Craftsman 358798270 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

Operator's

Manual

Model No.

358.798270-32ce

CUSTOMER

ASSISTANCE

_k WARNING:

Read the Operator's Manual and

Follow All Warnings and Safety

Instructions. Failure To Do So

Can Result in Serious Injury.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S_.

Always Wear Eye Protection

CRRFTSMRNo

32 ce 2-Cycle Engine

18" Semi-Automatic Head

Straight Shaft

Brushwacker

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Storage

• Repair Parts

530.082432-1-03/31/94 © 1994, Sears, Roebuck and Co.

TABLF, OF CONTENTS

WARNINGS AND SAFETY INSTRUCTIONS 3

KNOW YOUR UNIT ........................ 5

ASSEMBLY ................................ 6

FUELING YOUR ENGINE . 9

STARTING YOUR ENGINE ................ 10

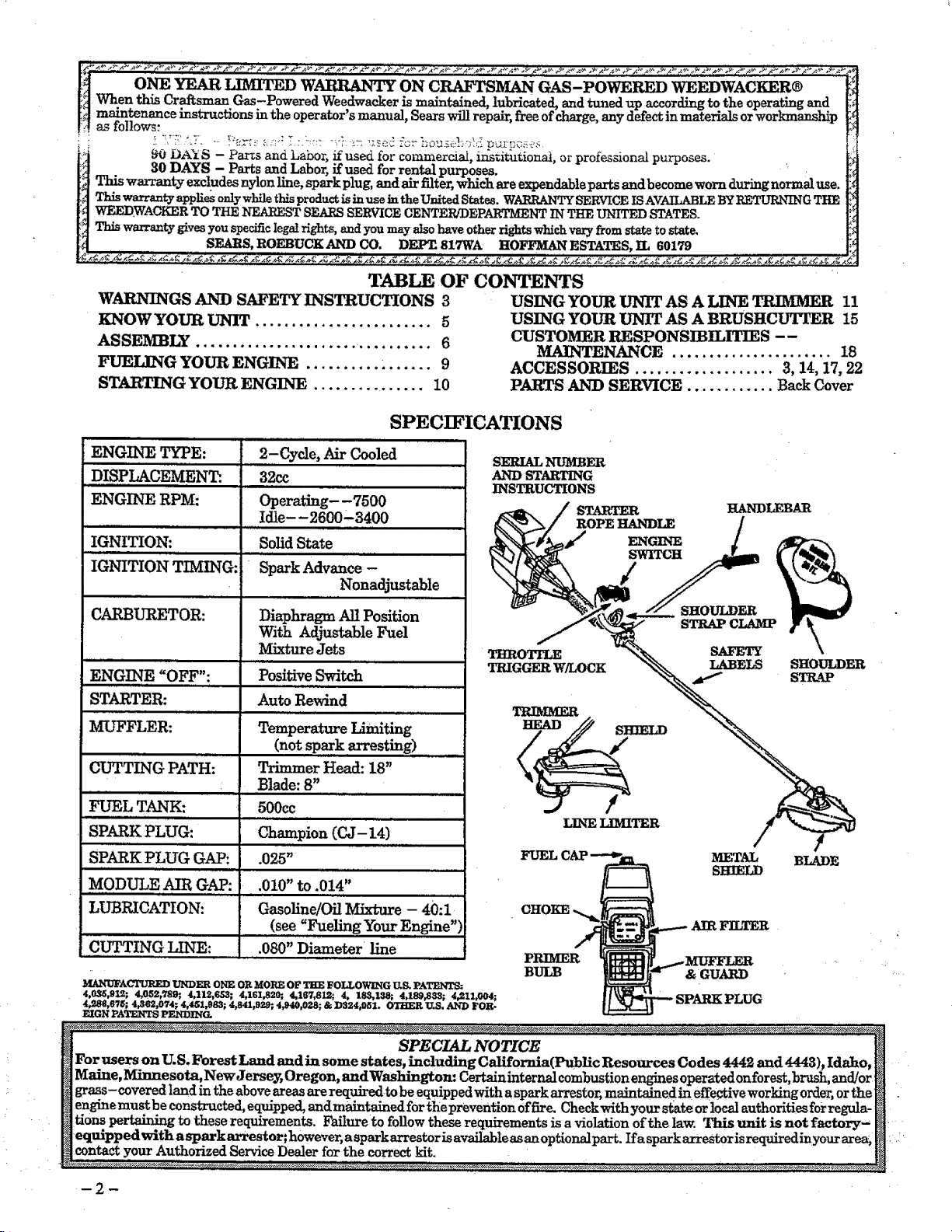

SPECIFICATIONS

USING YOUR UNIT AS A LINE TRIMMER 11

USING YOUR UNIT AS A BRUSHCUTTER 15

CUSTOMER RESPONSIBILITIES --

MAINTENANCE ...................... 18

ACCESSORIES ................... 3, 14, 17, 22

PARTS AND SERVICE ............ Back Cover

ENGINE TYPE: 2-Cycle, Air Cooled

DISPLACEMENT: 32cc

SERIAL NIFMBER

AND STARTING

INSTRUCTIONS

ENGINE RPM: Operating-,7500

Idle- -2600-3400

IGNITION: Solid State

IGNITION TIMING: Spark Advance -

m,, .,,,,, . ,,. ,, ............

Nonadjustable

CARBtYRETOR: Diaphragm All Position

With Adjustable Fuel

,N .... • ,,R ,,,,,,,,,,u, i i

ENGINE "OFF": Positive Switch

.ll , i .................................

Mixture Jets

STARTER: Auto Rewind

THRO_

TRIGGERW/LOCK

TRIMMER

MUFFLER: Temperature Limiting

(not spark arresting)

CUTTING PATH: Trimmer Head: 18"

HHI.ll I ,I I,.,I ll,ll

Blade: 8"

FUEL TANK: 500ee

SPARK PLUG: Champion (CJ- 14)

SPARK PLUG GAP: .025" '....................

, ,,, ,,,,,,

FUEL(

MODULE AIR GAP: .010"to.014"

LUBRICATION: Gasoline/OilMixture- 40:1

CUTTING LINE: .060"Diameter line

Y_t.N_FACTUR]RD U'NDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS:

4,0_,9L_; 4,052,789; 4,112,653; 4,161,820;, 4,16_',812_ 4, 185,138; 4,189,833; 4_I1,004;

4_8B,67_; 4,362,074; 4,451,983; 4,841,929; 4,940r028; & D324,051. OTHER U.S. AND FOR-

EIGN PATENTS PENDING.

PRIMER

BULB & GUAP,D

STARTER

ROPE HANDLE

ENGINE

SWITCH

/

LINE LIMITER

HANDLEBAR

SHOULDER

STRAP CLAMP

SAFETY

LABELS SHOULDER

METAL BLADE

SHIELD

FILTER

STRAP

/

SPECIAL NOTICE

For users on U.S. Forest Land and in some states, including California(Public Resources Codes 4442 and 4443), Idaho,

Maine, Minnesota, New Jerse_ Oregon, andWashington: Certain internal combustion engines operated on forest, brush, and/or

grass-covered land in the above areas are requiredto be equipped with a spark arrestor, maintaine d ineffective working order, or the

engine must be constructed, equipped, and maintained for the prevention of fire. Check with your state or local authorities for regula-

tions pertaining to these requirements. Failure to follow these requL_ements is a violation ofthe law. This unit is not factory-

equipped with asparkarrestor; however, a spark arrestoris available as an optionalpart. Ira sparkarrestoris requiredinyour area_

content your Authorized Service Dealer for the correct kit.

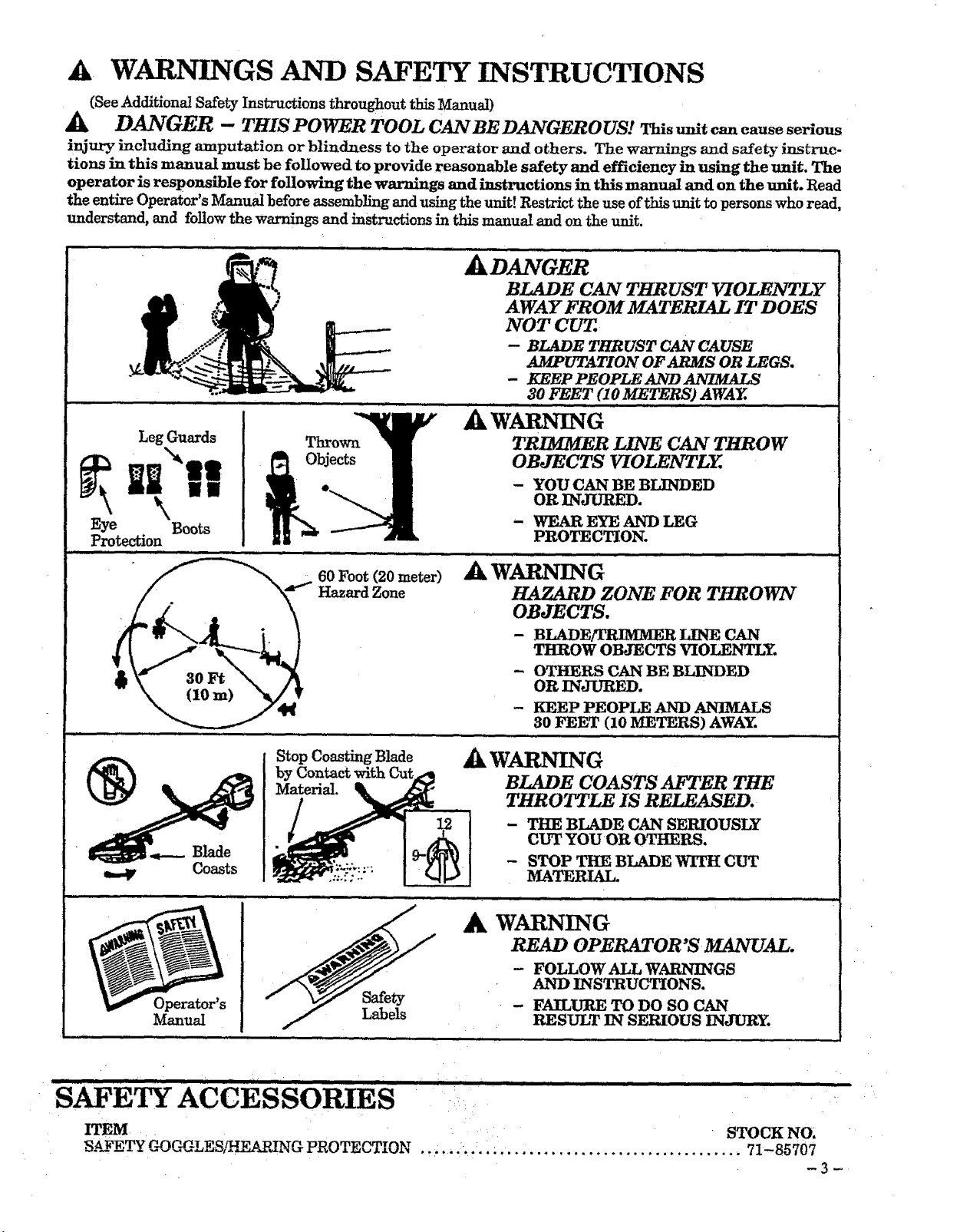

WARNINGS AND SAFETY INSTRUCTIONS

(See Additional Safety Instructions throughout this Manual)

,_, DANGER -- THIS POWER TOOL CAN BE DANGEROUS! This unit can cause serious

injury including amputation or blindness to the operator and others. The warnings and safe_- ins_r_tc-

tions in this manual must be followed to provide reasonable safety and efficiency in using the unit. The

operator is responsible for following the warnings and instructions in this manual and on the unit. Read

the entire Operator's Manual before assembling and using the unit! Restrict the use of this unit to persons who read,

understand, and follow the warnings and instructions in this manual and on the unit.

ADANGER .......

BLADE CAN THRUST VIOLENTLY

AWAY FROM MATERIAL IT DOES

NOT CUT..

-- BLADE THRUST CAN CAUSE

AMPUTATION OF ARMS OR LEGS.

- KEEP PEOPLE AND ANIMALS

30 FEET (10 METERS) AWAY.

W_NING

Leg Guards

Thrown

bjects

TRIMMER LINE CAN THROW

OBJECTS VIOLF,NTLY.

- YOU CAN BE BI3NDED

OR INJ't_.ED.

- WEAR EYE AND LEG

PROTECTION.

.....,,,H ,,,,,,,, i i ,,,N

Operator's

Manual

60 Foot (20 meter-)

Hazard Zone

Stop Coasting Blade

by Contact with

Material.

Safety

Labels

HAZARD ZONE FOR THROWN

OBJECTS.

- BLADE/TRIMMER LINE CAN

THROW OBJECTS VIOLENTLY.

- OTHERS CAN BE BLINDED

OR INJURED.

- KEEP PEOPI.E AND ANIMALS

30 FEET (10 METERS) AWAY.

_k WAP,NING

BLADE COASTS AFTER THE

THROTTLE IS RELEASED.

- THE BLADE CAN SERIOUSLY

CUT YOUOR OTHERS.

- STOP THE BLADE WITH CUT

MATERIAL.

A WARNING

READ OPERATOR'S MANUAL.

- FOLLOW ALL WARNINGS

AND INSTRUCTIONS.

- F'_URE TO DO SO CAN

RESULT IN SERIOUS INJURY.

SAFETY ACCESSORIES

ITE_

S._____,_ C_)GGLESL_NG PROTECTION

STOCK NO.

•. :..... • ._.•.. ................................ 71-85707

_3_

ARNINGS AND SAFETY INSTRUCTIONS....(Continued)

A OPERATOR SAFETY

o A]w_v_ _,_r s_e_ eve Drotect_0_.

boots, and gloves. Wearing safety leg guards is rec-

ommended. Do not go barefoot or wear sandals,

jewelry, short pants, short sleeves, loose clothing,

or clothing with loosely hangingties, straps, tas-

sels, etc.; they can be caught in moving parts. Be-

_fgtfully covered w;ffihelp protect you from pieces

oxic plants such as poison ivy thrown by blade

or trimmer head which could be more of a hazard

than touching the plant itself.

• Secure hair so it is above shoulder length.

• Do not operate unit when you are tired, ill, or un-

der the influence of alcohol, drugs, or medication.

• Wear hearing protection if you use the unit for

more than I- 1/2 hours per day.

• Never start or run the engine inside a dosedroom

or building. Breathing exhaust fumes can kill.

• Keep handles free of off and fuel.

• Always use the handlebar and a properly adjusted

shoulder strap with a blade. See '_kssembly."

A UNIT/MAIntENANCE SAFETY

• Look for and replace damaged or loose parts be-

fore each u_. Look for and repair fuelleaks before

use. Keep the unit in good working condition.

• Throw away blades that are bent, warped,

cracked, broken, or damaged in any other way.

Replace trimmer head parts that are cracked,

Ch_pped,broken, or damaged in any other waybe-

fore using the unit.

• Maintain the unit accordingto recommended pro-

eedures. Keep the blade sharp. Keep the cutting

line at the proper length.

• Use only .080" diameter SEAB._SLaser Line®

brand line. Never use wire, rope, string, etc.

• Install the required shield properly before using

the unit. Use the metal shield for all weed blade

use. Use the plastic shield for all line trimmer use.

• Use only specified blade or trimmer head; make

sure it is properly installed and securely fastened.

• Never start engine with dutch shroud removed.

The clutch can fly off and cause serious injury.

• Be sure blade or trimmer head stopsturningwhen

engine idles.

• Disconnect the spark plug before performing

maintenance (except carburetor adjustments).

• Make carburetor adjustments with the lower end

supported to prevent the blade or trimmer line

from contacting any object. Hold the unit by hand;

do not use the shoulder strap for support.

• Keep others away when making carburetor ad-

justments.

• Use only genuine SEARS accessories as recom-

mended for this unit.

If situations occur which are not covered in this manual, use care and good judgment.

If you need assistance, contact your Authorized Service Dealer or the

CUSTOMER ASSISTANCE HOTLINE at 1-800-235-5878.

_k FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the

unit or while using the unit.

• Wipe up all fuel spills before starting engine.

• Move at least 10 feet (3 meters) away from fueling

site before star_g engine.

Stop engine and allow it to cool before removing

fuel cap.

• Empty the fuel tank before storing the unit. Use

up fuel lef_ in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fi_eI in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, furnaces, etc.

A CUTTING SAFETY

• Inspect the areato be cut before eachuse. Remove

objects (rocks, broken glass, nails, wire, string,

etc.) which can be thrown or become entangled in

the blade or trimmer head.

• Keep others including children, animals, bystand-

ers, and helpers outside the 60 foot (20 meter)

Hazard Zone. Stop the engine immediately if you

are approached.

• Always keep engine on the right-hand side of

yourbody.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do not over-

reach.

• Keep blade or trimmer head below waist level.

• Do not raise the engine above your waist.

• Keep allparts ofyour body away from blade, trim-

mer head, and muffler when engine is runrming.

• Cut from your right to your left.

• Use only for jobs explained in this manual.

A TRANSPORTINGAND STORAGE

: Stop the unit before carrying.

Keep the muffler away from yourbody.

Allow engine to cool and secure unit before stor-

ing or transporting it in a -vehicle.

Empty the fuel tank before storing or transport-

ing the unit. Use up fuel left in the carburetor by

starting the engine andlettingit run until it stops.

• Store unit and fuel in an area where fuel vapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, fbxnaces, etc.

• Store unit so the blade or line limiter cannot acci-

dentally cause injury. The unit can be hung by the

bracket below engine or by drive shaft housing.

• Store the unit out of reactfof children.

-4-

IIIIIIIIIII IIIIIII I III IIIIIIIIIIIIIIIIIIIIIIII II IIIII II,,,,IH ,I I I ,,,,,,,,,II II I,II I I ,,,,, ,ll I I ,,,,,,,,,,,,

KNOW "fOUR UNIT

i J ,,,,,, , ,,,,,,,, .......................................

A.

INTRODUCTION

Your too! is a versatile product developed for large

lawns and to make short work of a variety of lawn

care tasks -- trimming, scalping, mowing, and

sweeping.

Special Features Include:

t 18" Cutting Path

o

Semi-Automatic Trimmer Head

o

Heavy Duty Precision Clutch _

32cc Engine

o

8" Brush Blade

c.CARTONCONTENTS

DESCRIPTION

" En_ne

• _DriveShaftAssemb!y

• • Meta! Shield

• • 8" Brush Blade

• • 8" Weed Blade

• • Trimmer Head

w/SafetyLabel

• Plastic Shield

Handlebar with Throttle Trigger

Assembly

0

Shoulder Strap w/Warning

40:1, 2-cycle Engine Off

Operator's Manual

Loose Parts Bag

QTY

1

I

i

I

i

1

I

i

I

i

1

I

B. DNPACKING INSTRUCTIONS

1. After removing the contents from the carton,

check parts against the Carton Contents list.

2. Examine the parts for damage. Do not use dam-

agedparts.

3. Notil_ yaur SEARS Store immediately if a part

is missing or damaged.

Your unit has been shipped with a plastic

shipping guard over the primer bulb (see "Spec-

ifications" for location). Remove and discard

the plastic shipping guard. [ * A WARNING [

It is normal to hear the _el filter rattle in [Parts marked with * are critical and must be sup.

• :an empty fuel tank, {plied by your SEARS Service Center. Failure to{

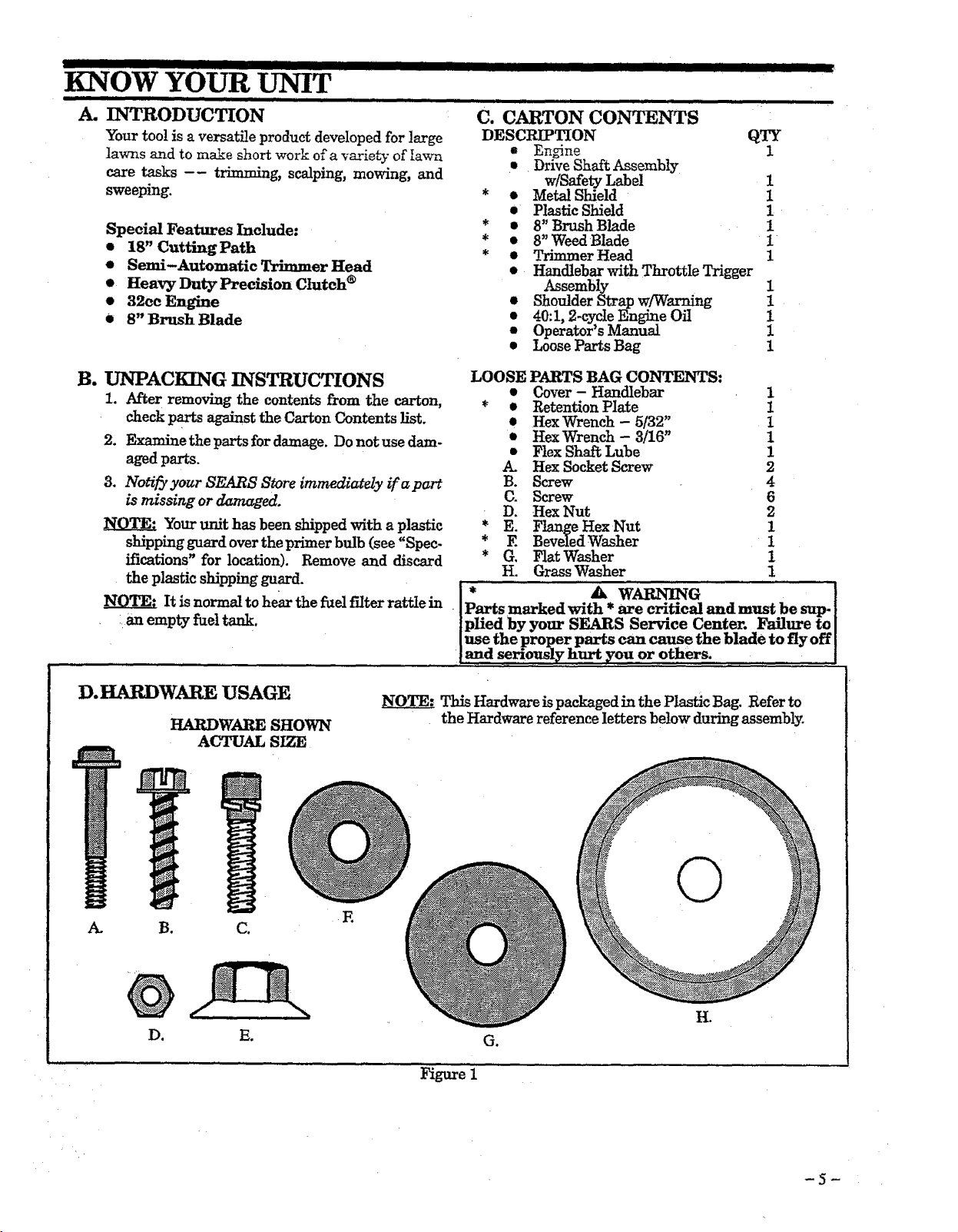

D.HARDWAREUSAGE

HARDWARE SHOWN

ACTUAL SIZE

NOT ThisHardware is packaged in the Plastic Bag. Refer to

LOOSE PARTS BAG CONTENTS:

• Cover- Handlebar

* • Retention Plate

• Hex Wrench - 5/32"

• Hex Wrench - 3/16 _

• Flex Shat_ Lube

Hex Socket Screw

B. Screw

C. Screw

D. Hex Nut

* E. Flange HexNut

* E Beveled Washer

* G. FlatWasher

H. Grass Washer 1

]use the proper parts can cause the blade to fly off

, ,i,_!_d sen_l_hurty0u or0thers, ...... .....................:, [

the Hardware reference letters below during assembly.

1

t

1

1

1

2

4

6

2

1

1

1

A. B. C.

©

R

H.

E.

Figure 1

G,

-5-

ASSEMBLY

(if tool is received assembled, repeat all steps in this section to be sure assembly is correct and is ad-

justed for the operator.)

This Operator's Manual is designed to help you as-

semble the tool and to provide its safe operation. It is

important that you read the entire manual to become

familiar with the tool before you begin assembly. If

you have any questions or need further assistance,

call our CUSTOMER ASSISTANCE HOTLINE at

1-800-235-5878.

i i ,,,m,,,,, ii i ii iii i,,,,,,,,, ,,,i i

B.ASSEMBLY STEPS

Hardware referred to in the following sections

are shown in actual size in Figure I.

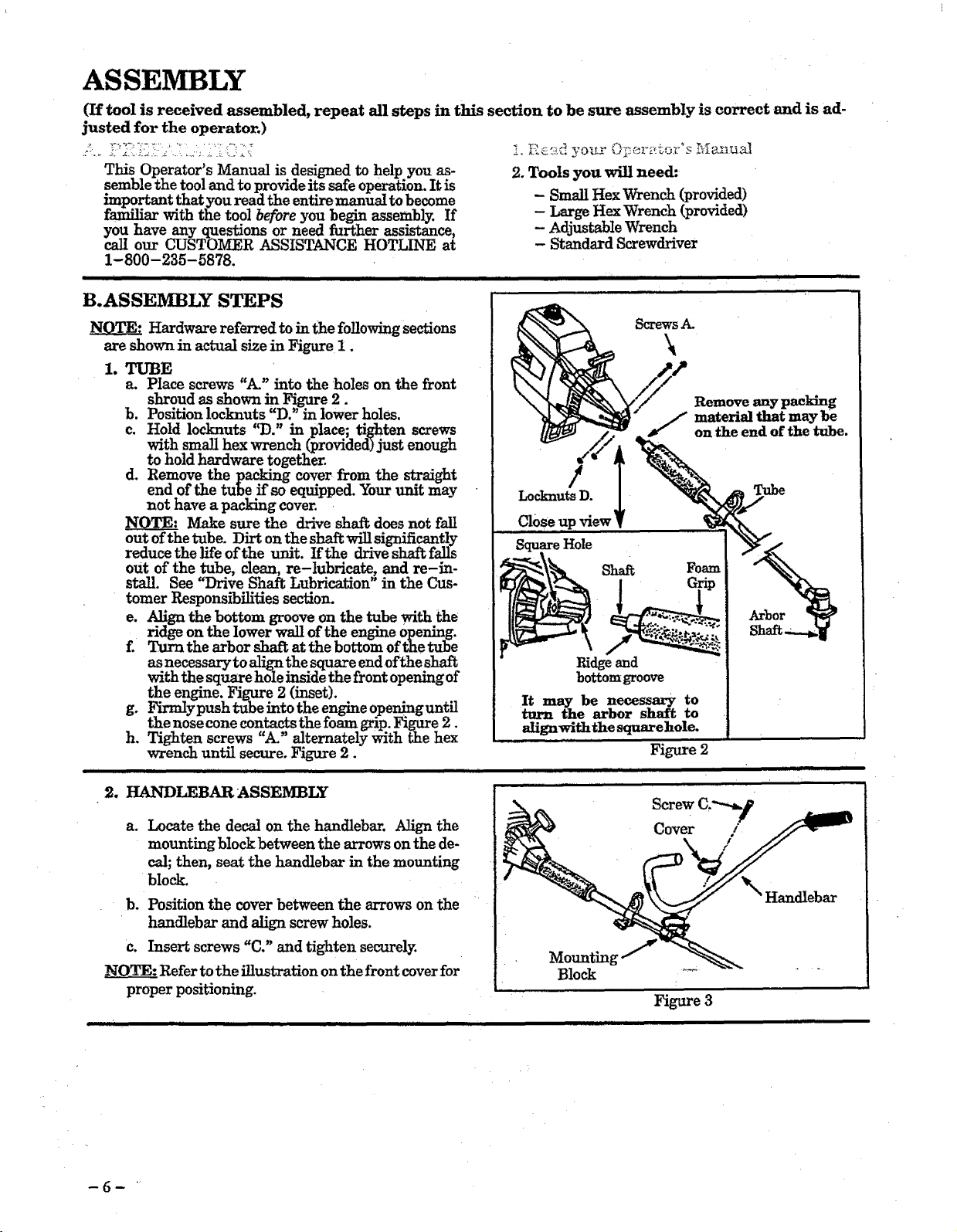

1. TUBE

a. Place screws "A." into the holes on the front

shroudas shown in Figure2.

b. Positionlocknuts"D."inlowerholes.

c. Hold locknuts "D." in place; tighten screws

with small hex wrench (provided) just enough

to hold hardware together.

d. Remove the packing cover from the straight

end of the tube if so equipped. Your unit may

not have a packing cover.

_TE: Make sure the drive shaft does not fall

out of the tube. Dirt on the shaft will significantly

reduce the life of the unit. If the drive shaft falls

out of the tube, dean, re-lubricate, and re-in-

stal!. See "Drive Shaft Lubrication" in the Cus-

tomer Responsibilities section.

e. Align the bottom groove on the tube with the

ridge on the lower wall of the engine opening.

f. Turn the arbor shaft at the bottom of the tube

as necessary to _ the square endofthe shaft

with the square h01e inside the front opening of

the engine. Figure 2 (inset).

g. Firmlypush _abeinto the engine openinguntil

the nose cone contacts the foam grip. Figure 2.

h. Tighten screws "A_" alternately ,_ith the hex

wrench until secure. Figure 2.

ii i ii MII u IV I ,,,,,,, ,,,,JUl, II

2. HANDLEBAR ASSEMBLY

2. Tools you will need:

- Small Hex Wrench (provided)

- Large Hex Wrench (provided)

- Adjustable Wrench

- Standard Screwdriver

iiiiiiiiiiiiii i ii ii iiii i H

ScrewsA.

\

/

Locknuts D.

Close up view

;Hole

It may be necessary to

turn the arbor shaft to

align with the square hole.

Figure 2

|, i , i

material that may be

onthe end of the tube.

a. Locate the decal on the handlebar. Align the

mounting block between the arrows on the de-

cal; then, seat the handlebar in the mounting

block.

b.Positionthe coverbetweenthe arrowson the

handlebarand alignscrewholes.

c. Insertscrews"C."and tightensecurely.

NOTE: Refer to the illustration on the front cover for

proper positioning.

,,,11111 i iiii ii iii i i !

Cover /

Handlebar

Block

Figure 3

3_

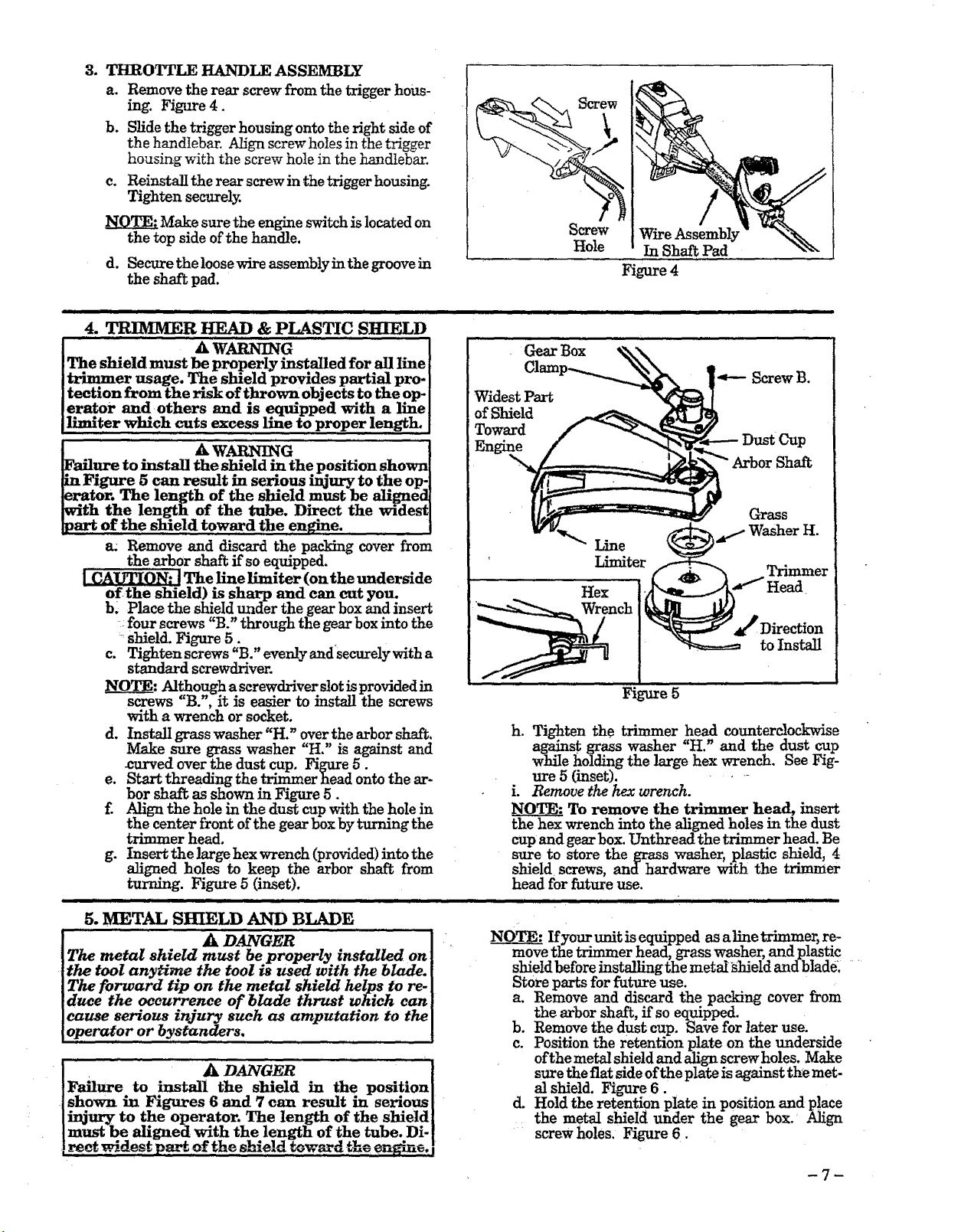

THROTTLE HANDLE ASSEMBLY

a. Remove the rear screw from the trigger hous-

ing. Figure 4.

b. Slide the trigger housing onto the right side of

the handlebar. Align screw holes in the trigger

housing with the screw hole in the handlebar.

c. Reinstall the rear screwin the trigger housing.

Tighten securely.

Make sure the engine switch is located on

the top side of the handle.

d. Secure the loosewire assemblyin the groove in

the shaft pad.

.............. i IIHI II I IIIIIIIIIIIIIIIII

4. TRIMMER HEAD & PLASTIC SHIELD

[ _ A WARNING

,_tv_e to install the shield in the position shown

_in Figure 5 can result in serious injury to the op-

[era tor, The length of the shield must be ali_rned

[with the length of the tube. Direct the widest

]part of the shield toward the engine,

a: Remove and discard the packing cover from

the arbor shaft ffso equipped,

The, line limiter (on the underside

ld) m sharp and can cut you.

b3 Place the shield under the gear box and insert

four screws "B." through the gear box into the

=shield. Figure 5.

c, Tighten screws "B." evenlyandsecurelywith a

standard screwdriver.

O__0___-:_,Althou h ascrowdrivers!otmpromdedm

go . •

screws "B.', It Is easier to mstall the screws

with a wrench or socket.

d. Install grass washer "H." over the arbor shaft.

Make sure grass washer "H," is against and

___ved over the dust cup, Figure 5.

e. b2art threading the trimmer head onto the ar-

bor shai_ as shown in Figure 5.

f. Align the hole in the dust cup with the hole in

the center front of the gear box by turning the

trimmer head.

g. Insert the large hex wrench (provided) into the

aligned holes to keep the arbor shaft from

turning. Figure 5 (inset).

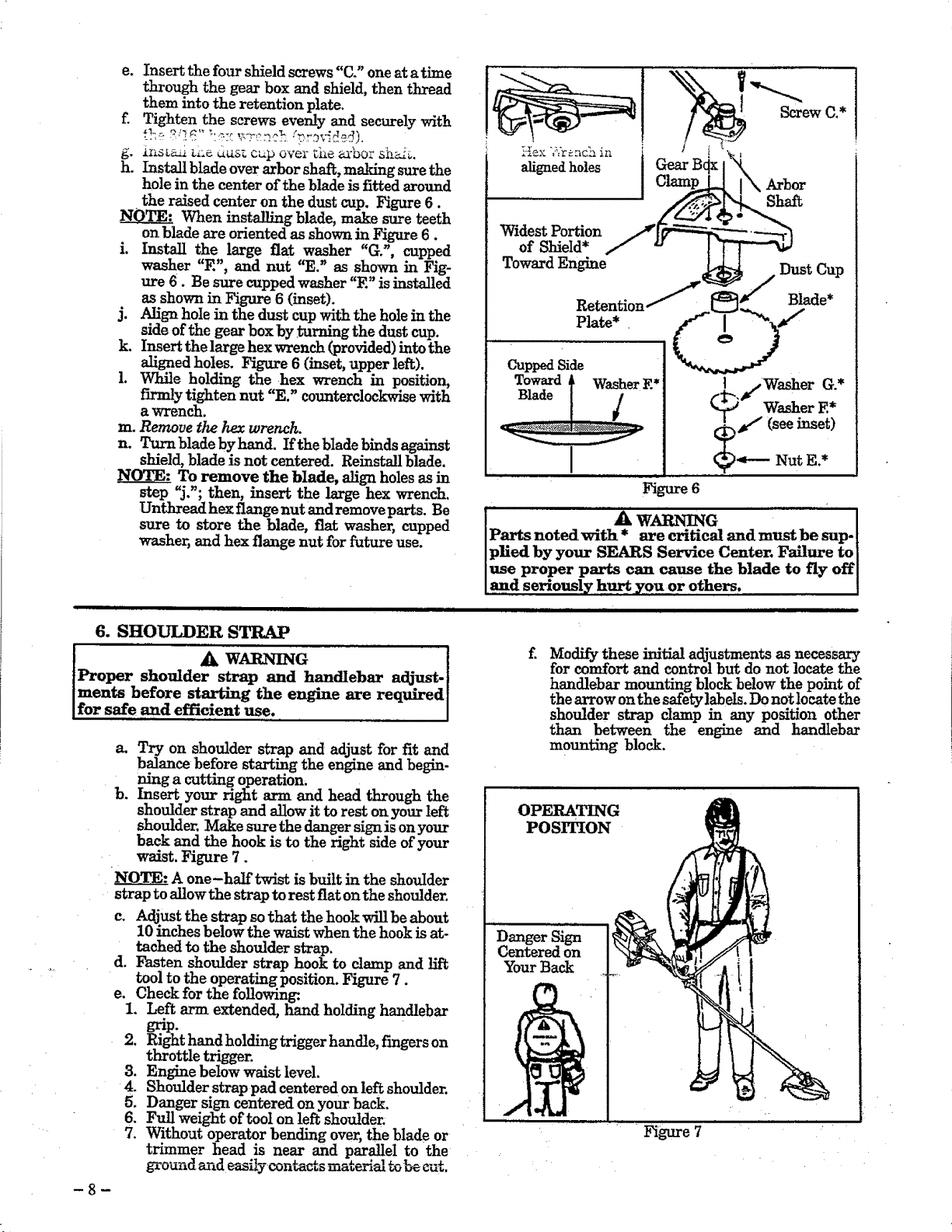

5, METAL SHIELD AND BLADE

A DANOER

The metal shield must be properly installed on

the tool any_m, e the tool _s used with the blade.

The forward tip on the metal shield helps to re.

duce the occurrence of blade thrust which can

cause serious injury such as amputation to the

operator or bystanders.

ApAN E ....!

Failure to _astall the shield in the position I

shown in Figures 6 and 7 can result in serious [

injury to the operator. The length of the shield[

must be aligned with thelength of the tube. Di- [

reef widest pa.-_of the shleldtow ,ardthe engine.[

Screw Wire Assembly

Hole In Shaft Pad

Figure 4

Gear Box

Widest Part

of Shield

Toward

Dust Cup

Arbor Shaft

Line

Trimmer

_Direction

to Install

Figure 5

h. Tighten the trimmer head counterclockwise

against grass washer "H." and the dust cup

while holding the large hex wrench. See Fig-

ure 5 (inset). - . --

i. Remove the hex wrench.

NOTE: To remove the trimmer head, insert

the hex wrench into the aligned holes in the dust

cup and gear box. Unthread the trimmer head. Be

sure to store the grass washer, plastic shield, 4

shield screws, and hardware with the trimmer

head for future use.

iii ii ,,,,,,,,m i i ,,li!,mu,llli i IHIIlll

NOTE: Ifyour unit is equipped as aline trimmer, re-

move the trimmer head, grass washer, and plastic

shield before instalh'ngthe metalshield and blade: ....

Store parts for future use.

a. Remove and discard the packing cover from

the arbor shaft, ff so equipped.

b. Remove the dust cup. Save for later use.

e. Position the retention plate on the underside

of the metal shield and align screw holes. Make

sure the flat side ofthe plate is against the met-

alshield.Figure6.

d. Hold theretentionplateinpositionand place

the metal shieldunder the gear box. Align

screwholes.Figure6.

-7-

e. Insert the four shield screws "C." one at a time

through the gear box and shield, then thread

them into the retention plate.

f. Tighten the screws evenly and securely with

g. iI_.DL_ _i=_d_s_ o_p over _i_ ea'bor sh_.

h. Install blade over arbor shaft, making sure the

hole in the center of the blade is fitted around

the raised center on the dust cup. Figure 6.

When installing blade, make sure teeth

on blade are oriented as shown in Fig-are 6.

i. Install the large flat washer "Go', cupped

washer "E", and nut "E." as shown in Fig-

ure 6. Be sure cupped washer "E" is installed

as shown in Figure 6 (inset).

j. Align hole in the dust cup with the hole in the

side of the gear box by _ting the dust cup.

k. Insert the large hex wrench (provided) into the

aligned holes. Figure 6 (inset, upper left).

1. While holding the hex wrench in position,

firmly tighten nut "E." countp_rclockwise with

a wrench.

rn_Remove thehexwrench.

n. Turn blade by hand. If the blade binds against

shield, blade is not centered. Reinstall blade.

NOTE: To remove the blade, align holes as in

step "j.'; then, insert the large hex wrench.

Unthread hex flange nut andremoveparts. Be

sure to store the blade, fiat washer, cupped

washer, and hex flange nut for future use.

Toward I Washer E*

Blade ........./

I

...................................Figure 6

Screwc.* !

I j, Washer G.*

Washer E*

#€I (see inset)

NutZ.*

6. SHOULDER STRAP

i A wAm ]r G I

Proper shoulder strap and handlebar adjust-[

ments before starting the engine are required[

for safe and efficient use. [

a_ Try on shoulder strap and adjust for fit and

balance before starting the engine and begin-

ning a cutting operation,

b. Insert your right arm and head through the

shoulder strap and allow it to rest on your left

shoulder. Make sure the danger sign is on your

back and the hook is to the right side of your

waist. Figure 7.

A one-half twist is built in the shoulder

strap to allow the strap to rest fiat on the shoulder.

c. Adjust the strap so that the hook will be about

10 inches below the waist when the hook is at-

tached to the shoulder strap.

d. Fasten shoulder strap hook to clamp and lift

tool to the operating position. Figure 7.

e. Check for the following

1. Left arm extended, hand holding handlebar

grip.

2. Right hand holding trigger handle, fingers on

throttle triggen

3. Engine below waist level.

4. Shoulder strap pad centered on left shoulder.

5. Danger sign centered on your back.

6. Full weight of tool on left shoulder.

7. Without operator bending over, the blade or

trimmer head is near and parallel to the

ground m_d easfiyconta_s material to be cu_.

-8-

Modify these initial adjustm __ts as necess _ary

for comfort and control but do not locate the

handlebar mounting block below the point of

the arrow on the safety labels. Do not locate the

shoulder strap clamp in any position other

than between the engine and handlebar

m0un_g block.

OPERATING

POSITION

Danger Sign

Centered on

"four Back

Figure 7

................................................. _,,_,_........................................ , .............. J ill i ,,,,,ill i i i

OPERATION

BEFORE STARTING ENGIr_: 2-CYCLE OIL:

WARNING

A

GASOLINE

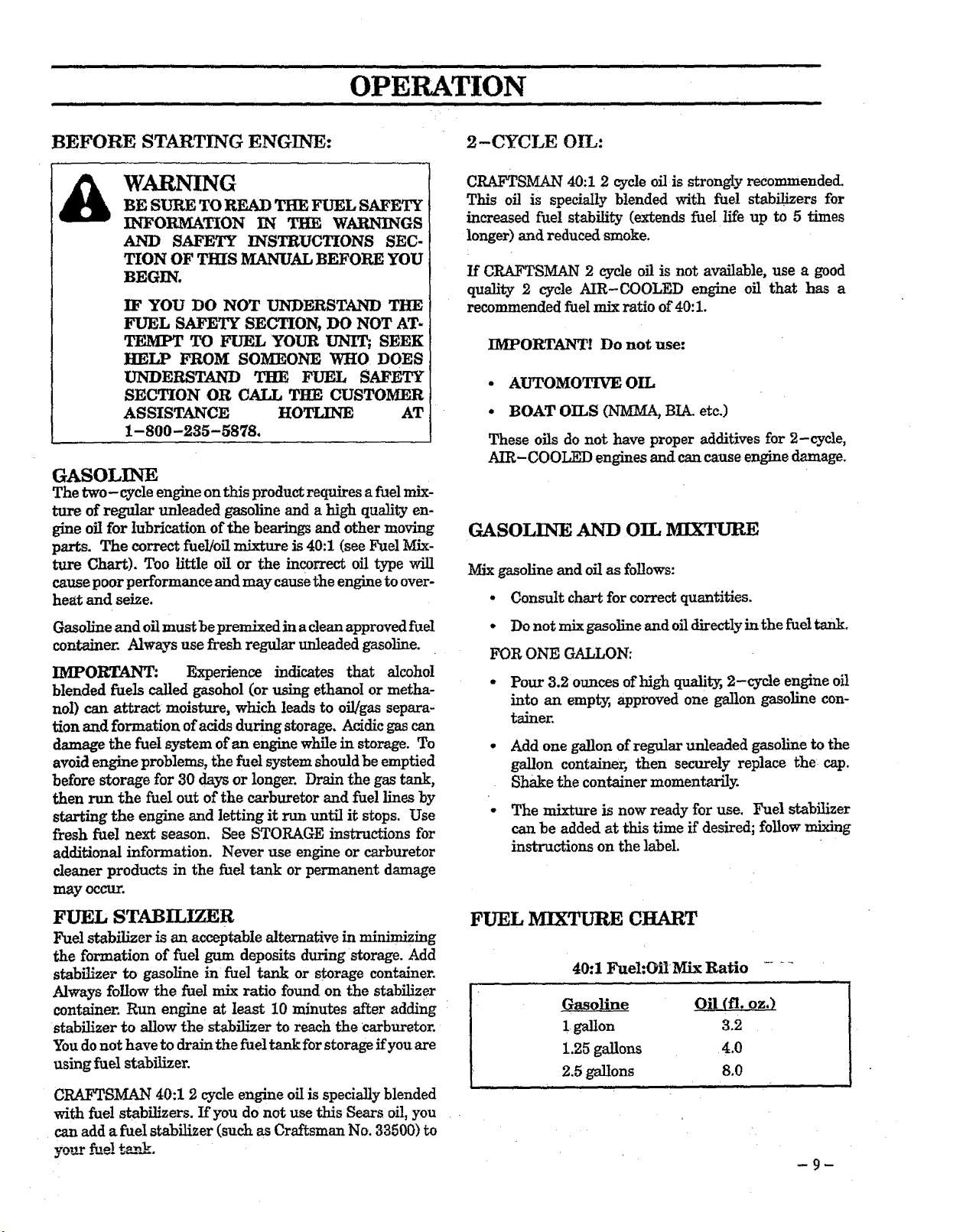

The two-cycle engine on this product requires a fuel mix-

ture of regular unleaded gasoline and a high quality en-

gine oil for Iubrication of the bearings and other moving

parts. The correct fuel/oil mixture is 40:1 (see Fuel Mix-

ture Chart). Too little oil or the incorrect oil type will

cause poor performance and may cause the engine to over-

heat and seize.

BE SURE TO READ THE FUEL SAFETY

INFORMATION IN THE WARNINGS

AND SAFETY INSTRUCTIONS SEC-

TION OF THIS MAN-tlAL BEFORE YOU

BEGIN.

IF YOU DO NOT UNDERSTAND THE

FUEL SAFETY SECTION, DO NOT AT-

TO FUEL YOUR I_NIT;, SEEK

HELP FROM SOMEONE WHO DOES

UNDERSTAND THE FUEL SAFETY

SECTION OR CALL THE CUSTOMER

ASSISTANCE HOTLINE AT

1-800 -235-5878.

CRAFTSMAN 40:1 2 cycle oilis strongly recommended.

This off is specially blended with fue! stabilizers for

increased fuel stability (extends fuel life up to 5 times

longer') and reduced smoke.

If CRAFTSMAN 2 cycle oil is not available, use a good

quality 2 cycle AIR-COOLED engine oil that has a

recommended fuel mix ratio of 40:1.

IMPORTANT! Do not use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA. etc.)

These oils do not have proper additives for 2-cycle,

AIR-COOLED engines and can cause engine damage.

GASOLINE AND OIL iVIIXTURE

Mix gasoline and oil as follows:

• Consult chart for correct quantities.

Gasoline and oil must be premlxed in a clean approved fuel

container. Always use fresh regular unleaded gasoline.

IMPORT _ANT: Experience indicates that alcohol

blended fuels called gasohol (or using ethanol or metha-

nol) can attract moisture, which leads to oi!/gas separa-

tion and formation of acids during storage. Acidic gas can

damage the fuel system of an engine While in storage. To

avoid engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank,

then run the fuel out of the carburetor and fuel lines by

starting the engine and letting it run until it stops. Use

fresh fuel next season. See STORAGE instructions for

ad&'tional information. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage

may occur.

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Add

stabilizer to gasoline in fuel tank or storage container.

Always follow the fuel mix ratio found on the stabilizer

container. Run engine at least 10 minutes after adding

stab'_zer to allow the stabilizer to reach the carburetor.

You do not have to drain the fuel tank for storage if you are

using fuel stabilizer.

CRAFTSMAN 40:1 2 cycle engine off is specially blended

with fuel stabilizers. If you do not use this Semrs off, you

can add afuel stabilizer (such as Craftsman No. 33500) to

y_r ._aelta_.

• Do not mix gasoline and oil directly in the fuel tank.

FOR ONE GALLON:

- Pour 3.2 ounces of high quality, 2-cycle engine oil

into an empW, approved one gallon gasoline con-

tainer.

° Add one gallon of regular unleaded gasoline to the

gallon container, then securely replace the cap.

Shake the container momentarily.

• The mixture is now ready for use. Fuel stabilizer

can be added at this time if desired; follow mixing

instructions on the label.

FUEL MIXTLrRE CHART

40:1 Fuel:Oil Mix Ratio .....

t

Oil (ft. oz,) ]

1 gallon 3.2

1.25 ga!lons 4.0

2.5 gallons 8.0

Loading...

Loading...