Operator's Manual

ICRRFTSMRN°I

33cc/2.0 cu.in. 2-Cycle

GASOLINE WEEDWACKER ®

Model No.

358.795920

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espa_ol, p. 29

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 <Hoots listed are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

545212846 Rev. 1 1/15/09 BRW

Warranty Statement 2 Storage 22

Identification of Symbols 3 Troubleshooting Table 23

Safety Rules 5 Emissions Statement 24

Assembly 7

Operation 11 Parts List 26

Maintenance 19 Spanish 29

Service & Adjustments 20 Parts and Ordering Back Cover

CRAFTSMAN FU LL WARRANTY

If this Craftsman product fails due to a defect in material or workmanship within two

years from the date of purchase, return it to any Sears store, Parts & Repair Service

Center, or other Craftsman outlet in the United States for free repair (or replacement if

repair proves impossible).

This warranty applies for only 90 days if this product is ever used for commercial

or rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will

NOT pay for:

• Expendable items that can wear out from normal use within the warranty period,

such as cutting line, filters or spark plugs.

• Repairs necessary because of accident or failure to operate or maintain the

product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel mixture,

contaminated or stale fuel.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Congratulations on making a smart purchase. Your new Craftsman product is

designed and manufactured for years of dependable operation. But like all products,

it may require repair from time to time. That's when having a Repair Protection

Agreement can save you money and aggravation.

Here's what the Repair Protection Agreement* includes:

_" Expert service by our 10,000 professional repair specialists

_" Unlimited service and no charge for parts and labor on all covered repairs

_" Product replacement up to $1500 if your covered product can't be fixed

_" Discount of 10% from regular price of service and related installed parts

not covered by the agreement; also, 10% off regular price of preventive

maintenance check

_" Fast help by phone - we call it Rapid Resolution - phone support from a

Sears representative. Think of us as a "talking operator's manual".

Once you purchase the Repair Protection Agreement, a simple phone call is all

that it takes for you to schedule service. You can call anytime day or night, or

schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any

reason during the product warranty period, we will provide a full refund. Or, a pro-

rated refund anytime after the product warranty period expires. Purchase your

Repair Protection Agreement today!

Some limitations and exclusions apply, For prices and additional informa-

tion in the U.S.A. call 1-800-827-6655,

*Coverage in Canada varies on some items. For full details call Sears

Canada at 1-800-361-6665.

2

Sears Installation Service

For Sears professional installation of home appliances, garage door openers,

water heaters, and other major home items, in the U.S.A. or Canada call

1-800-4-MY-HOME®.

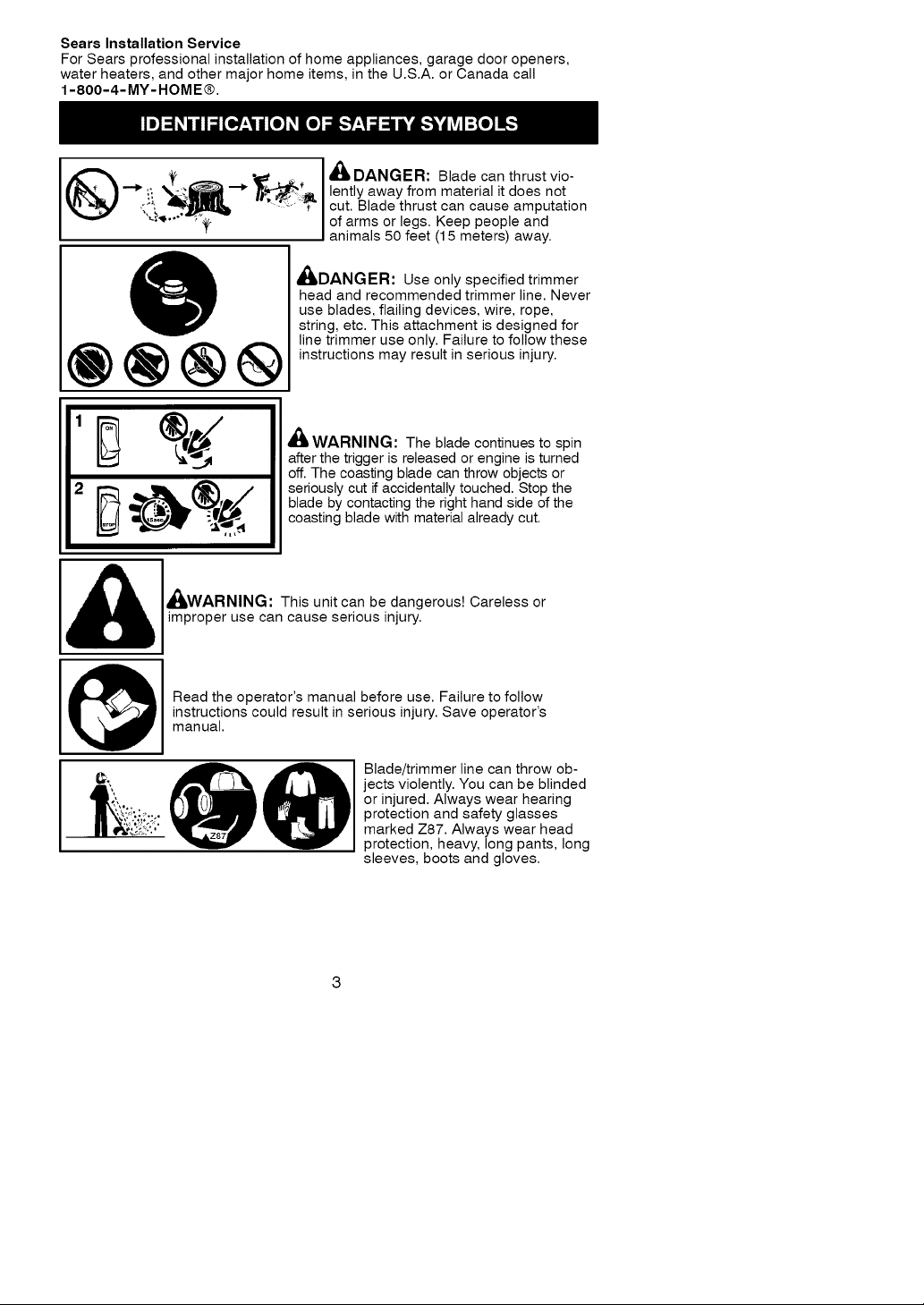

.. ,J ,c_. _/L DANGER: Blade can thrust vio-

.:.!__ ...... -'T" cut. Blade thrust can cause amputation

_*_, lently away from material it does not

of arms or legs. Keep people and

anima s 50 feet (15 meters) away.

A A

_DAN_iER: Use only specified trimmer

head and recommended trimmer line. Never

use blades, flailing devices, wire, rope,

string, etc. This attachment is designed for

line trimmer use only. Failure to follow these

instructions may result in serious injury.

®®®®

WARNING: The blade continues to spin

after the trigger is released or engine is turned

off. The coasting blade can throw objects or

seriously cut if accidentally touched. Stop the

blade by contacting the right hand side of the

coasting blade with material already cut.

improper use can cause serious injury.

_/LWARNING: This unit can be dangerous! Careless or

instructions could result in serious injury. Save operator's

_1 Read the operator's manual before use. Failure to follow

manual.

Blade/trimmer line can throw ob-

jects violently. You can be blinded

or injured. Always wear hearing

protection and safety glasses

marked Z87. Always wear head

protection, heavy, long pants, long

sleeves, boots and gloves.

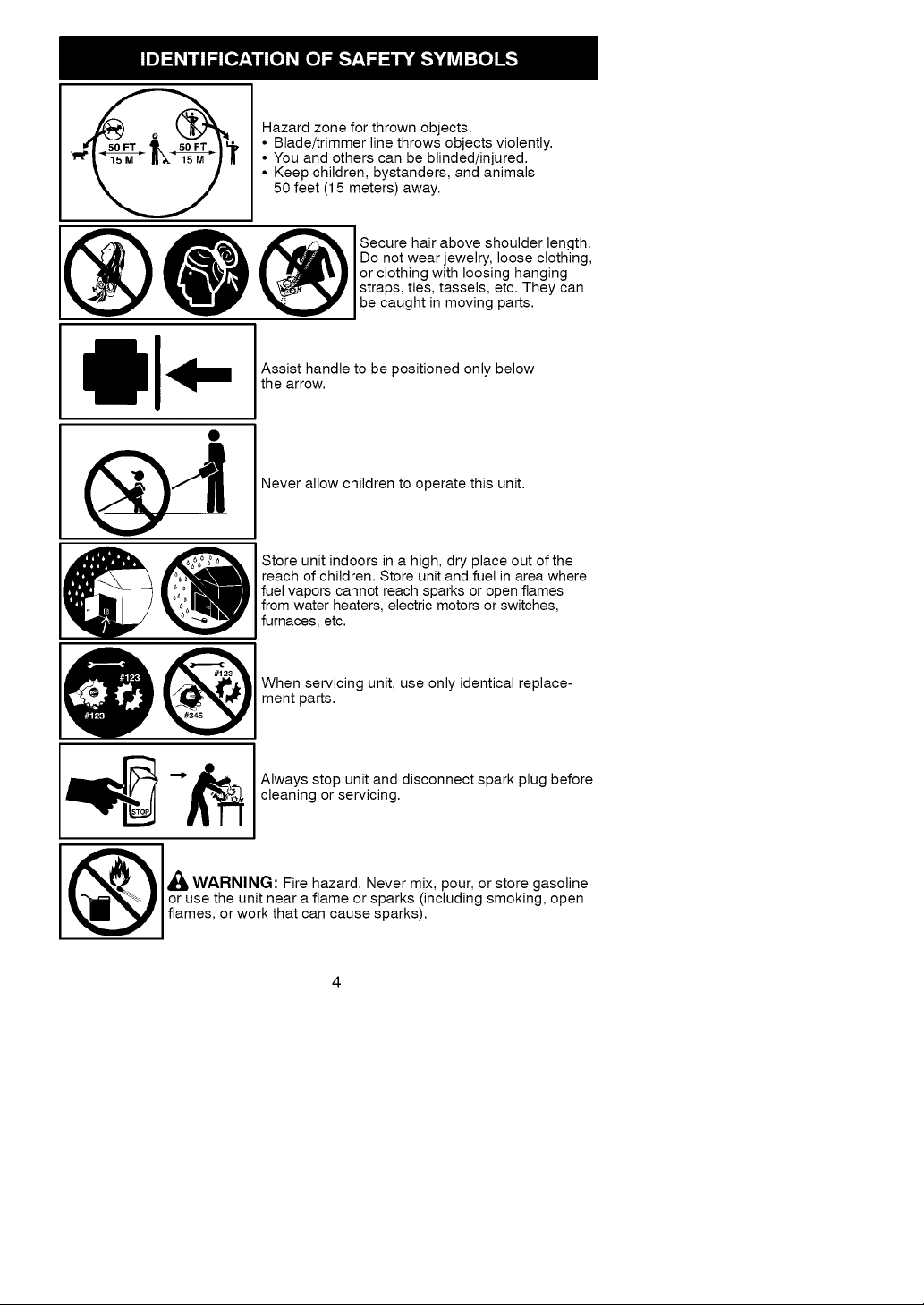

Hazardzoneforthrownobjects.

• Blade/trimmer line throws objects violently.

• You and others can be blinded/injured.

• Keep children, bystanders, and animals

50 feet (15 meters) away.

Do not wear jewelry, loose clothing,

or clothing with loosing hanging

O secureha'rab°vesh°u'der'ength.

Assist handle to be positioned only below

the arrow.

Never allow children to operate this unit.

Store unit indoors in a high, dry place out of the

reach of children. Store unit and fuel in area where

fuel vapors cannot reach sparks or open flames

from water heaters, electric motors or switches,

furnaces, etc.

straps, ties, tassels, etc. They can

be caught in moving parts.

When servicing unit, use only identical replace-

ment parts.

Always stop unit and disconnect spark plug before

cleaning or servicing.

or use the unit near a flame or sparks (including smoking, open

,_k WARNING: Fire hazard. Never mix, pour, or store gasoline

flames, or work that can cause sparks).

Useunleadedgasolineandtwo-strokeoilmixedata

ratioof40:1(2.5%).

_WARNIN_I:Whenusinggarden-

ingappliances,basicsafetyprecautions

mustalwaysbefollowedtoreducethe

riskoffireandseriousinjury.

_/L DANGER: This power tool can

be dangerous! This unit can cause se-

rious injury including amputation or

blindness to the operator and others.

The warnings and safety instructions

in this manual must be followed to pro-

vide reasonable safety and efficiency

in using the unit. The operator is re-

sponsible for following the warnings

and instructions in this manual and on

the unit. Read the entire operator's

manual before assembling and using

the unit! Restrict the use of this unit to

persons who read, understand, and

follow the warnings and instructions in

this manual and on the unit. Never al-

low children to operate this unit.

OPERATOR'S SAFETY INFORMATION

MANUAL ON THE UNIT

A

4_ DANGER: Never use blades with

line trimmer attachment. Never use flail-

ing devices with any attachment. This

unit (when used with supplied line trim-

mer attachment) is designed for line

trimmer use only. Use of any other ac-

cessories with line trimmer attachment

will increase the risk of injury.

If situations occur which are not cov-

ered in this manual, use care and

good judgment. If you need assis-

tance, contact your Sears Service

Center or call 1-800-235-5878.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when

operating, or performing maintenance

on your unit. (Safety glasses are

available.) Eye protection should be

marked Z87.

• Always wear face or dust mask if op-

eration is dusty.

• Always wear heavy, long pants, long

sleeves, boots, and gloves. Wearing

safety leg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals.

• Secure hair above shoulder length.

Secure or remove loose clothing and

jewelry or clothing with loosely hang-

ing ties, straps, tassels, etc. They can

be caught in moving parts.

• Being fully covered also helps protect

you from debris and pieces of toxic

plants thrown by spinning line/blade.

• Stay Alert. Do not operate unit when

you are tired, ill, upset or under influ-

ence of alcohol, drugs, or medication.

Watch what you are doing; use com-

mon sense.

• Wear hearing protection.

• Never start or run the engine inside

a closed room or building. Breathing

exhaust fumes can kill.

• Keep handles free of oil and fuel.

• Always use the handlebar and a

properly adjusted shoulder strap

with a blade (see ASSEMBLY).

UNIT/MAINTENANCE SAFETY

_WARNING: Stop unitand dis-

connect the spark plug before per-

forming maintenance (except carbure-

tor adjustments).

• Look for and replace damaged or

loose parts before each use. Look for

and repair fuel leaks before use. Keep

unit in good working condition.

• Throw away blades that are bent,

warped, cracked, broken, or damaged

in any other way. Replace trimmer

head parts that are cracked, chipped,

broken, or damaged in any other way

before using the unit.

• Maintain unit according to recom-

mended procedures. Keep blade

sharp. Keep cutting line at the proper

length.

•UseonlyCraftsmanbrandreplace-

mentline.Neverusewire,rope,

string,etc.

•Installrequiredshieldproperlybefore

usingtheunit.Usethemetalshield

forallmetalbladeuse.Usetheplastic

shieldforalllinetrimmeruse.

•Useonlyspecifiedtrimmerheador

blade;makesureitisproperlyin-

stalledandsecurelyfastened.

•Neverstartenginewithclutchshroud

removed.Theclutchcanflyoffand

causeseriousinjury.

•Besuretrimmerheadorbladestops

turningwhenengineidles.

•Makecarburetoradjustmentswiththe

lowerendsupportedtopreventtrim-

merlineorbladefromcontactingany

object.Holdunitbyhand;donotuse

theshoulderstrapforsupport.

•Keepothersawaywhenmakingcar-

buretoradjustments.

•UseonlyrecommendedCraftsman

accessoriesandreplacementparts.

•Haveallmaintenanceandservicenot

explainedinthismanualperformedby

yourSearsServiceCenter.

FUELSAFETY

•Mixandpourfueloutdoors

•Keepawayfromsparksorflames

•Donotsmokeorallowsmokingnear

fuelortheunitorwhileusingtheunit

•AvoidspillingfueloroilWipeupall

fuelspillsbeforestartingengine

•Moveatleast10feet(3meters)away

fromfuelingsitebeforestartingen-

gine

•Stopengineandallowittocoolbe-

foreremovingfuelcap

•Emptythefueltankbeforestoringor

transportingtheunitUseupfuel]eft

in the carburetor by starting the en-

gine and letting it run until it stops

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc

• Always store gasoline in a container

approved for flammable liquids

CUTTING SAFETY

_LWARNING: Inspect the area to

be cut before each use Remove ob-

jects (rocks, broken glass, nails, wire,

string, etc.) which can be thrown or be-

come entangled in the blade or trimmer

head

• Keep others including children, ani-

mals, bystanders, and helpers at least

50 feet (15 meters) away. Stop engine

immediately if you are approached.

• Always keep engine on the right-

hand side of your body.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do

not overreach.

• Keep blade or trimmer head below

waist level. Do not raise engine

above your waist.

• Keep all parts of your body away

from blade, trimmer head, and muf-

fler when engine is running. A hot

muffler can cause serious burns.

• Cut from your left to your right.

Cutting on right side of the shield will

throw debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual.

TRANSPORTING AND STORAGE

• Stop the unit before carrying

• Keep muffler away from your body

• Allow the engine to cool and secure

the unit before storing or transport-

ing it in a vehicle

• Empty the fuel tank before storing or

transporting the unit Use up fuel ]eft

in the carburetor by starting the en-

gine and letting it run until it stops

• Store unit so the blade or line limiter

blade cannot accidentally cause inju-

ry The unit can be hung by the shaft

• Store unit out of reach of children

This unit is not equipped with an anti-

vibration system and is intended for

occasional use only.

SAFETY NOTICE: Exposure to vibra-

tions through prolonged use of gasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to cir-

culation disorders or abnormal swell-

ings. Prolonged use in cold weather has

been linked to blood vessel damage in

otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture,

or loss of feeling in the fingers, hands,

or joints, discontinue the use of this tool

and seek medical attention. An anti-

vibration system does not guarantee the

avoidance of these problems. Users

who operate power tools on a continual

and regular basis must monitor closely

their physical condition and the condi-

tion of this tool.

SPECIALNOTICE:Thisunitisequip-

pedwithatemperaturelimitingmuffler

andsparkarrestingscreenwhichmeets

therequirementsofCaliforniaCodes

4442and4443.AllU.S.forestlandand

thestatesofCalifornia,Idaho,Maine,

Minnesota,NewJersey,Oregon,and

Washingtonrequirebylaw that many

internal combustion engines be

equipped with a spark arresting screen.

If you operate in a locale where such

regulations exist, you are legally re-

sponsible for maintaining the operating

condition of these parts. Failure to do so

is a violation of the law. For normal

homeowner use, the muffler and spark

arresting screen will not require any ser-

vice. After 50 hours of use, we recom-

mend that your muffler be serviced or

replaced by your Sears Service Center.

WARNING: The engine exhaust

from this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm.

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358,795920

• Powerhead

• Trimmer attachment

• Brushcutter attachment

• aex wrench

• Handlebar

• Bracket cover

• Bracket cover screws (2)

• Plastic shield

• Wing nut (screwed onto shield)

• Shoulder strap with warning

• Container of oil

• Container of line

Examine parts for damage. Do not

use damaged parts.

NOTE: If you need assistance or find

parts missing or damaged, call

1-800-235-5878.

It is normal for the fuel filter to rattle in

the empty fuel tank.

Finding fuel or oil residue on muffler is

normal due to carburetor adjustments

and testing done by the manufacturer.

ASSEMBLY

_WARNING: Always stop unit

and disconnect spark plug before per-

forming any assembly procedures.

_WARNING: If received as-

sembled, repeat all steps to ensure

your unit is properly assembled and all

fasteners are secure.

TOOLS REQUIRED

• Hex Wrench (provided)

• Adjustable Wrench

• Phillips Screwdriver

INSTALLING ATTACHMENT

CAUTION: When installing attach-

ment, place the unit on a flat surface

for stability.

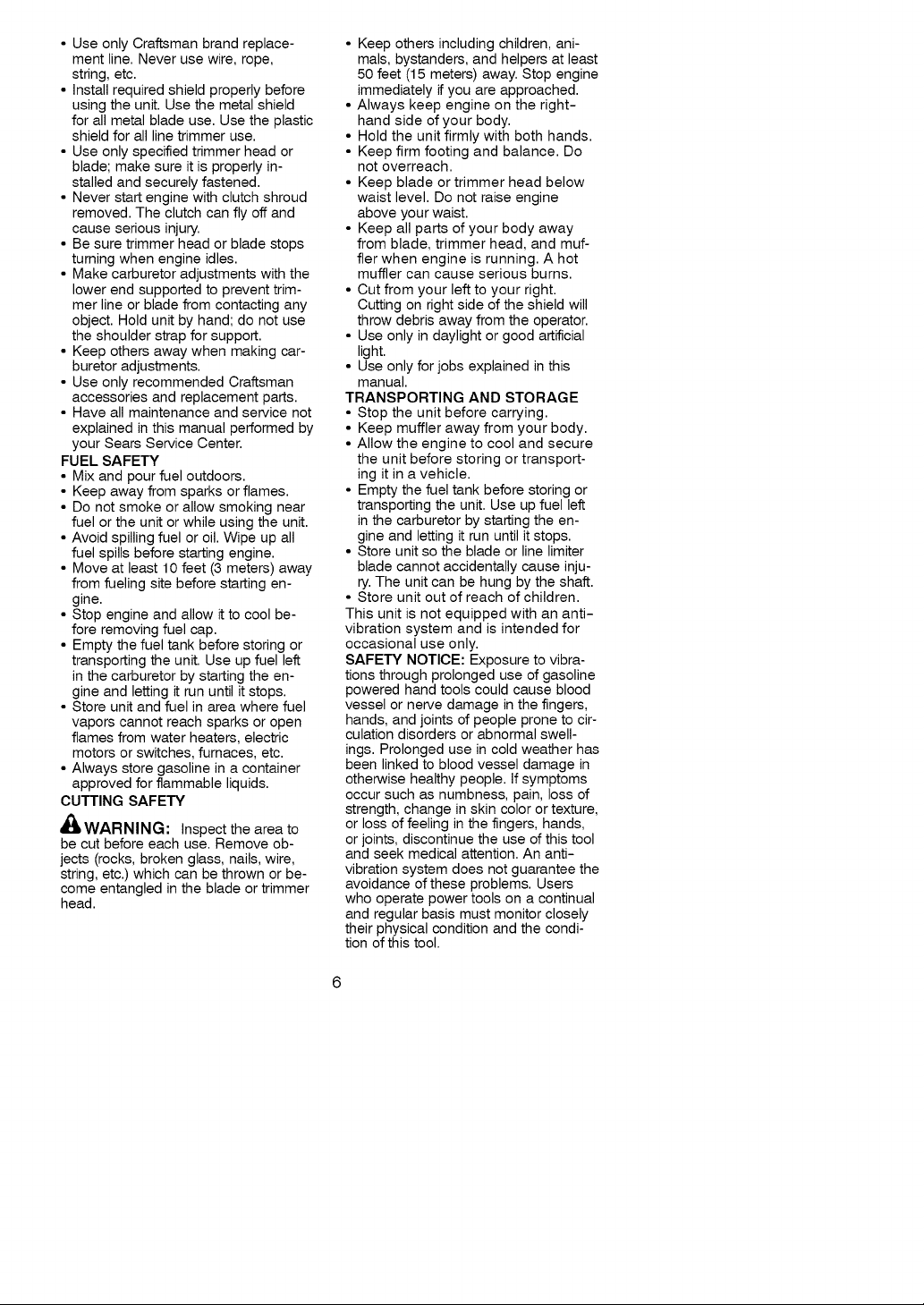

1,

Loosen the coupler by turning the

knob counterclockwise.

Coupler

Shipping

protector

TIGHTEN

2. Remove shipping protector from

coupler.

3. Remove the shaft cap from the

attachment (if present).

4. Position locking/release button of

attachment into guide recess of

coupler.

5. Push the attachment into the cou-

pler until the locking/release button

snaps into the primary hole.

6. Before using the unit, tighten the

knob securely by turning clockwise.

Coupler Primary Hole

_/ Guide Recess

/ Locking/ " "

Upper Release Attachment

Shaft

dlIIWARNING: Make sure the lock-

ing/release button is locked in the pri-

mary hole and the knob is securely

tightened before operating the unit. All

attachments are designed to be used in

the primary hole unless otherwise

stated in the applicable attachment op-

erator's manual. Using the wrong hole

could lead to serious injury or damage

to the unit.

Button

LOOSEN

Knob

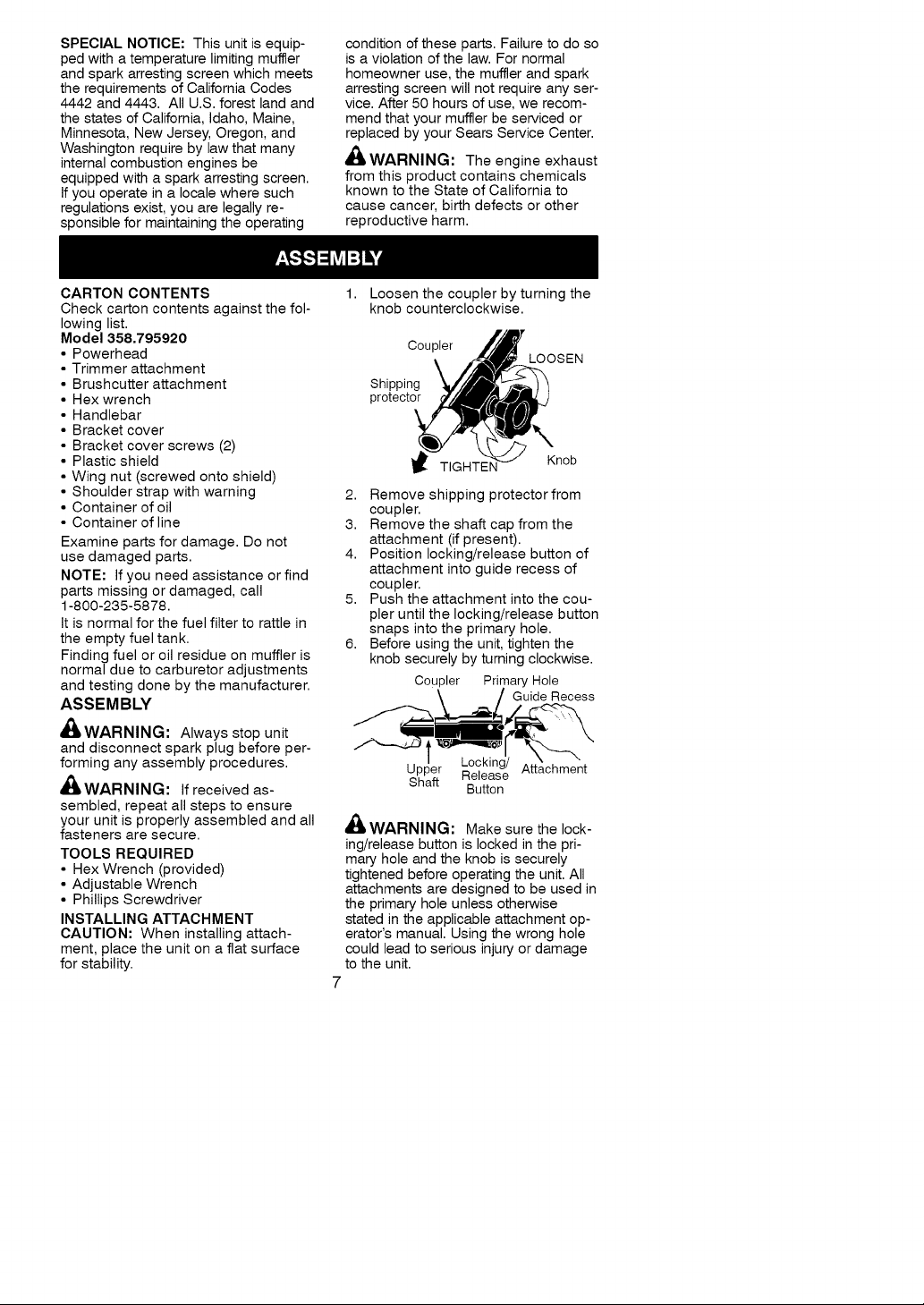

Locking/Release

Button in Primary Hole

For assembly of optional attachments

(see list on page 13), refer to the

ASSEMBLY section of the applicable

attachment operator's manual.

ASSEMBLY INFORMATION -

LINE TRIMMER ATTACHMENT

%t TRIMMER

HEAD

INSTALLATION OF THE TRIMMER

HEAD

NOTE: Before installing the trimmer

head, make sure the dust cup and re-

taining washer are positioned on the

shaft of the gearbox. The retaining

washer must be positioned with the

raised section toward the gearbox.

1. Align hole in the dust cup with the

hole in the side of the gearbox by

rotating the dust cup.

2. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

trimmer head.

NOTE: Make sure all parts are prop-

erly installed as shown in the illustra-

tion before installing the trimmer head.

3. While holding the screwdriver in

position, thread trimmer head onto

the shaft by turning counterclock-

wise (looking from bottom of unit).

Only tighten hand tight!

GearboxJ__

Dust cup _ \

_ Aligned holes

Retaining

washer _,

Trimmer head L_--_J_i,_

4. Remove the screwdriver.

ATTACHING THE PLASTIC SHIELD

_IkWARNING: The shield must be

properly installed. The shield provides

partial protection from the risk of

thrown objects to the operator and

others and is equipped with a line lim-

iter blade which cuts excess line to the

proper length. The line limiter blade

(on underside of shield) is sharp and

can cut you.

1. Remove wing nut from shield.

2. Insert bracket into slot on shield.

3. Pivot shield until bolt )asses

through hole in bracket.

4,

Reinstall wing nut and tighten se-

curely.

4

Shield

Slot

ADJUSTING THE HANDLE

,i_ WARNING: When adjusting the

assist handle, be sure it remains above

the safety label and below the mark or

arrow on the shaft.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an

upright position; retighten wing nut.

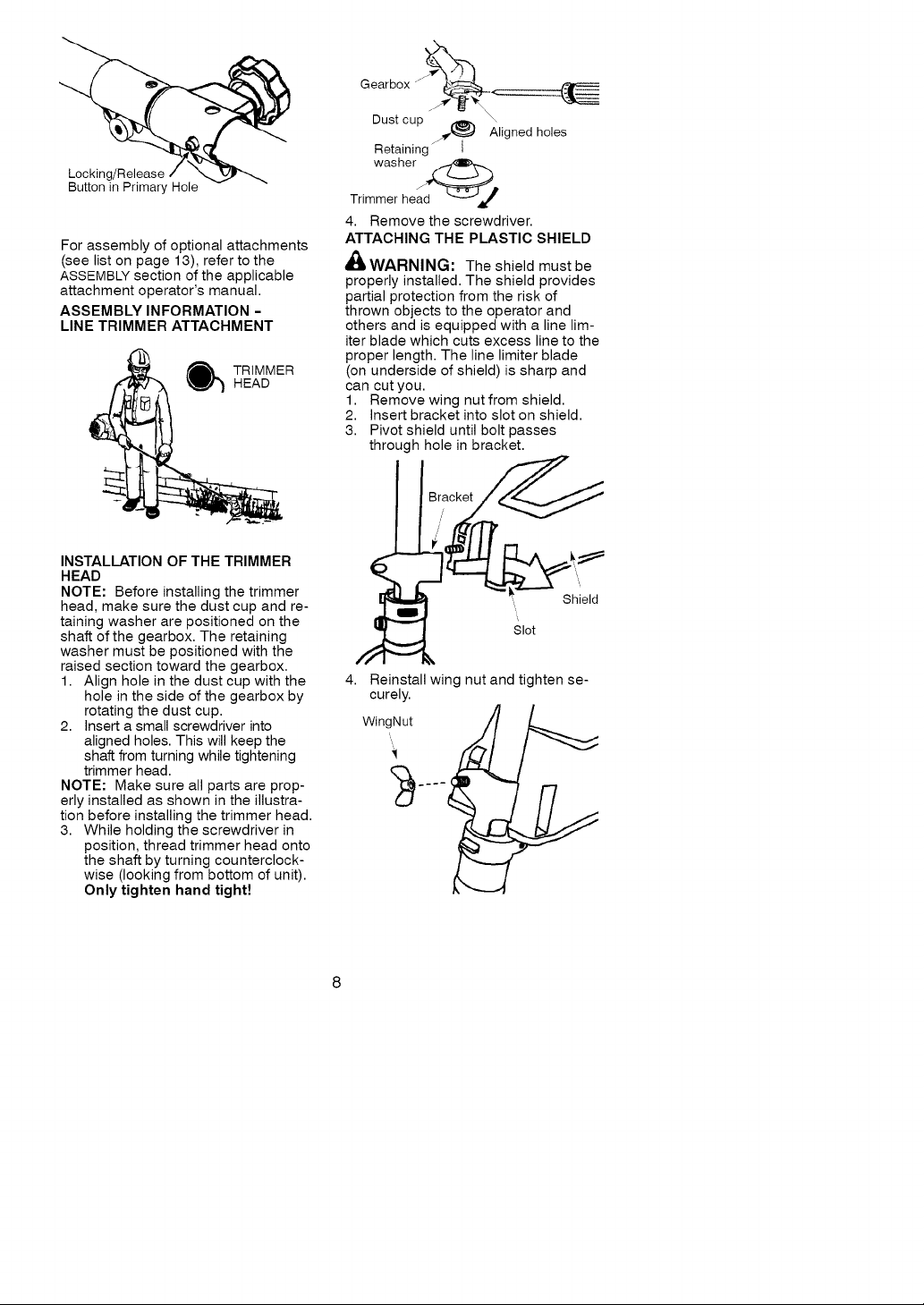

ASSEMBLY INFORMATION -

BRUSHCUTTER ATTACHMENT

WEED

BLADE

ATTACHING THE HANDLEBAR

_I, DANGER: Ensure handlebar

is installed when using brushcutter

attachment. To avoid serious injury,

the barrier portion of the handlebar

must be installed as shown to provide

a barrier between operator and the

spinning blade.

1. Locate the decal on the handlebar.

This decal includes an arrow. Posi-

tion the handlebar with the mount-

ing bracket at the end of the arrow.

2. Position the bracket cover over the

handlebar. Again make sure the

handlebar is at the end of the arrow.

3. Insert screws and hand tighten

only. Be sure the handlebar is

installed correctly; then, tighten

each screw securely with the hex

wrench.

Handlebar , ,,_---Screw

Shoulder _

trap Clamp _ J)

_ Bracket Cover

Mounting - _"_

Bracket

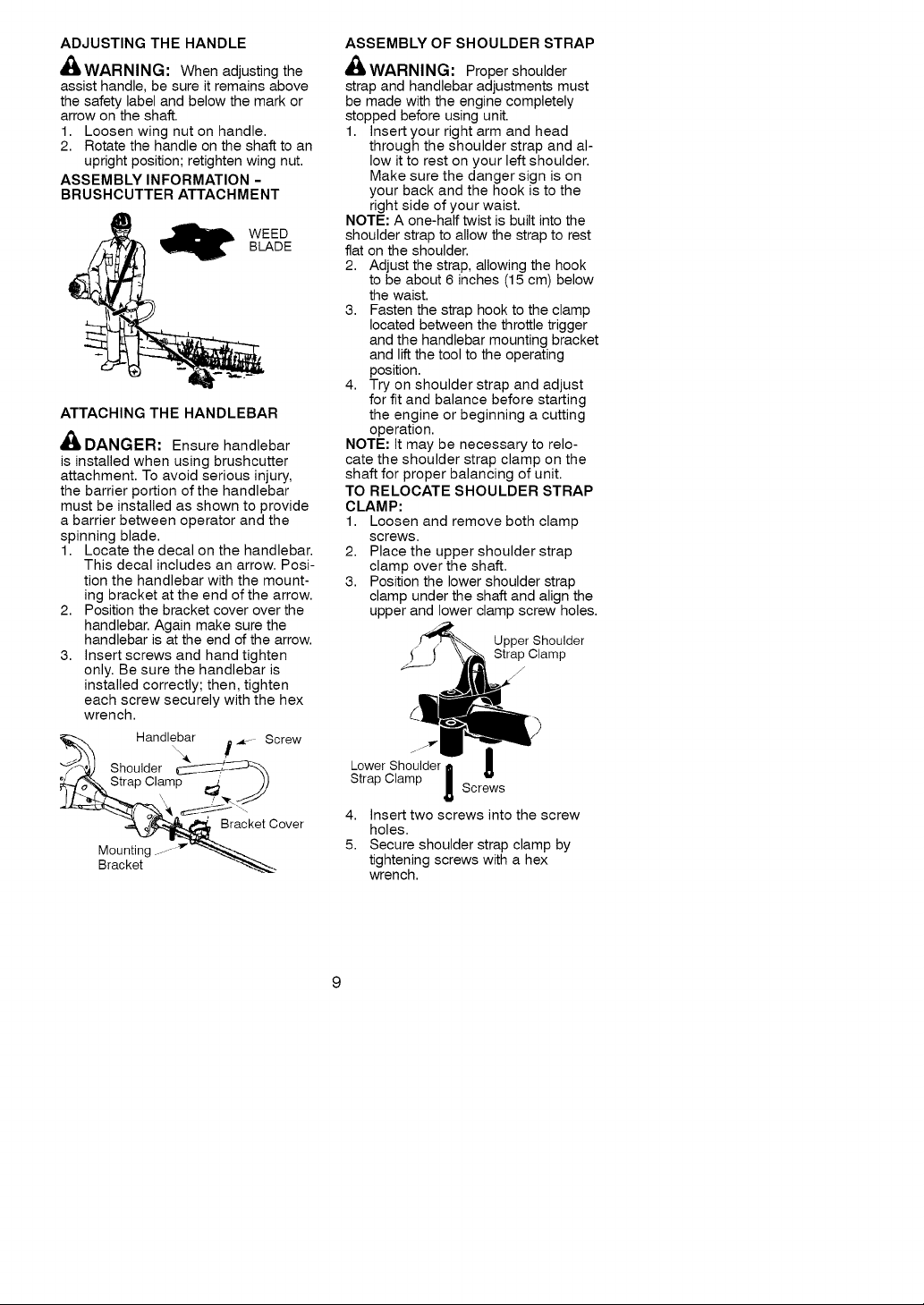

ASSEMBLY OF SHOULDER STRAP

,I_WARNING: Proper shoulder

strap and handlebar adjustments must

be made with the engine completely

stopped before using unit.

1. Insert your right arm and head

through the shoulder strap and al-

low it to rest on your left shoulder.

Make sure the danger sign is on

your back and the hook is to the

right side of your waist.

NOTE: A one-half twist is built into the

shoulder strap to allow the strap to rest

flat on the shoulder.

2. Adjust the strap, allowing the hook

to be about 6 inches (15 cm) below

the waist.

3. Fasten the strap hook to the clamp

located between the throttle trigger

and the handlebar mounting bracket

and lift the tool to the operating

position.

4. Try on shoulder strap and adjust

for fit and balance before starting

the engine or beginning a cutting

operation.

NOTE: It may be necessary to relo-

cate the shoulder strap clamp on the

shaft for proper balancing of unit.

TO RELOCATE SHOULDER STRAP

CLAMP:

1. Loosen and remove both clamp

screws.

2. Place the upper shoulder strap

clamp over the shaft.

3. Position the lower shoulder strap

clamp under the shaft and align the

upper and lower clamp screw holes.

Upper Shoulder

Strap Clamp

J

j. j_l,-

I

Lower Shoulder II A

Strap Clamp ! Screws

4. Insert two screws into the screw

holes.

5. Secure shoulder strap clamp by

tightening screws with a hex

wrench.

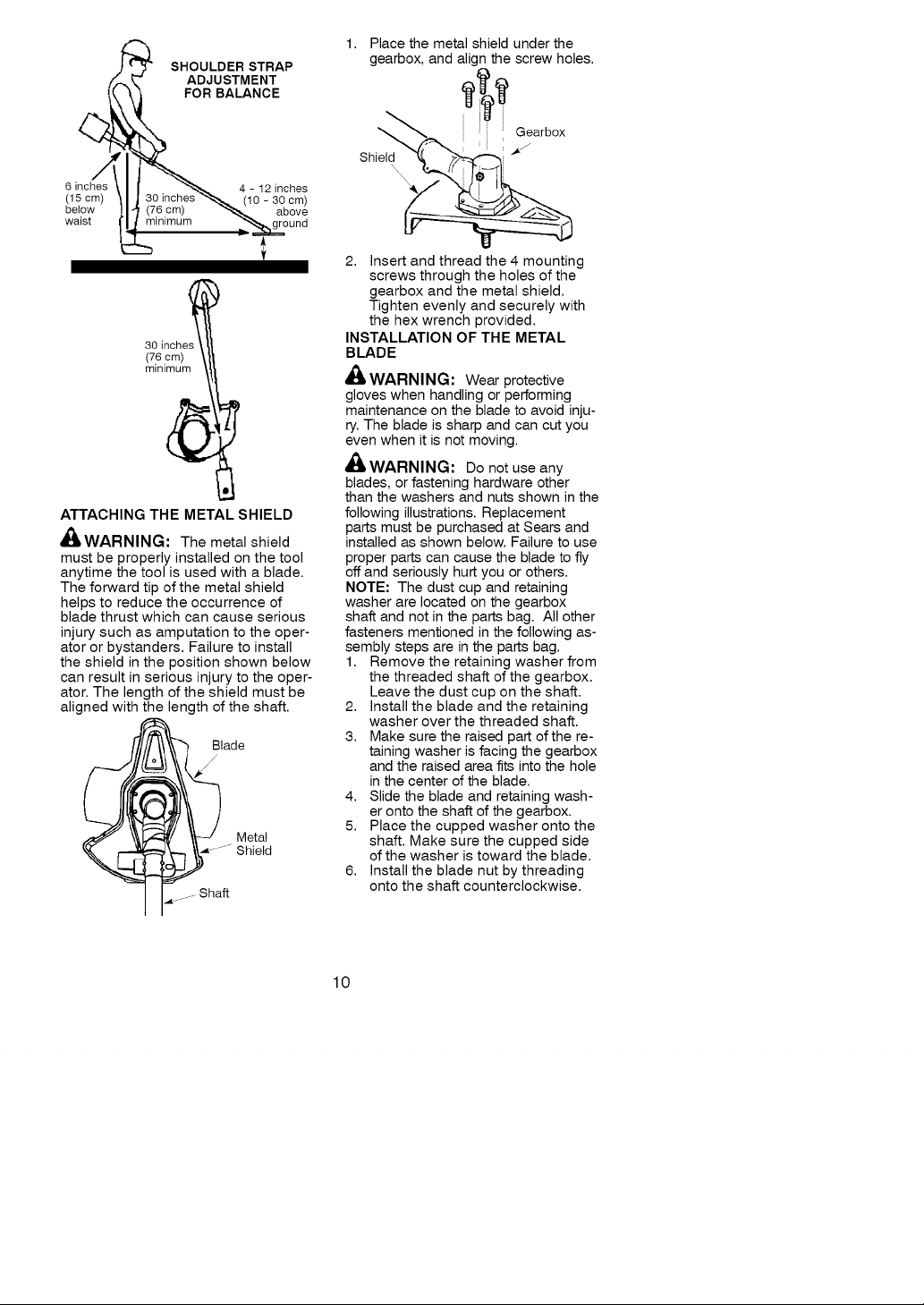

SHOULDER STRAP

ADJUSTMENT

FOR BALANCE

1. Place the metal shield under the

gearbox, and align the screw holes.

.'-..

6 inches 4 - 12 inches

(15 cm) (10 - 30 cm)

below above

waist round

30 inches

(76 cm)

minimum

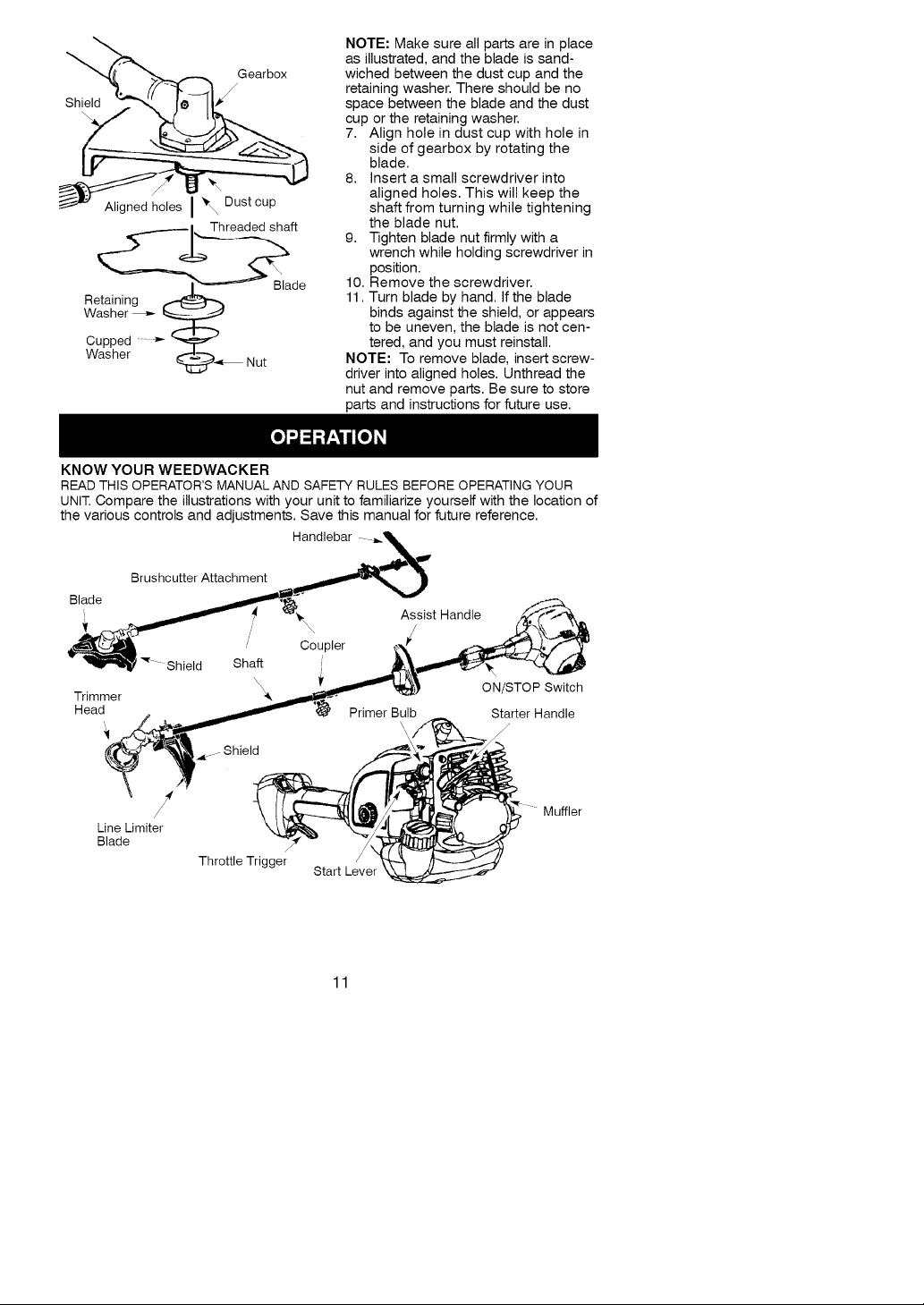

ATTACHING THE METAL SHIELD

,_IkWARNING: The metal shield

must be properly installed on the tool

anytime the tool is used with a blade.

The forward tip of the metal shield

helps to reduce the occurrence of

blade thrust which can cause serious

injury such as amputation to the oper-

ator or bystanders. Failure to install

the shield in the position shown below

can result in serious injury to the oper-

ator. The length of the shield must be

aligned with the length of the shaft.

lade

I p Sha

ShielX ; i

2. Insert and thread the 4 mounting

screws through the holes of the

gearbox and the metal shield.

Tighten evenly and securely with

the hex wrench provided.

INSTALLATION OF THE METAL

BLADE

'_ WARNING: Wear protective

gloves when handling or performing

maintenance on the blade to avoid inju-

ry. The blade is sharp and can cut you

even when it is not moving.

_,WARNING: Do not use any

blades, or fastening hardware other

than the washers and nuts shown in the

following illustrations. Replacement

parts must be purchased at Sears and

installed as shown below. Failure to use

proper parts can cause the blade to fly

off and seriously hurt you or others.

NOTE: The dust cup and retaining

washer are located on the gearbox

shaft and not in the parts bag. All other

fasteners mentioned in the following as-

sembly steps are in the parts bag.

1. Remove the retaining washer from

the threaded shaft of the gearbox.

Leave the dust cup on the shaft.

2. Install the blade and the retaining

washer over the threaded shaft.

3. Make sure the raised part of the re-

taining washer is facing the gearbox

and the raised area fits into the hole

in the center of the blade.

4. Slide the blade and retaining wash-

er onto the shaft of the gearbox.

5. Place the cupped washer onto the

shaft. Make sure the cupped side

of the washer is toward the blade.

6. Install the blade nut by threading

onto the shaft counterclockwise.

10

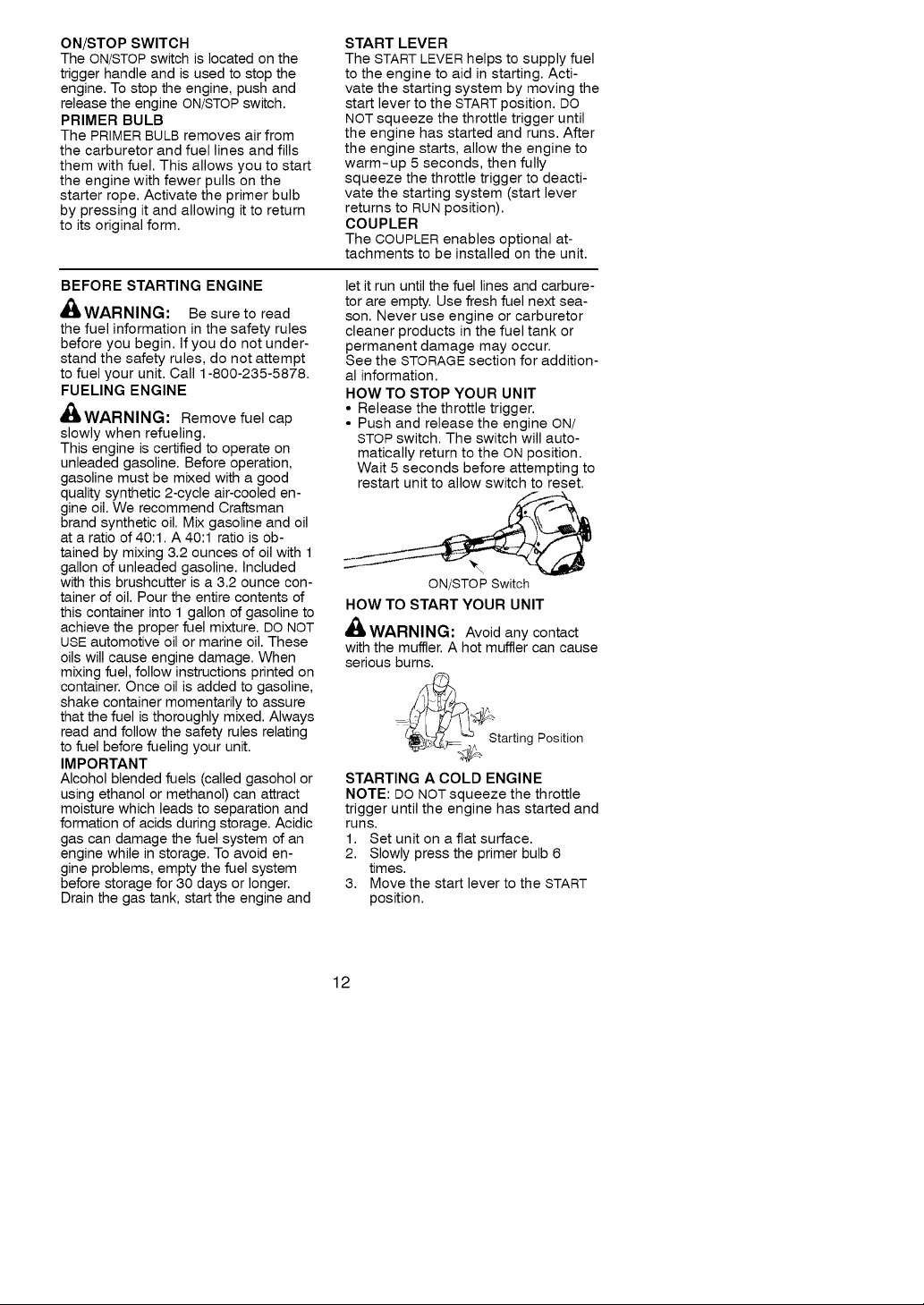

NOTE: Make sure all parts are in place

Gearbox

/

Shield

as illustrated, and the blade is sand-

wiched between the dust cup and the

retaining washer. There should be no

space between the blade and the dust

cup or the retaining washer.

7. Align hole in dust cup with hole in

side of gearbox by rotating the

blade.

8. Insert a small screwdriver into

aligned holes. This will keep the

Aligned holes J _ Dust cup

_l Threaded shaft

shaft from turning while tightening

the blade nut.

9. Tighten blade nut firmly with a

wrench while holding screwdriver in

position.

Re_ de

Washer _

Cupped ....._

Washer _i_-,t Nut

10. Remove the screwdriver.

11. Turn blade by hand. If the blade

binds against the shield, or appears

to be uneven, the blade is not cen-

tered, and you must reinstall.

NOTE: To remove blade, insert screw-

driver into aligned holes. Unthread the

nut and remove parts. Be sure to store

parts and instructions for future use.

KNOW YOUR WEEDWACKER

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT.Compare the illustrations with your unit to familiarize yourself with the location of

the various controls and adjustments. Save this manual for future reference.

Handlebar

Brushcutter Attachment

Blade

Assist Handle __

_' \ / (2"i\\ ._._

_ Coupler _,_k __,_

_1 Shield Shaft i _'__

_. _. __) ON/STOP Switch

I_reJamdmer. _" Primer B_lb Starter Handle

.,_ --Shield

/ Muffler

Line Limiter

Blade

Throttle Trigger /

Start Lever

11

ON/STOP SWITCH

The ON/STOP switch is located on the

trigger handle and is used to stop the

engine. To stop the engine, push and

release the engine ON/STOPswitch.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate the primer bulb

by pressing it and allowing it to return

to its original form.

START LEVER

The START LEVER helps to supply fuel

to the engine to aid in starting. Acti-

vate the starting system by moving the

start lever to the START position. DO

NOT squeeze the throttle trigger until

the engine has started and runs. After

the engine starts, allow the engine to

warm-up 5 seconds, then fully

squeeze the throttle trigger to deacti-

vate the starting system (start lever

returns to RUN position).

COUPLER

The COUPLER enables optional at-

tachments to be installed on the unit.

BEFORE STARTING ENGINE

_ILWARNING: Be sureto read

the fuel information in the safety rules

before you begin. If you do not under-

stand the safety rules, do not attempt

to fuel your unit. Call 1-800-235-5878.

FUELING ENGINE

_ILWARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality synthetic 2-cycle air-cooled en-

gine oil. We recommend Craftsman

brand synthetic oil. Mix gasoline and oil

at a ratio of 40:1. A 40:1 ratio is ob-

tained by mixing 3.2 ounces of oil with 1

gallon of unleaded gasoline. Included

with this brushcutter is a 3.2 ounce con-

tainer of oil. Pour the entire contents of

this container into 1 gallon of gasoline to

achieve the proper fuel mixture. DO NOT

USE automotive oil or marine oil. These

oils will cause engine damage. When

mixing fuel, follow instructions printed on

container. Once oil is added to gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed. Always

read and follow the safety rules relating

to fuel before fueling your unit.

IMPORTANT

Alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract

moisture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage. To avoid en-

gine problems, empty the fuel system

before storage for 30 days or longer.

Drain the gas tank, start the engine and

let it run until the fuel lines and carbure-

tor are empty. Use fresh fuel next sea-

son. Never use engine or carburetor

cleaner products in the fuel tank or

permanent damage may occur.

See the STORAGE section for addition-

al information.

HOW TO STOP YOUR UNIT

• Release the throttle trigger.

• Push and release the engine ON/

STOP switch. The switch will auto-

matically return to the ON position.

Wait 5 seconds before attempting to

restart unit to allow switch to reset.

ON/STOP Switch

HOW TO START YOUR UNIT

WARNING: Avoid any contact

with the muffler. A hot muffler can cause

serious burns.

Starting Position

STARTING A COLD ENGINE

NOTE: DO NOT squeeze the throttle

trigger until the engine has started and

runs.

1. Set unit on a flat surface.

2. Slowly press the primer bulb 6

times.

3. Move the start lever to the START

position.

12

Primer Bulb

Starter Handle

\

Start Lever

4. This unit has the Sim-pulTM starting

system. You do not have to pull the

starter rope handle sharply or brisk-

ly. Pull starter rope handle with a

controlled and steady motion until

engine starts and runs.

5. Allow unit to run for 5 seconds, then

fully squeeze the throttle trigger to

disengage the starting system (start

lever returns to RUN position) and

begin normal operation.

STARTING A WARM ENGINE

Pull starter rope handle with a con-

trolled and steady motion until engine

starts and runs.

NOTE: Normally, the warm starting

procedure can be used within 5-10

minutes after the unit is turned off. If

the unit sits for more than 10 minutes

without being used, it will be neces-

sary to start the unit by following the

steps under STARTING A COLD EN-

GINE or following the starting instruc-

tion steps shown on the unit.

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the start lever in the RUN posi-

tion. Fully squeeze throttle trigger.

Pull the starter handle repeatedly

while squeezing throttle trigger until

engine starts and runs. This could re-

quire pulling the starter handle many

times, depending on how badly the

unit is flooded. If the unit still doesn't

start, refer to TROUBLESHOOTING

TABLE or call 1-800-235-5878.

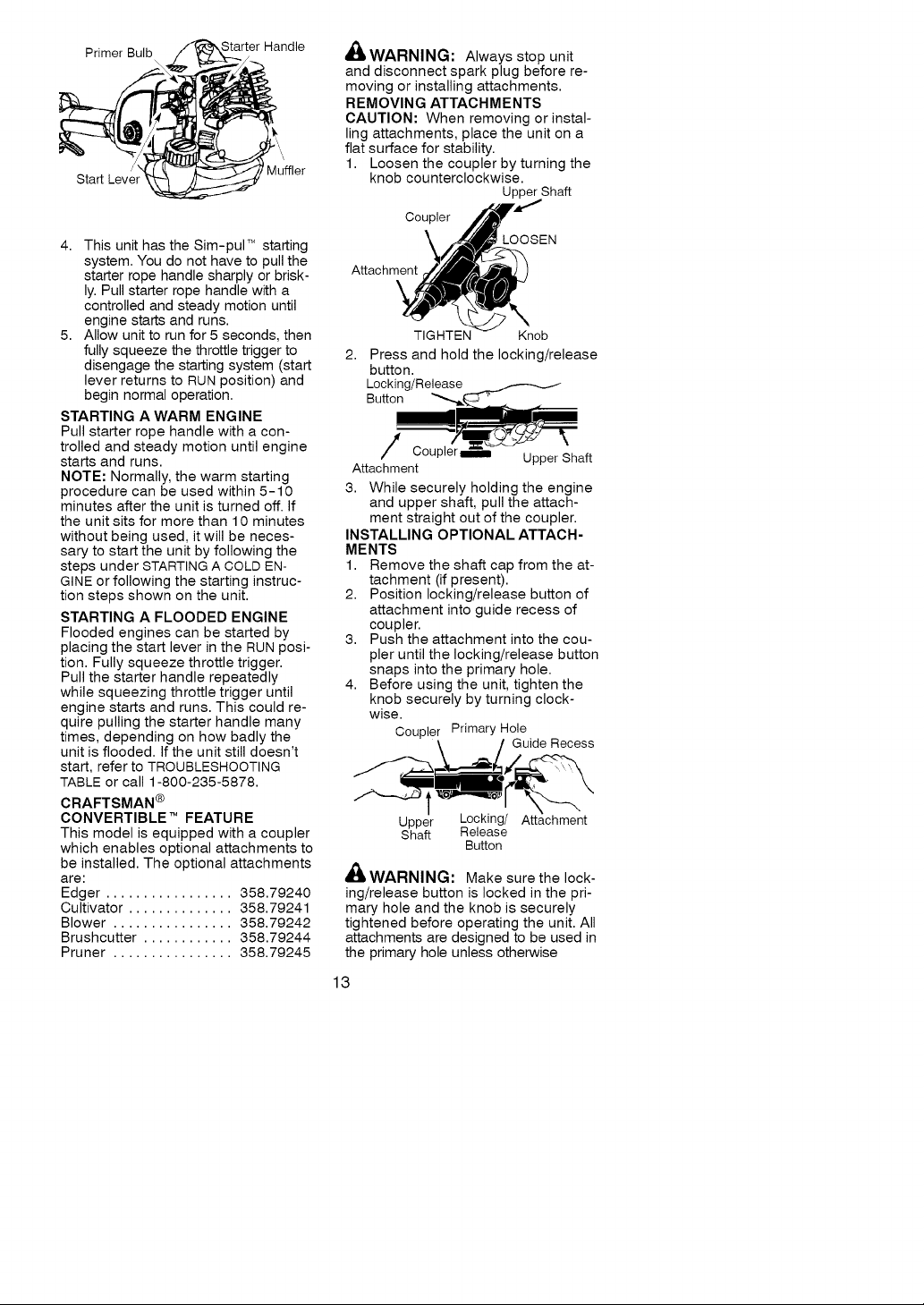

CRAFTSMAN ®

CONVERTIBLE TM FEATURE

This model is equipped with a coupler

which enables optional attachments to

be installed. The optional attachments

are:

Edger ................. 358.79240

Cultivator .............. 358.79241

Blower ................ 358.79242

Brushcutter ............ 358.79244

Pruner ................ 358.79245

Muffler

,_ WARNING: Always stop unit

and disconnect spark plug before re-

moving or installing attachments.

REMOVING ATTACHMENTS

CAUTION: When removing or instal-

ling attachments, place the unit on a

flat surface for stability.

1. Loosen the coupler by turning the

knob counterclockwise.

Coupler

Attachment

Upper Shaft

LOOSEN

\

TIGHTEN Knob

2,

Press and hold the locking/release

button.

Locking/Release

Button

Attachment

3. While securely holding the engine

INSTALLING OPTIONAL ATTACH-

MENTS

1. Remove the shaft cap from the at-

2. Position locking/release button of

3. Push the attachment into the cou-

4. Before using the unit, tighten the

,_WARNING: Make surethe lock-

ing/release button is locked in the pri-

mary hole and the knob is securely

tightened before operating the unit. All

attachments are designed to be used in

the primary hole unless otherwise

13

Cou_ Upper Shaft

and upper shaft, pull the attach-

ment straight out of the coupler.

tachment (if present).

attachment into guide recess of

coupler.

pler until the locking/release button

snaps into the primary hole.

knob securely by turning clock-

wise.

Coupler Primary Hole

Upper Locking/ Attachment

Shaft Release

Guide Recess

Button

stated in the applicable attachment op-

erator's manual. Using the wrong hole

could lead to serious injury or damage

to the unit.

Locking/Release

Button in Primary Hole

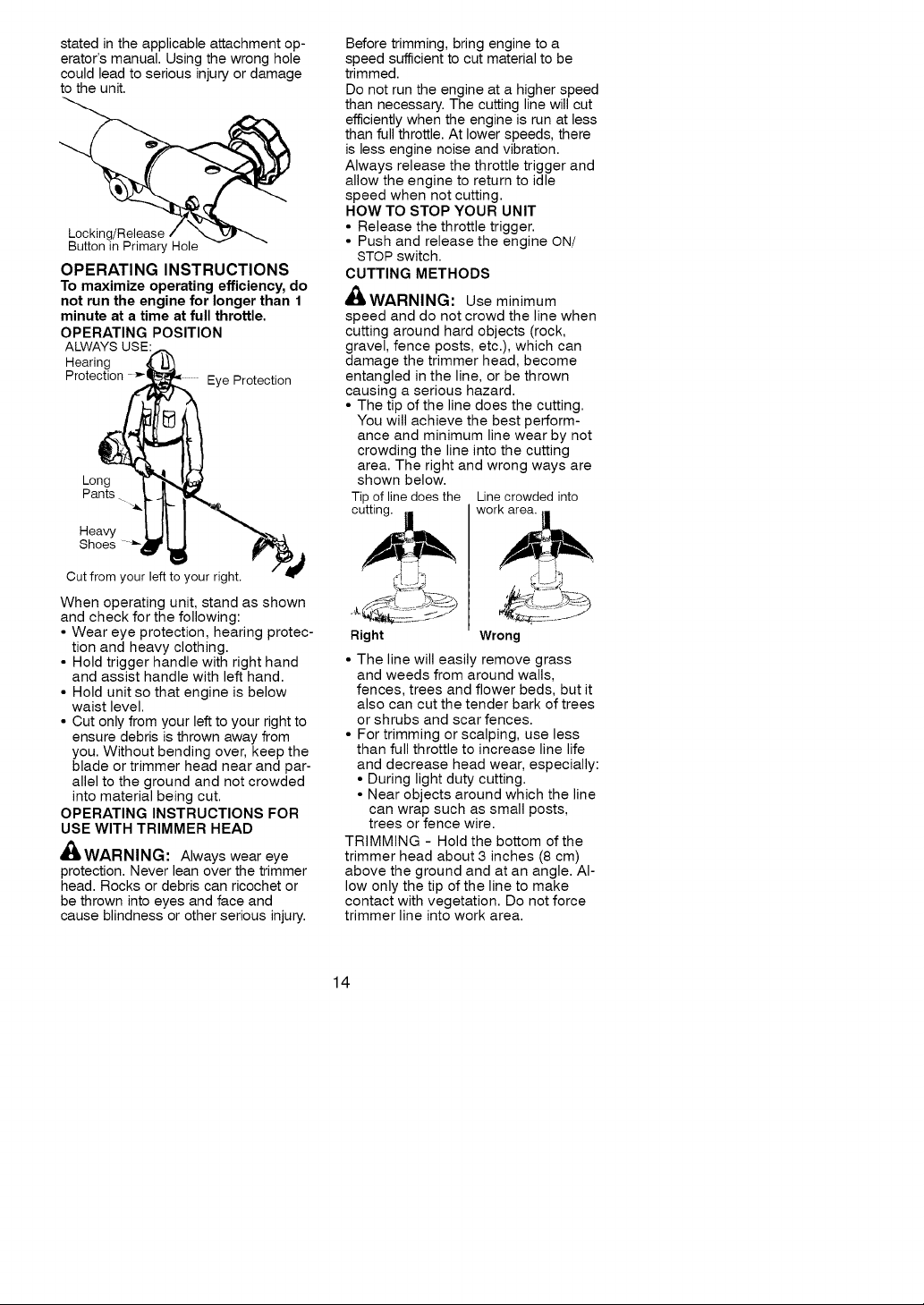

OPERATING INSTRUCTIONS

To maximize operating efficiency, do

not run the engine for longer than 1

minute at a time at full throttle.

OPERATING POSITION

ALWAYS USE:

Hearing J-t

Protection Eye Protection

Long

Pants

Shoes

Heavy _,I_

Cutfrom yourle_to yourright.

When operating unit, stand as shown

and check for the following:

• Wear eye protection, hearing protec-

tion and heavy clothing.

• Hold trigger handle with right hand

and assist handle with left hand.

• Hold unit so that engine is below

waist level.

• Cut only from your left to your right to

ensure debris is thrown away from

you. Without bending over, keep the

blade or trimmer head near and par-

allel to the ground and not crowded

into material being cut.

OPERATING INSTRUCTIONS FOR

USE WITH TRIMMER HEAD

WAR NI N G: Always wear eye

protection. Never lean over the trimmer

head. Rocks or debris can ricochet or

be thrown into eyes and face and

cause blindness or other serious injury.

Before trimming, bring engine to a

speed sufficient to cut material to be

trimmed.

Do not run the engine at a higher speed

than necessary. The cutting line will cut

efficiently when the engine is run at less

than full throttle. At lower speeds, there

is less engine noise and vibration.

Always release the throttle trigger and

allow the engine to return to idle

speed when not cutting.

HOW TO STOP YOUR UNIT

• Release the throttle trigger.

• Push and release the engine ON/

STOP switch.

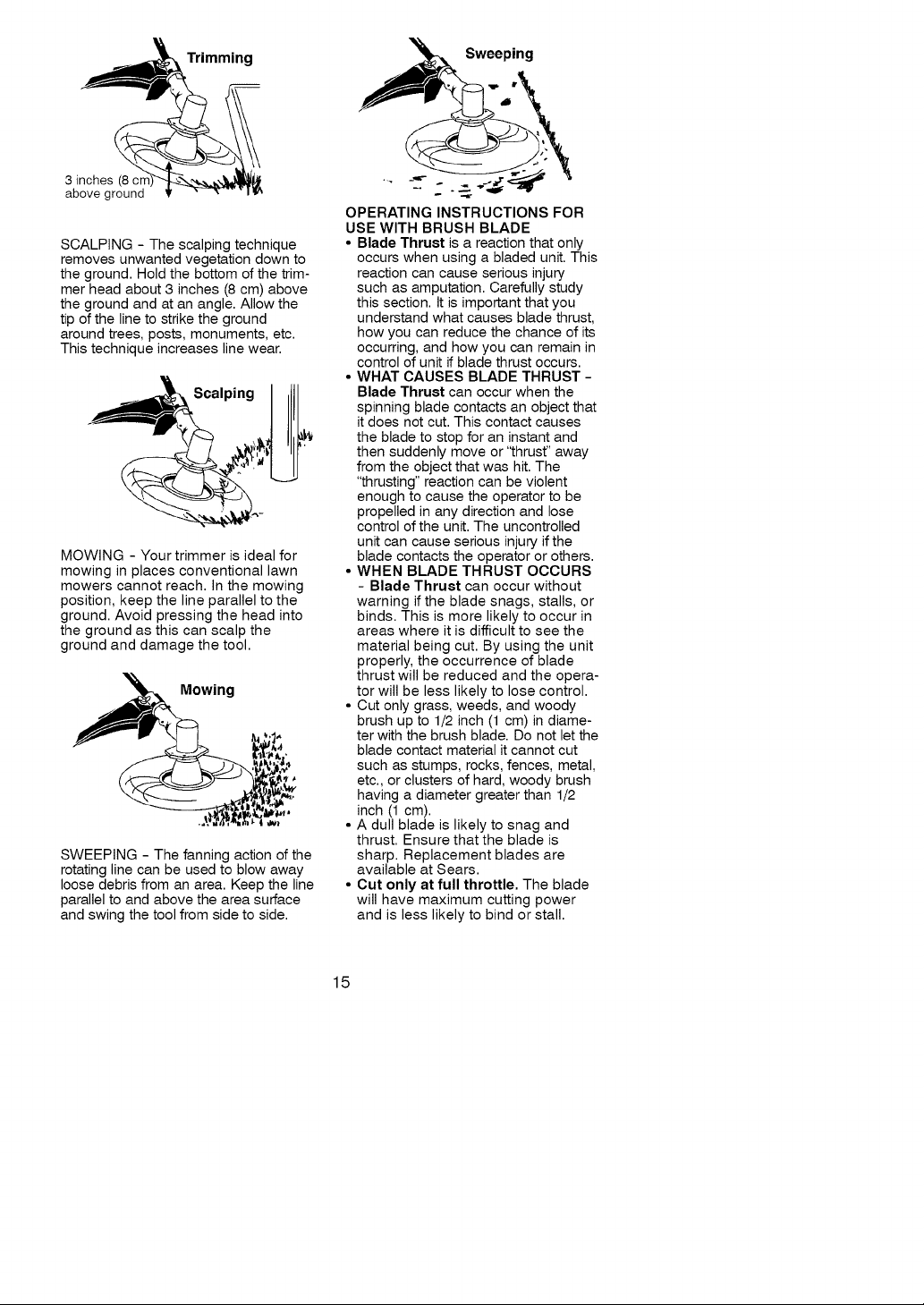

CUTTING METHODS

4(_WARNING: Use minimum

speed and do not crowd the line when

cutting around hard objects (rock,

gravel, fence posts, etc.), which can

damage the trimmer head, become

entangled in the line, or be thrown

causing a serious hazard.

• The tip of the line does the cutting.

You will achieve the best perform-

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

Tip of line does the Line crowded into

cutting, worl

Right Wrong

• The line will easily remove grass

and weeds from around walls,

fences, trees and flower beds, but it

also can cut the tender bark of trees

or shrubs and scar fences.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

• During light duty cutting.

• Near objects around which the line

can wrap such as small posts,

trees or fence wire.

TRIMMING - Hold the bottom of the

trimmer head about 3 inches (8 cm)

above the ground and at an angle. Al-

low only the tip of the line to make

contact with vegetation. Do not force

trimmer line into work area.

14

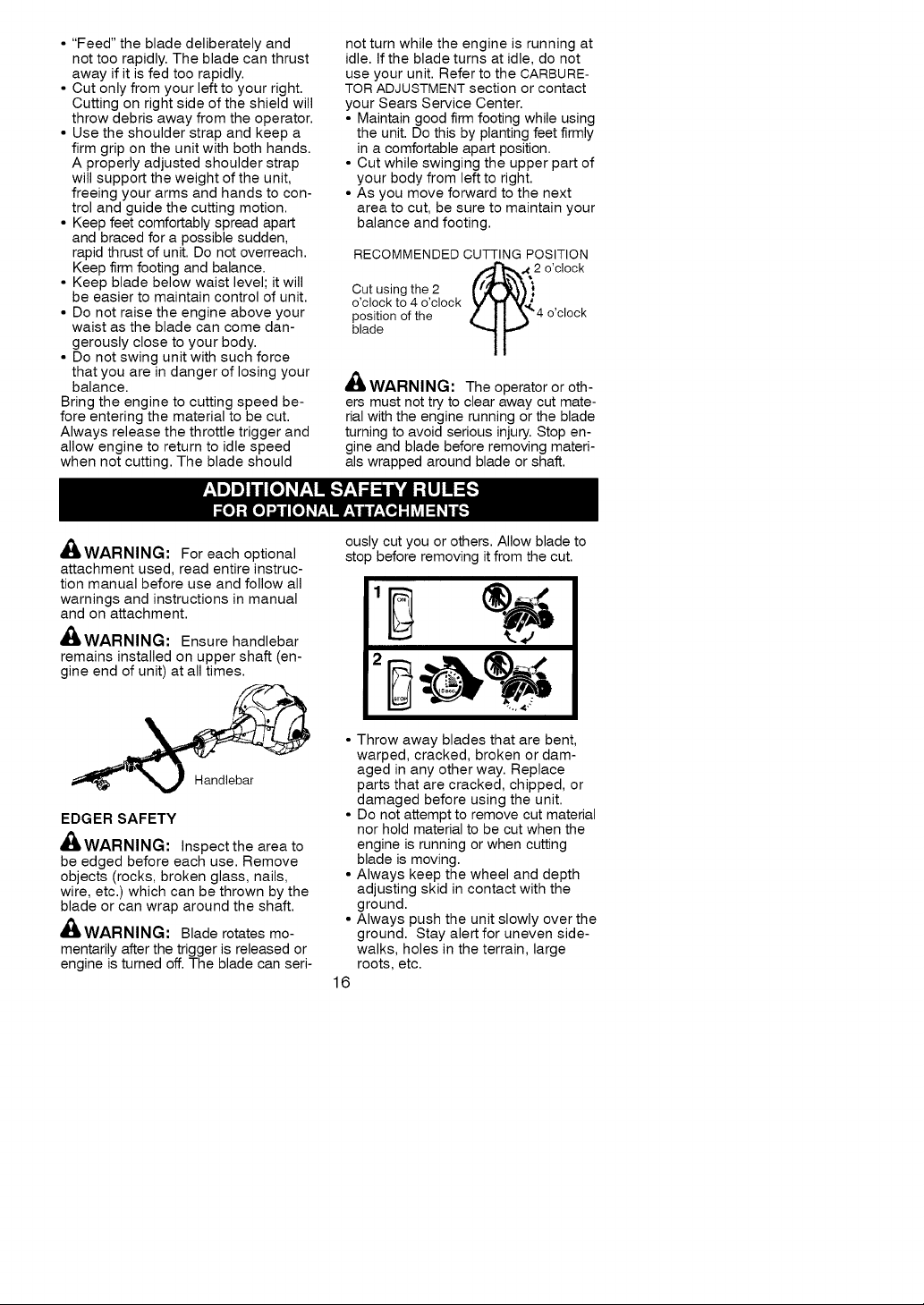

Trimming

3 inches (8 cn

above ground

SCALPING - The scalping technique

removes unwanted vegetation down to

the ground. Hold the bottom of the trim-

mer head about 3 inches (8 cm) above

the ground and at an angle. Allow the

tip of the line to strike the ground

around trees, posts, monuments, etc.

This technique increases line wear.

Scalping

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action of the

rotating line can be used to blow away

loose debris from an area. Keep the line

parallel to and above the area surface

and swing the tool from side to side.

Sweeping

OPERATING INSTRUCTIONS FOR

USE WITH BRUSH BLADE

• Blade Thrust is a reaction that only

occurs when using a bladed unit. This

reaction can cause serious injury

such as amputation. Carefully study

this section. It is important that you

understand what causes blade thrust,

how you can reduce the chance of its

occurring, and how you can remain in

control of unit if blade thrust occurs.

• WHAT CAUSES BLADE THRUST -

Blade Thrust can occur when the

spinning Made contacts an object that

it does not cut. This contact causes

the Made to stop for an instant and

then suddenly move or 'thrust" away

from the object that was hit. The

"thrusting" reaction can be violent

enough to cause the operator to be

propelled in any direction and lose

control of the unit. The uncontrolled

unit can cause serious injury if the

blade contacts the operator or others.

• WHEN BLADE THRUST OCCURS

- Blade Thrust can occur without

warning if the Made snags, stalls, or

binds. This is more likely to occur in

areas where it is difficult to see the

material being cut. By using the unit

properly, the occurrence of blade

thrust will be reduced and the opera-

tor will be less likely to lose control.

• Cut only grass, weeds, and woody

brush up to 1/2 inch (1 cm) in diame-

ter with the brush blade. Do not let the

Made contact material it cannot cut

such as stumps, rocks, fences, metal,

etc., or clusters of hard, woody brush

having a diameter greater than 1/2

inch (1 cm).

• A dull blade is likely to snag and

thrust. Ensure that the blade is

sharp. Replacement blades are

available at Sears.

• Cut only at full throttle. The blade

will have maximum cutting power

and is less likely to bind or stall.

15

• "Feed" the blade deliberately and

not too rapidly. The blade can thrust

away if it is fed too rapidly.

• Cut only from your left to your right.

Cutting on right side of the shield will

throw debris away from the operator.

• Use the shoulder strap and keep a

firm grip on the unit with both hands.

A properly adjusted shoulder strap

will support the weight of the unit,

freeing your arms and hands to con-

trol and guide the cutting motion.

• Keep feet comfortably spread apart

and braced for a possible sudden,

rapid thrust of unit. Do not overreach.

Keep firm footing and balance.

• Keep blade below waist level; it will

be easier to maintain control of unit.

• Do not raise the engine above your

waist as the blade can come dan-

gerously close to your body.

• Do not swing unit with such force

that you are in danger of losing your

balance.

Bring the engine to cutting speed be-

fore entering the material to be cut.

Always release the throttle trigger and

allow engine to return to idle speed

when not cutting. The blade should

_WARNING: For each optional

attachment used, read entire instruc-

tion manual before use and follow all

warnings and instructions in manual

and on attachment.

,_WARNING: Ensure handlebar

remains installed on upper shaft (en-

gine end of unit) at all times.

not turn while the engine is running at

idle. If the blade turns at idle, do not

use your unit. Refer to the CARBURE-

TOR ADJUSTMENT section or contact

your Sears Service Center.

• Maintain good firm footing while using

the unit. Do this by planting feet firmly

in a comfortable apart position.

• Cut while swinging the upper part of

your body from left to right.

• As you move forward to the next

area to cut, be sure to maintain your

balance and footing.

RECOMMENDED CUTTING POSITION

Cut using the 2

o'clock to 4 o'clock

position of the / _ %'€'4o'clock

blade

2 o'clock

'lr-

,_ WARNING:

ers must not try to clear away cut mate-

rial with the engine running or the blade

turning to avoid serious injury. Stop en-

gine and blade before removing materi-

als wrapped around blade or shaft.

ousl

cut you or others. Allow blade to

sto

before removing it from the cut.

The operator or oth-

%, •

EDGER SAFETY

'_ WARNING: Inspect the area to

be edged before each use. Remove

objects (rocks, broken glass, nails,

wire, etc.) which can be thrown by the

blade or can wrap around the shaft.

_WARNING: Blade rotates mo-

mentarily after the trigger is released or

engine is turned off. The blade can seri-

• Throw away blades that are bent,

warped, cracked, broken or dam-

aged in any other way. Replace

parts that are cracked, chipped, or

damaged before using the unit.

• Do not attempt to remove cut material

nor hold material to be cut when the

engine is running or when cutting

blade is moving.

• Always keep the wheel and depth

adjusting skid in contact with the

ground.

• Always push the unit slowly over the

ground. Stay alert for uneven side-

walks, holes in the terrain, large

roots, etc.

16

BLOWER/VACUUM SAFETY

_WARNING: Inspect area before

starting unit. Remove all debris and

hard objects such as rocks, glass,

wire, etc. that can ricochet, be thrown,

or otherwise cause injury or damage

during operation.

• Do not set unit on any surface except

a clean, hard area while engine is

running. Debris such as gravel, sand,

dust, grass, etc., could be picked up

by the air intake and thrown out

through discharge opening, damaging

unit, property, or causing serious injury

to bystanders or operator.

• Never place objects inside the blow-

er tubes, vacuum tubes or blower

outlet. Always direct the blowing de-

bris away from people, animals,

glass, and solid objects such as

trees, automobiles, walls, etc. The

force of air can cause rocks, dirt, or

sticks to be thrown or to ricochet

which can hurt people or animals,

break glass, or cause other damage.

• Never run unit without the proper

equipment attached. When using

your unit as a blower, always install

blower tubes.

• Check air intake opening, blower

tubes or vacuum tubes frequently,

always with engine stopped and

spark plug disconnected. Keep

vents and discharge tubes free of

debris which can accumulate and

restrict proper air flow.

• Never place any object in air intake

opening as this could restrict proper

air flow and cause damage to the unit.

• Never use for spreading chemicals,

fertilizers, or other substances which

may contain toxic materials.

• To avoid spreading fire, do not use

near leaf or brush fires, fireplaces,

barbecue pits, ashtrays, etc.

CULTIVATOR SAFETY

_,WARNING: Rotating tines can

cause serious injury. Keep away from

rotating tines. Stop the engine and dis-

connect the spark plug before unclog-

ging tines or making repairs.

,_ WARNING: Inspect the area to

be cultivated before starting the unit.

Remove all debris and hard and sharp

objects such as rocks, vines,

branches, rope, string, etc.

• Avoid heavy contact with solid objects

that might stop the tines. If heavy con-

tact occurs, stop the engine and in-

spect the unit for damage.

• Never operate the cultivator without

the tine cover in place and properly

secured.

• Keep the tines and guard clear of

debris.

• After striking a foreign object, stop

the engine, disconnect the spark

plug and inspect the cultivator for

damage. Repair before restarting.

• Disconnect attachment from the drive

engine before cleaning the tines with

a hose and water to remove any

build-up. Oil the tines to prevent rust.

• Always wear gloves when servicing or

cleaning the tines. The tines become

very sharp from use.

• Do not run unit at high speed unless

cultivating.

HEDGE TRIMMER SAFETY

DANGER: RISK OF CUT KEEP

HANDS AWAY FROM BLADE - Blade

moves momentarily after the trigger is

released or engine is turned off. Do not

attempt to clear away cut material when

the blade is in motion. Make sure en-

gine is turned off, the spark plug wire is

disconnected, and the blade has

stopped moving before removing

jammed material from the cutting blade.

Do not grab or hold the unit by the cut-

ting blade.

lID ®

1_1111111111_

!............ !

,_ WARNING: Inspect the area be-

fore starting the unit. Remove all de-

bris and hard objects such as rocks,

glass, wire, etc. that can ricochet, be

thrown, or otherwise cause injury or

damage during operation.

• Do not use a cutting blade that is

bent, warped, cracked, broken or

damaged in any other way. Have

17

wornordamagedpartsreplacedby

anauthorizedservicedealer.

•Alwayskeepunitinfrontofyour

body.Keepallpartsofyourbody

awayfromthecuttingblade.

• Keepthecuttingbladeandairvents

clearofdebris.

POLEPRUNERSAFETY

'_ WARNING: The reciprocating

Made/ rotating chain can cause se-

vere injury. Inspect the unit before

use. Do not operate unit with a bent,

cracked or dull blade or dull chain.

Keep away from the blade/chain.

WARNING: The reciprocating

blade/rotating chain is sharp. Do not

touch. To prevent serious injury, always

stop engine and ensure blade/chain

has stopped moving, disconnect spark

plug, and wear gloves when changing

or handling the blade or chain.

WAR NI N G: A coasting blade/ro-

tating chain can cause injury while it

continues to move after the engine is

stopped. Maintain proper control of the

unit until the blade/chain has completely

stopped moving. Keep hands, face and

feet at a distance from all moving parts.

Do not attempt to touch or stop the

blade or chain when it is moving.

WARNING: Keep the pruner

away from power lines or electrical

wires.

• Only use for pruning limbs or

branches up to 6 inches (15 cm) in

diameter.

• Do not operate the unit faster than

the speed needed to prune. Do not

run the unit at high speed when not

pruning.

• Always stop the unit when work is

delayed or when walking from one

cutting location to another.

• If you strike or become entangled

with a foreign object, stop the engine

immediately and check for damage.

Have any damage repaired by an

authorized service dealer before at-

tempting further operations. Discard

blades that are bent, warped,

cracked or broken.

• Stop the unit immediately if you feel

excessive vibration. Vibration is a sign

of trouble. Inspect thoroughly for loose

nuts, bolts or damage before continu-

ing. Contact an authorized service

dealer for repair or replacement of af-

fected parts as necessary.

SNOW THROWER SAFETY

WARNING: Keep hands and

feet away from the rotor when starting

or running the engine. Never attempt

to clear the rotor with the engine run-

ning. Stop engine and disconnect

spark plug before unclogging snow or

debris from discharge chute or when

adjusting vanes.

,_LWARNING: Falling objects can

cause severe head injury. Wear head

protection when operating this unit

with a pole pruner attachment.

WAR NI N G: To prevent serious

injury, do not use more than one boom

extension with a pole pruner attach-

ment.

Z_

_,WARNING: Never lean over dis-

charge chute. Rocks or debris could

be thrown into the eyes and face and

cause serious injury or blindness.

,_ WARNING: Inspect the area

where the unit is to be used. Remove

objects that could be thrown or dam-

age the unit. Some objects may be

hidden by fallen snow - be alert for

the possibility.

• Direct material discharge away from

glass enclosures, automobiles, etc.

18

• Do not run engine at high speed

while not removing snow.

• Be attentive when using the snow-

thrower, and stay alert for holes in the

terrain and other hidden hazards.

• Make sure the rotor will spin freely be-

fore attaching the snowthrower to the

powerhead.

• If the rotor will not rotate freely due

to frozen ice, thaw the unit before

thoroughly before attempting to op-

erate under power.

• Keep the rotor clear of debris.

• Do not throw snow near other

people. The snow thrower could pro-

pel small objects at high speed

causing injury.

• After striking a foreign object, stop

the engine, disconnect spark plug

and inspect the snowthrower for

damage and repair if necessary be-

fore restarting unit.

MAINTENANCE SCHEDULE

,_ WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

CARE & MAINTENANCE TASK

Check for loose fasteners and parts

Check for damaged or worn parts

Inspect and clean unit and decals

Clean air filter

Inspect muffler and spark arresting screen

Replace spark plug

• Never operate the snowthrower near

glass enclosures, automobiles and

trucks.

• Never attempt to use the snow-

thrower on a roof.

• Never operate the snowthrower near

window wells, dropoffs, etc.

• Never discharge snow onto public

roads or near moving traffic.

• Clear snow from slopes by going up

and down; never across. Use cau-

tion when changing directions. Nev-

er clear snow from steep slopes.

• Let snowthrower run for a few min-

utes after clearing snow so moving

parts do not freeze.

• Look behind and use care when

backing up. Exercise caution to avoid

slipping or falling, especially when op-

erating in reverse.

• Know how to stop quickly.

WHEN TO PERFORM

Before each use

Before each use

After each use

Every 5 hours of operation

Every 50 hours of operation

Yearly

GENERAL RECOMMENDATIONS

The warranty on this unit does not

cover items that have been subjected

to operator abuse or negligence. To

receive full value from the warranty,

the operator must maintain unit as

instructed in this manual. Various ad-

justments will need to be made peri-

odically to properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

• Blade Nut

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re-

placement of damaged or worn parts.

• ON/STOP Switch - Ensure ON/STOP

switch functions properly by pushing

and releasing the switch. Make sure

engine stops. Wait 5 seconds before

attempting to restart unit to allow

switch to reset. Restart engine and

continue.

• Fuel Tank - Discontinue use of unit

if fuel tank shows signs of damage

or leaks.

• Debris Shield - Discontinue use of

unit if debris shield is damaged.

• Blade - Discontinue use of unit if

blade becomes damaged or worn.

INSPECT AND CLEAN UNIT AND

DECALS

• After each use, inspect complete

unit for loose or damaged parts.

Clean the unit and decals using a

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

19

CLEANAIRFILTER

Adirtyairfilterdecreasesengineper-

formanceandincreasesfuelcon-

sumptionandharmfulemissions.Al-

wayscleanafterevery5hoursof

operation.

1. Cleanthecoverandthearea

aroundittokeepdirtfromfalling

intothecarburetorchamberwhen

thecoverisremoved.

2. Loosenknob.Removeairfilter

coverandairfilter.

NOTE:Toavoidcreatingafirehazard

orproducingharmfulevaporative

emissions,donotcleanfilteringaso-

lineorotherflammablesolvent.

3. Washthefilterinsoapandwater.

4. Allowfiltertodry.

5. Replaceparts.

Air Filter

/

V

Air Filter Cover

Knob

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_, WARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As your unit is used, carbon deposits

build up on the muffler and spark ar-

resting screen.

For normal homeowner use, however,

the muffler and spark arresting screen

will not require any service. After 50

hours of use, we recommend that your

muffler be serviced or replaced by your

Sears Service Center.

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Set spark plug gap at

0.025 inch (0.6 mm). Ignition timing is

fixed and nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard.

3. Replace with Champion RCJ-6Y

spark plug and tighten securely

with a 3/4 inch (19 mm) socket

wrench.

4. Reinstall the spark plug boot.

LINE REPLACEMENT

• Always use Craftsman replacement

line.

Choose the line size best suited for

the job at hand. Red line is designed

for cutting grass and small weeds.

The black colored line is designed for

cutting larger weeds and light brush.

1. Remove the old line from the trim-

mer head.

NOTE: The line glide plate is held in

place by the cutting line. The line must

be removed to release the line glide

plate from the trimmer head.

2. Remove the line glide plate.

3. Clean entire surface of trimmer

head.

4. Reinstall line glide plate (see il-

lustration). Align arrow with:

(_) when using medium (red) or

large (black)line

when using lines with diameter

(_ smaller than medium (red)line

(optional)

Line glide Arrow

plate

Trimmer head

NOTE: The line glide plate must be re-

installed in trimmer head before insert-

ing new line. Identify the proper holes.

Follow directions as shown on the line

glide plate.

5. Insert both ends of your line

through the proper holes in the

side of the trimmer head.

2O

', Positioning

Tunnel

!

\

Pull the line and make sure

6,

the line is against the hub and

extended fully through the

positioning tunnels.

Positioning

Tunnel \

7. Correctly installed line will be the

same length on both ends

BLADE REPLACEMENT

Refer to the ASSEMBLY section for

blade replacement instructions and

illustrations.

CARBURETOR IDLE SPEED

ADJUSTMENT

_ILWARNING: Keep others away

when making idle speed adjustments.

The trimmer head or blade will be

spinning during most of this proce-

dure. Wear your protective equipment

and observe all safety precautions.

After making adjustments, the trimmer

head or blade must not move/spin at

idle speed.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol-

lowing conditions:

• Engine will not idle when the throttle is

released.

• The trimmer head or blade moves/

spins at idle.

Make adjustments with the unit sup-

ported so the cutting attachment is off

the ground and will not make contact

with any object. Hold the unit by hand

while running and making adjust-

ments. Keep all parts of your body

away from the cutting attachment and

muffler.

Line against

the hub

To adjust idle speed:

Allow engine to idle. Adjust speed until

engine runs without trimmer head or

blade moving or spinning (idle too fast)

or engine stalling (idle speed too slow).

• Turn idle speed screw clockwise to

increase engine speed if engine

stalls or dies.

• Turn idle speed screw counterclock-

wise to decrease engine speed if

trimmer head or blade moves or

spins at idle.

_,WARNING: Recheck the idle

speed after each adjustment. The

trimmer head or blade must not move

or spin at idle speed to avoid serious

injury to th_ 3erator or others.

Idle Speed

Screw

\

'\

Air Filter

Cover

If you require further assistance or are

unsure about performing this proce-

dure, contact your Sears Service Cen-

ter or call our customer assistance

help line at 1-800-235-5878.

21

_WARNIN_I: Perform the follow-

ing steps after each use:

• Allow engine to cool before storing

or transporting.

• Store unit and fuel in a well venti-

lated area where fuel vapors cannot

reach sparks or open flames from

water heaters, electric motors or

switches, furnaces, etc.

• Store unit with all guards in place.

Position unit so that any sharp ob-

ject cannot accidentally cause injury.

• Store unit and fuel well out of the

reach of children.

SEASONAL STORAGE

Prepare unit for storage at end of sea-

son or if it will not be used for 30 days

or more.

If your unit is to be stored for a period

of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces.

FUEL SYSTEM

Empty the fuel system before storage

for 30 days or longer. Drain the gas

tank, start the engine and let it run un-

til the fuel lines and carburetor are

empty. Use fresh fuel next season.

Under FUELING ENGINE in the OPERA-

TION section of this manual, see mes-

sage labeled IMPORTANT regarding

the use of gasohol in your engine.

Fuel stabilizer is an acceptable alter-

native in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to the gasoline in the fuel

tank or fuel storage container. Follow

the mix instructions found on stabilizer

container. Run engine at least 3 min-

utes after adding stabilizer.

Craftsman 40:1,2-cycle engine oil (air

cooled) is already blended with fuel

stabilizer. If you do not use this Sears

oil, you can add a fuel stabilizer to

your fuel tank.

ENGINE

• Remove spark plug and pour 1 tea-

spoon of 40:1,2-cycle engine oil (air

cooled) through the spark plug

opening. Slowly pull the starter rope

8 to 10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam-

aged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea-

son to another.

• Replace your gasoline can if it starts

to rust.

22

TROUBLESHOOTING TABLE

WARNING: Always stop unit and disconnect spark plug before perform-

ing all of the recommended remedies below except remedies that require

unit to be operating.

TROUBLE

Engine will not

start.

Engine will 1. Carburetor requires 1.

not idle adjustment.

properly. 2. Crankshaft seals worn. 2.

Engine will not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Engine runs

hot.

CAUSE

1. Engine flooded.

2. Fuel tank empty.

3. Spark plug not firing.

4. Fuel not reaching

carburetor.

5. Carburetor requires

adjustment.

3. Compression low. 3.

1. Air filter dirty. 1.

2. Spark plug fouled. 2.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Fuel mixture incorrect.

2. Air filter dirty.

3. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

REMEDY

1. See "Starting a Flooded Engine" in

Operation Section.

2. Fill tank with correct fuel mixture.

3. Install new spark plug.

4. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

5. Contact Sears Service (see back cover).

See "Carburetor Idle Speed Adjustment''

in Service and Adjustments Section.

Contact Sears Service (see back cover).

Contact Sears Service (see back cover).

Clean or replace air filter.

Clean or replace plug

and regap.

Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

1. Empty fuel tank and refill with

correct fuel mixture.

2. Clean or replace air filter.

3. Contact Sears Service (see back cover).

1.

See "Fueling Engine" in Operation

section.

2.

Replace with correct spark plug.

3.

Contact Sears Service (see back cover).

4.

Contact Sears Service (see back cover).

23

YOUR WARRANTY RIGHTS AND

OBLIGATIONS: The U.S. Environ-

mental Protection Agency/California

Air Resources Board and Sears, Roe-

buck and Co., U.S.A., are pleased to

explain the emissions control system

warranty on your year 2009 and later

small off-road engine. In California, all

small off-road engines must be de-

signed, built, and equipped to meet

the State's stringent anti-smog stan-

dards. Sears must warrant the emis-

sion control system on your small off-

road engine for the periods of time

listed below provided there has been

no abuse, neglect, or improper main-

tenance of your small off-road engine.

Your emission control system includes

parts such as the carburetor, the ignition

system and the fuel tank. Where a war-

rantable condition exists, Sears will

repair your small off-road engine at no

cost to you. Expenses covered under

warranty include diagnosis, parts and

labor. MANUFACTURER'S WAR-

RANTY COVERAGE: If any emis-

sions related part on your engine (as

listed under Emissions Control War-

ranty Parts List) is defective or a de-

fect in the materials or workmanship of

the engine causes the failure of such

an emission related part, the part will

be repaired or replaced by Sears.

OWNER'S WARRANTY RESPONSI-

BILITIES: As the small off-road en-

gine owner, you are responsible for

the performance of the required main-

tenance listed in your operator's

manual. Sears recommends that you

retain all receipts covering mainte-

nance on your small off-road engine,

but Sears cannot deny warranty solely

for the lack of receipts or for your fail-

ure to ensure the performance of all

scheduled maintenance. As the small

off-road engine owner, you should be

aware that Sears may deny you war-

ranty coverage if your small off-road

engine or a part of it has failed due to

abuse, neglect, improper mainte-

nance, unapproved modifications, or

the use of parts not made or approved

by the original equipment manufactur-

er. You are responsible for presenting

your small off-road engine to a Sears

authorized repair center as soon as a

problem exists. Warranty repairs

should be completed in a reasonable

amount of time, not to exceed 30

days. If you have any questions re-

garding your warranty rights and re-

sponsibilities, you should contact your

nearest authorized service center, call

Sears at 1-800-469-4663, or send

e-mail correspondence to emission.

warranty@ HCOP- emission.com.

WARRANTY COMMENCEMENT

DATE: The warranty period begins on

the date the small off-road engine is

purchased. LENGTH OF COVER-

AGE: This warranty shall be for a peri-

od of two years from the initial date of

purchase. WHAT IS COVERED: RE-

PAIR OR REPLACEMENT OF

PARTS. Repair or replacement of any

warranted part will be performed at no

charge to the owner at an approved

Sears Service Center. If you have any

questions regarding your warranty

rights and responsibilities, you should

contact your nearest authorized service

center, call Sears at 1-800-469-4663,

or send e-mail correspondence to

emission.warranty@ HCOP- emission.

corn. WARRANTY PERIOD: Any war-

ranted part which is not scheduled for

replacement as required mainte-

nance, or which is scheduled only for

regular inspection to the effect of "re-

pair or replace as necessary" shall be

warranted for 2 years. Any warranted

part which is scheduled for replace-

ment as required maintenance shall

be warranted for the period of time up

to the first scheduled replacement

point for that part. DIAGNOSIS: The

owner shall not be charged for diag-

nostic labor which leads to the deter-

mination that a warranted part is de-

fective if the diagnostic work is

performed at an approved Sears Ser-

vice Center. CONSEQUENTIAL

DAMAGES: Sears may be liable for

damages to other engine components

caused by the failure of a warranted

part still under warranty. WHAT IS

NOT COVERED: All failures caused

by abuse, neglect, or improper main-

tenance are not covered. ADD-ON

OR MODIFIED PARTS: The use of

add-on or modified parts can be

grounds for disallowing a warranty

claim. Sears is not liable to cover fail-

ures of warranted parts caused by the

use of add-on or modified parts. HOW

TO FILE A CLAIM: If you have any

questions regarding your warranty

rights and responsibilities, you should

24

contactyournearestauthorizedser-

vicecenter,callSearsat

1-800-469-4663,orsende-mailcorre-

spondencetoemission.warranty

@HOOP-emission.com.

WHERE TO GET WARRANTY SER-

VICE: Warranty services or repairs

shall be provided at all Sears Service

Centers. Call 1-800-469-4663 or send

e-mail correspondence to emission.

warranty@HOOP-emission.com.

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RE-

LATED PARTS: Any Sears approved

replacement part used in the perfor-

mance of any warranty maintenance

The information on the product label indicates which standard your engine is certified.

Example: (Year) EPA and/or CALIFORNIA.

or repair on emission related parts will

be provided without charge to the

owner if the part is under warranty.

EMISSION CONTROL WARRANTY

PARTS LIST: Carburetor, air filter (cov-

ered up to maintenance schedule),

ignition system: spark plug (covered up

to maintenance schedule), ignition mod-

ule, muffler including catalyst (if

equipped), fuel tank. MAINTENANCE

STATEMENT: The owner is responsi-

ble for the performance of all required

maintenance as defined in the opera-

tor's manual.

61 I sl I

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

25

Declaraci6n de Garantia 29 Servicio y Ajustes 49

Identificaci6n de los Simbolos Almacenaje 51

de Seguridad 30 Tabla Diagn6stica 52

Reglas de Seguridad 32

Montaje 34 Declaraci6n de Emision 53

Uso 39 Lista de Piezas 26

Mantenimiento 48 Repuesto y Encargos Contratapa

GARANTiA COMPLETA DE CRAFTSMAN

Si este producto falla por un defecto en el material o de mano de obra dentro de

dos (2) a_os a partir de la fecha de compra y este se ha utilizado y mantenido de

acuerdo al manual del usuario, envielo a cualquier tienda Sears, Centro de Servi-

cios Sears u otra tienda Craftsman en los Estados Unidos para su reparaci6n gra-

tuita (o reemplazo si no es posible repararlo).

Esta garantia es aplicable por s61o 90 dias desde la fecha de compra si este pro-

ducto se usa con fines comerciales o se usa para arriendo.

Esta garantia cubre SOLAMENTE defectos en material y de mano de obra.

Sears NO pagara:

• Partes desechables que pueden desgastarse al usarlas normalmente dentro

del periodo de la garantia, tal como linea del corte, filtros o bujias.

• Reparaciones necesarias debido a accidente o falta de funcionar o de manten-

er el producto segdn todas las instrucciones provistas.

• Mantenimiento preventivo, o reparaciones necesarias debido a mezcla de com-

bustible incorrecto, combustible contaminado o combustible rancio.

Esta garantia le otorga derechos legales especificos, y usted tambien puede

tener otros derechos que varian de estado a estado.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

iFelicitaciones! ilia realizado una compra inteligente! Su nuevo producto Crafts-

man est& diseSado y fabricado para brindar muchos aSos de funcionamiento

confiable. Pero como todos los productos, puede requerir reparaciones peri6di-

cas. En ese momento, tener un Acuerdo de protecci6n para reparaciones puede

ahorrarle dinero y trastornos.

El Acuerdo de Proteccion para Reparaciones* incluye Io siguiente:

_" Servicio experto por parte de nuestros 10 000 especialistas en repara-

ciones profesionales

_" Servicio ilimitado y ningun costo por las piezas y la mano de obra en

todas las reparaciones cubiertas

_" Reemplazo del producto hasta $1500 si el producto cubierto no puede

ser reparado

_" Descuento de110% sobre el precio normal del servicio y las piezas

instaladas asociadas no cubiertas por el acuerdo; adem_.s, 10% de des

cuento sobre el precio normal de la verificaci6n de mantenimiento preventivo

_" Ayuda telefonica rapida - la Ilamamos Resoluci6n r&pida; asistencia

telef6nica por parte de un representante de Sears. Piense en nosotros

como un "manual del propietario parlante".

Una vez que compre el Acuerdo de protecci6n para reparaciones, bastard, con que

realice una simple Ilamada telef6nica para programar servicios. Puede Ilamar a cual-

quier hora, de dia o de noche, o programar una visita de servicios en Internet.

El Acuerdo de Protecci6n para Reparaciones es una compra libre de riesgos. Si

cancela por cualquier motivo durante el periodo de garantia del producto, le pro-

porcionaremos un reembolso completo. O un reembolso prorrateado en cualquier

momento posterior al vencimiento del periodo de garantia del producto.iCompre

su Acuerdo de protecci6n para reparaciones ya mismo!

29

Aplican algunas limitaciones y exclusiones. Para conocer los precios e in-

formacion adicional en EE.UU, Ilame al 1-800-827-6655.*La cobertura en

Canada varia en algunos articulos. Para obtener los detalles completos,

Ilame a Sears Canada al 1-800-361-6665.

Servicio de instalacion de Sears

Para la instalaci6n profesional de Sears de electrodomesticos, abrepuertas de

garajes, calentadores de agua y otros articulos domesticos importantes, en

EE.UU. o Canad& Ilame a 1-800-4-MY-HOME®.

A

PELIGRO: Use exclusivamente la ca-

bezal de corte y la bobina especificada y la

I[nea de corte recomendado. Nunca use

cuchillas ni dispositivos desgrandores,

alambre, soga, hilo, etc. Este accesorio ha

sido diseSado exclusivamente como corta-

dora I[nea. El incumplimiento de cualquiera

®®®®

uso descuidado o indebido de esta herramienta puede causar

,_/L ADVERTENCIA: iEste aparato puede ser peligrosa! El

graves heridas.

ciones podia causar graves heridas. Guarde el manual de

_1 ea el manual de usuario antes de usar. No seguir las instruc-

usuario.

de las instrucciones puede causar graves

heridas.

La I[nea de corte arroja objetos vio-

lentamente. Los objetos arrojados

pueden cegarlo o herirlo a usted y

a terceros. Use protecci6n de oidos

y anteojos de seguridad marcar con

Z87. Use siempre pantalones pesa-

dos y largos, mangas largas, botas y

guantes.

Zona de peligro por objetos arrojados al aire.

• La I[nea de corte arroja objetos violentamente.

• Los objetos arrojados pueden cegarlo o herirlo

a usted y a terceros.

• Mantenga a personas y animales 15 metros

(50 pies) alejados de la zona de trabajo.

AsegQrese de tener el cabello re-

cogido por encima de los hombros.

No use joyeria, ropa suelta ni ropa

con corbatas, tiras, borlas, etc. que

cuelgan libremente. Pueden enre-

darse en las piezas en movimiento.

30

El mango auxiliar debe colocarse siempre por

debajo de la flecha.

No permita que los ni_os usen este aparato.

Guarde el aparato al abrigo de la intemperie, desen-

chufado, en un lugar alto, seco y fuera del alcance

de los ni_os. Guarde el aparato y el combustible en

un lugar donde los vapores del combustible no pue-

dan alcanzar chispas ni llamas provenientes de los

termotanques, los motores o interruptores electricos,

los calefactores centrales, etc.

AI mantener este aparato, use solamente las

piezas de reemplazo identicas.

"-_ JSiempre apague el aparato y desconecte la bujia

J antes de dar mantenimiento.

vierta, o almacene el combustible o utilice el aparato cerca de

llamas o fuentes de chispas (inclusive los cigarrillos, las llamas

J'_ ADVERTENClA: Riesgo de incendios. Nunca mezcle,

abiertas, y cualquier trabajo que cause chispas).

Utilice gasolina sin plomo y aceite para motores de dos

tiempos mezclado en proporci6n al 40:1 (2.5%).

31

_/L ADVERTENClA: AI usar cualqui-

er herramienta de fuerza de jardineria,

deber&n observarse precauciones

b&sicas de seguirdad en todo momento

para reducir el riesgo de incendio y

graves heridas.

_/L PELIGRO: iEsta herramienta

motorizada puede ser peligrosa! Puede