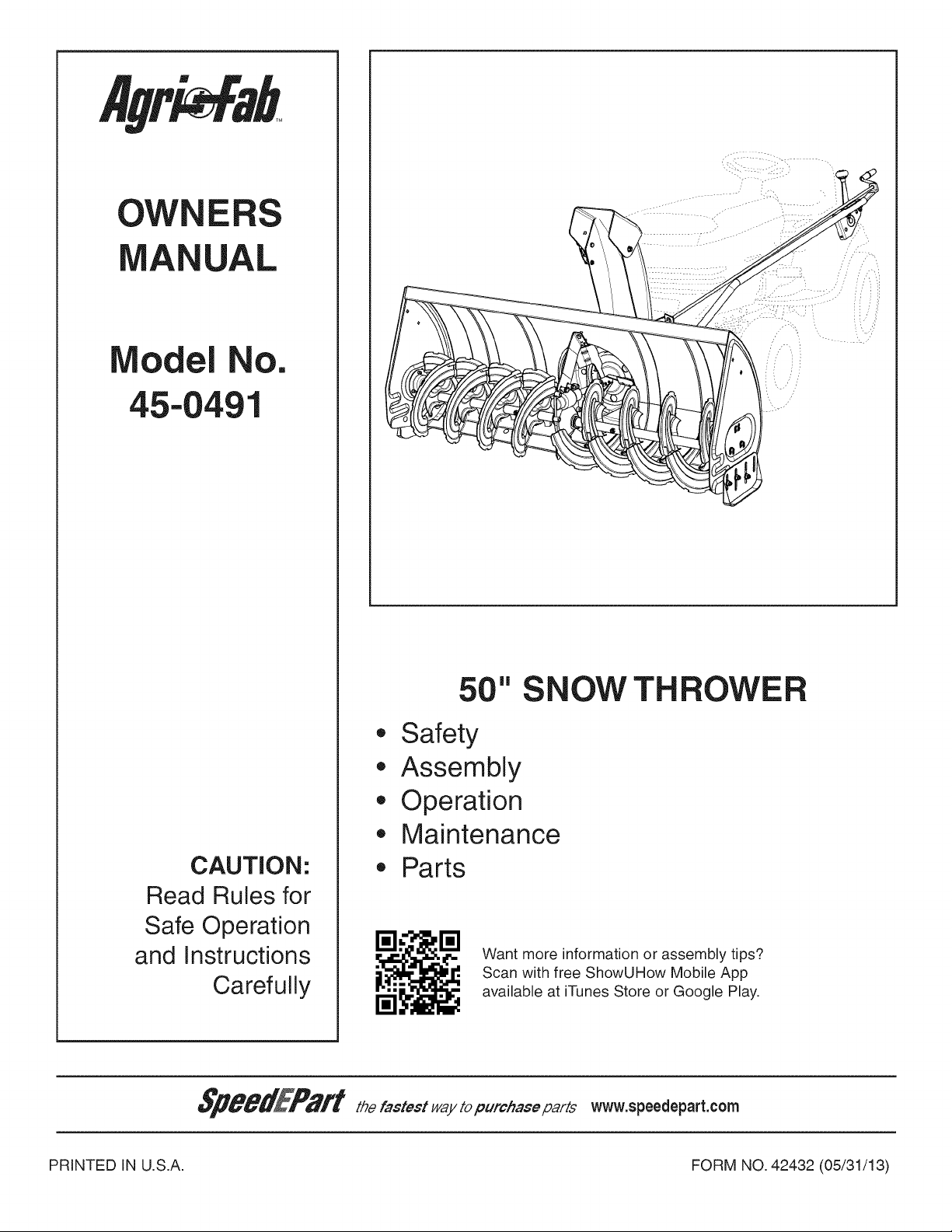

Craftsman 48625840, 45-0491 Owner’s Manual

A AL

odel No.

45-0491

/

50" SNOW THROWER

,, Safety

,, Assembly

,, Operation

,, Maintenance

CAUTION'.

Read Rules for

Safe Operation

and Instructions

Carefully

PRINTED IN U.S.A. FORM NO. 42432 (05/31/13)

,, Parts

Want more information or assembly tips?

Scan with free ShowUHow Mobile App

available at iTunes Store or Google Play.

ACCESSORIES...............................................................2

SAFETYRULES..............................................................3

FULLSIZEHARDWARECHART.................................4,5

CARTONCONTENTS.....................................................6

ASSEMBLY......................................................................7

OPERATION..................................................................18

MAINTENANCE............................................................19

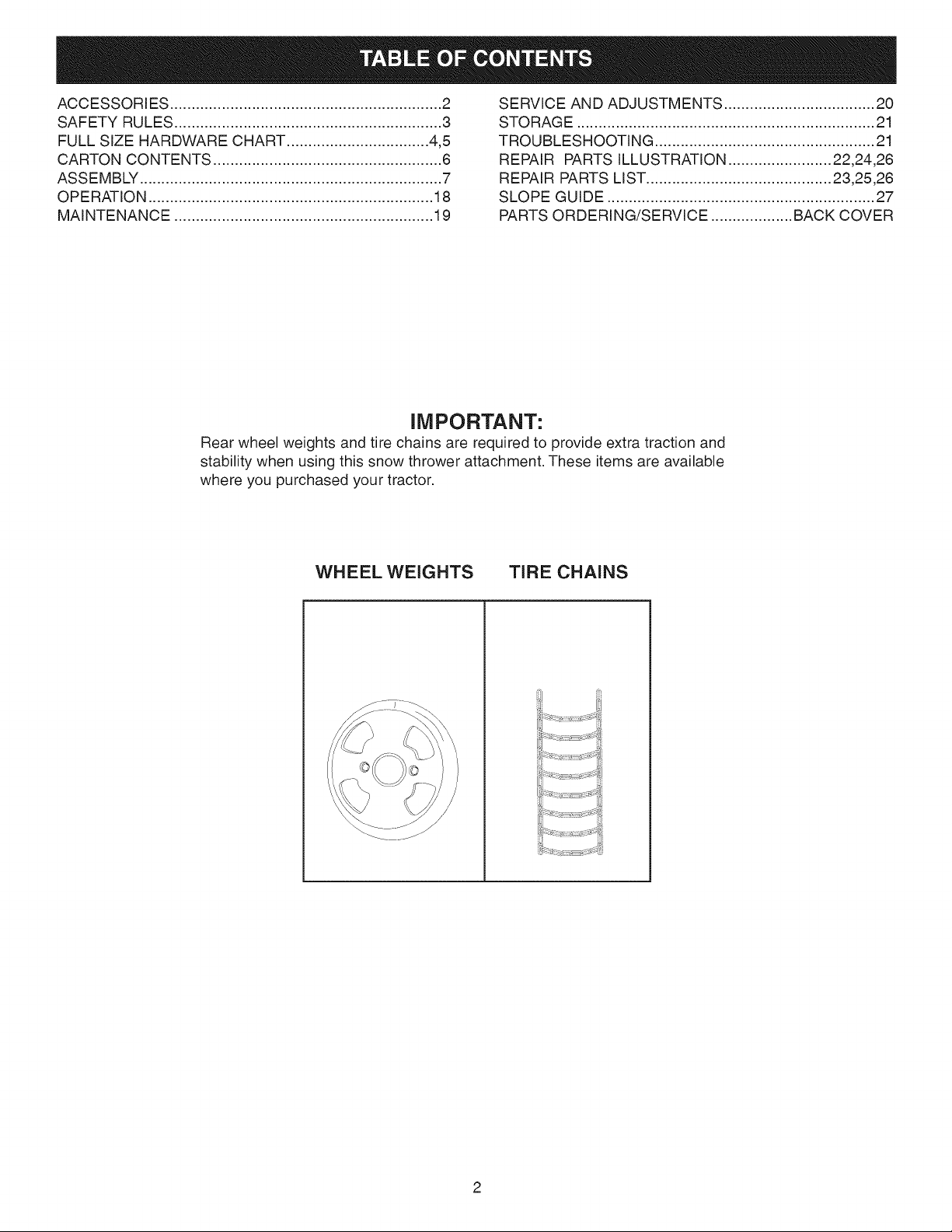

IMPORTANT:

Rear wheel weights and tire chains are required to provide extra traction and

stability when using this snow thrower attachment. These items are available

where you purchased your tractor.

SERVICEANDADJUSTMENTS...................................20

STORAGE.....................................................................21

TROUBLESHOOTING...................................................21

REPAIRPARTSILLUSTRATION........................22,24,26

REPAIRPARTSLIST...........................................23,25,26

SLOPEGUIDE..............................................................27

PARTSORDERING/SERVICE...................BACKCOVER

WHEEL WEIGHTS TIRE CHAINS

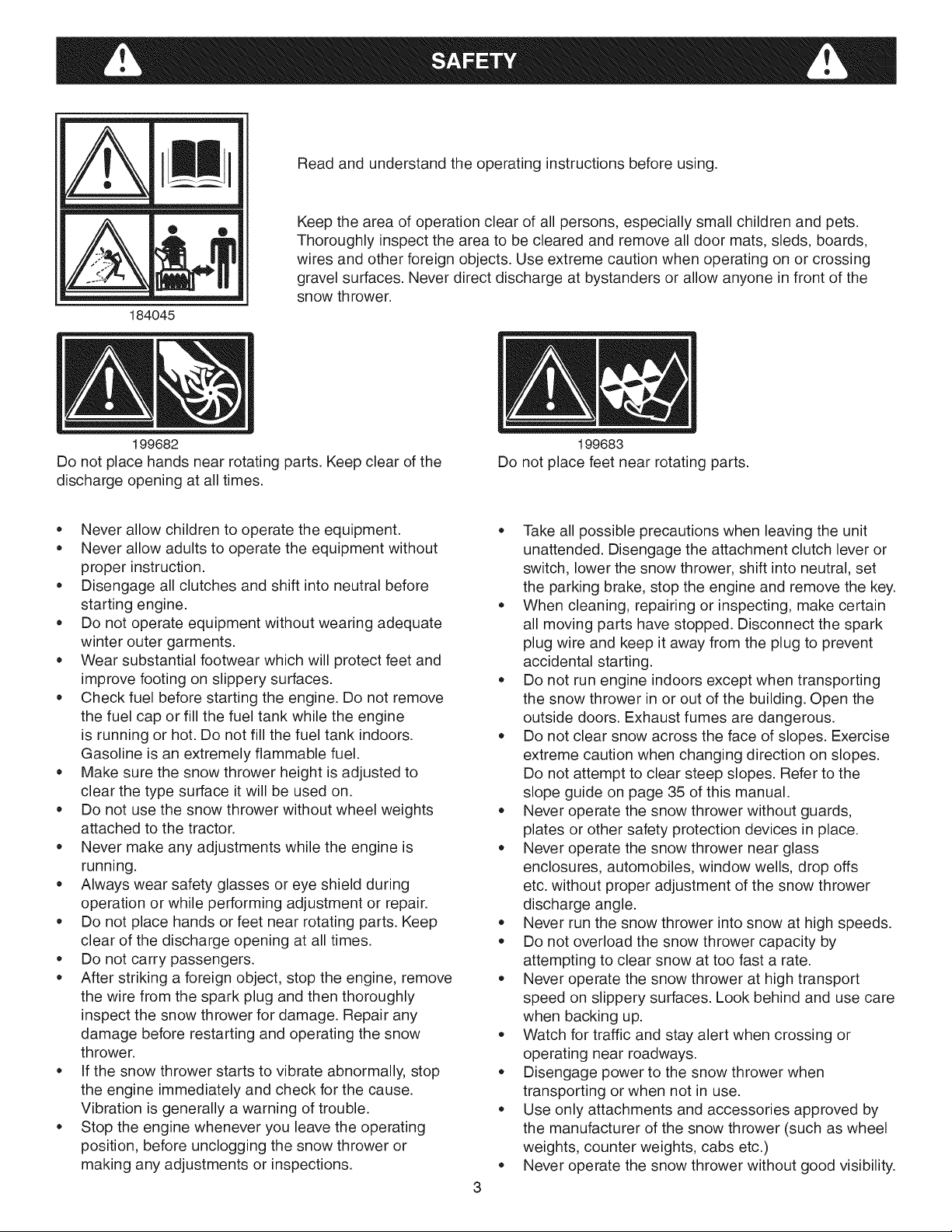

184045

Read and understand the operating instructions before using.

Keep the area of operation clear of all persons, especially small children and pets.

Thoroughly inspect the area to be cleared and remove all door mats, sleds, boards,

wires and other foreign objects. Use extreme caution when operating on or crossing

gravel surfaces. Never direct discharge at bystanders or allow anyone in front of the

snow thrower.

199682

Do not place hands near rotating parts. Keep clear of the

discharge opening at all times.

• Never allow children to operate the equipment.

Never allow adults to operate the equipment without

proper instruction.

Disengage all clutches and shift into neutral before

starting engine.

Do not operate equipment without wearing adequate

winter outer garments.

Wear substantial footwear which will protect feet and

improve footing on slippery surfaces.

Check fuel before starting the engine. Do not remove

the fuel cap or fill the fuel tank while the engine

is running or hot. Do not fill the fuel tank indoors.

Gasoline is an extremely flammable fuel.

Make sure the snow thrower height is adjusted to

clear the type surface it will be used on.

Do not use the snow thrower without wheel weights

attached to the tractor.

Never make any adjustments while the engine is

running.

Always wear safety glasses or eye shield during

operation or while performing adjustment or repair.

Do not place hands or feet near rotating parts. Keep

clear of the discharge opening at all times.

Do not carry passengers.

After striking a foreign object, stop the engine, remove

the wire from the spark plug and then thoroughly

inspect the snow thrower for damage. Repair any

damage before restarting and operating the snow

thrower.

If the snow thrower starts to vibrate abnormally, stop

the engine immediately and check for the cause.

Vibration is generally a warning of trouble.

Stop the engine whenever you leave the operating

position, before unclogging the snow thrower or

making any adjustments or inspections.

199683

Do not place feet near rotating parts.

Take all possible precautions when leaving the unit

unattended. Disengage the attachment clutch lever or

switch, lower the snow thrower, shift into neutral, set

the parking brake, stop the engine and remove the key.

When cleaning, repairing or inspecting, make certain

all moving parts have stopped. Disconnect the spark

plug wire and keep it away from the plug to prevent

accidental starting.

Do not run engine indoors except when transporting

the snow thrower in or out of the building. Open the

outside doors. Exhaust fumes are dangerous.

Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes. Refer to the

slope guide on page 35 of this manual.

Never operate the snow thrower without guards,

plates or other safety protection devices in place.

Never operate the snow thrower near glass

enclosures, automobiles, window wells, drop offs

etc. without proper adjustment of the snow thrower

discharge angle.

Never run the snow thrower into snow at high speeds.

Do not overload the snow thrower capacity by

attempting to clear snow at too fast a rate.

Never operate the snow thrower at high transport

speed on slippery surfaces. Look behind and use care

when backing up.

Watch for traffic and stay alert when crossing or

operating near roadways.

Disengage power to the snow thrower when

transporting or when not in use.

Use only attachments and accessories approved by

the manufacturer of the snow thrower (such as wheel

weights, counter weights, cabs etc.)

Never operate the snow thrower without good visibility.

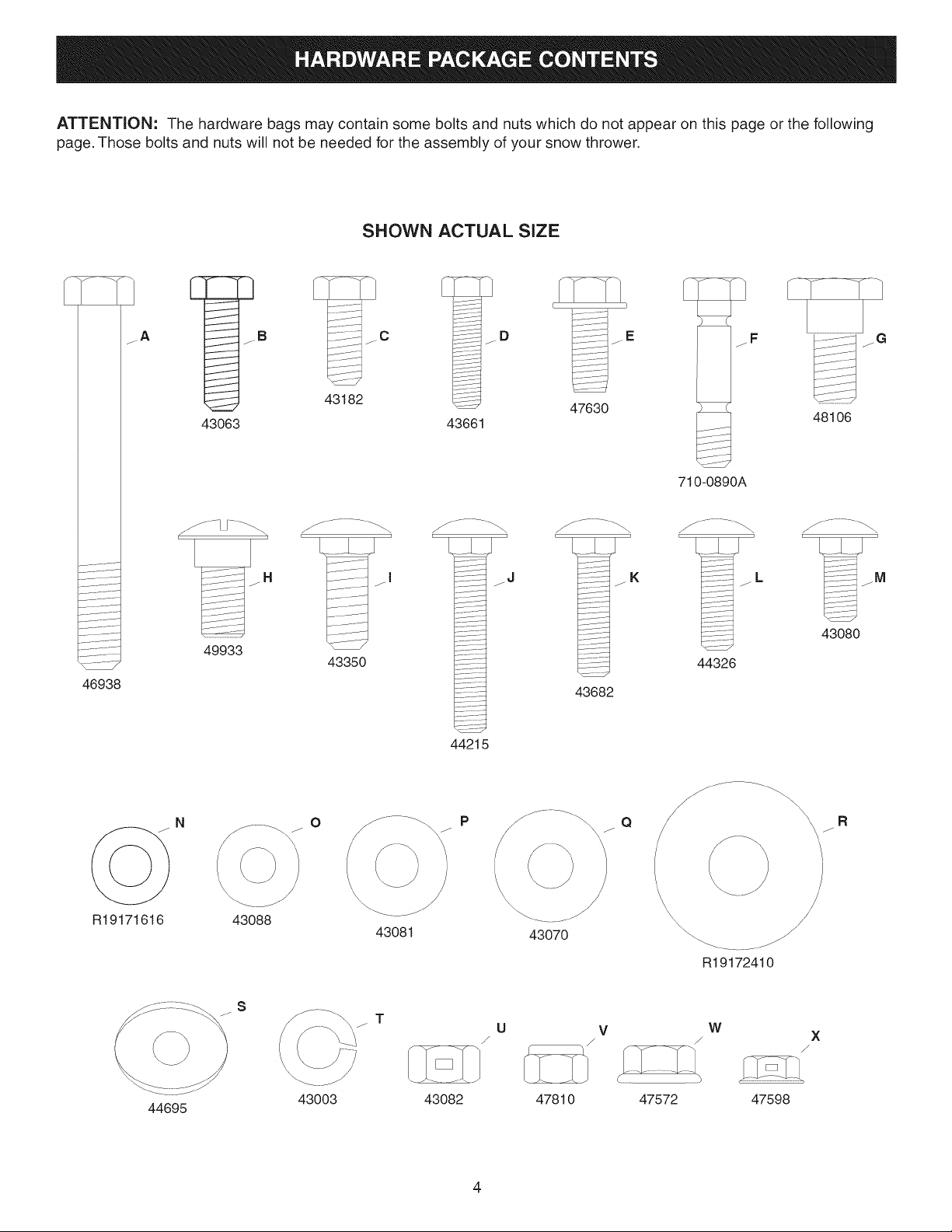

ATTENTION:Thehardwarebagsmaycontainsomeboltsandnutswhichdonotappearonthispageorthefollowing

page.Thoseboltsandnutswillnotbeneededfortheassemblyofyoursnowthrower.

SHOWN ACTUAL SIZE

46938

i

f

J

i

i

fA

i B

j J

/

J

J

J

J

/

i

J

43182

43063

C

.D

47630

43661

)

J

jG

48106

710-0890A

j_-_-q _

_- .............._,

fJ

43080

49933

43350

44326

43682

44215

R19171616

44695

Y

N

43088

S

O

43003

43081

T

Q

/

43070

R19172410

U

/

V W

/

43082 47810 47572 47598

/

X

x

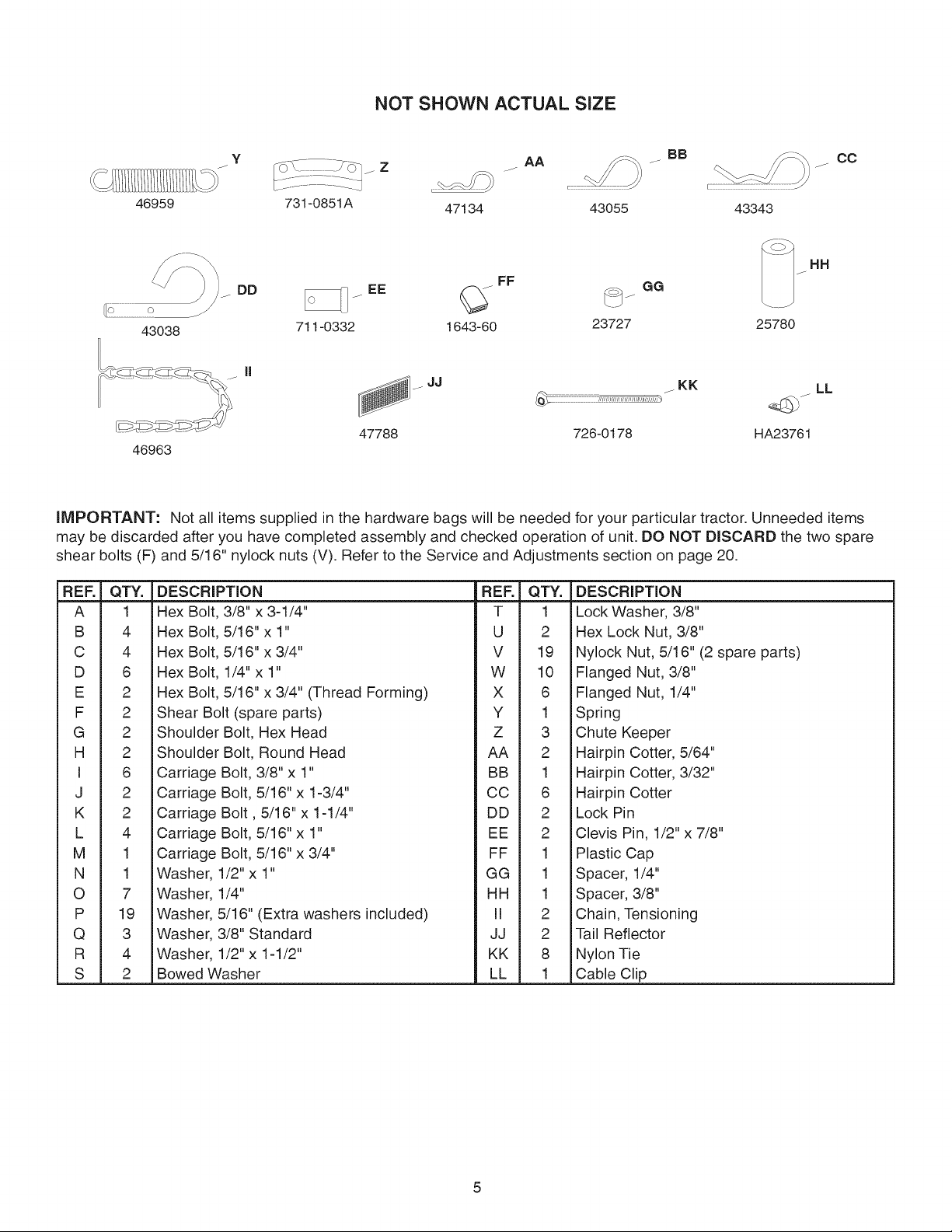

NOT SHOWN ACTUAL SIZE

BB

J

25780

CO

HH

LL

46959

43038

46963

Y

J

731-0851A

DD

711-0332 1643-60 23727

47788 726-0178 HA23761

47134 43055 43343

J JJ KK _J

AA

J

IMPORTANT: Not all items supplied in the hardware bags will be needed for your particular tractor. Unneeded items

may be discarded after you have completed assembly and checked operation of unit. DO NOT DISCARD the two spare

shear bolts (F) and 5/16" nylock nuts (V). Refer to the Service and Adjustments section on page 20.

REF. QTY. DESCRIPTION REF. QTY. DESCRIPTION

A 1 Hex Bolt, 3/8" x 3-1/4" T 1 Lock Washer, 3/8"

B 4 Hex Bolt, 5/16" x 1" U 2 Hex Lock Nut, 3/8"

C 4 Hex Bolt, 5/16" x 3/4" V 19 Nylock Nut, 5/16" (2 spare parts)

D 6 Hex Bolt, 1/4" x 1" W 10 Flanged Nut, 3/8"

E 2 Hex Bolt, 5/16" x 3/4" (Thread Forming) X 6 Flanged Nut, 1/4"

F 2 Shear Bolt (spare parts) Y 1 Spring

G 2 Shoulder Bolt, Hex Head Z 3 Chute Keeper

H 2 Shoulder Bolt, Round Head AA 2 Hairpin Cotter, 5/64"

I 6 Carriage Bolt, 3/8"x 1" BB 1 Hairpin Cotter, 3/32"

J 2 Carriage Bolt, 5/16"x 1-3/4" CC 6 Hairpin Cotter

K 2 Carriage Bolt, 5/16" x 1-1/4" DD 2 Lock Pin

L 4 Carriage Bolt, 5/16" x 1" EE 2 Clevis Pin, 1/2" x 7/8"

M 1 Carriage Bolt, 5/16" x 3/4" FF 1 Plastic Cap

N 1 Washer, 1/2"x 1" GG 1 Spacer, 1/4"

O 7 Washer, 1/4" HH 1 Spacer, 3/8"

P 19 Washer, 5/16" (Extra washers included) II 2 Chain, Tensioning

Q 3 Washer, 3/8" Standard JJ 2 Tail Reflector

R 4 Washer, 1/2" x 1-1/2" KK 8 Nylon Tie

S 2 Bowed Washer LL 1 Cable Clip

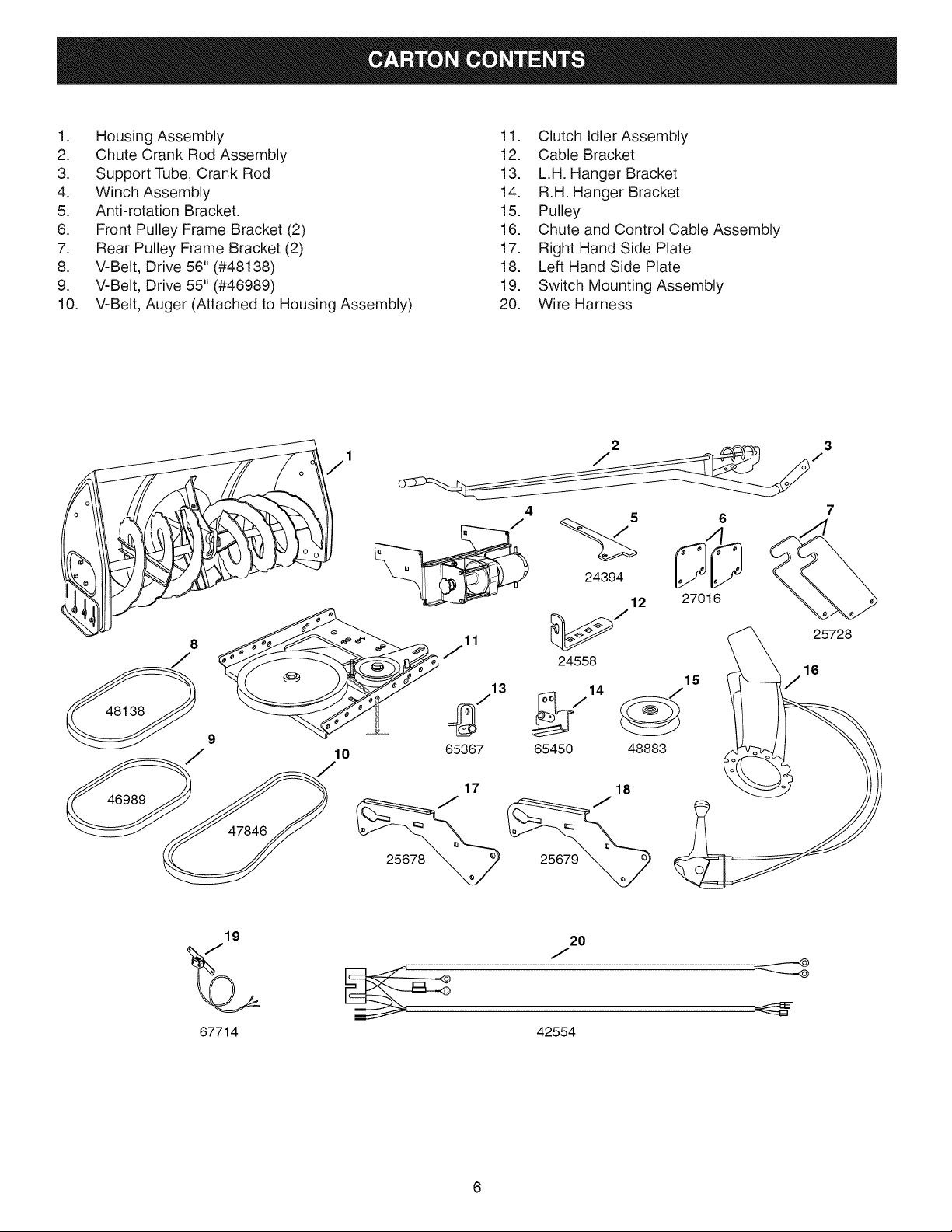

1. HousingAssembly

2. ChuteCrankRodAssembly

3. SupportTube,CrankRod

4. WinchAssembly

5. Anti-rotationBracket.

6. FrontPulleyFrameBracket(2)

7. RearPulleyFrameBracket(2)

8. V-Belt,Drive56"(#48138)

9. V-Belt,Drive55"(#46989)

10. V-Belt,Auger(AttachedtoHousingAssembly)

11. ClutchIdlerAssembly

12. CableBracket

13. L.H.HangerBracket

14. R.H.HangerBracket

15. Pulley

16. ChuteandControlCableAssembly

17. RightHandSidePlate

18. LeftHandSidePlate

19. SwitchMountingAssembly

20. WireHarness

46989

19

4 5 6

12 27016

jll 25728

24558 16

J_713 b714 _15

lO

65367 83

20

J

7

67714

42554

TOOLS REQUIRED FOR ASSEMBLY ATTACHING PARTS TO TRACTOR FRAME

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(2) 3/4" Wrenches

(1) Screw Driver

(1) Knife

REMOVAL OF PARTS FROM CARTON

Remove all loose parts, parts bags and hardware

bags from the carton. Lay out and identify parts and

hardware using the illustrations on pages 4, 5 and 6.

IMPORTANT: Not all items supplied in the hardware

bag will be needed for your particular tractor. Unneeded

items may be discarded after you have completed

assembly and checked operation of unit. DO NOT

DISCARD the two spare shear bolts and 5/16" nylock

nuts. Refer to the Service and Adjustments section on

page 20.

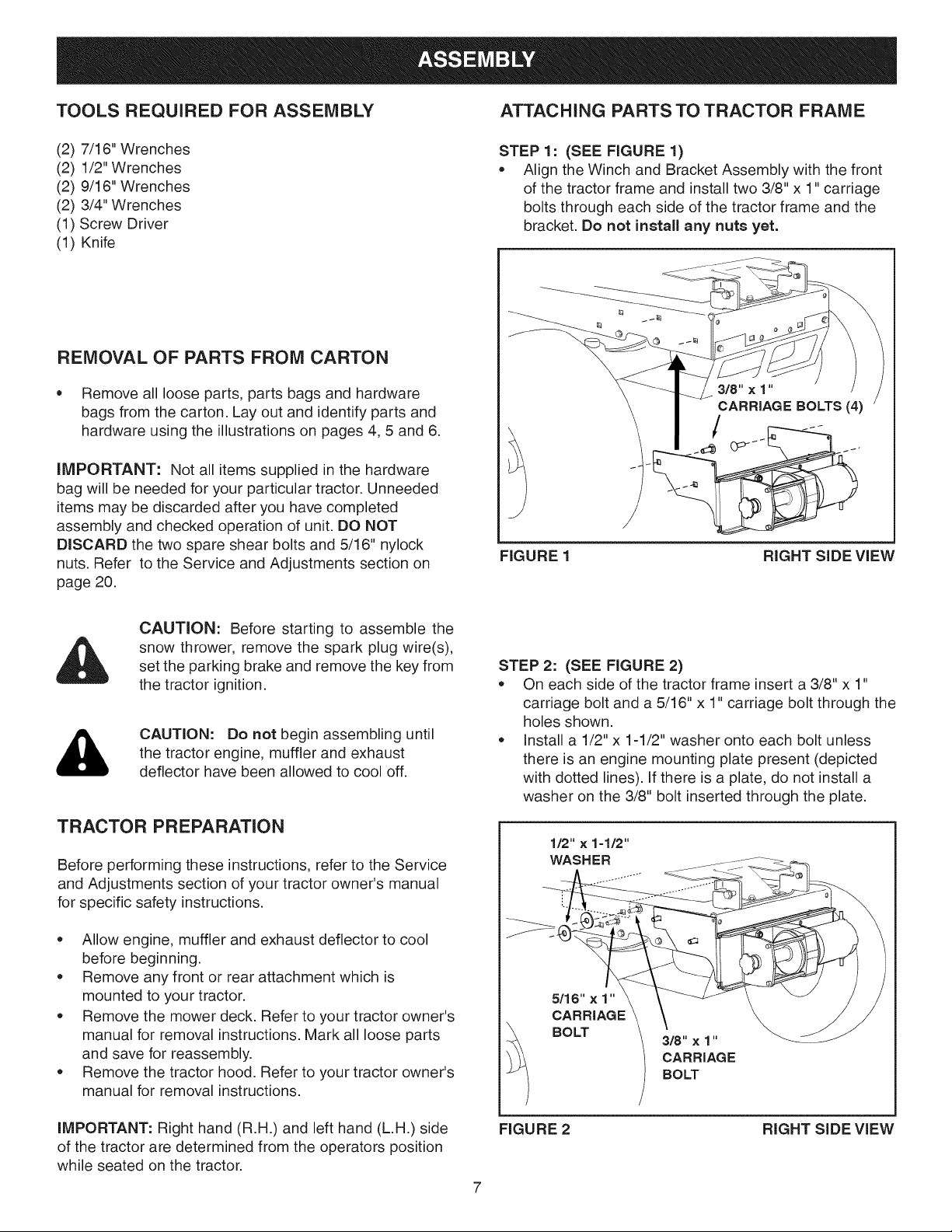

STEP 1: (SEE FIGURE 1)

• Align the Winch and Bracket Assembly with the front

of the tractor frame and install two 3/8" x 1" carriage

bolts through each side of the tractor frame and the

bracket. Do not install any nuts yet.

FIGURE 1 RIGHT SIDE VIEW

CAUTION: Before starting to assemble the

snow thrower, remove the spark plug wire(s),

set the parking brake and remove the key from

the tractor ignition.

CAUTION: Do not begin assembling until

&

the tractor engine, muffler and exhaust

deflector have been allowed to cool off.

TRACTOR PREPARATION

Before performing these instructions, refer to the Service

and Adjustments section of your tractor owner's manual

for specific safety instructions.

Allow engine, muffler and exhaust deflector to cool

before beginning.

Remove any front or rear attachment which is

mounted to your tractor.

Remove the mower deck. Refer to your tractor owner's

manual for removal instructions. Mark all loose parts

and save for reassembly.

Remove the tractor hood. Refer to your tractor owner's

manual for removal instructions.

STEP 2: (SEE FIGURE 2)

On each side of the tractor frame insert a 3/8" x 1"

carriage bolt and a 5/16" x 1" carriage bolt through the

holes shown.

Install a 1/2" x 1-1/2" washer onto each bolt unless

there is an engine mounting plate present (depicted

with dotted lines). Ifthere is a plate, do not install a

washer on the 3/8" bolt inserted through the plate.

1/2" x 1-1/2"

WASHER

5/16" x 1"

CARRIAGE

BOLT

3/8"×1"

CARRIAGE

BOLT

iMPORTANT: Right hand (R.H.) and left hand (L.H.) side

of the tractor are determined from the operators position

while seated on the tractor.

FIGURE 2 RIGHT SIDE VIEW

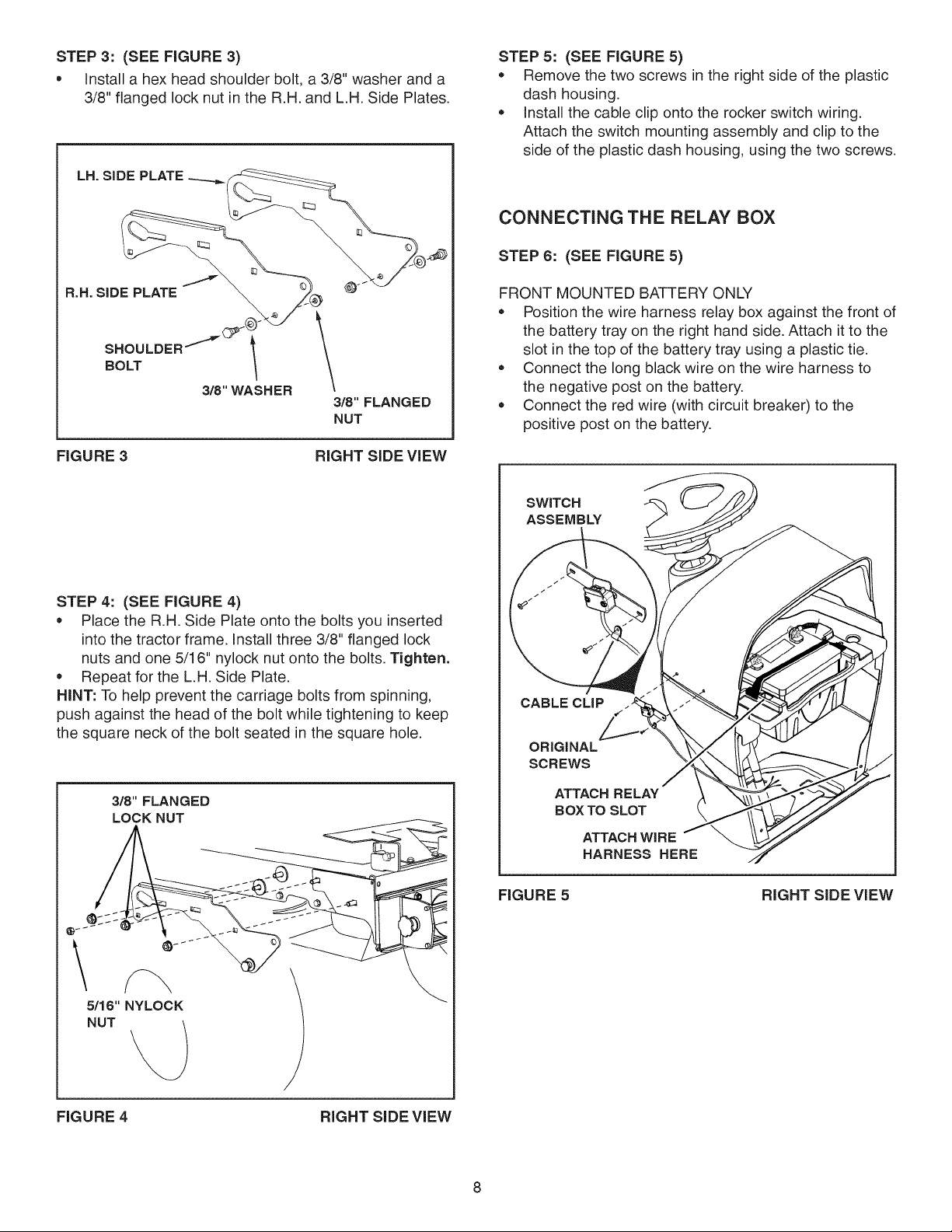

STEP3: (SEEFIGURE3)

• Installahexheadshoulderbolt,a3/8"washeranda

3/8"flangedlocknutintheR.H.andL.H.SidePlates.

LH. SiDE PLATE ---_i

STEP 5: (SEE FIGURE 5)

Remove the two screws in the right side of the plastic

dash housing.

install the cable clip onto the rocker switch wiring.

Attach the switch mounting assembly and clip to the

side of the plastic dash housing, using the two screws.

CONNECTING THE RELAY BOX

STEP 6: (SEE FIGURE 5)

R.H. SIDE PLATE @

SHOULDER_ l

BOLT

3/8"WASHER

FIGURE 3 RIGHT SiDE ViEW

3/8" FLANGED

NUT

STEP 4: (SEE FIGURE 4)

Place the R.H. Side Plate onto the bolts you inserted

into the tractor frame, install three 3/8" flanged lock

nuts and one 5/16" nylock nut onto the bolts. Tighten.

Repeat for the L.H. Side Plate.

HINT: To help prevent the carriage bolts from spinning,

push against the head of the bolt while tightening to keep

the square neck of the bolt seated in the square hole.

FRONT MOUNTED BATTERY ONLY

Position the wire harness relay box against the front of

the battery tray on the right hand side. Attach it to the

slot in the top of the battery tray using a plastic tie.

Connect the long black wire on the wire harness to

the negative post on the battery.

Connect the red wire (with circuit breaker) to the

positive post on the battery.

SWITCH

ASSEMBLY

CABLE CLiP

ORiGiNAL

SCREWS

3/8" FLANGED

LOCK NUT

5/16" NYLOCK

FIGURE 4 RIGHT SiDE ViEW

ATTACH RELAY

BOX TO SLOT

ATTACH WiRE

HARNESS HERE

FIGURE 5 RIGHT SiDE ViEW

STEP 7:

REAR MOUNTED BATTERY ONLY

• Mount the wire harness relay box in front of the

solenoid on the right hand side of the gas tank,

attaching it with a plastic tie.

• Attach the long black wire of the wire harness under

the head of the screw that fastens down the right

hand side of the gas tank.

• Attach the red wire (with circuit breaker) to the rear

solenoid terminal where the battery cable is attached.

• Connect the short red, black and green wires to the

three wires of the switch mounting assembly, joining

together like colored wires.

iNSTALLiNG THE WiRE HARNESS

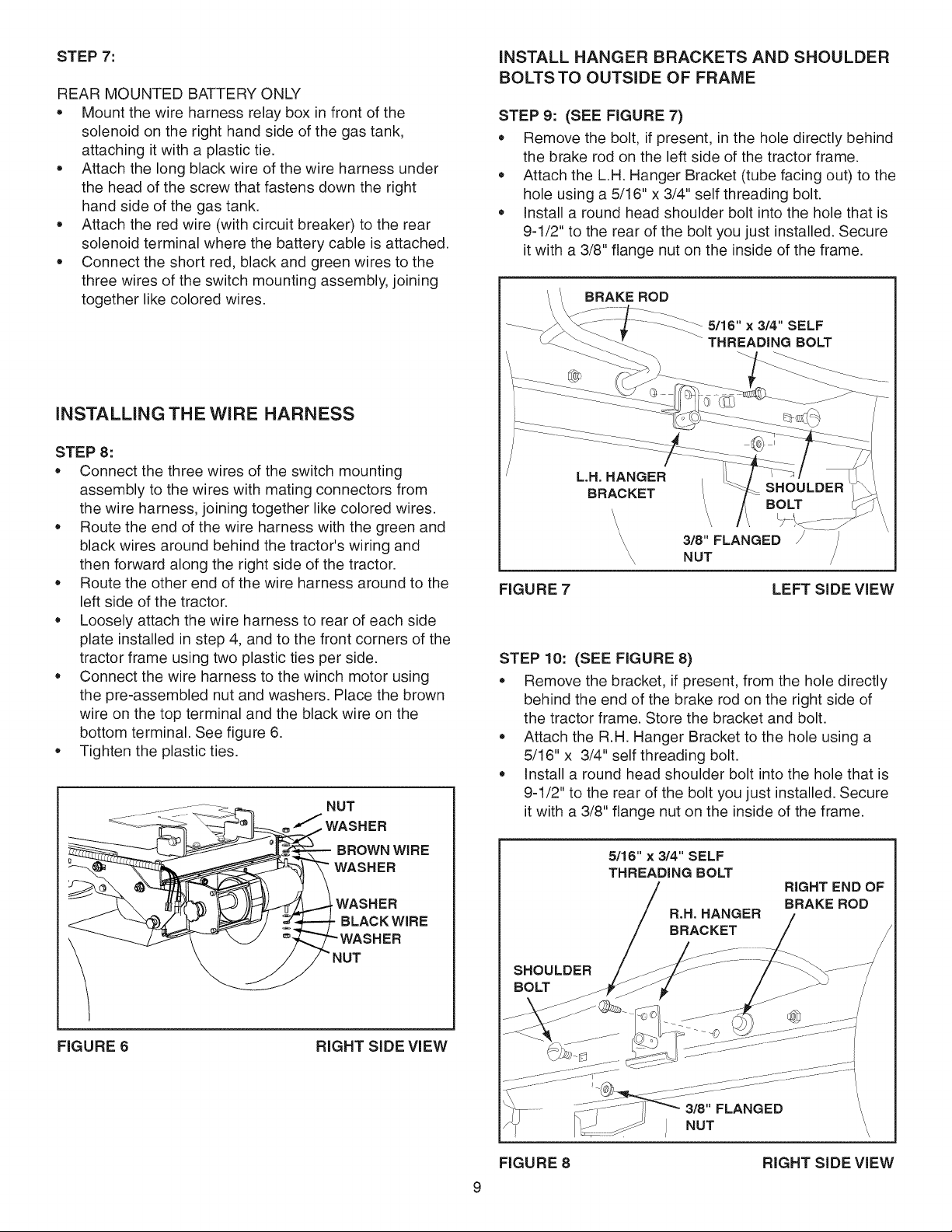

STEP 8:

• Connect the three wires of the switch mounting

assembly to the wires with mating connectors from

the wire harness, joining together like colored wires.

• Route the end of the wire harness with the green and

black wires around behind the tractor's wiring and

then forward along the right side of the tractor.

• Route the other end of the wire harness around to the

left side of the tractor.

• Loosely attach the wire harness to rear of each side

plate installed in step 4, and to the front corners of the

tractor frame using two plastic ties per side.

• Connect the wire harness to the winch motor using

the pre-assembled nut and washers. Place the brown

wire on the top terminal and the black wire on the

bottom terminal. See figure 6.

• Tighten the plastic ties.

NUT

WASHER

BROWN WiRE

WASHER

,WASHER

BLACK WiRE

INSTALL HANGER BRACKETS AND SHOULDER

BOLTSTO OUTSIDE OF FRAME

STEP 9: (SEE FIGURE 7)

• Remove the bolt, if present, in the hole directly behind

the brake rod on the left side of the tractor frame.

• Attach the L.H. Hanger Bracket (tube facing out) to the

hole using a 5/16" x 3/4" self threading bolt.

• Install a round head shoulder bolt into the hole that is

9-1/2" to the rear of the bolt you just installed. Secure

it with a 3/8" flange nut on the inside of the frame.

BRAKE ROD

5/16" x 3/4" SELF

THREADING BOLT

L.H. HANGER

BRACKET

, \

\\ \, \

\

\ 3/8" FLANGED

\

Y, NUT

FIGURE 7

LEFT SIDE VIEW

STEP 10: (SEE FIGURE 8)

• Remove the bracket, if present, from the hole directly

behind the end of the brake rod on the right side of

the tractor frame. Store the bracket and bolt.

• Attach the R.H. Hanger Bracket to the hole using a

5/16" x 3/4" self threading bolt.

• Install a round head shoulder bolt into the hole that is

9-1/2" to the rear of the bolt you just installed. Secure

it with a 3/8" flange nut on the inside of the frame.

5/16" x 3/4" SELF

THREADING BOLT

R.H. HANGER

BRACKET

RIGHT END OF

BRAKE ROD

FIGURE 6 RIGHT SIDE VIEW

SHOULDER

BOLT

FIGURE 8

\

\

RIGHT SIDE VIEW

Loading...

Loading...