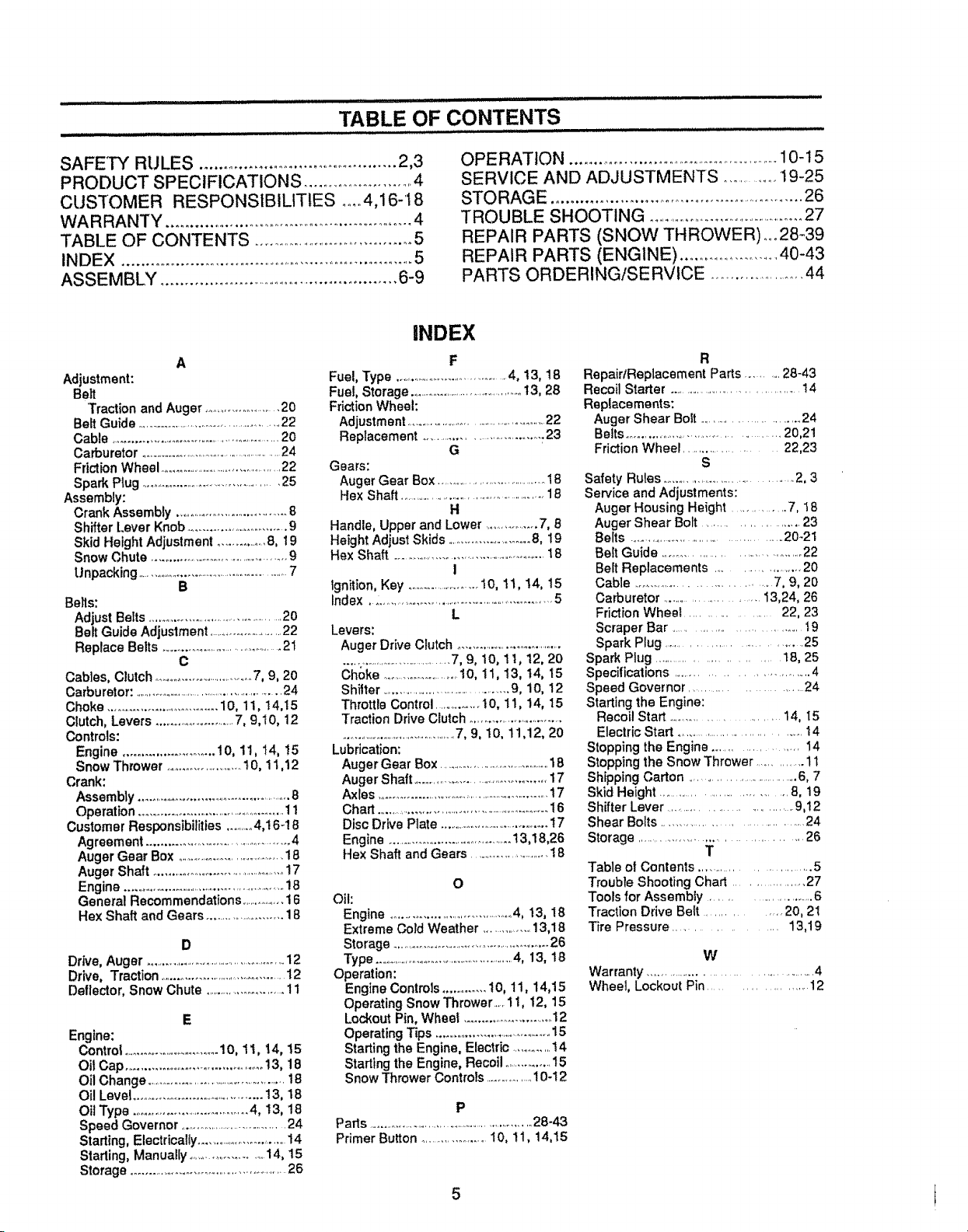

SA FEm_ RULES ........................................ 2_3

PRODUCT SPECIFICATIONS .......................... 4

CUSTOMER RESPONSIBILITIES .... 4,16-t8

WARRANTY ........................................................ 4

TABLE OF CONTENTS ............................................5

INDEX ......................................................................5

ASSEMBLY ..................................................... 6-9

A

Adjustment:

Belt

Traction and Auger .......................20

Belt Guide ..................................................22

Cable .........................................................20

Carburetor ....................................................24

Frictbn Wheel ................................................22

Spark Plug .............................................25

Assembly:

Crank Assembly ..................................8

Shifter Lever Knob .............................9

Skid Height Adjustment ...............8, 19

Snow Chute ...........................................9

Unpacking .........................................................7

B

Bells:

Adjust Belts .............................................20

Belt Guide Adjustment ..........................22

Replace Belts ...........................................21

C

Cables, Clutch ..............................7, 9, 20

Carburetor: ...................................................24

Choke ................................10, 11, t4,15

Clutch, Levers .............................7, 9,10, 12

Controls:

Engine ......................... 10, 11, 14, 15

Snow Thrower ........................10, 11,12

Crank:

Assembly ...............................................8

Operation ................................................11

Customer Responsibilities ..........4,16-18

Agreement .............................................4

Auger Gear Box ........................................18

Auger Shaft ............................................17

Engine....................................................i8

General Recommendations ................16

Hex Shaft and Gears .........................18

D

Drive, Auger ..................................................12

Drive, Traction..........................................12

Deflector, Snow Chute ...........................11

E

Engine:

Control ..................................10, tl, 14, 15

Oil Cap .........................................13, 18

OilChange ...................................................18

OilLevel ......................................13, 18

OUType ..................................4, 13, 18

Speed Governor .....................................24

Starting, Electrically...............................14

Starting, Manually ......................14, 15

Storage ...................................................26

Fuel, Type ....................................4, 13, 18

Fuel, Storage .......................................t3, 28

Friction Wheel:

Adjustmen!..................................................22

Replacement ...................................23

Gears:

Auger Gear Box .......................................18

He× Shaft ................................................18

Handle, Upper and Lower .................7, 8

Height Adjust Skids ...............................8, 19

Hex Shaft ...................................................18

Ignition, Key .......................I0, 11, !4, 15

Index.....................................................5

Levers:

Auger Drive Clutch .................................

........................................7, 9, 10, 11, t2, 20

Choke .........................10, 11, 13, !4, 15

Shitter .............................................9, 10, 12

Throttle Control ..............I 0, 11, 14, 15

Traction Drive Clutch ...............................

..........................................7, 9, 10, 11,12, 20

Lubrication:

Auger Gear Box .........................................18

Auger Shaft .............................................17

Axles ......................................................17

Chart .............................................................16

Dfsc Drive Plate ........................................17

Engine ....................................13,18,26

Hex Shaft and Gears ...........................18

Oil:

Engine ........................................4, !3, 18

Extreme Cold Weather ...............13,18

Storage .....................................................26

Type ......................................................4, 13, 18

Operation:

Engine Controls .............10, 11, 14,15

Operating Snow Thrower., 11, 12, 15

Lockout Pin, Wheel ............................12

Operating Tips ........................................15

Startingthe Engine, Electric .............14

Starting the Engine, Recoil ................15

Snow Thrower Controls ...............10-12

Parts ..............................................................28-43

Primer Button .....................10, 11, 14,15

INDEX

F

G

H

I

L

O

P

OPERATION .......................................................10-t 5

SERVICE AND ADJUSTMENTS ..............I9-25

STO RAG E ..................................................... 26

TROUBLE SHOOTING ..............................................27

REPAIR PARTS (SNOW THROWER),,,. 28-39

REPAIR PARTS (ENGINE) .........................40-43

PARTS ORDERING/SERVICE ....................... 44

R

RepairtReplacement Parts .......... 28-43

Recoil Starter ......................................14

Replacements:

Auger Shear Bolt .............................24

Belts ......................................... 20,21

Friction Wheel .................... 22,23

S

Safety Rules ......................................2, 3

Service and Adjustments:

Auger Housing Height .............. 7, !8

Auger Shear Boft ........................ 23

Belts ........................................... 20-21

Bell Guide ..................................... 22

Belt Replacements .................... 20

Cable ................................. 7, 9, 20

Carburetor .......................... 13,24, 26

Friction Wheel ..................... 22, 23

Scraper Bar .............................. t9

Spark Plug .............................. 25

Spark Plug .............................. t8, 25

Specifications ................................. 4

Speed Governor ........................... 24

Starting the Engine:

Recoil Start ........................ 14, t5

Electric Start ................................... t 4

Stopping the Engine ................. 14

Stopping the Snow Thrower ............ 11

Shipping Carton ...................................6, 7

Skid Height ......................................8, 19

Shifter Lever ................................ 9,12

Shear Bolts ....................................... 24

Storage ........................................... 26

T

Table of Contents ............................. 5

Trouble Shooting Chart ................... 27

Tools for Assembly .......................... 6

Traction Drive Belt .............. 20, 2t

Tire Pressure ................... 13,19

W

Warranty ............................................. 4

Wheel, Lockout Pin ...................... 12

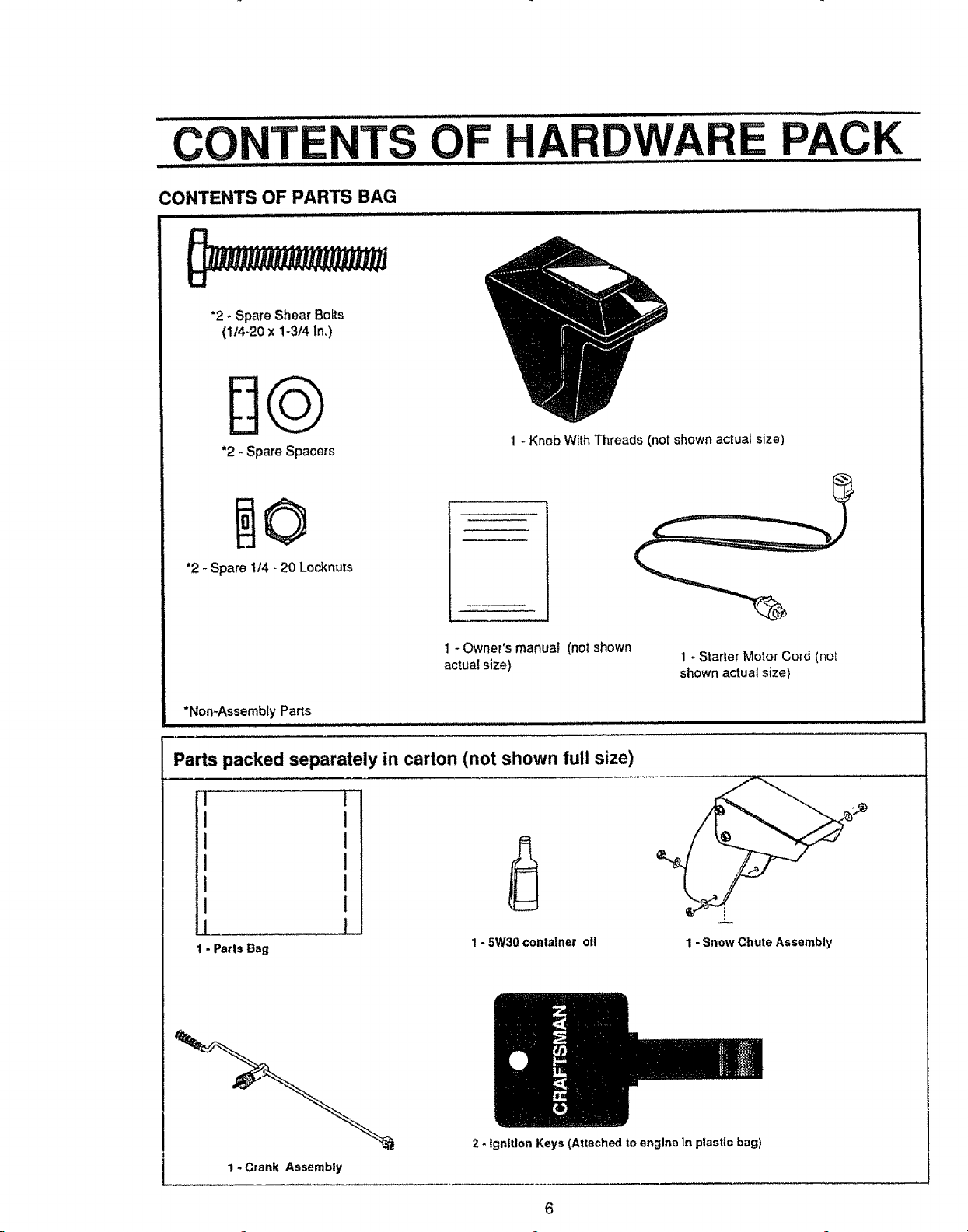

CONTENTS OF

CONTENTS OF PARTS BAG

................................. ,,,,, ,,,,,,,,,,,,,,,,,,

"2 - Spare Shear Bolts

(1/4.20 x 1-3/4 In.)

DQ

*2 - Spare Spacers

"2 - Spare 1t4 - 20 Locknuts

HARDWARE PACK

1- Knob WithThreads (not shown actual size)

1 - Owner's manual (not shown

actual size)

*Non-Assembly Parts

Parts packed separately in carton (not shown full size)

I

I

I

i

I

1 - Parts Bag

1- 5W30 container oft

1 - Starter Molor Cord (not

shown actual size)

='_L

1 -Snow Chute Assembly

1 - Crank Assembly

2 - Ignition Keys (Attached to engine In ptastlc bag)

6

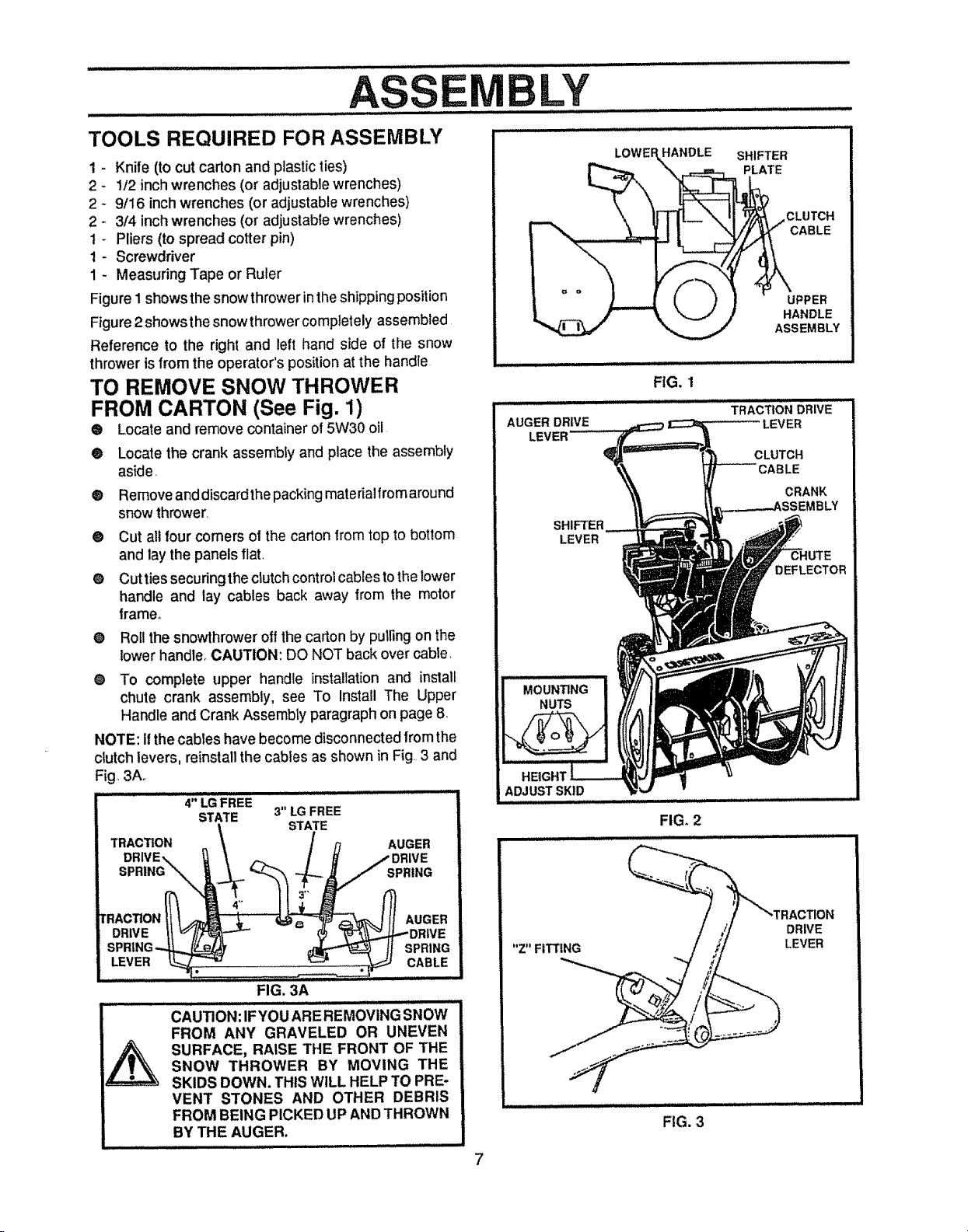

H ,,,,,i ,,i IIIIH,.I. II.I I I ,I Illll II I ,/'/ I,,,,,,, .....

AS LY

TOOLS REQUIRED FOR ASSEMBLY ......................................................

1 - Knife (to cut carton and plastic ties)

2 - !12 inch wrenches (or adjustable wrenches)

2 - 9116 inch wrenches (or adjustable wrenches)

2 - 3/4 inch wrenches (or adjustable wrenches)

t - Pliers (to spread cotter pin)

I- Screwdriver

1 - Measuring Tape or Ruler

Figure 1 shows the snowthrower in theshipping position

Figure 2showsthe snowthrowercomptetely assembled

Reference to the right and left hand side of the snow

thrower is from the operator's position at the handle

TO REMOVE SNOW THROWER

FROM CARTON (See Fig. 1)

® Locate and remove container of 5W30 oil

• Locate the crank assembly and place the assembly

as{de,

® Remove and discardthe packing materialfrom around

snow thrower,

® Cut all four comers of the carton from top to bottom

and lay the panels flat.

e Cut ties securing the clutch control cables to the lower

handle and lay cables back away from the motor

frame°

O

Roll the snowthrower off the carton by puli_ngon the

lower handle_CAUTION: DO NOT back over cable.

O

To complete upper handle installationand install

chute crank assembly, see To Install The Upper

Handle and Crank Assembly paragraph on page 8

NOTE: Itthe cables have become disconnected from the

clutch levers, reinstall the cables as shown in Fig,3 and

Fig, 3Ao

........... 4" LG FREE

STATE 3" LG FREE

i i ill iqt ii mE HqLI II

STATE

LOWE HANDLE

FIG. 1

ADJUST SKID

FIG. 2

SHIFTER

PLATE

UPPER

HANDLE

ASSEMBLY

DRIVE.,.. / DRIVE

SPRING_\.. J SPRING

tRACTION_"__ _--"_ f_ AUGER

TRACTION __ AUGER

DRIVE _1_"//,, _,_DRIVE

SPR|NG-.._ _ H SPRING

LEVER 1___2 ......i,;,,'i,,,i,,ii'i,i,_ CABLE,

FIG. 3A

CAU]ION :IF YOUARE REMOVING SNOW

FROM ANY GRAVELED OR UNEVEN

SNOW THROWER BY MOVING THE

SURFACE, RAISE THE FRONT OF THE

SKIDS DOWN. THIS WiLL HELP TO PRE-

VENT STONES AND OTHER DEBRIS

FROM BEING PICKED UP ANDTHROWN

BY THE AUGER.

DRIVE

LEVER

FIG. 3

7

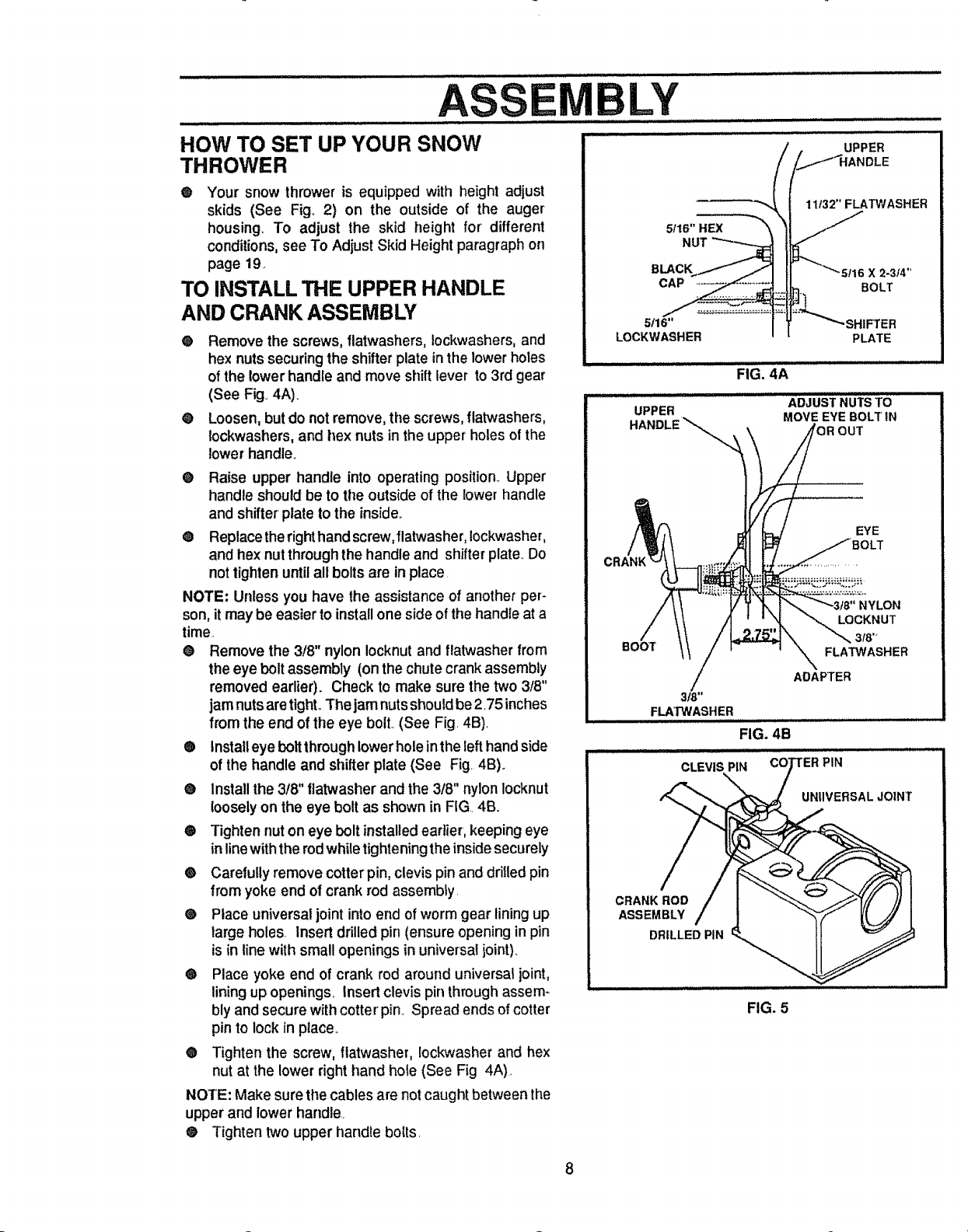

LY

HOW TO SET UP YOUR SNOW

THROWER

® Your snow thrower is equipped with height adjust

skids (See Fig_ 2) on the outside of the auger

housing. To adjust the skid height for different

conditions, see To Adjust Skid Height paragraph or]

page 19.

TO INSTALL THE UPPER HANDLE

AND CRANK ASSEMBLY

® Remove the screws, flatwashers, lockwashers, and

hex nuts securing the shifter plate in the lower holes

of the lowerhandle and move shift lever to 3rd gear

(See Fig. 4A)_

@ Loosen, but do not remove, the screws, flatwashers,

tockwashers,and hex nuts in the upper' holes of the

lowerhandle.

® Raise upper handle into operating position. Upper

handle should be to tile outside of the lower handle

and shifter plate to the inside.,

® Replace theright hand screw,flatwasher, Iockwasher,

and hex nut through the handle and shifter plate,.Do

not tighten until all bolts are in place

NOTE: Unless you have the assistance of another per-

son, it may be easier to installone side of the handle at a

time.

® Remove the 3/8" nylon Iocknut and flatwasher from

the eye bolt assembly (on the chute crank assembly

removed eadier). Check to make sure the two 3t8"

jamnuts are tight., The jam nuts should be2.75 inches

from the end of the eye bolt. (See Fig. 4B).

® Install eye bolt through lower holeinthe left hand side

of the handle and shifter plate (See Fig. 4B).

e Install the 3!8" flatwasher and the 3t8" nylon Iocknut

looselyon the eye bolt as shown in FIG 4B.

® Tighten nut on eye bolt installedearlier, keeping eye

in line with the rod while tightening the inside securely

® Carefully remove cotterpin, clevis pinand drilled pin

from yoke end of crank rod assembly.

® Place universal joint into end of worm gear lining up

large holes. Insert drilled pin (ensure opening in pin

is in line with small openings in universal joint).

® Place yoke end of crank rod around universal joint,

lining up openings, Insert clevis pin throughassem-

bly and secure with cotter pin.. Spread ends of cotter

pin to lock in place..

• Tighten the screw, flatwasher, !ockwasher and hex

nut at the lower right hand hole (See Fig 4A).

NOTE: Make sure the cables are not caught between the

upper and lowerhandle,

® Tighten two upper handle boils.

UPPER

)LE

11t32" FLATWASHER

NUT

BLACK 2.3_ ,_

CAP BOLT

5/16" HIFTER

LOCKWASHER PLATE

FIG, 4A

UPPER

HANDLE_,_ MOVE EYE BOLTIN

3/8"

FLAW='ASHER

ADJUSTNUTSTO

OUT

EYE

LOCKNUT

FLATWASHER

ADAPTER

FIG. 4B

CLEVIS PiN 'ER PIN

UNIIVERSALJO]NT

CRANK ROD

ASSEMBLY

DRILLED PIN

FIG. 5

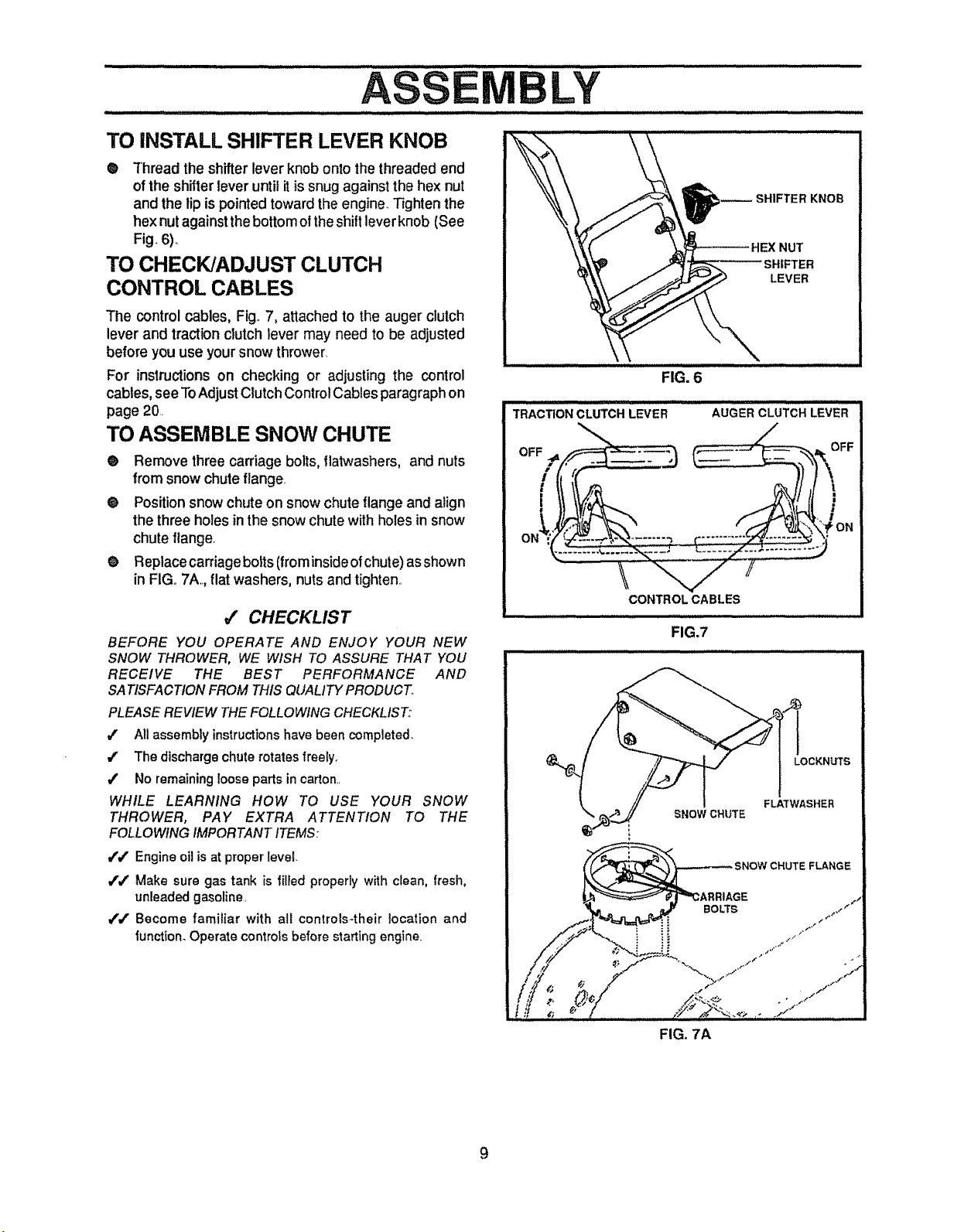

TO iNSTALL SHIFTER LEVER KNOB

@ Thread the shifter lever knob onto the threaded end

of the shifter lever until itissnug against the hex nut

and the lip is pointed toward the engine. Tighten the

hex nutagainst the bottom o! the shiftlever knob (See

Fig. 6).,

TO CHECK/ADJUST CLUTCH

CONTROL CABLES

The control cables, Fig_7, attached to the auger clutch

lever and traction clutch lever may need to be adjusted

before you use your snow thrower.

For instructionson checking or adjusting the control

cables, seeToAdjust Clutch Control Cables paragraph on

page 20.

TO ASSEMBLE SNOW CHUTE

• Remove three carriage bolts, flatwashers, and nuts

from snow chuteflange.

e Position snow chute on snow chute flange and align

the three holes inthe snow chute with holes insnow

chute flange.

e Replace carriage bolts(from inside of chute) asshown

in FIGo7A. flat washers, nuts and tighten..

_/ CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

SNOW THROWER, WE WISH TO ASSURE THAT YOU

RECEIVE THE BEST PERFORMANCE AND

SATISFACTION FROM THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

#' All assembly instructionshave been completed.

4' The discharge chute rotates freely.

/ No remaining !oose parts incarton_.

WHILE LEARNING HOW TO USE YOUR SNOW

THROWER, PAY EXTRA ATTENTION TO THE

FOLLOWING IMPORTANT ITEMS:

/./' Engine oil is at proper level.

i'v" Make sure gas tank is filied properly with clean, fresh,

unleaded gasoline.

/,/' Become familiar with all controls-their location and

function.Operate controts before starting engine.

LEVER

FIG. 6

T.A'c:noNcLuTC.L E. Au E"CLuTc,LEVER

CONTROL CABLES

FIG.7

LOCKNUTS

SNOW CHUTE

BOLTS

FLA'TWASHER

FLANGE

_,GE

FIG. 7A

9

......... i iiiillll Ill I I,,11I, ul Ill I ll,,I.

O T

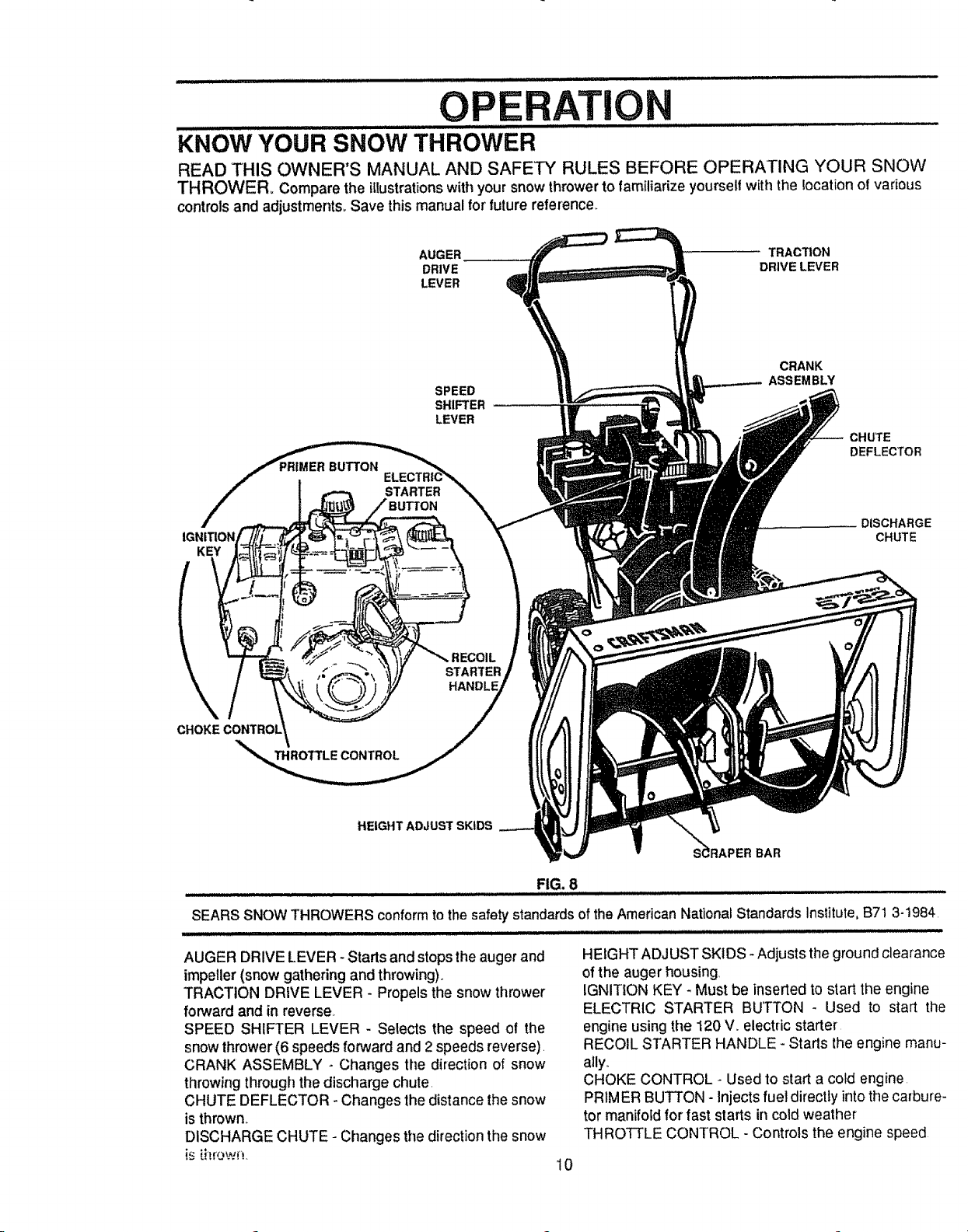

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR SNOW

THROWER= Compare the illustrationswithyour snow throwerto familiarize yourselfwith the location of various

controlsand adjustment& Save thismanualfor future reference.

AUGER TRACTION

DRIVE DRIVE LEVER

LEVER

CRANK

SPEED

SHIFTER

LEVER

BUTTON

STARTER

KEY

ASSEMBLY

CHUTE

DEFLECTOR

DISCHARGE

CHUTE

STARTER

\

THROTTLE CONTROL

HEIGHT ADJUST SKIDS

HANDLE

S_RAPER BAR

FIG. 8

SEARS SNOW THROWERS conformto the safety standards of the American National Standards Institute, B71 3-1984

........................ . ..... ,,,, , ,,,,,,,,, , ,,,,

AUGER DRIVE LEVER - Starts and stops the auger and

impeller (snow gathering and throwing).,

TRACTION DRIVE LEVER - Propels the snow thrower

forward and in reverse,

SPEED SHIFTER LEVER - Selects the speed of the

snow thrower (6 speeds forward and 2 speeds reverse).

CRANK ASSEMBLY - Changes the direction of snow

throwing through the discharge chute.

CHUTE DEFLECTOR - Changes the distance the snow

is thrown,,

DISCHARGE CHUTE - Changes the direction the snow

is_itrown.

HEIGHT ADJUST SKIDS - Adjusts theground clearance

of the auger housing,

IGNITION KEY - Must be inserted to start the engine

ELECTRIC STARTER BUTTON - Used to start the

engine using the 120 V,. electric starter

RECOIL STARTER HANDLE - Stads the engine manu-

ally,.

CHOKE CONTROL - Used to start a cold engine

PRIMER BUTTON - Injects fuel directty into the carbure-

tor manifofd for fast starts in cold weather

THROTTLE CONTROL - Controls the engine speed

10

OPE

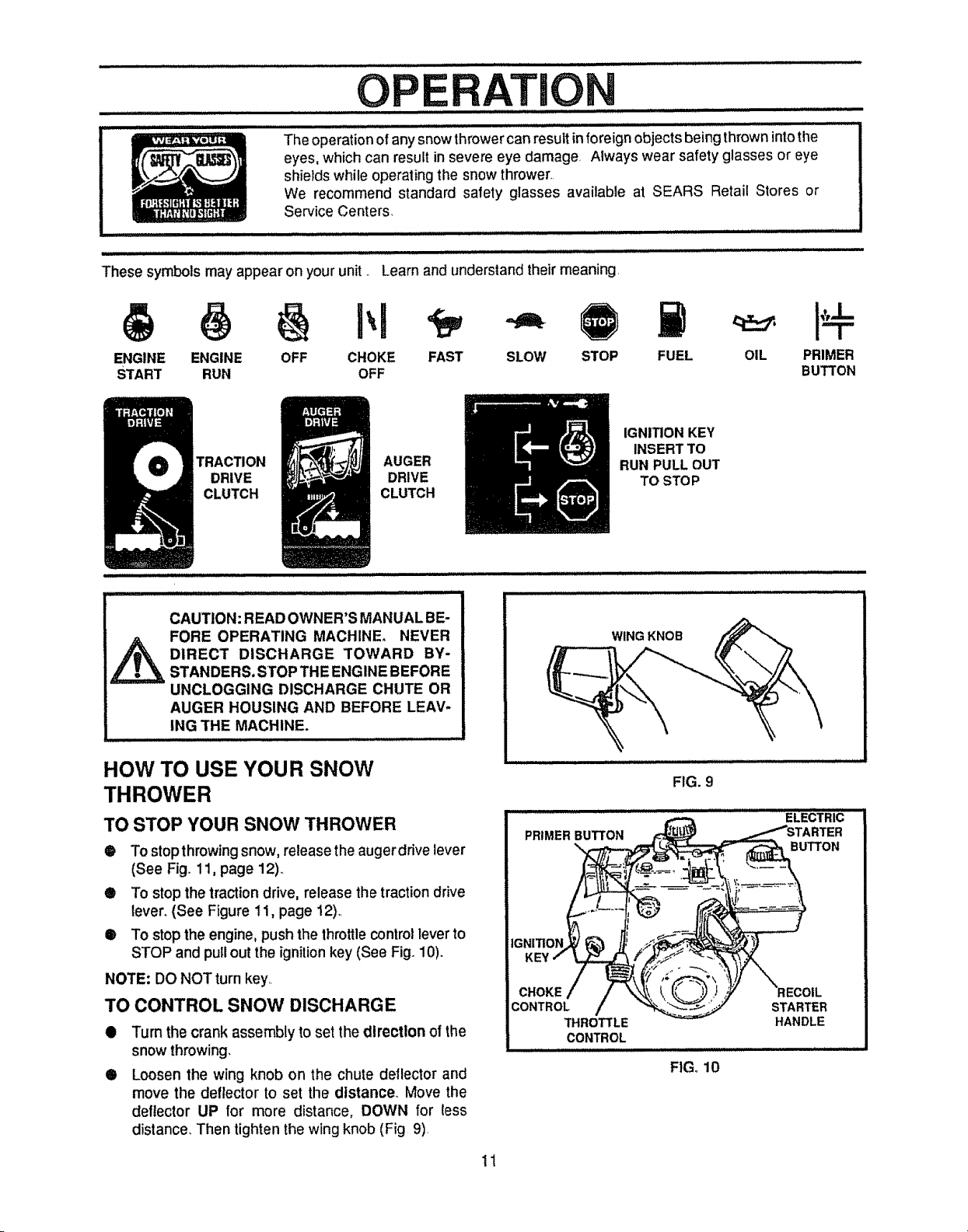

The operation of anysnow thrower can result in foreign objects being thrownintothe

eyes, which can result in severe eye damage. Always wear safety glasses or eye

shields while operating the snow thrower.

We recommend standard safety glasses available at SEARS Retail Stores or

Service Centers

u

These symbols may appear on your unit° Learn and understand their meaning.

TION

ENGINE

START

ENGINE OFF CHOKE FAST SLOW

RUN OFF

TRACTION

DRIVE

CLUTCH

CAUTION: READ OWNER'S MANUAL BE-

FORE OPERATING MACHINE, NEVER

DIRECT DISCHARGE TOWARD BY-

STANDERS. STOP THE ENGINE BEFORE

UNCLOGGING DISCHARGE CHUTE OR

AUGER HOUSING AND BEFORE LEAV-

ING _'HE MACHINE.

HOW TO USE YOU R SNOW

THROWER

AUGER

DRIVE

CLUTCH

STOP FUEL

IGNI_ON KEY

INSERTTO

RUN PULL OUT

TO STOP

WING KNOB

FIG. 9

OIL PRIMER

BUTTON

TO STOP YOUR SNOW THROWER

• To stopthrowing snow, release the augerdrive lever

(See Fig. 11, page 12)..

® To stop the traction drive, release the traction drive

lever. (See Figure ! 1, page ! 2),.

® To stop the engine, push the throttle control lever to

STOP and pullout the ignition key (See Fig. 10).

NOTE: DO NOT turn key..

TO CONTROL SNOW DISCHARGE

O

Turn the crank assembly to set the direction of the

snow throwing,

O

Loosen the wing knob on the chute deflector and

move the deflector to set the distance,, Move the

deflector UP for more distance, DOWN for less

distance. Then tighten the wing knob (Fig 9)

11

THROTTLE

CONTROL

STARTER

HANDLE

FIG. 10

/1111 i IIH,

O

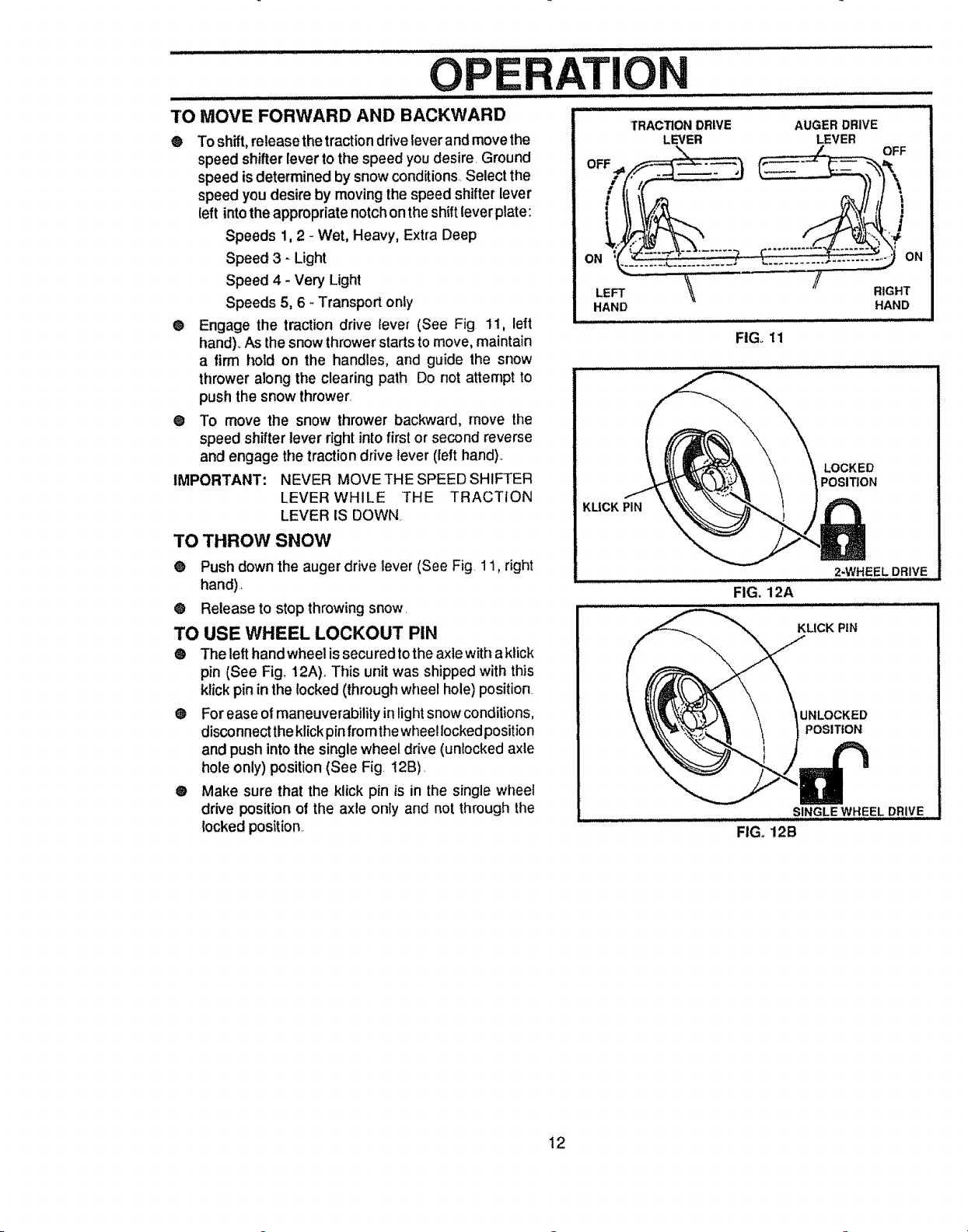

TO MOVE FORWARD AND BACKWARD

@ To shift, re]easethe tractiondrive lever andmovethe

speed shifter lever to the speed youdesire, Ground

speed is determined by snow conditions,,Selectthe

speed you desire by movingthe speedshifterlever

(eft intotheappropriatenotchonthe shiftlever plate:

Speeds 1, 2 - Wet, Heavy, Extra Deep

Speed 3 - Light

Speed 4 - Very Light

Speeds 5, 6 _Transportonly

• Engage the traction drive lever (See Fig 11, left

hand)_As the snow thrower starts to move, maintain

a firm hold on the handles, and guide the snow

thrower along the clearing path Do not attempt to

push the snow thrower.

@ To move the snow thrower backward, move the

speed shifter lever right into first or second reverse

and engage the traction drive lever (left hand).,

IMPORTANT: NEVER MOVE THE SPEED SHIFTER

LEVER WHILE THE TRACTION

LEVER IS DOWN

TO THROW SNOW

@ Push down the auger drive lever (See Fig. 11, right

hand)

@ Release to stop throwing snow.

TO USE WHEEL LOCKOUT PIN

® The left hand wheel is secured tothe axle with aklick

pin (See Fig_!2A). This unit was shipped with this

klick pin in the locked (through wheel hole) position_

Q For ease of maneuverability in light snow conditions,

disconnect the klickpin from the wheel locked position

and push into the single wheel drive (unlocked axle

hole only) position (See Fig. t2B).

® Make sure that the klick pin is in the single wheel

drive position of the axle only and not through the

locked position

ATION

TRACTION DRIVE

LEVER

HAND

KUCK PIN

AUGER DRIVE

LEVER

\

FIGo 11

FIG, 12A

FIG. 12B

/ RIGHT

HAND

LOCKED

POSITION

2-WHEEL DRIVE

KLICK PiN

UNLOCKED

POSITION

SINGLE WHEEL DRIVE

12

i ,,, ,,,,,,,,,,,,,,,,,, ..................................................................

OP T

® If the snowthrowermustbe moved withouttheaidof

theengine,itis easier topullthesnow throwerbythe

handles rather than pushing

O Before you service or start the engine, familiarize

yourself with the snow thrower Be sure you

understand the function and locatfonof allcontrols.

NOTE: Check tension of clutch cables before starting the

engine_(See ToAdjust The Control Cables paragraph on

page 20).

• Be sure that all fasteners are tight

® Make sure the height adjust skids are properly

adjusted (See To Adjust Skid Height paragraph on

page 19)o

® Check tire pressure (14 to 17 pounds) See side of

tire for maximum inflation Do not exceed maximum

pressure

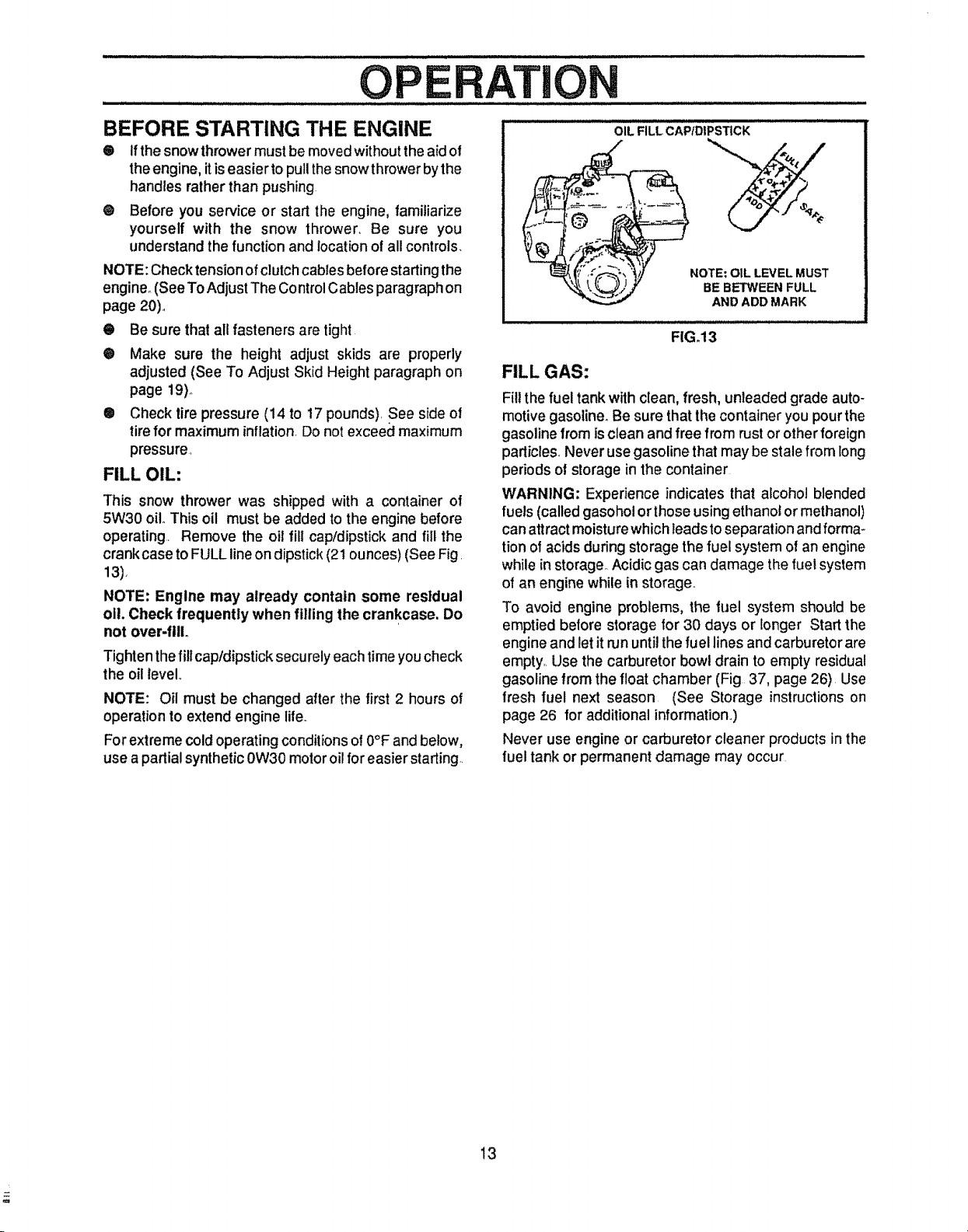

FILL OIL:

This snow thrower was shipped with a container of

5W30 oil. This oil must be added to the engine before

operating Remove the oil fill cap/dipstick and fill the

crankcase to FULL line on dipstick (2t ounces) (See Fig

13).

NOTE: Engine may already contain some residual

oil. Check frequently when filling the crankcase, Do

not over-filL

Tighten the fill cap/dipstick securely each time you check

the oil level

NOTE: Oil must be changed after the first 2 hours of

operation to extend engine life.

For extreme cold operating conditions o! 0°F and below,

use apartial synthetic 0W30 motoroil for easier starting

OIL FILL CAP/DIPSTICKBEFORE STARTING THE ENGINE

NOTE: OIL LEVEL MUST

BE BETWEEN FULL

AND ADD MARK

FIG_13

FILL GAS:

Fill thefuel tank withclean, fresh, unleaded grade auto-

motive gasoline° Be sure that the container you pour the

gasoline from is clean and free from rust or other foreign

particles. Never use gasoline that may be stale from long

periods of storage in the container

WARNING; Experience indicates that alcohol blended

fuels (called gasohol orthose using ethanol ormethanol)

can attract moisture which leads toseparation andforma-

tion of acids during storage the fuel system of an engine

while in storage_Acidic gas can damage the fuel system

of an engine while instorage°

To avoid engine problems, the fuel system should be

emptied before storage for 30 days or longer Start the

engine and let it run until the fuel lines and carburetor are

empty. Use the carburetor bowl drain to empty residual

gasoline from the float chamber (Fig 37, page 26) Use

fresh fuel next season (See Storage instructionson

page 26 for additional information,,)

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur

13

TO STOP ENGINE

® To stop engine, move the throttle control lever to

STOP positionand remove key Keep the key in a

safe place_The enginewiltnotstartwithoutthekey_

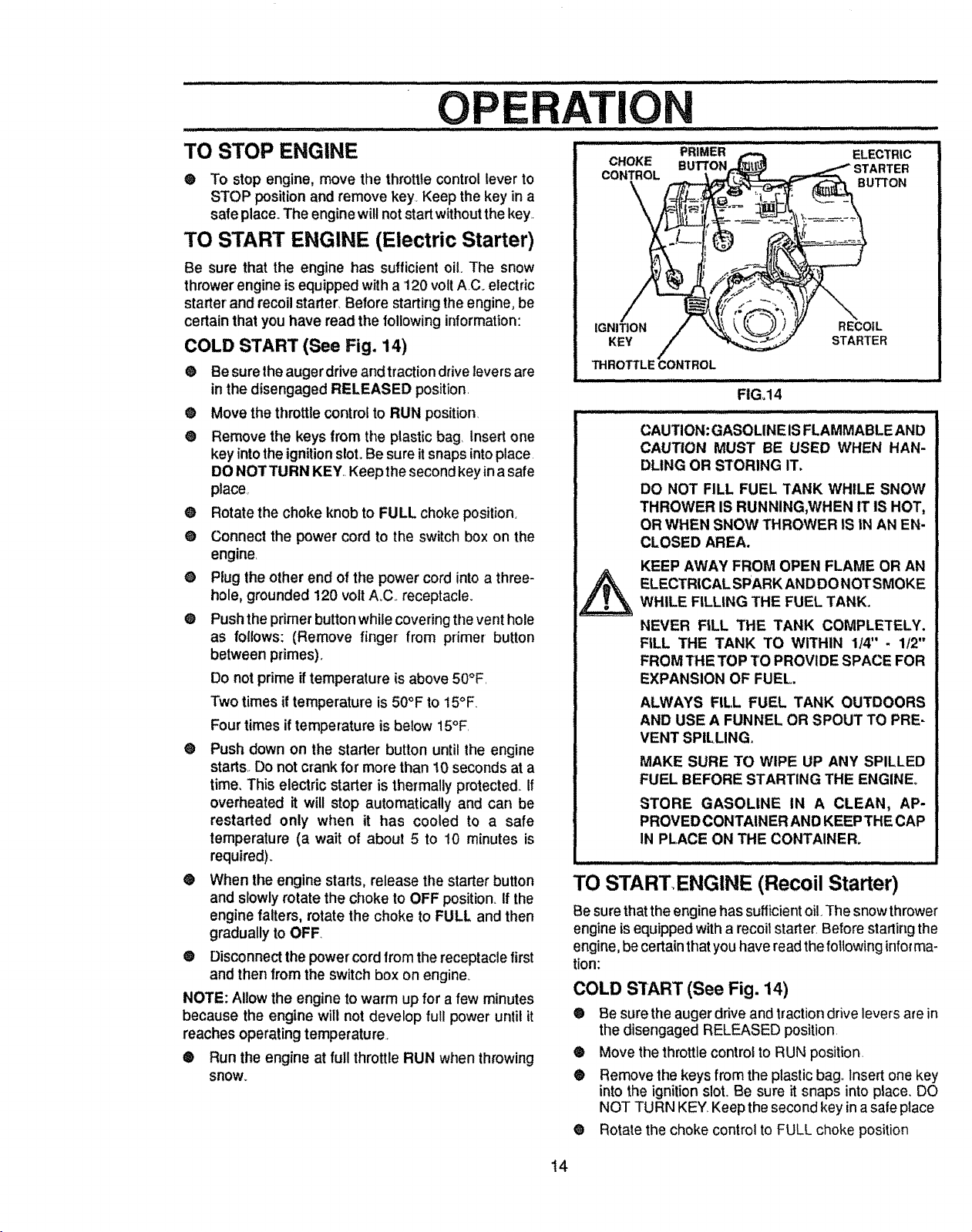

TO START ENGINE (Electric Starter)

Be sure that the engine has sufficientoil. The snow

throwerengine isequippedwith a 120 voltAC_electric

starter and recoil starter, Before starting the engine, be

certain that you have read the following information:

COLD START (See Fig. 14)

® Be sure the auger drive andtraction drive leversare

in the disengaged RELEASED position.

e Move the throttle controlto RUN position

® Remove the keys from the plastic bag, Insert one

key into the ignition slot. Be sure itsnaps intoplace

DO NOTTURN KEY..Keep thesecond key in a safe

place,

@ Rotate the choke knob to FULL choke position.

® Connect the power cord to the switch box on the

engine.

® Plug the other end of the power cord intoa three-

hole, grounded 120 volt A_C..receptacle.

® Pushthe primer button while covering the vent hole

as follows: (Remove finger from primer button

between primes).

Do not prime if temperature is above 50°F.

Two times iftemperature is 50°F to 15°F.

Four times if temperature is below 15°F.

® Push down on the starter button until the engine

starts.. Do not crank for more than 10seconds at a

time, This electric starter isthermally protected_If

overheated it will stop automatically and can be

restarted only when it has cooled to a safe

temperature (a wait of about 5 to 10 minutes is

required).

® When the engine starts, release the starter button

and slowly rotate the choke to OFF position. If the

engine falters, rotate the choke to FULL and then

gradually to OFF.

® Disconnect the powercord from the receptacle first

and then from the switch box on engine.

NOTE: Allow the engine to warm up for a few minutes

because the engine will not develop full power until it

reaches operating temperature.

® Run the engine at full throttle RUN when throwing

snow.

CHOKE BU'FI'ON rER

CONTROL

,_ BUTTON

/

IGNITION RECOIL

KEY STARTER

PRIMER ELECTRIC

FIG,14

CAUTION: GASOLINE ISFLAMMABLE AND

CAUTION MUST BE USED WHEN HAN-

DLING OR STORING IT.

DO NOT FILL FUEL TANK WHILE SNOW

THROWER IS RUNNING,WHEN IT IS HOT,

OR WHEN SNOW THROWER IS IN AN EN-

CLOSED AREA.

KEEP AWAY FROM OPEN FLAME OR AN

ELECTRICAL SPARK ANDDO NOT SMOKE

WHILE FILLING THE FUEL TANK.

NEVER FILL THE TANK COMPLETELY.

FILL THE TANK TO WITHIN 114" - 1t2"

FROM THE TOP TO PROVIDE SPACE FOR

EXPANSION OF FUEL.

ALWAYS FILL FUEL TANK OUTDOORS

AND USE A FUNNEL OR SPOUT TO PRE-

VENT SPILLING.

MAKE SURE TO WIPE UP ANY SPILLED

FUEL BEFORE STARTING THE ENGINE,

STORE GASOLINE IN A CLEAN, AP-

PROVED CONTAINER AND KEEP THE CAP

IN PLACE ON THE CONTAINER_

TO STARTENGINE (Recoil Starter)

Be sure thatthe engine has sufficient oil.The snow thrower

engine is equipped with a recoit starter, Before starting the

engine,be certain that you have readthe foUowinginforma-

rion:

COLD START (See Fig. 14)

® Be sure the augerdfive and tractiondrive levers arein

thedisengaged RELEASED position.

® Move thethrottle controlto RUN position.

® Remove the keysfrom the plasticbag.,Insertone key

intothe ignitionslot. Be sure it snaps into place. DO

NOT TURN KEY Keep thesecond key inasafe place

® Rotate the choke control to FULL choke position

t4

' OPE ...................................AT

CAUTION: NEVER RUN ENGINE

INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS°ENGINE EXHAUST

CONTAINS CARBON MONOXIDE, AN

ODORLESS AND DEADLY GAS. KEEP

HANDS, FEET, HAIR AND LOOSE

CLOTHING AWAY FROM ANY MOVING

PARTS ON ENGINE AND SNOW

THROWER.

WARNING: TEMPERATURE OF

MUFFLER AND NEARBY AREAS MAY

EXCEED 150° F. AVOID THESE AREAS.

DO NOT ALLOW CHILDREN OR YOUNG

TEENAGERS TO OPERATE OR BE NEAR

SNOW THROWER WHILE IT IS

OPERATING.

CAUTION: DO NOT ATTEMPT TO RE-

MOVE ANY ITEM THAT MAY BECOME

LODGED IN AUGER WITHOUT TAKING

THE FOLLOWING PRECAUTIONS:

RELEASE AUGER DRIVEAND TRACTION

DRIVE LEVERS,,

- MOVETHROTTLELEVERTOSTOP PO-

SITION.

o REMOVE (DO NOT TURN) IGNITION

KEY.

o DISCONNECT SPARK PLUG WIRE,

• DO NOT PLACE YOUR HANDS IN THE

AUGER OR DISCHARGE CHUTE. USE

A PRY BAR.

O

Push the primer button while covering the vent hole

as follows: (Remove finger from primer button be-

tween primes)_

Do not prime if temperature is above 50°E

Two times iftemperature is 50°F to 15°F

Four times if temperature is below 15°F.

® Pull the recoilstarter handle rapidly.Do not allow the

handleto snap back, but allow ittorewind slowlywhile

keeping a firm hold on the starter handle.

• As the engine warms up and begins to operate

evenly, rotate the choke control slowly to the OFF

position,. If the engine falters, return to FULLchoke,

then slowly move to the OFF position.

NOTE: Allow the engine to warm up for a few minutes

because the engine will not develop full power until it

reaches operatingtemperature,

• Run the engine at full throttle (RUN) when throwing

snow°

WARM START

If restarting a warm engine after ashort shutdown, leave

choke at OFF and do not push the primer button. If the

engine fails to start, follow the Cold Start instructions

above.

FROZEN STARTER

tf the starter is frozen and will not turn engine:

O Pull as much rope out of the starter as possible

• Release the starter handle and let it snap back

against the starter

Ifthe engine still failsto start, push the primer button two

or three times again and repeat the two previous steps

until the engine starts. Then continue with the directions

for cold slart.

To heip prevent possible freeze-up of recoil starter and

engine controls, proceed as follows after each snow

removal job

e With the engine running, pull the starter rope hard

with a continuous full arm stroke three or four times.

Pullingof starter rope will produce a loud clattering

sound This isnot harmlul to the engine or starter.

e With the engine not running, wipe all snow and

moisture fromthe carburetor cover inarea ofcontrol

levers. Also move throttle control, choke control, and

starter handte several times

SNOW THROWING TIPS

e For maximum snow thrower efficiency in removing

snow, adjust ground speed, NEVER the throttle.. Go

slower in deep, freezing, or wet snow. tf the track

slips, reduce forward speed, The engine is designed

to deliver maximum pedormance at full throttle and

should be run at this power setting at alltimes

e Most efficient snow throwing isaccomplished when

the snow is removed immediately after it falls.

® For complete snow removal, slightly overlap each

path previously taken.

e The snow should be discharged down windwhenever

possible_

@ For normal usage, set the skids so that the scraper

bar is 1/8"above the skids. For extremely hardpacked

snow surfaces, adjust the skids upward so that the

scraper bar touches the ground.

O On gravel orcrushed rock sudaces, set the skids at

1-1/4" below the scraper bar (see To Adjust Skid

Height paragraph on page 19). Stones and gravel

must not be picked up and thrown by the machine

• After the snow throwing job has been completed,

allow the engine to idle fora few minutes, whichwill

melt snow and accumulated ice off the engine

• Clean the snow thrower thoroughlyafter each use

I, Remove ice and snow accumufation and all debris

from the entire snow thrower, and flush with warer(if

possible) to remove all salt or other chemicals Wipe

snow thrower dry.

15

CUSTOM ILITI

J .,,,,,,,,

,,,uL.... ,,J,..................

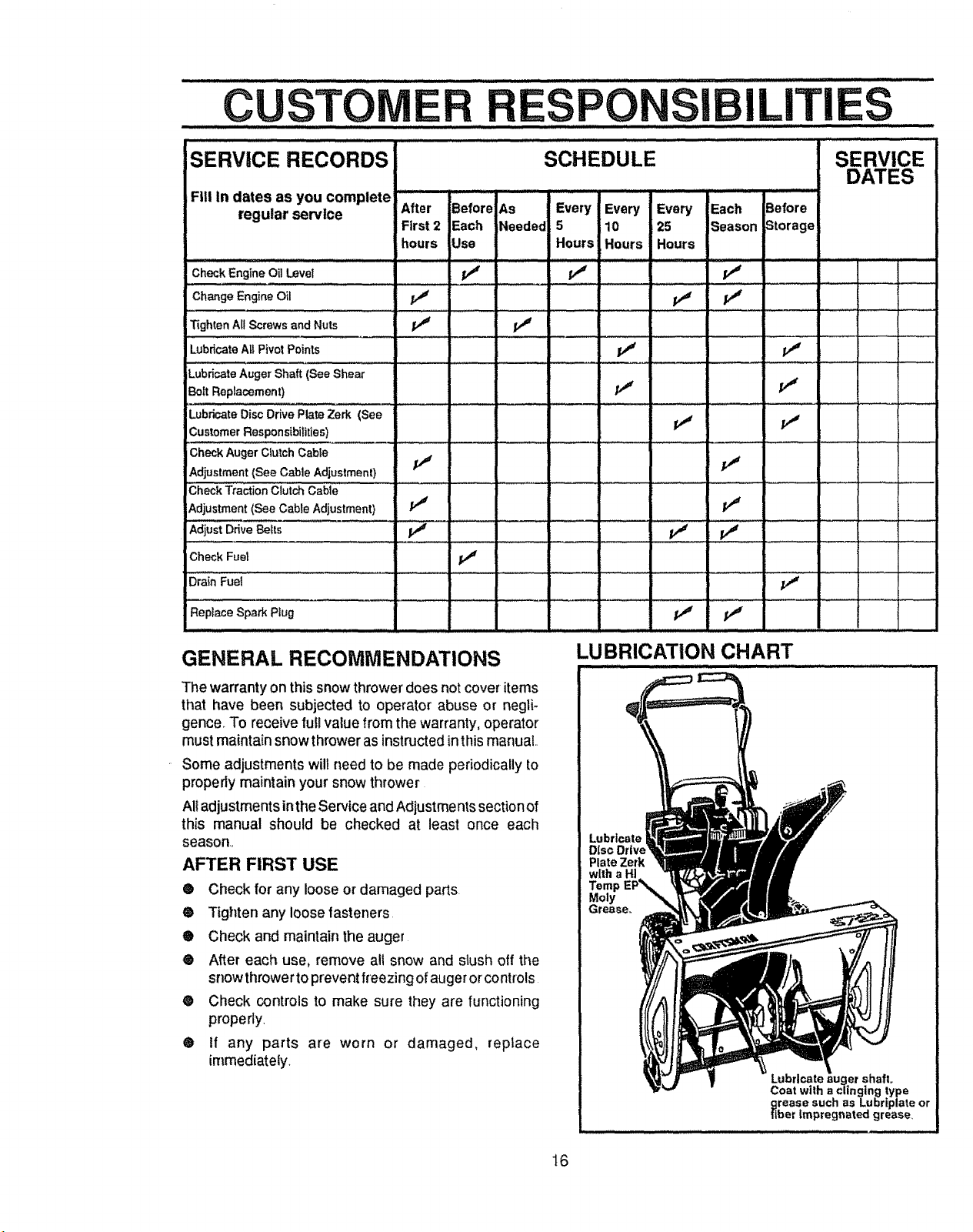

SERVICE RECORDS

Fill in dates as you complete

regular service After Before As

Check Engine Oil Level _ pJ

Change Engine Oil _

Tighten Al! Screws and Nuts PJ .............. PJ I......

Lub,=teA,Pi,otPoint, V" _'

Lubricate Auger Shaft (See Shear

Bolt Replacement) _ PJ

Lubricate Disc Drive Plate Zerk (See

Customer Responsibilities) PJ PJ

iCheck Auger Clutch Cable

Adjustment (See Cable Adjustment) PJ

Check Traction ciUtch Cable ' i

Adjustment (See Cable Adjustment) _

AdjustD,iveSe,_ _" 11 I,"

Check Fuel

Drain Fuel

First2 Each Needed

hours Use

- = =

, , ,......... , ,,,,,.......

,,,,, ,,,

SCHEDULE

Every IEvery Every Each Before

5 10 25 Season Storage

Hours Hours Hours

J

SERVICE

DATES

Replace Spark Ptug

GENERAL RECOMMENDATIONS

The warranty on thissnowthrowerdoes notcover items

that have been subjected to operator' abuse or negli-

gence, To receive full value from thewarranty, operator

must maintain snow thrower as instructed inthismanuat..

Some adjustments will need to be made periodically to

properly maintain your snow thrower

All adjustments inthe Service and Adjustments section of

this manual should be checked at least once each

season,,

AFTER FIRST USE

® Check for any loose or damaged parts.

® Tighten any loose fasteners.

® Check and maintain the auger

® After each use, remove all snow and slush off the

snow throwerto prevent freezing ofauger orcontrols

® Check controls to make sure they are functioning

properly,

® If any parts are worn or damaged, replace

irnmediately.

LUBRICATION CHART

Lubricate

Diso Drive

Plate Zerk

Moly

rease,,

Coat with a clinging type

grease such as Lubriplate or

fiber Impregnated grease_

Pate auger shafL

16

............ i i i ill ii ,,ll ,lllll,i,illllllllllllll

' CUSTO.........

SNOW THROWER

LUBRICATION - EVERY TEN HOURS

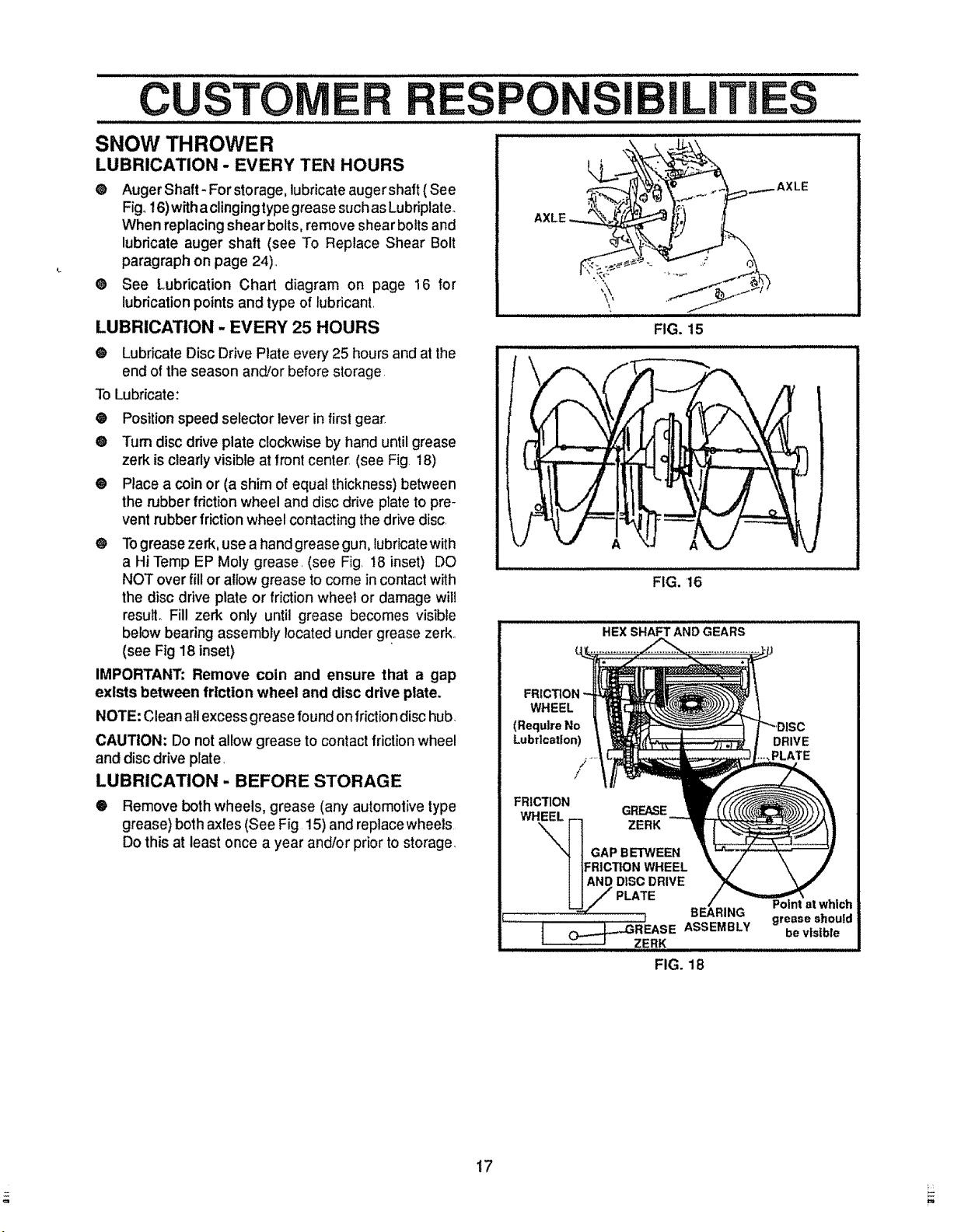

@ Auger Shaft- For storage, lubricate auger shaft ( See

Fig, 16)with aclinging type grease such asLubriplate.

When replacing shear bolts, remove shear bolts and

lubricate auger shaft (see To Replace Shear Bolt

paragraph on page 24).,

@ See Lubrication Chart diagram on page 16 for

lubrication points and type of lubricant,

LUBRICATION - EVERY 25 HOURS

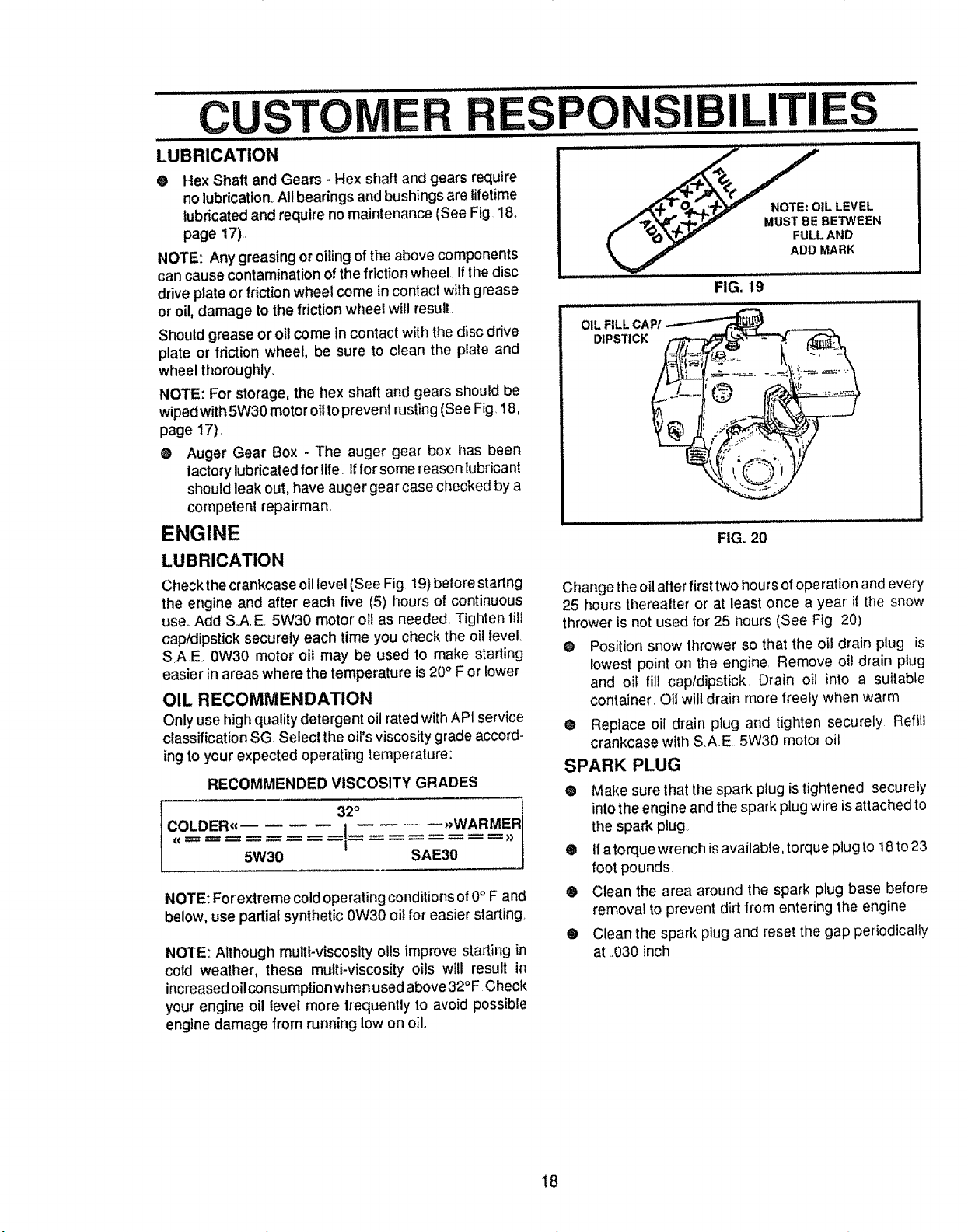

@ Lubricate Disc Drive Plate every 25 hours and at the

end of the season and/or before storage,

To Lubricate:

@ Position speed selector lever in first gear

@ Tum disc drive plate clockwise by hand until grease

zerk is clearly visible at front center (see Fig. 18)

@ Place a coin or (a shim of equal thickness) between

the rubberfdction wheel and disc drive plate to pre-

vent rubber friction wheel contacting the drive disc,

@ Togrease zerk, use a hand grease gun, lubricate with

a Hi Temp EP Moly grease, (see Fig, 18 inset) DO

NOT over fill or allow grease to come in contact with

the disc drive plate or friction wheel or damage will

resulL Fill zerk only until grease becomes visible

below bearing assembly located under grease zerk,

(see Fig 18 inset)

IMPORTANT; Remove coin and ensure that a gap

exists between friction wheel and disc drive plate.

NOTE: Clean all excess grease found on friction disc hub.

CAUTION; Do not allow grease to contact friction wheel

and disc drive plate,

LUBRICATION - BEFORE STORAGE

@ Remove both wheels, grease (any automolive type

grease) both axles (See Fig 15) and replacewheels

Do this at least once a year and/or prior to storage,

AXLE

FRICTION

WHEEL

(Require No

Lubrication)

FRICTION

WHEEL

i ILmTES

'_,

FIG. 15

FIG. 16

HEX SHAFT AND GEARS

/

/

GREASE

ZERK

GAP BETWEEN

:RiCTION WHEEL

DISC DRIVE

........AXLE

i i / iiii

DRIVE

..,PLATE

17

FIG. 18

.......................................................................................................... , ,, ,,,, ...............................

CUSTOM ILITIES

LUBRICATION .........

® Hex Shaft and Gears - Hex shaft and gears require

no lubrication All bearings and bushings are lifetime

lubricated and require no maintenance (See Fig. 18,

page 17).

NOTE: Any greasing or oiling of the above components

can cause contamination of the friction wheel Ifthe disc

ddve plate or friction wheel come in contact with grease

or oil, damage to the friction wheel willresult.,

Should grease or oil come in contact with the disc drive

plate or friction wheel, be sure to clean the plate and

wheel thoroughly_

NOTE: For storage, the hex shaft and gears should be

wipedwith 5W30 motor oitto prevent rusting(See Fig. t8,

page 17).

@ Auger Gear Box - The auger gear box has been

factory lubricated for life. if for some reason lubricant

should leak out, have auger gear case checked by a

competent repairman.

ENGINE

LUBRICATION

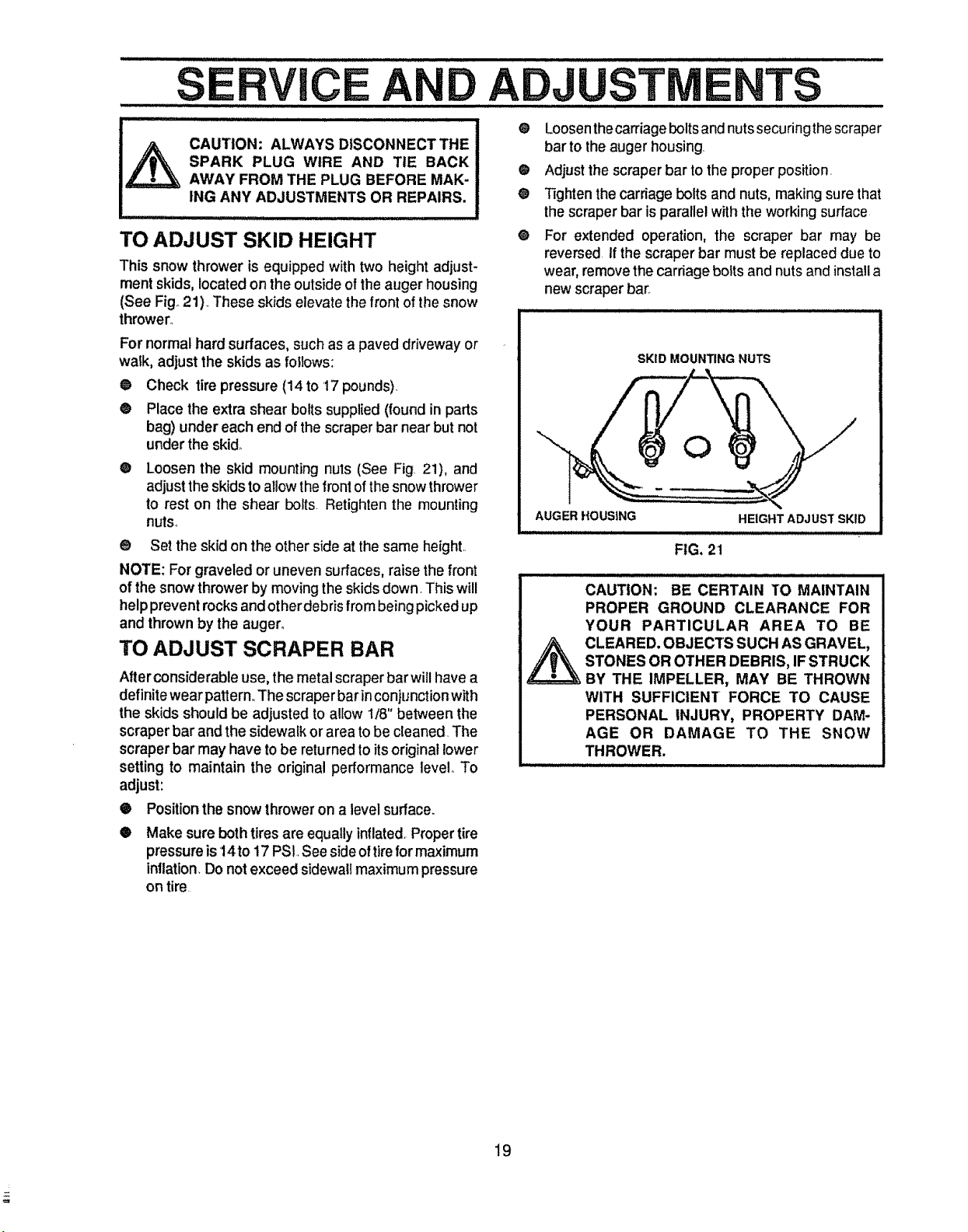

Check the crankcase oil level (See Fig. 19)before startng

the engine and after each five (5) hours of continuous

use.,Add S.,A.E. 5W30 motor oil as needed. Tighten fill

cap/dipstick securely each time you check the oil Ievel,

SrAE 0W30 motor oil may be used to make starting

easier in areas where the temperature is 20° For lower.

OIL RECOMMENDATION

Only use high quality detergent oil ratedwith API service

classification SG Select the oi!'s viscosity grade accord-

ing to your expected operating temperature:

RECOMMENDED VISCOSITY GRADES

LDER_€ .{ _WARMER

5W30 SAE30

NOTE: Forextreme cold operating conditions of0° F and

below, use partial synthetic0W30 oilfor easier starting

NOTE: Although multi-viscosity oils improve starting in

cold weather, these multi-viscosityoils will result in

increasedoilconsumptionwhen used above32°F Check

your engine oil level more frequently to avoid possible

engine damage from running low on oil,,

i, i i i i ....,i lira. I II.lJ IL i HI] ,,i m.,

Change theoil after first two hours ofoperation and every

25 hours thereafter or at least once a year if the snow

thrower is not used for 25 hours (See Fig 20)

e Position snow thrower so that the oil drain plug is

_owestpoint on the engine Remove oil drain plug

and oil fill capfdipstick Drain oil into a suitable

container. Oil will drain more freely when warm

0 Replace oil drain plug and tighten securely Refill

crankcase with S.AE 5W30 motor oil

SPARK PLUG

• Make sure that the spark plug is tightened securely

into the engine andthe spark plug wire is attached to

the spark plug

® ifa torque wrench isavailable, torque plug to 18 to23

foot pounds,

® Clean the area around the spark plug base before

removal to prevent dirt from entering the engine

® Clean the spark plug and reset the gap periodically

at .030 inch.

FIG. 19

FIG. 20

18

_ CAUTION: ALWAYS DISCONNECT THE

SPARK PLUG WIRE AND TiE BACK

AWAY FROM THE PLUG BEFORE MAK-

ING ANY ADJUSTMENTS OR REPAIRS.

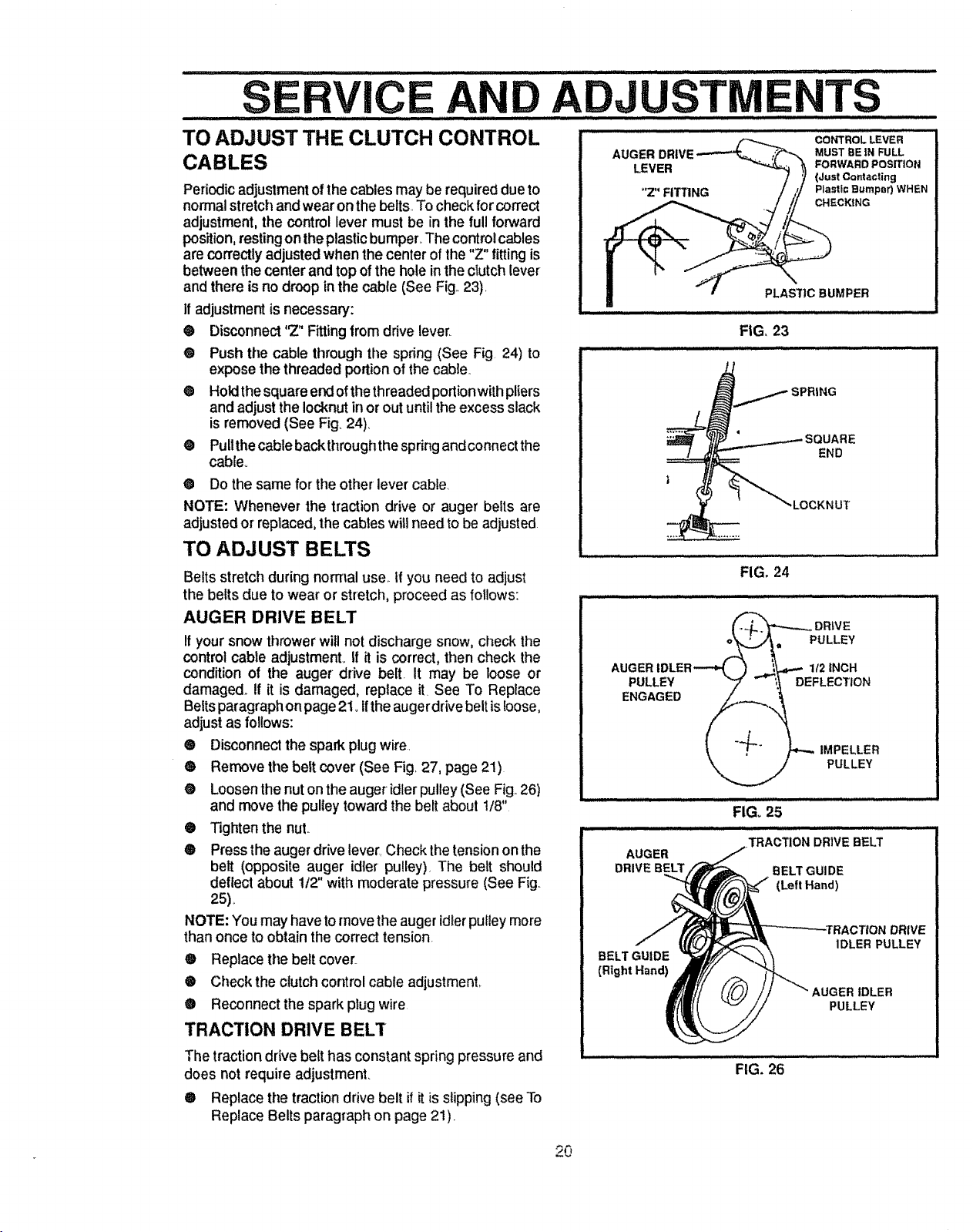

TO ADJUST SKID HEIGHT

This snow thrower is equipped with two height adjust-

ment skids, located on the outside of the auger housing

(See Fig°21). These skids elevate the front of the snow

thrower°

• Loosenthecarriage boltsand nuts securingthe scraper

bar to the auger housing.

® Adjust the scraper bar to the proper position.

@ Tighten the carriage bolts and nuts, making sure that

the scraper bar is parallel with the working surface

@ For extended operation, the scraper bar may be

reversed if the scraper bar must be replaced due to

wear, remove the carriage bolts and nuts and install a

new scraper bar_

For normal hard surfaces, such as apaved driveway or

walk, adjust the skids as follows:

@

Check tire pressure (14 to 17 pounds).

@

Place the extra shear bolts supplied (found in parts

bag) under each end of the scraper bar near but not

under the skid_

O

Loosen the skid mounting nuts (See Fig 21), and

adjust the skids to allow the frontof the snow thrower

to rest on the shear bolts. Retighten the mounting

nuts_

® Set the skid on the other side at the same height..

NOTE: For graveled or uneven surfaces, raise the front

of the snow thrower by moving the skids down. This will

help prevent rocks and other debris from being picked up

and thrown by the auger°

TO ADJUST SCRAPER BAR

After considerable use, the metal scraper barwifl have a

definite wear pattern,.The scraper bar inconjunction with

the skids should be adjusted to allow 1t8" between the

scraper bar and the sidewalk or area to be cleaned. The

scraper bar may have to be returned toitsoriginal lower

setting to maintain the original performance level_To

adjust:

• Position the snow thrower on a level surface.

O

Make sure both tiresare equally inflated,Propertire

pressure is 14to 17 PSt,See side oftire formaximum

inflation, Do not exceed sidewall maximum pressure

on tire.

SKID MOUNTING NUTS

AUGER HOUSING

FiG, 21

CAUTION: BE CERTAIN TO MAINTAIN

PROPER GROUND CLEARANCE FOR

YOUR PARTICULAR AREA TO BE

_ CLEARED. OBJECTS SUCH AS GRAVEL,

STONES OR OTHER DEBRIS, IF STRUCK

BY THE IMPELLER, MAY BE THROWN

WITH SUFFICIENT FORCE TO CAUSE

PERSONAL INJURY, PROPERTY DAM-

AGE OR DAMAGE TO THE SNOW

THROWER.

HEIGHT ADJUST SKID

!9

Periodic adjustment of the cables may be required due to

normal stretch and wear on the belts. Tocheck for correct

adjustment, the control lever must be in the full forward

position, restingonthe plasticbumper._The control cables

are correctly adjusted when the center of the "Z" fitting is

between the center and top ofthe hole inthe ctutch lever

and there is no droop in the cable (See Fig._23)

If adjustment is necessary:

® Disconnect "Z" Fitting from drive lever,

@ Push the cable through the spring (See Fig 24) to

expose the threaded portion of the cable

® Holdthe square er_ofthe threaded portionwith pliers

and adjust the Iocknut inor out until the excess slack

is removed(See Fig.24),

@ Pullthe cable backthroughthe springand connect the

cable°

@ Do the same for'the otherlever cable,

NOTE: Whenever the traction drive or auger belts are

adjusted or replaced, the cabtes willneed to be adjusted

TO ADJUST BELTS

Belts stretch during norrnal use._Ifyou need to adjust

the belts due to wear or stretch, proceed as follows:

AUGER DRIVE BELT

Ifyour snow thrower will not discharge snow, check the

control cable adjustmenL if it is correct, then check the

condition of the auger drive belt. It may be loose or

damaged., If it is damaged, replace it See To Replace

Belts paragraph on page2t., Ifthe auger drivebelt isloose,

adjust as follows:

® Disconnect the spark plug wire.

® Remove the belt cover (See Fig 27, page 21)

® Loosen the nut on the auger idlerpulley (See Fig 26)

and movethe pulley toward the belt about t/8"

® Tighten the nut..

® Press the auger drive lever, Check the tension onthe

belt (opposite auger idler pulley). The belt should

deflect about 112"with moderate pressure (See Fig.

25),

NOTE: You may have tomove the auger idlerpulley more

than once to obtain the correct tension

® Replace the belt cover..

® Check the clutch control cable adjustment,.

® Reconnect the spark plug wire

TRACTION DRIVE BELT

AUGER MUST REIN FULL

LEVER FORWARD POSmON

"Z" FITTING Plastic Bumper) WHEN

PLASI']C BUMPER

(Just Contacting

CHECKING

FIG, 23

,__/SPRING

,LOCKNUT

FIG. 24

DR|VE

PULLEY

PULLEY

ENGAGED

112INCH

DEFLECTION

IMPELLER

PULLEY

FIG, 25

I I /I IIIIIIII II II IIII II IIIIII

AUGER

DRIVE BELT BELT GUI DE

BELT GUIDE

(Right Hand)

_TRACTION DRIVE BELT

(Left Hand)

AUGER IDLER

PULLEY

IDLER PULLEY

!IVE

The traction drive belt has constant spring pressure and

does not requireadjustment.

® Replace the traction drive belt if it isslipping (see To

Replace Belts paragraph on page 21).

FIG. 26

.....SE ....................CE ADJ.................................................................TS

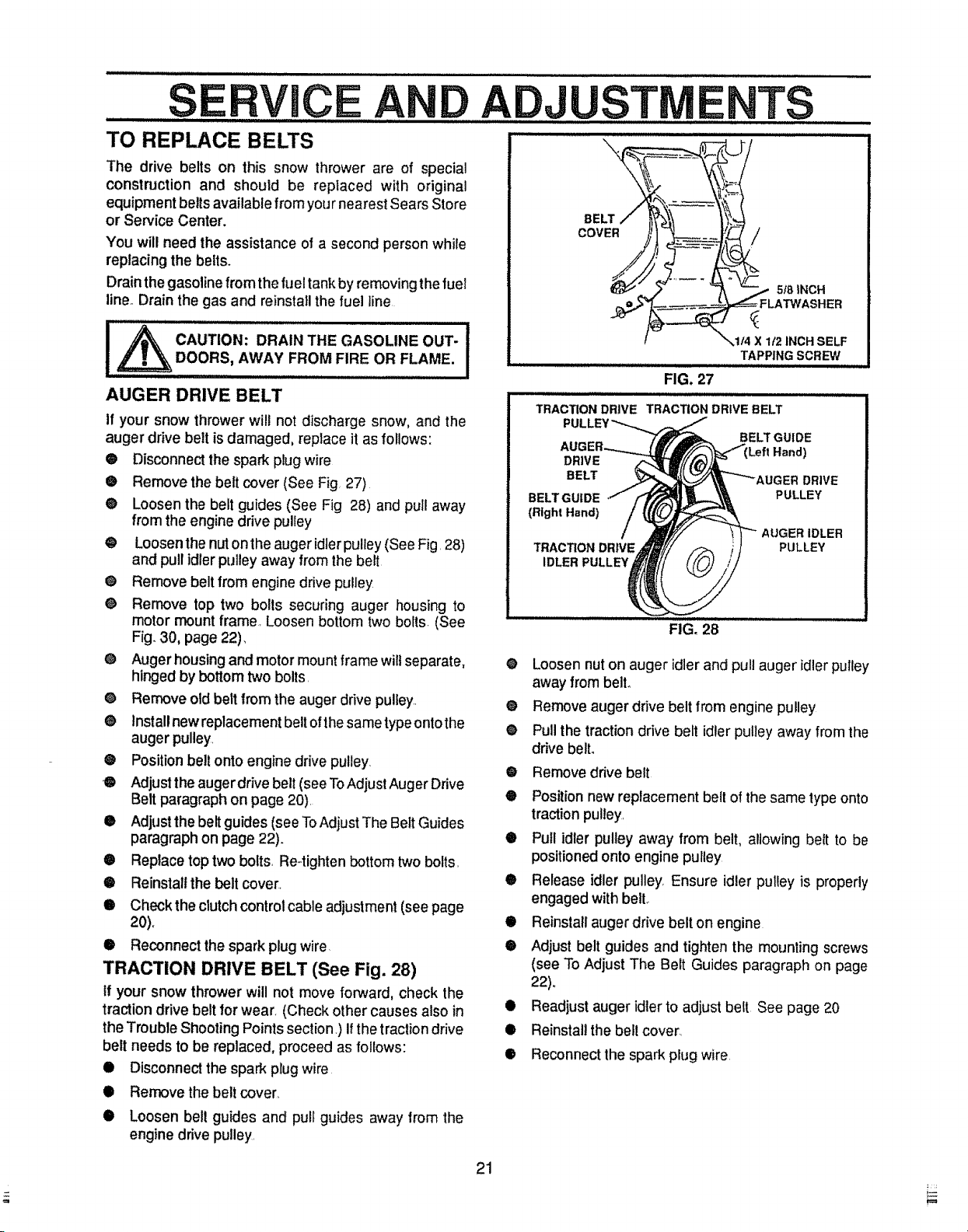

TO REPLACE BELTS

The drive belts on this snow thrower are of special

construction and should be replaced with original

equipmentbelts available from yournearest Sears Store

or Service Center.

You will need the assistance of a second personwhile

replacingthe belts.

Drainthegasolinefrom the fu el tankby removingthefuel

liner Drain the gas and reinstallthe fuel line

X 1/2 INCH SELF

DOORS, AWAY FROM FIRE OR FLAME.

AUGER DRIVE BELT

If your snow thrower will not discharge snow, and the

auger drive belt is damaged, replace it as follows:

® Disconnect the spark plug wire

• Remove the belt cover (See Fig 27)

@ Loosen the belt guides (See Fig 28) and pull away

from the engine drive pulley

@ Loosen the nut onthe auger idler pulley (SeeFig. 28)

and pull idler pulley away from the belt

@ Remove belt from engine drive pulley

@ Remove top two bolls securing auger housing to

motor mount frame, Loosen bottom two bolts. (See

Fig. 30, page 22),

@ Auger housing and motor mount frame wilt separate,

hinged by bottom two bolls.

@ Remove old belt from the auger drive pulley..

@ Install new replacement beltof thesame typeontothe

auger pulley.

@ Position belt onto engine drive pulley.

O Adjust theauger drive belt (seeToAdjust Auger Drive

Belt paragraph on page 20).

• Adjust the belt guides (seeToAdjust The Belt Guides

paragraph on page 22).

• Replace top two bolts, Re-tighten bottom two bolts.

• Reinstall the belt cover_

@ Check the clutch control cable adjustment (see page

20).

@ Reconnect the spark plug wire.

TRACTION DRIVE BELT (See Fig. 28)

tf your snow thrower will not move forward, check the

traction drive belt for wear. (Check other causes also in

the Trouble Shooting Points section.) if the traction drive

belt needs to be replaced, proceed as follows:

• Disconnect the spark plug wire

@ Remove the belt cover,

@ Loosen bell guides and pull guides away from the

engine drive pulley.

FIG. 27

iiii ilJlllllllllllllllllllllliji1¸/111i i

TRACTION DRIVE TRACTION DRIVE BELT

DRIVE

BELT

BELT GUIDE

(Bight Hand)

TRACTION DRIVE

IDLER PULLEY

FIG, 28

@

Loosen nuton auger idlerand pull auger idler pulley

away from belt@

@

Remove auger drive belt from engine pulley

®

Pull the traction drive belt idler pulley away from the

drive belt.

0

Remove drive belt

@

Positionnew replacement belt of thesame type onto

traction pulley.

@

Pull idler pulley away from belt, allowing belt to be

positioned onto engine pulley

@

Release idler pulley Ensure idler pulley is properly

engaged with bell

@

Reinstall auger drive belt on engine

®

Adjust belt guides and tighten the mounting screws

(see To Adjust The Belt Guides paragraph on page

22).

0

Readjust auger idler to adjust belt See page 20

0

Reinstall the bell cover.

®

Reconnect the spark plug wire

TAPPING SCREW

BELT GUIDE

PULLEY

AUGER IDLER

PULLEY

iiiiHu

DRIVE

21

S ...........CE ADJUST ..........TS

......... ..... Jl iiiii u i iiiiiii ,111,,,i / ,, ................ii : : : ................................... .

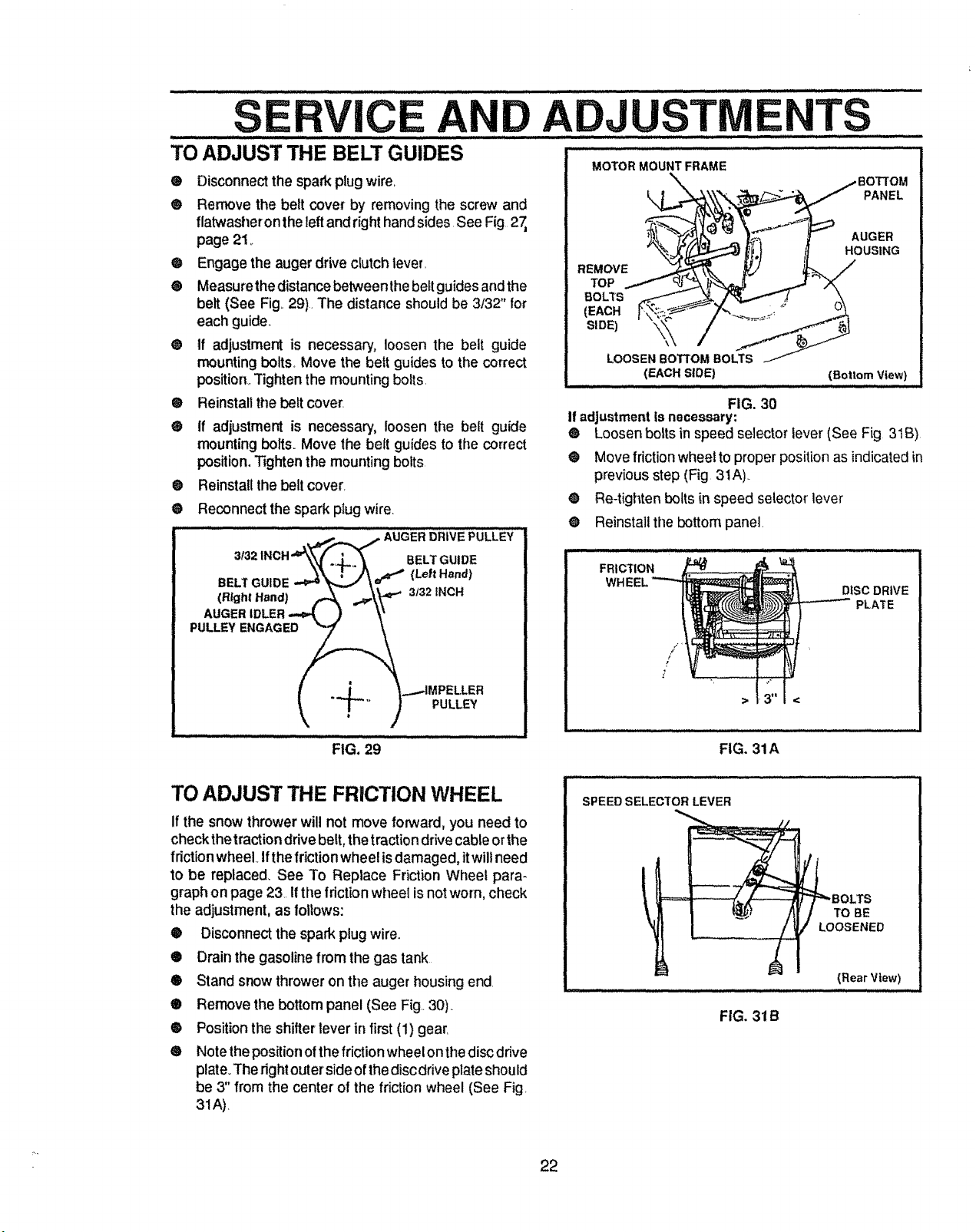

TO ADJUST THE BELT GUIDES ...................... .........................

® Disconnect the spark plugwire.

® Remove the belt cover by removing the screw and

flatwasheron the leftand right hand sides See Fig 27,

page 21_

Q Engage the auger drive clutch lever.

® Measurethe distance betweenthe beltguides and the

belt (See Fig..29). The distance should be 3/32" for

each guide.,

@ tf adjustment is necessary, loosen the belt guide

mounting bolts. Move the beit guides to the correct

position,.Tighten the mounting bolts.

® Reinstall the belt cover.

® If adjustment is necessary, loosen the belt guide

mounting bolts. Move the belt guides to the correct

position. Tighten the mounting bolts

®

Reinstall thebelt cover.

®

Reconnect the spark plug wire.

........" : ......... ,--_ -,,-,,_,...__ AUaER_RiVEPULLEY

3132

1NCH'W_ ._,.,. _ BELT GUIDE

,4,.-.-\W

3132INCH

MOTOR MOUNT FRAME

PANEL

AUGER

HOUSING

REMOVE

TOP

BOLTS

(EACH

(EACH SLOE)

(Bottom View}

FIG. 30

If adjustmentisnecessary:

® Loosen bolts in speed selector lever (See Fig 31B)

• Move friction wheel to proper positionas indicatedin

previous step (Fig 3tA)..

®

Re-tighten boltsin speed selector lever

O

Reinstall the bottom panel.

FRICTION

DISC DRIVE

PLATE

I .d _...-IMPELLER

_ T-'" ) PULLEY

FIG. 29

TO ADJUST THE FRICTION WHEEL

If the snowthrower will not move forward, you need to

checkthetractiondrive belt,thetractiondrivecableorthe

fdction wheel Ifthefriction wheel is damaged,itwill need

to be replaced_See To Replace FrictionWheel para-

graphon page 23. Ifthe frictionwheel is notworn, check

the adjustment, as follows:

® Disconnectthe spark plugwire°

® Drainthe gasolinefrom the gas tank

® Stand snowthroweron the auger housing end.

® Remove the bottom panel (See Fig 30)..

® Positionthe shifter lever in first(1) gear.

• Notethe positionofthefriction wheelonthe disc drive

plate.The rightouterside of thedisc drive plateshould

be 3" from the center of the friction wheel (See Fig.

31A).

/

p

!

SPEED SELECTOR LEVER

_...- - ........ .. __ .......

FIG. 31A

=_BOLTS

TO BE

LOOSENED

(Rear View)

FIG. 31B

22

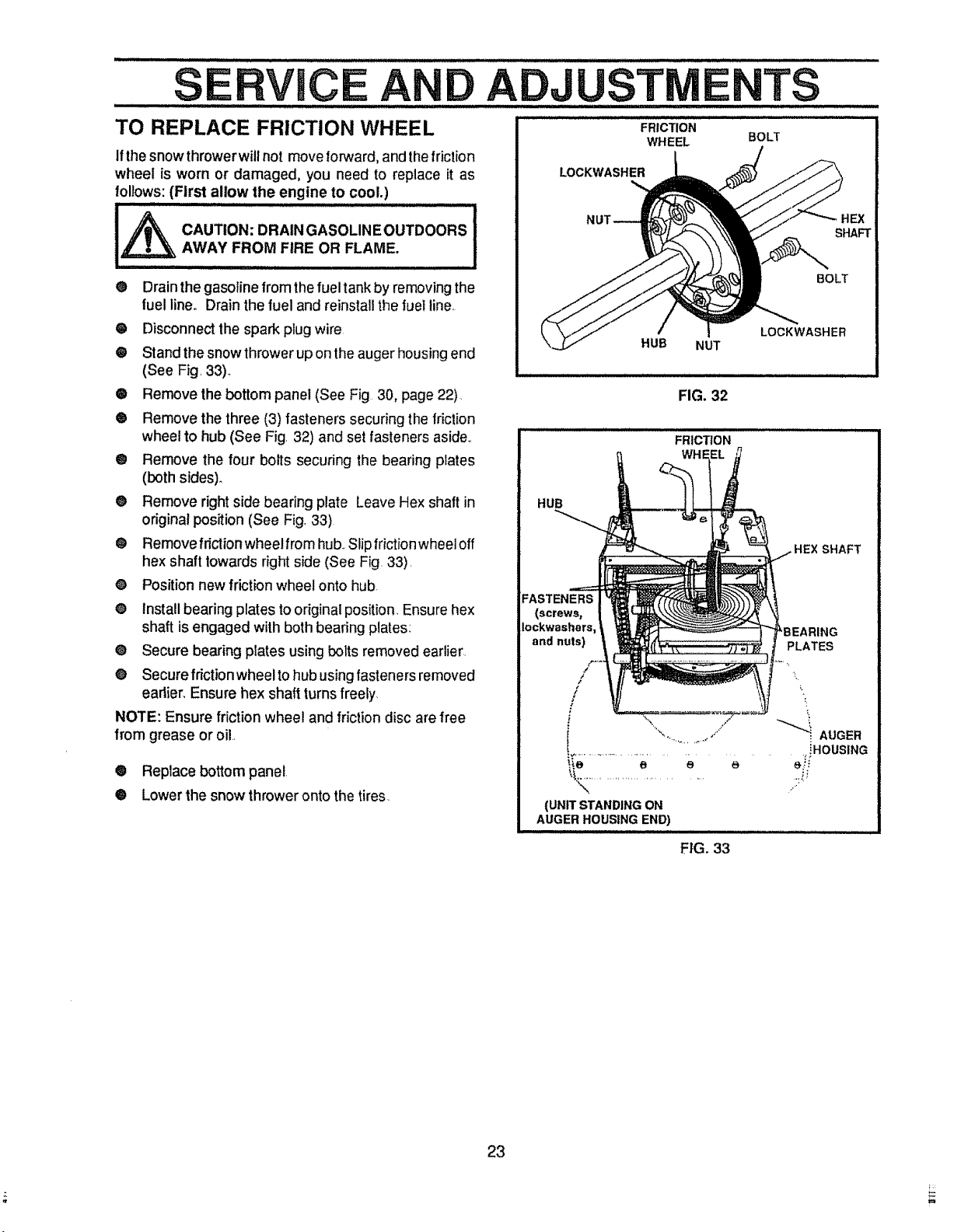

S CE ADJUSTNIE TS

TO REPLACE FRICTION WHEEL BOLT

FRICTION

WHEEL

Ifthe snow thrower willnot move forward, and the friclion

wheel is worn or damaged, you need to replace it as

LOCKWASHER

follows: (First allow the engine to cool.)

_ CAUTION: DRAIN GASOLINEOUTDOORS

AWAY FROM FIRE OR FLAME.

® Drainthe gasoline from the fuel tank by removing the

fuel line. Drain the fuel and reinstall the fuet line

Q Disconnect the spark plugwire

@ Stand the snow thrower up onthe auger housing end

HUB

NUT

LOCKWASHER

(See Fig. 33)_

® Remove thebottom panel (See Fig 30, page 22)_

FIG. 32

® Remove the three (3) fasteners securing the friction

wheel to hub (See Fig. 32) and set fasteners aside,.

FRICTION

@ Remove the four bolts securing the bearing plates

(both sides).

@ Remove right side bearing plate Leave Hex shaft in

HUB

original position (See Fig. 33)

® Removefriclionwheelfromhub..Slipfrictionwheeloff

hex shaft towards right side (See Fig. 33).

O Position new friction wheel onto hub.

• Install bearing plates to original position. Ensure hex

shaft is engaged with both bearing plates:

@ Secure bearing plates using bolts removed earlier.

FASTENERS

(screws,

Iockwashers,

and nuts)

@ Secure friction wheel to hub using fasteners removed

eadier. Ensure hex shaft turns freely

NOTE: Ensure friction wheel and friction disc are free

from grease or oil

• Replace bottom panel

@ Lowerthe snow throweronto the tires,

"_K_............................. ..::i._

(UNIT STANDING ON

AUGER HOUSING END)

".... '/ _ AUGER

%,. . J _"

SHAFT

BOLT

SHAFT

PLATES

L

,,iHOUSING

23

FIG. 33

Loading...

Loading...