Craftsman 358795310 Owner’s Manual

i

I

Operator's Manual

CRRFTSMRN

24cc/1.3 cu. in. 2-Cycle

17 Inch Cutting Path / .080 In. Line

GASOLINE WEEDWACKER _

Model No.

358.795310

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product,

call 7am'7pm, Mon.-Sat., or 10am-7pm, Sun.

1-800-235-5878 €.ou_,,=od_oco._o,_,.._

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-084638 01/16/98

Warranty Statement 2 Storage 11

Safety Rules 2 TroubleshootingChart 12

Assembly 4 Parts List 13

Operation 5

Maintenance 9 Spanish 16

Service &Adjustments 10 Partsand Ordering Back

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS POWERED

WEEDWACKER _ LINE TRIMMER.

Forone year from thedate of purchase, whenthis Craftsman Gas Powered

Weedwaoker® Line Tdmmer ismaintained, lubricated, and tuned up according to

theoperating and maintenance instructionsinthe Operator's Manual, Sears will

repair,free of charge, any defect in materials orworkmanship.

This warranty excludes nylon line,spark plug, and air filter,whtchare expendable

partsand becomeworn duringnormal use.

Ifthis Weedwacker® Line Trimmer is usedfor commercialpurposes, this warran-

ty applies for only90 daysfrom the date of purchase. If this Weedwacker® Line

Tdmmer is usedfor rental purposes, thiswarranty applies foronly30 days from

the date of purchase. This warrantyapplies onlywhile this productis in use inthe

UnitedStates.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHEWEEDWACKER®LINE

TRIMMERTOTHE NEARESTSEARSSERVICECENTERINTHE UNITEDSTATES.

Thiswarranty givesyou specific legal dghts, and you may also have other dghts

whichvary from state to state.

Sears, Roebuck and Co., 01817 WA Hoffman Estates, IL 60179

WARNING: When usinggardening

appliances,basic safety precautions

mustalways be followedto reducethe

riskoffire and sedous injury.Read and

fellow all instructions.

Thispower un# can be dangerous!

Operatoris responsiblefor following

instructionsand warnings on unitand

in manual. Read entire Operator's

Manualbefore usingunit!Be thorough-

lyfamiliar with the controlsand the

properuse of the unit.Restrictthe use

ofthis unit to personswho haveread,

understand,and willfollowthe instruc-

tionsand wamings on the unitand in

the manual. Never allowchildrento

operatethis uniL

Safetyinformationontheurdt

DANGER: Never use blades orflail-

ing devices.This unit isdesigned for

linetdmmer use only. Use of any other

accessoriesor attachments will in-,

crease the dskof injury.

WARNING: Tdmrnerlinethrowsob-

jectsviolently.Youand othersCanbe

blindedlinjursd.Weareyeandleg

2

protection.Keep bodyparts clear of

rotatingline. Keep children,bystand-

ers, and animals 50 feet (15 meters)

away.If approached stop unitimmedi-

ately.

EyeProtec_on

If situationsoccur which are not

coveredin this manual, usecare and

goodjudgement. If you need

assistance,contact yourAuthorized

Service Dealer or call 1-800-235-5878.

OPERATOR SAFETY

• Always wear safety eye protection.

• Always wear long pants, long

sleeves, boots, and gloves.Wearing

safety leg guards is recommended.

Do notgo barefoot orwear sandals.

Stayclear of spinningEne.

• Secure hair above shoulder length.

Secure or remove Jooseclothingor

clothingwith loosely hangingties,

straps,tassels, ets. They can be

caught in moving parts. Beingfully

coveredalso helps protect youfrom

debrisand pieces oftoxic plants

thrownby spinning line.

• Do not operate when you are tired,

ill,or under the influenceof alcohol,

drugs,or medication.

° Wear hearing protection ifyou use

unitfor more than 1-1./2hourspar

day.

• Never start or run inside a dosed

roomor building. Breathingexhaust

fumes can kill.

• Keep handles free of oil and fuel.

UNIT / MAINTENANCE SAFETY

• Disconnectthe spark plug before

performingmaintenance except car-

buretoradjustments.

• Lookfor and replace damaged or

looseparts before each use. Look

for end repair fuel leaks before use.

Keep ingood workingcondition.

, Replace trimmer head parts that are

chipped,cracked, broken, ordarn-

aged in any other way before using

the unit.

• Make sure unit is a_embled correct-

lyas shown in this manual.

• Make carburetor adjustmentswith

lower end supportedto prevent line

from contacting any object.

• Keep othersaway when making car-

buretoradjustments.

• Use only recommended Craftsman

accessories and mptacementparts,

FUEL SAFETY

- Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do notsmoke or allow smokingnear

fuet or the ur_

• Wipe upall fuel spills.

• Move at least 10 feet (3 meters)

away fromfueling site before starting

engine.

• Stop engine and allow to cool before

removingfuel cap.

CU'I'rlNG SAFETY

, Use on_ for trimming, mowing, and

sweeping. Do not use forpruning or

hedge trimming.

• inspect the area before each use.

Remove objects (rocks,broken

glass, nails, wire, etc.) which canbe

thrownby orbecome entangled in

line. Hard objects can damage the

tdmmer head andbe thrown causing

seriousinjury.

• Keep firmfooting and balance. Do

not overreach.

• Keep all partsof your bodyaway

from muffler and spinning line. Keep

en_ne below waist level. A hotmuf-

fler can cause serious bums.

• Cutting on leftside ofthe shield will

throw debrisaway from the operator.

TRANSPORTING AND STORAGE

• Allowengine to cool;,secure unit be-

fore storingortransporting in vehicle.

• Empty the fuel tank before storingor

transportingthe unit.Use up fuel left

inthe carburetorby starting the en-

gine and letting it run untilit stops,

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric

motors orswitches, furnaces, etc_

• Stere unitso line limitercannot acci-

dentallycause injury.The unitcan be

hungby the tube.

° Store unitoutof reach of children.

3

• If situations occur which are notcov-

ered in this manual, use care and

good judgment, If you need assis.

tance, call 1-800-235_5878.

SPECIAL NOTICE: This unit isnot

equippedwith atemperature limiting

mufflerand spark arresting screen

whichmeets the requirementsofCall+

fomia Codes 4442 and 4443. All U.S.

forest land and the states ofCalifornia,

Idaho,Maine, Minnesota, New Jersey,

Oregon, and Washington requireby

law that many internalCombustionen-

gines be equipped with a spark arres-

/

torscreen. If you operatein a locale

where such regulationsexist, you are

legallyresponsiblefor installingand

maintaining the operating conditionof

these parts. Failure to do so isa viola-

tion of law. Contact yourAuthorized

Service Dealer for the Corre_ parts,

SPECIAL NOTICE: Exposure to

vibrationsthrough _rolonged useof

gasoiine poweredhand tools could

cause blood vessel or nerve damage

in the fingers, hands, and joints of

people prone to circulationdisordersor

abnormal swellings. Prolonged use in

cold weather has beenlinked to blood

vessel damage in otherwise healthy

people, if symptomsoccur such as

numbness, pain, loss of strength,

change in skincolor ortexture, orloss

offeeling inthe fingers, hands, or

joints, discontinuethe use of this tool

and seek medical attention. An anti-

vibrationsystem does notguarantee

the avoidance ofthese problems. Us-

ere who operate power toolson a con-

tinual and regularbasis must monitor

closely their physicalconditionand the

condition of this tool,

CARTON CONTENTS

Check carton contentsagainst the fol-

lowing list.

Model 358.795310

• Trimmer

. Shield

• Wing Nut (screwed ontoshield)

• Extra Spool with line

• Gas Tank (1 gal.)

• Container of Oil

Exam;_e partsfor damage. Do not use

damaged parts.

NOTE: If you need assistanceor find

partsmissing or damaged, call

1-800-235-5878.

It is normalfor the fuel filterto rattlein

the empty fueltank.

Findingfuel or oil residueon muffler is

normaldue tocarburetoradjuStments

and teslJngdone bythe manufacturer.

ASSEMBLY

WARNING: If received assembled,

repeat all steps to ensureyour unit is

propedy assembled and allfasteners

are secure.

ADJUSTING THE HANDLE

WARNING: When adjustingthe han-

dle, be sure it remains between the

trigger and the safety label.

* Loosen wingnut or knob onhandle.

• Rotate the handleonthe tube to an

updght position;retightenwing nut,

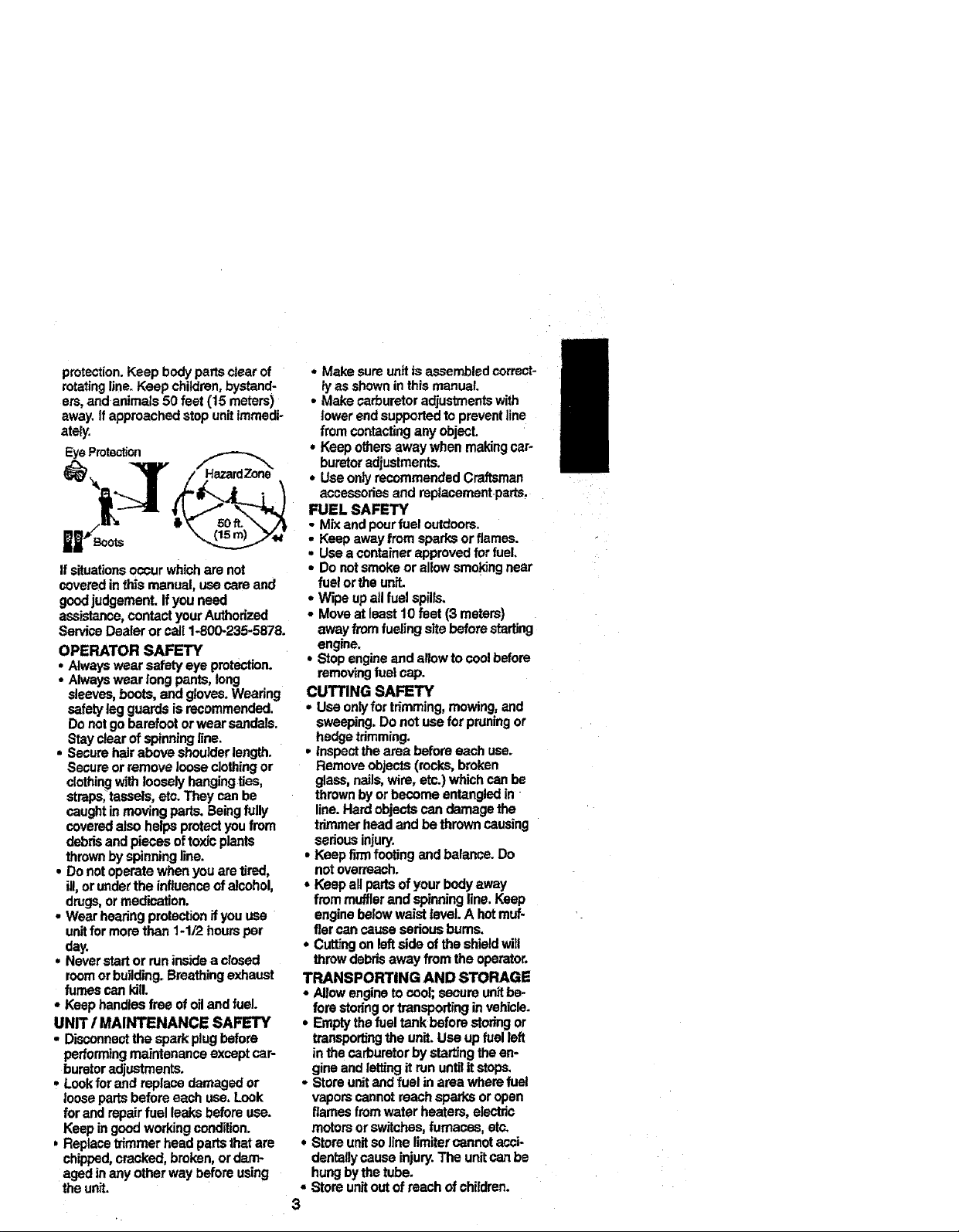

ATTACHING SHIELD

WARNING: The shieldmustbe properly

installed.The shieldprovidespafdal

protectionfromthe riskof thrownobjects

to the operatorand othersand is

equippedwitha linel_miterwhichcuts

excess line to the properlength. The fine

timiter (onundersideofshield) is sharp

and can cutyou. Forproperorientation,

see iliustralioninOperalionsection.

• Remove wing nut fromshield.

• insert bracket into slotas shown.

• Pivot shield until boltpasses through

hole in brackeL

• Secure_' tightenwing nut onto bolt.

Slot

Shield _ cket

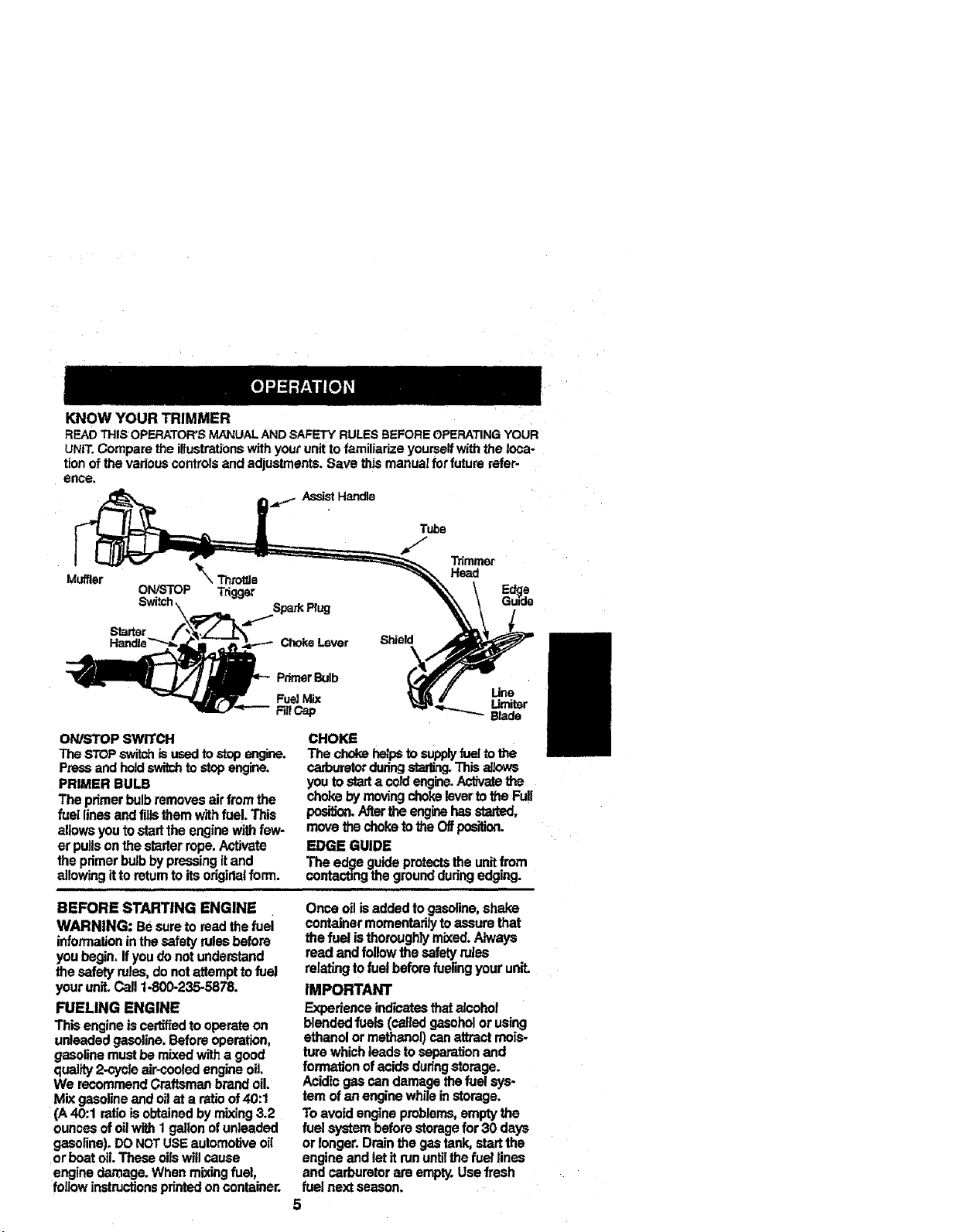

KNOWYOURTRIMMER

READTHISOPERATOR'SMANUALANDSAFETY"RULESBEFOREOPERATINGYOUR

UNIT.Compare the illustmti0nswith your unitto familiarize yourselfwith the Joca-

tionof the vadouscontrolsand adjustments. Save thismanual forfuture refer-

ence.

AssistHandle

Trh'nmer

Muffler

ON/STOP Trigger

Switch\

Starter

Handh

Choke Lever Shield

Head

ON/STOP SWITCH

The STOPswitchis usedto stop engine.

Pressand hold_ to stopengine.

PRIMER BULB

The primer bulbremoves air from the

fuel lines and fillsthem with fuel. This

allows you to start the engine withfew-

er pullson the starter rope. Activate

the primer bulbby pressing itand

allowingit to returnto its origirlalform.

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

informationinthe safety rulesbefore

you begin. If you do not understand

the safety roles,do not attempt to fuel

your unit.Call 1-800-235-5878.

FUELING ENGINE

Thisengine is certifiedtooperate on

unleaded gasoline. Before operation,

gasolinemust be mixed witha good

quality2-cyclo air-cooled engine oil.

We recommend Craftsman brand oil.

Mix gasoline and oilat a ratioof 40:1

(A 40:1 ratiois obtained by mixing3.2

ounces of oilwith I gallonof unleaded

gasoline). DONOTUSE automotive o_

or boat oil.These oilswillcause

engine damage. When mixing fuel,

follow instructionsprintedon container.

PrimerBulb

FuelMix Lirniter

Fi_Gap Blade

CHOKE

The choke helps to supplyfuel tothe

carburetordudngstarling.This allows

you tostart a coldengine.Activatethe

choke by movingchoke leverto the Full

position.Afterthe enginehas stetted,

move the choketothe Off position.

EDGE GUIDE

The edge guide protectsthe unitfrom

contactingthe groundduring edging.

Once oil is added to gasoline, shake

container momantadly to assure that

the fuel isthoroughly mixed. Always

read andfollow the safety rules

relatingto fuel beforefueling your unit.

IMPORTANT

Experience indlcatasthatalcohol

blended fuels (csIted gasoholor using

ethanol or meti_nol) can attract mois-

ture which leads to separationand

formation of acids durfngstorage.

Acidic gas can damage the fuel sys-

tem of an engine while instorage.

To avoid engine problems,empty the

fuel system before storage for 30 days

or longer. Drain the gastank, start the

engine andlet it rununtilthe fuel lines

and carburetor are empty.Use fresh

fuel next season.

Line

5

Never use engineor carburetorclean-

or productsin the fuel tank or perma-

nentdamage may occur.

See the STORAGE sectionforaddi-

tional information.

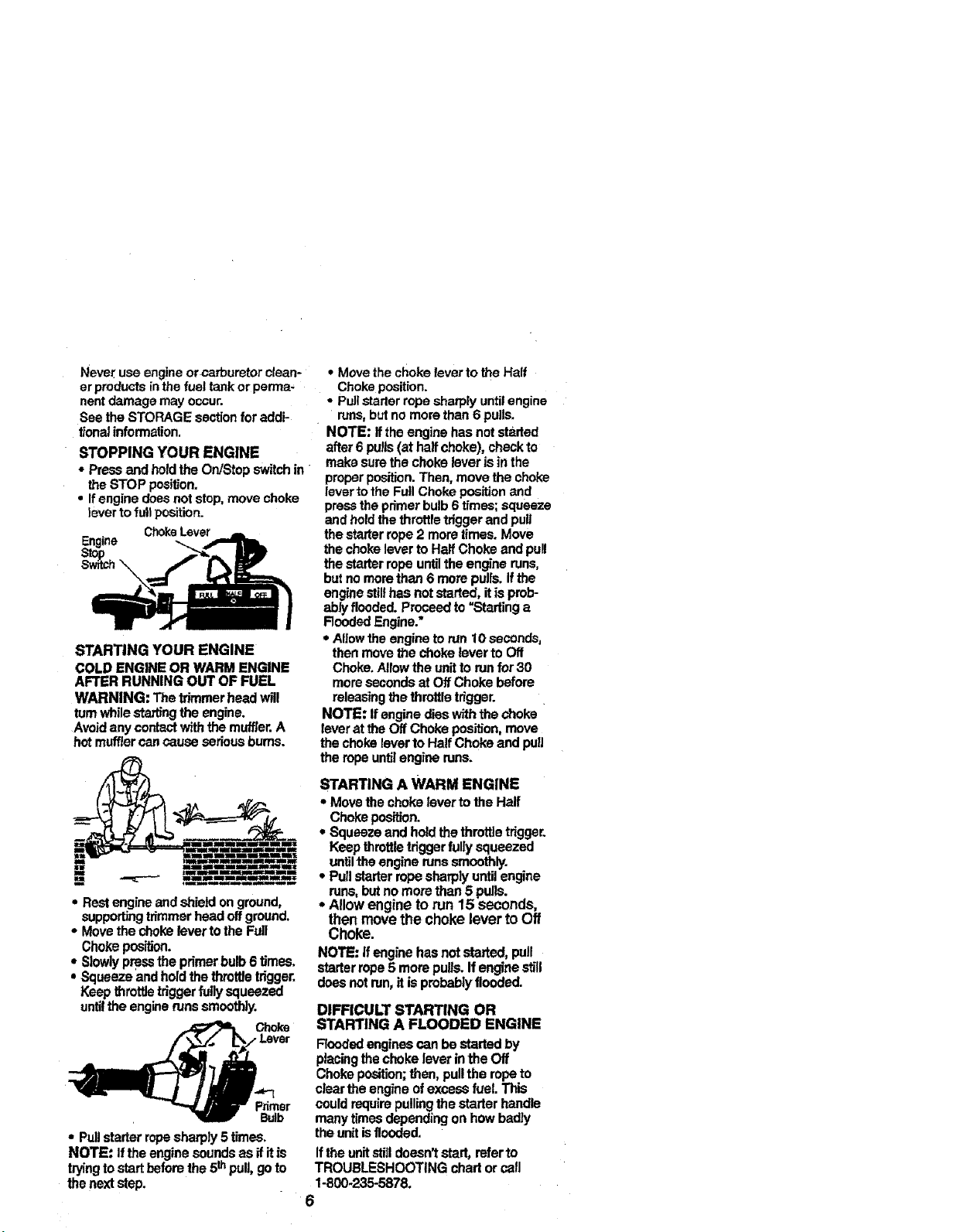

STOPPING YOUR ENGINE

• Press and hold the On/Stop switchin

theSTOP pos_on.

• If engine does not stop, move choke

leverto full position.

ChokeLever

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

WARNING: The trimmerhead will

turnwhile staxtingtheengine.

Avoid any contactwiththe muffler.A

hotmuffler can cause serious bums.

• Restengineandshieldonground,

suppOrtingtrimmerheadoffground.

• MovethechokelevertotheFull

Chokepos_on.

• Slowlypresstheprimerbulb6times.

• Squeezeandholdthethretfletrigger.

Keepthrottletriggerfullysqueezed

untiltheenginerunssmoothly.

_tv Ch°ke

er

• Pullstealerrope sharply 5 times.

NOTE: If the engine sounds as if itis

tryingtostart before the 5thpull, go to

the next step.

• Move the choke lever to the Half

Choke position.

• Pull starter rope sharply untilengine

runs,but no more than 6 pulis.

NOTE: Ifthe engine has not staded

after 6 pulls(at half choke), checkto

make surethe choke lever is in the

proper position.Then, move the choke

lever to the Full Choke position and

press the primer bulb6 times; squeeze

and holdthe throttle triggerand pull

the starterrope 2 more times. Move

the choke lever to Half Choke and pull

the starterrope untilthe engine runs,

butno morethan 6 more pulls. If the

engine stillhas not started, it is prob-

ablyflooded. Proceed to "Startinga

Rooded Engine."

• Allowthe engine to run 10 seconds,

then move the choke lever to Off

Choke.Allow the unit to run for30

more seconds at Off Choke before

releasingthe throttle trigger.

NOTE: If engine dies withthe choke

lever at the Off Choke position,move

the chokelever to Half Choke and pull

the rope untilengine runs.

STARTING A WARM ENGINE

• Movethe choke lever tothe Half

Chokeposition.

• Squeeze and holdthe throttle trigger.

Keepthrottle trigger fully squeezed

untilthe engine runs smoothly.

• Pull starterrope sharply until engine

runs,but no more than 5 pulls.

- Allow engine to run 15 seconds,

then move the choke lever to Off

Choke.

NOTE: Ifengine has not started, pull

starterrope 5 more pulls. If engine still

doesnot run, it isprobablyflooded.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

Floodedengines can bestarted by

placingthe choke lever in the Off

Chokeposition;then, pull the rope to

¢lsar the engine ofexcess fuel This

could require pullingthe starter handle

many times depending on how badly

the unitisflooded.

Ifthe unit stilldoesn't start, refer to

TROUBLESHOOTING chart or call

1-800-235-5878.

6

OPERATING INSTRUCTIONS

OPERATINGPOSITION

ALWAYS WEAR: _------_

Eye Protection

To eelvance line, tap bottom of trimmer

head on groundone _me.

Line IJ

properlength,

LongPants -_

HeavyShoes

Cutfromyourfighttoyourraft.

Bringthe engineto cuttingspeed be-

fore enteringthe materialto be cut.

Do not runthe engine at a higher

speedthan necessary. The cutting line

willcutefficientlywhen the engine is

runat lessthan full throttle.At lower

speeds,there is less engine noise and

vibration.The cuttingline will last

longerand willbe less likelyto"weld _

ontothe spool.

Ifthe trimmer head does not turn when

the engine isin operation,make sure

the drive shafthousingis properly

seated in engine shroud.

Always releasethe throttle trigger and

allowthe engine to retum to idlespeed

when not cutting.

Tostop engine:

• Release the throttletdgger0

• Pushand hold down the oldstop

switchuntilthe engine hasstopped

completely.

TRIMMER UNE ADVANCE

The trimmer line willadvance approxi-

mately 2 in. (5 cm) each time the bot-

tomof the trimmer head istapped on

the ground_ the engine runningat

fullthrottle.

The mostefficientline lengthis the

maximum lengthallowed by the line

llmiter.

Alwayskeep the shieldin place when

the too)is being operated.

ToAdvance Line:

• Operate the engine at fullthrottle.

• Hold the trimmer head paraJletto and

above the grassyarea.

• Tapthe bottom ofthe trimmer head

lightlyonthe groundone time. Ap-

proximately2 in. (5 cm)of line will be

advanced witheach tap.

Always tapthe trimmer head ona

grassy area. Tapping on surfacessuch

as concrete orasphalt can cause ex-

csssive wear tothe trimmerhead.

If the line is worn downto 2 in.(5 cm)

or teas, more than one tap will be re-

quiredto obtain the most efficient line

length.

WARNING: Use only .080" (2 ram)

diameter line. Other.sizes of line will

notadvance properly and can cause

seriousinjury. Do not use other materi-

als such as wire, string,rope, etc, Wire

can break off during cuttingand be-

come a dangerous missilethat can

cause seriousinju_.

CUTTING METHODS

WARNING: Use minimumspeed and

do not crowd the linewhen cutting

around hard objects (rock, gravel,

fence posts,etc.), whichcan damage

the trimmer head, become entangled

in the line,or be thrown causing a sad*

due hazard.

• The tip of the line does the cutting.

YOuwill achieve the bestperform-

ance and minimum line wear by not

crowdingthe line into the cutting

area. The right and wrongways are

shown below,

T_poftheUne LineCrowdedInto

DoesTheCutting Work/Vea

Right

• The linewilleasily remove grass and

weeds fromaround walls,fences,

trees and flowerbeds, butit also can

cutthe tender bark oftrees or shrubs

and scar fences, To help avoid dam-

age especiallyto delicate vegetation

ortrees with tender bark,shorten line

to 4-5 in. (10-13 cm) and use at less

than full throttle.

• For trimmingor scalping, use less

than fu_throttle to increase line life

and decrease head wear, especially:

• During lightdutycutting.

• Near objectsaround whichthe line

can wrap such as small posts,

trees or fence wire.

• For mowing orsweeping, use full

throttlefor a goodclean job,

WARNING: Always wear eye protec-

tion. Never lean over the trimmer head.

Rocks or debds can ricochet or be

thrown into eyes and f_e and cause

blindness or otherserious injuly.

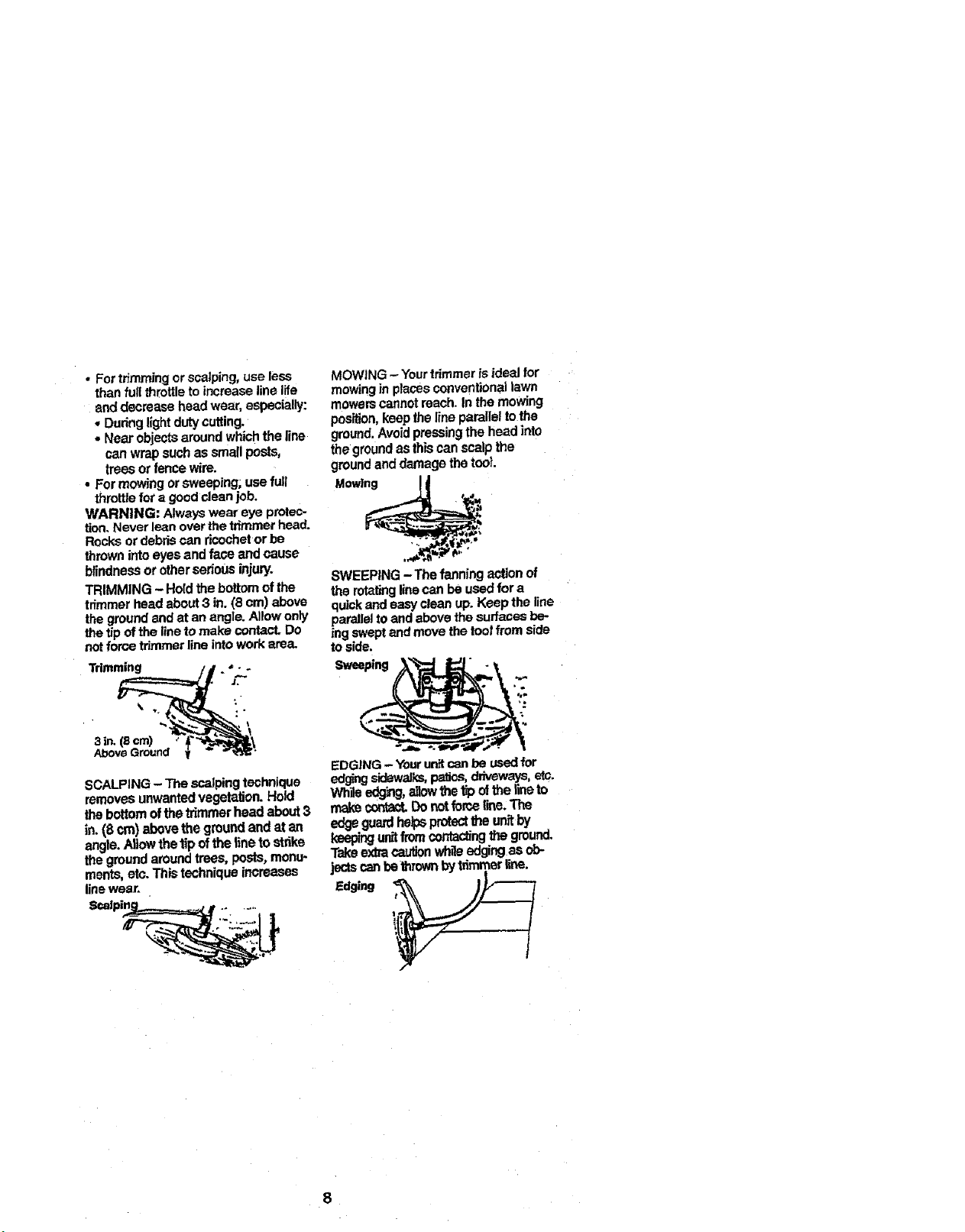

TRIMMING - Holdthe bottom of the

tdmmer head about3 in. {8 cm) above

the ground end at an angle. Allow only

the tip of the lineto make contact, Do

notforce trimmerline into work area.

Trimming .. o.

SCALPING - The scalping technique

removes unwanted vegetation. Hold

the bottom of the trimmer head about 3

in. (8 cm) above the groundand at an

angle. Allow the tip of the line to strike

the ground around trees, posts, monu-

ments, etc. This technique increases

linewear.

Scalpt_ jr ......

MOWING - Yourtrimmer is ideal for

mowing in places conventional lawn

mowerscannot reach. In the mowing

pos_on, keep theline parallel to the

ground.Avoidpressing the head into

the ground as thiscan scalp the

groundand damage the tool

Mowing I1

8WEENNG - The fanning action of

the rotatinglinecan be used for a

quickarmeasy' clean up, Keep the line

paralleltoand above the surfaces be-

ing swept and move the toolfrom side

tOside.

EDGING - Your unitcan be usedfor

edgingsidewalks,patios,driveways,etc,

While edging,_ow the t_pof the Freeto

nt_e contact.Do notforce line. The

edgeguardhelpsprotectthe urfitby

keepingunitfromcontactingthe ground.

Take extracautionwh_eedgingas ob-

jects canbe thrown bytdmmer line.

Edging

8

MAINTENANCE SCHEDULE

CARE & MAINTENANCE TASK

Checkfor Loosefasteners and parts...........

Checkfor damaged or worn parts

Clean unitand labels

Clean air filter

Replace spark plug

I

WHEN TO, PERFORM

Before each use

Before ead_ use _

Aftereantf use

Every 5 hoursof operation ..........

Yeady .........

GENERAL RECOMMENDATIONS

The warranty onthis unitdoes not cov-

er itemsthathave been subjectedto

operatorabuse ornegligence. To re-

ceivefullvalue from the warranty, the

operatormust maintain unitas instruct-

ed in this manual. Vadous edju,,%_nents

willneed tobe made period_callyto

properlymaintain your unit,

CHECK FOR LOOSE

FASTENERS AND PARTS

• SparkPlug Boot

')Air Filter

• HousingScrews

• As_st Handle Screws

• DebrisShield

CHECK FOR DAMAGED OR

WORN PARTS

Referreplacement ofdamaged/worn

partsto your Sears Service Center.

• On/StopSwitch - Ensure On/Stop

switchfunctions properly by pressing

andholdingthe switch in the "Stop"

position.Make sure engine stops;

then restart engine and continue.

• FuelTank- Discontinue use of un_if

fueltankshows signs ofdamage or

leaks.

= Debds Shield- Discontinue use of

unitif debdsshield is damaged.

CLEAN UNIT & LABELS

• Cisanthe unit using a daJ'npcloth

witha mild detergent.

• Wipeoff unitwith a clean drycloth.

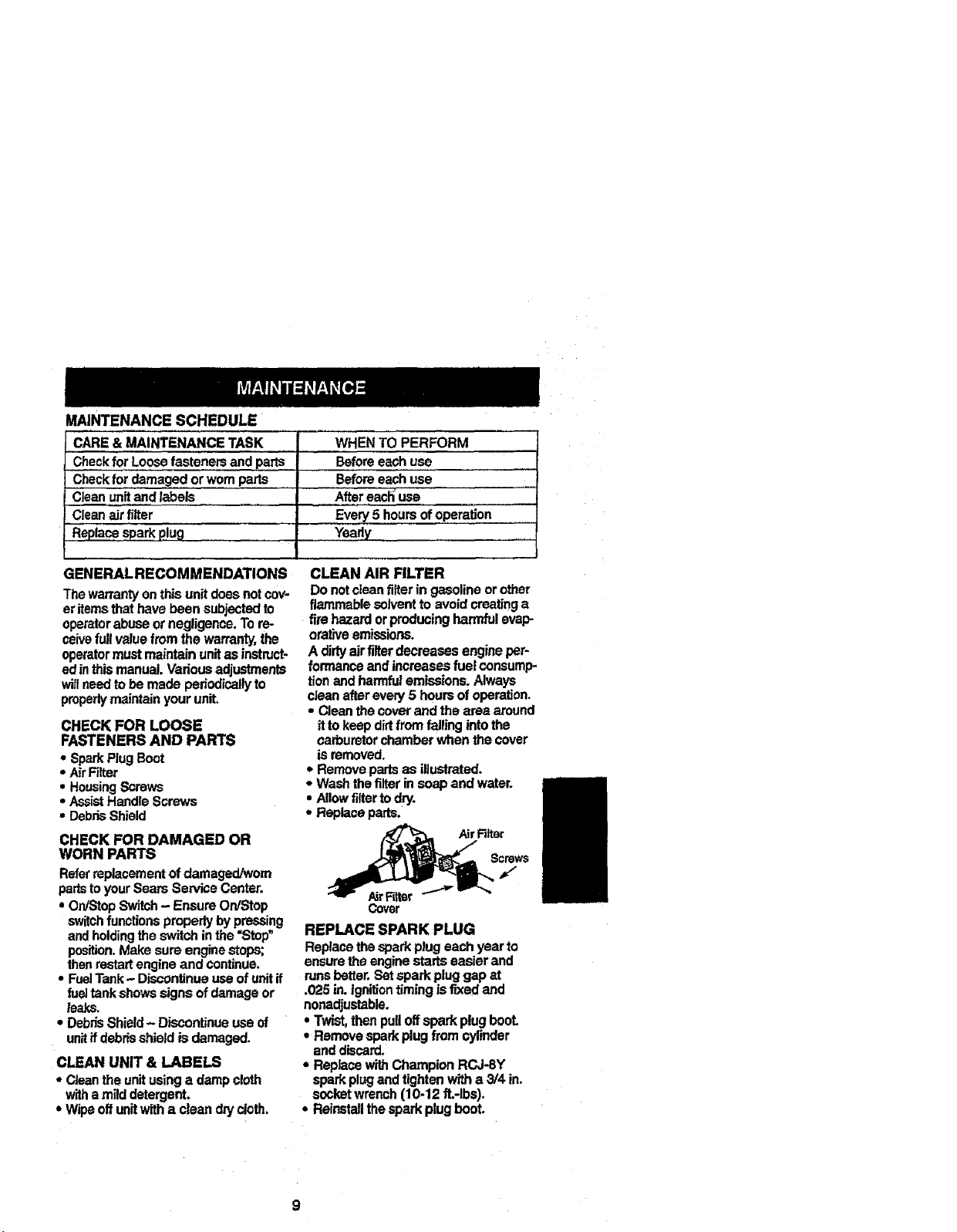

CLEAN AIR FILTER

Do not clean filter in gasoline or other

flammable solventto avoid creating a

firehazard orproducing harmful evap-

orathte emissions.

A dirty air filter decreases engine per-

formance and increases fuel consump-

tionand harmfulemissions. Always

clean after every 5 hOUrsof operation.

• Clean the cover and the area around

it to keep dirt from Pallingintothe

carburetor chamber when the cover

is removed.

* Remove partsas illustrated.

• Wash the filter in soap and water,

* Altowfilterto drY.

o Replace parts.

Cover

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Setspark plug gap at

.025 in. ignitiontiming is fixed and

nonadjustable.

• Twist,then pull off spark plug boot.

• Remove spark plug from cylinder

and discard.

- Replace with Champion RCJ-SY

spark plugand tighten witha 3/4 in.

sockst wrench (10-12 ft.-ibs),

• Reinstallthe spark plug boot.

ADVANCINGTHECUTTINGLINE

Advanceline bytapping bottomof cut-

ting head lightlyon the groundwhile

engine is running at full speed. A metal

blade attached tothe shieldwillcut the

lineto the proper length.

REPLACING THE LINE

* Pressthe Iocktabs and removecover.

. Remove the spool.

* Check the indexingteeth on the spool

and hub forwear.

• Usa a clean clothtowipe the inner/out-

ersurfaces of the spool and hub.

, Useonly.O8Oinch(2ram}diamsterline.

. Cuta _ngth oflineabout22feet(6.5m}.

. Bendthe lineat the midpoint.

Fs,°t

, Insert thebend intothe slotinthe inner

dm of the spool.

. Wind the line evenly and tighffyonto

the spool;,wind in directionof arrow

found on spool.

, Push the line intothe notches,leaving

3-5 inches (8--12 cm) unwound.

o insertline intotineexithoh_sas shown.

* Align notcheswiththe lineexit holes.

, Push the spool into the hub until it

osnaps into place.

Pull the ends of the line to seat the

spool in the hub.

• Re-install the cover.

LockTab Unein

TJ Lineexithois notches

! !

Une exit hole

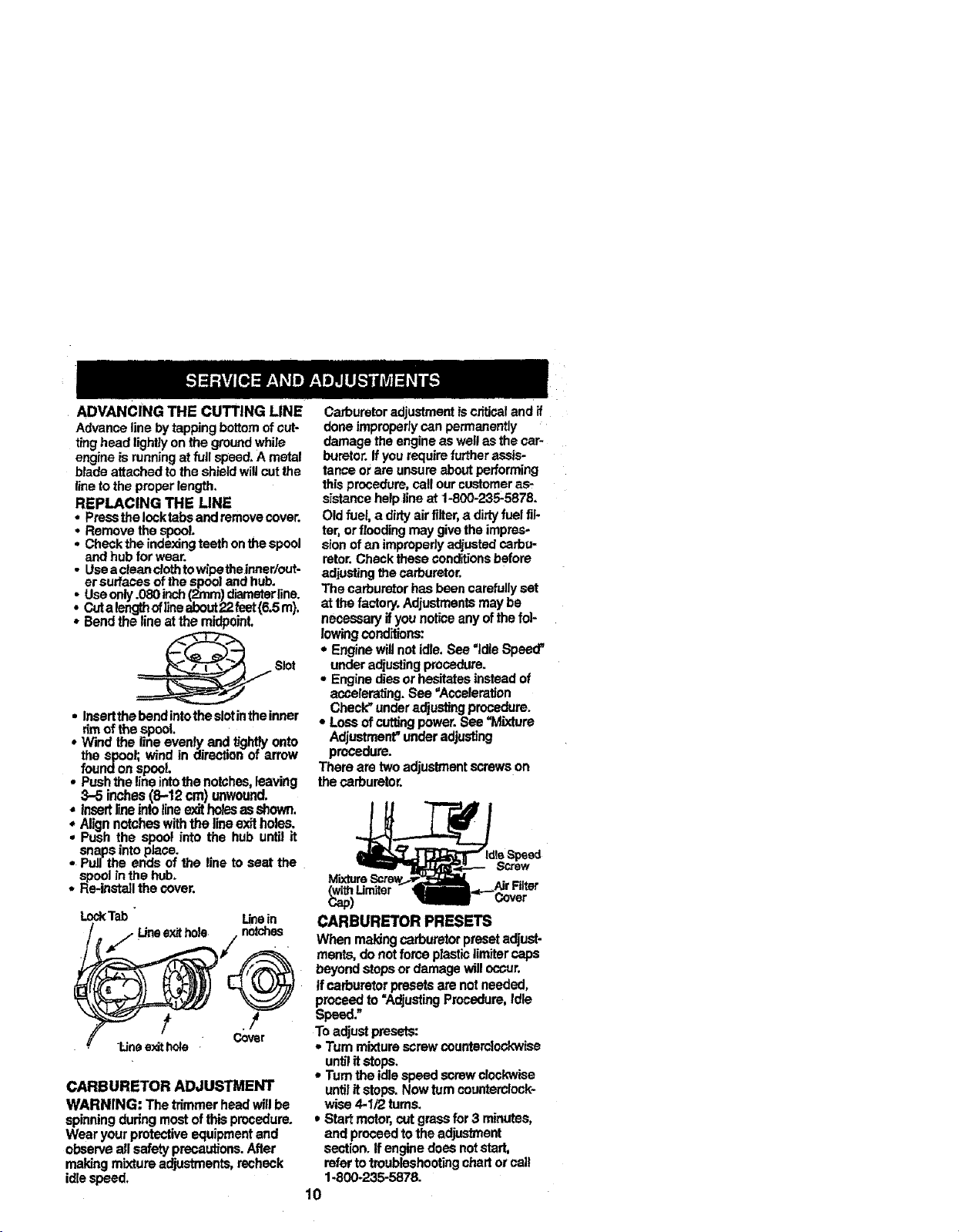

CARBURETOR ADJUSTMENT

WARNING: The trimmer head wigbe

spinning duringmost of this procedure.

Wear yourprotective equipmentand

observe all safety precautions. After

making mixture adjustments, recheck

idlespeed.

Cover

Carburetor adjustmentis c"nticaland if

done improperly can permanently

damage the engine as well as the cap

buretor. Ifyou requirefurther assis-

tance orare unsureabout performing

this procedure, call ourcustomeras-

sistance help line at 1-800-235-5878.

Old fuel, a dirtyair filter, a dirtyfuel fil-

ter,or floodingmay give the impres-

sionof an improperlyadjustedcarbu-

retor.Check these conditionsbefore

adjustingthe carburetor,

The carburetorhas beencarefully set

at the factory. Adjustmentsmay be

necessary if you noticeany ofthe fol-

lowingcond_ons:

* Engine will not idle, See =idleSpeed'

under adjustingprocedure.

, Engine dies or hesitatesinstead of

accelerating. See =Acceleration

Check" underadjusting procedure.

* Loss of cuttingpower.See =Mixture

Adjustment"underadjusting

procedure.

There are twoadjustmentscrews on

the carburetor.

_Umiter

CARBURETOR PRESETS

When making carburetorpreset adjust-

ments, do not force plasticlimitercaps

beyondstops or damage will oscur.

If carburetorpresets are notneeded,

proceed to =Adjusting Procedure,Idle

Speed."

Toadjust presets:

• Turn mixture screw counterclockwise

untilitstops.

• Turn the idle speed screw clockwise

untilitstops. Nowturn counterclock-

wise 4-I/2 rums.

• Start motor, cut grass for3 minutes,

and proceed to the adjustment

section. Ifengine does notstart,

refer to troubleshootingchart or call

1-800-235-5878.

10

Loading...

Loading...