Craftsman 50168 Owner's Manual

Operator’s Manual

4 Ton Low Profile Service Jack

Model 50168

For Trouble Shooting / Service / Parts:

Call 8 AM - 5 PM PST., Monday - Friday

1-888-448-6746

PARA VENTA DE PARTES Y SERVICIO:

Llame 8 AM - 5 PM Tiempo Pacifico., Lunes - Viernes

1-888-448-6746

WARNING : Before using this

appliance, read this Operator’s

Manual and follow all its Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com

Printed in China

• Safety

• Operation

• Maintenance

• Español, p. 4

SAFETY INSTRUCTIONS

Read Operating Instructions

Study, understand and follow all instructions in this

manual before operating the jack. Failure to heed these

warnings may result in loss of load, damage to the jack

and/or jack failure resulting in personal injury or property

damage.

Position the Jack

Position the jack to only lift on the areas of the vehicle

specified by the vehicle manufacturer.

Use Support Stands

After lifting the vehicle always support the load with

appropriately rated vehicle supports stands before

working on the vehicle.

Do Not Overload Jack

Do not overload this jack beyond its rated capacity.

Overloading this jack beyond its rated capacity can

cause damage to or failure of the jack.

Use on Hard Level Surface

This jack is designed only for use on hard level surfaces

capable of sustaining the load. Use on other than hard

level surfaces can result in jack instability and possible

loss of load.

Center Load on Jack Saddle

Center load on jack saddle before lifting vehicle.

Off-center loads and loads lifted when the jack is not

level can cause loss of load or damage to the jack.

KEEP HANDS AND FEET CLEAR OF THE JACK

HINGE MECHANISM AND GROUND CONTACT AREA

WHEN LOWERING THE LOAD !

THIS JACK IS A LIFTING DEVICE ONLY!

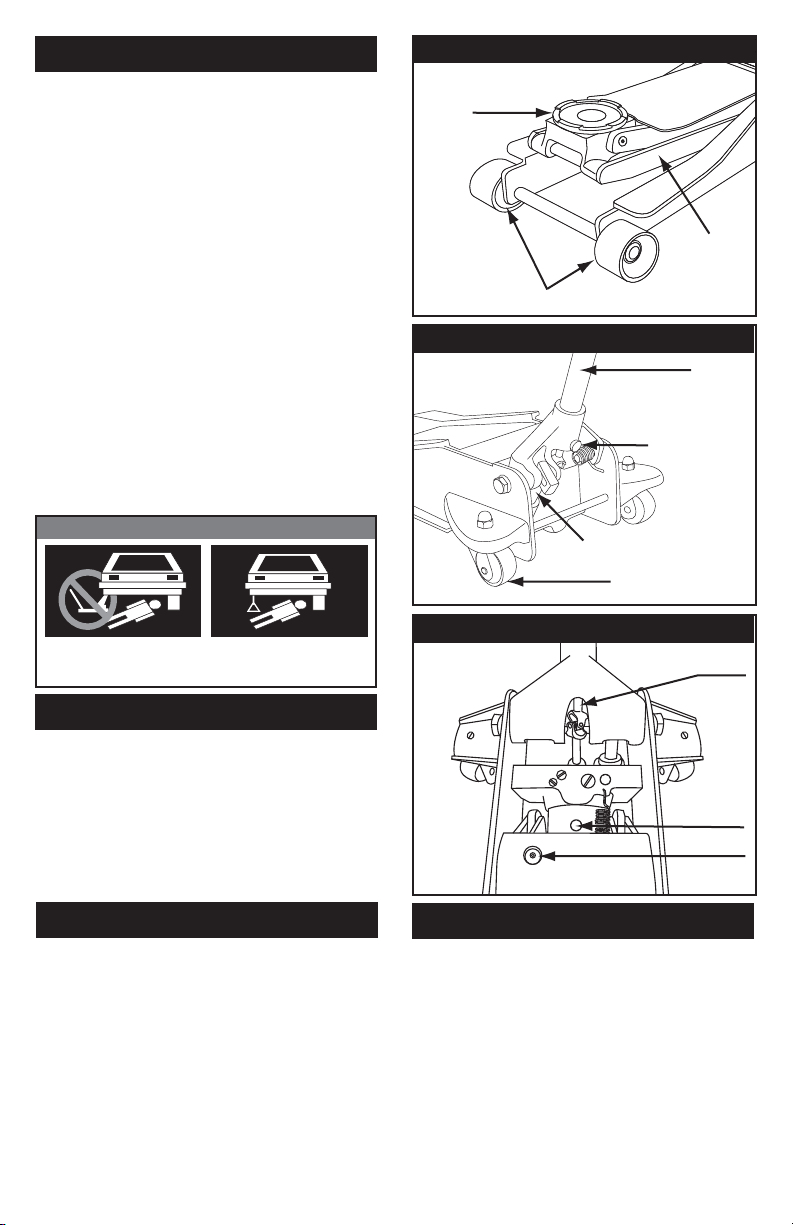

FRONT OF THE JACK

Saddle

Lifting Arm

Front Wheels

BACK OF THE JACK

Handle

Handle

Socket Screw

Plunger

Rear Swivel Casters

THIS JACK IS DESIGNED ONLY FOR LIFTING PART OF THE

TOTAL VEHICLE. DO NOT MOVE OR DOLLY THE VEHICLE

WHILE IT IS ON THE JACK.

WARRANTY

CRAFTSMAN ONE YEAR FULL WARRANTY

If this Craftsman product fails due to a defect in material

or workmanship within one year from the date of

purchase, return it to any Sears store or other Craftsman

outlet in the United States for free replacement.

This warranty applies for only 90 days from the date of

purchase if this product is ever used for commercial or

rental purposes.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

DESCRIPTION

Craftsman model 50167 features an 8,000 lbs.

maximum capacity. Lifting range for this jack is 4 inches

to 21 inches. Jack features an overload valve which

helps prevent equipment failure. Bypass system

provides safe operation.

Specifications

Compact design allows use in confined spaces

Maximum load capacity.......................4 tons (8000 lbs.)

Lift range..................................................4 to 21 inches

Size (LxWxH)..............................29.27” x 15.82” x 7.07”

Weight w/handle..............................................99.23 lbs.

POWER UNIT

U-Joint Release Valve

Oil Fill Plug

Grease Fitting

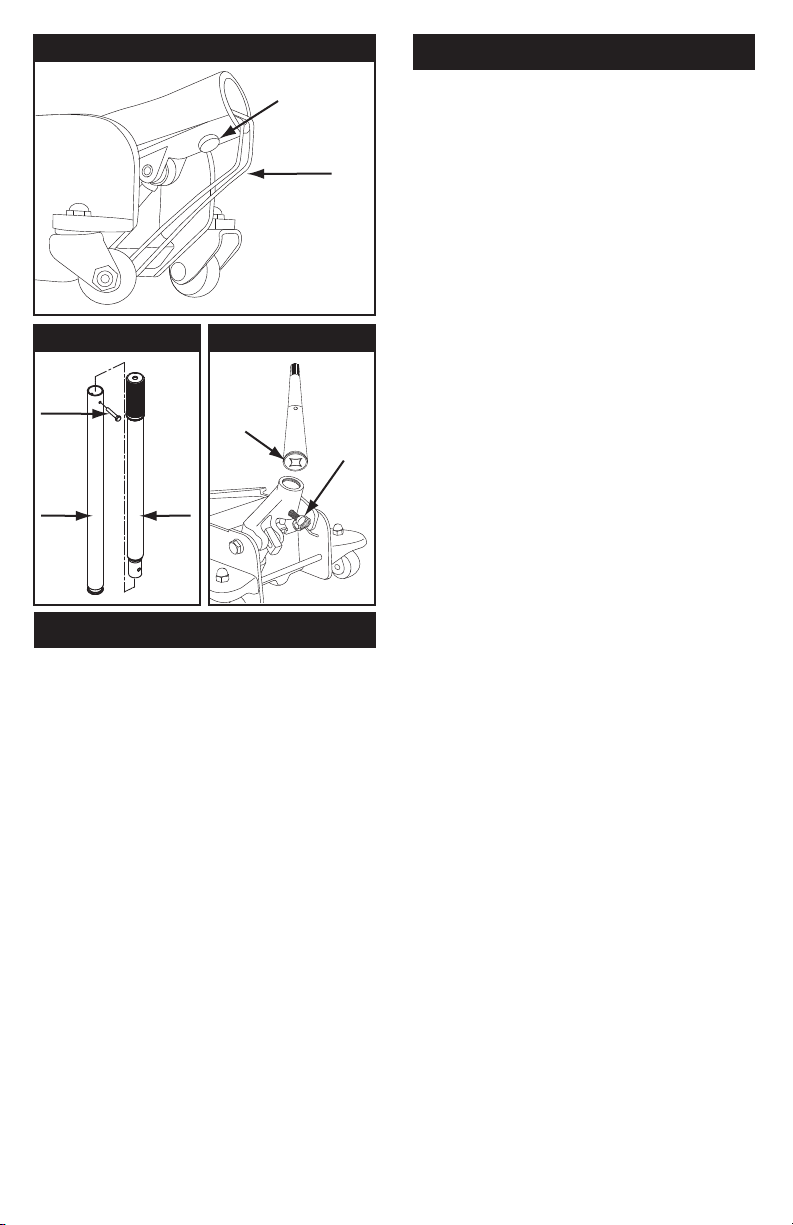

ASSEMBLY

Assembly

Handle Assembly

• Prior to assembly please remove the clip attached to

the handle socket (picture 1).

• Refer to picture 2 when performing this step. Take off

the screw located on handle piece 1. Attach handle

piece 1 and 2 making sure to align the holes on both

pieces. Reinsert the screw and tighten it.

• Fully unfasten the screw located in the Handle

Socket to insert the assembled handle (picture 3).

• Line up the square hole located at the bottom of the

handle over the square bolt inside the Handle Socket.

• Secure the handle in place by tightening the screw

in the Handle Socket.

1

PICTURE 1

Handle

Socket Screw

Clip

PICTURE 2 PICTURE 3

Bottom of

Handle

Screw

Handle

pc. 1

Handle

pc. 2

FEATURES & OPERATION

Operation

Raising the Jack

• Close the release valve by turning the handle

clockwise as far as it will go.

• Block the vehicle’s wheels for lifting stability.

• Refer to the vehicle manufacturer owner’s manual to

locate approved lifting points on the vehicle.

Position the jack so that the saddle is centered and

will contact the load lifting point firmly.

• Pump jack handle until saddle nears contact with

the vehicle. Check to see that the saddle is centered

and will contact the load lifting point firmly.

• Continue to pump the jack handle to lift the vehicle

to the desired height. After lifting, support the load

with appropriately rated vehicle support stands

before working on the vehicle.

Lowering the Jack

• Carefully open the release valve by slowly turning

the handle counterclockwise.

How it Works

With Release Valve Closed

• An upward stroke of the jack handle draws oil from

the reservoir tank into the plunger cavity. Hydraulic

pressure holds the valve closed, which keeps the

oil in the plunger cavity.

• A downward stroke of the jack handle releases oil

into the cylinder, which forces the ram out.

This raises the saddle.

• When the ram reaches maximum extension, oil is

bypassed back into the reservoir to prevent an over

extended ram stroke and possible damage to the

jack.

• Opening the release valve allows oil to flow back

into the reservoir. This releases hydraulic pressure

on the ram, which results in lowering the saddle.

MAINTENANCE

To Add Oil:

• Position the jack on level ground and lower the

saddle.

• Use a Phillips head screwdriver to remove the

cover plate.

• Remove the oil plug.

• Fill the oil case until oil level is just beneath the

lower rim of oil fill hole. Replace oil plug.

• Perform the Air Purge Procedure described below.

To Replace Oil:

• Fully open release valve by turning handle

counterclockwise as far as it will go.

• Turn the jack over so that old oil will drain from

the oil fill hole.

• Refill through oil fill hole. Keep dirt and other

material clear when pouring. Fill to just beneath

lower rim of hole. Replace oil plug.

• Perform Air Purge Procedure described below.

Lubrication

• Add lubricating oil (WD-40) to all moving parts

when needed.

• For light duty use lubricate every six months.

• For heavy and constant use lubrication

recommended every month.

Rust Prevention:

• Check ram and pump plunger on the Power Unit

Assembly every two months (or sooner, based on

usage) for any signs of rust or corrosion. Lift the jack

as high as it goes and look under and behind the

lifting arm. If signs of rust are visible clean as needed

and wipe down with an oily cloth or WD-40.

• When storing the jack, always have the saddle and

pump plunger in the down position.

ALWAYS USE A GOOD GRADE HYDRAULIC JACK

OIL. DO NOT USE HYDRAULIC BRAKE FLUID,

ALCOHOL, GLYCERINE, DETERGENT, MOTOR OIL

OR DIRTY OIL. USE OF AN UN-RECOMMENDED

FLUID CAN CAUSE DAMAGE TO YOUR JACK.

Grease Fitting

There is grease fitting located on top of the jack. It is

for manufacturing purposes only. The jack has been

filled with sufficient grease by the factory for the lifetime

of the jack. Do not add more grease.

Air Purge Procedure

During shipment or after oil refill, air may get into the

hydraulic system causing poor lifting performance.

Then system air purge is required as follows:

1. Turn the release valve fully counterclockwise to fully

open the release valve.

2. Pump handle rapidly several times.

3. Turn the release valve clockwise to close the release

valve.

4. Pump handle until the lift arm reaches maximum

height and continue to pump several times to remove

trapped air in the ram.

5. Turn the release valve fully counterclockwise to lower

lift arm to lowest position. Use force on saddle

if necessary.

6. Turn the release valve clockwise to closed position

and check for proper pump action. It may be

necessary to perform the above steps more than

once to assure air is evacuated totally.

2

Loading...

Loading...