Craftsman 358360831 Owner’s Manual

Instruction Manual

ICRAFTSMAN°I

2.4 cu.in./40cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358,360831 - 18 in, Bar

Q

Safety

Q

Assembly

Operation

Maintenance

Parts List

Espar_ol

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon-Sat; Sun, 10 am-7 pm

1-800-235-5878 (Hours listed are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530164586 1/10/05

Warranty 2 Storage 18

Safety Rules 2 Troubleshooting Table 19

Assembly 6 Emissions Statement 21

Operation 7 Parts List 23

Maintenance 13 Spanish 25

Service and Adjustments 17 Parts & Ordering Back Cover

FULL ONE YEAR WARRANTY ON CRAFTSMAN _RGAS CHAIN SAW

For one year from the date of purchase, when this Craftsman _ Gas Chain Saw is

maintained, lubricated and tuned up according to the instruction manual, Sears

will repair, free of charge, any defect in material or workmanship.

This warranty excludes the bar, chain, spark plug and air filter, which are

expendable parts, and become worn during normal use.

If this Gas Chain Saw is used for commercial or rental purposes, this warranty

applies for 30 days from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE

NEAREST SEARS STORE OR SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

A

rot, WARNING: Always disconnect

spark plug wire when making repairs

except for carburetor adjustments. Be-

cause a chain saw is a high-speed

woodcutting tool, special precautions

must be observed to reduce risk of ac-

cidents. Careless or improper use of

this tool can cause serious injury.

PLAN AHEAD

• Restrict tile use of your saw to adult

users who understand and can fol-

low the safety rules, precautions,

and operating instructions found in

this manual.

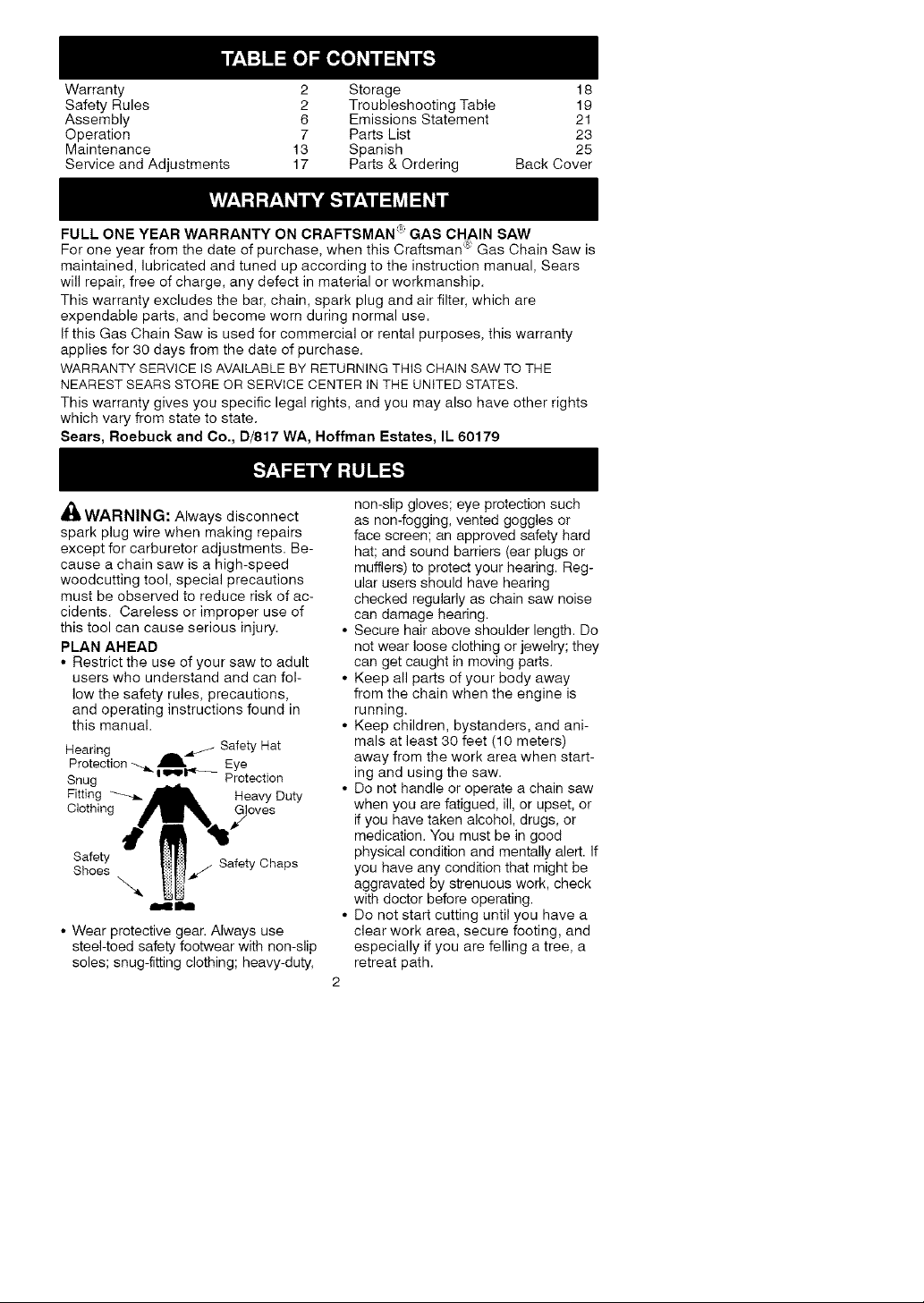

Hearing ,_L_J Safety Hat

Protection _ _ Eye

Snug Iu'ur_-_ Protection

Pitting _--_, ,_ Heavy Duty

Safety Safety Chaps

Clothing'_T Gloves

Shoes _ _

at_

• Wear protective gear. Always use

steel-toed safety footwear with non-slip

soles; snug-fitting clothing; heavy-duty,

non-slip gloves; eye protection such

as non-fogging, vented goggles or

face screen; an approved safety hard

hat; and sound barriers (ear plugs or

mufflers) to protect your hearing. Reg-

ular users should have hearing

checked regularly as chain saw noise

can damage hearing.

• Secure hair above shoulder length. Do

not wear loose clothing or jewelry; they

can get caught in moving parts.

• Keep all parts of your body away

from the chain when the engine is

running.

• Keep children, bystanders, and ani-

mals at least 30 feet (10 meters)

away from the work area when start-

ing and using the saw.

• Do not handle or operate a chain saw

when you are fatigued, ill, or upset, or

if you have taken alcohol, drugs, or

medication. You must be in good

physical condition and mentally alert. If

you have any condition that might be

aggravated by strenuous work, check

with doctor before operating.

• Do not start cutting until you have a

clear work area, secure footing, and

especially if you are felling a tree, a

retreat path.

2

OPERATE YOUR SAW SAFELY

• Do not operate with one hand. Seri-

ous injury to the operator, helpers, or

bystanders may result from one-

handed operation. A chain saw is in-

tended for two-handed use.

• Operate the chain saw only in a well-

ventilated outdoor area.

• Do not operate saw from a ladder or

in a tree.

• Make sure the chain will not make

contact with any object while starting

the engine. Never try to start the saw

when the guide bar is in a cut.

• Do not put pressure on the saw, es-

pecially at the end of the cut. Doing

so can cause you to lose control

when the cut is completed.

• Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Carry with muffler away

from body; guide bar & chain project-

ing behind you; guide bar preferably

covered with a scabbard.

• Do not operate a chain saw that is

damaged, improperly adjusted, or not

completely and securely assembled.

Always replace bar, chain, hand

guard, chain brake, or other parts im-

mediately if they become damaged,

broken, or are otherwise removed.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

• Have all chain saw service per-

formed by a qualified service dealer

except the items listed in the MAINTE-

NANCE section of this manual.

• Make certain the saw chain stops

moving when the throttle trigger is

released. For correction, refer to

CARBURETOR ADJUSTMENTS.

• Keep the handles dry, clean, and

free from oil or fuel mixture.

• Keep caps and fasteners securely

tightened.

• Nonconforming replacement compo-

nents or the removal of safety devices

may cause damage to the unit and

possible injury to the operator or by-

standers. Use only Craftsman acces-

sories and replacement parts as rec-

ommended. Never modify your saw.

• Maintain chain saw with care.

• Keep unit sharp and clean for better

and safer performance.

• Follow instructions for lubricating and

changing accessories.

• Check for damaged parts. Before fur-

ther use of the chain saw, a guard or

other part that is damaged should be

carefully checked to determine that it

will operate properly and perform its

intended function. Check for alignment

of moving parts, binding of moving

parts, breakage of parts, mounting and

any other conditions that may affect its

operation. A guard or other part that is

damaged should be properly repaired

or replaced by a Sears Service Center

unless otherwise indicated elsewhere

in the instruction manual.

• When not in use, chain saws should

be stored in a dry, high or locked-up

place out of the reach of children.

• When storing saw, use a scabbard or

carrying case.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or

while operating the saw.

• Eliminate all sources of sparks or

flame in areas where fuel is mixed or

poured.

• Mix and pour fuel in an outdoor area

and use an approved, marked con-

tainer for all fuel purposes. Wipe up

all fuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting.

• Turn the engine off and let saw cool

in a non-combustible area, not on

dry leaves, straw, paper, etc. Slowly

remove fuel cap and refuel unit.

• Store the unit and fuel in a cool, dry

well ventilated space where fuel va-

pors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

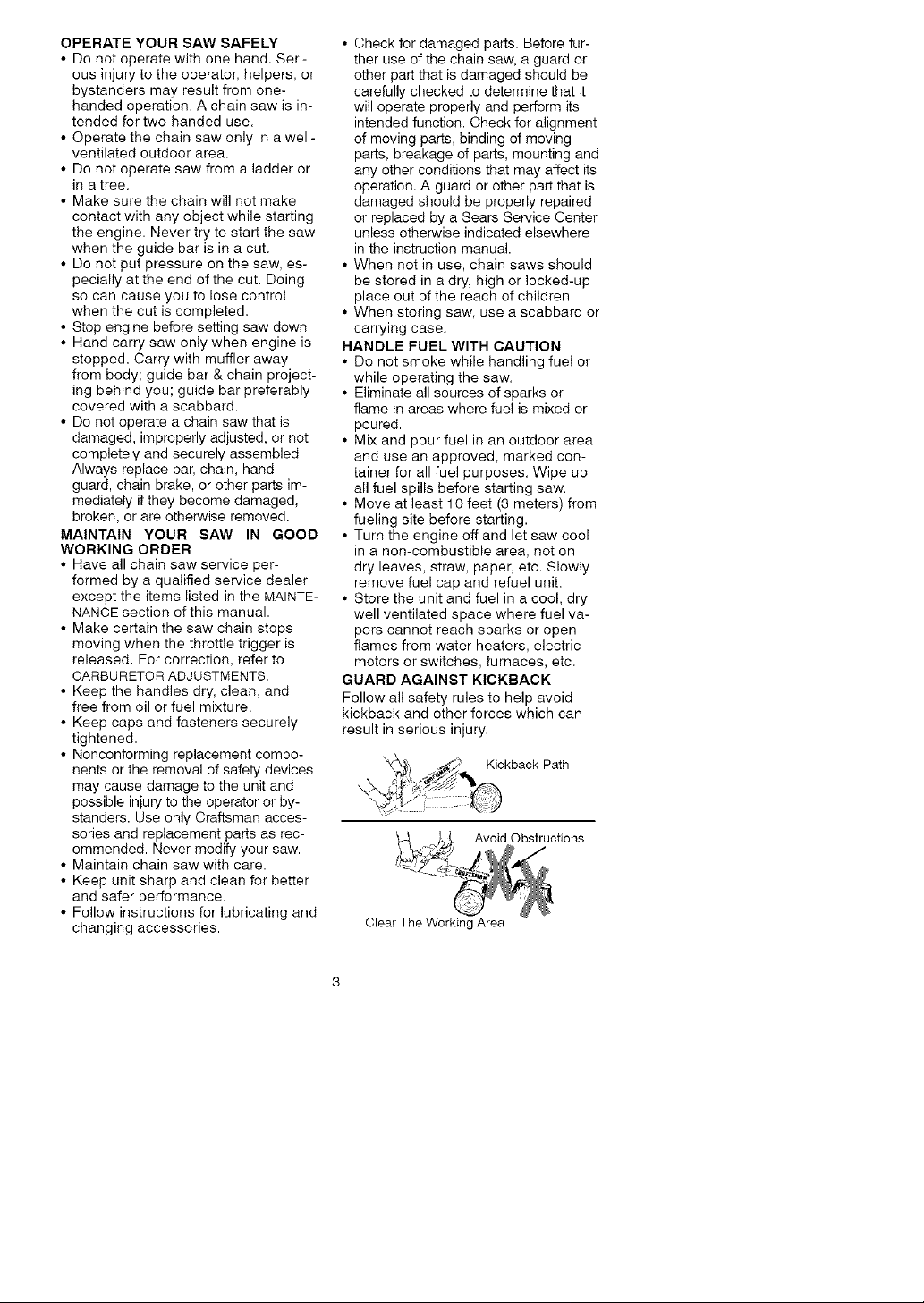

GUARD AGAINST KICKBACK

Follow all safety rules to help avoid

kickback and other forces which can

result in serious injury.

x_'_', ._.._ Kickback Path

Avoid Obstructions

Clear The Working Area

A

411 WARNING: Avoid kickback which

can result in serious injury. Kickback

is the backward, upward or sudden for-

ward motion of the guide bar occurring

when the saw chain near the upper tip

of the guide bar contacts any object

such as a log or branch, or when the

wood closes in and pinches the saw

chain in the cut. Contacting a foreign

object in the wood can also result in

loss of chain saw control.

• Rotational Kickback can occur

when the moving chain contacts an

object at the upper tip of the guide

bar. This contact can cause the

chain to dig into the object, which

stops the chain for an instant. The

result is a lightning fast, reverse

reaction which kicks the guide bar up

and back toward the operator.

• Pinch-Kickback can occur when the

the wood closes in and pinches the

moving saw chain in the cut along the

top of the guide bar and the saw chain

is suddenly stopped. This sudden

stopping of the chain results in a re-

versal of the chain force used to cut

wood and causes the saw to move in

the opposite direction of the chain

rotation. The saw is driven straight

back toward the operator.

• Pull-In can occur when the moving

chain contacts a foreign object in the

wood in the cut along the bottom of

the guide bar and the saw chain is

suddenly stopped. This sudden stop-

ping pulls the saw forward and away

from the operator and could easily

cause the operator to lose control of

the saw.

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen.

With a basic understanding of kick-

back, you can reduce the element of

surprise which contributes to acci-

dents.

• Never let the moving chain contact

any object at the tip of the guide bar.

• Keep working area free from obstruc-

tions such as other trees, branches,

rocks, fences, stumps, etc. Eliminate

or avoid any obstruction that your saw

chain could hit while cutting.

• When cutting a branch, do not let the

guide bar contact another branch or

other objects around it.

• Keep saw chain sharp and properly

tensioned. A loose or dull chain can

increase the chance of kickback. Fol-

low manufacturer's chain sharpening

and maintenance instructions. Check

tension at regular intervals, but never

with engine running. Make sure chain

brake nuts are securely tightened.

• Begin and continue cutting at full

speed. If the chain is moving at a

slower speed, there is greater chance

of kickback occurring.

• Use extreme caution when reentering

a cut.

• Do not attempt cuts starting with the

tip of the bar (plunge cuts).

• Watch for shifting logs or other forces

that could close a cut and pinch or fall

into chain.

• Use the specified Reduced-Kickback

Guide Bar and Low-Kickback Chain.

Avoid Pinch-Kickback:

• Be extremely aware of situations or

obstructions that can cause material

to pinch the top of or otherwise stop

the chain.

• Do not cut more than one log at a

time.

• Do not twist saw as bar is withdrawn

from an undercut when bucking.

Avoid Pull-In:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open.

MAINTAIN CONTROL

Stand to the left of the saw

underside ,[

Thumb on \[

Elbow

locked

Never reverse hand positions

• A good, firm grip on the saw with both

hands will help you maintain control.

Don't let go. Grip the rear handle with

your right hand whether you are right

or left handed. Wrap the fingers of

your left hand over and around the

front handlebar, and your left thumb

under the front handlebar. Keep your

left arm straight with the elbow locked.

• Positionyourlefthandonthefront

handlebarsoitisinastraightlinewith

yourrighthandontherearhandle

whenmakingbuckingcuts.Stand

slightlytotheleftsideofthesawto

keepyourbodyfrombeinginadirect

linewiththecuttingchain.

• Standwithyourweightevenlybal-

ancedonbothfeet.

• Donotoverreach.Youcouldbedrawn

orthrownoffbalanceandlosecontrol.

• Donotcutaboveshoulderheight.Itis

difficulttomaintaincontrolofsaw

aboveshoulderheight.

KICKBACKSAFETY FEATURES

WARNING: The following features

are included on your saw to help reduce

hazard of kickback; however, such fea-

tures will not totally eliminate this danger.

Do not rely only on safety devices. Fol-

low all safety rules to help avoid kick-

back and other forces which can result

in serious injury,

• Front Hand Guard: designed to reduce

the chance of your left hand contact-

ing the chain if your hand slips off the

front handlebar.

• Position of front and rear handlebars:

designed with distance between han-

dles and "in-line" with each other. The

spread and "in-line" position of the

hands provided by this design work

together to give balance and resis-

tance in controlling the pivot of the

saw back toward the operator if kick-

back occurs.

• Reduced-Kickback Guide Bar: de-

signed with a small radius tip which

reduces the size of the kickback dan-

ger zone on the bar tip. This type bar

has been demonstrated to significantly

reduce the number and seriousness of

kickbacks when tested in accordance

with ANS! B175.1.

Tip Guide Bar

__ Small Radius

Large Radius { "_

Tip Guide Bar

• Low-Kickback Chain: has met kick-

back performance requirements when

tested on a representative sample of

chain saws below 3.8 cubic inch dis-

placement specified in ANS! B175.1.

Low-Kickback Chain

_._,_ longated Guard Link

CHAIN BRAKE

• Chain Brake: designed to stop the

chain in the event of kickback.

m'_ WARNING: WE DO NOT REP-

RESENT AND YOU SHOULD NOT AS-

SUME THAT THE CHAIN BRAKE WiLL

PROTECT YOU IN THE EVENT OF A

KICKBACK, Kickback is a lightning fast

action which throws the bar and rotat-

ing chain back and up toward the op-

erator. Kickback can be caused by al-

lowing contact of the bar tip in the

danger zone with any hard object.

Kickback can also be caused by

pinching the saw chain along the top

of the guide bar. This action may push

the guide bar rapidly back toward the

operator. Either of these events may

cause you to lose control of the saw

which could result in serious injury or

even death. DO NOT RELY UPON ANY

OF THE DEVICES BUILT INTO YOUR

SAW. YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK, Reduced-kickback guide

bars and low-kickback saw chains re-

duce the chance and magnitude of

kickback and are recommended. Your

saw has a low kickback chain and bar

as original equipment. Repairs on a

chain brake should be made by an au-

thorized Sears Service Center, Take

your unit to the place of purchase orto

your nearest Sears Service Center.

• Tip contact in some cases may cause

a lightning fast reverse REACTION,

kicking guide bar up and back toward

operator.

• Pinching the saw chain along the top

of the guide bar may push the guide

bar rapidly back toward the operator.

• Either of these reactions may cause

you to lose control of the saw which

could result in serious injury. Do not

rely exclusively upon safety devices

built into your saw.

Contoured Depth Gauge

deflects kickback

force And allows

wood to gradually

ride into Cutter

SAFETYNOTICE:Exposuretovibra-

tionsthroughprolongeduseofgasoline

poweredhandtoolscouldcauseblood

vesselornervedamageinthefingers,

hands,andjointsofpeopleproneto

circulationdisordersorabnormalswell-

ing.Prolongeduseincoldweatherhas

beenlinkedtobloodvesseldamagein

otherwisehealthypeople.Ifsymptoms

occursuchasnumbness,pain,lossof

strength,changeinskincolorortexture,

orlossoffeelinginthefingers,hands,or

joints,discontinuetheuseofthistool

andseekmedicalattention.Ananti-vi-

brationsystemdoesnotguaranteethe

avoidanceoftheseproblems.Users

whooperatepowertoolsonacontinual

andregularbasismustcloselymonitor

theirphysicalconditionandthecondition

ofthistool.

CHAINBRAKE:Ifthissawistobe

usedforcommerciallogging,achain

brakeisrequiredandshallnotbere-

movedorotherwisedisabledtocomply

withFederalOSHARegulationsfor

CommercialLogging.

SPARK ARRESTING SCREEN: Your

saw is equipped with a temperature lim-

iting muffler and spark arresting screen

which meets the requirements of Califor-

nia Codes 4442 and 4443. All U.S. for-

est land and the states of California, Ida-

ho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by law

that many internal combustion engines

be equipped with a spark arresting

screen. Ifyou operate a chain saw in a

state or locale where such regulations

exist, you are legally responsible for

maintaining the operating condition of

these parts. Failure to do so is a viola-

tion of the law. Refer to Customer Re-

sponsibilities chart in the MAINTENANCE

section.

STANDARDS: This chain saw is listed

by Underwriters Laboratories, Inc. in ac-

cordance with American National Stan-

dards for Gasoline-Powered Chain

Saws Safety Requirements (ANSI

B175=1-2000).

,_ WARNING: Before using chain

saw, ensure all fasteners are secure.

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358.360831

• Chain saw (fully assembled)

• Chain adjustment tool (Bar tool)

• 2-cycle engine oil

• Carrying case

Examine parts for damage. Do not use

damaged parts.

If you need assistance or find that parts

are missing or damaged, please call

1-800-235-5878.

NOTE: It is normal to hear the fuel filter

rattle in an empty fuel tank.

Your unit has been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fuel residue on the muffler

when you unpack the unit.

ASSEMBLY

Your saw is fully assembled; no

assembly is necessary.

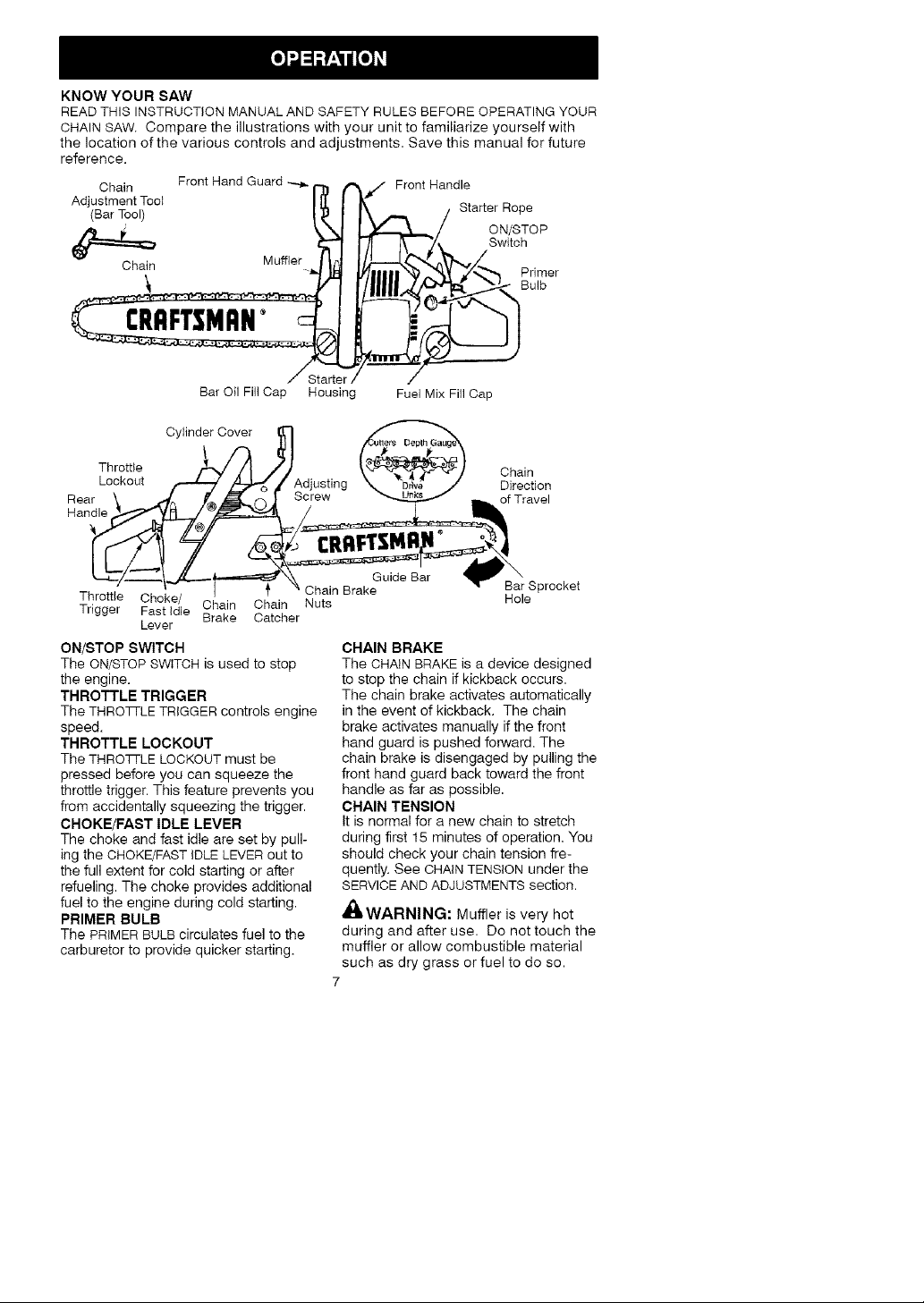

KNOWYOURSAW

READTHISINSTRUCTIONMANUALANDSAFETYRULESBEFOREOPERATINGYOUR

CHAINSAW,Comparetheillustrationswithyourunittofamiliarizeyourselfwith

thelocationofthevariouscontrolsandadjustments.Savethismanualforfuture

reference.

Chain FrontHandGuard_ r'J)(,_,_ Front Handle

Adj(UBstm_-°nt°I_Col [_ _ / StarteoR/°sPTop

Primer

swith

Bar Oil FillCap Housing Fuel Mix Fill Cap

Cylinder Cover

Throttle Chain

Lockout Adjusting Direction

of Travel

Throttle Choke/ Chain Chain Nuts Hole

Trigger Fast Idle Brake Catcher

ON/STOP SWITCH

The ON/STOP SWITCH is used to stop

the engine.

THROTTLE TRIGGER

The THROqq-LETRIGGER controls engine

speed.

THROTTLE LOCKOUT

The THROTTLE LOCKOUT must be

pressed before you can squeeze the

throttle trigger. This feature prevents you

from accidentally squeezing the trigger.

CHOKE/FAST IDLE LEVER

The choke and fast idle are set by pull-

ing the CHOKE/FAST IDLE LEVER out to

the full extent for cold starting or after

refueling. The choke provides additional

fuel to the engine during cold starting.

PRIMER BULB

Tile PRIMER BULB circulates fuel to tile

carburetor to provide quicker starting.

Lever

Chain Brake Bar Sprocket

Guide Bar

CHAIN BRAKE

The CHAIN BRAKE is a device designed

to stop the chain if kickback occurs.

The chain brake activates automatically

in the event of kickback. The chain

brake activates manually if the front

hand guard is pushed forward. The

chain brake is disengaged by pulling the

front hand guard back toward the front

handle as far as possible.

CHAIN TENSION

It is normal for a new chain to stretch

during first 15 minutes of operation. You

should check your chain tension fre-

quently. See CHAIN TENSION under the

SERVICEAND ADJUSTMENTS section.

,_ WARNING: Muffler is very hot

during and after use. Do not touch the

muffler or allow combustible material

such as dry grass or fuel to do so.

7

BEFORE STARTING ENGINE

_ WARNING: Be sure to read the

fuel handling information in the safety

rules section of this manual before you

begin. If you do not understand the

fuel handling information do not at-

tempt to fuel your unit. Seek help from

someone that does understand the in-

formation or call the customer assis-

tance help line at 1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The bar and chain require lubrication.

The chain oiler provides continuous

lubrication to the chain and guide bar.

Be sure to fill the bar oil tank when you

fill the fuel tank (Capacity = 6.8 ft. oz.).

Lack of oil will quickly ruin the bar and

chain. Too little oil will cause overheat-

ing shown by smoke coming from the

chain and/or discoloration of the bar.

For maximum guide bar and chain life,

we recommend you use Craftsman

chain saw bar oil. If Craftsman bar oil

is not available, you may use a good

grade SAE 30 oil until you are able to

obtain Craftsman brand. The oil output

is automatically metered during opera-

tion. Your saw will use approximately

one tank of bar oil for every tank of fuel

mix. Always fill the bar oil tank when

you fill the fuel tank.

FUELING ENGINE

Al_ WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality synthetic 2-cycle air-cooled en-

gine oil. We recommend Craftsman

brand synthetic oil. Mix gasoline and

oil at a ratio of 40:1. A 40:1 ratio is ob-

tained by mixing 3.2 ounces of oil with

1 gallon of unleaded gasoline. In-

cluded with this saw is a 3.2 ounce

container of Craftsman brand synthetic

oil. Pour the entire contents of this con-

tainer into 1 gallon of gasoline to

achieve the proper fuel mixture.

DO NOT USE automotive oil or marine oil.

These oils will cause engine damage.

When mixing fuel follow the instructions

printed on the oil container.

Once oil is added to the gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed. Al-

ways read and follow the safety rules

relating to fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract mois-

ture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage. To avoid engine

problems, the fuel system should be

emptied before storage for 30 days or

longer. Drain the gas tank, start the en-

gine and let it run until the fuel lines and

carburetor are empty. Use fresh fuel

next season. See STORAGE instructions

for additional information.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

See the STORAGE section for additional

information.

CHAIN BRAKE

Ensure chain brake is disengaged by

pulling the front hand guard back to-

ward the front handle as far as pos-

sible. The chain brake must be disen-

gaged before cutting with the saw.

_lk WARNING: The chain must not

move when the engine runs at idle

speed. If the chain moves at idle

speed, refer to CARBURETOR ADJUST-

MENT within this manual. Avoid con-

tact with the muffler. A hot muffler can

cause serious burns.

STOPPING YOUR ENGINE

• Move ON/STOP switch to the STOP

position.

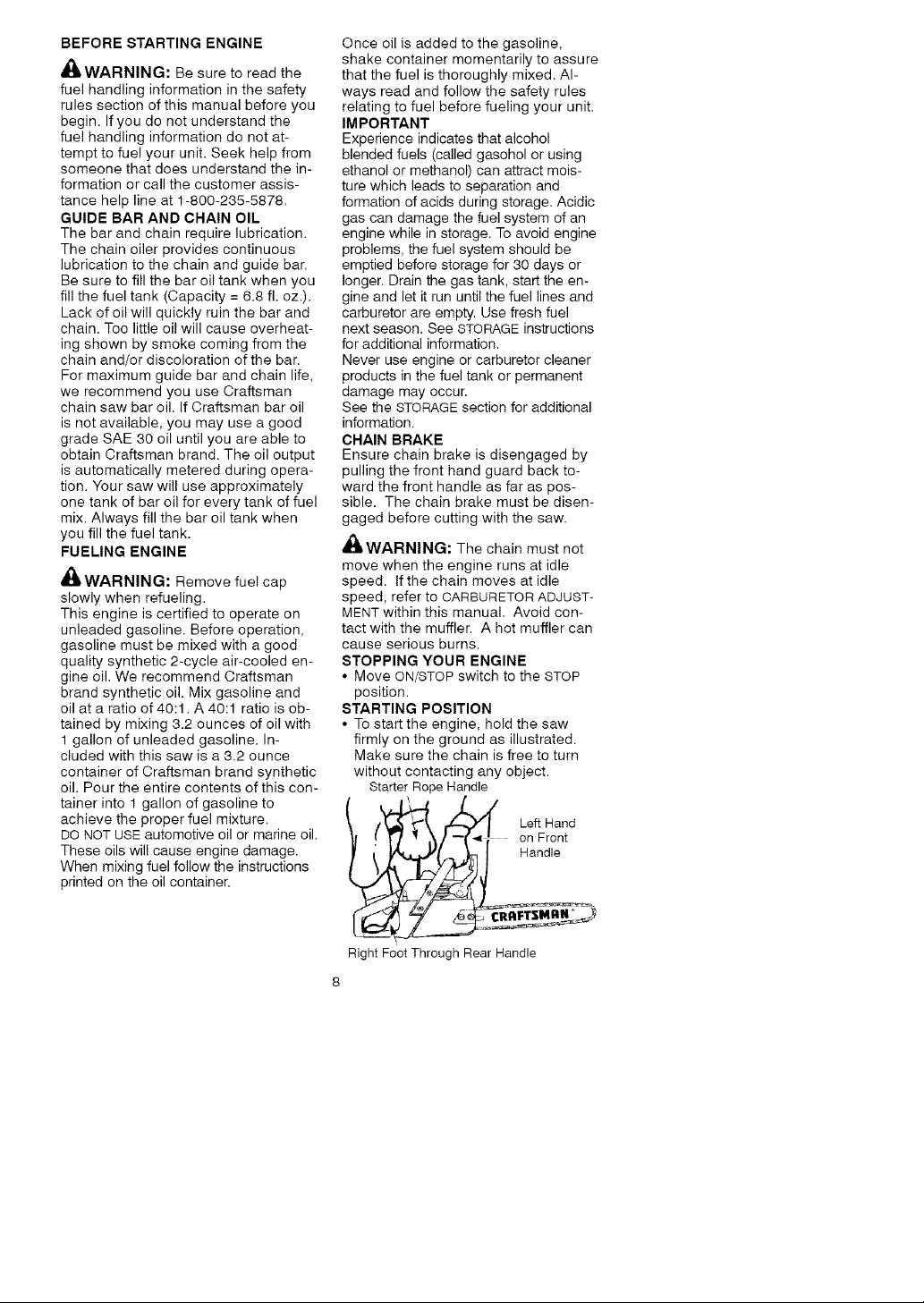

STARTING POSITION

• To start the engine, hold the saw

firmly on the ground as illustrated.

Make sure the chain is free to turn

without contacting any object.

Starter Rope Handle

'_ t'_ Left Hand

Right Foot Through Rear Handle

IMPORTANT POINTS TO REMEMBER

When pulling the starter rope, do not

use the full extent of the rope as this

can cause the rope to break. Do not let

starter rope snap back. Hold the han-

dle and let the rope rewind slowly.

For cold weather starting, start the unit

at FULL CHOKE; allow the engine to

warm up before squeezing the throttle

trigger.

NOTE: DO NOT attempt to cut material

with the choke/fast idle lever in the

FULL CHOKE position.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

NOTE: In the following steps, when

the choke/fast idle lever is pulled out to

the full extent, the correct throttle set-

ting for starting is set automatically.

ON/STOP SWITCH

(_SIDE VIEW)

ON

" ~'2' STOP

1. Move ON/STOP switch to ON posi-

tion.

2. Pull choke knob out to the full ex-

tent (to the FULL CHOKE position).

3. Slowly press primer bulb 6 times.

4. Pull the starter rope quickly with

your right hand 5 times. Then, pro-

ceed to the next step.

NOTE: If the engine sounds as if it is

trying to start before the 5th pull, stop

pulling and immediately proceed to the

next step.

5. Push the choke/fast idle lever in to

the HALF CHOKE position.

CHOKE/FAST IDLE LEVER

o_IEW)

Ch _

fast idte lever OFF HALF FULL

6. Pull the starter rope quickly with your

right hand until the engine starts.

7. Allow the engine to run for approxi-

mately 5 seconds. Then, squeeze

and release throttle trigger to allow

engine to return to idle speed.

STARTING A WARM ENGINE

1. Move ON/STOP switch to the ON

position.

2. Pull the choke/fast idle lever out to

the HALF CHOKE position.

_ @"_l,= D@%li

3. Slowly press primer bulb 6 times.

4. Pull the starter rope quickly with your

right hand until the engine starts.

5. Squeeze and release throttle trig-

ger, allowing engine to return to

idle speed.

DIFFICULT STARTING (or starting a

flooded engine)

The engine may be flooded if it has not

started after 10 pulls. Flooded engines

can be cleared of excess fuel by push-

ing the choke/fast idle lever in com-

pletely (to the OFF CHOKE position)

and then following the warm engine

starting procedure listed above. En-

sure the ON/STOP switch is in the ON

position. Starting could require many

pulls depending on how badly the unit

is flooded. If engine still fails to start,

refer to the TROUBLESHOOTING TABLE

or call 1-800-235-5878.

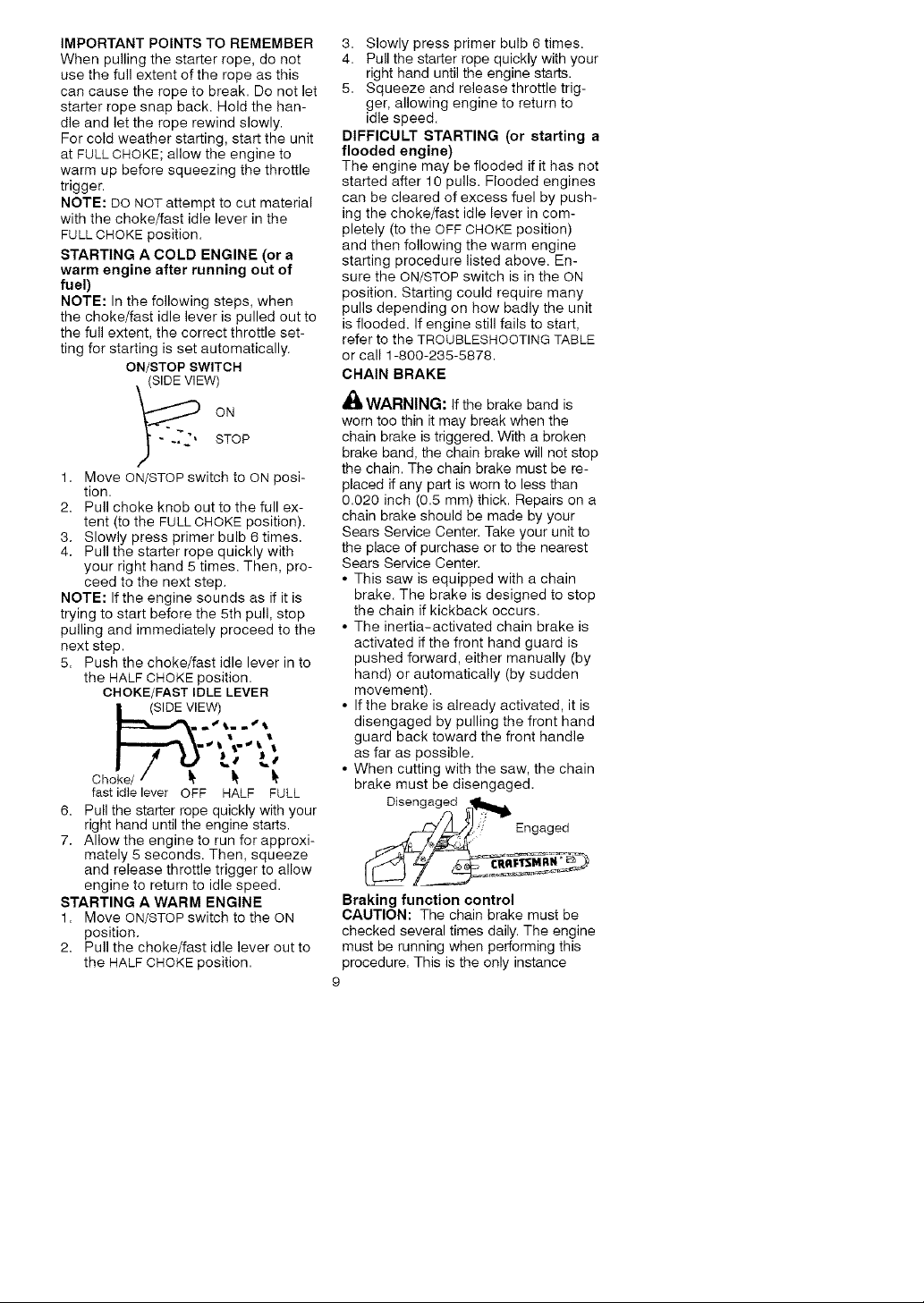

CHAIN BRAKE

WARNING: If the brake band is

worn too thin it may break when the

chain brake is triggered. With a broken

brake band, the chain brake will not stop

the chain. The chain brake must be re-

placed if any part is worn to less than

0.020 inch (0.5 ram) thick. Repairs on a

chain brake should be made by your

Sears Service Center. Take your unit to

the place of purchase or to the nearest

Sears Service Center.

• This saw is equipped with a chain

brake. The brake is designed to stop

the chain if kickback occurs.

• The inertia-activated chain brake is

activated if the front hand guard is

pushed forward, either manually (by

hand) or automatically (by sudden

movement).

• If the brake is already activated, it is

disengaged by pulling the front hand

guard back toward the front handle

as far as possible.

• When cutting with the saw, the chain

brake must be disengaged.

Disengaged 'tlm._.

Braking function control

CAUTION: The chain brake must be

checked several times daily. The engine

must be running when performing this

procedure. This is the only instance

9

whenthesawshouldbeplacedonthe

groundwiththeenginerunning.

Placethesawonfirmground.Gripthe

rearhandlewithyourrighthandand

thefronthandlewithyourlefthand.

Applyfullthrottlebyfullydepressing

thethrottletrigger.Activatethechain

brakebyturningyourleftwristagainst

thehandguardwithoutreleasingyour

griparoundthefronthandle.Thechain

shouldstopimmediately.

Inertiaactivating function control

_.WARNING: When performing the

following procedure, the engine must

be turned off.

Grip the rear handle with your right hand

and the front handle with your left hand.

Hold the chain saw approximately 14"

(35 cm) above a stump or other wood-

en surface. Release your grip on the

front handle and let the tip of the guide

bar fall forward and contact the stump.

When the tip of the bar hits the stump,

the brake should activate.

OPERATING TIPS

• Check chain tension before first use

and after 1 minute of operation. See

CHAIN TENSION in the MAINTENANCE

section.

• Cut wood only. Do not cut metal,

plastics, masonry, non-wood building

materials, etc.

• Stop the saw if the chain strikes a

foreign object. Inspect the saw and

repair parts as necessary.

• Keep the chain out of dirt and sand.

Even a small amount of dirt will

quickly dull a chain and increase the

possibility of kickback.

• Practice cutting a few small logs using

the following steps. This will help you

get the "feel" of using your saw before

you begin a major sawing operation.

• Squeeze the throttle trigger and al-

low the engine to reach full speed

before cutting.

• Begin cutting with the saw frame

against the log.

• Keep the engine at full speed the

entire time you are cutting.

• Allow the chain to cut for you. Exert

only light downward pressure.

• Release the throttle trigger as soon

as the cut is completed, allowing

the engine to idle. If you run the

saw at full throttle without a cutting

load, unnecessary wear can occur.

It is recommended that the en-

gine not be operated for longer

than 30 seconds at full throttle.

• To avoid losing control when cut is

complete, do not put pressure on

saw at end of cut.

• Stop engine before setting saw down.

TREE FELLING TECHNIQUES

_WARNING: Check for broken or

dead branches which can fall while

cutting causing serious injury. Do not

cut near buildings or electrical wires if

you do not know the direction of tree

fall, nor cut at night since you will not

be able to see well, nor during bad

weather such as rain, snow, or strong

winds, etc. If the tree does make con-

tact with any utility line, the utility com-

pany should be notified immediately.

• Carefully plan your sawing operation

in advance.

• Clear the work area. You need a

clear area all around the tree so you

can have secure footing.

• The chain saw operator should keep

on the uphill side of the terrain as the

tree is likely to roll or slide downhill

after it is felled.

• Study the natural conditions that can

cause the tree to fall in a particular

direction. These conditions include:

• The wind direction and speed.

• The lean of the tree. The lean of a

tree might not be apparent due to

uneven or sloping terrain. Use a

plumb or level to determine the di-

rection of tree lean.

• Weight and branches on one side.

• Surrounding trees and obstacles.

• Look for decay and rot. If the trunk is

rotted, it can snap and fall toward the

operator.

• Make sure there is enough room for

the tree to fall. Maintain a distance of

2-1/2 tree lengths from the nearest

person or other objects. Engine

noise can drown out a warning call.

• Remove dirt, stones, loose bark,

nails, staples, and wire from the tree

where cuts are to be made.

10

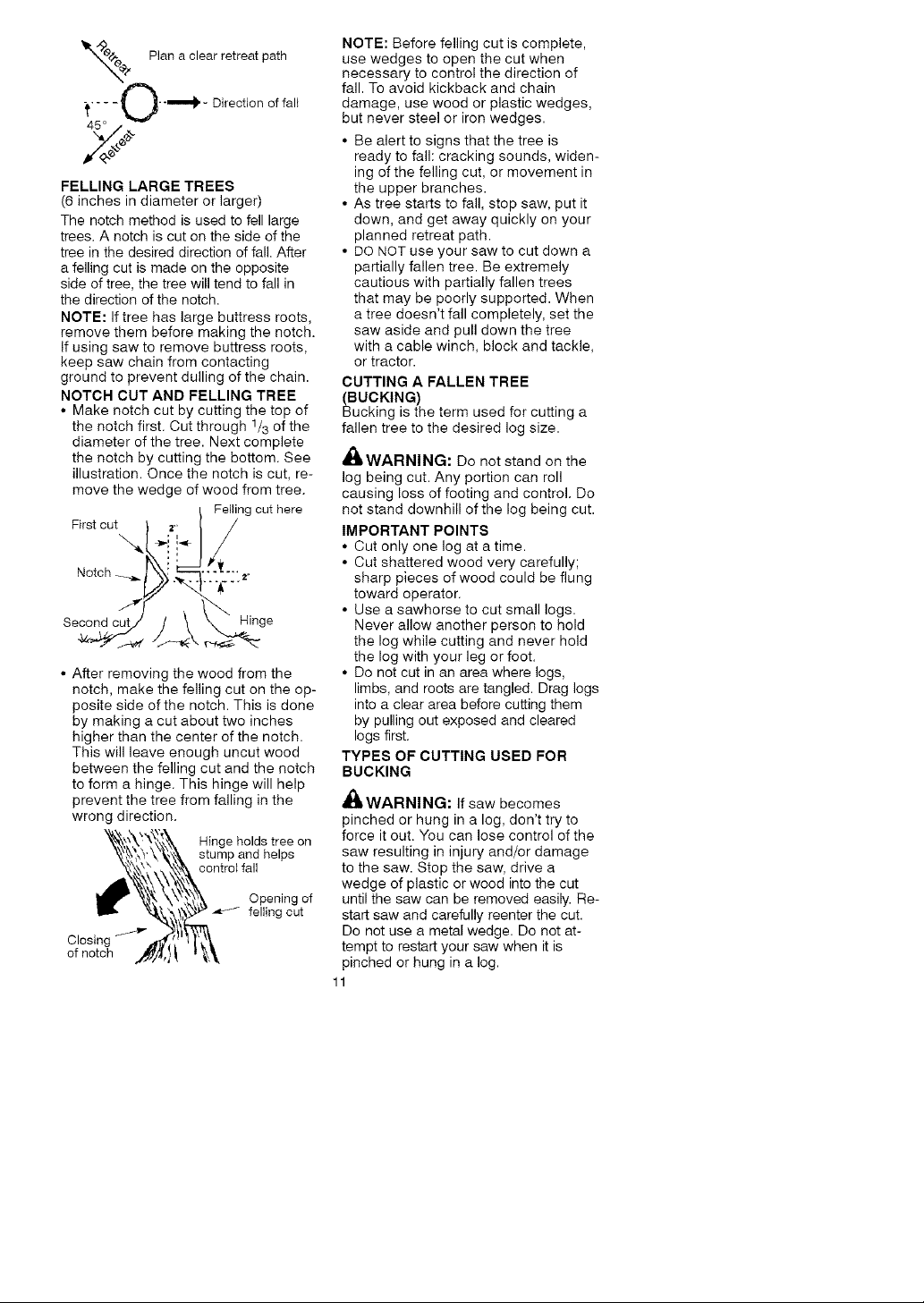

o_zPlanaclearretreatpath

.... _. J--_'- Directionoffall

45°/

",./"e¢

FELLING LARGE TREES

(6 inches in diameter or larger)

The notch method is used to fell large

trees. A notch is cut on the side of the

tree in the desired direction of fall. After

a felling cut is made on the opposite

side of tree, the tree will tend to fall in

the direction of the notch.

NOTE: If tree has large buttress roots,

remove them before making the notch.

If using saw to remove buttress roots,

keep saw chain from contacting

ground to prevent dulling of the chain.

NOTCH CUT AND FELLING TREE

• Make notch cut by cutting the top of

the notch first. Cut through 1/3 of the

diameter of the tree. Next complete

the notch by cutting the bottom. See

illustration. Once the notch is cut, re-

move the wedge of wood from tree.

Firstcut

Secondcut_"/ t

• After removing the wood from the

notch, make the felling cut on the op-

posite side of the notch. This is done

by making a cut about two inches

higher than the center of the notch.

This will leave enough uncut wood

between the felling cut and the notch

to form a hinge. This hinge will help

prevent the tree from falling in the

wrong direction.

Closing

of notch

Felling cut here

Hinge holds tree on

stump and helps

control fall

Opening of

felling cut

NOTE: Before felling cut is complete,

use wedges to open the cut when

necessary to control the direction of

fall. To avoid kickback and chain

damage, use wood or plastic wedges,

but never steel or iron wedges.

• Be alert to signs that the tree is

ready to fall: cracking sounds, widen-

ing of the felling cut, or movement in

the upper branches.

• As tree starts to fall, stop saw, put it

down, and get away quickly on your

planned retreat path.

• DO NOT use your saw to cut down a

partially fallen tree. Be extremely

cautious with partially fallen trees

that may be poorly supported. When

a tree doesn't fall completely, set the

saw aside and pull down the tree

with a cable winch, block and tackle,

or tractor.

CUTTING A FALLEN TREE

(BUCKING)

Bucking is tile term used for cutting a

fallen tree to the desired log size.

&WARNING: Do not stand on the

log being cut. Any portion can roll

causing loss of footing and control. Do

not stand downhill of the log being cut.

IMPORTANT POINTS

• Cut only one log at a time.

• Cut shattered wood very carefully;

sharp pieces of wood could be flung

toward operator.

• Use a sawhorse to cut small logs.

Never allow another person to hold

the log while cutting and never hold

the log with your leg or foot.

• Do not cut in an area where logs,

limbs, and roots are tangled. Drag logs

into a clear area before cutting them

by pulling out exposed and cleared

logs first.

TYPES OF CUTTING USED FOR

BUCKING

A

,I_ WARNING: If saw becomes

pinched or hung in a log, don't try to

force it out. You can lose control of the

saw resulting in injury and/or damage

to the saw. Stop the saw, drive a

wedge of plastic or wood into the cut

until the saw can be removed easily. Re-

start saw and carefully reenter the cut.

Do not use a metal wedge. Do not at-

tempt to restart your saw when it is

pinched or hung in a log.

11

Use a wedge to remove pinched saw

Turn saw OFF and use a plastic or

wooden wedge to force cut open.

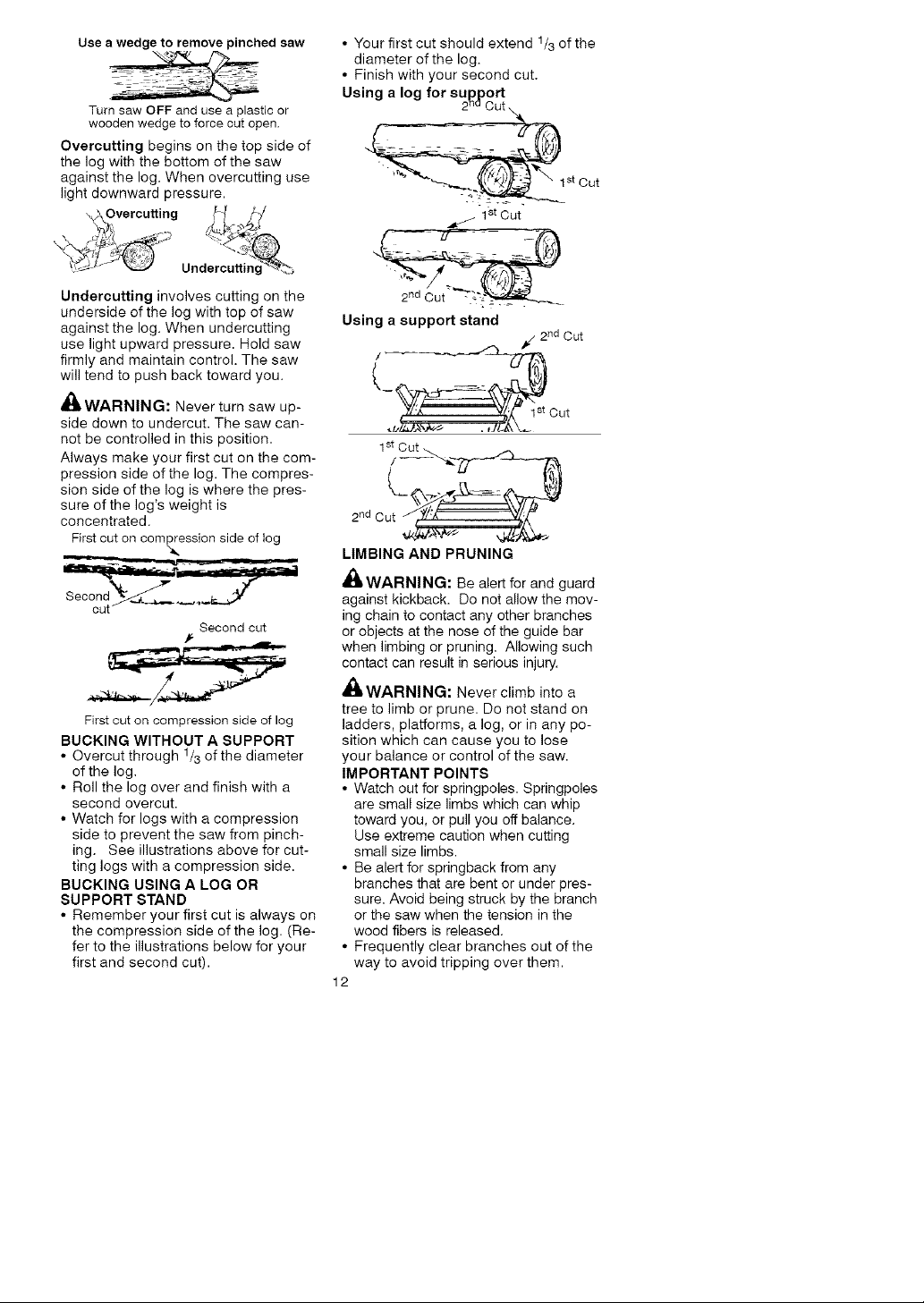

Overcutting begins on the top side of

the log with the bottom of the saw

against the log. When overcutting use

light downward pressure.

,_.Overcutting ,j_ _/_/

Undercutting involves cutting on the

underside of the log with top of saw

against the log. When undercutting

use light upward pressure. Hold saw

firmly and maintain control. The saw

will tend to push back toward you.

WARNING: Never turn saw up-

side down to undercut, The saw can-

not be controlled in this position.

Always make your first cut on the com-

pression side of the log. The compres-

sion side of the log is where the pres-

sure of the log's weight is

concentrated.

Firstcut on compression side of log

Second cut

First cut on compression side of log

BUCKING WITHOUT A SUPPORT

• Overcut through /3 of the diameter

1

of the log.

• Roll the log over and finish with a

second overcut.

• Watch for logs with a compression

side to prevent the saw from pinch-

ing. See illustrations above for cut-

ting logs with a compression side.

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut is always on

the compression side of the log. (Re-

fer to the illustrations below for your

first and second cut).

• Your first cut should extend 1/3 of the

diameter of the log.

• Finish with your second cut.

Using a log for support

2na Cut

I st Cut

1st Cut

Using a support stand

_/2 ndCut

__Cut

1st/Cut _..,_

LIMBING AND PRUNING

_lJ WARNING: Be alert for and guard

against kickback. Do not allow the mov-

ing chain to contact any other branches

or objects at the nose of the guide bar

when limbing or pruning. Allowing such

contact can result in serious injury.

,_ WARNING: Never climb into a

tree to limb or prune. Do not stand on

ladders, platforms, a log, or in any po-

sition which can cause you to lose

your balance or control of the saw.

IMPORTANT POINTS

• Watch out for springpoles. Springpoles

are small size limbs which can whip

toward you, or pull you off balance.

Use extreme caution when cutting

small size limbs.

• Be alert for springback from any

branches that are bent or under pres-

sure. Avoid being struck by the branch

or the saw when the tension in the

wood fibers is released.

• Frequently clear branches out of the

way to avoid tripping over them.

12

LIMBING

• Limbatreeonlyafteritiscutdown.

• Leavethelargerlimbsunderneaththe

felledtreetosupportthetreeasyou

work.

• Startatthebaseofthefelledtree

andworktowardthetop,cutting

branchesandlimbs.Removesmall

limbswithonecut.

• Keepthetreebetweenyouandthe

chain.

• Removelargerbrancheswiththe

cuttingtechniquesdescribedin

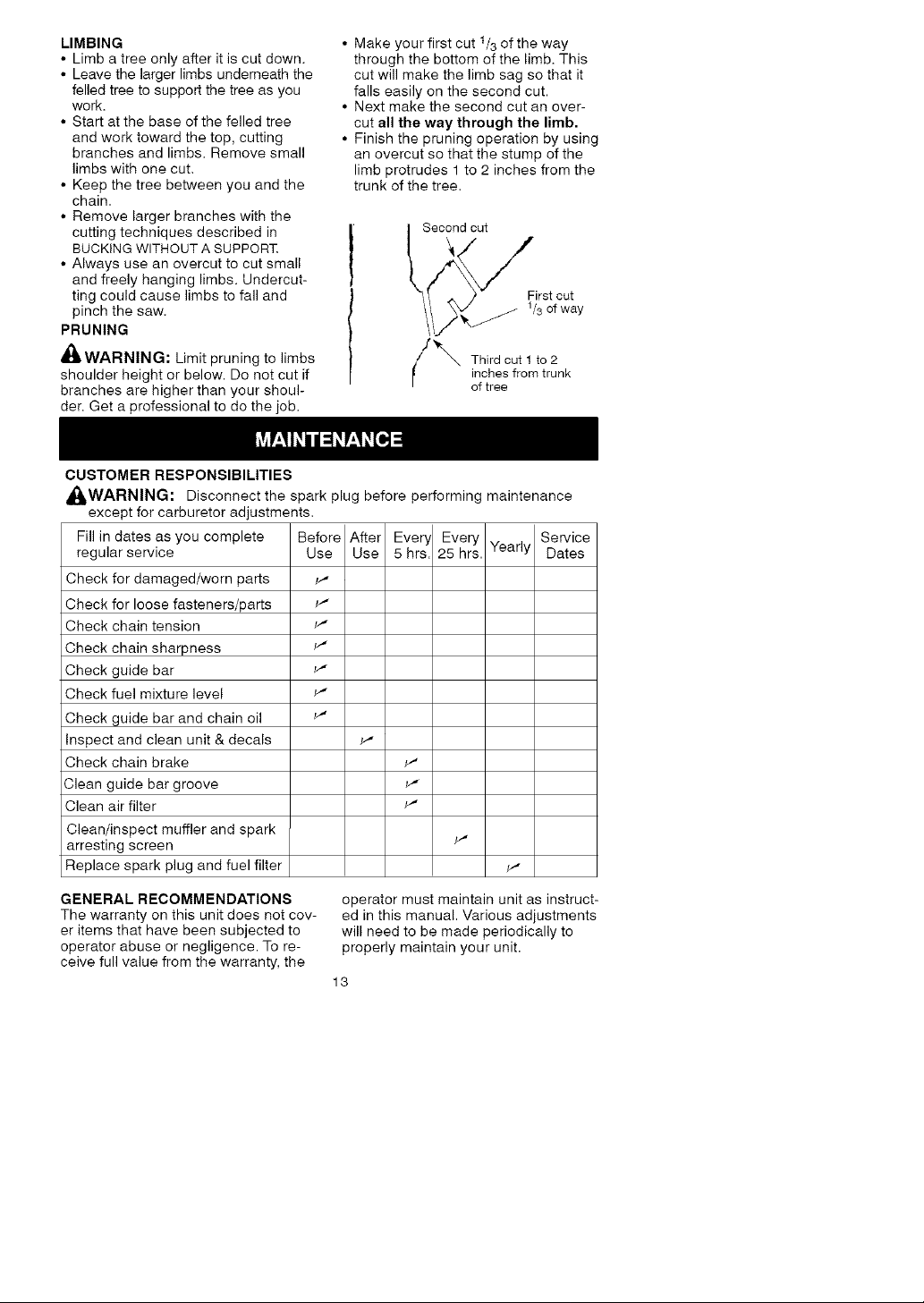

• Make your first cut t/3 of the way

through the bottom of the limb. This

cut will make the limb sag so that it

falls easily on the second cut.

• Next make the second cut an over-

cut all the way through the limb.

• Finish the pruning operation by using

an overcut so that the stump of the

limb protrudes 1 to 2 inches from the

trunk of the tree.

out

BUCKINGWITHOUTASUPPORT.

• Alwaysuseanovercuttocutsmall

andfreelyhanginglimbs.Undercut-

tingcouldcauselimbstofalland

pinchthesaw.

PRUNING

_WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoul-

der. Get a professional to do the job.

CUSTOMER RESPONSIBILITIES

_WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

Fill in dates as you complete Before After Ever Every Service

regular service Use Use 5 hrs. 25 hrs. Yearly Dates

Check for damaged/worn parts _,'

Check for loose fasteners/parts _"

Check chain tension _"

Check chain sharpness _"

Check guide bar _"

Check fuel mixture level _"

Check guide bar and chain oil _"

Inspect and clean unit & decals _"

Check chain brake _"

Clean guide bar groove _"

Clean air filter _"

Clean/inspect muffler and spark

arresting screen _"

Replace spark plug and fuel filter _,'

ISecond First cut

1/3 of way

/_ hird cut 1 to 2

inches from trunk

of tree

GENERAL RECOMMENDATIONS

The warranty on this unit does not cov-

er items that have been subjected to

operator abuse or negligence. To re-

ceive full value from the warranty, the

operator must maintain unit as instruct-

ed in this manual. Various adjustments

will need to be made periodically to

properly maintain your unit.

13

• Onceayear,replacethesparkplug,

airfilterelement,andcheckguidebar

andchainforwear.Anewsparkplug

andairfilterelementassuresproper

air-fuelmixtureandhelpsyourengine

runbetterandlastlonger.

CHECKFORDAMAGEDOR

WORNPARTS

ContactSearsServiceCenterforre-

placementofdamagedorwornparts.

NOTE:Itisnormalforasmallamount

ofoiltoappearunderthesawafteren-

gine stops. Do not confuse this with a

leaking oil tank.

• ON/STOP Switch - Ensure ON/STOP

switch functions properly by moving

the switch to the STOP position.

Make sure engine stops; then restart

engine and continue.

• Fuel Tank - Do not use saw if fuel

tank shows signs of damage or leaks.

• Oil Tank - Do not use saw if oil tank

shows signs of damage or leaks.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Chain Brake Nuts

• Chain

• Muffler

• Cylinder Shield

• Air Filter

• Handle Screws

• Vibration Mounts

• Starter Housing

• Front Hand Guard

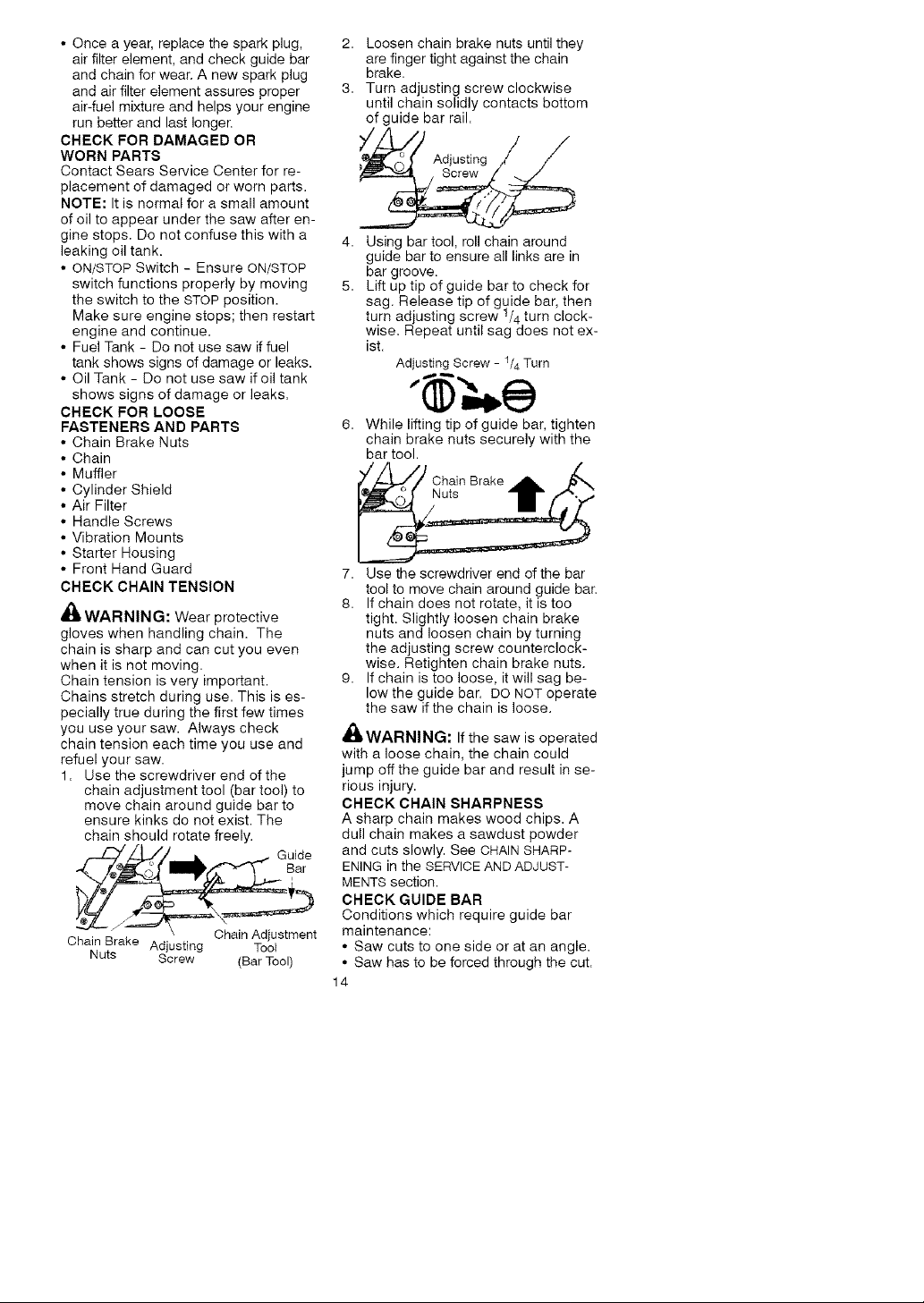

CHECK CHAIN TENSION

WARNING: Wear protective

gloves when handling chain. The

chain is sharp and can cut you even

when it is not moving.

Chain tension is very important.

Chains stretch during use. This is es-

pecially true during the first few times

you use your saw. Always check

chain tension each time you use and

refuel your saw.

1. Use the screwdriver end of the

chain adjustment tool (bar tool) to

move chain around guide bar to

ensure kinks do not exist. The

chain should rotate freely.

f-_ .S_,/,._IIL Guide

• \ Chain Adjustment

Chain Brake Adjusting Tool

Nuts Screw (Bar Tool)

2. Loosen chain brake nuts until they

are finger tight against the chain

brake.

3. Turn adjusting screw clockwise

until chain solidly contacts bottom

of guide bar rail.

4. Using bar tool, roll chain around

guide bar to ensure all links are in

bar groove.

5. Lift up tip of guide bar to check for

sag. Release tip of guide bar, then

turn adjusting screw 1/4turn clock-

wise. Repeat until sag does not ex-

ist.

Adjusting Screw - 1/4Turn

6. While lifting tip of guide bar, tighten

chain brake nuts securely with the

bar tool.

YJ_///Chah_ Brake .,d_ .t_

7. Use the screwdriver end of the bar

tool to move chain around guide bar.

8. If chain does not rotate, it is too

tight. Slightly loosen chain brake

nuts and loosen chain by turning

the adjusting screw counterclock-

wise. Retighten chain brake nuts.

9. If chain is too loose, it will sag be-

low the guide bar. DO NOT operate

the saw if the chain is loose.

WARNING: If the saw is operated

with a loose chain, the chain could

jump offthe guide bar and result in se-

rious injury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A

dull chain makes a sawdust powder

and cuts slowly. See CHAIN SHARP-

ENING in the SERVICE AND ADJUST-

MENTS section.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

14

• Inadequatesupplyofoiltobar/chain.

Checktheconditionofguidebareach

timechainissharpened.Awornguide

barwilldamagethechainandmake

cuttingdifficult.

Aftereachuse,ensureON/STOP

switchisintheSTOPposition,then

cleanallsawdustfromtheguidebar

andsprockethole.

Tomaintainguidebar:

• MoveON/STOPswitchtoSTOP.

• Loosenandremovechainbrake

nutsandchainbrake.Removebar

andchainfromsaw.

• Cleantheoilholesandbargroove

aftereach5hoursofoperation.

RemoveSawdustFrom

GuideBarGroove

\

• Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

• When rail top is uneven, use a flat

file to restore square edges and

sides.

7_LjT_ File Rail Edges_r] r]

Worn Groove Correct Groove

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of

the rails occurs. If replacement is nec-

essary, use only the guide bar speci-

fied for your saw in the repair parts list

or on the decal located on the chain

saw.

CHECK FUEL MIXTURE LEVEL

• See FUELING ENGINE under the OP-

ERATION section.

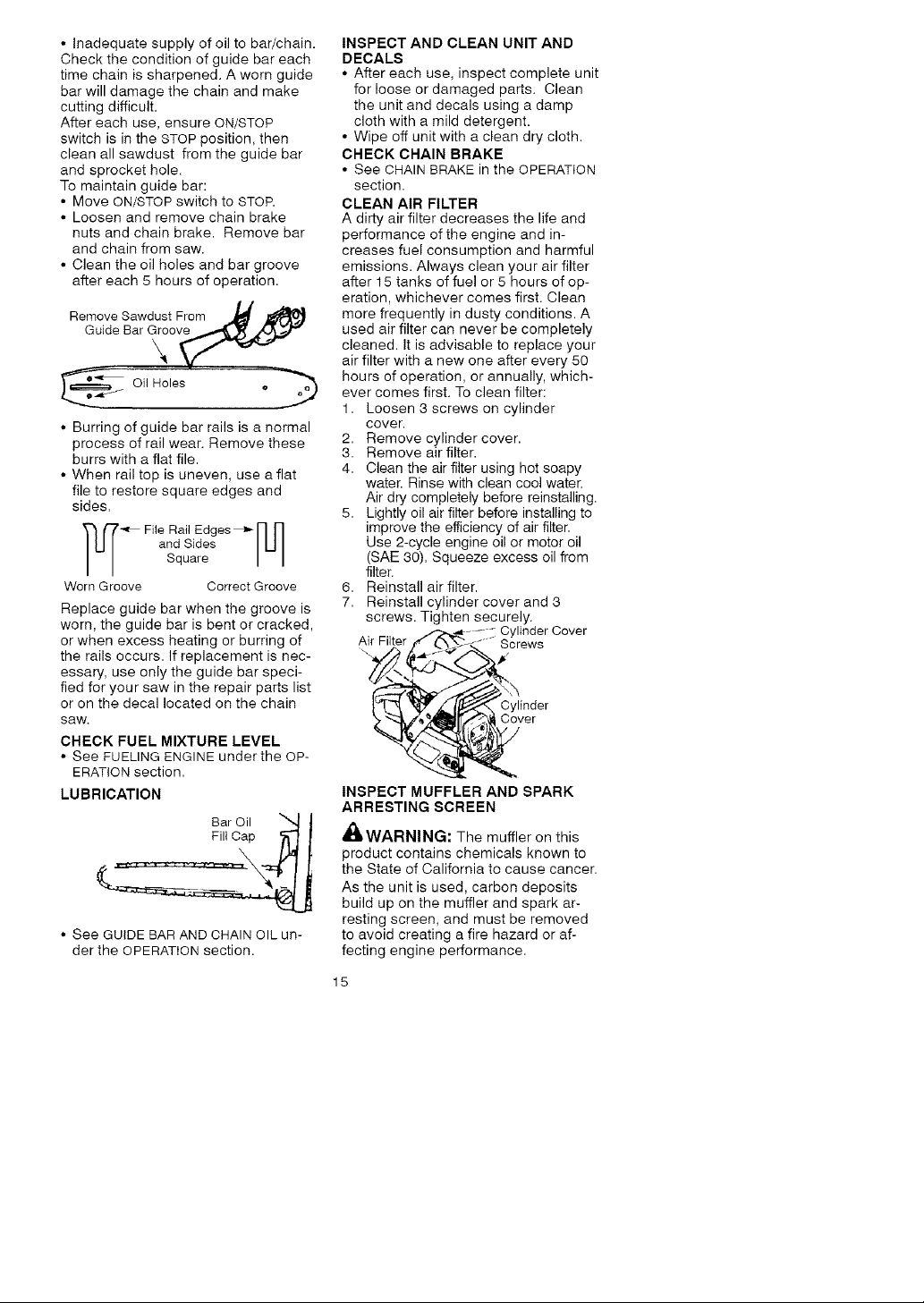

LUBRICATION

• See GUIDE BAR AND CHAIN OIL un-

der the OPERATION section.

and Sides [ U [

square [ ]

Bar Oil

Fill Cap _

INSPECT AND CLEAN UNIT AND

DECALS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit and decals using a damp

cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

CHECK CHAIN BRAKE

• See CHAIN BRAKE in the OPERATION

section.

CLEAN AIR FILTER

A dirty air filter decreases the life and

performance of the engine and in-

creases fuel consumption and harmful

emissions. Always clean your air filter

after 15 tanks of fuel or 5 hours of op-

eration, whichever comes first. Clean

more frequently in dusty conditions. A

used air filter can never be completely

cleaned. It is advisable to replace your

air filter with a new one after every 50

hours of operation, or annually, which-

ever comes first. To clean filter:

1. Loosen 3 screws on cylinder

cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean the air filter using hot soapy

water. Rinse with clean cool water.

Air dry completely before reinstalling.

5. Lightly oil air filter before installing to

improve the efficiency of air filter.

Use 2-cycle engine oil or motor oil

(SAE 30). Squeeze excess oil from

filter.

6. Reinstall air filter.

7. Reinstall cylinder cover and 3

screws. Tighten securely.

Air Filter Screws

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_IWARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As the unit is used, carbon deposits

build up on the muffler and spark ar-

resting screen, and must be removed

to avoid creating a fire hazard or af-

fecting engine performance.

15

..,_-- _Cylinder Cover

ver

Loading...

Loading...