CRI:iFTIHnN°

_6 Operator's Manual g

1.4 cu.in./24cc 2-Cycle

GASOLINE POWERED BLOWER

Model No.

358.797030

WARNING:

&

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

B

Ii

For answers to your questions about this product:

Call 7 am-7 pro, Mon-Sat; Sun, 10 am-7 pm

[] 1-800-235-5878

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-094583 11/20/96

WarrantyStatement 2 Storage 9

SafetyRules 2 TroubleshootingChart 10

Assembly 4 PartsList 11

Operation 6

Maintenance 8 Spanish 14

Service&Adjustments 9 Partsand Ordedng Back

FULLTWO YEAR WARRANTYON CRAFTSMAN®GAS BLOWER

Fortwo (2) yearsfrom date ofpurchase,when thisGas Blowerismaintained,

lubricated,andtuned upaccordingtotheinstructionsin theoperator'smanual,

Searswill repair,freeofcharge,any defectsin matedal orworkmanship.

Thiswarrantyexcludesblowertubes,sparkplug,and aircleaner,whichareex-

pendablepartsand becomeworn duringnormaluse.

Ifthisblowerisusedforcommercialpurposes,thiswarrantyappliesfor 90daysfrom

thedate ofpurchase.IfthisBlowerisusedforrentalpurposes,thiswarrantyapplies

for30 daysfrom the dateof purchase.Thiswarrantyappliesonlywhiisthisproduct

isin use intheUnitedStates.

WARRANTYSERVICE ISAVAILABLEBY RETURNING THE BLOWERTO THE

NEAREST SEARS SERVICE CENTER IN THE UNITEDSTATES.

Thiswarrantygivesyou specificlegalrights,andyoumay alsohave otherrights

whichvaryfrom statetostate.

Sears, Roebuck end Co. Dept.DI817WA Hoffman Estates,IL 60179

Failuretofollow allSafetyRulesandPre-

cautionscan resultinseriousinjury.

KNOW YOUR UNIT

- ReadyourOperator'sManualcare-

fully untilyou completelyunderstand

andcanfollowall warningsand

safetyrulesbeforeoperatingtheunit.

• Restrictunittouserswhounderstand

andwillfo!low all warningsandsafety

rulesinthismanual.

PLANAHEAD

• Always wear eyeprotectionwhenop-

erating,servicing,orperformingmain-

tenancaon unit.Weadngeyeprotec-

tion willhelptopreventrocksordebris

from beingbrownor ricochetinginto

eyesandface whichcanresultin

btin_ess and/orseriousinjury.

• Alwayswear respiratororface mask

whenworkingwithunitindustyenvi-

ronments.

• Securehairabove shoulderlength.

Secureor removejewelry,loose

clothing,orclothingwithloosely

hangingstraps,ties,tassels,etc.

They canbe caughtinmovingparts.

-2-

• Donotoperatethe unitwhenyouare

tired,ill,upset,orif youare underthe

influenceofalcohol, drugs,ormedi-

cation.

• Keepchildren,bystanders,and ani-

mals awayfrom workareaa mini-

mumof 50 feet (15 m) whenstarting

oroperatingunit.

• inspectthe area beforestartingthe

unit.Removeall debrisandhardob-

jectssuch as rocks,glass,wire,etc.

thatcan ricochet,bethrown,orother-

wisecauseinjuryordamageduring

operation.

HANDLE FUEL WITH CAUTION

• Eliminateall sourcesofsparksor

flame(includingsmoking,open

flames,orworkthatcan cause

sparks)inthe areas wherefuel is

mixed,poured,or stored.

• Mixandpourfuelin anoutdoorarea;

storefuelina cool,dry,wellventilated

place;usean approved,markedcon-

tainerforallfuel purposes.

+ Donotsmokewhilehandlingfuelor

whileoperatingthe unit.

• Donotfillfueltankwhileengineis

running.

• Wipeup fuel spillsbeforestarlingen-

gine.

• Moveat least10 feet (3 meters)

away from fuel andfuelingsitebefore

startingengine.

OPERATE YOUR UNIT SAFELY

• Stoptheenginebeforeopeningthe

vacuuminletdoor.The enginemust

bestoppedandthe impellerblades

nolongerturningtoavoidseriousin-

juryfrom the rotatingblades.

• Inspectunitbeforeeach usefor

worn,loose, missing,ordamaged

parts.Do notuse untilunitis in

properworkingorder.

• Keepoutsidesurfacesfree of oi!and

fuel.

° Neverstart or runengineinsidea

closedroomor building.Breathing

exhaustfumes can kill.

• Toavoidstaticelectdcityshock, do

notwearrubberglovesorany other

insulatedgloveswhile operatingunit.

• Donotset uniton any surfaceexcept

a clean,hard area whileengineis

running.Debrissuch as gravel,sand,

dust,grass,etc.couldbe pickedup

bythe air intakeandthrownout

throughdischargeopening,damag-

ingunit,property,orcausingsedous

injurytobystandersor operator.

° Avoiddangerousenvironments.Do

notuse inunventilatedareasor

whereexplosivevaporsorcarbon

monoxidebuildup couldbe present.

° Do notoverreachor use from unsta-

blesurfacessuchas ladders,trees,

steepslopes,rooftops,etc, Keepfirm

footing andbalanceat alltimes.

• Neverplaceobjectsinsidetheblower

tubes;alwaysdirecttheblowingde-

brisawayfrom people, animals,

glass,and solidobjectssuchas

trees,automobiles,walls,etc.The

forceofair can cause rocks,dirt,or

sticksto bethrownor to ricochet

which canhurtpeopleor animals,

breakglass,or cause otherdamage.

• Neverrununitwithouttheproper

equipmentattached.When using

yourunitas a blower,alwaysinstall

blowertubas.When usingtheoption-

al vacuumkit, alwaysinstallvacuum

tubesand vacuumbag assembly.

Makesurevacuumbag assemblyis

completetyzipped.

° Checkair intakeopening,blower

tubes,andvacuumtubesfrequently,

alwayswithenginestoppedand

sparkplugdisconnected.Keepvents

and dischargetubesfree ofdebris

whichcanaccumulateandrestrict

properairflow.

• Neverplaceanyobjectintheair in-

take openingasthiscouldrestrict

properairflow andcause damageto

theunit.

• Neverusefor spreadingchemicals,

fertilizers, orothersubstanceswhich

maycontaintoxicmaterials.

• Toavoidspreadingfire, donotuse

near leaforbrushfires,fireplaces,

barbecuepits,ashtrays,etc.

• Useonlyforjobsexplainedin this

manual.

MAINTAIN YOUR UNIT PROPERLY

• Haveall maintenanceotherthanthe

recommendedproceduresdescn'bed

inthe Operator'sManualperformed

bySears Service.

• Disconnectsparkplugbeforeper-

formingmaintenanceexceptfor car.

buretoradjustments.

• Useonlyrecommended CRAFTS-

MANereplacementparts;useofany

otherpartsmay voidyourwarranty

andcausedamageto yourunit.

• Emptyfueltankbeforestoringtheunit.

Useupfuel leftincarburetorby starting

engineand lettingit rununtilitstops.

• Donotuseanyaccessoryorattach.

meritotherthan those recommended

bymanufacturerfor usewithyourunit.

• Donotstorethe unitorfuel in a

closedarea wherefuelvaporscan

reachsparksoran open flamefrom

hotwaterheaters,electricmotorsor

switches,fumaces, etc.

• Storeinadryarea outofreachof

children.

SPECIAL NOTICE: For userson U.S.

ForestLandand insomestates, in-

cludingCaltfomia(PublicResources

Codes4442 and 4443), Idaho,Maine,

Minnesota,NewJersey,Oregon,and

Washington:Certaininternalcombus-

tionenginesoperatedonforest,brush,

and/orgrasscovered landinthe above

areas are requiredtobe equippedwith

a sparkarrestor,maintainedineffective

-3-

workingorder,or theenginemustbe

constructed,equipped,andmaintained

forthe preventionoffire. Checkwith

yourstate orlocalauthoritiesfor regu-

lationspertainingtotheserequire-

ments.Failureto follow theserequire-

mentsis a violationofthe law.Thisunit

isnotfactory equippedwitha spark ar-

restor,however,a sparkarrestoris

availableas an optionalpart.Ifa spark

arrestoris requiredinyourarea,con-

tact SearsService forthe correctkiL

The sparkarrestor,blowertubes,and

nozzlesmustbe assembledto unitto

beinfull compliancewithregulations.

SPECIAL NOTICE: Exposuretovibra-

tionsthroughprolongeduseofgaso-

linepoweredhand toolscouldcause

bloodvesselor nervedamagein the

fingers, hands,and jointsofpeople

pronetocirculationdisordersor abnor-

malswelling.Prolongeduseincold

weatherhasbeen linkedto bloodves-

sel damagein otherwisehealthy

people.If symptomsoccursuchas

numbness,pain,lossof strength,

changein skincolorortexture,orloss

offeeling in thefingers,hands,or

joints,discontinuethe useof thistool

andseek medicalattention.An

antivibraUonsystemdoesnotguaran-

tee theavoidanceoftheseproblems.

Userswhooperatepowertoolsona

continualand regularbasismustmoni-

torcloselytheirphysicalconditionand

the conditionofthistool.

CARTON CONTENTS

Checkcartoncontentsagainstthefol-

lowing lisL

Model 358.797030

• Blower

• Blowerfube

• 2-CycleEngineOil

NOTE; Itis normalfor the fuel filterto

rattleinthe emptyfuel tank.

ASSEMBLY

WARNING: If receivedassembled,

repeatallstepsto ensureyourunitis

properlyassembledandall fasteners

aresecure.

• Notoolsare requiredfor assembly.

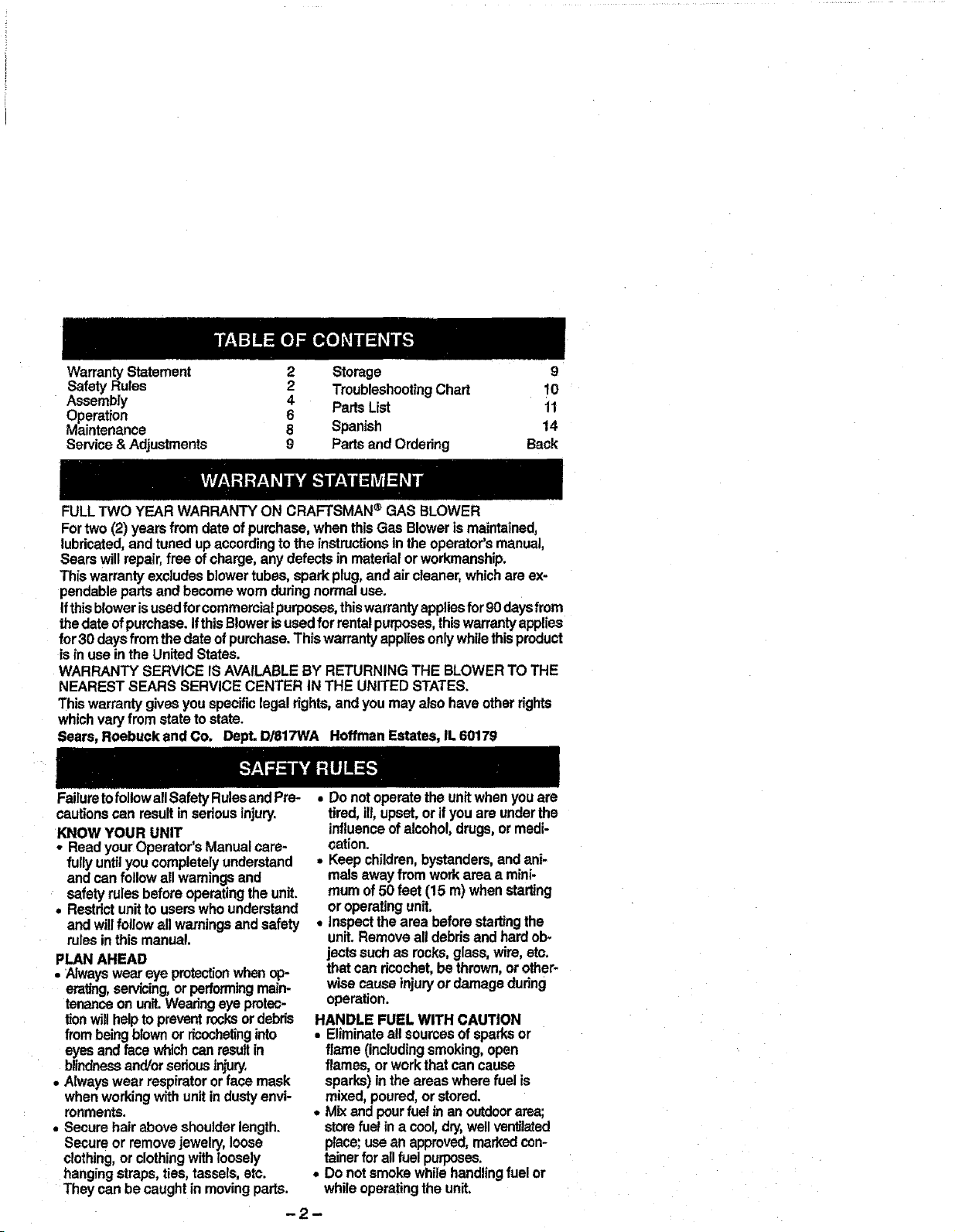

BLOWER TUBE ASSEMBLY

, Aligntherib onthe blowertubewith

thegrooveinthe bloweroutlet;slide

thetubeintoplace.

_ _Btower

Outlet Blower

Tube

Gmova-_ _ Rtb

• Tightenthe tubeclampbyturningthe

knobclockwise.

• Toremovethetube, rumtheknob

counterclockwiseto loosendamp;

removetube.

OPTIONAL VACUUM KIT

Yourblowercan beconvertedtoa vac-

uumbyinstallingoptionalVacuumKit

#358.799900. Thiskitcanbe pur-

chasedat yournearestSearsstore.

VACUUM BAG ASSEMBLY

• Placethe smallendof vacuumbag

overthebloweroutletandclamp_.

Btower

Ve]cmStrap

Tightenthe Ve/crostrapsecurely.

•"Make sure thezipperon thebag is

closedcompletely.

• Securethe endsoftheshoulder

strapbyroutingthe strapthroughthe

buckleas shown.

-4-

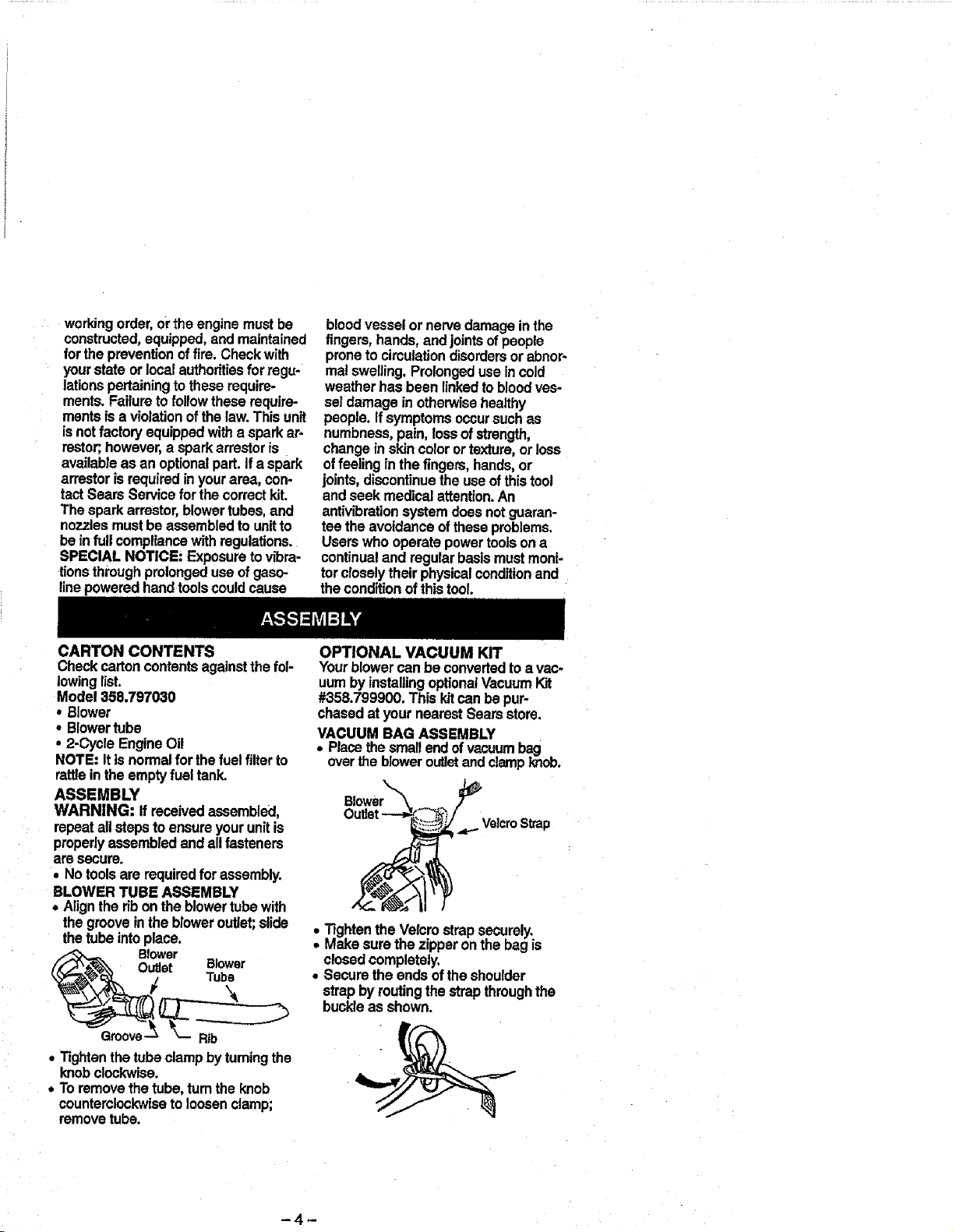

VACUUMTUBEASSEMBLY • Hold thevacuum inletcoveropen un-

WARNING Stopengineand be sure til uppervacuumtubeis installed.

the impellerbladeshave stoppedturn-

ingbeforeopeningthevacuuminlet

doororattemptingtoinsertor remove Vacuumlnle L

the vacuumtubes.The rotating blades _ /JJ_ \

canc=usese_ousinju_. - i \ !-_L \_

• Removeblowertubefromengine. HetaningPost "_ _ 't\l_

• Alignthelowervacuumtubeas _ I _! ))J

shown.Pushlowervacuumtubeinto Vacuum _ ___j/ //7

uppervacuumtube, Inlet t-- _ /_'

Upper _._ _°v°r"_'-_ _7:::_

VacuumTube-----_/.<_..._ "_ • Placethe hooksonthevacuumtube

( _ ) _ onthe retainingposts;pivottubeinto

./ ! J_ position.Securevacuumtubeby

_f /" _ Lower tumingtheknobclockwiseuntiltight.

• Inserta screwdriverintothe latch

areaon the vacuuminletcover.

I Latch _,._,.--_ Blower

-i._ ",-,l((_'_ Vacuum

_ _/_.__ InletCover Hooks

• Gentlytiltthe handleofthescrewdriv-

ertowardtheback ofthe unitwhile ° When convertingbacktothe blower

pullinguponthe vacuuminletcover feature, makesurelatchonthevacu-

withyourother hand. uminletcoverissecurelyfastened.

_ VacuumTube

,,__Areaj F _,. Outlet

-5-

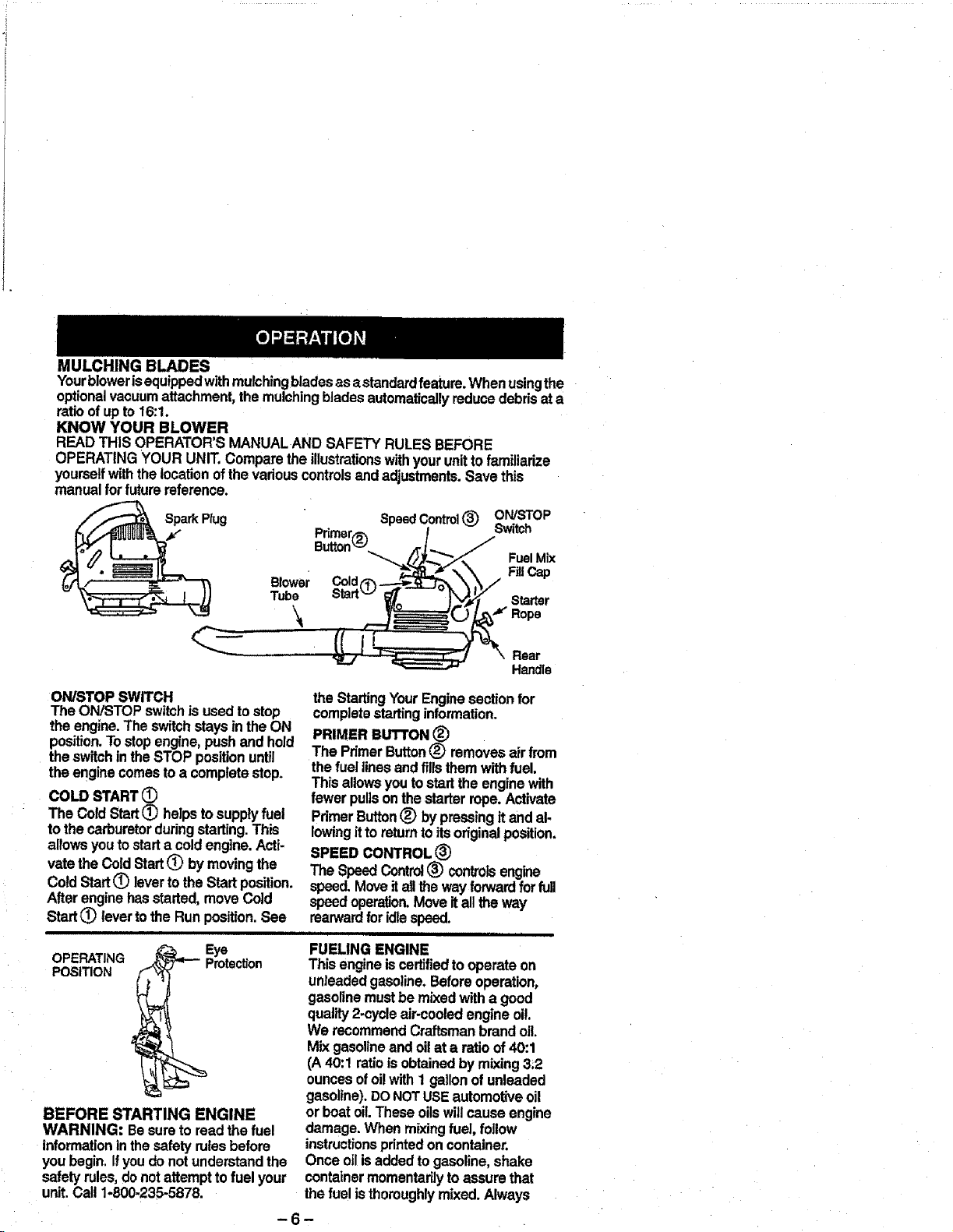

MULCHINGBLADES

Yourblowerisequippedwithmulchingbladesasastandardfeature.Whenusingthe

optionalvacuumattachment,themulchingbladesautomaticallyreducedebrisata

ratioof upto 16:1.

KNOW YOUR BLOWER

READTHIS OPERATOR'S MANUALAND SAFETY RULES BEFORE

OPERATINGYOUR UNIT. Comparetheillustrationswithyour unitto familiarize

yourselfwiththelocation of thevadouscontrolsandadjustments.Save this

manualforfuturereference,

SparkPlug SpeedControl(_) ON/STOP

Blower _:o,o(_) -_-'_-_o_. '_ _/

ON/STOP SWITCH

The ON/STOP switchis usedtostop

the engine.The switchstaysin theON

position.Tostopengine,pushand hold

theswitchinthe STOP positionuntil

theenginecomestoa completestop.

COLD START(_

The ColdStart(_) helpstosupplyfuel

tothe carburetorduringstarting.This

allows youtostarta coldengine. Acti-

vate theColdStart(_) by movingthe

ColdStart_ levertotheStartposition.

After enginehasstarted, moveCold

Start(_) leverto the Run position.See

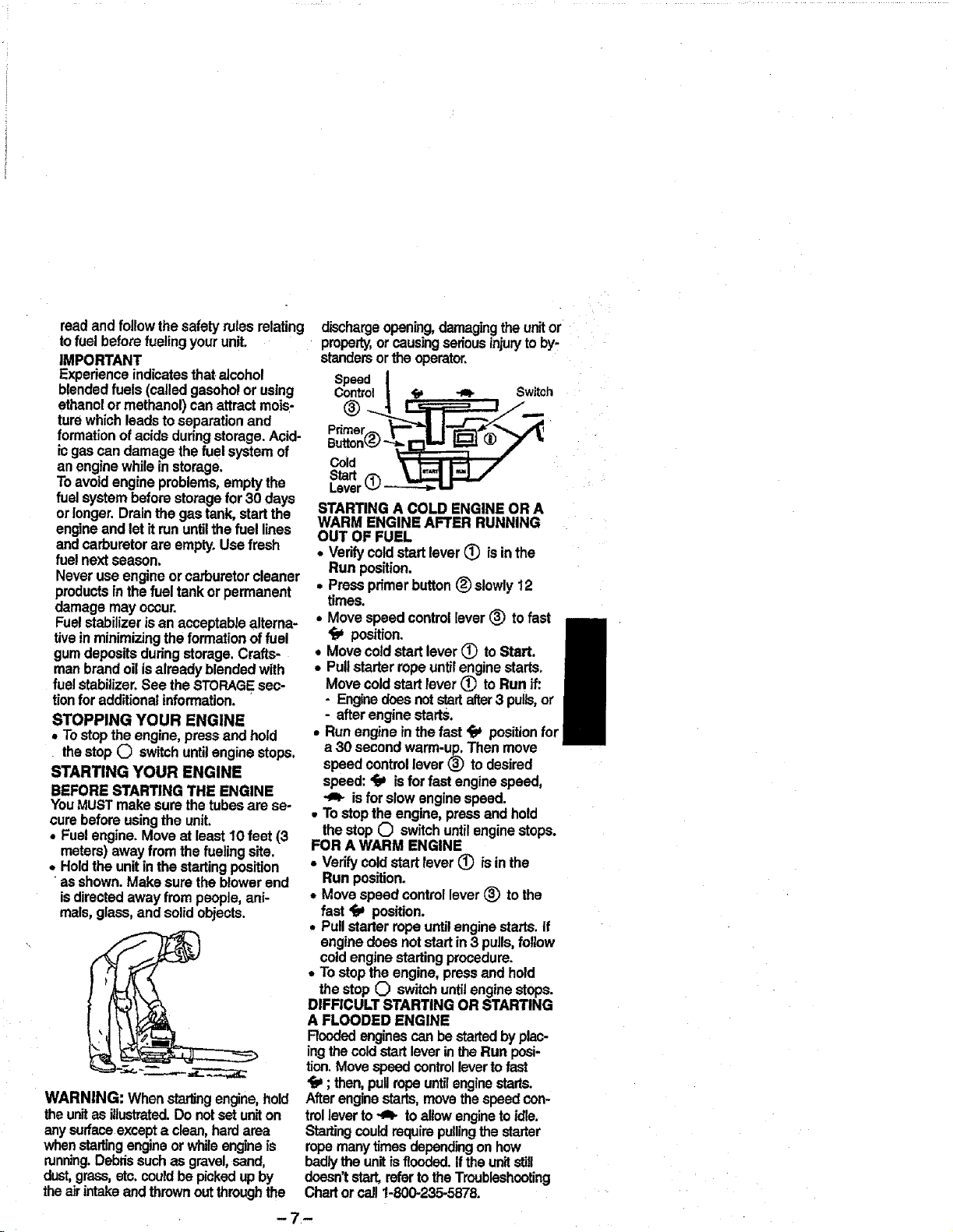

OPERATING

POSITION

Eye

Protection

BEFORE STARTING ENGINE

WARNING: Be sureto readthe fuel

informationinthesafetyrulesbefore

youbegin.Ifyoudonotunderstandthe

safetyrules,do notattemptto fuelyour

unit.Call 1-800-235-5878.

-6-

Pdmer(5_, _

Button"_J _I_. /

_. [)_--_'_ FuelMix

Switch

A.. _---._-f--\ FtltCap

Handle

the StartingYourEnginesectionfor

completestartinginformation.

PRIMER BUTTON_)

The PrimerButton(_ removesairfrom

thefuel linesand fillsthemwithfuel.

Thisallowsyoutostartthe enginewith

fewerpullsonthe starterrope.Activate

PrimerButton_) by pressingitandal-

lowing itto returntoitsoriginalposition.

SPEED CONTROL _)

The SpeedControl(_) controlsengine

speed.Moveitallthewayforwardfor full

speedoperation.Moveitall theway

rearwardforidlespeed.

m i i =

FUELING ENGINE

Thisengineiscertifiedto operateon

unleadedgasoline.Beforeoperation,

gasolinemust be mixedwitha good

quality2.cycleair-cooledengineoil.

We recommendCraftsmanbrandoil.

Mixgasolineandoil at a ratioof 40:1

(A40:1 ratioisobtainedbymixing3;2

ouncesof oilwithI gallonof unleaded

gasoline),DONOTUSEautomotiveoil

orboat oil.These oilswillcause engine

damage.When mixingfuel,follow

instructionsprintedon container.

Once oilisaddedtogasoline,shake

containermomentarilyto assurethat

the fuelis thoroughlymixed.Always

readand follow thesafetyrulesrelating

tofuel beforefuelingyouruniL

IMPORTANT

Experienceindicatesthat alcohol

blendedfuels (calledgasoholorusing

ethanolor methanol)canattract mois-

turewhichleadsto separationand

formation of acidsduringstorage.Acid-

icgas candamagethe fuel systemof

anenginewhilein storage.

Toavoidengineproblems,emptythe

fuelsystembeforestoragefor 30 days

orlonger.Drainthegas tank,startthe

engineandletit rununtilthefuel lines

andcarburetorare empty.Usefresh

fuel nextseason.

Neveruseengineorcarburetorcleaner

productsinthe fuel tankor permanent

damagemay occur.

Fuelstabilizeris an acceptable alterna-

tivein minimizingtheformation of fuel

gumdepositsduringstorage.Crafts-

manbrandoil isalreadyblendedwith

fuel stabilizer.See theSTORAGEsec-

tionfor additionalinformation.

STOPPING YOUR ENGINE

• Tostop theengine,pressand hold

thestop(_ switchuntilenginestops.

STARTING YOUR ENGINE

BEFORE STARTINGTHE ENGINE

YouMUSTmakesurethe tubesare se-

curebeforeusingthe unit.

• Fuelengine. Moveat least10feet (3

meters)awayfrom the fueling site.

• Holdtheunitinthestartingposition

•as shown.Makesurethe blowerend

isdirectedawayfrom people,ani-

mals,glass,and solidobjects.

WARNING: Whenstarlingengine,hold

theunitas illustrated.Donotset uniton

anysurfaceexcepta clean,hardarea

whenstartingengineorwhileengineis

running.Debrissuchas gravel,sand,

dust,grass,etc.couldbe pickedupby

theairintakeandthrown outthroughthe

dischargeopening,damagingtheunitor

property,orcausingseriousinjurytoby-

standersorthe operator.

Speed I

ControlI _ "_e Switch

LSeta_r(_ --.___

STARTINGA COLD ENGINE OR A

WARM ENGINE AFTER RUNNING

OUT OF FUEL

• Verifycoldstartlever(_) is inthe

Run position.

• Pressprimerbutton(_)slowly12

times.

• Movespeedcontrollever_) tofast

_i* position.

• Movecoldstartlever(_) toStart.

• Pullstarterropeuntilenginestarts.

Movecoldstartlever (_ to Run if:

- Enginedoesnotstartalter3 pulls,or

- afterenginestarts.

• Runengineinthefast _-_positionfor

a 30 secondwarm-up.Then move

speedcontrollever(_) to desired

speed:_ isfor fastenginespeed,

isfor slowenginespeed.

• Tostoptheengine, pressand hold

thestop (_ switchuntilenginestops.

FOR A WARM ENGINE

• Verifycoldstart lever (_) is in the

Runposition.

• Movespeedcontrollever(_) tothe

fast '_ position.

° Pullstarterropeuntilenginestarts.If

enginedoesnotstart in3 pulls,follow

coldenginestartingprocedure.

• Tostoptheengine, pressand hold

the stopO switchuntilenginestops.

DIFRCULT STARTING OR STARTING

A FLOODED ENGINE

Rcodedenginescanbe startedbyplac-

ingthe coldstartleverinthe Run posi-

tion.Movespeedcontrollevertofast

_a*;then,pullrope untilenginestarts.

Afterenginestarts,movethespeedcon-

trolleverto _ toallowengineto idle.

Startingcouldrequirepullingthestarter

ropemanytimesdependingon how

badlythe unitisflooded.Ifthe unitstill

doesn'tstart,refertotheTroubleshooting

Chartorcell1-800-235-5878.

-7-

CUSTOMER RESPONSIBILITIES

CARE& MAINTENANCE TASK

Checkfor Loosefastenersandpads

Checkfordamaged0r wornparts

Cleanunitand labels

Cleanair filter

Replacesparkplug

Replacefuelfilter

GENERALRECOMMENDATIONS

The warrantyonthisunitdoesnotcov-

eritemsthathave beensubjectedto

operatorabuseornegligence.To re-

calvefujivaluefromthewarranty,the

operatormustmaintain unitas instruct-

edin thismanual. Vadousadjustments

willneedto be made periodicallyto

properlymaintain yourunit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• SparkPlugBoot

• AirFilter

• HousingScrews

CHECK FOR DAMAGED OR

WORN PARTS

Refer replacementof damaged/worn

partstoyourSearsServiceCenter.

• On/StopSwitch- EnsureOn/Stop

switchfunctionsproperly.Tostopen-

gine,pushandhoJdswitchinthe STOP

positionuntilenginecomestoa com-

pletestop.Makesureenginestops;

thenrestartengineand continue.

• FuelTank- Do notuseunitiffueltank

showssignsofdamageorleaks.

• OptionalVacuumBag- Do notuse

vacuumbagifit istom or damaged.

CLEAN UNIT & LABELS

• Cleanthe unitusinga dampcloth

witha milddetergent.

• Wipeoffunitwitha cleandrycloth.

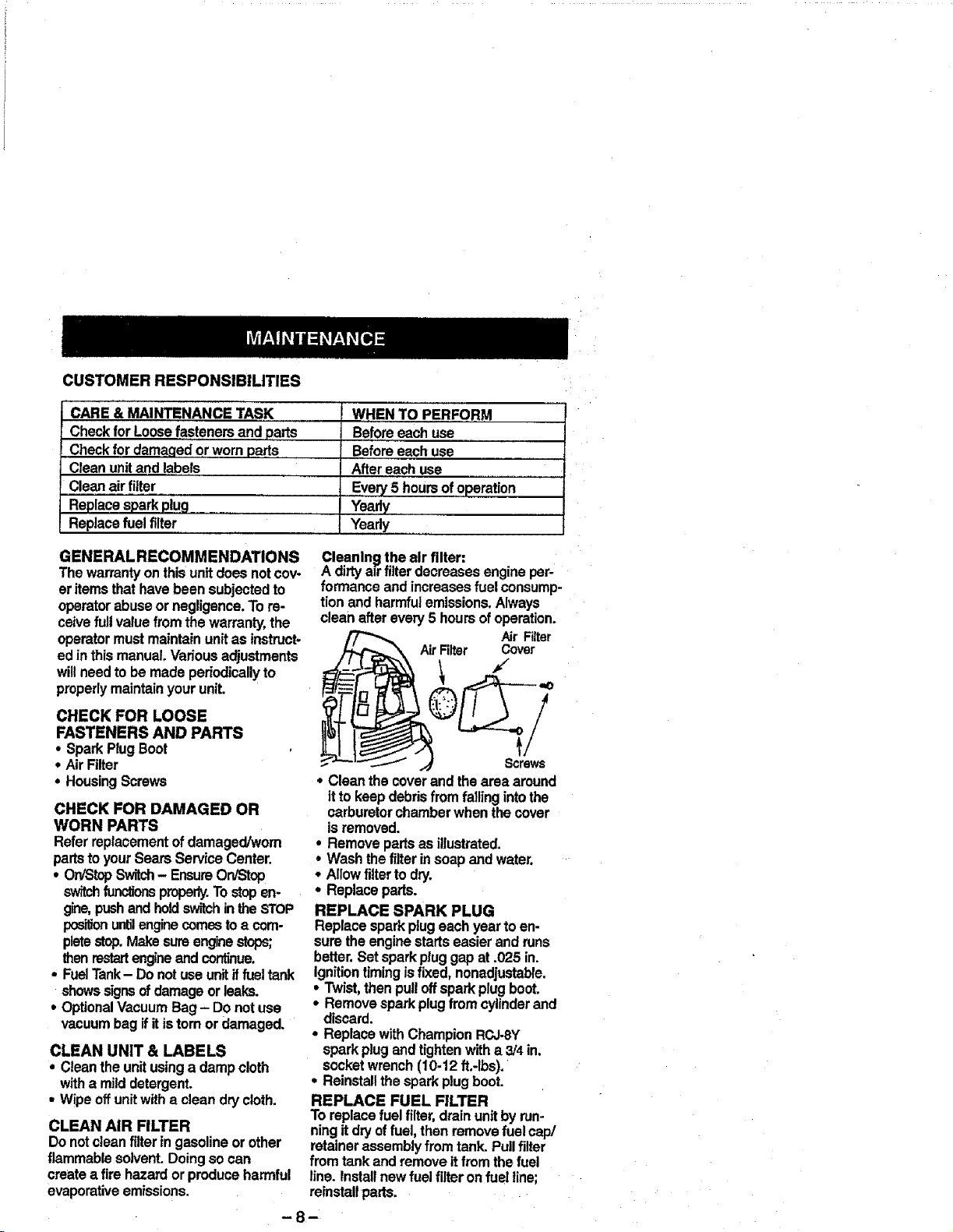

CLEAN AIR FILTER

Donotcleanfilterin gasolineorother

flammablesolvent.Doingso can

createa fire hazardorproduceharmful

evaporativeemissions.

WHEN TO PERFORM

Beforeeach use

Beforeeachuse

Aftereachuse

Every5 hoursofoperation

Yeady

Yearly

Cleanln9 the air filter:

A dirtyairfilterdecreasesengineper-

formanceandincreasesfuel consump-

tionandharmfulemissions.Always

clean afterevery5 hoursofoperation.

.__ Air Filter

AirRlter Cover

• Cleanthecoverandthe areaaround

itto keepdebrisfrom falling intothe

carburetorchamberwhen thecover

isremoved.

• Removepartsas illustrated.

• Washthefilter insoapand water,

• Allowfilterto dry.

• Replaceparts.

REPLACE SPARK PLUG

Replacesparkplugeach yearto en-

surethe enginestartseasierand runs

better,Setsparkpluggapat .025 in.

Ignitiontimingisfixed,nonadjustable.

• Twist,thenpulloffsparkplugboot.

• Removesparkplugfromcylinderand

discard.

• ReplacewithChampionRCJ-SY

sparkplugandtightenwitha 3/4in.

socketwrench(10-12 ft,-Ibs).

• Reinstallthesparkplugboot.

REPLACE FUEL FILTER

Toreplacefuel filter,drainunitby run-

ningitdryof fuel, then removefuel cap/

retainerassemblyfromtank. Pullfilter

from tankandremoveitfrom the fuel

line. Installnewfuel filteronfuelline;

reinstallpads.

Werecommendallserviceandadjust-

mentsnotlistedinthismanualbeper-

formed byyourSearsServiceCenter.

CARBURETOR ADJUSTMENT

Carburetoradjustmentiscriticaland if

doneimproperlycan permanentlydam-

agethe engineas well as thecarbure-

tor.tfyou requirefurther assistanceor

are unsureaboutperformingthispro-

cedure,call ourcustomerassistance

helplineat 1-800-235-5878.

Oldfuel, a dirtyairfilter,a dirtyfuel fil-

ter, orflooding may givethe impression

ofan improperlyadjustedcarburetor.

Checktheseconditionsbeforeadjust-

ingthe carburetor.

The carburetorhas beencarefullyset

atthefactory. Adjustmentsmaybe

necessaryifyounoticeanyof thefol-

lowingconditions:

• Enginewiltnotidle.See =IdleSpeed"

and=Mixture"underadjusting

procedure.

• Enginediesorhesitatesinstead of

accelerating.See =Acceleration

Check"underadjustingprocedure.

o Lossof power.See =Mixture"under

adjustingprocedure.

CARBURETOR PRESETS

Whenmakingcarburetorpresetadjust-

ments,do notforce plasticlimitercape

beyondthe stopsordamage willoccur.

Ifcarburetorpresetsare not needed,

proceedto=ADJUSTINGPROCEDURE,

IdleSpeed."

Toadjustpresets:

• Turnthe mixturescrewcounterclock-

wiseuntilit stops.

° Turnthe idlespeed screwclockwise

untilitstops. Nowturn countemlock-

wise4-1/2turns.

Startmotor,letit runfor3 minutes,and

proceedtothe adjustment section.If

enginedoesnotstart, refertotrouble-

shootingchartorcall 1-800-235-5878.

If engineperformanceisacceptableat

thepresetpositions,nofurther adjust-

mentsare necessary.

_dleSpeed

Screw

Mixture Screw

(withUrniterCap)

ADJUSTING PROCEDURE

Idle Speed "IDLE"

Allowenginetoidle.Adjustspeeduntil

enginerunswithoutstalling.

° Turnclockwisetoincreaseengine

speedifenginestallsordies.

• Turncounterclockwisetodecrease

speed.

Nofurtheradjustments .-

performanceissatisfactory.

Mixture "MIX"

Allowenginetoidle.Then accelerate

theengineand noteperformance.If

enginehesitates,bogsdown,or

smokesduringacceleration,tummix-

tursscrewclockwisein 1/16-tumincre-

ments untilperformanceissatisfactory.

Repeatthisprocedureas necessary

forproperadjustment.Aftercompleting

adjustments,checkfor acceleration.

Resetif necessary.

Acceleration Check

Ifenginediesor hesitatesinsteadof

accelerating, turnmixturescrewcoun-

terclockwiseuntilyouhave smoothac-

celeration.Recheckandadjustas nec-

essaryforacceptableperformance.

Prepareunitfor storageat endof sea-

sonor ifitwillnotbe usedfor 30 days

or more.

WARNING:

• Allowenginetocool,and securethe

unitbeforestoringortransporting.

• Storeunitandfuel ina wellventilated

areawherefuel vaporscannotreach

sparksoropenflamesfromwater

heaters,electricmotorsorswitches,

furnaces, etc.

-9-

• Store unitwithallguardsinplace.

Positionunitso thatanysharpobject

cannotaccidentallycauseinjury.

• Storeunitandfuelwelloutofthe

reachofchildren.

EXTERNAL SURFACES

• Ifyour unitistobe storedfor a period

oftime, cleanit thoroughlybefore

storage.Storeina cleandryarea.

• Lightlyoilextema!metalsurfaces.

FUEL SYSTEM

UnderFuelingEngineintheOperating

Sectionofthismanual,see message

labeledIMPORTANTregardingtheuse

ofgasoholinyourengine.

Fuelstabilizeris anacceptablealterna-

te in minimizingtheformationoffuel

gumdepositsduringslom_ge,Addstabi-

lizerto gasdineinfueltankorfuelstor-

agecontainer.Followthemixin.structicns

foundonstabi_er container.Runengine

at least5 minutesafteraddingstabilizer.

CRAFTSMAN40:1, 2-cycleengineoil

(aircooled)isalreadyblendedwithfuel

stabilizer.Ifyou donotuse thisSeam

o_,youcan add a fuel stabilizertoyour

fueltank.

INTERNAL ENGINE

• Removesparkplugandpour1tea-

spoonof40:1, 2-cycleengineoil(air

cooled)throughthesparkpfugopen-

ing.SJowlypul!thestarterrope8 to

10 timesto distributeoil.

• Replacesparkplugwithnewoneof

recommendedtypeand heatrange.

• Cleanair filter.

• Checkentireunitfor loosescrews,

nuts, and bolts.Replaceanydam-

aged, broken,Orwornparts.

• Atthe beginningofthe nextseason,

useonlyfresh fuel havingtheproper

gasolineto oilratio.

OTHER

• Donotstoregasolinefrom one sea-

sonto another.

• Replaceyourgasolinecanif itstarts

to rust.

TROUBLESHOOTING CHART

TROUBLE CAUSE

Enginewillnot _• Engineflooded.

start. • Fueltankempty. .

• Sparkplugnotfiring.

• Fuelnotreachingcarburetor.

REMEDY

• Sea=StartingInstructions."

• Filltankwithcorrectfuelmixture.

• tnstatlnewsparkplug.

• Checkfordirtyfuelfilter;,replace.

Checkforkinkedorsplitfueltins;

repairor replace.

• Compressionlow.

Engine willnot • Carburetorrequtresadjustment.

idleproperly. • Crankshaftsealsworn.

• Compressionlow.

,Enginewillnot • Airfilterdirty.

accelerate, • Sparkplugfouled.

lackspower,or • Carburstorrequiresadjustment_

diesundera ° Carbonbuildup.

load,

• Compressionlow,

Engine ° Chokepartiaflyon.

smokes • Fuelmixtureincorrect.

excessively.

• Airfilterdirty.

• Carburetorrequiresadjustment.

Engine • Fuelmixtureincorrect.

runshot. • Sparkplugincorrect.

• Carburetorrequiresadjustment.

• Carbonbuildup.

• ContactSearsService.

• See_CarburstorAdjustments."

• ContactSearsService.

• ContactSearsService.

• Cleanorreplaceairfilter.

• Cleanorreplacesparkplug;re-gap

• See"CarburetorAdjustments."

;• ContactSearsService.

• ContactSearsService.

• Adjustchoke.

• Emptyfueltankandrefillwith

correctrue!mixture.

• Cleanorreplaceairfilter.

• See_CarburetorAdjustments."

° See"FuelingYourUnit."

• Replacewithcorrectsparkplug.

• See=CarburetorAdjustments."

• ContactSearsService.

Ifsituationsoccurwhichare not covered inthismanual, use careand good

judgement.Ifyouneed assistance,contactyourSears ServiceCentedDepart-

mentor callthe CustomerAssistanceHelplineat 1-800-235-5878.

-10-

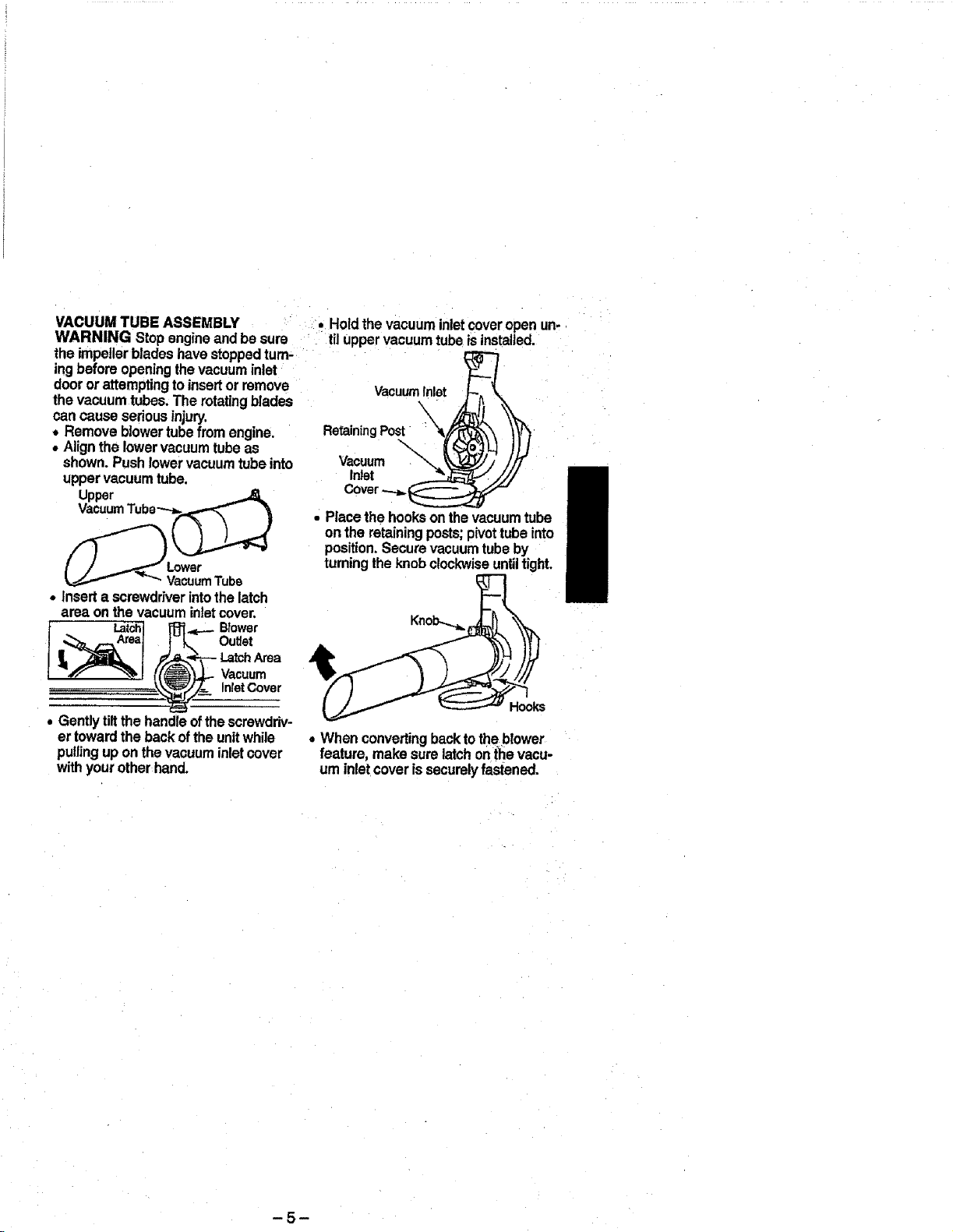

REPAIR PARTS "

,_k WARNING

All repal_ adjustments end

maintenance not €l_Crlbeel

I. the Operator's Manual

must be pe_ormed by quag.

fled eewJce personnel

39

40

45

41

42

48 44

Ref,

Pad:NO,

1.

2,

530049_

3,

_16209

4,

5_

530049_4

6.

5_049_9

7,

530015254

8,

5300_5852

9.

53O015775

I0+

21,

22.

23.

24.

25.

26.

27.

17,

18.

19.

20.

12,

13,

14.

15.

16.

I1.

530049SS4

530049495

530049494

,530069e2l

530049496

530049A_98

5304_044

530015966

530015849

530049315

5_04956_

530049325

53OO19246

530016211

53OO69572

530049537

530016212

530016207

Knob-ThrottleLever

Leazlwire-S_Ch

WTmClamp

CorbAss3,,

Lead_'re-Ground

ChokePJete

SP,_rertngCoverL_toh

Screw

AirBox Cover

Knob=Chel(eLever

ThrottleLever

Rlter-ChokePiete

Retainer-PurgeButton

Switch

PurgeButton

Sp_ing-PurgeButton

Nut

43

Oesorlpttor*

BlowerTube

CarburetorAdaptor

Screw

"throttlePJete

ThrottleUnkage

Cl_okeLever

Wave Washer

ChokeSlicer

Screw

W

SEARS MODEL 358.797030

1630 29

28

32

28, 530049312

29, 530049617

30. 530049323

31. 5300367_

_?.. 530049311

33. 530015_

34, 530015880

35. 530015820

37. 530049563

39. 5,._004_9314

40. 5300158,80

41, 530069247

42. 5,3_014362

43. 53OO49491

44. 530049527

45. 530069216

46, 5..'30049386

47. 530069813

48. 530049316

49. 530049383

NotShown

11

27 14 12

53O084583

53O084403

530049290

24 25 26

48 49 19 17

J

47

!

, DeeurlpUon

Housing-Left

GuideStarterRope II

leolator

I_Iulor

Housing-Right

Screw

Suew

BOR

Olamp-.a3!owerTube

Knob

Hsnd_e

MurmurCover

Screw

Line_Purge

FuetPl¢k-up Ass'y,

FuelTank Assay,

Gasket-Fuel Tank

LineI_Tank!Pu_le

FuelCap w/Retninur

Ga_et K'_

Nr Box

AirRlter

OperatorManu_l

EngineStop Decal

RightDecal

1

]

I

i ii innllnlll IHII IIIHIIIII III IIIIn I I In n

REPAIR PARTS

34 35

3347 [

86 37

36 4O

7 17

1 49 l_j

45 3 5

IRef. Part No.

1. 530015880

2. 530068_.32

3. 530069888

4. 530C_5.69

5. 530016164

& 530049501

7. 530015810

8. 530015815

9, 53001_40

10. 530029182

11, 530069817

12. 530095461

13_1 530015828

14,i 530626605

15, 530049318

16. 530402043

17. 530049297

lB. 530019181

19. 530049429

20. 530032125

21. 530032124

22. 530019179

2& 530015945

_4. 530_18

25. 530069819

E6, 530023817

27. 530016190 FlywheelSpaonr

I

18

_: 22 32

I T'lr

6 7468

Des_ptlon

,Screw

Rote

StarterPulley Kit

Starter Handle

Stader Sprbg

Fan HousingwfQeertng

8crew

8cmw

Isotator-pan Hag.

Eyelet

tmpel]er (Ind, 10)

MuinhB_.de Ass'y.

Washer-Flat

Nut

#tlat Door

Spring4=letumCover

Cra_case Cover

Gasket-Cree_<caselShroud

CranP.shettASS_.

Inner Beadng

OuterBee_'fng

CrankcaseSeal

RetainingPJng

Cra_k_ Ass'y÷

(tnca.20-23)

Flywhee!Ass'_.

(Incl.26)

_d_ater Dog

12

11

Ref. Part No.

28, 530049713

29, 530016203

80. 530049454

81, 530069816

32. 530015941

3& 530049502

34, 530015953

35. Champion

86. 530069818

37,i 5_19247

38. 530039163

89, 530016208

40. 530069864

41. 530049903

42, 530015162

43. 530069615

44. 53006_812

45, i 530016226

46. 530032108

47. 530069665

4& 530019162

49. 53C016080

NotShown

530049820

530084404

24

12 13 14

FoamSeal

MufflerBolt

Muffler CoverPlate

Muffer 10t

RetainerRtng-C'chaft

MufflerShield

,Screw

8p=rkRug (RCJ-SY)

Gasket10t

AirDam

tgnitlon Module

Bolt

Spark._,restor

PistonRing

Retailer

ConnectingRod

Ass_.

Pistonlot

(_n¢l,41 & 42}

PulteyRetainer

Beefing

rommat4gn. _odule

8P.m'/P-StmterPulley

Instru_ Dee_l

WarningDe¢_

13 26 27

16

I

I

REPAIR PARTS

i= r

CarburetorAssernbtvPartNumber 530069821 - 11NA-298_

1

Key Part Descr_on

No. No,

1 53003_1_ UmiterCap

2 530069811 C_rb. Repair Kit

3 530069844 Gask_ti;Dla.KR

2 3

Ootlon_l - Vacuum lot _Lq_7_N

1

5 6

,11

KEY PART DESCR|P'noN

NO. NO.

1 _ Va¢ Bagw/Slrsp

2 530094653 VacTube-Upper

-3 530095589 V=oT_be--Lower

4 530095468 Va¢ Tube-Upper

5 530049485 Knob-Vat Tube

6 530049686 Clip-Va¢ Tube

2

13

Declaraci6nde Garantfa 14 Servicioy Ajustes 22

Reglasde Seguridad 14 Almacenaje 23

Montaje 17 TablaDiagn6stica 24

Uso t9 Listade Plazas Centrode Manual

Mantenimiento 21 Repuestosy Encargos Contratapa

GARANTIADE DOSA_IOS COMPLETOS PARAEL PROPULSORDEAIRE A GA-

SOLINA DE LA MARCA CRAFTSMAN

Durantedoe (2) afios a partirdela fecha decompra,siemprequasehagael

mantenimiento,la lubricaci6ny losajustesenestePropulsorde Aim a Gasolina

segtlnlas instruccionesde ueoy mantenimiento enel manualdelusuario,Searsm

reparar_cualquierdefectode material o manode obragranturaitamente.

Estagarantfaexcluyelostubosdel propulsorde alre, la bujfay el fltrode aim,

quasonpiezas prescindiblesqua se puedangastarconel usonormal.

Siestepropulsordeaimesusadoconfines deusocomercial,estagarantfaaplicar&

solamentepor90dfasdespu_sdelafecha originalde compra.Siestepropuleoree

usadocon fines de alquiler,estagarantfa aplicardporsolo30 d{asdespu_sdela

fechaoriginal decompra.Estagarantfatienevalidezexclusivamentecuandoelapa-

ratoes uUlizadodentinde losEstadosUnidos.

SE OBTEDRA SERVtCIO BAJOGARANTIA DEVOLVIENDO ELAPARATOAL

CENTRO DESERVICIO SEARS MAS CERCANO EN LOS ESTADOS UNIDOS.

Estagarantfaconfieredetacheslegales especfficosal propletarfo,quetalvez

tengaasimismootrosderechosquavari'anentreestados.

Sears,Roebuck and Co. Dept.DI81TWA HoffmanEstates, IL 60179

De no sumplircon todas I_s Reglasy

Precaucionesde Seguddad,cotter&el

riesgodeaccidentesmuygraves.

CONOZCA SU APARATO

• Leael ManualdelUsuarfocuidado-

samentehasta quacomprendaper-

fectarnente todaslas advertenciase

instruccionesde seguddady las pue-

dacumplir,antesde ponerel aparato

enfuncionamlento.

• Limiteel uso del aparatoa aquellas

personasqua comprendantodaslas

advertenciase |nstrucciones dese-

guridaden estemanualy vayana

cumplirconelias.

PIENSE ANTES DE PROCEDER

• Useslempreproteccidnparalosojos

al haceruso, servicioo mantenimlen-

todel aparato. El usodeproteci6nde

ojosayudard a prevenirla pdrdidade

la vistay/u otrasheddasgraves,pro-

vocadasporpiedraso escombrosue

rebotenen losojosyen la cam atser

propulsadospot el aparato.

-14-

• Usesiempremascarilladefiltraci6nO

de protecci6npara la caraal trabajar

en ambientespolvorientos.

• Mantengaelcabellopor encimade

loshombros,atdndolo paratatefecto

sies necesado.Nousejoyas,ropa

suelta,niropa conliras,corbatas,

bodas,etc.qua cuelgenlibremente,

porquepodrfanquedarenredadasen

laspiezas enmovimiento delapara-

to.

• No useel aparatoestandocansado,

enfero,ansioso,nibajola infuencia

detalcohol,las drogasuotrosmedi-

camentos.

• Mantengaa nifios,espectadoresy

animalesa una distanciaminimade

15 metros(50 pies)al poneren mar-

cha o al usarel aparato.

• Inspeccioneel d.reaantesdeporter

en matodoslosescombrosy objetos

s(_lidostalescomopiedras,vidrio,

alambre, etc, qua el aparatopueda

arrojar al aim o hacerrebotarcau-

sandoheridasdeesteocualquier

ottomodeduranteelusedelmismo.

MANEJEELCOMBUSTIBLECONEX-

TREMeCUIDADO

• Eliminetodas lasposiblesfuentes de

chispanollamas (inclusiveloscigar-

dflos,lasllamasabertas,y cualquier

trabajoque causechispas)en las

dreas dondese mezcla,vierteo al-

macenael combustible.

° Mezcle y viertael combustibleal aire

libre,almaceneel combustibleen un

lugarfresco, secoy bienventilado;

sueunrecipienteaprobado para

combus_blesymamadopara todo

manejo de combusUble.

• No fumemientrastrabajaconel com-

bustiblenicuandoest_haciendouse

del aparato.

° NoIleneel tanquedecombustible

mientrasel motorseencuentreen

marcha.

° Limp_etodoslosderramesdecom-

bust_le antesde ponerel aparatoen

mamha.

• Al6jeseper Iomanes 3 metros(10

pies)de!combustibleydel lugarde

abasteciminetoantesde ponerel

motoren marcha.

HAGA USO SEGURO DE SU

APARATO

• Detengael motorantesde abrirla

compuertade entradadeaire delas-

pirador. El motordeberdencontrarse

detenidoy las cuehillasdelimpulsor

no deberdnestar girandopara evitar

sedosaecidentes provocadosperlas

cuchillasgirantes.

• Verifiqueper inspecct6n,antesde

cadause, que no hayapiezasgasta-

des, sueltas,nidafiadaso piezas

que falten. No use elaparato hasta

que este se encuentreenperfectas

condicionesdefuncionamiento.

• mantengalassuperficiesextems

libresde aceitie y de combustible.

• Nuncaponga el motoren marchani

Io deje en mamha dentrodeun recin-

too edificiocerrado.Respirarlosva-

poresdel combustiblele podriacau-

sar la muerte.

• Paraevitar el chequeper electricidad

estdtica,no use guantesde goma ni

ningLInotroguanteaislado al usarel

aparato.

° No apoye elaparatoconel motoren

mamha en ningunasuperficieque no

-15-

est6 limpiaoque noseas6fida.El

aparatopodriaaspirarescombros

talescomegavilla,arena,polvo,

c_sped,etc. per laentradade aspira-

ci6ny arrojarlos per lasalidade pro-

pulsion,dafiandoelaparatoy/u otros

objetos,ocausandogravesheridas

a espectadoreso al usuario.

• Eviteambientespeligrosos.No use

el aparatoenlugaressinventilaci6n

ni dondepudahabervaporesexplo-

siveso mon6xidodecarbono.

• No se extiendaexcesivamenteniusa

el aparatoensuperficiesinestables

talescomeescaleras,drboles, de-

clivesacentuadas,techos,etc.Man-

tenga el eqqilibrio,conlospiesen

unasuperfieieestableen todome-

mento.

• Nunca coloqueobjetosdentrode los

tubesde propulsi6n;siempredirija

losescombrosen direcoi6ncontrada

a dondepersonas,animales,vidrier-

asuotrosobjetoss61idostales come

drboles, autom6viles,paredes,etc.

se encuantran.Lafuerza del aim

puedearrojarohacerrebotarpie-

dras,tierraoramas,hidendoaperso-

naso animales,rompiendovidderas

ocausande otrosdafios.

• Nuncapongael aparatoan marcha

sin tonertodoetequipocorrespon-

dienteinstalado.AIusarel aparato

comepmpulsorde aim,siempre

instalelostubesde pmpulsi6n.AI

usarel equipoopcionalde aspira-

ci6n,siempminstalelostubesy la

bolsade aspiraci6n.AsegQreseque

lacremallerade labolsadeaspira-

ci6nse encuentreeompletamente

cerrada.

• Inspeccionefrecuentemente laaber-

tufade entradade aim,lostubesde

pmpulsin,lostubesde aspiraci6ny

eltubeen forma decodesiempre

conelmotordetenidoyla bujfades-

conectada.Mantengalasaberturas

de ventilaci6ny lostubesdedescar-

ga libresde escombrosque sepue-

den acumulary limitarla cir_ulaci6n

debidadeaire.

• Nuncacoloqueobjetoalgunodentro

dela entradade aireya que dehac-

adopodrfalimitarla circulaci6nclaire

y dafiarel aparato.

• Nuncause el aparato para esparcir

substanciasqufmieas,fertilizantes u

!

otrassubstanciasque puedancon-

tenermaterialest6xicos.

• Pare evitarla propagaci6nde incen-

dios,nouseel aparatocerca deho-

guerasde hogassecasode mator-

tales,de hogaresde leSa,deparril-

las,barbacoas,ceniceros,etc.

• Use elaparetoexclusivamentepare

los fines descdtoseneste manual.

HAGA EL MANTENIMIENTO DEL

APARATOEN LA FORMA DEBIDA

• Permitaque todomantenimiento

apartede losprocedimientosre.

omendadosdescritoseneste Manu-

al del Usuado,seenefectuadospor

un Centrode ServicioSears.

• Desconectela bujfaantesde hacer

cualquiermantenimiento,conla ex-

cepci6nde losajustesal carburador.

° Useexclusivamentelos repuestos

recomendadosd lamaroaCRAFTS-

MAN;el usodecualquierottore-

puestopodrdinvalidar la garantfao

da_arel aparato.

° Vacfael tanquede combustibleantes

de almacenarel aparato.Consuma

elcombustiblerestanteen elcarbu-

radorponiendoelmotoren marsha y

dejdndoloen mamhahasteque se

_ste se detenga.

• Nouseningdnaccesorio nipieza

adicionalapartede losrecomenda-

dospotelfabricante pareusercon

suaparato.

• Noalmaceneelaparato nielcom-

bustibleen un recintocerradodonde

losvaporesdtcombustiblepuedan

entraren contactoconchispasolla-

mas abiertasprocedentesdecalen-

tadoresde ague,motoreso interrup-

toreseldctrieos,calefactorescen-

trales,etc.

• Almaceneelaparatoenunlugar

seco,fuera del alcancede losniSos.

AVISO ESPECIAL: Paralosusuarios

en TierrasForestadasen losEstados

Unidosyen algunos estados,incluyen-

do California(C6digosde Recummos

Pdblicos4442y 4443), Idaho,Maine,

Minnesota,Nueva Jersey,Oreg6ny

Washington:Se requierea ciertosmo-

toresdecombusti6nintemaoperados

entierrascubiertasporbosques,ma-

torralesy/opasto,en lasdrea anterior-

mente mencionedas,quevenganequi-

padoscon rejillaanti-chispas,manten-

ida enperfoectoestadodefunciona-

miento, o queel motorest_construido

y equipadoparelaprevenci6nde in-

cendiosymantenidocorrectamente,

Consultecontasautoridedesestatales

o localesacerca de losreglamentsque

se relacionenconestosrequisitos,De

nocumplirconestosrequtsitos,usted

estate,en violaci6nde la ley.

Esteaparatonovieneequipdode

fdbdca con rejiltaanti-chispa;sinem-

bargola rejillaanti-chispavienedis-

poniblecomopiezaopcional.Sise re-

quiemreji[laanti-chispaen laIocalidad

dondeustedse encuentra,entreen

contactoconel Serviciode Searspare

obtenerelequipoderepuestoscorres-

pondiente.La rejillaanti-chispa,lostu-

bosde pmpulsi6nylas boqutllasdeb-

erdnester instaladosen elaparato

pare estaren totalcumplimientocon el

reglamento.

AVISO ESPECIAL: Elestarexpuestoa

lasvibracionesatrav6sdelusoprolon-

gadode herramientasde fuerzaa ga-

soline,puede causerdafiosalosva-

sossangufneosoa los nerviosde los

dedos,las manos y las coyunturasa

aquellas personaspropensasa los

trastomosde laeirculaci6noalas hin-

chazones anormales.El usoprolonga-

do enclimesfrfosha sidoasociado

con da_os a losvasossangufneosa

personasque pototraparteseen-

cuentranenperfectoestadode salud.

Si ocurrierasfntomastalescomoelen-

tumecimiento,eldolor,la falta desenti-

do enlos dedos,lasmanosoen las

coyunturas,pare de userestamdquina

de inmediatoy procureatenci6nm_di-

ca. Lossistemasdeanti-vibraci6nno

garantizanque se evitantalesproble-

mas. Los usuariosque hacenusocon-

tinuoy prelongadode las herramientas

de fuerza debenfiscaUzaratentamente

su estadoffsico y el estadodelapara-

to.

-16-

CONTENIDO DE LA CAJA

Verifiquequatodoslosarb'culosde la

sigu_entelistaest6nincluidos:

Modelo 358.797030

• PropulsordeAire

• Tubode Propulsi6n

• Aceitede Motora 2 Tiempos

AVISO: Es normalqua elfiltre de com-

bustiblegolpeteeen eltanque vac_'o.

MONTAJE

ADVERTENCIA: SI recibi6 elapara-

toya armado, repitatodoslospasos

pareasegumrsaquoel aparatohaya

sidoarmado correctamentey quato-

doslosfr]adoresse ecuentrenbien

fijos.

• Nose requiereningunaherramienta

parael montaje.

INSTALACION DEL TUBO DE

PROPULSION

• Alineelamoldura salientedef tubo

depropulsi6nconla renura en la sall-

da de aire dela proputsora;girehas-

ta encajar en su lugar.

EQUIPO OPCIONAL DE

ACCESORIOS DEL ASPIRADOR

Sopodr_convertirelpropulsoren as-

piradorainstalandoel Juegopare Aspi-

radoreoptativoN_358.799900,dispon-

ibleen lasucursaSearsrodscemana.

MONTAJE DE LA BOLSA DE

ASPIRACION

• Coloquelapuntapequefiade labol*

sa de aspiraci6nsobrela saiidade

propulsi6ny sujetela peritlaconla

abrazadera.

Banda

Salida o Airodo|Propulsor

Tubode Propulsi6n

_' MolduraSatiento

• Aprietelaabrazaderadeltubogiran-

do la perillahaciala derecha.

• Pare removerel tubo,giretaperilla

haciala izquierdapara aflojarla

abrazadera;remuevael tubo.

• Ajustebientabanda veicro,

• Asegdresedequa lacremallerase

encuentrecompletamentecerrada.

• Asegurelaspuntasde labandadel

hombrometiendo la bandaa trav6s

dela hebillaccmose ilustraa conti-

nuaci6n.

/

-17-

MONTAJE DEL TUBO DE

ASPIRACION

ADVERTENCIA: Detenga el motor

y aseg(Jrese de que las cuchillas

del imputsor no se encuentren gi-

rando antes de abrir la compuerta

de entrada de aire del aspirador o

de intentar introducir o remover los

tubos de aspiraciSn. Las cuchillas

girantes podrfan causar serios ac-

cidentes.

• Retireel tobo de propulsi6n

• Alineeel tubo de aspiraci6n inferior

comose ilustra. Introduzca el tubo de

aspiraci6n inferiordentro de!tubo de

aspiraci6nsuperior.

TubodeAspiraci6n__

• Introduzcaun destomillador dentro

del dreaajustadaen la compuertade

entradade aim delaspirador.

1% Area

• Coloquelosganchosquese encuen-

tranenel tubode aspiraci6nenel

postede retenci6n;gireel tubohasta

quedar en posici6n.Asegureeltubo

de aspiracidngirandola perillahacia

laderechahastaquedarajustado.

ioAIvolvera convertirel aparatoen

propulsorde aire,aseg,_resedeque

laparteajustadade ta compuertde

entradade aimdel aspiradorseen-

cuentrebienflja.

__ de Entrada

• Suavemente,gireel mangodel des-

tomilladorhaciala partetraseradel

aparato,mientras,tirehaciaardba de

la compuertade laentradade aim

del aspiradorconsu otramano.

• Sostengalacompuertadeentrada

de airedetaspiradorabiertahasta

queel tubode aspiraci6nquede

instalado.

2 i;2o,ooo,aN

-18-

CUCHILLAS DESMENUZADORAS

Su propulsorvieneequipadocon cuch,lasdesmenuzadorascomocaracter[stica

standard.Cuandouseeste accesorio opcionaldel aspirador,lascuchillasdesme-

nuzadorasreducirdnlosescombrosen unaproporci6ndehasta16:1.

CONOZCA SU PROPULSOR

LEA EL MANUALDEL USUARIO Y SUS REGLAS DE SEGURIDADANTES DE

COMENZAR A USAR ESTE PRODUCTO. Comparelas ilustracionessiguientes

consuaparatoparafamiliadzame conta Iocalizaci6ndeloscontrolesy ajustes

del mismo.Guardeeste manualparafuturasreferencias.

Interruptor

ControldeVe]ocidad(_

Bombeador_)

Tubode

Propulsl6n

ON/STOP

Mezclade

Combus-

tible.

Cuerda

\

MangoTrasero

iNTERRUPTOR ON/STOP

ElinterruptorON/STOP es usadopara

detenerel motor,el irrterruptorse man-

tendrden la posici6nON. Para detener

.el motor,presioneysostengael inter-

ruptoren laposici6nSTOP hastaque

el motorse detengaporcompleto.

ARRANQUE EN FRIO _),

ArranqueenFrfo _) ayudaa suplir

dconcombustibleelcarburadordu-

mnteel arranque.Estole permitirdar-

rancarel motorcuandose enouentre

fdr. Paraactivarel Arranqueen Frfr _

muevata palancadelArranqueen Fda

_a la posicibnRUN. Yea lasecci6n

de Arranquede Motorpara una infor-

.H I I I

POSIC{ON

DE USO

Pmtecci6n

Pgralos

jos

maci6nmdsdetaUadasobrela puesta

enmarcha.

BOMBEADOR_)

El Bombeador(_ retiraaim de las

Ifneasdecombustibleylas |lena con

combustible.Estole permitirdarrancar

elmotorconmenostironesde la euer-

da de arranque.Para activarel Bomb-

eador_ presioneel botbny luego

permitaquevuelvaa su posioi6norigi-

nal

CONTROL DE VELOCIDAD (_-

ElContro_de Velocidad_, controlala

velocidad'delmotor.Mu_valototalmente

haciadelanteparaconseguirmdxima

velocidad.Mudvalototalmentehacia

detrdspara¢onsegutrla marchalenta.

ANTES DE PONER EL MOTOR

EN MARCHA

ADVERTENCIA: AsegOresede

haberlerdo todala informaci6nsobre

el combustibleenlas reglasde

seguridadantes decomenzar,Sino

comprendelas

intenteabacstecer el aparatocon

combustible.Llameal 1-800-235-5878.

ABASTEClMIENTO DEL MOTOR

Este motorestdhabilitadopara

funcionar congasolinasinplomo.

Antesde usar,deberd mezclarla

gasolinaconun aceitede buena

-19-

calidadpara motoresde 2 tiempos

enfriadosaaire.

Recomendarcosel aceite dela marcha

WeedEater.Mezclela gasolinaconel

aceiteen laproporci6nde 40:1 (Se

obtieneunaproporci6nde40:1

mezclando3.2 onzasde aceitecon

cedegak_ndegasolinasinplomo).NO

USE aceitepara autom6viles ni para

barcas.Estosaceites da_ardnel

motor.AI mezclarelcombustible,siga

lasinstruccionesimpresasenel

recipiente.Unavez que hayaaSadido

elaceite a la gasolna,agiteel

recipientebrevementepare asegurar

queelcombustibleest_

completamentercezclado. SJemprelea

y sigalasreglasde seguridadque

tienenquever conel combustible

antesde abastecer el aparato.

IMPPORTANTE

Laexperienciaindicaqueloscombus-

tiblesmezcladosconalcohol,(loslla-

rcadosgasoholo losque tienenetano!

o metanol)puedenatraer hurcedad,Io

que puedecauserla separaci6ny la

formaci6nde tic!dosduranteel alrca-

cenaje.Lagasolina dcida puededa_ar

elsistercade combustibledel motor

duranteelalmacenaje.

Pareevitarproblemasconel motor,

deberdvaciarseelsistemade combus-

tibleantesde almacenarelaparato por

30 dfaso mds/

Vacfeel tanquede combustible,ponga

elmotoren marchay ddjeleen marcha

hastequelas Ifneasde combustibley

elcarburadorquedenvac|os.Use

combustiblefresco en lapro6x_matem-

rada.

_nca useproductosde limplezade

motorocarburadoren eltanquede

corcbustibleyaquede hacedopuede

provocardanospermanentes.

Unestabilizadorde combustiblees

unaaltemativaaceptablepareminimi-

zer laforrcaci6n de dep6sitosde goma

enel combustibleduranteel alrcace-

naje. Elaceite de lamamha Weed Eat-

er vleneya mezcladocon estabilizador

de combustible. Vea la secci6nde AL-

MACENAJEpare mds informaci6n.

PARA DETENER EL MOTOR

• paredetenerel motor,presioney

sostengael interruptorStop O has-.

ta queelmotorse detenga.

PARA PONER EL MOTOR

EN MARCHA

ANTES DE PONER EL MOTOR EN

MARCHA

-20-

Es OBLIGATORIOasegurarse quelos

tubosest_nbienfijosantesde usarel

aparato.

• Abastezcael motor,Ap_rtese porIo

menos 3 metros(10 pies) dellugar

deabastecirciento.

• Sostengaelaparato enta posici6n

dearranqueilustrada.Asegdresede

que laboquillade propulsi6nnoest6

direccionadahacia personas,an!-

males,vidrterasy otrosobjetoss61i-

dos.

ADVERTENCIA: AI arrancarel mo-

tor,sostengael aparatocomose iiustra

en lafigure. Apoyeel aparatoexclusi-

varcenteenuna superficie!ircpiay

s61idasiemprequevayaa efecturae!

arranqueysiemprequetenga que

apoyarel aparatoconel motoren Imar-

cha. Losescombrostalescorcogravil-

la, arena,tierm, c_sped,etc,, pueden

sersuccionadosporlaentradade aim

y arrojadesporlasalidade propulsi6n,

daSando el aparato uotros bienes

o causando graves heridas a es-

pectadores o al usuario.

Controlde

Vetocidad _ _ Interruptor

Palancade_ !

Arr q en\ i"--1/

PARA ARRANCAR UN MOTOR FRIO

O CALIENTE DESPUES DE QUEDAR

SIN COMGBUST|BLE

• Lentamente presione el bombeador

12 veces.

• Muevalapalancadelcebadorala po-

sici6nFull

• Mueva lapalanca del aceleradorala

posici6n_.

• "l]rede la cuerda de arranquefirme-

rcente hastaque el motorintentear-

rancar,pero no m_.sde 5 tirones(en

temperaturespordebajo de los 30° F,

tratecon8 tironesde la cuerdade ar-

ranque).

AVISO: Si el motortrata de arrancar

antes del quinto tir6n, procedacon el

pasosiguienteinmediatamente.

* Muevala palancadelcebadorala po-

sici6nHalfChoke,

oTire de la cuerda de arrenque firme-

rnentehastaqueelmotorse pongaen

marcha, perono mdsde 5 tirones(en

temperaturespordebajode los30° F,

tratrecon I0 tirones).Permitaque el

motormarchepot 5 segundos,luego

mueva lapalancadelcebadorala po-

sioi6nOff Choke.

° Permita que el aparato mamhe por

otros30 segundoscon ]apalancadel

cebador en la posici6n Off Choke

antesdemoverlapalancadelacelera-

dora la posici6n._P.

Si el motornoarranca despu6sde tirar

de lacuerdapor 5 veces(enla posioi6n

HalfChoke),repitadelpasode comoar-

rancarun motor"fifo". Si el motorper-

sistesin arrancar,procedacon "Arran-

que de MotorAhogado"i

RESPONSABILIDADDEL USUARIO

TAREADE CUIDADOY MANTENIMINENTO WHEN TO PERFORM

Verificarque nohayafijadoresflojosniptezas Antesde cada use

sueltas

Verificarque no hayapiezas dafiadaso Antesde cacJauso

gestadas

Umpiar el aparatoy susplasas Despu_sde cadauso

Limpiarel filtro de aire Cada 5 horasde uso

Cambiarlabuifa...... Anualmente

Cambiarelfiltor deJcombustible Anualmente

VERIFICAR QUE NO HAYA que el motorse detengacompleta-

PIEZAS SUELTAS NI FIJA- mente. Aseg_resede queel motor

DORES FLOJOS se detenga;luego vuelvaa arrancar

Cepuchade la Bujl'a elmotory contin6e.

Ffltrode Aire • TanquedeCompustible.Parede

• Torn,losde laCaja userelaparato sihay indiciosde

VERIFICAR QUE NO HAYA dafioso p_rdidasen el tanquede

PIEXZAS DAi_IADAS N! combustible.

GASTADAS • Bolasde laAspiradora.Pare deuser IIInl

El Centrode ServicioSearsdeber& labolsade aspiraci6nsi seenouen-

efecturatodocambiode piezas dana- tra dealquna manerarotaoda_ada.

deso gastadas.

• InterruptorOn/Stop.Aseg6rasede LIMPIE EL APARATO Y SBS

que el mterruptorOn/Stopfuncione PLACAS

deunaforma apropiade,para deten- ° Umpie el aparatousandountrapo

er el motor,presioney sostengael hdmedocon detergentesuave.

interruptoren la posici6n Stop hasta • S_queloconuntrapolimpio,

ARRANQUE DE MOTOR CALIENTE

CON COMBUSTIBLE

• Muevalapalancadelcebadoraiapo-

sici6nHalf Choke.

Mueva lapalanca del aceleradorala

i posici6n_.

Tire de la cuerda de arranque firme.

mentehastaqueelmotorse pongaen

marcha, perono mdsde 5 veces.

• Permitaqueelmotormarchepor5se-

gundostuego, mueva lapalancadel

cebadora a pisici6nOffChoke.

AVISO:lSi elmotornoarranca,tiredela

cuerdade arranque otras5 veces.Si el

motorcontinuasm arrancar,probabte-

mentese eneuentreahogado.

ARRANQUE DE MOTOR AHOGADO

Mueva lapalancadel cebadora la po-

sici6nOffChoke.Mueva te palancade-

laceleradorala posici6n,tB. Tire dela

cuerdade arranqueparaaclararelmo-

tordel excesode combustible.Esto

podrd,requerir quese tirede la cuerda

dearranquemuchasveces.

Si el aparato contimla sinarrancar,yea

la Table Diagn6stica o llame al

1-800-235-5878.

-21-

I

LIMPIEELFILTRODEAIRE

Nolimpis elfittrodeairs congasolina

niningdnottosolventeinflamable,ya

que de hacertopuedecrest peligrode

incendioy de emicionesevaporativas

noclvas.

Limpieza de! filtro del aire"

Losfiltros de airssuciosdisminuyenel

rendimientodelmotore incrementanel

consumode combustibley laproduc-

ci6nde emisionesnocivas.Siempre

limpieelfiltrode airs despudsded

cada5 boresdeuso,

7_ Cubie_a

Fiitride Airs _FeelAF'i:_er°

• Limpielacubiertay el dreacontigua

parsevitarquecaJgatierraen la

cdmarade|carburadorcuando

remuevalacubierta.

• Retire/aspiezascomose ilustra.

Permita9us el filtrose seque.

i aveelfiltroconaguay jab6n.

repongamspiezas.

CAMBIE LA BUJIA

Cambiela bujfaanualmente.La sepa-

raci6nde loselectrodosde ta bujfa

deberdserde .025 de pulgada.El en-

cendidoesfijoy noes ajustable.

• Gireyluegoretirelacapuchade la

bujfa.

• Retireiabujfadetcilindroy des_che-

la.

• Cdmbielapot unabujfaRCJ-SYy

ajustelaconunallavede 3/4 de pul-

gada.

• Vuelvaainstalarlacapuoha.

CAMBIE EL FILTRO DEL

COMBUSTIBLE

Parscambiarelfiltrodelcombustible,

vacieel aparatode todocombustible

dejandoel motoren mamhahaste que

se detenga.Luego,remuevael mon-

taje de latapa/retenedordeltanque.

Tiredelfiltroquese encuentraen el

tanquey retfrelodela Ifneade com-

bustible.Instaleunfiltor nuevoen la

Ifneade combustible;vuelvaa instalar

todaslaspiezas.

Recomendamosquetodoelmantenimi-

entoy todoslosajustes no listadosen

este manual sean efectuados pot un

Centrode ServicioAutorizado.

AJUSTES AL CARBURADOR

El ajusteal carburadoresde vitalim-

portanciaysi se haoeincorrectamente,

puededafiartantoelmotorcomoel

carburadorpermanentemente.Si usted

necesitamdsayudao no estdseguro

dec6mo hacerel procedimiento,flame

a_.nuestmteldfonodoayuda al consu-

midor,al 1-800-235-5878.

Elcombustiblevencido,elfiltrode sire

ode combustiblesucios,o elmotor

ahogadopuedendarla impresi6nde

carburaci6ndesajustada.Verifiquees-

tes condicionesantes de hacer cualqu-

ier ajuste.

Elcarburadorhasido cuidadosamente

ajustadoenla fdbrica. Posiblemente

serd necesarioIhacerajustessi se

notacualquierade las siguientescon-

die|ones:

• Elmotornoands enmercha lenta.

Vea =mamhaLenta"y "Mezcla" bajo

procedimientode ajuste.

- 22 -

• Elmotorse pars ose ah0ga cuando

debe acelerar.Vea _Ajustede Aceler:

aci6nbajoprocedimientode ajuste.

•Falta de potencia.Vea"Mezcla" bajo

proeedimientode ajuste.

PUNTOS DE PRECALIBRACION

AI hacerajustesno fueme tastapes

limitadoras de pldsticomdsslid de los

retenedoresopuedehaber dafios.Si

nose necesitanlospuntosde precalF

braci6n,passala secci6nde "Procedi-

miento deAjuste,Mamha Lenta'.

Parsajustar la precalibraci6n:

• Gireel tomlllodemezcla haciala iz-

quierdahastequese detenga.

• Gireeltomitlode la marchalenta ha-

cia la derechahasta quese detenga.

Luego,gfrelohaciala izquierda4

vueltasy media.

Pongael motoren marcha, permits

quemarcheper 3 minutos, luegopro-

cedecon la secci6nde ajustes.Si el

motornoarranca,veala table

diagn6sticao Ilameal 1-800-235-5878.

Siel funcionamiento del motores

aceptableconla posieionesantsriores,

no hardfalta hacer rodsfalta hacer

rods ajustes.

( Lenta

Tom_llod_la Marcha

o'T-_miflode MezcTa

(contapaslimita.

doras)

PROCEDIMIENTO DE AJUSTE

Marcha Lenta

Permitaclueel motortrabajeen mar-

chalenta.Ajustelas revolucioneshas-

ta queel motorse mantenga en mar-

chasinahogarse.

• Gtrehacia la derechaparaincremen-

tarta velocidaddel motorsiel motor

se ahogao se aparga.

• Gireeltomitlode |a marchalenta ha-

ciala derechahastaquese detenga.

Luego,gfrelohaciala izqulerda4

vueltasy media.

PROCEDIM1ENTODE AJUflTE

_ Permitaque el motortrabajeen mar-

" cha lenta.Ajustelasrevolucloneshas-

_ taque el motorse mantengaen mar-

chasinahogarse.

• Girehacialaderechaparainoremen-

tar ta veJocidaddel motorsiel motor

se ahoga o se apaga.

• Girehacia la izquierdaparabajar las

revoluciones. No ser_necesadoel

hacerm_sajustessiel rendimiento

es satisfactorlo,

Mezcla

Permita queel motortrabajeen mar-

chalenta,luegoacelereel motory

tomenotadel funcionamiento, siel mo-

torse ahoga,noacelera bienohumea

al ace|erar,gireeltomiltode ajuste de

mezcfa hacialaderecha enincmmen-

losde 1/16 devuelta0nicamentehas-

ta obtenerunfuncionamientocatisfac-

torio,Repitaeste procedimiento las

veces que sea neossario hasta obten-

er un rendimiento saUsfactorio,des-

pu6s de completarestos ajustes, verifi-

que la aceleraci6n. Ajuste nuevamente

sies neoesario.

Verificaci6n de Aceleraci6n

S!el motorse apaga ovacilaen lugar

deacelerar,gireel tomillodeajustede

mezclahaciala izquierdahastaconse-

guirunaaceieraci6npareja,Verifique

nuevamentey haga los ajustesnece-

sariosparaconseguirunfunclona-

miento aceptable.

Prepareel aparatopara el almacenaje

al finalde latemporadao sica a estar

sin usarporrods de30 dfas.

ADVERTENClA:

• Permitaqueel motorse enfrfey file

blenel aparatoantesde guardarloo

tmnsportarlo.

• Guardeet aparatoy elcombustible

en untugar bien ventUadodondelos

vaporesde combustibleno puedan

entraren contactoconchispaso lla-

masabiertasprovenientesde termo-

tanques,motoresointerruptores

el_ctricos,calefactorescentrales,etc.

• Guardeelaparatocon todoslospro-

tectoresen su lugary colo_ueel

aparatode modoque las plezasfilo-

sas no puedancausarbetidespot

accidente.

- Guardeel aparatoy el combustible

comp.letamentefuera delalcancede

losnmos.

SUPERFICIES EXTERNAS

• Siva a almacenar elaparatoporun

periodolargodetiempo,I/mpmlori-

gurosamenteprimero.Gu_rdeloen

unlugarlimpioyseco.

• Apl_queuna pequeSacantidadde

aceitealas superficiesmetdlicas ex-

temas.

SISTEMA DE COMBUSTIBLE

Bajoel Abastecimientodel Motor,en

laseccidnde Usode este manual,yea

elmensaje marchadocomoIMPOR-

TANTE referenteal usode gasoholen

sumotor,

Losestabilizadoresdecombustible

sonuna alternativa aceptable para

minimizarlaformaci6n delosdeposi-

tosde gomaduranteelalmacenaje.

Afiadaestabiiizadora la gasolinaenel

tanquede combustibleo enel reci-

pientepara alacenaje de combustible.

Siga lasinstruccionesde mezcla que

se encuentranen losenvasesdel esta-

bilizador,Pongael motoren mamhay

-23--

ddjeloen marchaporIorrenos5 minu-

tosdespu_sdehabedepuestoel esta-

bilizador Elaceitede la mamaWeed

Eater40:1 para motores a 2 tiempos

(enfriadosaaire)ya viene mezclado

conestabilizadorde combustiblesino

usaesteaceite,entoncespuedea_a-

dirunestabilizadoraltanquede com-

bustible

INTERIOR DEL MOTOR

• Retirela bujfay viertaunacucharadi-

ta deaceite 40:1 paremotores de 2

tiempos(enfriadosa aim)por laaber-

tufade labujfa Lentamentetirede la

cuerdade arranquede 8 a 10 veces

paradistribuirel aceite

TABLA DIAGNOSTICA

PROBLEMA CAUSA

E!motorno • Elmotorestdahogado

arranca • Eltanquedecombustibleest_

Elmotor no Elcarburadorrraquieraajuste

endaen ," Lasjuntasdelcig0etialestdn

marchalenta gastadas

comodebe • Lacompresi6nestdbaja

El motor no • ElfiltrodeaJraestdsucio

acelera,te • Labujfaest_carbonizada

faltapotencia

o seapaga * Elcarburadorrequieraajuste

bejocarga • Acumutaci6nde carb6im

Elmotor • Elcebadorest_ parcialmente

humea . accionado

excesivamente Lamezcla de combustiblese

Elmotor , La mezclade combustiblese

marcha hehechoincorractamente

contern • Seha instaladola bujraincor-

_eratura recta

elevada • Elcarburadorrequiere ajuste

vacfo

: La bujfano hacechispa

Elcombustiblenoestd

iltegandoalcarburador

• La compresi6nestdbaja_

• Lacomprasi6n estd baja

ha hechoincorrectarnente

• Elfiltrade aJraest_sucio.

• ElcarburadorrequieraaJuste

• AcumulacJ6nde carb6n.

• Reemptacela bujfaconotranueva

deltipoyde la gamadecalor recom-

endados

Examinetodoel aparatopareverifi-

carque no hayantomitlos,quebra

i Limpieelfiltro deairs

das o gastadas

AI principiode la pr6ximatemporada,

useexclusivamentecombustible

nuevoconla proporcl6ncorrectade

gasolinayaceite

OTROS

• Noguardela _gasolinadeunatempo-

radaa lasigutente

° Cambie elrecipientsde gasolinesi

se empiezaa oxidar

SOWC=ON

• Vea las=lnstruccionesde Arranque

* Lienseltanque conlamezcla

correctade combustible

• Instalsunabujfanueva

• Vedfiquesielfiltro de combustible

estd sucio;cdmbieloVerifiquesi

haydoblecesen la ffneade

combustibleo si dstase encuentra

[ panda; repdralaocdmbiela

i - Entreen contactoconsuCentrode

Servicio

• Vea"Ajustesal Carburado¢'

• EntreencontactoconsuCentro

de Serviclo.

• Entre encontactoconsuCentre

de $ervicio.

• Limpieocambieeltiltrodeairs.

• Limpieocambielabujfay calibre

fa separacldn.

• Vea "Ajustesa_Carburador".

• Entre en contactoconsuCentro

de Servicio,

• Entreen contactoconsuCentro

de Servicio,

Vea =Abastoc!mientode|Aparato;.

i uamD=ezaoujia pot correcta

Vea "Ajustosal Carburador"

• Entre en contatoconsuCentrode

Sewicio

• Vea "Abastecimiento delAparato"

• Cambie labujfaporla corracta

* Vea"Ajustas _dCarburador"

. Entre en contatocon suCentrode

Servicio

la

Sisituacionessurgieranno descritasen este manual,actue concuidadoyuseel

buensenUdocom0n Si necesitaraasistencia,entreen contactoconsu Centro/

Departamentode ServicioSearso Ilameal Tel_fonode Ayudaal Consumidoral

1-800-235.5878

-24-

For the repairor replacement parts you need

delivered directly toyour home

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

Para ordenar piezas con entrega a

domicilio - 1-800-659-7084

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

Para pedir servicio de reparaci6n a

domicilio - 1-800-676-5811

For the location of a Sears Parts and

Repair Center in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

Call 9 am - 5 pm, Monday-Saturday

1-800-827-6655

When requestingserviceor orderingparts,always

provide thefollowinginformation:

• ProductType • PartNumber

• ModelNumber • Part Description

America'sRepairSpecialists

Loading...

Loading...