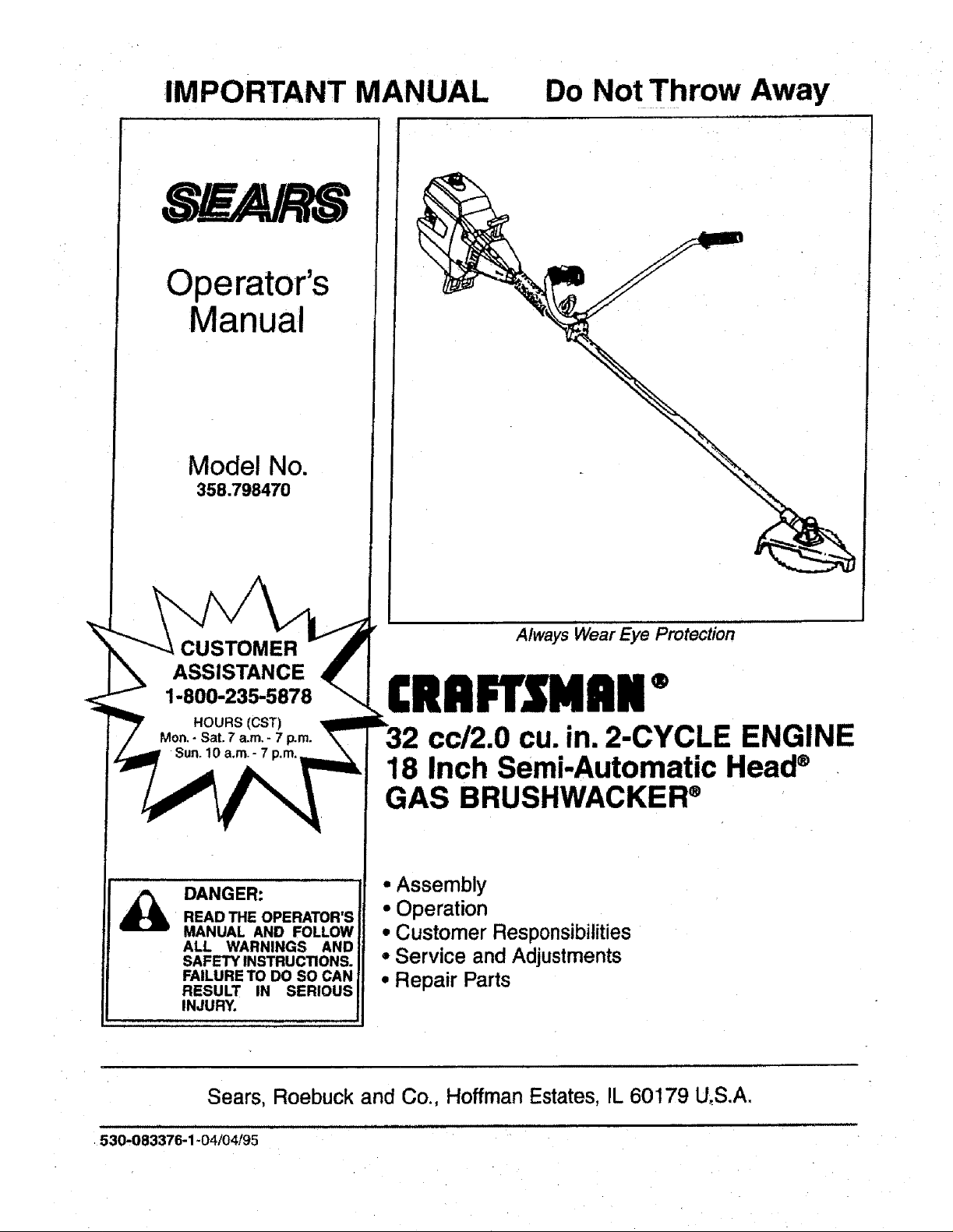

Craftsman 358798470 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

Operator's

Manual

Model No.

358.798470

CUSTOMER

ASSISTANCE

1-800-235-5878

DANGER:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

Always Wear Eye Protection

®

cc/2.0 cu. in. 2-CYCLE ENGINE

18 Inch Semi-Automatic Head®

GAS BRUSHWACKER®

• Assembly

° Operation

• Customer Responsibilities

° Service and Adjustments

° Repair Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U_S.A.

530.083376-1-04/04/95

ii i tIJL

SAFETY RULES

cAUT|oNI ALWAYS D SCONNECT SPARK PLUG RE A........ I Wl ND PLACE WIRE WHERE IT CANNOT

CONTACT SPARK PLUGTO PREVENTACCIDENTALSTARTING WHEN SETTING UP, TRANSPORTING,

ADJUSTING OR MAKING REPAIRS.

OPERATOR SAFETY

• Alwayswear safetyeye protection,

• Always wear longpants, tong sleeves,bootsand

gloves.Wearing safety leg guardsis recom-

mended. Do notgo barefoot or wear sandals,

shortpants, shortsleeves.Beingfully covered

heJpsto protectyou from piecescf toxicplants

thrownby the bladeor cuttinghead.

• Secure hair so it is above shoulderlength. Secure

looseclothingorjewelry, or clothingwithloosely

hangingties, straps,tassels,etc.;theycan be

caught in movingparts.

• Do not operatethisunitwhen youare tired,it!,or

underthe influenceof alcohol,drugs,ormedica-

tion.

• Wear hearing protectionifyou usethisunitfor

more than 1-1/2 hoursper day.

• Never startor run the engine insideaclosed

roomor building. Breathingexhaustfumes can

kill.

• Keep handlesfree of oil and fuel

• Alwaysuse the handlebarand a properlyadjusted

shoulderharness.

• If situationsoccurwhich are notcoveredinthis

manual, usecare and good judgement.

UNIT MAINTENANCE/SAFETY

• Lookfor and replacedamaged or loosepartsbe-

fore each use. Lookfor and repairfue!leaksbe-

fore use. Keep theunit in goodworkingcondi-

lion.

° Throw away bladesthat are bent,warped,

cracked, broken,or damaged inany otherway.

• Replace trimmer head parts that arechipped,

cracked, broken,ordamaged inany otherway

beforeusing theunit.

° Use only .080" diameter monofilamentline.

Never use wire, rope,string, etc.

• Keep the blade sharpand thecuttinglineat the

properlength.

• Make sure the unitis maintainedand assembled

correctlyas listedinthis manual.

• Installthe requiredshield properlybefore using

the unit. Use themetal blade shieldfor blades_

and the plasticlinetrimmer shieldfor linetrimmer

use.

• Use only the specifiedbladeor trimmerhead.

• Be sure blade ortrimmerhead stopsturning

when engine idles,

• Make carburetoradjustmentswiththelowerend

supportedto preventthe blade ortrimmerline

from contactingany object. Hold unitby hand;do

not useshoulderharnessfor support.

• Keep othersaway when makingcarburetorad-

justments.

I SAFETY'NOTICE . .............

JExposure to vibrations through prolonged use of gasoline powered hand toots could cause blood vessel or nerve damage in the

I fingers, hands, and joints of people prone to circulation disorders or abnormal swel|ings. Prolonged use in cold weather haS been

| linked to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of strength, change

] in skin color or texture, or loss of feeling in the fingers, hands or joints, discontinue the use of this unit and seek medical a_en-

Itton. An anti-vibration system does not guarantee the avoidance of these problems. Users who operate power tools on a continu-

I al and regular basis must monitor closely their physical condition and the condition of this unit.

• Use only goodquality SEARS accessories and

replacement parts as recommended for this unit.

• Have air maintenance and service not explained

in this manual performed by your SEARS Service

Center.

FUEL SAFETY

• Mix and pourfue! outdoors.

• Keep away fromsparks orflames.

• Use a containerapproved for fuel.

• Do not smoke or allow smokingnear fuel orthe

unitor whileusingthe unit.

• Wipe up all fuel spillsbefore startingengine.

• Move at least 10 feet (3 meters) away from fuel-

ingsite beforestarlingengine.

• Stop engine and allow the engine tocool before

removingfuel cap.

CUTTING SAFETY

• Inspectthe area to be cutbefore each use. Re-

moveobjects (rocks,broken glass,nails,wire,

string,etc.) whichcan be thrownor become en-

tangled in the blade ortdmmer head.

• Keep others includingchildren, animals, bystand-

ers and helpers at least 50 feet (15 meters) away.

Stop the engine immediately if youare

approached.

• Always keep the engineon the right-hand side of

yourbody.

• Hold the unitfirmly with both hands.

• Keep firm footing and balance. Do not over-

reach.

• Keep the blade or trimmerhead below waist level.

• Do not raise the engine above yourwaist.

• Keep all partsof your bodyaway from the blade

or trimmerhead and muffler when engine is run-

ning.

• Cut from your right to your left.

• Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

° Stop the unitbeforetransporting.

• Allowthe engine tocool, and secure the unit be-

fore storingor transportingin a vehicle.

• Emptythe fuel tank before storingor transporting

the unit. Use up any fuel left inthe carburetor by

startingthe engineand lettingthe engine rununtil

it stops.

• Store unitand fuel inan area where fuel vapors

cannotreach sparksor open flames from water

heaters,electric motors or switches,furnaces,

etc.

• Store unitso the blade or line fimiter cannot acci-

dentallycause injury.

• Store the unitout of the reach of children.

I

IT MEANS - AI"FENTIONtll BECOME ALERTllf YOUR SAFETY IS INVOLVED.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

"2-

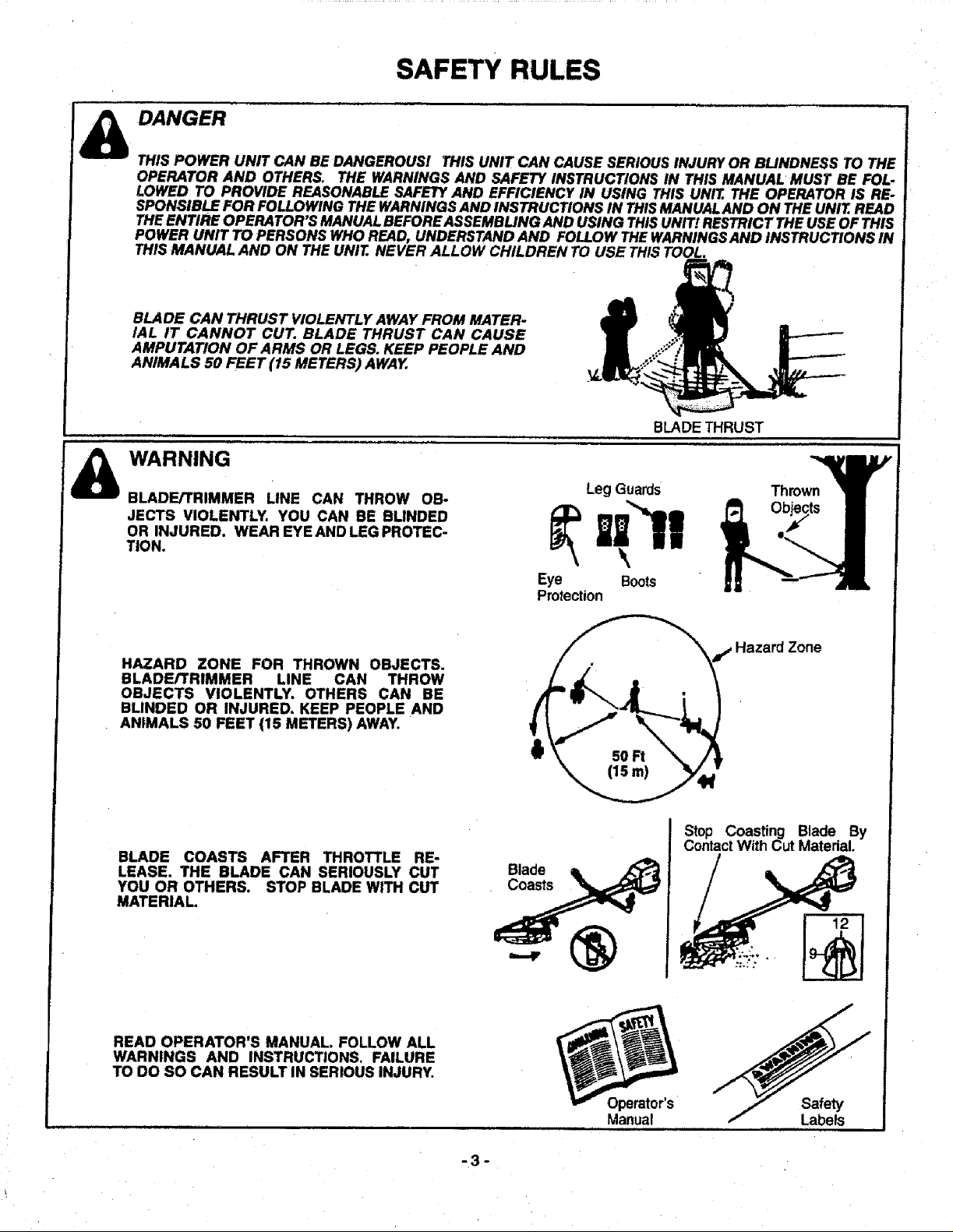

SAFETY RULES

DANGER

THIS POWER UNIT CAN BE DANGEROUS! THIS UNIT CAN CAUSE SERIOUS INJURY OR BLINDNESS TO THE

OPERATOR AND OTHERS, THE WARNINGS AND SAFETY INSTRUCTIONS IN THIS MANUAL MUST BE FOL-

LOWED TO PROVIDE REASONABLE SAFETYAND EFFICIENCY IN USING THIS UNIT. THE OPERATOR IS RE-

SPONSIBLE FOR FOLLOWING THE WARNINGSAND INSTRUCTIONS IN THISMANUALAND ON THE UNIT.READ

THEENTIRE OPERATOR'S MANUALBEFOREASSEMBLING AND USING THISUNIT! RESTRICT THE USE OF THIS

POWER UNIT TO PERSONS WHO READ, UNDERSTAND AND FOLLOW THEWARNINGSAND INSTRUCTIONS IN

THIS MANUAL AND ON THE UNIT. NEVER ALLOW CHILDREN TO USE THISTOOL.

BLADE CAN THRUST VIOLENTLY AWAY FROM MATER-

IAL IT CANNOT CUT. BLADE THRUST CAN CAUSE

AMPUTATION OF ARMS OR LEGS. KEEP PEOPLE AND

ANIMALS 50 FEET (15 METERS) AWAY.

BLADE THRUST

WARNING

BLADE/TRIMMER LINE CAN THROW OB-

JECTS VIOLENTLY. YOU CAN BE BLINDED

OR INJURED. WEAR EYE AND LEG PROTEC-

TION.

HAZARD ZONE FOR THROWN OBJECTS.

BLADE/TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY. OTHERS CAN BE

BLINDED OR INJURED, KEEP PEOPLE AND

ANIMALS 50 FEET (15 METERS) AWAY.

BLADE COASTS AFTER THROTTLE RE-

LEASE. THE BLADE CAN SERIOUSLY CUT

YOU OR OTHERS. STOP BLADE WITH CUT

MATERIAL.

Eye Boots

Protection

Blade

Coasts

Leg Guards

Thrown

ird Zone

Stop Coasting Blade By

ContactWith Cut Material.

READ OPERATOR'S MANUAL. FOLLOW ALL

WARNINGS AND INSTRUCTIONS. FAILURE

TO DO SO CAN RESULT IN SERIOUS INJURY.

-3-

Manual

Safety

Labels

ill

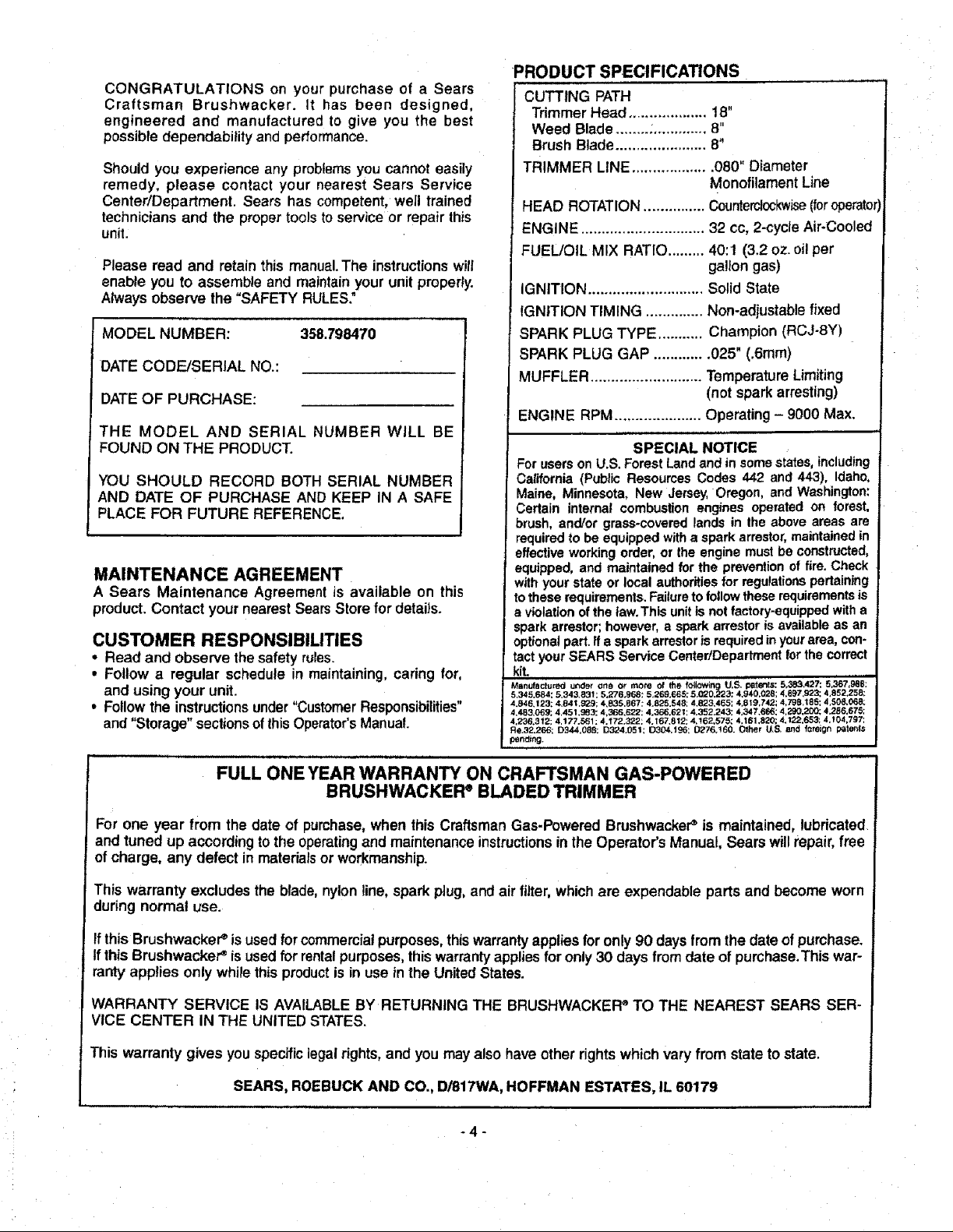

CONGRATULATIONS on your purchase of a Sears

Craftsman Brushwacker. It has been designed,

engineered and manufactured to give you the best

possibledependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service

Center/Department. Sears has competent, well trained

technicians and the proper tools to service or repair this

unil.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your unit property.

Always observe the "SAFETY RULES."

MODEL NUMBER: 358.798470

DATE CODE/SERIAL NO.:

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON THE PRODUCT.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears Store for detaiIs.

CUSTOMER RESPONSIBILITIES

• Read and observe thesafety rules.

• Follow a regular schedule in maintaining,caring for,

and using your unit.

• Follow the instructionsunder"CustomerResponsibilities"

and "Storage" sectionsofthisOperator'sManual.

PRODUCT SPECIFICATIONS

,, ,,, ,,,,

CUTTING PATH

Trimmer Head ................... 18"

Weed Blade........_............. 8"

Brush Blade ...................... 8"

TRIMMER LINE ................... 080" Diameter

Monofilament Line

HEAD ROTATION ............... Counterclockwise(foroperator)

ENGINE .............................. 32 cc, 2-cycle Air-Cooled

FUEL/OIL MIX RATIO ......... 40:1 (3.2 oz. oilper

gallon gas)

iGNITION ............................ Solid State

IGNITION TIMING .............. Non-adjustable fixed

SPARK PLUG TYPE ........... Champion (RCJ-8Y)

SPARK PLUG GAP ............. 025" (.6mm)

MUFFLER ........................... Temperature Limiting

(not spark arresting)

ENGINE RPM ..................... Operating - 9000 Max.

SPECIAL NOTICE

ForusersonU.S.ForestLandandinsomestates,including

California (Public ResourcesCodes442 and443), Idaho,

Maine, Minnesota,New Jersey,Oregon,and Washington:

Certain internalcombustionengines operatedon forest,

brush, and/or grass-covered lands in theaboveareasare

required to beequipped witha spark arrestor,maintainedin

effectiveworkingorder,orIhe enginemustbeconstructed,

equipped, and maintainedforthe prevention of fire.Check

withyourstateor localauthoritiesfor regulationspertaining

totheserequirements. Failuretofollowtheserequirements is

a violationofthe taw.Thisunitisnotfactory=equipped witha

sparkarrestor;however,a sparkarrestorisavailableasan

optionalpart.ffa sparkarrestoris requiredinyourarea,con-

tactyourSEARS ServiceCentedDepartmentfor thecorrect

kit.

Manufactured under one or more _f the following U,S, patet_ls: 5,_,427: 5.367,988:

5,345.684; 5,343_831; 5.276.968: 5,269.665; 5.G_0,L_23: 4,940,028: 4,697,923: 4,852,258:

4,846,123; 4,84 t,929; 4.835,867; 4,825.548; 4,823,465; 4,819,742; 4,798,185: 4,508,068;

4,483,069; 4,451,983: 4,366,622:4.366.62114.352,243; 4,347,666: 4,L_0,200; 4.286,675;

4,236.312; 4,177,_61 ; 4,172.322; 4.167,812; 4,!62,575; 4,161,820; 4,122.653: 4,104,797:

Re,32.266; D344,088; D324.051: 1_304.196; 0276,!60. Other U,S. and foreign patents

periling.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS-POWERED

BRUSHWACKER e BLADED TRIMMER

For one year from the date of purchase, when this Craftsman Gas-Powered Brushwacker_ is maintained, lubricated

and tuned up according to the operating and maintenance instructions in the Operator's Manual, Sears willrepair, free

of charge, any defect in materials or workmanship.

This warranty excludes the blade, nylon line, spark plug, and air filter,whichare expendable parts and become worn

during normal use.

If this Brushwacke_' is used forcommercialpurposes,thiswarrantyapplies foronly 90 days from the date of pumhase.

If this Brushwacket _ is used for rental purposes, this warranty applies for only 30 days from date of purchase.This war-

rant',/applies only while this product is in use in the United States.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE BRUSHWACKEFP TO THE NEAREST SEARS SER-

VICE CENTER IN THE UNITED STATES.

This warranty gives you specificlegal rights, and you may also have otherrights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

-4-

,, ,,,,,,,,,, ,,, i

TABLE OF CONTENTS

Safety Rules .................................................................... 2

Product Specifications ................ :..................................... 4

Warranty .......................................................................... 4

Accessories ..................................................................... 5

Assembly ......................................................................... 7

Operation ...................................................................... 12

A

Accessories...,,................................................................ 5

Adjustments

Carburetor .................................................................. 29

Handlebar .................................................................. 17

Idle Speed....................................... ........................... 29

Line Advance ............................................................. 17

Air Filter......................................................................... 22

Assembly

Blades ............................................................... 10 & 11

Semi-automatic Head .................................................. 9

Handlebar .................................................................... 8

Metal Debris Shield ................................................... 10

Plastic Debris Shield .................................................... 8

Throttle Handle ............................................................ 9

B

Blade Sharpening ......................................................... 28

Blade Thrust.................................................................. 14

C

Carburetor Adjustments ................................................ 29

Carton Contents .............................................................. 6

Customer Assistance

Hotline................................. ;........................... Back Cover

Customer Responsibilities ............................................. 21

CuttingMethods

Trimmer Operating Tips ............................................. 20

Blade Operating Tips ................................................. 15

D

Drive Shaft Lubrication .................................................. 22

E

Engine

Fuel/Oil....................................................................... 18

Spark Plug................................................................... 4

Starting ...................................................................... t 9

Storage ...................................................................... 30

Customer Responsibilities ............................................. 21

Service and Adjustments .............................................. 24

Storage.......................................................................... 30

Trouble Shooting ........................................................... 31

Repair Parts Ordering/Service ....................... Back Cover

INDEX

F

Fue!ing .......................................................................... 18

Fue! Filter ...................................................................... 23

H

Handlebar .............................................................. _........:8

K

Know Your Brushwacker ................................................ 12

L

Line Advancement ........................................................ 17

Line Replacement ......................................................... 26

M

Maintenance Schedule ....i............................................ 21

Model Number................................................................. 4

O

Operation

Brushwacker .............................................................. 18

Line Trimmer .............................................................. 20

Ordering Repair Parts .................................... Back Cover

R

Repair Parts List ........................................................... 32

S

Service and Adjustments.............................................. 24

Specifications.................................................................. 4

Starter Rope .................................................................. 24

Starting.......................................................................... 19

Storage.......................................................................... 30

T

Throttle Handle ................................................................ 9

Trouble Shooting .......................................................... 31

W

Warranty .......................................................................... 4

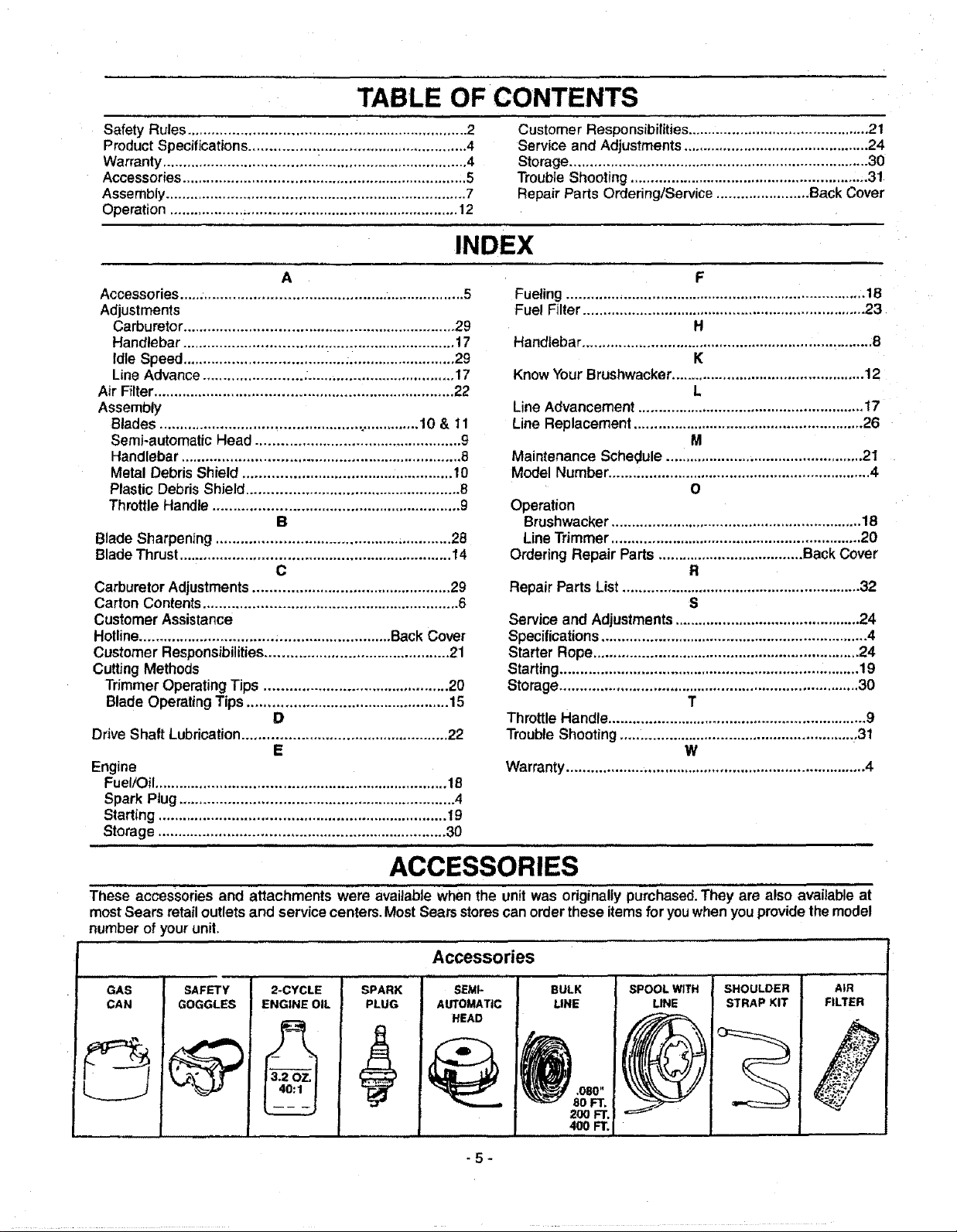

ACCESSORIES

These accessories and attachments' Were available when the unit was originallypurchased.They are also availableat

mostSears retail outletsand service centers.Most Searsstorescan orderthese items foryouwhen youprovidethemodel

number of your unit.

Accessories

,,,,,,,,,,,,,,,

GAS

CAN

SAFETY

GOGGLES

2-CYCLE

ENGINE OIL

3.2 OZ.

40:1

,,, _ ,,,i ,

SPARK SEMI-

PLUG AUTOMATIC

HEAD

-5-

BULK

LINE

400 FT.

SPOOL WITH

LINE

SHOULDER

STRAP KIT

AIR

FILTER

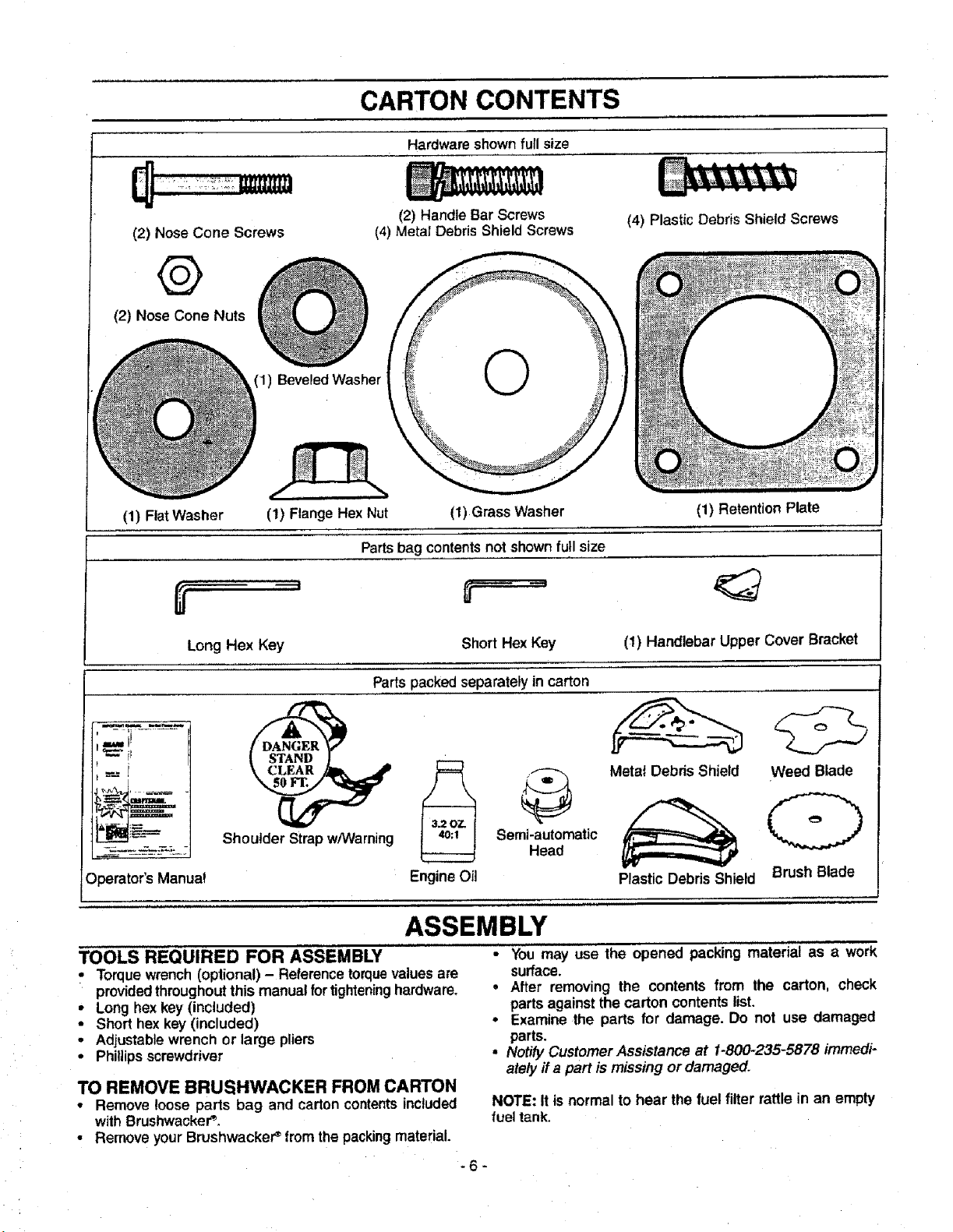

CARTON CONTENTS

Hardware shownfull size

(2) Nose Cone Screws

(2) Handle Bar Screws

(4) Metal Debris Shield Screws

(4) Plastic Debris Shield Screws

@

(2) Nose Cone Nuts

(1) BeveledWasher

(1) Flat Washer (1) Flange Hex Nut (1)Grass Washer (1) Retention Plate

Parts bag contents not shown full size

Long Hex Key Short Hex Key

(1) Handlebar Upper Cover Bracket

Partspacked separately in carton

;-il...........

!

Shoulder Strap w/Warning

Operator'sManua_ EngineOil

TOOLS REQUIRED FOR ASSEMBLY

• Torquewrench (optional) - Referencetorquevaluesare

providedthroughoutthis manual fortighteninghardware,

• Long hex key (included)

• Short hex key (included)

• Adjustablewrench or large pliers

• Phillipsscrewdriver

TO REMOVE BRUSHWACKER FROM CARTON

• Remove loose parts bag and carton contents included

with Brushwacker _

• Remove yourBrushwackeP from the packingmaterial.

_ Semi-i_Uta_dmatic

ASSEMBLY

Metat Debris Shield

Weed Blade

(D

Plastic Debris Shield

• You may use the opened packing material as a work

surface

° After removing the contents from the carton, check

parts againstthe carton contents list

• Examinethe parts for damage Do not use damaged

parts

• Notify Customer Assistance at 1-800-235-5878 immedi-

ately ffa part is missing or damaged

NOTE: It is normal to hear the fuel filter rattle in an empty

fueltank.

-6-

Brush Blade

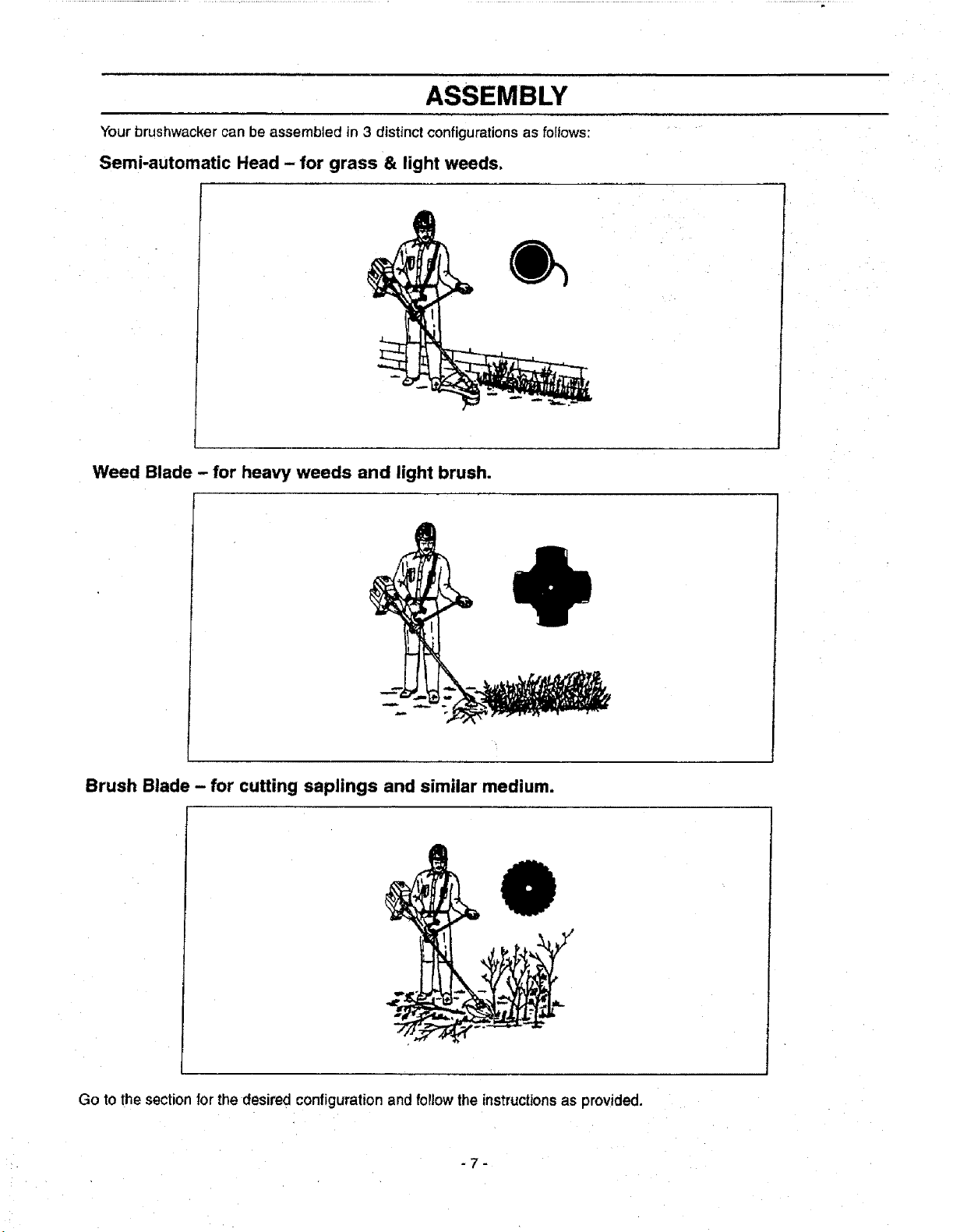

ASSEMBLY

Your brushwacker can be assembled in 3 distinct configurations as follows:

Semi-automatic Head - for grass & light weeds,

Weed Blade - for heavy weeds and light brush.

Brush Blade - for cutting saplings and similar medium.

Go to the section for the desired configuration and follow the instructionsas provided.

-7-

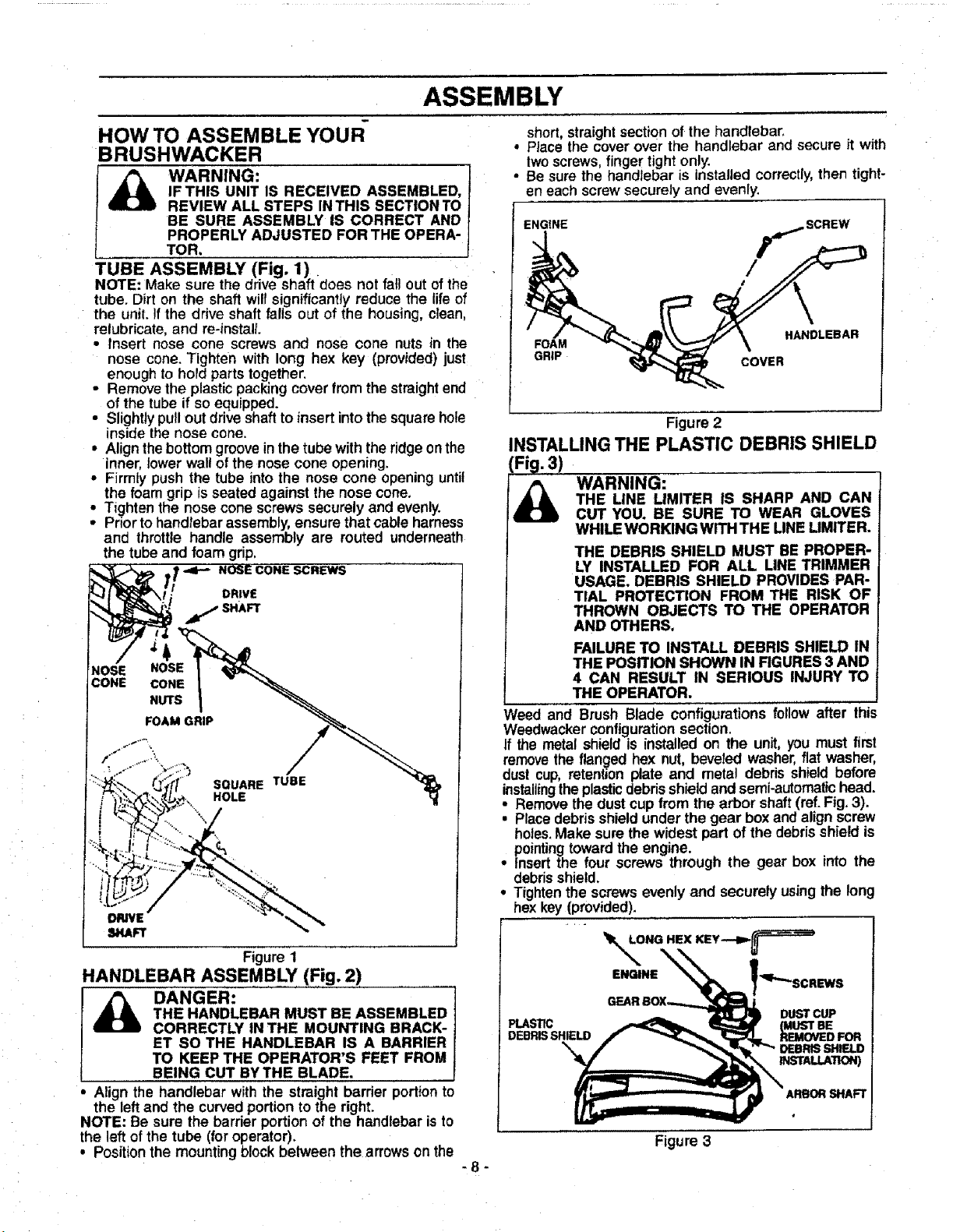

ASSEMBLY

HOW TO ASSEMBLE 'fOUR"

BRUSHWACKER

_ ARNING:

TUBE ASSEMBLY (Fig. I)

NOTE: Make sure the drive shaft does not fall out of the

tube. Dirt on the shaft will significantly reduce the life of

the unit. !fthe drive shaft fails out of the housing, clean,

relubricate, and re-instalL

• Insert nose cone screws and nose cone nuts in the

nose cone. Tighten with long hex key (provided) just

enough to hold parts together.

• Remove the plastic packing cover from the straightend

of the tube if so equipped.

• Slightly pull out drive shaft to insert into the square hole

inside the nose cone.

• Align the bottom groove in the tube withthe ridge on the

inner, lower wall of the nose cone opening.

• Firmly push the tube into the nose cone opening until

the foam grip isseated against the nose cone.

• Tighten the nose cone screws securely and evenly.

• Prior to handlebar assembly, ensure that cable harness

and throttle handle assembly are routed underneath

the tube and foam grip,

NOSE NOSE

CONE CONE

IF THIS UNIT IS RECEIVED ASSEMBLED,

REVIEW ALL STEPS IN THIS SECTION TO

BE SURE ASSEMBLY IS CORRECT AND

PROPERLY ADJUSTED FOR THE OPERA-

TOR,

NOSE CONE SCREWS

DRIVE

j SHAFT

NUTS

FOAM GRIP

short, straight section of the handlebar.

° Place the cover over the handlebar and secure it with

twoscrews, finger tight only.

• Be sure the handlebar is installed correctly, then tight-

en each screw securely and evenly.

ENGINE

SCREW

FOAM HANDLEBAR

GRIP COVER

Figure 2

INSTALLING THE PLASTIC DEBRIS SHIELD

_ ARNING:

Weed and Brush Blade configurations follow after this

Weedwacker configurationsection.

If the metal shield is installed on the unit, you must first

remove the flan_ed hex nut, beveled washer, flat washer,

dust cup, retenbon plate and metal debris shield before

installingthe plastic debris shield and semi-automatic head.

o

Remove the dust cup from the arbor shaft (ref. Fig. 3).

• Place debris shield under the gear box and align screw

holes. Make sure the widest part of the debris shield is

pointing toward the engine.

• Insert the four screws through the gear box into the

debris shield.

° Tighten the screws evenly and securely using the long

hex key (provided).

THE LINE LIMITER IS SHARP AND CAN

CUT YOU. BE SURE TO WEAR GLOVES

WHILE WORKING WITH THE LINE LIMtTER.

THE DEBRIS SHIELD MUST BE PROPER-

LY INSTALLED FOR ALL LINE TRIMMER

USAGE. DEBRIS SHIELD PROVIDES PAR-

TIAL PROTECTION FROM THE RISK OF

THROWN OBJECTS TO THE OPERATOR

AND OTHERS.

FAILURE TO INSTALL DEBRIS SHIELD IN

THE POSITION SHOWN IN FIGURES 3 AND

4 CAN RESULT IN SERIOUS INJURY TO

THE OPERATOR.

Figure 1

HANDLEBAR ASSEMBLY (Fig. 2)

i_ DANGER:

Align the handlebar with the straight barrier portion to

the left and the curved portion to the right.

NOTE: Be sure the barrier portion of the handlebar is to

the left of the tube (for operator).

, Position the mounting block between the arrows on the

THE HANDLEBAR MUST BE ASSEMBLED

CORRECTLY IN THE MOUNTING BRACK-

ET SO THE HANDLEBAR IS A BARRIER

TO KEEP THE OPERATOR'S FEET FROM

BEING CUT BYTHE BLADE.

-8-

r-

ENGINE

PLASTIC (MUST BE

DEBRISSHIELD REMOVED FOR

"_ DEBRIS SHIELD

Figure 3

DUST CUP

INSTALLATION)

ARBOR SHAFT

ASSEMBLY

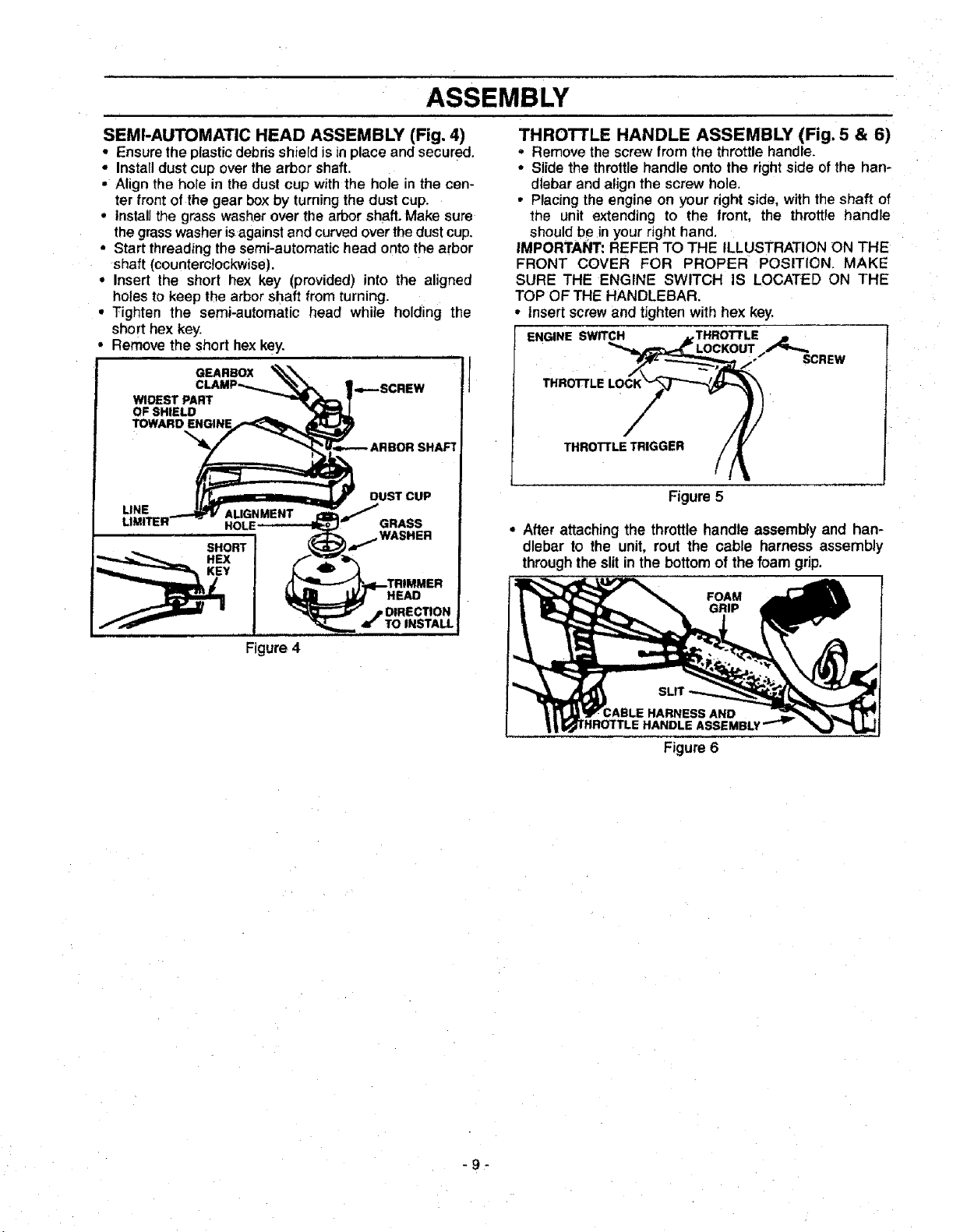

SEMI-AUTOMATIC HEAD ASSEMBLY (Fig. 4)

• Ensure the plasticdebrisshieldisin place and secured.

• Installdust cup overthe arbor shaft.

• Align the hole in the dust cup withthe hole in the cen-

ter front of the gear box by turning the dust cup.

• Installthe grass washer over the arbor shaft. Make sure

the grass washer is against and curved over the dust cup.

• Start threading thesemi-automatic head onto the arbor

shaft (counterclockwise).

• Insert the short hex key (provided) into the aligned

holes to keep the arbor shaft from turning.

• Tighten the semi-automatic head while holding the

short hex key.

• Remove the short hex key.

GEARBOX

WIDEST PART

OF SHIELD

THROTTLE HANDLE ASSEMBLY (Fig. 5 & 6)

• Remove the screwfrom the throttle handle.

• Slide the throttlehandle onto the rightside ofthe han-

dlebar and align the screw hole.

• Placing the engine on your right side, with the shaft of

the unit extending to the front, the throttle handle

should be in your right hand,

IMPORTANT: REFER TO THE ILLUSTRATION ON THE

FRONT COVER FOR PROPER POSITION. MAKE

SURE THE ENGINE SWITCH IS LOCATED ON THE

TOP OF THE HANDLEBAR.

• Insert screw and tighten with hex key.

ENGINE SWITCH THROT'rLE

SCREW

THROTTLE

THRO'FrLE TRIGGER

Figure 5

• After attaching the throttle handle assembly and han-

dlebar to the unit, rout the cable harness assembly

through the slit in the bottom of the foam grip.

FOAM

GRIP

ABLE HARNESS AND

HANDLE ASSEMBLY

Figure 6

-9-

ASSEMBLY

I I iii

BRUSHWACKER CONFIGURATION

Assembly information for Weedwacker configuration is

located before this section, the Brush Blade configura-

tion follows after thissection.

DANGER:

THE METAL SHIELD MUST BE PROPERLY

INSTALLED ON THE TOOL ANYTIME THE

TOOL IS USED WITH THE BLADE. THE

FORWARD TIP ON THE METAL SHIELD

HELPS TO REDUCE THE OCCURRENCEOF

BLADE THRUST WHICH CAN CAUSE

SERIOUS INJURY SUCH AS AMPUTATION

TOTHEOPERATORORBYSTANDERS.

FAILURETO INSTALLTHE DEBRIS SHIELD

IN THE POSITION SHOWNCAN RESULT IN

SERIOUSINJURYTO THE OPERATOR.THE

LENGTHOF THE DEBRISSHIELD MUST BE

ALIGNEDWRH THE LENGTHOF THE DRIVE

SHAFTHOUSING.

THE BLADEIS SHARP ANDCAN CUT YOU.

BE SURE TO WEAR GLOVES WHILE

WORKING WITH BLADES

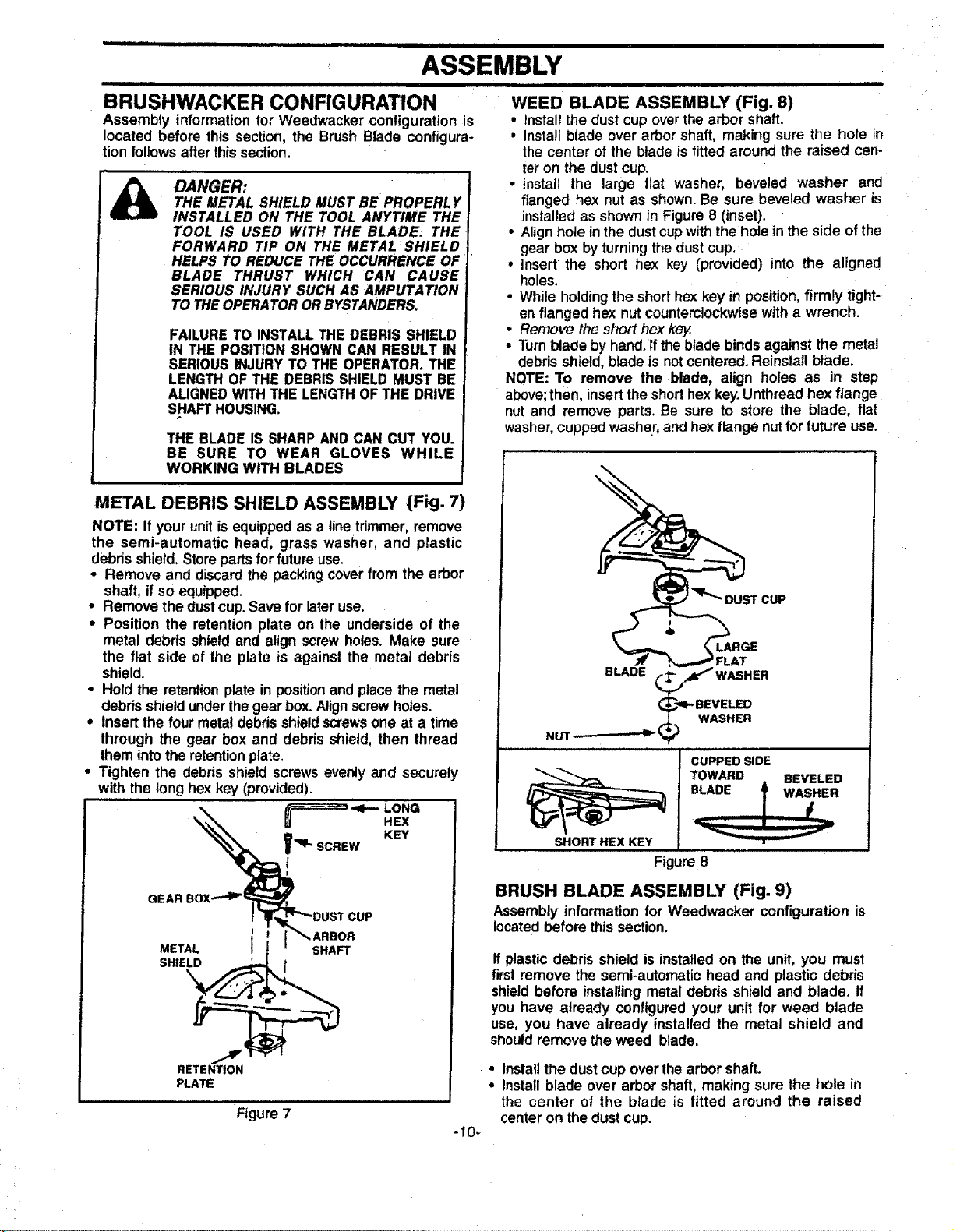

METAL DEBRIS SHIELD ASSEMBLY (Fig. 7)

NOTE: If your unitis equippedas a line trimmer,remove

the semi-automatic head, grass washer, and plastic

debris shield.Storepartsfor future use.

• Remove and discardthe packingcoverfrom the arbor

shaft, if so equipped_

• Remove the dustcup.Save for later use.

• Position the retention plate on the underside of the

metal debris shield and align screw holes. Make sure

the flat side of the plate is against the metal debris

shield.

• Hold the retentionplate in positionand place the metal

debrisshield underthegear box. Alignscrewholes.

• Insert the four metaldebdsshield screwsone at a time

through the gear box and debris shield, then thread

them intothe retentionplate,

• Tighten the debris shield screws evenly and securely

with the long hex key (provided),

ii ii i iiiiIIIH

WEED BLADE ASSEMBLY (Fig. 8)

• Installthe dust cup overthe arbor shaft.

• Install blade over arbor shaft, making sure the hole in

the center of the blade is fitted around the raised cen-

ter on the dust cup.

• Install the large flat washer, beveled washer and

flanged hex nut as shown. Be sure beveled washer is

installed as shown in Figure 8 (inset).

• Align hole in the dust cupwith the holein the side of the

gear box by turningthe dust cup.

• insert the short hex key (provided) into the aligned

holes.

• While holding the short hex key in position, firmly tight-

en flanged hex nutcounterclockwisewith a wrench.

• Remove the short hex key.

• Turnblade by hand. ft the blade binds against the metal

debris shield, blade is not centered. Reinstall blade.

NOTE: To remove the blade, align holes as in step

above;then, insert the short hex key. Unthread hex flange

nut and remove parts. Be sure to store the blade, flat

washer,cupped washer, and hex flange nutfor future use.

T CUP

_.. _ __ FLAT

BLADE _ _4_I"WASHER

NUT-- _ _

Ji _ i,J , . L,. LI

%LARGE

_1- BEVELED

(_";) WASHER

CUPPED SIDE

TOWARD BEVELED

_'q_ SCREW KEY

GEAR

_I_'_DUST CUP

METAL I SHAFT

SHIELD _

RETENTION

PLATE

i I _-*" ARBOR

Figure 7

HEX

SHORT HEX KEY

Figure 8

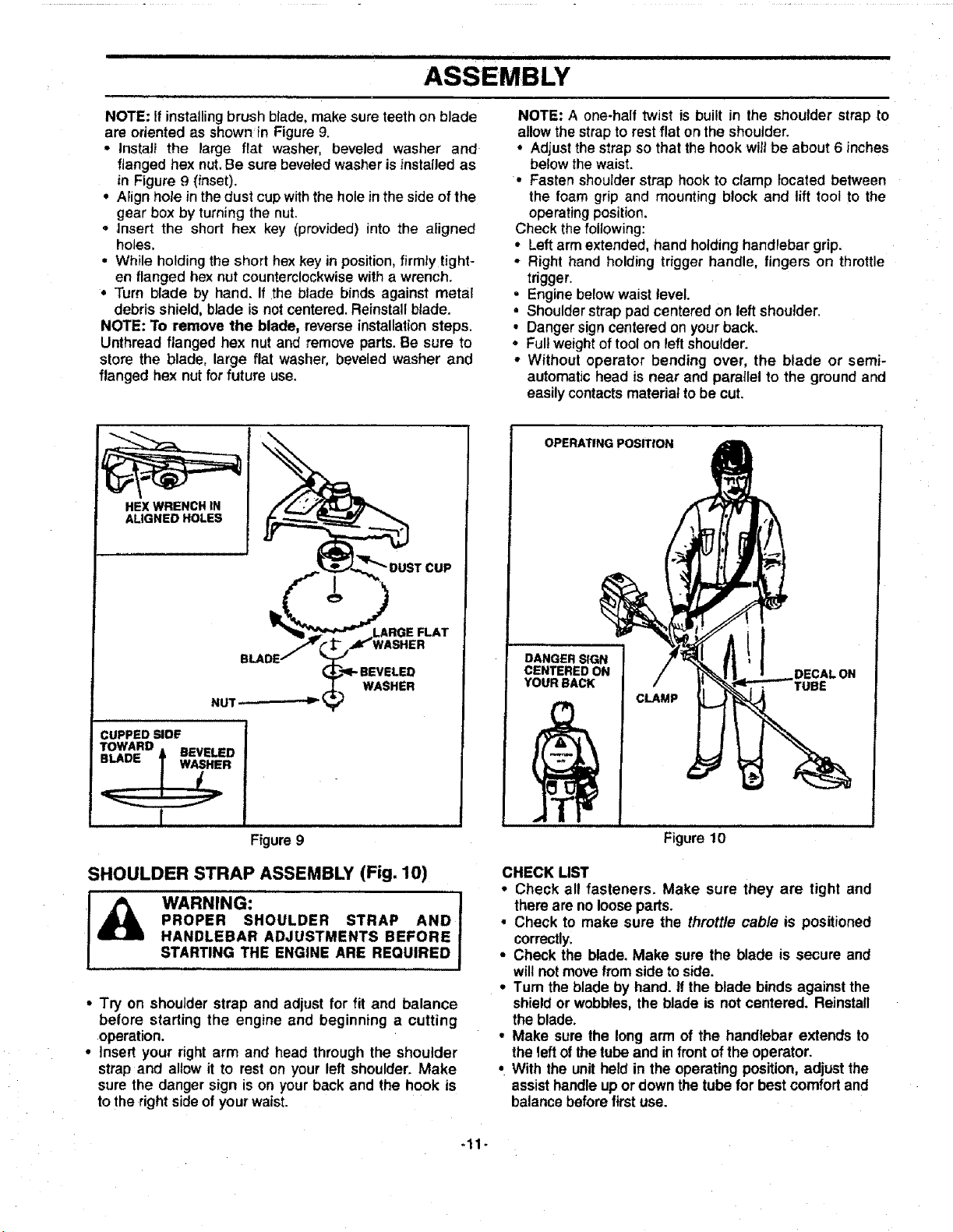

BRUSH BLADE ASSEMBLY (Fig. 9)

Assembly informationfor Weedwacker configuration is

locatedbefore this section.

If plastic debris shield is installed on the unit, you must

first remove the semi-automatic head and plastic debris

shield before installing metal debris shield and blade. If

you have already configured your unit for weed blade

use, you have already installed the metal shield and

should remove the weed blade.

• Installthe dust cup overthe arbor shaft.

, Install blade over arbor shaft, making sure the hole in

the center of the blade is fitted around the raised

center on the dust cup.

-10-

ASSEMBLY

NOTE: If installing brush blade, make sure teeth on blade

are oriented as shownin Figure 9.

• Instal_ the large flat washer, beveled washer and

flanged hex nut. Be sure beveled washer is instaiJed as

in Figure 9 (inset).

• Aiign hole inthe dust cup withthe hole in the side of the

gear box by turning the nut.

° Insert the short hex key (provided) into the aligned

holes,

• While holding the short hex key in position,firmIy tight-

en flanged hex nut counterclockwise with a wrench.

° Turn blade by hand. If the blade binds against metal

debris shield, blade is not centered. Reinstall blade.

NOTE: To remove the blade, reverse installation steps.

Unthread flanged hex nut and remove parts. Be sure to

store the blade, large flat washer, beveled washer and

flanged hex nut for future use,

HEX WRENCH IN

ALIGNED HOLES

NOTE: A one-half twist is built in the shoulder strap to

allow the strap to rest flat on the shoulder.

° Adjust the strap so that the hook wilt be about 6 inches

below the waist.

• Fasten shoulder strap hook to clamp located between

the foam grip and mounting block and lift tool to the

operating position.

Check thefollowing:

• Left arm extended, hand holding handlebar grip.

• Right hand holding trigger handle, fingers on throttle

trigger.

• Engine below waist tevel.

• Shoulder strap pad centered on left shoulder.

• Danger sign centered on your back.

• Fullweight of tool on leftshoulder.

• Without operator bending over, the blade or semi-

automatic head is near and parallel to the ground and

easily contacts material to be cut.

OPERATING POSITroN

VASHER

WASHER

NUT _-

CUPPED SIDE

TOWARD

==1An= _ BEVELED

ii i

Figure 9

SHOULDER STRAP ASSEMBLY (Fig. 10)

PROPER SHOULDER STRAP AND 1

I_ WARNING: J

HANDLEBAR ADJUSTMENTS BEFORE !

STARTING THE ENGINE ARE REQUIRED J

• Try on shoulder strap and adjust for fit and balance

before starting the engine and beginning a cutting

operation.

• Insert your right arm and head through the shoulder

strap and allow it to reston your left shoulder. Make

sure the danger sign is on your back and the hook is

to the rightsideof your waist.

DANGER SIGN

CENTERED ON

YOUR BACK

CLAMP

DECALON

Figure 10

CHECK LIST

• Check all fasteners. Make sure they are tight and

there are no loose pads.

• Check to make sure the throttle cable is positioned

correctly.

° Check the blade. Make sure the blade is secure and

willnot movefromside to side.

° Turn the blade by hand. if the blade binds against the

shield or wobbles, the blade is not centered. Reinstall

the blade.

° Make sure the long arm of the handlebar extends to

the left of the tube and in front of the operator.

• With the unit held in the operating position, adjust the

assisthandle up or down the tube for best comfort and

balance before first use.

-11-

Loading...

Loading...