Craftsman 358798430 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

Operator's

Manual

Model No.

358.798430

CUSTOMER

ASSISTANCE

1-800-235-5878

:_ HOURS (CST)

Mort.- SaL7 a.m.- 7 p.m. \ I

_ WARNING:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

Always Wear Eye Protection

®

32 cc/2.0 cu. in. 2-CYCLE ENGINE

17 Inch Semi-Automatic Head®

GAS WEEDWACKER®

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

° Repair Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 u.S.A. '

530-O83546-4:O9/20/95

SAFETY RULES

...... : ii i i lllll i ,i,,ll i i i . ill i ,,,H II. .........

i_ CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CON-

OPERATOR SAFETY

. Always wear safety eye protection.

* Always wear long pants, long sleeves, boots and

gloves. Wearing safety leg guards is recommended. Do

not go barefoot or wear sandals, short pants, short

sleeves. Being fully covered helps to protect you from

pieces of toxic plants thrown by the cutting head.

* Secure hair so it is above shoulder length. Secure loose

clothing or jewelry, or clothing with loosely hanging ties,

straps,tassels, etc.;they can be caught in moving parts.

* Do not operate this unitwhen you are tired, ill or under

the influenceof alcohol, drugs, or medication.

• Wear hearing protection if youuse this unit for more

than 1-1/2 hours per day.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kill.

* Keep handles free of oil and fuel.

• If situations occur which are not covered in this manu-

al, use care and good judgement.

UNIT MAINTENANCE/SAFETY

• Look for and replace damaged or loose parts before

each use. Look for and repair fuel leaks before use.

Keep the unit in good working condition.

• Replace semi-automatic head parts that are chipped,

cracked, broken, or damaged in any other way before

using the unit.

• Maintain the unit according to recommended proce-

dures. Keep the cutting line at the proper length.

* Use only .080" diameter monofitament line. Never use

wire, rope, string, etc.

• Install the required debris shield properly before using

the unit.

• Use only specified semi-automatic head. Make sure it

is properly installed and securely fastened.

• Disconnect the spark plugs before performing mainte-

nance (except carburetor adjustment).

• Make carburetor adjustments with the lower end sup-

ported to prevent.the trimmer line from contacting any

object. Hold the unit by hand.

• Keep others away when making carburetor adjust-

ments.

. Use only quality SEARS accessories and replace-

ment parts as recommended for this unit.

• Have all maintenance and service not explained in this

manual performed by your SEARS Service Center.

TACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING,

ADJUSTING OR MAKING REPAIRS.

FUEL SAFE7_.

• Mix and pour fuel outdoors.

o Keep away from sparks orflames.

* Use a container approved forfuel.

• Do not smoke or allow smoking near fuel or the unitc

while using the unit.

o Wipe up all fuel spills before starting engine.

• Move at least 10 feet (3 meters) away from fueling sit,

before starting engine.

• Stop engine and allow unit tocoot before removing fuc

cap.

CUTTING SAFETY

• inspect the area to be cut before each use. Rem0'_{

objects (rocks, broken glass, nails, wire, string, etc.

which can be thrownor become entangled in the semi

automatic head.

• Keep others including children, animals, bystander.,

and helpers a minimum of 50 feet (15 meters) away

Stop the engine immediatelyifyou are approached.

• Always keep {he engine on the right-hand side of yot

body.

* Hold the unit firmly with both hands.

• Keep firm footing and balance. Do not over-reach.

• Keep the semi-automatic head below waist level.

• Do not raise the engine above your waist.

* Keep all parts of your body away from semi-automat!

head and muffler when engine is running.

• Cut from your right to your left.

- Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

• Stop the unitbefore transporting.

• Allow the engine to cool, and secure the unit befor,

storing or transporting in a vehicle.

° Empty the fuel tank before storing or transporting th,

unit. Use up any fuel left in the carburetor by startin!

the engir_and-letting the engine run until it stops.

° Store unit and fue! in an area where fuel vapors cann(

reach sparks or open flames from water heaters, elec

tdc motor or switches, furnaces, etc.

• Store unit so line limiter cannot accidentally caL_s,

injury.

• Store the unit out of the reach of children.

J SAFETY NOTICE ,

Exposure to vibrationsthroughprolongeduseof gasolinepoweredhandunitscouldcausebloodvesselor nervedamageinthefin-

gers, hands,and joints of peopleproneto circulationdisordersor abnormal sweltings. Prolongeduse in cold weather has been

linkedto bloodvesseldamagein otherwisehealthypeople. Ifsymptomsoccursuchas numbness,pain,lossofstrength,change.in

skinti,viC°l°r°rtexture,or lossof feelinginthe fingers, hands orjoints,discontinuethe us_of thisunitandseek medicalattention.

ant'- ibrat'on,system,doesnotguaranteethe avoidance,of theseproblems... Users.whooperatepowertoolsona continualandregu-

liar basis must monitor closely theirphysicalconditlonandthe condft!onof thisunit.

I _b) LOOK FOR TH'S SYMBOl TO PO|NT OUT |MPORTA"T SAFE_ PREOAUT|O"S.

|T MFANS - A_ENT|ON.f.I, BECOME ALI_RTH' YOUR SAFE_ |S 'NVOLVE_.

-2-

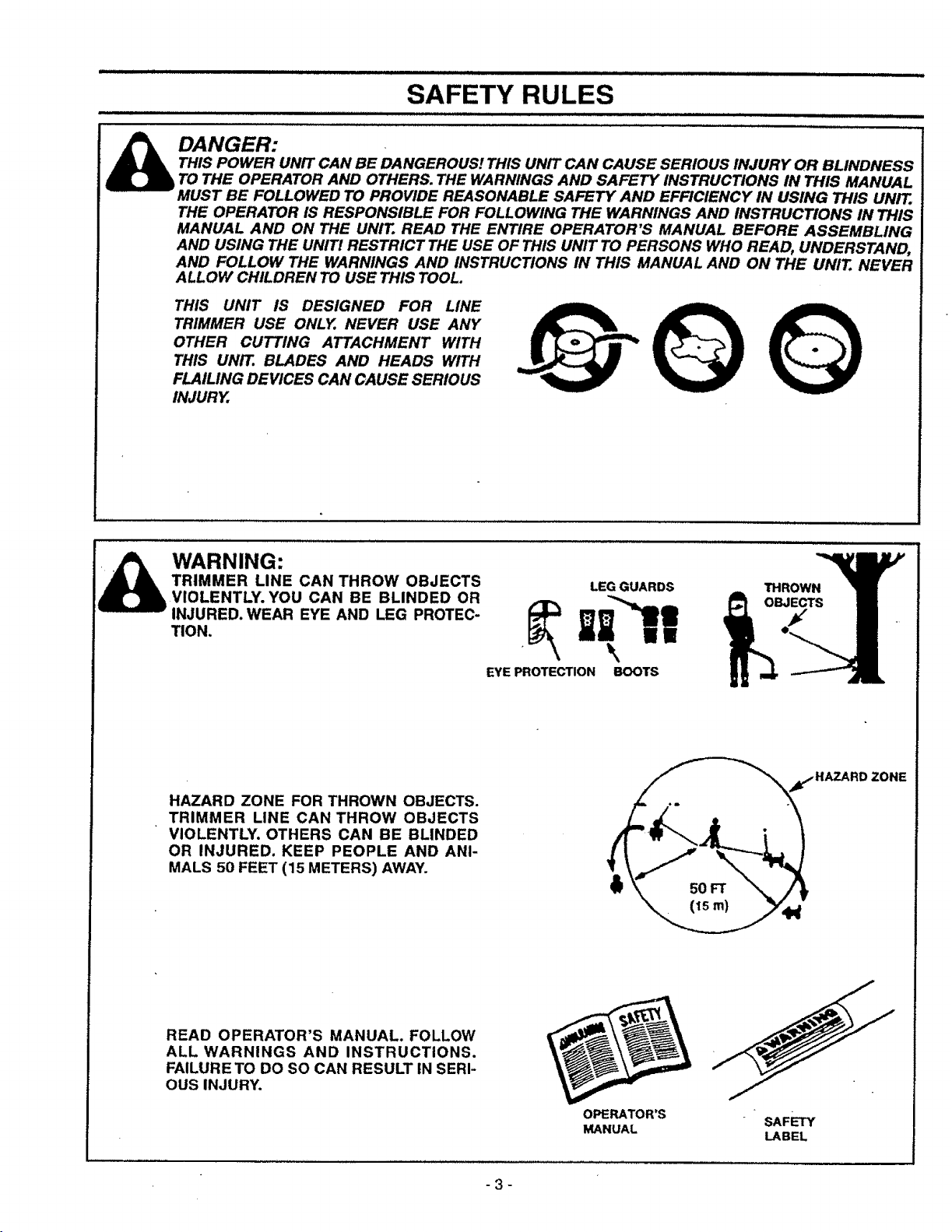

An

DANGER:

THIS POWER UNIT CAN BE DANGEROUS! THIS UNIT CAN CAUSE SERIOUS INJURY OR BLINDNESS

TO THE OPERATOR AND OTHERS. THE WARNINGS AND SAFETY INSTRUCTIONS IN THIS MANUAL

MUST BE FOLLOWED TO PROVIDE REASONABLE SAFETY AND EFRCIENCY IN USING THIS UNrl;,

THE OPERATOR IS RESPONSIBLE FOR FOLLOWING THE WARNINGS AND INSTRUCTIONS IN THIS

MANUAL AND ON THE UNIT. READ THE ENTIRE OPERATOR'S MANUAL BEFORE ASSEMBLING

AND USING THE UNIT! RESTRICT THE USE OF THIS UNIT TO PERSONS WHO READ, UNDERSTAND,

AND FOLLOW THE WARNINGS AND INSTRUCTIONS IN THIS MANUAL AND ON THE UNIT. NEVER

ALLOW CHILDREN TO USE THIS TOOL.

THIS UNIT IS DESIGNED FOR LINE

TRIMMER USE ONLY. NEVER USE ANY

OTHER CUTTING ATTACHMENT WITH

THIS UNIT* BLADES AND HEADS WITH

FLAILING DEWCES CAN CAUSE SERIOUS

INJURY,

WARNING:

TRIMMER LINE CAN THROW OBJECTS

VIOLENTLY. YOU CAN BE BLINDED OR

INJURED. WEAR EYE AND LEG PROTEC-

TION.

LEG GUARDS

HAZARD ZONE FOR THROWN OBJECTS.

TRIMMER LINE CAN THROW OBJECTS

VIOLENTLY. OTHERS CAN BE BLINDED

OR INJURED. KEEP PEOPLE AND ANI-

MALS 50 FEET (15 METERS) AWAY.

READ OPERATOR'S MANUAL. FOLLOW

ALL WARNINGS AND INSTRUCTIONS.

FAILURE TO DO SO CAN RESULT IN SERI-

OUS INJURY.

EYE PROTECTION BOOTS

OPERATOR'S SAFETY

MANUAL

HAZARD ZONE

LABEL

-3-

CONGRATULATIONS on your purchase of a Sears

Craftsman Gas Weedwacker. It has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department. Sears has competent, well trained tech-

nicians and the proper tools to service or repairthis unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES,"

MODEL NUMBER: 358.798430

DATE CODE/SERIAL NO.:

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON THE PRODUCT.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OR PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAIkrrENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules+

• Follow a regular schedule in maintaining, caring for,

and using your unit.

• Follow the instructions under "Customer Responsibili-

ties" and "Storage" sections of this Operator's Manual.

PRODUCT SPECIFICATIONS

CUTTING PATH.................. 17" (43 cm)

TRIMMER LINE ................... 080" Diameter

Monofitament

SEMI-AUTOMATIC

HEAD ROTATIOnal............... Clockwise (for operator)

ENGINE .............................. 32 cc, 2-cycle Air-Cooled

FUEL/OIL MIX RATIO ......... 40:1 (3.2 oz. oil per

gallon gas)

IGNITION ............................ Spark Advance

(air gap .010" to .014")

IGNITION TIMING .............. Non-adjustable, fixed

SPARK PLUG ..................... Champion (RCJ-8Y)

SPARK PLUG GAP .............. 025" (.6mm)

ENGINE RPM ..................... 7,500 RPM Max. :

SPECIAL NOTICE

For userson U.S. ForestLand and in some states, includ_

ing California (Public Resources Codes 442 and 443),

Idaho, Maine, Minnesota, New Jersey, Oregon, and

Washington:Certaininternalcombustionenginesoperated

on forest,brush,and/or grass-coveredlandsin the above

areas are requiredto be equippedwith a+sparkarrestor,

maintainedineffectiveworkingorder,orthe enginemustbe

constructed,equipped,and maintainedfor the preventionof

fire.Checkwithyourstateor localauthoritiesfor regulations

pertainingto these requirements.Failure to follow these

requirementsisa violationof the law. This unitisnotfacto-

ry-equippedwitha sparkarrestor;,however,a sparkarrestor

is available as an optional part. If a spark arrestor is

required in your area, contact your SEARS Service

Center/Departmentforthecorrectkit.

M_m,_ctuPed under ot_e or more of t_e fo_,_,t_ U,S, patents:. 5,383,427; 54,387,988;

5,345,684: 5,343.831;5276,9_: 5+269,665;5,_z0,_23;4,940,(_8; 4,897,9"23; ,8582_;

4,846,123; 4,841,929; 4,835,667; 4,825,548; 4,823,465; 4.819,742; 4,'/98+185; 4,508, 7 :

4.483o_69; 4,45t+983'. 4o366.622; 4+366,621; 4,352,243; 4,347,666; 4.290,200; 4.286+6 5;

4,236.312; 4,177+561; 4,172,322; 4,167.812; 4,16_+575; 4,16'_,820; 4,122.653; 4,104.79_

Re.32+266; {3344.088; D324+051; D304,19_: D276,t60. Other U.S, _ !oreign p_te_

perKr_g.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS-POWERED

WEEDWACKER ®LINE TRIMMER.

For one year'from the date of purchase, when this Craftsman Gas-Powered WeedwackeP Line Trimmer is maintained,

lubricated and tuned up according to the operating and maintenance instructionsin the Operator's Manual, Sears wilt

repair, free of charge, any defect in materials or workmanship.

This warranty excludes nylon line, spark plug, and air filter, which are expendable parts and become worn during nor-

mal use.

if this Weedwacker _LineTrimmer is used for commercial purposes, this warranty applies for only 90 days from the date

of purchase. If this Weedwacker _ Line Trimmer is used for rental purposes, this warranty applies for only 30 days from

date of purchase. This warranty applies only while this product is in use in the United States.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE WEEDWACKER ®LINE TRIMMER TO THE NEAREST

SEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., DI817WA, HOFFMAN ESTATES, IL 6.0179

-4-

J_ JUUll Ii [ Ill I I IHI III L i .,l,,. , , , ....

Safety Rules .................................................................... 2

Product Specifications ............................. _....................... 4

Warranty .......................................................................... 4

Assembly ......................................................................... 7

Operation ......................................................................... 8

,,,,i,,,,, iiill i ii i1,,i,,i,,11,1HH II I J IHI I

INDEX

A

Accessories ..................................................................... 5

Adjustments

Assist Handle ............................................................. 10

Carburetor .................................................................. 20

Air Filter ......................................................................... 15

Assembly .............................................. :.......................... 7

C

Carburetor Adjustments ................................................. 20

Carton Contents .............................................................. 6

Customer Responsibilities ............................................. 14

Spark Plug .................................................................. 15

Cutting Methods ............................................................ 13

D

.Debris Shield .................... _........ :..................................... 7

Drive Shaft Lubrication .................................................. 15

E

Engine

Fue!/Oil ....................................................................... 11

Spark Plug .................................................................. 15

Starting ....................................................................... 12

Storage ....................................................................... 2t

F

Fueling ........................................................................... 11

IIII

Customer Responsibilities ............................................. 14

Service and Adjustments ............................................... 17

Storage .......................................................................... 21

Trouble Shooting ......... :.......:.......................................... 22

Repair Parts Ordering/Service ........................ Back Cover

iiii ] i ........ i111 ii iiiiiii11[i iiiii

'" i

K

Know Your Weedwacker .................................................. 8

L

Line Advancement ......................................................... 10

Line Replacement .......................................................... 18

M

Maintenance Schedule .................................................. 14

Model Number ........... :..................................................... 4

O

Operation ......................................................................... 8

Ordering Repair Parts ................................................... 26

R

Repair Parts ................................................................... 23

Ordering ....................................................... Back Cover

S

Service and Adjustments ................................ ............... 20

Specifications................................................................... 4

Starting ................. ......................................................... 12

Storage .......................................................................... 21

T

Trouble Shooting ............................................................ 22

W

Warranty .......................................................................... 4

IIIIIIIIIIIlull]l]l] nlllullllullll 1111 I jjlllllll 111111 I IIIIIIIIII I I I I [llllllllrlrr II

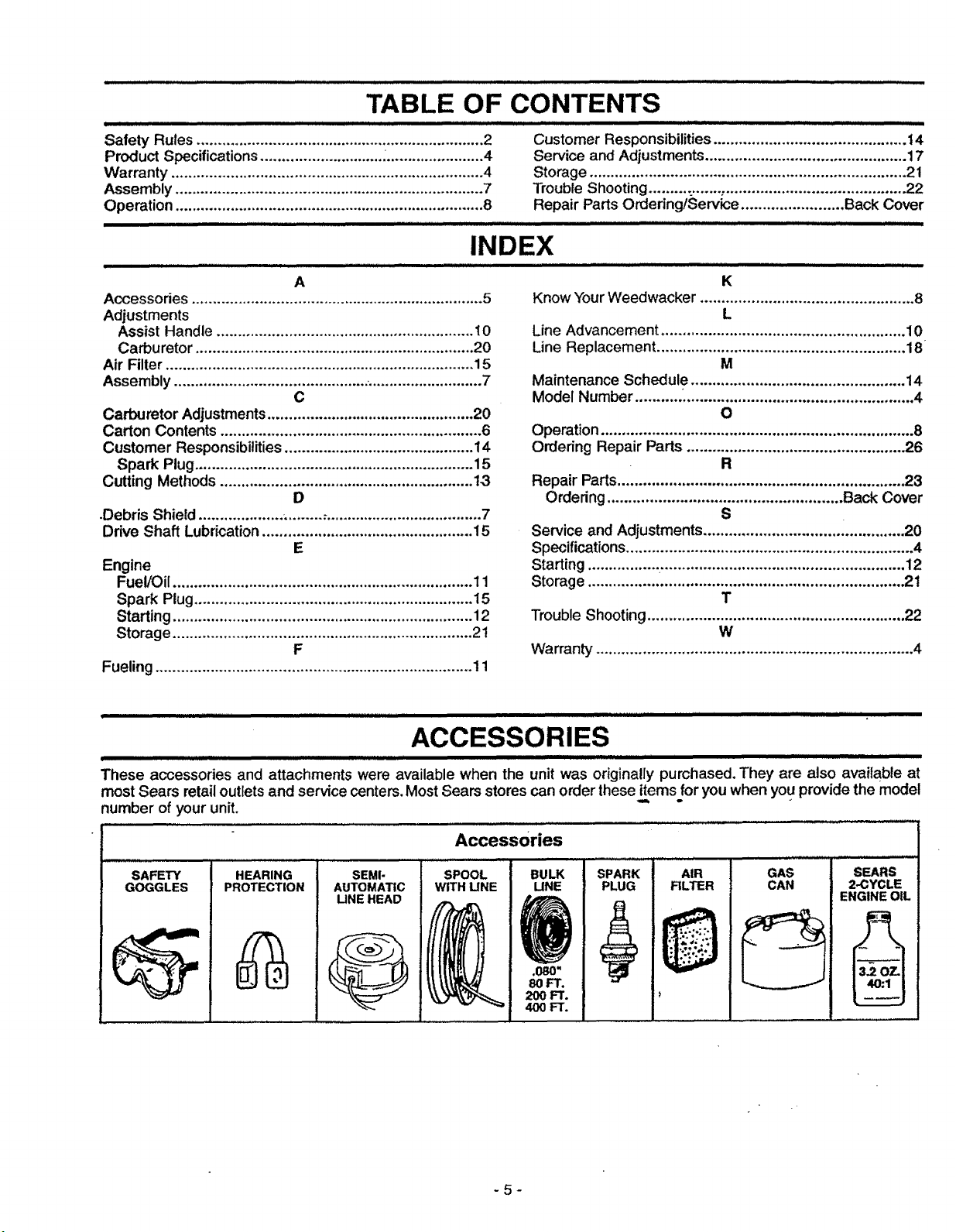

AccEssORIEs

Ilul jlllllllll]llllr I_I) IJUIIIII 1 1 IqlLIllrlllllllllllll I i I IIIIIIIrllll rrrl Irl 1

These accessories and attachments were available when the unit was originally purchased. They are also available at

most Sears retail outlets and service centers. Most Sears stores can order these items for you when you provide the model

number of your unit. _ "

Accessories

SAFETY

GOGGLES

HEARING

PROTECTION

SEMI-

AUTOMATIC

LINE HEAD

SPOOL

WITH UNE

BULK

UNE

80FT.

200 Flr.

400 FT.

SPARK

PLUG

AIR GAS

FILTER CAN

SEARS

2_CYCLE

ENGINE OIL

3-

40:1 i

-5-

..................... _ ......................................................... ill i L/ I

CARTON CONTENTS

........... i=l i ii ,i illli,,ll i i ,,,,,,,,,,,,,,,,, i i jl i i ill i : ,.............................................

Hardware shown full size

(1) Debris Shield Knob

Parts bag contents not shown full size

Long Hex Key

Parts packed separately in carton

Operator's Manual

Plastic Debris Shield Engine Oil

ASSEMBLY

IJ 11 I I III1[ I III111 I II . II II111 I

TOOLS REQUIRED FOR ASSEMBLY

• Torque Wrench (optional)- Reference torque values are

provided throughout this manual for tightening hard-

ware.

• Long Hex Key (included)

' Adjustable wrench or large pliers

TO REMOVE WEEDWACKER

FROM CARTON

• Remove loose parts bag included with Weedwacker.

• Remove the packing material from your Weedwacker,

including the clear protectivecover from the tube.

• You may use the opened packing material as a work

surface.

.... iiii i i

NOTE: Model 358.798430 is partially assembled.

• After removing the contents from the carton, chec

parts against the Carton Contents list.

• Examine the parts for damage. Do not use damage,

parts.

° Notify your SEARS store immediately if a part is miss

ing or damaged.

NOTE: It is normal to hear the fuel filter rattle in an empt

fuel tank.

-6-

,,, ,,, ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, , , , ...........................

ASSEMBLY

-- ttttttit t I ii ..., , ......................

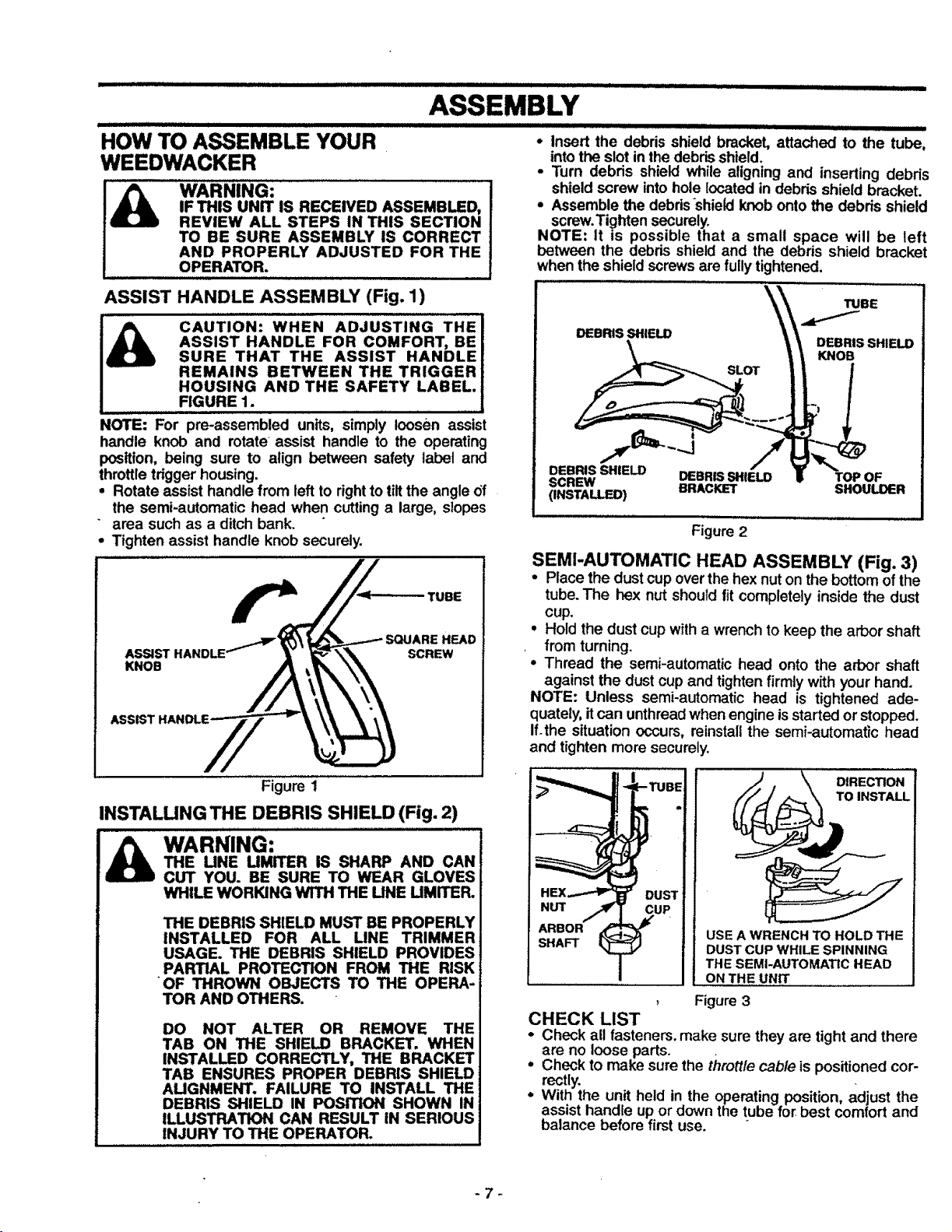

HOW TO ASSEMBLE YOUR • Insert the debris shield bracket, attached to the tube,

WEEDWACKER

intothe slot in the debris shield.

• Turn debris shield while aligning and inserting debris

shield screw into hole located in debris shield bracket.

- Assemble the debds"shield knob onto the debris shield

screw.Tighten securely.

NOTE: It is possible that a small space will be left

between the debris shield and the debds shield bracket

when the shield screwsare fully tightened.

ASSIST HANDLE ASSEMBLY (Fig. 1)

CAUTION: WHEN ADJUSTING THE

ASSIST HANDLE FOR COMFORT, BE

SURE THAT THE ASSIST HANDLE

REMAINS BETWEEN THE TRIGGER

HOUSING AND THE SAFETY LABEL.

FIGURE 1.

NOTE: For pre-assembled units, simply loosen assist

handle knob and rotate assist handle to the operating

position, being sure to align between safety label and

throttle trigger housing.

• Rotate assist handle from left to rightto tiltthe angle of

the semi-automatic head when cutting a large, slopes

area such as a ditch bank.

• Tighten assist handle knob securely.

TUBE

ASSIST

KNOB

ASSmT

SQUARE HEAD

SCREW

TUBE

DEBRIS SHIELD

SLOT

DEBRIS SHIELD DEBRIS SHIELD

SCREW

(INSTALLED) BRACKET

DEBRIS SHIELD

KNOB

SHOULDER

Figure 2

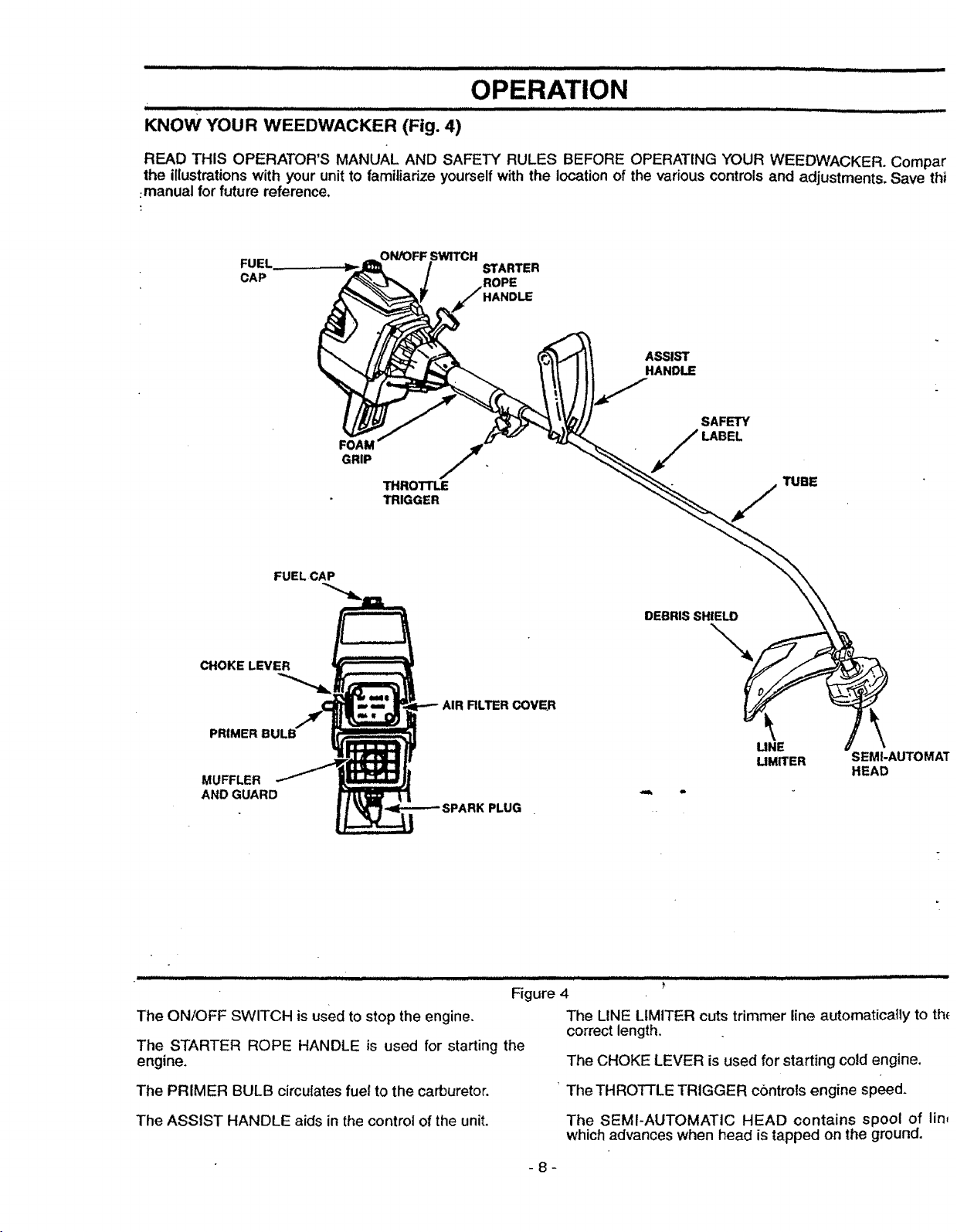

SEMI-AUTOMATIC HEAD ASSEMBLY (Fig. 3)

• Place the dust cup over the hex nut on the bottom of the

tube. The hex nut should fit completely inside the dust

cup.

• Hold the dust cup with a wrench to keep the arbor shaft

from turning

• Thread the semi-automatic head onto the arbor shaft

against the dust cup and tighten firmly with your hand.

NOTE: Unless semi-automatic head is tightened ade-

quately, it can unthread when engine is started or stopped.

If the situation occurs, reinstall the semi-automatic head

and tighten more securely.

Figure1

INSTALUNG THE DEBRIS SHIELD (Fig. 2)

WARNING:

THE UNE UMITER IS SHARP AND CAN

CUT YOU. BE SURE TO WEAR GLOVES

WHILE WORKING WITH THE LINE MMITER.

THE DEBRIS SHIELD MUST BE PROPERLY

INSTALLED FOR ALL LINE TRIMMER

USAGE. THE DEBRIS SHIELD PROVIDES

PARTIAL PROTECTION FROM THE RISK

OF THROWN OBJECTS TO THE OPERA-

TOR AND OTHERS.

DO NOT ALTER OR REMOVE THE

TAB ON THE SHIELD BRACKET. WHEN

INSTALLED CORRECTLY, THE BRACKET

TAB ENSURES PROPER DEBRIS SHIELD

AUGNMENT. FAILURE TO INSTALL THE

DEBRIS SHIELD IN POSITION SHOWN IN

ILLUSTRATION CAN RESULT IN SERIOUS

INJURY TO THE OPERATOR.

-7-

TUBI

HEX.---"P

NUT J

ARBOR

SHAFT

, Figure 3

CHECK LIST

° Check all fasteners, make sure they are tight and there

are no loose parts.

• Check to make sure the throttle cable is positioned cor-

rectly.

• With the unit held in the operating position, adjust the

assist handle up or down the tube for best comfort and

balance before first use. -

USEA WRENCHTOHOLDTHE

DUSTCUPWHILESPINNING

THE SEMI-AUTOMATICHEAD

ONTHE UNIT

ill. iill i illl ii iiill i • .... : ................

i ,.HI. IIIIlllI JI I

OPERATION

_- i,,,m i ii i

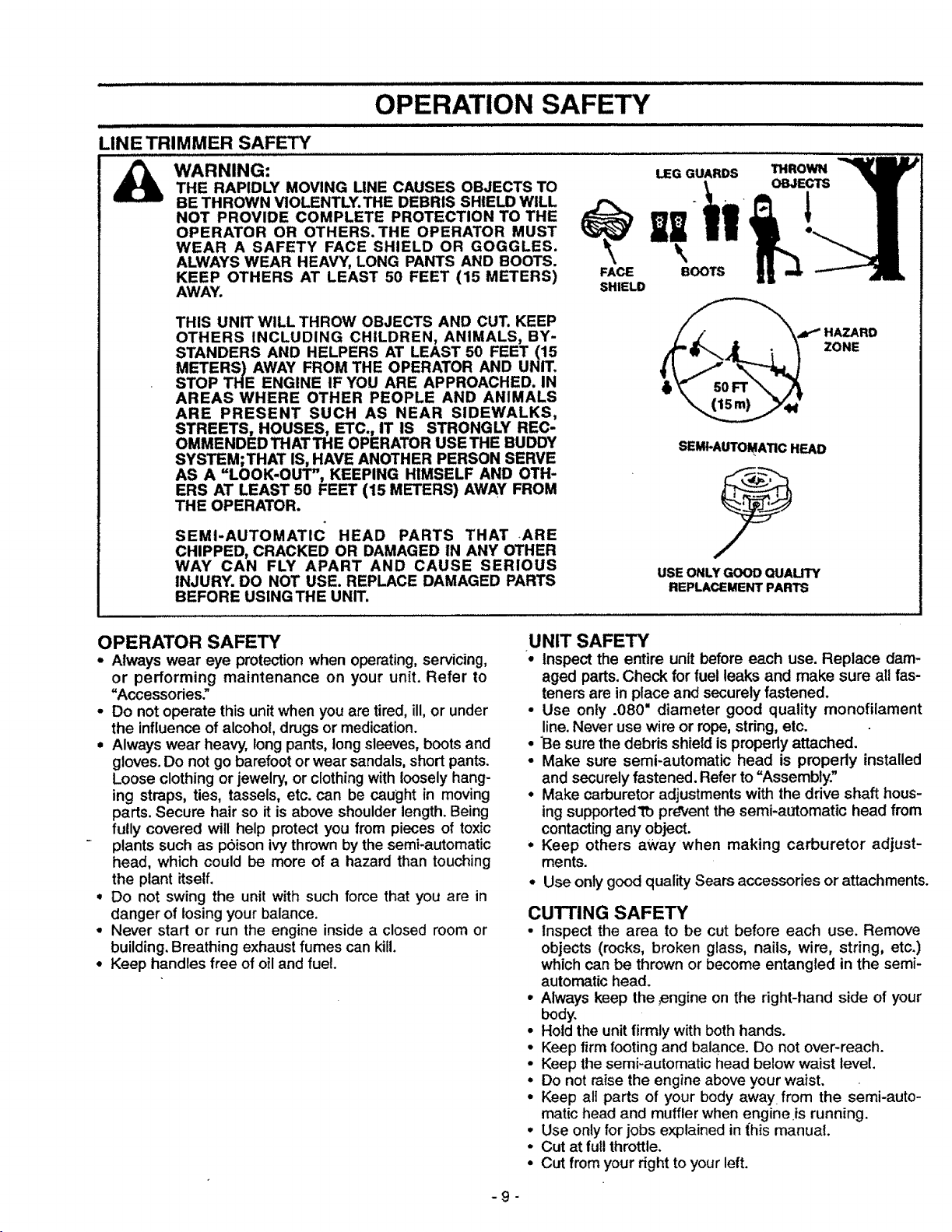

KNOW YOUR WEEDWACKER (Fig. 4)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR WEEDWACKER. Compar

the illustrations with your unit to familiarize yourself with the location of the various controls and adjustments. Save thi

manual for future reference.

i

CAP

CHOKE LEVER

FUEL CAP

FOAM

GRIP

THROTTLE

TRIGGER

STARTER

ROPE

4ANDLE

ASSIST

HANDLE

SAFETY

TUBE

DEBRIS SHIELD

AIR RLTER COVER

PRIMER

MUFFLER

AND GUARD

SPARK PLUG

UNE

UMITER

SEMI-AUTOMAT

HEAD

Figure 4

The ON/OFF SWITCH is used to stop the engine, The LINE LIMITER cuts trimmer line automatically to th_

correct length,

The STARTER ROPE HANDLE is used for starting the

engine, The CHOKE LEVER is used for starting cold engine.

The PRIMER BULB circulates fuef to the carburetor. • The THROTTLE TRIGGER cbntrots engine speed.

The ASSIST HANDLE aids in the control of the unit. The SEMI-AUTOMATIC HEAD contains spool of lin_

which advances when head is tapped on the ground.

-8-

LINE TRIMMER SAFETY

OPERATION SAFETY

_ WARNING: LeGGUARDS THROWN

BE THROWN VIOLENTLY.THE DEBRIS SHIELD WILL |

NOT PROVIDE COMPLETE PROTECTION TO THE

OPERATOR OR OTHERS.THE OPERATOR MUST

WEAR A SAFETY FACE SHIELD OR GOGGLES.

ALWAYS WEAR HEAVY, LONG PANTS AND BOOTS.

KEEP OTHERS AT LEAST 50 FEET (15 METERS) FACE

AWAY. SHIELD

THIS UNIT WILL THROW OBJECTS AND CUT. KEEP

OTHERS INCLUDING CHILDREN, ANIMALS, BY-

STANDERS AND HELPERS AT LEAST 50 FEET (15

METERS) AWAY FROM THE OPERATOR AND UNIT.

STOP THE ENGINE IF YOU ARE APPROACHED. IN

AREAS WHERE OTHER PEOPLE AND ANIMALS

ARE PRESENT SUCH AS NEAR SIDEWALKS,

STREETS, HOUSES, ETC., IT IS STRONGLY REC-

OMMENDEDTHATTHE OPERATOR USE THE BUDDY

SYS_M;THAT IS, HAVE ANOTHER PERSON SERVE

AS A "LOOK-OUT", KEEPING HIMSELF AND OTH-

ERS AT LEAST 50 FEET (15 METERS) AWAY FROM

THE OPERATOR.

SEMI-AUTOMATIC HEAD PARTS THAT ARE

CHIPPED, CRACKED OR DAMAGED IN ANY OTHER

WAY CAN FLY APART AND CAUSE SERIOUS

INJURY. DO NOT USE. REPLACE DAMAGED PARTS

BEFORE USING THE UNIT.

OPERATOR SAFETY

• Always wear eye protection when operating, servicing,

or performing maintenance on your unit. Refer to

"Accessodes."

• Do not operate this unit when you are tired, ill, or under

the influence of alcohol, drugs or medication.

• Always wear heavy, long pants, long sleeves, boots and

gloves. Do not go barefoot or wear sandals, short pants.

Loose clothing or jewelry, or clothing with loosely hang-

ing straps, ties, tassels, etc. can be caught in moving

parts. Secure hair so it is above shoulder length. Being

fully covered will help protect you from pieces of toxic

plants such as p6ison ivy thrown by the semi-automatic

head, which could be more of a hazard than touching

the plant itself.

• Do not swing the unit with such force that you are in

danger of losing your balance.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kill.

• Keep handles free of oil and fuel.

SEMI'AUTOMATIC HEAD

USE ONLY GOOD QUALITY

REPLACEMENT PARTS

UNIT SAFETY

• Inspect the entire unit before each use. Replace dam-

aged parts. Check for fuel leaks and make sure all fas-

teners are in place and securely fastened.

• Use only .080" diameter good quality monofilament

line. Never use wire or rope, string, etc.

• Be sure the debris shield is propedy attached.

• Make sure semi-automatic head is propedy installed

and securely fastened. Refer to =Assembly."

• Make carburetor adjustments with the drive shaft hous-

ing supportedTo pr,tvent the semi-automatic head from

contacting any object.

° Keep others away when making carburetor adjust-

ments.

• Use only good quality Sears accessories or attachments.

CUTTING SAFETY

• Inspect the area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string, etc.)

which can be thrown or become entangled in the semi-

automatic head.

• Always keep the ,engine on the right-hand side of your

body,

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do not over-reach.

• Keep the semi-automatic head below waist level,

• Do not raise the engine above your waist,

• Keep all parts of your body away=from the semi-auto-

matic head and mufflerwhen engine is running.

• Use only for jobs explained in [his manua!.

• Cut at full throttle.

• Cut from your right to your left.

N

ZONE

-9-

Loading...

Loading...