Craftsman 358356242 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

Operator's

Manual

@

Model No.

358.356242

READ THE OPERATOR'S

WARNING

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

530--083047-438/03/94

Always Wear Eye Protection

CRAFTSMAN+

2.5 cu. in./40 cc 2-CYCLE

18 in. Guide Bar

GASOLINE CHAIN SAW

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

• Table of Contents-

Inside Back Cover

SAFETY RULES

WARNING: ....

&

ALWAYSDISCONNECT SPARK PLUG WIREAND PLACE WIRE WHERE IT CANNOT CONTACT SPARK

PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP,TRANSPORTING, ADJUSTING OR

MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW 1S A HIGH-SPEED WOOD-CUTTING TOOL, SPECIAL SAFETY

PRECAUTIONS MUST BE OBSERVED TO REDUCE THE RISK OF ACCIDENTS. CARELESS OR

IMPROPER USE OFTHIS TOOL CAN CAUSE SERIOUS INJURY.

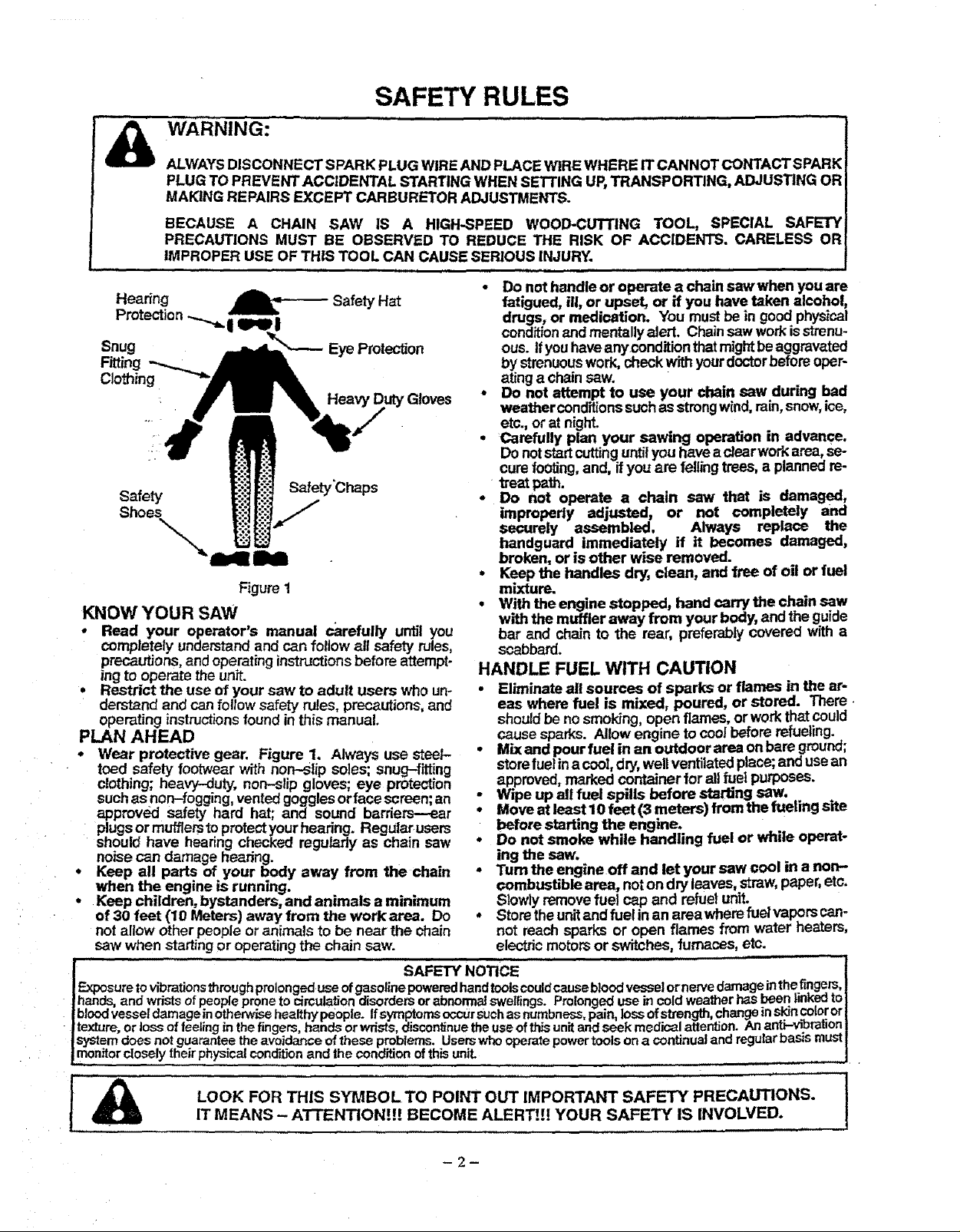

Hearing _ Safety Hat

Protection

Snug Eye Protection

Fitting

Clothing

Gloves

Safety Safety'Chaps

Shoes

Figure t

KNOW YOUR SAW

• Read your operator's manual carefully until you

completely understandand can follow all safety rules,

precautions,and operating instructions before attempt-

ingto operate theunit.

• Restrict the use of your saw to adult users who un-

derstand and can follow safety rules, precautions,and

operating instructionsfound inthis manual

PLAN AHEAD

° Wear protective gear. Figure 1. Always use stee/-

toed safety footwear with non-slip soles; snug-f_ting

clothing; heavy-duty, non-slip gloves; eye protection

suchas non-fogging,ventedgoggles orface screen;an

approved safety hard hat; and sound barriers---_r

plugsor mufflersto protectyour hearing. Regular users

should have hearing checked regu/ady as chain saw

noisecan damage hearing.

when the engine is running.

Keep all parts of your body away from the chain

Keep children, bystanders, and animals a minimum

of 30 feet (10 Meters) away from the workarea. Do

not aliow other people or animals to be near the chain

saw when startingor operating the chain saw.

I ...... SAFETY NOTICE

F-xposuretovibra_onsthroughprolongeduseofgasolinepoweredhandtoolscouldcausebloodvesselornervedamageinthefinge_,

hands,and wdstsofpeoplepronetocircula_ondisordersorabnormalswellings.Prolongeduseincoldweatherhasbeen,nKeam

bloodvessefdamageinotherwbehealthypeople.Ifsymptomsoccursuchasnumbness=pain,lossofstrength,changeinskinco|_or

texture,or lossoffeelingin thefingers,handsorwrists,discontinuetheuseof_ unitandseekmedicalattention_ ante-wt_rauon

system.......doesnotguaranteetheavoidanceofthese problems Userswhooperatepowertoolsona continualandregularbasismust

lmontlor closelytheirphys=catconditionand theconditionofth=sunit

• Do not handle or operate a chain sawwhen you are

fatigued, ill, or upset, or if you have taken alcohol,

drugs, or medication. You mustbein good physical

conditionandmentallyalert Chainsaw workisstrenu-

ous If youhaveany condition thatmightbeaggravated

by strenuouswork,checkwith yourdoctorbeforeoper-

ating a chainsaw

• Do not attempt to use your chain saw during bad

weather conditions suchas strongwind.rain,snow,ice,

etc, or at night.

• Carefully plan your sawing operation in advance.

Do notstart cuttinguntilyou have a c/earwo_ area,se-

cure footing,and, ifyou are fellingtrees, a planneo re-

" _'eat path.

• Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace the

handguard immediately if it becomes damaged,

broken, or is other wise removed.

• Keep the handles dry, clean, and free of oil or fuel

mixture.

• W'dhthe engine stopped, hand carry the chain saw

with the muffler away from your body, and the guide

bar and chain to the rear, preferably coverea with a

scabbard,

HANDLE FUEL WITH CAUTION

• Eliminate all sources of sparks or flames in the ar-

eas where fuel is mixed, poured, or stored. There •

should be no smoking, open flames, or workthatcould

causesparks Allow engine to coo! before refueling.

• Mixand pour fuel in an outdoorarea on bare ground;

storefuelina coot,dry, wellventilatedplace;andusean

approved, marked container for all fuel purposes

Wipe up all fuel spills before starting saw.

:, Move at least 10 feet (3 meters) from the tueling site

before starting the engine.

• Do not smoke while handling fuel or white operat-

ing the saw.

- Turn the engine off and let your saw cool in anon-

combustible area, noton dry leaves, straw, paper,etc.

Slowlyremove fuel cap and refuel unit.

• Storethe unit and fuel in an areawhere fuelvapors can-

not reach sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

j

i

I _ LOOK FOR THIS SYMBOL TO POINT OUT 'MPORT_NT SAFETY PRECAUTIONS" t

IT MEANS - AT£ENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

-2-

SAFETY RULES

OPERATE YOUR SAW SAFELY

• Do not operate a chain saw with one hand. Serious

injuryto the operator, helpers,bystanders or any com-

binationofthese persons may resultfrom one-handed

operation. A chain saw is intendedfor two-handed use.

• Operate the chain saw only in well-ventilated out-

door areas.

specificallytrained to do so.

Do not operate saw from a ladder or in a tree, unless

Position all parts of your body to the left of cut and

away from the chain when the engine is running.

• Cut wood only. Do not use your saw to pry or shove

away limbs, roots,or otherobjects.

• Make sure the chain will not make contact with any

object while starting the engine. Nevertry tostad the

saw when the guide bar is in a cut or kerr.

• Use extreme caution when cuffing small size brush

and saplings. Slender matedal can catch the chain

•and be whippedtoward you or pullyou offbaJance.

- Be alert for springback when cuttinga limbthatis un-

der tensionsoyou will not be struck by IP_ limbor saw

when the tension in the wood fibersis released.

• Do not put pressure on the saw at the end of a cut.

Applying pressurecan cause you to lose controlwhen

the cut is completed.

• Stop the engine before setting the saw down.

- Keep fuel and oil caps, screws, and fasteners se-

curely tightened.

,, , , IH,I ,,,, iii i i i I,,II,H,,II,I ii i

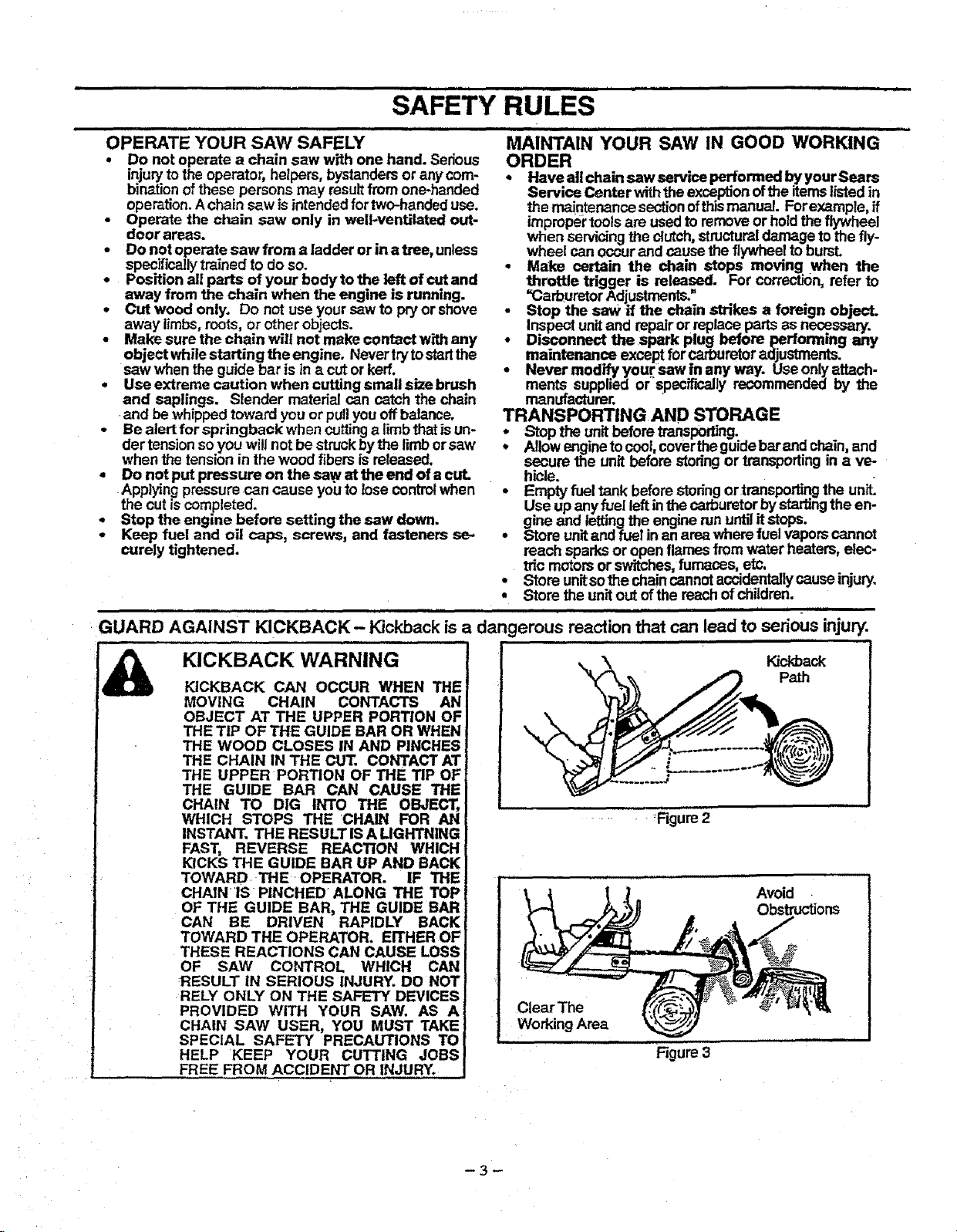

GUARD AGAINST KICKBACK- Kickback is

' serious injury.

KICKBACK WARNING

IA .....

KICKBACK CAN OCCUR WHEN THE

MOVING CHAIN CONTACTS AN

OBJECT AT THE UPPER PORTION OF

THE TIP OF THE GUIDE BAR OR WHEN

THE WOOD CLOSES IN AND PINCHES

THE CHAIN IN THE CUT. CONTACT AT

THE UPPER PORTION OF THE TIP OF

THE GUIDE BAR CAN CAUSE THE

CHAIN TO DIG INTO THE OBJECT,

WHICH STOPS THE CHAIN FOR AN

INSTANT. THE RESULT IS A LIGHTNING

FAST, REVERSE REACTION WHICH

KICKS THE GUIDE BAR UP AND BACK

TOWARD• THE OPERATOR. IF THE

CHAIN IS PINCHED ALONG THE TOP

OF THE GUIDE BAR, THE GUIDE BAR

CAN BE DRIVEN RAPIDLY BACK

TOWARD THE OPERATOR. EITHER OF

THESE REACTIONS CAN CAUSE LOSS

OF SAW CONTROL WHICH CAN

RESULT IN SERIOUS INJURY. DO NOT

RELY ONLY ON THE SAFETY DEVICES

PROVIDED WITH YOUR SAW. AS A

CHAIN SAW USER, YOU MUST TAKE

SPECIAL SAFETY PRECAUTIONS TO

HELP KEEP YOUR CUTTING JOBS

FREE FROM ACCIDENT OR INJURY.

MAINTAIN YOUR SAW IN GOOD WORKING

ORDER

* Have all chain saw service performed byyour Sears

Service Center with the exceptionofthe itemslisted in

the mainter_ncesection ofthismanual. Forexample, if

impropertoolsare used to removeor holdtheflywheel

when servicing the dutch, structural damage to thefly-

wheel canoccur and cause the flywheel to burst.

. Make certain the chain stops moving when the

throttle trigger is released. For correction,refer to

"Carburetor Adjustments."

• Stop the saw if the chain strikes a foreign objec'L

Inspect unitand repairor replace partsas necessary.

- Disconnect the spark plug I_lore performing any

maintenance except forcarburetoradjustments.

• Never modify yoursaw in any way. Use onlyattach-

ments supplied or'specificaJlyrecommended by the

manufacturer,

TRANSPORTING AND STORAGE

: Stop the unitbeforetransporting.

Allow enginetocool,covertheguidebarand chain,and

secure the unit before stodng or transportingin a ve-

hicle.

* Empty fuel tank before storingortransportingthe unit.

Use up anyfuel leftinthe carburetorbystartingthe en-

gine and lettingthe engine run until _st.ops.

° Store un_ and fuetin anarea where lueI vaporscannot

reach sparks or open flamesfrom water heaters, elec-

tric motors or switches,furnaces, etc.

• Store unitsothe chaincannot accidentallycause injury.

. Store the unit out of the reachof children.

a dangerous reaction that can lead to

Clear The

Working Area

.ll ......H.i

Kickback

Path

........ Rgure 2

Avoid

Obstructions

,,,,,,

Figure 3

-3-

i,i ii iii iii i HI I IIII I mlllr

SAFETY RULES

MAINTAIN CONTROL

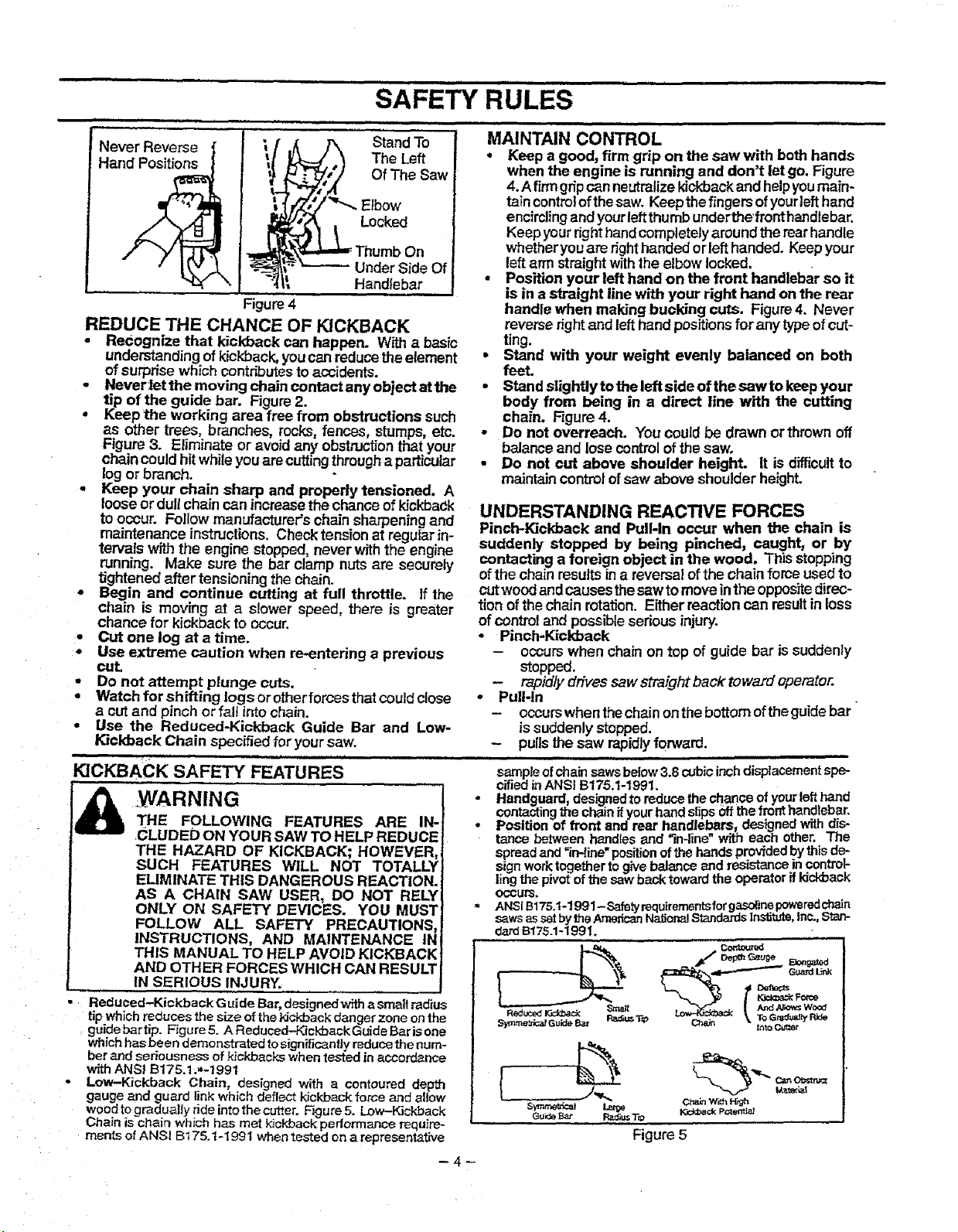

4

Hand Positions The Left

• Locked

OfThe Saw

Elbow

iNevRvee 1 sno

UnderSide Of

\ Handlebar

Figure 4

REDUCE THE CHANCE OF KICKBACK

• Recognize that kickback can happen. With a basic

understandingof kickback, youcen reducetheelement

of surprisewhichcontributes toaccidents.

• Never let the moving chain contact any object at the

tip of the guide bar. Figure 2.

• Keep the working area free from obstructions such

as other trees, branches, rocks, fences, stumps, etc.

Figure 3. Eliminate or avoid any obstructionthat your

chaincouldhitwhile youare cuttingthrougha particular

logor branch.

• Keep your chain sharp and properly tensioned. A

loose or dullchaincan increase the chance of kickback

to occur. Follow manufacturer'schain sharpening and

maintenance instructions. Check tensionat regufarin-

terva{s with the engine stopped,never with the engine

running. Make sure the bar clamp nutsare securely

tightened after tensioningthe chain.

• Begin and continue cutting at full throttle. If the

chain is moving at a slower speed, there is greater

chance for kickback to occur.

_, Cut one log at a time.

• Use extreme caution when re-entering a previous

cut.

• Do not attempt plunge cuts.

• Watchforshiftinglogsorotherforoesthatcouldclose

a cut and pinchor fall into chain.

• Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for your saw.

KICKBACK SAFETY FEATURES

I&No

Reduced-KickbackGuide Bar,designedwitha smallradius

tip whichreducesthesize ofthe Idckback dangerzoneonthe

guidebartip. Figure5. AReduced-KickbackGuideBarisone

whichhasbeendemonstratedtosignificantly reducethenum-

berand seriousness ofkickbackswhentested in accordance

with ANSI B175.1 ;*-1991

Low-Kickback Chain, designed with a contoured depth

gauge and guard link which deflect kickback force and allow

wood to gradually ride into the cutter. Figure 5. Low-K-Jckback

Chain is chain which has met £Jcl4_backperformance require*

ments of ANSI B175.1-1991 when tested on a representative

THE FOLLOWING FEATURES ARE IN-

CLUDED ON YOUR SAW TO HELP REDUCE

THE HAZARD OF KICKBACK; HOWEVER,

SUCH FEATURES WILL NOT TOTALLY

ELIMINATE THIS DANGEROUS REACTION.

AS A CHAIN SAW USER, DO NOT RELY

ONLY ON SAFETY DEVICES. YOU MUST

FOLLOW ALL SAFETY PRECAUTIONS,

INSTRUCTIONS, AND MAINTENANCE IN

THIS MANUAL TO HELP AVOID KICKBACK

AND OTHER FORCES WHICH CAN RESULT

IN SERIOUS INJURY.

, Hi i Jw, i H,,,I,H

-4-

Keep a good, firm grip on the saw with both hands

when the engine is running and don't let go. Figure

4.A firmgrip can neutralizekickbackand helpyou main-

taincontrolofthe saw. Keep thefingersofyourleft hand

encirclingand yourleftthumb underthe fronthandlebar.

Keep your right handcompletelyaround therearhandle

whetheryou are righthanded orlefthanded. Keepyour

leftarm straightwiththe elbow locked.

• Position your left hand on the front handlebar so it

is in a straight line with your right hand on the rear

handle when making bucking cuts. Figure4. Never

reverseright and lefthand positionsfor any typeof cut-

• _d with your weight evenly balanced on both

feet.

• StandslighUyto theleft side of the sawto keepyour

body from being in a direct line with the cutting

chain. Figure 4.

• Do not overreach. You could be drawn orthrown off

balance and lose controlofthe saw.

• Do not cut above shoulder height, it is difficultto

maintaincontrolofsaw above shoulder heighL

UNDERSTANDING REACTIVE FORCES

Pinch-Kickback and Pull-In occur when the chain is

suddenly stopped by being pinched, ¢aught_ or by

contacting a tore_n object in the wood. Troisszopp_ng

ofthe chainresults in a reverea]of the chain forceusedto

cutwood and causes thesawto moveinthe oppositedirec-

tionof the chainrotation. E[therreactioncan resultinloss

of control and possibleserious injury.

• Pinch.Kickback

- occurswhen chainon top of guide bar is suddenty

- rapidlydfivessawstraightbacktowardoperator.

• Puli-ln

- OCcurswhen thechainonthe bottom ofthe guide bar

- pulls the saw rapidlyforward.

sampleofchainsawsbelow3.8cubicinchdisplacementspe-

cifiedinANSI B175.1-1991,

• Handguard,designedtoreducethechanceofyourlefthand

contacting"{hechainifyour handsli.pcOffthe_ro_hand!elo_r.

• Positionof front and rear handlebars, oestgneOw_na=s-

tahoebetweenhandlesand =in-line witheach other, i ne

spreadand=in4ine"positionofthe handsprovided bythisde-

signworktogethertogivebalanceand resistar_cein.p?.ntro.I,-

lingthepivotofthe sawbacktowardtheoperazor_ lac_acK

OCCURS.

•sawsas set bythe American Naliot_ Standaras _, .,

Syra met_i_f Guide Bar

stopped.

is suddenly stopped.

,,,,,,,, i i ,, ,i H ,,,

B TS+l-199 ..,........ "

_educe_ _c_ I_us T_P

Syr_f_t _ 1_€_ p_ettt_J

Gui_e_ar P_d_usT=#

Figure5

Cor_er_

• A,-_ _ Wood

|_tO Cg_et

i,ll

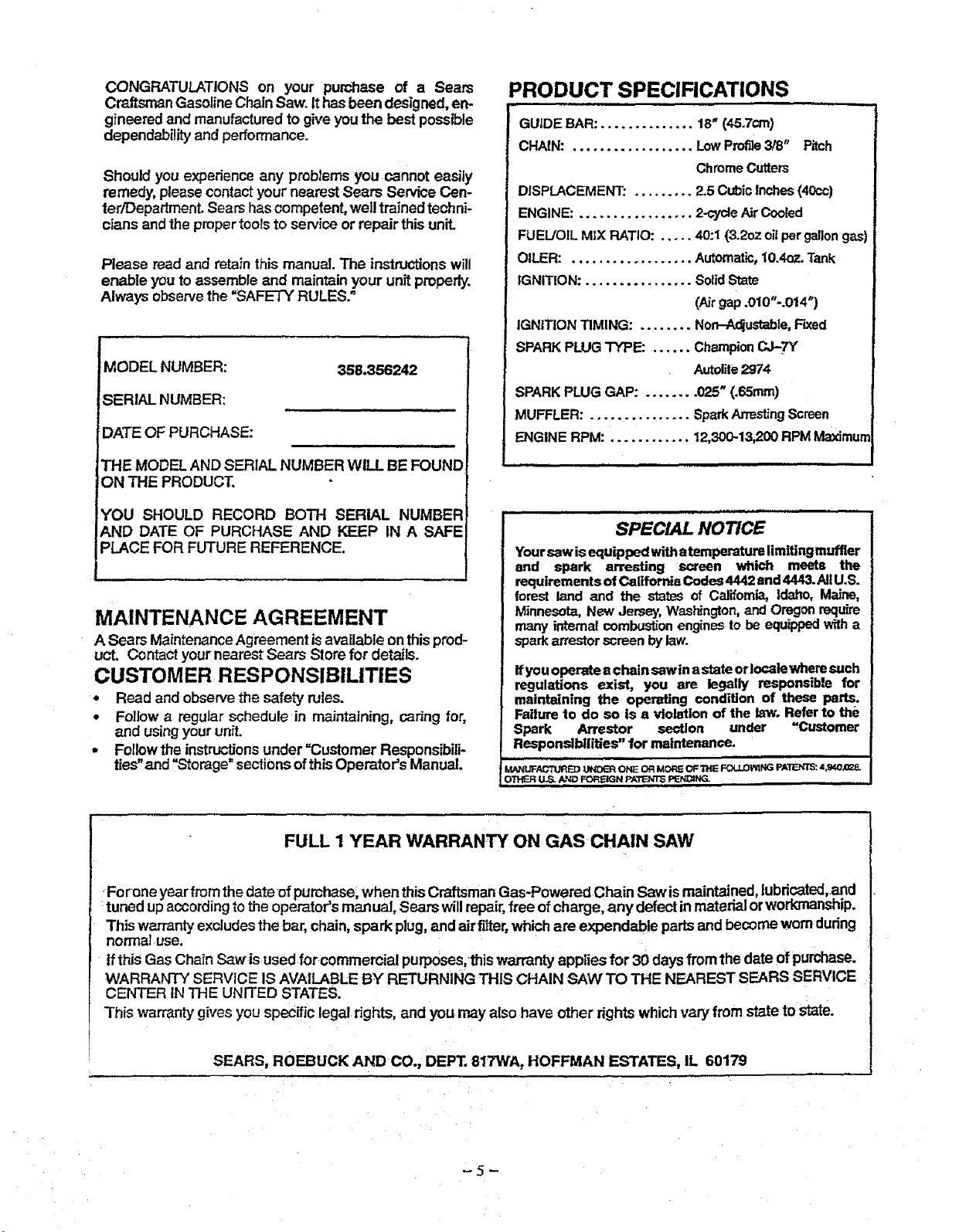

CONGRATULATIONSon your purchase of a Sears

Craftsman GasolineChainSaw. Ithasbeen designed, en-

gineered and manufactured to giveyou the best possible

dependabilityand performance.

Should you experience any prob2ems you cannot easily

remedy, please contactyour nearest Sears Service Cen-

tedDepartment Searshas competent, wel!trained techni-

cians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions w_l

enable you to assemble and maintain your unit pmpedy.

Always observethe =SAFETY RULES."

MODEL NUMBER:

_ERIAL NUMBER:

)ATE OF PURCHASE:

"HE MODEL AND SERI_ NUMBER WILL BE FOUND

ON THE PRODUCT.

358.356242

PRODUCT SPECIFICATIONS

GUIDE BAR: .............. 18_ (45.7cm}

CHAIN: .................. LowProfile3/8" Pitch

Chrome Cutters

DISPLACEMENT: ......... 2.5 Cubic Inches (40cc)

ENGINE: ................. 2-cycle/dr Cooled

FUEL/OIL MIX RATIO: ..... 40:1 (3.2oz oil per gallongas)

OILER: .................. Automatic, 10.4oz. Tank

IGNITION: ................ Solid State

(Airgap .010"-.014")

IGNITION TIMING: ........ Non-Adjustable, Fixed

SPARK PLUG TYPE: ...... Champion CJ-TY

Autoi_te2974

SPARK PLUG GAP: ........ 025" (.65ram)

MUFFLER: ............... Spark Atre_ng Screen

ENGINE RPM: ............ 12,300-13,200 RPM Maximum

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

Yoursawis equippedwithatemperaturelimltingmuffler

SPECIAL NOTICE

end spark arresting screen which meets the

requirementsofCaliforniaCodes4442and4443.AIIU.S.

forest land and the statesof Califom_ Idaho, Maine,

MAINTENANCE AGREEMENT

A Sears MaintenanceAgreement isavailable onthisprod-

Minnesota,New Jersey,Washington,andOregonrequire

manyinternal combustionenginesto beequippedwitha

sparkarre.._orscreenbylaw.

uct, Contact yournearest Sears Storefor details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for,

and using your uniL

• Follow the instructions under =Customer Responsibili-

ties"and"Storage" sections ofthis Operator's Manual.

ifyouoperatea chainsawinastateorlocalewhere such

regulations exist, you are legally responsible for

maintaining the operating condition of these parts.

Failure to do so is s violationof the law. Referto the

Spark Arrestor section under ,Customer

Responsibilities"for maintenance,

MANL_FA_"tlJRB)UND_q ONE OR_ORS OFTHE FOt/.OW;NGPA_: 4,940X_.

OTHERUS. AND FOrtH PATENTSPEP,_NG.

FULL 1 YEAR WARRANTY ON GAS CHAIN SAW

Fo rune year from the date ofpurchase, when thisCraftsman Gas-Powered Chain Saw is maintained,lubricated, and

tuned upaccording te theoperator'smanual, Sears will repair,free of charge, any defectin material orworkmanship.

Thiswarranty excludesthe bar, chain,spark plug, and air fitter,whichare expendable parts and become wornduring

nomla] use,

If thisGas ChainSaw is used for commercial purposes/thiswarranty applies for 30 days from the date ofpurchese.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES.

This warrantygives you specific legalrights, and you mayalso have other rightswhich vary from state tostate.

SEARS, ROEBUCK AND CO,, DEPT. 817WA, HOFFMAN ESTATES, IL 60179

-5-

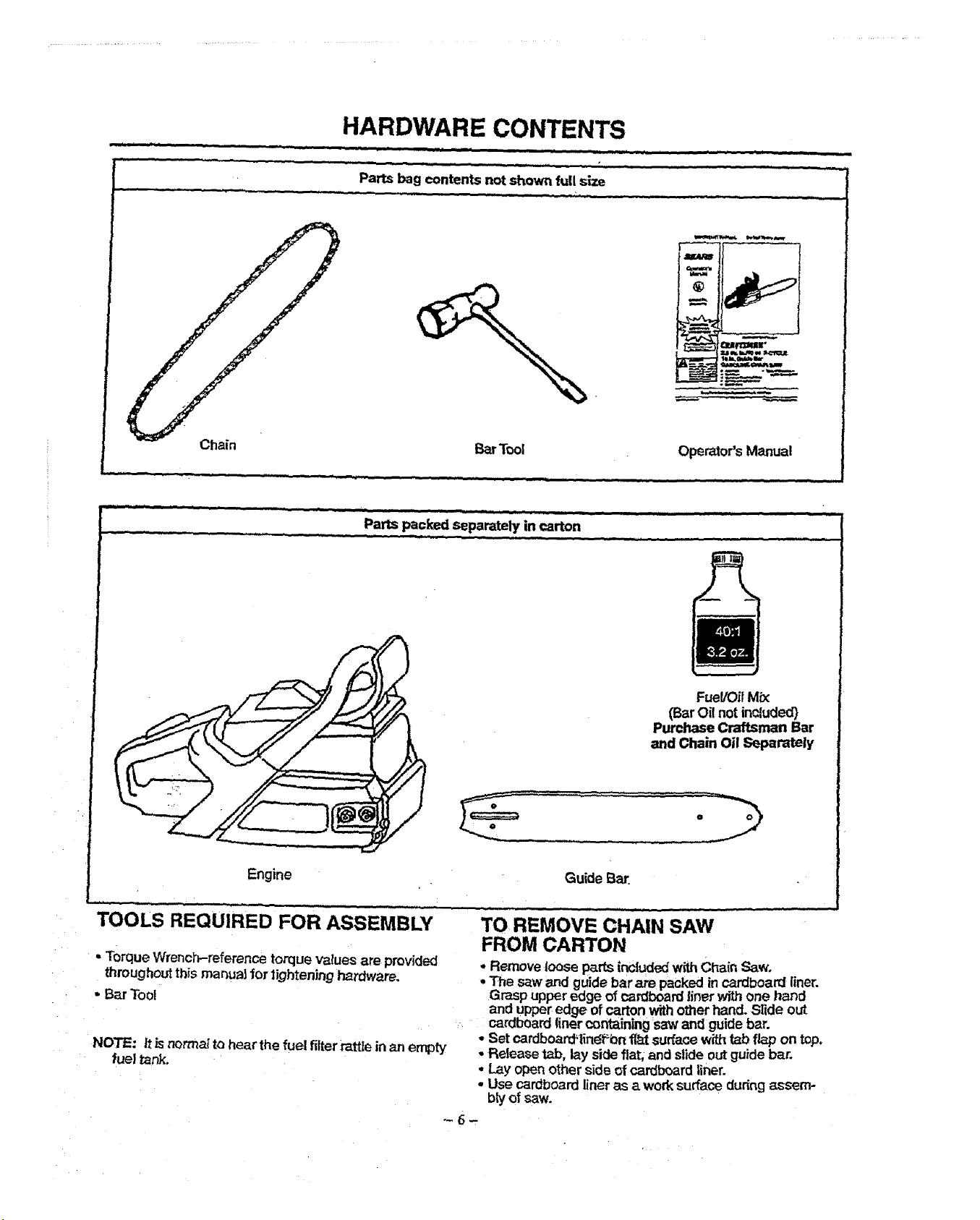

HARDWARE CONTENTS

m

Chain i_r Tool

Parts bag contents not shown full size

I

Operator's Manual

Engine

TOOLS REQUIRED FOR ASSEMBLY

• Torque Wrench-referenc_ torque values are provided

throughout this manu_ for tighten)rig hardware,

• Bar Tool

NOTE: tt isnorma_to hear the fuel filter rattle in _mempty

fuel tank.

Fuel/Oii Mix

(BarOil not included)

Purchase Craftsman Bar

and Chain Oil Separately

Gukie Bar.

TO REMOVE CHAIN SAW

FROM CARTON

Remove loose p_rts included with Chain Saw,

The saw and guide barare packed incardboa_ finer.

Grasp upper edge of cardboard 5ner with one nano.

and upper edge of carton withother nand. _lide out

cardboard liner containing s_w and guide bar.

• Set cardboard_En_f_bnfl_t surface with tab flap on top.

•Release t,_b,lay siOefiat, and sSde outguide bar.

• Lay openother side of cardboard liner.

• Use cardboard finer as a worksurface dudng assem-

bly of saw.

,m, = , ,,,i,ii = , i,,,,,= = =r ,,,,=

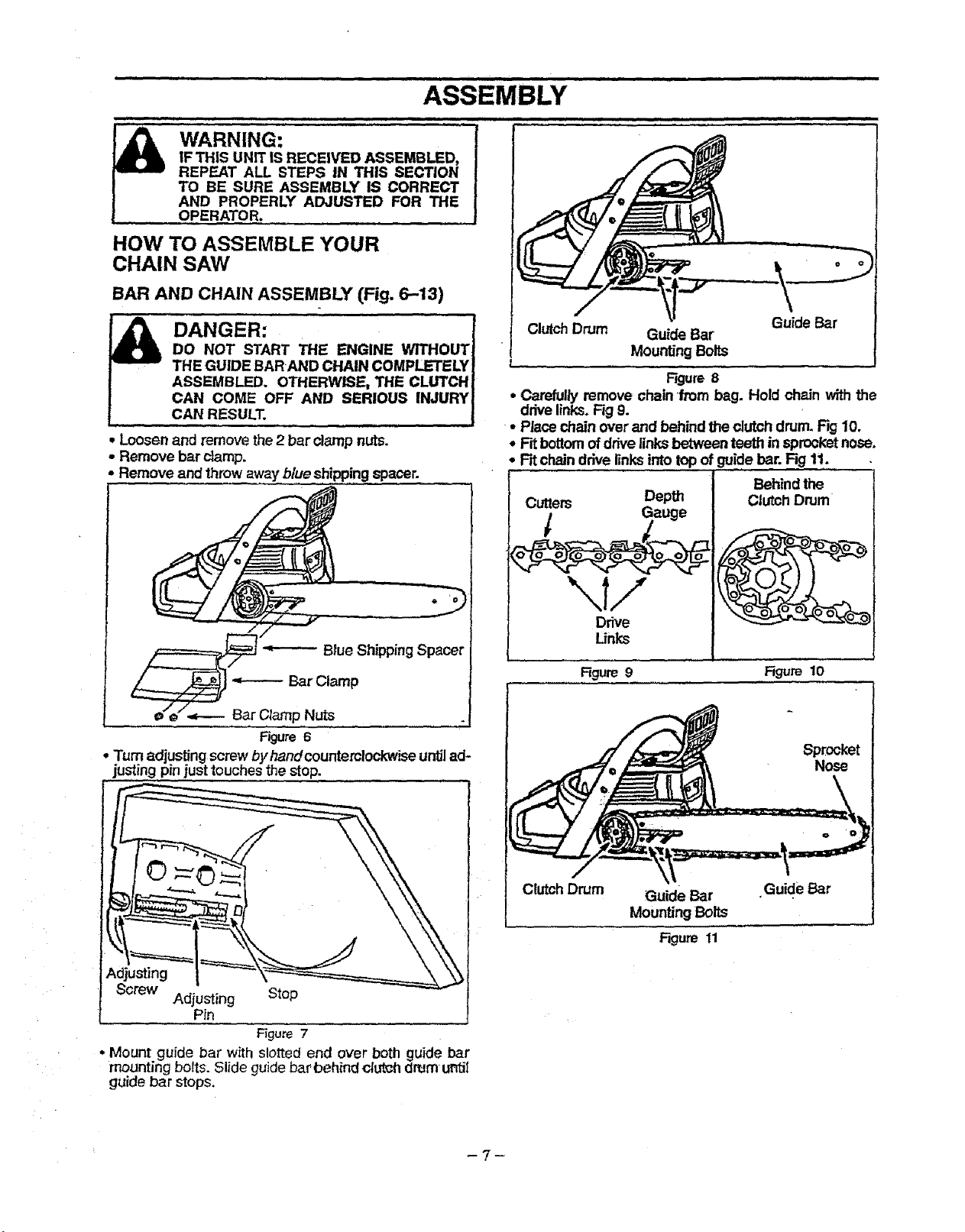

WARNING: .............!

IF THIS UNIT IS RECEWED ASSEMBLED, I

REPEAT ALL STEPS IN THIS SECTION |

TO BE SURE ASSEMBLY IS CORRECT |

AND PROPERLY ADJUSTED FOR THE i

OPERATOR. !

HOW TO ASSEMBLE YOUR

CHAIN SAW

= i J,,== ,,,,,

BAR AND CHAIN ASSEMBLY (Fig. 6-13)

DANGER:

DO NOT START THE ENGINE WITHOUT

THE GUIDE BARAND CHAIN COMPLETELY

ASSEMBLED. OTHERWISE,, THE CLUTCH

CAN COME OFF AND SERIOUS INJURY,

CAN RESULT.

• Loosen and remove the2 bar clamp nuts.

• Remove bar damp.

- Remove andthrow away blue shippingspacer.

-=------- Bar Clamp

=--.- Bar Clamp Nuts

Figure 6

• Turn adjusting screw byhandcountemlockwise untilad-

justing pin justtouches the stop.

, i

\

ClutchDrum Guide Bar

f

• Carefully remove chainfrom bag. Hold chain withthe

i ddve links.Fig 9.

• Place chain over and behind the clutch drum. Fig 10.

* Frtbottomofdrive links between teeth in sprocketnose.

• Rt chaindrive linksinto top of guide bar. Rg 11.

Cutters Depth Clutch Drum

t Gauge

Mounting Bolts

Figure8

Guide Bar

Behindthe

\1/

Drive

Links

Rgure 9

Rgure 10

Nose

Adjusting

Screw

*Mount guidebar withslottedend overbothguidebar

mounting bolts. Slide guide bar t_ehindctut_hdrum' until

guide bar stops.

Adjusting Stop

Pin

Figure7

-7-

Guideear

MountingBelts

Figure 11

Guide Bar

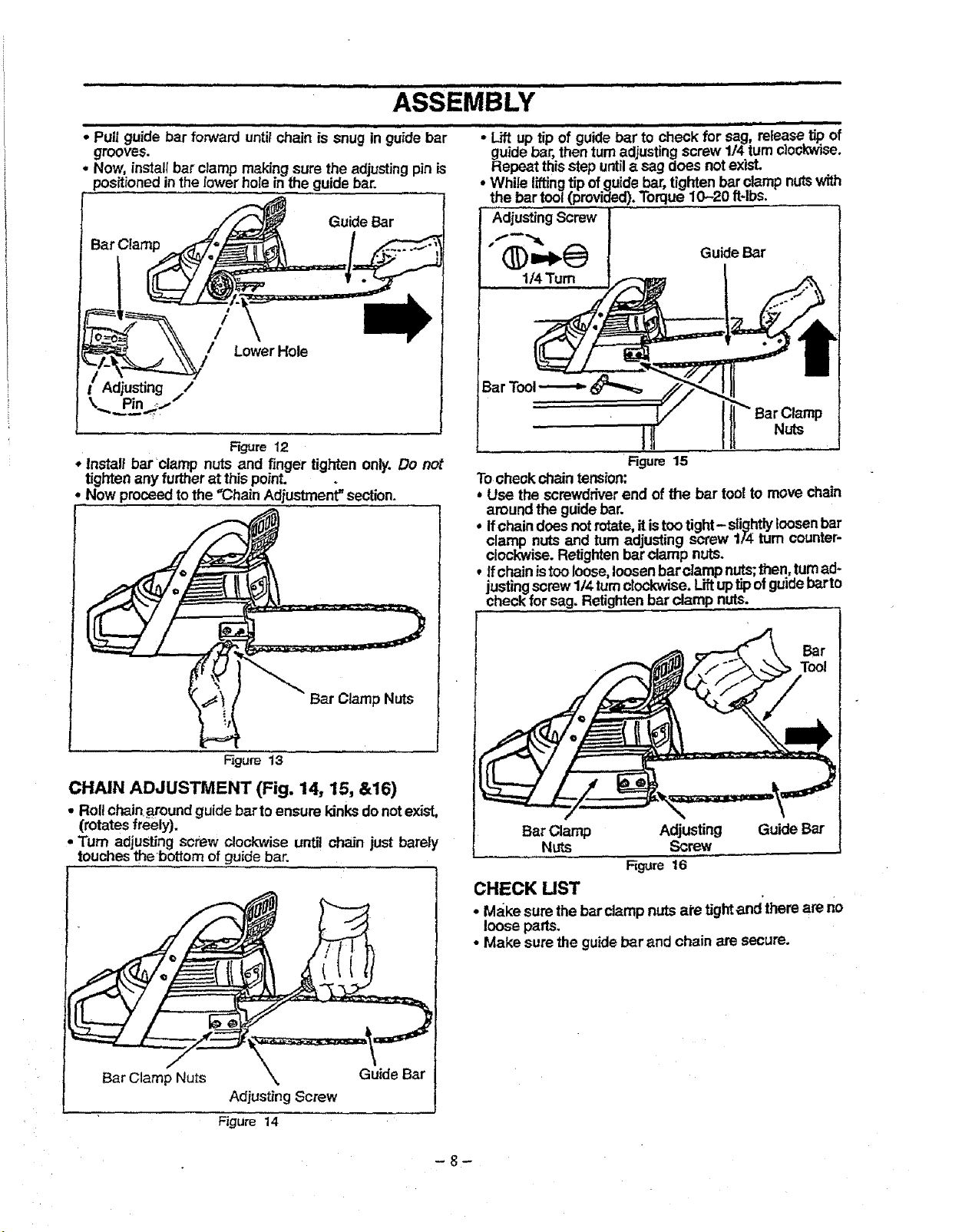

.... guide bar 'fo .............. snug '

• Pull rward untitchain is in guidebar

grooves.

• Now, installbar clamp making sure the adjusting pin is

positioned in the lower holein the guide bar.

Guide Bar

/

/

LowerHole

Adjusting /

Pin ,,I /

Figure 12

* Install bar clamp nuts and finger tighten only. Do not

tighten any further at this point.

Now proceedtothe "Chain Adjustment" section.

• Lift uP""tipof g.ide bar 'iocheck for Sa'gi"release tip of

guide bar, then turn adjusting screw 1/4 turncJoc_ise.

Repeat thisstep untila sag does notexis_

• While liftingtip ofguide bar,tighten barclamp nutswith

the bar tool(provided).Torque 10-20 ft4bs.

Adjusting Screw

"_(_)_b._ Guide Bar

1/4"rum

Bar Clamp

Nuts

Figure 15

Tocheck chain tension:

* Use the screwdriverend of the bar too! to move chain

around the guidebar.

° Ifchain does notrotate,itistootight- slightlyloosenbar

clamp nuts and tum adjusting screw 1/4 turn counter-

clockwise. Retightenbar clamp nuts.

, Ifchainistoo loose,loosenbar clamp nuts;then, turnad-

justingscrew 1/4turnc!ockwise.Liftuptipof guidebutte

check for sag. Retightenbar clamp nuts°

Bar Clamp Nuts

Figure 13

CHAIN ADJUSTMENT (Fig. 14, 15, &16)

• Rollchain around guidebarto ensure kinksde notexist,

(rotates freely).

• "rum adjusting screw clockwise until chain just barely

touchesthe bottomof guide bar.

l

Bar Clamp Adjusting Guide Bar

Nuts Screw

Figure 16

l

CHECK UST

• Make sure the bar clamp nuts ale tight andthere are no

looseparts.

• Make surethe guidebar and chain are secure.

Bar Clamp Nuts Guide Bar

Adjusting Screw

Figure 14

-8-

i = _1 ,,,,ill i i, ,, ,_ i i ,,,i,i = ii IILIIII IIII ill ILl Ill, I, .

OPERATION

,, , ,=,,, == ill _N

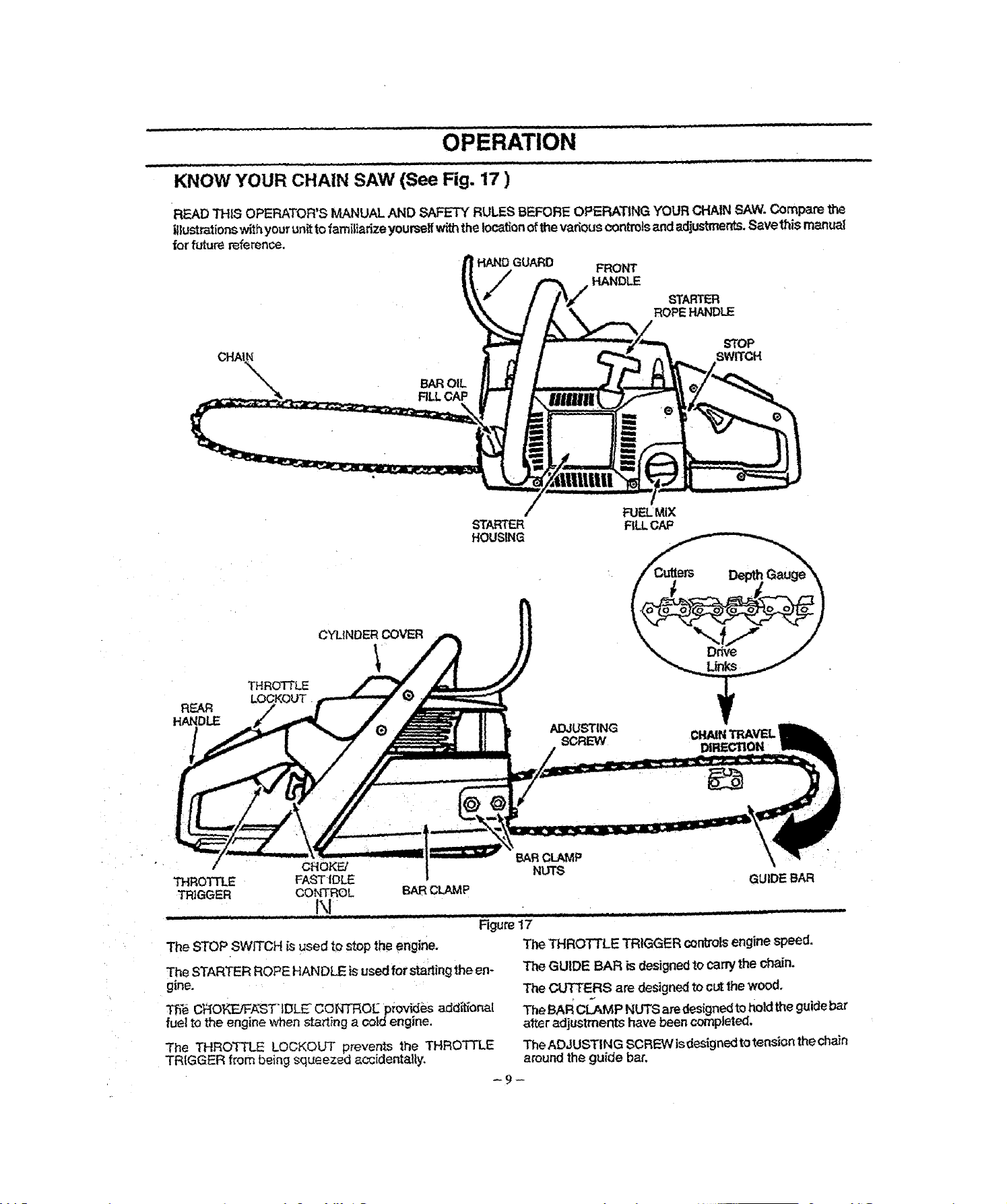

KNOW YOUR CHAIN SAW (See Fig. 17 )

READ THiS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHAIN SAW, Compare the

i_lustrationswith yourunit to familiarize yourseffwiththe location ofthe various controlsandadjustments, Save this manu_I

for future reference.

HANDGUARD FRONT

HANDLE

STARTER

ROPEHANDLE

STOP

SWITCH

CYLINDERCOVER

THROTTLE

REAR

HANDLE

• CHOKE/

THROTTLE FASTIDLE

TRIGGER CO_q3:{OL

BARCLAMP

t\1

...................Figur_1_........................

The STOP SWITCH is used to stop the engine,

The STARTER ROPE HANDLE is used for starting the en-

gine,

TheeC_IO_'E!F,_ST'IDLE CONTROL_ p_ovidi_sadder{oral

fuel to the engine when sta_t}ng a cold engine.

The THROTTLE LOCKOUT prevents the THROTTLE

TRIGGER from being squeezed accidentally,

STARTER

HOUSING

-9-

FUELMiX

FILLCAP

ADJUSTING

SCREW

_RCLAMP

NUTS

The THROTTLE TRIGGER controlsengine speed.

The GUIDE BAR is designedto carry the chain.

The CUTTERS are designed to cutthewood,

The BAF_CI_vl P NUTS are designedto hold the guidebar

after adjustments have been completed.

The ADJUSTING SCREW isdesignedtotension the chain

around the guide bar,

CHAINTI_VEL

DIRECTION

GUIDE BAR

STOPPING YOUR ENGINE

• Move stop switch to the "STOP" position.

o If engine does not stop, pullchoke lever outfully.

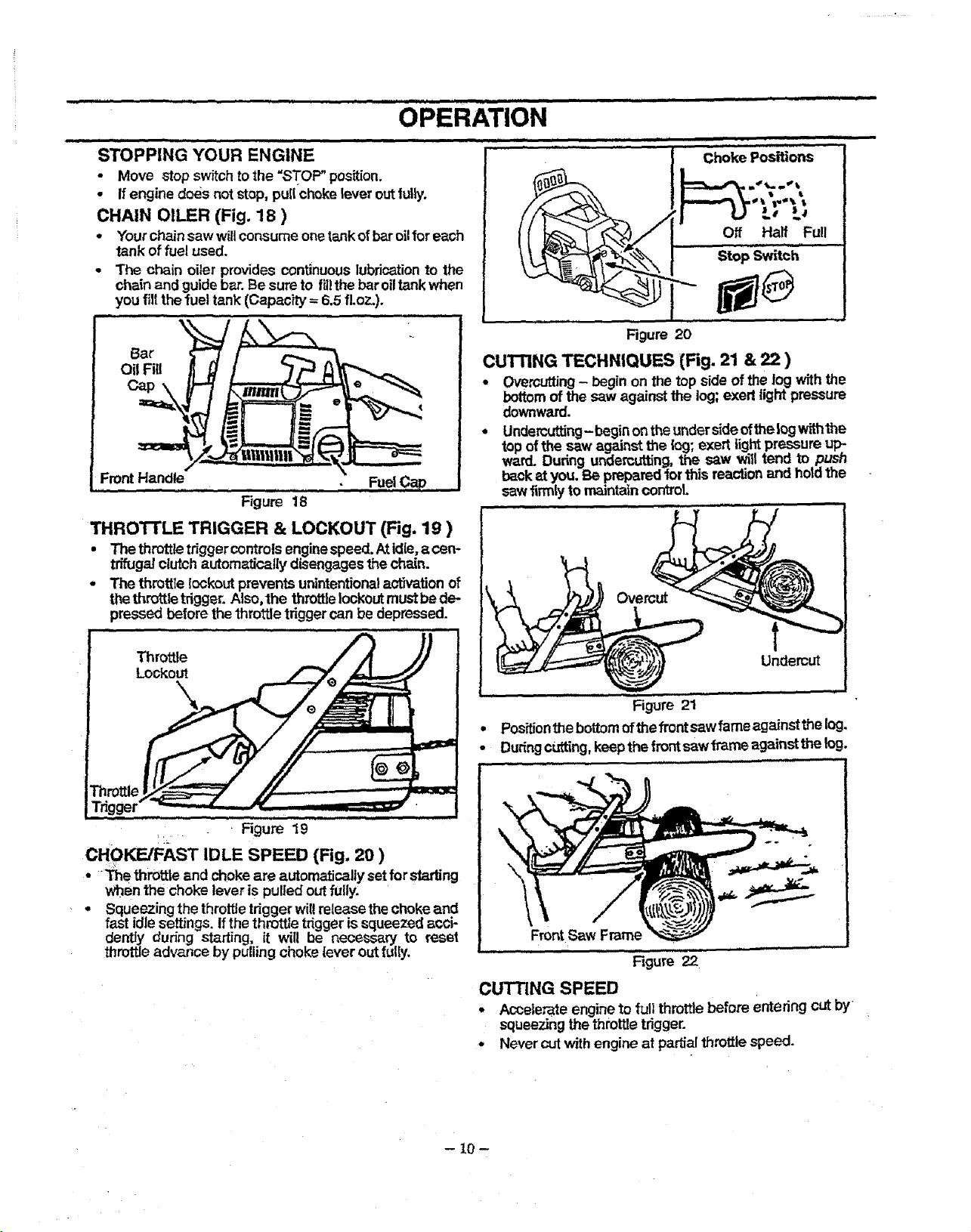

CHAIN OILER (Fig. 18 )

• Yourchainsaw willconsume onetankof baroil for each

tank of fuel used.

• The chain oiler provides continuouslubricationto the

chainand guidebar. Be sureto fg]thebaroiltank when

you fillthefuel tank (Capacity = 6.5 fl.oz.).

Oil Fill

\i

Bar \

Front Handle

..................... Figure 18

THROI-rLE TRIGGER & LOCKOUT (Fig. 19 )

• Thethmttletdggercontrols enginespeed.Atidle, acen-

trifugat ctutch automatically disengagesthe chain.

• The throttte lockout prevents unintentional actuation of

the throttle tdgger. Also, the throttle lockout must be de-

pressed before the throttle trigger can be depressed.

!

Fuel CaD

a

Figure 20

CuI"rlNG TECHNIQUES (Fig. 21 & 22 )

• Overcutting- begin on the top sideof the log with the

bottomof the saw against the log;exert light pressure

downward.

• Undercutting-begin on theundersideofthelog withthe

top ofthe s_wagainst the Io9; exert light pressure up:.

ward. During undercutting,the saw will tend to pusn

backat you. Be prepared1orthis reactionand holdthe

saw firmly to maintatn control.

Throttle

Lo_out

:_ Figure 19

CHOKE/FAST IDLE SPEED (Fig. 20 )

• The throttle and choke are a,utomaticallysetfor starling

when the choke lever is pulled out fully.

• Squeezing the throttletriggerwiltreteasethe choke and

fast idle settings. If the throttle trigger is squeezed acc'_-

dently during starting, it will be necessary to reset

throttleadvance by pulling choke lever out fulb'.

Figure 21

• Pos_onthe bottomofthefront sawfame against thelog-

• Duringcutting,keep thefrontsaw frame against the log.

FrontSaw Frame

Figure 22

CUTTING SPEED

• Accelerate engine to full throttlebefore entering cut by

squeezing the throttletrigger.

• Never cut withengine at partialthrottle speed.

- 10 -

IIIIIIH I I . I IIIIIIIIII I .-- I IIII I I II I I IIIHI

OPERATION

iiiiiiiii i i,,111 i , i i ii IHI

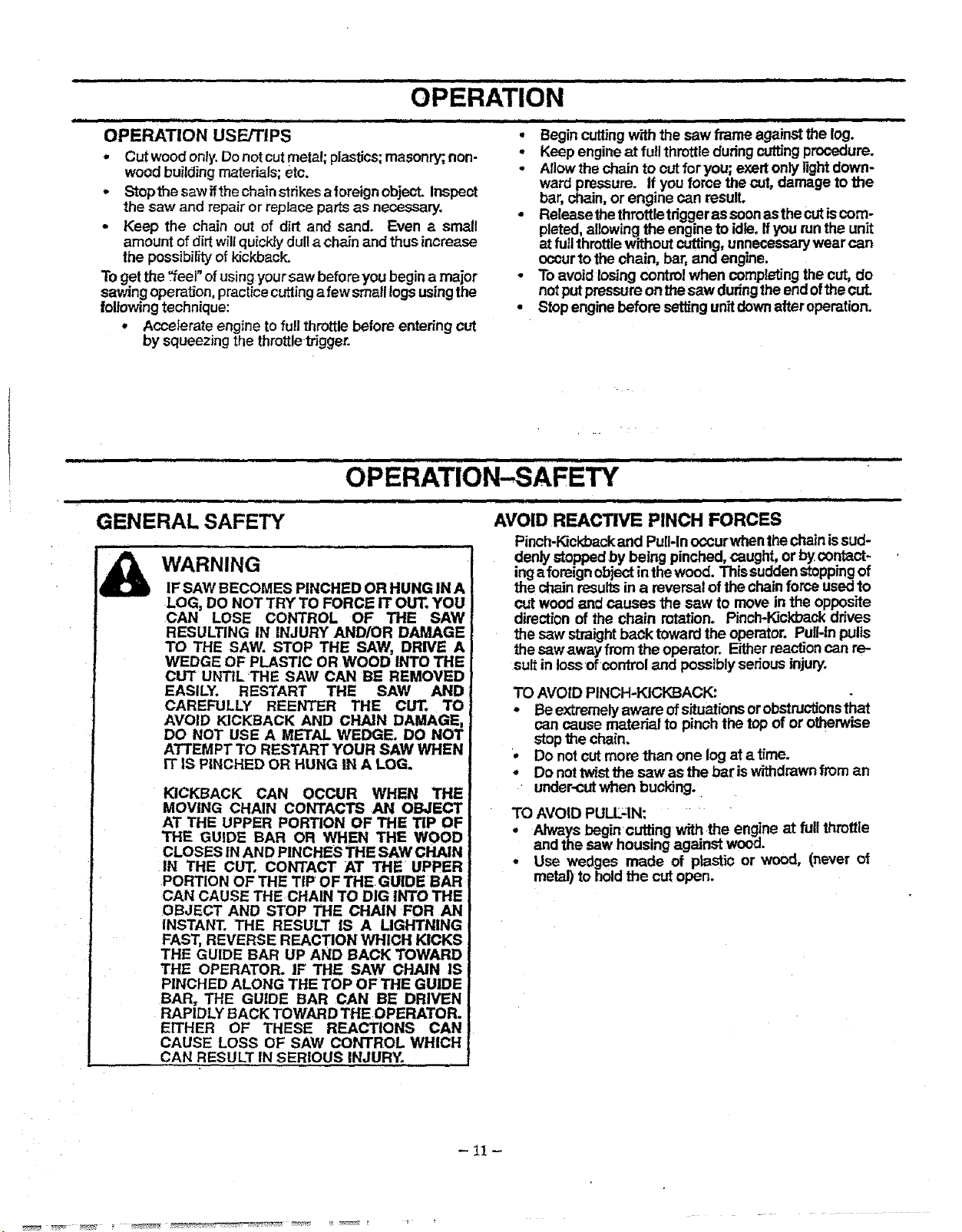

OPERATION USE/TIPS

• Cutwoodonly.Donot cutmetat; plastics; masonry;,non-

woodbuilding materials; etc.

, Stopthe saw ifthe chain strikes aforeign object. Inspect

the saw and repair or replace parts as necessary.

• Keep the chain cut of dirt and sand. Even a small

amount of dirt wilt quickty dull achainand thus increase

the possibility of kickback.

To getthe _eel" of usingyour saw before you begin a major

sawing opera, on,practice cutting a few small togs usingthe

followingtechnique:

• Accelerate engine to full throttle before entedng cut

by squeezing the throttle trigger.

III IIII IIIIIIIIIIIIII I I I

Q

Begin cuttingw_ththe saw frame againstthe log.

,, ,,,,,,,,,,,,,,, i iiii i iii ii i

Keep engine at fullthrottleduring cuttingprocedure.

Allowthe chain to cut foryou; exertonly lightdown-

ward pressure. If youforce the cut, damageto the

bar, chain, or engine can result.

Release thethrottletriggeras soonas the cutis com-

pleted,allowing the engine to idle. Ifyou runthe unit

at futlthrottlewithout cutting,unnecessarywear can

occurto the chain, bar, and engine.

t

To avoid losing controlwhen completingthe cut, do

notputpressureon thesaw dunngthe endof the cut.

Stopengine before settingunitdownafter operation.

OPERATION-SAFETY

i i i ,, H

GENERAL SAFETY

,,,,,,,L,,ii

WARNING

IF SAW BECOMES PINCHED OR HUNG IN A

LOG, DO NOT TRY TO FORCE IT OUT. YOU

CAN LOSE CONTROL OF THE SAW

RESULTING IN INJURY AND/OR DAMAGE

TO THE SAW. STOP THE SAW, DRIVE A

WEDGE OF PLASTIC OR WOOD INTO THE

CUT UNTIL THE SAW CAN BE REMOVED

EASILY. RESTART THE SAW AND

CAREFULLY REENTER THE CUT. TO

AVOID KICKBACK AND CHAIN DAMAGE,

DO NOT USE A METAL WEDGE, DO NOT

ATTEMPT TO RESTART YOUR SAW WHEN

IT IS PINCHED OR HUNG IN A LOG.

KICKBACK CAN OCCUR WHEN Tile

MOVING CHAIN CONTACTS AN OBJECT

AT THE UPPER PORTION OF THE TiP OF

THE GUIDE BAR OR WHEN THE WOOD

CLOSES IN AND PINCHES THE SAW CHAIN

IN THE CUT. CONTACT AT THE UPPER

PORTION OF THE TiP OF THE GUIDE BAR

CAN CAUSE THECHAIN TO DIG INTO THE

OBJECT AND STOP 3"HE CHAIN FOR AN

INSTANT. THE RESULT IS A LIGHTNING

FAST, REVERSE REACTION WHICH KICKS

THE GUIDE BAR UP AND BACK TOWARD

THE OPERATOR. IF THE SAW CHAIN IS

PINCHED ALONG THE TOP OF THE GUIDE

BAR, THE GUIDE BAR CAN BE DRIVEN

RAPIDLY BACK TOWARD THE!OPERATOR.

EITHER OF THESE REACTIONS CAN

CAUSE LOSS OF SAW CONTROL WHICH

CAN RESULT IN SERIOUS INJURY.

iii i i i ,,,,,, ,,,,,,,,,,,,,,,,,,,,i i ii iiiiiiii

AVOID REACTIVE PINCH FORCES

Pinch-Kickbackand PulHn occur whenthe chain issud-

denly stoppedby being pinched,caught, or bycontact-

ingaforeign object in thewood. Thissuddenstopping of

the chainresults ina reversal of the chain force usedto

cut wood and causes the saw to movein the opposite

direction of the chain rotation. Pinch-Kickbackdrives

the sawstraightback toward the operator. PuU-tnpulls

the sawaway fromthe operator. Eitherreactioncan re-

sult in lossof controland possibly seriousinjury.

TO AVOID PINCH-KICKBACK:

* Be extremelyaware of situationsorobstructionsthat

can cause rnatedal to pinch the top of or otherwise

stop the chain.

o Do notcut more than one log at a time.

. Donottwistthesawasthebariswithdrawnfrom an

under-cutwhen bucking.

TO AVOID PULL-IN:

o Always begincuffing with the engine at full throttle

and the saw housing against wooo.

- Use wedges made of ptastic or wood, (never of

metal) tohold the cut open.

- 11 -

Loading...

Loading...