Craftsman 358796170 Owner’s Manual

operator'sl

manual.,

MODEL NO.

358,7r96170 '

_/ , STCRRFTSMRN®t

r22.2CC GASOLINE EDGER

.• , •%,j•

2 Cycle Engine

" !fl,WARN;NG:

read and follow all

Safety Rules, Precationsand

Operating Instructions, Fail-

ure to do so can result in

serious personal injury,

=Assembly

= Operation

i_Always Wear Eye Protection During Operation

.... : Sold by Sears. Roebuck and Co.,, Chicago. Ill. 60684 U.S.A._' •

666654-0108_t-01086: • - .

Fuel Mix 16:1

=Maintenance

= Repair Parts "

TABLE OF CONTENTS

• !Safety Rules,Cautions&Dangers ................ 3

•KnowYourUnit ............................... 4

:Assembly'. .................................. 5,

_.EngineInformation ............................ 6

• A. FuelingYour Unit .......................... 6

B.StartingInstructions.... .................... 7

: C.Pre-operationChecks ....................... 7

D.OperatingInstructions ...................... 8

E.Engine Adjustments ........................ 8

:UsingYourEdger +............................ 9

• A, Opera_nglnstructions ' .9

13.SettingtheDepthAdjusting Wheet ............. 9

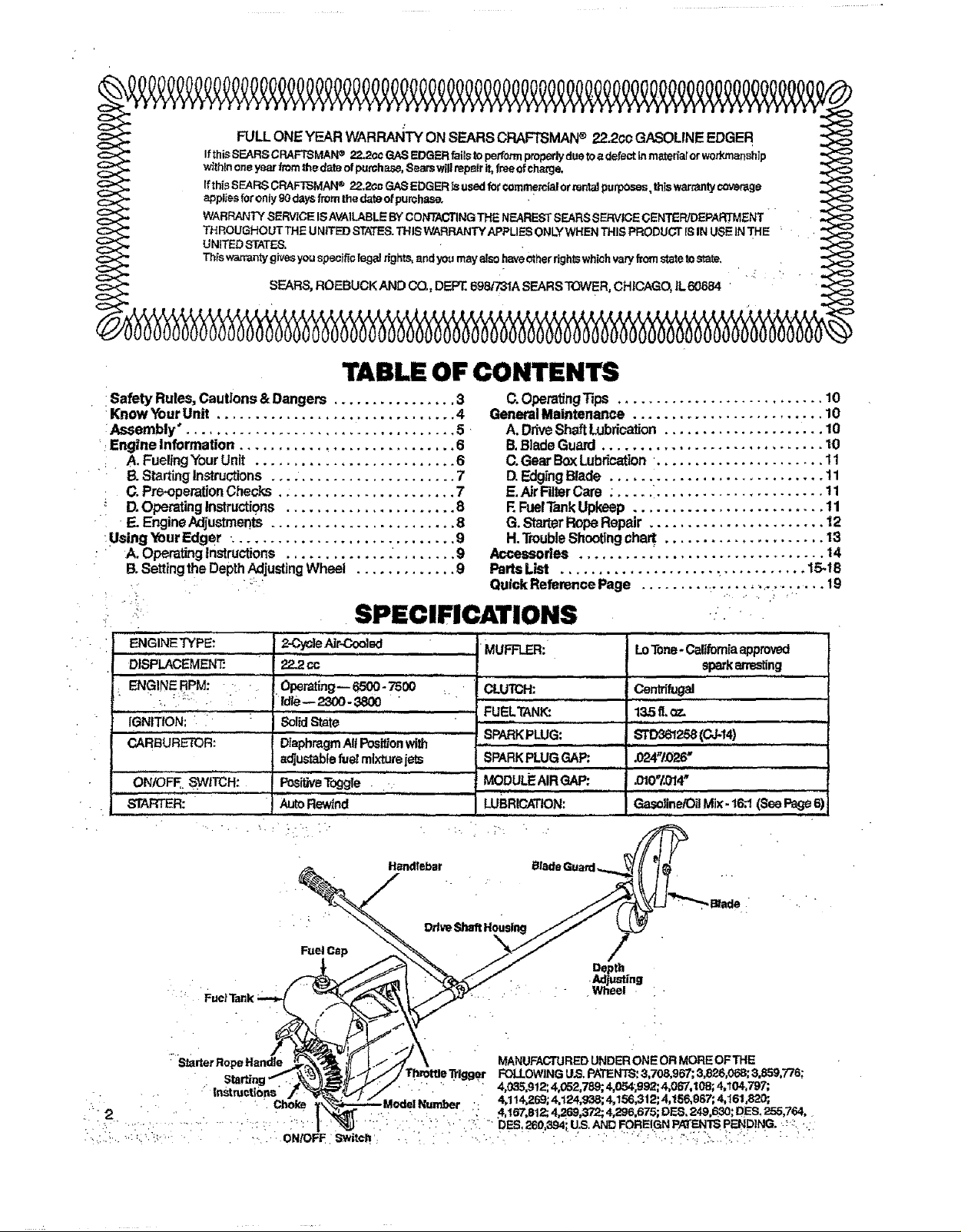

SPECIFICATIONS

ENGINE TYPE:

DISPLACEMENT."

ENGINE RPM:

IGNITION:

CARBURETOR:

...........ON/OFF SWITCH: .

STARTER:

2-CycleAJr-Ooolad "................MUFFLER::

22_cc

Operating-- 6500.7500 :.. CLUTCH:

fdle-- 2300-3800 ..........

SolidState

..... FUELTANK:

......................SPARKPLUG:"

D_aphmgmAltPosPJonwith .......

adjustablefuetmixturejets SPARKPLUGGAP;.

,,,, ,, • , ",

AutoRewind

(3.OperatingTips ........................... 10

GeneralMaintenance ......................... 10

A.DriveShaftLubrication..................... 10

B.BladeGuard ............................. 10

C.GearBoxLubrication. ..................... 11

D.EdgingBlade ............................ 11

E,AirRlterCare ; ..... :...................... 11

F.FuelTankUpkeep ......................... 11

G.StarterRopeRepair ....................... 12

H.TroubleShootingchart ..................... 13

Accessories ................................ 14

PartsLiSt .................... _ .......... 15.t8

QUickReferencePage ......... :.............. .,. 19

, ' , .

LoTone-Californiaapproved

sparkarresting

Centd_gal

13,5g.<_

............

MODULEAIRGAP:

u i

LUBRICATION:

.024"i_26"

iiiiiiii ii ..................

iiiiiiiiiiiiiii i i i

Gasoline/OilMix-16:1(SeePage6)

Handlebar Blade Guard,.._ (( l_ '

'; Ddve,_rt H

Fuel Cap /

Depth

•Adjusting

: 'StarterRope Handle rottleTdgger FOi.LOWING LI.S.PATENTS:3,708.967; 3,826,068; 3.859,776;

" : " 2 ' " " '" " ......... : ': ...... : " M" :" " ' " '_ rr " DES 260,394iU.S ANDFOREIGN PATENTSPENDING. _::

_j_. " • MANUFACTUREDUNDER ONE OR MORE OFTHE

. . " " 4.035,912;4052,789; 4,054;g92;4,05"7,108;4,104,797;

•Model Number . 4.114.269;4.124,938; 4,156,312; 4.156,987; 4,161,820;

: . 4 167,812;4,269,372; 4 296,675; DF._,249,630; DES, 255,764,

SAFETY RULES, CAUTIONS & DANGERS

Failureto observethe followingSafetyRules andPrecautions canresultin seriouspersonal injury.

A. KNOW YOUR UNIT

1, Read your Operator's Manual carefully until you

completely understandand followall safety rules,

precautions_ and operating instructions before

operating theunit.

2. Restrict your unit to users Whounderstand and

follow all safetyrules,precautions, and operating

instructions inthis manual,

13. PLAN AHEAD

1. Always wear eye protection. The

blade guard will not prevent rocks

and debris from being thrown or

ricocheting into the eyes and face

which can resultin loss of vision or sedous per.

sona/ injur_.

2. Dress safely in long pants and wear boots or

safety shoe_ Donotwearlooseclothing,jewelry,short

pants orsandals;orgobarefoot.

& Do not operate the unitwhen you aretired, ill,or

upset; or ifyouateundertheinfluence ofalcohol,

: drugs or medication.

4. Inspect the areato be cut, Removealtdebris and

objectsthatcouldricochet,bethrownorcouldother-

wisecause injuryordamageduringedging.

5. Keepchitdren,bystanders,andanimatsaminimum

_ :of30 feet (10meters) away when starting oroper-

ating the unit.

C. HANDLE FUEL WITH CAUTION

1. Eliminateallsoumes of sparksorflame(incfuding

smoking, open flames, or work that could cause

sparks) in theareas where fuel is mixed,pouredor

stored.

2. Mix and pour fuel in an outdoor area; storefuel in

a cool, dry, well-ventilated place; and use an

approved, markedcontainer for allfuelpurposes.

3. Do not smoke while handling fuel or while

• operating the unit.

• •4. Wipe up allspills before starting the engine.

5. Move atleast10feet {3meters) awayfromfuel and

• fueling site beforestartingthe engine.

D. OPERATE YOUR UNIT SAFELY

1. Do not use any attachment other than those

supplied and recommended by Searsfor usewit.h

this unit,

2. Inspect the entire unit before each usefor worn,

loose,missing ordamagedparts.Donotuseuntilthe

unitis inproperworkingorder.

3. Keep the handles free of oil and fuel. unitfor 30 daysor more,

4. Neverstartorruntheengineinsideaclosedroom ..... 7. D0notstomtheunitorfuelinactosedareawhere

orbudding.Exhaustfumescontaindangerousearbon • ; hot water heaters,.furnaces,etc.

, monoxide.

5. Neveroperetethe edger without the blade guard : 8.Storeinadryareaoutofthereachofchildren.•

and handlebar securely in place, r J. _ ........ "

6. Make sure the blade stops turning when the

throttle trigger Is released and the engine runs

at idle speed. Forcorrection,referto "Carburetor

Adjustments"page8.

7. Stop the engine and let the unit cool off before

removing the fuel cap and refueling. Always

replacethe fuel cap securely.

8. Keep all parts of your body away from the blade

when startingor runningthe engine.

9. Avoidbodilycontact withthe muffler. Usecaution

whenchangingoperatingpos_onsThe muffler area

can be hotandcauseseriousbums.

10. Do nct overreach.Keepfirmfootingand balanceatall

times

11. Usetheedgerfromyourrightsideonly.Keepyour

lefthandonthehandlebarandyourrighthandonthe

powerunithandle.

Directthe dischargeof debds away from people,

animals, glass, and solid objects such as trees,

automobiles,walls, e_c,asthe unit isbeing operated

12. The fastturningblademaycauserocks,dirt, or sticks

to be thrown or to dcochetwhich may hurt people or

animals, breakglass,or causeotherdamage

13. Do not use the edger on graveled surfaces or in

extremely muddyareas.

14. Always push the unit slowly over rough ground.

StayaJertfor unevensidew_ks,holesinterrain,orother

similar conditions

15. Followthestepsbelowifthe bladestrikesaforeign

object or ffthe unitoperatesabnormally. Stopthe

engine, disconnectthe spark ptug and inspectfor

damage Donotuseuntilthe unit isinproperworkJng

• order

16. Stop the enginewhen theunitisnotinuse. Donot

leavea runningengineunattended.

17. Use only forjobs explained inthis manual.

E. MAINTAIN YOUR UNIT PROPERLY

1, Have allservice other then the items listed inthis

manual performed byyour SearsService Center,

2. Maintainthe unitaccording torecommended pro-

cedum,_

3. Disconnect the spark plug l_fom performing any

adjustment, inspectionor maintenanc_ _pt for

: carburetoradjustment.

•4. Be certain the blade will not contact any object

before making engine adjustments.

5. Use only genuine replacement parts as recom.

: mended bySeam. Theuseofanypart,or accessory

notspecifically recommendedforthisunitmaycreate

a hazardandlorvoid_ur warranty.

; 6. Always drainfuel from thetank beforestoring the

• _ fuelvaporscanreachsparksoran openflame from

r

SAVE THESE INSTRUCTIONS

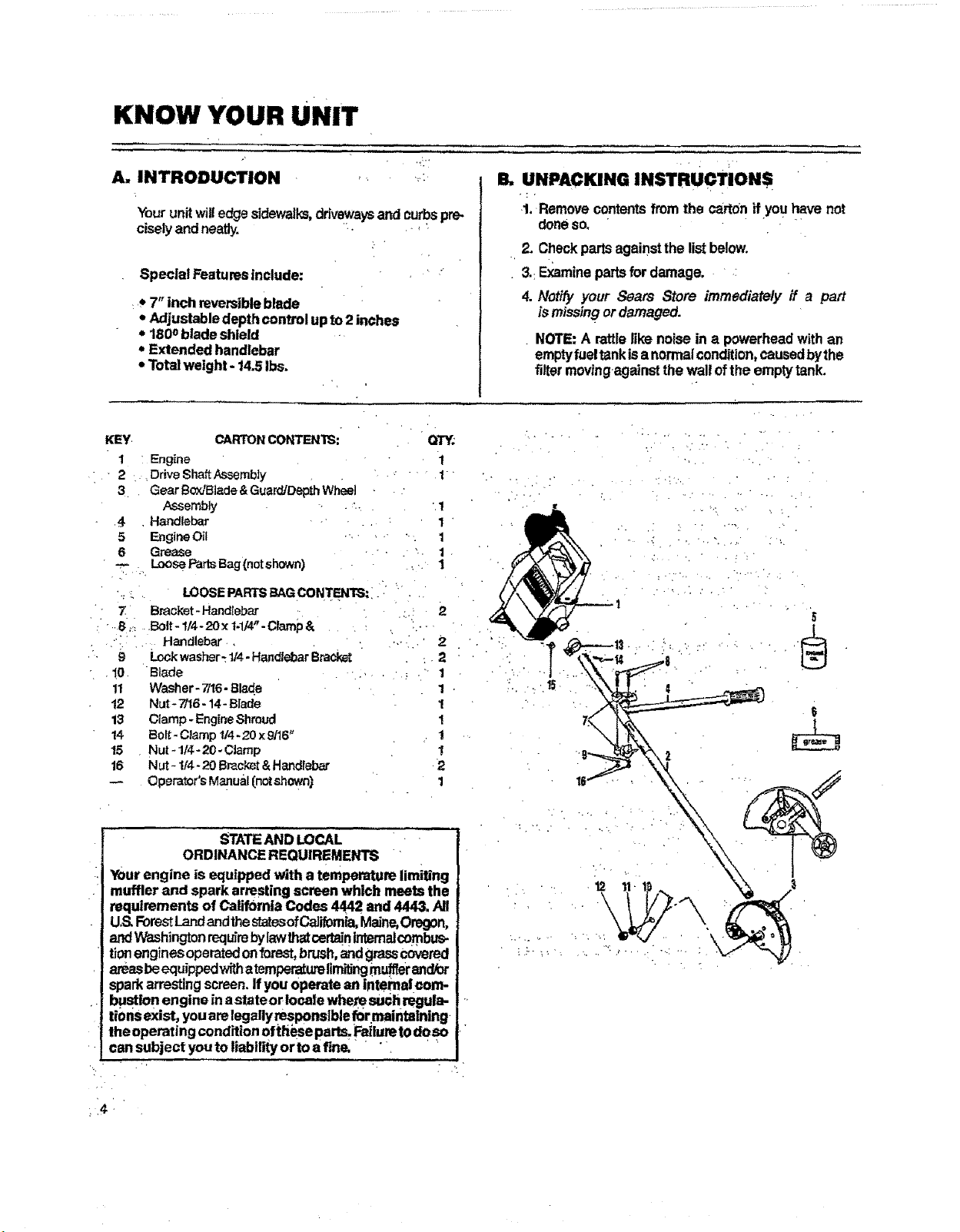

KNOW YOUR UNIT

,i , ,,, ,,,,,,,,,

A, INTRODUCTION ..... _':

Yourunit willedgesidewalks,drivewaYsandcurbspre-

ciselyand neatly. ' '

Special Festumsinclude:

* 7" inch reversibleblade

- Adjustabledepth controlupto 2 inches

1800blade shield

* Extended handlebar

- Total weight - 14.5tbs.

KEY CARTON CONTENTS: QT_

1 Engine 1

2 . .Drive Shaft Assembly " " 1

3 , Gear BccdBl_e & Guard/Depth Wheel

,4 Handlebar 1

Assembly .... 1

5 Engine Oil ........ 1

6 Grease " - " 1

"_7-, LoosePartsBag(notshown) 1

'.,_.. LOOSEPARTSBAGCONTENTS:

7 Bracket-Handlebar :- " • _ 2

: " r r 8" ' P_ ".Bolt - I/4 - 20Xt-1/4"- Clamp & --

. . .. Handlebar., 2

L_k washer- 1/4. HandlebarBracket

Blade

•!0.

11

Washer- 7/16-Blade

Nut-7/16-14- Blade

12

13

Clamp- EngineShroud

14

Bolt_Clamp t14.20 x9116"

15

Nut- 1/4-20- Clamp

16

Nut- I/4 -20 Brecht &Handlebar

Operator's Manual(notshown)

.2

B, UNPACKING INSTRUCTIONS _

1.Remove contents from the carton ifyo u havenot

doneso.

2. Checkpartsagainstthe listbelow.

3.:Examinepartsfordamage..:

4. Notify your Sears Store immediately if a part

ismissing or damaged.

NOTE: A rattlelike noise ina powerheadwith an

emptyfueltankisanormalcondition,causedbythe

filtermoving againstthewallofthe emptytank.

" ' "J _k

1

1

!

!

1

_TATEAND LOCAL

ORDINANCEREQUIREMENTS "

Yourengine is equipped with atemperature limiting

muffler and spark arresting screen which meets the

requirements of California Codes 4442 and 4443. All

U.S.ForestLandandthestatesofCalifomia_Maine,Oregon,

andWashingtonreqL_rebylawthst¢_ertainInternalcombus-

! tionenginesoperatedonfoP.st,brush,andgrasscovered

: amesbeequippedwithatemperaturefimitingmufflerand/or

sparkarrestingscreen.Ifyou operate an intern!!corn-

: bustlonengine inastateorlocalewhe_ suchregula-

tionsexist, youare legallyresponsibleformaintsining

theoperating conditionoftheseparts, Pailuretodoso

can subject youto liabilityorto a fine,.... . ' '

r, . ,

:141"

ASSEMBLY

. ,. . •

Your Operator's ManuaJhas been developed to help you

assemble the unit and tounderstand its safe operation. It is

important that you readyour manual completely to bacome

familiar with the unit before you begin assembly.

A, PREPARATION

1. READ YOUR OPERATOR'S MANUAL

2. Tools you will need: ' •

a. Slotted Screwdriver _'_

b.

11116inchwrench

(2)7/16inchwrenches

OF

(2)Adjustablewrenches

B. ASSEMBLY STEPS

1. DRIVE SHAFT HOUSING TO GEAR BOX

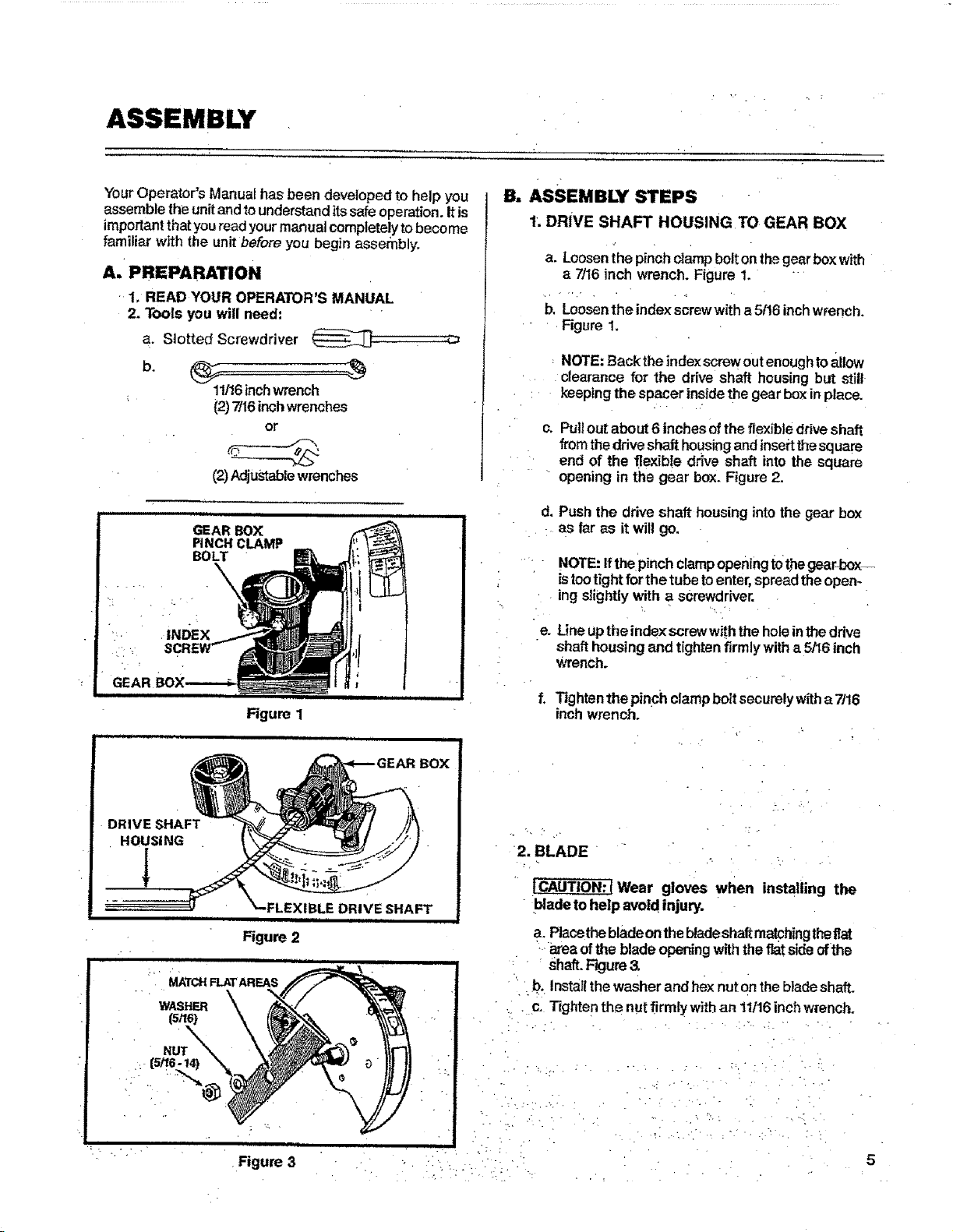

a. Loosenthe pinch clampbolt onthegearbox with

a 7116inch wrench. Figure 1.

b, Loosenthe index screw with a 5f16inch wrench.

Figure 1.

NOTE:Backthe indexscrew outenoughtoallow

clearance for the drive shaft housingbut still

keeping the spacer insidethe gearbox in place.

c. Pull out about 6 inches of the flexibleddve shaft

from the driveshaft housingandinse_tthe square

end of the flexib!e drive shaft into the square

opening in the gear box. Figure 2.

d, Push the drive shaft housing into the gear box

as far as it will go.

" NOTE:IfthePinch clampopeningl:0thegear-box-.-

istootight forthetubetoenter, spreadtheopen-

ing slightly with a screwdriver.

• L , ':

e. Line uptheindexscrewwiththe holeintheddve

shafthousingand tightenfirmlywitha 5/16inch

Wrench.

DRIVE SHAFT

HOUSING

NUT

Figure 1

DRIVE SHAFT

iii iiii ii i

f, _ghten the pinch clamp bolt securely witha 7/16

inchwrench.

2. BLADE

Wear gloves when installing the

bladeto help avoid injury.

a. Placethebladeonthebladeshaft matchingtheflat

area ofthe blade openingwiththe flatsideofthe

Shaft.Figure

" b. Installthe washerand hex nut on the bladeshaft.

• c- Tighten the nutfirmty with an 11116inch wrench.

Figure 3

3.HANDLEBAR

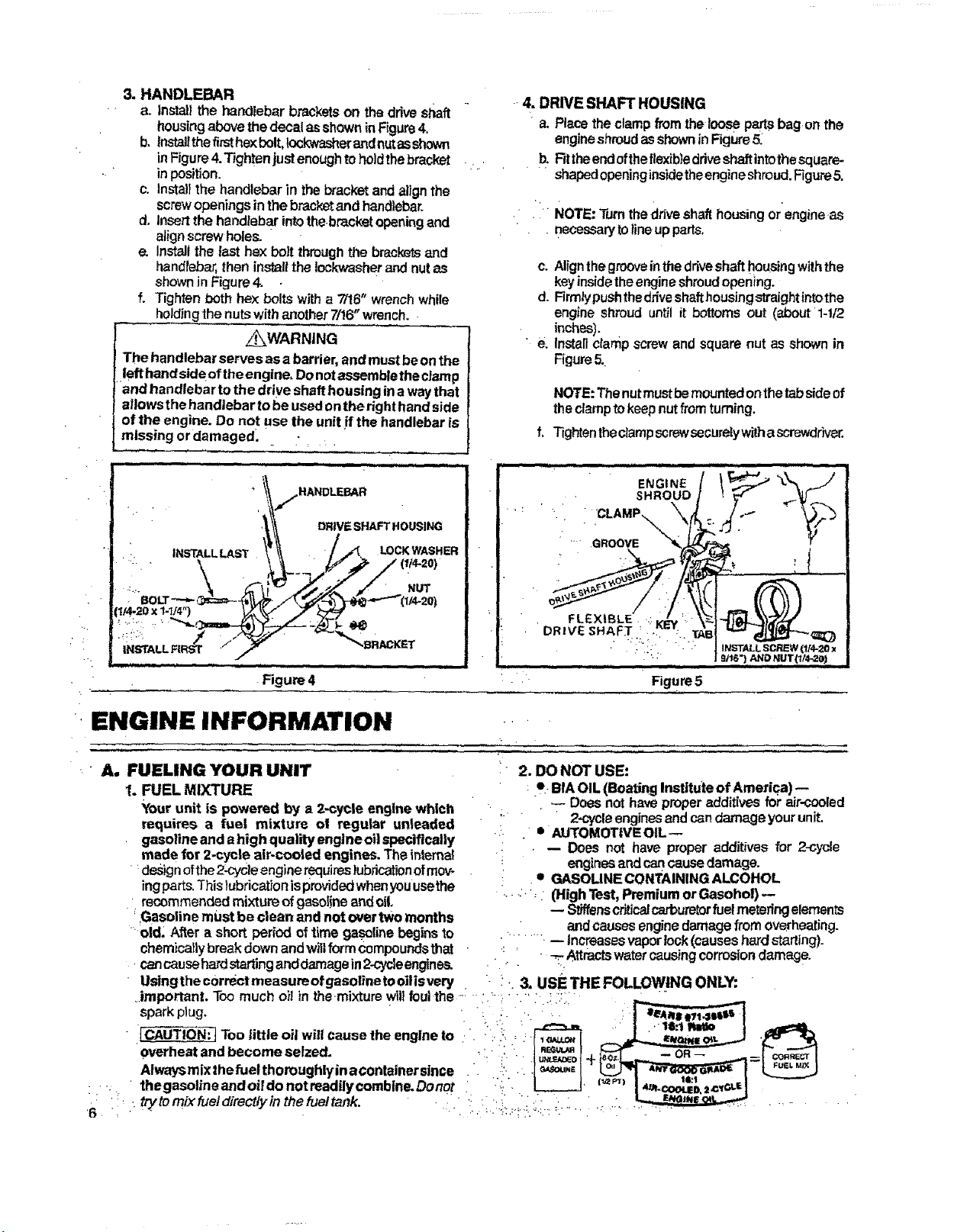

a. installthe handlebarbracketsonthe driveshaft

housingabovethedecal asshowninFigure4.

b. Installthefirsthexbolt,lockwasherandnutasshown

inFigure4.Tightenjustenoughtoholdthebracket

inposition.

c. lnstatithe handlebarin the bracketandalignthe

screwopeningsin thebracketandhandlebar.

d. Insertthehandlebarintothebracket openingand

alignscrewholes.

e. Install the tast hexboil throughthe bracketsand

handlebar,then installthe Iockwasherand nutas

ShOWn Jn Figure4.

f. Tighten bothhex boltswith a ?/16r' wrench while

holdingthe nutswith another7/16"wrench..

z_WARNING

The handlebar servesasa barder,and mustbe onthe

lefthandsideof theengine, Donotassembletheclamp

'and handlebar to the drive shafthousing inawaythat

allowsthe handlebar tobe usedonthe righthandside

of the engine. Do not usethe unitif the handlebaris

missing or damaged.. ;

-.4. DRIVE SHAFT HOUSING

"a. Placethe clampfrom theloose partsbag,onthe

engineshroudasshowninFigure5.

b. Rt theendoftheflexibledriveshaftintothesquare-

" .... shapedopeninginsidetheengineshroud.Figure5.

. " NOTE:Turnthe driveshafthousingorengineas

. necessaryto lineupparts.

c. Alignthe groovein thedriveshafthousingwiththe

keyinsidetheengineshroudopening.

d. Firmlypushthedriveshafthousingstraightintothe

engine shroud until it bm'toms out (aboutl-tt2

inches).

• e. Installclamp screwand square nut as shown in

Figure5.

NOTE:Thenutmustbe mountedonthetabsideof

theclamptokeepnutfromturning.

f, Tightentheclarnpscrewsecurelywithascrewdr'rver.

. ,,,,,,,,, •

Figure 4 Figure5

ENGINE INFORMATION ....

• A, FUELING YOUR UNIT

1. FUEL MIXTURE

Your unit is powered by a 2-cycle engine which

requires a fuel mixture ot regular unleaded

gasolineand e high quality engine oilspecifically

made for 2*cyele air-cooled engines. Theinternal

designofthe2-cycleenginerequireslubricationofmov- .

ingparts.Thislubricationisprovidedwhenyouusethe

• recommendedmixture ofgasolineand oil,

' Gasoline mustbe clean andnot overtwo months

'old; After a short periodof time gasolinebeginsto

chemicallybreakdown andwillformCompoundsthat •

cancausehardstartinganddamagein2-cycleengines.

Usingthe c0rrectmeasure of gasolineto oilisvery .

.important. Too much oil in themixture wiltfoul-the--. - :.--. • -.' • ._i:. " _

sparkplug. " ' : -:; t I

TOO little oil will cause theengineto ..".' _r'_,,'. _ _ __ '_

overheatandbecomeselzed. '::: + I

Alwaysmixthefuelthoroughlyinacontainersinca .. !:- .. :J_ou,, I _L_,7 *_A__..I--L_

:.. thegasolineandoildonotreadilycombine.Donot :i,'.. L___J

6 :'• ttYt°mixfueldirectlyinthefueltank" "•. "_ ' _ ::'_r_'_'_'_' ;';'''_ _:." :" '' r_ '__ .......

• 2. DO NOT USE:

• .!- Bib,OIL(Boating Institute of America) --

Doesnot haveproperadditives forair-cooled

: " 2-cycleenginesandcandamageyour unit.

,!. .- • AUTOMOTIVEOIL

•: , -- Does not have proper additivesfor 2-cycle

engir_sand can_ damage.

• GASOLINECONTAININGALCOHOL

..--.., (HighTest,PremiumorGasohol)

-- Stiffenscriticalcarburetorfuel meteringelements

and causesenginedamagefrom overheating.

....... ,-- increasesvaporlock (causeshardstarting).

' _ Attractswatercausingcorrosiondamage.

. 3. use THE FOLLOWING ONLY: r

Loading...

Loading...