Operator's Manual

I P R 0 F E S S I 0 N A L I

28cc/1.7 cu.in. 2-Cycle

GASOLINE WEEDWACKER ®

Model No.

358.792011

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espa_ol, p. 21

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 <Hoots listed are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

115264226 Rev. 2 2/2/10 BRW

Warranty Statement 2 Storage 15

Identification of Safety Symbols 3 Troubleshooting Table 16

Safety Rules 4 Emissions Statement 17

Assembly 6

Operation 7 Parts List 19

Maintenance 11 Spanish 21

Service & Adjustments 12 Parts and Ordering Back Cover

CRAFTSMAN PROFESSIONAL FULL WARRANTY

If this Craftsman product fails due to a defect in material or workmanship within three

(3) years from the date of purchase, return it to any Sears store, Parts & Repair Ser-

vice Center, or other Craftsman outlet in the United States for free repair (or replace-

ment if repair proves impossible).

This warranty applies for only 1 year if this product is ever used for commercial or

rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will

NOT pay for:

• Expendable items that can wear out from normal use within the warranty period,

such as cutting line, filters or spark plugs.

• Repairs necessary because of accident or failure to operate or maintain the

product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel mixture,

contaminated or stale fuel.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Congratulations on making a smart purchase. Your new Craftsman product is

designed and manufactured for years of dependable operation. But like all products,

it may require repair from time to time. That's when having a Repair Protection

Agreement can save you money and aggravation.

Here's what the Repair Protection Agreement* includes:

_" Expert service by our 10,000 professional repair specialists

_" Unlimited service and no charge for parts and labor on all covered repairs

_" Product replacement up to $1500 if your covered product can't be fixed

_" Discount of 10% from regular price of service and related installed parts

not covered by the agreement; also, 10% off regular price of preventive

maintenance check

_" Fast help by phone - we call it Rapid Resolution - phone support from a

Sears representative. Think of us as a "talking operator's manual".

Once you purchase the Repair Protection Agreement, a simple phone call is all

that it takes for you to schedule service. You can call anytime day or night, or

schedule a service appointment online.The Repair Protection Agreement is a

risk-free purchase. If you cancel for any reason during the product warranty peri-

od, we will provide a full refund. Or, a prorated refund anytime after the product

warranty period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply, For prices and additional informa-

tion in the U.S.A. call 1-800-827-6655,

*Coverage in Canada varies on some items. For full details call Sears

Canada at 1-800-361-6665.

SearsInstallation Service

For Sears professional installation of home appliances, garage door openers,

water heaters, and other major home items, in the U.S.A. or Canada call

1-800-4-MY-HOME®.

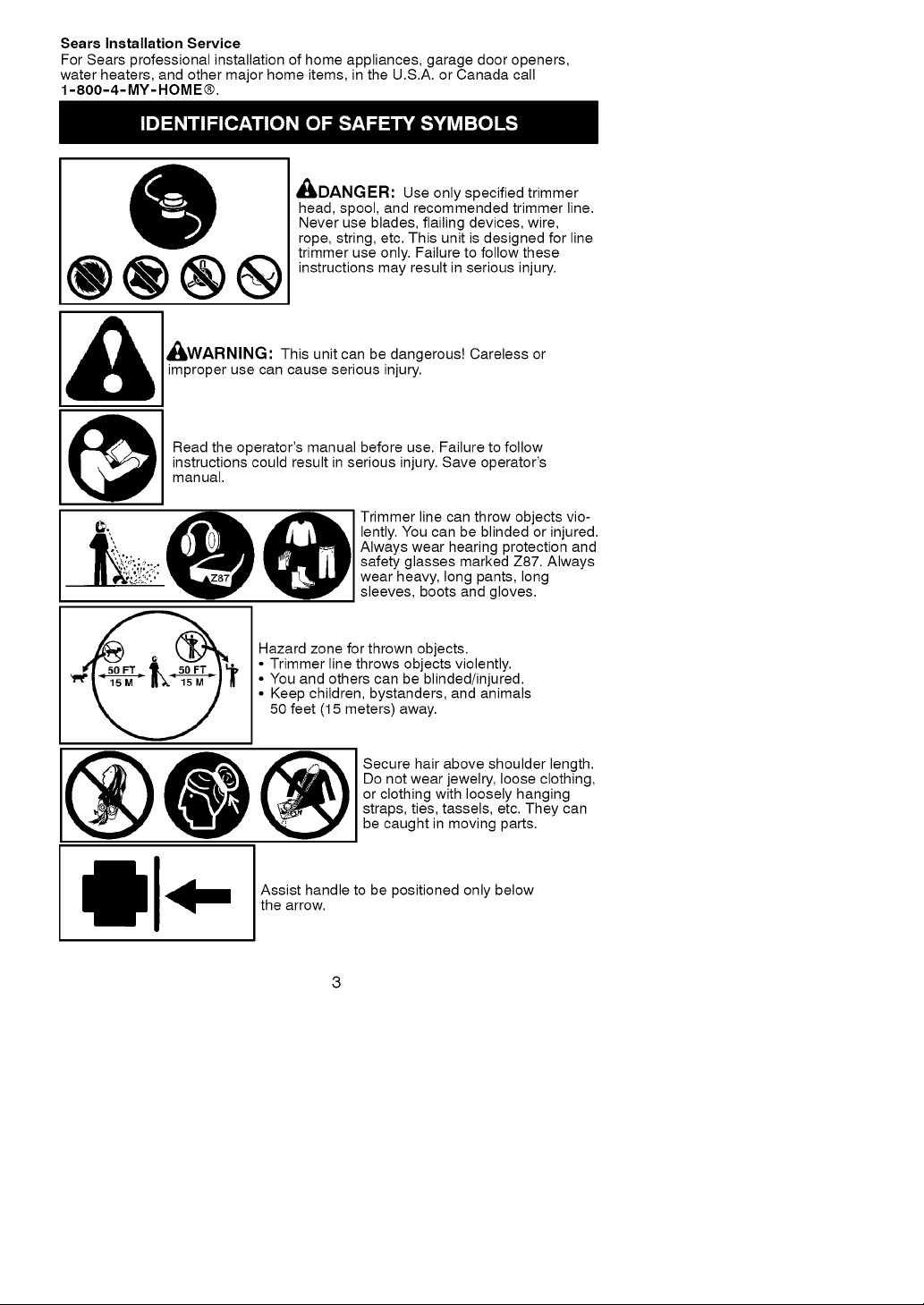

,_DANGER: Use only specified trimmer

head, spool, and recommended trimmer line.

Never use blades, flailing devices, wire,

rope, string, etc. This unit is designed for line

trimmer use only. Failure to follow these

instructions may result in serious injury.

®®®®

improper use can cause serious injury.

_/LWARNING: This unit can be dangerous! Careless or

Read the operator's manual before use. Failure to follow

instructions could result in serious injury. Save operator's

manual.

lently. You can be blinded or injured.

Always wear hearing protection and

_] Trimmer line can throw objects vio-

safety glasses marked Z87. Always

wear heavy, long pants, long

sleeves, boots and gloves.

Hazard zone for thrown objects.

• Trimmer line throws objects violently.

• You and others can be blinded/injured.

• Keep children, bystanders, and animals

50 feet (15 meters) away.

Do not wear jewelry, loose clothing,

or clothing with loosely hanging

straps, ties, tassels, etc. They can

securehairab°vesh°u'der'ength'

be caught in moving parts.

Assist handle to be positioned only below

the arrow.

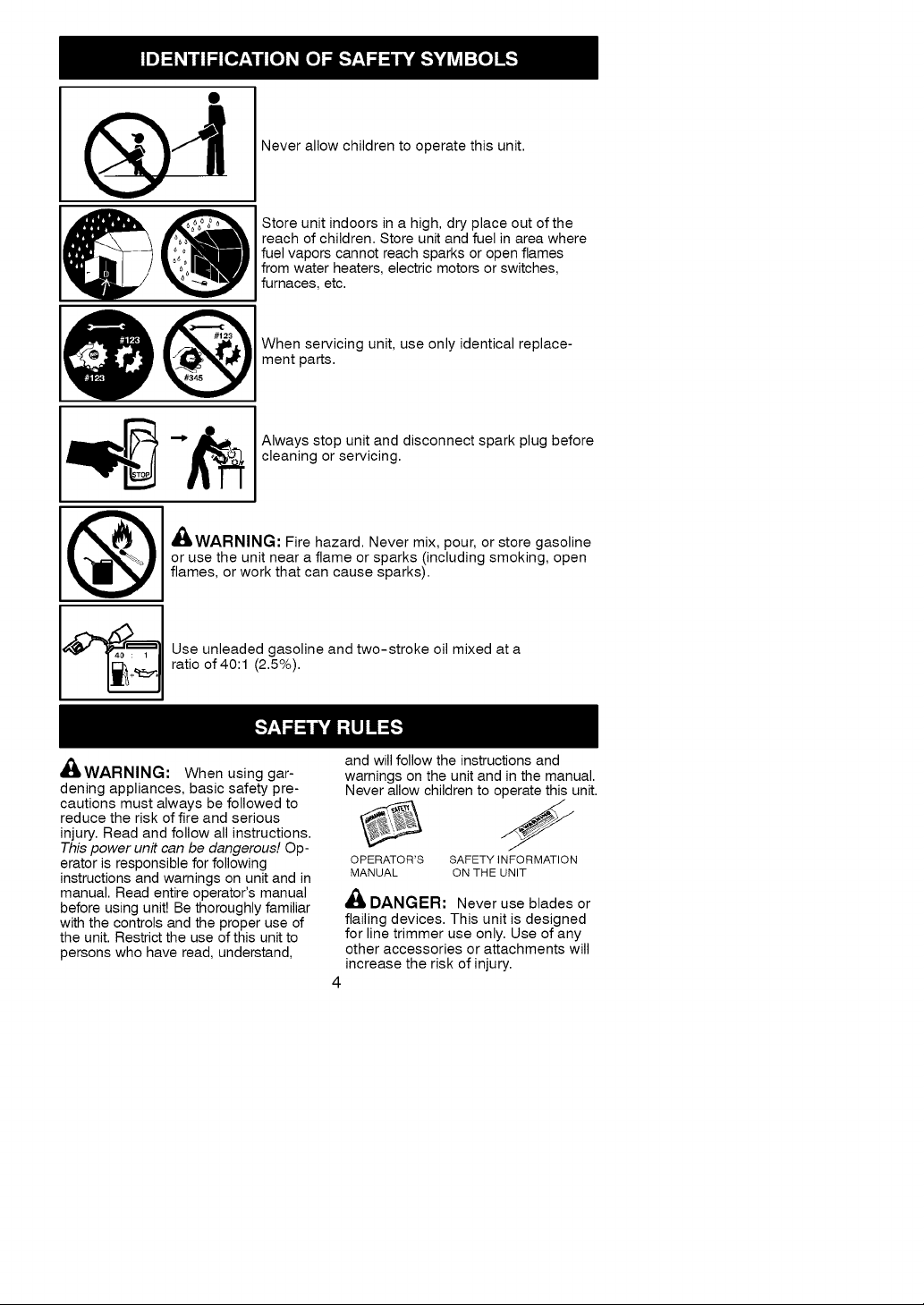

Never allow children to operate this unit.

Store unit indoors in a high, dry place out of the

reach of children. Store unit and fuel in area where

fuel vapors cannot reach sparks or open flames

@

,_/LWARNING: Fire hazard. Never mix, pour, or store gasoline

or use the unit near a flame or sparks (including smoking, open

flames, or work that can cause sparks).

v

Use unleaded gasoline and two-stroke oil mixed at a

ratio of 40:1 (2.5%).

I

from water heaters, electric motors or switches,

furnaces, etc.

When servicing unit, use only identical replace-

ment parts.

Always stop unit and disconnect spark plug before

cleaning or servicing.

_WARNIN_I: When using gar-

dening appliances, basic safety pre-

cautions must always be followed to

reduce the risk of fire and serious

injury. Read and follow all instructions.

This power unit can be dangerous! Op-

erator is responsible for following

instructions and warnings on unit and in

manual. Read entire operator's manual

before using unit! Be thoroughly familiar

with the controls and the proper use of

the unit. Restrict the use of this unit to

persons who have read, understand,

and will follow the instructions and

warnings on the unit and in the manual.

Never allow children to operate this unit.

OPERATOR'S SAFETY INFORMATION

MANUAL ON THE UNIT

_, DANGER; Never use blades or

flailing devices. This unit is designed

for line trimmer use only. Use of any

other accessories or attachments will

increase the risk of injury.

Ifsituationsoccurwhicharenotcov-

eredinthismanual,usecareand

goodjudgment.Ifyouneedassis-

tance,contactyourSearsService

Centerorcall1-800-235-5878.

OPERATORSAFETY

•Dressproperly.Alwayswearsafety

glassesorsimilareyeprotection

whenoperating,orperformingmain-

tenance,onyourunit(safety

glassesareavailable).Eyeprotec-

tionshouldbemarkedZ87.

•Alwayswearfaceordustmaskif

operationisdusty.

•Alwayswearheavy,longpants,long

sleeves,boots,andgloves.Wearing

safetylegguardsisrecommended.

•Alwayswearfootprotection.Donot

gobarefootorwearsandals.Stay

clearofspinningline.

•Securehairaboveshoulderlength.

Secureorremovelooseclothingor

clothingwithlooselyhangingties,

straps,tassels,etc.Theycanbe

caughtinmovingparts.

•Beingfullycoveredalsohelpspro-

tectyoufromdebrisandpiecesof

toxicplantsthrownbyspinningline.

•StayAlert.Donotoperatethisunit

whenyouaretired,ill,upsetorun-

dertheinfluenceofalcohol,drugs,

ormedication.Watchwhatyouare

doing;usecommonsense.

•Wearhearingprotection.

•Neverstartorruninsideaclosed

roomorbuilding.Breathingexhaust

fumescankill.

•Keephandlesfreeofoilandfuel.

UNIT / MAINTENANCE SAFETY

,_WARNING: Disconnect the

spark plug before performing mainte-

nance except carburetor adjustments.

• Look for and replace damaged or

loose parts before each use. Look

for and repair fuel leaks before use.

Keep in good working condition.

• Replace trimmer head parts that are

chipped, cracked, broken, or dam-

aged in any other way before using

the unit.

• Maintain unit according to recom-

mended procedures. Keep cutting

line at proper length.

• Use only Craftsman replacement line.

Never use wire, rope, string, etc.

• Install required shield properly before

using the unit. Use only specified trim-

mer head; make sure it is properly

installed and securely fastened.

• Make sure unit is assembled cor-

rectly as shown in this manual.

• Make carburetor adjustments with

lower end supported to prevent line

from contacting any object.

• Keep others away when making car-

buretor adjustments.

• Use only recommended Craftsman

accessories and replacement parts.

• Have all maintenance and service

not explained in this manual per-

formed by a Sears Service Center.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Do not smoke or allow smoking near

fuel or the unit or while using the unit.

• Avoid spilling fuel or oil. Wipe up all

fuel spills before starting engine.

• Move at least 10 feet (3 meters)

away from fueling site before start-

ing engine. Stop engine and allow it

to cool before removing fuel cap.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

• Always store gasoline in a container

approved for flammable liquids.

CUTTING SAFETY

,_ WARNING: Inspect the area be-

fore each use. Remove objects

(rocks, broken glass, nails, wire, etc.)

which can be thrown by or become

entangled in line. Hard objects can

damage the trimmer head and be

thrown causing serious injury.

• Keep others including children, ani-

mals, bystanders, and helpers at least

50 feet (15 meters) away. Bystanders

should be encouraged to wear safety

glasses. Stop engine immediately if

you are approached.

• Use only for trimming, scalping, mow-

ing, edging and sweeping. Do not use

for pruning or hedge trimming.

• Keep firm footing and balance. Do

not overreach.

• Keep all parts of your body away

from muffler and spinning line. Keep

engine below waist level. A hot muf-

fler can cause serious burns.

• Cut only from your right to your left.

Cutting on left side of the shield will

throw debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual.

TRANSPORTINGANDSTORAGE

•Stoptheunitbeforecarrying.

•Allowenginetocoolbeforestoring

ortransportinginvehicle.

•Emptythefueltankbeforestoringor

transportingtheunit.Useupfuelleft

inthecarburetorbystartingtheen-

gineandlettingitrununtilitstops.

•Storeunitandfuelinareawherefuel

vaporscannotreachsparksoropen

flamesfromwaterheaters,electric

motorsorswitches,furnaces,etc.

•Storeunitsolinelimiterbladecan-

notaccidentallycauseinjury.The

unitcanbehungbytheshaft.

•Storeunitoutofreachofchildren.

Thisunitisnotequippedwithananti-

vibrationsystemandisintendedfor

occasionaluseonly.

SAFETYNOTICE:Exposuretovibra-

tionsthroughprolongeduseofgaso-

linepoweredhandtoolscouldcause

bloodvesselornervedamageinthe

fingers,hands,andjointsofpeople

pronetocirculationdisordersorab-

normalswellings.Prolongedusein

coldweatherhasbeenlinkedtoblood

vesseldamageinotherwisehealthy

people.Ifsymptomsoccursuchas

numbness,pain,lossofstrength,

changeinskincolorortexture,orloss

offeelinginthefingers,hands,or

joints,discontinuetheuseofthistool

andseekmedicalattention.Ananti-

vibrationsystemdoesnotguarantee

theavoidanceoftheseproblems.Us-

erswhooperatepowertoolsonacon-

tinualandregularbasismustmonitor

closelytheirphysicalconditionandthe

conditionofthistool.

SPECIALNOTICE:Thisunitis

equippedwithatemperaturelimiting

mufflerandsparkarrestingscreen

whichmeetstherequirementsofCali-

forniaCodes4442and4443.AllU.S.

forestlandandthestatesofCalifornia,

Idaho,Maine,Minnesota,NewJersey,

Oregon,andWashingtonrequireby

lawthatmanyinternalcombustionen-

ginesbeequippedwithasparkarrest-

ingscreen.Ifyouoperateinalocale

wheresuchregulationsexist,youare

legallyresponsibleformaintainingthe

operatingconditionoftheseparts.

Failuretodosoisaviolationofthe

law.Fornormalhomeowneruse,the

mufflerandsparkarrestingscreenwill

notrequireanyservice.After50hours

ofuse,werecommendthatyourmuf-

flerbeservicedorreplacedbya

SearsServiceCenter.

CARTONCONTENTS

Checkcartoncontentsagainstthefol-

lowinglist.

Model358.792011

•Trimmer

•Shield

•WingNut(screwedontoshield)

•Containerofline

•Containerofoil

•Bonusfixedlinetrimmerhead

Examinepartsfordamage.Donot

usedamagedparts.

NOTE:Ifyouneedassistanceorfind

partsmissingordamaged,call

1-800-235-5878.

Itisnormalforthefuelfiltertorattlein

theemptyfueltank.

Findingfueloroilresidueonmuffleris

normalduetocarburetoradjustments

andtestingdonebythemanufacturer.

ASSEMBLY

,_,WARNING: If received as-

sembled, repeat all steps to ensure

your unit is properly assembled and all

fasteners are secure.

ADJUSTING THE HANDLE

,_ WARNING: When adjusting the

assist handle, be sure it remains above

the safety label and below the mark or

arrow on the shaft.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an

upright position; retighten wing nut.

ATTACHING SHIELD

_/LWARNING: The shield must be

properly installed. The shield provides

partial protection from the risk of thrown

objects to the operator and others and

is equipped with a line limiter blade

which cuts excess line to the proper

length. The line limiter blade (on under-

side of shield) is sharp and can cut you.

For proper orientation of shield, see

KNOWYOUR TRIMMER illustration in

OPERATION section.

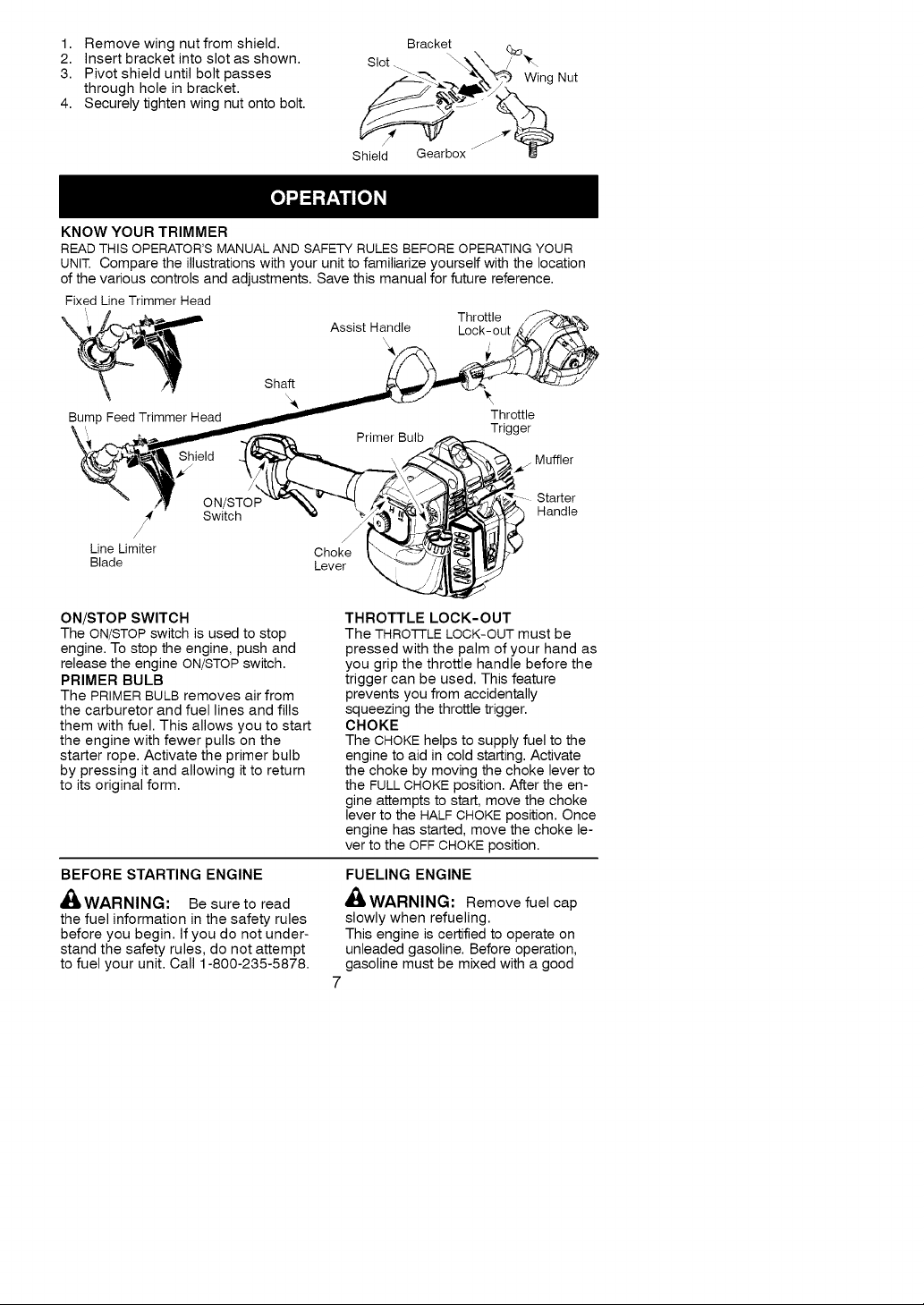

1. Removewingnutfromshield.

2. Insertbracketintoslotasshown.

3. Pivotshielduntilboltpasses

throughholeinbracket.

Bracket

Slot.

Wing Nut

4. Securelytightenwingnutontobolt.

Shield Gearbox

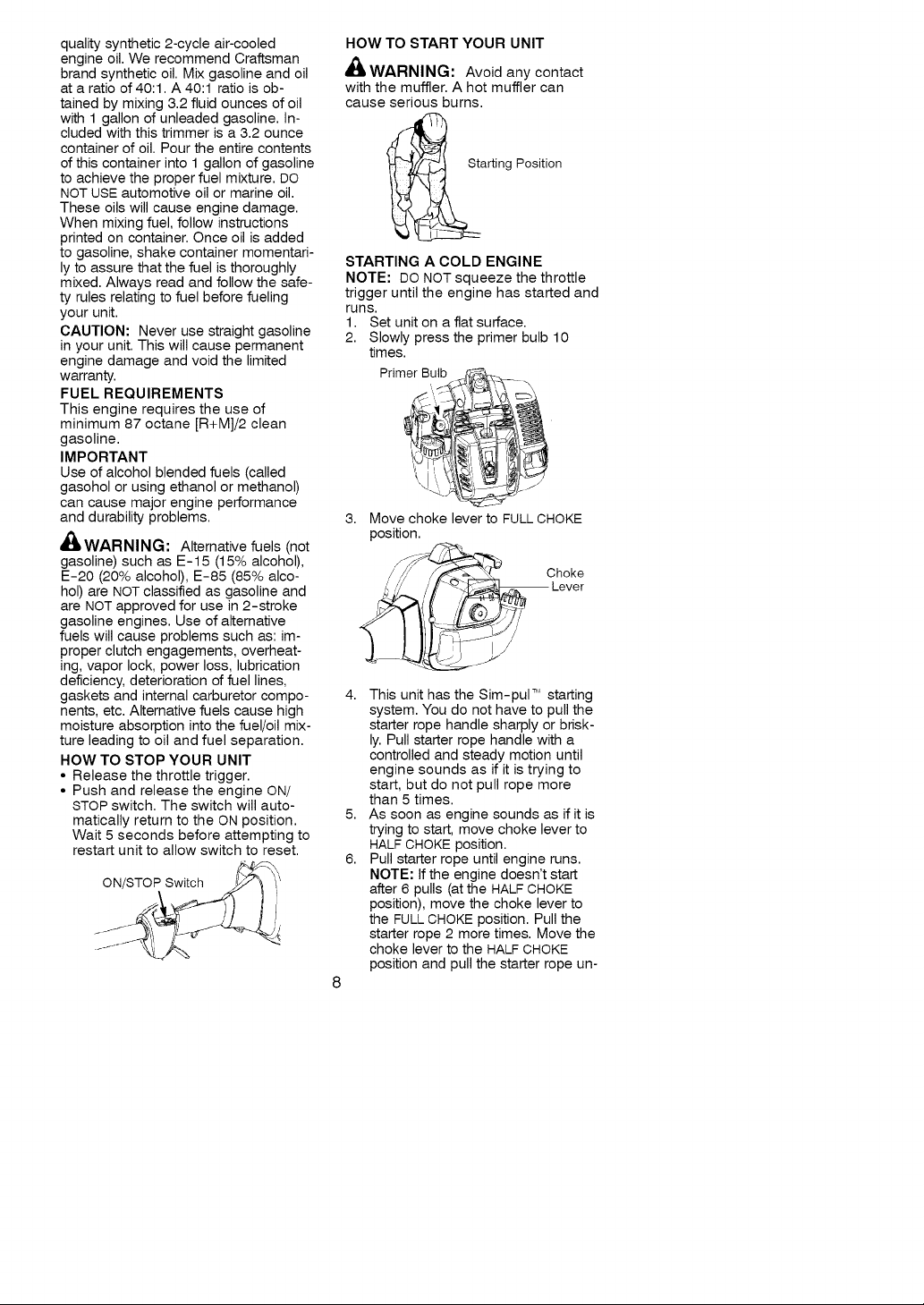

KNOW YOUR TRIMMER

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT. Compare the illustrations with your unit to familiarize yourself with the location

of the various controls and adjustments. Save this manual for future reference.

Fixed Line Trimmer Head

""_ Assist Handle_ Lock-out

_.__ Throttle

Bump Feed Trimmer Head

Shield

ON/STOP

Switch

/

Line Limiter

Blade

Shaft

Choke

Lever

Throttle

Trigger

!_ Muffler

Starter

Handle

ON/STOP SWITCH

The ON/STOP switch is used to stop

engine. To stop the engine, push and

release the engine ON/STOPswitch.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate the primer bulb

by pressing it and allowing it to return

to its original form.

BEFORE STARTING ENGINE

,_/LWARNING: Be sureto read

the fuel information in the safety rules

before you begin. If you do not under-

stand the safety rules, do not attempt

to fuel your unit. Call 1-800-235-5878.

THROTTLE LOCK-OUT

The THRO-FFLELOCK-OUT must be

pressed with the palm of your hand as

you grip the throttle handle before the

trigger can be used. This feature

prevents you from accidentally

squeezing the throttle trigger.

CHOKE

The CHOKE helps to supply fuel to the

engine to aid in cold starting. Activate

the choke by moving the choke lever to

the FULL CHOKE position. After the en-

gine attempts to start, move the choke

lever to the HALF CHOKE position. Once

engine has started, move the choke le-

ver to the OFF CHOKE position.

FUELING ENGINE

WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

qualitysynthetic2-cycleair-cooled

engineoil.WerecommendCraftsman

brandsyntheticoil.Mixgasolineandoil

ataratioof40:1.A40:1ratioisob-

tainedbymixing3.2fluidouncesofoil

with1gallonofunleadedgasoline.In-

cludedwiththistrimmerisa3.2ounce

containerofoil.Pourtheentirecontents

ofthiscontainerinto1gallonofgasoline

toachievetheproperfuelmixture.DO

NOTUSEautomotiveoilormarineoil.

Theseoilswillcauseenginedamage.

Whenmixingfuel,followinstructions

printedoncontainer.Onceoilisadded

togasoline,shakecontainermomentari-

lytoassurethatthefuelisthoroughly

mixed.Alwaysreadandfollowthesafe-

tyrulesrelatingtofuelbeforefueling

yourunit.

CAUTION:Neverusestraightgasoline

inyourunit.Thiswillcausepermanent

enginedamageandvoidthelimited

warranty.

FUELREQUIREMENTS

Thisenginerequirestheuseof

minimum87octane[R+M]/2clean

gasoline.

IMPORTANT

Use of alcohol blended fuels (called

gasoho] or using ethanol or methanol)

can cause major engine performance

and durability problems.

,_ WARNING: Alternative fuels (not

gasoline) such as E-15 (15% alcohol),

E-20 (20% alcohol), E-85 (85% alco-

hol) are NOT classified as gasoline and

are NOTapproved for use in 2-stroke

gasoline engines. Use of alternative

fuels will cause problems such as: im-

proper clutch engagements, overheat-

ing, vapor lock, power loss, lubrication

deficiency, deterioration of fuel lines,

gaskets and internal carburetor compo-

nents, etc. Alternative fuels cause high

moisture absorption into the fuel/oil mix-

ture leading to oil and fuel separation.

HOW TO STOP YOUR UNIT

• Release the throttle trigger.

• Push and release the engine ON/

STOP switch. The switch will auto-

matically return to the ON position.

Wait 5 seconds before attempting to

restart unit to allow switch to reset.

ON/STOP Switch _:_" _i\

HOW TO START YOUR UNIT

,_LWARNING: Avoid any contact

with the muffler. A hot muffler can

cause serious burns.

_arting Position

STARTING A COLD ENGINE

NOTE: DO NOT squeeze the throttle

trigger until the engine has started and

runs.

1. Set unit on a flat surface.

2. Slowly press the primer bulb 10

times.

Primer Bulb___.

3. Move choke lever to FULL CHOKE

position.

/ // /_. "\4[- Choke

/_/A_/" q_ Lever

4. This unit has the Sim--pulTM starting

system. You do not have to pull the

starter rope handle sharply or brisk-

ly. Pull starter rope handle with a

controlled and steady motion until

engine sounds as if it is trying to

start, but do not pull rope more

than 5 times.

5. As soon as engine sounds as if it is

trying to start, move choke lever to

HALF CHOKE position.

6. Pull starter rope until engine runs.

NOTE: Ifthe engine doesn't start

after 6 pulls (at the HALF CHOKE

position), move the choke lever to

the FULL CHOKE position. Pull the

starter rope 2 more times. Move the

choke lever to the HALF CHOKE

position and pull the starter rope un-

tiltheengineruns,butnomorethan

6pulls.Iftheenginestilldoesn't

start,itisprobablyflooded.Proceed

toSTARTINGAFLOODEDENGINE.

7. Oncetheenginestarts,allowitto

run10seconds,thenmovethe

chokelevertotheOFFCHOKE

positionandbeginnormalopera-

tion.NOTE:Ifenginedieswiththe

chokeleverintheOFFCHOKE

position,movethechokeleverto

theFULLCHOKEpositionandpull

theropeuntilengineruns,butno

morethan6pulls.

STARTING A WARM ENGINE

1. Move the choke lever to the HALF

CHOKE position.

2. Pull starter rope with a controlled

and steady motion until engine

runs, but no more than 6 pulls.

3. Allow engine to run 15 seconds,

then move the choke lever to OFF

CHOKE and begin normal operation.

NOTE: If engine has not started, pull

starter rope 5 more pulls. If engine still

does not run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the choke lever in the OFF

CHOKE position; then, pull the rope to

clear the engine of excess fuel. This

could require pulling the starter handle

many times depending on how badly

the unit is flooded.

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-235-5878.

OPERATING INSTRUCTIONS

To maximize operating efficiency, do

not run the engine for longer than 1

minute at a time at full throttle.

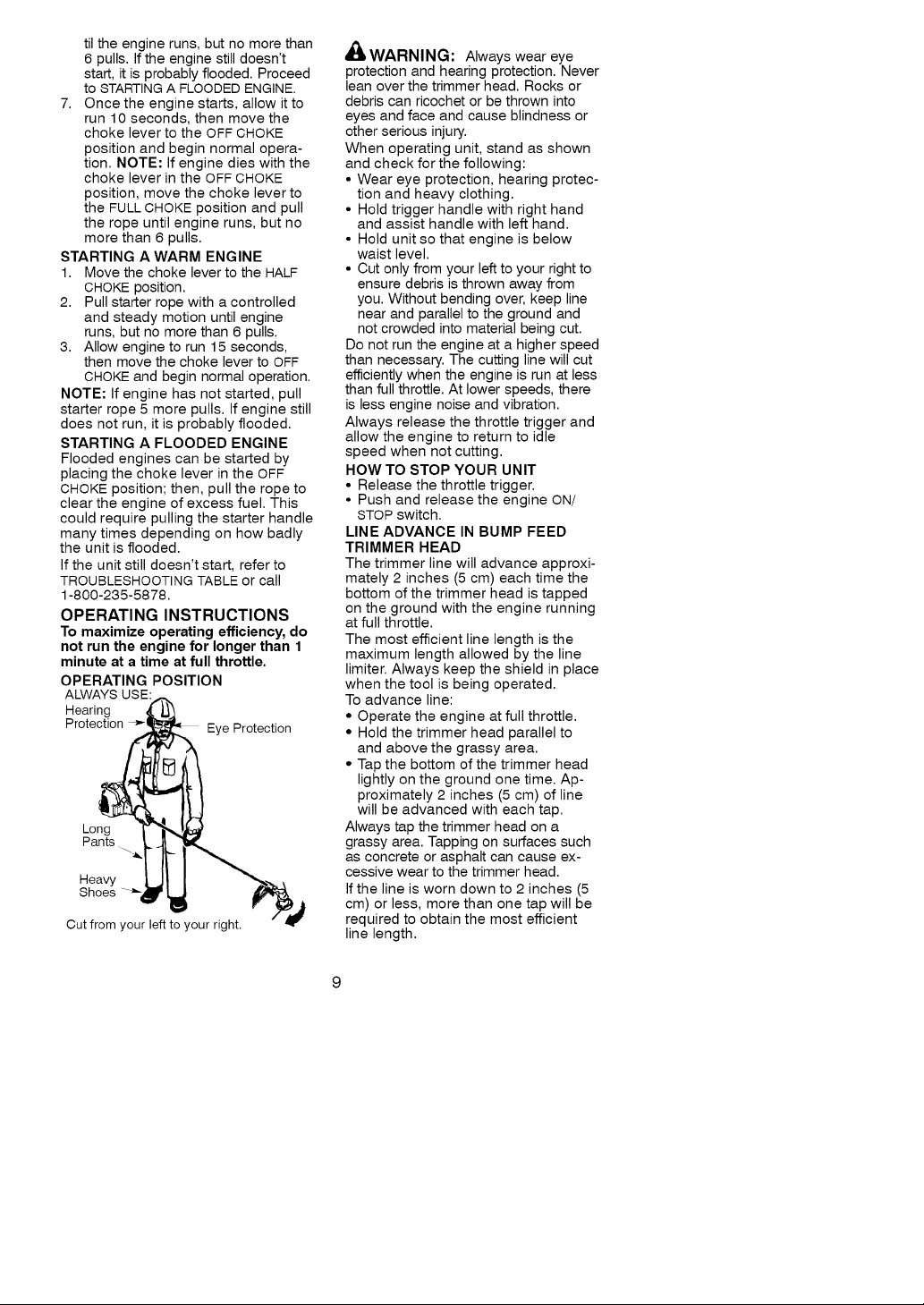

OPERATING POSITION

ALWAYS USE:

Hearing *'-i

Protection Eye Protection

Long

Pants

Shoes

Heavy _,I_

Cutfrom yourle_to yourright.

_/L WARNING: Always wear eye

protection and hearing protection. Never

lean over the trimmer head. Rocks or

debris can ricochet or be thrown into

eyes and face and cause blindness or

other serious injury.

When operating unit, stand as shown

and check for the following:

• Wear eye protection, hearing protec-

tion and heavy clothing.

• Hold trigger handle with right hand

and assist handle with left hand.

• Hold unit so that engine is below

waist level.

• Cut only from your left to your right to

ensure debris is thrown away from

you. Without bending over, keep line

near and parallel to the ground and

not crowded into material being cut.

Do not run the engine at a higher speed

than necessary. The cutting line will cut

efficiently when the engine is run at less

than full throttle. At lower speeds, there

is less engine noise and vibration.

Always release the throttle trigger and

allow the engine to return to idle

speed when not cutting.

HOW TO STOP YOUR UNIT

• Release the throttle trigger.

• Push and release the engine ON/

STOP switch.

LINE ADVANCE IN BUMP FEED

TRIMMER HEAD

The trimmer line will advance approxi-

mately 2 inches (5 cm) each time the

bottom of the trimmer head is tapped

on the ground with the engine running

at full throttle.

The most efficient line length is the

maximum length allowed by the line

limiter. Always keep the shield in place

when the tool is being operated.

To advance line:

• Operate the engine at full throttle.

• Hold the trimmer head parallel to

and above the grassy area.

• Tap the bottom of the trimmer head

lightly on the ground one time. Ap-

proximately 2 inches (5 cm) of line

will be advanced with each tap.

Always tap the trimmer head on a

grassy area. Tapping on surfaces such

as concrete or asphalt can cause ex-

cessive wear to the trimmer head.

If the line is worn down to 2 inches (5

cm) or less, more than one tap will be

required to obtain the most efficient

line length.

m_WARNING:Useonly0.095inch

(2.4mm)diameterline.Othersizesof

linewillnotadvanceproperlyandwill

resultinimpropercuttingheadfunc-

tionorcancauseseriousinjury.Do

notuseothermaterialssuchaswire,

string,rope,etc.Wirecanbreakoff

duringcuttingandbecomeadanger-

ousmissilethatcancauseseriousin-

jury.

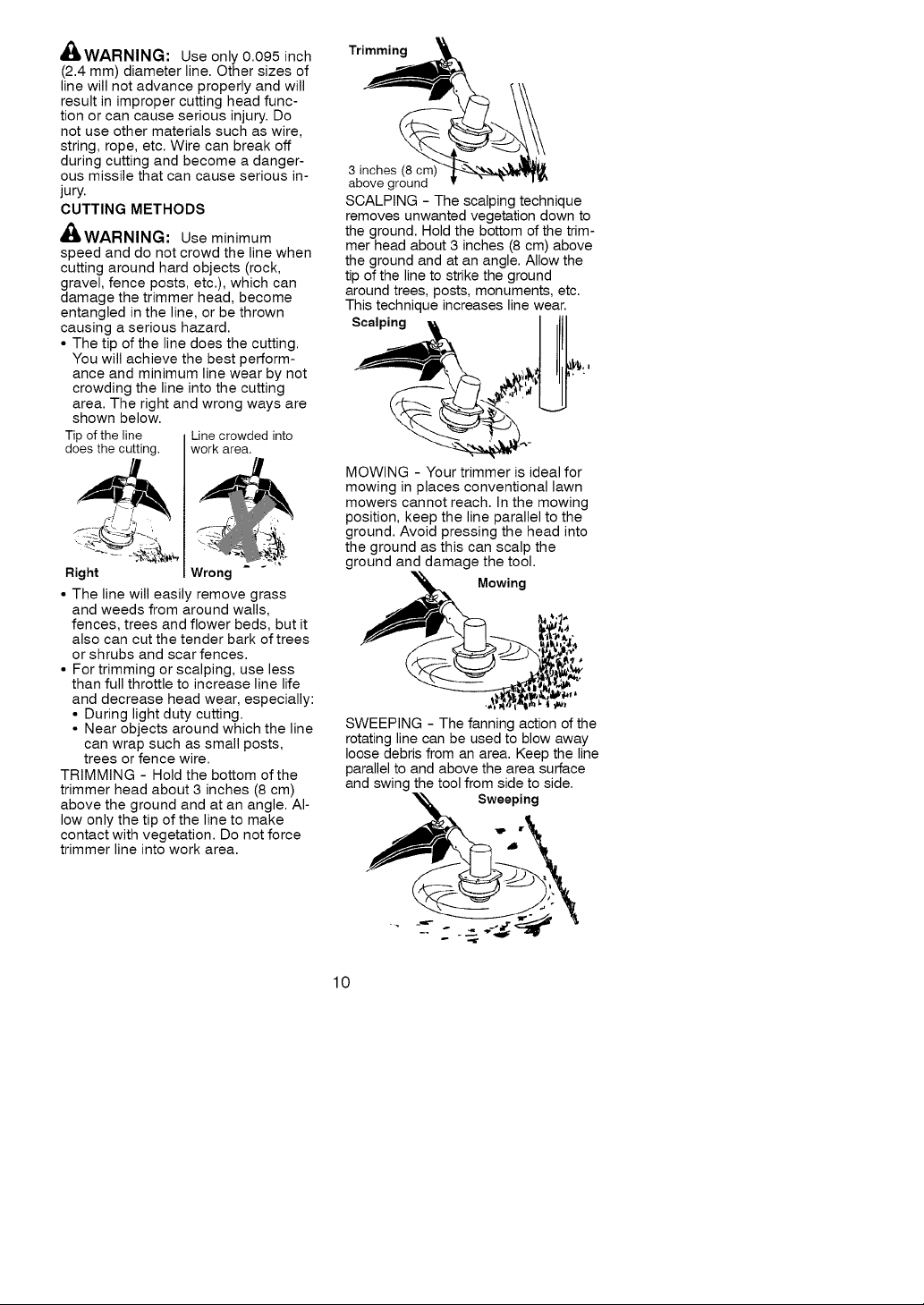

CUTTINGMETHODS

,_/kWARNING: Use minimum

speed and do not crowd the line when

cutting around hard objects (rock,

gravel, fence posts, etc.), which can

damage the trimmer head, become

entangled in the line, or be thrown

causing a serious hazard.

• The tip of the line does the cutting.

You will achieve the best perform-

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

Tip of the line Line crowded into

does the cutting, work area.

Right Wrong

• The line will easily remove grass

and weeds from around walls,

fences, trees and flower beds, but it

also can cut the tender bark of trees

or shrubs and scar fences.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

• During light duty cutting.

• Near objects around which the line

can wrap such as small posts,

trees or fence wire.

TRIMMING - Hold the bottom of the

trimmer head about 3 inches (8 cm)

above the ground and at an angle. Al-

low only the tip of the line to make

contact with vegetation. Do not force

trimmer line into work area.

Trimming

3 inches (8 cm)

above ground

SCALPING - The scalping technique

removes unwanted vegetation down to

the ground. Hold the bottom of the trim-

mer head about 3 inches (8 cm) above

the ground and at an angle. Allow the

tip of the line to strike the ground

around trees, posts, monuments, etc.

This technique increases line wear.

Scalping

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action of the

rotating line can be used to blow away

loose debris from an area. Keep the line

parallel to and above the area surface

and swing the tool from side to side.

Sweeping

10

MAINTENANCE SCHEDULE

WARNING: Disconnect the spark plug

except for carburetor adjustments.

CARE & MAINTENANCE TASK

Check for loose fasteners and parts

Check for damaged or worn parts

Inspect and clean unit and decals

Clean air filter

Inspect muffler and spark arresting screen

Replace spark plug

GENERAL RECOMMENDATIONS

The warranty on this unit does not

cover items that have been subjected

to operator abuse or negligence. To

receive full value from the warranty,

the operator must maintain unit as

instructed in this manual. Various ad-

justments will need to be made peri-

odically to properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re-

placement of damaged or worn parts.

• ON/STOP Switch - Ensure ON/STOP

switch functions properly by pushing

and releasing the switch. Make sure

engine stops. Wait 5 seconds be-

fore attempting to restart unit to al-

low switch to reset. Restart engine

and continue.

• Fuel Tank - Discontinue use of unit

if fuel tank shows signs of damage

or leaks.

• Debris Shield - Discontinue use of

unit if debris shield is damaged.

INSPECTAND CLEAN UNITAND DE-

CALS

• After each use, inspect complete

unit for loose or damaged parts.

Clean the unit and decals using a

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

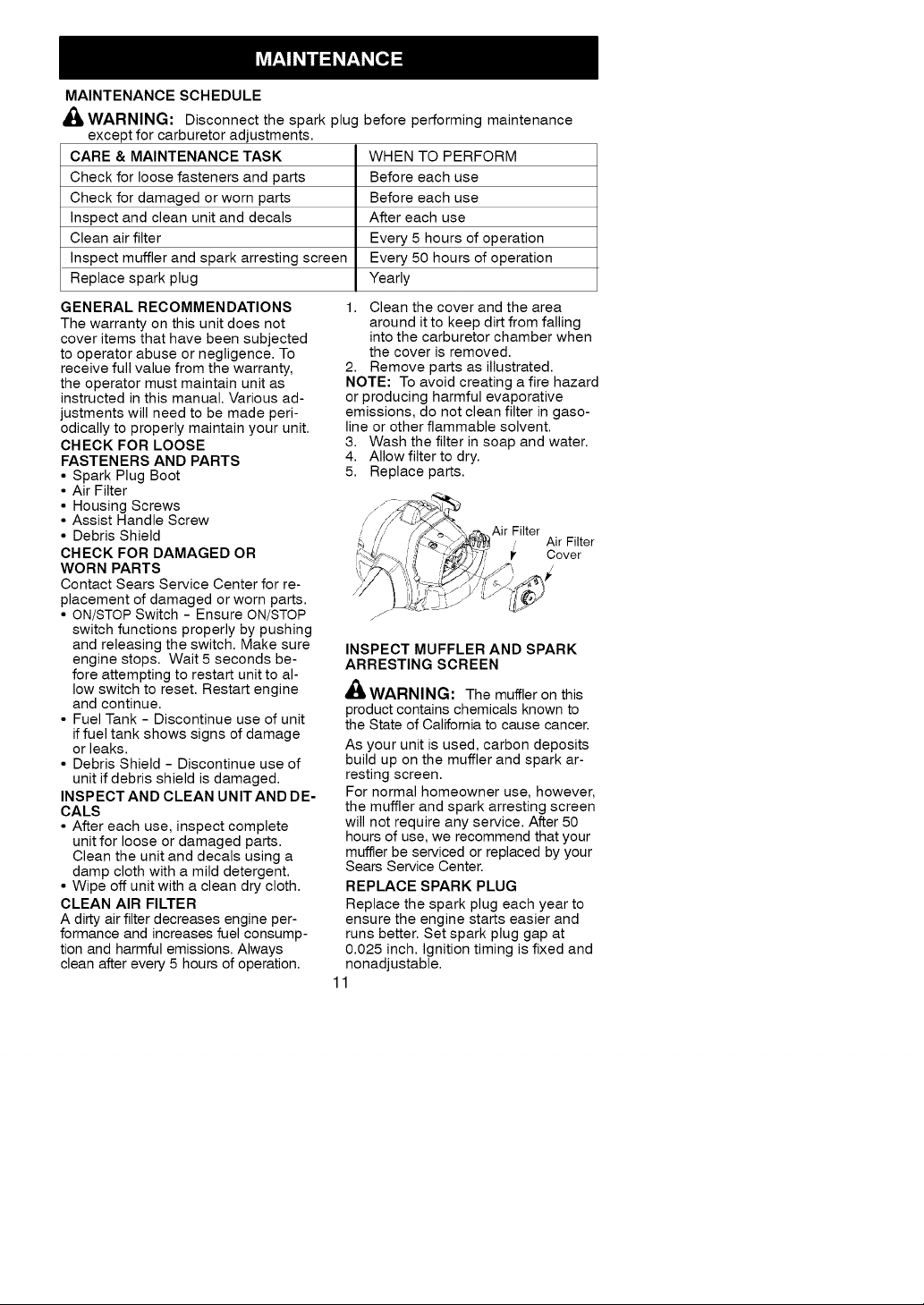

CLEAN AIR FILTER

A dirty air filter decreases engine per-

formance and increases fuel consump-

tion and harmful emissions. Always

clean after every 5 hours of operation.

before performing maintenance

WHEN TO PERFORM

Before each use

Before each use

After each use

Every 5 hours of operation

Every 50 hours of operation

Yearly

1. Clean the cover and the area

around it to keep dirt from falling

into the carburetor chamber when

the cover is removed.

2. Remove parts as illustrated.

NOTE: To avoid creating a fire hazard

or producing harmful evaporative

emissions, do not clean filter in gaso-

line or other flammable solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

Air Filter

/ Air Filter

I_ Cover

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_L WARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As your unit is used, carbon deposits

build up on the muffler and spark ar-

resting screen.

For normal homeowner use, however,

the muffler and spark arresting screen

will not require any service. After 50

hours of use, we recommend that your

muffler be serviced or replaced by your

Sears Service Center.

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Set spark plug gap at

0.025 inch. Ignition timing is fixed and

nonadjustable.

11

1.Twist,thenpulloffsparkplugboot.

2. Removesparkplugfromcylinder

anddiscard.

Yourunitisequippedwithabump

feedtrimmerhead.Abonusfixed

linecuttingheadisalsoincluded.

Bothcuttingheadscanbeused

interchangeably(seeCHANGINGTHE

TRIMMERHEADsectionforremoval

andinstallationinstructions).

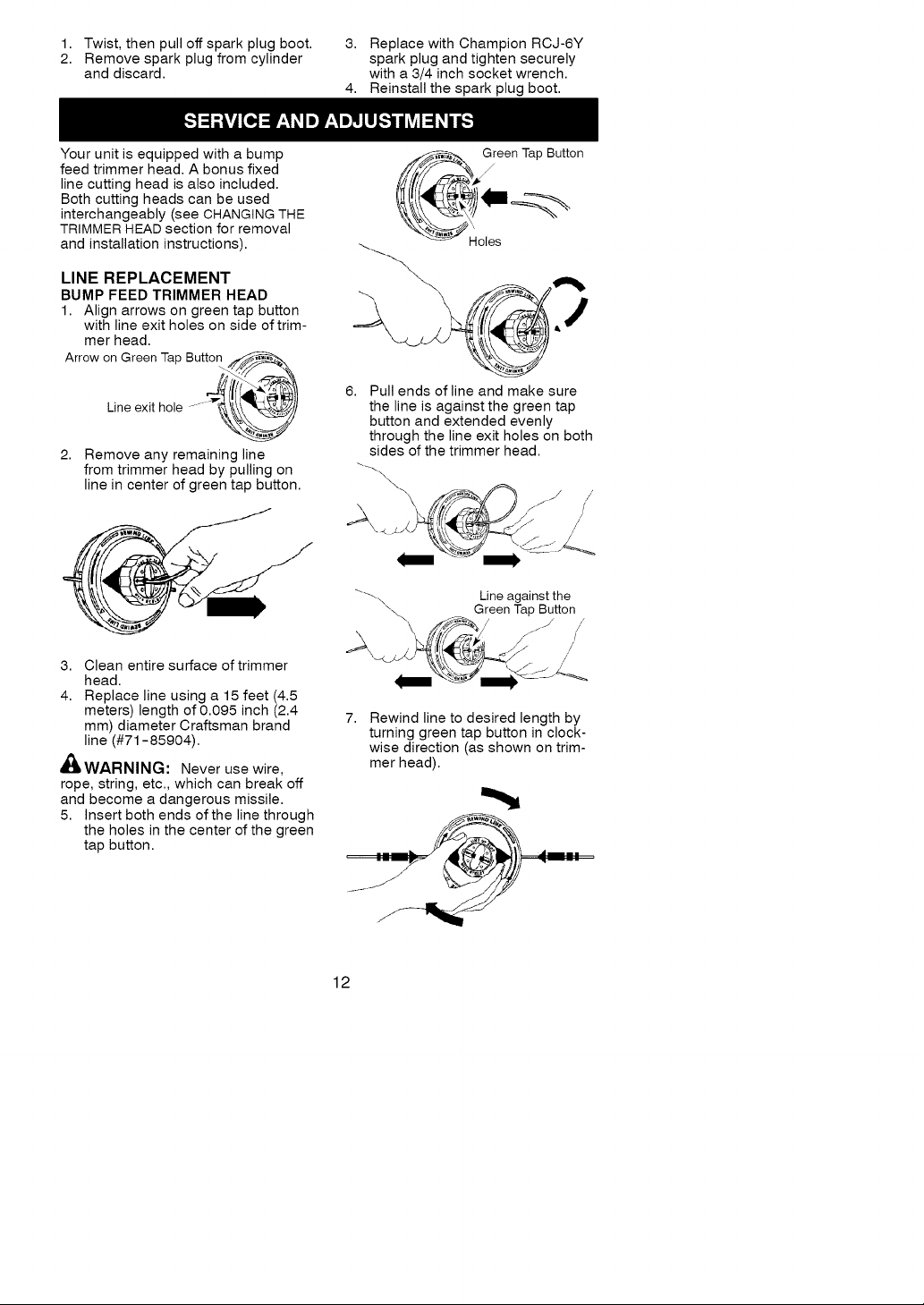

LINE REPLACEMENT

BUMP FEED TRIMMER HEAD

1. Align arrows on green tap button

with line exit holes on side of trim-

mer head.

Arrow on Green Tap

Line exit hole .... _'-'__

2. Remove any remaining line

from trimmer head by pulling on

line in center of green tap button.

Button

3. ReplacewithChampionRCJ-6Y

sparkplugandtightensecurely

witha3/4inchsocketwrench.

4. Reinstallthesparkplugboot.

_reen Tap Button

6. Pull ends of line and make sure

the line is against the green tap

button and extended evenly

through the line exit holes on both

sides of the trimmer head.

\,

3. Clean entire surface of trimmer

head.

4. Replace line using a 15 feet (4.5

meters) length of 0.095 inch (2.4

mm) diameter Craftsman brand

line (#71-85904).

_WARNING: Never use wire,

rope, string, etc., which can break off

and become a dangerous missile.

5. Insert both ends of the line through

the holes in the center of the green

tap button.

__-,,,, Line against the

\ //" /

7,

Rewind line to desired length by

turning green tap button in clock-

wise direction (as shown on trim-

mer head).

12

Green Tap Button

Loading...

Loading...