Craftsman 358797121 Owner’s Manual

IMPORTANT MANUAL

Operator's

Manual

Do Not Throw Awa_

i i i iHi .ll...,.

MODEL NO.

358.797121-26cc

(16" Cutting Par

A WARNING:

Read theOperator'sManual

md Follow All Warnings

and Safety Instructions.

_ure ToDo So Can Result

in Serious I_iury.

Always Wear Eye Protection During Operation

26€€ GAS WEEDWACKER _

2 Cycle Engine

®Assembly

o Operation

Fuel Mix 40:1

o Maintenance

• Repair Parts

Sold by Sears, Roebuck and Coo, Chicago, Iti. 60684 U.S.A.

.................... N,

530-067909-4-07112/91 ©Sears, Roebuck and Co, 1991

ONE YEAR LIMITED WARRANIY ON CRAlrl'SMAN WEEKWACKER ®

For One Year from dale of archase when this Weedwacke¢ _ is maintained lubricated and tuned up according to the operating

and maintenance instructionPs in the operators manual Sears will repair free of charge any defect in rnateria] or workmanship

This wammly excludes nylon line spark plug and a r c eaner" wb ch are expendable paris and become worn during nomlal use ._

WARRANTY SERVICE IS AVAILABLE BY CONIACTING IHE NEARESI" SEARS SERVICE CENIER/DEPARIMENI

IN THE UNIFED STALES 7his warranty applies only while this product is in ase in the United States

'This '_trvant)' gives you specific legal rights and you may also have other rights which vary from state to stale _.

SEARS, ROEBUCK AND CO, DEPT D/731CR-W, SEARS rOWER CHICAGO, IL 60684 .,_

TABLE OF CONTENTS

WARNINGS AND SAFETY INSTRUCTIONS

KNOW YOUR TRIMMER

ASSEMBLY ..

ACCESSORIF_ .....

ENGINE INFORMATION

A Fueling YourEngine

B. Pre-Operation Checks

C Starting Instructions

D Operating Instructions

USING YOUR TRIMMER

A Irimmer Safety

B Trimmer Line Advance

C Cutting Methods

D Line Replacement

3 GENERAL MAINTENANCE ................ 17

6 A Maintenance Safety .................... 17

7 B_ Air Filter.................... 17

I0 C. StarterRope ............................ 18

11 D Flexible Drive Shaft Lubrication .............. 19

11 E Carburetor Adjustments ................ 20

12 F. Storage ............................. 22

12 G, Trouble Shooting Chart ....................... 22

13 REPAIR PAR'IS LIST ......................... 23

13 INDEX ........................................ 26

14 QUICK REFERENCE PAGE ..................... 27

14

15

16

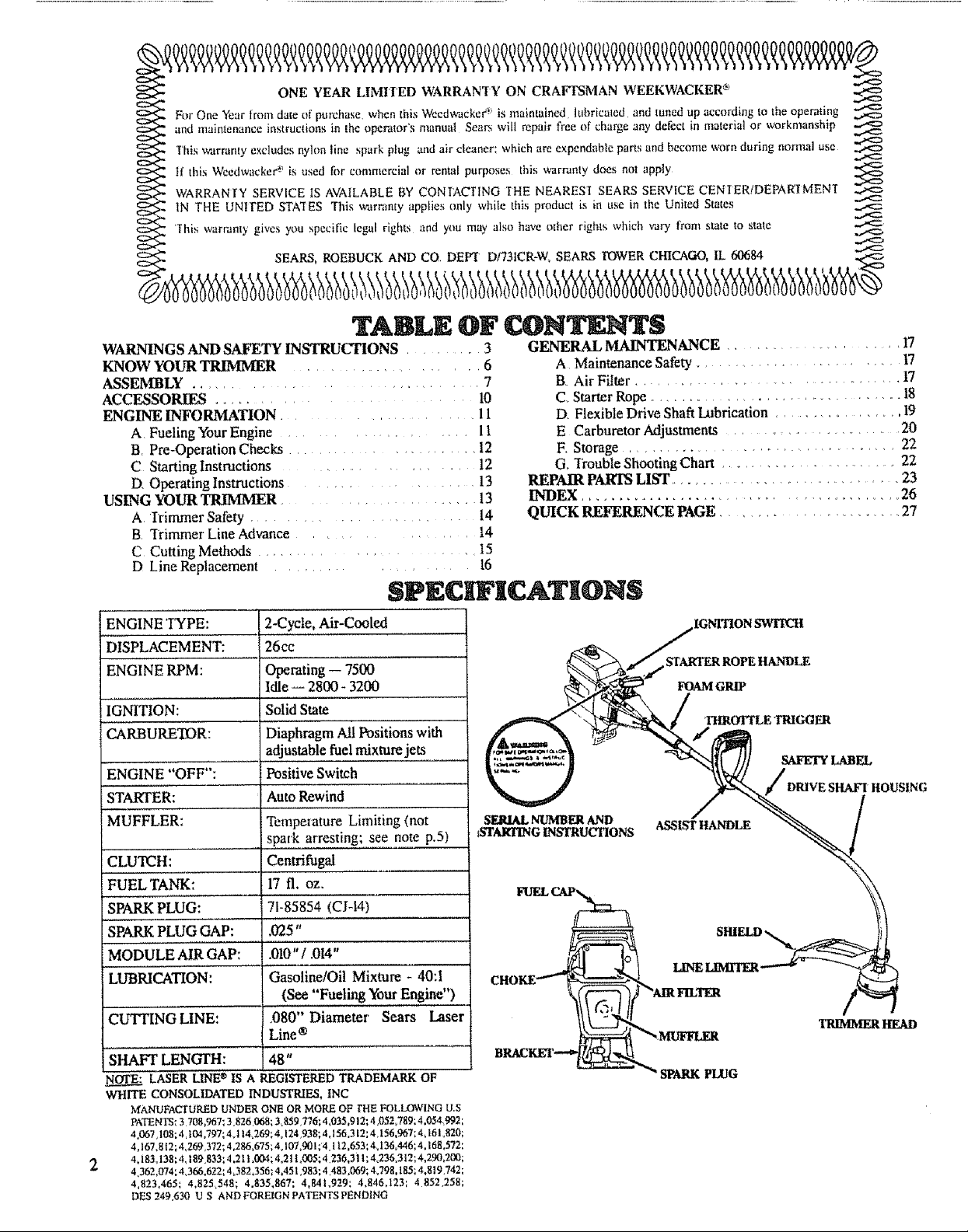

SPEC F| ATION

"ENGINE' 'TTPE:

i DISP,LACEMENT! ...........

ENGINE R_M:

2-Cycte, Air-Cooled

26cc

Operating ' 7500

Idle -- 2800 - 3200

I NmON:................

CARBURETOR:

SoiidS te

Diaphragm All Positions with

adjustable fue! mixture jets

ENGINE "OFF":

STARTER:

MUFFLER:

Positive Switch

Auto Rewind

2bmpemture Limiting (not

spark arresting; see note p,5)

CLUTCH:

FUEL TANK:

SPARK pLUG:

SPARK,,PLUG GAP:

MODULE AIR GAP:

17 tL 0Z, '.................

71-85854 <€i_i4)

.025"

.010"/ .0t4"

LUBRICATION:

(See "Fueling Your'Engine")

CUTIING LINE:

DS0" Diameter Sears Laser

Line®

"SHAFT LEN_: 48"

NOTE: LASER LINE ® tS A REGISTERED TRADEMARK OF

WHITE CONSOLIDATED INDUSTRIES, INC

M'ANUFACI_UREDUNDERONE OR MORE OF tHE FOLLOWINGU.S

PATENTS:3 708,967;3 826 068;3_859,776;4_035,912;4,052_789:4,054,992;

4_067,108:4, t04,797;4.114=269;4_1245)38;4,156_31214,156,967;4_161,820;

4,167,8|2; 4_269;372;4,286,675;4_107,901;4. t t2,653; 4_136o446;4,168,572;

4,183,138;4,189.833;4,21t,004;4°211_005;4.236,311:4_236_312;4,290,200;

4.362,ff/4;4_366,622;4_382,356;4,451,983;4,483,069;4.798,185;4,819.742;

4,823,465; 4,825_548; 4,835,867; 4,841.929; 4.846,123; 4852.258;

DES 249.630 U S AND FOREIGNPATENIS PENDING

IGNITION SWITCH

SHIELD

"_'_MUFFLI_ I'RIMbtF_ HE.M)

B_--"e _"_ SPARK PLUG

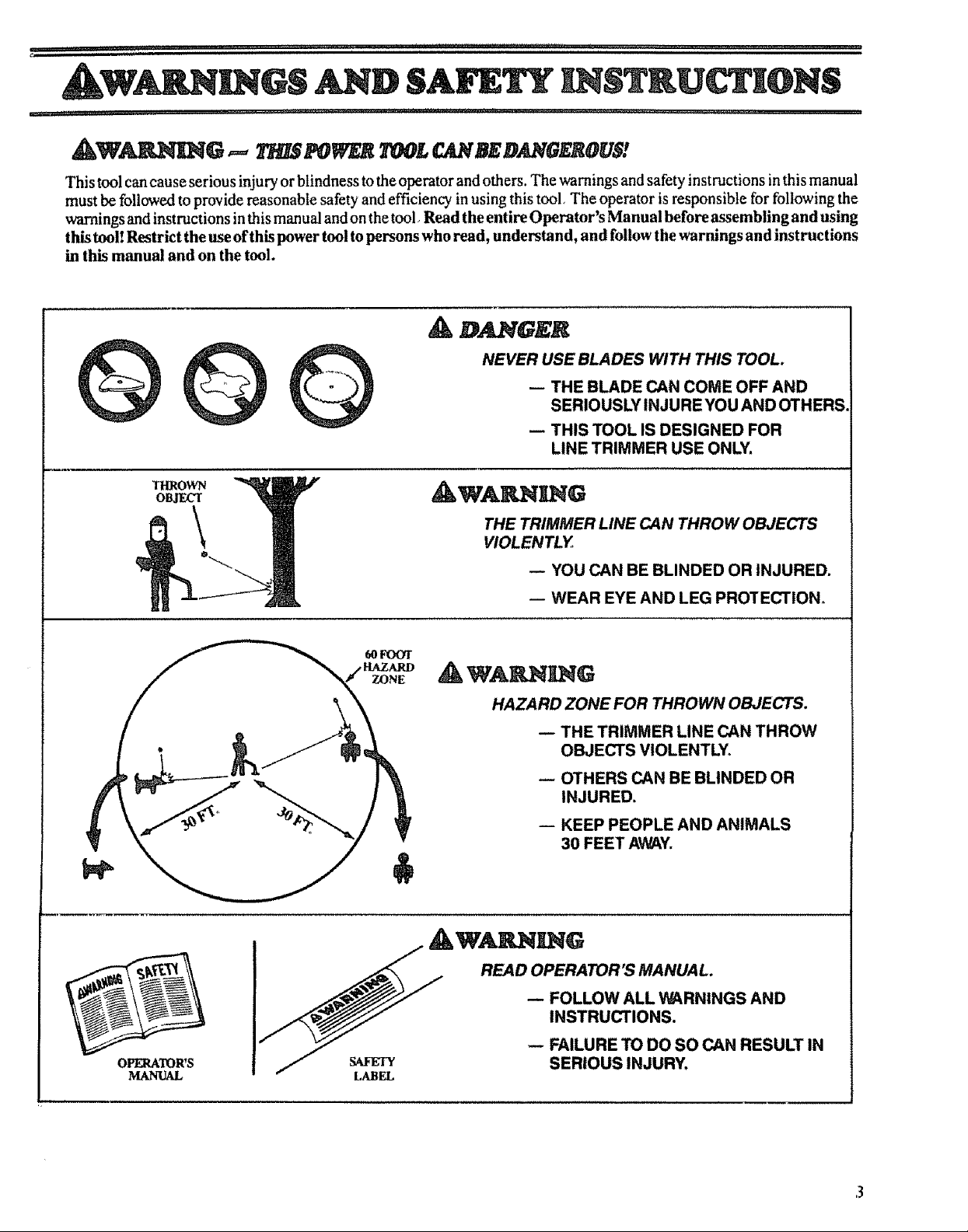

This tool can cause serious injury or blindness to the operator and others. The warnings and safety instructions in this manual

must be followed to provide reasonable safety and efficiency in using this tool, The operator is responsible for following the

warnings and instructions in this manual and on the tool Read the entire Operator's Manual before assembling and using

this tool! Restrict the use of this power tool to persons who read, understand, and follow the warnings and instructions

in this manual and on the tool.

A D GEK

NEVER USE BLADES WITH THIS TOOL.

-- THE BLADE CAN COME OFF AND

SERIOUSLY INJURE YOU AND OTHERS.

-- THIS TOOL IS DESIGNED FOR

LINE TRIMMER USE ONLY.

AW&I IG

THE TRIMMER LINE CAN THROW OBJECTS

VIOLENTLY

YOU CAN BE BLINDED OR INJURED.

-- WEAR EYE AND LEG PROTECTION.

OPERATOR'S

MANUAL

HAZARD ZONE FOR THROWN OBJECTS.

-- THE TRIMMER LINE CAN THROW

OBJECTS VIOLENTLY°

-- OTHERS CAN BE BLINDED OR

INJURED.

-- KEEP PEOPLE AND ANIMALS

3O FEET AWAY.

READ OPERATOR'S MANUAL.

-- FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

........................ i,i ..... i

WARNINGS AND SALTY IIgSTN,

i i,i ,111ii1,1 ,,i,iiiii1,1,,,,,,,i , , i ........ r

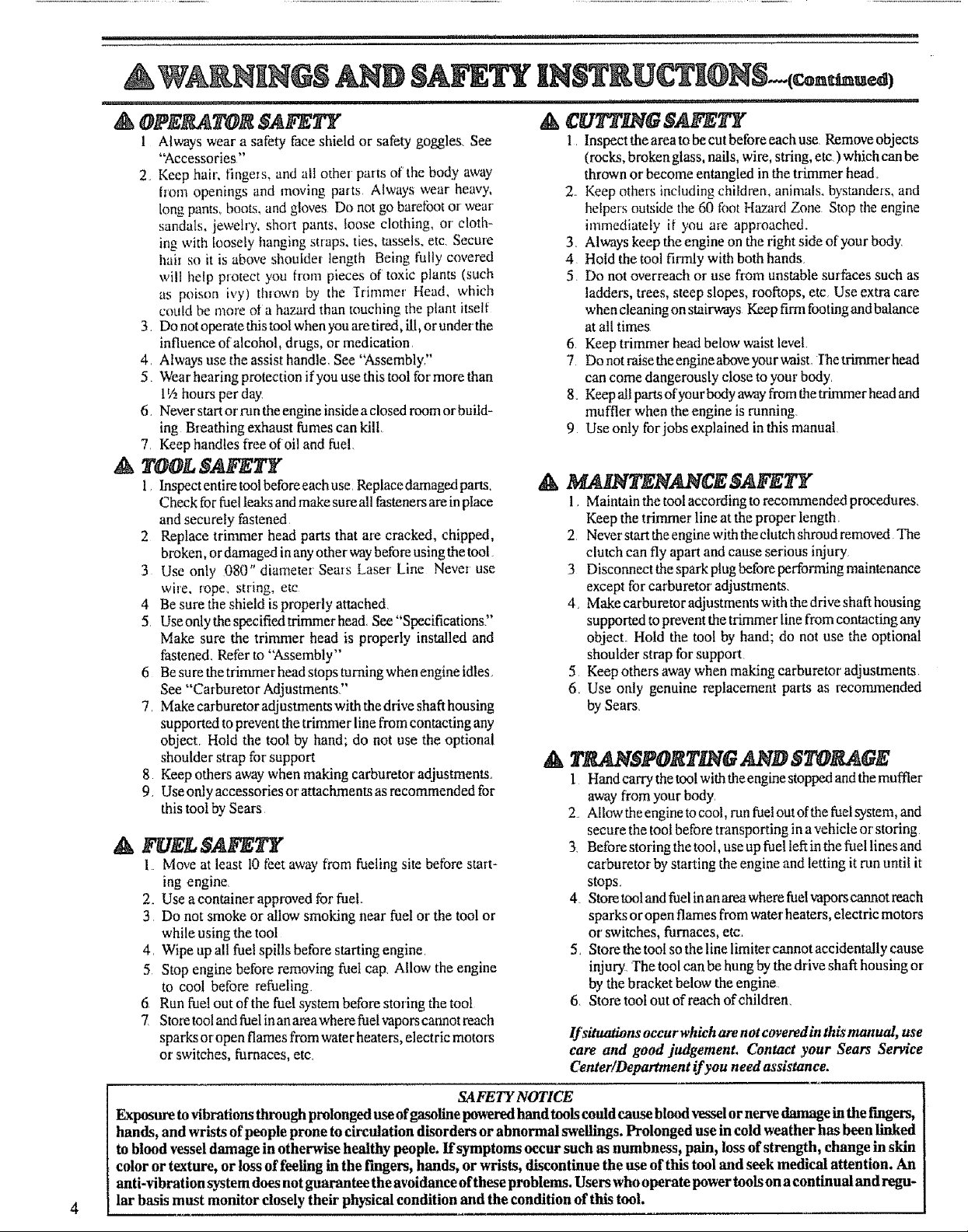

A OPERATOR SAFETY

1 Always wear a safety face shield or safety goggles. See

"Accessories"

2 Keep hair, fingeIs, and all othet parts of the body away

h'om openings and moving parts Always wear heavy,

long pants,,boots, and gloves Do not go barefbot or wear

sandals, jewelry, short pants, loose clothing, or cloth-

ing with loosely hanging straps, ties. tassels, etc, Secure

hair so it is above shoulder length Being fully covered

will help protect you from pieces of toxic p)ants (such

as poison ivy) thrown by the Trinmaer Head, which

could be more of a hazard than touching the plant itself

3. Do not operate this toolwhen youare tired, ill, or under the

influence of alcohol, drugs, or medication.

4. Always use the assist handle. See "Assembly,"

5. Wear hearing protection if you use this tool for more than

!V2hours per day.

6. Never startor run the engine insidea closed room orbuild-

ing Breathing exhaust fumes can kilt

7. Keep handles fi'ee of oil and fuel.

& TOOLSAFETY

1. Inspectentiretoolbeforeeachuse. Replacedamagedparts.

Check for fuel leaksand make sure all fasteners are in place

and securely fastened

2 Replace trimmer head parts that a_e cracked, chipped,

broken, or damaged inany other waybefore using the tool_

3 Use only 080" diameter Sears Laser Line Never use

wi_e. rope. string, etc

4 Be sure the shield is properly attached.

5. Useonly the specifiedtrimmer head See "Specifications."

Make sure the trimmer head is properly installed and

fastened. Refer to "Assembly"

6 Besure the trimmer head stops turning when engine idtes_

See "Carburetor Adjustments."

7. Make carburetor adjustrnents with the drive shaft housing

supported to prevent the trimmer line from contacting any

object Hold the tool by hand; do not use the optional

shoulder strap for support

8 Keep others awaywhen making carburetor adjustments..

9. Use only accessories or attachments as recommended for

this tool by Sears

FUEL SAt Ir"I "

A

1_ Move at least 10(Letaway from fueling site betbre start_

ing engine.

2. Use a container approved for fuel..

3 Do not smoke or allow smoking near fuel or the tool or

while using the tool

4. Wipe up all fuel spills before starting engine.

5 Stop engine before removing fuel cap, Allow the engine

to cool before refueling.

6. Run fuet out of the rue! system before storing the tool

2 Store tooland fuelinanarea where fuel vapors cannot reach

sparks or open flames from water heaters, electric motors

or switches, furnaces, etc

CD' t'/NG r

1. Inspect the area to be cut before each use Remove objects

(rocks, broken glass, nails, wire, string, etc )which can be

thrown or become entangled inthe trimmer head_

2. Keep others including children, animals, bystanders, and

helper'soutside the 60 tbot Hazard Zone Stop the engine

immediately i[ you are approached.

3. Always keep the engine on the right side of your body,

4 Hold the tool firmly with both hands

5. Do not overreachor use from unstable surfaces such as

ladders, trees, steep slopes, rooftops, etc, Use extra care

when cleaning on stairways Keep firnafooting and b',dance

atall times

6 Keep trimmer head below waist level

7 Do not raisethe engine aboveyour waist The trirrmaerhead

can come dangerously elose to your body.

8 Keepalt parts ofyourbody awayfrom thetrimmer head and

muffler when the engine is running

9 Useonly forjobs explained in this manual.

A MAINTENANCESAFETY

1_Maintain the toot according to reco_ranended procedures.

Keep the trimmer line at the proper length.

2 Never start the engine with the clutch shroud removed The

clutch can fly apart and cause serious injury

3 Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

4. Make carburetor adjustments with the drive shaft housing

suppoaed to prevent the trimmer line from contacting any

object.. Hold the toot by hand; do not use the optional

shoulder strap for support

5 Keep others away when making carburetor adjustments

6. Use only genuine replacement parts as recommended

by Sears_

• T L4 .SPORTL G/ D STOOGE

l Hand carry the toolwith theengine stopped and themuffler

away from your body

2o Allow the engine tocool, run fuelout ofthe fuel system, and

secure the toot before transporting in a vehicle or storing

3. Before storing the tool, use up fuel left in the fuel lines and

carburetor by starting the engine and letting it run until it

stops.

4. Store tooland fuel inanarea where fuelvapors cannot reach

sparks or open flames from water heaters, electric motors

or switches, furnaces, etc.

5_ Store the tool so the line limiter cannot accidenta!ly cause

injury. The tool can be hung by the drive shaft housing or

by the bracket below the engine

6. Store tool out of reach ofchildren,

Ifsituations occur which are not covered in thismanual, use

care and good judgement. Contact your Sears Service

Center/Depa_nent ifyou need assistance.

SAFETY NOTICE

Exposure to vibrations through prolonged use of gasoline powered hand tools could cause blood vessel or nervedamage inthe fingers,

hands, and wrists ofpeople prone to circulation disorders or abnormal swellings. Prolonged use incold weather has been linked

to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of strength, change in skin

color or texture, or loss of feeling in the fingers, hands, or wrists, discontinue the use of this tool and seek medical attention. An

anti-vibrati onsystem does not guarantee the avoidance of these problems. Users wh ooperate power tools on acontinual and regu-

lar basis must monitor closely their physical condition and the condition of this tool.

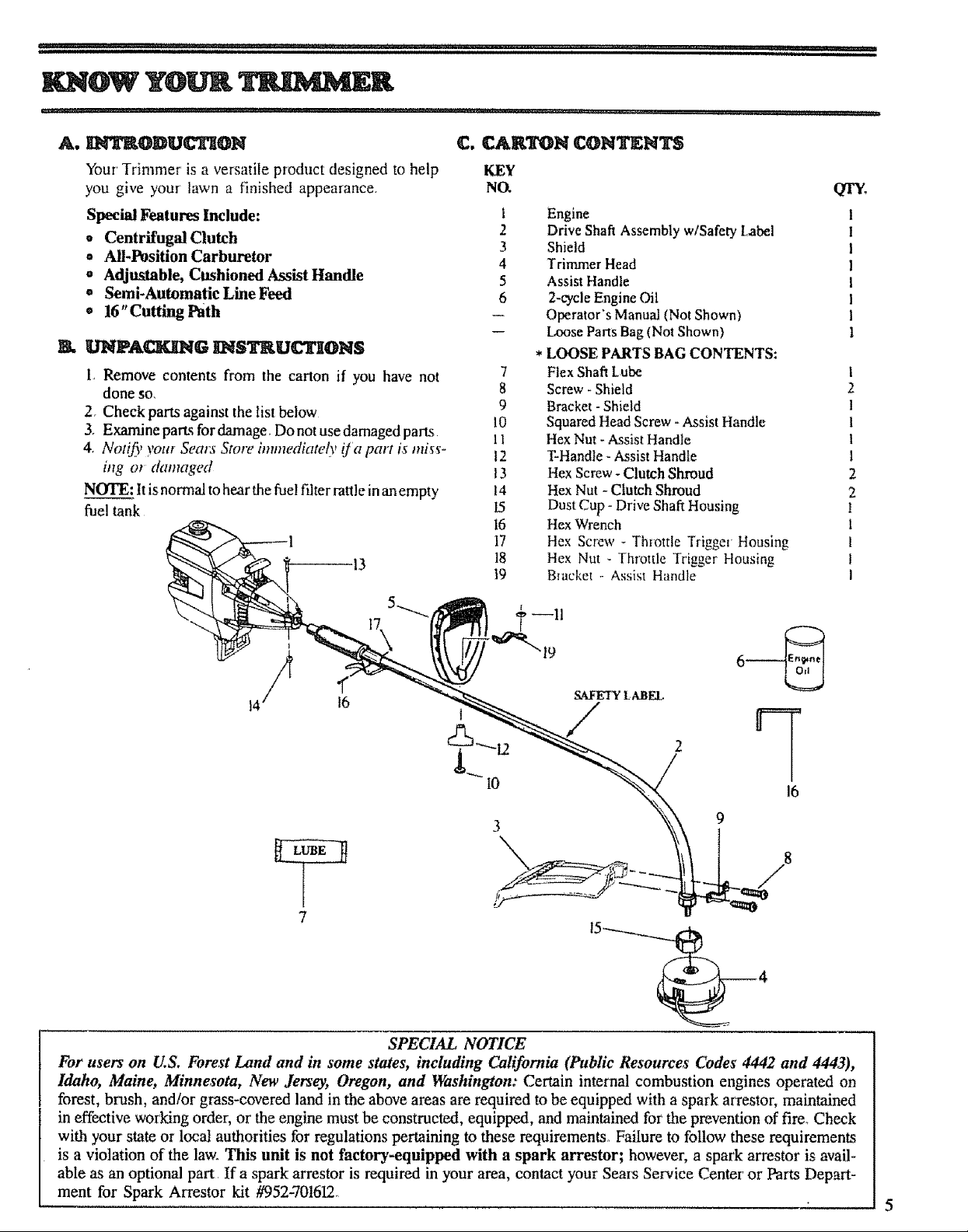

KNOW YOUR TRIMMER

._1,11.................

A. _ODU_'ION

Your Tr'immer is a versatile product designed to help

you give your lawn a finished appearance.

Special Features Include:

• Centrifugal Clutch

• All-Position Carburetor

e Adjustable, Cushioned Assist Handle

• Semi-Automatic Line Feed

o 16"Cutting Path

K UNP&_G _ISTRU_ON$

L Remove contents from the canon if you have not

done so.

2. Check parts against the list below

3. Examfinepartsfordamage Donotusedamagedpans

4 Notifi/),our Sears Store immediately ija part is miss'-

ing cn damaged

NOTE: it is normal to hear the fuel fdter rattle in an empty

fue! tank

!3

C. _RTON CONTENTS

KEY

NO.

1 Engine

2 Drive Shaft Assembly w/Safety Label

3 Shield

4 Trimmer Head

5 Assist Handle

6 2-cycle Engine Oil

-- Operator's Manual (Not Shown)

-- Loose Parts Bag (Not Shown)

* LOOSE PARTS BAG CONTENTS:

7 Flex Shaft Lube

8 Screw - Shield

9 Bracket -Shield

10 Squared Head Screw - Assist Handle

i1 Hex Nut - Assist Handle

12 T-Handle - Assist Handle

13 Hex Screw - Clutch Shroud

t4 Hex Nut - Clutch Shroud

15 Dust Cup - Drive Shaft Housing

16 Hex Wrench

17 Hex Screw - Thfottle Trigge_ Housing

18 Hex Nut - Throttle Trigger Housing

19 Bracket - Assist Handle

QTY_

I

2

1

1

I

1

2

2

!

1

I

I

I

14 16

7

SPECIAL NOTICE

For users on U.S. Forest Land and in some states, including Cahfornia (Public Resources Codes 4442 and 4443),

Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington: Certain internal combustion engines operated on

forest, brush, and/or grass-covered land in the above areas are required to be equipped with a spark arrestor, maintained

in effective working order, or the engine must be constructed, equipped, and maintained for the prevention of fire_ Check

with your state or local authorities for regulations pertaining to these requirements, Failure to follow these requirements

is a violation of the law. This unit is not factory-equipped with a spark arrestor; however, a spark arrestor is avail-

able as an optional part If a spark arrestor is required in your area, contact your Seres Service Center or Parts Depart-

ment for Spark Arrestor kit #952-701612_

SAFETY LABEL

...........................................,,,,,i?,?_I;,L'_I_,:_??+_;,i?,+i';L,,,;,i,:;,'',,+,+........ r.......................................................

___P' (_'too| is rece|vedas_embJed, repeat all steps in thissecthm to be sure assembly is_

and is m_ijusted for the operator.)

This Operator's Manual has been developed to help you

assemble the tool and to provide its safe operation, It is

important thai you read the entire manual to become

familiar with the tool below you begin assembly

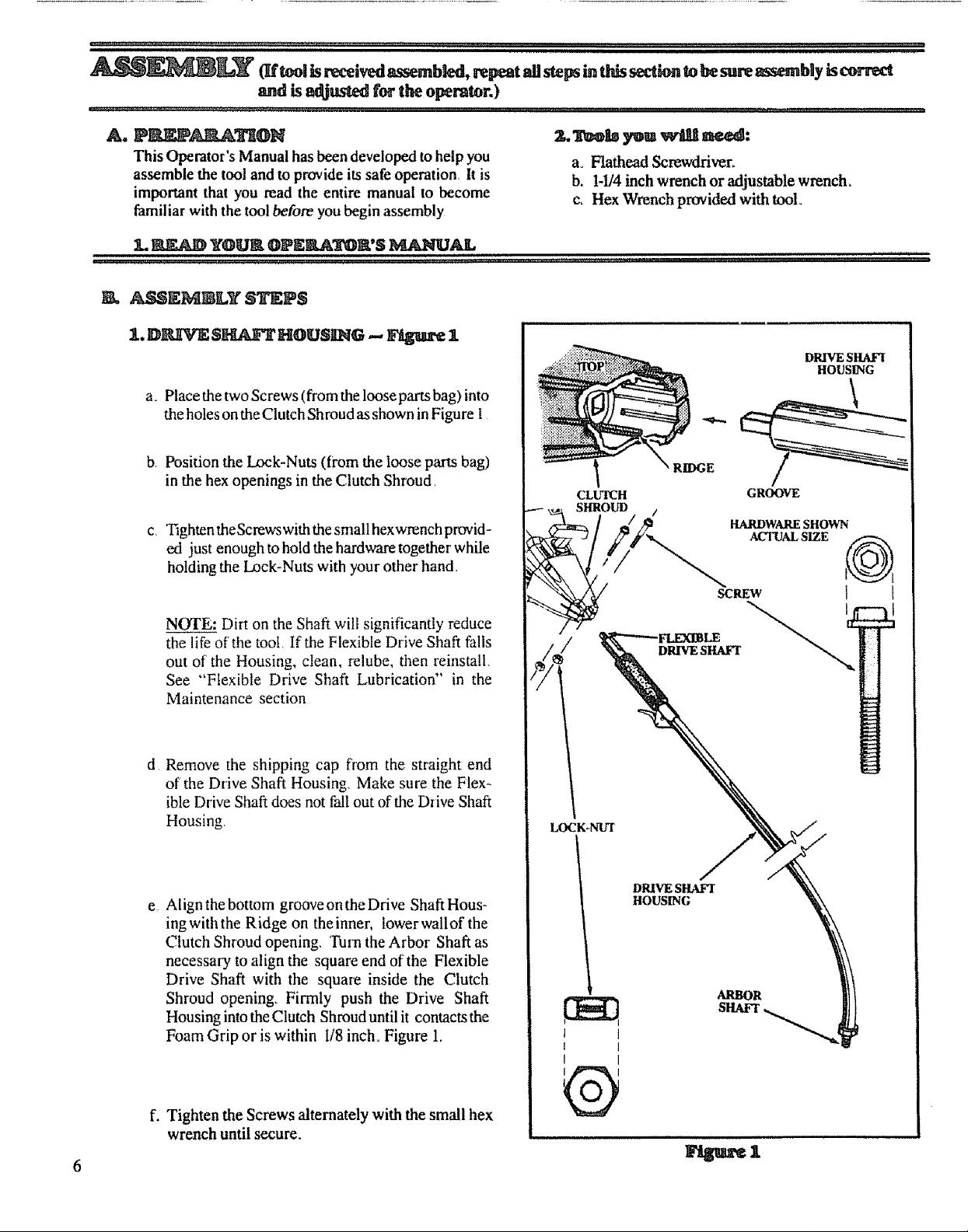

B, AS._EMBLY S_PS

1. D[_IVE $_ HOUSING -- Figure 1

a o Place the two Screws (from the loose parts bag) into

the holes on the Clutch Shroud as shown in Figure I

b, Position the Lock-Nuts (from the loose parts bag)

in the hex openings in the Clutch Shroud,

c, Tighten theScrewswith the smatl hexwrench provid -

ed just enough to hold the hardware together while

holding the Lock-Nuts with your other hand,,

a+ Flathead Screwdriver+

b. 1-1/4inch wrench or adjustable wrench+

c, Hex Wrench provided with tool+

DRIVE SHAFI

HOUSING

' RIDGE

CLUTCH

SHROUD

GROOVE

.............3,','.......

NOTE: Dirt on the Shaft will significantly reduce

the life of the tool, Ifrthe Flexible Drive Shaft falls

out of the Housing, clean, telube, then reinstall,

See "Flexible Drive Shaft Lubrication" in the

Maintenance section

d Remove the shipping cap fl'om the straight end

of the Drive Shaft Housing, Make sure the Flex-

ible Drive Shaft does not fall out of the Drive Shaft

Housing,

e Align the bottom groove on the Drive Shaft Hous-

ingwiththe Ridge on theinner, lowerwallof the

Clutch Shroud opening, Turn the Arbor Shaft as

necessary to align the square end of the Flexible

Drive Shaft with the square inside the Clutch

Shroud opening+ Firmly push the Drive Shaft

Housing into the Clutch Shroud until it contacts the

Foam Grip or is within I/8 inch+ Figure 1.

+ I

I I

I t

f. Tighten the Screws alternately with the small hex

wrench until secure.

®

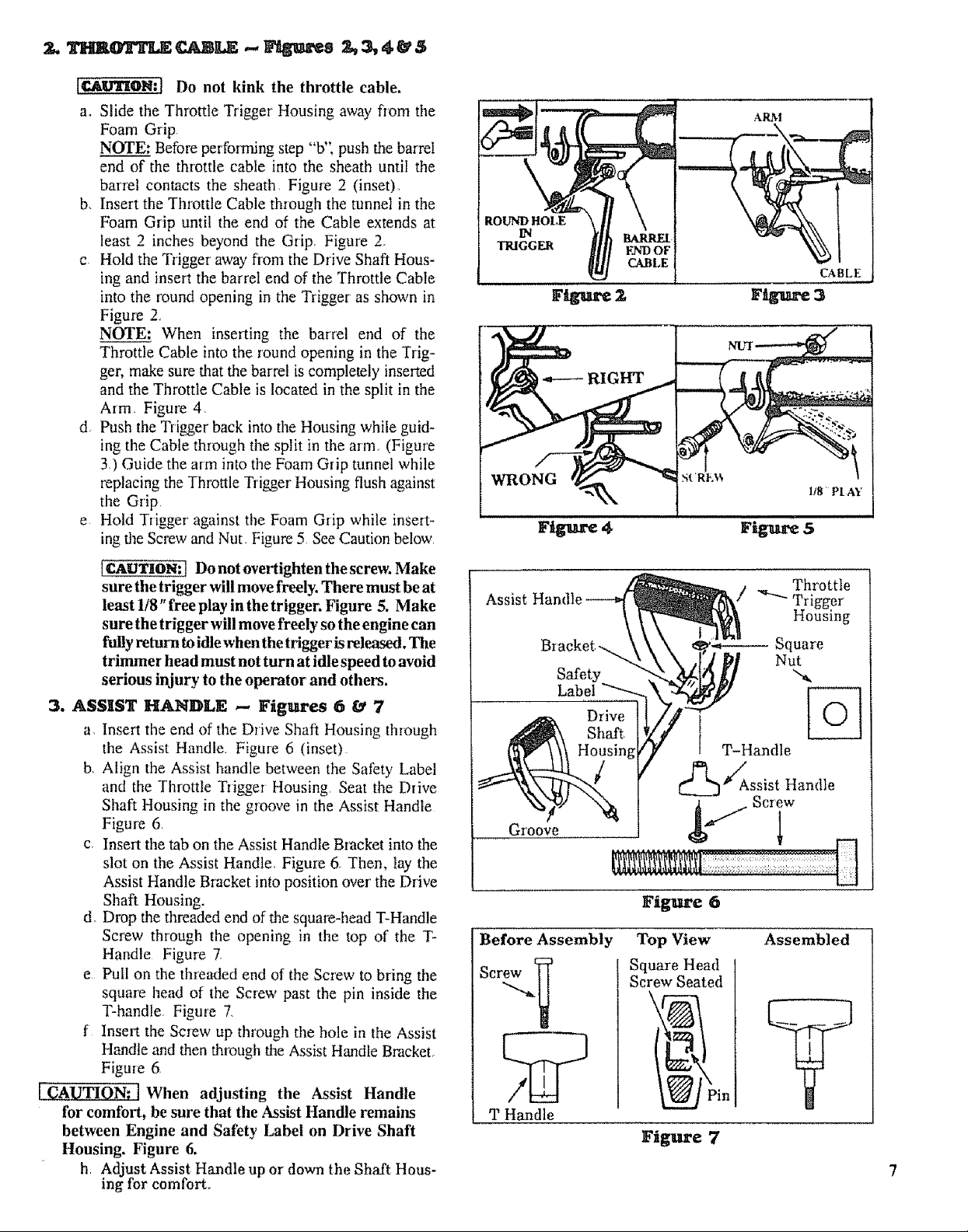

I_WI'ION:J Do not kink the throttle cable.

ao Slide the Throttle Trigger Housing away flora the

Foam Grip

NOTE: Betbre performing step "b', push the barrel

end of the throttle cable into the sheath until the

barrel contacts the sheath, Figure 2 (inset)

b, Insert the Throttle Cable through the tunnel in the

Foam Grip until the end of the Cable extends at

least 2 inches beyond the Grip, Figure 2,

c Hold the Trigger away flora the Drive Shaft Hous-

ing and insert the barrel end of the Throttle Cable

into the round opening in the Trigger as shown in

Figure 2,

NOTE: When inserting the barrel end of the

Throttle Cable into the round opening in the Trig-

ger, make sure that the barrel is completely inserted

and the Throttle Cable is located in the split in the

Aim, Figure 4,

d, Push the Triter back into the Housing while guid-

ing the Cable through the split in the arm (Figure

3,) Guide the arm into the Foam Grip tunnel while

replacing the Throttle Trigger Housing flush against

the Grip

e Hold Trigger against the Foam Grip while insert-

ing the Screw and Nut Figure 5 See Caution below

ROUND HOLE

IN

TRIGGER

Z

ICAUTION:] Do not overtighten the screw. Make

sure the trigger will move freely. There must be at

least 1/8" free play in the trigger. Figure 5. Make

sure the trigger will move freely so the engine can

fully return to idle when the trigger isreleased. The

trimmer head must not turn at idle speed to avoid

serious injury to the operator and others.

3. ASSIST HAN]r)LE ,-- Figures 6 & 7

a, Insert the end of the Drive Shaft Housing through

the Assist Handle, Figure 6 (inset)

b, Align the Assist handle between the SatEty Label

and the Throttle Trigger Housing Seat the Drive

Shaft Housing in the groove in the Assist Handle

Figure 6,

c, Insert the tab on the Assist Handle Bracket into the

slot on the Assist Handle, Figure 6o Then, lay the

Assist Handle Bracket into position over the Drive

Shaft Housing.

do Drop the threaded end of the square-head T-Handle

Screw through the opening in the top of the T-

Handle Figure 7,

e Pull on the threaded end of the Screw to bring the

square head of the Screw past the pin inside the

T-handle Figure 7,

f Insert the Screw up through the hole in the Assist

Handle and then through the Assist Handle Bracket,

Figure 6,

['-C'-AUTION:'_ When adjusting the Assist Handle

for comfort, be sure that the Assist Handle remains

between Engine and Safety Label on Drive Shaft

Housing. Figure 6.

h Adjust Assist Handle up or down the Shaft Hous-

ing for comfort.

Assist

Groove

Before Assembly

Sere_

T Handle

Throttle

/ _ Trigger

Housing

Square

Nut

%

T-Handle

_Assist Handle

Screw

Figure 6

Top View Assembled

Square Head

Screw Seated

Figure 7

Loading...

Loading...