Craftsman 358799211 Owner’s Manual

IMPORTANT MANUAL

8E_A/_S

Operator's

Manual

Model No.

358.799211

Do Not Throw Away

Always Wear Eye Protection

8E/_,_8/C RI:1FT$MI:1N_o

21cc GAS WEEDWACKER

_k WARNING:

Read the Operator's Manual and

FollowAH Warnings and Safety

Instructions. Failure To Do So

Can Result in Serious Inju_.

. Sears, Roebuck and Co,, Hoffman Estates, IL 60179 USA

530--082430-05/24/94 © 1994, Sears, Roebuck and Co.

2 Cycle Engine

* Assembly

e Operation

Fuel Mix 40:1

• Maintenance

• Repair Parts

i ii ii i i , ii ,,i, ,,i,i1,,,111111ii , • . _ _ i _

[ i ,,,, , , ,,,,,,,

up_ tlmo_rati_a_d_instruct_intlmapera_r'a mam_ Searsw'-lIx_ _ eamrg_any_ec_

in _ or worxmansmp [;_1

This warrantye=ludes the blade, nylon lizze,sparklxlua andairf_e_; wh_h areexpenda_ _rts andbe_on_ worndur_

uorm_use _

w_r_s_c_ _ Av_"_ _ _G _ _SswAC_ ro_ _-_r_s___ H

TABLE OF CONTENTS

WARNINGS AND SAFETY INSTRUCTIONS ... 3

KNOW YOUR UNIT .......................... 5

ASSEMBLY .................................. 6

OPERATION -- Fueling Your Engine .......... 9

STARTING YOUR ENGINE ................... 10

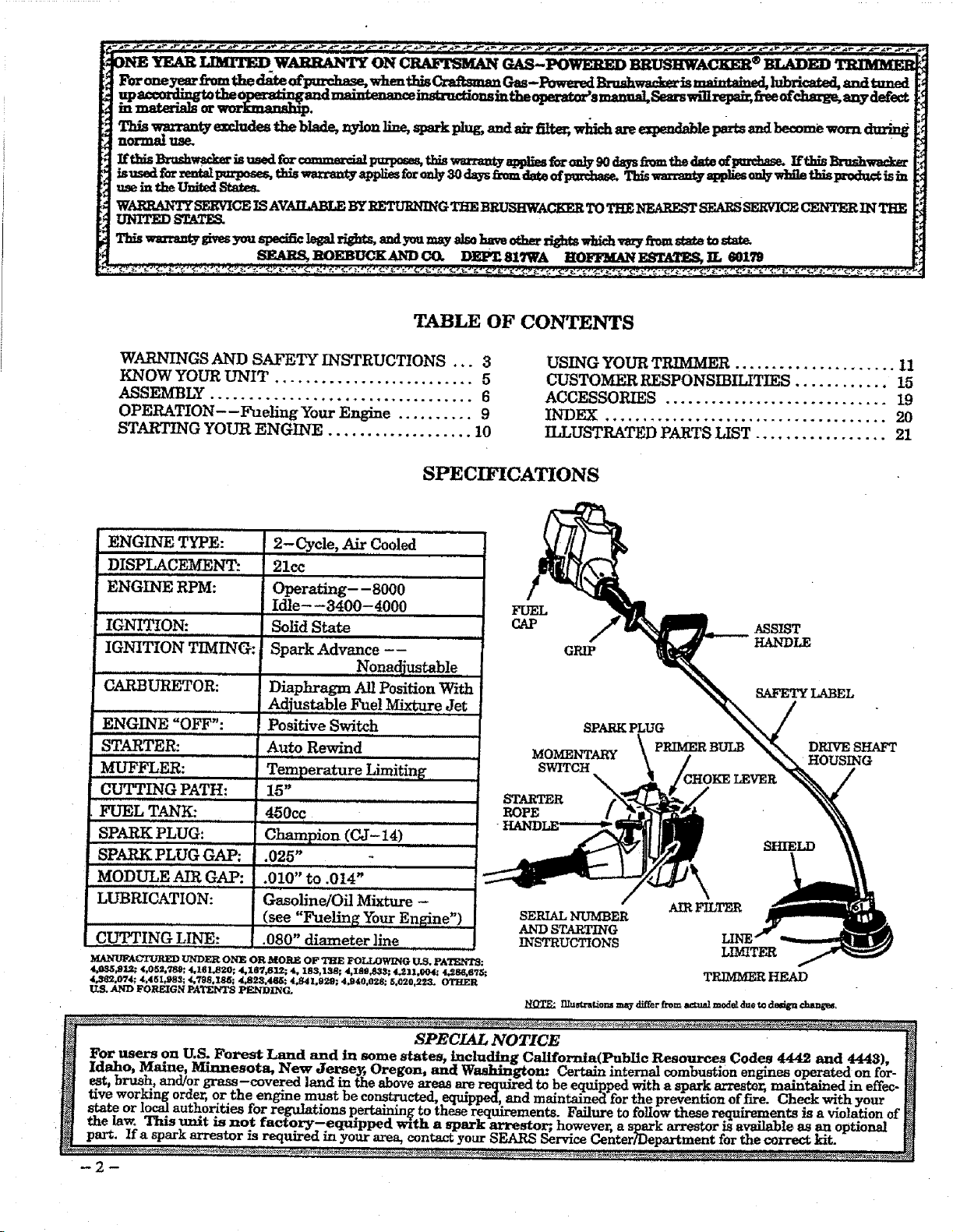

SPECIFICATIONS

ENGINE TYPE:

DISPLACEMENT:

ENGINE RPM:

i,,,,, ,,, , ,

IGNITION:

IGNITION TIMING:

CARBURETOR:

,,,, ,,,,, ,

ENGINE "OFF":

STARTER:

UF LER:

CUTTING PATH:

FUEL TANK:

i ,,,,,,,,,,,,,,,i

SPARK PLUG:

SPARK PLUG GAP:

, ,,,, ,,, ,, ,,

MODULE AIRGAP:

LUBRICATION:

CUTTING LI_:

MANUFACTURED UNDER O_E OR MOREOF T_E _O_OW_O US. PATE_rrS_

_S.AND FOREIGN PATENTS PENDING.

!21cc

Operating---8000

SolidState

Spark Advance --

Nonadjustable ,

Diaphragm All Position With

Adjustable Fuel _e Jet

Positive Switch

Auto Rewind

Temperature Limiting

15"

,,_0cc

Champion (CJ' 14)

.025"

.01o" to:'0'i4"

Gasoline/OilMixture-

(see "Fuelin GYour Engine')

.080" diameter line

USING YOUR TRIMMER ..................... 11

CUSTOMER RESPONSIBILITIES ............ 15

ACCESSORIES ............................. 19

INDEX ..................................... 20

ILLUSTRATED PARTS LIST ................. 21

FUEL

CAP

ASSIST

HANDLE

SAFETY LABEL

SPARK PLUG

DRIVESHAFT

HOUSING

SWITCH _'_

STARTER

ROPE

SHIELD

SERIALNUMBER

AND STARTING

INSTRUCTIONS

]]luvixatio_may differfrom a_tml model due to d_n _.

AIRFILTER

LIMITE_

TRIMMER HEAD

_j SPECIAL NOTICE

For users on U.S. Forest Land and in some states, tncludf:ug Califor_ia(PubHc Resources Codes 4442 and 4443),

_] Idaho, Maine, Minnesota, New Je ._e_ Oregon, and Washingtom Certain. internal combustion engines operated.on for-

|_ _ brush, and/or grass-covered land m the above areas _ required to be equip _pgdw_th a spark arresto_ maintained m etlec- [_

tire working order, or the engine must be constructed,.eqmppe_ and maintaine_ for the prevention of fire. Check vnth your . _]

[_ stateorlocalauthoritiesforregulationspertalnin_totheserequirements.Failuretofollowthesere_tiremer_tsisa violationof

the law. This unit isnot factory--equipped w_th a spark arrestor;,however,a sparkarrestorisavailableas_ optional

part. If a spark arrestor is required in your area, contact your SEAR_ Service Center/Department for the correct kit.

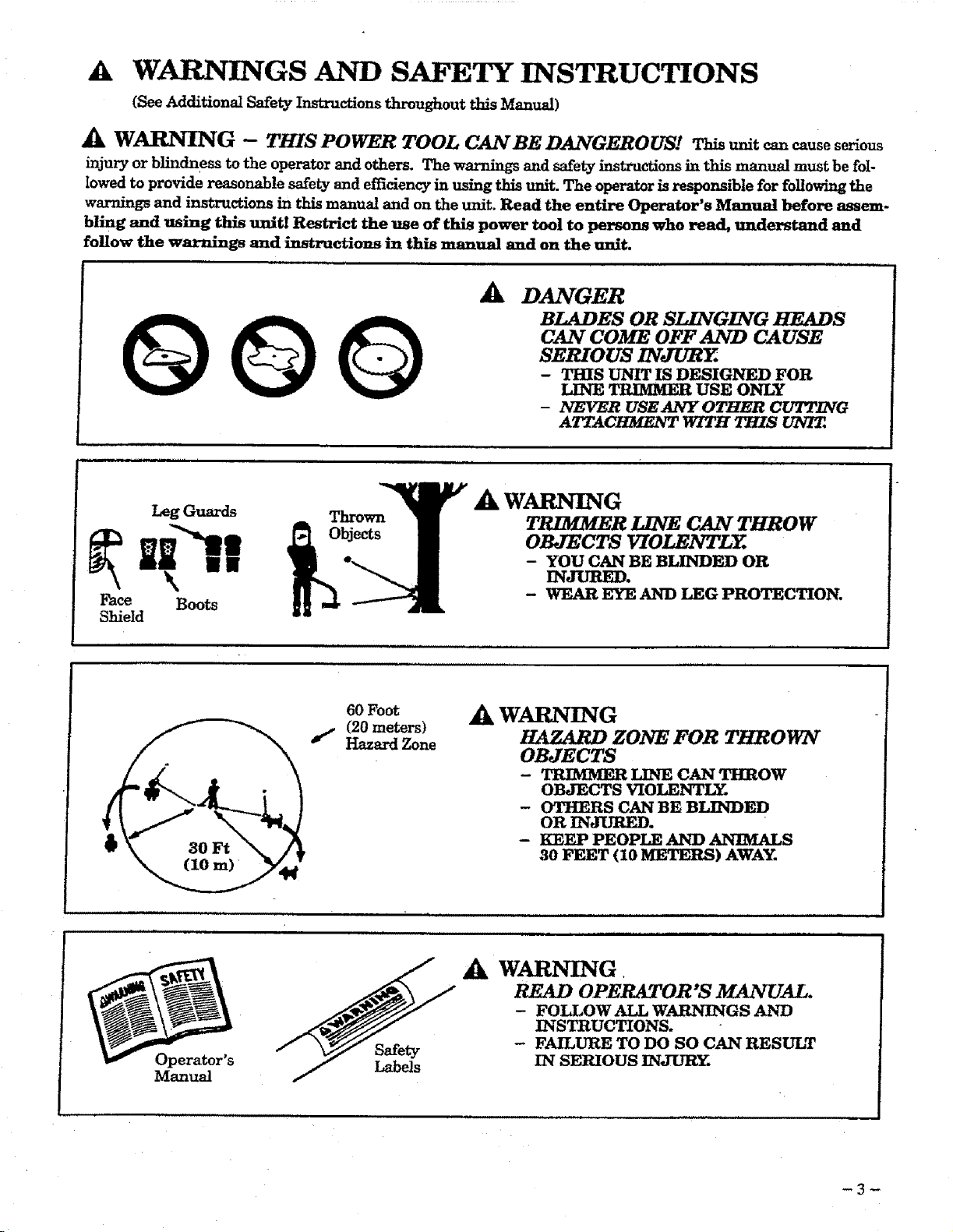

A WARNINGS AND SAFETY INSTRUCTIONS

(See Adch'tional Safety Instructions throughout this Manual)

WARNING - THIS POWER TOOL CANBE DANGEROUS! This unit can cause serious

injury or blindness to the operator and others. The warnings and safety instructious in this manual must be fol-

lowed to provide reasonable s_'ety and efficiency in using this unit. The operator is responsible for following the

warnings and instructions in this manual and on the unit. Read the entire Operator's Manual before assem-

bling and using this unit! Restrict the use of this power tool to persons who read, understand and

follow the warnings and instructions in this manual and on the unit.

A

DANGER

BLADES OR SLINGING HEADS

CAN COME OFF AND CAUSE

SERIOUS INJURY.

QOQ

- THIS UNIT IS DESIGNED FOR

LINE TRIMMER USE ONLY

- NEVER USEANY OTHER CUTTING

ATTACItME_T WITH THIS UNIT,

L_gG_d_ _ Thro A

• d Boots - WEAR EYE AND LEG PROTECTION.

'_ - YOU CAN BE BLINDED OR

60 Foot

(20 meters)

t/ Hazard Zone

W.AA_qNG

OBJECTS VIO_NTLY.

INJURED.

_k WARNING

HAZARD ZONE FOR THROWN

OBJECTS

- TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY.

- OTHERS CAN BE BLINDED

OR INJURED,

- KEEP PEOPLE AND ANIMALS

30 FEET (10 METERS) AWAY.

Operator's

Manual

Safety

Labels

_k WARNING

READ OPERATOR'S MA_vTJAL.

- FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

- FAILURE TO DO SO CAN RESULT

IN SERIOUS INJUR_

-3-

WARNINGS AND SAFETY INSTRUCTIONS....(Continued)

A OPERATOR SAFETY

• Always wear safety eye protection.

• Always wear long pants, Iong sleeves, boots and

gloves. Wearing safety leg guards is recom-

mended. Do not go barefoot or wear sandals, jew-

ehT, short pants, short sleeves, loose clothing, or

clothing with loosely hanging ties, straps, tassels,

etc.; they can be caught in moving parts.

•. Secure hair so it is above shoulder length.

• Do not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medica-

tion.

• Wear hearing protection if"you use this unit for

more than 1-1/2 hours per day.

• Never start or run the engine inside a closed room

or building.BreathingexhaustRnnes can kill.

• Keep handlesfreeofelland fuel.

A UNIT/MAINTENANCE SAFETY

* Look forand replacedamaged or looseparts be-

foreeachuse.Look forand repairfad leaks before

use.Keep the unitingood working condition_

• Replacetrimmer head parts that are chipped,

cracked,broken,ordamage in any otherway be-

foreusingthe unit.

* Use only SEARS .08,0" diameter line. Never use

wire, rope, string, etc.

• Make sure the unit is assembled correctly as listed

in this manual.

• M_e carburetoradjustmentswith thelower end

supportedtopreventthe trimmer linefrom con-

tactinganyobject.

• Keep othersaway when making carburetorad-

justments.

• Disconnect the spark plug before performing

maintenanceexceptcarburetoradjustments.

• Use onlygenuineSEARS accessories and replace-

ment parts as recommended for this unit.

A FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames:

• Use a containerapproved forfuel.

• Do not smoke or allowsmoking near fuelor the

unitor whileusingtheunit.

• Wipe up allfuelspillsbeforestextingengine.

• Move atleastI0 feet(3meters)away fromfueling

sitebeforestartingengine.

• Stop engineand allowunittocoolbeforeremov-

ingfuelcap.

• Empty thefueltankbeforestoringtheunit.Use

up fuelleftinthecarburetorby startingtheen-

gineand lettingtheenginerun untilitstops.

• Store unit and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, fiLrnaces, etc.

A CUTTING SAFETY

• Inspect the area to be cut before each usc. Remove

objects (rocks, broken glass, nails, wire, string,

etc.) which can be thrown or become entangled in

the trimmer head.

• Keep others including children, animals, bystand-

ers and helpers outside the 60 foot (20 meter) Haz-

ard Zone. Stop the engine immediately if you are

approached.

• Always keep the engine on the fight-hand side of

your body.

• Hold theunit firmly with beth hands.

• Keep firm footingand balance.Do not over-

reach.

• Keep thetrimmer head belowwaistlevel.

° Do notraisethe engineaboveyour waist.

• Keep allpartsofyour body away from trimmer

headand mufflerwhen engineisrunning.

• Cut from your right to your left.

• Use only for jobs explained in this manual.

A TRANSPORTING AND STORAGE

• Stop the unit before carrying.

° Keep the muffler away from your body.

* Allow the engineto cool,and securetheunitbe-

forestoringortransportingina vehicle.

* Empty the fueltank beforestoringortransport.

ingtheunit.Use up fuelleftinthecarburetorby

startingtheengineand lettingtheenginerun un-

tilitstops.

• Store unit and fuel in an area where fuel vapors

cannotreach sparks or open flamesfrom water

heaters, electric motors or switches, furnaces, etc.

• Stere unit so line limitercannot accidentally

cause injury. The unit can be hung by the bracket

below the engine or by drive shaft housing.

• Store the unit out of the reach of children.

If situations occur which are not covered in this manual, use care and goodjudgment.

[/'you need assistance, contact your Authorized Service Dealer or the

CUSTOMER ASSISTANCE HOTLtNE, 1-800-235-5878.

SAFETY NOTICE

Exposure t.o.vibrati_nsthr_ughpr_.ngeduse_fgas_inep_eredhandto_sc_u_dcauseb_dvesse_rnerve [_

aama_e m erie tzngers,_hands, and wr_s.ts of people prone to circulation disorders or abnormal swe_gs. Pro- [_

,ongect us$ m cola wea[ner has t_een_llnked to blood vessel damage in otherwise healthy people. If symptoms [_i

_su?n .as numbness, pare: loss of _s_. ngth, change m s k_. color or texture, or loss of feelingln the fingers, [_

arias or wrts_s, axe. onrmue .r_e use o_ _ tool and seek medical attention. An anti-vibration system does not [_

guarflnree..r_eavo,aa_tceo_ r_ese prot)tems.. Users who opex_tte power tools on a continual and regular basis [_

m_ member ctosety their pnystcat con_tion and the condition of this tooL _]

-4-

III I I I IIII I • I I I I ,,I,l_llllll,l,iiIIIII I _ • | | I I II I I' [ II | i I IIII

I I I I IIII II IIII II IIIIIIIIIIII IIIIIIHI

KNOW YOUR UNIT

fill IIII I I I I I

A. C. CARTON CONTENTS

INTRODUCTION

Your Trimmer is a versatile product developed for

large lawns and to make short work era variety of

lawn care tasks -- trimming, scalping, mowing,

and sweeping.

Special Features Include:

• 15" Cutting Path

• Semi-Automatic Trimmer Head

• Adjustable Assist Handle

• 2lee Engine

B. UNPACKING INSTRUCTIONS

L After removing the contents from the car_n,

check parts against the Carton Contents list.

2. Examine the parts for damage. Do not use

damagedparts.

3. NetifyyourSEARSStoreimmediatelyifapart

is missing or damaged.

Your unit has been shipped with a plastic

shipping guard over the primer bulb (see

"Specifications" for location). Remove and

discardthe plastic shipping guarcL

It is normal to hear the fue! falter rattlein

an empty fuel tank.

i i i iii iiiiii i iiii ii | i

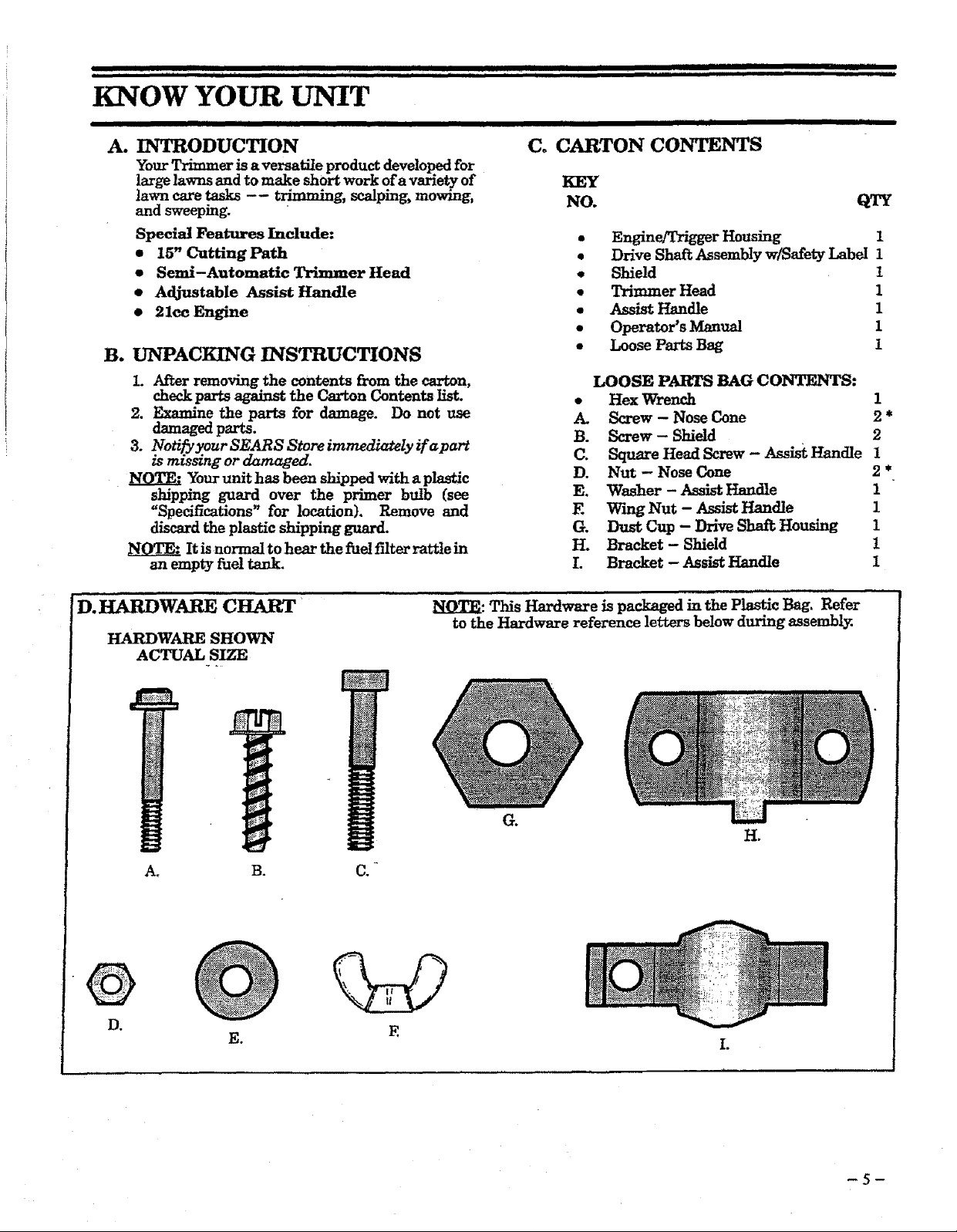

KEY

NO. QTY

• Engine/Trigger Housing 1

• Drive Shai_ Assembly w/Safety Label 1

• Shield 1

• Trimmer Head 1

• Assist Handle 1

• Operator's Manual I

• Loose PartsBag i

LOOSE PARTS BAG CONTENTS:

Hex Wrench 1

Screw - Nose Cone 2 *

B.

Screw - Shield 2

C.

Square Head Screw - Assist Handle 1

D.

Nut - Nose Cone 2 *

E.

Washer - AssistHandle 1

E

W'mg Nut - AssistHandle 1

G.

Dust Cup - DriveShaftHousing i

H.

Bracket - Shield !

I.

Bracket - Assist Handle 1

D. HAP_DWARE CHART

HARDWARE SHOWN

ACTUAL SIZE

A. B. C.

D. E. E

]XOL]_: This Hardware is packaged in the Plastic ]_g. Refer

to the Hardware reference letters below during assembly.

G.

H,

I°

-5-

ASSEMBLY

(If tool is received assembled, repeat all steps in this section to be sure assembly is correct and is ad-

justed for the operator.)

A. PREPARATION

This Oparator's Manual is designed to help you as-

semble the tool and to provide its safe operation. It is

important that you read the entire manual to become

familiarwith the toolbe/oreyou beginassembly.If

you have any _estions or need _er assistance,

callour CUSTOMER ASSISTANCE HOTLINE at

1-800-235-5878.

Hardware referred to in the following sections

is shown actual size in the Hardware Chart, page 5.

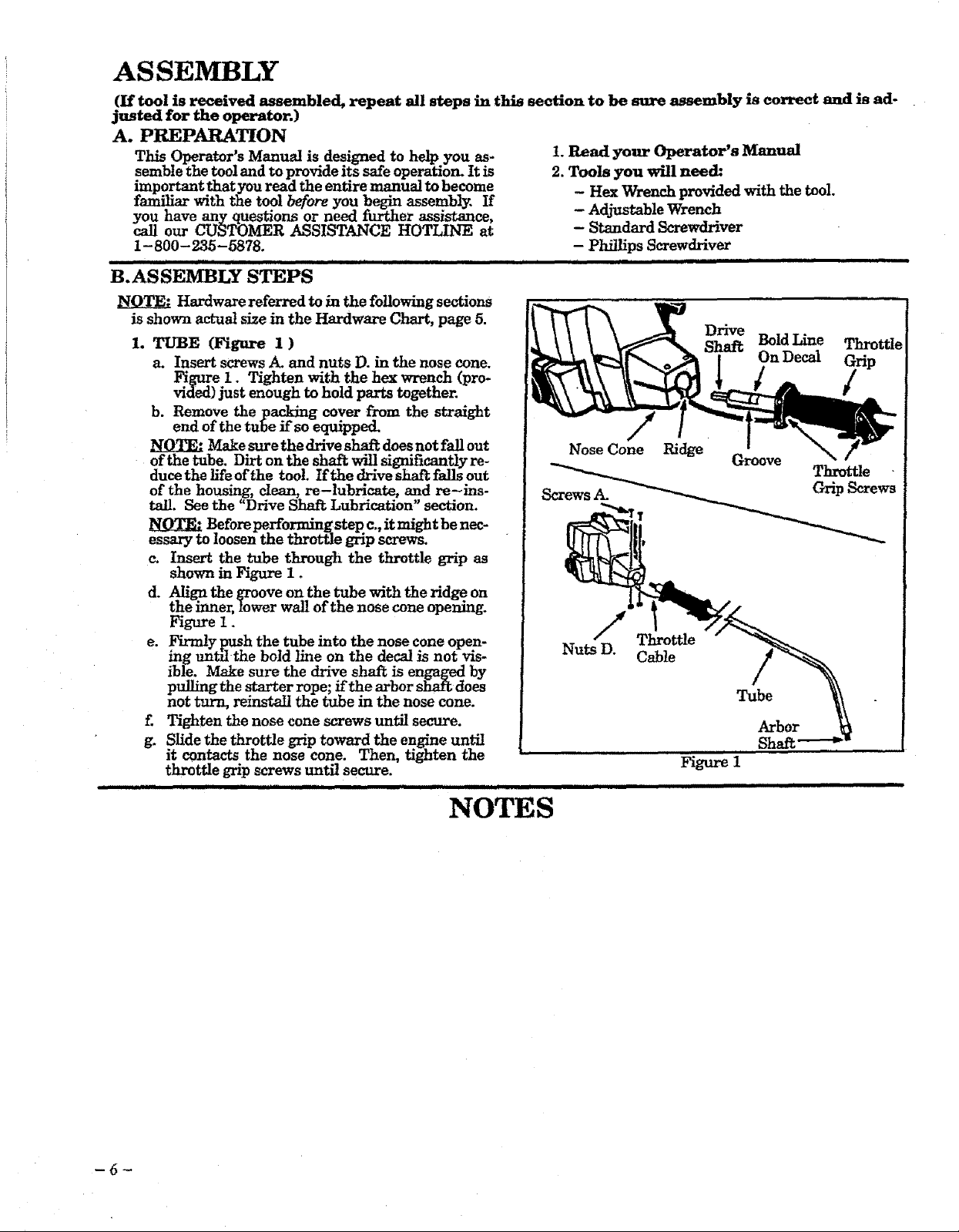

I. TUBE (Figure 1 )

a. InsextscrewsA. and nuts D. inthe nosecone.

Figurei. Tightenwith the hex wrench (pro-

vided)justenough to held partstogether.

b. Remove thepacking coverfrom the straight

end of the tube if so equipped.

Make sure the drive shaft does not fall out

of the tube. Dirt on the shaft will significantly re-

duce the life of the tool. If the drive sha_ falls out

ofthe hous_ dean, re-lubricate,and re-ins-

tal!.See the Drive ShaftLuhricatlon" section.

Before performingstep c., it might be nec-

essary to loosen the throttle grip screws.

c. Insert the tube through the throttle grip as

shown in Figure 1.

d. Align the groove on the tube with the ridge on

the inner, lower wall of the nose cone opening.

Figure 1.

e. Firmly push the tube into the nose cone open-

ing until the bold Rue on the decal is not vis-

ible. Make sure the drive shaft is eng_ed by

pulling the starter rope; if the arbor shaft does

not turn, reinstall the tube in the nose cone.

fi Tighten the nose cone screws until secure.

g. Slide the throttle grip toward the engine until

it contacts the nose cone. Then, tighten the

throttle grip screws until secure.

,,,,,,,,,,,,,.,,,,, i ,,,,,,.,,

1.Read your Operator's Manual

2.Tools you willneed:

- Hex Wrench providedwiththetool.

- AdjustableWrench

- Standard Screwdriver

- PhillipsScrewdriver

Nose Cone Ridge

Throttle

Nuts D. Cable

Figure i

Drive

Shaft

Groove

i l ii

BoldLine

On Decal

Tube

Arbor

ShafL----_

Throttle

Grip

/

-6-

NOTES

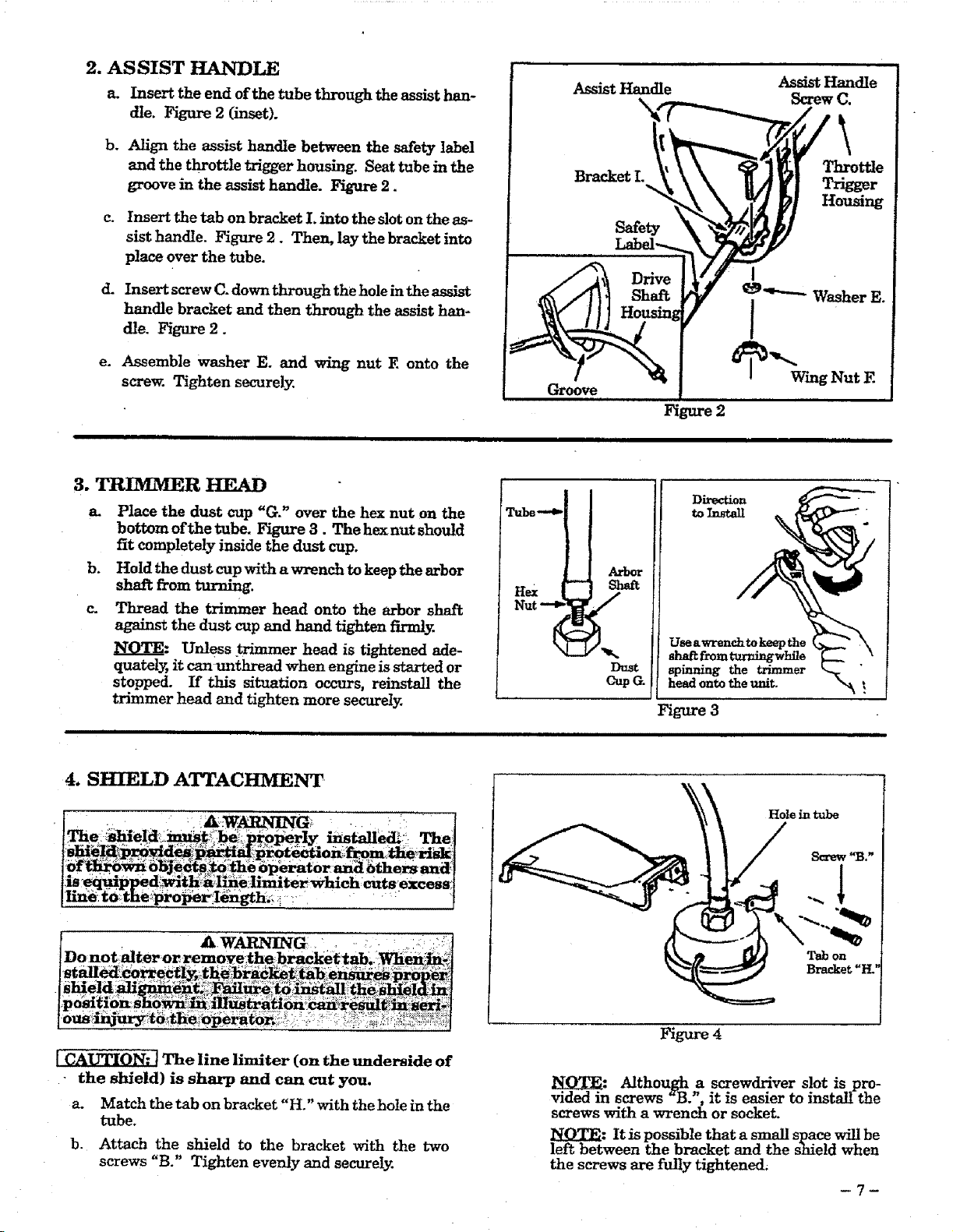

2. ASSIST HANDLE

w Insert the end of the tube through the assist han-

dle. Figure 2 (inset).

b. Align the v.ssist handle between the safety label

and the throttle trigger housing. Seat tube in the

groove in the assist handle. Figure 2.

Co

Insert the tab on bracket I. into the slot on the as-

sist handle. Figure 2. Then, lay the bracket into

place over the tube.

d_

Insert screw C. down through the hole in the assist

handle bracket and then through the assist han-

dle. Figure 2.

e. Assemble washer E. and wing nut E onto the

screw. Tighten securely.

Assist Handle

Handle

Screw C.

Figure 2

3. 'rRI313_R HEAD

v. Placethe dust cup "G._ over the hex nut on the

bottom ofthetube.Figure 3. The hexnutshould

fitcompletelyinsidethe dust cup.

b. Hold thedust cup withawrench tokeepthearbor

shaftfrom turning.

c. Thread the trimmer head onto the arbor shaft

againstthe dust cup and hand tightenfirmly_

NOTE: Unless trimmer head istightenedade-

quately,itcan:unthreadwhen engineisstartedor

stopped. Ifthissituationoccurs,reinstallthe

trimmer head and tightenmore securely.

4. SHIELD ATTACHMENT

tisequipped_tk a_b!l_ter which cutsexcess_ I

[Iinb: t°: thei_proP_'iIeng th_:: !,: ': I

H-- i

Nut --'P

Dust

CupG.

Direction

toI_t_1

Use awrenchto k_p the

shaftfrommmingwhile

spinning the trimmer

headonto the unit.

Figure 3

Hole m tube

[ CAUTION: IThe line limlter (on the underside of

the shield) is sharp and can cut you.

a. Match the tab on bracket "H." with the hole in the

tube.

b. Attach the shield to the bracket with the two

screws "B." Tighten evenly and securely.

Figure 4

NOTE: Although a screwdriver slot is pro-

vided in screws "B. ", it is easier to install the

screws with a wrench or socket.

NOTE: It is possible that a small space will be

left between the bracket and the shield when

the screws are fi_y tightened.

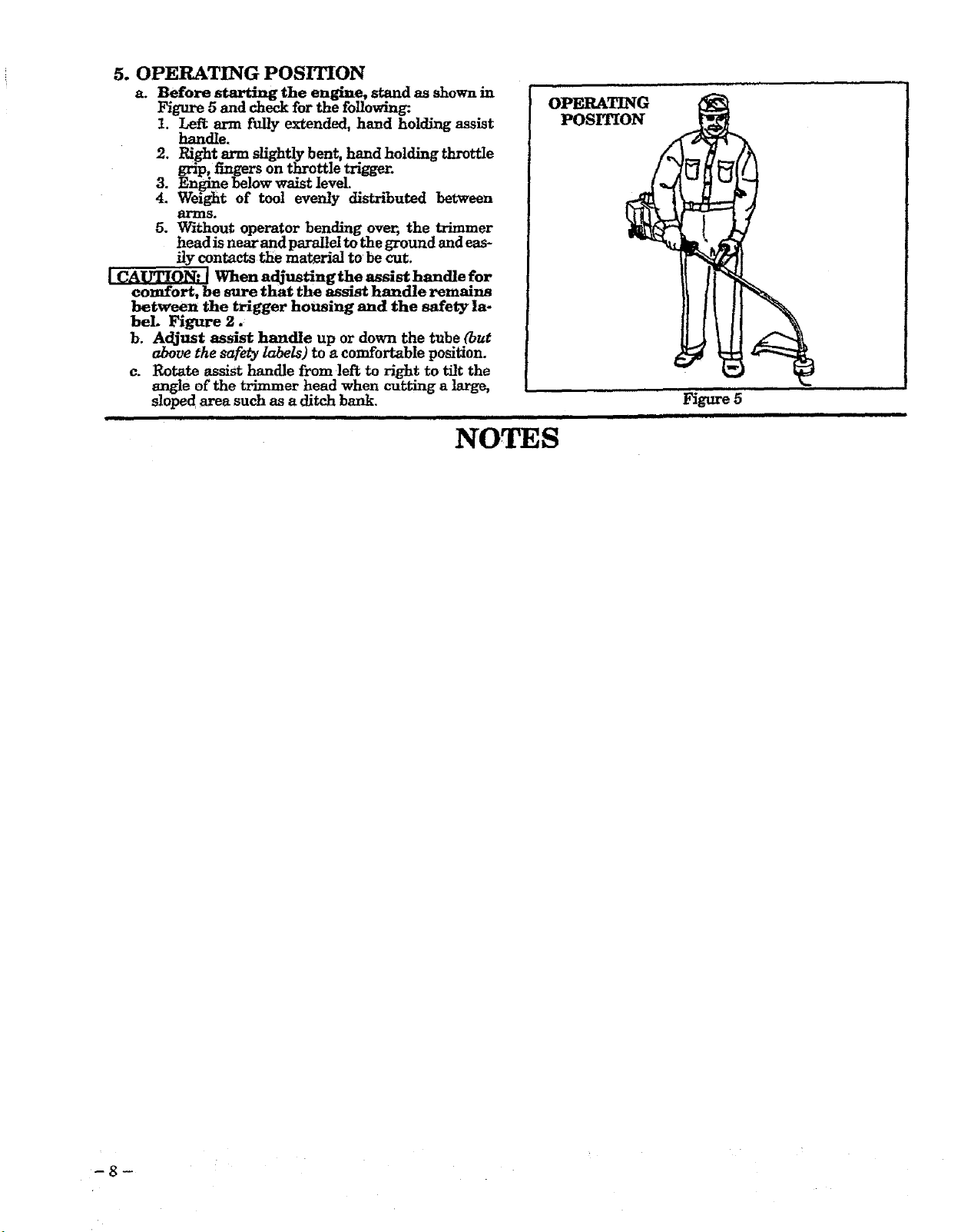

5. OPERATING POSITION

a. Before starting the engine, stand as shown in "

Figure 5 and check for the following:

1. Left arm fully extended_ hand holding assist

handle.

2. Right arm slightly bent, hand holding throttle

grip,fingerson throttletrigger.

3. Engine below waistlevel

4. Weight of toolevenly distributedbetween

5. Without operatorbending over,the trimmer

head isnearand paralleltotheground andeas-

ilycontacts the material to be cur.

When adjustingthe assist handle for

comfort, be sure that the assist handle remains

between the trigger housing and the safety la-

bel. Figure 2.

b. Adjust assist handle up or down the tube (but

above the safety labels) to a comfortable position.

e. Rotate assist handle from left to right to tilt the

s_ngle of the trimmer head when cutting a large,

oped area such as a ditch bank.

,,,,,,,,,,,,,,,,,, ..................

NOTES

OPERATING

POSITION

-8-

IIII I • I I IIIL I

IIII IIIII i I I I I I

FUELING YOUR ENGINE

ii ii i .......

BEFORE FUELING ENGINE:

A WARNING

Be sure to read the fuel safety information in the Warn-

ings and Safety Instructions section on page 4 of this

manual before you begin.

l Ifyou do not understand the fuel safety section DO NOT

attempt to fuel your unit; seek help from someone that

does understand the fuel safety section or call the Cus-

tomer Assistance Hotline at 1-800-235-5878.

GASOLINE

The two-cycle engine on this product requires a fuel mix-

ture of regular unleaded gasoline and a high quality en-

gine oil for lubricationofthe bearings and othermoving

parts.The correctfuel!oilmixture is40:1(seeFuel Mix-

tureChart). Too 1ittte oil or the incorrect oil type will

cause poor performance and maycausethe engine to over-

heat and seize.

Gasolineand oilmust be premixedin a cleanapprovedfuel

container.Always use freshregularunleadedgasoline.

IMPORTANT:. Experience indicates that alcohol

blended fuels called gasohol (or using ethanol or meth-

anol) can attract moisture, which leads to oil/gas sepa-

ration and formationofacidsduring storage.Acidic

gascan damage the fuelsystem ofan enginewhile in

storage.To avoidengineproblems,the fuelsystem

shouldbe emptiedbeforestoragefor30 daysor longer.

Drainthegastank,thenrun thefuelout ofthecarbure-

torand fuellinesby startingthe engine and lettingit

run untilitstops.Use freshfuelnext season. See

STORAGE instructionsfor additionalinformation.

Neveruseengineorcarburetorcleanerproductsinthe

fueltank orpermanent damage may occur.

2-CYCI OIL:

CRAFTSMAN 40:12 cycleoilisstronglyrecommended.

This oilis speciallyblended with fuelstabilizersfor

increased fuel stability (extends fuel life up to 5 times

longer) and reduced smoke.

If CRAFTSMAN 2 cycle oil is not available, use a good

quality 2 cycle AIR-COOLED engine oil that has a

recommended fuel mix 40:1.

IMPORTANT! Do not use:

• AUTOMOTIVE OIL

* BOAT OILS (NMMA, BIA. etc.)

These oils do not have proper additives for 2-cycle,

AIR-COOLED engines and can cause engine damage.

GASOLINE ANDOIL'MIXTURE

Mix gasoline and oil as follows:

* Consult chart for correct quantities.

* Do notmixgasolineandoildirectlyinthefueltank_

FOR ONE GALLON:

• Pour 3.2 ounces of ldgh quality, 2-cycie engine oll

into an empty, approved one gallon gasoline con-

tainer,

• Add one gallonof regularunleadedgasolineto the

galloncontainer,then securelyreplacethe cap.

Shake the containermomentarily.

• The mixture isnow ready foruse. Fuelstabilizer

can be added at thistime ifdesired;followmixing

instructionson the label.

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing

the formationoffuelgum depositsduring storage.Add

stabilizerto gasolinein fueltank or storagecontainer.

Always followthe fuelmix ratiofound on the stabRizer

container.Run engineat leastI0 minutes afteradding

stabilizertoallowthe stabilizertoreach thecarburetor.

Youdo nothavetodrainthefueltankforstorageifyouare

usingfuelstabilizer.

CRAFTSMAN 40:1 2 cycle engine oil is specially blended

with fuel stabilizers. If you do not use this Sears oil, you

can add a fuel stabilizer (such as CraRsman No. 33500) to

yourfuel tank.

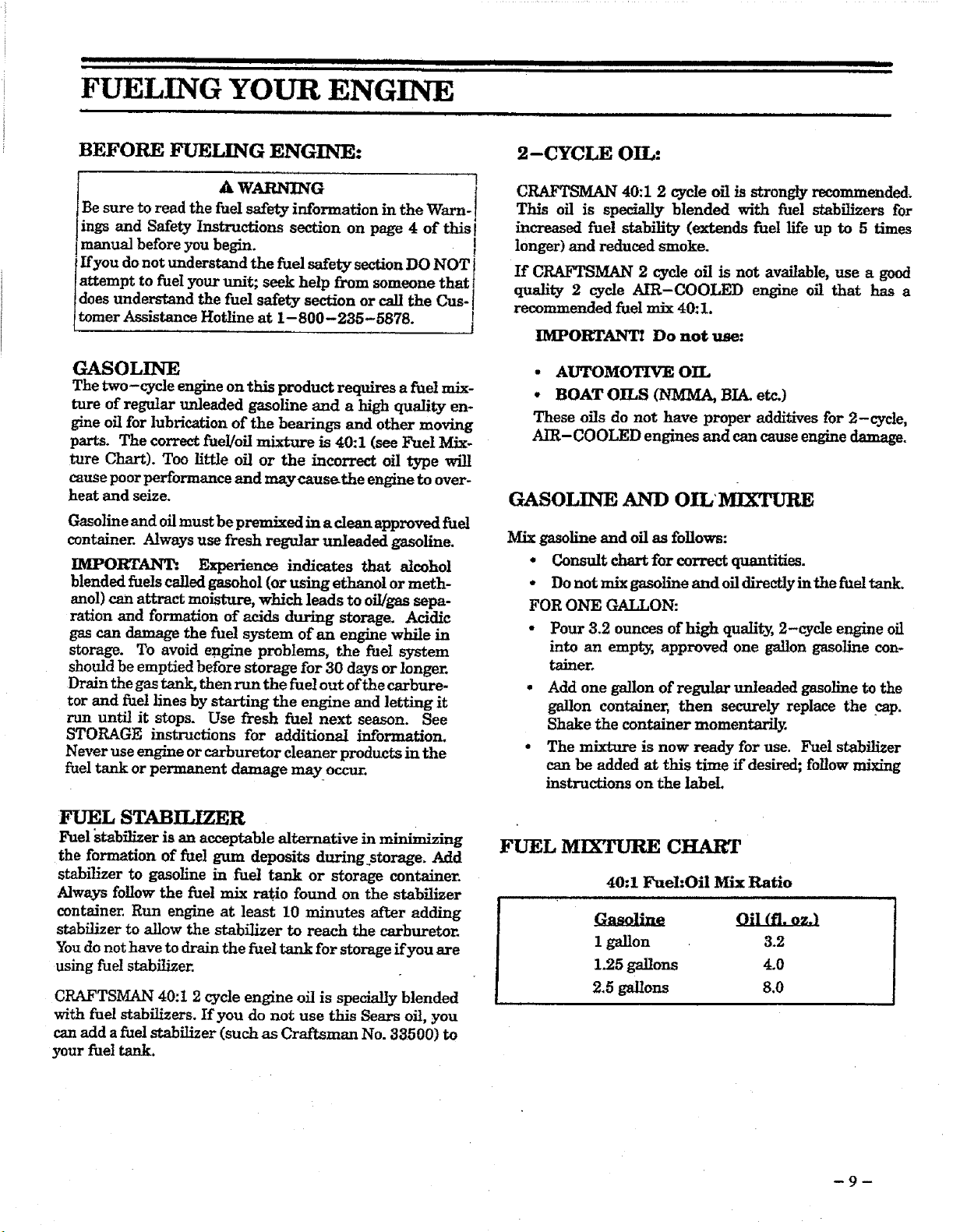

1W_L MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

Ga_line Oil (fl. oz.)

1 gallon 3.2

1.25 gallons 4.0

2.5 gallons 8.0

STARTING YOUR ENGINE

(For location of controls, refer to "Speclfieatiozls.")

BEFORE STARTING THE ENGINE:

• Fuel engine. Move 10 feet (3 meters) away from fuel-

ing site.

The trimmer head will turn while starting the

f A WARNING

e_ #i_.

• Rest engine and shield on ground, supporting trim-

mer head off ground.

guard on the primer bulb (if so equipped).

Remove and discard the plastic shipping

STARTING A WARM ENGINE THAT HAS NOT

RUN OUT OF FUEL:

• Move the choke lever to the "I-IalfCh0ke" position.

• Squeeze and hold the throttle .l_igger. Keep the

throttle trigger fully squeezed un_ t_ engine runs

smoothly.

• Pull starter rope sharply until engine runs, but no

more than 5 pulls.

• Allow the engine to run 15 seconds, then move the

choke lever to "Off Choke.

If engine has not started, pull starter rope 5

more pulls. Ii_engine still does not run, it is probably

flooded. Proceed to "Starting a Hooded Engine. _

• To stop the en_ine, push and hold the momentary

switch in the "Off' position; do not release until the

engine has completely stoppe&

STARTING A COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL:

• Move the choke lever to the "Full Choke" position.

• Slowly press the primer bulb 6 times.

• Squeeze and hold the throttle trij_ger. Keep the

throttle trigger fully squeezed _ntil the engine lwns

smoothly.

• Pull starter rope sharply 5 times.

The eng_e may sound as if it is trying to

start before the 5rn pull If so, go to the next step im-

mediately

• Move the choke lever to the "Half Choke" position.

• Pull the starter rope shanty until the engine runs,

but no more than 6 pulls.

Iftheenginehas notstartedafter6pulls(at

halfchoke),checkto make surethechoke leverisin

the properposition.Then, move the choke'leverto

the"FullChoke" positionandpresstheprimerbulb6

times;squeezeand holdthethrottletriggerand pull

thestarterrope2 more times.Move theChoke lever

to "Half Choke _ and pull the starter rope until the en-

gine runs, but no more than 6 more pulls.

Iftheenginestillhas not started,itisprob-

ablyflooded.Proceed to "Startinga Flooded En-

gine."

STARTING A FLOODED ENGINE:

Flooded engines can be started by placing the choke

lever in the "Off Choke" position; then, pull the rope

to clear the engine of excess fuel This could requh'e

pulling the starter rope many times depending on

how badly the unit is floode_

If the unit still doesn't start, call the Customer Assis-

tance Hotline at 1-800-235-5878.

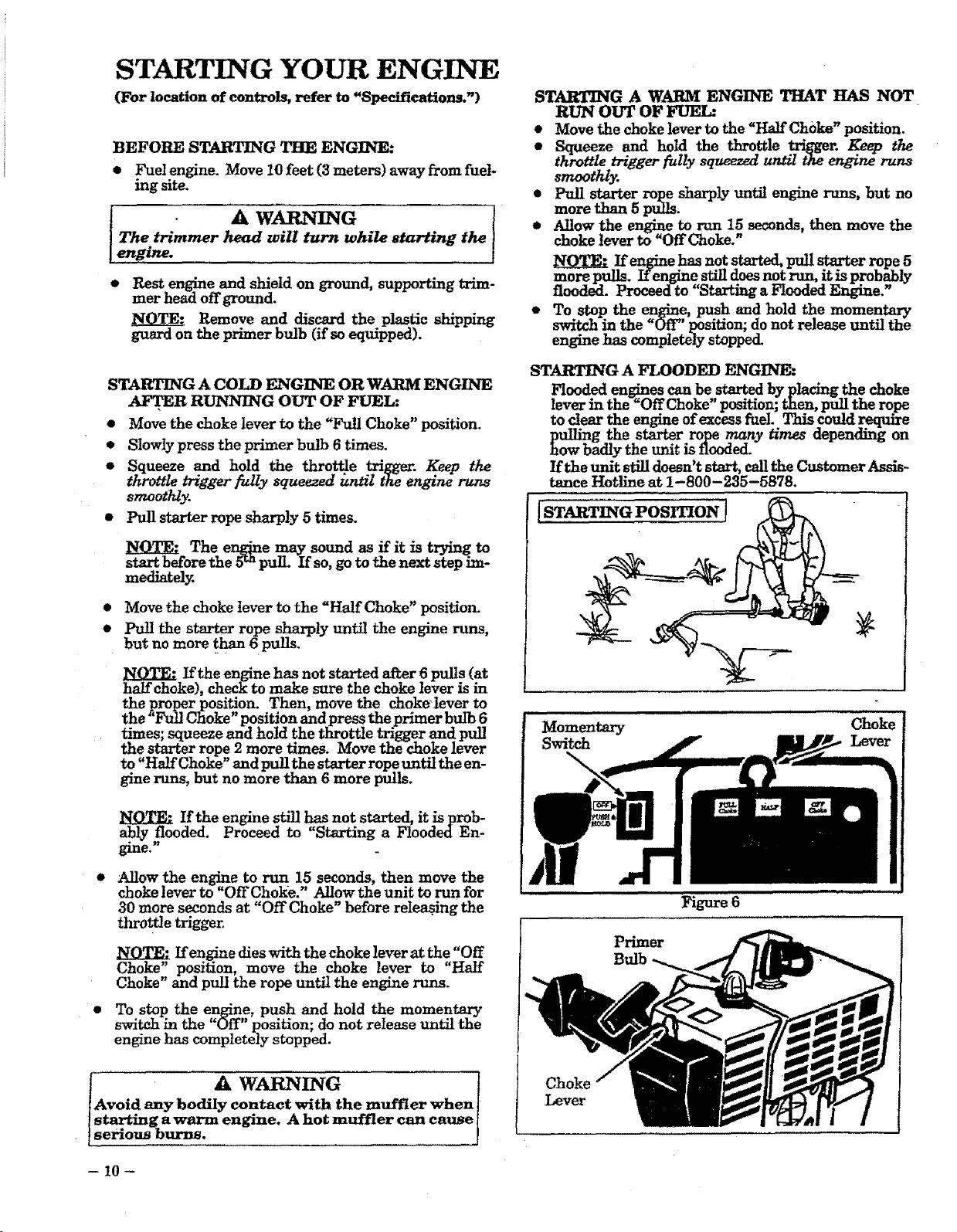

ISTART£NGPOSmON I

Momentary Choke

Switch

Allow the engine to run 15 seconds, then move the

choke lever to "OffChoke." Allow the unit to run for

30 more seconds at "Off Choke _ before releasing the

throttle trigger.

If engine dies with the choke lever at the"Off

Choke" position, move the choke lever to "Half

Choke" and pull the rope until the engine runs.

To stop the engine, push and hold the momentary

switch in the "Off" position; do not release until the

engine has completely stopped.

l A WARNING

Avoid any bodily contact with the muffler when

starting a warm engine. A hot muffler can cause

serious burns.

- 10-

Figure 6

Primer

Bulb

Choke

Lever

OPERATING INSTRUCTIONS

Bring the engine to cutting speed before entering

the material to be cut.

• Do not run the engine at a higher speed

than necessary. The cutting line will cut effi-

_hrottentlywhen the engine is run at less than full

le. At lower speeds, there is less engine noise

and vibration. The cutting llne will last longer

and will be less likely to "weld" onto the spool.

• If the trimmer head does not turn when the

engine is in operation, make sure the tube is

properly seated in engine shrou& Refer to "As-

sembly-Tube."

i nail iiiiiiii

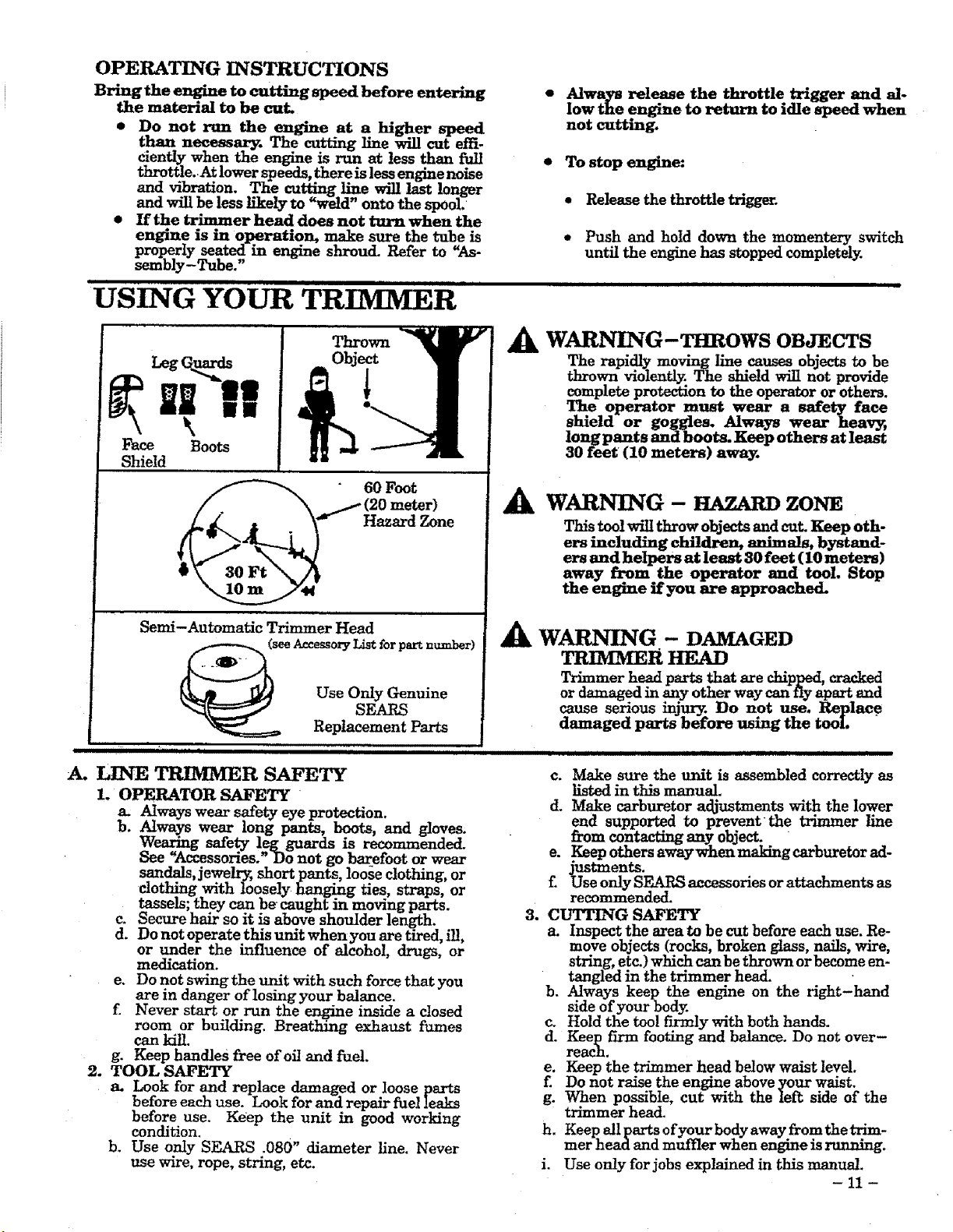

USING YOUR TRIMMER

t9

n ..

Face Boots

Shield

.L I

• Alwa_s release the throttle trigger and al-

low the engine to return to idle speed when

not cutting.

• To stop engine:

• Release the throttle t_ggex.

• Push and hold down the momentery switch

until the engine has stopped completely.

i ii

WARNING- THROWS OBJECTS

The rapidly moving line causes objects to be

thrown violently. The shield will not provide

complete protection to the operator or others.

_e operator must wear a safety face

shield or goggles. Always wear heav_

longpants and boots. Keep others at Ieast

30 feet (10 meters) awa_

(20 meter)

_._30_ _ Hazard Zone

ii ,11 i

Semi-Automatic Trimmer Head

(see Accessory List for part number)

Replacement Parts

A. LINE TRIMMER SAFETY

1. OPERATOR SAFETY

a. Always wear safety eye protection.

b. Always wear long pants, boots, and gloves,

Wearing safety leg guards is recommended.

See _Accessories. _Do not go barefoot or wear

sand_, jewelry,shortpants, looseclothing,or

clotl_ng with looselyhanging ties,straps,or

tassels;theycan be-caughtinmoving parts.

c. Securehairso itisabove shoulderlength.

d. Do notoperatethisunltwhenyou aretired,ill,

or under the influenceof alcohol,drugs,or

medication.

e. Do notswing theunitwith such forcethatyou

are in danger oflosingyour balance.

f. Never startor run the engine insidea closed

room or building.Breathing exhaust fumes

can kiil.

g. Keep handlesfreeofoiland fuel.

2. TOOL SAFETY

a, Look forand replacedamaged or looseparts

beforeeachuse. Look forand repairfuelleaks

beforeuse. Keep the unit in good working

condition.

b. Use only SEARS .080"diameter line.Never

use wire,rope,string,etc.

WARNING - HAZARDZONE

This tool will throw objects and cut. Keep oth-

ers including children, animals, bystand-

ers end helpers at least 30 feet ( 10 meters)

away f_om the operator and tool. Stop

the engine if you are approached.

A

WARNING - DAMAGED

TRIMMERHEAD

Trimmer head parts that are chipped_ cracked

or damaged in any other way can fly apart and

cause serious injury. Do not use. Replace

damaged parts before using the tool

c. Make sure theunit isassembledcorrectlyas

listedinthismanual.

d. Make carburetora_justmentswith the lower

end supportedto prevent the trimmer line

fromcontactinganyobject.

e. Keep othersawaywhen making carburetorad-

justments.

f. Use onlySEARS accessoriesorattachmentsas

recommended.

3. C_G SAFETY

a. Inspect the area to be cut before each use. Re-

move objects (rocks, broken glass, nails, wire,

string, etc.) which can be thrown or become en-

tangled in thetrimmer head.

b. Always keep the engine on the right-hand

sideofyour body.

c. Hold the toolfLrmlywith bothhands.

d. Kee_ firm footingand balance.Do notover-

rcaCIL

e. Keep the trimmer head belowwaistlevel.

f. Do not raisethe engineaboveyour waist.

g. When possible,cut with the leftsideof the

trimmer head.

h. Keep allpartsofyourbody away fromthetrim-

mer head and mufflerwhen engineisrunning.

i. Use only for jobs explained in this manual.

- 11 -

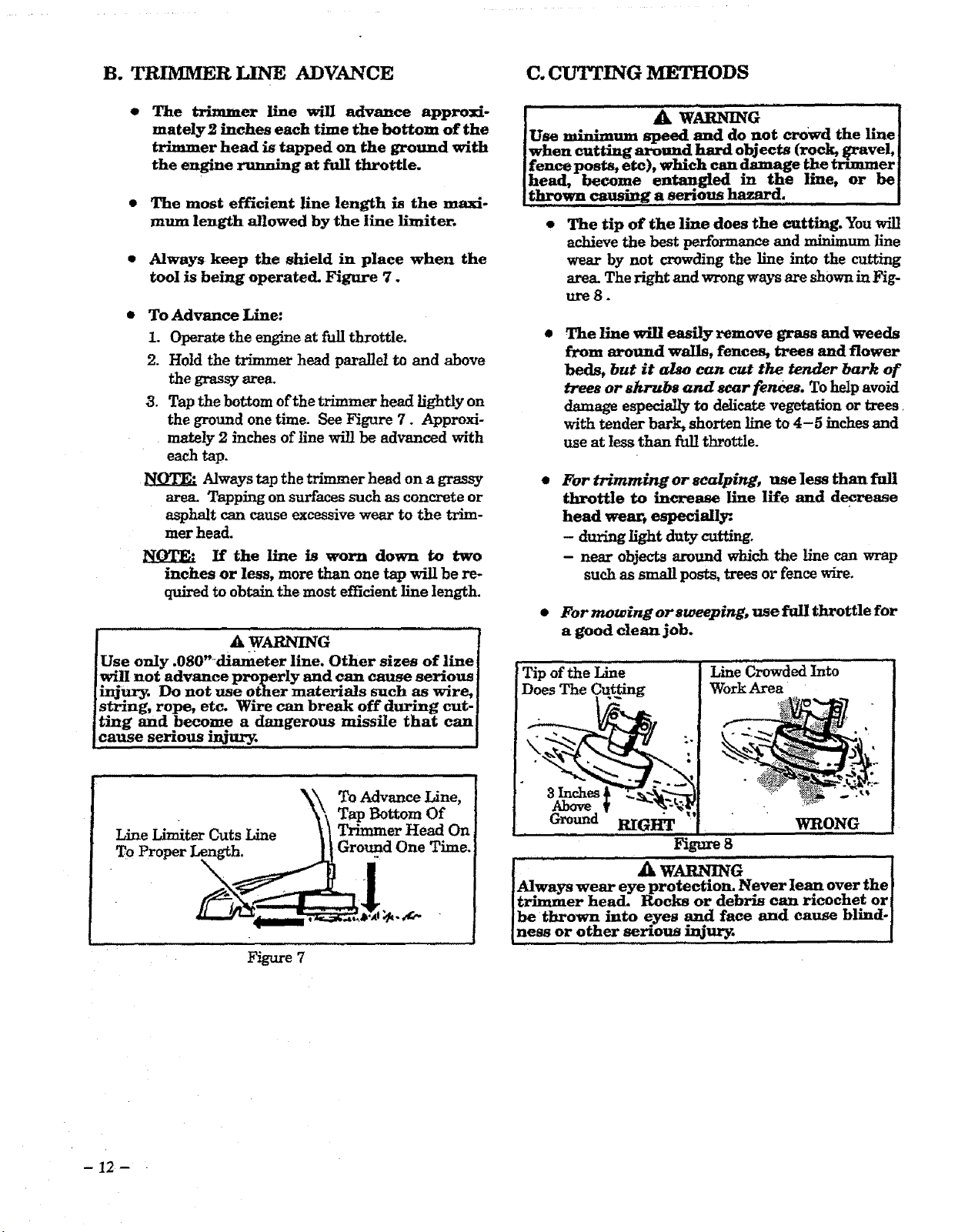

B. TRIMMER LINE ADVANCE

@

The trimmer line wilI advance approxi-

mately 2 inches each time the bottom of the

trimmer head is tapped on the ground with

the engine running at full throttle.

• The most efficient Hne length is the maxl-

mum length allowed by the line Hmiter.

• Always keep the shield in place when the

tool is being operated. Figure 7.

To Advance Line:

1. Operate the engine at full throttle.

2. Held the trimmer head parallel to and above

the grassy area.

3. Tap the bottom of the trimmer head tightly on

the ground one time. See Figure 7. Approxi-

mately 2 inches of line will be advanced with

each tap.

Always tap the trimmer head on a grassy

area. Tapping on surfaces such as concrete or

asphalt can cause excessive wear to the trim-

mer head.

If the line is worn down to two

inches or less, more than one tap will be re-

quired to obtain the most efficient line tength_

, ,,,,,,,,,,,vu,,,Lw, , ,,,,,,,,,

A WARNING

Use only .080"-diameter line. Other sizes of line

will not advance properly and can cause serious

injur_ Do not use other matemals such as wire,

string, rope, etc. Wire can break off during cue-

ring and become a dangerous missile that can

cause serious injury.

C. CUTTING METHODS

A WARN G

Use nnmmm speed mad do not _owd the line [

when cutting m-oun .dhard objects (rock, _ravel, !

fence posts, etc), which van damage the trimmer |

p ..

head, become entangled m the line, or be[

thrown causing a serious hazard, i

The tip of the line does the cutting. You will

achieve the best performance and minimum line

wear by not crewdJ_g the line into the catting

areal The right and wrong ways are shown in Fig-

ure8.

The llne will easily remove grass and weeds

from around wails, fences, trees and flower

beds, but it also can cut the tender bark of

trees or shrubs and scar fences. To help avoid

damage especially to delicate vegetation or trees

with tender bark, shorten line to 4-5 inches and

use at less than full throttle.

For trimming or scalping, use less than full

throttle to increase llne life and decrease

head wear, especially:.

- duringlight dutycutting.

- near objects around which the llne can wrap

such as small posts, trees or fence wire.

• For mowing or sweeping, use full throttle for

a good clean job.

of the Line

Line Crowded Into

Work Area

I

Line L/miter Cuts Line

To ProperI_ngt______

- 12-

Figure 7

To Advance Line,

Tap Bottom Of

Trimmer Head On

Ground One Time.

WRONG

Figure 8

I ...... Aw q I

Always wear eye protection. Never lean over the

trimmer head. Rocks or debris can ricochet orl

be thrown into eyes and face and cause blind-[

ness or other serious injury. [

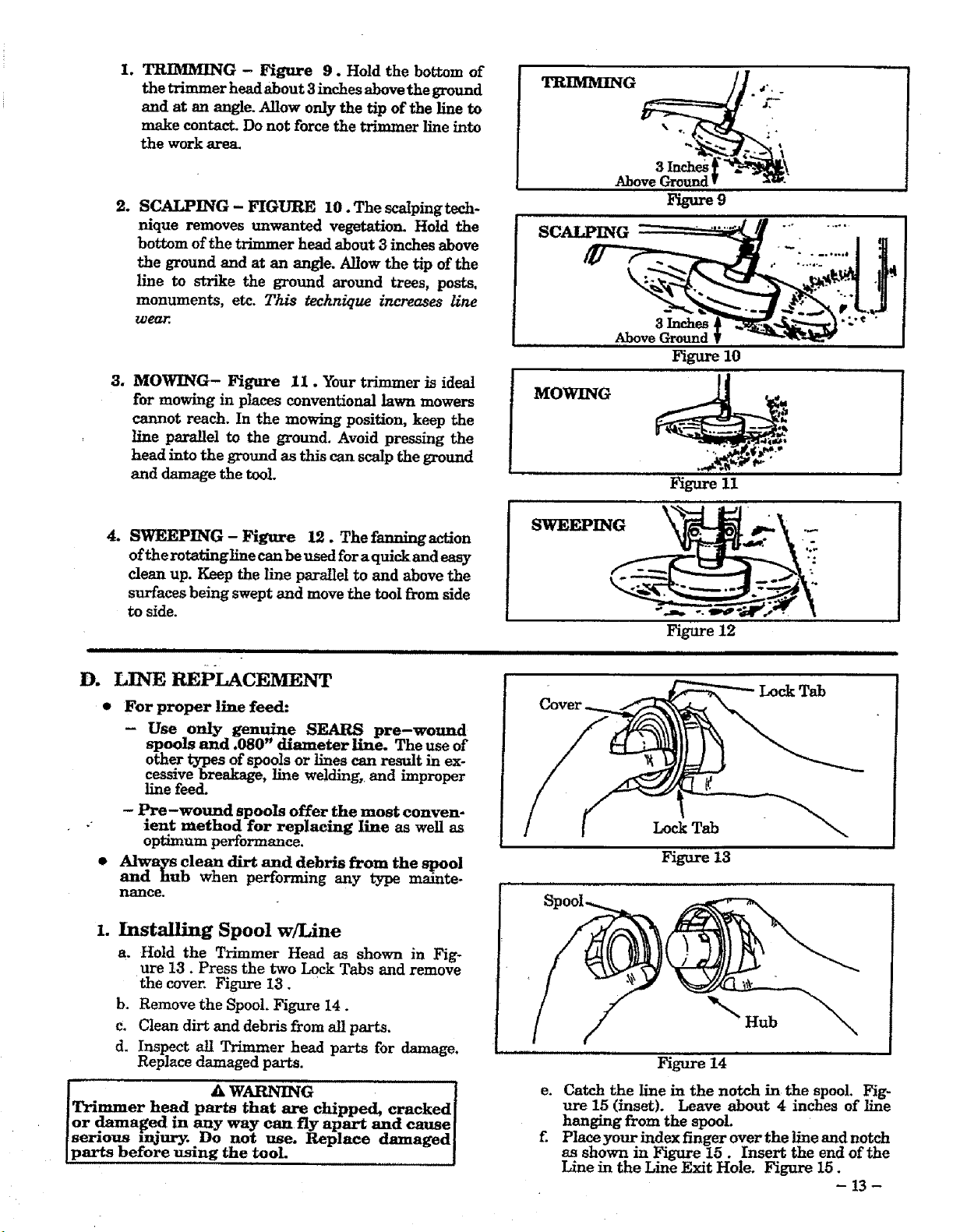

I. TRIMMING - Figure 9. Hold the bottom of

the trimmer head about 3 inches above the ground

and at an angle. Allow only the tip of the line to

make contact. Do not force the trimmer line into

the work are_

2. SCALPING- FIGUP_ 10. The scalpingtech-

nique removes unwanted vegetation. Hold the

bottom of the trimmer head about 3 inches above

the ground and at an angle. Allow the tip of the

line to strike the ground around trees, posts,

monuments, etc. This technique increases line

3. MOWING- Figure I1. Your trimmer is ideal

for mowing in places conventional lawn mowers

cannot reach. In the mowing position, keep the

line parallel to the ground. Avoid pressing the

head into the ground as this can scalp the ground

and damage the tool.

Above Ground v _,."

9

SCALPING

Above Ground '

Figure 10

MOWING

FIN 11

4. SWEEPING - Figure 12. The fanning action

of the rotating]ine can be used fora quick and easy

clean up. Keep the line parallel to and above the

surfaces being swept and move the tooI from side

to side.

i i iiiii i IIHIII

D. LINE REPLACEMENT

• For proper line feed:

- Use only genuine SEARS pre-wound

spools and .080" diameter line. The use of

other types of spools or lines can result in ex-

cessive breakage, line welding, and improper

line feed.

- .Pre-wound spools offer the most conven-

ient method for replacing Iine as well as

optimum performance.

• Always clean dirt and debris from the spool

and hub when performing any type mamte.

nance.

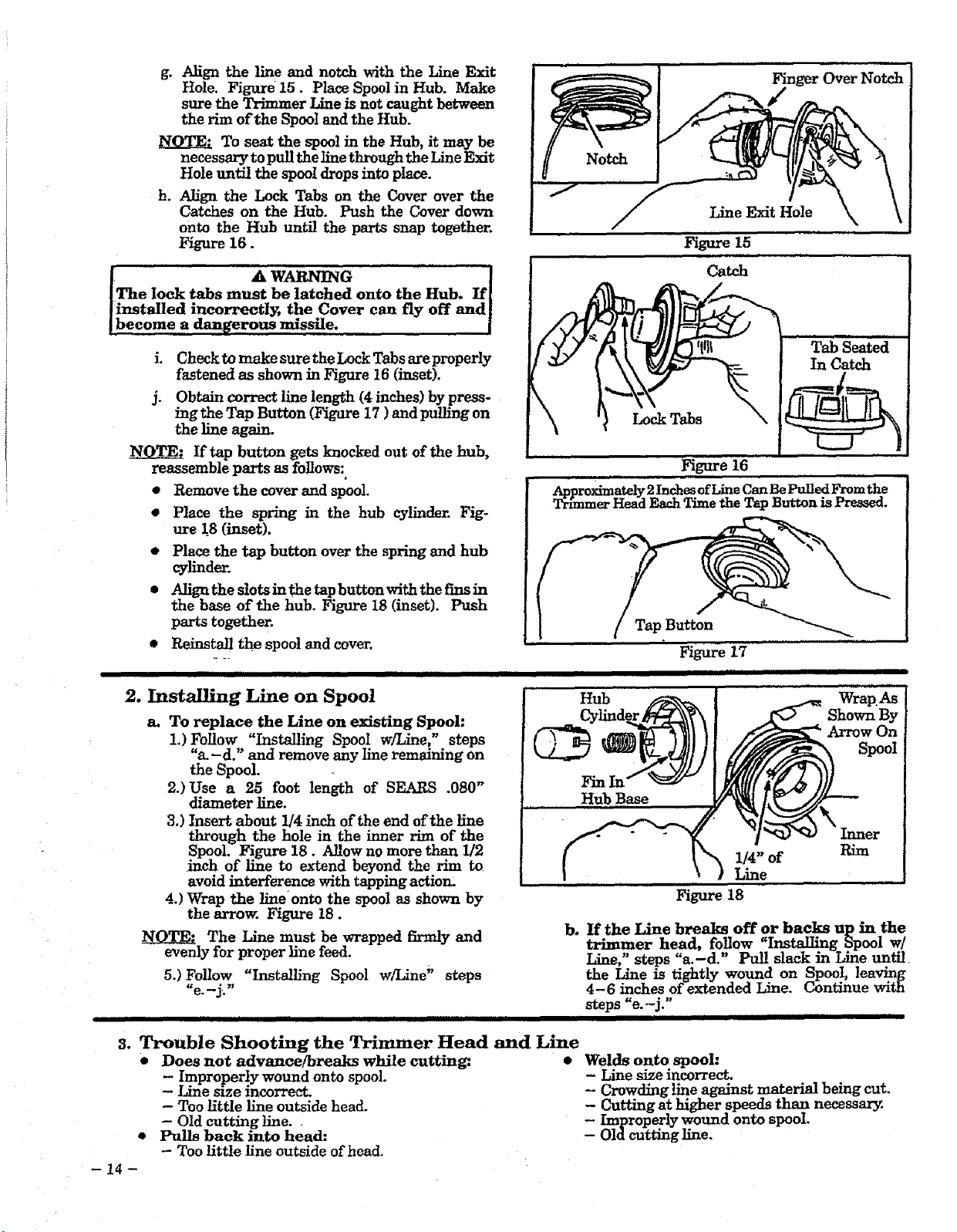

1. Installing Spool w/Line

a. Hold the Trimmer Head as shown in Fig-

ure 13. Press the two Lock Tabs and remove

the cover. Figure 13.

b. Remove the Spool. Figure 14.

c. Clean dirt and debris from all parts.

d. Inspect all Trimmer head parts for damage.

Replace damaged parts.

SWEEPING

Figure 12

i

Lock Tab

Lock Tab

Figure 13

Hub

Figure 14

i WARNING i

Trimmer head parts that are chipped, cracked[

or .d_a_ed m any way can fly apart and cause[

serlot_s _njury. Do not use. Replace damaged[

par_s Dezore using the tool. [

e. Catch the line in the notch in the spool. Fig-

ure 15 (inset). Leave about 4 inches of line

hanging from the spool.

fi Placeyour index finger over the line and notch

as shown in Figure 15. Insert the end of the

Line in the Line Exit Hole. Figure 15.

- !3 -

g. Align the line and notch with the Line Exit

Hole. Figuxe 15. Place Spool in Hub. Make

sure the Trimmer Line is not caught between

the rim of the Spool and the Hub.

N__QTFATo seat the spool in the Hub, it may be

necessary to pull the Line through the Line Exit

Hole until the spool drops into place.

h. Align the Lock Tabs on the Cover over the

Catches on the Hub. Push the Cover down

onto the Hub until the parts snap together.

Figure 16.

I A WARNING

The lock tabs must be latched onto the Hub, If[

installed incorrectl_ the Cover can fly off and]

become a dangerous missile. |

i. Check to make sure the Lock Tabs are properly

fastened as shown in Figure 16 (inset).

j. Obtain correct line length (4 inches) by press-

ing the Tap Button (Figure 17 ) and pulling on

the line agviu.

If tap button gets knocked out of the hub,

reassemble parts as follows:

• Remove the cover and spool.

• Place the spring in the hub cylinder. Fig-

ure 18 (inset).

• Place the tap button over the spring and hub

cylinder.

• Align the slotsin the tap button with the fins in

the base of the hub. Figure 18 (inset). Push

parts together.

• Reinstall the spool and cover.

Finger Over Notch

.Line Exit Hole

Figure 15

Catch

,ml ,,,

Figure 16

Approximately 2Inches of Line Can BePulled _Fromthe

THmmer Head Each Time the Tap Button is 1"_.

Tap Button

Figure 17

2. Installing Line on Spool

a. To replace the Line on existing Spool:

1.) Follow "Installing Spool w/Line," steps

"_-d." and remove any line remaining on

the Spool.

2.) Use a 25 foot length of SEARS .080 _

diameter line.

3.) Insert about 1/4 inch of the end of the line

through the hole in the inner rim of the

Spool. Figure 18. A_ow no more than 1/2

inch of line to extend beyond the rim to

avoid interference with tapping action.

4.) "Wrapthe llne onto the spool as shown by

the arrow. Figure 18.

The Line must be wrapped firmly and

evenly for proper line feed.

5.) Follow "Installing Spool w/Line _ steps

3. Trouble Shooting the Trimmer Head and Line

• Does not advance/breaks while cutting: •

- Improperly wound onto spool.

Line size incorrect.

- Too little line outside head.

- Old cutting line.

Pulls back into head:

- Too little line outside of head.

Hub WmpoAs

Shown By

Spool

Fin In

Hub Base

Rim

b, If the Line breaks off or backs up in the

trimmer head, follow "Installing Spool w/

Line," steps "a.-d. Pull slack in Line until.

the Line is tightly wound on Spool, leaving

4-6 inches of extended Line. Continue with

steps "e.-j."

Welds onto spool:

- Line sizeincorrect.

- Crowding lineagainstmate_rialbeingcut.

- Cuttingathigherspeedsthau.necessary.

- Improperlywound ontospool.

- Oldcuttingline.

Loading...

Loading...