Craftsman 358795631 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

S _AUR8

Operator's

Manual

Model No.

358.795631

DANGER:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

Always Wear Eye Protection

CRRFTSMRNo

21 cc (1.3 cu. in.) 2-CYCLE

22 Inch Blade

GAS HEDGE TRIMMER

• Assembly

• Operation

• Customer Responsibilities

• Service Adjustments

• Repair Parts

i

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530-084237 03/12/96

iiii ,,i,= ii iiiiii ii i ,i.,11,1,11ii iiiiiiiiiiiii iiii

SAFETY RULES

===================,,,,,H,= ,.i ii HII i i i i ,i = ,,,,,,,,,,,,,,,,,, ,,,=

• • TACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING,

i ^ CAU.iON,ALWAYSO,SCONNEOTSPA.KPLUGW,.=ANOP .OEW,.EW.ERECANNOTCONI

O' ADJ USTING OR MAKING RE,PAIRS.

OPERATOR SAFETY

• Always wear safety eye protection.

• Alwayswear heavy long pants, long sleeves,boots and

gloves. Do not go barefoot or wear sandals, short

pants, short sleeves. Being fully covered helps to pro-

tect you from pieces of toxic pfants thrown by the

blade.

• Secure hair so it above shoulder length. Secure loose

clothing or jewelry. Clothing with loosely hanging ties,

straps, tassels, etc. can be caught in moving pans.

Do not operate this unit when you are tired, il! or under

the influence of alcohol, drugs, or medication.

• Wear hearing protection ff you use this unit for more

than 1-1/2 hours per day.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kill.

• Keep handles free of oiland fuel.

• if situations occur which are not covered in this manu-

al, use care and good judgement.

UNIT MAINTENANCE/SAFETY

• Look for and replace damaged or loose parts before

each use. Look for and repair fuel leaks before use.

Keep the unit in good workingcondition.

• Make sure the unit is maintained and assembled cor-

rectly as listed in this manual.

• Make carburetor adjustments with the blade supported

to prevent it from contacting any object. Hold the unit

by hand.

• Keep others away when making carburetor adjust-

ments.

• Use only quality SEARS accessories and replacement

parts as recommended for this unit.

• Have all maintenance and service not explained in tills

manual performed by your SEARS Ser_ce Center.

FUEL SAFETY

• Mix and pour fuet outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the unit or

while using the unit.

• Wipe up all fuel spills before starting engine.

• Move at least 10 feet (3 meters) away from fueling site

before starting engine.

• Stop engine and allow unit to cool before removing_fue!

cap.

CUTTING SAFETY

• Inspectthe area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string, etc.)

whichcan become entangled in the blade.

• Keep others including children, animals, bystanders

and helpers a minimum of 15 feet (5 meters) away.

Stopthe engine immediatelyif you are approached.

• Always keep the engine on the right-hand side of your

body.

• Hold the unit firmly with both hands.

• Keepfirm footing and balance. Do not over-reach.

• Keepthe blade below waist level.

• Do not raise the engine above your shoulder.

• Keep all parts of your body away from the blade and

muffler when engine is running.

• Useonly for jobs explained in this manual.

TRANSPORTING AND STORAGE

• Stopthe unit before transporting.

• Allow the engine to cool, and secure the unit before

storing or transporting in a vehicle.

• Empty the fuel tank before stodng or transporting the

unit. Use up any fue! left in the carburetor by starting

the engine and letting theengine run until it stops.

• Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, elec-

tric motor or switches,furnaces, etc.

• Store unit so the blade cannot accidentally cause

injury.

• Store the unit out of the reach of children.

SAFETY NOTICE .... I

jExposure to vibrationsthrough prolongeduseof gasolinepowered hand units could cause blood vessel or nerve damage in the tin-]

Jgers, hands, and joints of people prone to circulationdisorders or abnormal swellings. Prolonged use in cold weather has been|

Ilinked to blood vessel damage in otherwise healthy people. If symptoms occursuch as numbness, pain, loss of strength, change int

|skin color or texture, or lossof feeling in the fingers, hands or joints,discontinuethe use of thrs unitand seek medicala_ent=on. An|

]anti-vibration system does notguarantee the avoidance of these problems.Users who operate powertoo=son a continuatano regu-]

[lar basis must monitor closely their physical conditionand the conditionofthis unit.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS - ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

-2-

i i HIIIIIII, I II I II I II Illll III

SAFETY RULES

j ii I II i ii ii

DANGER:

THIS POWER UNIT CAN BE DANGEROUS! THIS UNIT CAN CAUSE SERIOUS INJURY INCLUDING

AMPUTATION OR BLINDNESS TO THE OPERATOR AND OTHERS. THE WARNINGS AND SAFETY

INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE REASONABLE SAFETY AND

EFFICIENCY IN USING THIS UNI'I;.THE OPERATOR IS RESPONSIBLE FOR FOLLOWING THE WARN-

INGS AND INSTRUCTIONS IN THIS MANUAL AND ON THE UNI7;.READ THE ENTIRE OPERATOR'S

MANUAL BEFORE ASSEMBLING AND USING THE UNITTRESTRICT THE USE OF THIS POWER TOOL

TO PERSONS WHO READ, UNDERSTAND, AND FOLLOW THE WARNINGS AND INSTRUCTIONS IN

THIS MANUAL AND ON THE UNIT.NEVER ALLOW CHILDREN TO USE THIS TOOL.

WARNING:

CUTTING BLADE CAN THROW OBJECTS

VIOLENTLY. YOU CAN BE BLINDED OR

INJURED. ALWAYS WEAR EYE AND LEG

PROTECTION.

BLADE MOVES MOMENTARILY AFTER

TRIGGER IS RELEASED. THE CUTTING

BLADE CAN SERIOUSLY CUT YOU OR

OTHERS. ALLOW CUTTING BLADE TO

STOP BEFORE REMOVING IT FROM THE

CUT.

HAZARD ZONE FOR CUTTING BLADE.

THE CUTTING BLADE CAN SERIOUSLY

CUT YOU OR OTHERS. OTHERS CAN BE

BLINDED OR INJURED. KEEP PEOPLE

AND ANIMALS A MINIMUM OF 15 FEET

(5 METERS) AWAY.

LEG GUARDS

Ii

EYE PROTECTION BOOTS

HAZARDZONE

READ OPERATOR'S MANUAL. FOLLOW

ALL WARNINGS AND INSTRUCTIONS.

FAILURE TO DO SO CAN RESULT IN SERI-

OUS INJURY.

-3-

OPERATOR'S

MANUAL

SAFETY

LABEL

CONGRATULATIONS on your purchase of a Sears

Craftsman Gas Hedge Trimmer. It has been designed,

engineered and manufactured to give you the best possi-

ble dependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department. Sears has competent, well trained tech*

niciansand the proper tools to serviceor repair this unit.

Please read and retain this manual. The instructionswill

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES."

PRODUCT SPECIFICATIONS

CUTTING BLADE ............... 22"

ENGINE .............................. 21 cc, 2-cycle Air-Cooled

FUEL/OIL MIX RATIO......... 40:1 (3.2 oz. oil per one

gallon of gasoline

IGNITION ............................ Solid State

(air gap .010" to .014")

IGNITION TIMING .............. Non-adjustable, fixed

SPARK PLUG .......:............. Champion (RCJ-SY)

MODEL NUMBER: 358.795631

SPARK PLUG GAP.............. 024 to .028"

DATE CODF__JSERIALNO.:

ENGINE RPM ..................... 9,000 RPM Max.

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON THE PRODUCT.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATEOR PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

i i ,

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product.Contactyour nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety ruJes.

• Follow a regular schedule in maintaining, caring for,

and using your unit.

For users on U.S. Forest Land and in some states, includ-

ing California (Public Resources Codes 442 and 443),

Idaho, Maine, Minnesota, New Jersey, Oregon, and

Washington: Cert_n internal combustion engines operated

on forest, brush, and/or grass-covered lands in the above

areas are required to be equipped with a spark arrestor,

i

maintained in effectiveworkingorder,or the enginemust be

constructed, equipped, and maintained for theprevention of

fire. Check with your state or local authoritiesfor regulations

pertaining to these requirements. Failure to follow these

requirements is a violation of the law. This unitis not facto-

ry.equipped with a sparkarreston however, a spark arrestor

is available as an optional part. If a spark arrestor is

required in your area, contact your SEARS Service

Center/Department for the correctk_t.

MANUFACTURED UNDER ONE OR MORE OF THE FOU_OWtNG U.S.

PATENTS:4,940,028; 4,904,827; 4,846,123, 4,463,544; 4,45,1,983; 4,364,

435; 4,286,675;/re,32,266 Other U.S. and Foreign Pat_ts Psr'_ng.

SPECIAL NOTICE

• Follow the instructions under'Customer Responsibili-

ties"and "Storage" sections of this Operator's Manual.

FULL ONE YEAR WARRANTY ON CI_AFTSMAN GAS-POWERED HEDGE TRIMMER

Forone (1) year from the date or purchase,whenthisCraftsmanGas-Powered HedgeTrimmerismaintained,lubri-

cated and tuned-up according to the owners manual,Sears will repair, free of charge, any defect in materials or

workmanship.

, ii

This warranty excludes spark plug,airfilter, and the bladewhich are expendable parts and may become worn dur-

ingnormal use.

If this Hedge Trimmer is usedfor commercialpurposes,this warranty applies for only90 daysfrom the date of pur-

chase, ff this Hedge Trimmer is used for rental purposes, this warranty applies for only 30 days from the date of

purchase.

THIS WARRANTY APPLIES ONLYWHILE THIS PRODUCT IS USED IN THE UNITED STATES

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HEDGE TRIMMER TO THE NEAREST SEARS

SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, andyou may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

-4-

i iii iii i ii iii IHIII | I II

TABLE OF CONTENTS

i , ii i1|11 i i iii iiiiii i

Safety Rules .................................................................... 2 Service and Adjustments............................................... 16

Product Specifications ..................................................... 4 Storage .......................................................................... 17

Warranty.......................................................................... 4 TroubleShooting..........:.................................................18

Operation.........................................................................7 RepairParts...................................................................19

Customer Responsibilities ............................................. 13 Ordering Repair Parts/Service ........................ Back Cover

i i1| ii ii i i i i iiiii i iii

INDEX

I IIIIIHI II I I I II

A

Accessories.................................................... ................. 5

Air Fitter ......................................................................... 14

C

Carburetor Adjustments ................................................. 16

Customer Responsibilities ............................................. 13

Cutting Blade Lubrication .............................................. 13

E

Engine

FueVOil ....................................................................... t 1

Spark Plug .................................................................. 14

Starting ....................................................................... 12

Storage ....................................................................... 17

F

Fuel Filter....................................................................... 15

Fueling........................................................................... 11

H

Hardware Contents .......................................................... 6

K

Know Your Hedge Trimmer ............................................... 7

iiiilll iiiii ii i iii iiii IIIIIIHII I

Maintenance Schedule ................. ................................. 13

Model Number ................................................................ .4

Operation ......................................................................... 7

Ordering Repair Parts ..................................... Back Cover

Service and Adjustments ............................................... 16

Spark Plug ..................................................................... 14

Specifications ................................................................... 4

Starting .......................................................................... 12

Storage .......................................................................... 17

Trimming Methods ......................................................... 10

Trouble Shooting ............................................................ 18

Warranty ....................................................................... ..4

i IHI IIIIH, IIIIIII III

M

O

S

T

W

ACCESSORIES

i ,i illll ii i iiii iiiii ii i

These accessories and attachments were available when the unit was originally purchased.They are also available at

most Sears retail outlets and service centers. Most Sears stores can order these items for you when you provide the

model number of your unit.

i i iiiii

SAFETY

GOGGLES

Accessories

SPARK AIR

PLUG RLTER

-5-

2-CYCLE

ENGINE OIL

m!

I

ii ,=ll|=ll I,,,,H,I ,,I II II I ,ll I I Ill

HARDWARE CONTENTS

i i i iiiiiiiiii i iiiiiiiii ii i / .i i i iiiiiiil,lml ii i i iiiiiii i ii i i

ENGINE OIL OPERATOR'S MANUAL

THIS MODEL COMES FULLY ASSEMBLED

NOTE: It is normalto hear the fue! filter rattlein an empty

fuel tank.

TO REMOVE HEDGETRIMMER FROM

CARTON

• Remove loose parts includedwith Hedge Trimmer.

• Remove all packing material.

• Check carton thoroughlyfor additionalloose parts.

. Use cardboard lineras work surface during inspection

of unit.

,..6 _

i illlliiillii i |lllll i i iiiiml ii iiiiiiiii

OPERATION

iiiiiiiiiiii ii i i i i iiiiiiiii i iiiii iii i ii iiiiiii i ii ii iiiiiiiii

KNOWYOUR HEDGETRIMMER (Fig. 1)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR HEDGE TRIMMER. Compare

the ittustratienswith yourunit to familiarize yourselfwith the location of the various controlsand adjustments. Save this

manual for future reference.

AIR R LTER

CHOKE LEVER SWITCH

ON/OFF

REAR

HANDLE

|

SPARK PLUG

u w

\

FUEL CAP

CUTTING BLADE

THROTrLE THROTTLE

LOCK-OUT LOCK

THROTTLE

TRIGGER

FRONT

._r.,,HAND GUARD

/_

STARTER MUFFLER

HANDLE

ii i = i1,1 iiii iii i i i iiiiiiiii1=111 i iii iiiiii

Figure 1

The ON/OFF SWITCH is used to stop the engine. The CHOKE LEVER activates the choketo provide addi-

tional fuel to the engine when starting a cold engine.

The STARTER ROPE HANDLE is used for starting the

engine. The THROTTLE TRIGGER controls engine speed.

The PRIMER BULB cimulates fuelto the carburetor.

-7-

| ....................

OPERATION - SAFETY

................................ , ,,,, ,, ,

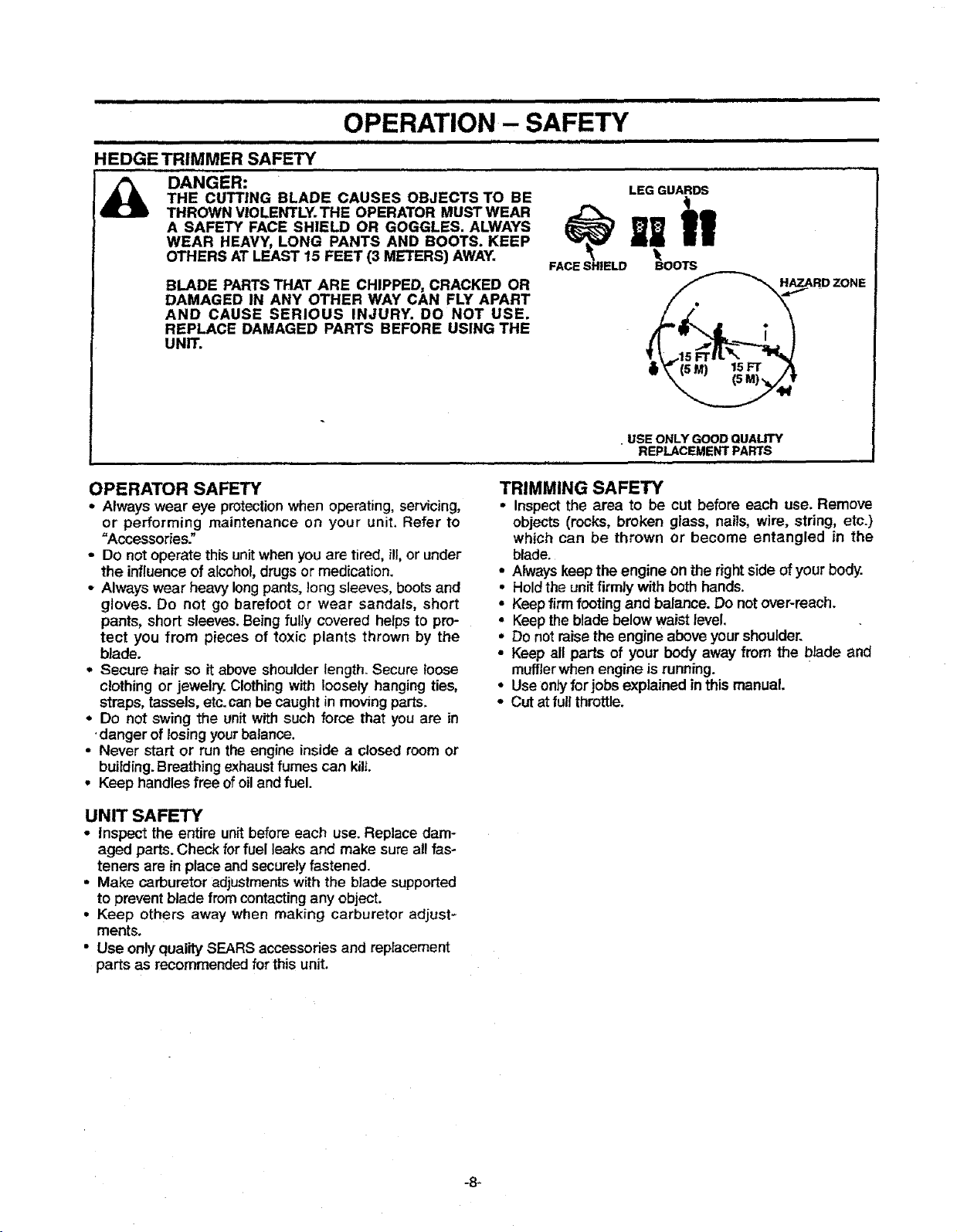

HEDGE TRIMMER SAFETY

i_ DANGER:

THE CUTTING BLADE CAUSES OBJECTS TO BE

THROWN VIOLENTLY.THE OPERATOR MUST WEAR

A SAFETY FACE SHIELD OR GOGGLES. ALWAYS

WEAR HEAVY, LONG PANTS AND BOOTS. KEEP

OTHERS AT LEAST 15 FEET (3 METERS) AWAY.

BLADE PARTS THAT ARE CHIPPED, CRACKED OR

DAMAGED IN ANY OTHER WAY CAN FLY APART

AND CAUSE SERIOUS INJURY. DO NOT USE.

REPLACE DAMAGED PARTS BEFORE USING THE

UNIT.

ill = 111

÷

FACE SHIELD

i

LEG GUARDS

|1

BOOTS

USE ONLY GOOD QUALITY

REPLACEMENT PARTS

OPERATOR SAFETY

• Always wear eye protectionwhen operating, servicing,

or performing maintenance on your unit. Refer to

=Accessories."

• Do not operate this unit when you are tired, ill,or under

the influence of alcohol drugs or medication.

o Always wear heavy long pants, long sleeves, boots and

gloves. Do not go barefoot or wear sandals, short

pants, short sleeves. Being fulJy covered helps to pro-

tect you from pieces of toxic plants thrown by the

blade.

o Secure hair so it above shoulder length. Secure loose

clothing or jewelry. Clothing with loosely hanging ties,

straps, tassels, etc.can be caught in moving parts.

• Do not swing the unit with such force that you are in

•danger of losing your balance.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kilt.

• Keep handles free of oiland fuel.

UNIT SAFETY

• Inspect the entire unitbefore each use. Replace dam-

aged parts. Check for fuel leaks and make sure al!fas-

teners are in place andsecurelyfastened,

• Make carburetor adjustments with the blade supported

to preventblade from contactingany object.

• Keep others away when making carburetor adjust-

ments.

• Use only qualitySEARS accessoriesand replacement

parts as recommended forthis unit.

TRIMMING SAFETY

• Inspect the area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string, etc.)

which can be thrown or become entangled in the

blade.

• Always keep the engine on the right side of your body.

• Holdthe unit firmly with both hands.

• Keepfirm footing and balance. Do not over-reach.

, Keep theblade below waist level.

• Do not raise the engine above your shoulder.

• Keep all parts of your body away from the blade and

muffler when engine is running.

• Useonty forjobs explained !n this manual.

• Cut at full throttle.

i i i

OPERATION

HOWTO USE YOUR HEDGE TRIMMER NOTE' Verity the throttle trigger stays in the advanced

position.

STOPPING YOUR ENGINE

• Move start/stop switch to the "STOP" position.

• If engine does not stop, pull choke knob out fully.

THROTTLE CONTROL GROUP (Fig. 2)

THROTTLE LOCKOUT

• The throttle lockout prevents unintentional actuation of

the throttletrigger.

• You must depress the throttle lockout with thepalm of

yourhand before actuatingthe throttletrigger.

THROTTLE TRIGGER

• The throttle trigger allows for variable controlof engine

speed.

• The throttle triggerisactuated by the index fingeron your

righthand.(After the throttlelockout is depressed).

THROTTLE LOCK

• The throttle lock allows the faster engine speeds during

starting.

• The throttle lockis engaged by the following steps:

- Grasp the rear handle and depress the throttle lockout.

- Squeeze the throttle trigger fully and hold.

- Depress the throttle lockw_thyour forefinger and hold.

- Release your grip on the throttle trigger and throttle

lockout.

• Squeezing the throttle trigger will release the fast idle

setting. If the throttle trigger is squeezed accidentally

during starting, it will be necessary to reset throttle lock.

CHOKE

• The choke is set by pullingthe choke lever out.fully for

coldor refueledengine starts.

PRIMER BULB

• The primer bulb is usedto circulate fuel to the carburetor.

• The primer bulb is activated by pressing on it with your

thumb.

PRIMER

BULB

CHOKE THROTTLE

ON/OFF LOCK

THROTTLE

TRIGGER

Figure 2

,9,

i ,,,, ,,,,i,u,iiiiii m. ,,,,,i,,,,, i ilUl u i,iiiii i

OPERATION

=11 ,,,,,= i = , ,=,= i

STOPPING "fOUR ENGINE

• Move the ONIOFF switchtothe OFF position.

• If engine does not stop, move thechokelevertothefull

choke position.

THROTTLE TRIGGER (Fig. 3)

The throttle trigger controlsthe enginespeed.

NOTE: The blade should stop when the throttle trigger is

released and the engine returns to idlespeed.

THROTrLE TRIGGER

Figure 3

OPERATIN G/USE TIPS (Fig. 4)

ALWAYS CUT AT MAXIMUM SPEED. DO

w...,.o

NOT CROWD THE BLADE INTO THE CUT

WHICH CAN DAMAGE THE BLADE,

BECOME ENTANGLED, OR BE THROWN

CAUSING A SERIOUS HAZARD.

ALWAYS WORK GOING AWAY FROM PEO-

PLE AND SOLID OBJECTS SUCH AS

WALLS, LARGE STONES, TREES, AUTO-

MOBILES, ETC.

ALWAYS WEAR EYE PROTECTION.NEVER

LEAN OVER THE BLADE. ROCKS OR

DEBRIS CAN RICOCHET OR BE THROWN

INTO EYES AND FACE AND CAUSE BLIND-

NESS OR OTHER SERIOUS INJURY.

• Allow the cutting blades to reach full speed before

entering the material to be cut.

• Always work going away from peopleand solid objects

such as walls, large stones, trees, automobiles,etc.

• If blade stalls, immediately stop the engine. Make sure

the ON/OFF switch is off, the spark plug is disconnect-

ed, and the blade has stopped moving before clearing

ioammeddebris from the cutting blade.Inspect the blade

r damage and have _trepaired or replaced as needed.

° To stop the engine, move the ON/OFF switch to the

OFF position.

o Always keep the air vents clean. Stop the unit, make

sure the cutting blade has completely stopped moving,

and disconnect the spark plug before cleaning.

TRIMMING METHODS (Fig.5_ & 6)

NOTE: Do nottryto cut stems larger than 3/8"thick.

TOP cu'n'ING

• For new or young growth: When trimming new or

younggrowth,use a wide, sweeping motion. Figure 5A.

A slight,downwardtiltof the cuttingblades in the direc-

tion ofmotion gives the best cuttingresults.

• For older, thicker growth: Trim older, thicker growth

byusinga sawing motion. Figure5!3.

• For precise, level cuts: If a precisely level cut is

desired, stretch a piece of string across the length of

the hedge. Guide the cutting blades slowly across the

top of the string.Figure 6.

SIDE cu'n'ING

• When tdmming the sides of the hedge, begin at the

bottom and cut upward, tapering the hedge inward at

the top., Figure 6' (inset). Cutting in this method will

leave the body of the hedge narrower at the top.This

shape will expose more ofthe hedge, resulting in more

uniform growth.

Figure 5

A B

Figure 4

Figure 6

AIR VENTS

-10-

HI iii i I i ii i i= ii

OPERATION

i H= H

BEFORE STARTING ENGINE

WARNING:

BE SURE TO READ THE FUEL SAFETY

INFORMATION IN THE SAFETY RULES

SECTION ON PAGE 2 OF THIS MANUAL

BEFORE YOU BEGIN.

IFYOU DO NOT UNDERSTAND THE FUEL

SAFETY SECTION DO NOT ATTEMPT TO

FUEL YOUR UNIT; SEEK HELP FROM

SOMEONE WHO DOES UNDERSTAND

THE FUEL SAFETY SECTION'OR CALL

THE CUSTOMER ASSISTANCE HOTLINE

AT 1-800235-5878.

GASOLINE

The two-cycle engine on this product requires a fuel mix-

ture of regular unleaded gasoline and a high quality 40:1

2-cycle engine oil (AIR-COOLED) for lubrication of the

bearings and other moving parts.The correct fuel/oil mix-

ture is 40:1 (see Fuel Mixture Chart). Too little oil or the

incorrect oil type will cause poor performance and may

cause the engine to overheatand seize.

Gasoline and oil mustbe premixed in a clean approved

fuel container. Always use fresh regular unleaded gaso-

line.

This engine is certifiedto operate on unleaded gasoline.

IMPORTANT: Experience indicates that alcoholblended

fuels called gasohol (or using ethanolor methanol) can

attract moisture, which leads to oil/gas separation and

formation of acids during storage. Acidic gas can dam-

age the fuel system of an engine while in storage. To

avoid engine problems,the fuel system should be emp-

tied before storage for 30 days or longer. Drain the gas

tank, then runthe fuel out ofthe carburetorandfuel lines

by startingthe engineand lettingit rununtilit stops. Use

fresh fuel next season. See STORAGE instructions for

additional information. Never use engine or carburetor

cleaner productsin the fuel tank or permanent damage

may occur.

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fue! gum deposits dudng storage. Add

stabilizer to gasoline in fuel tank or storage container.

Always follow the fuel tank or storage container. Always

follow the fuel mix ratio found on the stabilizer container.

Run engine at [east 5 minutes after adding stabilizer to

allow the stabilizer to reach the carburetor. You do not

have to drain the fuel tank for storage ff you are using

fue! stabilizer.

i = = ,,= ,= i ill

2-CYCLE AIR-COOLED ENGINE OIL

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

strongly recommended.This oil is specially blended with

fuel stabilizersfor increasedfuel stability(extends fuel life

upto 5 times longer)and reducedsmoke.

If CRAFTSMAN 2-cycte engine oil (AIR-COOLED) is not

available, use a good quality 2-cycle engine oil (AIR-

COOLED) that has a recommended fuel mix ratio of40:1.

IMPORTANT! Do no use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA, etc.)

These oils do not have proper additivesfor 2-cycle AIR-

COOLED engines and can cause engine damage.

GASOLINE AND OIL MIXTURE

Mix gasoline and oilas follows:

• Consult chart for correct quantities.

• Do not mix gasoline and oil directly in the unit's fuel

tank.

FOR ONE GALLON:

• Pour 3,2 ounces of high quality,40:1 2-cycle engine oil

(AIR-COOLED) into an empty, approved one gallon

gasoline container.

• Add one gallon of regular unleaded gasoline to the gal-

lon container, then securely replace the cap.

- Shake the container.

• The mixture is now readyforuse.Fuel stabilizercan be

added at this time if desired;follow mixing instructions

on the label.

FUEL MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

Gasoline Oil (fl. oz.)

1 gallon 3.2

I

NOTE: Fuel containers may hold more thanthe specified

amount. If too much gasoline is in the container, the

resulting gas-to-oil fue! mixture will not be correct for

proper engine operation.

2.5 gallons 8.0

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

specially blended with fuel s_abilizers, if you do not use

this Sears oil, you can add a fuel stabilizer (such as

CRAFTSMAN No.33500) to your fuel tank.

-1"1-

i ii i I,IHI IIIIIII I =11 IIIIIIIII I IIIII ,I,,,11,11111II IIII ]

OPERATION

,,,,,,=r= ,= =,,,= I I

STOPPING YOUR ENGINE

- Move the ON/OFF switch to the OFF position.

• If engine does not stop, move the choke lever to full

choke.

DANGER:

THE CUTTING BLADE WILL TURN WHEN

THE ENGINE STARTS.

FOR SAFE STARTING AND OPERATION,

FOLLOW AtL SAFETY PRECAt_rlONS IN

THIS OPERATOR'S MANUAL AND

LABELS ON THE UNIT. DRESS PROP-

ERLY BEFORE STARTING ENGINE.

AVOID ANY CONTACT WITH THE MUF-

FLER, A HOT MUFFLER CAN CAUSE

SERIOUS BURNS.

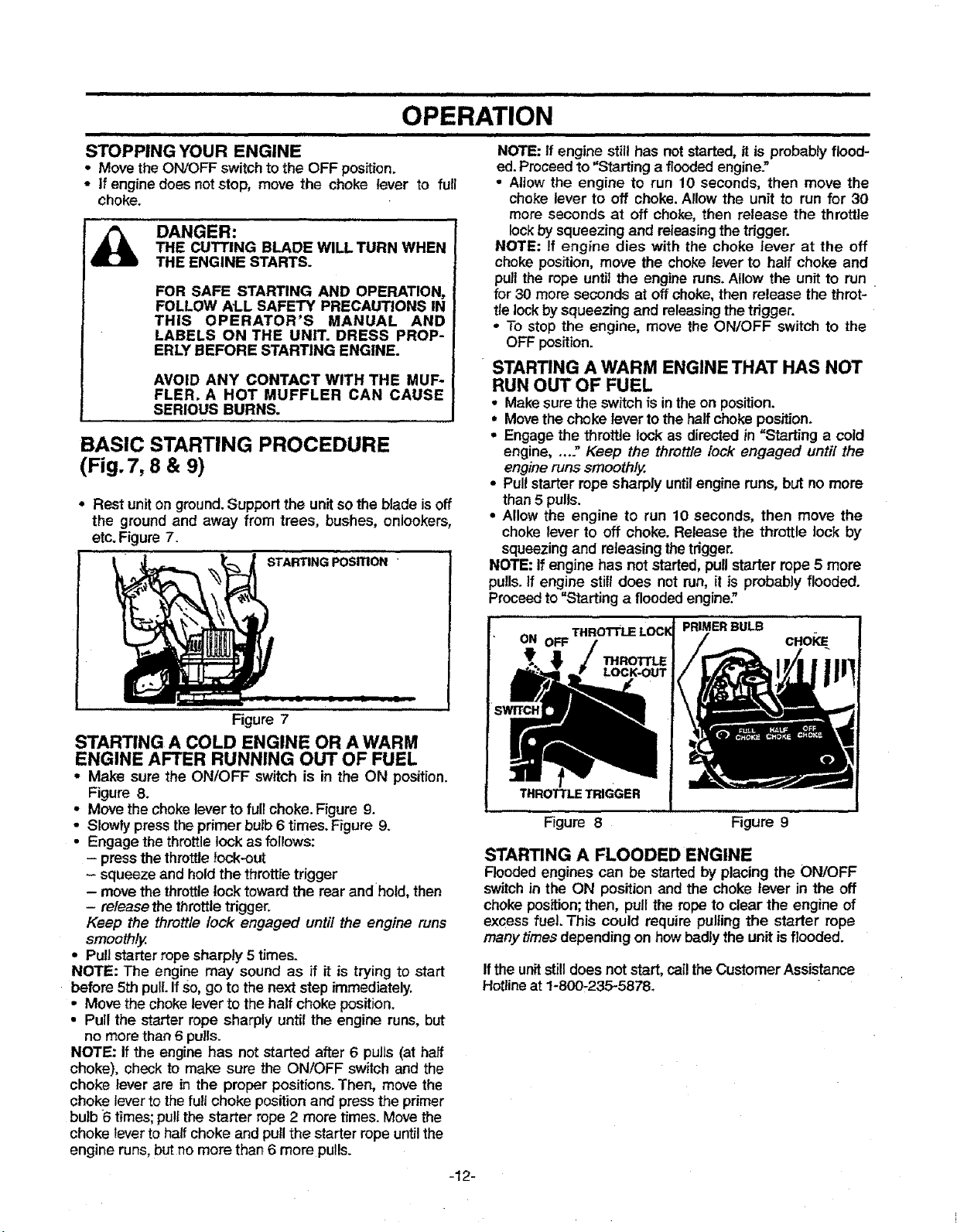

BASIC STARTING PROCEDURE

(Fig. 7, 8 & 9)

• Rest uniton ground. Support the unitso the blade is off

the ground and away from trees, bushes, onlookers,

etc. Figure 7.

q STARTING Posmo_

=,,= i,==

NOTE: ff engine still has not started, it is probably flood-

ed. Proceed to "Starting a flooded engine."

• Altow the engine to run 10 seconds, then move the

choke lever to off choke. Allow the unit to run for 30

more seconds at off choke, then release the throttle

lock by squeezing and re!easing the trigger.

NOTE: If engine dies with the choke lever at the off

choke position, move the choke lever to half choke and

pull the rope unt_ the engine runs. Allow the unit to run

for 30 more seconds at off choke, then release the throt-

tie lock by squeezing and releasing the trigger.

• To stop the engine, move the ON/OFF switch to the

OFF position.

STARTING A WARM ENGINE THAT HAS NOT

RUN OUT OF FUEL

• Make sure the switchis inthe on position.

• Movethe chokelever to the halfchokeposition.

• Engagethe throttle lock as directedin =Starting a cold

engine.... / Keep the throttle lock engaged until the

engine runs smoothly.

• Pullstarter rope sharply until engine runs, but no more

than 5 pulls.

• Allow the engine to run 10 seconds, then move the

choke lever to off choke. Release the throttle lock by

squeezing and releasing the trigger.

NOTE: If engine has not started, pullstarter rope 5 more

pulis.If engine still does not run, it is probably flooded.

Proceedto "Starting a flooded engine."

L ----It.

Figure 7

STARTING A COLD ENGINE OR A WARM

ENGINE AFTER RUNNING OUT OF FUEL

° Make sure the ON/OFF switch is in the ON position.

Figure 8.

- Move the chokelever to full choke. Figure 9.

• Slowlypress the primer bulb6 times.Figure 9.

• Engage thethrottlelockas follows:

- pressthe throttlelock-out

- squeeze and holdthe throttletrigger

- movethe throttlelock toward the rearandhold, then

- releasethe throttletrigger.

Keep the throttle lock engaged until the engine runs

smoothly.

• Pull starter rope sharply 5 times.

NOTE: The engine may sound as if it is trying to start

before 5th pull. If so, go to the next step immediately.

• Move the choke lever to the half choke position.

• Pull the starter rope sharply until the engine runs, but

no more than 6 pulls.

NOTE: If the engine has not started after 6 pulls (at half

choke), check to make sure the ON/OFF switch and the

choke lever are in the proper positions. Then, move the

choke leverto the full choke position and press the primer

bulb 6 times; pullthe starter rope 2 more times. Move the

choke lever to half choke and pull the starter rope until the

engine runs, but no more than 6 more pulls.

ON OFF

THROTTLE

LOCK*OUT

THROTrLE TRIGGER

Figure 8 Figure 9

STARTING A FLOODED ENGINE

Floodedengines can be started by placing the ON/OFF

switchin the ON position and the choke lever in the off

choke position;then, pull the ropeto clear the engine of

excess fuel, This could require pullingthe starter rope

manytimesdepending on howbadly the unitis flooded.

Ifthe unitstill does not start, cat! theCustomer Assistance

Hctline at 1-800-235-5878.

-12-

Loading...

Loading...