Craftsman 390.251483 User Manual

SEARS

OWNER'S

MANUAL

MODELNO.

390.251483

390.251883

CRRFTSMRN°

CAUTION:

Readand Follow

All SafetyRulesand

OperatingInstructions

BeforeFirstUseof

ThisProduct.

SaveThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRINTED IN U.S.A. Form No F642-9906 (Rev, 4/18/01)

PROFESSIONAL

"HYDROGLASS ''®

SHALLOW WELL JET PUMP

• Safety Instructions

• Installation

• Operation

• Troubleshooting

• Repair Parts

READ AND FOLLOW SAFETY INSTRUCTIONS!

This is the ,safety alert symbol. When you see this sTmbol on your

pump or in this manual, look for one of the following signal words

and be alert to the potemial for personal injury:

DANGER warns about hazards that will cause serious personal

injury, death or major property damage L_ignored.

WARNING warns about hazards that will or can cause serious

personal injury., death or major property damage if ignored.

CAUTION warns about hazards that will or can cause minor per-

sonal injury or property damage if ignored.

The label NOTICE indicates special instructions which are im-

portant but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Relief valve must be capable of passing full pump flow at 75 PSI.

Pump water only with this pump.

Electrical Safety

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply.

Make workshop_ childproof; use padlocks and master switches;

remove starter keys.

Wire motor for correct

voltage. See "Electrical"

section of this manual

and motor nameplate.

Ground motor before

connecting to power

supply.

Meet National Elect-

rical Code and local

codes for all wiring.

Follow wiring instruc-

tions in this manual

when connecting mo-

tor to power lines.

General Safety

Do not allow pump, pressure tank, piping, or any other system

component containing water to freeze. Freezing may damage sys-

tem, leading to injury or flooding. Allowing pump or system com-

ponents t_ freeze will void warranty.

General Safety

WARNING I

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Periodically inspect pump and system components.

Wear safety #asses at all times when working on pumps.

Keep work area clean, uncluttered and propedy lighted; store

properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

[_l_WARNING] Pump body may explode if'used as a booster

pump unless relief valve capable of passing full pump flow

at 75 PSl (517 kPa) is installed.

CAUTION_ Motor normally operates at high temperature and

will be too hot to touch. It is protected t_'om heat damage during

operation by an automatic internal cut oiff'switch. Before handling

pump or motor, stop motor and allow it tO cool for 20 minutes.

TABLE I - Pump Performance (InGallons per Minute)

Model Discharge Pumping Depth in Feet

No. Description Suct. Disch. Pressure PSI 5' 10' 15' 20'

390.251483 1/2 HP S.W. Jet 1-1/4" 1" 40 8.2 7.3 5.2 5.0

390.251883 3/4 HP S.W. Jet 1-1/4" 1" 40 10.9 10.4 8.6 7.5

CONTENTS

Safety .............................................................................................. 2

Warranty/Introduction ................................................................... 3

Pump Performance ........................................................................ 3

Major Components ........................................... _ ........................ 3-4

Piping ............................................................................................. 4

Electrical ......................................................................................... 5

Installation ...................................................................................... 6

Operation ....................................................................................... 6

Maintenance ................................................................................ 7-8

Helpful Hints .................................................................................. 8

Troubleshooting Guide ................................................................. ._9

Repair Parts ............................................................................. 10-11

INTRODUCTION

We suggest you take a few minutes to read the instructions con-

tained in this manual before installing and using your pump. This

will help you obtain the full benefits of the quality and convenience

built into this equipment. It will also help you avoid any needless

service expense resulting from causes beyond our control which

naturally cannot be covered in our warranty.

RULES FOR SAFE INSTALLATION AND OPERATION

1. Read the Owners Manual and Rules for Safe Operation and

installation Instructions carefully. Failure to follow these Rules

and Instructions could cause serious bodily injury, and/or prop-

erty damage.

2. Check your local electrical wiring codes before installation. If

your local codes are not followed, your pump will not work to

its full rated capacity. If in doubt, contact your local Power

Company.

3. Be certain your pump installation meets all local plumbing,

pump and well codes.

4. While installing the pump, always keep the well covered to pre-

vent leaves and foreign matter from falling into the well and con-

tanlinating the water and/or causing possible serious damage to

the mechanical operation of the pump.

MAJOR COMPONENTS / PIPING

MAJOR COMPONENTS AND WHAT

THEY DO

NOTICE: Use Teflon tape supplied with the pump for making all

threaded connections to the pump.

Impeller and Jet

Impeller turns with motor shaft, causing water to fly out from its

rim by centrifugal force. Impeller rotation creates a vacuum which

pulls in more water. Part of the water is diverted back to the jet

5. Always test the well water for purity before using. Check with

local health department for testing procedure.

6. Before installing or servicing your pump, BE CERTAIN pump

power source is disconnected.

7. Be sure your pump electrical circuit is properly grom_ded.

8. Complete pump and piping system MUST be protected against

below freezing temperature. Failure to do so could cause severe

damage and voids the Warranty.

9. Make sure the line voltage and frequency of the electrical circuit

supply agree with the motor wiring. If motor is dual voltage

type, BE SURE it is wired correctly for your power supply.

IO. The correct fusing and wiring sizing is essential to proper motor

operation. Recommended fusing and wire size data is in the

mallual.

where it passes through the nozzle and venturi. This creates more

vacuum to draw in more water.

In shallow wells (less than 20 feet deep), the vacuum created at the

pump is enough to pull water to the pump. Therefore, the jet as-

sembly is built into the pump.

Air Volume Control

The air volume control (AVC) maintains the cushion of air in

Standard tanks.

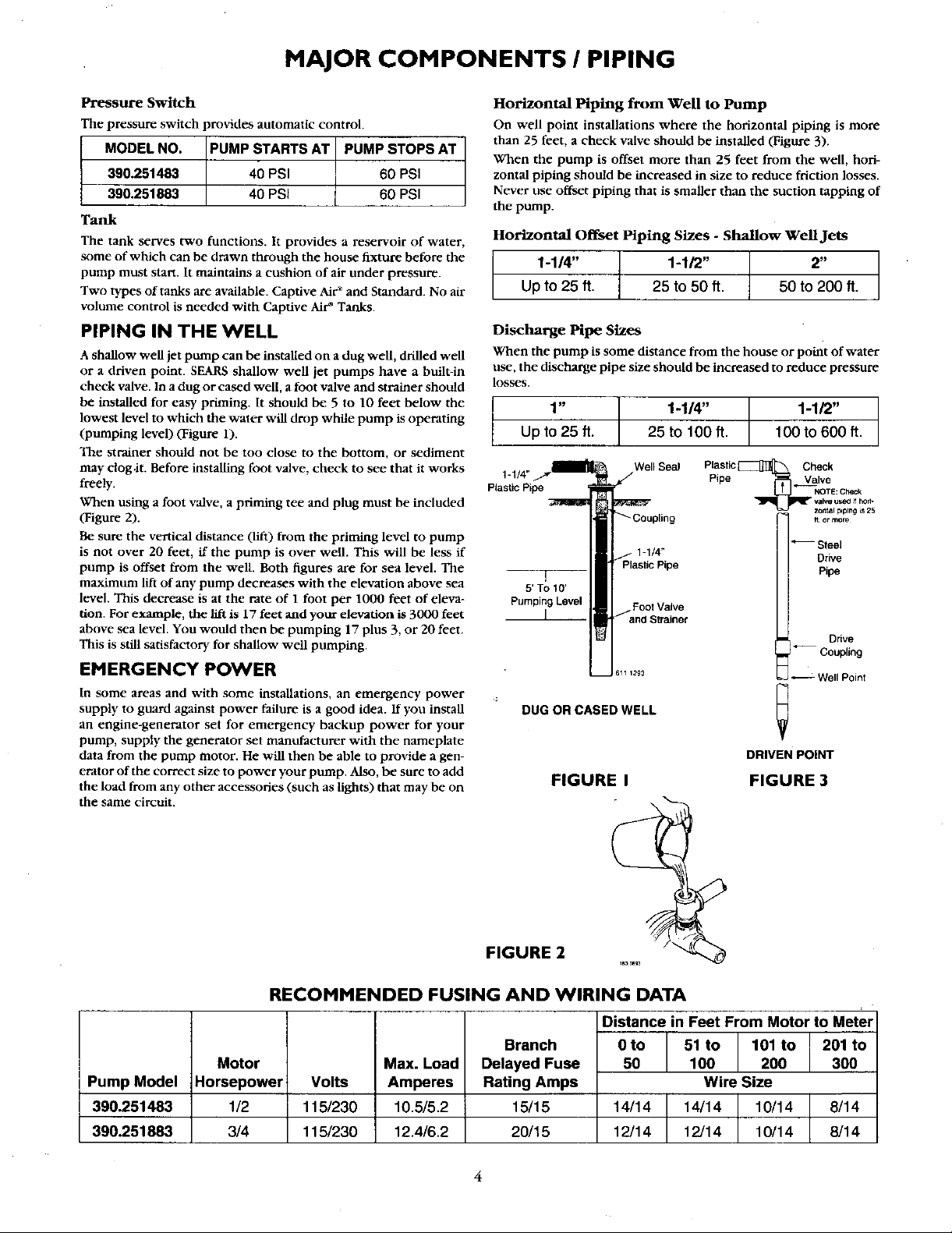

MAJOR COMPONENTS / PIPING

Pressure Switch

The pressure switch provides automatic control.

MODEL NO. PUMP STARTS AT PUMP STOPS AT

390.251483 40 PSI 60 PSI

390.251883 40 PSI 60 PSI

Tank

The tank serves two functions. It provides a reservoir of water,

some of which can be drawn through the house fixture before the

pump must start. It maintains a cushion of air under pressure.

Two types of tanks are available. Captive Air _ and Standard. No air

volume control is needed with Captive Air* Tanks.

PIPING IN THE WELL

A shallow well jet pump can be installed on a dug well, drilled well

or a driven point. SEARS shallow well jet pumps have a built-in

check valve. In a dug or cased well, a foot valve and strainer should

be installed for easy priming. It should be 5 to 10 feet below the

lowest level to which the water will drop while pump is operating

(pumping level) (Figure 1).

The strainer should not be too close to the bottom, or sediment

may clog.it. Before installing foot valve, check to see that it works

freely.

When using a foot valve, a priming tee and plug must be included

(Figure 2).

Be sure the vertical distance (lift) from the priming level to pump

is not over 20 feet, if the pump is over well. This will be less if

pump is offset from the well. Both figures are for sea level. The

maximum lift of any pump decreases with the elevation above sea

level. This decrease is at the rate of 1 foot per 1000 feet of eleva-

tion. For example, the lift is 17 feet and your elevation is 3000 feet

above sea level. You would then be pumping 17 plus 3, or 20 feet.

This is still satisfactory for shallow well pumping.

EMERGENCY POWER

In some areas and with some installations, an emergency power

supply to guard against power failure is a good idea. If you install

an engine-generator set for emergency backup power for your

pump, supply the generator set manufacturer with the nameplate

data from the pump motor. He will then be able to provide a gen-

erator of the correct size to power your pump. Also, be sure to add

the load from any other accessories (such as lights) that may be on

the same circuit.

Horizontal Piping from Well to Pump

On well point installations where the horizontal piping is more

than 25 feet, a check valve should be installed (Figure 3).

When the pump is offset more than 25 feet from the well, hori-

zontal piping should be increased in size to reduce friction losses.

Never use offset piping that is smaller than the suction tapping of

the pump.

Horizontal Offset Piping Sizes - Shallow Well Jets

1-1/4" t 1-1/2" t 2"

Up to 25 ft. 25 to 50 ft. 50 to 200 ft.

Discharge Pipe Sizes

When the pump is some distance from the house or point of water

use, the discharge pipe size should be increased to reduce pressure

losses.

1" 1-1/4" | 1-1/2"

Up to 25 ft. 25 tolOOft. T 100 to 600 ft.

1-1/4" WellSeal

Plastic Pipe

1-1/4"

T

5' TOtO'

Pumping Lovel Foot Valve

1

DUG OR CASED WELL

Pipe ._aValve

Plastic C_leck

DRIVEN POINT

NOTE: Check

valve useO _f how

zontal p_ping _s 25

Steel

Drive

Pipe

Coupling

Well Point

or more

Drive

FIGURE I FIGURE 3

\

Pump Model

390.251483

390.251883

FIGURE 2

RECOMMENDED FUSING AND WIRING DATA

Distance in Feet From Motor to Meter

Branch

Motor

Horsepower

1/2

3/4 12.4/6.2 20/15 12/14 12/14 10/14 8/14

Volts

115/230

115/230

Max. Load

Amperes

10.5/5.2

Delayed Fuse

Rating Amps

1_15

4

Oto 51 to 101 to 201 to

50 100 200 300

Wire Size

14/14 14/14 10/14 8/14

Loading...

Loading...