Page 1

Operator's Manual

3.4 HP, 2-Cycle

53 cc/3.2 cu. in.

235 mph/705 cfm

BACKPACK AIR BLOWER

Model 360.796900

CAUTION:

Before using this product, read this

manual and follow all Safety Rules and

Operating Instructions.

Sears. Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

V=s=four Craftsmanwebsite ;vwwsears COmlCrattsman

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Espa_ol

Page 2

Dear Valued Customer,

When you operateyournew Craftsmanair blowerdon't expect !o hear the high-pitchedengine noisecommonly

associatedwith motorizedpowerequipment. L

This isa blowerdesignedto meet the needs of both professionaland occasional usersand complywithfuture noise

and emissionstandards.Many years of reseamh and engineeringwent intocreating thisquieter, more efficientunit.

Byredesigningthe engine,fan, and blowerhousingcomponents,noise emissionswere cut by 50%. Engine speed

was loweredby 2,500 RPM, which reducesnoise,fuel consumption,and emissions, while increasingoperatingtime

between refuelingwiththe addedbenefitof a longer engine life.

Incorporatinga verypowerfulengine and speciallydesignedhighvolumefan the Craftsman blower is able to achieve

maximumair power at only4,800 RPM. Competitive blowerstypicallyrunat 7,000 to 8,000 RPM. This air bloweris

quietand powerful,features you and your neighborswillquicklyappreciate.

• Warranty Pg. 2

• Safety Pg. 3

• Contentsof Carton Pg. 4

• Accessories Pg. 4

• Assembly Pg. 4

• Operation Pg. 5

• Storage Pg. 8

• Troubleshooting Pg. 9

• CaliforniaEmission Control Pg.10

Warranty Statement

• Parts Pg.11

• Espal_ol Pg.17

• Maintenance Pg. 7

LIMITED TWO YEAR WARRANTY

Fortwo (2) yearsfrom thedate of pumhase if the backpack air blower is maintained, lubricatedand tunedup

accordingto the instructionsin the Operator's Manual, Sears willrepair or replace, free of charge, any partsfound to

bedefective in materialor workmanship.Ifthis productis usedcommemially, thiswarranty onlyappliesfor 90 days.

Thiswarranty does notcover:.

• Exper{_ableitems which becomeworn duringnormal use, suchas spark plugs and air filters.

• Repairsnecessarybecause of operator abuse, negligence, improperstorage, accident, or the failure to

maintainthe equipmentaccordingtothe instructionscontained in the Operator's Manual.

Warrantyservice is available byretumingthe air blowertothe nearest Sears Service Center in the UnitedStates. This

warrantygives you specificlegal rights,and you may also have other rightswhich may vary from stateto state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

PRODUCT SPECIFICATIONS

Horse Power

Fuel-Oil Capacity

FueFOII Mix

Spork Rug

IGop .020 In)

AirVelo¢_

Air Volume

Maximum RPM

Dry Weight

3.4

1.6U.S. qt.

40-1

_sch WSR6F

3hamplonRCJ--6Y

Z35mph

705cfm

_500rpm

20.5Ibs.

© Sears, Roebuckand Co.

Model No. 360.796900

Serial No.

Date of Pumhase

"rhemodel and serial numberwillbe

found to the left of the fuel cap. You

shouldrecordbothserial number and

date of pumhase and keep ina safe

place for future reference.

2

Page 3

CAUTION: Always disconnect spark plug wire and place',Where it cannot contact spark plug to prevent

accidental starting when setting up, transporting, adjusting or making repairs.

TRAINING

Read the operator'smanualcarefuUy.Become familiar

withthe controlsand know howto operate your air

blower"properly.

• Do not allow childrento use yourair blower. Never

allow adultsto useair blowerwithoutproper

instructions.

• Keep the area ofoperationclear of all persons,

especiallysmallchildrenand pets..

• Use air blower onlyas described in this manual.

• Do notoperate air blower ifit has been droppedor

damaged in any manner. Always have damage

repairedbefore usingyour air blower.

• Do not use accessoryattachmentsthat are not

recommendedby the manufacturer.Use of such

attachmentsmay be hazardous.

PREPARATION

• Alwayswear safetyglasses or eye shieldswhen

startingand while usingyour air blower.

• Dress properly.Do notoperate air blowerwhen

barefootor weadng open sandals. Wear only solid

shoeswith goodtraction.

• Wear long-sleevedclothesthat are snug fitting.

Avoidwearing loose clothing.

• Wear eithertightlycuffed or cufflesspants.

• Wear hearing protectioneven when workingfor a

shortperiod of time. Remember - hearingdamage

iscumulative.

• Wear protective,non-slipglovesfor safer

operation_

• Check fuel.tank before startingengine. Do notfill

fueltank indoors,when the engine isrunningor

when the engine is hot. Allowthe engineto cool

for several minutesbeforefillingthe fueltank.

Clean off any spilledgasolinebeforestartingthe

engine.

• Always make adjustmentsbefore startingyour air

blower.Never attemptto do this whilethe engine

is running.

• Use onlyin daylightor goodartificial light.

OPERATION

• Keep your eyes and mind on your air blower and

thearea being blown.Don't let otherinterests

distractyou.

• Always be sureof your footing.Use extra caution

in wet or slipperyareas. WALK - DON'T RUN.

• Do not put hands or feet near rotatingpads. Keep

clear of the nozzleopeningat alltimes.

• Always stopthe enginewheneveryou leave orare

notusingyourair blower.

• Beforecleaning, inspecting,or repairingyourair

blower,stop the engine and make absolutelysure

all movingparts have stopped.Then disconnect

the sparkplug wire and keep it away fromthe

spark plugto preventaccidentalstarting.

• Do not adjustcarburetor,Overspeeding,engine

damage or personal injurymay result.

• Do not operate your air blower if itvibrates

abnormally.Excessivevibrationisan indication of

damage; stopthe engine,safelycheckfor the

causeof vibrationand repairas needed.

• Do not run the engine indoors.Exhaustfumesare

dangerous.

• Never operateyour air blower withoutproper

guards,tubes, or other safetydevices in place.

WARNING: CaliforniaProposition65

The engineexhaust fromthis productcontains

chemicalsknown to the State ofCaliforniato

cause cancer,birthdefects, orother reproductive

harm.

MAINTENANCE AND STORAGE

• Check the engine mountingboltsoftento be sure

theyare tightenedproperly.

• Check all bolts,nuts, and screwsat frequent

intervalsfor proper tightnessto be sureair blower

is insafe workingcondition.

• Keep all safety devicesin place and working.

• To reducefire hazard, keep the engine free of

debrisand excessive grease and oil.

Allowengineto cool before storingin any

enclosure.

• Never storeair blowerwith fuel inthe tankinsidea .

buildingwhere fumes may reach an open flame or

an ignitionsourcesuchas hotwater heater, spacd

heater,clothes dryer, etc.

CUSTOMER RESPONSIBILITIES

• Read and observethe Safety Rules.

• Followa regularschedulein maintaining,

caringand usingyour air blower.

• Followthe instructionsunderthe Maintenanceand

Storagesectionsof thismanual

3

Page 4

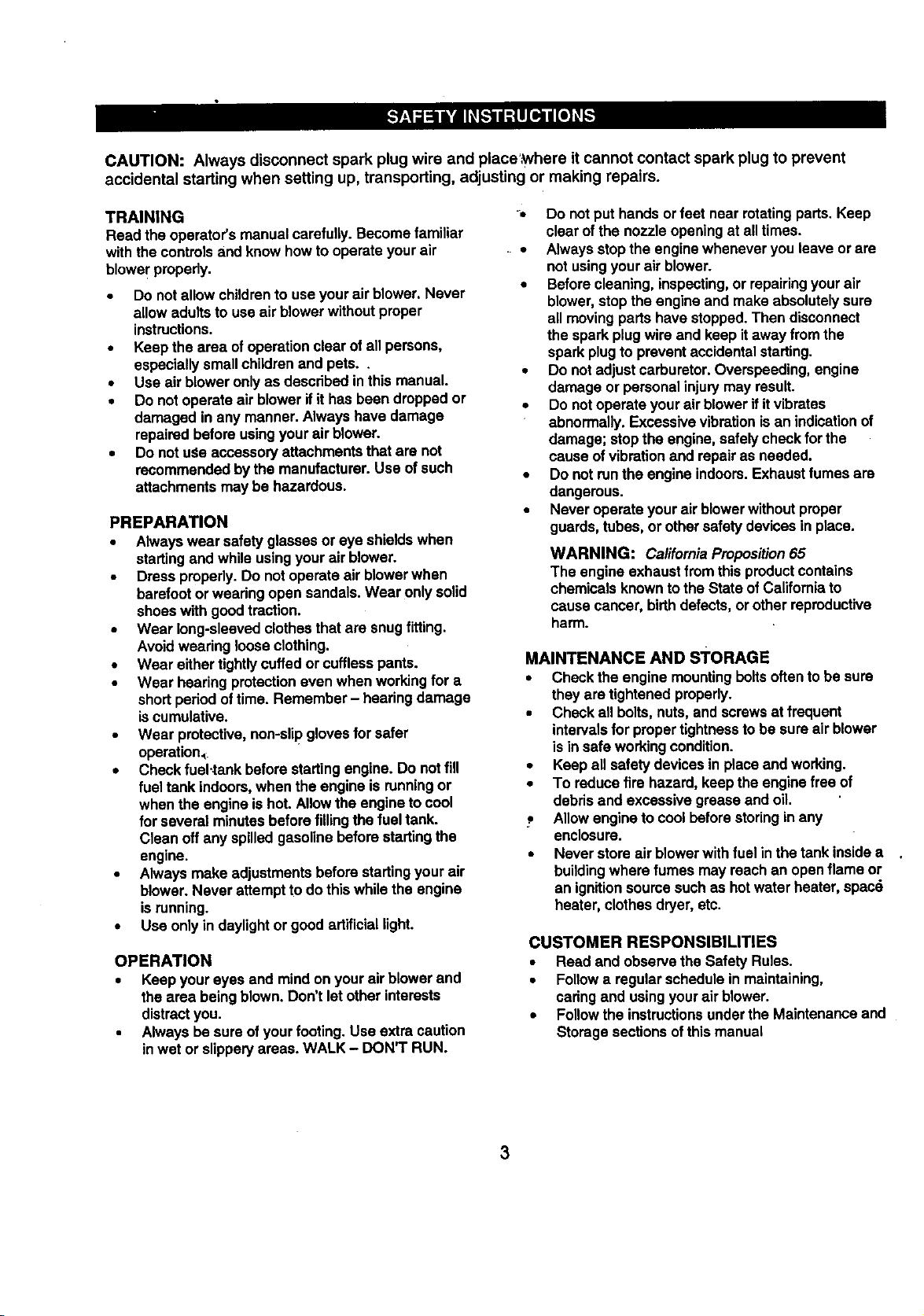

:lead these instructionsandthe operatingmanual initsentirety_beforeyou attemptto operate your new air blower.

BlowerTube CurvedNozzle Tube

Clamp (_,

ExtensionTube

Cable Guide

Clamp with

Blower

Pleated Tube

Combi-Wrench

_TO][o.]:_,,,."[._o_tl_[.,._

The following items for the operation ofyour blowerare availableat your nearest Searsstore.

• Safety goggles • Airfilter

• Hearing protection • Fuelstabilizer

• Gloves • Sparkplug

• 2-Cycle air cooled engine oil • Gas can

V-!.'%'1_hVd:]lWd

Read these instructionsand the operating manual in

itsentirety before you attempt to assemble or operate

yournew backpack air blower.

Your new backpack air blower has been assembled at

thefactory except for the blowertubes. The necessary

clampsto complete assembly as well as a combination

wrenchare included inthe parts bag enclosedwiththe

unit.

2.

Slidethe pleatedtube (Fig. 2, E) ontothe elbow

(Fig.2, B)and secure withthe clamp (Fig. 2, C)

that hasanattachedcable guide. Installthrottle

cable(Fig. 2, D) intothe clampcable guide.

FIGURE 2

To ensure safe and proper operationof your backpack

air blower,any clamp that you installmustbe

tightenedsecurely.

HOW TO ASSEMBLE

1. The elbow tube is already insertedintothe blower

housing.Insure that the two screws(Fig. 1, A) are

tight,but notso tight that the tube cannot be easily

swiveled.

FIGURE 1

3,

Loosenthe two screws (Fig. 3, H) on the bottomof

theattachedhandleclamp. Make sure thatthe

clampgoes overthe topof the raised_ on the

undersideofthe blowertube, and that the leg of

the"T" isalignedwiththe slot on the clamp. Push

blowertube into the pleated tube and secure with

the plasticclamp(Fig. 3, G). The multi-function

handle(Fig. 3, F) has a 2-inchadjustment range.

Locatethemostcomfortablehandle locationand

4

Page 5

then tighten the multi-functionhandleto blower

with the two screws (Fig. 3, H).

FIGURE 3

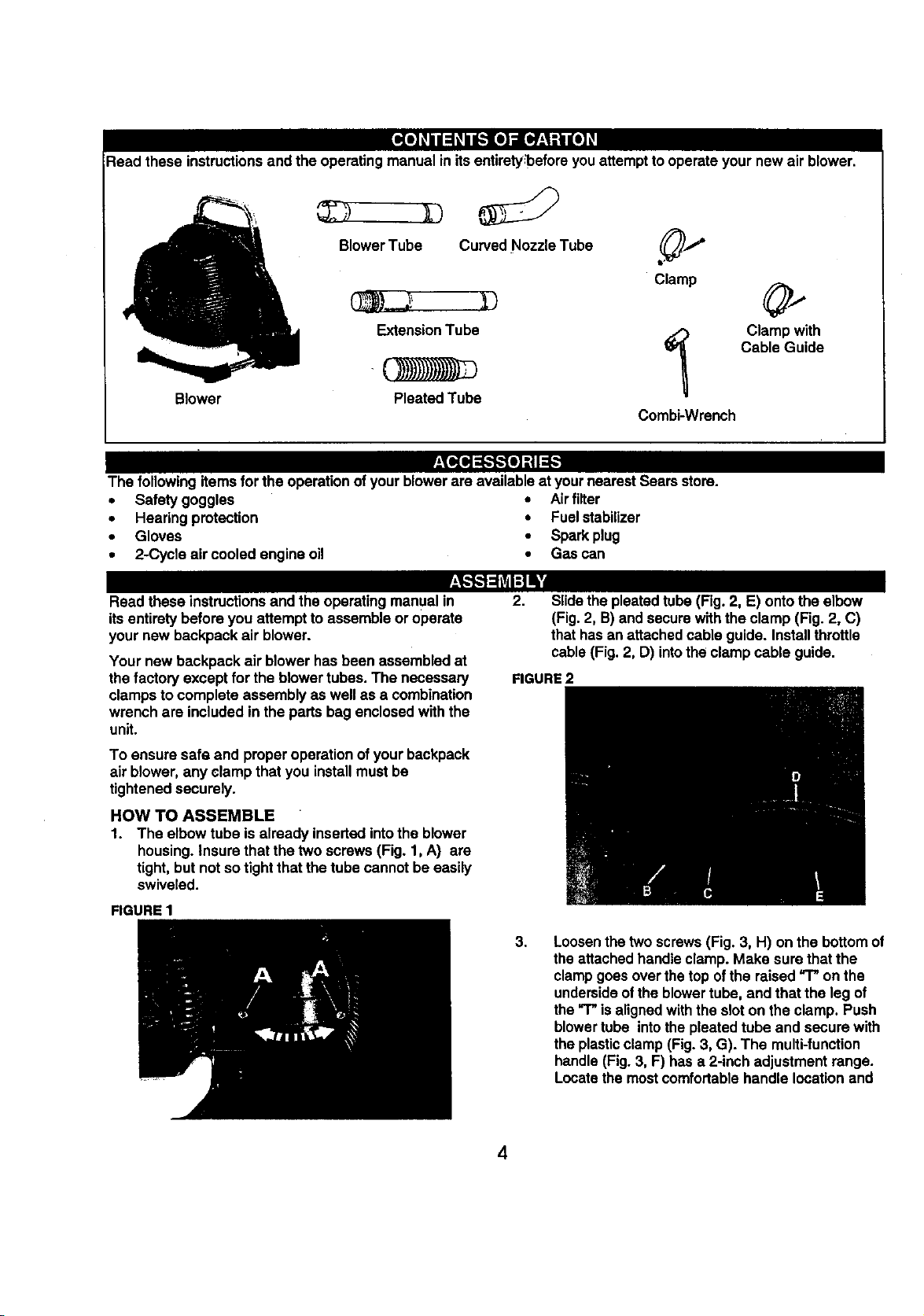

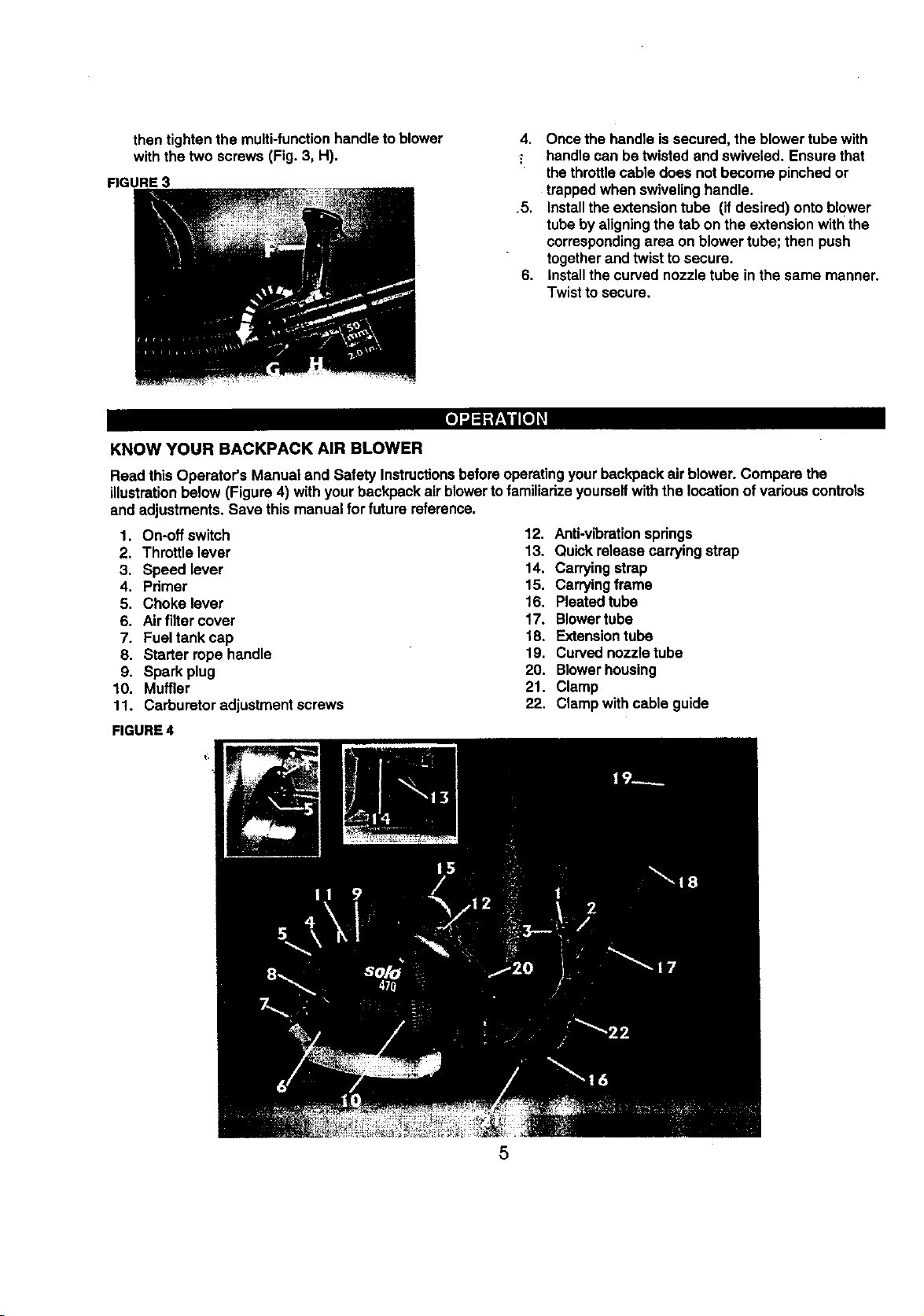

KNOW YOUR BACKPACK AIR BLOWER

Read this Operator's Manual and Safety Instructionsbeforeoperatingyour backpackair blower. Compare the

illustrationbelow (Figure4) with yourbackpack airblowertofamiliarize yourselfwith the locationof variouscontrols

and adjustments. Save this manualfor future reference.

1. On-off switch

2. Throttlelever

3. Speed lever

4. Pdmer

5. Choke lever

6. Airfilter cover

7. Fueltank cap

8. Starter rope handle

9. Spark plug

10. Muffler

11. Carburetoradjustment screws

FIGURE 4

4. Once the handle issecured, the blower tubewith

- handle can be twisted and swiveled. Ensure that

thethrottlecable does not become pinchedor

trappedwhen swiveling handle.

.5. Installthe extensiontube (if desired) ontoblower

tube by aligningthe tab on the extensionwiththe

correspondingarea on blower tube; then push

togetherand twist to secure.

6. Installthe curvednozzle tube in the same manner.

Twistto secure.

12. Anti-vibrationsprings

13. Quickrelease carryingstrep

14. Carryingstrap

15. Carryingfreme

16. Pleated tube

17. Blowertube

18. Extensiontube

19. Curved nozzletube

20. Blowerhousing

21. Clamp

22. Clampwithcable guide

5

Page 6

HOW TO USE YOUR BACKPACK AIR

BLOWER

GASOUNE AND OIL MIXTURE

Important! Do not use automotiveor boatoils in

yourair blower. These oilsdo nothave proper

additivesfor 2-cycle, air-cooled enginesand can

cause engine damage.

The 2.cycle engine onthis productrequiresa fuel

mixtureof regularunleaded gasolineand a highquality

2-cycleair-cooled engine oilfor lubricationofthe

bearingsand other movingpads.The correctfuel:oil

mixtureis 40-1 (see Fuel MixtureChad). Too littleoil

or the incorrectoil type will cause poorperformance

and may cause the engine to overheatand seize.

Gasoline and oil must be premixedina clean

approvedfuel container.Alwaysuse fresh regular

unleadedgasoline. This engine iscertifiedto operate

on unleaded'gasoline.

I

FUELMIXTURECHART I

GASOLINE OIL

I Gallon 3+2Dunces

2.5Gallons 8.0Dunces

IMPORTANTI Alcoholblendedfuelscalledgasohol

(usingethanolor methanol)can attract moisture,

whichleads to oil/gas separation andformationof

acidsduringstorage. Acidicgas can damage thefuel

systemof an engine while in storage.To avoidengine

problems,the fuel systemshouldbe emptied before

storageof 30 days or longer.Drainthe gastank, then

runthe fuel out of the carburetor andfuel linesby

startingthe engine and lettingitrununtilitstops.Usa

fresh fuel nextseason. See storageinstructionsfor

additionalinfot'mation.Never use engineor carburetor

cleaner produc_sinthe fuel tank or permanentdamage

may occur.

2-CYCLE OIL

Craftsman2-cycle, air-cooledengine oilisspecially

blendedwithfuel stabilizers. If you do not usethis

Sears oil,you can add a fuel stabilizer,suchas

CraftsmanNo. 33500, toyourfuel mix.

FUEL STABILIZER

A fuel stabilizerisan acceptablealtamativein

minimizingthe formation of fuel gumdepositsduring

storage. Add stabilizerto gasolinemixtureinfuel

storagecontainer and mix well. Alwaysfollow the fuel

mix ratiofound onthe stabilizercontainer.Run engine

at least5 minutesafter adding stabilizertoallowthe

stabilizerto reach the carburetor.You donot haveto

drain the fuel tank for storage if youare usingfuel

stabilizer.

USING THE MULTI-FUNCTION HANDLE

_Themulti-functionhandlehas an on-off switch (Fig. 5,

A), a throttlelever (Fig. 5, B), and a speed lever (Fig.

5, C). It can be rotated to assure the operator's

•comfort.Once started,the speed lever can be set at a

desired RPM. This frees the operatorfrom holdingthe

throttlelever. If notset on maximumRPM and a

• greater RPM is required, simplysqueeze the throttle

lever. To returnto the lower RPM, release the throttle

lever. If the operator planson blowingat the maximum

RPM for a long periodoftime, the speed lever is

movedtothe =max"setting. Ifthe operator is only

blowingin shortburstsleave the speed lever at the

"min" settingand use the throttlelever to controlthe

speed.

FIGURE 5

STARTING COLD

1. Moveon-off switchto the on positionidentified

withan "1"(Fig. 5).

2. Set speed lever halfway between the =rain" '_

and"max"'_ positions(Fig. 5).

3. Move choke lever (Fig. 6, A) to the =START"

position.

4. Press primer bulb(Fig. 6, B) untilitis halffull and

resistanceis felt.

5. Place lefthand on top of the blower housingnear

carryinghandle. Pullthe starter ropehandle'with

righthandslowlyuntilresistanceisfelt. Then pull

forcefullyand repeatedly until engine attemptsto

start;usually2-3 pulls,no more than 5 pulls.

6. When engine attempts to start, immediately move

choke lever t0 "RUN" posifion.Continue to pull

starterropehandle untilengine starts.

FIGURE 6

6

Page 7

STARTING WARM

Followcold startinginstructionsbutleave choke lever

in"RUN" position.

STOPPING

To stopengine, release thethrottleleverand adjust

the speed leverto "min_position.Moveswitchto

STOP (O) position.In an emergency,immediately

movethe switchto the STOP (O) position.

ADJUSTING THE CARRYING STRAPS

Putthe blower on your back and yourarms through

the carryingstrapsas shown.The back plate of the

blowershouldrestsecurelyagainstyourback. If the

straps need tobe tightened (Fig. 7), pullthe quick

adjustdng ends downwardas needed. If the straps

need tobe loosened,liftthe couplingslocatedat the

bottomof the padded straps.

FIGURE 7

MAINTENANCESCHEDULE

.OWER

Check for loose

fasteners

Clean air filter X

Inspect muffler x

4GINE

Replace spark plug X X

Clean fuel filter X

Clean onglne cooling X X

fins

Clean spark arrestor

screen

X

X

BLOWER

-0

GENERAL RECOMMENDATIONS

The warrantyon thisair blowerdoes notcover items

that have been subjectedto operator abuse or

negligence.To receive fullvalue fromthe warranty,

operatormust,maintainair bloweras instructedin this

manual.

Allitems in the Maintenance sectionofthis manual

shouldbe checkedat least once eachseason.

1,

Service more often whenoperatingin dustyor

dirtyconditions.

2.

Once a year you shouldreplacethe sparkplug

and clean or replace the air filter. A new spark

plug and a clean air filter assure properair-fuel

mixtureand helpyourengine run batter and last

longer.

CHECK FASTENERS

Check all fasteners, includingnuts, bolts,screws and

clamps,to insurethat they are tightand secure. If not,

make all necessary adjustmentspdor to usingair

blower.

CLEAN AIR FILTER

Your engine willnot run properlyand may be damaged

by usinga dirty air filter. Replace air filter element if

deteriorationoccurs.Service more often ifyou use

yourair blowerin very dustyor dirty conditions.

To Clean Air Filter

1. Remove airfiltercover bytuming black knob

counterclockwise.

2. Remove foam air filter.

3. Shake outair filter. If heavily soiled,rinsein a mild

soapand water solution.

4. Dry air fiifercompletelyand oil slightlybyplacinga

smallamountof oil on filterand kneading until

evenly distdbuted.Wipe off excess oil.

5. Reassemble the air filterand cover;ensure that

thefilter is correctlyseated in its slot before

reinstallingcover.

6. Replace air filter element if detedorated.

INSPECT MUFFLER

Inspectmufflerevery25 hoursof use and replace if

corroded.

Page 8

ENGINE

REPLACE SPARK PLUG

Change your spark plugeach year to make your

engine start easy and runbetter.Set spark pluggap at

.020".

CLEAN FUEL FILTER

The fuel filter is located insidethe fuel tank and is

attachedtothe fuel line. To clean, scrub fuel filter

surfacewith a small brush,Replace if deteriorated.

CLEAN ENGINE CYLINDER COOLING FINS

Forbest performance,keep dirt from accumulating

aroundthe enginecoolingfins. Clogged coolingfins

cause the engineto runhotterand shortenengine life.

Coolingfinsmay be cleaned usinga toothbrushor stiff

bristle brush.

CLEAN SPARK ARRESTOR SCREEN (ifinstalled)

Afterevery 25 hoursof usethe spark arrestor screen

mustbe cleaned. Replace screen if detadorating(part

no.2048391).

To clean:

1. Remove the four screws fromthe engine cover.

2. Remove the four screwsfromthe end of the

muffler,

3. Remove the screen and clean with a wire brush.

Replacethe screen if deteriorated.

4. Re-installthe screen and muffler end. Securewith

the fourscrews.

5. Re-installthe engine cover.

CARBURETOR ADJUSTMENT

To complywithemissionregulations,the carburetor

mixtureis pre-set at the factory and can not be

adjustedwithoutpropertools. Any adjustmentmustbe

performedby _ service center.

The idle speed'canbe adjusted.The idlespeed set

screwis located on the top of the unit and to the leftof

thespark plug. It is indicated by the letter=r". To

adjustthe idlespeed, turn clockwiseto increaseand

counterclockwiseto decrease idle speed. Idlespeed is

2100 + 100 RPM.

_n[ol :P,_[_

Prepare yourbackpack air blowerfor storage at the

end of the season or if the unitwill notbe used for 30

daysor more.

BEFORE STORING

1. Use soap and water to wipe down unit.

2. Be sure that all nuts, bolts,screws,and fasteners

are securelyfastened. Inspectfor damaged or

wornparts. Replace if necessary.

BLOWER TUBES

The straightblowertubes can be removed to ease

storage. Use care notto "kink" thethrottlecable.

ENGINE

It isimportantto preventgum depositsfromformingin

essentialfuel system partssuch as the carburetor,fuel

filter, fuel hose, or tank duringstorage.Also, alcohol

blendedfuels, such as gasohol,ethanolor methanol,

can attractmoisture,which leads to separationand

formation of acids duringstorage.Acidicgascan

damage the fuel system of an engine while instorage.

Do notstore gasolinefrom one season tothe next.

Two-cyclemix ages quicklyand can causeengine

damage. Replace your gasolinecontainerif itstarts to

rust.Rustor dirt in yourgasolinewillcause engine

problems.

To avoidengine problems,the fuel systemshouldbe

emptiedbefore storage of 30 daysor more.

Followthese instructions:

1. Drainthe fuel tank.

2. Start engine and let it run untilthe fuel linesand

carburetorare empty. (The engine willstop.)

3. Usefresh gas nextseason.

4. Ifyou use a fuel stabilizer, thegasolinecan be left

inthe tank. CAUTION: Never storeair blower

insidea buildingwithfuel in the tank{ Fumescan

concentrateand possibly reacha source of

ignition. Allow engineto cool before storage.

5. Remove spark plug.

6, Pour a few drops ofoil intothe cylinder.

7. Pull the starter handleslowlyto distributethe oil.

8. Replace spark plug,

STORAGE TIPS

If possible,storeyour unitindoorsand cover itto give

it protectionfrom dust and dirt. Do notuseplastic.

Plasticcannotbreath, which will allowcondensationto

form and will cause yourunitto rust.IMPORTANT:

Never coverair blower whileengine and mufflerare

stillwarm.

8

Page 9

PROB..BJI

Enginesmokese._cessively.

Enginehardtostart,willnot

startorstartsandonlyrunsa

fewseconds.

CAUSE

1. Dirtyairfilter.

2. Fuelmixtureincorrect.

3. Carburetorrequiresmaintenance.

1.Fueltankempty.

2. Engineflooded.

3. Sparkplugnotfiring.

4. Didyairfllten

5. Carburetorrequiresadjuslment.

5.Stalefuelmixorwaterinfuelmix.

7.Sparkplugwire disconnected.

El.SwitchinSTOP(O)posilion.

I

_ON

1.Clean or replaceairfilter.

2. Vedfyyouhave40-1 fuel mixture,

3. ContactSearsSe_ce Center.

1.RII tankwi_ correctfuelmi)_

2.Removeandcleansparkplug;with sparkplug

removedand engineswitchedoff,crankengineafew

timesto removee_cessfuelfromcylinder.Reinstall

sparkplug.

3. Replacesparkplug.

4. Cleanorreplaceair filter.

5. ContactSearsServiceCanter,

6. Draintankandrefillwithfresh,deanfuel mix.

7. Connectwiretoplug.

8, Moveswitchto RUN(I)position.

Enginewill notaccelerate,

!lackspowerordies undera

load.

1. Dirtyairfilter.

2. Sparkplugfouled.

3. Sparkarrestorscreendogged

(ifapplies).

4. Carburetorrequiresmaintenance.

1.Cleanorreplaceairfilter.

2. Cleanorreplacesparkplugand re-gap(.020").

3.Cleanor replacescreen.

4. Contact Sears Service Canter.

9

Page 10

The Celifomia Air Resources Board and Sears are pleased to explain the

eadssisn control system warranty on your t 996 and later lawn and garden

equipment engine. In California, now lawn and garden equipment engines

m_sl be des_jned, builf, and equipped to meet the state's stringent anli-smog

standards. Sears must warrant the emission contrdisystem on your lawn and

garden equipment engine for the period of time listed below provided there

has been no abuse, neglect, or Improper maintenance of your lawn and

garden equipment engine.

Your emission control system includes parts such as the caYouratororfuel

injected system, the ignition system, and connectors end other emlaelon-

mlatnd a_;sembllas.

Where a warrantable condition exists, Sears will repair your lawn and garden

equipment engine at no cost to you including diagnosis, parts, and labe_

MANUFACTURER'S WARRANTY COVERAGE:

"n_e1996 and later lawn and garden equipment engines are warranted fur two

years. If any emiselon-relatod pan on your engine isdefective, the partwill be

repaired or replaced by Sears.

OWNER'S WARRANTY RESPONSIBILITIES:

AS the lawn and garden equipment engthe owner, you are responelb_ forthe

performance of the required maintenance listed in your Operator's Manuel.

Sears recommend_ that you retain all receipts covedeg maintenance on your

lawn and g_d__ engine. Seem cannot deny warranty solely for the

leek of recelpta o_ tor your fultom to ensure the perfomlance of ell sshedulnd

maintenance.

ASthe lawn and garden equipment eugine owner, you should howiNer be

aware that Sears may deny you warranty coverage If your lawn and garden

equipment engine or a part has failed due to abuse, neglect, ir_oropar

maintenance or unapproved moddicat_es.

You are responsible for pmsendng your lawn and garden equipment engine to

a Sears mpelr center as soon as a problem exists. 1he warranty repelm

should be completed in a reasonable amount of _me, not to exceed 30 days.

If you have any questions regarding your warranty dghbl and respon_"o4T_es,

you should contact Sears at 1-800-473-7247.

A. WARRANTY COMMENCEMENT DATE

The warranty pe_od begins on the date the equipment is purchased by

a reta}l customei_

B,

LENGTH OF WARRANTY COVERAGE

Sears warrants tothe initial owner and each subsequent purchaser that

the engine is free from defects in matehals and wedananship for a

period of two years from date of odgfoel purchase from Sears.

C.

WHAT iS COVERED

1. REPAIR OR REPLACEMENT OF PARTS

Raper or replacement of any warranted part will be pedormed at

no cberge to the owner at a warranty station. To locate a

warranty station, you may call Sears it 1-800-473-7247, (24

hours, 7 days I week).

2. WARRANTY PERIOD

Any warranted bert which Is-not scheduled for rep_cement as

required rnalntenance, or which isscheduled only for regular

inspactfon to the effect of *repair or replace as necdssa_" shall

be warranted forthe warranty pedod. Any warranted part which is

scheduled for replacement as required maintenance shall be

warranted for the pedod of time up to the first scheduled

reqlacement point for thatpart.

3. DIAGNOSIS

The owner shall _ be charged for diagnostic labor, w_ibh leads

to the determination that a warranted pan la defective, if the

diagnostic work Is performed it Sears.

4. CONSEQUENTIALDAMAGES

'i

The engine manufacturer is liable fordamages to the engine

components caused by the failure of a warranted part still under

warranty.

WHAT IS NOT COVERED

1. Failures caused by abuse, ne_ect, o_Improper maintenance.

2. ACid-onor mod'dindparts. The use of add-on or mod_lfed parts can

be groundsfor disallowing a warranty claim. The engine

manufacturer is not liable to cover failures of warranted parts

caused by the use of add-on or modified parts.

3. Any indirect or cc_.sequentild damages that may result from the

lailum or malfunction of the Sears product. S_ne states do not

allowthe exclusion or limitation of consequential damages so

these limitations may not apply to you.

4. Normal sen'ice requirements adelng dudng the warranty period

suchas carburetor or ignition adjustment, cleablug, nonnst wea¢.

lubrication, spark plugs, lfhars, starter ropes, etc.

5. Normal service work over and above the repair or replacement of

defectivepads.

6. Any failure that results from an accident, customer abuse, noanof

wear, neglect or failure to operate the product in accordance with

the insm._-tlads provided in the Operators Manual or provided

with the prnduct,

7. Pre-delfvePjset-up time.

8. Operslfon of an engine with an lacomlot fuel:o_ ratfo, air filter

removed or speeds in excess of Sears' recommendaUons

ap_icaMa).

9. Transportationcosts assoclatnd with dalivedug and ratum of

productto a Sears warranty station.

E.

HOW TO FILE A CLAIM

Warranty claims may be submitted on several c_ffemntforrr_:

Sears Warranty Claim Request

Outdoor Power Equipment Institute

UniversalWarranty Claim Report

En_ne Service AssoctalfonClaim

Warranty claims must be received at Sears within 60 days of the date

of repair noted on the delm.

F°

WHERE TO GET WARRANTY SERVICE

Warranty eawine or repairs shall be provided at Sears Sewi,.'_ Centers.

Forthe address of a Service Center near you call Sears at 1-800-473-

7247, {24 hours. 7 days a week).

G.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION

RELATED PARTS

Sears replacement parts must ha used in the pedoanance of any

warranty maintenance or repairs on emlaelen-mlatnd parts and will be

providedwithout charge during the warranty pedod.

H.

EMISSION CONTROL WARRANTY PARTS LIST

Seam' warranty incfudes the fo_owing parts (ubless said part was

scheduled for tenement as required maintenance): Air FlfteL,Fuel

Rltor. Carburetorand internal parts, Choke Mechanism, Intake

Manifold, Spark Plug, Flywheel. ign_on Mndute.

MAINTENANCE STATEMENTS

Follownormal maintenance set.Ace, recommended fuel mixl_m (whom

applicable), lubdcatlan, operation and storage of the product as

explained in the Oparatc_'s Manual. The owner shall not be charged for

diugnoslfc labor, which leads to the determination that a warranted dart

isdefective, if the diagnostic work is performed at Sears.

I0

Page 11

_, 140

146

--155

--156

--157

135

/

125

///

/

/ f

_15o

74

F----95

I I

21

20

Page 12

Pos.-No.Ord,er..No.

1 )018346

2 )016428

5 )020104

6 )034135

10 2300 774

11 2074294

12 :)054220

13 _050102

14 _31375

15 2200249

17 0075101

18 0052226

20 0018340

21 0072140

22 8033358

25 2100629

26 2063334

31 2280248

33 2031 117P

34 0055207"

40 2011802

41 2500 732

42 0018348

43 8021 256

44 4063160

45 2300730

47 0018363

48 0072144

49 2074562

50 25O0731

51 )028100

52 1072143

53 _061510

54 )018421

57 )084600

58 3073385

59 2380783

50 Z380773

(57) :)084600

(58) _073385

259) Z3O0783

6 _072148

63 0018327

70 2061512

71 0018337

72 2074916

73 8021235

74 2061 515

75 2380805

80 0064407

81 0064436

82 2700322

85 0062321

86 8062325

87 2074917

88 0010107

90 0062263

91 2074914

95 2800566

180 6880286

101

(1_ 68800286

(103)8055279

(104)8069721

screw

activator

nut

cltcfip

fl_heel

sleeve

oilseal

ballbearing

washer

crankshaft

springwasher

needlebearing

screw

springwasher

spacertubu

crankcase,compi.

pistonpin

pistonpindrdip

cylinder

flap

screw

nut

saal

sparkping

screw

tendonwasher

insulator

muffler

nut

tendonwasher

exhaustgasket

screw

sparkplugcap

contactslxing

ignitioncoil

ignitioncoil,compl.,incl.

sparkplugcap

contactspring

ignitioncoil

washer

screw

manifoldgasket

screw

manifold

nut

carburetorgasket

hose

hose

nng

nng

suctionflange

screw

nng

chokeflap

throttlecable

s_c'w

exhaustcover,incl.

screw

safetydng

decal

Po_-N_

7

"102

103

104

105

106

107

108

110

111

120

121

122

125

126

128

129

130

"135

137

138

140

142

145

146

147

150

155

156

157

Order-No.

4048380

8055279

8069721

40736790GN

8018363

0069168

8069716

2073503

8018363

4073676DGN

8018363

0018342

2042667

8018362

0015155

0033393

4061908

4480241

8034135

8020104

4073677DGN

8020101

4036415

4042800

0018362

0080580

0510949

0510975

0510976

:_uantity

1

1

1

1

4

1

1

1

3

1

12

1

1

1

_p_on

filterplate

safetyring

decal

enginecover

screw

decal

decal

airguide

Screw

blowerhousing1

screw

screw

dampingplate

screw

screw

spacer

airfiltergasket

fanwheoi

drclip

nut

blowerhousing2

nut

_rotedinnscreen

supportplate

mew

comblwrench

_ket-kit-carburetor

repair-_-carburetor

throttleaxlekit<ahoretor

12

Page 13

MODELNUMBER360.796900

I

2

1

Pox'No,_er-No. I quantit 3escdption

1 )01825711 s_ew

2 )01833812 so'ew

5 !I00 58311 starterhousing

8 )06319511 start_rope

9 ZO745691I startergrip

12 Z6O028411 springcassette

13 Z07491511 ropepulley

15 ZO7434311 staderpawl

16 _0316111 washer

17 20749771 template

18 Z0319651 spacer

19 O0733651 pin

20 00341261 slxingwasher

21 DO105191 screw

22 D0341521 drdip

25 26O0293| starter,compl.

13

Page 14

MODEL NUMBER 360.796900

25

Po_-No.

1

2

5

(7)

(8)

(9)

(lo)

(11)

(12)

7

8

9

10

11

12

15

16

18

20

21

25

_der,No,I Quantity

4073682I 1

_01836312

Z700409I I

1071272 I 1

D067114I 1

0073351 I 1

6063328 I 1

O073_52 I 1

2700327 I I

4071272 I 1

0067114 I 1

0073351 I 1

6063328 I 1

0073352 I '1

2700327 I 1

O061280I 1

27O0395I 1

0018274|2

0064435 I 1

0064300 I 1

4O35904I 1

Description

ho_omplate

5_ew

fueltank,incl.:

fueltank

socket

r_et

_el pidc-up

fueltank

so_et

el

_mmet

I pi_-up

lidgasket

tanEcap,compl.

screw

hose

hose

carr/ingframe

30 4042577

31 0073396

32 6043107

33 0018363

35 4046100

40 0018363

41 4074126

42 4074275

45 4073680

46 4074962

48 0098147

50 0018369

55 4074921

56 43O0355

57 4074412

60 43O0332

(55) 4074921

(56) 43O0335

(57) 4074412

61 0018370

_nt_

2

4

4

8

2

2

2

2

1

5

1

1

2

2

2

2

2

2

De_ription

tensi_plate

avspnng

flangeplate

screw

tensionbracket

screw

cap

strapholder

ba_plate

cushionrivet

backcushion

scmw

strapclamp

shoulderstrap

strapholder,black

shoulder_ap,inc.:

strapclamp

shoulderstrap

strapholder,black

screw

14

Page 15

MODEL NUMBER 360.796900

Operator's

Manual

40

10

11

1

2

I_.-No.

Order-No. _antity Description

1

4071289 1 curvednozzletube

2

4071288 1 extensiontube2

5

4400248 I _tmvertube1

7

0066399 I damp,compL

4071148 deatedtube

8

10

0066130 clampwithcableguide

11

0018257 sere,.,'

15

4073124 elbowtube

0020101 nut

2O

22

48O0222 griphalfleft,compL

25

O073408 spdng

26

4073673 throttlelever

27

O035159 washer

30

4074938 outergriphalf

33

0018356 screw

34

0018357 screw

00644151 hose

35

36

0084477 on..offswitch

37

28(30566 throttlecable

O084855 on-offcable

39

4o

I_47OlO_ Operatur'sManual

15

Page 16

Loading...

Loading...