Craftsman 50239 Operator's Manual

50239-0M

Operators Manual

(RRFTSMRH

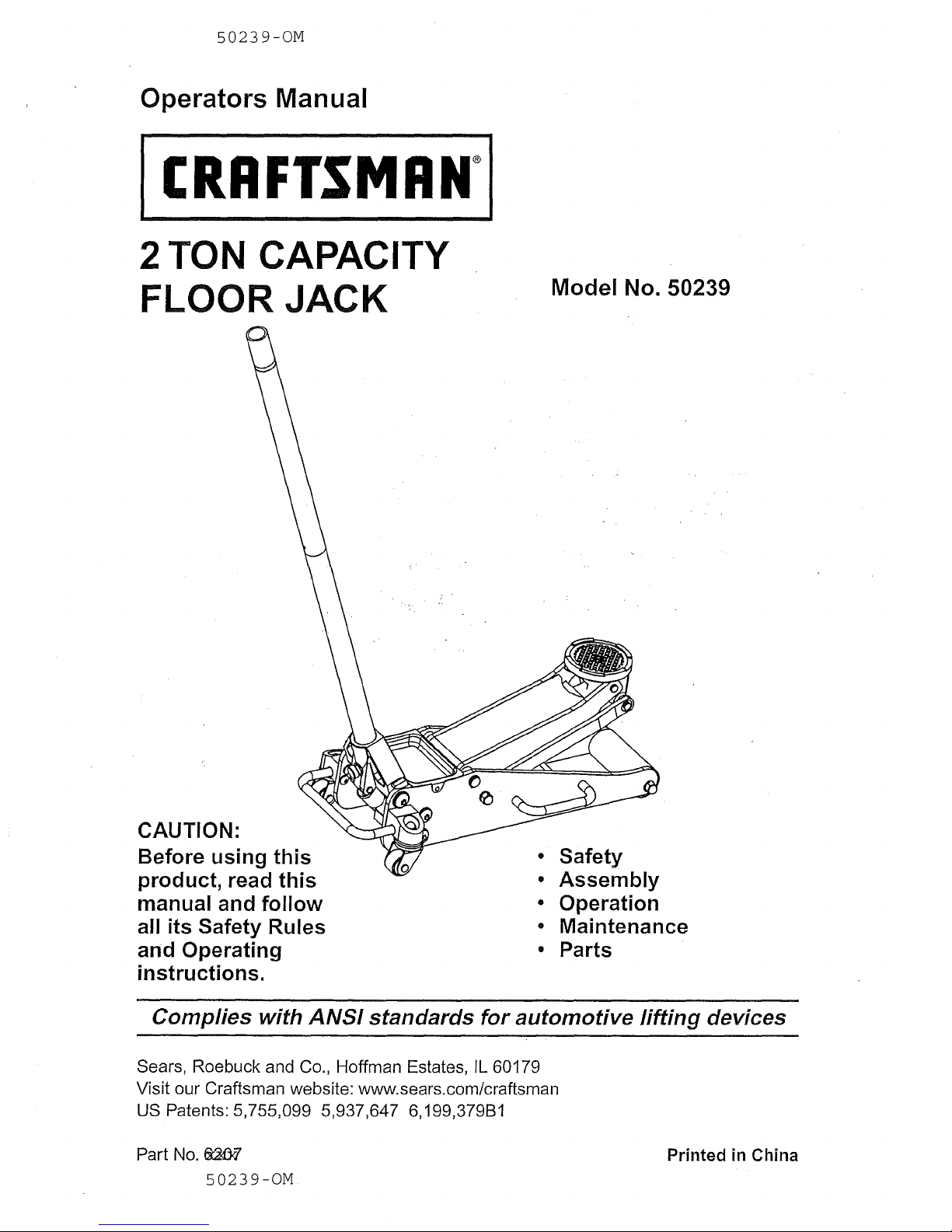

2 TON CAPACITY

FLOOR JACK

Model No. 50239

CAUTION:

Before using this

product, read this

manual and follow

all its Safety Rules

and Operating

instructions.

• Safety

° Assembly

° Operation

° Maintenance

° Parts

Complies with ANSi standards for automotive lifting devices

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

US Patents:5,755,099 5,937,647 6,199,379B1

Part No. e2_:7

50239-0M

Printed in China

Warranty ..... R 2

Save these instructions ..... R 2

Safety instructions ..... R 3

Assembly ..... R 3

Operation ..... R 4

Maintenance ..... R 5

Troubleshooting .....R 6

Parts ..... R 6

Service .....Back page

One Year Full Warranty on Craftsman Floor Jack

If within one year from date of purchase, this Craftsman floor jack fails due to a defect in

material or workmanship, return it to the nearest Sears store in United States and Sears

will replace it, free of charge.

If this floor jack is used for commercial or rental purposes, this warranty will apply for only

30 days from date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears Roebuck and Co., Dept° 817WA, Hoffman Estales, IL 60179

For your safety, read, understand, and follow, the information provided with and on this

jack.

• The owner and operator of this equipment shall have an understanding of this jack and

safe operating procedures before attempting to use. The owner and operator shall be

aware that use and repair of this product may require special skills and knowledge.

Instructions and safety information shall be conveyed in the operator's native language

before use of this jack is authorized. If any doubt exists as to the safe and proper use of

this jack, remove from service immediately.

° Inspect before each use. Do not use if broken, bent, cracked, or damaged parts

(including labels) are noted. Any jack that appears damaged in any way, operates

abnormally or is missing parts, shall be removed from service immediately.

° If the jack has been or suspected to have been subjected to a shock load (a load

dropped suddenly, unexpectedly upon it), immediately discontinue use until jack has

beenchecked by a factory authorized service center. It is recommended that an annual

inspection be done by qualified personnel.

° Labels and Owner's Manuals are available from manufacturer (see PARTS section on

page 6).

2

WARNING

• Study, understand, and follow all

instructions with and on this device

before operating this device.

• Do not exceed rated capacity.

° Use only on hard, level surfaces capable

of sustaining rated capacity loads.

• Lift only on areas of the vehicle as

specified by the vehicle manufacturer.

• This is a lifting device only. Immediately

after lifting, support the vehicle with

appropriately rated vehicle stands.

• Never work on, under, or around a load

supported only by this device.

o Do not move or dolly the vehicle while on

the jack.

• No alterations shall be made to this

product.

° Failure to heed product markings or

warnings may result in personal injury or

property damage.

CAUTION BEFORE USING

Occasionally during shipment and/or

handling the hydraulic oil can become

unstable or air can get trapped in the

system, both of which can interfere with the

jacks lifting performance.

To stabilize the oil it is recommended to

cycle the jack a few times prior to putting

a load on it.

To release air from the hydraulic system:

° Open the release valve by turning the

jack handle counterclockwise, but

never by more than 1/2 full turns.

• Remove the air vent valve from the

cylinder. (see Fig. 4)

° Rapidly pump jack handle through

several full strokes.

° Replace the air vent valve into the

cylinder again and jack is now ready to

use.

BEFORE EACH USE

Make a visual inspection before each use

of the floor jack by checking for abnormal

conditions, such as cracked welds, leaks

and damaged, loose, or missing parts.

DAMAGE TO JACK

If you think jack has been subjected to an

abnormal load or shock, have it inspected

for damage at a Sears Service Center

before using it again.

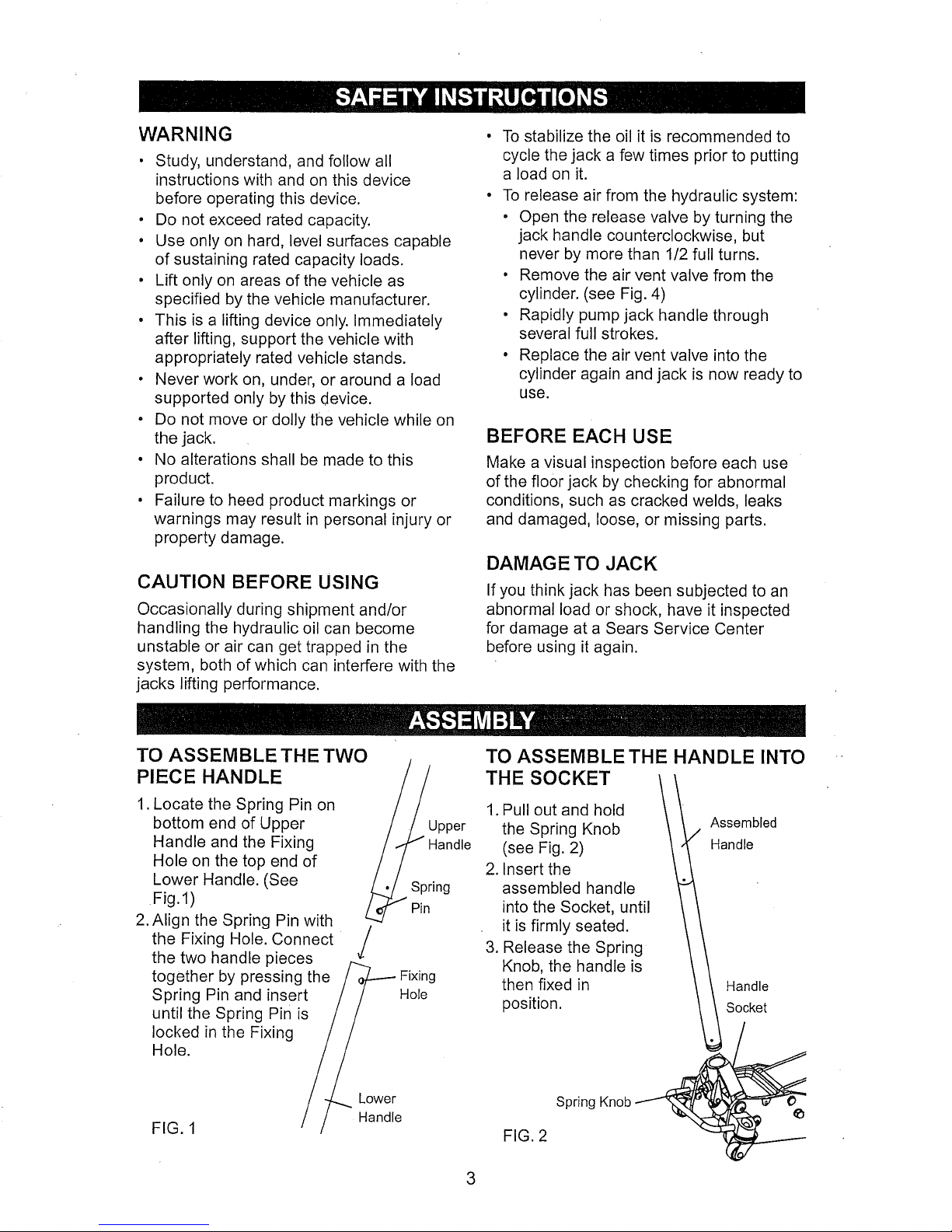

TO ASSEMBLE THE TWO

PIECE HANDLE

1. Locate the Spring Pin on

bottom end of Upper

Handle and the Fixing

Hole on the top end of

Lower Handle. (See

Fig.l)

2. Align the Spring Pin with

the Fixing Hole. Connect

the two handle pieces

together by pressing the

Spring Pin and insert

until the Spring Pin is

locked in the Fixing

Hole.

FIG. 1

TO ASSEMBLE THE HANDLE INTO

THE SOCKET

,_p8 pnrlpper 1.

andle 2.

ng

J 3.

Fixing

Hole

Lower

Handle

3

Pull out and hold

the Spring Knob

(see Fig. 2)

Insert the

assembled handle

into the Socket, until

it is firmly seated.

Release the Spring

Knob, the handle is

then fixed in

position.

FIG. 2 Spring Knob ._

Assembled

Handle

Handle

Socket

/

Loading...

Loading...