Craftsman 358795551 Owner’s Manual

Instruction Manual

ICRRFTSMRN°J

25cc/1.5 cu.in. 2-Cycle

17 Inch Cutting Path / 0.080 In. Line

GASOLINE WEEDWACKER ®

Model No.

358.795551

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espahol

For Occasional Use Only (_)

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 l,ours listed are Centra, T,me)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530163461 10/7/02

Warranty Statement 2 Storage 11

Safety Rules 2 Troubleshooting Chart 12

Assembly 4 Emissions Statement 12

Operation 5 Parts List 14

Maintenance 8 Spanish 16

Service & Adjustments 9 Parts and Ordering Back

FULL ONE YEAR WARRANTY ON CRAFTSMAN ® GAS POWERED

WEEDWACKER ® LINE TRIMMER.

For one year from the date of purchase, when this Craftsman Gas Powered

Weedwacker Line Trimmer is maintained, lubricated, and tuned up according to

the operating and maintenance instructions in this manual, Sears will repair, free

of charge, any defect in materials or workmanship.

This warranty excludes nylon line, spark plug, and air filter, which are expendable

parts and become worn during normal use.

If this Weedwacker line trimmer is used for commercial purposes, this warranty ap-

plies for only 90 days from the date of purchase. If this Weedwacker line trimmer is

used for rental purposes, this warranty applies for only 30 days from the date of pur-

chase. This warranty applies only while this product is in use in the United States.

WARRANTYSERVICE IS AVAILABLE BY RETURNINGTHE WEEDWACKER LINETRIMMER

TO THE NEAREST SEARS STORE OR SERVICECENTER INTHE UNITEDSTATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state,

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

_Ib,WARNING: When using gar-

dening appliances, basic safety pre-

cautions must always be followed to

reduce the risk of fire and serious

injury. Read and follow all instructions.

This power unit can be dangerous! Op-

erator is responsible for following

instructions and warnings on unit and in

manual. Read entire instruction manual

before using unit! Be thoroughly familiar

with the controls and the proper use of

the unit. Restrict the use of this unit to

persons who have read, understand,

and will follow the instructions and

warnings on the unit and in the manual.

Never allow children to operate this unit.

INSTRUCTION SAFETY INFORMATION

MANUAL ON THE UNIT

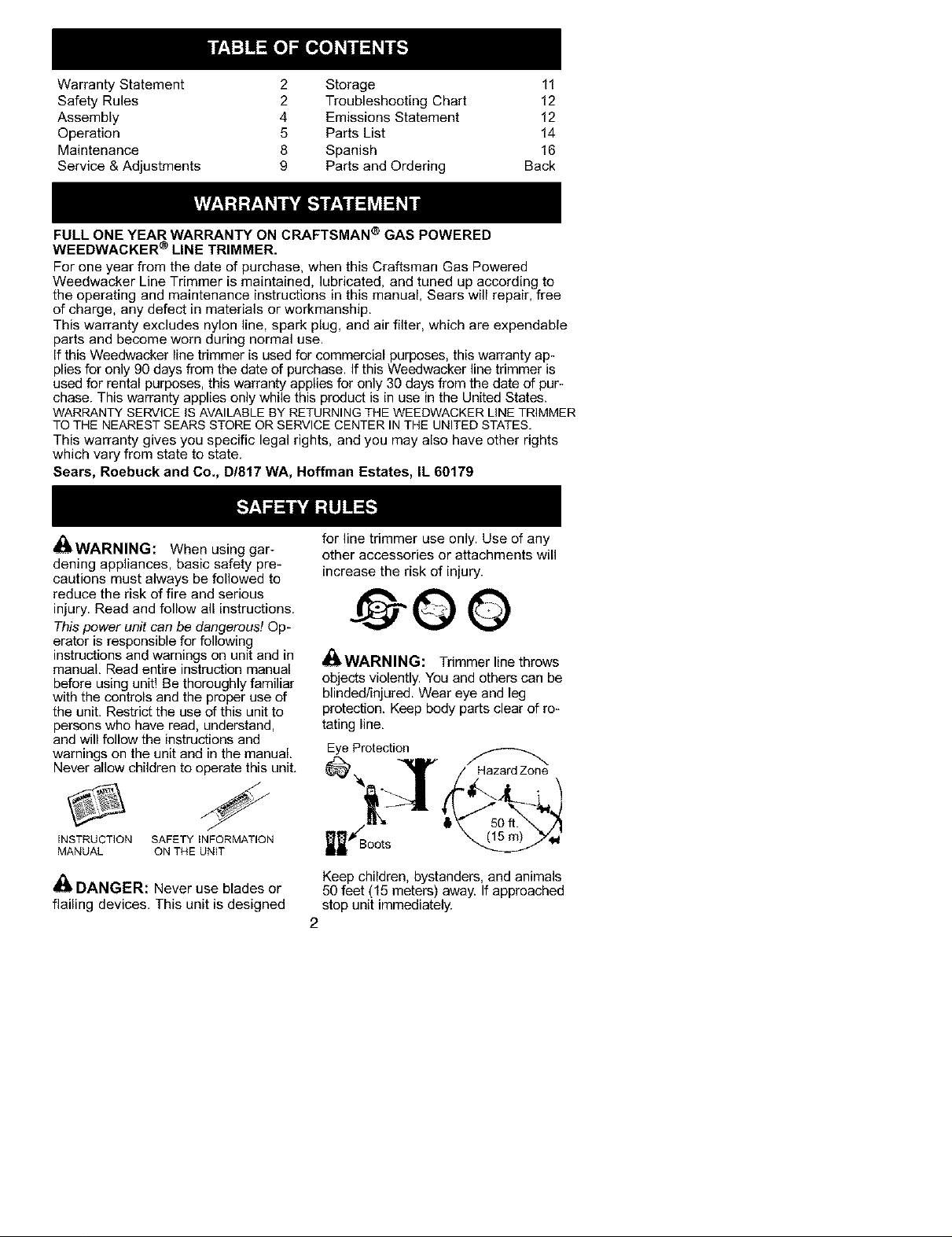

DANGER: Never use blades or

flailing devices. This unit is designed

J

for line trimmer use only. Use of any

other accessories or attachments will

increase the risk of injury.

@@O

_IkWARNING: Trimmer line throws

objects violently. You and others can be

blinded/injured. Wear eye and leg

protection. Keep body parts clear of ro-

tating line,

Eye Protection

;_B o_o_]__ HazardZone

Keep children, bystanders, and animals

50 feet (15 meters) away. If approached

stop unit immediately.

2

Ifsituationsoccurwhicharenotcov-

eredinthismanual,usecareand

goodjudgment.Ifyouneedassis-

tance,contactyourSearsService

Centerorcall1-800-235-5878.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when

operating, or performing maintenance,

on your unit (safety glasses are avail-

able). Eye protection should be

marked Z87.

• Always wear face or dust mask if op-

eration is dusty.

• Always wear heavy, long pants, long

sleeves, boots, and gloves. Wearing

safety leg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals. Stay

clear of spinning line.

• Secure hair above shoulder length.

Secure or remove loose clothing or

clothing with loosely hanging ties,

straps, tassels, etc. They can be

caught in moving parts.

• Being fully covered also helps protect

you from debris and pieces of toxic

plants thrown by spinning line.

• Stay Alert. Do not operate this unit

when you are tired, ill, upset or under

the influence of alcohol, drugs, or

medication. Watch what you are do-

ing; use common sense.

• Wear hearing protection.

• Never start or run inside a closed

room or building. Breathing exhaust

fumes can kill.

• Keep handles free of oil and fuel.

UNIT / MAINTENANCE SAFETY

• Disconnect the spark plug before per-

forming maintenance except carbure-

tor adjustments.

• Look for and replace damaged or

loose parts before each use. Look for

and repair fuel leaks before use. Keep

in good working condition.

• Replace trimmer head parts that are

chipped, cracked, broken, or dam-

aged in any other way before using

the unit.

• Maintain unit according to recom-

mended procedures. Keep cutting

line at proper length.

• Use only 0.080 in.(2 ram) diameter

Craftsman@ brand line. Never use

wire, rope, string, etc.

• Install required shield properly before

using the unit. Use only specified

trimmer head; make sure it is properly

installed and securely fastened.

• Make sure unit is assembled correctly

as shown in this manual.

• Make carburetor adjustments with

lower end supported to prevent line

from contacting any object.

• Keep others away when making car-

buretor adjustments.

• Use only recommended Craftsman

accessories and replacement parts.

• Have all maintenance and service not

explained in this manual performed by

a Sears Service Center.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near

fuel or the unit.

• Avoid spilling fuel or oil. Wipe up all

fuel spills.

• Move at least 10 feet (3 meters) away

from fueling site before starting em

gine.

• Stop engine and allow to cool before

removing fuel cap.

• Always store gasoline in a container

approved for flammable liquids.

CUTTING SAFETY

,i_ WARNING: Inspect the area be-

fore each use. Remove objects

(rocks, broken glass, nails, wire, etc.)

which can be thrown by or become

entangled in line. Hard objects can

damage the trimmer head and be

thrown causing serious injury.

• Use only for trimming, scalping, mow-

ing and sweeping. Do not use for edg-

ing, pruning or hedge trimming.

• Keep firm footing and balance. Do not

overreach.

• Keep all parts of your body away from

muffler and spinning line. Keep engine

below waist level. A hot muffler can

cause serious burns.

• Cut from your right to your left. Cut-

ting on left side of the shield will throw

debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual

TRANSPORTING AND STORAGE

• Allow engine to cool; secure unit be-

fore storing or transporting in vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

3

• Store unit so line limiter blade cannot

accidentally cause injury. The unit

can be hung by the tube.

• Store unit out of reach of children.

SAFETY NOTICE: Exposure to vibra-

tions through prolonged use of gaso-

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or ab-

normal swellings. Prolonged use in

cold weather has been linked to blood

vessel damage in otherwise healthy

people, If symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention, An anti-

vibration system does not guarantee

the avoidance of these problems, Us-

ers who operate power tools on a con-

tinual and regular basis must monitor

closely their physical condition and

the condition of this tool.

SPECIAL NOTICE: This unit is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of Cali-

fornia Codes 4442 and 4443. All U.S.

forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by

law that many internal combustion em

gines be equipped with a spark arrest-

ing screen. If you operate in a locale

where such regulations exist, you are

legally responsible for maintaining the

operating condition of these parts.

Failure to do so is a violation of the

law. For normal homeowner use, the

muffler and spark arresting screen will

not require any service. After 50

hours of use, we recommend that your

muffler be serviced or replaced by

your Sears Service Center.

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358,795551

• Trimmer

• Shield

• Container of Oil

• Extra Spool

Examine parts for damage. Do not

use damaged parts.

NOTE: If you need assistance or find

parts missing or damaged, call

1-800-235-5878.

It is normal for the fuel filter to rattle in

the empty fuel tank,

Finding fuel or oil residue on muffler is

normal due to carburetor adjustments

and testing done by the manufacturer.

ASSEMBLY

,tt _

4_WARNING: If received as-

sembled, repeat all steps to ensure

your unit is properly assembled and all

fasteners are secure.

ADJUSTING THE HANDLE

zt _____.__

_WARNING: When adjusting the

handle, be sure it remains between

the trigger and the safety label.

1. Loosen wing nut on handle.

2. Rotate the handle on the tube to an

upright position; retighten wing nut.

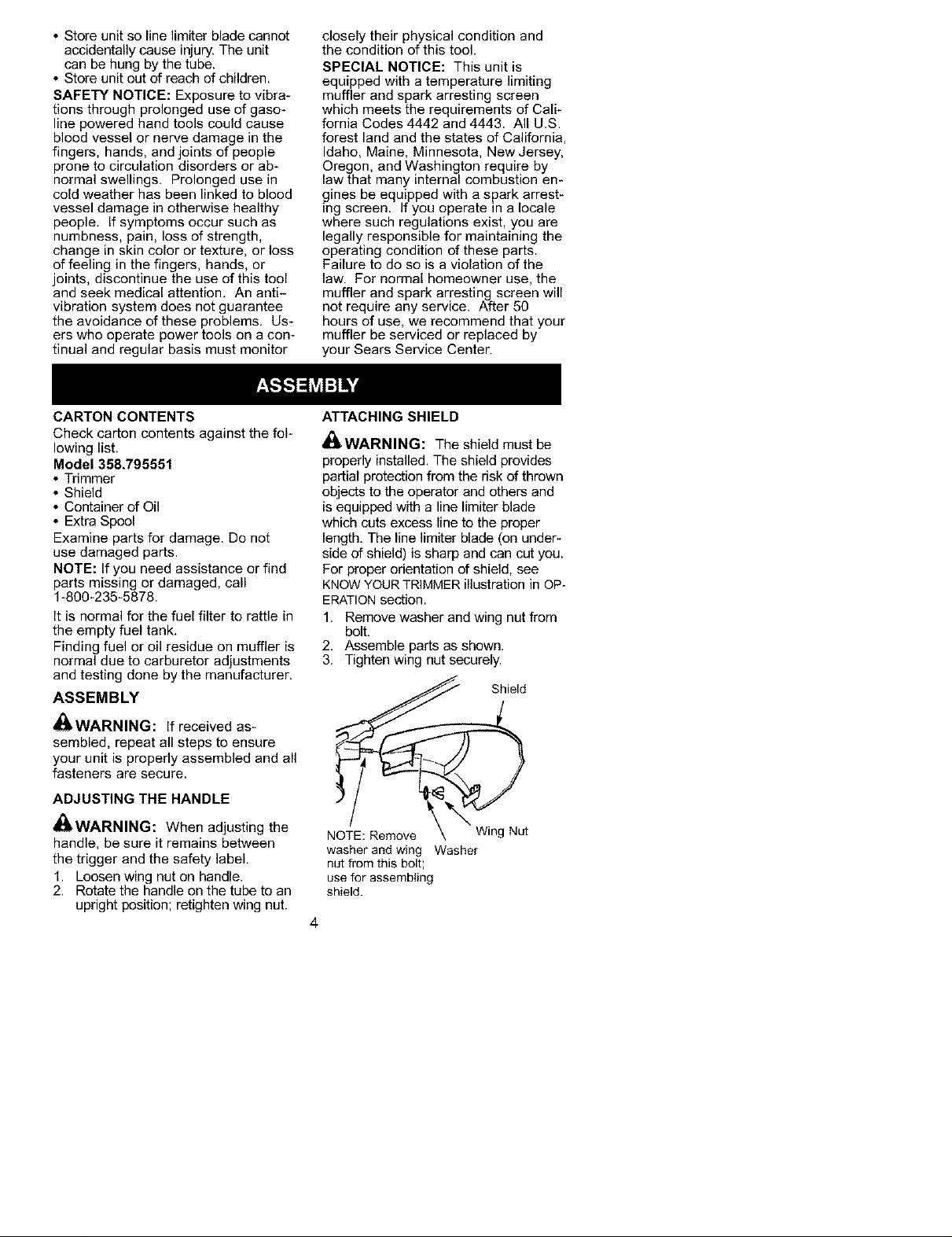

ATTACHING SHIELD

_WARNING: The shield must be

properly installed. The shield provides

partial protection from the risk of thrown

objects to the operator and others and

is equipped with a line limiter blade

which cuts excess line to the proper

length, The line limiter blade (on under-

side of shield) is sharp and can cut you.

For proper orientation of shield, see

KNOWYOURTRIMMER illustration in OP-

ERATIONsection.

1. Remove washer and wing nut from

bolt,

2, Assemble parts as shown.

3. Tighten wing nut securely.

Shield

washer and wing Washer

nut from this bolt;

usefor assembling

shield.

4

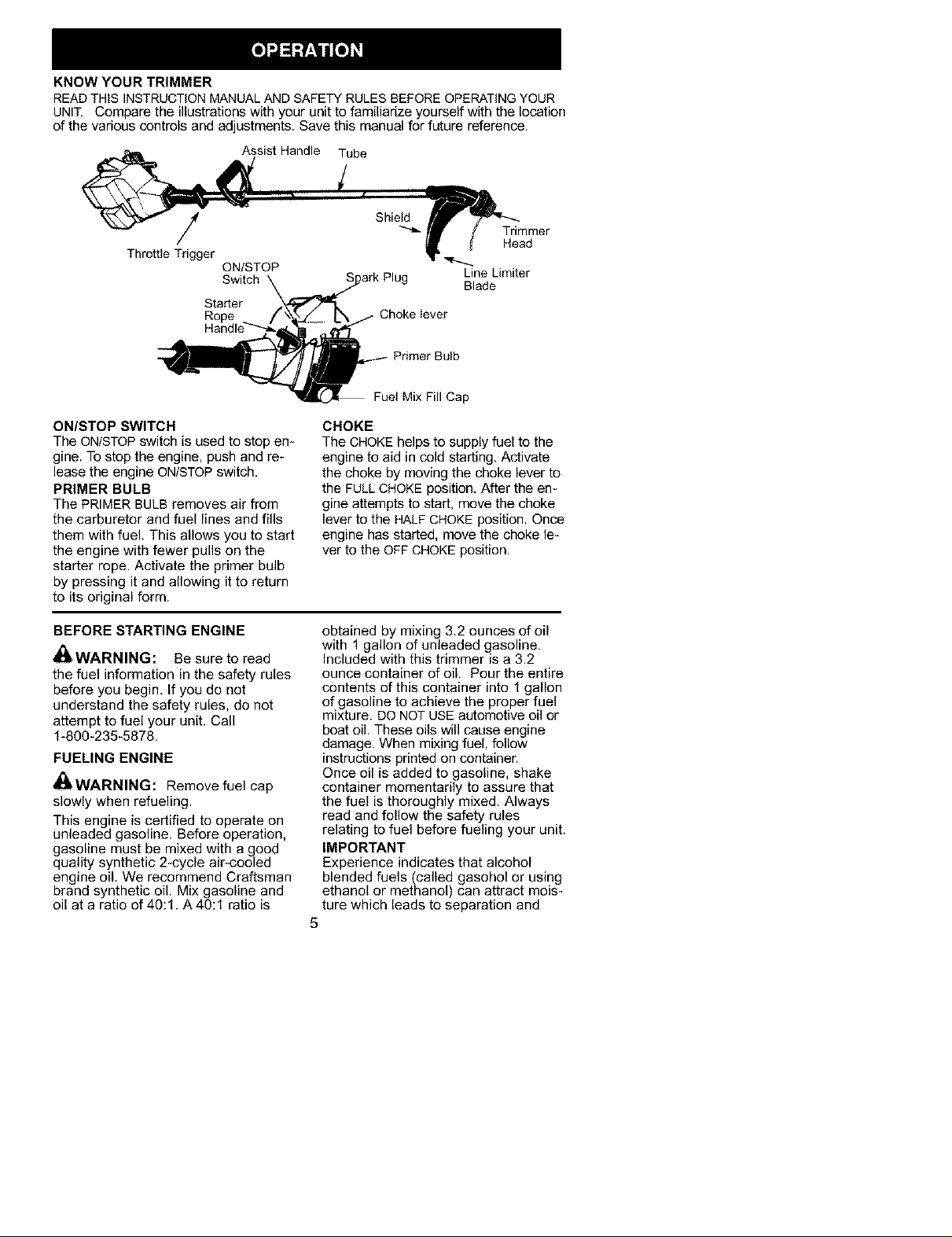

KNOW YOUR TRIMMER

READTHiS INSTRUCTIONMANUALAND SAFETY RULES BEFORE OPERATINGYOUR

UNIT. Compare the illustrationswith your unit to familiarize yourself with the location

of the various controls and adjustments. Save this manual for future reference.

Assist Handle Tube

/

Throttle Trigger

ON/STOP SWITCH

The ON/STOPswitch is used to stop en-

gine. Tostop the engine, push and re-

lease the engine ON/STOPswitch.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate the primer bulb

by pressing it and allowing it to return

to its original form.

BEFORE STARTING ENGINE

z%_____.__

_IbWARNING: Be sure to read

the fuel information in the safety rules

before you begin, If you do not

understand the safety rules, do not

attempt to fuel your unit. Call

1-800-235-5878.

FUELING ENGINE

_J_WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality synthetic 2-cycle air-cooled

engine oil, We recommend Craftsman

brand synthetic oil, Mix gasoline and

oil at a ratio of 40:1. A 40:1 ratio is

ON/STOP

Switch

Sta_er

Rope

Shield

Bulb

Fuel Mix Fill Cap

CHOKE

The CHOKE helps to supply fuel to the

engine to aid in cold starting. Activate

the choke by moving the choke lever to

the FULLCHOKE position. After the en-

gine attempts to start, move the choke

lever to the HALF CHOKE position. Once

engine has started, move the choke le-

ver to the OFF CHOKEposition.

obtained by mixing 3.2 ounces of oil

with 1 gallon of unleaded gasoline.

Included with this trimmer is a 3.2

ounce container of oil. Pour the entire

contents of this container into 1 gallon

of gasoline to achieve the proper fuel

mixture. DO NOTUSE automotive oil or

boat oil. These oils will cause engine

damage. When mixing fuel, follow

instructions printed on centainen

Once oil is added to gasoline, shake

container momentarily to assure that

the fuel is thoroughly mixed. Always

read and follow the safety rules

relating to fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract mois-

ture which leads to separation and

5

Trimmer

Head

Line Limiter

Blade

formationofacidsduringstorage.

Acidicgascandamagethefuelsys-

temofanenginewhileinstorage.

Toavoidengineproblems,emptythe

fuelsystembeforestoragefor30days

orlonger.Drainthegastank,startthe

engineandletitrununtilthefuellines

andcarburetorareempty.Usefresh

fuelnextseason.

Neveruseengineorcarburetorclean-

erproductsinthefueltankorperma-

nentdamagemayoccur.

SeetheSTORAGEsectionforaddition-

alinformation.

HOWTOSTOPYOURUNIT

• Tostoptheengine,pushandre-

leasetheengineON/STOPswitch.

Theswitchwillautomaticallyreturn

totheONposition.Wait5seconds

beforeattemptingtorestartunitto

allowswitchtoreset.

• Ifenginedoesnotstop,movechoke

totheFULLCHOKEposition.

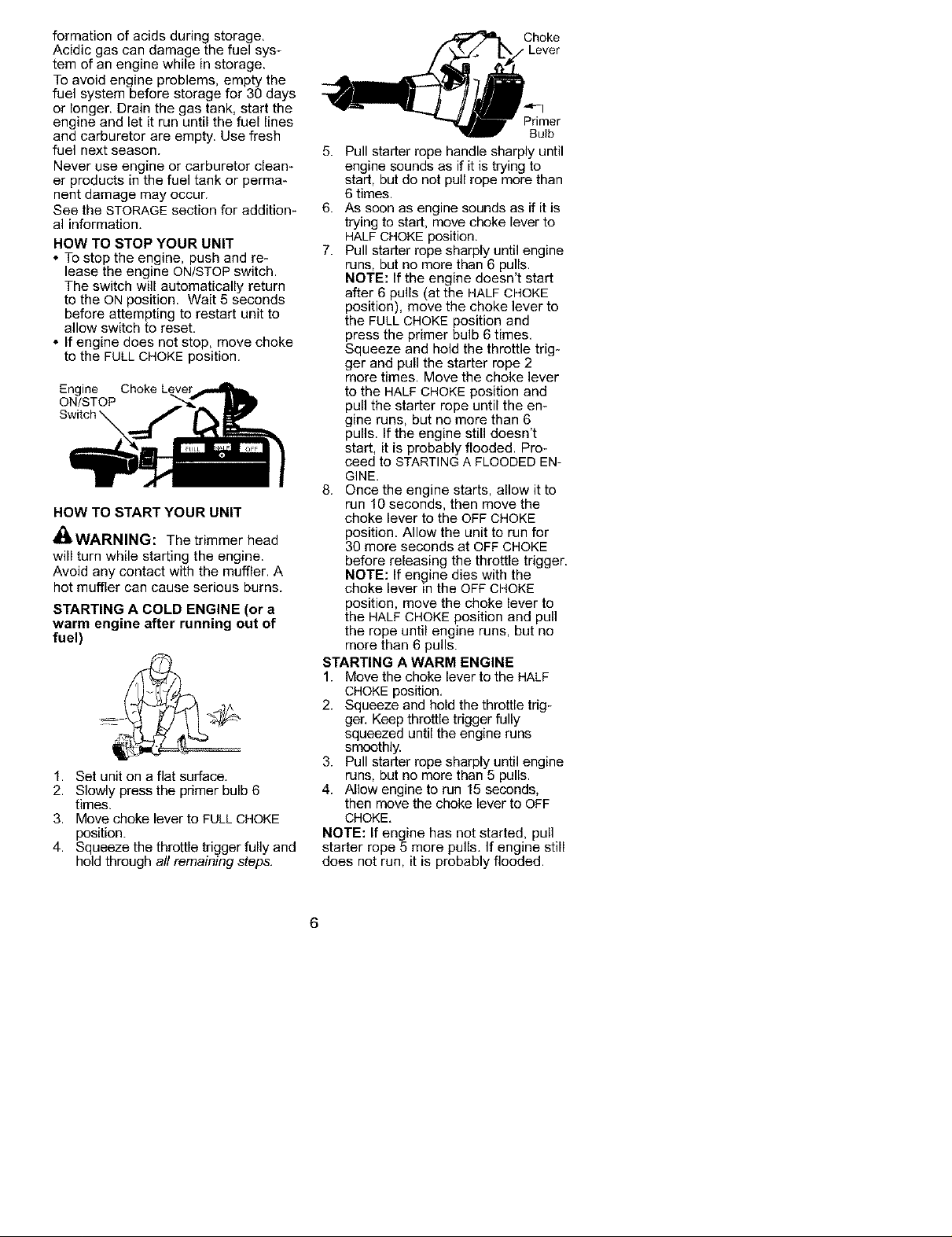

Engine Choke Lever

ON/STOP

HOW TO START YOUR UNIT

_JkWARNING: The trimmer head

will turn while starting the engine.

Avoid any contact with the muffler. A

hot muffler can cause serious burns.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

1. Set unit on a flat surface.

2. Slowly press the primer bulb 6

times.

3. Move choke lever to FULL CHOKE

position.

4. Squeeze the throttle trigger fully and

hold through all remaining steps.

._._ Lever

_i h°ke

5. Pull starter rope handle sharply until

engine sounds as if it is trying to

start, but do not pull rope more than

6 times.

6. As soon as engine sounds as if it is

trying to start, move choke lever to

HALFCHOKE position.

7. Pull starter rope sharply until engine

runs, but no more than 6 pulis.

NOTE: If the engine doesn't start

after 6 pulis (at the HALF CHOKE

position), move the choke lever to

the FULL CHOKE position and

press the primer bulb 6 times.

Squeeze and hold the throttle trig-

ger and pull the starter rope 2

more times. Move the choke lever

to the HALF CHOKE position and

pull the starter rope until the en-

gine runs, but no more than 6

pulls. If the engine still doesn't

start, it is probably flooded. Pro-

ceed to STARTING A FLOODED EN-

GINE.

8. Once the engine starts, allow itto

run 10 seconds, then move the

choke lever to the OFF CHOKE

position. Allow the unit to run for

30 more seconds at OFF CHOKE

before releasing the throttle trigger.

NOTE: If engine dies with the

choke lever in the OFF CHOKE

position, move the choke lever to

the HALF CHOKE position and pull

the rope until engine runs, but no

more than 6 pulis.

STARTING A WARM ENGINE

1. Move the choke lever to the HALF

CHOKEposition.

2. Squeeze and hold the throttle trig-

ger. Keep throttle trigger fully

squeezed until the engine runs

smoothly.

3. Pull starter rope sharply until engine

runs, but no more than 5 pulis.

4. Allow engine to run 15 seconds,

then move the choke lever to OFF

CHOKE.

NOTE: If engine has not started, pull

starter rope 5 more pulls. If engine still

does not run, it is probably flooded.

Primer

Bulb

6

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the choke lever in the OFF

CHOKE position; then, pull the rope to

clear the engine of excess fuel. This

could require pulling the starter handle

many times depending on hew badly

the unit is flooded,

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-235-5878,

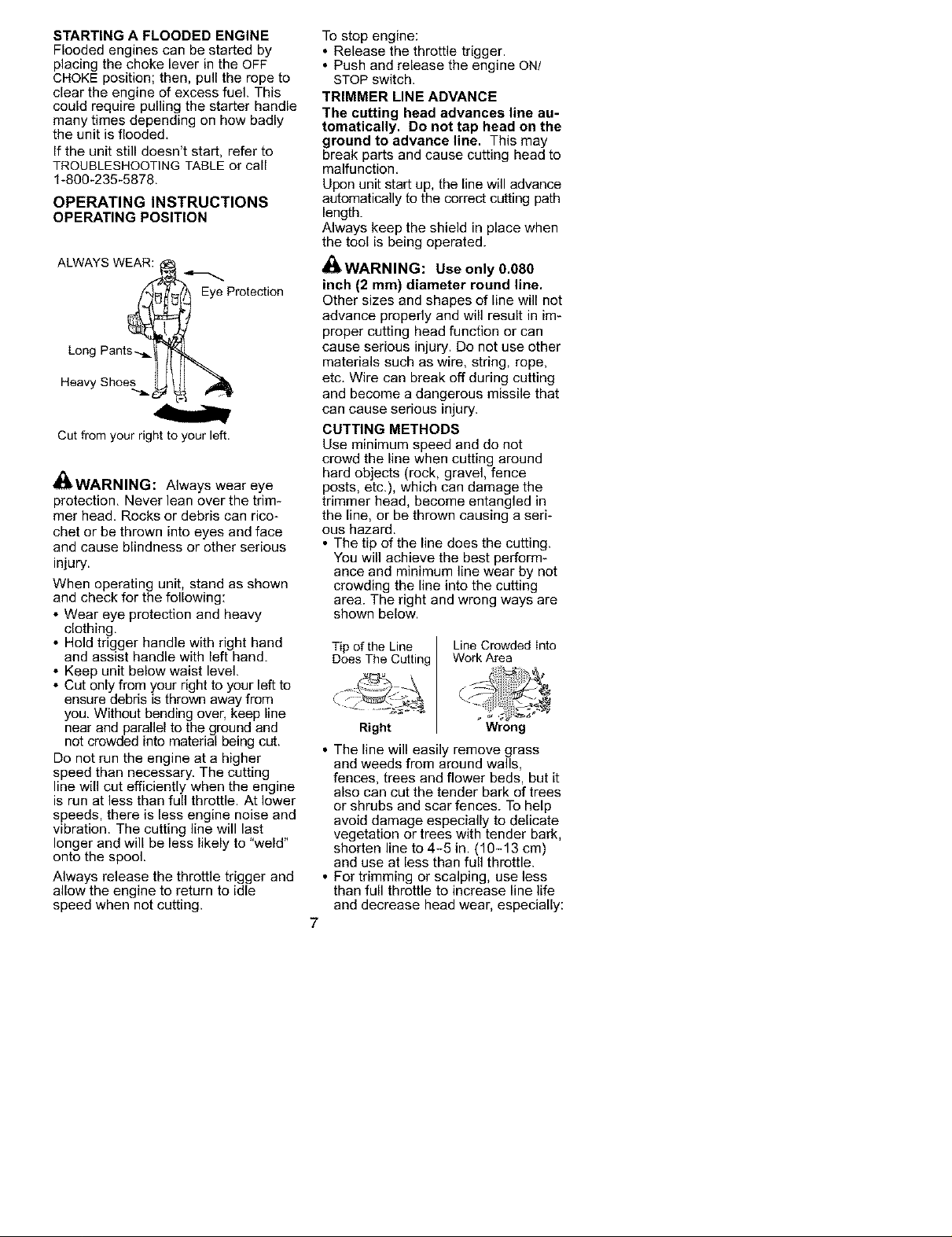

OPERATING INSTRUCTIONS

OPERATING POSITION

ALWAYS WEAR:

Eye Protection

Long

Heavy Shoe_

Cut from your right to your left.

dl_ WARNING: Always wear eye

protection, Never lean over the trim-

mer head, Rocks or debris can rico-

chet or be thrown into eyes and face

and cause blindness or other serious

injury.

When operating unit, stand as shown

and check for the following:

• Wear eye protection and heavy

clothing,

• Hold trigger handle with right hand

and assist handle with left hand.

• Keep unit below waist level.

• Cut only from your right to your left to

ensure debris is thrown away from

you. Without bending over, keep line

near and parallel to the ground and

not crowded into material being cut.

Do not run the engine at a higher

speed than necessary. The cutting

line will cut efficiently when the engine

is run at less than full throttle. At lower

speeds, there is less engine noise and

vibration. The cutting line will last

longer and will be less likely to "weld"

onto the spool.

Always release the throttle trigger and

allow the engine to return to idle

speed when not cutting.

To stop engine:

• Release the throttle trigger.

• Push and release the engine ON/

STOP switch.

TRIMMER LINE ADVANCE

The cutting head advances line au-

tomatically. Do not tap head on the

ground to advance line. This may

break parts and cause cutting head to

malfunction,

Upon unit start up, the line will advance

automatically to the correct cutting path

length.

Always keep the shield in place when

the tool is being operated.

_I_WARNING: Use only 0.080

inch (2 mm) diameter round line.

Other sizes and shapes of line will not

advance properly and will result in im-

proper cutting head function or can

cause serious injury. Do not use other

materials such as wire, string, rope,

etc, Wire can break off during cutting

and become a dangerous missile that

can cause serious injury.

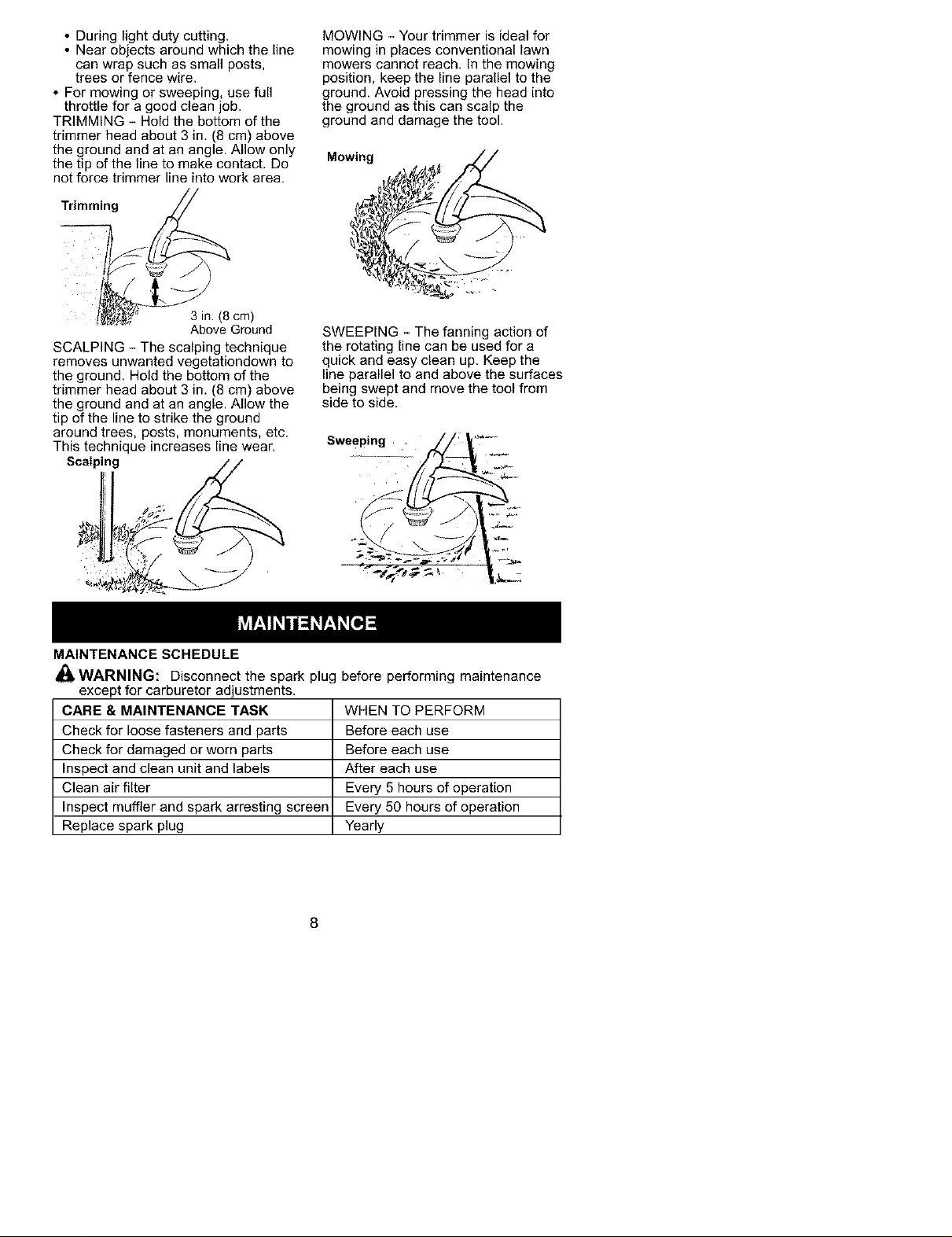

CUTTING METHODS

Use minimum speed and do not

crowd the line when cutting around

hard objects (rock, gravel, fence

posts, etc.), which can damage the

trimmer head, become entangled in

the line, or be thrown causing a seri-

ous hazard.

• The tip of the line does the cutting.

You will achieve the best perform*

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

Tip of the Line

Does The Cutting

Right

Line Crowded Into

Work Area

Wrong

• The line will easily remove grass

and weeds from around walls,

fences, trees and flower beds, but it

also can cut the tender bark of trees

or shrubs and scar fences. To help

avoid damage especially to delicate

vegetation or trees with tender bark,

shorten line to 4-5 in. (10-13 cm)

and use at less than full throttle.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

7

• Duringlightdutycutting.

• Nearobjectsaroundwhichtheline

canwrapsuchassmallposts,

treesorfencewire.

• Formowingorsweeping,usefull

throttleforagoodcleanjob.

TRIMMING- Holdthebottomofthe

trimmerheadabout3in.(8cm)above

thegroundandatanangle.Allowonly

thetipofthelinetomakecontact.Do

notforcetrimmerlineintoworkarea.

3in.(8cm)

AboveGround

SCALPING- Thescalpingtechnique

removesunwantedvegetationdownto

theground.Holdthebottomofthe

trimmerheadabout3in.(8cm)above

thegroundandatanangle.Allowthe

tipofthelinetostriketheground

aroundtrees,posts,monuments,etc.

Thistechniqueincreaseslinewear.

Scalping

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

SWEEPING - The fanning action of

the rotating line can be used for a

quick and easy clean up. Keep the

line parallel to and above the surfaces

being swept and move the tool from

side to side.

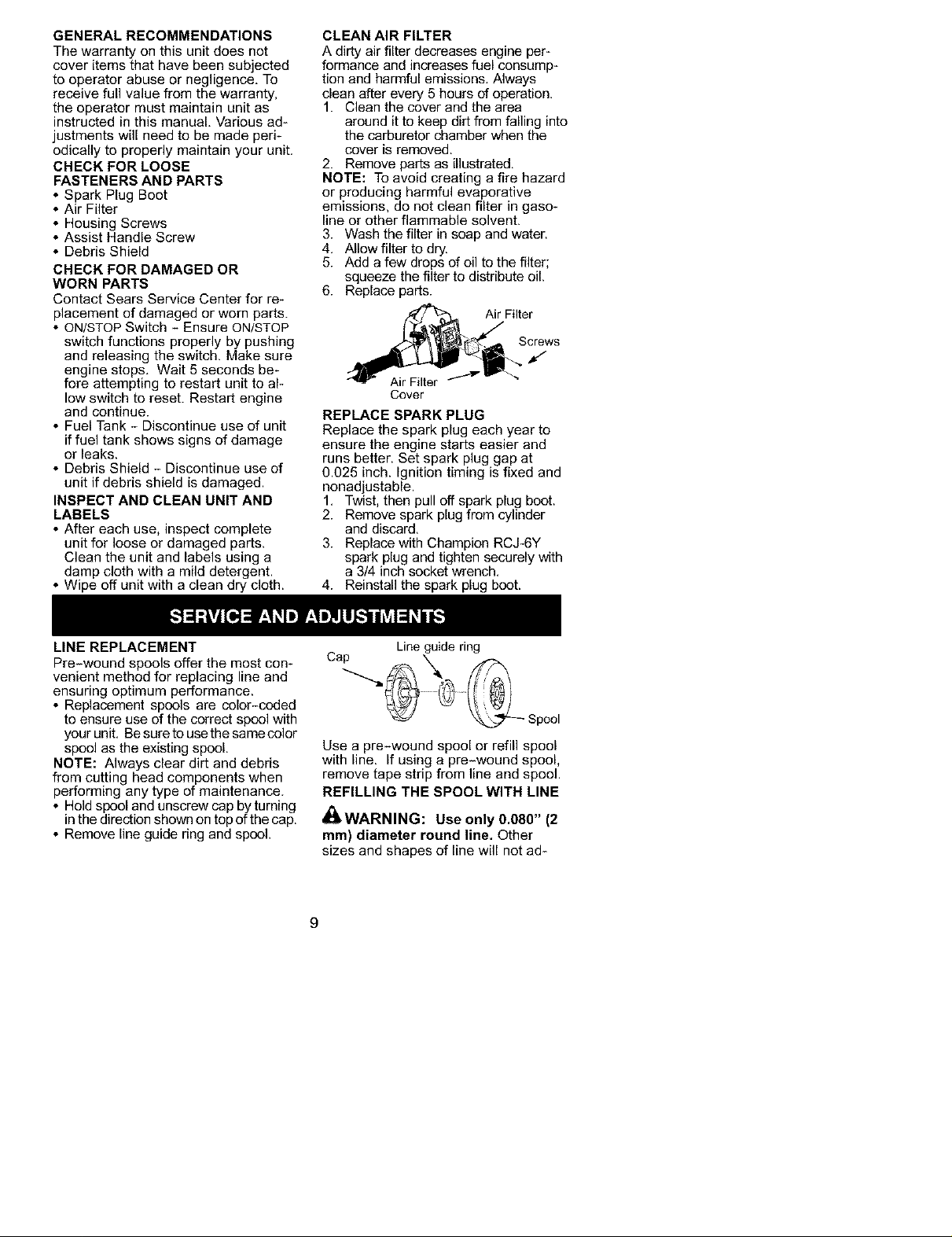

MAINTENANCE SCHEDULE

WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

CARE & MAINTENANCE TASK

Check for loose fasteners and parts

Check for damaged or worn parts

Inspect and clean unit and labels

Clean air filter

Inspect muffler and spark arresting screen

Replace spark plug

WHEN TO PERFORM

Before each use

Before each use

After each use

Every 5 hours of operation

Every 50 hours of operation

Yearly

8

GENERAL RECOMMENDATIONS

The warranty on this unit does not

cover items that have been subjected

to operator abuse or negligence, To

receive full value from the warranty,

the operator must maintain unit as

instructed in this manual, Various ad-

justments will need to be made peri-

odically to properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re-

placement of damaged or worn parts.

• ON/STOP Switch - Ensure ON/STOP

switch functions properly by pushing

and releasing the switch. Make sure

engine stops, Wait 5 seconds be-

fore attempting to restart unit to al-

low switch to reset. Restart engine

and continue.

• Fuel Tank - Discontinue use of unit

if fuel tank shows signs of damage

or leaks.

• Debris Shield - Discontinue use of

unit if debris shield is damaged.

INSPECT AND CLEAN UNIT AND

LABELS

• After each use, inspect complete

unit for loose or damaged parts.

Clean the unit and labels using a

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine per-

formance and increases fuel consump-

tion and harmful emissions, Always

clean after every 5 hours of operation.

1. Clean the cover and the area

around it to keep dirt from falling into

the carburetor chamber when the

cover is removed.

2. Remove parts as illustrated,

NOTE: To avoid creating a fire hazard

or producing harmful evaporative

emissions, do not clean filter in gaso-

line or other flammable solvent.

3. Wash the filter in soap and water.

4, Allow filter to dry.

5. Add a few drops of oil to the filter;

squeeze the filter to distribute oil.

6. Replace parts.

_S_gilter

Cover

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Set spark plug gap at

0.025 inch. Ignition timing is fixed and

nonadjustable.

1, Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard,

3. Replace with Champion RCJ-GY

spark plug and tighten securely with

a 3/4 inch socket wrench,

4. Reinstall the spark plug boot.

LINE REPLACEMENT

Pre-wound spools offer the most con-

venient method for replacing line and

ensuring optimum performance.

• Replacement spools are color-ceded

to ensure use of the correct spool with

your unit, Be sure to use the same color

spool as the existing spool,

NOTE: Always clear dirt and debris

from cutting head components when

performing any type of maintenance.

• Hold spool and unscrew cap by turning

in the direction shown on top of the cap.

• Remove line guide ring and spool.

Cap

Line guide ring

Use a pre-wound spool or refill spool

with line. If using a pre-wound spool,

remove tape strip from line and spool.

REFILLING THE SPOOL WITH LINE

_IkWARNING: Use only 0.080" (2

mm) diameter round line. Other

sizes and shapes of line will not ad-

9

Loading...

Loading...