Craftsman 358795320 Owner’s Manual

Operator's Manual

®

CRRFTSMRN

24cc/1.46 cu. in. 2-Cycle

17 Inch Cutting Path

GASOLINE WEEDWACKER ®

//

Model No.

358.795320

WARNING:

&

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

I

I

For answers to your questions about this product:

Carl 7 am-7 pm, Mon-Sat; Sun, 10 am-7 pm

1-800-235-5878

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-084661 03/16/97

WarrantyStatement 2 Storage 10

SafetyRules 2 TroubleshootingChart 1!

Assembly 4

Operation 5 RepairPartsList 12

Maintenance 8 Spanish 16

Service&Adjustments 9 Partsand Ordering BackCover

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS POWERED

WEEDWACKER ® LINE TRIMMER

For one year from the date of pumhase, when this Craftsman Gas Powered

Weedwacker_ Line Trimmer is maintained, lubricated, and tuned up according to

the operating and maintenance instructionsin the Operator's Manual, Sears will

repair,free of charge, any defect in materials or workmanship.

This warranty excludes nylonline, spark plug, and air filter, whichare expendable

parts and become worn duringnormal use.

if th_sWeedwacker® Line Trimmer is used for commercial purposes, this warran-

ty applies for only90 days from the date of pumhase. If this Weedwacker_ Line

Trimmer is used for rental purposes, this warranty applies for only 30 days from

the date of purchase. This warranty applies only while this product is in use in the

United States.

WARRANTYSERVICE IS AVAILABLEBY RETURNINGTHE WEEDWACKER® LINE

TRIMMER TO THE NEARESTSEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights,and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D/817 WA Heffman Estates, IL 60179

WARNING: When usinggardening

appliances,basicsafetyprecautions

mustalwaysbefollowedtoreducethe

riskoffireandseriousinjury.Readand

follow all instructions.

Thispower unitcanbe dangerous!

Operatorisresponsibleforfollowing

instructionsandwarningsonunitand

in manual.ReadentireOperator's

Manualbeforeusingunit!Bethorough-

lyfamiliar withthe controlsandthe

properuseofthe unit.Restrictthe use

ofthisunittopersonswhohaveread,

understand,andwillfollow theinstruc-

tionsandwarningsontheunitand in

themanual. Neverallowchildrento

operatethisunit.

Safetyinformationontheunit

DANGER: Neverusebladesorflail-

ingdevices.Thisunitisdesignedfor

linetrimmeruseonly.Useofanyother

accessoriesor attachmentswillin.

creasethe riskofinjury.

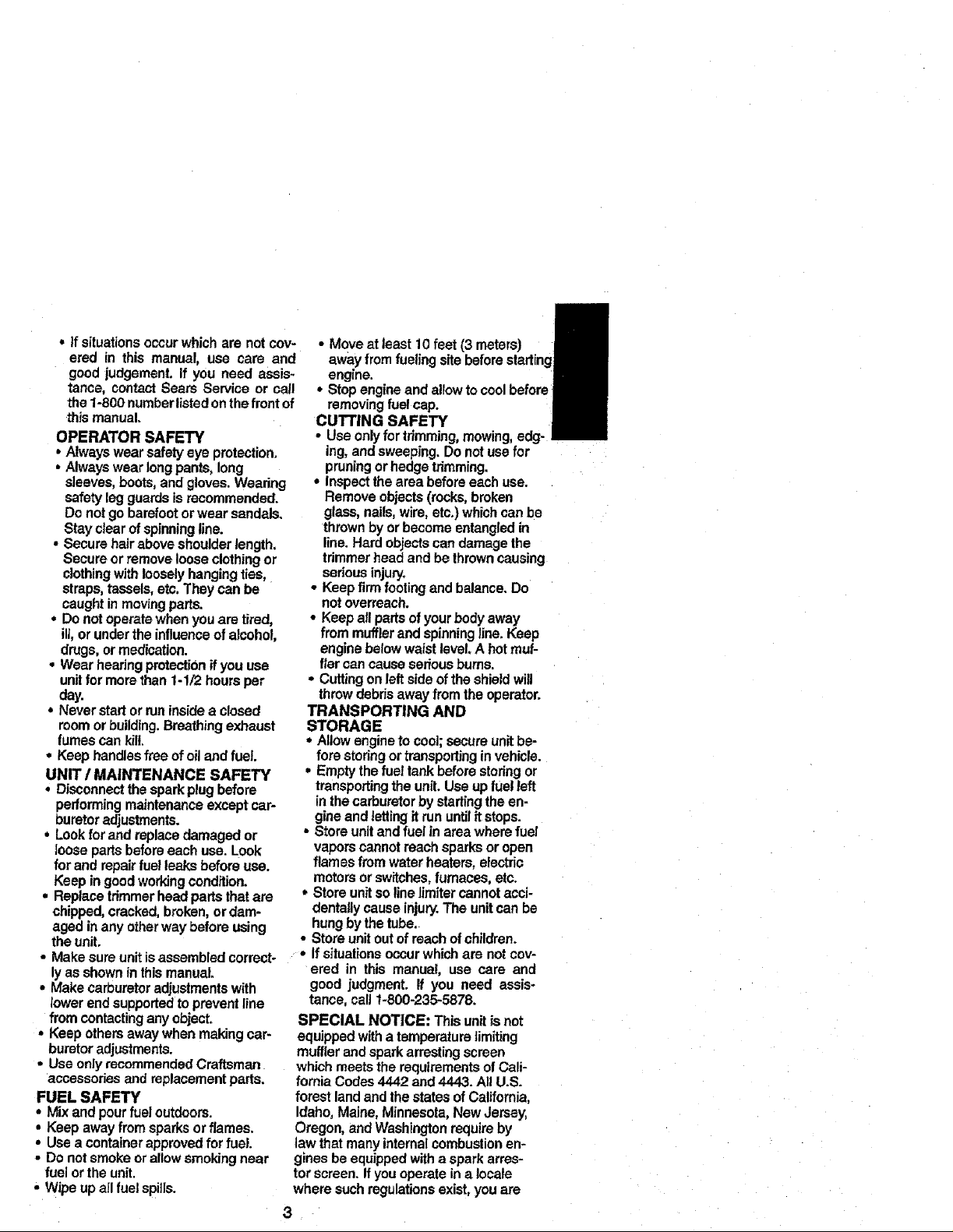

WARNING: Trimmerlinethrowsob-

jectsviolently.Youand otherscanbe

blinded/injured.Weareye andleg

protection.Keep bodypartsclearof

rotatingline.Keepchildren,bystand-

ers, and animals 50 feet (15 m) away.

Ifapproached,stopunitimmediately.

_Prote_on

2

• tfsituationsoccurwhichare notcov-

ered in this manual, use care and

goodjudgement.If you need assis-

tance, contactSearsServiceor call

the1-800numberlistedonthefront of

thismanual.

OPERATOR SAFETY

• Alwayswearsafetyeye protection.

• Always,wearlongpants,long

sleeves,boots,and gloves.Wearing

safetylegguardsisrecommended.

Do notgo barefootorwearsandals.

Stay clearofspinningline.

• Securehairaboveshoulderlength.

Secureorremove looseclothingor

clothingwithlooselyhangingties,

straps,tassels,etc.They can be

caughtinmovingparts.

• Do notoperatewhenyouare tired,

ill,or undertheinfluenceofalcohol,

drugs,ormedication.

• Wear hearingprotectionifyouuse

unitfor morethan1-1/2 hoursper

day.

• Neverstartorruninsidea closed

roomorbuilding.Breathingexhaust

fumescan kilt.

• Keephandlesfreeofoilandfuel.

UNIT / MAINTENANCE SAFETY

• Disconnectthesparkplugbefore

performingmaintenanceexceptcar-

buretoradjustments.

• Lookforandreplacedamagedor

leosepartsbeforeeachuse.Look

for and repairfuelleaksbefore use.

Keepingoodworkingcondition.

• Replacetrimmerheadpartsthatare

chipped,cracked,broken,ordam-

aged inanyotherwaybeforeusing

theunit.

• Makesureunitisassembledcorrect-

lyas showninthismanual.

• Makecarburetoradjustmentswith

lowerendsuppertedtopreventline

from contactinganyobject.

• Keepothersawaywhenmakingcar-

buretoradjustments.

• UseonlyrecommendedCraftsman

accessoriesandreplacementparts.

FUEL SAFETY

° Mixandpourfueloutdoors.

° Keepawayfromsparksorflames.

• Useacontainerapprovedfor fuel.

• Donotsmokeorallowsmokingnear

fuel ortheunit.

' Wipeupall fuelspills.

• Moveat least 10 feet (3 meters)

away fromfuelingsit=

engine.

• Stopengineand allowtocoolbefore

removingfuel cap.

CUTTING SAFETY

• Useonlyfortrimming,mowing,

ing,andsweeping.Do notusefor

pruningorhedgetrimming.

• Inspecttheareabeforeeachuse.

Removeobjects(rocks,broken

glass,nails,wire,etc.)whichcanbe

thrownbyorbecomeentangledin

line.Hardobjectscandamagethe

trimmerbeadandbe throwncausing

seriousinjury.

• Keepfirmfoolingand balance.Do

notoverreach.

• Keepall partsofyourbodyaway

from mufflerandspinningline.Keep

enginebelowwaistlevel A hotmuf-

fler cancauseseriousbums.

• Cuttingonleftsideoftheshieldwill

throwdebrisawayfromthe operator.

TRANSPORTING AND

STORAGE

• Allowenginetocool;secureunitbe-

forestoringortransportinginvehicle.

• Emptythefueltankbeforestoring or

transportingtheunit.Useupfuelleft

inthecarburetorby startingtheen-

gineand lettingit rununtilitstops.

• Storeunitandfuelinareawherefuel

vapors cannot reachsparksor open

flames from water heaters,electric

motorsor switches,furnaces,etc.

• Storeunitsolinelimitercannotacci-

dentally causeinjury.The unitcanbe

hung by the tube.

• Storeunitout of reachofchildren.

• If situationsoccur which are notcov-

ered in this manual, use care and

good judgment.If you need assis-

tance,call 1-800-235-5878.

SPECIAL NOTICE: This unitisnot

equippedwitha temperaturelimiting

mufflerandsparkarrestingscreen

whichmeetsthe requirementsofCali-

forniaCodes4442and4443. AllU.S.

forest landandthe statesofCalifornia,

Idaho,Maine,Minnesota,New Jersey,

Oregon,andWashingtonrequireby

lawthat manyinternalcombustionen-

ginesbe equippedwitha sparkarres-

torscreen.If youoperateina locale

wheresuchregulationsexist,youare

3

legally responsible for installing and tionof the law, Contact your Sears

maintaining the operating condition of Service Center for the correct parts.

these parts. Failure to do so is a viola-

CARTON CONTENTS

Check carton contents against the fol-

lowinglist.

Model 358,795320

• Trimmer

• Shield with wing nut

• Assist Handle with'bolt and wing nut

• Container of Oil

• Spool with 20 ft. of line

Examine parts for damage, Do not use

damaged parts.

NOTE: it you need assistance or find

pads missing or damaged, call

1-800-235-5878.

It is normal forthe fuel filterto rattle in

the empty fuel tank,

Findingfuel or oil residue on muffler is

normaldue to carburetor adjustments

and testing done by the manufacturer.

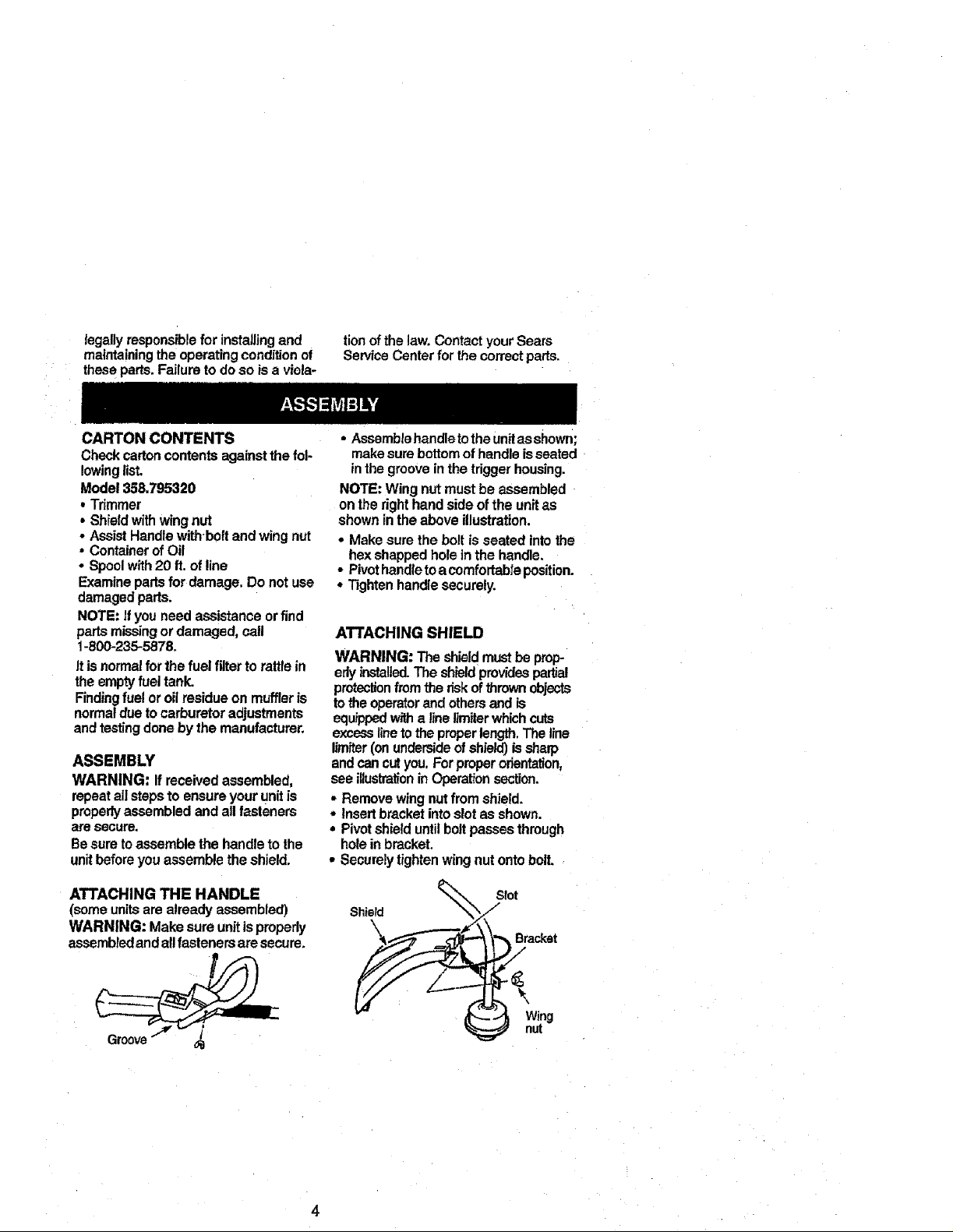

ASSEMBLY

WARNING: Ifreceivedassembled,

repeatallstepstoensureyourunitis

pmpedyassembledand allfasteners

aresecure.

Besuretoassemblethehandleto the

unitbeforeyouassembletheshield.

• Assembiehandletotheunitasshown;

make sure bottom of handle isseated

inthe groove in the trigger housing.

NOTE: Wing nut must be assembled

on the right hand side of the unit as

shown in the above illustration.

• Make sure the bolt is seated into the

hex shapped hole in the handle.

• Pivot handle to acomfortable position.

• Tighten handle securely.

ATTACHING SHIELD

WARNING: The shield must be prop-

erly installed.The shield providespartial

protectionfromthe risk ofthrown objects

to the operator and othersand is

equippedwitha line llm_terwhichcuts

excess lineto the proper length. The line

limtter(on undersideofshield) is sharp

and can cutyou. For proper orientation,

see illustrationin Operationsection.

• Remove wing nutfrom shield.

- Insert bracket into slot as shown.

• Pivot shield untilbolt passes through

hole in bracket.

• Securely tighten wing nut onto bolt.

ATTACHING THE HANDLE

(some unitsare already assembled)

WARNING: Make sure unit is propedy

assembled and allfasteners are secure.

_-_ Slot

"_,__ Bracket

Wing

nut

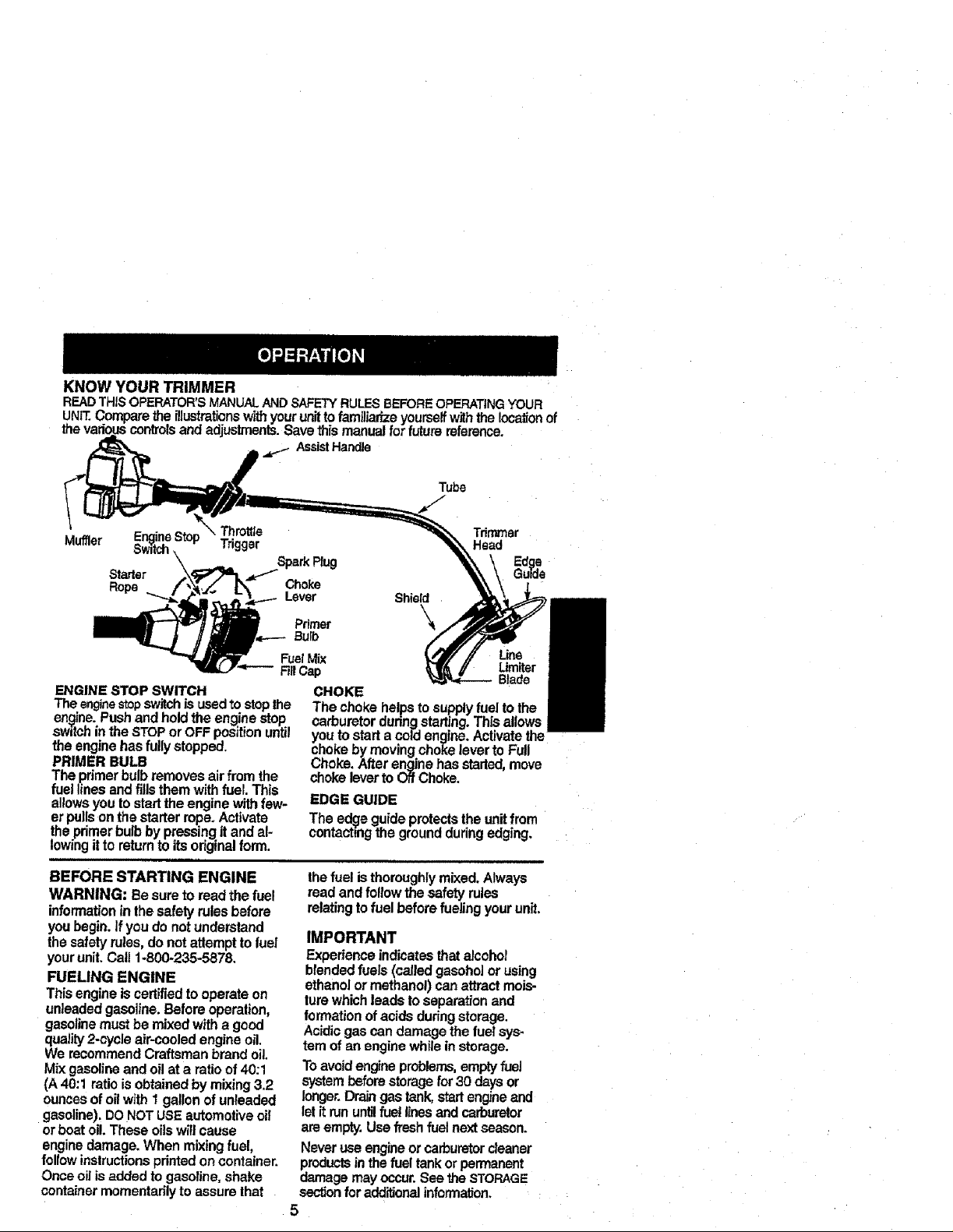

KNOWYOURTRIMMER

READTHiSOPERATOR'SMANUALANDSAFETYRULES BEFOREOPERATINGYOUR

UNIT.Compare the illustrations with your unit b familiarize yourself withthe !ocationof

e various controlsand adjustments. Save this manual for future mferenca.

AssistHandle

Tube

Muffler EngineStop Throttle Tdrr_rner

ENGINE STOP SWITCH

Theenginestopswitchis usedtostopthe

engine.Pushandholdthe enginestop

swltcnintheSTOPorOFFpositionuntil

theenginehas fully stopped.

PRIMER BULB

Theprimerbulb removesairfrom the

fuellinesandfillsthem withfuel. This

allowsyouto starttheenginewithfew-

erpullson thestarterrope,Activate

theprimerbulbby pressingit andal-

Switch Trigger Head

Starter

Rope

Choke

Lever

Primer

Bulb

FuelMix Line

FillCap Limiter

CHOKE

Shield

\

The chokehelps tosupplyfueltothe

carburetorduringstarting.This allows

youtostarta coldengine.Activatethe

chokebymovingchokeleverto Full

Choke.After enginehasstarted,move

chokelevertoOff Choke.

EDGEGUIDE

The edQeguideprotectstheunitfrom

contactingthe groundduringedging,

lowingitto return toitsoriginalform.

BEFORE STARTING ENGINE

WARNING: Besureto readthefuel

informationin thesafetyrulesbefore

youbegin.Ifyou do notunderstand

thesafelyrules,do notattemptto luel

yourunit.Call1-800-235-5878,

FUELING ENGINE

Thisengineis certifiedtooperateon

unleadedgasoline.Beforeoperalion,

gasoiinemust be mixedwitha good

quality2-cycleair-cooledengineoil,

We recommendCraftsmanbrandoil.

Mixgasolineandoilat a ratioof40:1

(A40:1 ratioisobtainedby mixing3.2

ouncesof oilwith_ gallonofunFeaded

gaseline),DONOTUSEautomotiveoil

orboatoil.Theseoilswillcause

enginedamage.When mixingfuel,

follow inslructionspdntedoncontainer.

Onceoil isaddedtogasoline,shake

containermomentarilyto assurethat

thefuel isthoroughlymixed,Always

readandfollow the safetyrules

relatingtofuel beforefuelingyourunit.

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasehol or using

ethanol or methanol) can attract mois-

lure which leads to separation and

formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage.

Toavoid engine problems,empty fuel

system before storage for30 days or

longer.Drain gas tank, start engine and

let it mn until fuel line,sand carburetor

are empty. Use freshfuel next season.

Never use engine or carburetor cleaner

productsin the fuel tank or permanent

damage may occur. See the STORAGE

sectionfor additional information.

5

B!ade

HOW TO STOP YOUR UNIT

Push and hold the engine stop switch

in the STOP or OFF position until the

unit has fully stopped.

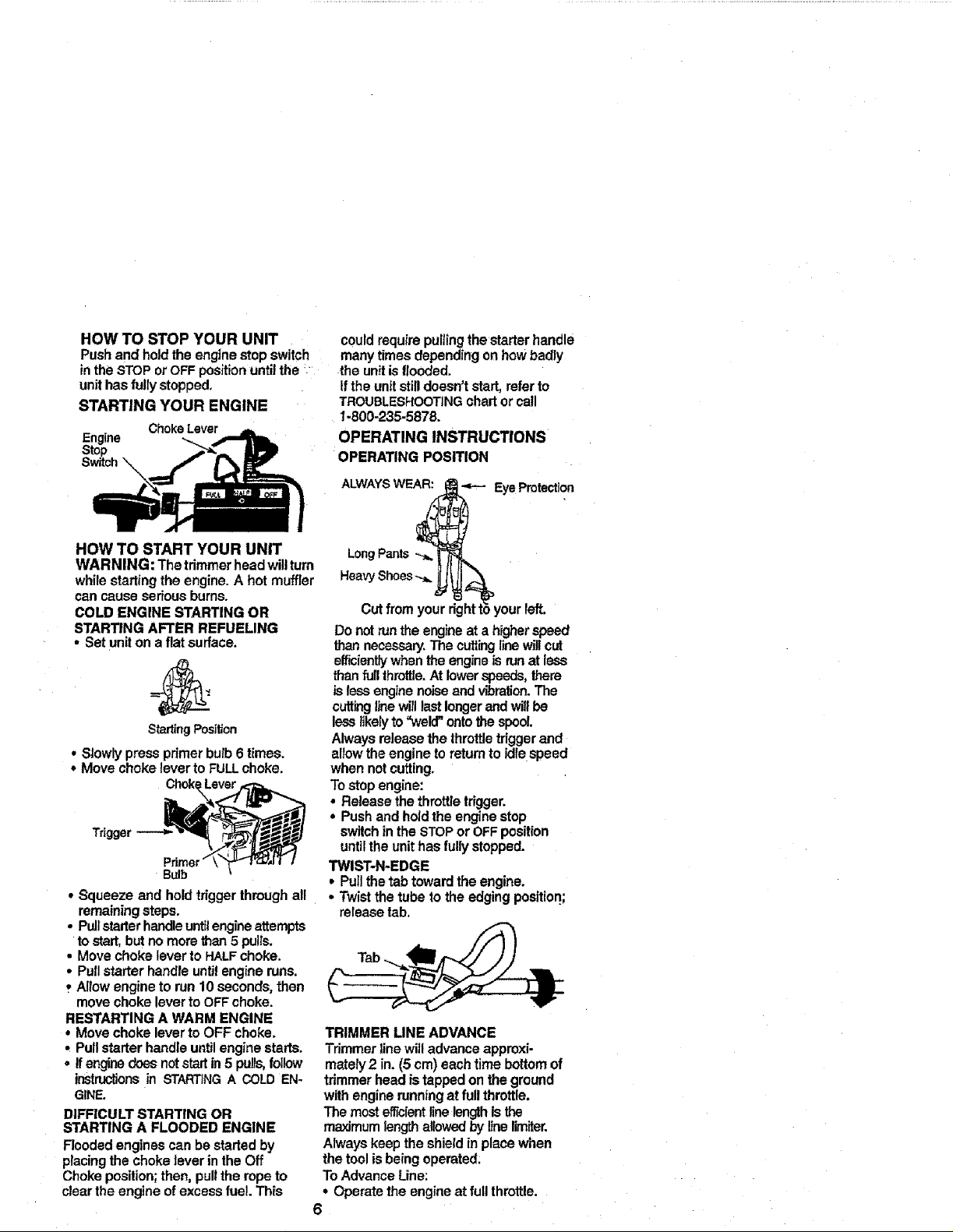

STARTING YOUR ENGINE

Engine -__

Stop

Switch_

HOW TO START YOUR UNIT

WARNING: The tdmmer head will turn

while starting the engine. A hot muffler

can cause serious burns.

COLD ENGINE STARTING OR

STARTING AFTER REFUELING

• Set unit on a flat surface.

ChokeLever

StartingPosition

• Slowlypressprimerbulb6limes.

• MovechokelevertoFULLchoke.

Trigger

Bulb

• Squeeze and hold trigger through all

remaining steps.

° Pullstarter handleuntilengine attempts

to start,but no more than 5 pulls.

• Move choke lever to HALFchoke.

• Pull starter handle until engine runs.

Allow engine to run 10 seconds, then

move choke lever to OFFchoke.

RESTARTING A WARM ENGINE

• Move choke lever to OFF choke.

• Pull starter handle untilengine starts.

° If engine does notstart in 5 pulis,follow

ir_truclionsin STARTINGA COLDEN-

GINE.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the choke lever in the Off

Choke position; then, pull the rope to

clear the engine of excess fue!. This

could require pullingthe starter handle

many times depending on how badly

the unit is flooded.

Ifthe unit still doesn't start, refer to

TROUBLESHOOTINGchart or call

1-800-235-5878.

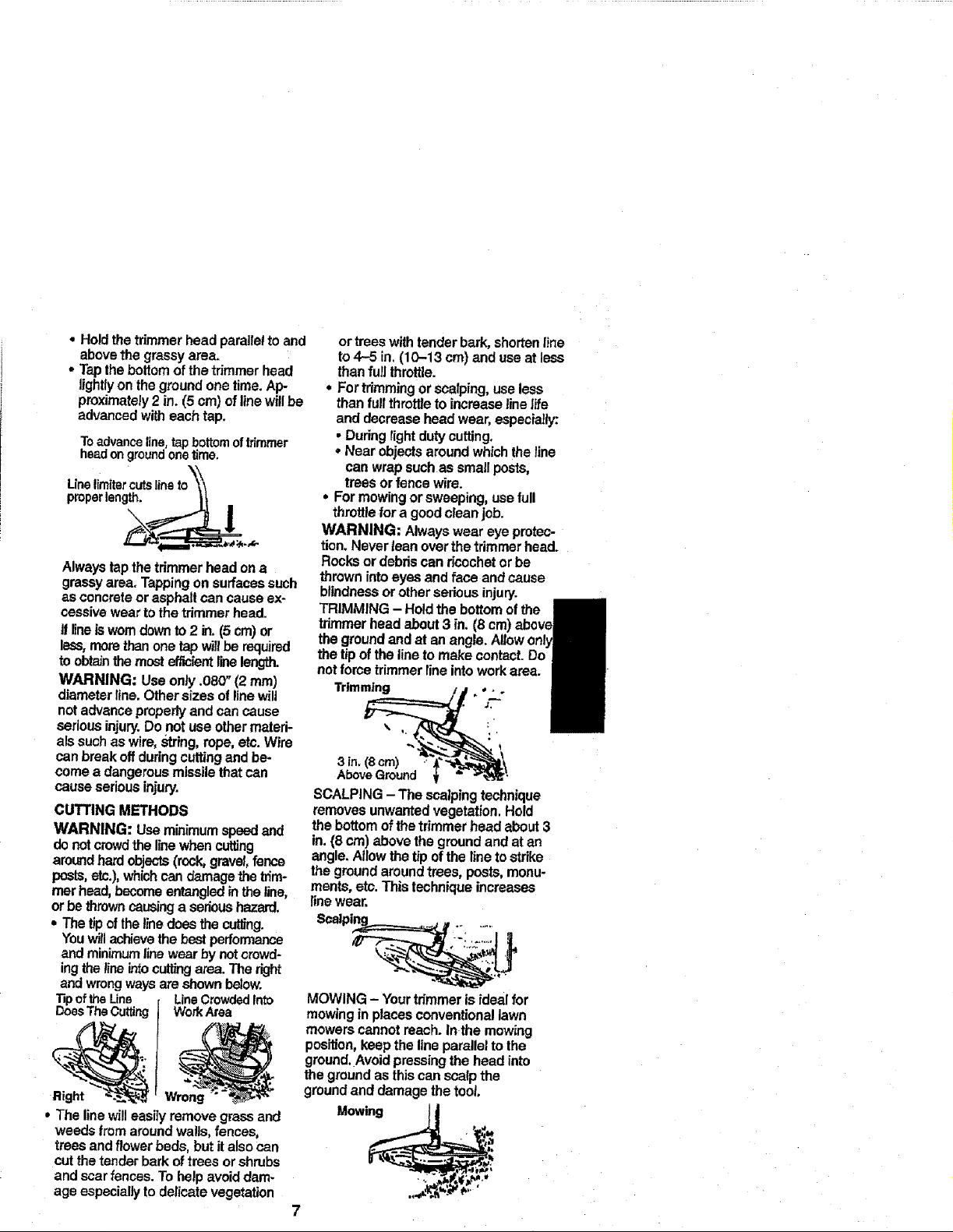

OPERATING INSTRUCTIONS

OPERATING POSITION

ALWAYS WEAR: _ Eye Protection

Cut from your dghtI left.

Do not run the engine at a higher speed

than necessa_,.The cutting linew_ cut

efficiently when the engineis runat less

than full throttle.At lowerspeeds, there

is less engine noise and vlbralion.The

cuttinglinewill lastlonger andwill be

lesslikely to"weld" ontothe spool.

Always release the throttle triggerand

allow the engine to return to idle speed

when notcutting.

To stop engine:

• Release the throttle trigger.

• Push and hold the engine stop

switch in the STOPor OFF position

untilthe unit has fully stopped.

TWIST-N-EDGE

• Pull the tab toward the engine.

• Twist the tube to the edging position.;

release tab.

TRIMMER UNE ADVANCE

Trimmer line will advance approxi-

mately 2 in. (5 cm) each time bottom of

tdmmer head is tapped on the ground

with engine running at full throttle.

The most efficientlinelength is the

maximum length allowedby linelimiter.

Always keep the shield in place when

the tool is being operated;

ToAdvance Line:

° Operate the engine at full throttle.

6

• Holdthetrimmerheadparalleltoand

abovethegrassyarea.

• Tapthebottomof thetrimmerhead

lightlyonthe groundonetime.Ap-

proximately2 in. (5 cm)oflinewillbe

advancedwitheachtap.

Toadvance line,tapbottomoftrimmer

headongroundonetime.

Always tap the trimmer head on a

grassy area. Tapping on surfaces such

as concrete or asphalt can cause ex-

cessive wear to the trimmer head.

If line isworn downto 2 in.(5 cm) or

less,more than one tap willbe required

to obtain the most officiantline length.

WARNING" Use only .080" (2 ram)

diameter line. Other sizes o!line will

not advance properly and can cause

serious injury. Do not use other materi-

als such as wire, String, rope, etc. Wire

can break off during cutting and be-

come a dangerous missile that can

cause serious injury.

CUTTING METHODS

WARNING: Use minimum speed and

do not crowdthe line when cutting

around hard objects (rock, gravel, fence

posts,etc.), which can damage the trim-

mer head, become entan_ed inthe line,

or be thrown causing a serious hazard,

* The tipof the linedoes the curing.

Youwillachieve the best performance

and minimum linewear by notcrowd-

ingthe lineinto cuttingarea. The right

and wrong waysare shown below.

Tipofthe Une LineCrowdedInto

DoesTheCutting WorkArea

Right

* The line willeasily remove grass and

weeds from around walls, fences,

trees and flower beds, but it also can

cut the tender bark of trees or shrubs

and scar fences. To help avoid dam-

age especially to delicate vegetation

or trees with tender bark, shorten line

to4-5 in. (10-13 cm) and use at less

than full throttle.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

• During light duty cutting,

• Near objects around which the line

can wrap such as small posts,

trees or fence wire.

° For mowing or sweeping, use full

throttle for a good clean job.

WARNING: Always wear eye protec-

tion. Never teen over the trimmer head.

Rocks or debris can ricochet or be

thrown into eyes and face and cause

blindness or other serious injury.

TRIMMING - Hold the bottom of the

trimmer head about 3 in. (8

the ground and at an

the tip of the line to make contact.

notfome trimmer line into work area.

Trimming

:3in. (8 cm)

AboveGround

SCALPING - The scalping technique

removes unwanted vegetation. Hold

the bottom of the trimmer head about 3

in. (8 cm) above the ground and at an

angle. Allow the tipof the line to strike

the ground around trees, posts, monu-

ments, etc. This technique increases

line wear.

Scelpi_o... .

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground, Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

Mowing Ii

SWEEPING- Thefanningactionof

rotatinglinecanbe usedfor a quick

andeasycleanup.Keeplineparallel

to and abovethesurfacesbeingswept

and movethetoolfromsideto side.

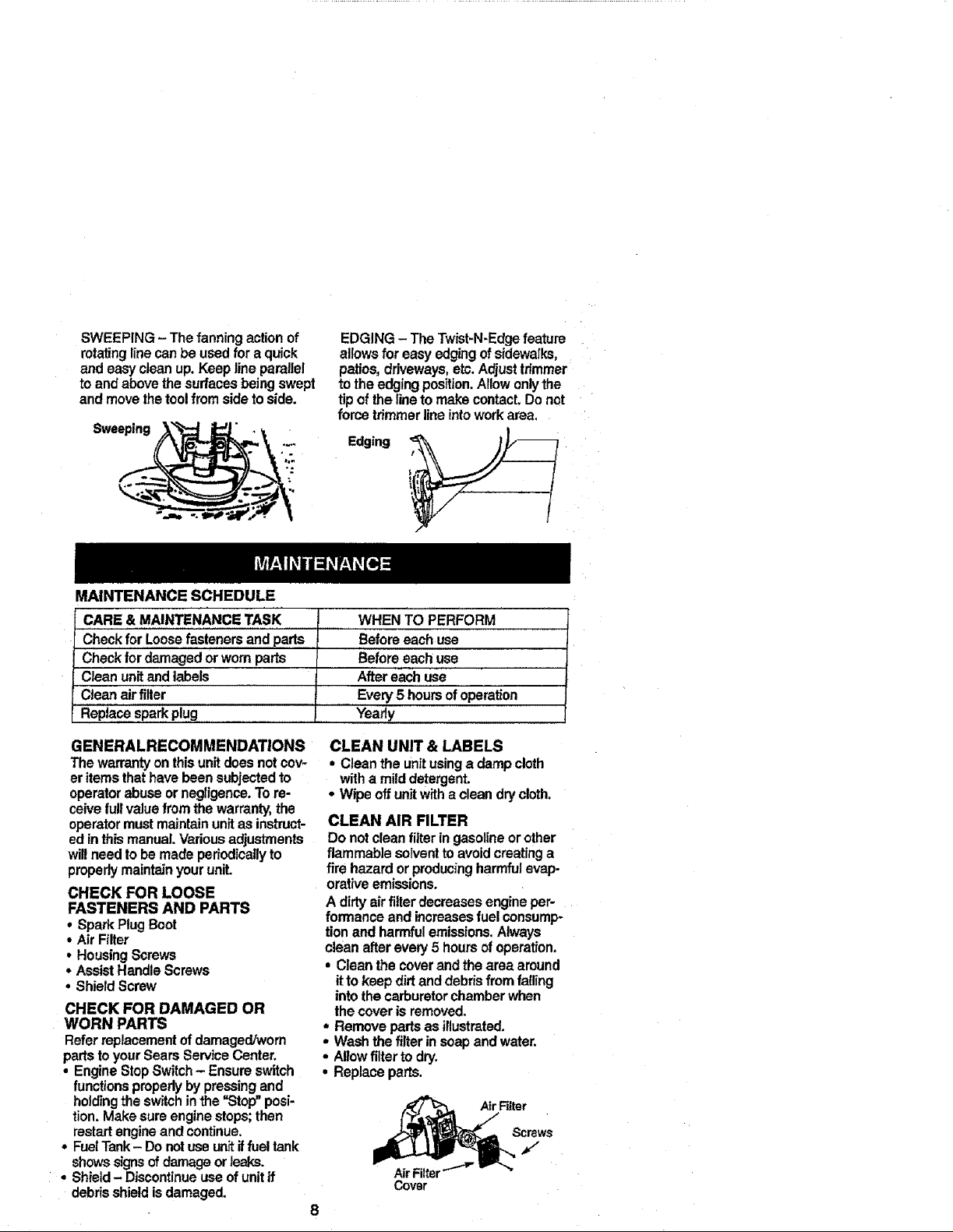

MAINTENANCESCHEDULE

CARE& MAINTENANCETASK

CheckforLoosefastenersandparts

Checkfor damagedorwornparts

Cleanunit andtabels

Cleanair filter

Replace sparkplug

EDGING- TheTwist-N-Edgefeature

allows for easy edgingof sidewalks,

patios,driveways,etc.Adjust trimmer

to the edging position.Allow onlythe

tipof thelineto make contact.Do not

forcetrimmerline intoworkarea.

Edging _',_1

WHEN TO PERFORM

Beforeeachuse

Beforeeachuse

Aftere_h use..........

.........Every5 hoursofoperation

Yearly

GENERALRECOMMENDATIONS

The warrantyonthisunitdoesnotcov-

er itemsthathavebeensubjectedto

operatorabuseornegligence.Tore-

ceivefull valuefromthewarranty,the

operatormustmaintainunitas instruct-

edinthismanual Variousadjustments

willneedto bemadeperiodicallyto

properlymaintainyourunit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• SparkPlugBoot

• AirFilter

, HousingScrews

• Assist HandleScrews

• ShieldScrew

CHECK FOR DAMAGED OR

WORN PARTS

Referreplacementofdamaged/worn

partstoyourSearsService Center.

• EngineStopSwitch- Ensureswitch

functionspropedybypressingand

holdingthe switchinthe "Stop"posi-

tion.Makesureenginestops;then

restartengineandcontinue.

• FuetTank- Donotuseunititfueltank

showssignsof damageorleaks.

• Shield- Discontinueuse ofunit if

debrisshieldisdamaged.

CLEAN UNIT & LABELS

• Cleanthe unitusinga dampcloth

witha milddetergent.

• Wipeoffunitwithacleandrycloth.

CLEAN AIR RLTER

Do notcleanfilteringasolineorother

flammablesolventtoavoidcreatinga

fire hazardorproducingharmfulevap-

orativeemissions.

A dirtyair filter decreasesengineper-

formanoeand increasesfuelconsump-

tionandharmfulemissions.Always

cleanafterevery5 hoursofoperation.

• Cleanthecoverandtheareaaround

itto keepdirt anddebrisfrom failing

intothecarburetorchamberwhen

thecoveris removed.

• Removeparts asillustrated.

• Washthefilterinsoapandwater.

• Allowfiltertodry.

• Replaceparts.

SFdter .

Cover

REPLACE SPARK PLUG

Replacethe spark plugeachyear to

ensuretheenginestarts easierand

runsbetter. Setsparkpluggapat

,025in. ignitiontimingisfixedand

nonadjustable.

• Twist,thenpu!loffsparkplugboot.

• Removesparkplugfromcylinder

anddiscard.

• ReplacewithChampionRCJ-SY

sparkplugand tightenwitha 3/4 in.

socketwrench(10-12 ft.-Jbs).

° Reinstallthe sparkplugboot.

ADVANCING THE CU'R'ING LINE

Advancelinebytappingbottomofcut-

ringheedtightlyonthegroundwhile

engineis runningat fullspeed.A metal

bladeattachedtotheshieldwillcutthe

line totheproperlength.

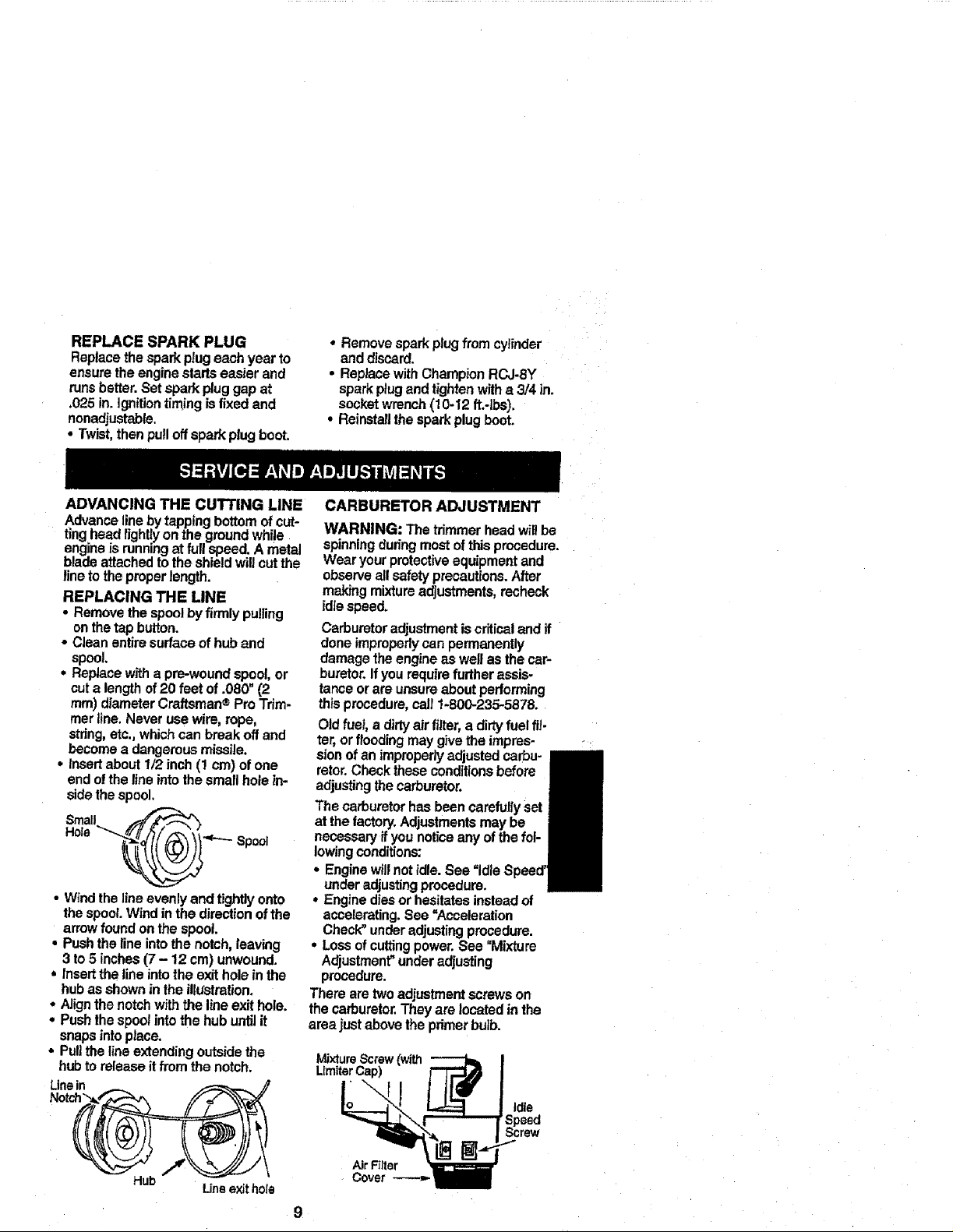

REPLACING THE LINE

• Removethespoolbyfirmlypu!ling

onthetap button.

• Cleanentiresurfaceofhuband

spool.

• Replacewitha pre-woundspool,or

cuta lengthof20 feet of.080" _2

ram)diameterCraftsman®ProTrim-

merline.Neveruse wire,rope,

string,etc,,whichcanbreakoffand

becomea dangerousmissile.

• insertabout1/2inch(1 cm)of one

endo!the lineintothesmallholein-

sidethespool.

Smati ._'-.P"_

Hole__' _,..__Spool

• Windthelineevenlyand tightlyonto

thespool.Windinthe directionof the

arrowfoundonthe spool.

• Pushthelineintothe notch,leaving

3 to5 inches(7- 12 cm)unwound.

• Inserttheline intothee_dtholeinthe

hubas shownintheillustration.

• Alignthenotchwiththeline exithole.

• Pushthespoolintothe hubuntilit

snapsinto place.

• Pullthelineextendingoutsidethe

hub toreleaseit from thenotch.

CARBURETOR ADJUSTMENT

WARNING: The trimmerheadwillbe

spinningduringmostofthisprocedure.

Wearyourprotectiveequipmentand

observeall safetyprecautions.After

makingmixtureadjustments,recheck

idtespeed.

Carburetoradjustmentiscriticalandif

doneimproperlycanpermanently

damagetheengineas wellas thecar-

buretor.Ifyourequ|refurtherassis-

tanceorare unsureaboutperforming

thisprocedure,call1.800-235-5878.

Oldfuel, a dirtyairfilter,adirtyfuelIll-

ter,orfloodingmay givethe impres-

sionof animproperlyadjustedcarbu-

retor.Checktheseconditionsbefore

adjustingthecarburetor.

The carburetorhasbeencarefullySet

at thefactory.Adjustmentsmay be

necessaryifyounoticeanyofthefol-

lowingconditions;

° Enginewillnotidle.

underadjustingprocedure.

• Enginediesorhesitatesinsteadof

accelerating.See =Acceleration

Check"underadjustingprocedure.

• Lossofcuttingpower.See "Mixture

Adjustment"underadjusting

procedure.

Thereare twoadjustmentscrewson

thecarburetor.Theyarelocatedin the

area justabovethe primerbulb.

MixtureScrew(with

LirniterCap)

Line exit hole

AirF{Iter

Cover

Idle

Speed

Screw

Loading...

Loading...