Craftsman 3902511, 390251101, 390251181, 390251901, 390251981 Owner’s Manual

...

English

Fran¢ais

Stock Nos.

2645/2655

26945 / 26955

• Do not run pump dry or leave unattended whde running.

The pump must be unplugged immediately once the

water is pumped away.

• Use only 1/2" or larger garden hose.

• If pump is stopped and restarted whde pumping, an air

blockage may form in the discharge hose. To restart

pumping, unplug the pump and drain all water from the

hose.

• Not recommended for use m fountains or ponds with

fish

• If installed with an extension cord, be sure the cord is 14

gauge wire.

• Regularly inspect pump inlet and clean away any debris.

N°Sde stock

2645 /2655

26945 / 26955

Ne faites pas fonct_onner la pompe _ sec et ne la laissez

pas sans surveillance, pendant qu'elle fonctionne. La

pompe dolt _tre imm_diatement d_branch_e Iorsque

toute l'eau a _t_ pomp_e.

N'utlhsez qu'un tuyau d'arrosage de 1/2 de pouce de

dlam_tre ou plus gros.

Si la pompe est arr_t_e et red_marr_e alors qu'eile fonc-

tionnait, un bouchon d'air peut se former dans le tuyau

de refoulement. Pour recommencer le pompage,

d_branchez la pompe et vJdez toute I'eau du tuyau.

Utdlsation non recommand_e avec les r_servolrs ou [es

6tangs dans lesquels iI y a des polssons.

Si un cordon prolongateur est ut_l_s_ pour ['ahmentatLon

en courant, assurez-vous que les conducteurs du cordon

prolongateur sont du cahbre 14.

tnspectez r_guh_rement ['admission de la pompe et

enlevez tousles d_bris.

(800) 432-4029 (800) 432-4029

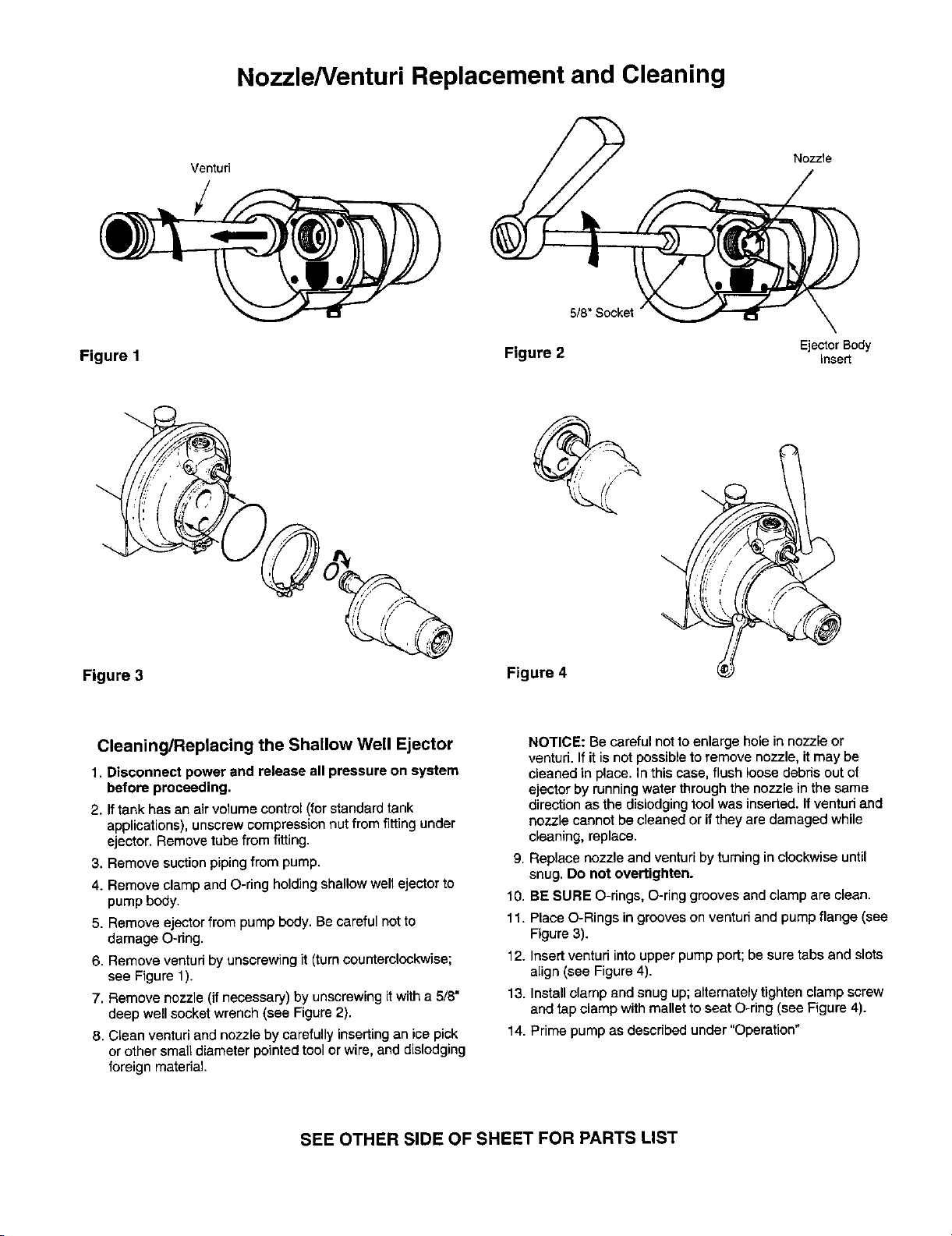

Nozzle/Venturi Replacement and Cleaning

Figure 1

Venturi

Nozzle

5/8" Socket

Figure 2 insert

Ejector Body

Figure 3

Cleaning/Replacing the Shallow Well Ejector

1. Disconnect power and release all pressure on system

before proceeding.

2. If tank has an air volume control (for standard tank

applications), unscrew compression nut from fitting under

ejector. Remove tube from fitting.

3, Remove suction pipingfrom pump.

4. Remove clamp and O-ring holdingshallow well ejector to

pump body.

5. Remove ejectorfrom pump body. Be careful notto

damage O-ring.

6. Remove ventudby unscrewing it (turnoountemlockwise;

see Figure 1).

7, Remove nozzle (if necessary) by unscrewing it with a 5/8"

deep well socket wrench (see Figure 2).

8, Clean venturi and nozzle by carefully inserting an ice pick

or other small diameter pointed tool or wire, and dislodging

foreign material

Figure 4

NOTICE: Be careful not to enlarge hole in nozzle or

venturi. If it is not possible to remove nozzle, it may be

cleaned in place. In this case, flush loose debris out of

ejector by running water through the nozzle in the same

direction as the dislodging tool was inserted. If venturi and

nozzle cannot be cleaned or if they are damaged while

cleaning, replace.

9. Replace nozzle and venturi by turning in clockwise until

snug. Do not overtighten.

10. BE SURE O-rings, O-ring grooves and clamp are clean.

11. Place O-Rings in grooves on venturi and pump flange (see

Figure 3).

12. Insert venturi into upper pump port; be sure tabs and slots

align (see Figure 4).

13. Install clamp and snug up; alternatelytighten clamp screw

and tap clamp with mallet to seat O-ring (see Figure 4).

14. Prime pump as described under "Operation"

SEE OTHER SIDE OF SHEET FOR PARTS LIST

Loading...

Loading...