Operator's Manual

iPROFESSIONAL I

4.1 HP/2-Cycle

51 ccJ3.15 cu. in.

CHAIN SAW

Model No. 360.352001 - 20-inch Bar

NOTICE: There Is a typographlcal

_rror in this manual. The correct model

number is:

360.352010

CAUTION:

Before using this product, read this

manual and follow all its Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.conYcraftsman

• Safety

• Operation

• Maintenance

• Service & Adjustments

• Parts LIBRARY:

• EspaSol

• Warranty Pg. 2

• Safety Pg. 3

• Assembly Pg. 4

• Contents of Carton Pg. 4

• Accessories Pg 5

• Operation Pg. 5

• How to Use Your Chain Pg. 5

Saw

• Safe Felling and Cutting Pg. 7

Techniques

UMITED TWO YEAR WARRANTY

For two (2) years from the date of pumhase if the chain saw is maintained, lubricated and tuned up according to the

instructions in the Operator's Manual, Sears will repair or replace, free of charge, any parts found to be defective in

material or workmanship. If this product ls used commemially, this viarranty only applies for 90 days.

This warranty does not cover:.

• Expendable items which become worn during normal use, such as spark plugs and air filters.

• Repairs necessary because of operator abuse, negligence, improper storage, accident or the failure to

maintain the equipment according to the instructionscontained in the operator's manual

Warranty service is available by returning the chain saw to the nearest Sears Service Center in the United States.

This warranty gives you specific legal fights, and you may also have other rightswhich may vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

• _ Maintenance Pg.10

• Service & Adjustments Pg.12

• Storage Pg.14

* Troubleshooting Pg.15

• California Emission Control Pg.15

Warranty Statement

• Parts Pg.17

• Espafiol Pg.21

PRODUCT SPECIFICATIONS

Horse Power _.

:ue-Otl Capacity,

:ueI-Oil Mix

_parkRug

'_Gap .020In)

DIITankCapacity

Engine

Displacement

Maximum RPM

Dry Weight

4.1

U.S.o1"20 oz.

40-I

BoschWSR6Y

Champion RCJ-bY

20 oz.

51 cc

12,500rpm

10.75lbs.

YlodelNo. 360.352001

Serial No.

Dateof Purchase

The model and serial number will be

found on the rear handle. You should

record both serial number and date of

purchase and keep in a safe place for

future reference.

2

(,,,"9'_!_1_ nk,"dllL_,=,_ijt]lllO]llU_o_

CAUTION: Always disconnect spark plug wire and place where it cannot contact sparl_plug to prevent

accidental starting when setting up, transporting, adjusting or making repairs.

TRAINING

Read the operator's manual carefully prior to

operation. Become familiar with the controls and know

how to operate your chain saw properly.

• Keep the area of operation clear of all persons,

especially small children and pets.

• Use the chain saw only as described in this

manual.

• Do not allow children to operate your chain saw.

Never allow adults to use the chain saw without

proper instructions.

• Do not operate the chain saw ifit has been

dropped or damaged in any manner. Always have

damage repaired before using your chain saw.

• Use only recommended Craftsman accessories

and replacement parts. Use of non-Craftsman

parts and accessories may be hazardous.

PREPARATION

• Always wear safety glasse s or eye shields when

starting and while using your Chain saw.

• Dress properly. Do not operate chain saw when

barefoot or wearing open sandals. Wear only solid

shoes with good traction.

• Wear long-sleeved clothes that are snug fitting.

Avoid wearing loose clothing.

• Wear either tightly cuffed or cuffless pants.

• Wear hearing protection even when working for a

short period of time. Remember - hearing damage

is cumulative.

• Wear protective, non-slip gloves for safer

operation.

• Always wear a =hard hat" in the working area.

Overhead hazards such as falling limbs present

danger of injury.

• Always wear safety boots with steel toes.

• Check fuel tank before starting engine. Do not fill

fuel tank indoors, when the engine is running or

when the engine is hot. Allow the engine to cool

for several minutes before filling the fuel tank.

Clean off any spilled gasoline before starting the

engine.

• Always make adjustments before starting your

chain saw. Never attempt to make adjustments

while the engine is running.

• Use only in daylight or good artificial light.

OPERATION

• Keep your eyes and mind on your chain saw. Do

not let yourselfbe distracted.

• Always be sure of your footing. Use extra caution

in wet or slipperygrass. WALK - DON_f RUN.

• Do not put hands or feet near rotating parts. Keep

clear of chain at all times.

• Always stop the engine whenever you leave or are

not using your chain saw.

• Before cleaning, inspecting, or repairing your

chain saw, stopthe engine and make absolutely

sure all movingparts have stopped. Then

disconnect spark plug wire and keep it away from

the sPark plug to prevent accidental starting.

• D° not adjust carburetor. Overspeeding engine

may result in engine damage or personal injury.

• Do not runthe engine indoors. Exhaust fumes are

dangerous.

• Never operate your chain saw without proper

guards or othersafety devices in place.

• Never remove hands from chain saw handles

when actively cuttingwith the saw.

WARNING: Ca/ifemia Proposition 65

The engine exhaust from this product contains

chemicals knownto the State of California to cause

cancer, birth defects, or other reproductive harm.

KICKBACK CONDITIONS AND PREVENTION

Kickback occurswhen the upper quadrant of the bar

nose contacts a solid object in the wood or is pinched.

This type of contactstops the chain for an instant. The

result is a lightningfast reverse reaction of the chain;

causing the bar to "kick"up and back toward the

operator. Under some circumstances the operator

(Fig. 1) may suffersevere or fatal injury. Kickback may

also occur during limbing (See LIMBING).

FIGURE 1

Kickback path

3

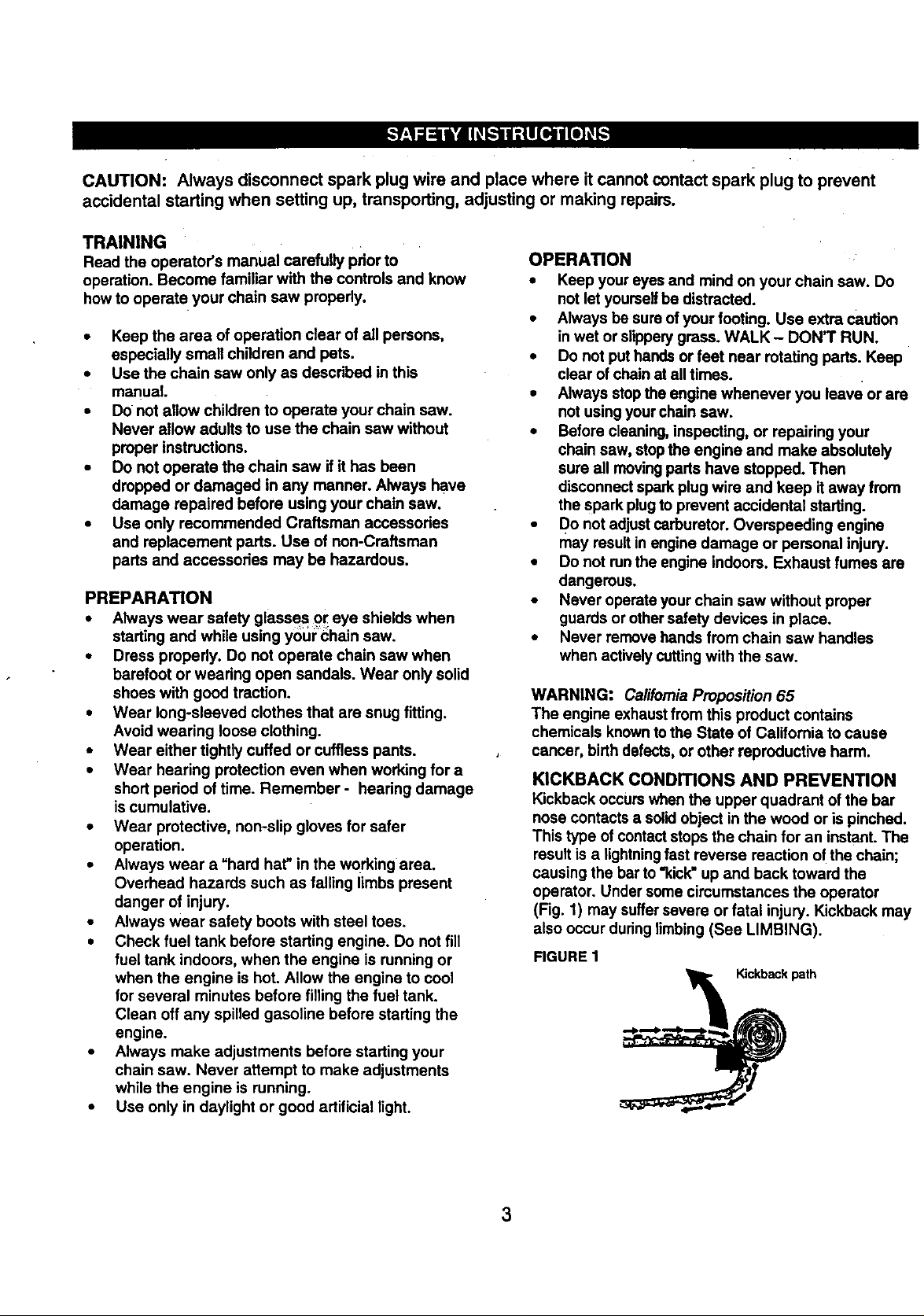

TO AVOID KICKBACK

The best protection from personal injury that may

result from Kickback is to avoid Kickback situations.

• Hold the chain saw firmly with both hands and

maintain a secure grip.

• Be aware of the location of the guide bar nose at

all times (Fig. 2).

FIGURE 2

Donot let the barcontacttheground

• Never bring the nose of the guide bar in contact

with any object. Do not cut limbs with the nose of

the guide bar. Be especially careful with small,

tough limbs, small-size brush, and saplings which

may easily catch the chain.

• Don't overreach.

• Don't cut above shoulder height. Do not use a

chain saw while standing on a tree or laddeH

• Begin and continue cutting at fullthrottle.

• Cut only one lot at a time.

• Use extreme caution when re-entering a previous

cut.

• Do not attempt plunge cuts ifyou are not familiar

with these cutting techniques.

• Be alert of shifting log or other forces that may

cause the cut to close and pinch the chain.

• Maintain saw chain properly. Cut with a correctly

sharpened, properly tensioned chain at all times

(Use a 4.5-mm file).

• Stand to the side of cutting path of the chain saw.

• If the cut closes on the bar, STOP the saw. Use a

wedge to free the saw. Do not try to free it by

pullingthe handle.

WARNING: A dull or improperly sharpened chain may

increase the dsk of Kickback. Always cut with a

properly sharpened saw. Improper lowering of the

depth gauges also increases the chance of kickback.

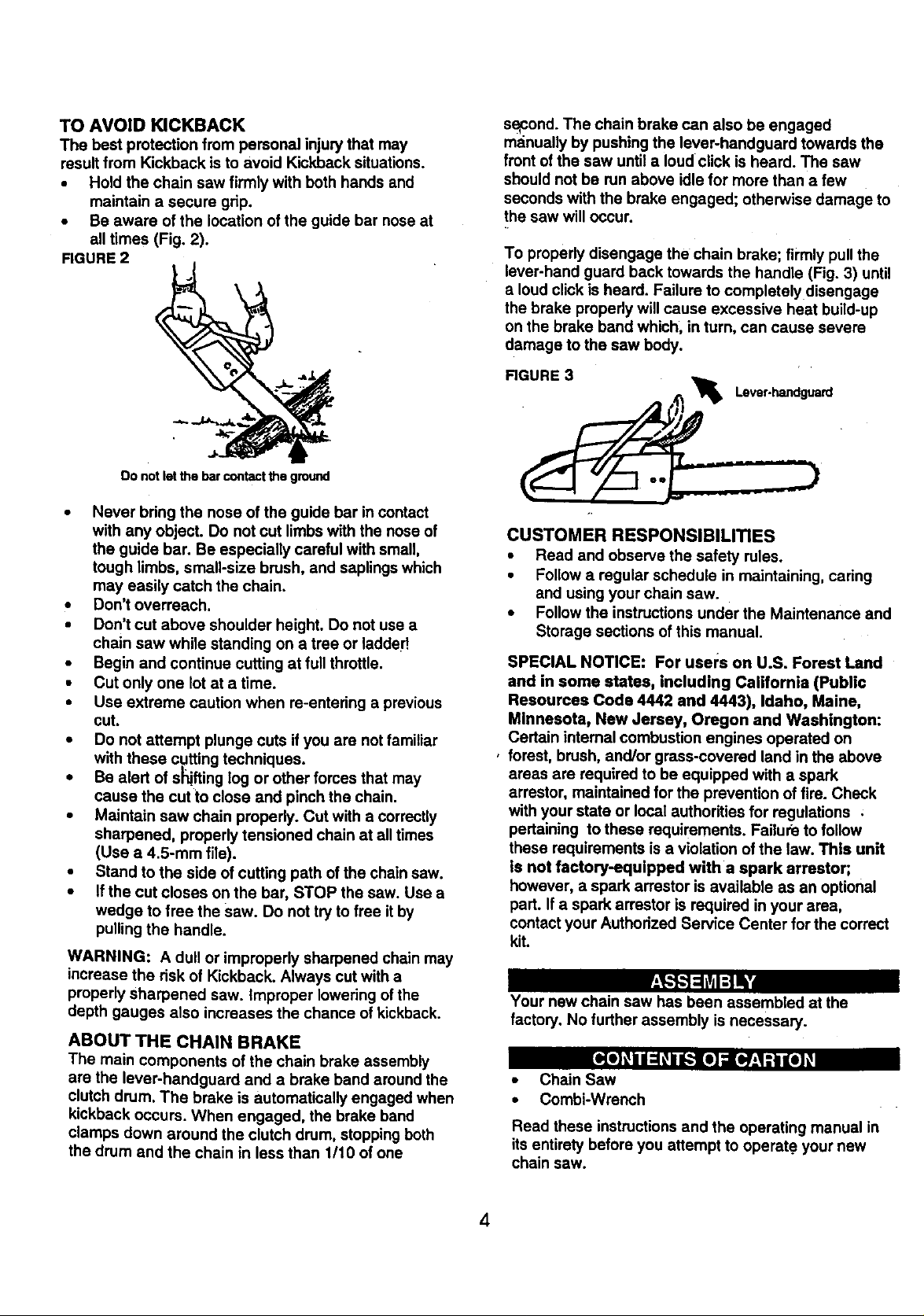

ABOUT THE CHAIN BRAKE

The main components of the chain brake assembly

are the lever-handguard and a brake band around the

clutch drum. The brake is automatically engaged when

kickback occurs. When engaged, the brake band

clamps down around the clutch drum, stopping both

the drum and the chain in less than 1/10 of one

s_cond. The chain brake can also be engaged

manually by pushing the lever-handguard towards the

front of the saw until a loud click is heard. The saw

should not be run above idle for more than a few

seconds with the brake engaged; otherwise damage to

the saw will occur.

To propedy disengage the chain brake; firmly pull the

lever-hand guard back towards the handle (Fig. 3) until

a loud click is heard. Failure to completely disengage

the brake propedy will cause excessive heat build-up

on the brake band which, in turn, can cause severe

damage to the saw body.

RGURE 3

• ,_,._ Lever.handguard

r •

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring

and using your chain saw.

• Follow the instructions under the Maintenance and

Storage sections of this manual.

SPECIAL NOTICE: For usel:s on U.S. Forest Land

and in some states, including California (Public

Resources Code 4442 and 4443), Idaho, Maine,

Minnesota, New Jersey, Oregon and Washington:

Certain internal combustion engines operated on

forest, brush, and/or grass-covered land in the above

areas are required to be equipped with a spark

arrestor, maintained for the prevention of fire. Check

with your state or local authorities for regulations •

pertaining to these requirements. Failure to follow

these requirements is a violation of the law. This unit

is not factory-equipped with a spark arrestor;,

however, a spark arrestor is available as an optional

part. If a spark arrestor is required in your area,

contact your Authorized Service Center for the correct

kit.

Your new chain saw has been assembled at the

factory. No further assembly is necessary.

• Chain Saw

• Combi-Wrench

Read these instructions and the operating manual in

its entirety before you attempt to operate your new

chain saw.

4

The following items for the operation of your chain saw are available at your nearest Sears store.-

, Safety goggles • Airfilter

• Hearing protection • Fuel Stabilizer

• Gloves * Spark plug

• 2-Cycle air cooled engine oil • Gas can

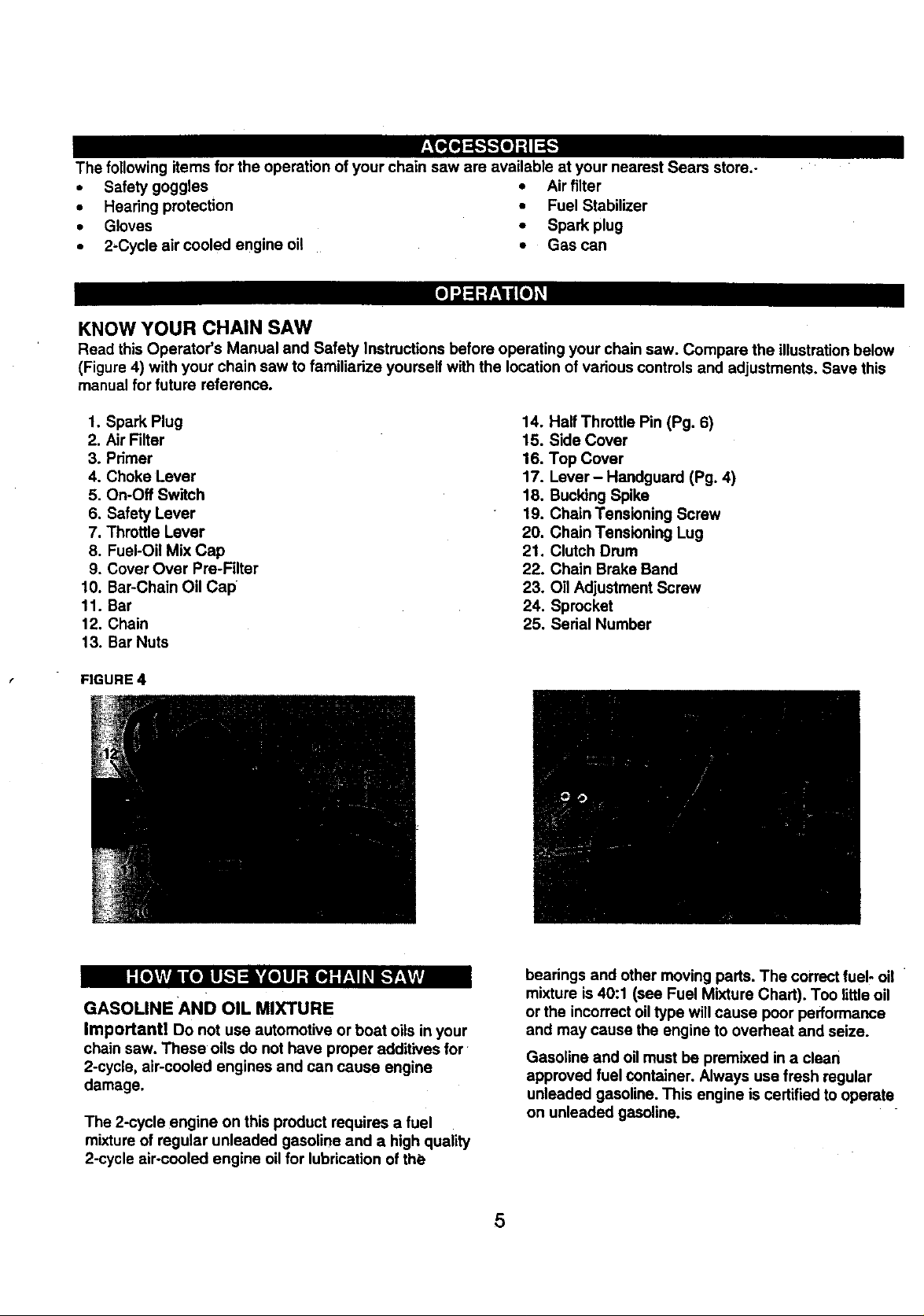

KNOW YOUR CHAIN SAW

Read this Operator's Manual and Safety Instructions before operating your chain saw. Compare the illustration below

(Figure 4) with your chain saw to familiarize yourself with the location of various controls and adjustments. Save this

manual for future reference.

1. Spark Plug

2. Air Filter

3. Primer

4. Choke Lever

5. On-Off Switch

6. Safety Lever

7. Throttle Lever

8. Fuel-Oil Mix Cap

9, Cover Over Pre-Filter

10. Bar-Chain Oil Cap

11. Bar

12. Chain

13. Bar Nuts

FIGURE 4

14. Half Throttle Pin (Pg. 6)

15. Side Cover

16. Top Cover

17. Lever- Handguard (Pg. 4)

18. Bucking Spike

19. Chain Tensioning Screw

20. Chain Tensioning Lug

21. Clutch Drum

22. Chain Brake Band

23. Oil Adjustment Screw

24. Sprocket

25. Serial Number

_,[o]l,_?jdo] [1_I= i'Lo]ll;7 [_ _?:lvlvA

GASOLINE AND OIL MIXTURE

Importantl Do not use automotive or boat oils in your

chain saw. These oils do not have proper additives for

2-cycle, air-cooled engines and can cause engine

damage.

The 2-cycle engine on this product requires a fuel

mixtureof regular unleaded gasoline and a high quality

2-cycle air-cooled engine oil for lubrication of the

bearings and other moving pads. The correct fuel- oil

mixture is 40:1 (see Fuel Mixture Chart). Too littleoil

or the incorrectoil type will cause poor performance

and may cause the engine to overheat and seize.

Gasoline and oil must be premixed in a clean

approved fuel container. Always use fresh regular

unleaded gasoline. This engine is codified to operate

on unleaded gasoline.

5

FUEL MIXTURE CHART

GASOUNE OIL

I Gallon 3.2 Ounces

2.5 Ganons 8.0 Ounces

MPORTANT! ,Alcohol blended fuels called gasohol

using ethanol or methanol) can attract moisture,

_hich leads to fuel - oil separation'and formation of

Lcidsduring storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage of 30 days or longer. Drain the gas tank, then

run the fuel out of the carburetor and fuel lines by

starling the engine and letting it run until it stops. Use

fresh fuel next season. See storage instructionsfor

eddltior_l information. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage

may occur.

2-CYCLE OIL

Craftsman 2-cycle, air-cooled engine oil is specially

blended with fuel stabilizers. If you do not use this

Sears oil, you can add a fuel stabilizer, such as

Craftsman No. 33500, to your fuel mix.

FUEL STABILIZER

A fuel stabilizer is an acceptable altemative in

minimizing the formation of fuel gum deposits during

storage. Add stabilizer to gasoline mixture in fuel

storage container and mix well. Always follow the fuel

mix ratio found on the stabilizer container. Run engine

at least 5 minutes after adding stabilizer to allow the

stabilizer to reach the carburetor, You do not have to

drain the fuel tank for storage if you are using fuel

stabilizer.

BAR AND CHAIN OIL

We recommend a special chain oil (low sling, high

tack) to lubricate your bar and chain; consult your local

Sears retailer. During chain saw operations at

temperatures below freezing (0°C/32°F), the chain oil

viscosity increases creating an ovedoad to the

automatic oil pump. Overloading results in damage to

the driver gear, pump mechanism, and bar and chain.

A special cold-climate chain oil should be used. Refill

chain oil each time you refuel. CAUTION: Never use

waste engine oil; it will damage the pump.

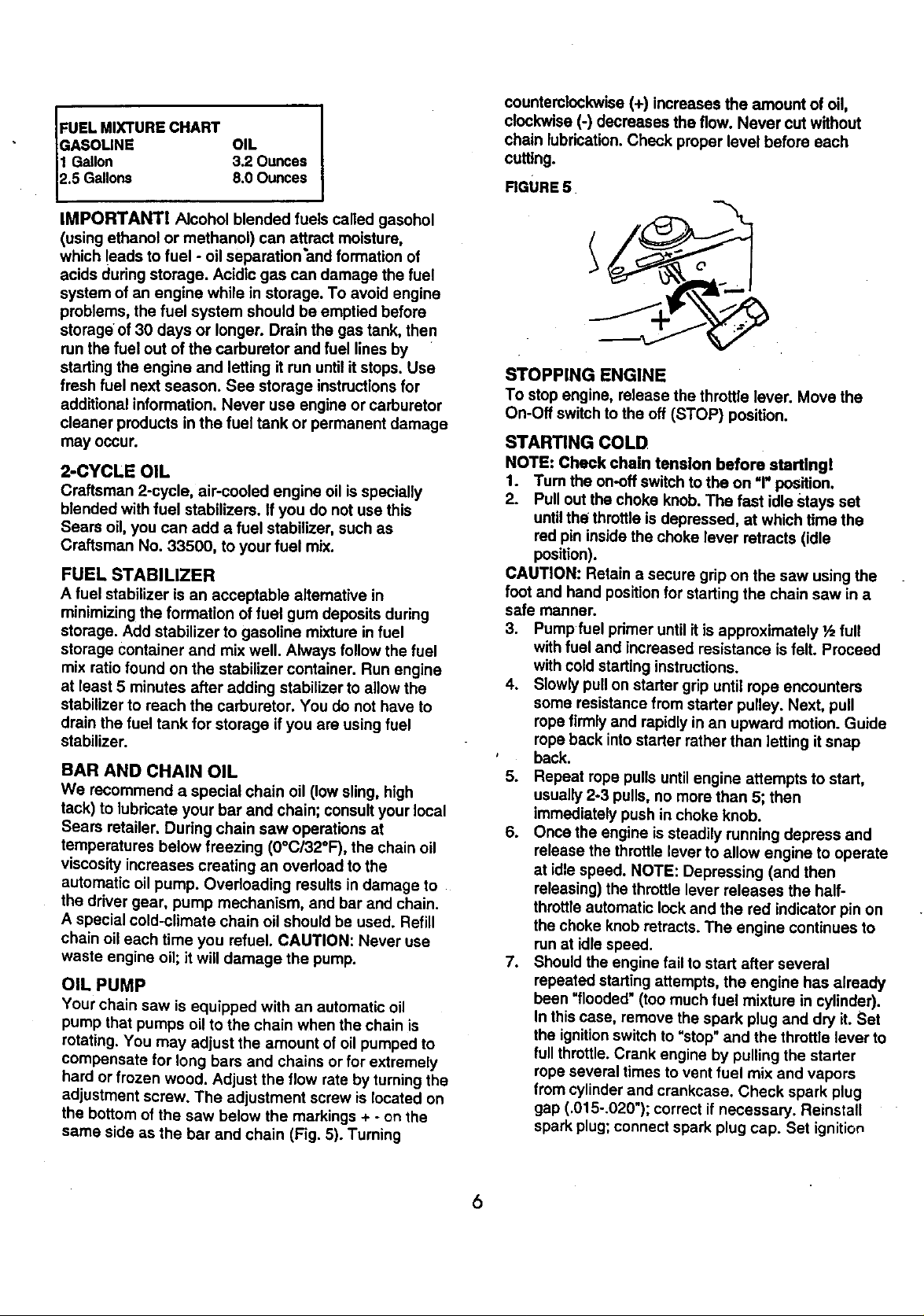

OIL PUMP

Your chain saw is equipped with an automatic oil

pump that pumps oil to the chain when the chain is

rotating. You may adjust the amount of oil pumped to

compensate for long bars and chains or for extremely

hard or frozen wood. Adjust the flow rate by turning the

adjustment screw. The adjustment screw is located on

the bottom of the saw below the markings + - on the

same side as the bar and chain (Fig. 5). Turning

counterclockwise (+) increases the amount of oil,

clockwise (-) decreases the flow. Never cut without

chain lubrication. Check proper level before each

cutting.

RGURE 5

STOPPING ENGINE

To stop engine, release the throttle lever. Move the

On-Off switch to the oft (STOP) position.

STARTING COLD

NOTE: Check chain tension before startingl

1. Tum the on-off switch to the on "1"position.

2. Pull out the choke knob. The fast idle stays set

untilthe throttle isdepressed, at which time the

red pin inside the choke lever retracts (idle

position).

CAUTION: Retain a secure gdp on the saw using the

foot and hand position for starting the chain saw in a

safe manner.

3. Pump fuel primer until it is approximately ½ full

with fuel and increased resistance is felt. Proceed

with cold starting instructions.

4. Slowly pull on starter grip until rope encounters

some resistance from starter pulley. Next, pu_l

rope firmly and rapidly in an upward motion. Guide

rope back into starter rather than letting itsnap

back.

5. Repeat rope pulls until engine attempts to start,

usually 2-3 pulls, no more than 5; then

immediately push in choke knob.

6. Once the engine is steadily running depress and

release the throttle lever to allow engine to operate

at idle speed. NOTE: Depressing (and then

releasing) the throttle lever releases the half-

throttle automatic lock and the red indicator pin on

the choke knob retracts. The engine continues to

runat idle speed.

7. Should the engine fail to start after several

repeated starting attempts, the engine has already

been "flooded"(too much fuel mixture in cylinder).

In this case, remove the spark plug and dry it. Set

the ignitionswitch to "stop"and the throttle lever to

fullthrottle. Crank engine by pulling the starter

rope several times to vent fuel mix and vapors

from cylinder and crankcase. Check spark plug

gap (.015-.020"); correct if necessary. Reinstall

spark plug;connect spark plug cap. Set ignition

b

STARTING WARM

I. Pull choke knob out.

2. Push choke knob back into open position, red

indicator pin on choke button remains visible.

3. Crank engine and allow to run briefly.

4. Depress throttle lever to allow engine to run at idle

speed (indicator pin disappears).

Ifyou are unsuccessful in starting the engine, consult

the Troubleshooting guide in your Craftsman chain

saw handbook or contact a Sears Sen/ice Center.

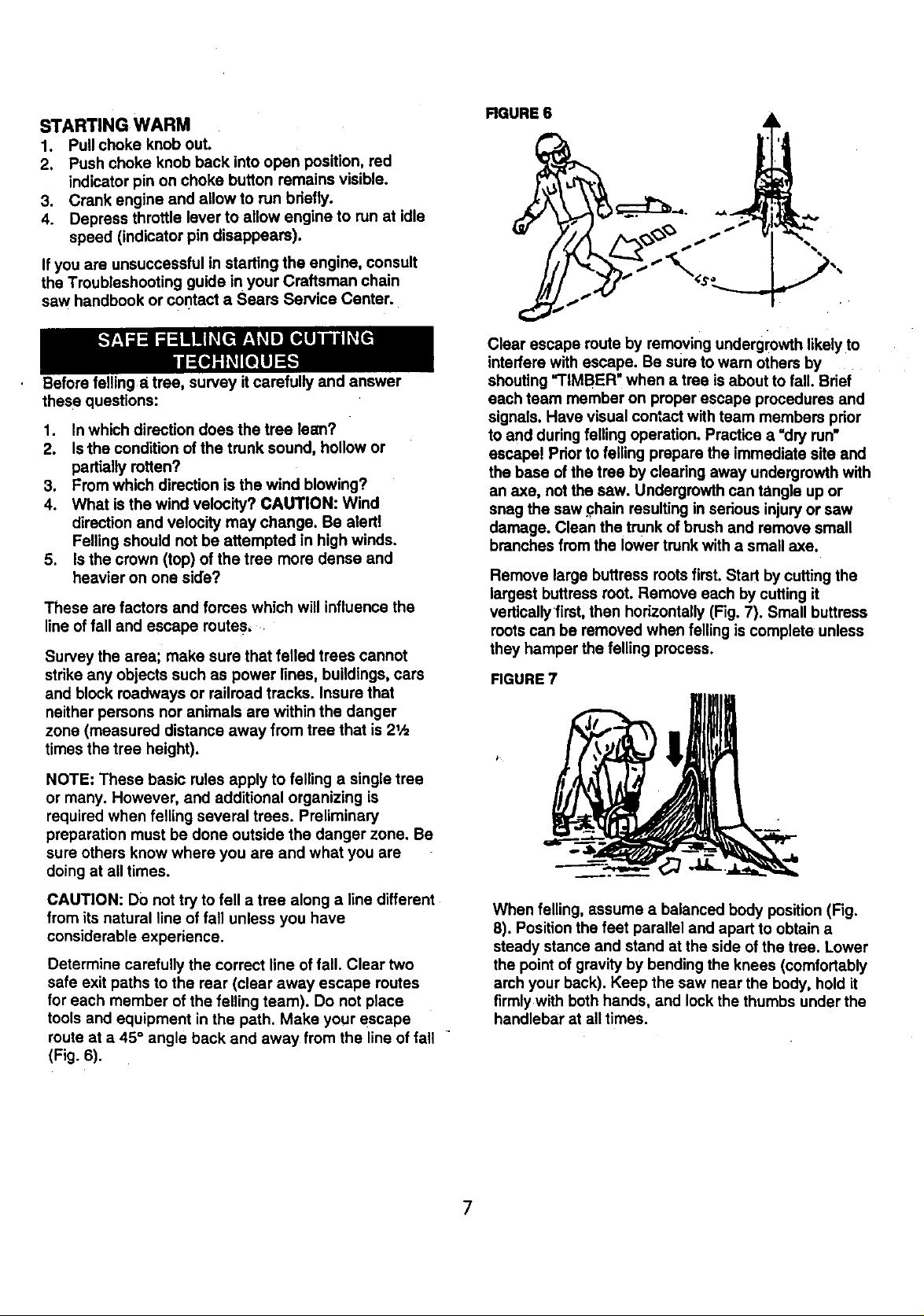

Before felling a tree, survey itcarefully and answer

these questions:

1. In which direction does the tree lean?

2. Is the condition of the trunk sound, hollow or

partially rotten?

3. From which direction is the wind blowing?

4. What is the wind velocity? CAUTION: Wind

direction and velocity may change. Be alert!

Felling should not be attempted in high winds.

5. Is the crown (top) of the tree more dense and

heavier on one side?

These are factors and forces which will influence the

line of fall and escape routes,

Survey the area; make sure that felled trees cannot

strike any objects such as power lines, buildings, cars

and block roadways or railroad tracks. Insure that

neither persons nor animals are within the danger

zone (measured distance away from tree that is21/=

times the tree height).

RGURE 6

Clear escape route by removing undergiowth likely to

interfere with escape. Be sure to warn others by ....

shouting =TIMBER" when a tree is about to fall. Brief

each team member on proper escape procedures and

signals. Have visual contact with team members prior

to and during felling operation. Practice a "dry run"

escape! Prior to felling prepare the immediate site and

the base of the tree by clearing away undergrowth with

an axe, not the saw. Undergrowth can tangle up or

snag the saw Fhain resulting in serious injuryor saw

damage. Clean the trunk of brush and remove small

branches from the lower trunk with a small axe.

Remove large buttress roots first. Start by cutting the

largest buttress root. Remove each by cutting it

vertically first, then horizontally (Fig. 7). Small buttress

rootscan be removed when felling is complete unless

they hamper the felling process.

RGURE 7

NOTE: These basic rules apply to felling a single tree

or many. However, and additional organizing is

required when felling several trees. Preliminary

preparation must be done outside the danger zone. Be

sure others know where you are and what you are

doing at all times.

CAUTION: DO not try to fell a tree along a line different

from its natural line of fall unless you have

considerable experience.

Determine carefully the correct line of fall. Clear two

safe exit paths to the rear (clear away escape routes

for each member of the felling team). Do not place

tools and equipment in the path. Make your escape

route at a 45 ° angle back and away from the line of fall "

(Fig. 6).

When felling, assume a balanced body position (Fig.

8). Position the feet parallel and apart to obtain a

steady stance and stand at the side ofthe tree. Lower

the point of gravity by bending the knees (comfortably

arch your back). Keep the saw near the body, hold it

firmlywith both hands, and lock the thumbs under the

handlebar at all times.

7

FIGURE 8

CAUTION: Maintain good footing, body balance and

insure a safe escape path has been established.

Never fell a tree without making a proper felling notch

(undercut).

The next cut (Fig. 11) is called the felling cut (back

cut). Make it at least 2" higher than the lower cut of the

felling notch by cutting horizontally and parallel to the

felling notch. Do not cut through to the felling notch.

Leave a "hinge" of uncut wood approximately 1/10 of

the tree diameter (Fig. 11).

CUTTING FELLING NOTCH

Start fellingby making a careful felling notch

(undercut) first (Fig. 9). This notch determines the line

of fall. Position it at a dght angle. Cut the felling notch

to a depth of about t/, of the trunk diameter. It must be

wide enough and should never be higher than its

depth.

FIGURE 9

Felling

To make the felling notch, start with the upper cut

facing the line of fall. This is a directional cut

downwards at an angle (Fig. 10, 1). Next, make the

lower felling notch cut. Cut hodzontally and straight

into the tree until it meets the upper cut forming a

wedge (Fig. 10, 2).

RGURE 10

WARNING: To avoid personal injury, do not cut

through the hinge! A proper hinge prevents the tree

from possibly =sitting back" or "butt kicking" the back of

the stump, twisting off the stump, or falling prematurely

and uncontrolled.

When felling a large tree, drive wedges into the felling

cut. Use only wooden or plastic wedges. Never use

steel or iron wedges which can cause kickback and

damage to the chain. Wedges prevent the tree from

settling back on the bar and help control the direction

of the fall toward the felling notch (fig. 12)o

FIGURE 12

SMALL TREES

If the trunk diameter issmaller than the guide bar

cutting length, be careful making the felling cut and

forming the hinge. Once the felling cut has been made,

,place the bucking spike at the base line dght behind

the hinge, and do a fan cut (Fig. 13).

FIGURE 13

The ex_ when the tree is on a slope; then the

lower cut should be on an upward angle to cut a

larger, more open wedge and to gain greater control

dudng the fall of the tree (Fig. 11).

FIGURE 11

Direction of fan cut

Hinge_

The bucking spike is the toothed metal piece attached

to the front of the saw body and found to the left of the

bar. With the bucking spike teeth against the logfirm

contact between the saw body and the log are

maintained. A fan cut isaccomplished by first

contacting the teeth of the bucking spike to the log and

then, using the bucking spike as the pivot point,

rotating the bar through the log in a counterclockwise

direction.

8

LIMBING (Removing limbs from felled trees)

WARNING: Of all the cutting operations, limbing is the

one that holds the most chance of unforeseen injury.

The danger of kickback is most prevalent during

limbing if the bar nose comes in contact with another

branch or the side of the tree (see "Kickback

Conditions and Prevention").

Professional loggers have developed various safe,

efficient and effective limbing techniques which you

must follow. The following instructions are a few of the

basic safe work habits for a chain saw operator while

limbing or removing branches from a tree.

.1. Before starting to limb, be sure the branch is on a

safe side of the log, uphill, and on the side

opposite of any potential motion the cut branch

might make (Fig. 14).

FIGURE 14

6. Craftsman saws are designed to allow the

powerhead to glide over the trunk during limbing.

Cut the branches in a swinging back and forth

movement with the saw remaining on the tree.

This is known as the =pendulum method."

7. Prior to cutting the branches, consider the

direction in which the branches may fall. This will

determine whether you cut from the top down

(overbuck, Fig. 16) or from below up (underbuck,

Fig. 17).

8. Watch out for branches under tension which can

snap back. Tension must be removed before

these branches can be safely cut. Beware of

potential kickback situations.

9. If large branches are to be used for firewood, cut

them to length while still attached to the tree. This

is an easier and safer method than bucking

branches on the ground (Fig. 16 & 17).

10. If you tire during limbing, STOP! Rest, then

resume work.

11. Never change the position of the feet or hands

while in the midst of a cut. ._

FIGURE 16

Overbucklng

2. Do not stand on a log while limbing. You may slip,

fall or the log may roll. Maintain sure footing.

3. Never use the bar nose to cut branches.

4. Bend the knees slightly. Position the right leg

behind the left side of the chain saw and the left

leg forward and outward away from contact range

of bar. Assume a comfortable stance with the feet

spread apart. CAUTION: If you change position,

the bar must always be on the side of the tree

opposite you. Keep the tree trunk between you

and the bar.

5. Rest the chain saw body on the trunk as much as

possible(Fig. 15).

FIGURE 15

FIGURE 17

Underbucking

9

BUCKING (The cutting of a log into sections):

1. Be alert to the stress and motion of logs. Always

position yourself to prevent the rolling of a cut log

section or the stress forces within a log from

acting against you.

2. Never stand directly behind the chain saw when

cutting. Stand to the left side of the cutting path of

the chain saw to reduce the chances of injury from

kickback or a broken chain shooting backwards

towards you (Fig. 18, 1).

3. Bend the knees slightly. Assume a comfortable

stance with the feet spread apart (Fig. 18, 2).

4. Keep the left elbow straightwhile cutting (Fig. 18,

3).

5. Lock the thumb under the handlebar (Fig. 18, 4).

FIGURE 18

FIGURE 20

WARNING: Logs and branches may be under stress

or tension. Before cutting check to see ifstress exists.

If stress does exists, start to cut on the right side of the

log or branch to prevent pinching and possible

kickback situations so that the branch does not whip

back and strike you.

9. If the chain bar is pinched while bucking, shut off

the engine immediately.

IMPORTANT! Ifthe bar and chain become pinched,

do not try to wrench or twist the bar free. Move the log

intoanother position or lift up with a rod or lever (Fig.

21).

FIGURE 21

6. Set the bucking spikes firmly against the log.

7. When cutting firewood, place the log on a suitable

support such as a saw buck (Fig. 19).

RGURE 19

8. Free hanging ends can be cut off without risk of

bar pinching. But if the wood is not to split or tear,

make an undercut (underbucking, Fig. 20, 1) of

about 1/3 the depth of the log diameter, then apply

the finishing cut (overbucking, Fig. 20, 2).

GENERAL RECOMMENDATIONS

The warranty on thischain saw does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

operator must maintain chain saw as instructed in this

manual.

All items in the Maintenance section of this manual

should be checked at least once each season.

1. Service more often when operating in dusty or

dirtyconditions.

2. Once a year you should replace the spark plug

and clean or replace the air filter. A new spark

plug and a clean air filter assure proper air-fuel

mixture and help your engine run better and last

longer.

]0

MAINTENANCE SCHEDULE

FIGURE 22

m

Check for loose fasteners & parts

Checkfor,_damagedorworn parts

Check chai_tension X

Checkchainsharpness

:_efill.barand chainoil

Inspectbar

.?.leanenginecoolingfins X

_leanair filter& pre-filter

Replacesparkplug X

Cleanfuelfilter X

Inspectmuffler X

Cleansparkarrestor X

CHECK FOR LOOSE FASTENERS & PARTS

Check all fasteners, including nuts, bolts, screws and

clamps, to insure that they are tight and secure, If not,

make all necessary adjustments prior to using chain

saw.

CHECK FOR DAMAGED OR WORN PARTS

Replacement of damaged orworn parts should be

referred to your Sears Service Center

• On-Off Switch - Check function of the switch by

running the saw then turning the switch to the "off"

position. The engine should stop; then turnto the

"on"position and restart.

• Fuel Tank & Oil Tank - Do not use the saw if oilor

fuel leaks from the unit. NOTE: It is normal for a

small amount of oil to drip from the bar and the

side where the chain adjustment pin is located.

CHECK CHAIN TENSION

Ifthe chain is too loose it can come off the bar and

possibly cause injury. DO NOT operate the saw if the

chain is loose. To set your chain to the proper tension

refer to Chain Tension in the Service and Adjustment-

section.

x

x

x

X

X

X

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dullchain makes

a sawdust powder and cuts slowly. Chain sharpening

requires special tools. You can purchase sharpening

tools at Sears or go to a professional chain sharpener.

REFILL BAR AND CHAIN OIL

Your saw will use approximately one tank of bar oil for

every tank of fuel mix. Always fill bar oil tank when you

fill the fuel tank. For maximum bar and chain life,we

recommend you use Craftsman chain saw bar oil. If

Craftsman bar oil is not available, you may use a high

quality bar and chain oil. CAUTION: Only use bar and

chain oil; do not use motor oil. Motor oilwill damage

the saw.

INSPECT BAR

Keep bar rails square and flat. Check for inside groove

wear as follows. Place a straight edge (Fig. 23, A)

against side of bar and one cutter. If there is clearance

(Fig. 23, B) between bar and straight edge, the bar

rails are good. If the chain leans (Fig._24) and there is

no clearance between bar and straight'edge (Fig. 24,

B), the bar rails are wom. Straightening worn bars,

under certain circumstances, can only be done by

service technicians. Replace bar if un-repairable.

IMPORTANT: To prevent One-sided wear of the bar,

flip the bar over after each chain sharpening.

RGURE 23

ii

.-.%,.._

M Good

RGURE 24

r---1

_.j. ,._

M Wom

WARNING: Be Sure chain is properly tensioned. A

sagging chain (Fig. 25) can jump out of the bar groove

and even break.

FIGURE 25

1]

Sagging chain

Clean the oil inlet hole (Fig. 26, A) and the bar groove RGURE 28

priorto placing the chain in the bar groove.

FIGURE 26

Pre-fllter

REPLACE SPARK PLUG

Change your spark plug each year to make your

engine start easy and run better. Set spark plug gap at

.020".

With sprocket nose bars (Fig. 27), grease the bearings

of the sprocket with a grease gun containing bearing

grease. Pump the grease into the clean.edout holes

while rotating the sprocket. WARNING: Wear gloves

when handling chain to prevent injury.

RGURE 27

CLEAN FUEL FILTER

The fuel filter is located inside the fuel tank and is

attached to the fuel line. To clean, scrub with a small

brush. Replace if deteriorated,

INSPECT MUFFLER

Inspect muffler every 25 hours of use and replace if

corroded.

CLEAN SPARK ARRESTOR SCREEN (if installed)

After every 25 hours of use the spark arrestor screen

must be cleaned. Replace screen if deteriorating (part

no. 2048391).

To clean:

1. Remove screen.

IMPORTANTI The bar is designed specificallyto be a

track for the chain. Never use bar to pry, liftor twist.

2. Clean using a wire brush.

3. Reinstall.

CLEAN ENGINE COOLING RNS

For best performance, keep dirtfrom accumulating

around the engine cooling fins. Clogged cooling fins

cause the engine to run hotter and shorten engine life.

Cooling fins may be cleaned using a toothbrush or stiff

bdstle brush.

CHAIN TENSION

Correct chain tension isvery important to insure a long

service life for the chain. Check the chain tension each

[.,._=l;_rJ[_Idr-1_1,1-I m]lJl_-]l|_[:l_

time the saw is stopped and the bar and chain have

CLEAN AIR FILTER & PRE-FILTER

Your engine will not run properly and may be damaged

by using a dirty air filter and/or pre-filter. Replace if

deterioration occurs. Service more often ifyou use

your chain saw in very dusty or dirtyconditions.

To Clean Air Filter & Pre-Filter:

1. Remove air filter Cover.

2. Remove pre-fllter and air filter (Fig. 28). To

remove air filter, slide retaining clipoff and pull up

on air filter.

3. Clean air filter with soft brush or tap lightly, If

heavily soiled, rinse in a mild soap and water

cooled off. Check the tension and the chain and bar

lubdcation frequently during prolonged pedods of

cutting. Ifthe chain is loose, lubricate it well and let it

cool off before readjusting the tension.

WARNING: Be sure the chain is properly tensioned. A

sagging chain can jump out of the bar groove, break,

and cause sedous injury,

The chain tension needs adjusting ifthe chain is

sagging away from the underside of the bar when the

saw is held updght (Fig. 29).

RGURE29

solution. The pre-filter must be blown clean with

compressed air,

4. Dry air filter completely. Reassemble the pre-filter

and air filter; ensui'e that they are correctly seated

before reinstalling.

5. Replace filters if deteriorating,

Retainingclip

Air filter

12

Saggingchain

WARNING: Shut off engine before attempting to adjust

the chain tension. Additionally, disconnect the spark

plug wire. Wear gloves when handling chains to

prevent injury.

To adjust the tension:

1. Loosen the bar nuts using the Combi-wrench.

2. Turn the tension screw clockwise (Fig. 30, 1) until

'the chain touches and no longer sags at the

underside of the bar.

FIGURE 30

3. The saw chain is correctly tensioned when the

chain fits snuggly against the underside of the bar,

but can stillbe easily rotated on the bar by hand.

Be sure the chain fits correctly on the sprocket and

the bar (Fig. 30). NOTE: The chain will not rotate if

the chain brake is engaged.

4. Hold up the bar tip.Tighten the bar nuts securely

with the Combi-wrench provided. Only use the

provided Combi-wrench to tighten the bar nuts

(Fig. 31). CAUTION: Excessive force will stripthe

bar studs out of the saw case.

FIGURE 3i

RGURE 33

2. Clean the surface between the bar and the guide

plate (Fig. 34, A); and the oilier opening (Fig 34,

B).

3. Turn the chain tensioning screw (Fig. 34, C)

counterclockwise to position the tension lug (Fig.

34, D) to the far left.

4. Slide the bar over the tension tug and fit securely

into lughole. Failure to fit the lug into the hole may

resultin the tension screw being bent when the

side cover is tightened down.

RGURE 34

.

Feed the chain around the chain sprocket into the

bar groove (Fig. 35). Cutters (the sharp edge on

top) must point forward toward bar nose. Insure

the chain drive links engage the chain sprocket

and the sprocket nose on the bar.

FIGURE 35

INSTALLING NEW CHAIN

CAUTION: injury hazard! Wear safety gloves when

handling saw chain at any time.

1. Be sure chain brake is disengaged first (Fig. 32).

Pull backwards on hand guard until it clicks

audibly. Remove the two bar nuts (Fig. 33) and

side cover.

FIGURE 32

6. Attach the side cover and bar nuts by hand

tightening only. Lifting the bar nose slightly; turn

the chain clockwise and tighten the chain with the

tension screw until the chain touches the bar

without sagging. The chain tension is correct if the

chain is snug against the underside of the bar but

can stillbe easily rotated by hand. NOTE: The

chain will not rotate if the chain brake is engaged!

7. Hold her tip up; tighten bar nuts securely with

Combi wrench supplied. CAUTION: Excess force

will stripthe bar studs out of the case.

]3

NOTE:Checkchaintensionfrequently.Chaintension

willbeaffectedbysuchconditionsasdurationofwork,

outsidetemperature,hardnessofwood,lubrication,

etc.Ifthechainbecomesloose,shutoffsaw,loosen

retainingnutsandreadjustchainaccordingtoprevious

instructions.

CARBURETORADJUSTMENT

Tocomplywithemissionregulations,thecarburetor

mixtureispre-setatthefactoryandcannotbe

adjustedwithoutthepropertools.Anymixture

adjustmentmustbeperformedbyaservicecenter.

The idle speed can be adjusted. The idle speed set

screw is located on the top of the unit and to the left of

the spark plug. It is indicated by the letter "T.* To

adjust the idle speed, turn clockwise to increase and

counterclockwise to decrease idle speed. Idle speed is

2500 ± 100 RPM.

Prepare your chain saw for storage at the end of the

season or if the unit will not be used for 30 days or

more.

BEFORE STORING

1. Use soap and water to wipe down unit.

2. Be sure that all nuts, bolts, screws, and fasteners

are securely fastened. Inspect for damaged or

worn pads. Replace ifnecessary.

ENGINE

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel

filter, fuel hose, or tank during storage. Alcohol

blended fuels, such as gasohol, ethanol, or methanol,

can attract moisture, which leads to separation and

formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage.

Do not store gasoline from one season to the next.

Two-cycle mix ages quickly and can cause engine

damage. Replace your gasoline container if it starts to

rust. Rust or dirt in your gasoline will cause engine

problems.

6, Pour a few drops of oil into the cylinder.

7. Pull the starter handle slowly to distribute the oil.

8. Replace with new spark plug.

STORAGE TIPS

If possible, store your unit indoors and cover itto give

it protection from dust and dirt. Do not use plastic.

Plastic cannot breath, which will allow condensation to

form and will cause your unitto rust. IMPORTANT!

Never cover chain saw while engine and muffler are

stillwarm.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or more.

Follow these instructions:

1. Drainthe fueltank

2. Start engine and let it run until the fuel lines and

carburetor are empty (The engine will stop.)

3. Use fresh gas next season.

4. If you use a fuel stabilizer, the gasoline can be left

in the tank. CAUTION: Never store chain saw

inside a building with fuel in the tank! Fumes can

concentrate and possibly reach a source of

ignition.Allow engine to cool before storage.

5. Remove spark plug.

14

PROBLEM

CAUSE SOLUTION

Engine does not start.

;hain rotates in idle mode.

Exhaust is smokey.

Chain cuts poody.

1, Fuel tank is empty.

2. Stale fuel mix.

3. Ignition switch off.

4. Spark plug fouled.

1. idle speed too fast.

•1. Idle speed mixture too rich,

2. Too much oil in fuel mixture.

3. Air filter clogged.

4. Choke only partially open.

1. Blunt chain or incorrectly

sharpened.

2. Carburetor adjusted

incorrectly.

3. Air filter clogged.

1, Refuel with fresh fuel.

2. Drain and flush the fuel

tank. Refuel with fresh fuel mix.

See =Fuel Mixture Chart" in

Operations.

3, Set switch to" I ."

4. Clean or replace plug.

1. Turn idle speed set screw

countemlockwise until

chain stops while the

engine idles.

1. Contact Sears Service Center.

2. Adjust the fuel-oil mixture

ratio. "_

3. Clean or replace air filter.

4. Open choke all the way.

1. Sharpen chain.

2. Contact Sears Service Center.

3. Clean or replace air filter.

The CaliforniaAirResourcesBoardandSears arepleased

to explainthe emissioncontrolsystemwarrantyonyour

1996 and laterlawn andgardenequipmentengine.In

Caiifomla,newlawnand gardenequipment enginesmust be

designed,built,andequippedto meetthe state's stflngent

anti-smog standards.Sears mustwarrantthe emission

controlsystemon yourfawn andgardenequipmentengine

forthepedodoftimelistedbelowprovidedthere has been

no abuse, neglect,or impropermaintenanceofyour lawn

and gardenequipmentengine.

Youremissioncontrolsystemincludespartssuchas the

carburetororfuel injectedsystem,theign'dionsystem,and

connectorsandotheremisslan-relatsdassemblies.

Where a warrantableconditionexists,Sears willrepairyour

lawnand gardenequipmentengineat no costtoyou

includingdiagnosis,parts,and labor.

MANUFACTURER'S WARRANTY COVERAGE:

The 1996 andlater lawnand gardenequipmentenginesare

warrantedfor twoyears. Ifany emission-mistedparton you

engineisdefective,thepartwillbe repairedor replacedby

Seam.

OWNER'S WARRANTY RESPONSIBILITIES:

As the lawn and garden equipment engine owner, you are

responsible for the pedormance of the required maintenance;!,

listed in your Operatol's Manual. Sears recommends that

youretainall receiptscoveringmaintenanceonyour lawn

and gardenequipmentengine.Searscannotdenywarranty

solelyforthe lack of receiptsor foryourfailureto ensurethe

performanceofall scheduledmaintenance.

Asthe lawnand gardenequipment engineowner,you

shouldhoweverbe awarethatSeam may denyyouwarranty

coverageifyourlawnand gardenequipmentengineor a

pert has faileddueto abuse, neglect,impropermaintenance

or unepprovedmodifications.

You are responsiblefor presentingyourlawn andgarden

equipmentengineto a Sears repaircenteras soon as a

problemexists.The warrantyrepairsshouldbe completedin

a reasonableamountof time, nottoexceed 30 days.

Ifyou haveany questionsregardingyourwarrantydghtsand

responsibilities,you shouldcontactSearsat 1-800-473-

7247.

A. WARRANTY COMMENCEMENT DATE

The warrantypedodbeginsonthe datethe equipment

ispurchasedbya retail customer.

a.

LENGTH OF WARRANTY COVERAGE

Sears warrants to the initial owner and each

subsequent purchaser that the engine is free from

defects in matedais and workmanship for a pedod of

two years from date of odginai purchase from Seam.

15

C. WHAT IS COVERED

1,gREPAIR OR REPLACEMENT OF PARTS

Repai_or replacementof anywarrantedpartwill

be performedatno chargetothe ownerata

warranty station.To locatea warrantystation,you

may callSears at 1-800-473-7247, (24 hours,7

daysa week).

WARRANTY PERIOD

Any warrantedpartwhichisnotscheduledfor

replacementas requiredmaintenance,orwhichis

scheduledonlyfor regularinspectionto theeffect

of "repairorreplaceas necessary"shallbe

warrantedfor the warrantypedod.Anywarranted

partwhichis scheduledfor replacementas

requiredmaintenanceshallbe warrantedfor the

peded.oftimeup to the first scheduled

replacementpointforthatpart.

e DIAGNOSIS

The ownershallnotbecharged fbrdiagnostic

labor,whichleadsto the determinationthat a

warrantedpart is defective,ifthe diagnosticwork

isperformedat Sears.

4. CONSEQUEN_ALDAMAGES

The enginemanufacturerisliablefordamagesto

the enginecomponentscausedbythe failure ofa

warrantedpartstillunderwarranty.

D.

WHAT IS NOT COVERED

1. Failurescausedbyabuse,neglect,orimproper

maintenance.

2. Add-on ormodifiedparts.The useofadd-onor

modified padscan be groundsfordisallowinga

warrantyclaim.The enginemanufacturerisnot

liabletocoverfailures of warrantedpartscaused

bythe use of add-onormodifiedpads.

3. Any indirectorconsequentialdamagesthat may

resultfrom thefailure or malfunctionoftheSears

product.Somestatesdo notallowtheexclusionor

limitationofconsequentialdamagessothese

limitationsmay notapplytoyou.

4. Normalservicerequirementsarisingdudngthe

warrantyperiodsuchas carburetororignition

adjustment,cleaning,normalwear,lubrication,

sparkplugs,filters,starterropes,etc.

5. Normalserviceworkoverand abovetherepairor

replacementofdefectivepads.

6. Anyfailurethat resultsfroman accident,customer

abuse, norrnslwear, neglector failureto operate

the productinaccordancewiththe instructions

providedin the OperatorsManual orprovidedwith

the product.

7. Pre-deliven/set-up time.

8. Operationofan engine withan incorrectfuel:oil

ratio,airfilterremovedor speedsin excessof

Sears' recommendations(ifapplicable).

9. Transpodationcostsassociatedwithdelivering and

rstumof producttoa Sears warrantystation.

E.

HOW TO RLE A CLAIM

Warrantyclaimsmay be submittedon severaldifferent

forms:

Seers WarrantyClaimRequest

OutdoorPower EquipmentInstitute

UniversalWarrantyCIalm Report

EngineServiceAssociationClaim

Warrantyclaims mustbe receivedat Seers within60

daysof the date of repairnotedonthe claim,

F,

WHERE TO GET WARRANTY SERVICE

Warrantyserviceor repairsshall be providedat Sears

ServiceCanters.Forthe addressof a ServiceCenter

nearyoucall Sears at 1-800-473-7247, (24 hours,7

daysa week).

G,

MAINTENANCE, REPLACEMENT AND REPAIR OF

EMISSION RELATED PARTS

Sears replacementpads must beused inthe

performanceofany warrantymaintenanceor repairs

on emission-relatedpads and willbe providedwithout

chargedudngthe warrantyperiod.

H.

EMISSION CONTROL WARRANTY PARTS LIST

Sears'warrantyincludesthe followingpads (unless

saidpad was scheduledforreplacementas required

maintenance):Air Filter,Fuel Filter,Carburetorand

internalpads, Choke Mechanism,IntakeManifold,

J

Spark Plug,Flywheel, IgnitionModule.

MAINTENANCE STATEMENTS

Follow normal maintenance service, recommended fuel

mixture (where applicable), lubrication, operation and

storage of the product as explained in the Operator's

Manual. The owner shall not be charged for diagnostic

labor, which leads to the determination that a

warranted part is defective, if the diagnostic work is

performed at Sears.

]6

CRAFTSMAN CHAIN SAW MODEL NO. 360.352001

140

141

14217 151

168 ","., •_'-- i

k,_ff W _el,wm,4m _g

187 I

188

189

I

q

201 ]

r5 130

131

"111

,.17

212

I

I

76 75

I

I

236 -

"I

200

LI

I

_3

1 _.o .

213 212 210

I

I 14. T

212

213

CRAFTSMANCHAINSAWMODELNO.360.352001

Poe.Number Part

.Number DescrlpUon

1 6073641 Air guide

2 0020148 Nut

3 0072145 Tendon spring

5 2400289

6 0010158 Screw

7 0034201 Clml_p

10 2100624DGN Crankcase, complete

11 0054252 Oil seal

12 0050187 Grooved bail bearing

13 0018267 Screw

14 0018336 Screw

15 20744160GN Pro-rifler cover

16 2500582 Pro-rifler assembly

17 0021232 Nut

18 2300489 Short circuit switch

19 2061473 Crankcase gasket

21 0040190 Pin

22 2700382 Check valve

23 2800285 Throffie linkage

24 2074908DGN ConsOle

25 6074401 Plug

26 0062256 O-ring

27 6400183 Pin

28 6074409 Stop plate

29 0018280 Screw

30 2042726 Stop plate

31 0018267 Screw

32 0073381 Torsion spring

33 0050188 Ball bearing

34 0054265 Oil seal

35 6063329 Oil hose

36 6400209 Pump housing

37 0062276 O-ring

38 0018280 Screw

39 6700124 Oil strainer

40 6063299 Hose

41 0044271 Rivet

42 6074447 Cover

45 0031529 FdcSon washer

46 0070265 Pressure spring

48 6031330 Pump piston _

49 6400207 Oil pump, complete

50 0055136 Circrip

51 0031209 Washer

52 6074976 Drivingworm

60 6042817 Washer

61 0071172 Clutch spring

62 3500405 Clutch, complete

63 _5_b_. _ Clutchdrom

64 0052257 Needle beadng

70 6200131 Broke band

71 0070254 Spring

72 6300208 Adjuster

75 6300175 Pressure plate

76 0070253 Spring

80 0031534 Washer

81 0055104 Washer

85 6074999 Brake band cover

86 0018280 Screw

90 6100371DGN Chain Guard

91 6074696 Guide shoe

92 00202147 Nut

110 2200238 Crankshaft

111 0075100 Disc spring

112 0052255 Needle beanng

115 0055287 Piston pin circlip

116 2031249 Piston pin

120 2200265 Piston

Pos. Part

Number Number Description

121 2048357 Piston dng

122 2061478 Cylinder foot gasket

125 2011756 C_er

128 0034201 Clrsiip

127 0010541 Screw

128 0094252 Spacer

129 2300730 Spark plug

130 0015286 Stud screw

131 2061441 Murilergesket

132 2500604 Muffler

135 0072144 Washer

136 00_8137 Lock nut

137 0018336 Screw

140 2061439 Manifold gasket

141 2300732 Manifold

142 0034201 Cirdip

143 0010112 Screw

144 2061443 Carburator gasket

150 2300709 Carburetor

151 6074916 Lever

152 2074441 Guide nozzle

153 . 6043247 Support

154 0018267 Screw

155 0034147 Spring dng

156 0015279 Screw

160 2500641 Air rifler assembly

161 0062246 O-ring

162 0011282 Screw

163 2074946 Profits

164 2074423 Filter housing

165 0018230 Tension screw

166 6032640 Chain tension bolt

168 6900814 Repair Idt

170 0018398 Screw

171 6643329 Guide plate

172 0010478 Screw

175 6900221N Guide par

176 6043323 Bucking spike

177 0034201 Clrdip

178 0010559 Screw

179 6071248 Scabbard

180 6900220N Chain

187 0030101 Washer

188 0072148 Tension spdng

189 0018327 Screw

190 2300752 Ignitioncoil

191 0084600 Spark plug cap

192 0073385 Contact spring

193 0064292 Hose

194 2063333 Grommet

195 0084702 Short circuitcable

196 0066335 Grommet

199 0066314 Grommet

200 2700345 Oil tank cap

201 0062288 O-dng

210 6300155 Rubber metal connection

211 0030115 Washer

212 0018280 Screw

213 0018274 Screw

214 0033318 Spacar tube

215 0018257 Screw

220 6074422DGN ProtesSve cap

?_22 6043352 Chain proteclJonplate

235 0510952 Carburetor gasket kit

236 0510951 Carburetor repair kit

240 0510953 Throttle axle k_t

241 0510965 Choke axle kfl'_

?

18

CRAFTSMAN CHAIN SAW MODEL NO. 360.352001

Pos. Number Pert

Number Descrlpfton Number Number Oes(:rlptlon

1

3

4

5

6

7

8

9

15

16

17

20

21

22

23

25

26

28

29

30

33

34

35

37

38

42

43

44

45

47

50

52

53

54

6100413DGN Main housing 57 0072140 Spring washer

0073392 Throt_e control spflng 58 6032639 BoR

2074429 Gas lever 60 0028118 Nut

0073339 Spring 61 6032669 Bolt

6074292 Stop lever 62 6063328 Fuel hose

6074443 Safetylever 63 0013214 Screw

20_381 Throttle linkage 64 2500744 Ventilation hose

0010531 Screw 65 0067124 Nipple

6073681 Gdp cup, left 66 6063304 Vent hose

0010512 Screw 67 6063302 Fuel hose

0010531 Screw 68 0073351 Hose inop

60736810GN Gdp cup, left 69 6063301 Hose guide

0070147 Spdng 70 2700321 Hose

6074381 Lever 71 0063191 Seallng cord

6031247 Pin 72 2074469 Plug

0061356 Gasket 73 2074470 Frame

27003.53 Tank lid 75 6073683 Cover, Black

0098140 Safetycetch 76 6800334 Screw

0018274 Screw 79 0018336 Screw

6800241 Handle bar 80 0018337 Screw

0094288 Rubber metal connection 82 6074993 Choke lever

0030102 Washer 83 6074992 Pin

0098141 Safety catch 85 2700322 Pdmer

0028130 Nut 86 0064407 Hose

0018274 Screw 87 0064432 I-k_e

0018274 Screw 88 6074958 Pdmer support

0010157 Screw 89 6042753 Isolating foil

0030102 Washer 90 0(_J4252 Rubber spacer

0098142 Safety catch 100 6073566 Hub cover, black

0098143 Safety catch 104 6074426 Choke lever

6800235 Hand protection . 105 0011258 Screw

0044280 Rivet 106 0030108 Washer

00G4152 Clr_ip 110 2700354 Fuel pick-up,complete

0010188 Screw 111 2700327 Fuelplck-up

• Pos. Pert

112 2700335 Fuel pick-up, ind in 6100402

5O

3 52

-_ --69

•" 68

58

111 _ 67

6O

I

112

76

74

79

89

8 88 82

_:6_ 8 I

19

CRAFTSMANCHAINSAWMODELNO.360.352001

Pos, Number

1

3

4

5

6

7

10

11

12

13

14

part Descdptlon

2600282DGN Starter, complete

0018336 Screw

2100o-78- Starter housing

0063186 Starter rope

2074206 Starter handle

2600283 Spring cassette

2074419 Starter pulley

0031260 Washer

2074209 Starter pawl

2074408 Template

0073365 Pin

J

o

J

2O

For in-home major brand repair service:

Call 24 hours a day, 7 days a week

1-800-4-MY-HOME = (1-800-469-4663)

Para pedir servicio de reparaci6n a domiciiio - 1-800-676-5811

In Canada for all your service and parts needs call

-1-800-665-4455

Au Canada pour tout le service ou les pi_ces

For the repair or replacement parts you need!

Call 6 aim. - 11 p.m. CST, 7 days a week

PartsDirect"

1-800-366-PART (1-800-366-7278)

Para ordenar piezas con entrega a domicilio - 1-800-659-7084

For the location of a Sears Service Center in your area:

Call 24 hours a day, 7 days a week

1-800-488-1222

To purchase orinquire about a Sears Maintenance Agreement:

Call 7 a.m. - 5 p.m. CST, Monday - Saturday

1-800-488-6655

r

HomeCentral

Loading...

Loading...