Craftsman 358799240 Owner’s Manual

IMPORTANT MANUAL

Operator' s

Manual

Model No.

Do Not Throw Away

358.799240-32cc

CE

_k WARNING:

Read the Operator's Manual and

Follow All Warnings and Safety

Instructions. Failure To Do So

Can Result in Serious Injury.

Always Wear Eye Protection

qS/CRRF MnN,o

32cc GAS WEEDWACKER

2 Cycle Engine

o Assembly

Fuel Mix 40:1

• Maintenance

• Operation

Sears, Roebuck and Co., Hoffman Estates, IL 60179 UoS.A.

530-082597-04/19/94 © 1994, Sears, Roebuck and Co,

• Repair Parts

_,m _,,_,"u-_" _ _, _. ,_ _. _,- ._,x_- ,,- ._ _- ,_ ,_,_, ,,. _ _, _- .t,:,! ,,- _ _,, _,- ._ x_,,_- ._ ,x_, ,,_ ,, _-, _,- ,_ ,_,- _-- ,_ x_.,:,- ,_ _ _- ,, _, _:, ._ ,_- _. ,, _, _, ,, _- :,- ,, ,,_, _, ,_ ,x -¸ ;_- ,, y.

ONE YEAR LIMITED WARRANTY ON CRAFTSMAN GAS-POWERED WEEDWACKER ® TRIMMER

For one year from the date of purchase, when this Craftsman Gas- Powered Weedwacker is maintained, lubricated, and tuned

up accordingto the operating and maintenance instructions in the operator's manual, Seres will repair, free of charge, any defect

in materials or workraanehip_

This warranty excludes nylon line, spark plug, and air filter, which are expendable parts and become worn during normal use

If this Weedw_ckar is used for commarcial purposes, this warranty applies for only 90 days from the date of purchase If the

Weedwacker is used for rental pmlposes, this warranty applies for only 30 days from date of purchase. This warranty applies

only while this product is in use in the United States. WARRANTY SERVICE IS AVAILABLE BYRETURNING THE WEEDWACKER

TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES

This warranty gives you specific legal rlghtB, and you may also have other rights which vary from state to state

SEARS, ROEBUCK AND CO. DEPT. 817WA HOFFMANESTATES, IL 60179

TABLE OF CONTENTS

WARNINGS AND SAFETY INSTRUCTIONS •.. 3

KNOW YOUR UNIT ............................. 5

ASSEMBLY .................................. 6

ACCESSORIES ............................. 7

OPERATION (Fueling Your Engine) ............ 8

OPERATION (Stai'ting Your Engine) ....

USING YOUR TRIMMER ...............

CUSTOMER RESPONSIBILITY- -

GENERAL MAINTENANCE ........

REPAIR PARTS LIST ........................ 19

.... • 9

.... 10

.... 14

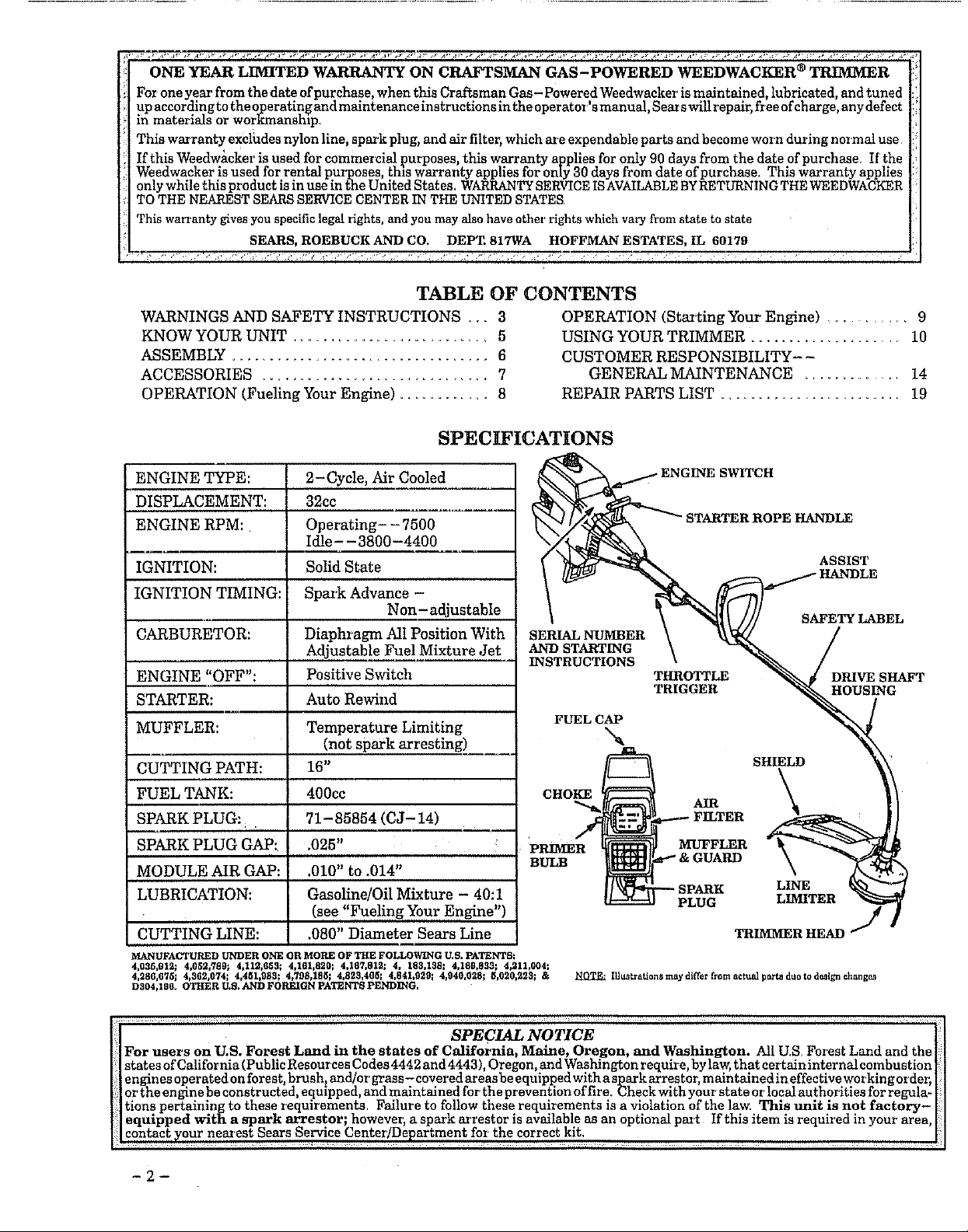

SPECIFICATIONS

ENGINE TYPE:

DISPLACEMENT:

ENGINE RPM:

IGNITION:

IGNITION TIMING:

2-Cycle, Air Cooled

32cc

Operating- - 7500

Idle- -3800-4400

Solid State

Spm'k Advance -

_ ENGINE SWITCH

_ _ STARTER ROPE HANDLE

_ _ ASSIST

o

Non-adiustable

CARBURETOR'.

ENGINE "OFF":

STARTER:

MUFFLER:

Diaphragm All Position With

Adiustable Fuel Mixture Jet

Positive Switch

Auto Rewind

Temperature Limiting

SERIAL NUMBER \ _ /

AND STARTING X _'_"'_ /

INSTRUCTIONS \ _ /

THROTTLE _ _ DRIVE SHAFT

TRIGGER "_"_OU SING

(not spark arresting)

CUTTING PATH:

FUEL TANK:

SPARK PLUG: .

SPARK PLUG GAP"

MODULE AIR GAP:

LUBRICATION:

CUTTING LINE:

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS_

4,035,S12_ 4,052.789_ 4,11S.653; 4,1SI,820_ 4.167.812; 4. 183.138_ 4.189.833_ 4,21L004_

4,286,675_ 4,3t_2,074; 4_451,I}8S; 4,798,18_; 4,823,4(1_I 4,84LB29; 4,940,028_ _,020,223; & _ IUun_ration_ may differ from actual parte duoto design ¢hango_

D304,198. OTHER U,S, AND FOREIGN pATENTS PENDING.

16"

400cc

71-85854 (CJ-14)

.025"

.010" to .014"

Gasoline/Oil Mixture - 40:1

(see "Fueling Your Engine")

.080" Diameter Sears Line

CHOKE \

, /

SPAR] LINE _'_:

PLUG LIMITER

SHIELD kii '

TRINfMER HEAD J

For users on U.S. Forest Land in the states of California, Maine, Oregon, and Washington. All U.S Farest Land and the

states of California (Public Resources Codes 4442 and 4443), Oregon, and Washington require, by law, that certain internal combustion

engines operated on forest, brush, and]or grass - covered areas be equipped with a spark arrestor, maintained in effective working order_

or the engine be constructed, equipped, and maintained for the prevention of fire. Check with your'state or local authorities for regula-

tions pertaining to these requirements. Failure to follow these requirements is a violation of the law. Thin unit is not factory-

equipped with a spark arrestor; however, a spark arrestar is available as an optional paz t If this item is required in your area,

contact _our nearest Sears Service Center/Department for the correct kit.

--2--

SPECIAL NOTICE

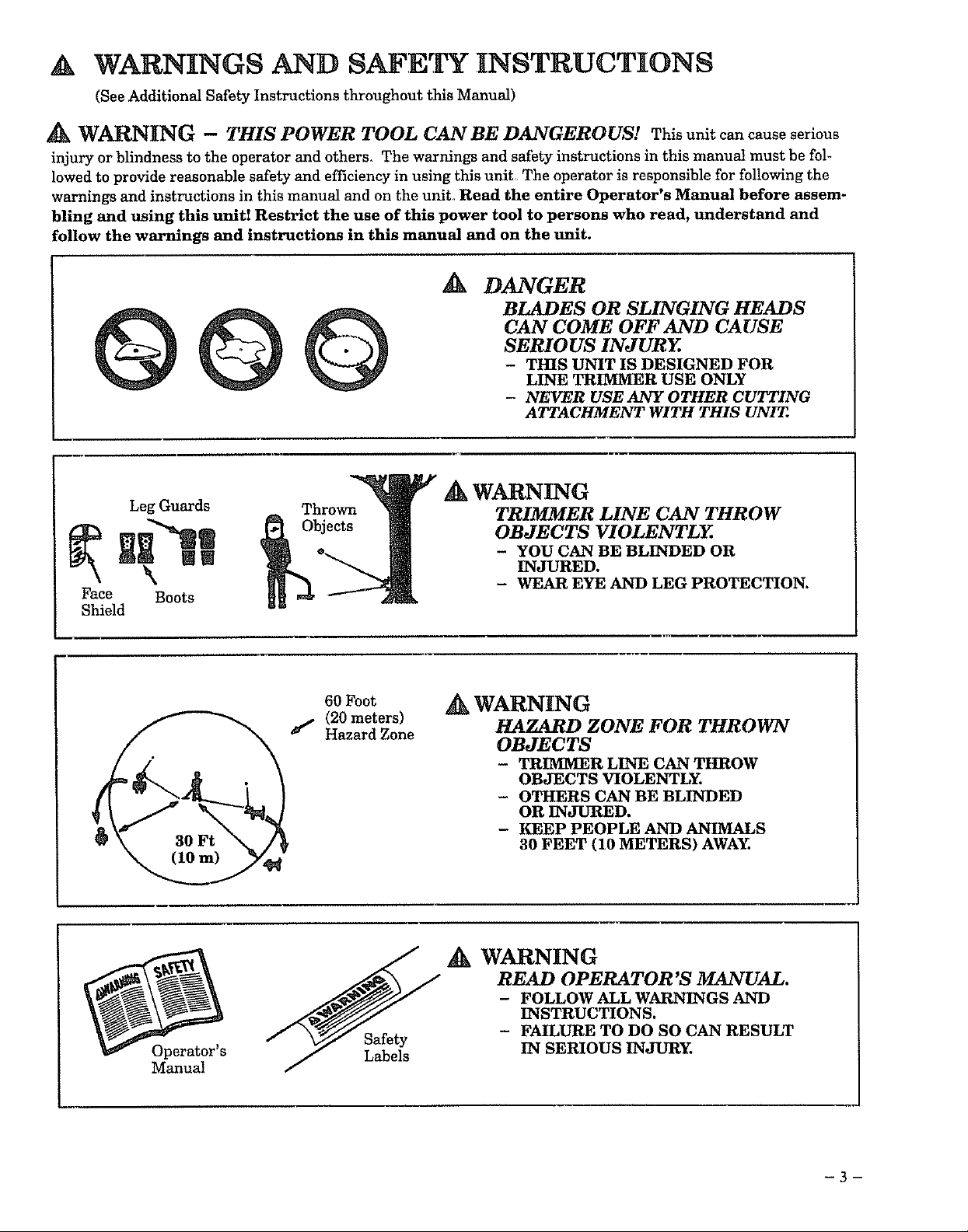

WARNINGS AND SAFETY INSTRUCTIONS

(See Additional Safety Instructions throughout this Manual)

Ak WARNING - THIS POWER TOOL CAN BE DANGEROUS! This unit can cause serious

injury or blindness to the operator and others, The warnings and safety instructions in this manual must be fol-

lowed to provide reasonable safety and efficiency in using this unit The operator is responsible for following the

warnings and instructions in this manual and on the unit. Read the entire Operator's Manual before assem-

bling and using this unit! Restrict the use of this power tool to persons who read, understand and

follow the warnings and instructions in this manual and on the unit.

,A

DANGER

BLADES OR SLINGING HEADS

CAN COME OFF AND CAUSE

SERIOUS INJURY.

000

i

- THIS UNIT IS DESIGNED FOR

LINE TRIMMER USE ONLY

- NEVER USE ANY OTHER CUTTING

ATTACHMENT WITH THIS UNIT.

Face

Shield

Leg Guards

!1

\

Boots

60 Foot

I" Hazard Zone

(20 meters)

_k WARNING

TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY.

- YOU CAN BE BLINDED OR

INJURED.

- WEAR EYE AND LEG PROTECTION.

Ak WARNING

HAZARD ZONE FOR THROWN

OBJECTS

- TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY.

- OTHERS CAN BE BLINDED

OR INJURED.

- KEEP PEOPLE AND ANIMALS

30 FEET (10 METERS) AWAY.

Operator's

Manual

Safety

Labels

WARNING

READ OPERATOR'S MANUAL.

- FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

- FAILURE TO DO SO CAN RESULT

IN SERIOUS INJURY.

-3-

WARNINGS AND SAFETY INSTRUCTIONS....(Contlnued)

OPERATOR SAFETY

• Always wear safety eye protection.

• Always wear long pmlts, long sleeves, boots and

gloves. Wearing safety leg guards is recom-

mended. Do not go barefoot or wear sandals, jew-

elry, shoi_ pants, short sleeves, loose clothing, or

clothing with loosely hanging ties, straps, tassels,

etc.; they can be caught in moving parts.

• Secure hair so it is above shoulder length

• Do not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medica-

tiom

• Wear hearing protection if you use this unit for

more than 1 - 1/2 hours per day.

• Never start or run the engine inside a closed room

or building. Breathing exhaust fumes can kill

• Keep handles free of oil and fuel.

UNIT/MAINTENANCE SAFETY

• Look for and replace damaged or loose parts be-

fore each use. Look for and repair fuel leaks before

use. Keep the unit in good working condition

Replace trimmer head parts that are chipped,

cracked, broken, or damage in any other way be-

fore using the unit.

Use only _080" diameter SEARS Line. Never use

wire, rope, string, etc.

• Make sure the unit is assembled correctly as listed

in this manual.

• Make carburetor adjustments with the lower end

supported to prevent the trimmer line from con-

tacting any object.

• Keep others away when making carburetor ad-

justments.

o Disconnect the spark plug before performing

maintenance except carburetor adjustments.

• Use only genuine SEARS accessories and replace-

ment parts as recommended for this unit.

A FUEL SAFETY

• Mix and pour fuel outdoors.

Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the

unit or while using the unit,

Wipe up all fuel spills before starting engine.

• Move at least 10 feet (3 meters) away from fueling

site before starting engine.

• Stop engine and allow the engine to cool before re-

moving fuel cap.

• Empty the fuel tank before storing the unit. Use

up fuel left in the carburetor by starting the en-

gine and letting the engine run until it stops.

° Store unit and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors ar switches, furnaces, etc.

CUTTING SAFETY

• Inspect the area to be cut before each use_ Remove

objects (rocks, broken glass, nails, wh'e, string,

etc) which can be thrown or become entangled in

the trimmer head.

• Keep others including childl'en, animals, bystand-

ers and helpers outside the 60 foot (20 meter) Haz-

ard Zone. Stop the engine immediately if you are

approached.

° Always keep the engine on the right-hand side of

your body.

Hold the unit firmly with both hands.

° Keep firm footing and balance Do not over-

reach.

• Keep the trimmer head below waist level

• Do not raise the engine above your waisL

• Keep all parts of your body away from trimmer

head and muffler when engine is running_

• Cut from your right to your left,

• Use only for jobs explained in this manual_

TRANSPORTING AND STORAGE

• Stop the unit before transporting.

• Keep the muffler away from your body_

• Allow the engine to cool, and secure the unit be-

fore storing or transporting in a vehicle_

o Empty the fuel tank before storing or transport-

ing the unit. Use up fuel left in the carburetor by

starting the engine and letting it run until it stops.

° Store unit and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motars or switches, furnaces, etc.

o Store unit so line limiter cannot accidentally

cause injury. The unit carl be hung by the bracket

below the engine or by the tube_

• Store the unit out of the reach of children.

If situations occur which are not covered in this manual, use care and good judgment.

If you need assistance, contact your SEARS Service Center/Department or the

CUSTOMER ASSISTANCE HOTLINE, 1-800-235-5878.

S ET NOTIC

H Exposure to vibrations through prolongeduse of gasaline powered hand tools could cause blood vessel or nerve

M damage in the fingers, hands, and wrists of people prone to circulation disorders or abnormal swellings. Pro-

|!!| longed use in cold weather has been linked to blood vessel damage in otherwise healthy people. If symptoms

H occur such as numbness, pain, loss of strength, change m skin calor or texture, or loss.of feeling in the fingers,

|_| handsorwrlsts, discontinuetheuseofthlstoalandseekmedicalattention. Anantl-wbratlonsystemdoesnot

_!] guarantee the avmdance of these problems. Users who operate power tools on a continual and regular basis

F_ m_t m0nitor €!0sely their physicS, c0ndition and the c0ndit!°n 0 f thin t0ol. .......

-4-

KNOW YOUR UNIT

A. INTRODUCTION

Your Trimmer is aversatile product developed for

large lawns and to make short work of a variety of DESCRIPTION QTY

lawn care tasks - - trimming, scalping, mowing, e Engine/Drive Shaft Assembly

and sweeping+ w/Safety Label 1

Special Features Include: e Engine Oil 1

® All-Position Carburetor o Operator's Manual 1

e Adjustable Assist Handle . Loose Parts Bag 1

e Semi-Automatic Cutting Head LOOSE PARTS BAG CONTENTS:

e 16" Cutting Path • Hex Wrench 1

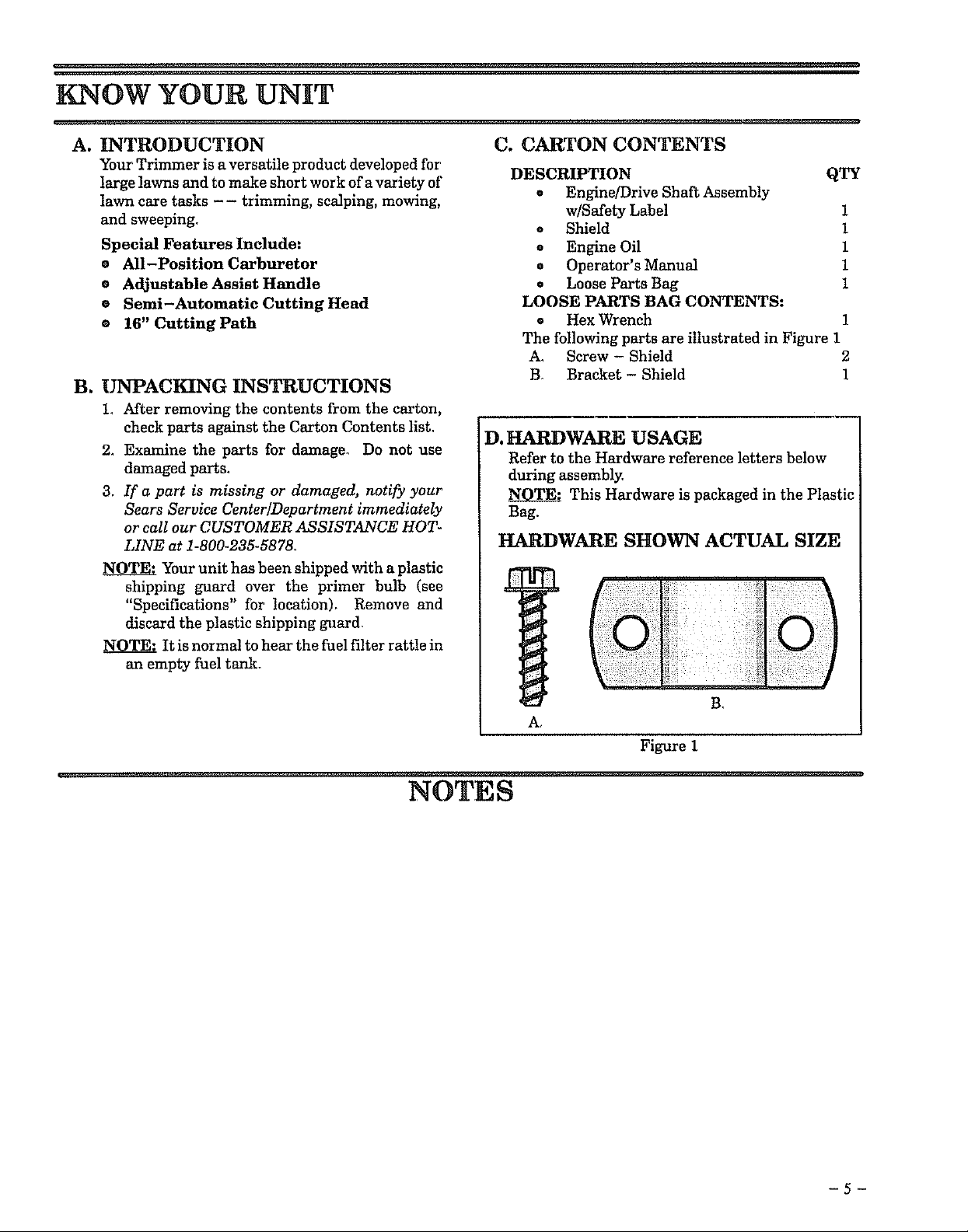

C. CARTON CONTENTS

e Shield 1

The following parts are illustrated in Figure 1

A. Screw - Shield 2

B+ Bracket - Shield 1

B. UNPACKING INSTRUCTIONS

1, After removing the contents from the carton,

check parts against the Carton Contents lisL

2_ Examine the parts for damage. Do not use

damaged parts,

3. If a part is missing or damaged, notify your

Sears Service Center/Department immediately

or call our CUSTOMER ASSISTANCE HOT-

LINE at 1-800-235-5878+

NOTE.' Your unit has been shipped with a plastic

shipping guard over the primer bulb (see

"Specifications" for location), Remove and

discard the plastic shipping guard,

N___O_T_AIt is normal to hear the fuel filter rattle in

an empty fuel tank+

D. HARDWARE USAGE

Refer to the Hardware reference letters below

during assembly.

This Hardware is packaged in the Plastic

Bag.

HARDWARE SHOWN ACTUAL SIZE

iiiili?iiYI?ifi!!fii!!!!+i

NOTES

B,

A,

Figure 1

ASSEMBLY

(If tool is received assembled, repeat all steps in this section to be sure assembly is correct and is ad-

justed for the operator.)

A. PREPARATION

This Operator's Manual is designed to help you as-

semble the tool and to provide its safe operation. It is

important thatTou read the entire manual to become

familiar with the tool before you begin assembly or

call our CUSTOMER ASSISTANCE HOTLINE at

1-800-235-5878.

B.ASSIST HANDLE

L Loosen the wing nut on the assist handle,

2.

Pivot the assist handle into place. Make sure the

assist handle is located between the throttle trig-

ger housing and the safety label on the tube Fig-

ure 2

3 Adjust the assist handle up or down the tube for

comfort.

4. Retighten the wing nut. Figure 2

C. SHIELD ATTACHMENT

The shmld must be properly installed. The I

shield provides partial protection from the riskl

of thrown objects to the operator and others and

is equipped with a hne limiter which cuts excess]

line to the proper length. J

A WARNING

Failure to install shield in the position shown in

the illustration can result in serious injury to

the operator. The length of the shmld must be

aligned with the length of the tube. Direct wid-

est part of shield toward engine.

CAUTION: The line limiter (on the underside

of the shield) is sharp and can cut you.

• Match key (raised area) on the shield with the

"V" slot on the tube. Figure 3.

Rest the bottom of the shield on top of the

shoulder (not on the dust cup) of the tube.

_LO_T_: The bottom of shield must rest on top of

the shoulder of the tube and not on dust cup.

• Install bracket "B." and screws "A?' as shown

in Figure 3 •

1, Read your Operator's Manual

2. Tools you will need:

- Adjustable Wrench

- Standard Screwdriver

Throttle Trigger

Safety

Label

Pivot Assist

Handle Into Place

NOTE: Although a screwdriver slot is provided in

screws "A/', it is easier to install the screws

with a wrench or socket_

• Tighten the screws evenly and securely.

_LO_T_: It is possible that a small space will be left

between the bracket and the shield when the

screws are fully tightened.

Wi:_s:PartofShieldToward _ _Braekst B

_andle

II SerewsA

"V" Slot _/"

Figure 3

-6-

NOTES

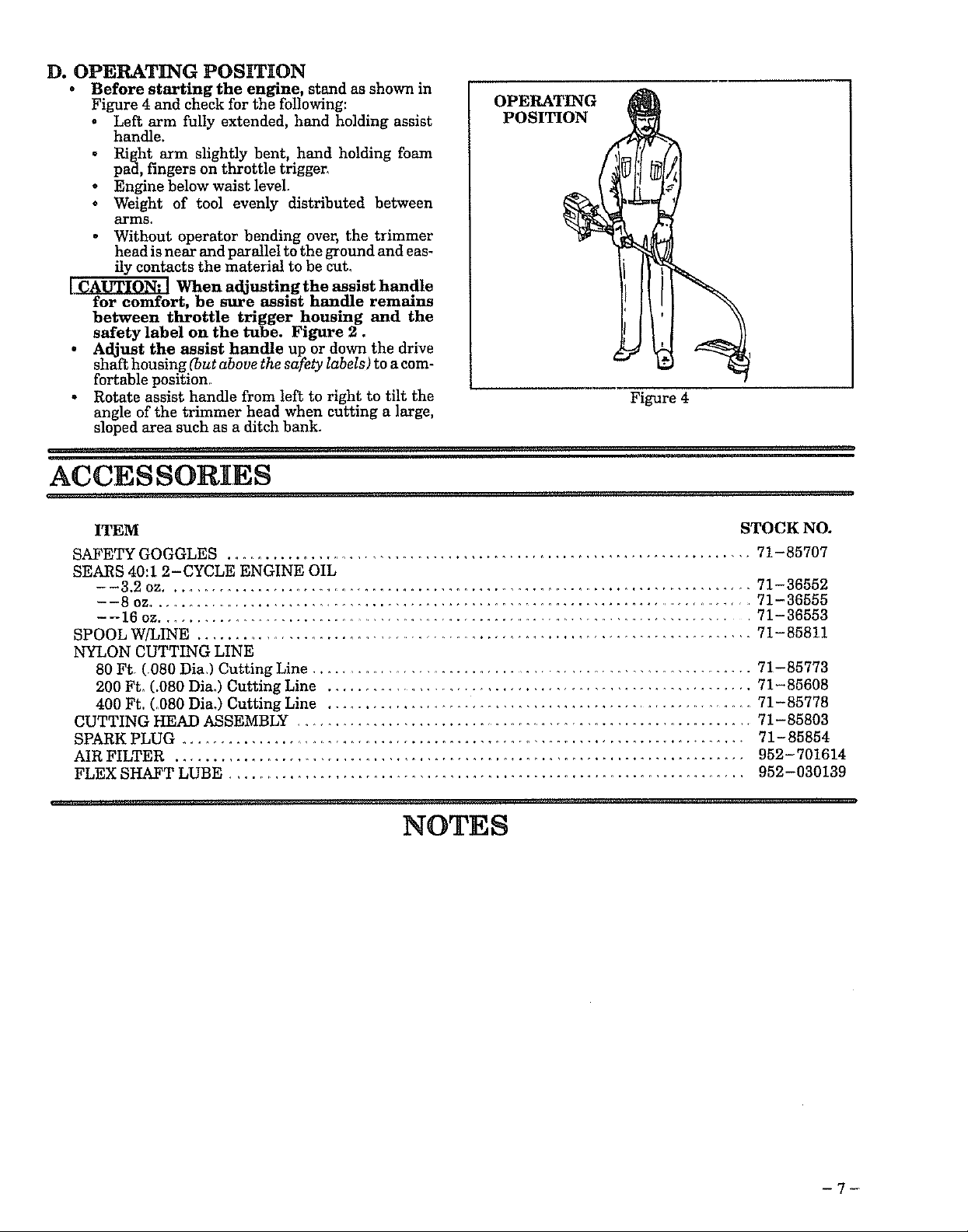

D. OPERATING POSITION

• Before starting the engine, stand as shown in

Figure 4 and check for the following:

• Left arm fully extended, hand holding assist

handle.

Right arm slightly bent, hand holding foam

pad, fingers on throttle triggen

• Engine below waist level.

o Weight of tool evenly distributed between

arms.

• Without operator bending over, the trimmer

head is near and parallel to the ground and eas-

ily contacts the material to be cut.

[ CAUTION: I When adjusting the assist handle

for comfort, be sure assist handle remains

between throttle trigger housing and the

safety label on the tube. Figure 2.

• Adjust the assist handle up or down the drive

shaft housing (but above the safety labels) to a com-

fortable position

, Rotate assist handle from left to right to tilt the

angle of the trimmer head when cutting a large,

sloped area such as a ditch bank.

ACCESSORIES

OPERATING

POSITION

Figure 4

ITEM STOCK NO.

SAFETY GOGGLES ...................................................................... 71-85707

SEARS 40:1 2-CYCLE ENGINE OIL

--3.2 oz ............................................................................... 71-36552

--8 oz................................................................................... 71-36555

- -16 oz ................................................................................. 71-36553

SPOOL W/LINE ............................................................................ 71-85811

NYLON CUTTING LINE

80 Ft, (,080 Dia,) Cutting Line ........................................................... 71-85773

200 Ft, (.080 Dia.) Cutting Line ........................................................ 71-85608

400 Ft. (.080 Dia,) Cutting Line ......................................................... 71-85778

CUTTING HEAD ASSEMBLY ............................................................. 71-85803

SPARK PLUG ........................................................................... 71-85854

AIR FILTER ........................................................................... 952- 701614

FLEX SHAFT LUBE .................................................................... 952-030139

NOTES

-7-

OPERATION

BEFORE STARTING ENGINE: 2-CYCLE OIL:

WARNING

BE SURE TO READ THE FUEL SAFETY

INFORMATION IN THE WARNINGS

AND SAFETY INSTRUCTIONS SEC-

TION ON PAGE 4 OF THIS MANUAL

BEFORE YOU BEGIN.

IF YOU DO NOT UNDERSTAND THE

FUEL SAFETY SECTION DO NOT AT-

TEMPT TO FUEL YOUR UNIT;, SEEK

HELP FROM SOMEONE THAT DOES

UNDERSTAND THE FUEL SAFETY

SECTION OR CALL THE CUSTOMER

ASSISTANCE HOTLINE AT

1-800-235-5878.

GASOLINE

The two-cycle engine on this product requires a fuel mix-

ture of regular unleaded gasoline and a high quality en-

gine off for lubrication of the bearings and other moving

parts. The correct fue!!oil mixtureis 40:1 (see FuelMix-

furs Chart). Too little oil or the incon'ect oil type _ll

cause poor performance and may cause the engine to over-

heat and seize.

CRAFTSMAN 40:1 2 cycle off is strongly recommended.

This oil is specially blended with fuel stabilizers for

increased fuel stability (extends fuel life up to 5 times

longer) and reduced smoke.

If CRAFTSMAN 2 cycle oil is not available, use a good

quality 2 cycle AIR-COOLED engine oil that has a

recommended fuel mix ratio of 40:l.

IMPORTANTI Do not use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA. etc.)

These oils do not have proper additives for 2-cycle,

AIR-COOLED engines and can cause engine damage.

GASOLINE AND OIL MIXTURE

Mix gasoline and oil as follows:

° Consult chart for correct quantities.

Gasoline and oil must be premixed in a clean approved fuel

container. Always use fresh regular unleaded gasoline.

IMPORTANt. Experience indicates that alcohol

blended fuels called gasohol (or using ethanol or metha-

nol) can attract moisture, which leads to oil]gas separa-

tion and formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage. To

avoid engine problems, the fuel system should be emptied

before storage for 30 days or longer° Drain the gas tank,

then run the fuel out of the carburetor and fuel lines by

starting the engine and letting it run until it stops. Use

fresh fuel next season. See STORAGE instructions for

additional information. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage

may occur.

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Add

stabRizer to gasoline in fuel tank or storage container.

Always follow the fuel mix ratio found on the stabilizer

container. Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the carburetor.

You do not have to drain the fuel tank for storage ifyan are

using fuel stabilizer.

CRAFTSMAN 40:1 2 cycle engine oil is speciany blended

with fuel stabi_ers. If you do not use this Sears off, you

can add a fuel stabilizer (such as Craftsman No. 33500) to

your fuel tank.

• Do not mix gasoline and oil directly in the fuel tank.

FOR ONE GALLON:

• Pour 3.2 ounces of high quality, 2-cycle engine oil

into an empty, approved one gallon gasoline con-

tainer.

• Add one gallon of regular unleaded gasoline to the

gallon container, then securely replace the cap_

Shake the container momentarily.

• The mixture is now ready for use. Fuel stabilizer

can be added at this time if desired; follow mixing

instructions on the label,

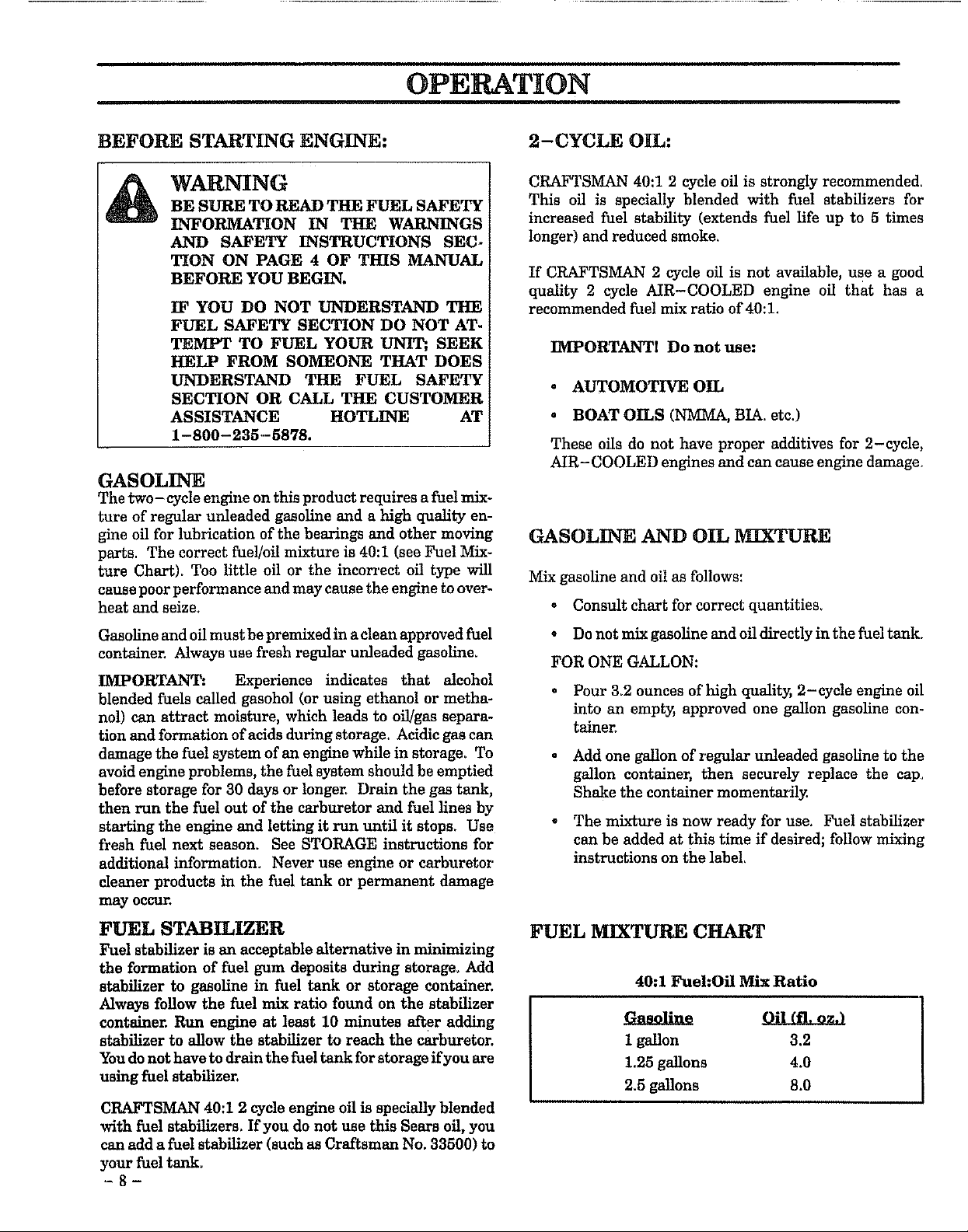

FUEL MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

1 gallon 3.2

1.25 gallons 4.0

2.5 gallons 8.0

Loading...

Loading...