Craftsman 358356332, 358356281 Owner’s Manual

IMPORTANT MA_-_AL

Operator's

Manual

• Assembly

Operation

• Maintenance

• Repair Parts

Do Not Throw Away

IIIIIIIIII II I i iii iiiiiiii iiiiiiii ij ii

MODEL NO.

358356281-2.8118"

358.356332,3.3120"

d_WARNING:

Carefully read and follow

Safety Rules, Precautions

and Operating instructions.

Failure to do so can result

in serious personal injury.

/C.RFIFTSMFIN,

2.8118" 33/20"

GASOLI NE CHAIN SAW

...................... ., ..... ,, ,- 1'- , ,,,, , ' i"

Record in the space provided below the Model No. and Serial No. of

your saw. These numbers are located on the starting instructions

decal.

Model No. Serial No.

Retain these numbers for future reference.

- k

Sold by Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

.... L i i -. ,,,,, ,

530.081372-2-09/15/93 © 1993, Sears, Roebuck and (20.

•• / | j • i i, ii

FULL ONE YEAR WARRANTY ON GASOLINE CHAIN SAW :__

(Excluding Bar, Chain, Spark Plush Air Filter and Starter RoPe)

For one year from date of purchase, when you maintain, lubncate, and tune up this chain saw according to the operating arid mam-

_nance instructions in the o.pe.ra,tor's,manual, Sears wifl repair defects in material or workmanship in this gasoline chain saw at no

cnarge. Ihiswarranty excludes oar, cnain, spark plug, air flRer, and starter rope which are expendable parts and become w0m our ng

normal use.

if this chain saw is used for commercial or rental purposes, this warranty does not apply.

WARRANTY SERVICE ISAVAILABLEBY REDJRNiNG THE CHAIN SAW TO THE NEAREST SEARS SERVICE CENTER/DEPARTMENT

IN THE UNITED STATES,

This warranty gives you specific legal dghts, and you may also have other rights which vary from state to state.

_>e_. .................... ....... Sears, ,Roebuck and Co., Dept. D/731-CR.W, Sears Tower, Ch!cago, !L 60684

Sold by Sears, Roebuck and Co., Dept. D/817W_ Hoffinan Estate, IL 60179 USA . _

TABLE OF CONTENTS

Specifications ............................... 2

SPECIAL SAFETY SECTION ..................... 3

Know Your Chain Saw 6

Preparing Your Saw For Use ................... 7

Accessories ......... _.......... ............ .1()

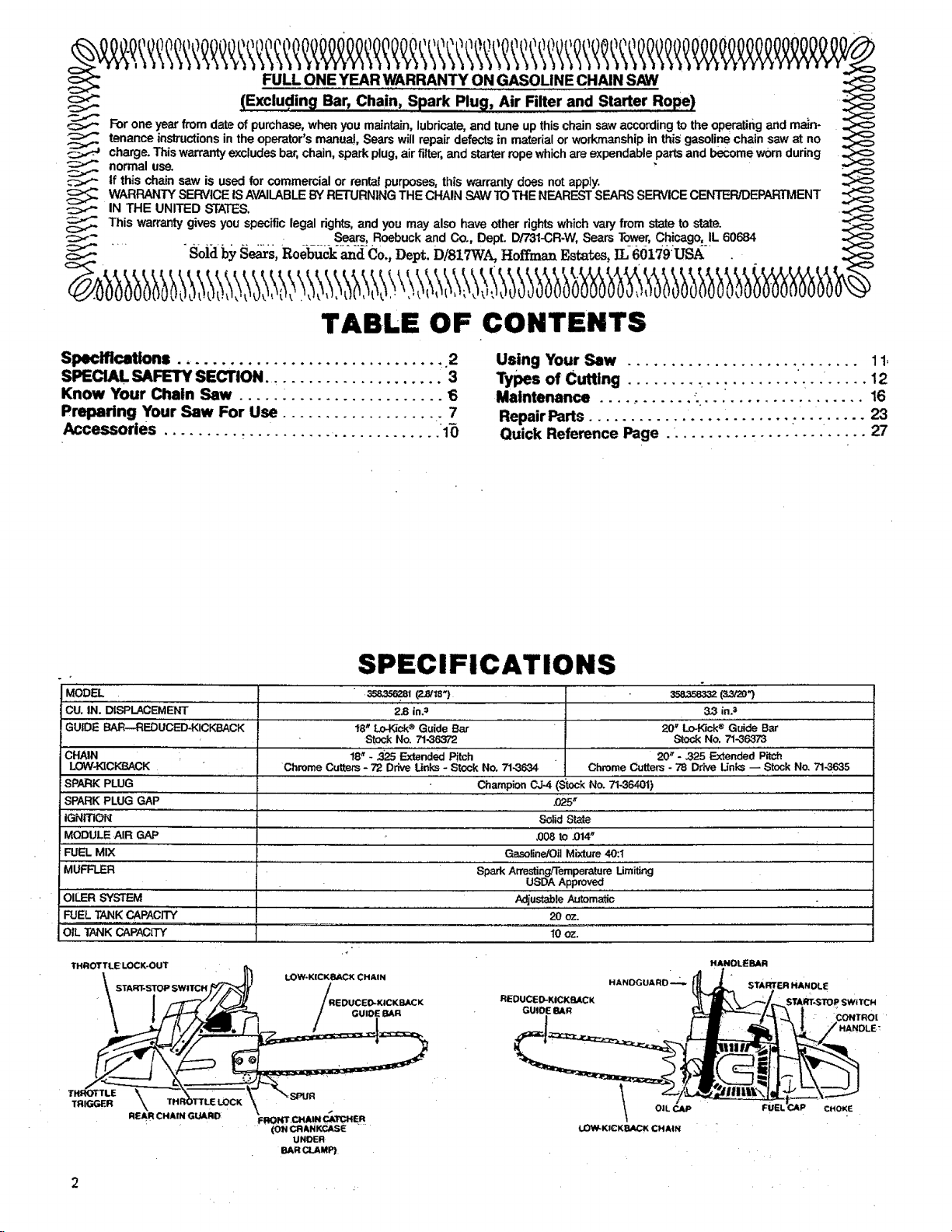

SPECIFICATIONS

3583ss2_ (2_;}

CU, IN. DISPLACEMENT

GU_D__--_UC_mCK_K' '

CHAIN

LOW-KICKE_CK

SPARKPLUG

SPARKPLUG GAP

iGNITiON

MODULE.AIRGAP

FUEL MIX

MUFFLER

,,, _ • , .......

OIL TANKCAPAX3WY

................... , , ,: ,

Chrome Cut_rs - 72 Drive Unks- StockNo. 71.3634

2.8 in._

18" Lo._ck® GuideBar

StockNo. 71-36372

!8" - 325 ExtendedPitch

Using Your Saw ........................... 11,

TyPes of Cutting ' " 12

Maintenance ........... : ................... 16

Repair Parts 23

Quick Reference Page " 27

33 in.=

20_Lo-Kick® Guide Bar

Stock No, 71-36373

ChromeCutters - 78 Drive Unks_ StockNo.71-3635

Champion CJ-4 (StOCkNo. 71-36401)

.025_

20_- 325 ExtendedPitch

......... s0:i_"_

,008tO.0i4"

Gasofine/OitMixture"40'it................

SparkArresting/TemperatureUmiting

USDA Approv.ed..............

AdjustableAutomatic

20 oz.

10oz.

THROTTLELOCK-OUT HANDLEBAR

START-STOP SW|TCH •

TRIGGER

LOW-KICK_C_ CHAIN HANOGUARD ---;,- STARTERHANDLE

REDUCE D-KICK_J_,CK START-STOP SWITCH

FRONT,CHA!N C_kTCHER

(ON CR AN¥,£TJkSE

UNDER

BARClAMP)

GUIDE BAR GU_tDE BAR CONTROl

2

FUEL CHOK_

! , ......... .IHI ii i iiii ,,,, ,,,,,,,,,,,,,,,,

SPECIAL SAFETY SECTION

,,,,,,,,,,,,,,,,,,,,,! ,,, ..............,=, ,, || i

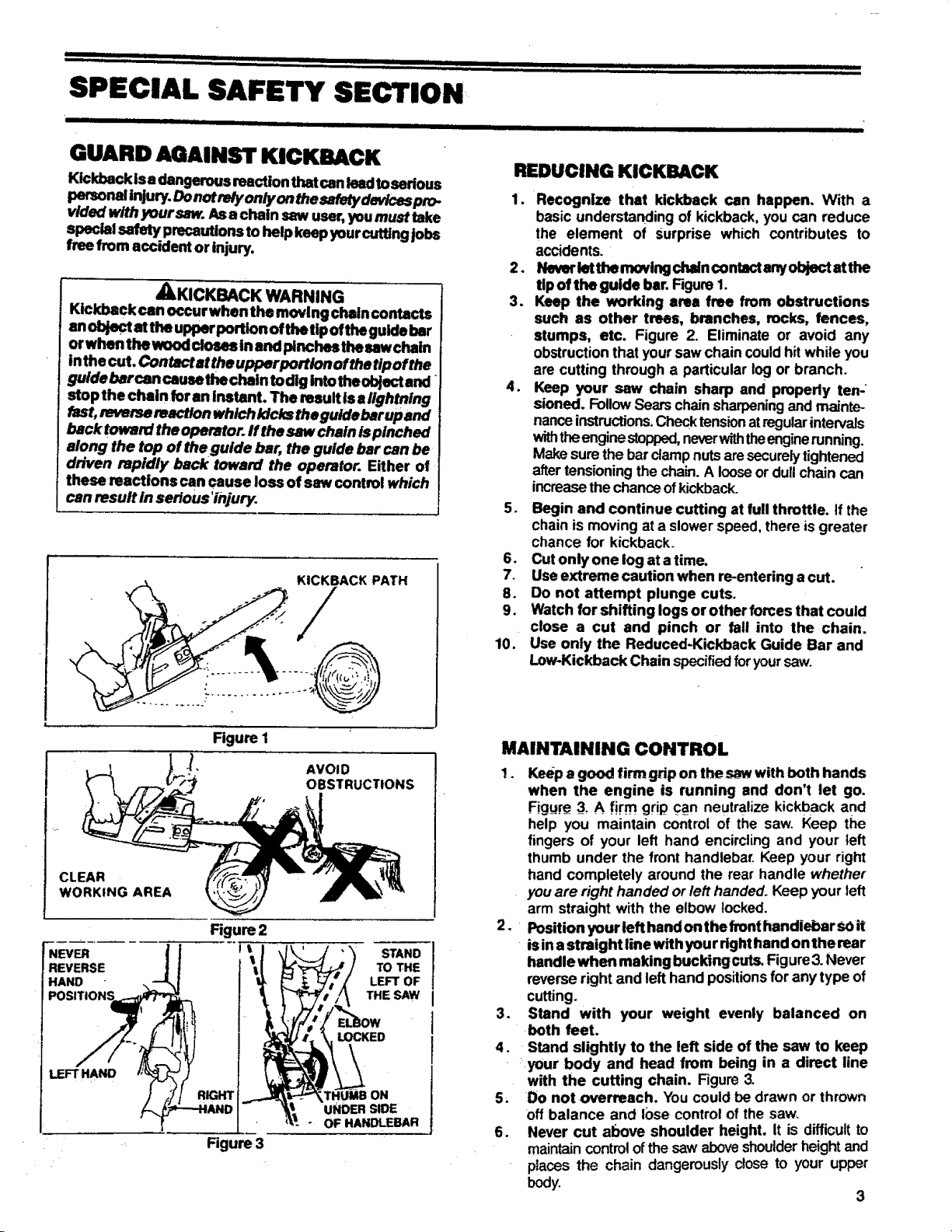

GUARD AGAINST KICKBACK

Kickback isadangerousreac onthatcanmeadtoserous

personalinjury.Donotretyonlyonthesafefydevicespro-

v/ded w/th yoursaw. Asa chain saw user, you must take

special safety precautionsto helpkeep yourcuttingjobs

free from accident or injury.

AKICKBACK WARNING

Kickback can occur when the moving chain contacts

an _ atthe upperportionofthetipoftheguide bar

orwhen thewood €loses inand ptncheethesew chain

inthe cut, Contact at the upper portton of thetip ofthe

guide barcan causethe chain todig intotheobject and

stop the chain for an Instant. The result is slightning

fast,reverse reaction which k_ckstheguide barupand

back toward the operator, ff the saw chain ispinched

along the top of the gulde bar, the guide bar can be

driven rapidly back toward the operator. Either of

these reactions can cause loss of saw control which

can result in serious 'injury.

KICKBACK PATH

/

REDUCING KICKBACK

1. Recognize that kickback can happen. With a

basic understanding of kickback, you can reduce

the element of Surprise which contributes to

accidents.

2. Neveriat themoving chain €ontactanyobject atthe

Up of the guide bar. Figure1.

3. Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Figure 2. Eliminate or avoid any

obstructionthat yoursaw chain couldhit while you

are cutting through a particular logor branch.

4. Keep your saw chain sharp and properly ten-

sioned. FollowSearschainsharpeningand mainte-

nanceinstructions.Checktensionat regular intervals

withtheenginestopped,neverwiththeenginerunning.

Makesure the barclampnutsaresecurelytightened

aftertensioningthe chain.A looseor dull chaincan

increasethe chanceof kickback.

5. Begin and continue cutting at lull throttle, if the

chain is moving at a slowerspeed, there isgreater

chance for kickback.

6. Cut only one log at a time.

7. Useextreme caution when re-entering a cut.

8. Do not attempt plunge cuts.

9. Watch for shifting logs orotherforces that could

close a cut and pinch or fail into the chain.

10. Use only the Reduced-Kickback Guide Bar and

Low.Kickback Chain specifiedforyoursaw.

CLEAR

WORKING AREA

NEVER

REVERSE

HAND

LEFTHAND

Figure I

Figure 2

!

Figure 31

AVOID

OBSTRUCTIONS

STAND

TO THE

LEFT OF

THE SAW

LOCKED

UNOF.RSlOe

OF HANDLEBAR

MAINTAINING CONTROL

1. Keep a good firm gdp on the saw with both hands

when the engine is running and don't let go.

Figu_r_e3, A firm grip can neutralize kickback and

help you maintain control of the saw. Keep the

fingers of your left hand encircling and your left

thumb under the front handlebar. Keep your right

hand completely around the rear handle whether

you are right handed or left handed. Keep your left

arm straight with the elbow locked.

2. Position your left handon the front handlebar SOit

isin astreight line with your dghthand onthe rear

handle when making bucking cuts. Figure3. Never

reverse right and left hand positionsfor any type of

cutting.

3. Stand with your weight evenly balanced on

both feet.

4. Stand slightly to the left side of the saw to keep

your body and head from being in a direct line

with the cutting chain. Figure3.

5. Do not overreach. You could be drawn or thrown

Loftbalance and lose control of the saw.

6. Never cut above shoulder height. It is difficultto

maintaincontrolofthe saw aboveshoulderheightand

places the chain dangerously close to your upper

body. 3

i i IIIIHIII II ..............................................................

ij i i, ,i

SPECIAL SAFETY SECTION (continued)

IIIIII i i

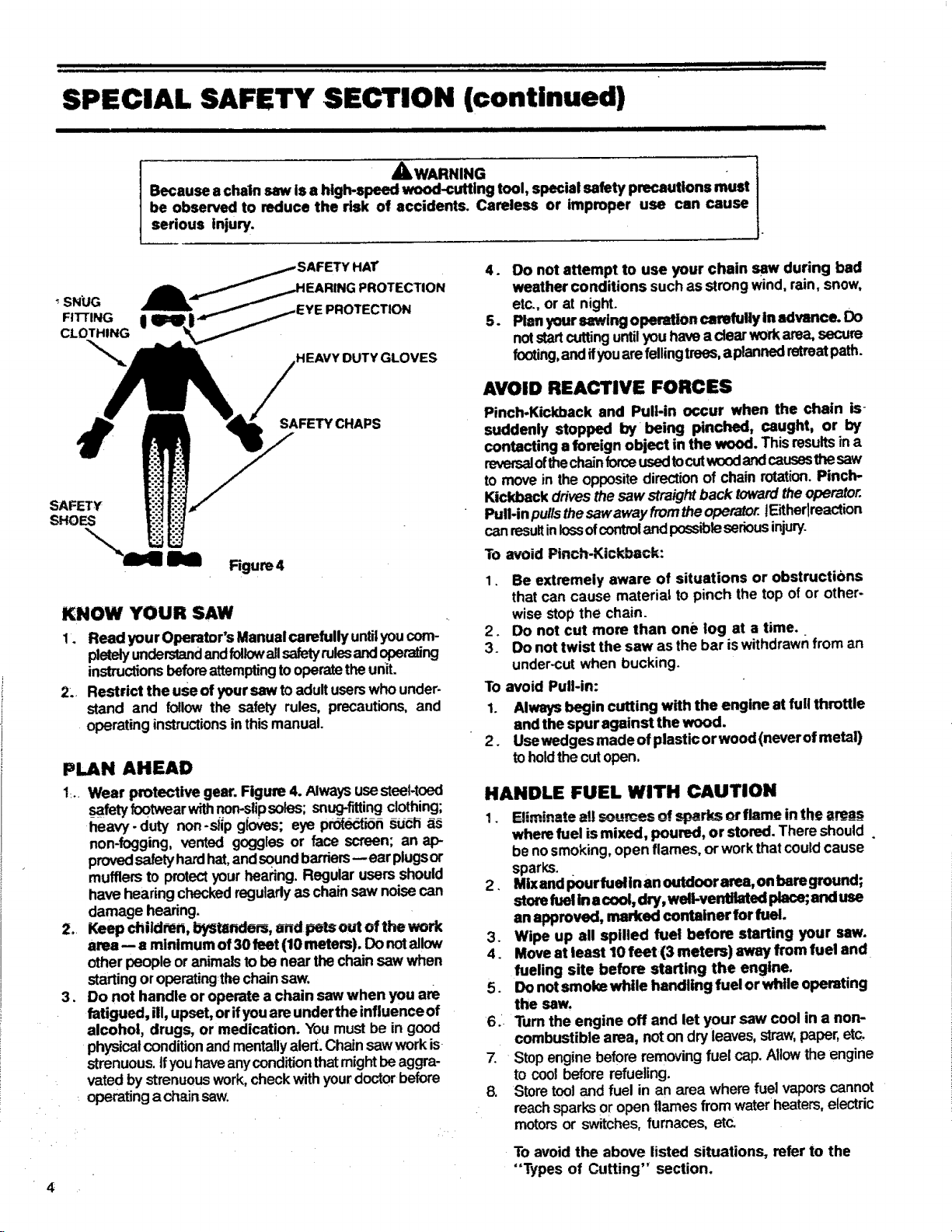

AWARNING

SNUG

FITTING

CLOTHING

Figure4

PROTECTION

GLOVES

SAFETY CHAPS

KNOW YOUR SAW

1. Read your Operator's Manualcarefully untilyoucom-

pletelyunderstandandfollowallsafetyrulesandoper_ng

instnJctionsbeforeattemptingto operatethe unit.

2.. Restrict the useof yoursew toadultuserswhounder-

stand and fo!low the safety rules, precautions, and

operating instructionsinthismanual.

PLAN AHEAD

Wear protective gear. Figure 4. Alwaysusesteel-toed

sa=fetyfootwear withnon-slipsoles;snug-fittingclothing;

heavy, duty non-sl_p g_:_s; eye pr(ff_"tion such a._

non-fogging, vented goggles or face screen; an ap-

provedsafetyhardhat,and soundbarriers-- ear plugsor

mufflers to protectyourhearing. Regular users should

have hearingcheckedregularlyaschainsawnoisecan

damage hearing.

2_L

Keep chiidrert, ly_staltdem,and petsout of the work

area-- a minimum of 30 feet (10 meters). Do notallow

otherpeople or animalsto be near the chain sawwhen

startingor operatingthechainsaw.

.

Do not handle or operate a chain saw when you are

fatigued, ill,upset,orif youare underthe influenceof

alcohol, drugs, or medication. Youmust be in good

physicalconditionandmentally alert. Chainsawwork is

strenuous, Ifyouhaveanycond_onthatmight beaggra-

vatedbystrenuous work,checkwithyourdoctorbefore

operatinga chain saw.

IIIIIIiii ,,,, IH iii

4. Do not attempt to use your chain Saw during bad

weather conditions suchas strong wind,rain,snow,

etc.. or at night.

5. Plan your sawing operation carefully inadvance. Do

notstartcuttinguntilyouhavea clearworkarea, secure

footjng,andifyouare fellingtrees,a plannedretreatpath.

AVOID REACTIVE FORCES

Pinch-Kickback and Pull-in occur when the chain is-

suddenly stopped bybeing pinched, caught, or by

contacting aforeign object inthe wood. Thisresultsina

reversalofthechainforceusedtocutwoodandcausesthesaw

to movein the oppositedirectionof chain rotation.Pinch-

Kickback drivesthe saw straightback towardthe operator.

Pull-inpullsthesawaway fromtheopera_. JEitherlreaction

canresultinlossofcontrolandpossibleserious injury.

To avoid Pinch-Kickback:

1, Be extremely aware of situations or obstructions

that can cause material to pinch the top of or other-

wise stop the chain.

2. Do not cut more than one log at a time,

3. Do not twist the saw as the bar is withdrawr_ from an

under-cut when bucking.

avoid Pull-in:To

1.

Always begin cutting with the engine at full throttle

and the spur against the wood.

2_

Usewedges made of plastic or wood (neverof metal)

toholdthe cut open,

HANDLE FUEL WITH CAUTION

I. Elimin=te a!! soumes of =,z_pa_rksorflame in the am_a_

where fuel ismixed, poured, or stored. Thereshould

be nosmoking,open flames, or workthat could cause

sparks.

2. Mixand pour fuelin an outdoor area, on bareground;

store fuel inacool, dry, wetl-venUlatedplace;and use

an approved, marked container for fuel.

3. Wipe up all spilled fuel before starting your saw.

4. Move at least 10 feet (3 meters) away from fuel and

•fueling site before starting the engine.

Do not smoke while handling fuel or while operating

the sew.

6. Turn the engine off and let your saw cool in a non-

combustible area, notondry leaves, straw,paper,etc.

7. Stop enginebeforeremovingfuel cap. Allowthe engine

to cool before refueling.

8. Store tooland fuel in an area where fuel vaporscannot

reachsparksor openflames fromwaterheaters,electric

motors or switches, furnaces, etc.

To avoid the above listed situations, refer to the

4

"Types of Cutting" section.

,,. iiiiiiiiiii

SPECIAL SAFETY SECTION (continued)

lllmlll ii ii i iiiii i iiiiiiiiiiiiiiiiiiiiiiiiiiiiii iiii

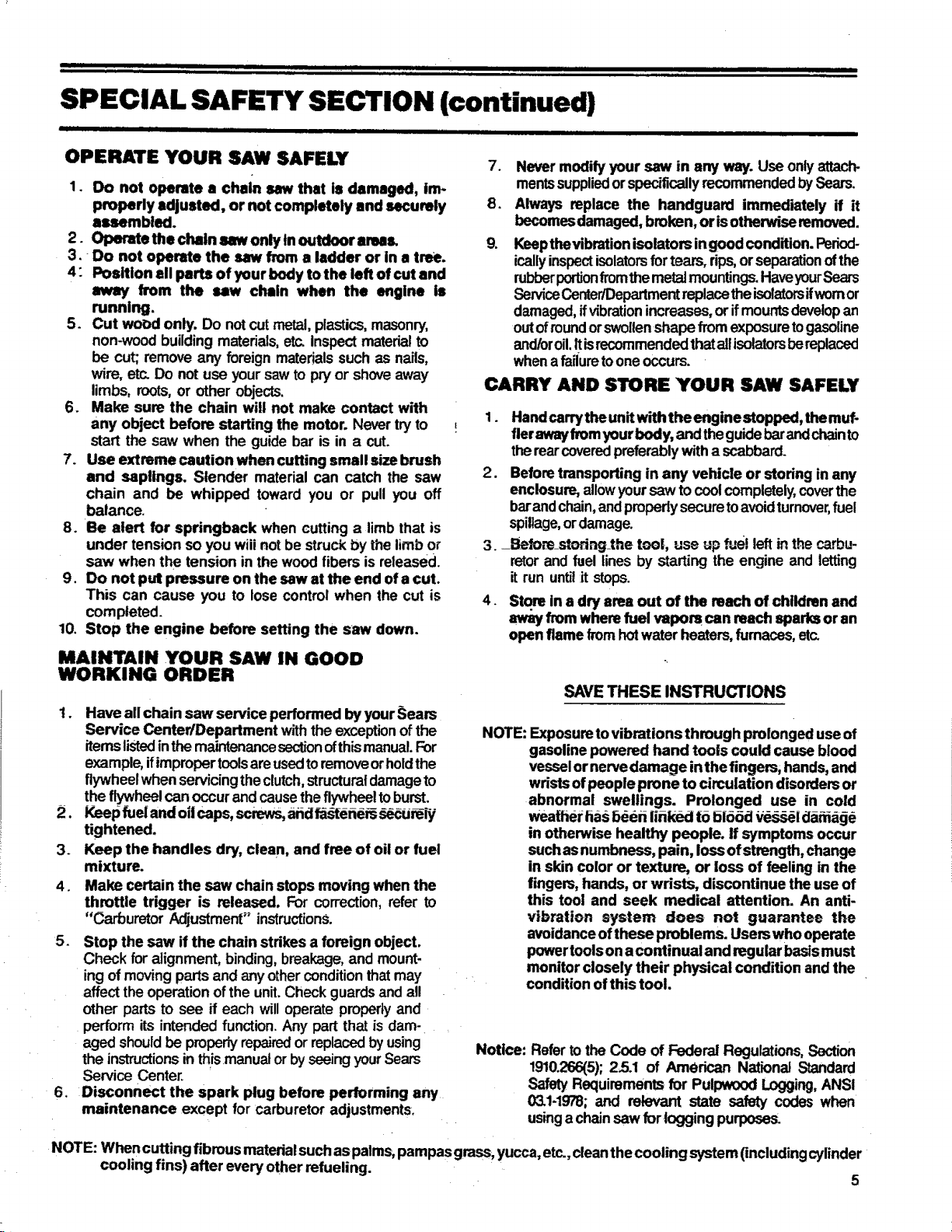

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged, im-

properly adjusted, or not completely and securely

assembled.

2. Operate the chain m only inoutdoor areal

3. Do not operate the saw from a ladder or in a tree.

4: Position all parts of your body to the left of cut and

away from the law cltlin when the engine is

running.

5. Cut wood only. Do not cutmetal,plastics,masonry,

non-woodbuildingmaterials,etc. Inspect materialto

be cut; remove any foreign materialssuch as nails,

wire, etc. Do not use yoursaw to pry or shoveaway

limbs, roots,or other objects.

6. Make sure the chain wilt not make contact with

any object before starting the motor. Nevertry to

start the saw when the guide bar is in a cut.

7. Use extreme caution when cutting small size brush

and saplings. Slender material can catch the saw

chain and be whipped toward you or pull you off

balance.

8. Be alert for springback when cutting a limbthat is

under tension so you wiii not be struck by the limb oF

saw when the tension in the wood fibers is released.

9. Do not put pressure on the saw at the end of a cut.

This can cause you to lose control when the cut is

completed.

10. Stop the engine before setting the saw down.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

1. Have all chain sawservice performed byyourSears

Service Center/Department withthe exceptionof the

itemslistedinthe maintenancesectionofthismanual.For

example,ifimpropertoolsareusedto removeorholdthe

flywheelwhen servicingtheclutch,structural damageto

the flywheel can occurand causethe flywheeltoburst.

2. Keep fueland oilcaps, screws,aiidP_tene_=iy

tightened.

3. Keep the handles dry, clean, and free of oil or fuel

mixture.

4. Make certain the saw chain stops moving when the

throttle trigger is released. For correction, refer to

"Carburetor Adjustment" instructions.

5. Stop the saw if the chain strikes a foreign object.

Check foralignment, binding,breakage,and mount-

ingofmoving partsand anyothercondition that may

affect theoperation of the unit.Check guardsandall

other parts to see if each willoperate propedyand

perform itsintended function. Anypart that is dam-

aged shouldbe propedy repairedor replacedbyusing

the instructionsin thismanualor by seeingyour Sears

Service Center.

6. Disconnect the spark plug before performing any

maintenance except forcarburetor adjustments,

,

Never modify your saw in any way. Use onlyattach.

mentssuppliedorspecificallyrecommendedbySears.

8.

Always replace the handguard immediately if it

becomesdamaged, broken, or isotherwise removed.

9.

Keepthevibrationisolators ingood condition.Period-

icallyinspectisolatorsfortears, rips,orseparationofthe

rubberportionfromthemetalmountings.HaveyourSears

ServiceCenter/Departmentreplacetheisolatorsifwomor

damaged,ifvibrationincreases,orifmountsdevelopan

outofroundorswollenshape from exposuretogasoline

and/oroil.Risrecommendedthatallisolatorsbereplaced

whena failuretoone occurs.

CARRY AND STORE YOUR SAW SAFELY

1. Handcarrythe unitwith theengine stopped, the muf-

tier awayfromyour body, andtheguidebarandchainto

therearcoveredpreferablywitha scabbard.

2. Before transporting in any vehicle or stodng in any

enclosure, allowyoursaw to coolcompletely,coverthe

barandchain,andproperlysecuretoavoid turnover,fuel

spillage,ordamage.

3. _B._fom=stodng=thetool, use up ,_,el left in the _-_rbu-

retorand fueltines by starting the engine and letting

it run until_itstops.

4. Store in a dry area out of the reach of children and

a_ from where fuel vapors can reach sparks or an

open flame from hotwater heaters,furnaces,et_

SAVE THESE INSTRUCTIONS

NOTE: Exposureto vibrations through prolonged use of

gasoline powered hand tools could cause blood

vesselor nervedamage inthe fingers, hands,and

wristsof people prone to circulation disorders or

abnormal swellings. Prolonged use in cold

weather hasbe6ri linked to b166diie_i dania_le

in otherwise healthy people. If symptoms occur

suchasnumbness, pain, loss ofstrength, change

in skin color or texture, or loss of feeling inthe

fingers, hands, or wrists, discontinue the useof

this tool and seek medical attention. An anti-

vibration system does not guarantee the

avoidanceof these problems. Users who operate

powertoolson acontinual and regularbasismust

monitor closely their physical condition and the

condition ofthis tool.

Notice: Referto the Code of Federal Regulations,Section

1910.266(5);2_5.1of American National Standard

SafetyRequirements for Pulpwood Logging,ANSI

03.1-1978;and relevant state safety codes when

usinga chainsaw fortoggingpurposes.

NOTE: When cutting fibrousmaterialsuch aspalms,pampas grass, yucca, etc.,cleanthecooling system(includingcylinder

cooling fins) after every other refueling.

5

KNOW YOUR CHAIN SAW

IIIIIIIIII III I I U I I , II II

A. INTRODUCTION

Yoursaw has been desig.nedwithsafetyin mindand

inc_Jdesthetoiiowing featuresasstandardequipment:

-- Reduced-KickbackGuide"Bar(Lo-Kicl_)

-- Low-Kickback Chain (ElongatedGuard Link)

-- Spark Arrestor

--Temperature Limiting Muffler

-- Handguards

"--Full VibrationIsolationSystem

AWARNING

The following features are includedon your saw tohelp

reduce the hazard ofkickback; however,such features

+will not totallyeliminate this dangerousreaction. Asa

chain sawuser,donot rely only onsafety devices. You

must follow all safety precautions, instructions, and

•maintenance in this manual to helpavoid kickbackand

other forces which can result inserious injury.

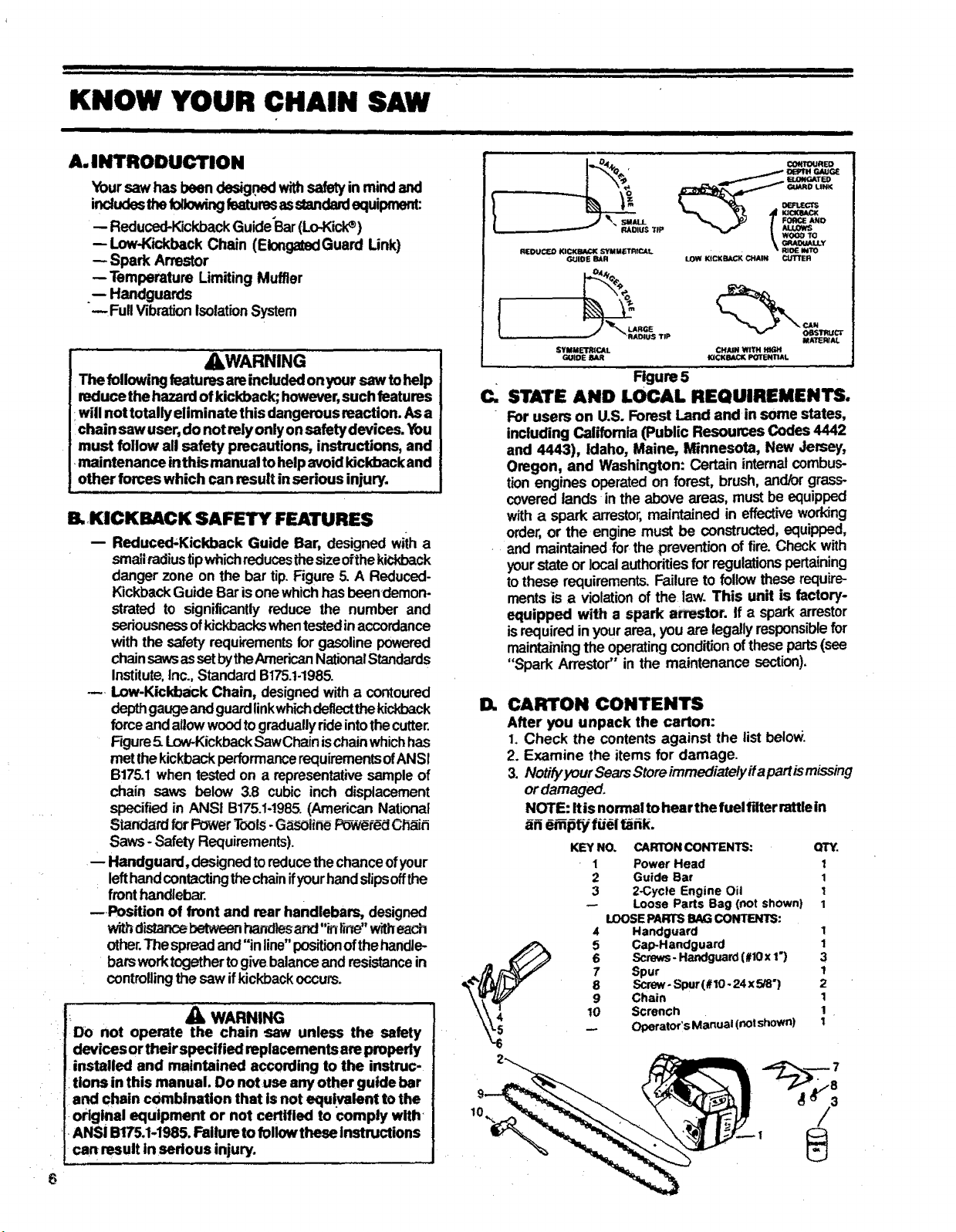

B, KICKBACK SAFETY FEATURES

-- Reduced;Kickback Guide Bar, designedwith a

srna;lradiustipwhichreducesthesizeofthekicld_ck

danger zone on the bar tip. Figure 5. A Reduced-

KickbackGuide Baris onewhichhas beendemon-

strated to significantly reduce the number and

seriousnessofkickbackswhentestedinaccordance

with the safety requkementsfor gasolinepowered

chainsawsassetbytheAmericanNationalStandards

Institute,inc., StandardBI75.1-1985.

-- Low-Kickback Chain, designedwitha contoured

depthgaugeandguardlinkwhichdeflectthe kickback

forceandallowwoodtograduallyrideintothecutter,

Figure.5Low-KickbackSawChainischainwhichhas

metthe kickbackperformancerequirementsofANSI

B175.1when tested on a representativesampleof

chain saws below 3.8 cubic inch displacement

specifiedin ANSI B175+1-1985.(AmericanNational

Stat_trd forPowerTo,is -G_3iine P_'_f_fCPi_i_

Saws- SafetyRequirements).

"Handguard, designedtoreducethechanceofyour

: lefthandcontactingthechain ifyourhandslipsoffthe

front handlebE

--Position of front and rear handlebars, designed

withdistancebetweenhandlesand"inline"witheach

other.Thespreadand"in line"positionofthehandle-

barsworktogetherto givebalanceand resistancein

controllingthe saw ifkickbackoccurs.

' A WARNING

Do not operate the chain saw unless the safety

devices or their specified replacements areproperly

installed and maintained according to the instruc-

itions in this manual. Do notuse any other guide bar

and chain combination that isnot equivalent to the

+original equipment or not certified to comply with

ANSI BI75.1-1985.Failureto followthese instructions

can result in serious injury.

6

_,_€+) • CO/(TtXN_ED

GUIDE BAR LOW KtCK_IkGK CHAI# CUTTER

..... J "RADIUS TIP OBSTRUCT

SYMML=R'RfCAL CHAIN WITH

GUIDE BAR KICKtMC;K POlrI_NTIAL

_....,---" _ GAUGE

/ _ONGATED

M/mERIAL

Figure 5

C, STATE AND LOCAL REQUIREMENTS.

For users on U.S. Forest Land and in some states,

including California(Public Resources Codes 4442

and 4443), Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington: Certain internalcombus-

tionengines operatedon forest, brush, and/or grass-

coveredlands in theabove areas, must be equipped

with a spark arrestor,maintained in effectiveworking

order,or the engine must be constructed, equipped,

+and maintained for the prevention of fire.Check with

yourstateor localauthoritiesfor regulationspertaining

tothese requirements.Failureto followtheserequire-

mentsis a violationof the law. This unit is factory-

equipped with a spark a_estor, if a spark arrestor

isrequiredin yourarea, you are lega!lyresponsiblefor

maintainingthe operatingconditionof theseparts(see

"Spark Arrestor" in the maintenance section).

D. CARTON CONTENTS

After you unpack the carton:

1. Check the contents against the list below.

2. Examine the items for damage.

3. Notih/yourSearsStoreimmediate/yffapartismissing

or damaged.

NOTE: itisnormaltohear the fuelfilter rattlein

an eml_tyf_iellank.

KEY NO. CARTON CONTENTS: QTY.

1 Power Head 1

2 Guide Bar 1

3 2,Cycle Engine Oil 1

-- Loose Parts Bag (not ShOwn) 1

LOOSE PARTS BAG CONTENTS:

4 Handguard 1

5 Cap-Handguard 1

6 Screws - Handguard (#10x t") 3

7 Spur 1

8 Screw -Spur (#I0 - 24 x 5/8") 2

9 Chain 1

!0 ScrenC,h 1

_ Operator's Manual (not shown) 1

........................ 7;......, ....... ....._....................................... I.................

PREPARING YOUR SAW FOR USE-

............................ iiiii i iiiiiiii i ,,,,,, ,,, ,,,,,,,,,,, . ,

A. GETTING READY

!. READ YOUR OPERATOR'S MANUAL

YourOperator'sManualhasbeendevelopedtohelp

youprepare yoursaw foruse andto understandits

safe operation. It is importantthat you read your

manualcompletelyto become familiarwiththe unit

beforeyoubeginassemblyor attemptoperation.

........................... ,,,,,,,,,,,,

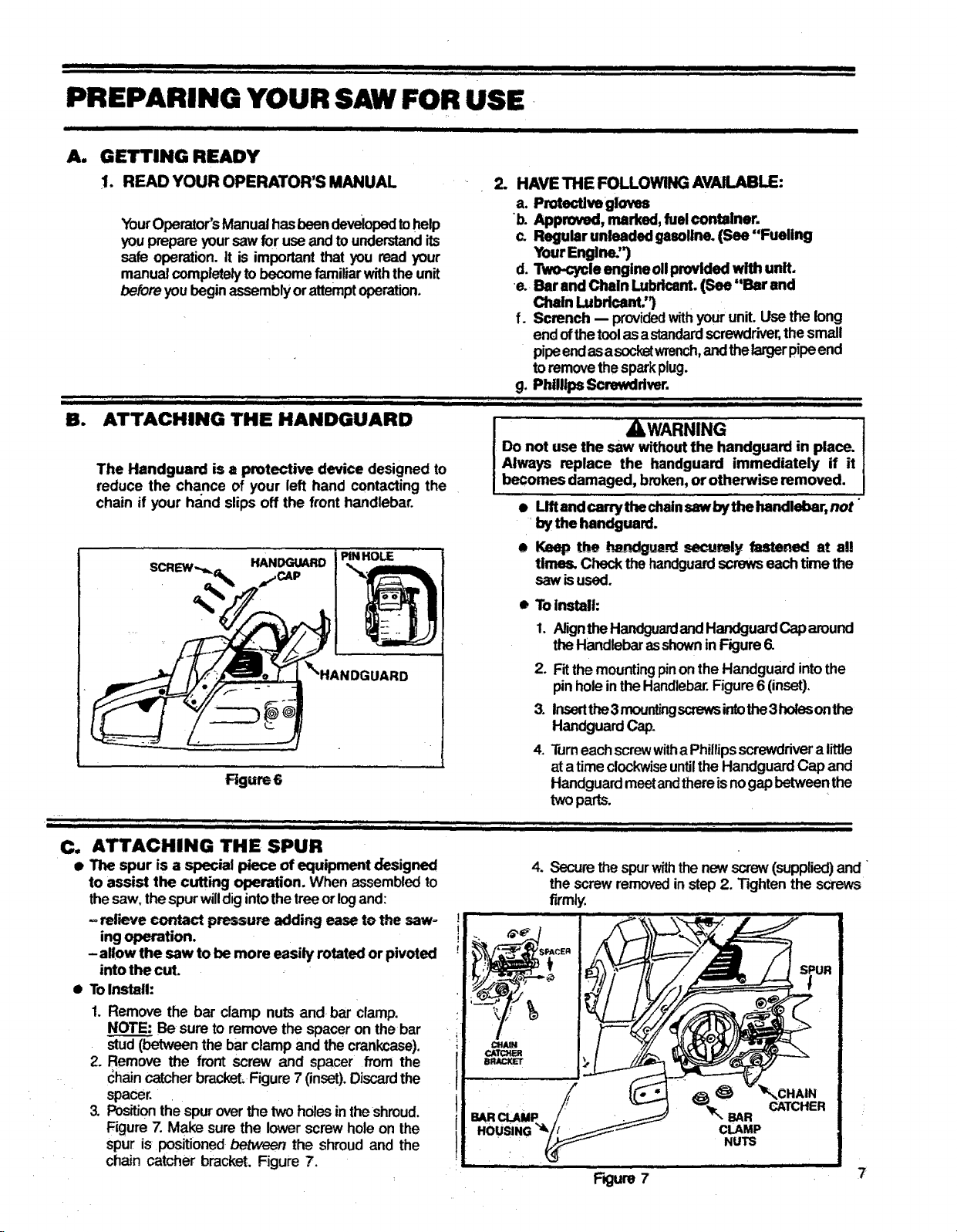

B. ATTACHING THE HANDGUARD

The Handguard is a protective device designed to

reduce the chance of your left hand contacting the

chain if your hand slips off the front handlebar.

HANDGUARD PINHOLE

UARD

i

Figure6

' ....... """':"':' "' " .... ' iiiiiiiiiii ' iiiii]1_11111_111iiii .......... i

C. ATTACHING THE SPUR

• The spur is a special piece of equipment designed

to assist the cutting operation. When assembledto

thesaw. thespurwilldigintothe tree orlogand:

=relieve contact pressure adding ease to the saw-

ingoperation.

-allow the saw to be more easily rotated or pivoted

into the cut.

• ToInstall:

1. Remove the bar clamp nuts and-bar clamp.

NOTE: Be sureto remove the spacer on the bar

stud (betweenthe bar clamp and the crankcase).

2. Remove the front screw and spacer from the

chaincatcherbrackeLFigure7 Onset).Discardthe

spacer.

3. Positionthe spuroverthe twoholesintheshroud.

Figure7. Make sure the lowerscrew hole on the

spur is positionedbetween the shroud and the

chain catcher bracket. Figure .7.

2. HAVE THE FOLLOWING AVAILABLE:

•,,!,,;;,;;...................

a. Proteotivegloves

"b. Approved, marked,fuelcontainer.

c_ Regular unleaded gasoline.(See "Fueling

YourEngine.")

d. Two-cycle engineoilprovidedwith unit.

e.. Bar and Chain Lubricant. (See "Bar and

Chain Lubdcant")

f. Scrench -- providedwithyour unit. Usethe long

end ofthetoolas astandardscrewdriver,thesmall

pipeendasasockBtwrench,andthelargerpipeend

toremovethesparkplug.

Phtlllps Screwddver.

_

, ,_,;,,,I.................. ' , , '......................................""_" '':

AWARNING

Do not use the saw withoutthe handguard in place.

Always replace the handguard immediately if it

becomes damaged, broken, or otherwise removed.

• Uftandcorrythechalnsawbythehandlebar, not"

bythe handguard.

• Keep Lhe .handguardL_,N:_mlyfastened at a!!

times. Check the handguardscrews each timethe

sawis used.

• ToInstall:

1. AligntheHandguardandHandguardCaparound

theHandlebarasshownin Figure6_

2. Fitthemountingpinonthe Handguardintothe

pinholein the Handlebar.Figure6 (inset).

3. Insertthe3 mountingscrewsintothe3holesonthe

HandguardCap.

4.

Turneachscrewwitha Phillipsscrewdnver a little

ata time clockwiseuntilthe HandguardCap and

Handguardmeetandthere is nogap between the

twoparts.

,,,i,,,,,i_ -, ................... ,,,,,,,,,,,,,,,,,,,,,

4. Securethe spurwiththenew screw(supplied)and

the screw removedinstep2. Tighten the screws

firmly.

Figure 7

7

. ii iiiiiii ii IIIIIHIIIIIIIIIIIII II Jill III IIII IIIIIII IIH IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII •

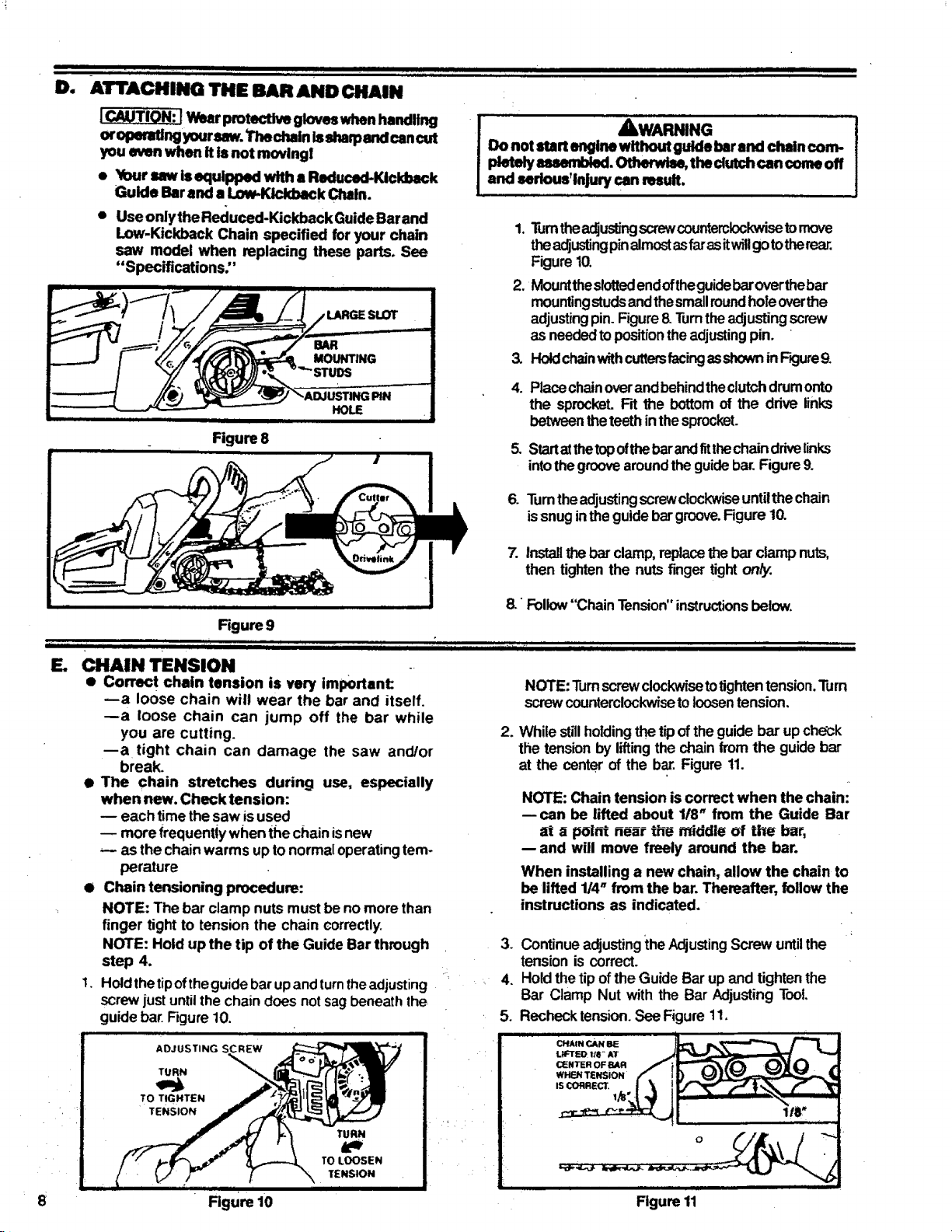

DI

"1 _m,r .... ,, ,,,,,I_UII,I,I I I .=, _,,, i i

Wear protective gloveswhan handltng

or _ yoursaw. Thechain ISsharpandcan _.t

you even when it Isnot movingl

• Your saw isequipped with a Reduced-KIckbeck

Guide Barand a Low-Kickbeck Chain.

• Use onlythe Reduced-Kickback GuideBarand

Low-Kickback Chain specified for your chain

s_rwmodel when replacing these parts. See

"Specifications:'

Figure 8

z

Do not start engine without guide barend chain com-

pletMy asumbisd. Otherwise, the dutch can comeoff

1 AWARNING

and serious'Injury can moult.

1. Tumtheadjustingscrewcounterclockwisetomove

theadjustingpinalmostasfar asitwillgotother_.

Figure10.

2. Mounttheslottsdendoftheguidebaroverthebar

mountingstudsandthesmallroundhole overthe

adjusting pin.Figure8 Turntheadjustingscrew

as neededtopositiontheadjustingpin.

HoldchainwithcuttersfacingaSshowninFK:jure9.

4.

Placechainoverandbehind theclutchdrumonto

the sprocket.Fit the bottomof the ddve links

between theteethinthesprocket.

Startatthetopofthebarandfitthechaindrivelinks

into thegroovearoundtheguidebar.Figure9.

.

Tumthea_usting screwclockwiseuntilthechain

issnug inthe guide bargroove.Figure10.

Figure 9

E. CHAIN TENSION

• Correct chain tension is very important:

--a loose chain wilt wear the bar and itself.

--a loose chain can jump off the bar while

you are cutting.

--a tight chain can damage the saw and/or

break.

• The chain stretches during use, especially

when new. Check tension:

each time the saw isused

-- more t_requentiywhen the chainisnew

as thechain warms up to normaloperatingtem-

perature

• Chain tensioning procedure:

NOTE: The bar clamp nuts must be no more than

finger tight to tension the chain correctly.

NOTE: Hold up the tip of the Guide Bar through

step 4.

1. Holdthetipof theguide barupandturntheadjusting

screwjust untilthe chain does notsag beneaththe

guide bar. Figure10.

7.

installthebarclamp,replace thebar clamp nuts,

then tightenthe nuts finger tighton_

8."Foliow"ChainTension"instructionsbelow.

NOTE: Turnscrewclockwisetotighten tension.Turn

screwcounterclockwiseto loosentension,

.

While still holdingthetipof the guidebar up che_k

the tensionby liftingthe chain fromthe guide bar

at the center of the b_ Figure 11.

NOTE: Chain tension is correct when the chain:

--can be lifted about 1/8" from the Guide Bar

at a point neat the middle of the bar,

--and will move freely around the bar.

When installing a new chain, allow the chain to

be lifted 114"from the bar, Thereafter, followthe

instructions as indicated,

3. Continueadjustingthe AdjustingScrew untilthe

tension is correct.

4. Holdthetipofthe Guide Bar up andtightenthe

Bar Clamp Nut with the Bar Adjusting Tool.

5. Rechecktension.SeeFigure 11.

IIIIIHIII

ADJUSTING SCREW

TURN

TO TIGHTEN

TENSION

Figure 10

11

TURN

TO LOOSEN

TENSION

Figure 11

ii,lllll

F. FUEUNG YOUR ENGINE

1. FUEL SAFETY

a. Use only recommended fuel mixtures.

b. MIx and pour fueloutdoors and where there are

no sparks or flames.

c. Use a container approved for fuel.

d. Do notsmoke or allow smoking near fuelor the

tool or while using the tool.

e. Wipe up all fuel spills before starting engine.

h Move at least 10 feet away from fueling site

before starting engine.

g, Stop engine before removing fuel cap. Allow

the engine to cool before refueling.

h. Before storing the tool, use up fuel left in the

carburetorand fue!linesbystartingthe engineand

letting it run until it stops.

i.

Store tooland fuel in an area where fuel vapors

cannot reach sparks or openflames fromwater

heaters, electric motors orswitches, furnaces,

etc.

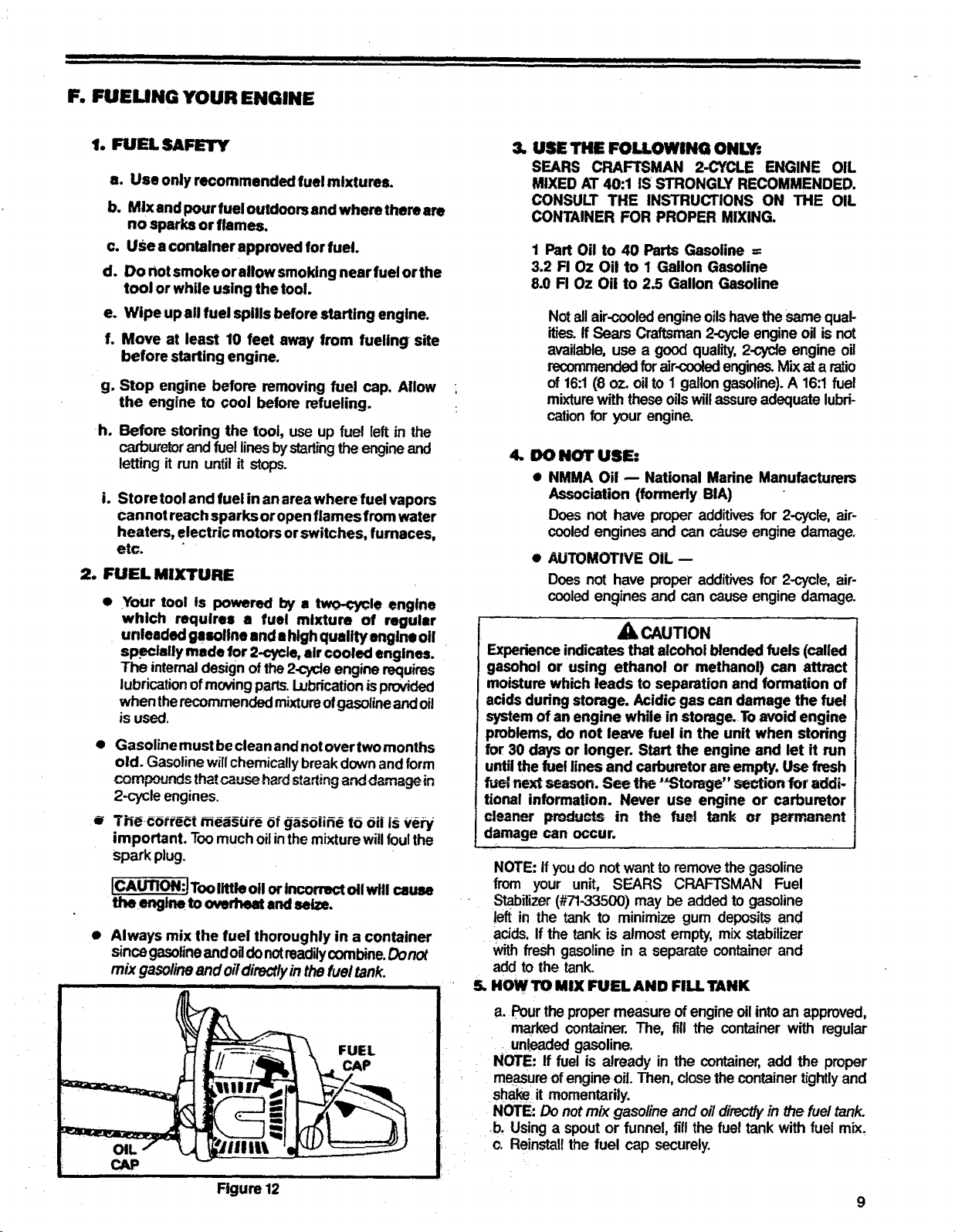

2. FUEL MIXTURE

* Your tool Is powered by • two-cycle engtne

which requires a fuel mixture of regular

• unleaded ga=ollneand ahigh quality engine oll

specially made for 2-cycle, air cooled engines.

The internal designof the 2-cycleengine requires

lubricationofmoving parts.Lubricationisprovided

when therecommendedmixture ofgasolineandoil

is used.

• Gasoline mustbe cleanandnot overtwo months

old. Gasolinewillchemicallybreakdownandform

compoundsthatcausehardsta_ingand damage in

2-cycle engines.

important. Toomuchoil inthemixturewill foulthe

spark plug.

[CAUTION:!Toolittleoil orincorrectoil will cause

the engine to overheat andseize.

• Always mix the fuel thoroughly in a container

sincegasolineandoildonotreadilycombine.Donor

mixgasolineand oi!directlyinthefuel tank.

3. USE THE FOLLOWING ONLY:

SEARS CRAFTSMAN 2-CYCLE ENGINE OIL

MIXED AT 40:1 IS*STRONGLY RECOMMENDED.

CONSULT THE INSTRUCTIONS ON THE OIL

CONTAINER FOR PROPER MIXING.

1 Part Oil to 40 Parts Gasoline :

3.2 FI Oz Oil to 1 Gallon Gasoline

8.0 FI Oz Oil to 2.5 Gallon Gasoline

Not allair-cooledengine oilshavethesame qual-

ities.If Sears Craftsman2-cycleengine oil is not

available, use a good quality,2-cycle engine oil

recommendedfor air-cooledengines Mixat a ratio

of 16:1(8 07. oilto 1 gallongasoline).A 16:1 fuel

mixturewiththeseoilswillassureadequate lubri-

cationfor your engine.

4. DO NOT USE:

• NMMA Oil -- National Marine Manufacturers

Association {formerly BIA)

Does not have proper additivesfor 2-cycle,air-

cooledengines and can c_use enginedamage.

• AUTOMOTIVE OIL --

Does not have proper additives for 2-cycle, air-

cooledengines and can cause enginedamage.

CAUTION

Experience indicates that alcohol blended fuels (called

gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of

acids dudng storage. Acidicgas can damage the fuel

system of an engine while in storage.To avoid engine

problems, do not leave fuel in the unit when storing

for 30 days or longer. Start the engine and let it run

untilthe fuel lines and carburetor areempty. Use fresh

fuel next season. See the "Storage" section for addi-

tional information. Never use engine or carburetor

cleaner pmdu,#_s in the fuel tank or permanent

damage can occur.

NOTE: if youdo notwant toremovethe gasoline

from your unit, SEARS CRAFTSMAN Fuel

Stabilizer(#71-33500) may be added to gasoline

te_ in the tank to minimize gum deposi_ and

adds. If the tank is almost empty,mix stabilizer

with fresh gasoline in a separate containerand

add to the tank.

5. HOWTO MiX FUELAND FILL TANK

a. pourthepropermeasure ofengine oilintoan approved,

marked container. The, fill the containerwith regular

unleaded gasoline,

NOTE: If fuel is already in the container, add the proper

measureofengine oil. Then, closethe containertightlyand

sh_i it momentarily.

NOTE.'Do notmix gasoline and oi/dimcth/in the rue/tank.

b, Using a spout or funnel, fill the fuel tank with fuel mix,

c. Reinstal!the fuel cap securely.

Rgure 12

9

Loading...

Loading...