Craftsman 358797961, 358797982, 358797990, 358797922, 358797950 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

Operator's

Manual

Model No.

358.797922-32cc

358.797950-22cc

358.797982-32cc

358.797961-22cc

358.797990-32cc

Hours (CST)

Mon + Sat 7 a.m+- 7 p.m.

Sun !0 a.m. - 7 p.m.

_ DANGER

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN "SERIOUS

INJURY.

Always Wear Eye Protection

.CRAFTSMAN®

22cc132cc 2-CYCLE ENGINE

155/170 Air Velocity

GASOLINE BLOWER

• Assembly

• Operation

• Customer Responsibilities

• Service Adjustments

• Repair Parts

° Table of Contents - Inside Back Cover

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530-083059-07/05t94 © t994, Sears, Roebuck and Co.

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE tT CANNOT I

i

OPERATOR SAFETY

• Always wear eye protection to preventrocks or debris

• Always wear a respirator or facemask when working

• Always wear heavy, long pants, boots, and gloves (To

• Donot operate this unit when you are tired, ill, or under

• Keep children, bystanders, and animals away from the

. Inspect the area before starting the unit. Remove all

UNIT/MAINTENANCE SAFETY

• Have all maintenance other than the recommended

° Disconnect spark plug before performing maintenance

• Use only genuine replacement parts as recommended

• Check air intake openings, blower tubes, elbow tube,

• Do not use an accessory andlor attachment other than

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the unit or

• Wipe up all fuel spills before starting engine.

, Move at least t0 feet (3 meters) away from fueling site

• Stop engine and allow unit to cool before removing fuel

OPERATION SAFETY

• Stop the engine before opening the vacuum inlet door

Exposure to vibrationsthrough prolonged use of gasoline powered hand units could cause blood vessel or nerve damage in the

fingers, hands, and wrists of people prone to circulation disorders or abnormal swellings. Prolonged use incold weather has been

linked to blood vessel damage in otherwise healthy people, tf symptoms occur such as numbness, pain, loss of strength, change

in skin color or texture, or loss of feeling in the fingers, hands or wrists, discontinue the use of this unit and seek medical atten-

tion. An anti-vibration system does not guarantee the avoidance of these problems. Users who operate power toolson a continu-

aJand regular basis must monitor closeJy their physical condition and the condition of this unit.

CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP.t

TRANSPORTING, ADJUSTING OR MAKING REPAIRS.

from being blownor ricocheting into eyes and face which

can result in blindness and!or other serious injury.

with the unit in dusty' environments.

avoid shock of static electricity, do not wear rubber

gloves). Do not go barefoot or wear short pants, san-

dais, jewelry, loose clothing, or clothing with loosely

hanging straps, ties, tassels, etc.; they can be caught in

moving parts. Secure hair so it is above shoulder

length.

the influence of alcohol, drugs, or medication.

work area at a minimum of 30 feet when starting or

operating the unit.

debris and hard objects such as rocks, glass, wire, etc.

that can ricochet, be thrown, or otherwise cause injury

or damage during operation.

procedures described in the Operator's Manual per-

formed by your Sears Service Center.

except for carburetor adjustment.

bySears to avoid creating a hazard and/or voiding your

warranty.

and vacuum tubes frequently, always with the engine

stopped. Keep vents and tubes free of debris whichcan

accumulate and restrict proper air flow.

those recommended by Sears with your unit.

while using the unit.

before starting engine.

cap.

or attempting to insert or remove the vacuum tubes.

The engine must be stopped and the impeller blades

SAFETY NOTICE

no longer turning to avoid serious injury from the rotat-

ing blades.

• Inspect the entire unit before each use for worn, loose,

missing, or damaged parts. Do not use untit the unit is

in proper working order.

° Keep the outside surfaces free of oil and fuel.

• Never start or run unit inside a closed room or building.

Breathing exhaust fumes can kill.

• Never use for spreading chemicals, fertilizers, or any

other material which may contain toxic substances.

• Do not set the unit on any surface except a clean, hard

area to start the engine or while the engine is running.

Debris such as gravel, sand, dust, grass, etc. could be

picked up by the air intake and thrown out through the

discharge opening, damaging the unit, property, or

causing serious injury to bystanders or the operator.

• Avoid dangerous environments. Do not use in unventi-

lated areas or where explosive vapors or carbon

monoxide build up could be present.

, Avoid situations which could set the vacuum bag on

fire. Do not vacuum discarded cigars or cigarettes or

ash from fireplaces, barbecue pits, brush piles, etc. To

avoid spreading fire, do not use blower near leaf or

brush fires, fireplaces, barbecue pits, ashtrays, etc.

• Do not overreach or use from unstable surfaces such

as ladders, trees, steep slopes, rooftops, etc. Use extra

care when cleaning on stairways. Keep firm footing and

balance at all times.

• Never place objects inside the blower tubes; always

direct the blowing debris away from people, animals,

glass, and solid objects such as trees, automobiles,

walls, etc. The force of air can cause rocks, dirt, or

sticks to be thrown or to ricochet which can hurt people

or animals, break glass, or cause other damage. Do not

allow the unit to be used as a toy.

- Never place any object in the air intake opening as this

could restrict proper air flow and cause damage to the

unit.

° Never run unit without the proper equipment attached.

When used as a blower, always install a blower tube.

When used as a vacuum, always install vacuum tubes

and vacuum bag assembly.

• Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

• Stop the unit before transporting.

• Allow the engine to cool, and secure the unit before

storing or transporting in a vehicle.

• Empty the fuel tank before storing or transporting the

unit. Use up any fuel left in the carburetor by starting

the engine and letting the engine run until it stops.

- Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, elec-

tric motors or switches, furnaces, etc.

• Store the unit out of the reach of children.

1

I ,, LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

dl3k

IT MEANS -- ATTENTION!!! BECOME ALERT!!] YOUR SAFETY IS INVOLVED.

-2-

SAFETY RULES

WARNING

THIS POWER UNIT CAN BE DANGEROUS! THIS UNIT CAN CAUSE SERIOUS INJURY OR

BLINDNESS TO THE OPERATOR AND OTHERS. THE WARNINGS AND SAFETY

INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE REASONABLE

SAFETY AND EFFICIENCY IN USING THIS UNIT. THE OPERATOR IS RESPONSIBLE FOR

FOLLOWING THE WARNINGS AND INSTRUCTIONS IN THIS MANUAL AND ON THE UNIT.

READ THE ENTIRE OPERATOR'S MANUAL BEFORE ASSEMBLING AND USING THIS

UNIT! RESTRICT THE USE OF THE POWER UNIT TO PERSONS WHO READ, UNDER-

STAND AND FOLLOW THE WARNINGS AND INSTRUCTIONS IN THIS MANUAL AND ON

THE UNIT.

THIS UNIT IS DESIGNED FOR BLOWER

AND VACUUM USE ONLY. NEVER USE

ANY OTHER ATTACHMENTS WiTH THIS

UNIT EXCEPT THE OPTIONAL GUTTER

ATTACHMENT.

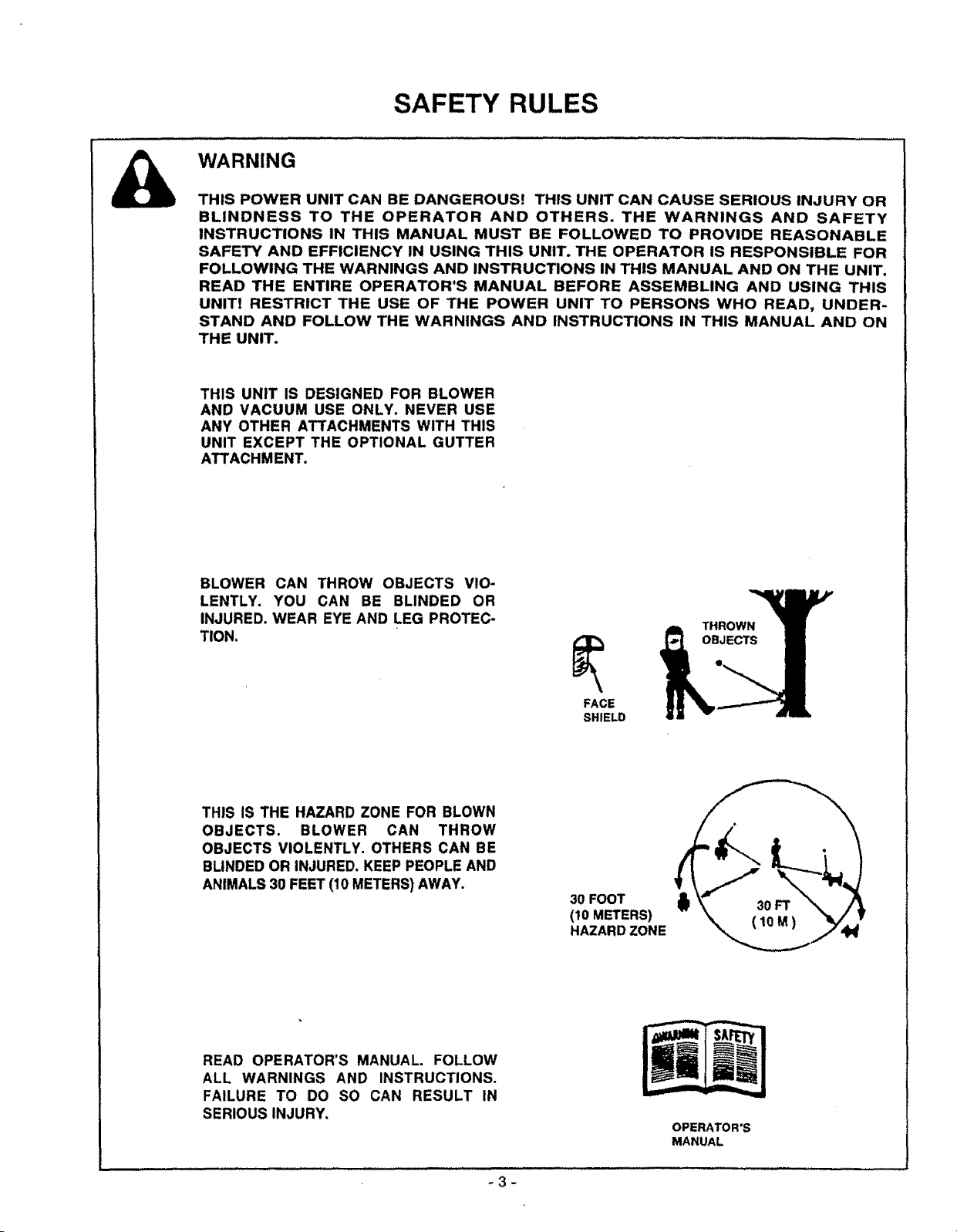

BLOWER CAN THROW OBJECTS VIO-

LENTLY. YOU CAN BE BLINDED OR

INJURED. WEAR EYE AND LEG PROTEC-

TION.

THIS IS THE HAZARD ZONE FOR BLOWN

OBJECTS. BLOWER CAN THROW

OBJECTS VIOLENTLY. OTHERS CAN BE

BLINDED OR INJURED. KEEP PEOPLE AND

ANIMALS 30 FEET (10 METERS)AWAY.

THROWN_r

OBJECTS I

FACE

SHIELD

30 FOOT

(10 METERS)

HAZARD ZONE

READ OPERATOR'S MANUAL. FOLLOW

ALL WARNINGS AND INSTRUCTIONS.

FAILURE TO DO SO CAN RESULT IN

SERIOUS INJURY.

OPERATOR'S

MANUAL

_3-

CONGRATULATIONSon yourpurchaseof a Sears

CraftsmanGasolineBlower.Ithasbeendesigned,engi-

neeredandmanufacturedtogiveyouthebestpossible

dependabilityandperformance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service

Center/Department or Call the 1-800 number listed on

the front of this manual. Sears has competent, well

trained technicians and the proper tools to service or

repair this unit.

Please read and retain this manual, The instructions will

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES."

MODEL NUMBERS:

SERIAL NUMBER:

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE FOUND

ON THE PRODUCT.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears Store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Followa regularschedule in maintaining, caring for, and

using your unit.

• Follow the instructions under "Customer Responsibili-

ties" and "Storage" sections of this Operator's Manual,

358.797922

358.797950

358.797982

358.797961

358.797990

PRODUCT SPECIFICATIONS

AIR VELOCITY

358.797950/358.797961 ...155mph

358.797922/358.797982

358.797990 ....................... 170mph

AIR VOLUME

358.7979501358.797961 ...350 cu. ftJmin.

358.797922/358.797982

358.797990 ....................... 360 cu. ftJmin.

ENGINE

358,797950/358.797961 ..22cc 2-cycle AIR-COOLED

358.797922/358.797982

358.797990 ...................... 32cc 2-cycle AIR-COOLED

ENGINE RPM

Od_eerating.......................... 7000-7600

..................................... 3800-4600

FUEL/OIL MIX RATIO .......40:t (3.2oz. per gallon

gasl

IGNITION .............................. Solid State

(air gap .010" to .014")

IGNITION TIMING ................ Non-adjustable, Fixed

SPARK PLUG ...................... Champion (CJ*8Y)

SPARK PLUG GAP ............. 025"

SPECIAL NOTICE

For users on U.S. Forest Land and in some states, including

California (Public Resources Codes 4442 and 4443), Idaho,

Maine, Minnesota, New Jersey, Oregon, and Washington:

Certain internal combustion engines operated on forest,

brush, and/or grass-covered lands in the above areas are

required to be equipped with a spark arrestor, maintained in

effective working order, or the engine must be constructed,

equipped, and maintained for the prevention of fire. Check

with your state or local authorities for regulations pertaining

to these requirements. Failure to follow these requirements

is a violation of the law. This unit is not factory-equipped with

a spark arrestor; however, a spark arrestor is available as an

optional part. If a spark arrestor is required in your area, con-

tact your SEARS Service Center/Department for the correct

kit.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATIENTS:

5,269,665; 5,035,5B5; 4,674.146; 4,940,028; RE 33,050; 4,798.185; 4,402,106;

D3:22,971. OTHER U.S. AND FOREIGN PATENTS PENDING,

FULL ONE YEAR WARRANTY ON SEARS BEST GAS BLC)WER MODEL 358.797950 & 358.797961

Foroneyearfromthedateofpurchase,whenthisGasBlowerismaintained,lubricatedandtuned-upaccordingtotheinstructionsintheowner'smanual,

Searswillrepair,freeofcharge,anydefectinmaterialorworkmanship.

Thiswarrantyexcludestheblowertubes,sparkplug,andaircleaner,whichareexpendablepartsandbecomewornduringnormaluse.

If thisBlowerisusedforcommercialpurposes,thiswarrantyappliesfor90daysfromthedateofpurchase.IfthisBlowerisusedforrentalpurposes,this

warrantyappliesfor30daysfromthedateofpurchase.Thiswarrantyappliesonlywhilethisproductis inuseintheUnitedStates.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHEBLOWERTOTHENEARESTSEARSSERVICECENTERINTHEUNITEDSTATES.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

SEARS,ROEBUCKANDCO. DEPT.817WAHOFFMANESTATES,IL 60179

FULLTWOYEARWARRANTYONSEARSBESTGASBLOWERMODEL358.797922,358.797982& 358.797990

Fortwoyearslromthedateofpurchdse,whenthisGasBlowerismaintained,lubricatedandtuned-upaccordingtotheinstructionsintheowner'smanual,

Searswillrepair,freeofcharge,anydefectinmaterialorworkmanship.

Thiswarrantyexcludestheblowertu_s,sparkplug,andaircleaner,whichareexpendablepartsandbecomewornduringnormaluse.

IfthisBlowerisusedforcommercialpurposes,thiswarranlyappliesfor90daysfromthedateofpurchase,ifthisBlowerisusedforrentalpurposes,this

warrantyappliesfor30daysfromthedateofpurchase.ThiswarrantyappliesonlywhilethisproductisinuseintheUnitedStates.

WARRANTYSERVICEISAVNLABLEBYRETURNINGTHEBLOWERTOTHENEARESTSEARSSERVICECENTERtNTHEUNITEDSTATES.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

SEARS,ROEBUCKANDCO. DEPT.817WAHOFFMANESTATES,IL60179

-4-

o

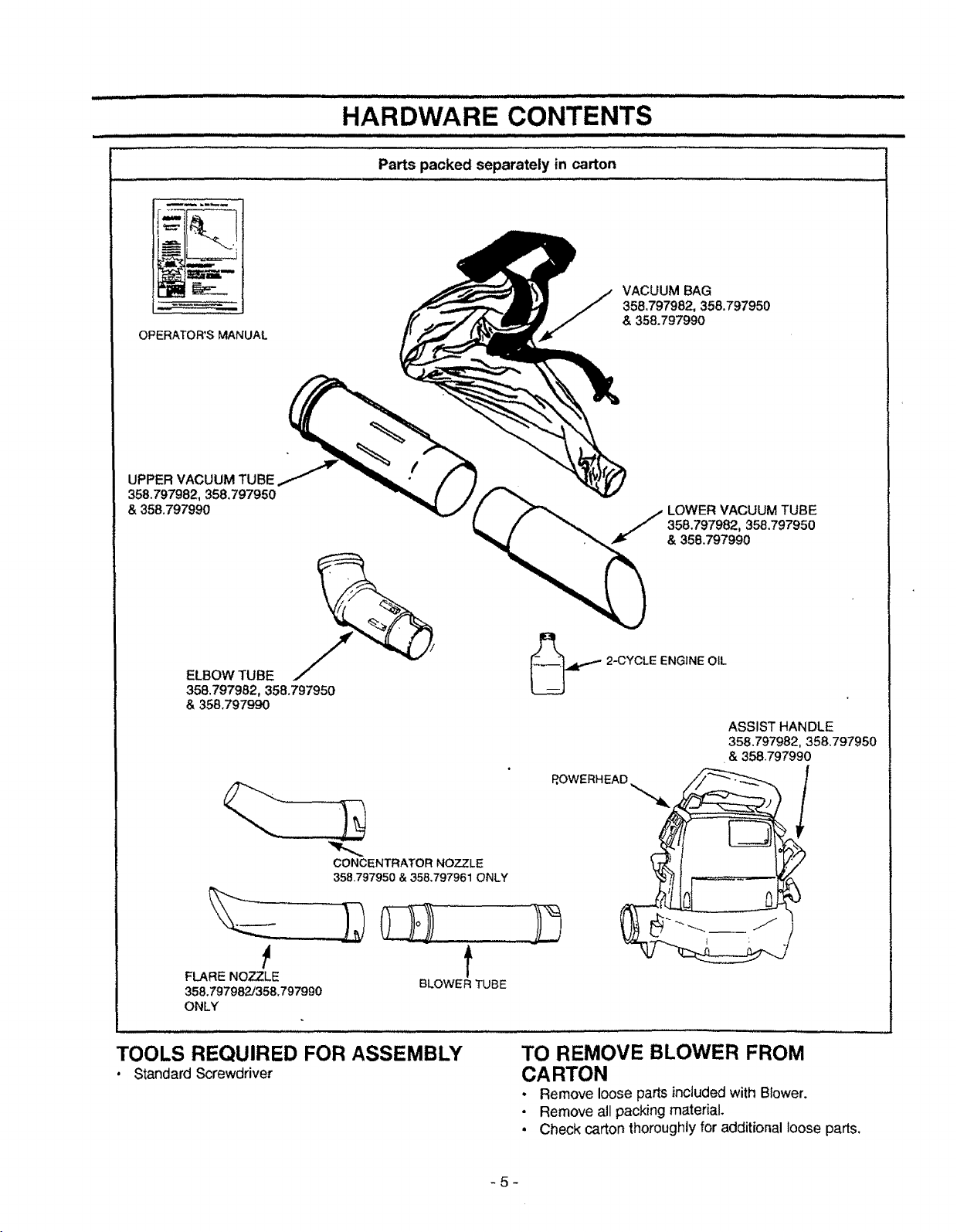

HARDWARE CONTENTS

_._ I.... i illiiiiiiiiiiiiiiiiii .......... i II II II IIIIIIIIIIIII III I nil lli I IllllIIIIIIIIIIllLlIIJlll I 7 IIIII iiii I iiN

Parts packed separately in carton

VACUUM BAG

358.797982, 358.797950

OPERATOR'S MANUAL

UPPER VACUUM TUBE

358.797982, 358.797950

&358.797990

& 358.797990

LOWER VACUUM TUBE

358.797982, 358.797950

& 358.797990

ELBOW TUBE

358.797982, 358.797950

& 358.797990

CONCENTRATOR NOZZLE

358.797950 & 358,797961 ONLY

FLARE NOZZLE BLOWER TUBE

358.797982J358_797990

ONLY

TOOLS REQUIRED FOR ASSEMBLY

• Standard Screwdriver

2-CYCLE ENGINE OIL

ASSIST HANDLE

358.797982, 358.797950

& 358.797990

f

TO REMOVE BLOWER FROM

CARTON

• Remove loose parts included with Blower.

• Remove all packing material.

• Check carton thoroughly for additional loose parts.

-5-

,,,,,,,,,,,,,,,,,,,,,,,,,,,, ................................................

HOW TO ASSEMBLE YOUR BLOWER

WARNING

STOP THE ENGINE BEFORE OPENING

THE VACUUM iNLET DOOR OR

ATTEMPTING TO INSERT OR REMOVE

THE VACUUM TUBES. THE ENGINE

MUST BE STOPPED AND THE IMPELLER

BLADES NO LONGER TURNING TO

AVOID SERIOUS INJURY FROM THE

ROTATING BLADES

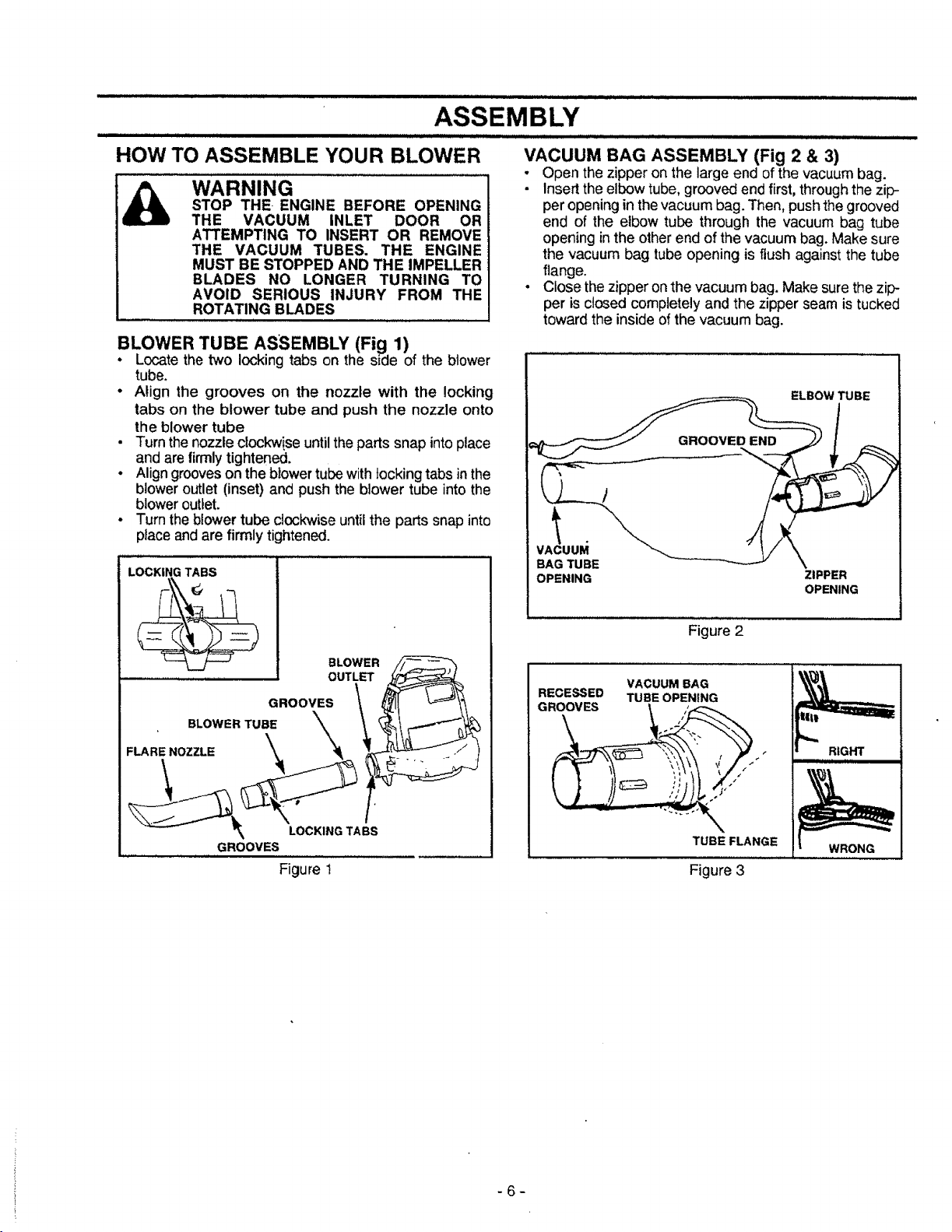

pLOWER TUBE ASSEMBLY (Fig 1)

Locatethe two locking tabs on the side of the blower

tube.

• Align the grooves on the nozzle with the locking

tabs on the blower tube and push the nozzle onto

the blower tube

• Turn the nozzle clockwise until the parts snap into place

and are firmlytightened.

• Align grooves on the blower tube with locking tabs in the

blower outlet (inset) and push the blower tube into the

blower outlet.

• Turn the blower tube clockwise until the parts snap into

place and are firmly tightened.

LOCKING TABS

VACUUM BAG ASSEMBLY (Fig 2 & 3)

• Open the zipper on the large end of the vacuum bag.

• Insert the elbow tube, grooved end first, through the zip-

per opening in the vacuum bag. Then, push the grooved

end of the elbow tube through the vacuum bag tube

opening in the other end of the vacuum bag. Make sure

the vacuum bag tube opening is flush against the tube

flange.

• Close the zipper on the vacuum bag. Make sure the zip-

per is closed completely and the zipper seam is tucked

toward the inside of the vacuum bag.

ELBOW TUBE

v_uu_i

BAG TUBE

OPENING

ZIPPER

OPENING

BLOWER TUBE

FLARE NOZZLE

GROOVES

GROOVES

LOCKING TABS

Figure 1

BLOWER

OUTLET

Figure 2

VACUUM BAG

RECESSED TUBE OPENING

TUBE FLANGE

Figure 3

WRONG

-6-

ASSEMBLY

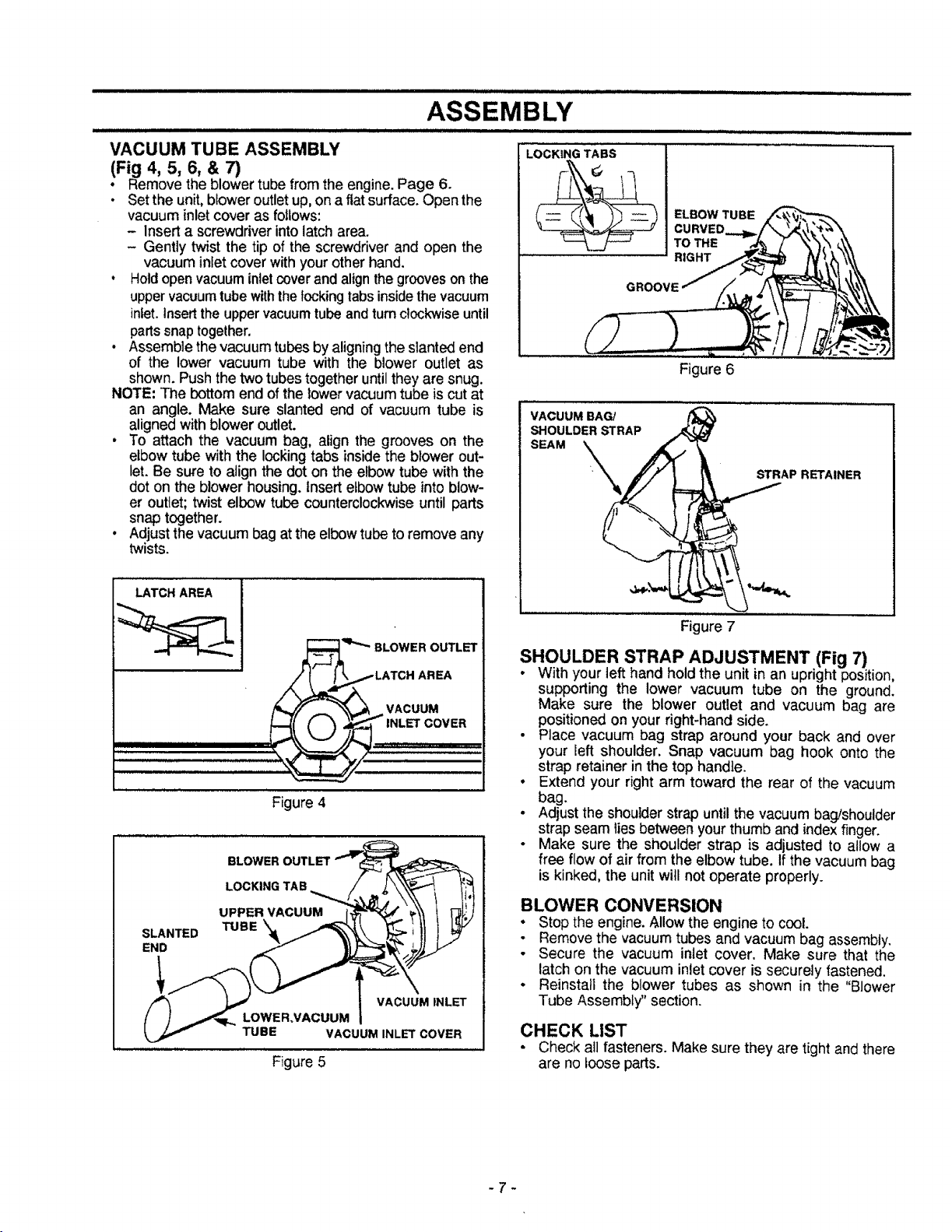

VACUUM TUBE ASSEMBLY

(Fig 4, 5, 6, & 7)

• Remove the blower tube from the engine.Page 6.

• Setthe unit,bloweroutletup,ona flat surface.Open the

vacuuminlet coveras follows:

- Inserta screwdriverintolatcharea.

- Gently twistthe tip of the screwdriverand open the

vacuum intet cover withyourotherhand.

, Holdopenvacuuminletcoverand alignthegroovesonthe

uppervacuumtubewiththelockingtabsinsidethe vacuum

inlet.Insertthe uppervacuumtubeandturnclockwiseuntil

partssnaptogether.

• Assemble the vacuum tubes by aligning the slanted end

of the lower vacuum tube with the blower outlet as

shown. Push the two tubes together until they are snug.

NOTE; The bottom end of the lower vacuum tube is cut at

an angle. Make sure slanted end of vacuum tube is

aligned with blower outlet.

• To attach the vacuum bag, align the grooves on the

elbow tube with the locking tabs insidethe blower out-

let. Be sure to atign the dot on the elbow tube with the

dot on the blower housing, insert elbow tube into blow-

er outlet; twist elbow tube counterclockwise until parts

snap together,

• Adjust the vacuum bag atthe elbow tube to remove any

twists.

LATCH AREA

LOCKING TABS

ELBOW TUBE

TO THE

RIGHT

GROOVE

Figure 6

VACUUM BAG! (

SLANTED

END

BLOWER OUTLET

VACUUM

INLET COVER

Figure 4

LOCKING TAB

UPPER VACUUM

TUBE

VACUUM INLET

LOWER.VACUUM

TUBE VACUUM INLET COVER

Figure 5

AREA

Figure 7

SHOULDER STRAP ADJUSTMENT (Fig 7)

• With your left hand hold the unit in an uprightposition,

supporting the lower vacuum tube on the ground.

Make sure the blower outlet and vacuum bag are

positionedonyour right-handside.

• Place vacuum bag strap around your back and over

your Ieft shoulder. Snap vacuum bag hook onto the

strap retainer inthe top handle.

• Extend your right arm toward the rear of the vacuum

bag,

• Adjust the shoulder strap until the vacuum bag/shoulder

strap seam liesbetween your thumb and index finger.

• Make sure the shoulder strap is adjusted to allow a

free flow of air from the elbow tube. If the vacuum bag

is kinked, the unit will not operate properly.

BLOWER CONVERSION

• Stop the engine. Allow the engine to cool.

- Remove the vacuum tubes and vacuum bag assembly,

- Secure the vacuum inlet cover. Make sure that the

latch on the vacuum inlet cover is securely fastened.

• Reinstall the blower tubes as shown in the "Blower

Tube Assembly" section.

CHECK LIST

• Check all fasteners. Make sure they are tight and there

are no loose parts.

-7-

OPERATION

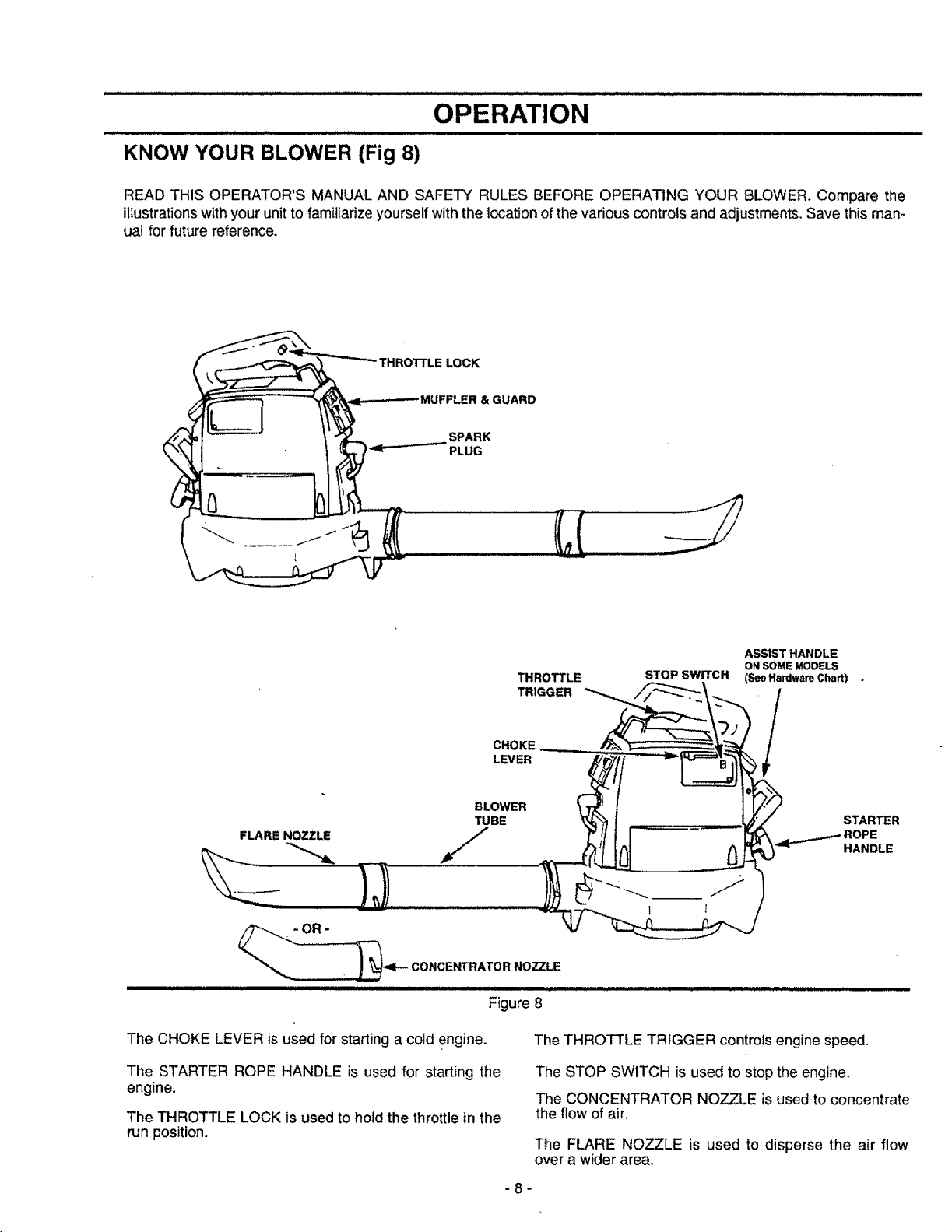

KNOW YOUR BLOWER (Fig 8)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR BLOWER. Compare the

illustrations with your unit to familiarize yourself with the location of the various controls and adjustments. Save this man-

ual for future reference.

LOCK

:FLER & GUARD

PLUG

BLOWER

TUBE

FLARE NOZZLE

_ CONCENTRATOR NOZZLE

The CHOKE LEVER is used for starting a cold engine.

The STARTER ROPE HANDLE is used for starting the

engine.

The THROTTLE LOCK is used to hold the throttle in the

run position.

ASSIST HANDLE

THROTTLE

TRIGGER

CHOKE

LEVER

Figure 8

The THROTTLE TRIGGER controls engine speed.

The STOP SWITCH is used to stop the engine.

The CONCENTRATOR NOZZLE is used to concentrate

the flow of air.

The FLARE NOZZLE is used to disperse the air flow

over a wider area.

STOP SWITCH

ON SOME MODF.LS

(See Hardware Chart)

/

-8-

IIIIIIIIIIII III Jl ILl IIII I ..................................................................... 111111 llll iiii II LU II III I[ i I.._

OPERATION -

...................................................................................... ,,,,,,,,,,,,,,,,,,,,,,, ...............

BLOWER SAFETY

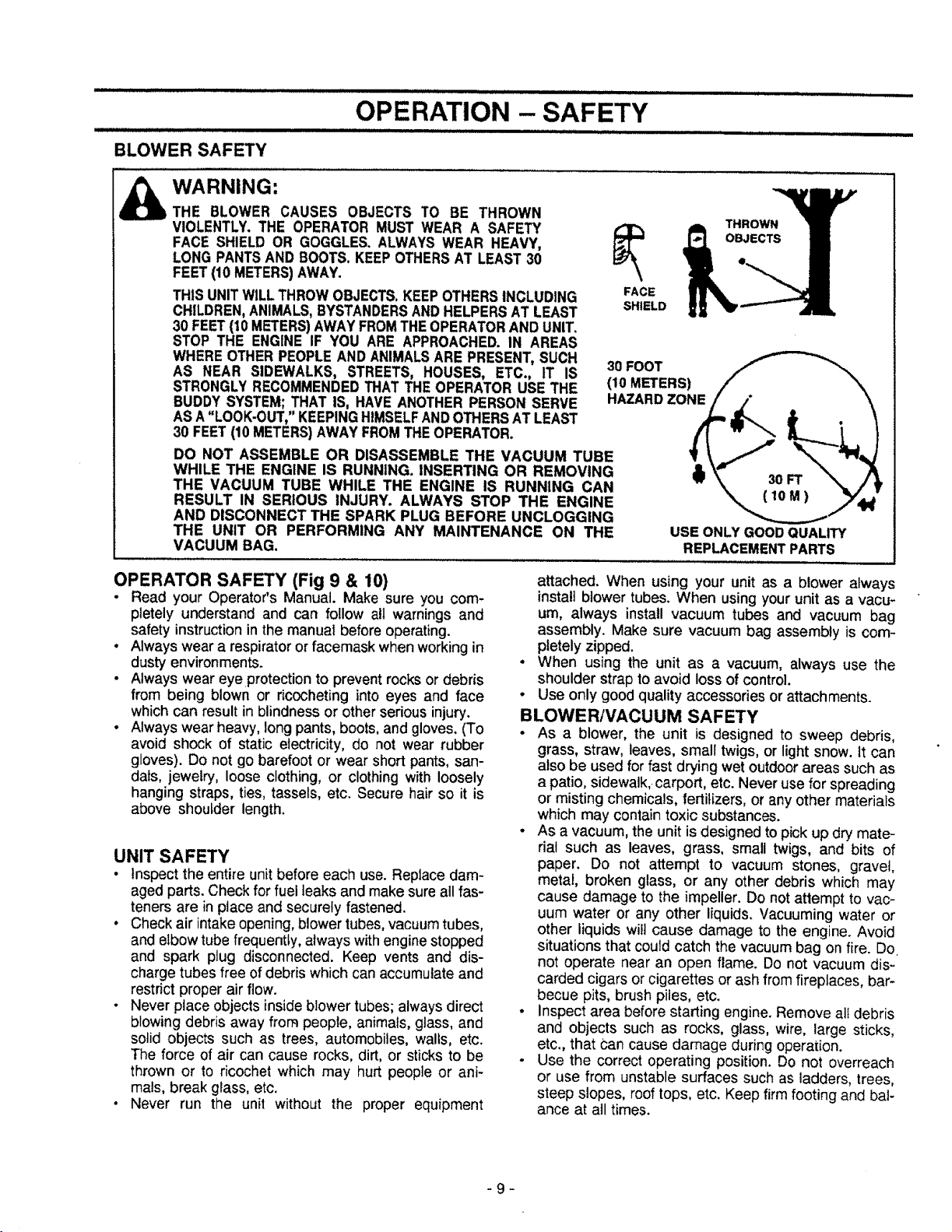

WARNING:

THE BLOWER CAUSES OBJECTS TO BE THROWN

VIOLENTLY. THE OPERATOR MUST WEAR A SAFETY

FACE SHIELD OR GOGGLES. ALWAYS WEAR HEAVY,

LONGPANTSAND BOOTS.KEEPOTHERSAT LEAST30

FEET(10 METERS)AWAY.

THIS UNITWILLTHROWOBJECTS.KEEPOTHERSINCLUDING FACE

CHILDREN,ANIMALS,BYSTANDERSANDHELPERSAT LEAST SHIELD

30 FEET(10METERS)AWAYFROMTHEOPERATORAND UNIT.

STOP THE ENGINE IF YOU ARE APPROACHED.IN AREAS

WHEREOTHER PEOPLEANDANIMALSARE PRESENT,SUCH

AS NEAR SIDEWALKS, STREETS, HOUSES, ETC.,/T.!S _100F_OETTERs)

STRONGLYRECOMMENDEDTHATTHE OPERATOR UsE ira:

BUDDY SYSTEM;,TI_ATIS, HAVE ANOTHERPERSONSERVE HAZARDZONE / /" \

ASA LOOK-OUT, KEEPINGHIMSELFANDOTHERS ATLEAST _'_ !11' •

30FEET (10METERS)AWAYFROMTHEOPERATOR. f[ "1" _ I_...,,.._J. , ]

DO NOT ASSEMBLE OR DISASSEMBLE THE VACUUM TUBE I _ __ _ 41qqJ

WHILE THE ENGINE IS RUNNING. INSERTING OR REMOVING 4!1\_ 30 FT _ /_.

THE VACUUM TUBE WHILE THE ENGINE IS RUNNING CAN "" \,,,. ,_1',; _ _ Y

RESULT IN SERIOUS INJURY. ALWAYS STOP THE ENGINE _ J'4kt

AND DISCONNECT THE SPARK PLUG BEFORE UNCLOGGING

THE UNIT OR PERFORMING ANY MAINTENANCE ON THE USE ONLYGOODQUALITY

VACUUM BAG. REPLACEMENTPARTS

/ \

OPERATOR SAFETY (Fig 9 & 10)

• Read your Operator's Manual. Make sure you com-

pletely understand and can follow all warnings and

safety instruction in the manual before operating.

• Always wear a respirator or facemask when working in

dusty environments.

• Always wear eye protection to prevent rocks or debris

from being blown or ricocheting into eyes and face

which can result in blindness or other serious injury.

• Always wear heavy, long pants, boots, and gloves. (To

avoid shock of static electricity, do not wear rubber

gloves). Do not go barefoot or wear short pants, san-

dais, jewelry, loose clothing, or clothing with loosely

hanging straps, ties, tassels, etc. Secure hair so it is

above shoulder length.

UNIT SAFETY

• Inspectthe entire unitbefore each use. Replace dam-

aged parts. Check for fuel leaks and make sure all fas-

teners are in place and securely fastened.

• Check air intake opening, blower tubes, vacuum tubes,

and elbow tube frequently, always with engine stopped

and spark plug disconnected. Keep vents and dis-

charge tubes free of debris which can accumulate and

restrict proper air flow.

- Never place objects insideblower tubes; always direct

blowing debris away from people, animals, glass, and

solid objects such as trees, automobiles, walls, etc.

The force of air can cause rocks, dirt, or sticks to be

thrown or to ricochet which may hurt people or ani-

mals, break glass, etc.

• Never run the unit without the proper equipment

attached. When using your unit as a blower always

install blower tubes. When using your unit as a vacu-

um, always install vacuum tubes and vacuum bag

assembly. Make sure vacuum bag assembly is com-

pletely zipped.

, When using the unit as a vacuum, always use the

shoulder strap to avoid loss of control.

, Use only good quality accessories or attachments.

BLOWER/VACUUM SAFETY

• As a blower, the unit is designed to sweep debris,

grass, straw, leaves, small twigs, or light snow. It can

also be used for fast drying wet outdoor areas such as

a patio, sidewalk, carport, etc. Never use for spreading

or misting chemicals, fertilizers, or any other materials

which may contain toxic substances.

• As a vacuum, the unit is designed to pick up dry mate-

rial such as leaves, grass, small twigs, and bits of

paper. Do not attempt to vacuum stones, gravel,

metal, broken glass, or any other debris which may

cause damage to the impeller. Do not attempt to vac-

uum water or any other liquids. Vacuuming water or

other liquids wilt cause damage to the engine. Avoid

situations that could catch the vacuum bag on fire. Do

not operate near an open flame. Do not vacuum dis-

carded cigars or cigarettes or ash from fireplaces, bar-

becue pits, brush piles, etc.

• Inspectarea before starting engine. Remove al[ debris

and objects such as rocks, glass, wire, large sticks,

etc., that _;ancause damage during operation.

- Use the correct operating position. Do not overreach

or use from unstable surfaces such as ladders, trees,

steep slopes, roof tops, etc. Keep firm footing and bal-

ance at all times.

-9-

Loading...

Loading...