Page 1

IMPORTANT MANUAL Do Not Throw Away

Operator’s

Manual

Model No.

358.707922-32CC

358.797950~22ec

358.797961-22CC

35a797982~32ce

A WARNING:

Bead faheC^erateat^sManaal aad

BoSmAB Safely

ISStìtìction^’'ÌÌÌ0Ì^- f o Do So

Can Besnlt in Serious Injury.

Always Wear Eye Froteetìon

EMi/CRflFTSMflN

GAS POWER BLOWER

2 Cycle Engine

• Assembly

• GperatioB

Fuel Mix

• Maintenance

• Repair Parte

Sold bj 60684 USA

530-081829-1-06/17/93 A 'tOClQ £3Ylfl fin

Page 2

LMTED WARRANTY ON CRAFTSMAN FOWER BLOWER

WARHANTS KBMOD: One Year - Models 368.7979S0 & 358.797961

Per tim Wan^ty Period spoiled above from the dale of parchase, when tfe Power Blower is maintained, btbicated, and toned up

Й

ajwronjg to toe w^tmg and mamtenaaee mstruct ions in the operator's maimal, Sears will repair free of Ашгве any defect in mate

rial or wwkmanship. ’ '

This warranty excludes bbwer tubes, spark plug, and air deansn which are expendable pans and become worn duriogniMriiud rise.

If this Power Blower is used for commercial or rental purposes, this wacmity applies for 90 days.

Mbrí I ilv ТИБ UNITED STATES. This warranty applies only white this product is in use in the United States.

This warranty gives you spenCc legal rights, and you may al^ have othm- rights which vary from state to swte.

Two Years - Models 358.797922 & 3SS.797982

THE UJCrr TO THE ЖДЕЕ5ТЗЕАВ8 SERVICE CEK'TERBIPAET-

SEARS, ROEBUCK AND CO./PEPT. D/817WA, HOFFMAN ESTATES, IL 69179

TABLE OP CONTENTS

WABNmGS AND SAFETY INSTRUCTIONS

A. Ogierator Safety ..................

B. Operating Tips*--Blower .

C. Operating Tips—Vhcumn

jD. Pre-operation Checks ..,.

., 3 GENERAL MAINTENANCE.........................

6

.. 8

.. 8

9

A. Air Filter

B, PuelTfflik ............

C. Starter Rope ... ,'t

D. Storage - -

F. TEotiiSa ShontiTie'Chart. ’...

ACGESS€№S

REPAIR PARTS LKT -

QinCK-REFERENCE PAGE..........................

PARTS AND SERVICE

..........

.................................

........................

................................

........

................................

.................................. ..

............

...........

......................

......................

..

.............

.........................

........

...............

.........................

..................

.........................

..........;:i it

........................12

.........................

****-_-,.,,*, 16

BadeCerver

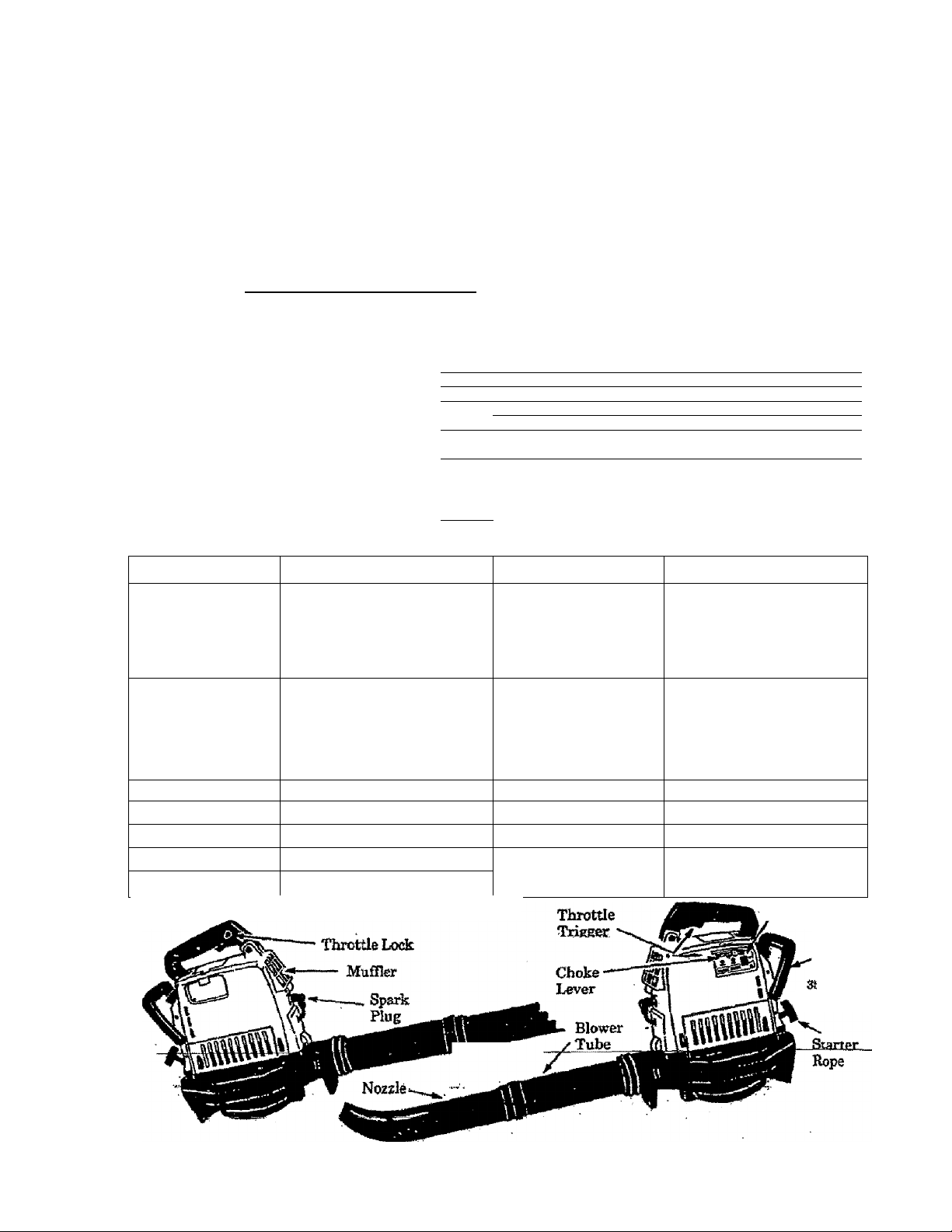

SPECIFICATIONS

10

10

ib

10

12

13

ENGINE TYPE:

DISPLACEMENT;

2 Cycle Air Cooled

22cc-- *

Model 368.797950

Model 358.797961 ,

32cc—

Model 358.797Se2

Model 358.797982

ENGINE RPM:

Operating—^7000 -7600-

All Models

Idle—3800-4600—

AH Models

IGNITION: _

CARBURETOR:

ON/OFF SWITCH:

STARTER:

Solid State

AU Position Diaphragen SPARK PLUG GAP:

Positive Rocker Switch MODULE АШ GAP:

Auto Rewind

FUEL TANK: l8;6fl.OZ.

JjaoBTAciiirtd юЛг я» вг ею« oTtb* Мэтвв* US, P»|«ot* <,«4.706; 4,ti3,371: <eí4,146:

SE »,»0;<7$S.IS$; <4Ce.l0«; 0299.074. Othe

VS. tai

fongu »Мент peater ‘

MUFFLER;

AIR VELOCITY:

AtR VOLUME:

ШШКРШСк

LUBRICATION:

Lo Tone .

155 mph—

Model 358.797950

Model 358.797961

170 mph**—

. . Moda^.797922

Model 358.797982

350 cuil-Anin.—

Model 358.797950

Model 368.797961

360 ca.ftAnin.—

Modd35U97922

Midel ^1^982

CU-ST(Cat, No. n-85853)

,025” .

.010”-.014”

Gaso£ne/Oil №xture—

See “Fu^gYourEngme”

ON/OPF Switch

Rear

Handle

(Model

18,797982

ОКШ

Page 3

•Ufa

A WARNINGS AND SAFETY INSTRUCTIONS

Failure io follow all Safely Rules and Precauiions can result in serious injury.

A. KNOWYOUK UNIT

1. Read yotir Operator’s Manual carefully rnitil

you completely understand and can follow a]] warn

ings and safety instructions before operating unit.

Z, Restrict yeur unit to users who understand and

will follow all wartjiixp and safety instructions in .

this manual.

B. FLAN AHEAD

l;;,Alzc<tys wear eye protection to prevent rocks or

debris from being bhwn or ricocheting into ^'e$ and

face which can result in blindness andfor other seri

ous injury.

2. Always wear a ret^irator or facemaslc when

working with the unit in dusty enviromnents.

3. Always wear hea^vy, long pscDts> boots^ and

gloves. Do not M barefoot or wear short pants,

sandals, jewelry, loose clothing, or clothing wtth

loosely han^g straps, ties, tassels, etc.; they can be

caught in moving Secure;^sdr so it is above

shoulder length, Beingfuily covir'ed will bdp pro

tect you from pieces of tooc plants suidi as poison

ivy ttffown by the blade, which could be more of a

hazard than touching the plant itself

4. Do not operate the unit when you are tired, ill,

upset, or tf you are under the influence of alcohol,

dmgs, or medication.

5. Keep children, bystanders, and animals away

from tHe work area a minimum of 30 feet wkmstarting or operating the unit.

6. Inspect the axeahefore starting the unit. Re

move all debris and hard objects such as rocks,

^ass, wire, etc. that can ricochet, be thrown, or oth-

. «wise cause injury or damage during operation,

C. HANDLE FUEL WTTH CAUTION

1. Eliminnte all sources of sparks or flame (in

' duding smoMng, open flames, or work that can

cause ^arks) in areas where fuel is mixed, poured,

or stored.

2. Mix and pour fuel in an outdoor arem; store

fhel in a cool, dry, weB—ventilated place; use an ap

..,. proved, marked cmtainw for.all |p^;paposes. ^ .

not aasdfee whRe handlii^^teror wnite ’

'Operating the unit. -

4. Do not ^ fuel task while engitie is running.

3. Stop the engme before reinovragthe fbel cap,.

Allow the engine to cool before reeling.

6. Wipe up aUfuel spills &^rc starting engine.

7. Move at least 10 feet away fkom ftiel and fuel

ing site before starting the mtgine.

p. OPERATE YOUB UNIT SAFELY

1. Stop the engine before opening the vacnunt

inlet door or attempting to insert or remove the

: vacuum tubes. Ji^^nginem^^tg^pped and the

impeller bladekiwphget toipi|3gi^^ serious

inijuiy from therotatinghlades.

2. Inspect the entire unit bef>re each use for worn,

loose, missing, or damaged parts. Do not use until

the unit is in proper working order.

3. Keep the outside surfaces free of oil and fueL

4. Never start or run unit inside a closed room

6. Never use for spreading dhemicals, fertiliz

ers, or any other material which may contain toric

substances.

7, Do not set the unit on any surface except a

dean, hard area to start the engine or while

the engine is running. Debris such as gravel,

sand, dust, grass, etc. could picked up by the air

intake and thrown out through the discharge open

ing, damagingthe unit, property, or causing serious

injury to bystanders or the operator.

S, Avoid dangerous enviromnents. Do not use in

unventilat^ ateas or where erqplteive vapors or

carbon monoxide build up could be present.

3. Avoid situations which could set the collec

tion bag on fire. Do not vacuum discarded cigars

or cigarettes or ash'from fireplaces, barbecue pits,

brush pües, etc. To avoid spreading fir^ do not use

blower near leaf or brush fires, fireplaces, barbecue

pits, ashtrcys, etc.

10, Do not overreach or use from unstable sur

faces suds as ladders, trees, steep tuoflops,

ete. Use extra care when cleaning on stairways.

Keep firm footing and balance at all tiroes.

11. Never placé objects inside the blower tubes;

always direct the blowing debris away from people,

animals, glass, and solid objects such as trees, auto

mobiles, walls, etc. The force of air can cause rocks,

dirt, or sticks to be thrown or to ricochet which can

hurt people or animals, break glass, or cause other

damage. Do not allow ^ unit to be used as a toy.

12, Never place any object in the mr intake open

ing as this could restrict proper air flow and cause

damage to the unit.

13. Mever ran unit without the proper^equljj^

ment attached. When used as gblower, always in

stall ablowertube, When used as a vacutan, always

install vacuum tubes and collection bag assembly.

. 14.Use only for jobs esplainedln this manual.

E.MAINTAIN YOUR UNIT PROPERLY

1. Have all maintenance other than the recommended

promkîresdescïfliedhîliié Gperatoris Manual per

. formed by your Sears Serrice Center.

2. Disconnect spark plug before performing

maintenance except for carburetor ^nstment.

3. Use only genuine replacement parts as xedommendedl^ Sears to avoid creating a hazard and/or

voiding your wairanty-

4. Check air intake openings, blower tubes, el

bow tube, and vacuum tabes frequently; al~

, ivayswithfrieenj5bttestopped, Keepventsandtubes

free of debris which can accummate and restrict

.. ror Sow. ;

5. Befoi^ storing the unit, use up fuel left in

carbaretor and mellhies by starting the engine and"

letting it run until it stops;. See “Stor^” section.

3. Do not use any accessory or attacbiEent other

thanthoserecommendedbySearsforusewithyour

7. Dd not store the unit or fiiel in a closed area

3. To avoid sliock from static electricity, do not*

wear robber or anv other insulated gloves whileotte.^,. ,

eratiag the unit. . .ss

If situations occur which are not covered in this manual, use care and good Judgement.

Contact your Sears Service Cenieg/Deparpnent if you need assistance.

from hot water heaters, dectricmotois or switches,

.furnate§.etc, , ,

»;• ■ Storb Ш ai dry area out of reach of children.

Page 4

KNOW YOUR UNIT

A.INTEODOCTION

Your blowor is a hi^ performance product

for tou^ jobs.

Special'Eeatures include:

• for fme-handed operation.

• DixectBrive.

a Viferation—Dampened Handle.

• Wei^t - 12 lbs.

• Comrenientx^rii^t storage.

• ATailable Gutter Attachmmt Kit #358.79992

B. UNPACKING INSTRUCTIONS

1. Hemove contents from, the carton if you have nc^

done so. ,

2. Check parts against the Carton Contents List

3. Bbcamine parts for damage. Do not use

parts.

A mUfyyofO'SeanSmAi^CaderlEhpftrtmmtirmne-

NOTE

.............

empty fiiei tank.

It Your unit is factory equipped wiUi a vibra-

t—dampened handle whida causes the handle to

appear to be loose. This condition Is normal

the Safety Notice at the bottom of this page.

NQTEi. Your u^'lm been factory tested and the car

buretor precisely adjusted. '№e3№fore,iti&possib!e

to smell gasoline or to find a drop of ou/fuel readne

on the muffler.

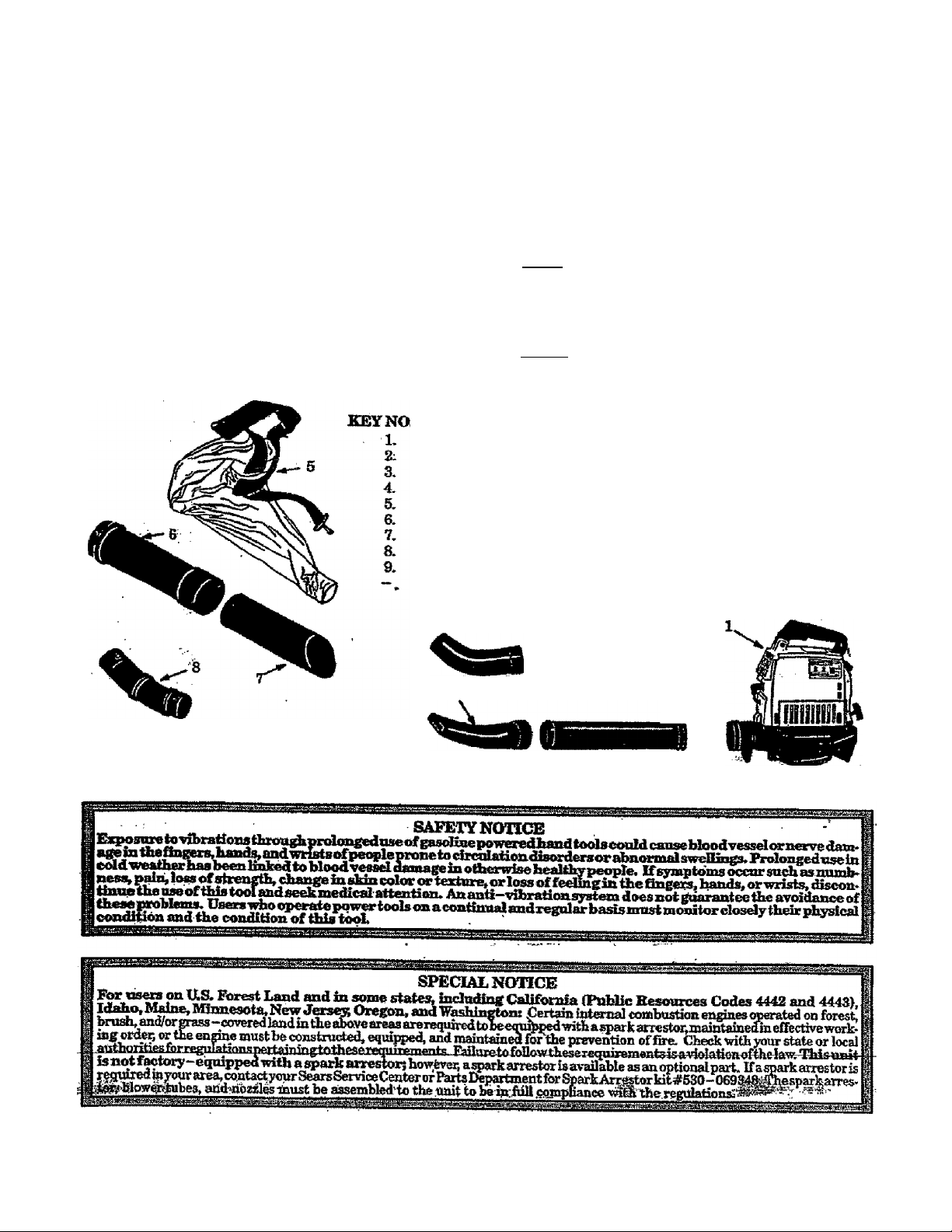

CARTON GONTENTS

Bowerhead ‘'1

Blower Tvdie i

Concentrator Nozzle 1

flare Nozzle 1

Vacuum Collection Bag 1

Upper VacBum Tube 1

Lower Vacuum l\ibe 1

Elbow Tube 1

2-cyde En^e Oil i

Operator's Manual (not shown) 1

........

rattle in an

<

Models '

3Sa797922Tfe3SSli9lS82

Models

358.797950

358,797961

2

V

Page 5

ASSEMBLY

A.PREFARATION

%nxr Operetoir^s Maxniid has been devejo{^ to h^

jpou assemble the uultand toimderstaitd its safe opera'

tkm.- It is iiai>ortai2t that you read your manual com

pletely to become familiar with the unit hefore you be-

t. BEAD YOliBOPERATOa'S MANUAL.

2» The <mly tool required is a standard screwdriver.

NOTE; Toease assembly; lubricate lockingtrfts before

assembling tubes.

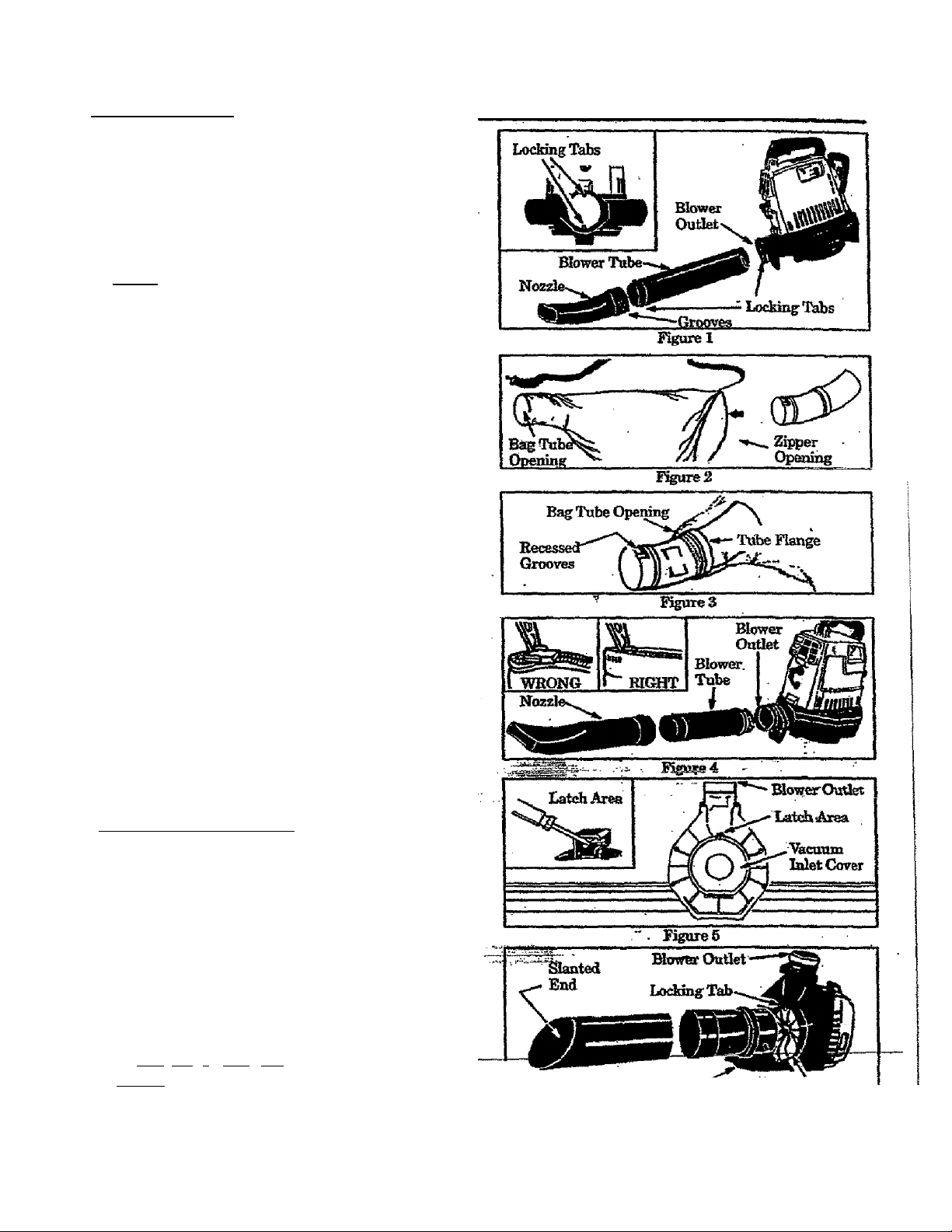

B'BLOWER TUBE ASSEMBLY

L Locatethetwolockingtabsonthesideoftbeblower

tube. Figure 1.

2. AMgn the grooves on the hozrle with the locking

tabs on the blower tube and push the nozzle onto

the blower tube.

3. Tom the nozzle clockwise until the parts snap into

. place and are firmly ti^teued.

4. Align Grooves on the Blower Tube with Locking

Tabsiathe Blower Outlet 0?gure 1, inset) andpu^

the Blower Tube into the Blower Outlet.

5. Tom the Blower Tidie clo«ikwise until the parts

snap into place and are firmly tighttaied-

a VACOtJM BAG ASSEMBLY

1. ' Opfio. the zijmer on thelai^ end of the vacurunhag.

2. Insert the Elbow Tube, grooved end first, throu^

_ the z%)p^ tpeningin the vaonim bag (Figure 2).

Then, pu^ the grooved end of the Elbow Tube

throughthebagtubecpemngin&eotfaerendofthe

bag. Kg^es2&3. Imke sure the bagtobeqpenmg

. is Qush against the tube flimge. Figure 3.

'3.- caosetbezipt^onthebag. fekesuretheKtoperis

'»dosed compLeteb^ and the zipper seam is tm£edto-

-ward the inside of the bag. Figure 4 Onset).

D. VACUUM TUBE ASSEMBLY

AWABNING

Stop the engine before opening the vactmm inlet

ntntobes. Theeni^eniastbestoppecland&elni'

pdQ^. blades no longer torrilng to acvoid serions

injgry fifom the rotatingbladeg.

1. Remove the blower tube fimm the engine. Figure 4

2. Settheunit,bloweroutletup,onaflBtsuifaeeG^-

ure 3). Open the vacuum imet cover as follows:

a. Irwert a screwdriver into latA area. Figures,

h. -Gently twist the tip of tiie screwdriver and oj^

&e vacuum inlet <»ver with your other hand.

3i HoH open vacuum inlet^vCT ^d aliga ^e^tr^

side the vacumn inlet. Figure 6. Insert upper

vacutna into the vacuum miet; twist the upp®* vac

uum tube docfcwise imtil parts snap together.

4 Assemble the vacuum tubes by aligning the slanted

end of the lower vacuum tube witfi the Wowcroutlet

as shown in Figure 6,_Push the two tubes together

-until thcy are snug. Ftgui'g-fe 7

NOTE? The bottom end of the lower vacuum tube is

. ;?^,cut:at an angle. Mafes siire slanted end of vacuum

tuhe h aligned with blower ouilet. Figure 6.

Vacuum M?^.Covkc ; ; i', -'^tcuum.Ialet

-----

....

...............................

.............

------------

Page 6

S- To attach lite vacuum bag, aSgn. the grooves 611 the

elbow tube with the lod&g tabs imsde the blower

qutìet. Figure 1 (inset). Be sure to align the dot on

the dbow tube wth the dot on ihe blower honrfng.

Insért elbow tube into blower outlet; twist elbow

tube counterdockwise until parts snap together.

6. A#ist the vacuum collection bag at the dhow tube

to remove any twists. Figures.

E. STOULDm STRAP ^JUSTMEìSÌT

_

„----------Collection Bag are positioned on your rigfat'-hand

side. sigure S. .

2.

Place collecticm bag strap around, your back and

over your left shoulder. Snap collection bag hook

onto the strap retainer in the top handle. Figure s.

3. EJctendyourri^tanutowardtherearofthecoUection bag. Figure 8.

4. Adjust the Moulder strap until the collection bag/

shoulder strap seam liesoetween your thun^ and

index finger. Figures.

6. Maj^ sure the shoulder strap is adjusted to aQow a

. Ìréèfibwofairfronitheelbowtube, iiguraS. iftbe

Bag is kinked, the unit will not operate properly.

---------

------—.----------

. Make surethe Blower Outlet and

prilli posi-

ube on the

E BLOWEK CONVERSION

1. Stop the engine. Allow the engine to cooL

2. Eemove the vacuum tubes and coliectfon bag as

sembly.

^3. Secure the vacuum inlet cover. Make.sorelhat the

latch on the vacuum islet ^c^ii^fastened.

4. BeinstaUtheblowerhibesasshowninme^Blower

Tube Assembly** section.

BoddngTabs

Figure?

Collection Bag/

Shoulder ^ap

Seam '

SteapBetainer

■■ ■ -

Figured

USING YOUR UNIT

A. OPERATOR SAFETY

A WASHING

Bo not assemble or disassmshle vacuum tuba

wiiilethean^^eisriiigmmg. Insextingorremov*

ingthe vacoftm t^e while the engine is rtmniros

can resnlt‘'1n serious injury. Always stop the mxgine find discoimect the spmrh plug l^ore un-

oi^^^^lleciaon. ba^.

As a blower, the unit is des^ned to sweep ^ri^

gras%^^:j^w^@avss, small tensor light snow. It can

alsp № HHtfast dryingwet outhmraix^sudbasa

sidews^ carport, etc.^ Never use for spreadi&g

' misting dhemicals, fertilizer^ or any Pthmr maim-

aib which may contain toxic substancés. As a vaca-

tempt to vacuum stones, gravd, nmtal, brokmi ^iss, enr

ai^ other debris which rnay cause damage to tbehn^-

texi Do not atimpt to vaetam water or any oth&‘lig-’

tads- *l%umundi%wat№orQtherU<piichiwjllcausedam-

s^totheeii^ine. Avmdsituatiora that could catch the

collection bag on-fire. Do not operate near an open

not vacuum discardbd dears or ctearettes or

ashfrcTO fireplaces, baihecue pits, brush p^, etc.

h Beadi your Operator's Hanttial. sure you

oompletdy understand and can follow all warnings

and safety insbructious in the manual before operat

ing die unit.

2. Always wear a respirator or facemash when

workhig in dusty environments.

-^rAJflPSys wear eye protection to prevent roihs or

d^rts from betttg-haifea.or deecheting into ey^s

aSS face which cairifimt in blindness or other sm-

ous injury.

Rear Handle

-Use

BLOWER

OPEBATION‘=

4. ' Alw«^ wear beavjs long pants, hooti^ and

0oves. Do not go barefoot or routs,

sand^ jewdry, loose ‘dothins witn

loTOd^hangmgstscanSffre^ tasselsj etc. Secarehair

so it Is dbdve ^oulo^ length. Being fiiQy covered

will help protect you from pfeces of tmuc plants sudi

as poison ivy thrown by toe blade, which could be

more of a hmiard than touching the plant itseE

5. Check toe unit before each operation. Look

for worn, loose, missing, or dama^ ^arts. Ito not

USB the umt tmtfldt-ts-m-ptoper workiug si'dai:

6. Inspect area before startog Remove

all debris and objects such as-rockspi|!ass, wite,large stidis, etc., that can cause damai^ darirg op

eration.

Eye

iLi—f^tection

VACUUM

OPERATION

Figaro 9

Page 7

7. Keep cfeildi^a, bystanders, andl animals safe-

away. Be/bi'c starting the engine and dttrin^ op-

efotion, make certain children, people, and animals

are a minmmm of 30 feet from the work area.

&. Cliecic air intake opening blower tubes, vac'

«1^ tubes, and elbow time &eqneiitil3%

tvitb engine stopped and spark plug disconnect^

Keep vents and mscharge tubes free of debris wiiidt

can amimulate and restrict proper flow.

9. Use the eorrect operating posiMcm. Figure 9.

Do not oyerreadi or use from unstable surfrtos

sudi as laddme, tr^ steep slopes roof tt^s, etc.

Keep firm footing and balance at all ttme&

10. To avoid shock front statu: electrieiiy, do not

wear rubber gloves or any other insulated gloves

while operatis^ the unit;

11. Never place objects inside blower tubes; al

ways ^red; blowing debm away from people, am-

mds, ^ass, and solid olgécls sadi as tms, automo

bile^ wails, etc. The force of air can cause rocks,

dirt, orsticks to be throum orto ricwchet which may

hiat people or apimals, break ÿass, etc.

12. Never run the «nit without the proper equip*

ment attached. Whenusingyoarumtasablower,

always install blower tubes, \roen umng your unit

as a vacmim, always install vacuum tubes and col

lection bag assembly. Make sure coll^ion bag as

sembly is complet^y zqped as shown In Figure 4.

13. When using tiie unit as a vacuum, always use

the shoulder strap to avoid loss of confrol.

B. OPEBAHNG TEPS — BLOWEB

Do not use die unit as a blower without the blow

er tubes prormrly attached to avoid flying ddbris

and/or impeller contact which can cause setious

infUry.

________________

1. Always work going away &om solid objects

such as waQs, frees, automoMi^ and fences.

2. Clean comers by starting in comers and mov

ing outward to stroi^t areas to prevent an accu

mulation of debris which could fly into free.

\B. Beioar^hal when working near plants. The

force of the air could damage tendm* plants.

4. Direct air flow by directing the nozzle down or

to one sMe.

5. Tary the air flow bv adj^isting your grip on the

. throttle triagsen

Awabking

_______________________

C. OPERATING TIPS — 'VACUUM

^ ^ ATm^mG

Do not use the unit as a vacimm without the meu-

um tube and coUqetio«. bag properly attoched to

avoid flaring debris apd/ox unp^er contact which

can cause serious injury; Always make sure the

coUec^onbagis cmm^etely zipped b^ore the en>

^ineisstarteh ’

1. WhenusingyourunitasayaaiiiBS^bestre&ults

are achieved when the unit is operated at Ml

throttle. Bugeye the Throttle Lode before beginningvscuumingprocedures.

2. Move the unit slowly back and forth over de

bris to be vaenumed. Avoid forcing the vacuum

' tube into a pile of debris as this css dog the unit.

3. The vacuum can pick up objecto that are too

big to pass through the impeller. This i^e of

object vrill fall out of the vacuum tubes when tiie en

gine is stqpped.

_________;___________

Alwmn wear eye protection to prevent rocks or

débris from being blown or riooebeting into the

^es and face which can result in blindness or se

rions injury;

$, Use the assist band|e}pcat^on the back ofthe

unit when working ^dve the waist or when a

two-handed grip is desfred.

7. Uses For Your Blower!

a. Sweeping debris or grass dippings from drive

ways, sidewalks, patios, parks, parking lots,

bams, stadium!^ etc.

b. Blowing grass dippings, straw, or leaves into

piles.

c. Fast drying wet outdoor areas sudx as a patío.

d. Bemoving debris from оогпма, artñmd joints,

and between bridks.

e. fflowingK^htsaowfeom driveways, sidewalks,

СИР patios. •

A If the unit becomes dogged: '

a. Stop the engine and disoamert the spark plug

wire. Donotcttempttoremove^^sfructumsioitk

AWABmNG

__________________

the en^ne running.

b. Wait until the impeller has completely stopped

tomingv then remove the vacuum tube.

c. Car^dly reach into the vacuum opening and

dearoufrdd>rts. _

5. The coBectionbagini^lfe'pri^rlfy emptied

' and mamtain^d to avoid detoioratnm and obsiruc-

tionof air flow which wiH reduce the performance

of the vacuum. ’

a. Empty the bag aitm-each use. ^

h; Remove the bag/elbow from tiieuhit by turning

itinadodcwisedli^ion. Donotstorebageontaining leaves, grass, etc.

c. Wash the bag once a year as follows:

1) Turn the bag inside out

2) Bmgitvip.

3| -Thproadi|y h^it4pw“-

dr^fhaghamg^ttlffdiy.

D. PRE-OPERATION CHECKS

Before operating your unit, always:

1. i^HECK OVER WARNINGS AND SAFETT

INSTRUCTIONS in this Operator's Manual.

Make certalin you mm^etaly iiaderstaad-md-Mlow each one.

2. i^GfeffiCK THE Am iTLipEl.

dirty^fefolelMperating the unit.

For location, see the “Air Palter” section.

3. i^CHECK THB UNIT FOR LOOSE BOLTS,

NUTS, OR FITTINGS.

Ti^ten, repair, or replace parts as п^зету. You

wffl need a PMlKps screwdriver and a hex

wrench ■. Useno^L^enmafe-r^lae^^t-parts-as-

recommended by Sears.

4. А^СЖЕСК’ГтЩШ.ТАКК.

Fill with a clean, fuel mirturf^^i^Mgl»

Йхе instructions in Ihe “Fuel Mixture” section.

_ 7-

Page 8

ENGTOE INFORMATION

A. FUELING ТОШ ENGINE

1. FtJELSAFETir

a. Cse only recommended fuel mixtures.

b. -Mis: and pour fuel outdoozs and where

there are no ^arhs or {lames*

c. Use a container approved for fiieL

d- Do not smoke or allow smoking near fuel

ox the unit or while u^g the unit.

e. Wipe np all fuel spills before starting the

en^e.

f. Move at lea^ Id feet away from ftteling

site before starting engine.

g. Stop mr^e before rcmovingftiel cap. Al

low the engine to cool before refueling.

. h* Before storing the unit, use up ftiel left in

fuel lines and carburetor by starting engine

^ and letting engine run until it stops.

i. Store unit and fuel in an area where isel

vapors cannot reach sparks or open

. switches, furnace^ etc#"

flames from water heaters, electric motors or

2. FUEL MmURB

a Tcn]r'anitispoweredl^a2-(^leengine

whichrequhes a fitel mixture of regolar

unleaded gasoline and ahigh quality en*

gjne oU specially made for 2-Qrcle, air

cooled engines. Ihe internal detign of the

2—lycle en^ne requnes hibtication of moving

parts. Lutuication is provided when recom

mended mixture of gasoline and oil is used.

* Gasoline must be <dean and &esh. After a

short period of time, gasolme will chemically

break down and form compounds that cause

hard starting and damage in 2>-<yde engines.

« 'The correct measure of gasoline to oil k

very important. Too much oil in the mixture

wiH foul the ^arkplug. •

I

CAU^ON; ) Too little tal will cause the engme to over

■ heat and seize, •

3. USE TBE FOLLOWING ONISi

WEíüD EATEE 40:1,2-cyde engine oil is strongty recommended. PAEAMOTJhn? POULAN, or

POULAN PRO brand 2-cycle engine oil is

acceptable if mixed according to the instmetions

on the container. .

1 PART OIL TO 40 PARTS GASOLINE«

3.2 fl. oz. oil to 1 gallon gasoline

8.0 Q. ÚZ. oil to 2S gallon ^soUne

Not all air cooled 2—eyde oils have the

sarnequaHties. If WEED EATER, PARAMOUNT,

POULAN, or POULAN PRO brand 2~<iycle en^

gine oil k not av^ábl^ Use a good quditr«

2—cycIe engine oil recommended for air—coolM

engines. Mix at a ratio of 40:1 (3.2 oz. oil to 1 gal

lon gasaBne). A 40:1 fad mktnre with these oQs

will assure adequate lubrication foryour engine.

4. DO NOT USE:

• NMMAOil——National Marine Manufac*

Does sot have propief^^i^^ftr^-~cycle, air

. Coded angmes and can cause engihe dann^

o AUTOMOTIVE OBL-

Does not have proper additives for 2-qyck, air

cooled engines and can cause en^ne dams^

B. STàimNGINSTBtTCTIONS

. AWiHïNING

When starting eagjue, bold the unit as shown in

iflgnre 10. Do not set the unit on any surface ex-

e^t a dean, hsM area udtili^tiie enghie is run-

nine. Ddnis such as gravel, sand, dti^ gmss, etc.

emuâ be picked u|p by the air Intake andthrawn

out thrombi the discharge opening, damaging the

unit or property or causing serious idury to by

standers or operator.

I. Before Starting the Engine:

a. Fuel toe enmne. Move at least 10 feet away

tfom thefueangaSel "" ;

b. Hold the unit in the starting position d^shpwn

inFignre 10. WhenutingtheniutasaSlbTitor^

make sure the blower end is directed avray

from people, animals, glass, and solid objects.

When using the unit as a vacuum, make sure

8-

Experience indicates that alcohol blended ftiels

(cMledgasohol or using ethanol or methanol) can

attrmk moistirre widdh leads to separsdiou ai^

forraationofacids during storage. Atddic gas can

damage the ftiel system of an englue while in stor

age., To avoid engine pmblems, do not leave fuel

A-OAUnON

andcarbm^toraro empty. Usefreshfuelnextseason. See the “Storage”' section for additiona] in

formation. Nevernseengiim or carboretor clean

er products in the fuel taiw or permanent damage

can occur. ' t

5. HOW TO MIX FUEL AND FILL TANK

a. Pourthe proper measureofe^ineoii into an

proved, marked container, 'mea, fill the con

tainer with regular unleaded gasoline.

NOTE: If fuel is already in the mntainer, add the

proper measure of engine olL Then,, close the

coiftam»^ti^^i%and8h3lmi%momentarik .

NCyrE: Do not mixgasoline mtd oil dStecÜy m the

b. Usmg a spout or finmel, ñR the hid tank with

fhetmix.

c. KeinstaU the ibdikps securely.

the vacuum mid is directed away from people,

animals, ^ass, and soM objects.

2. For a Cold Engine or a Warm Enghm After

Banning Out of Fuel.

a. Move Ignition Switch to the “ON" position.

. Figure 11. . f”

b. -Move Choke toilEULI?. figure 11.' .

c. Eng^e the Throttle Lock as fdlows:

1} Ihnly squeeze and hold the throttle trigger,

2) Press and hold the throttle lock button.

Figure 11 (inset).

3} Release'the throttle trigger Leave the

throttle Lock engaged thru step “g.”

d.

.......

Fall Starter Rope~iharply until engine at”

tempts to run, but no more than 8 pulls on full

choke* The engine “attempts to ko«” maj;

be hard to hear. The operator must listen

carefidly. After 8 pulls, proceed to step“«"

even if the engine has not attempted to run.

Page 9

e. Move Choke to “HALF”. Figure 11.

£ Puil Starter Hope sham]^ until engtue runs,

but no more tkin 6 pul&.

HflSEtJf ^giue has not started after 5 pulls, re^

peat steps "a” throu^ “f.”

f. Allow en^e to run &r 5 seconds, then move

Choke to “OFF" portion. Release Throttle

Lock hjr squeezing and releasing the Throttle

Trigger. Kgore 11.

KQTEh If engine dies with Choke at "OFT" posi*

tion, repeat steps "e” throng “g.” If engine does

not operate properly, refer to “Carburetor Adjust

ments.” .

h. To stop engine, move ignition Switch to “OFF”

■ position. Figure 11.

3. For a Warm Engine;

a. Move the ignition Switch to the“ON” position.

Figure 11. ■

b. Move Choke Lever to the “HALF” position.

Figure 11.

c. Engage Throttle Lock. Figure 11 Onset).

Diave throttle lock engaged thru step “d.”

d. Full Staler JStope sharply untfl engine runs,

but no nmie than Spills.

e. Move Choke to “OFF“. Figure 11.

f. Release Throttle Lockby squeezing and releaS'

ing the Throttle Trigger. Figure 11.

HOTEi If engine does ncd; run after S pulls, it is

V. probably flooded. Wait a few minutra and repeat

! procedure with Chofe at "OFF” position.

g. To stop engine, move Ignition Switch to

“OFF” positioa. Figure 11.

Blower

Stmrtittg

Position

Figure 10

Figure 11

Vacuum

Starting

PosititHa

(Model

m.7smi

ONLY)

Throttle Lock

Button.

C. CABBUBETOB ADJUSTMENTS

• Poor en^oJie performance can foe a residtdf

other causes snch as dirty air ffltejq caxhozt

• bnfld-up on muffler outlets, etc. See

■ . “Troafole Shooting Chart” heft>re proceedmg with carburetor adfustmeats.

• The carburetor has bem carehilly adjusted

at the f acto^ Due to changes in alti^e and op-

erettop condidpuf, yoiir c^faur^tor require

low the.procedure below.

1, PjKEPARATION

au Use fresh fuel mix. See the “Fueling Your

Engine" section.

b. Turn Mixture Screw (Figore 12) clockwise

until fuÜy closed, but do not overti^tea:

Figure 12. Turn mixture screw one fuß

tum cotmterdbckwise.

c. Turn Idle Sp^d Screw (Figure 12) clock-

wisejiotilit stops. Do NOT overti^ten.

three fiiM turns countenJoek-

Wise.

IDLE SPEED ADJUSTMENT

a. Start the engine and run the unit for 10

minutes to warm up engine.

b. Allow the engine to return to idle speed.

~ar-Adjnst-Mls"^jBed Sergw^ntil tiie engine^

idles as slowly as possible without stalling..

- Tu^ screw efeckwis^^^igin^glalls.-. '.

— TiÄ 'Screw coühterâ^TOraë' to’slow eh* ■ *

gine down.

-15

Mirtore

Idi&S^â

Adjastment

Screw .

A^iustinmt

Screw

Figure 12

1CAUTIQ^ The mixture setting Is a highly odti'

■ at Ml throttle for prolonged periods wMIe mai^g

the mixture adfusrnnent; The final nxfocture screw

setting sltoold be in^the^i^ge of 9/4,-tfèJl-1/4

open,

3, MKTDIIE ADJUSTMENTS

a. Accelsrate engine to fall throttle.

b. Turn the Mixture Screw slowly clockwise

until ttie eng^e speed is reduced. Note posi

tion.

Turn the screw slowly counterclockwise. Stop

when tibe engine just be^ns to nm rtm^y.

Turn the screw slowly the minimiiSi

araoimt clockwise until the engine

smoothly. . .

..Æ

-9-

Page 10

GENERAL MAINTENANCE

A. Air Filter

A air filter decreases engme performance and

increases fael consumptiott.

Clean the Air Filt^

• Freqiuenilj;

* Alwa^^ clean after 5 tanks offnel or 5 hoars

of operatioiit whichever is lessi.

Follow these steps;

L Move the (hote lever to “FhH", Figure 11,

2. Eemove the air SIter cover on top of the unit (tm

’ der the handle). Blgnie 13.

3. Eemove the air fihec FSpselS.

4. Wash the air filter wiffi soap and water.

ICACTIOI^ To avoid creating fire hazard, do not

cdeah filter in gasoline or other fianunable solvent.

5. Simeeze the air filter di7

6. Add 4 or 5 drops of oil to die the air filter.

NOTEi AvoM soaHng the air filtcr wilh oQ.

WtTTTT *¥*AXnr

B

1. Never use gasoline that is more than 2

months old in-a fuel mixture. Gasoline heg^

, to break down after a-short period of time and

fbrm compoundb that cause hard starting and

dam^ in 2-^cl8 en^es.

2. Inspecttheunitfor£uelleakseaohtime itis

used. R^air or replace parts as n^ssary.

C. STARTER ROPE

Replace the starter rope if the rope breaks or is

badly worn.

NOTE: Whm replacing an unbroken rope,^ cut the

rope and allow the rope to rewmd onto the pulley.

Air Filter

Cover

Air Filter

Figure 13

7. Sipeeze the air filter to distribute od.

8. Eressembie the air filter onto the cov^

I CAUTTONt I 'flic holes in the air filter must be fit*

ted over the posts on the air filter'Ooven When. In

stalling the air filter/covér assembly, be sure that

the filter dees not hang on the choke lever screw.

9. Beassemble ah fil^/cover assemble to unit. Be

tún» choke lever to the position. Figure 11.

3.

Using a ftifl mix orgq^oiine over 2 months,

oldteiUcmtse the engùteto bedifficultor im-

poeaihfe to staH. ■

4.

Empty the fuel tank before storing the unit.

Use up fiiel left: its the carburetor by starting the

engine and letting it run tmtil it sh^

Latch Area

Awabning

Do not remove the Pulley whe» replacing the

sitoirthr rope.. Alweys w^ar eye ^tit^lon when

servicing the starter rope. The recoil spring lo

cated beneath fite pulley, is under tension. If the

ispringpops out, serious inhiry can result.

To repair or replace;

L Dlscoimect spark plug wire fiom the spmk|dt|g; a

2., ^unit,blow^cmtletup,oii aflatsumce.jJi^.i

mel4. Opén the vacunmiukfe cover i^Mhnvs:

;lEsertascrewdrivm^.intothetefccho|íénhIig:Fig-

..;; ure 14(m&et). •

b. Gen% twist the screwdriver while openmg the

vacuttm inkt cover with your other hand.

3. Eemove the impeller nut and washers while hold

ing the impeller. Figure 14.

4.. Eemosre the 4 impwer shroud screws. Figuréis.

Then, remove the 2 engine shroud screws located

bytheq>arkplug. Figure IS. Itemoré the impel

id v&mB-m-

5. Emove the 5 screws &mu £оиШ|^:

then remove the pulley housing and pu0ey from

the engine. Figure 16.

6. Removethe rope retainer screw frompuBey; then,

remove the broken piece of repe, if ary. Figure 17,

7. Gi^ the puDey ratchet and wind the puUoy

dbekwise until the pulley stops. Then, slowly im

wind the pulley counterdodmse until the pulley

notch Is aHmed with the pulley Hbiasrag notch.

Figure 17. Insert the hex wrench into the hole

formed by the aligned notches. Fimre Ws

................

Figwe 15 .

E^<íve

Screws

PiiSirfe 16

-10-

Page 11

s. Моте away from tbefbel tank and melttheeaâs of

thetnpe,

9. AOoweadi malted end to drift onc^ then whSei&e

rope is stai hot, pull each melted end through a

clean rag to ohta£a a smooth, pointed end.

10. Insert one end of the rope throng the handle and

secure with a knot. Leave ЗД6” pàgtaüb^imâ the

knot. ISgure 18 Clhset).

11. hisertthe otlœr end of the rope throu^ denudai

grommet, then xmder the K(^e Guide, iïgure 18

12. Guide rope inside the pulley, then throat Pulley

Hole. Kgore 17.

13, Wrap rope counierdocfcwise around the pull^

ratchet and tuck the Jbose end bac|c_under. .Ihe

rope,leaivincaboutalinchtaiÌncsrttó8iièRetaineriîïb, KgurelD.

Id^InstaU and tighten the Betainer Screw/Washer.

Figure 17. ,

NCraii^ fio not overti^ten the Eetainer Screw,

Over tightening flie screw can саше the screw

postto strip oat- the screw until the bot

tom of the washer eUher (1) is snug against the

rope or (2) contacts the top of the screw post

15.Pull the rope ti^itly around the pull^ratchet.

РцДеу

Notdi

Po]teyB^aL»4Ì\

Tato ¿id 8стту''>А

б

Pulley Ratchet.

Housing Noteh

Kguyeie

РоИпУ Ratchet

Yl

Retainer Rib

Kit

Воре Betainer

Scsrew/Wariim’

l8.SKght!ypull the rope to relieve the poeessure on thè

bex wrmch. Remove the hex wrench and allbw

(he ropeito rewind slowly.

17.1Bea^embb the Pulley Housing to the engine,

lîghten screws secarefy.

yrOTEt Be sure the rubber O—Bing is installed

onto the i^ey housing. See

18~Align the hole in the impeDer rrith the impeller

slShmakfiig sure thé flat sides are aligned. KgUreSO. • '

NCynSi When reassembling the bni^iler Hous

ing to (he En^e Shroud, be sure not to over-

tii^ten screws. Overtightening the screws can

strip out the Ьпрейег Housing.

19. Assemble parts by reversing steps 1. tbroa^ 4-

Воре

Retainer

Screw/^asher

ВореВД

лесашт-

FigurelS

U-

Page 12

D. STORAGE

1. Clean the tmit before storing. Pay particular at

tention to the air mtske area» kee|img it &ee of de

bris. Use a mild detergent and spoD^ to clean the

dastk sur&ces.

2. Do not store the unit or file! In aclosed area where

ftteJ v^rs can re%ih sparlis or an open flame

from hot water heat^, dectric motors or

switd^, furnaces, etc.

3. Store m a diy area out of the reach of children.

NOTGit If you do not want to remove the gasoline

from your unit. SBABS CRAFTSMAN Fuel Stabi

liser 33500) mEqrbe added tog^lineleft in

the tank to minimize gum deposits and adds. If

the tank is almost empty, wdx stabilizer wifli fresh

gasoline in a separate container and add to the

tank.

E. TROUBLE SHOOTING CHABT

. ALWAYS FOLLOW INSTRUCTIONS ON THE

^ SEABILKEE CONTAlNEIt THEN, RUN THE

ENGINE AT LEAST 10 MINUTE AFTER STABILIZEB IS ADDED TO ALLOW MOKTORE TO

BEACH CARBURETOR. STORE UNIT IN A

. SAFE PLACE. SEE STEF 2 (this section).

AWARNING I

It is hnportazit to prevent gum deposits from:

forming is essential toel system parts such as i^e

carburetor fuel fuel hose or fuel tank dar

ing storage. Eaperience indicates that alcohol

blended fhels (called Gasohol or using ethanol or

methanol) can attract moisture -nhich leads to

separation andformaHon of acids duringstorage.

Acidic gas can damage the fuel system of an. en-

ginewMle in storage.

TROUBLE

Engine will not start. .

Engine WÎH not idle properly^

'

Engine win not aimelerate,

lac^ powex; or dicüs under a

load.

^ Eo^he^^smokee eafciessiv^y:

Engine runs hot.

CAUSE REMEDY

L Ignition switch off

2. Pueltankemp^.

3. Spark plug not firing,

4; БЧге! not reaching carbu3retor

5. Engine flooded.

6. Comprestion low.

1. Idle speed set too low.

2. Idle speed set too high.

3. Mixtrae screw requires adJustinmit.

4. Crankshaft seals won}.

5. Compression low.

1. Carburetor requires ai^ustment.

2. Air filter dirty.

3. Spark plug fouled.

4. Carbon build-up.

5. Compression tow.

1. Choke uartially OIL.

2. Air fifterdb^.* r , '

3. screw re<pîîres idjostiû«at.

4. Fuel mbdtnre incorrect.

1. Fuel mixture incorrect.

2. ^arkplugincorrect.

3. Càrbcm build—up. . . .

4. Mixture screw set too low.

J., filoye Ignition, switch to *ON"

¿'Wm'tank witii correíd; fuel mixture,

3. Install new spark plug.

4. Check for dirty fuel filter, clean.

Check for or split fuN Bne;

repair or replace. ,

5. See "Starting Ihstmcticms.”

6. Contact 3Tour Service (k;nteix .

1. Adjust idle ^eed screw dockwise to increase speed. .

2. Ai^ust idle speed screw counterdockwisc to reduce speed.

3. See ‘“Carburetor Adjustments.”

4v <kmtacty(TOr Service Centes

5. Contact your Service Center, t

1. See “Carburetor Adjustments.”

2.. dean or rephua air filter.

3. Oean or replace sjmrk plug and

regap,

4. Contact your Service Center.

L■'Jítí^isfcdíolcB. ... ... ,

RíiíReattofcreplaceafrfflt!^/..- ;;

S. ^ “Gaiburdxa Adjustments.”

4. EmptyfiieltankaMrefillwitii

correct fad mlrtaire, '

L See “FueUhgYour Unit.”

2. Replace with ccorectspiuk plug

.•3., Contact your Service Centec

4. See “Carburetor Adjustments."

your %rvicB Centet

ACCESSORIES______________________________________________________

The following acressoiies are available throud Sears Retail Stores, Catalog Outlets, or Service Caters.

JSm SÎÛ0E.N0.

SafefyGog^.................................................

2-C» J^jne Oil

SpaAPIag..-...............................................

(hitter Attachment Kit

Vacuum Attachment Kit

Spark Arrestor, . fe, ......................................................................... .. —.... f 3Dk|!^348*

Operator’s Maniial ..7;.... : 3SÔ—068243*

* Available through your SEARS Service Center/Cataîogue.

-12-

.............................................................................................................................................. 71-36551

-----------------------------

......

..................................

................................................................................................71-85707

................................................................................................

------

------- --

.............................

--------------

-----

------

................

---------------------------

....................

............... j 71-1^9,4

71-85853

71-79992

-------

Page 13

SEAES GAS BLOWEE KEPAIH PAHTS LIST - MQDELS868.79Ï922 858.

797960,358.797982

— <

101jQ2

Î3

Page 14

SEAES GAS BLOWER REPAIR PAETS LIST - MODELS358.797922,358.797960.358.797982

Key

No,

1

2

3

4

S 530-029130

6

7 530-029072

& 530-027597 Spittxig

S

10 530-029117

11 530-015840

12 530-024772

13

14 530-029967

15 530-019168

16

17

18 -

19 530-015814 S»e» .

20

21 530-010729 iliel Cap (Iricl O'Bwg)

22

23

24

25

26

27

28

29 530-030073

30

31

32

33

34

35

36

38

39

40

41

42

43

44

.45

46

47

48

49

$8

51

52 530-0^113

53

54 530-01916$

55

56

Part

No.

Description

630-094712

530-026S94

530-029111

530-015635

S30-D15813 Screw

530-015702

530-029068

630-029610

Front Iso!a.t<»r

8^cer

Screw

Rear Isolator

Trigger

X^dlp

Tiirottle Lode Button

«b .

Spring

Shroud-Left (Model 358.797960}

Shroud-Left {Model 358.797922 & 67

358.79798» 68

530-029609 Shwmd-K^t (Model 368.797922 &

630-069292

530-029129

.s 530-029089

530-014121

530-010897

530-014160

.530-029071

530-029112

530t094740 Assist Handle (Model 358.797932 Only)

530-069293

630-02911$

630-015239

—

630-012244

530-012235 Modd No. 358.797922 &

Shwnd-Right {Model 358.79ra€0)

3K.797982) 71 , 530-029175

Omumet

Swihsh 73

'Isolator ■ • 74

Isdator 75

iuel TaEkAss'y Chid. #21, 77

22&106} ■

Fuel Picit-Tjp Ass'jt

Handle Cover Ass*jt HncL 9,10 & 12)

Cover

Aar Filter 83 530-029110

Sjndng IKi

SpariePhtg 87

Screw

Cjdiider

Modd No. 358.797960

. 358.797982 92

530-029145

530-039137

530-015776

630-015816

530-019178

^P-026418 ..

539HKiSS75

530-069274

530-06^49

530-016162

530-01^06

530-029144

530-015849

630-016254

530-027528

5^-««9114

530-016771

630-029146 Cable Assemb^ (lad. #45}

530-029115

530-055263

530-019164

630-019165

530-015775

530-029070

630-027593

530-027594

Ignition Module

Screw

M6dd 358.79T960

Modd 358,797922 & 368.797982

Ga;^t

Piston Bing

ModelNo. 358.797960

’ BfodaNefe S5&3»m2 1

. 358,^7982 ■■

»ddhmilncL #38,33, j^Flri)

Model No.358.797960

MoM Nos. 358.797:^

368.797982

Betainer

Screw

Ground'№re

Screw ,

Wave’Wgd:^

^»cer

'{^Ise Shutter

Screw .

Plate ■

Carimretor

Gadiet

Seal

Screw

Ground Wire

Reed Block

Gaskel

Keedmre

Reed Stop

Key

No.

57

58

59 530-015126

60 Piston Rod

61

62

63

64

65

.6S

Part

No.

530-015241

530-014033

saj-oMoos

530-010960

530-015788

530-032103

530-015787

Screw

' CrankdiaftAea’y*

Key

Model No. 3^.797960

Modd Nos. 358.797922 &

Spacer

Inner Beating

Ring '

530-019158 Crankshaft Seal -

530-032102 Outer Bearing

530-015789

530-014015

RetaiurngBiu^

Qrarikease

530-039138 Flywheel

530-347987 Wadter

530-023817

70

530-014156

72

SM-01S823

530-01S49S

630-027523

76 530-069485

■ 630—029395

Spring

Spacer

Crankcase/ChankshaftAssy

Screw .

Screw

Starter Pulley <lncl73)

. Starter ^ring

78 530-069563 Fkn Houeing !Gt

(Ind. Starter PuHey)

79 ^0-027569

81 530-015769

62 530-032108.

530-015605

34

530-019187 *0’'Riiig .

89

$30-0^182 E^et

530-015805

88 530-m523

530-029119 'SoUFis

89

530-094710 l^wer Housiag (lR4>«r)

90

91 530-029173

- 630MH4157-.

630-029118

93 '

53ro-01S81S

94

530-015441

95

96

530-015472

97

530-094711

530-015367

98

100

. -536-015647

101

102

1S3

104

10

$

106

107

108

109

no

111

112

113

^4

530-094715„

.■SM-0ÌSW7'

586-015815

5^-015672

5^069348

530-069232

530-069247

530-068243

530-069294

^-029404

530-016811

530-027525

530-069303

530-0294^

. 99

1X5

Not Shown

. 530-061189

530-036274

530-029179

530-015843

530-061350

-530-061347 Carton (Model 358.797982)

Starter Handle

Screw.

-Beaiing .

Sisievr

Screw

Eetaiuer

' Band

Warier

Wodier

Nut

Blower HousTOf (Lo wear)

Cbid.99-103)

Secenr

Boor

^uing '

Pin 1

■ -Screw ■ j

SDring .

^>stfcAxTe$№r Bit

Rope Kit

XineElt

Opwaters Manual

GaitoBlt

AirBaffle .. ,

Wadier ' -

S[»Lcer 358.797960 Only

MhRler Guard

&p 358797922 & S©8.297Si)

<S0y r-,^”ir

He tafinstruction

Model Na 358.797922 &

Model No- 358.1^7966

Screw

: ►

Carton (Model 358.7979225

v^Carton (Modd 358.797860)

Description

358.797982

358.797982

14

Page 15

SEARS GAS BLOWER REPAIR PARTS LIST ~ MOǻBLSS58.797922,358.797960,358J97982

Oàrburetor Assembly Part Number 530-035262 WA-207/207A

12 13 14 15 T

16

Ifey

No,

1 530-035014

2 530-035151 * 4 Meteriag Dtaphra^ Gasket 11

3

4 530- 035268

5 530-035214

6

7

S 530-035166

9

Part

No,

530-035016 “ Metering Lever Pin Screw

530-035217

530-035218 “O’* Einglffixtiire 16 530-035178 * Pud Inlet Screen

530-035164

Desodptiozi

*+ Metallic Diaphragm 10

Mixture Needle

Mxture Needle Spring

Mixture Needle Washer 15 530-035106

Fuel Pump Diaphragm

Fuel Pump Gasket

Key

No-

12

13 530-035031

14

17

. 18

CWÎ).

Beoâir

Kit

Carb.

Gasket

IQt

----------—

Fart

No.

530-035203

530-035208

530-035028

530-035188

530-035260 Carb, Kwik Repair Kit

630-035219

*+-M'ëllÂig Lever Kn

Metering Lever

Metering Lever Spring

Carb. Gasket/Diaphtagm

Description

Idle Spe^ Screw

*+Idle ^eed Spring

» Inlet Needle Wive

{f Indicates Contents)

H3t (4 Indicates Contents)

18

Vacnimi Tube/Blower Tabe Ass*v.

{

5

KEY NO. PART Na

1

2

3

4

5

6

' 7

9

10

11

530-06923%^

530-0947®P^

530-069270

530-094662

530-351455

530-094664

530-Ô108SO

-M0-094230-~

530-067306

530-094740

530-015814

OFEBiiTOS’S

OBSCBIPTION

CpUecftHa-Safe WiStxsp

Tube

Vacuum Tube

Blowa: Nozale— -Flare

Blower Nozzle—Concentrator

Blow«* Tube

Handle

-iCllSBir

Operator’s Manual

Assist Hdndie

Screw "**

15

Page 16

QUICK REFERENCE PAGE

Eead and follow all Warnings and Safety Instfnctions.

Failure to do so can result in serious iidury*

A.WAKNINGS AND SAFETY INSTRUCTIONS

1. Wear eye protection.

. 2. Dress safely — boots or sa&fy ^oes and longpants.

3. Check for worn, loose, missing', or damaged parts and repain

4, Keep chQdren, bystanders, and animals a minimum of 30 feet away.

................................................

PAGE

.. 3

E, FUEIJNG YOUR ENGINE

1. Eliminate all sources of sparks or Dame where feel is mixed, poured, or stored.

2.. Use clean, ftesh gaso&ue.

3. Use 3,2 02.2~<ycle ermine oil to 1 gal. gasoline OR 8 oz. oil to 2.5 gaL gastdine.

4. Mix feel in an approved, marked container; mix and pour fed in an outdoor area.

5. Move a minimum of 10 feet away from feel and fading site before starting engine.

C. STARTING INSTRUCTIONS

1. idpye the ignition switch to the “ON” position.

2. Adfest the dboke properly

3. Grasp the handle and squeeze the throttle trigger feJ^y; engage the throttle fedc.

4. Maks sure the nozzle is directed away from people, animals, ^hss, and solid ol^cts.

5. Pol! the starter rope no more than 8 tones to avoid Hooding the en^e.

6. Stop the engine bsy^OT^^ the ignpoapiritdi to the “OFF” podri<Hi.,

D.GENEBAL MAINTENANCE

1. HaTOdlmaxd^ianceotlmr than the recommemted procedures described in the Operator’s

Manudpralbmedl^yotm Seam Service Center.

2. IMKonnect the ^mrk plug before performing maintenance except for carburetor adjustments.

3. Eun feel from the unit before storing. .

4. dean air filter frequently, hut always after 5 hours of operation or 6 tanks of fed, whidievesr

.............

...............

..................

................... ...................................

.....................................................................

....

.......................................................................

! » e « S

8

io

16'

5. Store in a dry place out oftbe reach of children.

Page 17

The Modd Kumb^ will be found below the top handle with the Serial

Nrunben Aliiiraiysinentioa the Model Nniober when requestit^servitor

repair parts for your unit.

Ail parts listed herdn I® tadered hom any Sears Service Center

and mostSears Stores. . .

Operator’s

Manual

Model No.

358.797922-S2ec

358.797950-22CC

358.797961-22CC

3S8.797982-32CC

How to Order

Repair Parts

WHEN OltDEBING EEPAIB PARTS ALWAYS GIVE THE FOLLOW

ING INFOEMATION AS SHOWN IN THIS LIST:

L The PART NUMBEB

7L The MODEL NUMBEB

358.797922-32CC

358.797950-22ce

358.797861-2200 '

358.797982-32CC

If the parts you need are not stocked locally jour ¿»der will be transniitted to a Sears R^air Parts Distribution Center for handling.

3. ThePAETDESCRDPTION

4, The NAME OP ITEM —

GAS POWER BLOWER

you bay merdiandise fetoa

Sears you get an «rtra value that

nobody else can offe — Sears Swvice.

Ai№S3 tovm or across the country

Sears Service is always near, providir^ trustworthy, competent

service technicians using only

Sears specified factory parts.

Ql?17irrr*Y9'

IS AT YOUR SERVICE

530-081829-1-06/17/93

Thur Sears Menhandise takes on added value when you discover that

SearshasSeiyiceUnitstlarOughoutthecountty. Eachisstagedby|^gs

trained, professional technicians urtng Sears approved methods.

Sold by Sears, Roebuck and Co., Chicago, IL 60684 USA

PIUNl®DDtC.S.A.

Loading...

Loading...