IMPORTANT MANUAL Do Not Throw Away

8F_A/RS

Operator's

Manual

Model No.

358,795630

CUSTOMER

ASSISTANCE

DANGER:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

Always Wear Eye Protection

CRRFTSMRNo

cc (1.3 cu. in.) 2-CYCLE

22" Blade

GAS HEDGE TRIMMER

• Assembly • Table of Contents -

• Operation Inside Back Cover

• Customer Responsibilities

• Service Adjustments

• Repair Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530-083472-1-02/11/95

i =i i inI INIII =11111==11=1

SAFETY RULES

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CON- I

TACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING,

IADJUSTING OR MAKING REPAIRS.

OPERATOR SAFETY

• Always wear safety eye protection.

• Always wear heavy long pants, long sleeves, boots and

gloves. Do not go barefoot or wear sandals, short

pants, short sleeves. Being fully covered helps to pro-

tect you from pieces of toxic plants thrown by the

blade.

• Secure hair so it above shoulder length. Secure loose

clothing or jewelry. Clothing with loosely hanging ties,

straps, tassels, etc. can be caught in moving parts.

• Do not operate this unit when you are tired, ill or under

the influence of alcohol, drugs, or medication.

• Wear hearing protection if you use this unit for more

than 1-t/2 hours per day.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kill.

• Keep handles free of oil and fuel.

• If situations occur which are not covered in this manu-

al, use care and good judgement.

UNIT MAINTENANCE/SAFETY

• Look for and replace damaged or loose parts before

each use. Look for and repair fuel leaks before use.

Keep the unit in good working condition.

• Make sure the unit is maintained and assembled cor-

rectly as listed in this manual.

= Make carburetor adjustments with the blade supported

to prevent it from contacting any object. Hold the unit

by hand.

• Keep others away when making carburetor adjust-

ments.

• Use only good quality SEARS accessories and re-

placement parts as recommended for this unit.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

= Do notsmoke or allow smoking near fuel or the unit or

while using the unit.

• Wipe up all fuel spills before starting engine.

• Move at least 10 feet (3 meters) away from fueling site

before starting engine.

•• Stop engine and allow unit to cool before removing fuel

cap_

CUTTING SAFETY

• Inspect the area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string, etc.)

which can become entangled in the blade.

* Keep others including children, animals, bystanders

and helpers a minimum of 50 feet (15 meters) away.

Stop the engine immediately if you are approached.

, Always keep the engine on the right-hand side of your

body.

. Hold the unit firmly with both hands.

= Keep firm footing and balance. Do not over-reach.

• Keep the blade below waist level

. Do not raise the engine above your shoulder.

• Keep all parts of your body away from the blade and

muffler when engine is running.

• Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

° Stop the unit before transporting.

• Allow the engine to cool, and secure the unit before

storing or transporting in a vehicle.

• Empty the fuel tank before storing or transporting the

unit. Use up any fuel left in the carburetor by starting

the engine and letting the engine run until itstops.

• Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, elec-

tric motor or switches, furnaces, etc.

• Store unit so the blade cannot accidentally cause

injury.

= Store the unitoutof the reach ofchildren.

I SAFETY NOTICE I

Exposure to vibrations through prolonged use of gasoline powered hand units could cause blood vessel or nerve damage in the fin- I

gers, hands, and joints of peopleproneto circulation disorders or abnormal swellings.Prolonged use in cold weather has beenJ

linkedto blood vessel damageinotherwisehealthypeople. If symptomsoccursuchas numbness,pain,loss of strength, change inl

skin color or texture, or loss of feeling in the fingers, hands orjoints,discontinuethe use ofthis unit and seek medical attention.An |

anti-vibrationsystem does not guaranteethe avoidance ofthese problems.Userswho operatepower tools on a continual and regu-_

lar basis must monitor closely their physical condition and theconditionofthisunit, J

[ _ LOOK FOR TH'S SYMBOl TO PO'NT OUT 'MPORTANT SAFE_ P"EOAU"O "'-

IT MEANS - ATI'ENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

-2-

DANGER:

THIS POWER UNIT CAN BE DANGEROUS! THIS UNIT CAN CAUSE SERIOUS INJURY INCLUDING

AMPUTATION OR BLINDNESS TO THE OPERATOR AND OTHERS. THE WARNINGS AND SAFETY

INSTRUCTIONS IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE REASONABLE SAFETY AND

EFFICIENCY IN USING THIS UNIT. THE OPERATOR IS RESPONSIBLE FOR FOLLOWING THE WARN-

INGS AND INSTRUCTIONS IN THIS MANUAL AND ON THE UNIT. READ THE ENTIRE OPERATOR'S

MANUAL BEFORE ASSEMBLING AND USING THE UNIT! RESTRICT THE USE OF THIS POWER TOOL

TO PERSONS WHO READ, UNDERSTAND, AND FOLLOW THE WARNINGS AND INSTRUCTIONS IN

THIS MANUAL AND ON THE UNIT. NEVER ALLOW CHILDREN TO USE THIS TOOL.

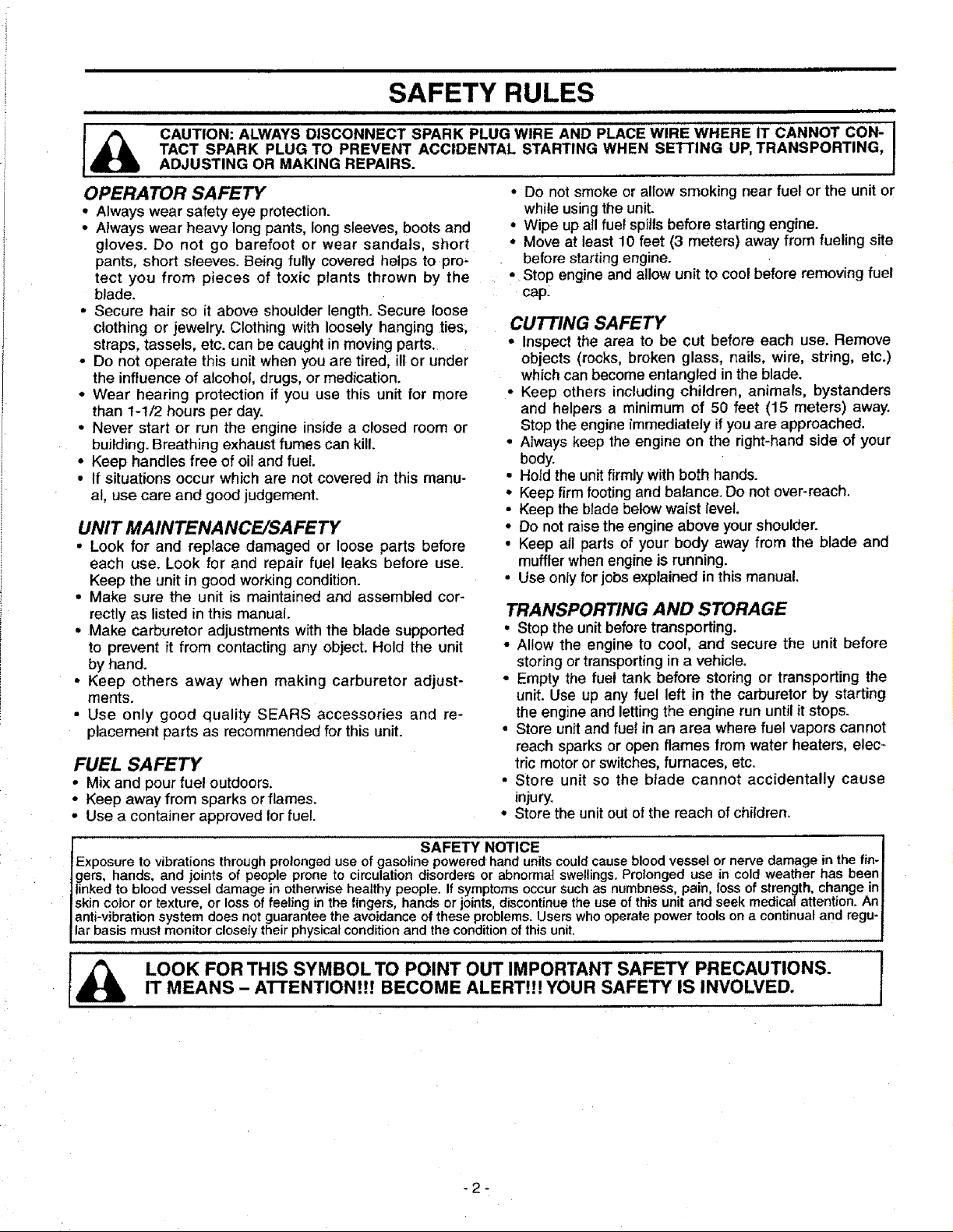

WARNING:

CUTTING BLADE CAN THROW OBJECTS

VIOLENTLY. YOU CAN BE BLINDED OR

INJURED. ALWAYS WEAR EYE AND LEG

PROTECTION.

BLADE MOVES MOMENTARILY AFTER

TRIGGER IS RELEASED. THE CUTTING

BLADE CAN SERIOUSLY CUT YOU OR

OTHERS. ALLOW CUTTING BLADE TO

STOP BEFORE REMOVING IT FROM THE

CUT.

LEG GUARDS

EYE PROTECT|ON BOOTS

HAZARDZONE

HAZARD ZONE FOR CUTTING BLADE.

THE CUTTING BLADE CAN SERIOUSLY

CUT YOU OR OTHERS. OTHERS CAN BE

BLINDED OR INJURED. KEEP PEOPLE

AND ANIMALS A MINIMUM OF 15 FEET

(5 METERS) AWAY.

READ OPERATOR'S MANUAL. FOLLOW

ALL WARNINGS AND INSTRUCTIONS.

FAILURE TO DO SO CAN RESULT IN SERI-

OUS INJURY.

-3-

OPERATOR'S

MANUAL

SAFETY

LABEL

CONGRATULATIONS on your purchase of a Sears

Craftsman Gas Hedge Trimmer. It has been designed,

engineered and manufactured to give you the best possi-

ble dependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department. Sears has competent, well trained tech-

nicians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions wilt

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES."

MODEL NUMBER: 358.795630

DATE CODE/SERIAL NO.:

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON THE PRODUCT.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OR PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

° Follow a regular schedule in maintaining, caring for,

and using your unit.

- Follow the instructions under "Customer Responsibili-

ties" and "Storage" sections of this Operator's Manual.

PRODUCT SPECIFICATIONS

CUTTING BLADE ............... 22"

ENGINE .............................. 21 cc, 2-cycle Air-Cooled

FUEL/OIL MIX RATIO......... 40:1 (3.2 oz.oil per

gallon gas)

IGNITION ............................ Solid State

(air gap .010" to .014")

IGNITION TIMING .............. Non-adjustable, fixed

SPARK PLUG ..................... Champion (RCJ-8Y)

SPARK PLUG GAP .............. 024 to .028"

ENGINE RPM ..................... 9,000 RPM Max.

SPECIAL NOTICE

For users on U.S. Forest Landand in somestates, includ-

ing California (Public Resources Codes 442 and 443),

tdaho, Maine, Minnesota, New Jersey, Oregon, and

Washington: Certain internal combustion engines operated

on forest, brush, and/or grass-covered lands in the above

areas are required to be equipped with a spark arrestor,

maintained in effective working order, or the engine must be

constructed,equipped, and maintainedfor the prevention of

fire. Check with your state or localauthorities for regulations

pertaining to these requirements. Failure to follow these

requirementsis a violation of the law. This unit is not facto-

ry-equippedwith a spark arrestor; however, a spark arrestor

is available as an optional part. if a spark arrestor is

required in your area, contact your SEARS Service

Center/Departmentfor the correct kit.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS:

4,035,912; 4.052.78.9; 4,236.312; 4,286,675; 4,290,200; 4_352,243; 4,366,621; 4,366.622;

4,451,983; 4,798,t85: 4,819,742; 4,823,465: 4,825,548: 4.835,867; 4,841,929: 4.852,25B;

4,897,923; 4.940,028; 5,020,223; & D304.196_ OTHER U.S. AND FOREIGN PATENTS

PENDING.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS-POWERED HEDGE TRIMMER

For one year from the date of purchase, when this Craftsman Gas-Powered Hedge Trimmer is maintained, lubricated

and tuned up according to the operating and maintenance instructions in the Operator's Manual, Sears will repair,

free of charge, any defect in materials or workmanship.

This warranty excludes blade, spark plug, and air filter, which are expendable parts and become worn during normal

use.

if this Hedge Trimmer is used for commercial purposes, this warranty applies for only 90 days from the date of pur-

chase, tf this Hedge Trimmer is used for rental purposes, this warranty applies for only 30 days from date of purchase.

This warranty applies only while this product is in use in the United States.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HEDGE TRIMMER TO THE NEAREST SEARS SER-

VICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

-4-

]

i iiiiiiii iiiiiiiiiiiiii iii

HARDWARE CONTENTS

lUlll iiii iiii i i

ENGINE OIL

THIS MODEL COMES FULLY ASSEMBLED

NOTE: It is normal to hear the fuel filterrattle in an empty

fuel tank.

OPERATOR'S MANUAL

, , J

TO REMOVE HEDGETRIMMER FROM

CARTON

• Removelooseparts included with Hedge Trimmer.

• Remove looseplastic parts bag from the carton.

° Remove all packingmaterial.

• Checkcartonthoroughlyfor additional loose parts.

• Usecardboard liner as work surface during inspection

of unit.

-- -_ • m,,, ,,,I m rim = =1 = = ........................................

OPERATION

nfi ._ ii J ,lllli i _ _ • ....

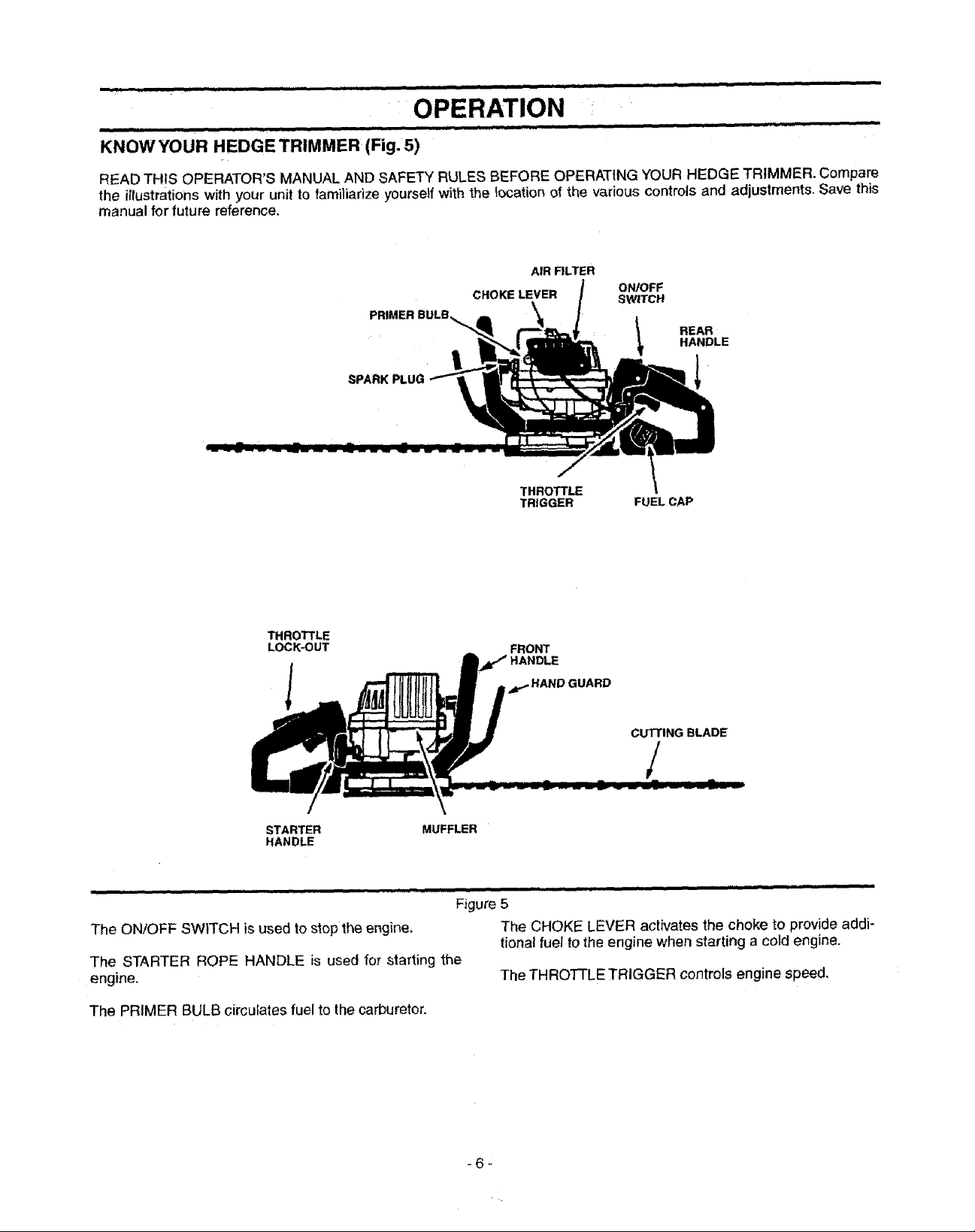

KNOW YOUR HEDGE TRIMMER (Fig. 5)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR HEDGE TRIMMER. Compare

the ittustrationswith your unit to familiarize yourself with the location of the various controls and adjustments. Save this

manual for future reference.

AIR FILTER

CHOKE LEVER SWITCH

PRIMER BULB.,_,..

ON/OFF

REAR

HANDLE

t

SPARK PLUG

THROTTLE

TRIGGER FUEL CAP

THROTTLE

LOCK-OUT

FRONT

HANDLE

r_ HAND GUARD

CUTTING BLADE

/

STARTER MUFFLER

HANDLE

Figure 5

The ON/OFF SWITCH is used to stop the engine, The CHOKE LEVER actfvates the choke to provide addi-

tional fueI to the engine when starting a cold engine.

The STARTER ROPE HANDLE is used for starting the

engine. The THROTTLE TRIGGER controls engine speed,

The PRIMER BULB circulates fuel to the carburetor.

-6-

Ul III I IIIIIIIIIIII I III _IHI Jlllll UJLI

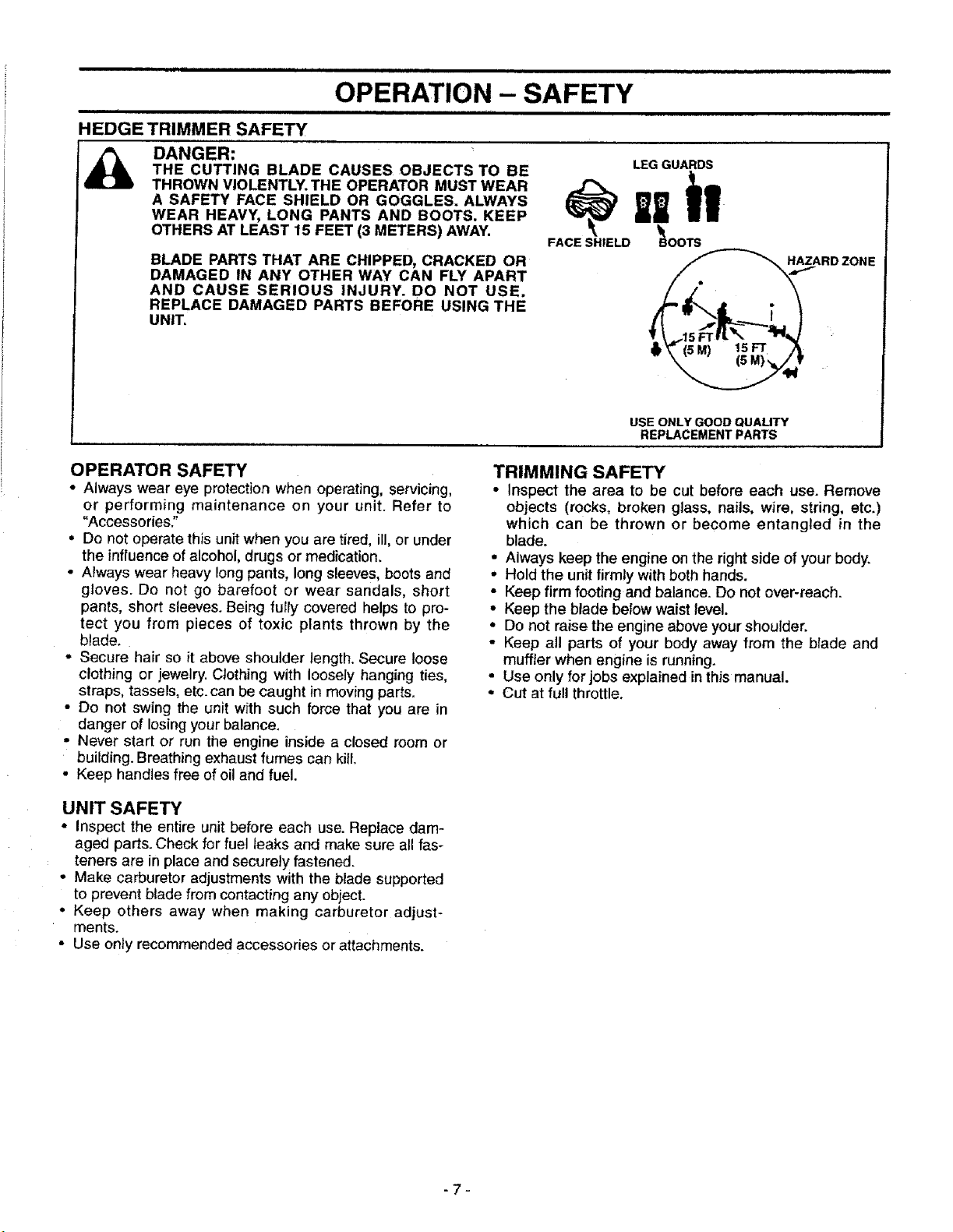

HEDGE TRIMMER SAFETY

DANGER:

THE CUTTING BLADE CAUSES OBJECTS TO BE

THROWN VIOLENTLY. THE OPERATOR MUST WEAR

A SAFETY FACE SHfELD OR GOGGLES. ALWAYS

WEAR HEAVY, LONG PANTS AND BOOTS. KEEP

OTHERS AT LEAST 15 FEET (3 METERS) AWAY.

BLADE PARTS THAT ARE CHIPPED, CRACKED OR

DAMAGED IN ANY OTHER WAY CAN FLY APART

AND CAUSE SERIOUS INJURY. DO NOT USE.

REPLACE DAMAGED PARTS BEFORE USING THE

UNIT.

OPERATION - SAFETY

iiiii, ii, iii iiiiiiihlllll

LEG GUARDS

@ ,il

FACE SHIELD BOOTS

HAZARDZONE

USE ONLY GOOD QUAUTY

REPLACEMENT PARTS

OPERATOR SAFETY

• Always wear eye protection when operating, servicing,

or performing maintenance on your unit. Refer to

"Accessories."

° Do not operate this unit when you are tired, ill, or under

the influence of alcohol, drugs or medication.

• Always wear heavy long pants, long sleeves, boots and

gloves. Do not go barefoot or wear sandals, short

pants, short sleeves. Being fully covered helps to pro-

tect you from pieces of toxic plants thrown by the

blade.

• Secure hair so it above shoulder length. Secure loose

clothing or jewelry. Clothing with loosely hanging ties,

straps, tassels, etc. can be caught in moving parts.

• Do not swing the unit with such force that you are in

danger of losing your balance.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kiIL

• Keep handles free of oil and fuel.

UNIT SAFETY

• Inspect the entire unit before each use. Replace dam-

aged parts. Check for fuel leaks and make sure all fas-

teners are in place and securely fastened.

• Make carburetor adjustments with the blade supported

to prevent blade from contacting any object.

• Keep others away when making carburetor adjust-

ments.

• Use only recommended accessories or attachments.

TRIMMING SAFETY

• Inspect the area to be cut before each use. Remove

objects (rocks, broken glass, nails, wire, string, etc.)

which can be thrown or become entangled in the

blade.

° Always keep the engine on the right side of your body.

° Hold the unit firmly with both hands.

• Keep firm footing and balance. Do not over-raach.

• Keep the blade below waist level.

• Do not raise the engine above your shoulder.

• Keep all parts of your body away from the blade and

muffler when engine is running.

• Use only for jobs explained in this manual.

• Cut at full throttle.

-7-

== i i =llllU i i

OPERATION

H =,,,,= H,

STOPPING YOUR ENGINE

° Move the ON/OFF switch to the OFF position.

• Ifengine does not stop, move the choke lever to the fuli

choke.

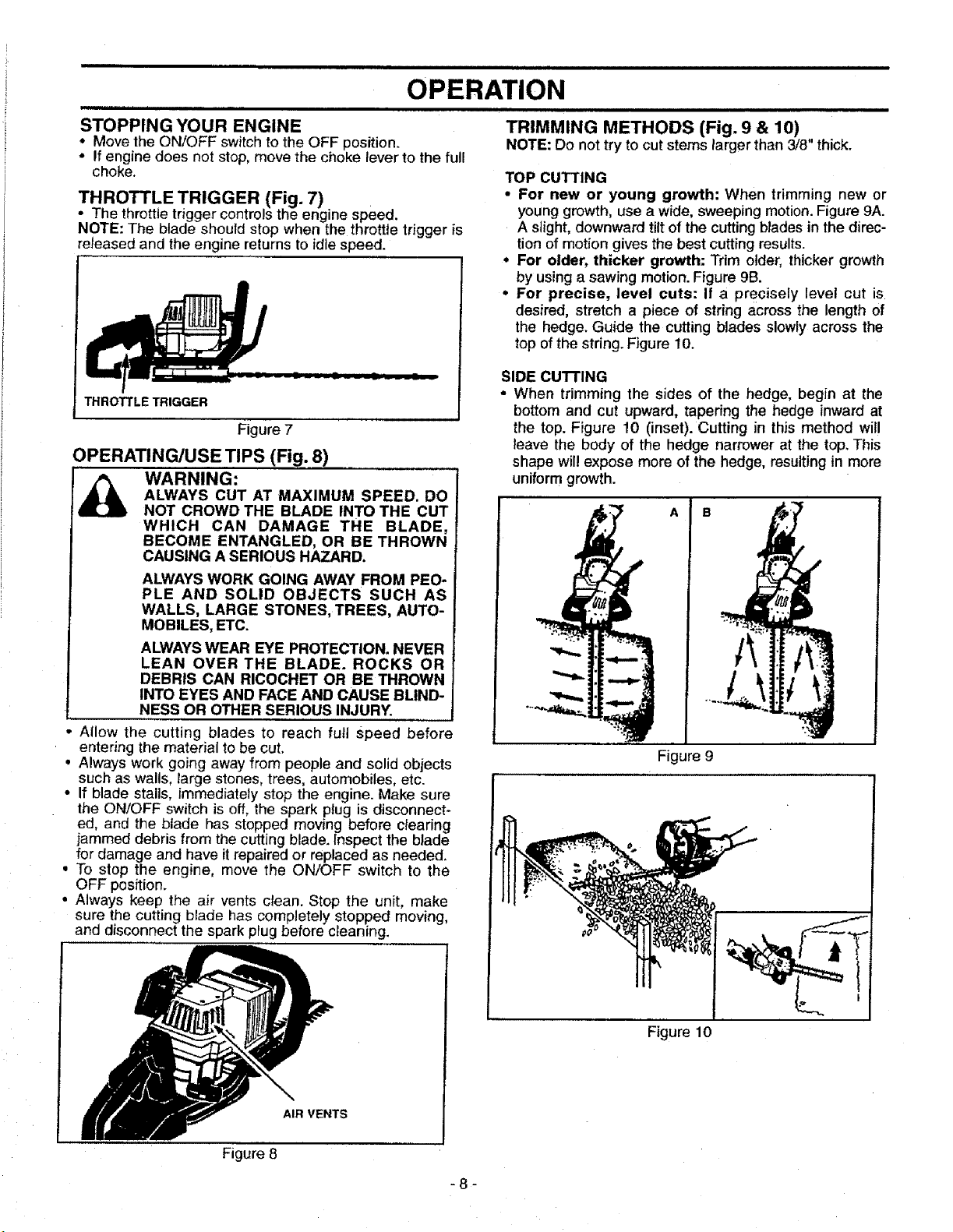

THROTTLE TRIGGER (Fig. 7)

• The throttle trigger controls the engine speed.

NOTE: The blade should stop when the throttle trigger is

released and the engine returns to idle speed.

THROTTLE TRIGGER

Figure 7

OPERATING/USE TIPS (Fig. 8)

I_ WARNING:

Allow the cutting blades to reach futl Speed before

entering the material to be cut.

• Always work going away from people and solid objects

such as walls, large stones, trees, automobiles, etc.

• If blade stalls, immediately stop the engine. Make sure

the ON/OFF switch is off, the spark plug is disconnect-

ed, and the blade has stopped moving before clearing

jammed debris from the cutting blade. Inspect the blade

for damage and have it repaired or replaced as needed.

• To stop the engine, move the ON/OFF switch to the

OFF position_

• Always keep the air vents clean. Stop the unit, make

sure the cutting blade has completely stopped moving,

and disconnect the spark plug before cleaning.

ALWAYS CUT AT MAXIMUM SPEED. DO

NOT CROWD THE BLADE INTO THE CUT

WHICH CAN DAMAGE THE BLADE,

BECOME ENTANGLED, OR BE THROWN

CAUSING A SERIOUS HAZARD.

ALWAYS WORK GOING AWAY FROM PEO-

PLE AND SOLID OBJECTS SUCH AS

WALLS, LARGE STONES, TREES, AUTO-

MOBILES, ETC.

ALWAYS WEAR EYE PROTECTION. NEVER

LEAN OVER THE BLADE. ROCKS OR

DEBRIS CAN RICOCHET OR BE THROWN

INTO EYES AND FACE AND CAUSE BLIND-

NESS OR OTHER SERIOUS INJURY.

TRIMMING METHODS (Fig. 9 & 10)

NOTE: Do not try to cutstems larger than 3/8" thick.

TOP CUTTING

• For new or young growth: When trimming new or

young growth, use a wide, sweeping motion.Figure 9A.

A stight,downward tiltof the cuttingbtades in the direc-

tion of motion gives the best cutting results.

• For older, thicker growth: Trim older, thicker growth

by using a sawing motion.Figure 9B.

° For precise, level cuts: If a precisely level cut is

desired, stretch a piece of string across the length of

the hedge. Guide the cutting blades slowly across the

top of the string. Figure 10.

SIDE CUTTING

• When trimming the sides of the hedge, begin at the

bottom and cut upward, tapering the hedge inward at

the top. Figure 10 (inset). Cutting in this method will

leave the body of the hedge narrower at the top. This

shape will expose more of the hedge, resultingin more

uniform growth.

Figure 9

Figure 8

Figure 10

AIR VENTS

-8-

i ii iilll i i i i i iiii, ,i i,,i i

OPERATION

BEFORE STARTING ENGINE

WARNING:

BE SURE TO READ THE FUEL SAFETY

INFORMATION IN THE SAFETY RULES

SECTION ON PAGE 2 OF THIS MANUAL

BEFORE YOU BEGIN.

IFYOU DO NOT UNDERSTAND THE FUEL

SAFETY SECTION DO NOT ATTEMPT TO

FUEL YOUR UNIT; SEEK HELP FROM

SOMEONE WHO DOES UNDERSTAND

THE FUEL SAFETY SECTION OR CALL

THE CUSTOMER ASSISTANCE HOTLINE

AT 1-800-235-5878.

GASOLINE

The two-cycle engine on this product requires a fuel mix-

ture of regular unleaded gasoline and a high quality 40:1

2-cycle engine oil (AIR-COOLED) for lubrication of the

bearings and other moving parts, The correct fuel/oil mix-

ture is 40:1 (see Fuel Mixture Chart). Too little oil or the

incorrect oil type will cause poor performance and may

cause the engine to overheat and seize.

Gasoline and oil must be premixed in a clean approved

fuel container, Always use fresh regular unleaded gaso-

line.

This engine is certified to operate on unleaded gasoline.

IMPORTANT: Experience indicates that alcohol blended

fuels called gasohol (or using ethanol or methanol) can

attract moisture, which leads to oil/gas separation and

formation of acids during storage. Acidic gas can dam-

age the fuel system of an engine while in storage. To

avoid engine problems, the fuel system should be emp-

tied before storage for 30 days or longer. Drain the gas

tank, then run the fuel out of the carburetor and fuel lines

by starting the engine and letting it run until it stops. Use

fresh fuel next season. See STORAGE instructions for

additional information. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage

may occur.

2-CYCLE AIR-COOLED ENGINE OIL

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

strongly recommended. This oil is specially blended with

fuel stabilizers for increased fuel stability (extends fuel life

up to 5 times longer) and reduced smoke.

If CRAFTSMAN 2-cycle engine oil (AIR-COOLED) is not

available, use a good quality 2-cycle engine oil (AIR-

COOLED) that has a recommended fuel mix ratio of 40:1.

IMPORTANT! Do no use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA, etc.)

These oils do not have proper additives for 2-cycle AIR-

COOLED engines and can cause engine damage.

GASOLINE AND OIL MIXTURE

Mix gasoline and oil as follows:

• Consult chart for correct quantities.

- Do not mix gasoline and oil directly in the unit's fuel

tank.

FOR ONE GALLON:

° Pour 3.2 ounces of high quality, 40:1 2-cycle engine oil

(AIR-COOLED) into an empty, approved one gallon

gasoline container.

• Add one gallon of regular unleaded gasoline to the gal-

lon container, then securely replace the cap.

• Shake the container.

° The mixture is now ready for use. Fuel stabilizer can be

added at this time if desired; follow mixing instructions

on the label.

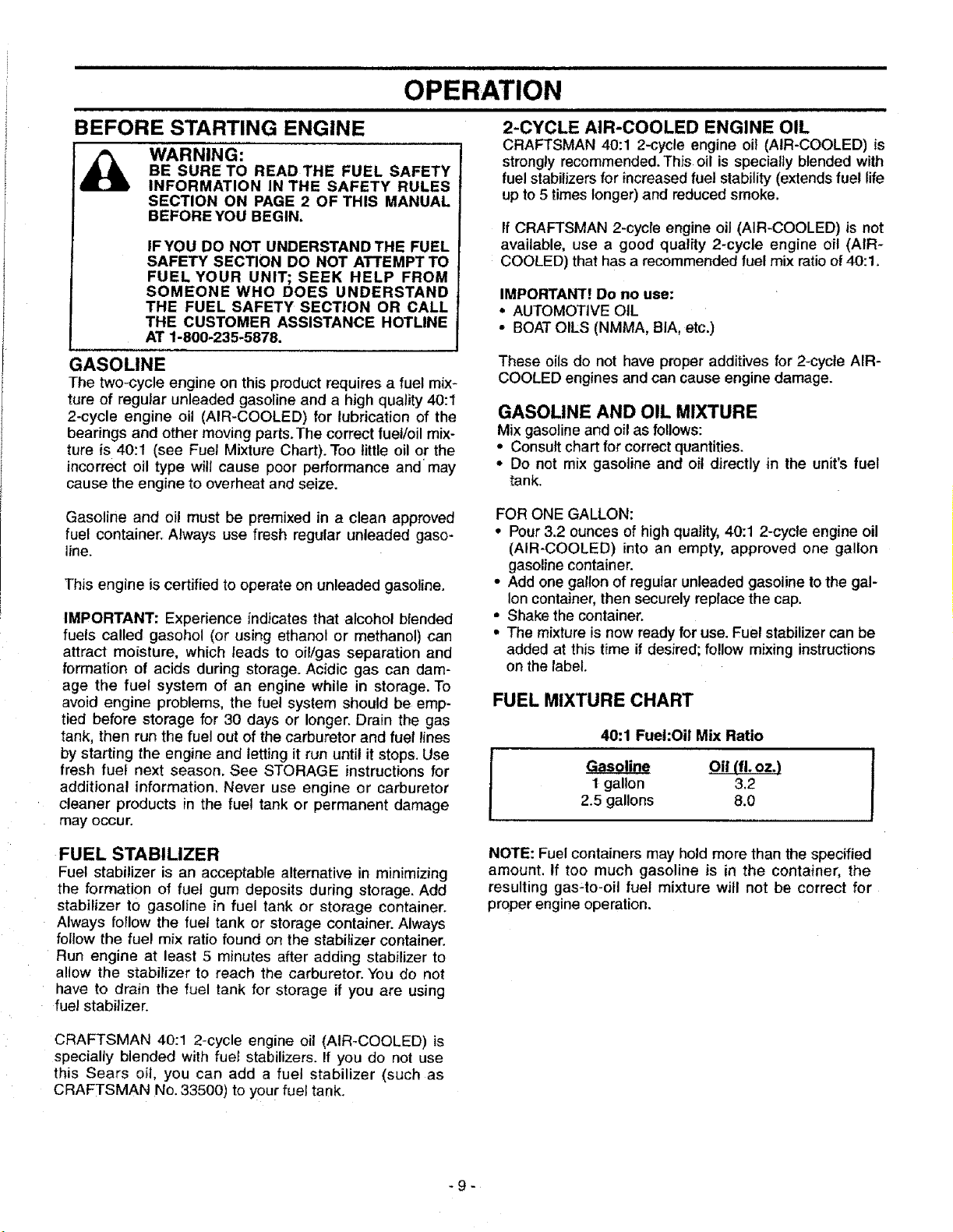

FUEL MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

Gasoline Oil (ft. oz.)

1 gallon 3,2

I

2.5 gallons 8.0 I

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Add

stabilizer to gasoline in fuel tank or storage container.

Always follow the fuel tank or storage container. Always

follow the fue! mix ratio found on the stabilizer container.

Run engine at least 5 minutes after adding stabilizer to

allow the stabilizer to reach the carburetor. You do not

have to drain the fuel tank for storage if you are using

fue! stabilizer.

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

specially blended with fuel stabilizers. If you do not use

this Sears oil, you can add a fuel stabilizer (such as

CRAFTSMAN No. 33500) to your fuel tank.

NOTE: Fuel containers may hold more than the specified

amount. If too much gasoline is in the container, the

resulting gas-to-oil fuet mixture will not be correct for

proper engine operation.

-9-

i

OPERATION

STOPPING YOUR ENGINE

• Move the ON/OFF switch to the OFF position.

• If engine does not stop, move the choke lever to the full

choke.

THE CUTTING BLADE WILL TURN WHEN

DANGER:

THE ENGINE STARTS,

FOR SAFE STARTING AND OPERATION,

FOLLOW ALL SAFETY PRECAUTIONS IN

THIS OPERATOR'S MANUAL AND

LABELS ON THE UNIT. DRESS PROP-

ERLY BEFORE STARTING ENGINE.

AVOID ANY CONTACT WITH THE MUF-

FLER. A HOT MUFFLER CAN CAUSE

SERIOUS BURNS.

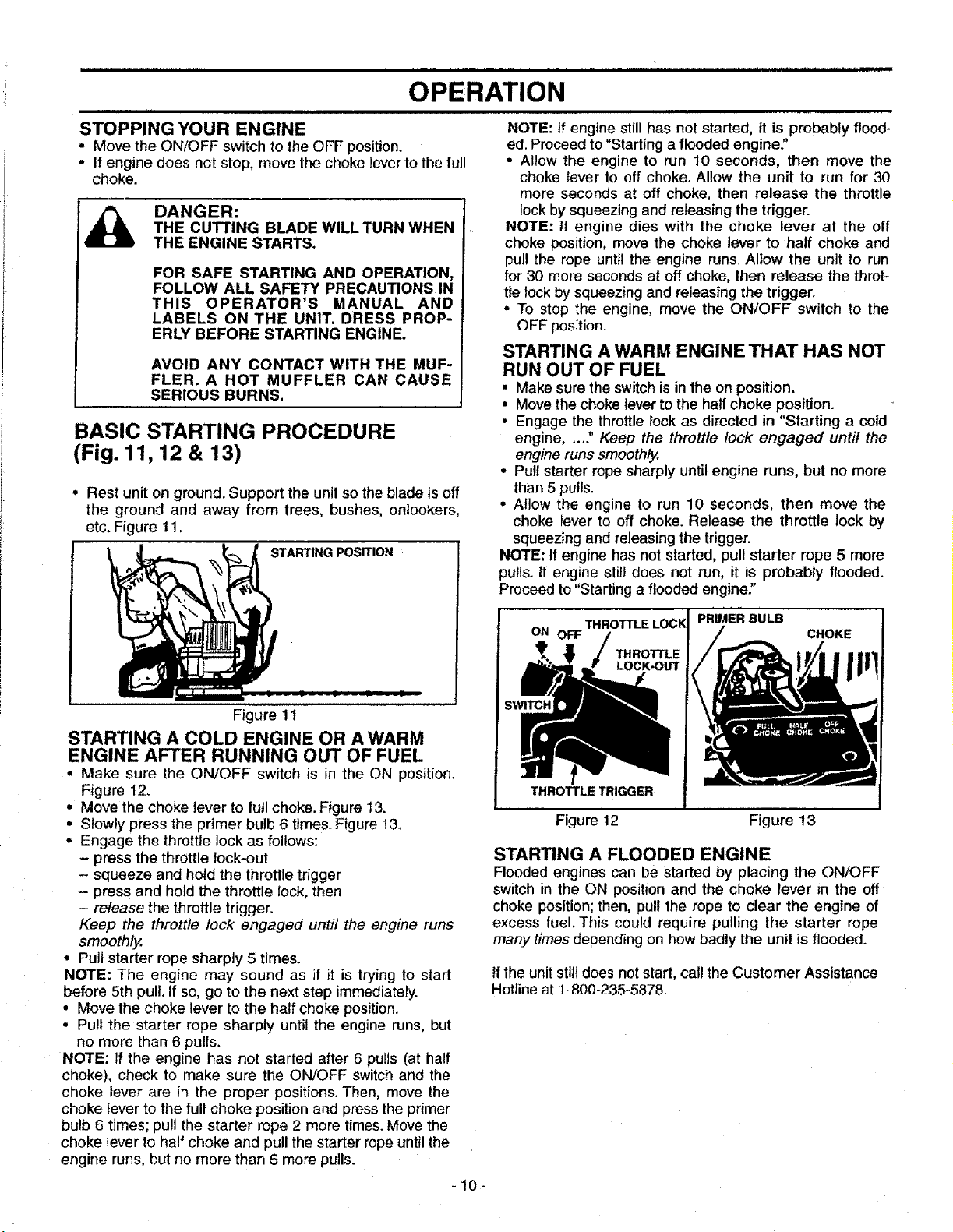

BASIC STARTING PROCEDURE

(Fig. 11, 12 & 13)

• Rest unit on ground. Support the unit so the blade is off

the ground and away from trees, bushes, onlookers,

etc. Figure 11.

STARTING POSITION

NOTE: If engine still has not started, it is probably flood-

ed. Proceed to "Starting a flooded engine:'

• Allow the engine to run 10 seconds, then move the

choke fever to off choke. Allow the unit to run for 30

more seconds at off choke, then release the throttle

lock by squeezing and releasing the trigger.

NOTE: If engine dies with the choke lever at the off

choke position, move the choke lever to half choke and

pull the rope until the engine runs. Allow the unit to run

for 30 more seconds at off choke, then release the throt-

tle lock by squeezing and releasing the trigger.

• To stop the engine, move the ON/OFF switch to the

OFF posJtion.

STARTING A WARM ENGINE THAT HAS NOT

RUN OUT OF FUEL

• Make sure the switchisin the on position.

• Move the choke lever to the half choke position.

• Engage the throttlelock as directed in "Starting a cold

engine .... ." Keep the throttle lock engaged until the

engine runs smoothly.

° Pull starter rope sharply until engine runs, but no more

than 5 pulls.

• Allow the engine to run 10 seconds, then move the

choke lever to off choke. Release the throttle lock by

squeezing and releasing the trigger.

NOTE: If engine has not started, pull starter rope 5 more

pulls.If engine still does not run, it is probably flooded.

Proceed to "Starting a flooded engine'.'

Figure 11

STARTING A COLD ENGINE OR A WARM

ENGINE AFTER RUNNING OUT OF FUEL

. Make sure the ON/OFF switch is in the ON position.

Figure 12.

= Move the choke lever to full choke. Figure 13.

• Slowly press the primer bulb 6 times. Figure 13.

• Engage the throttle lockas follows:

- press the throttle tock-out

- squeeze and hold the throttle trigger

- press and hold the throttle lock, then

- release the throttle trigger.

Keep the throttle lock engaged until the engine runs

smoothly.

• Pull starter rope sharpty 5 times.

NOTE: The engine may sound as if it is trying to start

before 5th pull If so, go to the next step immediately.

• Move the choke lever to the half choke position.

• Pull the starter rope sharply until the engine runs, but

no more than 6 pulls.

NOTE: If the engine has not started after 6 pulis (at half

choke), check to make sure the ON/OFF switch and the

choke lever are in the proper positions.Then, move the

choke lever to the full choke position and press the primer

bulb 6 times; pull the starter rope 2 more times.Move the

choke lever to half choke and pull the starter rope until the

engine runs, but no more than 6 more pulls.

ON OFF

THROTTLE TRIGGER

THROTFLE LOCK PRIMER BULB

THRO'fTLE

LOCK.OUT

Figure 12 Figure 13

STARTING A FLOODED ENGINE

Flooded engines can be started by placing the ON/OFF

switch in the ON positronand the choke lever in the off

choke position;then, pull the rope to clear the engine of

excess fuel. This could require pulling the starter rope

many timesdepending on how badly the unit is flooded.

If the unit still does not start, call the Customer Assistance

Hotiine at 1-800-235-5878.

-10-

CHOKE

CUSTOMER RESPONSIBILITIES

L ,,,HH= I Jl = ==,H,,,,

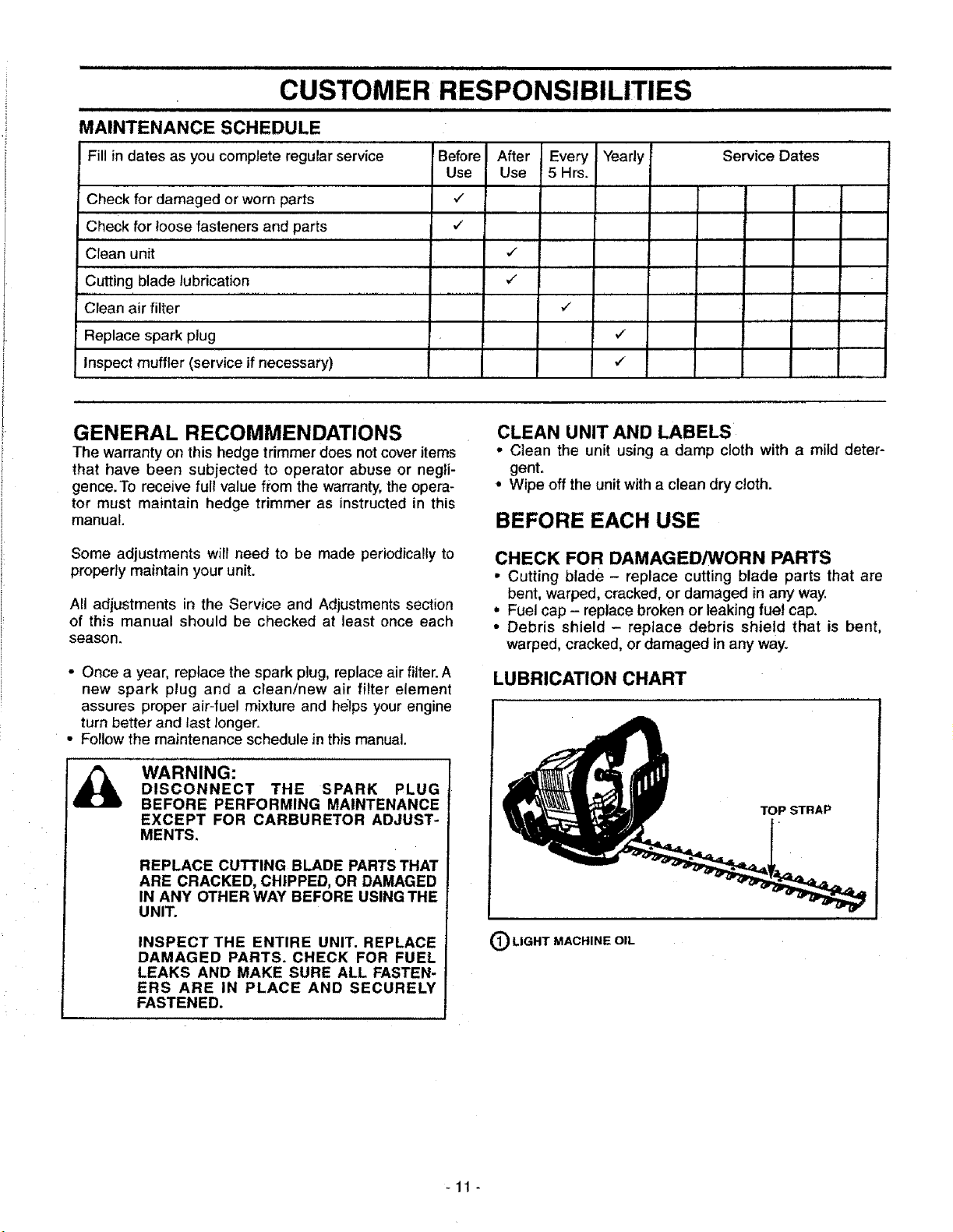

MAINTENANCE SCHEDULE

=H ,,i = , ===1=== ii

Fill in dates as you complete regular service Before After Every Yeady Service Dates

Use Use 5 Hrs.

Check for damaged or worn parts _"

Check for loose fasteners and parts _

Clean unit ,,"

,, ,

Cutting blade lubrication ,,"

Clean air filter

L ,. ,,,,

Replace spark plug ,/

Inspect muffler (service if necessary) v_

GENERAL RECOMMENDATIONS

The warranty on this hedge trimmer does not coveritems

that have been subjected to operator abuse or negli-

gence.To receive full value from the warranty,the opera-

CLEAN UNIT AND LABELS

• Clean the unit using a damp cloth with a mild deter-

gent.

• Wipe off the unit with a clean dry cloth.

tor must maintain hedge trimmer as instructed in this

manual.

Some adjustments will need to be made periodically to

properly maintain your unit

All adjustments in the Service and Adjustments section

of this manual should be checked at least once each

season

BEFORE EACH USE

CHECK FOR DAMAGED/WORN PARTS

. Cutting blade - replace cutting blade parts that are

bent, warped, cracked, or damaged in any way.

• Fuel cap - replace broken or leaking fuel cap.

• Debris shield - reptace debris shield that is bent,

warped, cracked, or damaged in any way.

• Once a year, replace the spark plug, replace air filter A

new spark plug and a clean/new air filter element

assures proper air-fuel mixture and helps your engine

turn better and last tonger.

• Follow the maintenance schedule in this manual.

DISCONNECT THE SPARK PLUG

WARNING:

BEFORE PERFORMING MAINTENANCE

EXCEPT FOR CARBURETOR ADJUST-

MENTS.

REPLACE CUTTING BLADE PARTS THAT

ARE CRACKED, CHIPPED, OR DAMAGED

IN ANY OTHER WAY BEFORE USING THE

UNIT.

INSPECT THE ENTIRE UNIT. REPLACE

DAMAGED PARTS. CHECK FOR FUEL

LEAKS AND MAKE SURE ALL FASTEN-

ERS ARE IN PLACE AND SECURELY

FASTENED.

LUBRICATION CHART

TOP STRAP

O LIGHT MACHINE OIL

-11 -

i i i i iiiiiiii i i Jill

CUSTOMER RESPONSIBILITIES

i i J

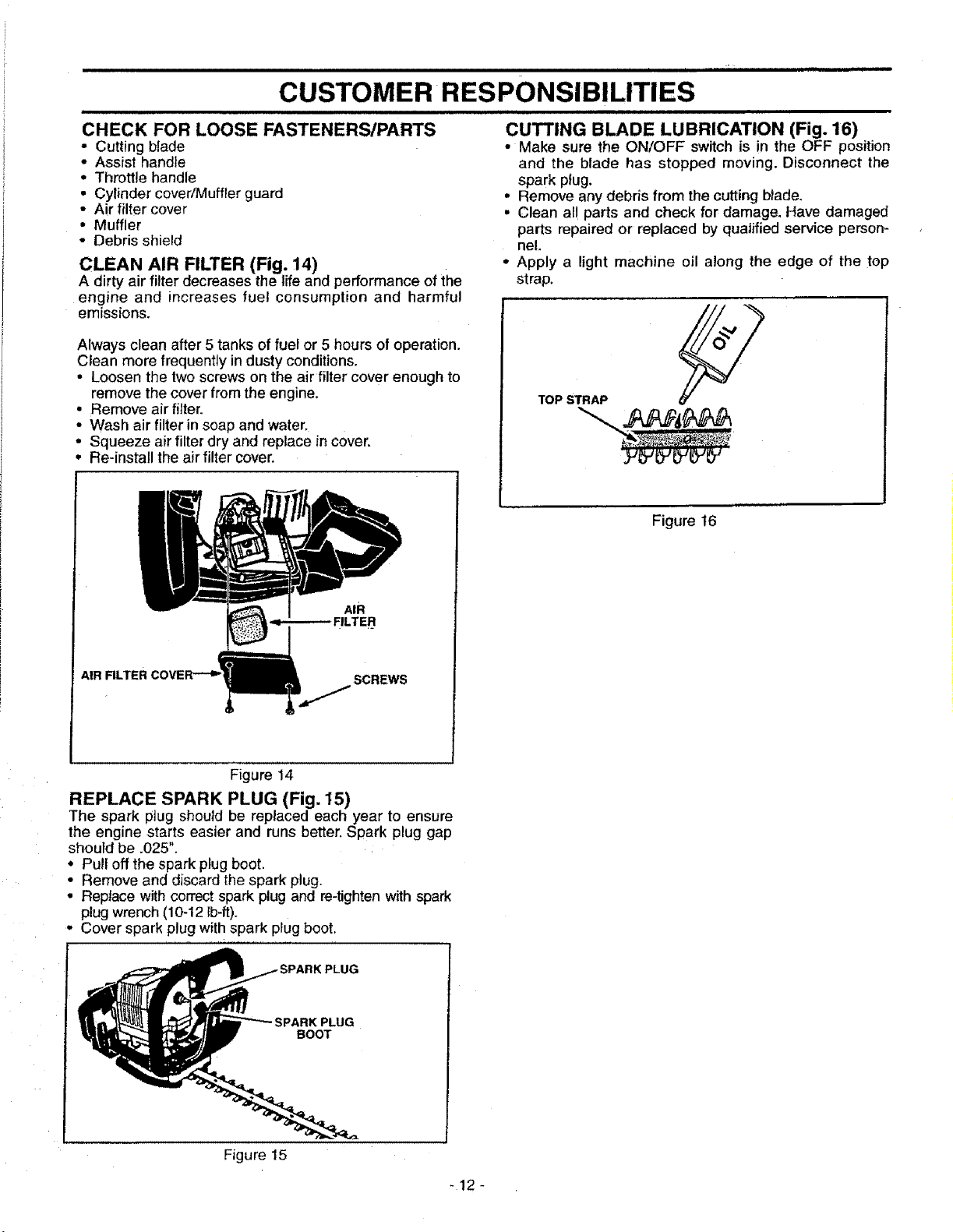

CHECK FOR LOOSE FASTENERS/PARTS CUTTING BLADE LUBRICATION (Fig. 16)

• Cutting blade • Make sure the ON/OFF switch is in the OFF position

• Assist handle and the blade has stopped moving. Disconnect the

• Throttle handle spark plug.

• Cylinder cover/Muffler guard • Remove any debris from the cutting blade,

• Air filter cover • Clean all parts and check for damage, Have damaged

• Muffler parts repaired or replaced by qualified service person-

* Debris shield nel.

CLEAN AIR FILTER (Fig. 14) - Apply a light machine oil along the edge of the top

A dirty air filter decreases the life and performance of the strap.

engine and increases fuel consumption and harmful

Always clean after 5 tanks of fuel or 5 hours of operation.

Clean more frequently in dusty conditions.

emissions.

• Loosen the two screws on the air filter cover enough to

remove the cover from the engine. TOPSTRAP

• Remove air filter. "___ _ ,,n_ __,!#'k_ _

• Wash air filter in soap and water.

• Squeeze air filter dry and replace in cover.

• Re-install the air filter cover. _JI_JlY_ J

AIR FILTER

SCREWS

Figure 14

REPLACE SPARK PLUG (Fig, 15)

The spark plug should be replaced each year to ensure

the engine starts easier and runs better. Spark plug gap

should be ,025".

* Pull off the spark plug boot.

° Remove and discard the spark plug.

, Replace with correct spark plug and re-tighten with spark

plug wrench (10-12 Ib-ft).

- Cover spark plug with spark plug boot.

Figure 16

Figure 15

BOOT

-12 -

i ii ii iiii i i iiiiiiii i i i HIIIIIIIIIIIIIIIIII

SERVICE AND ADJUSTMENTS

ii iii iii iiiiiiiiiii n ii iii ii iiiiiiiiiiiiiii

CARBURETOR ADJUSTMENTS

Carburetor adjustment is critical and if done improperly can permanently damage the engine as well as the carbure-

tor. Please readall instructions and consult theTroubleshooting section of this manual before beginning this process.

Ifthe engine does not operate according to these instructions after repeating the adjusting steps, do not use the unit.

Call the 1-800 number listed on the front of this manual for further assistance or take itto your nearest Sears Service

Center/Department.

If engine does not start, it may be flooded. If in doubt, LOWSPEED _,_

read the section on flooded engine in the starting section MIXTURE IDLESPEED

of this manual prior to beginning any adjustments. ADJUSTMENT ADJUSTMENT

If you are unsure about adjusting the carburetor or expe-

rience any problem while attempting this process, please

call the 1-800 number Iisted on the front cover of this

manual for further assistance,

The carburetor has been adjusted at the factory for sea

teve! conditions. Adjustments may become necessary if

the unit is used at significantly higher altitudes or if you

notice any of the following conditions:

• Engine will not continue to run at idle position. See

"Idle speed adjustment."

• Blade continues to move when the engine idles.See

"idle speed adjustment."

• Engine dies or hesitates when it should accelerate.

See "Acceleration check."

• Loss of cutting power which cannot be corrected by

cleaning the air filter. See "High speed adjustment."

NOTE: Do not attempt to turn the adjustments beyond

the stops as damage can occur.

WARNING:

MAKE CARBURETOR ADJUSTMENTS

WITH THE LOWER END SUPPORTED TO

PREVENT BLADE FROM CONTACTING

ANY OBJECT. HOLD UNIT WITH YOUR

HAND.

THE BLADE WILL BE SPINNING DURING

MOST OF THIS PROCEDURE. WEAR

YOUR PROTECTIVE EQUIPMENT AND

OBSERVE ALL SAFETY PRECAUTIONS.

HIGH SPEED

MIXTURE

Figure 17

ADJUSTING PROCEDURE

PREPARATION

• Use a fresh fuel mix. See the Fueling section.

• Start the engine. Trim hedges for 3 minutes to warm

engine. The engine must be at operating temperature

before carburetor adjustments can be performed cor-

rect/y.

IDLE SPEED ADJUSTMENT

• Allow engine to idle.

• Adjust idle speed until the engine continues to run

without stalling and without blade moving.

- Turn idle speed adjustment clockwise to increase

engine speed if the engine stalls or dies.

- Turn idle speed adjustment counterclockwise to slow

engine down and/or to keep blade from moving.

• No further adjustments are necessary if the blade does

not move at idle speed and if performance is satis-

factory.

Screwswith

LirniterCaps

H L

IN "LOW SPEED MIXTURE ADJUSTMENT"

RECHECK IDLE SPEED AFTER EACH

ADJUSTMENT. THE CUTTING BLADE

MUST NOT MOVE AT IDLE SPEED.

CARBURETOR PRESETS (Fig. 17)

NOTE: In most cases, your engine can be made to run

properly with minor carburetor adjustments. Refer to trou-

ble shooting suggestions above for the condition you are

experiencing and follow the instructions. The basic carbu-

retor settings are provided in the fo!lowing instructions.

• Turn low speed adjustment and high speed adjustment

counterclockwise to the limiter stops. Do not attempt to

turn beyond the stops as damage can occur.

• Turn the idle speed adjustment clockwise I furlturn.

-13-

====m= === ,11 =1 iii i i iiii

SERVICE AND ADJUSTMENTS

H =

LOW SPEED MIXTURE ADJUSTMENT

• Allow the engine toidle.

• Turn the low speed adjustment slowly clockwise until

the speed increases.Do not attempt to turn beyond the

stops as damage can occur.

• Turn the low speed adjustment counterclockwise until

the speed decreases. Do not attempt to turn beyond

the stops as damage can occur.

• Set the low speed adjustment at the midpoint between

the two positions.

• Readjust the idlespeed (see "Idle speed adjustment").

HIGH SPEED MIXTURE ADJUSTMENT

CAUTION: Do not operate the engine at

full throttle for prolonged periods while

making high speed adjustments as dam-

age to the engine can occur.

NOTE: Adjust the high speed adjustment 1/16 of a turn

at a time. A turn of 1/16 inch is about the width of the

screwdriver slot in the top of the adjustment.

CLEAN/REPLACE FUEL FILTER (Fig. 18 & 19)

• Run fuel tank dry of fuel before proceeding with this

step.

• Remove fuel cap and allow it to hang to side of motor.

• Using a small pair of needle nose pliers, grasp fuel cap

retainer, holding it in tank opening and pull out.

• With cap out of tank, use a small section of bent wire

similar to that shown in the illustration to catch fuel line

and slowly pull from tank. When fuel filter appears in

opening, grasp with fingers and remove from tank.

• Once filter is out of tank, hotd fuel line close to fuel fit=

ter. Remove fuel filter by twisting and pulling at the

same time.

• To clean fue! filter, submerge in warm soapy water for

10 minutes. (We recommend a very light mixture of

dish washing liquid.) Then agitate until filter is clean,

rinse thoroughly in warm water, air dry.

• Reverse process for installation.

• To replace fuel filter, use same procedure, but install

new filter.

• Allow the engine to idle, then squeeze the throttle fully.

NOTE: Perform the following steps at ful! throttle.

• Turn the high speed adjustment'counterclockwise until

it stops. Do not attempt to turn beyond the stops as

damage can occur.

• Turn the adjustment the minimum amount clockwise

until the engine runs smoothly. Do not attempt to turn

the beyond the stops as damage can occur.

• If the engine accelerates and runs smoothly, no further

adjustments are necessary.

• Recheck and follow steps in "Acceleration check."

CAUTION: If the engine does not operate

according to these instructions after

repeating the adjusting steps, do not use

the tool.Take it to your authorized service

dealer.

ACCELERATION CHECK

•AItow the engine to idle,

• Squeeze the throttle trigger iuIly. If the engine does

not accelerate smoothly, turn the low speed adjust-

ment counterclockwise a small amount (no more than

the width of the slot in the adjusting screw).

• Repeat previous step until smooth acceleration is

obtained. Do not attempt to turn beyond the stops as

damage can occur.

NOTE: It may be necessary to repeat "Idle speed adjust-

ment" through "Acceleration check" to obtain correct

adjustments.

FUELLINE

FUEL CAP

Figure 18

FUELUNE

FUEL-

FILTER FILTER ,'_

BARREL NECK

Figure 19

BENTWIRE

FUEL FILTER

-14-

STORAGE

=

Immediately prepare your unit for storage at the end of

the season or if it will not be used for 30 days or more.

I_ WARNING:ALLOW THE ENGINE TO COOL, AND

SECURE THE UNIT BEFORE STORING

OR TRANSPORTING IN A VEHICLE.

STORE UNIT AND FUEL IN AN AREA

WHERE FUEL VAPORS CANNOT REACH

SPARKS OR OPEN FLAMES FROM

WATER HEATERS_ ELECTRIC MOTORS

OR SWITCHES, FURNACES, ETC.

STORE UNIT WITH ALL GUARDS IN

PLACE. POSITION SO THAT ANY SHARP

OBJECT CANNOT ACCIDENTALLY

CAUSE INJURY TO PASSERS BY.

STORE THE UNIT OUT OF THE REACH

OF CHILDREN.

i ======================= = = H==,, ml

INTERNAL ENGINE

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur to fuet system

components. Follow these instructions:

• Drain the fuel from the unit into an approved fuel con-

tainer.

• Drain the fuet lines and carburetor by starting the

engine and letting it run until it stops.

• Allow the engine to cool before storage.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as the

carburetor, fuel fitter, fuel hose or tank during storage.

Also, experience indicates that alcohol blended fuels,

those that use ethanof or methanol (called gasohol or

oxygenated fuel), can attract moisture and form acidic

gas which will damage your engine. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer.

GAS TRIMMER STORAGE INSTRUCTIONS

If your trimmer isto be stored for a period oftime, clean it

thoroughly prior to storage. Remove any dirt, leaves, oil,

grease, etc. Store in a clean dry area.

• Clean the entire unit.

• Clean air filter. Refer to "Customer Responsibilities."

• Lightly oil external metal surfaces to prevent rust from

forming.

• Re-assemble all loose parts, being sure that all han-

dles and guards are in ptace and are securely fas-

tened. Reptace any damaged parts.

• The recommended storage position is either vertically

with the fuel cap on top, or horizontally with the fuel

cap up. Do not store unit with the cutting attach-

ment up, above the engine.

I& CAUTION: Wear protective gloves when

handling. The blade is sharp and can cut

you,

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fuei gum deposits during storage. Add

stabilizer to the gasoline in the fuel tank or fuel storage

container. Always follow the mix instructions found on

stabilizer containers. Run engine at least 5 minutes after

adding stabilizer to allow the stabilizer to reach the car-

buretor.

CRAFTSMAN 40:! 2-cycte engine oil (AIR-COOLED) is

specially blended with fuel stabilizer. If you do not use

this Sears oil, you can add a fuel stabilizer (such as

CRAFTSMAN No. 33500) to your fuel tank.

FUEL SYSTEM

• Remove spark plug and pour 1 teaspoon of 40:1

2-cycte engine oil (AIR-COOLED) through the spark

piug opening.Slowly pull the starter rope 8 to 10 times

to distribute oil to inner engine surfaces.

• Replacespark plug with a new one of the recommended

typeand heat range. Refer to "Product Specifications:

• Clean air filter. Refer to "Customer Responsibilities"

• Re-install all covers and hardware removedfor access;

tighten all screws and fasteners,

• Check entire unit for loose screws, nuts, and bolts.

Replace any damaged, broken, or worn parts.

• Lightly oil external metal surface to prevent rust from

forming.

= Use fresh fuel having the proper gasofine to oil ratioat

the beginning of the next season.

OTHER

• Do not store gasoline from one season to another.

° Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your fuel system willcause problem&

• Store your unit in a well ventilated area and covered, if

possible, to prevent dust and dirt accumulation.Do not

cover with plastic. Plastic cannot breathe and will

inducecondensation and eventual rust or corrosion.

IMPORTANT: Never cover unit while engine and exhaust

areas are stitl warm.

-15_

,,=h= ,=., =111i =11 inlnll

TROUBLE SHOOTING CHART

,,H ,H ================= I,.H= = = i

TROUBLE SHOOTING CHART

SYMPTOM

Engine wilt not start or

will run only for a few

seconds after starting.

,,,,,,,,

Engine will not idle

properly.

Engine will not

accelerate, lacks

power, or dies

; under a load.

Engine smokes

excessively.

Engine runs hot,

Cutting attachment

moves at idle speed.

, ,,,,,,,, ,,,

Cutting blade stops

under a toad or does

not turn when the

engine is accelerated.

CAUSE

t. Fueltankempty

2. Engine flooded.

3. Spark plug not firing.

4. Fuel not reaching carburetor.

5. Carburetor requires adjustment,

6. Air filter dirty.

7, Fue! filter dirty.

8. None of the above,

1. Idle speed set too fast or too slow.

2, Carburetor requires adjustment.

3. None of the above.

,,,,,,,,,,,,.........

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires adjustment.

4. Muffler outlets plugged.

5. None of the above,

1. Air filter dirty.

2. Fuel incorrect.

3. Carburetor requires adjustment.

1. Fuel incorrect.

2, Carburetor set too low (lean).

3. Spark plug incorrect.

4. None of the above.

,, , , ,

1, Carburetor requires adjustment.

2. Throttle cable binding.

3. Clutch requires repair.

, , ,,, , ,,

1. Forcing blade into material being cut.

2. Blade clogged with debris.

3. None of the above.

REMEDY

1. Filltank withcorrect fuel mixture.

2. See "Starting Instructions."

3. Installnew plug/check ignitionswitch.

4. Clean fuel filter; inspect fuel line.

5. See "CarbUretor Adjustments."

6, Clean or replace air fiffer.

7. Contact your SEARS Service Center/Dept.

8. Contact your SEARS Service Center/Dept.

1. See "Carburetor Adjustments."

2. See "Carburetor Adjustments."

3. Contact your SEARS Service Center/Dept.

1. Clean or replace air filter.

2. Clean and re-gap or replace spark plug.

3. See "Carburetor Adjustments7

4. Contact your SEARS Service Center/Dept,

5, Contact your SEARS Service Center/Dept.

,,,,, ,, ,,,,, , ,,,J,,,,,,, ,,,,Li,,

1. Clean or replace air filter.

2. Refuel with correct fuel mixture.

3. See "Carburetor Adjustments."

1. See "Fueling Your Unit."

2. See "Carburetor Adjustments:'

3. Replace withcorrect plug.

4. Contact your SEARS Service Center!Dept.

1. See "Carburetor Adjustments?

2. Contact your SEARS Service Center/Dept.

3. Contact your SEARS Service Center/Dept.

,,,,, ,,,,,,,,,, ,

1. Cut at a slower pace.

2. Clean debris from blade.

3. Contact your SEARS Service Center/Dept.

If situations occur which are not covered in this manual, use care and good judgement,

ff you need assistance, contact your SEARS Service Center/Department or the

CUSTOMER ASSISTANCE HOTLINE at 1-800,235-5878.

-16-

REPAIR PARTS

SEARS BUSHWACKER - MODEL 358.795630

44.

39. 43.

40.

\

41. 42.

\ \

\ 53.

52.

\

49.

48.

\

47.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23-

24.

Ref.

1.

2.

3.

4.

5.

6,

7,

8.

9.

Part No.

530-015935

530-037631

530-029929

530-019181

530-014307

530-032125

530-015945

530-019179

530-032124

530-014861

530-015941

530-016080

530-039149

530-036145

530-039163

530-015954

530-O37730

530-O29939

530-015828

530-015930

530-069232

530-015963

530-015496

530-069353

Description

Screw-Shrou_

Shroud

Crankcase Cover

Gasket-C'case

Crankshaft Ass'y.

Inner Bearing

Retaining Ring

Crankcase Seal

Outer Bearing

Crankcase Ass'y.

(Incl. 6-9)

Retaining Ring

Screw-Flywheel

Rywheel

Spacer-Ignition Module

Ignition Module

Screw-ignition Module

Spring-Starter Dog

Starter Dog

Washer-Thrust

Flywheel Spacer

Rope Kit

Retainer-Starter Putiey

Screw-Retaining

Starter Puiley

44.

Ref.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

45.

46.

47.

48.

Pert No.

530-029395

530-027569

530-015810

530-044396

530-014947

530-019182

530-069615

530-029930

530-014362

530-036180

530-O23877

53O-069352

530-019223_

530-029924i

530-O69613

530-015953

530-069614

STD PM2

530-019185

530-037632

530-016014

530-014384

530-015775

530-019194

Description

Starter Spring

Starter Handle

Screw

Clutch Ass_J.Kit

Fan Housing

Grommet

Connecting Rod Kit

Muffler Spring

Fue! Pick-up Ass'y.

Muffler Screen

Line Fitting

Muffler Kit

Cylinder Gasket

Piston Ring

Piston Kit

(Incl. 38 & 55)

Screw-Cylinder

Cylinder

Spark Plug

Gasket-CylindJCarb.

Carb. Adaptor

Screw-Carb. Adaptor

Throttle Cable Ass'y.

Screw

Gasket-CarbJAdaptor

Ref.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

NotShown

,_ WARNING

All repairs, adjustments

and maintenance not de-

scribed in the Operator's

Manual must be performed

by qualified service per-

sonnel.

Part No.

530-069652

530-036192

530-015849

530-029934

530-036193

530-015635

530-015162

530-014973

530-069616

530-069247

530-069599

530-016103

530-083038

530-085199

530-038294

Description

Carburetor Ass'y Kit

(incl. Limiter Caps)

Air Box

Screw-Air Box

Air Filter Foam

Air Fiiter Cover

Screw-Air Filter Cover

Piston Pin Retainer

C'cese & C'shaft Assy.

(Incl. 5 & 10)

Gasket Kit

(Incl. 4, 37, 43 & 48)

Fuel Line

Return Line

Retainer Clip

Operator Manual

Carton

Starting Instruction

-17-

26,

REPAIR PARTS

SEARS BUSHWACKER - MODEL 358.795630

_etor Assembly - _ 30_7.

# 830-069652

I Ref.

1.

2.

3.

4.

5.

6*

11.

12.

13.

14.

!6,

17.

18.

t9.

20.

2'L

Part No.

530-029954

530-036443

530-015775

530-029958

530-015940

530-015770

530-038305

530-029956

530-036122

530-036123

530-015934

530-047196

530-094992

530-029946

530-048113

530-015886

530-029916

530-03212!

530-095074

530-029948

530-036228

Description

IgnitionSwitch

LeadWireAss'y.

Screw-ThrottleTdgtger

TriggerLever

Screw-Handle Cover

Screw-HandleCover

HandleCover

ThrottleTrigger

Throffie Lockout

TriggerSpring

Screw-Gear Box

RearHandle& Tank

Ass'yo

Front Handle

isolator Spring

Ctutch Drum

Screw

Gear Box Plate

Bushing Bfade

Blade Ass'y. (22")

Blade Seal

Pinion Ass'y.

22.

23,

24.

25.

26.

27,

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

Ref.

Part No.

530-016013

530-069355

530-036046

530-01487 f

530-015955

530-015805

530-014399

530-035014

530-035389

530-035f64

530-035166

530-035028

530-035031

530-035172

530-035008

530-035139

530-035236

530-069656

............................. i i iii i

Description

Drive Gear Bearings

Ddve Gear Ass'y.

i Isolator Plate

Fuel Cap Ass,y.

Screw-Handle

Screw-Pinien

Gear Box Ass'y.

(Inc!. 21, 22 & 27)

Metering Diaphragm

Metering Diaphragm

Gasket

Pump Gasket

Pump Diaphragm

Metering Pin

Metedng Lever

Fuef Inlet Screen

Inlet Needie Valve

Metedng Lever

Spring

Metering Lever Pin

Screw

Carburetor Repair

Kit (IncL 33-38,

40 & 43-45)

-18-

Ref. Pan No.

40. 530-035319

41. 530-035313

42. 530-069652

43. 530-035361

44. 530-038317

45. 530-038318

Description

WeiGh Plug

Gasket!Diaphragm

Kit (Incl. 29-32)

Carburetor Ass'y. Kit

(Incl. LimiterCaps)

Primer Bulb

Limiter Cap-Low

Limiter Cap-High

i. i i i1,,,,,,,, ,,,,,,nllll,lll i iiiii i i ii ] i ] i

TABLE OF CONTENTS

,H,I,,,,,I I ,I I

Safety Rules .................................................................... 2 Service and Adjustments ............................................... 13

Product Specifications ..................................................... 4 Storage .......................................................................... 15

Warranty ........................................ .................................. 4 Trouble Shooting ........... ,................................................ 16

Operation......................................................................... 6 Repair Parts ........................ :.......................................... 17

Customer Responsibilities ...... _...................................... 11 Ordering Repair Parts/Service ................. ,..................... 20

INDEX

iii HII ,,,,1111,,11IH,,I I I I I I I I III II IIIIII I I IIIIIIIIII II I I ,11 III ,, I, II I,,I,,,111 I I

A

Accessories .................................................. i................ 19

Air Filter ......................................................................... 12

C

Carburetor Adjustments ................................................. 13

Customer Responsibilities ............................................. 11

Cutting Blade Lubrication .............................................. 12

E

Engine

Fuel/Oil ......................................................................... 9

Spark Plug .................................................................. 12

Starting ....................................................................... 10

Storage,. ..................................................................... 15

F

Fuel Filter ....................................................................... 14

Fueling............................................................................. 9

H

Hardware Contents .......................................................... 5

K

Know Your Hedge Trimmer ............................................... 6

Maintenance Schedule .................................................. 11

Model Number ............................................................... ,4

Operation ......................................................................... 6

Ordering Repair Parts .................................................... 20

Service and Adjustments ............................................... 13

Spark Plug ..................................................................... 12

Specifications.: ................................................................. 4

Starting ................................. ;........................................ 10

Storage .......................................................................... 15

Trimming Methods ........................................................... 8

Trouble Shooting ............................................................. 16

Warranty ..................................... ..................................... 4

M

O

S

T

W

ii itlllJiJiiiJt Nil III II I I I I I

ACCESSORIES

These accessories and attachments were available when the unit was originally purchased. They are also available at

most Sears retail outrets and service centers. Most Sears stores can order these items for you when you provide the

model number of your unit.

Accessories

SAFETY

GOGGLES

SPARK

PLUG

AIR

FILTER

2-CYCLE

ENGINE OIL

-19-

8 _A/k?8

CRRFTSMRN°

Operator's

Manual

Model No.

358.795630

IFYOU NEED REPAIR

SERVICE OR PARTS:

REPAIR SERVICE

1-800-4-REPAIR

(1-800-473-7247)

ORDERING PARTS

1-800,FON-PART

(1-800-366-7278)

21 cc (1,3 cu. in.) 2-CYCLE

22" Blade

GAS HEDGE TRIMMER

Each Gas Hedge Trimmer _ has its own model number. The

model number for your unit will be found on a decal attached to

the unit.

All parts listed herein may be ordered from any Sears,

Roebuck and Co. Service Centers and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST:

• PRODUCT-"GAS HEDGE TRIMMER"

• MODEL NUMBER- 358.795630

• PART NUMBER

CUSTOMER

ASSISTANCE

1-800-235-5878

HOURS(CST)

Mon.- Sat. 7 a.m. - 7 p.m.

Sun, 10 a.m.- 7p.m.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• PART DESCRIPTION

Your Sears Merchandise has added value when you consider

that Sears has service units nationwide staffed with Sears

trained technicians.., professional technicians specifically

trained on Sears products, having the parts, tools and equip-

ment to insure that we meet our pledge to you, we service what

we sell.

MANUAL IMPORTANTE No Io deseche

Manual del

Operario

Modelo No.

358.795630

ADVERTENClA:

LEA EL MANUAL DEL

OPERADOR Y SIGA

TODAS LAS INSTRUC-

CINES Y ADVERTEN-

CIAS DE SEGURIDAD.

SI NO LO HACE CORRE

EL RIESGO DE SUFRIR

LESIONES.

Use siempre una protecciSn para los ojos

DE 2 TIEMPOS 21cc

22" Cuchiila

GAS PROTEGE GUARNECEDOR

• Armado * Tabla de materias -

• Operaci6n

• Responsabilidades del cliente

• Ajustes de servicio

• Piezas de repuesto

Car&tula posterior int.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 EE.UU.

530-083472-1-02/11/95

REGLAS DE SEGURIDAD

ill i i ii, ill i liHillllll ii ii, i i i,ii

l_ ATENCION: PARA IMPEDIR EL ARRANQUE ACCIDENTAL DURANTE LA PREPARACION, TRANS-

SEGURIDAD DEL OPERADOR

* Usa siempre protecci_n ocular de seguddad.

• Usan siempre cu largos sudaderas pesados, cu largas man-

gas, betas y guantes. No van con los pies descalzos ousan

sandalias, sudaderas cortes, mangas cortas. Qua se cubrir

compietamente ayuda protegerle de piezas de plantas t6xicas

arrejadas per la cuchifla.

- El pale seguro de mode que Iongitud de hombre anterior. Los

vestidos de soltura seguros o joyas. Los vestidos con colgan-

do d_bilmente vinculos, fajas, bodas, etc. Puedan estar cogi-

do en moviendo partes.

• No manejar esta mdqu_na estando cansado, enfermo o

despu_s de haber ingerido bebidas alcoh61icas, dregas o

medicinas.

* Pretegerse los sides cuando se vaya a usar esta mdquina per

rods 1-I/2 horas al dia.

* Nunca arrancar o hacer funcionar el motor en un lugar encer-

rado o edificio, La aspiraciSn de los gases de escape puede

causar la muerte.

° Mantener los mangos libres de aceite y combustible.

• Si llegan a ocurrir situaciones no explicadas en este manual,

tarter cuidado y actuar juiciosamente.

SEGURIDAD/MANTENIMIENTO DE LA

MAQUINA

• Inspeccionar en busca de piezas da_adas o suettas y cam-

biarlas antes de usar la mdquina. Vet si hay fuga de com-

bustible y reparar antes de usar. Mantener la mdquina en

buenas condiciones.

• Asegurar de mantener y armar correctamente la m_quina

come se indica en este manual.

• Hagan ajustes de carburador con la cuchi]la sostenida para

evitarlo de contactar cualquiera objeto. Sestenga la unidad a

mane.

• No dejar que nadie se acerque mientras se ajusta el carbu-

fader.

• Utilice sotamente buena calidad SEARS accesodos y rempla-

zo parte come recomendados per esta unidad.

SEGURIDAD CON EL COMBUSTIBLE

• Mezclar y reabastecer de combustible al aire libra.

• Noacercarachsipas oltamas expuestas.

PORTE, AJUSTE O REPARACION, SIEMPRE DESCONECTAR EL CABLE DE LA BUJIA Y COLOCAR-

LO EN UN LUGAR DONDE NO PUEDATOCAR LA BUJIA,

• Usar un contenedor aprobado para combustible.

• No fumar ni dejar que nadie fume cerca det combustible o de

la mdquina o mientras se estd usando la mdquina.

• L'mpiar e! combustible derramado antes de arrancar e! motor.

• Alejarse al menos 10 pies (3 metros) de tugar de abastec-

imiento de combustible antes de arrancar el motor.

* Apagar el motor y (tejar que la m&quina se enfrie antes de

quitar la tapa det combustible.

SEGURIDAD DURANTE EL CORTE

• Inspecciene el &rea para set cortar antes de cada use.

Retiren objetos (rocas, vidrio quebrado, uSas, alambre, cuer-

da, etc.) cual puede se enreda en la cuchiHa.

* Mantengan otros ni_os incluyentes, animales, espectadores y

ayudantes un minims de 50 pies (15 metros) lejos. Detenga la

m&quina inmediatamente si usted estuviera enfocado.

• Siempre mantener el motor al lade derecho del cuerpo.

• Sujetar tam&quina firmemente con ambas manes.

• Mantener un paso firme y buen equilibrio. No tratar de alcan-

zar m_s art&de Io seguro.

• Mantenga la cuchilla (tebajo nivel de ta cintura.

• No ]evanta la m&quina anteriormente su hombre.

• Mantengan partes todas de su cuerpo lejos de la cuchilla y

silenciador cuando mdquina esta corriendo.

• Usar la m_quina solamente para los trabajos explicados en

este manual.

TRANSPORTING AND STORAGE

• Apajar la m_quina antes de transportada.

• Dejar qua el motor se engrie y sujetar bien la maquina antes

de guardada o transportarla en un vehiculo.

• Vaciar el tanque de gasolina antes de guardar o transportar la

mdquina. Gastar todo el combustible restante en el carbu-

radoro Para ells, arrancar el motor y dejarlo funcionar hasta

que se pare.

° Guardar la m,_quina y el combustible en un lugar donde los

vapores (tel combustible no alcancen las chispas o llamas

expuestas de calentadores de agua, restores electricos o

interruptores, calefactores, etc.

• Guardar la m&quina de tal manera que el cuchilla no pueda

causar accJ(tentalmente alguna lesi6n:

• Guarar la m_quina lejos del alcance de tos ni,fios_

AVISO DE SEGURIDAD

La exposicion a vibraciones a tray,s del use prolongadode herramientasmanualesimpulsadaspergasolina puedecausardar3osa Ios vases san-

uineoso a los nervlos de los dedos, manes y mur3ecasdelaspersonassusceptiblesa trastomoscirculatorioso a hinchazonesanormales. El use

pro!ongadoen ch'masfr{os ha side relacionado con lesionesa los vases sanguineossufridosperpersonasper Iodem&ssanas. Si se presentans_n-

tomas en las manes tales come adormecimiento, dolor,perdidade fuerza,cambioen el color o taxturade la piel, o p_rdida de sensibilidad en los

dedos, [asmaneso la muneca, discontinue el use deesta herramientaysolicitsatenciSnmedica.Un sistema antivibratoriono garantiza [aanulaci6n

de estos problemas. Lbs usuarfosqua operanherramientasde poder en una base continuay regulates tienen qua monitorear estrechamenta su

condici6n fisica y la condici6n de esta unidad.

t_ BUSQUE ESTE SIMBOLO PARA PUNTUALIZAR PRECAUCIONES IMPORTANTES DE SEGURIDAD" I

SIGNIFICA - iIiATENCION!!! iiiESTE ALERTA!!! ESTA EN JUEGO SU SEGURIDAD.

-2-

PELIGRO:

iESTA MAQUINA MOTORIZADA PUEDE SER PELIGROSA! ESTA MAQUINA PUEDE PROVOCAR

AMPUTACION DE INCLUIR DE LESI6N SERIA 0 CEGUERA AL OPERADOR Y DEMAS PERSONAS,

SE RECOMIENDA RESPETAR LAS INSTRUCCIONES DE SEGURIDAD Y ADVERTENCIAS QUE

APARECEN EN ESTE MANUAL PARA PROPORCIONAR UNA SEGURIDAD Y RENDIMIENTO RAZON-

ABLES DURANTE EL USO DE ESTA MAQUINA. EL OPERADOR ES RESPONSABLE DE RESPETAR

LAS ADVERTENCIAS Y SEGUIR LAS INSTRUCCIONES DADAS EN ESTE MANUAL Y EN LA

MAQUINA. LEER TODO EL MANUAL DEL OPERADOR ANTES DE ARMAR Y USAR ESTA MAQUINA.

PERMITIR EL USO DE LA MAQUINA MOTORIZADA SOLAMENTE A LAS PERSONAS QUE HAYAN

LEIDO. ENTENDIDO Y SEGUIDO LAS INSTRUCCIONES Y ADVERTENCIAS EN ESTE MANUAL YEN

LA MAQUINA. NUNCA PERMITEN NII_OS UTILIZAR ESTA HERRAMIENTA,

ADVERTENCIA:

EL CORTE DE CUCHILLA PUEDE LANZAR

OBJETOS VIOLENTAMENTE. USTED

PUEDE ESTAR CEGADO O ESTADO

DA_IADO. USA SIEMPRE PROTECClON

DE PIERNAY OJO.

CARETA

LA CUCHILLA SE MUEVE MOMENTh.NEA-

MENTE DESPUES DE QUE GATILLO ESTA

LIBERADO, LA CUCHILLA CORTADORA

PUEDE CORTARLE SERIAMENTE U

OTROS. PERMITA CUCHILLA CORTADO-

RA DETENER ANTES DE RETIRANDOLA

DEL CORTE.

PIERNERAS

BOTAS

ZONA DE PELIGRO PARA CUCHILLA

CORTADORA. LA CUCHILLA CORTADO-

RA PUEDE CORTARLE SERIAMENTE U

OTROS. OTROS PUEDEN ESTAR CEGADO

O ESTADO DANADO, MANTENGA GENTE

Y ANIMALES UN M|NIMO DE 15 PIES (5

METROS) LEJOS.

LEER EL MANUAL DEL OPERADOR.

RESPETAR TODAS LAS ADVERTENCIAS Y

SEGUIR LAS INSTRUCCIONES. EL NO

HACERLO PUEDE DAR POR RESULTADO

GRAVES LESIONES.

-3-

MANUAL DEL

OPERADOR

ZONE DEPEUGRO

ETIQUETA DE

SEGURtDAD

FELICITACIONES por su compra de un cortamalezas

Proteja Guarnecedor a gasolina Craftsman de Sears, Ha

sido dise6ado, concebido y fabricado para proporcionar la

mejor confiabilidad y rendimiento posibles.

En caso de experimentar algSn probleroa que no pueda

resovler f_cilmente, comun_quese con el centro/departa-

mento de servicio Sears mAs cercano. Sears cuenta con

t_cnicos competentes y capacitados y las herramientas

adecuadas para reparar esta mAquina.

Le rogamos que lea y conserve este manual. Estas instruc-

ciones le permit[ran armar y mentener su mAquina correc-

tamente. Siempre respete las "REGLAS DE SEGURIDAD."

NUMERO DE MODELO:

358.795630

C0DIGO DE FECHA/

NOMERO DE ORDEN:

FECHA DE COMPRA:

ESPECIFICACIONES DEL PRODUCTO

CORTE DE CUCHILLA ...... 22"

MOTOR ............................... 2 tiempos, 21 cc enfr[ado

por aire

PROPORCION DE MEZCLA

GASOLINAiACEITE ........... 40:1 (3.2 oz de aceite por

gal6n de gasolina)

ENCENDIDO ...................... Estado s61ido

(entrehierro .010" a .014")

REGULAClON DEL

ENCENDIDO ...................... No ajustable, fijo

BUJIA .................................. Champion (RCJ-8Y)

DISTANCIA ENTRE

ELECTRODOS .................... 024 to .028"

EL NUMERO DE MODELO Y DE SERIE SE ENCUENTRA

RPM DEL MOTOR .............. 9,000 RPM M_x.

EN LA CALCOMANIA PEGADA EN LA MAQUINA.

ANOTE EL NUMERO DE SERIE Y LA FECHA DE

COMPRA Y GUARDE LAINFORMACtON EN UN LUGAR

SEGURO PARA REFERENCtA FUTURA,

CONTRATO DE MANTENIMIENTO

Se ofrece un contrato de mantenimiento Sears para este

producto. Para detalles, comunicaroe con la tienda Sears mas

cercana.

RESPONSABILIDADES DEL USUARIO

• Lea y respete las reglas de seguridad.

• Siga un programa regular de mantenimiento, cuidado y uso

de la m_.quina.

-Siga las instrucciones dadas en las secciones de

"Responsabilidades det usuario" y "Almacenamiento" en

este manual del operador.

Para los usuarios en tierras forestales de EE.UU. yen algunos

estados,incluyendo California (Recursos P_blicoscodigos4442 y

4443), Idaho, Maine, Minnesota, New Jersey, Oregon y

Washington: Se requiem que ciertos motoros de combusti6n

intema operados en bosques, arbustos y/o tierras cubiertas de

_asto en las zonas antes mencionadas esten equipados con

chispero, mantenido en buenas condiciones,o el motordebe estar

construido,equipadoy mantenido para la prevenci6nde incendios.

Averiguar con tas autoridades estatales o Jocaleslas regulaciones

retativas a estos requisitos. El incumplimientode estos requisitos

infringe ]a ley. Esta mdquina no esta equipada de fabrica con un

chispero, no obstante se ofrece uno como equipo opcional.Si en

su zona se requiero el uso de chispero, comuniquese con el

centro/departamento de servicio de Sears para el conjunto

CO_Tec_o.

FABRICADO BAJO UNA O MAS DE LAS SIGUIENTES PATENTES DE EE.UU.:

4,035,912; 4,052,789; 4,161,820; 4,167,812; 4,1'83,138; 4,189,833; 4,2!1,004;

4,286,675; 4,362,074; 4,451,983; 4,798.185; 4,823,465; 4,841,929; 4,940,029;

5,020,223; OTRAS PATENTES DE EE.UU. Y EXTRANJERAS PENDIENTES.

AVISO ESPECIAL

GARANTIA COMPLETO DE UN AI_IO PARA EL CRAFTSMAN

PROTEJA GUARNECEDOR A GASOLINA

Per un (!) aSo desde la fecha de compra cuando esta unidad a gasolina Craftsman Proteja Guarnecedor a gasolina sea mantenida,

lubricada y puesta a punto de acuerdo con las instrucciones de operaciSn y mantenimiento en el manual del operario, Sears reparard

libre de costo cualquier defecto de material o de mano de obra.

Esta garantia exduye ta cuchi!la, buifa y filtro de aire, las cuales son partes desechabres que se desgastan durante el uso normal.

Esta garantla se aplica durante 90 dias solamente desde la fecha de compra si este Proteja Guarnecedor alinee guarnecedor se usa

para fines comerciales. Esta garantia se aptica durante 30 dias solamente desde la fecha de compra si este Proteja Guarnecedor ali-

nee guamecedor se usa para fines de alquiler. Esta garantfa se aplica s61omientras este producto se use en los Estados Unidos.

EL SERVICIO DE GARANTIA ESTA DISPONIBLE DEVOLVIENDO EL PROTEJA GUARNECEDOR AL CENTRO O DEPARTAMEN-

TO DE SERVIClO DE SEARS MAS CERCANO £N LOS ESTADOS UNIDOS.

Esta garantfa te otorga derechos legales especfficos y usted puede tambi4n tener otros derechos que vat,an de estado a estado.

SEARS, ROEBUCK AND CO. DI817WA, HOFFMAN ESTATES, IL 60179

-4-

==11111111 I, ILJ,=,IH,,HH=,III I1,111 I II II II I

CONTENIDO DE TORNILLERIA

ACEITIE DE MOTOR MANUAL DEL OPERADOR

ESTE MODELO VIENE COMPLETAMENTE

ENSAMBLADO

NOTA: Es norrnat para ofr el ruido de filtro de €omustible

en un tanquede comustiblevacio.

PARA RETIRAR PROTEGER

GUARNECEDOR DE CARTON

• Retiren partes de soltura incluidas con Protegen

Guarnecedor.

• Retire bolsa de partes de pt,_sticosuelta del cart6n.

• Retire material de empaque todo.

• Revise cart6n totalmente para soltura adicional parte.

• Utilice delineador de cart6n corn0 superficiede trabajo

durante inspecci6n de unidad.

-5-

H

OPERAClON

CONOZCA SU PROTEJA GUARNECEDOR (Fig. 5)

LEER ESTE MANUAL DEL OPERADOR Y LAS REGLAS DE SEGURIDAD ANTES DE MANEJAR ESTE PROTEJA

GUARNECEDOR. Comparar las ilustraciones con la m_quina para aprender la ubicaci6n de los distintos controtes y los

ajustes. Conservar este manual para referencia futura.

FILTRO DE AIRE

ESTRANGULADOR tNTERRUPTOR

PERA DE CEBADO

DE PARADA

ASA

TRASERO

|

GATILLO

ACELERADOR

TAPA DE

COMBUS_BLE

CERRADURA DE

GAZNATE FUERA

ASA DE SILENCIADOR

tNICIADOR

E! INTERRUPTOR DE PARADA se usa para apagar el

motor.

Ei ASA DE INICtADOR se usa para arrancar el motor.

La PERA DE DEBADO hace circular combustible por el

carburador.

ASA DE

.,w."GUARDIA DE MANO

CORTE DE CUCHILLA

/

Figura 5

El ESTRANGULADOR activa la estrangulaciSn por

proveer combustible adicional a la m_quina cuando

comenzar una rn_quina frfa.

El GATILLO DEL ACELERADOR controla la vetocidad

del motor.

-6.

== ii ==HI

OPERACION - SEGURIDAD

H= H== = =H,

SEGURIDAD DE PROTEJA GUARNECEDOR

PELIGRO:

LA CUCHILLA CORTADORA CAUSAN OBJETOS

PARA ESTAR ARROJADO VIOLENTAMENTE. EL

OPERADOR TIENE QUE USAR UN ESCUDO DE

CARA DE SEGURIDAD O GAFAS PROTECTORAS.

NO PERMITIR QUE NADIE SE ACERQUE MAS DE 15

PIES (5 METROS) DE DISTANCIA.

LOS COMPONENTES DEL CUCHILLA QUE ESTEN

PICADOS, TRIZADOS O DANADOS DE CUALQUIER

OTRA FORMA PUEDE SALIR LANZADOS ¥ CAUSAR

GRAVES LESIONES. NO USAR LA MAQUINA. COM-

BIAR LAS PIEZAS DANADAS ANTES DE USARLA,

PIERNERAS

@ ,iw

CARETA BOTAS

ZONA DE PELIGRO

USAR SOLAMENTE

REPUESTOS DE BUENA CALIDAD

SEGURIDAD DEL OPERADOR

• Usa siempre protecci6n ocular cuando operando,

prestar servicio, o ejecutar mantenimiento en su

unidad. Refieran "Accesorios."

• No manejar esta maquina estando cansado, enfermo o

despu_s de haber ingerido bebidas alcoh61icas, dro-

gas o medicinas.

• Usan siempre cu largos sudaderas pesados, cu largas

mangas, botas y guantes. No van con los pies descal-

zos o usan sandalias, sudaderas cortos, mangas cor-

tas. Que se cubrir completamente ayuda protegerle de

piezas de plantas t6xicas arrojadas per la cuchilla.

• El pelo seguro de modo que tongitudde hombro ante-

rior. Los vestidos de soltura seguros o joyas. Los vesti-

dos con colgando d_bilmente vinculos, fajas, borPas,

etc. Puedan estar cogido en moviendo partes.

• No se balancea la unidad con tai fuerza que usted est_

en peligro de perder su balance.

• Nunca arrancar o hacer funcionar el motor en un lugar

encerrado o edificio. La aspiraci6n de los gases de

escape puede causar ia muerte.

• Mantener !os mangos libres de aceite y combustible.

SEGURIDAD CON LA MAQUINA

• Inspeccionar toda la m_quina antes de cada uso.

Cambiar las piezas dahadas. Buscar si hay fuga de

combustible y asegurar que todos los tornillos y tuer-

cas est_n en su lugar y bien apretados.

• Hagan ajustes de carburador con la cuchitla sostenida

para evitar cuchilla de contactar cuatquiera objeto.

• No permitlr que nadie se acerque mientras se ajusta el

acelerador.

• Usar sotamente accesofios o fijaciones de buena cati-

dad.

SEGURIDAD DE ARREGLARSG

• Inspeccionar el lugar donde se va a cortar antes de

cada uso. Quffar los objetos {piedras, vidrios rotos,

clavos, alambre, cordeles, etc.) que puedan salir lanza-

dos o queden enredados en el cuchitla.

• Siempre mantener el motor al lado derecho del cuerpo.

* Sujetar la m_quina firmemente con ambas manos.

. Mantener un paso firme y buen equilibrio. No tratar de

alcanzar m,_s alia de Io seguro.

o Mantenga tacuchilla debajo nivel de la cintura.

• No levanta la m,_quina antedormente su hombro.

. Mantengan partes todas de su cuerpo lejos de la

cuchilla y silenciador cuando m_.quina est_ corriendo.

- Usar la m&quina sotamente para los trabajos explica-

dos en este manual.

o Corte en gaznate compteto.

-7-

OPERACION

=

PARADA DEL MOTOR

• Empujar y tener el interrupter en ia posici6n "off."

• Si el motor no pare, mover el estrangulador hacia abajo

estrangulaci6n m&xima.

GATILLO DEL ACELERADOR (Fig. 7)

o El gatiito del acelerador controlala velocidad del motor.

NOTA: La cuchilla deberia detener cuando el gatillo de gaznate

est_ I_erado y ta mdquina regresa a velocidadociosa.

GATILLO DEL ACELERADOR

Figure 7

OPI=RAOIONISUGI=FIENCIAS (Fig.B)

I_IL ADVERTENCIA:

- Permilan las cuchiltas cortadoras alcanzar a toda vetocidad

antes de entrando el material para ser cortar.

• Siempre trabajo yendo lejos de gente y objetos sblidos tal

como paredes, piedras grandes, &rboies, autom6viles, etc.

• Si pesebres de cuchilla, inmediatamente detienen la m&quina.

• Aseg6rese el EN / FUERA interruptor es fuera, el bujfa est&

desconectado, y la cuchitla se ha movimiento detenfdo antes

de limpiando restos estrujados de la cuchJlla cortadora.

Inspeccionen los por los dafios de cuchilla y hayan repar6 o

remplaz6 como se neces_te.

• Pare detener ta m,_quina, mover la EN / FUERA cambia ala

POSIClON DE APAGADO.

• Mantienen siempre los ventiletes de aire limpios.Detenga la

unidad, asegerese la cuchifla cortadora se ha movimiento

completamente detenido, y desconecta el bujla antes de

fimpiando.

CORTA SIEMPRE A VELOCIDAD MAXIMA. NO

AMONTONA LA CUCHILLA EN EL CORTE QUE

PUEDE DANAR LA CUCHILLA, SE ENREDA, O

SE ARROJE CAUSAR UN PEUGRO SERIO.

SIEMPRE TRABAJO YENDO LEJOS DE GENTE

Y OBJETOS S(_LIDOS TAL COMO PAREDES,

PIEDRAS GRANDES, ARBOLES,

AUTOMOVILES, ETC.

USA SIEMPRE PROTECCI6N OCULAR. NUNCA

DELGADO SOBRE LA CUCHILLA. LAS ROCAS

O RESTOS PUEDEN HACIENDO FUEGO DE

REBOTE O ESTANDO ARROJADO EN OJOS Y

CEGUERA DE CARA Y CAUSA U OTRA

LES1ON SERIA.

ARREGLARSG DE METODOS (Fig. 9 & 10)

NOTA: No intentan para cortar tallos mayores que 3/8" gruesos.

PRINCIPAL CORTADOR

• Por crecimiento nuevo o jdven: Cuando arreglarsg crec-

imiento nuevo o j6ven, utilize un ancho, barrer movimiento.

Figure 9A. Una ligeramente, hacia abajo inclinaci6n de Ias

cuchitlas cortadoras en direcci6n de movimiento da a los

mejores resuitados cortadores.

• Pare rods viejo, grueso crecimtento: Arregle mds viejo,

grueso crecimiento utiliza un serrar hacer. Figure 9B.

• Pare precise, nivd corta: Si un precisamente corte de nivel

est& deseado, alarga una pieza de cuerda a tray,s de le ion-

gitud de] protege. Guien las cuchiUas cortadoras lentamente a

trav6s de la parte superior de la cuerda. Figure 10.

CORTE DE LADO

- Cuando arreglarsg tos lados del protege, comienzan en et

fondo y corte hacfa arriba, disminuir la protege adentro en la

parte superior. Figura 10 (intercalaci6n). El interrumpir este

m6todo dejara et cuerpo de la protege m_s estrecha en la

parle superior. Esta forma expondr_ m_s det protege, crec-

imiento m&s uniforme de resultar en.

Figura 9

Figura 8

Figure 10

AIRE EXPRESA

-8-

iii ii iiii i i iiiiiii ,,,,,,,,,,,,,, ,,,,,,,,,,,,,,,,,,,,,,,,,,,

OPERACION

iii iiii iiiiii i i i iii iiiiiiiii i iiii iiiii IH I II

ANTES DE ARRANCAR EL MOTOR: ACEITE PARA MOTOR DE 2 TIEMPOS

ADVERTENCIA: