Craftsman 358356081 Owner’s Manual

$'-__A/RS

_perator's

manual

• Assembly

• Operation

• Maln!enance

• Renalr Parts

MODEL NO.

3s8.3sso81-3.o/_s-

_WARNING:

Carefully read and follow

Safety Rules, Precautions

and Operating Instructions.

Failure to do so can result

in serious personal injury.

i •

CRRI:T MRN, J

GASOLINE"CHAIN SAW

, ii

Record in the space provided below the Model No. and Serial NO:Of

your saw. These numbers are located on the starting instructions

decal.

Model No. Serial No.

Retain these numbers for future reference.

66647-:1-25285-1-25285

i

Sears, Roebuck and C_)., Chicago, IlL 60684 U.S.A.

PRINTED IN U. S. A.

FULL ONE YEAR WARRANTY ON GASOLINE CHAIN SAW

(Excluding Bar, Chain, Spark Plug, Air Filter and Starter Rope)

Forone year from date of purchase when you maintain, lubricate and tune upthis chain saw aocording to the operating

and maintenance instructionsin the owner's manual Sears will repairdefects In material orw_rkmanshiPiln this gasoline

chain saw at no charge.

This warranty excludes the bar,chain, spark plug,air filter, and starter ropewhich are expendable parts and become worn

during normal use.

If this chain saw is used for commercial or rental purposes, this warranty applies for only 30 days from date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CHAIN SAW TO THE NEAREST SEARS SERVICE CENTER

IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may a_sohave other rignts which vary from state to state.

Sears. Roebuck and Co.. Sears Tower, Dept. 698/731A, Chicago, IL 60684

TABLE OF CONTENTS •

Spect icatt_ns .............................. 2

SPECIAL SA_Y SECTION 3, 4 &5

Know Your Chain Saw ........................ 6

Preparing Your Saw For Use .................. :7

A. Getting Ready .......................... 7

B. Attaching the Handguard ................ 7

C. Attaching the Spur ...................... 7

D. Attaching the Barand Chain .............. 8

E. Chain Tension .......................... 9

F. Engine Fuel Mixture ..................... 9

G. Barand Chain Oil ....................... 10

Using Your Saw .............. : .............. 11

A. Corttrol Devices ........................ 11

B. Starting Instructions .................... 11

Types of Cutting ............................ . !2

A. Basic Cutting Technique ................. 12

B. Tree Felling Techniques ................. 12

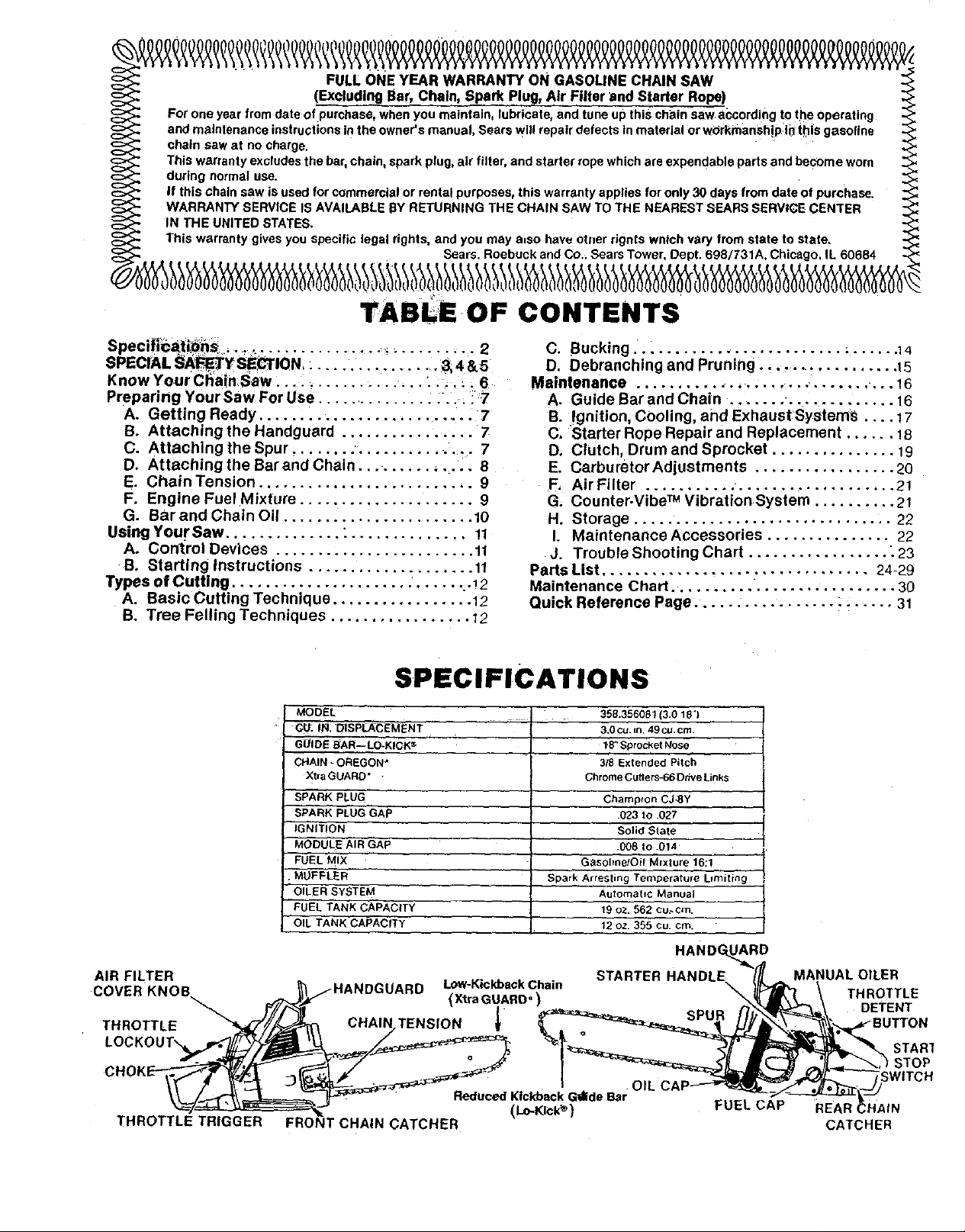

SPECIFICATIONS

MODEL

CU: IN; DISP_CEMENT

GUIDE BAR-:LO-KICK ®

CHAIN - OREGON*

Xtra GUARD* -

SPARK PLUG

SPARK PLUG GAP

IGNITION

MODULE AIR GAP

FUEL MIX

MUFFLER

OILER SYSTEM

FuEL TANK CAPACITY

'OIL TANK CAPACITY

C. Bucking ......................... _...... ] 4

D. Debranching and Pruning ................... 15

Maintenance ..................... ....... .,, 16

A. Guide Bar and Chain ....... . • ........... 16

B. Ignition, Cooling, and ExhaustSystems .... 17

(3. Starter Rope Repair and Replacement ...... 18

D. Clutch, Drum and Sprocket ............... 19

E. Carburetor Adjustments ................. 20

F. Air Filter ........... ................... 21

G. Counter-Vibe TM Vibration System .......... 21

H. Storage ............................... 22

I. Maintenance Accessories ............... 22

J. Trouble Shooting Chart ................. :23

Parts List ................................ 24-29

Maintenance Chart .......... ................. 30

Quick Reference Page ........................ 31

358.3560B1 (3.0 18")

3,0 cu. =n 49 CU.crn

18"Sprocket Nose

3/8 Extended Pitch

Chrome Cuaers-66 Ddve Links

Champron C J-BY

.023 to .027

Solid State

.008 to ,014

Gasoline/Oil Mrxture 16:1

Spark Arresting Temperature Limiting

Automatic Manual

19 oz. 562 cu.cm.

12 oz. 355 cu. cm.

HANDC

MANUAL OILER

THROTTLE

DETENT

REAR HAIN

CATCHER

STAR]

;TOP

SPECIAL SAFETY SECTION

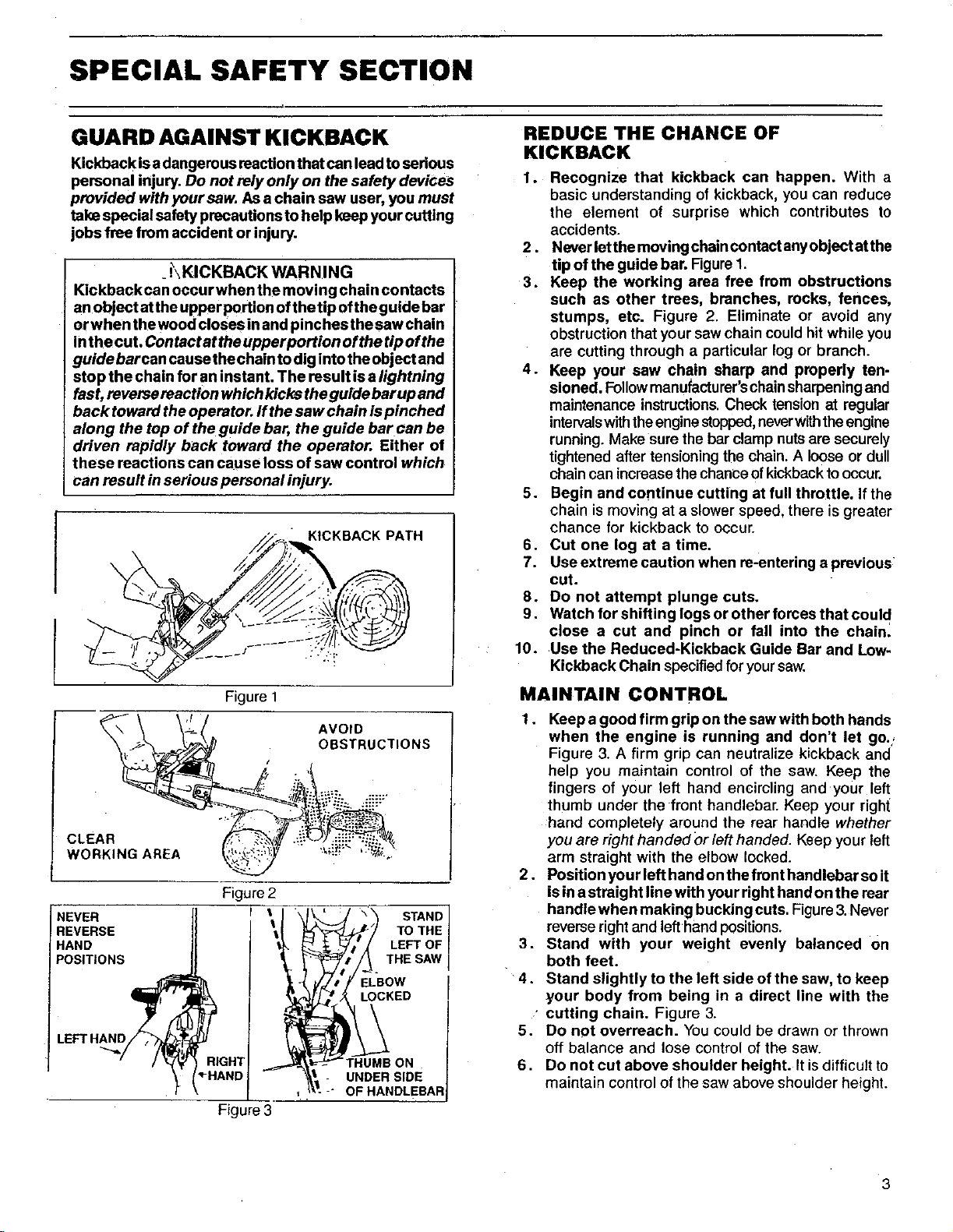

GUARD AGAINST KICKBACK

Kickback isa dangerous reaction that can lead to serious

personal injury. Do not rely only on the safety devices

provided with your saw. As a chain saw user, you must

take special safety precautions to help keep your cuffing

jobs free from accident or injury.

. _\KICKBACK WARNING

Kickback can occurwhen the moving chain contacts

anobject atthe upper portion ofthe tip of the guide bar

orwhen the wood closesin and pinches thesaw chain

inthecut, Contact at theupper portion of the tip of the

guide barcan cause the chain to dig intothe object and

stop the chain for an instant. The result is a lightning

fast, reverse reaction which kicks the guide bar up and

back toward the operator. If the saw chain is pinched

along the top of the guide bar, the guide bar can be

driven rapidly back toward the operator. Either of

these reactions can cause loss of saw control which

can result inserious personal injury.

, // i: . OKBACKPAT.

REDUCETHECHANCEOF

KICKBACK

1. Recognize that kickback can happen. With a

basic understanding of kickback, you can reduce

the element of surprise which contributes to

accidents.

2. Never letthemoving chain contact anyobject atthe

tip of the guide bar. Figure1.

3. Keep the working area free from obstructions

such as other trees, branches, recks, fences,

stumps, etc. Figure 2. Eliminate or avoid any

obstruction that your saw chain could hit while you

are cutting through a particular log or branch.

4. Keep your saw chain sharp and properly ten-

sioned. Followmanufacturer'schainsharpeningand

maintenance instructions.Check tension at regular

intervalswiththeenginestopped,neverwiththeengine

running. Make sure the bar clamp nutsare securely

tightened aftertensioningthe chain. A looseor dull

chaincan increasethechance of kickbacktooccur.

5. Begin and continue cutting at full throttle. If the

chain is moving at a slower speed, there is greater

chance for kickback to occur.

6. Cut one log at a time.

7. Use extreme caution when re-entering a previous

cut.

8. Do not attempt plunge cuts.

9. Watch for shifting logs or other forees that could

close a cut and pinch or fall into the chain.

10. Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specifiedfor your saw.

Figure I

AVOID

OBSTRUCTIONS

CLEAR

WORKING AREA '_i_ ':

Figure 2

NEVER II

REVERSE II

HAND li

POSITIONS

t

LEFTHAND/> T'

STAND

TO THE

LEFT OF

__ THE SAW

ELBOW

LOCKED

ON

UNDER SIDE

OF HANDLEBAR

MAINTAIN CONTROL

1. Keep a good firm grip on the saw with both hands

when the engine is running and don't let go.i

Figure 3. A firm grip can neutralize kickback and

help you maintain control of the saw. Keep the

fingers of your left hand encircling and your left

thumb under the front handlebar. Keep your right

hand completely around the rear handle whether

you are right handed Orleft handed. Keep your left

arm straight with the elbow locked.

2. Position your left hand on the front handlebar so it

isin a straight line with your right hand on the rear

handle when making bucking cuts. Figure3. Never

reverserightand lefthand positions.

3. Stand with your weight evenly balanced on

both feet.

4. Stand slightly to the left side of the saw, to keep

your body from being in a direct line with the

• cutting chain. Figure 3.

5. Do not overreach. You could be drawn or thrown

off balance and lose control of the saw.

6. Do not cut above shoulder height. It is difficult to

maintain control of the saw above shoulder height.

3

SPECIAL SAFETY SECTION (continued)

Because a chain saw is a high speed wood-cutting tool, special safety precautions must

be observed to reduce the risk of personal accidents. Careless or improper use can

I cause serious personal injury. I

SNUG ,_=mm, _I_ _ EYEPROTECTION

FITFING

CLOTHING

_ii_ _ HEARINGPROTECTION

• . L_WARNING

_ SAFETYHAT

_ _ Ftgure4

KNOW YOUR SAW

1. Read your Operator's Manual carefully untilyoucom-

pletely understand and can follow all safety rules and

operating instructions before attempting tooperatethe

unit.

2. Restrfot the use of your saw toadultusarswhounder-

stand and follow the safety rules, precautions, and

operating instructionsfoundin this manual.

PLAN AHEAD

1. Wear personal protective gear. Figure 4. Always use

steel-toedsafetyfootwear Withnon-slipsoles;snug-fitting

clothing;heavy-dutynon-s!ipgloves;eye protectionsuch

as non-fogging,vented g0ggles or face screen;an ap-

provedsafety hard hat, andsoundbarders -- earplugsor

mufflers to protectyour hearing. Regular users should

have hearingchecked regularly as chain saw noisecan

damage hearing.

2. Keep children, bystanders, and pets Out of the work

area -- a minimum of 30 feet (10 meters). Donotallow

other people or animals to be near the chainsaw when

starting oroperating the chain saw.

3. Do not handle or operate a chain saw when you are

fatigued, ill, or upset; or if you have taken alcohol,

drugs or medication. You must be in good physical

condition and mentally alert. Chain saw work is

strenuous. If you have any condition that might be

aggraveted bystrenuous work, check withyour doctor

before operating a chain saw.

4. Do not attempt to use your chain saw during ba

weather conditions such as strong wind, rain, sno_

etc., or at night.

5. Plan your sawing operation carefully in advance, r

notstart cuttinguntilyouhavea clear work area, sacul

footing, and ifyouarefelling trees,a planned retreatpatl

AVOID REACTIVE FORCES

Pinch-Kickback and Pull-in occur when the chain i

suddenly stopped by being pinched, caught, or b

contacting a foreign object in the wood. This resultsin,

reversalofthechainforce usedtocutvKx:x:landcausesthesat

to move in the oppositedirectionof chain rotation. Pinch

Kickback drives the saw straight back towardthe operato

Pull-in pulls the saw awayfrom the operator.Either reaction:

canresult inloss ofcontrolandpossibleseriouspersonalinjuq

To avoid Pinch-Kickback:

1.

Be extremely aware of situations or obstruction=

that can cause material to pinch the top of or other

wise stop the chain.

2.

Do not cut more than one log at a time.

3.

Do not twist the saw as the bar iswithdrawn from ar

under-cut when bucking,

TO

avoid Pull-in:

1.

Always begin cutting with the engine at full throttk

and the spur against the wood.

2;

Use wedges made of plastic or wood, (never of metar

to holdthe cutopen.

HANDLE FUEL WITH CAUTION

t. Eliminate all soumes of sparks or flame in the area._

where fuel is mixed, poured, or stored. There shoulc

be no smoking, open flames, orwork that couldcaus_

sparks.

2. Mix and pour fuelin an outdoor area, on bare ground

store fuel ina cool, dry,well-ventilated place; andusE

an approved, marked container for all fuel purposes

3. Wipe up all spilled fuel before starting your saw

4. Move at least .10feet (3 meters) away from fuel an(

fueling site before starting the engine.

5. Do not smoke while handling fuel or while operatin.(

the saw.

6. Turn the engine off and let your saw cool befon

removing the fuel tank cap and refueling the unit

7. Let the saw cool in a non-combustible area, notor

dry leaves, straw, paper, etc.

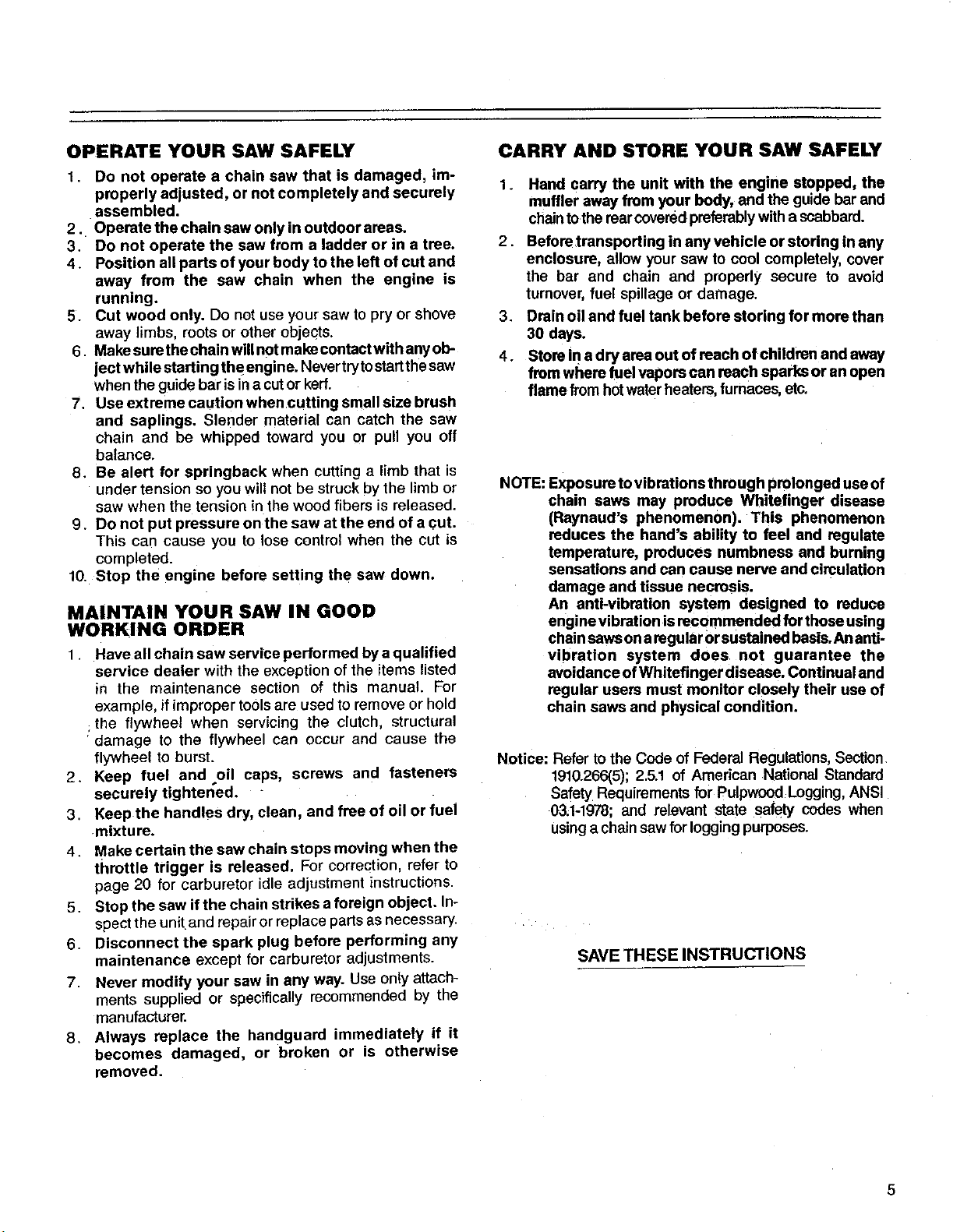

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged, im-

properly adjusted, or not completely and securely

assembled.

2. Operate the chain saw only in outdoor areas.

3. Do not operate the saw from a ladder or in a tree.

4. Position all parts of your body to the leff of cut and

away from the saw chain when the engine is

running.

5. Cut wood only. Do not use your saw to pry or shove 3.

away limbs, roots or other objects.

6. Make sure the chain willnot make contact with any ob- 4.

ject while starting the engine. Nevertrytostartthe saw

when the guide bar is in acutor kerf.

7. Use extreme caution when cutting small size brush

and saplings. Slender material can catch the saw

chain and be whipped toward you or pull you off

balance.

8. Be alert for springback when cutting a limb that is

under tension so you will not be struck by the limb or

saw when the tension in the wood fibers is released.

9. Do not put pressure on the saw at the end of a cut.

This can cause you to lose control when the cut is

completed.

10. Stop the engine before setting the saw down.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

1. Have all chain saw service performed by a qualified

service dealer with the exception of the items listed

in the maintenance section of this manual. For

example, if improper tools are used to remove or hold

the flywheel when servicing the clutch, structural

:damage to the flywheel can occur and cause the

flywheel to burst.

2. Keep fuel and oil caps, screws and fasteners

securely tightened.

3. Keep the handles dry, clean, and free of oil or fuel

mixture.

4. Make certain the saw chain stops moving when the

throttle trigger is released. For correction, refer to

page 20 for carburetor idle adjustment instructions.

5. Stop the saw if the chain strikes a foreign object. In-

spect the unit and repair or replace parts as necessary.

6. Disconnect the spark plug before performing any

maintenance except for carburetor adjustments.

7. Never modify your saw in any way. Use only attach-

ments supplied or specifically recommended by the

manufacturer.

8. Always replace the handguard immediately if it

becomes damaged, or broken or is otherwise

removed.

CARRY AND STORE YOUR SAW SAFELY

1. Hand carry the unit with the engine stopped, the

muffler away from your body, and the guide bar and

chaintothe rearcovered preferablywitha scabbard.

2.

Beforetransporting in any vehicle or storing in any

enclosure, allow your saw to cool completely, cover

the bar and chain and properly secure to avoid

turnover, fuel spillage or damage.

Drain oil and fuel tank before storing for more than

30 days.

Store in a dry area out of reach of children and away

from where fuel vapors can reach sparks or an open

flame from hotwaterheaters,furnaces, etc.

NOTE: Exposure to vibrations through prolonged use of

chain saws may produce Whitefinger disease

(Raynaud's phenomenon). This phenomenon

reduces the hand's ability to feel and regulate

temperature, produces numbness and burning

sensations and can cause nerve and circulation

damage and tissue necrosis.

An anti-vibration system designed to reduce

engine vibration is recommended for those using

chainsaws ona regular orsustained basis. An anti-

vibration system does not guarantee the

avoidance ofWhitefinger disease. Continual and

regular users must monitor closely their use of

chain saws and physical condition.

Notice: Refer to the Code of Federal Regulations, Section

1910.266(5); 2.5.1 of American National Standard

Safety Requirements for Pulpwood Logging, ANSI

03.1-1978; and relevant state safety codes when

usinga chainsaw for loggingpurposes.

SAVE THESE INSTRUCTIONS

5

KNOW YOUR CHAIN SAW

A. INTRODUCTION

• Yoursaw has been designed with safetyin mind and

includesthe followingfeatures as standardequipment:

- Reduced-Kickback Guide Bar (Lo-Kick ®)

- Low-Kickback Chain (,Xtra GUARD '-_')

- Spark Arrestor

-Temperature Limiting Muffler

- Handguards

- Counter-Vibe ® Anti-Vibration System

WARNING

[he following features are included on your saw to help

reduce the hazard of kickback, however, such features

will not totally eliminatethis dangerous reaction. As a

chain saw user, do not rely only on safety devices, You

must follow all safety precautions, instructions and

maintenance in this manual to help avoid kickback and

other forces which can result in serious personal injury.

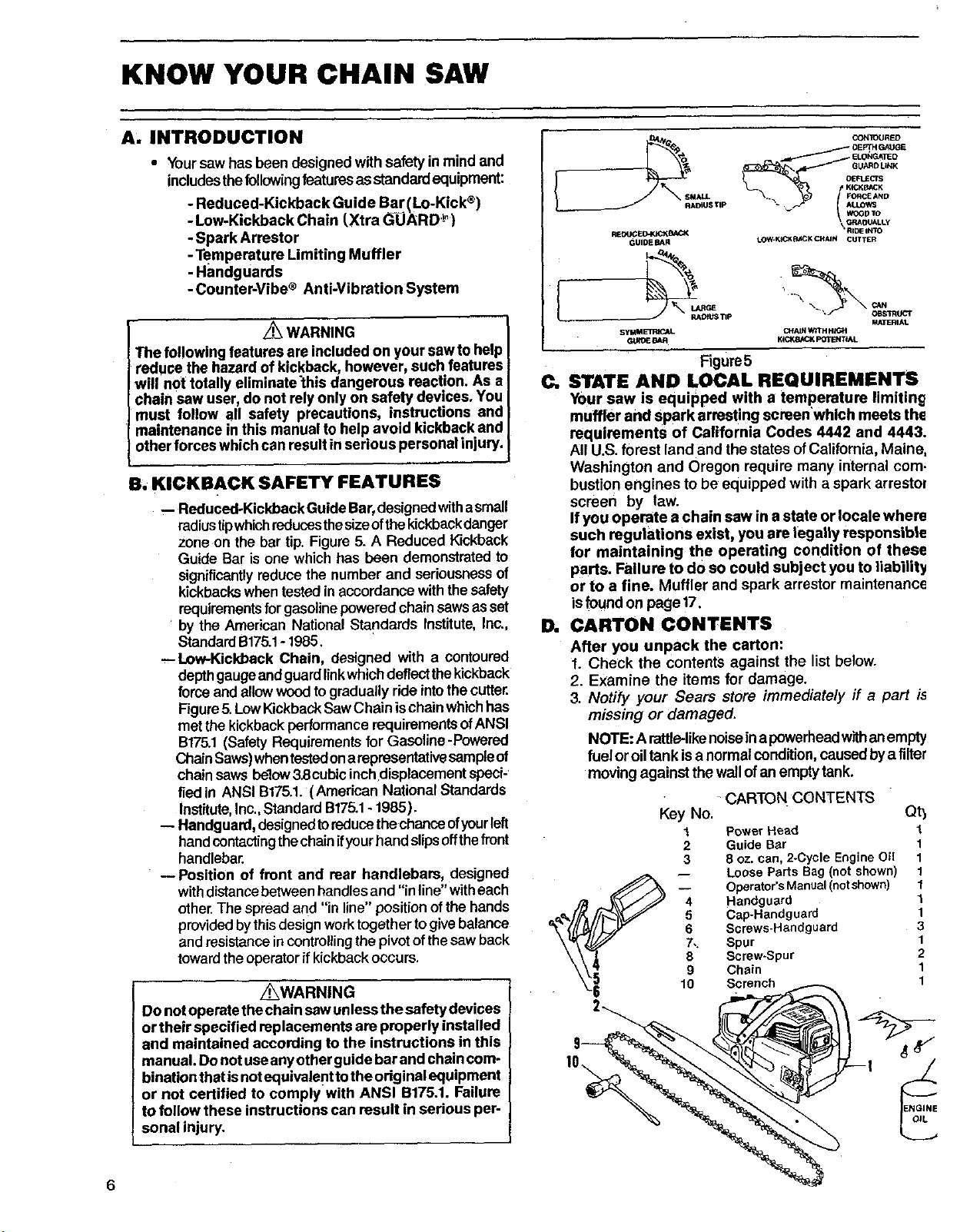

B. KICKBACK SAFETY FEATURES

-- Reduced-Kickback GuideBar,designed withasmall

radiustipwhichreducesthesizeofthe kickbackdanger

zoneon the bar tip. Figure 5. A Reduced Kickback

Guide Bar is one which has been demonstratedto

significantlyreduce the number and seriousnessof

kickbackswhentestedin accordancewiththe safety

requirementsforgasolinepoweredchain sawsasset

by the American National Standards Institute, Inc.,

StandardB175.1-1985.

--Low-Kickback Chain, designed with a contoured

depthgaugeand guardlinkwhichdeflectthe kickback

force and allow woodto graduallyrideintothe cutter.

Figure5. LowKickbackSaw Chain ischain whichhas

met the kickbackperformancerequirementsofANSI

B175.1(Safety Requirementsfor Gasoline-powered

ChainSaws)whentestedonarepresentativesampleof

chainsaws below _8cubic inchdisplacementspeci-

fied in ANSI B175.1. (American National Standards

Institute,Inc.,StandardB175.1-1985).

-- Handguard, designedtoreducethechanceofyourleft

handcontactingthechainifyourhand slipsoffthefront

handlebar.

--Position of front and rear handlebars, designed

withdistancebetween handlesand "in line"witheach

other.The spread and "in line" positionofthe hands

provided bythisdesignworktogethertogivebalance

andresistanceincontrollingthe pivotof the sew back

towardthe operatorifkickbackoccurs.

z_WARNING

Do not operetethechain sawunless the sefety devices

or their specified replacements are properly installed

and maintained according to the instructions in this

manual. Do not useanyother guide barand chain com-

binationthat isnotequivalent tothe original equipment

or not certified to comply with ANSI B175.1. Failure

to follow these instructions can result in serious per-

sonal injury.

I

CON1OURED

OEPTH GAUGE

ALL .. FORCELLOWsAND

-°,,. .'----Y

_IFJ_K_ \ RIDE INTO

GUIDE BAR tOW-K_CKBACK CHAIN CUTTER

5YMMETR_AL CHAIq W;TH H_GH

_EAFI KI_8,_CK POTENTIAL

Figure5

C. STATE AND LOCAL REQUIREMENTS

Your saw is equipped with a temperature limiting

muffler and spark arresting screen'whlch meets the

requirements of California Codes 4442 and 4443.

All U.S. forest land and the states ofCalifornia, Maine,

Washington and Oregon require many internal com.

bustion engines to be equipped with a spark arrestol

screen by law.

Ifyou operate a chain saw in a state or locale where

such regulations exist, you are legally responsible

for maintaining the operating condition of these

parts. Failure to do so could subject you to liability

or to a fine. Muffler and spark arrestor maintenance

isfound on page 17.

D. CARTON CONTENTS

After you unpack the carton:

f. Check the contents against the list below.

2. Examine the items for damage.

3. Notify your Sears store immediately ff a part is

missing or damaged.

NOTE: A rattle-likenoiseina powerhead withanempty

fuelor oiltank isa normalcondition,causedby a filter

moving against thewall of an emptytank.

CARTON CONTENTS

Key No. Qt3

I Power Head 1

2 Guide Bar 1

3 8 oz. can, 2-Cycle Engine Oil 1

-- Loose Parts Bag (notshown) 1

Handguard 1

Cap-Handguard 1

6 Screws-Handguard 3

7,. Spur 1

8 Screw-Spur 2

Operator's Manual(notshown) 1

9 Chain 1

10 Screneh 1

ENGINE

PREPARING YOUR SAW FOR USE

A. GETTING READY

1. READ YOUR OPERATOR'S MANUAL

CAREFULLY.

Your Operator's Manual has been developed to

help you prepare your saw for use and to under-

stand its safe operation. It is important that you

read your manual completely to become familiar

with the unit before you begin assembly.

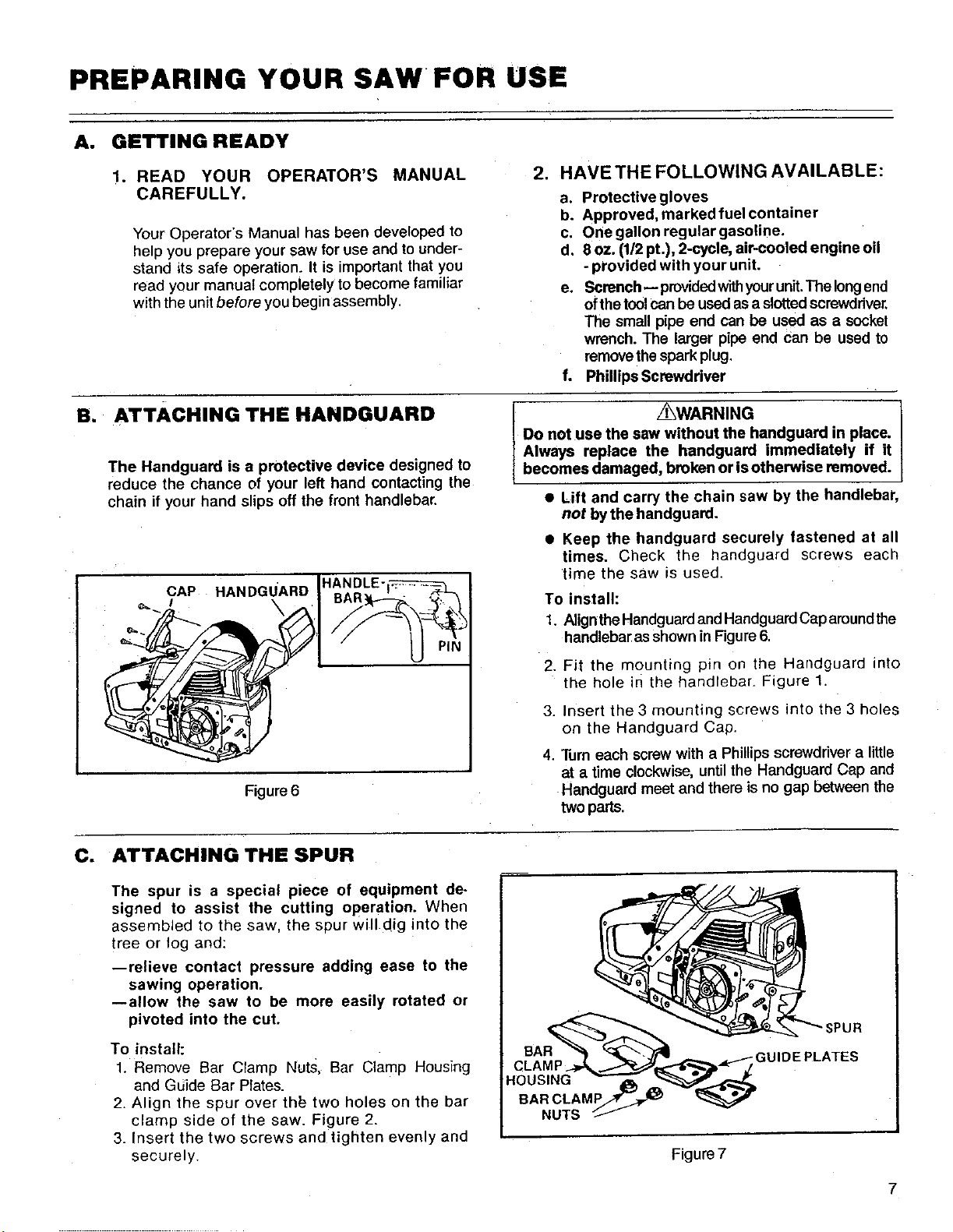

B. ATTACHING THE HANDGUARD

The Handguard is a protective device designed to

reduce the chance of your left hand contacting the

chain if your hand slips off the front handlebar.

CAP HANDGUARD

i \

HANDLE-I_

BAR)t_---_ _ \

/ U

2. HAVETHE FOLLOWING AVAILABLE:

a. Protective gloves

b. Approved, marked fuel container

c. One gallon regular gasoline.

d. 8 oz. (1/2pt.), 2-cycle, air-cooled engine oil

- provided with your unit.

e. Scrunch-- provided withyourunit.Thelongend

ofthetoolcanbe used as a slottedscrewdriver,

The small pipe end can be used as a socket

wrench. The larger pipe end can be used to

removethe sparkplug,

f. Phillips Screwdriver

Do not use the saw without the handguard in place.

I Always replace the handguard immediately if it

[ becomes damaged, broken or is otherwise removed.

• Lift and carry the chain saw by the handlebar,

not by the handguard,

• Keep the handguard securely fastened at all

times. Check the handguard screws each

time the saw is used.

To install:

1. AligntheHandguardandHandguardCap aroundthe

handlebaras shownin Figure6.

2. Fit the mounting pin on the Handguard into

the hole in the handlebar. Figure 1.

z_WARNING 1

Figure 6

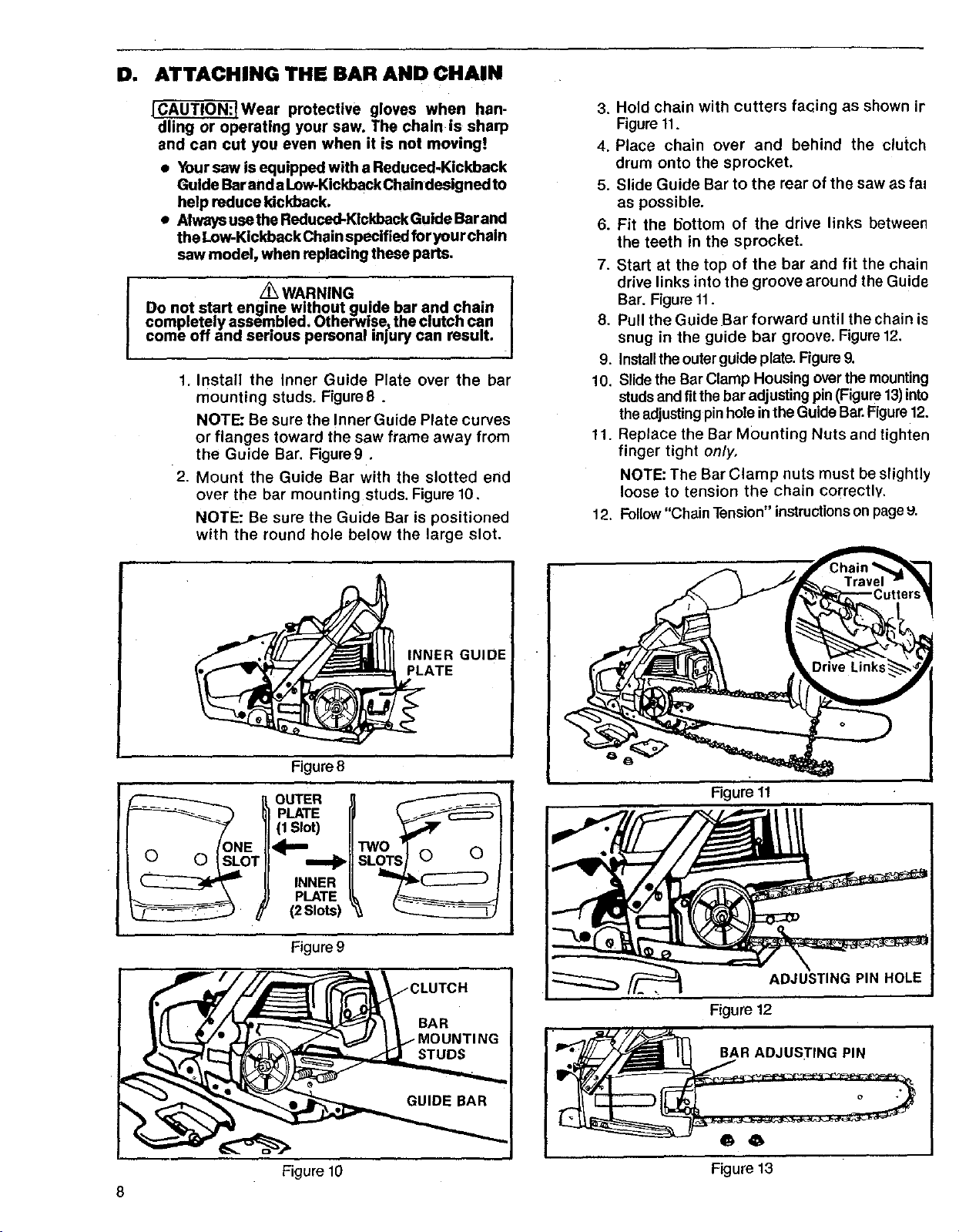

C. ATTACHING THE SPUR

The spur is a special piece of equipment de-

signed to assist the cutting operation. When

assembled to the saw, the spur will dig into the

tree or log and:

--relieve contact pressure adding ease to the

sawing operation.

--allow the saw to be more easily rotated or

pivoted into the cut.

To install:

1. Remove Bar Clamp Nuts, Bar clamp Housing

and Guide Bar Plates.

2. Align the spur over th§ two holes on the bar

clamp side of the saw. Figure 2.

3. Insert the two screws and tighten evenly and

securely.

3. Insert the 3 mounting screws into the 3 holes

on the Handguard Cap.

4. Turn each screwwith a Phillips screwdrivera little

at a time clockwise, until the Handguard Cap and

Handguard meet and there is no gap between the

two parts.

CLAMP.

HOUSING

BARCLAM_ _

NUTS

Figure 7

;GUIDE PLATES

;PUR

7

D. ATTACHING THE BAR AND CHAIN

[CAUTION:IWear protective gloves when han-

dling or operating your saw. The chain is sharp

and can cut you even when it is not moving!

• Your saw Is equipped with a Reduced-Kickback

Guide Barand a Low-Kickback Chain designed to

help reduce kickback.

• Always use the Reduced-Kickback Guide Bar and

the Low-Kickback Chainspecified for your chain

saw model, when replacing these parts.

Do not start engine without guide bar and chain

completely assembled. Otherwlse_ the Clutcn can

J z_ WARNING I

come off and serious persona! inlury can result.

1. Install the Inner Guide Plate over the bar

mounting studs. Figure8.

NOTE: Be sure the Inner Guide Plate curves

or flanges toward the saw frame away from

the Guide Bar. Figure9.

2. Mount the Guide Bar with the slotted end

over the bar mounting studs. Figure 10.

NOTE: Be sure the Guide Bar is positioned

with the round hole below the large slot.

3. Hold chain with cutters facing as shown ir

Figure 11.

4. Place chain over and behind the clutch

drum onto the sprocket.

5. Slide Guide Bar to the rear of the saw as fal

as possible.

6. Fit the 15ottom of the drive links between

the teeth in the sprocket•

7. Start at the top of the bar and fit the chain

drive links into the groove around the Guide

Bar. Figure 11.

8• Pull the Guide Bar forward until the chain is

snug in the guide bar groove. Figure 12,

9. Installthe outer guide plate. Figure 9.

10. Slide the BarClamp Housing over the mounting

studs and fitthe bar adjusting pin (Figure 13)into

the adjusting pin hole in the Guide Bar. Figure 12.

11. Replace the Bar Mounting Nuts and tighten

finger tight only,

NOTE: The Bar Clamp nuts must be slightly

loose to tension the chain correctly.

12. Follow "Chain Tension" instructions on page 9.

Figure8

OUTER

PLATE

(1 Slot)

INNER

PLATE

(2Slots)

Figure9

1 INNER GUIDE

wo l

;LOa_T,, 0 0

:LUTCH

Figure 11

ADJUSTING PIN HOLE

Figure 12

BAR ADJUSTING PIN

6 6

Figure 10 Figure 13

8

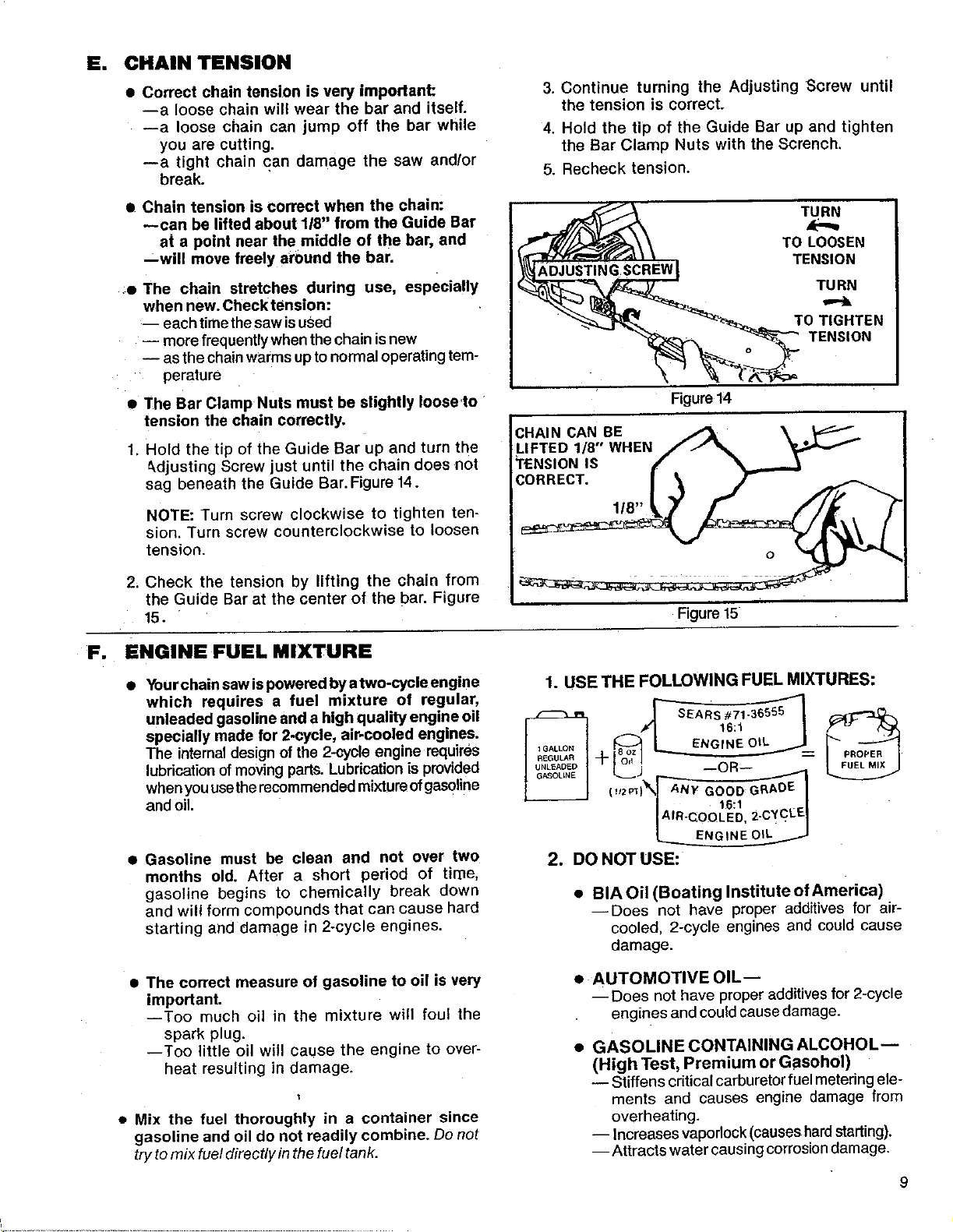

E. CHAIN TENSION

• Correct chain tension is very important:

--a loose chain will wear the bar and itself.

--a loose chain can jump off the bar while

you are cutting.

--a tight chain can damage the saw and/or

break.

• Chain tension is correct when the chain:

--can be lifted about 1/8" from the Guide Bar

at a point near the middle of the bar, and

--will move freely around the bar.

..• The chain stretches during use, especially

when new. Checktension:

-- each time the saw isused

-- more freduently when the chain isnew

-- as thechainwarms upto normal operating tem-

perature

• The Bar Clamp Nuts must be slightly loose,to

tension the chain correctly.

1. Hold the tip of the Guide Bar up and turn the

_djusting Screw just until the chain does not

sag beneath the Guide Bar.Figure 14.

NOTE: Turn screw clockwise to tighten ten-

sion. Turn screw counterclockwise to loosen

tension.

3. Continue turning the Adjusting Screw until

the tension is correct.

4. Hold the tip of the Guide Bar up and tighten

the Bar Clamp Nuts with the Scrench.

5. Recheck tension.

TURN

TO LOOSEN

=

Figure 14

CHAIN CAN BE _ \

LIFTED 1/8" WHEN fJ_

TENSION IS f .

TENSION

TU RN

TO TIGHTEN

TENSION

co..ECT.13,-/

2, Check the tension by lifting the chain from

the Guide Bar at the center of the bar. Figure

15.

F. ENGINE FUEL MIXTURE

• Your chain saw ispowered bya two-cycle engine

which requires a fuel mixture of regular,

unleaded gasoline and a high quality engine oil

specially made for 2-cycle, air-cooled engines.

The internaldesign of the 2-cycle engine requires

lubricationof moving parts. Lubricationis provided

when youusethe recommended mixtureofgasoline

and oil.

Gasoline must be clean and not over two

months old. After a short period of time,

gasoline begins to chemically break down

and will form compounds that can cause hard

starting and damage in 2-cycle engines.

• The correct measure of gasoline to oil is very

important.

--Too much oil in the mixture will foul the

spark plug.

--Too little oil will cause the engine to over-

heat resulting in damage.

• Mix the fuel thoroughly in a container since

gasoline and oil do not readily combine. Do not

try to mix fuel directly inthe fuel tank.

Rgure 15

1. USETHE FOLLOWING FUEL MIXTURES:

2. DO NOT USE:

• BIA Oil (Boating Institute of America)

--Does not have proper additives for air-

cooled, 2-cycle engines and could cause

damage.

• AUTOMOTIVE OIL-

- Does not have proper additives for 2-cycle

engines and could cause damage.

• GASOLINE CONTAINING ALCOHOL-

(High Test, Premium or Gasohol)

-- Stiffens critical carburetor fuel metering ele-

ments and causes engine damage from

overheating.

-- Increases vapodock (causes hard starting).

-- Attracts water causing corrosion damage.

9

3. HOW TO MIX FUEL 4. IMPORTANT POINTS

a. Pour one-half of the gasoline into an ap-

proved, marked container. Do not try to mix

oil and gasoline directly in the fuel tank.

b. Add entire measure of 2-cycle Engine Oil.

c. Mix.

d. Add remainder of gasoline.

e. Mix thoroughly for one minute.

Figure 16

G. BAR AND CHAIN OIL

• The guide bar and cutting chain require con-

tinuous lubrication in order to remain in

operating condition. Lubrication is provided

by the automatic oiler system when the oil

tank is kept filled.

--Lack of oil will quickly ruin the bar and

chain.

--Too little oil will cause overheating shown

by smoke coming from the chain and/or

discoloration of the guide bar rails.

• Use Sears Bar and Chain Lubricant #71-36554

or clean SAE 30W oil.

• In freezing weather oil will thicken, making it

necessary to thin bar and chain oil with a

sm_ill amount of Diesel Fue! #1 or Kerosene.

Bar and chain oil must be free flowing for the

oil system to pump enough oil for adequate

lubrication.

a. Use only recommended fuel mixtures.

b. Eliminate all soumes of sparks or flame inthe

areas where fuel is mixed, poured, or stored.

Thereshouldbe nosmoking,openflames orwork

thatcouldcause sparks.

c. Usean approved, marked container for all fuel

purposes.

d. Mix and pour fuel In an outdoor area on bare

ground. Store fuel in a cool, dry, well-

ventilatedplace. Gasolinevaporsare harmfulto

your healthand are a seriousfire hazard. Use a

funnel or spoutwhen pouringfuel.

e. Avoid overfilling the fuel tank. Allow3/4inchfor

expansion.Tighten FuelCap securely.Figure16.

f. Wipe up all fuelspllls. Wipooffanyfuel spilledon

thesaw.Completelydry thesaw before using.

g. Move at least 10feet(3 meters) away from fuel

_nd fueling site before starting the engine.

1. USE THE FOLLOWING:

3O°F or above -- Lubricant -- undiluted.

30°F - O°F -- 95% lubricant to 5% Diesel

Fuel #1 or Kerosene.

Below 0°F -- 90% lubricant to 10%

Diesel Fuel #1 or Kerosene.

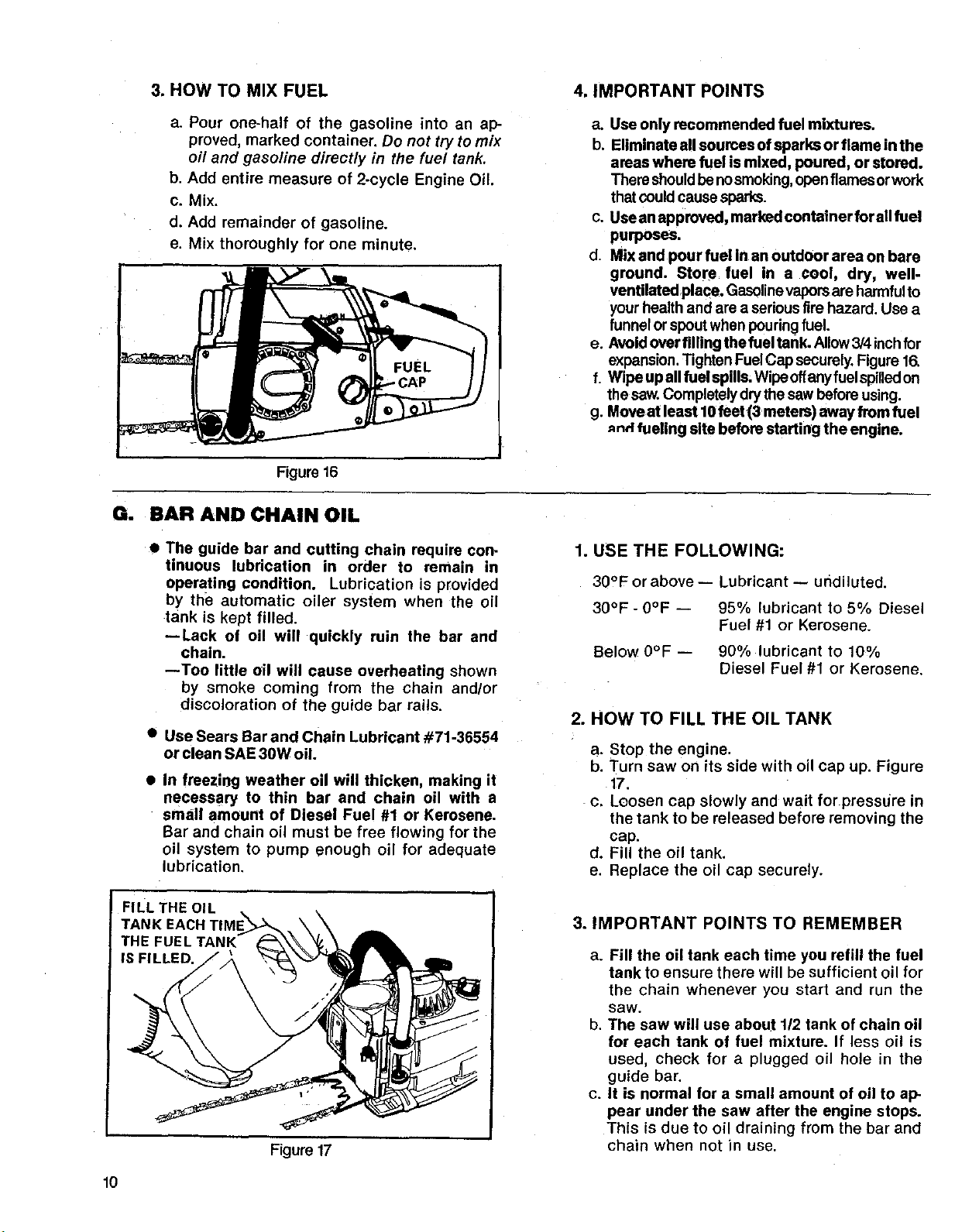

2. HOW TO FILL THE OIL TANK

a. Stop the engine.

b. Turn saw on its side with oil cap up. Figure

17.

c. Loosen cap slowly and wait for pressure in

the tank to be released before removing the

cap.

d. Fill the oil tank.

e. Replace the oil cap securely.

FILL THE OIL

TANK EACH

THE FUEL TANK

IS FILLED.

10

Figure 17

3. IMPORTANT POINTS TO REMEMBER

a. Fill the oil tank each time you refill the fuel

tank to ensure there will be sufficient oil for

the chain whenever you start and run the

saw.

b. The saw will use about 1/2 tank of chain oil

for each tank of fuel mixture. If less oil is

used, check for a plugged oil hole in the

guide bar.

c. It is normal for a small amount of oil to ap-

pear under the saw after the engine stops.

This is due to oil draining from the bar and

chain when not in use.

Loading...

Loading...