Craftsman 358355071, 358355061 Owner’s Manual

.IMPORTANT MANUAL

operator's

manual

• Assembly

• Operation

• Maintenance

Do Not Throw Away

• Repair Parts

MODEL NO.

358.355061-

2.3/16"AV

358.355071-

2.3/16" AVPS

al_ WARNING:

Carefully read and follow

_lfety Rules, Precautions and

Operating Instructions, FailUre

to do so can result in serious

SF_/ -RS RRFT$1qR

2.3/16" AV 2.,3/16" PS.AV

GASOLINE CHAIN SAWS

Record in the space provided below the Model No. andSerial No. of

your saw. These numbers are tocated on the starting instructions

decal.

Model No. Serial No.

530-066646-_19688

Retain these numbers for future•reference.

Sea,_, Ro(_btlok and Cx x, Chicag(), IlL 60684 U.S.A.

- @Sears,RoebuckandCo., 1988,,

ULLONI_Y rARRANTY ON GASOLINE CHA

(Excluding Bar, Chain, Spark Plug, Air Filter and Starter Rope)

For one year from date of purchase, when you maintain, lubricate, and tune up your 2.3 AV or 23 RS. AV gasoline chain saw

accOrdingt_ the _pemting maintenan_e Inst_u_ti_ns inthe _perat_r_s manua_ Sears wi_ repair defects in malaria_s _r w_rkmansh ip

in _is gesotine chain eaw at no charge.

This warranty exc_udesthe bar_cha_n'spark p_ug_ajr _lter_and starter r_e wt_ich are expendabIe pa_rtsand becOme w_m during

normaluse. ._

Ifthis2.3AVor2.,3RS.AVgasolinechainsawisusedforcommercialorrentalpurposes,thiswarrantyappliesforonly30

L<`-_:__daysfr_mdate_fpurchase_WARRANTYSERV|CE_SAVAILABLEBYRETURN_NGTHF-CHAINSAWT_THE_NEARESTSEARS

SC'-RVICECENTER/DEPARTMENTIN THEUNITEDSTATES.

Thi_ warranty gives y_u sped'_ _egalr_ghts_a.qdy_u m_y afs_ have _ther rights wh_ch_ary _mmstate t_state` -_

TABLE OF CONTENTS -

Specifications ................................ 2

SPECIAL SAFETY SECTION ....................3

Know'(our Chain Saw .......................... 6

Preparing Your Saw For Use ..................... 7

A.GettingReady ...........................7

B.AttachingtheBarand Chain ......-,..........7

C. ChainTension............................8

D.FuelingYourEngine .......................9

E. BarandChain Lubr_ant ................... 10

Using YourSaw ..............................10

A.PreOperationChecks .....................10

B.StartingInstructions......................11

Using thePowerSharp e System ................12

Types ofCutting.............................._3

A.Basic Cutting Technique ................... 13

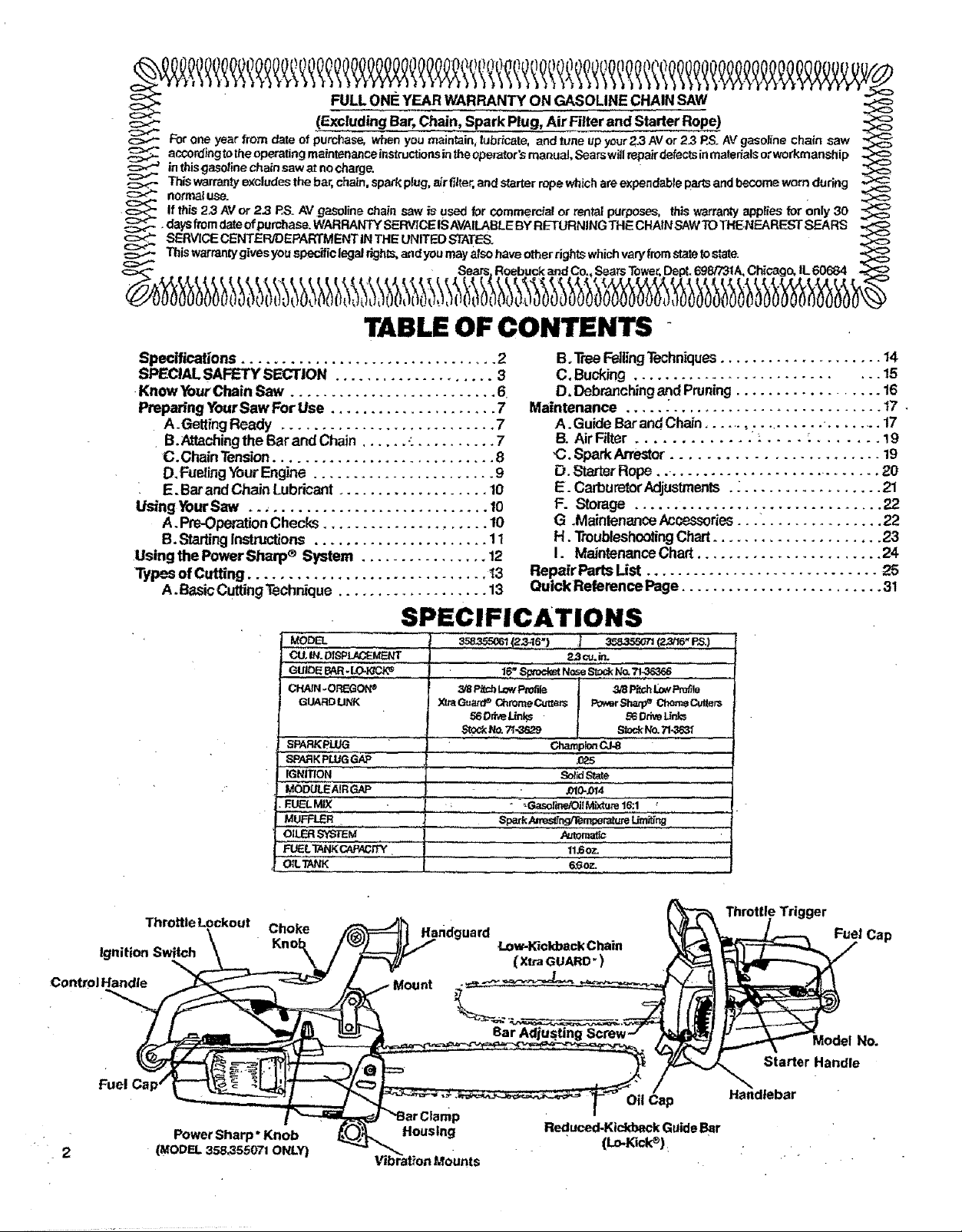

SPECIFICATIONS

MODEL

....._u._.o_,_L,_E_r

CHAIN-OREGONe

GUARD LINK

SPA_G ..........

SPARKPLUGGAP

M_O-DULEAIRGAP ,',':',',',':,,,,,,,' ...... : ' 'N0:,_,4

•EUEL MIX ; ....... :' - _Gasoline/Oi_Mixtum 16:1 '

Mu_-L_• : l s_"_U=_"g

OILERS_-EM ) _ Aut_,_¢

' _F'r,=,N_c,,,..4=W:..........i ............. "._o='"

O,.TANK { ..........s_o_

3/8P_c_LowProfile 3/8Pitch_ Pro_te

X_Guar_P Chr_eCt_er_ _rSha_ L"P_eCut_e:

SSOr_elinks 56Ddvel_n_

,._N_7_ _ h'o.7_-._s3_

...................Champk_C,Fa.............

B, TreeFellingTechniques.................... 14

C, Bucking ............................ _5

D. Debranchinga_dPruning.................. 16

Maintenance ................................ 17 •

A. GuideBarandChain................. ........ 17

B. Air Filter ............. _: .... . ....... 19

_. Spark Arrestor........................ 19

D. StarterRope.. ........................... _0

E. CarburetorAdjustments. : ................. 21

F. Storage ............................... 22

G .MaintenanceAcces,_ries .................. 22

H. TroubleshootingChart..................... 23

I. Maintenance Chart....................... 24

Repair Parts List ............................. 25

Quick Reference Page .........................31

(_'6') ..........! _(_'_;P_)

2,3cu.in.

,025

• _ Throttle Trigger

Throttle L°ck°ut Choke .)__ndguard _:__ F_,etCap

_Lf._---_I_ _ j _J_ starter Handle

\ ,.o\ I

....................

,,ow.,,.....oo,

tjibration Mounts

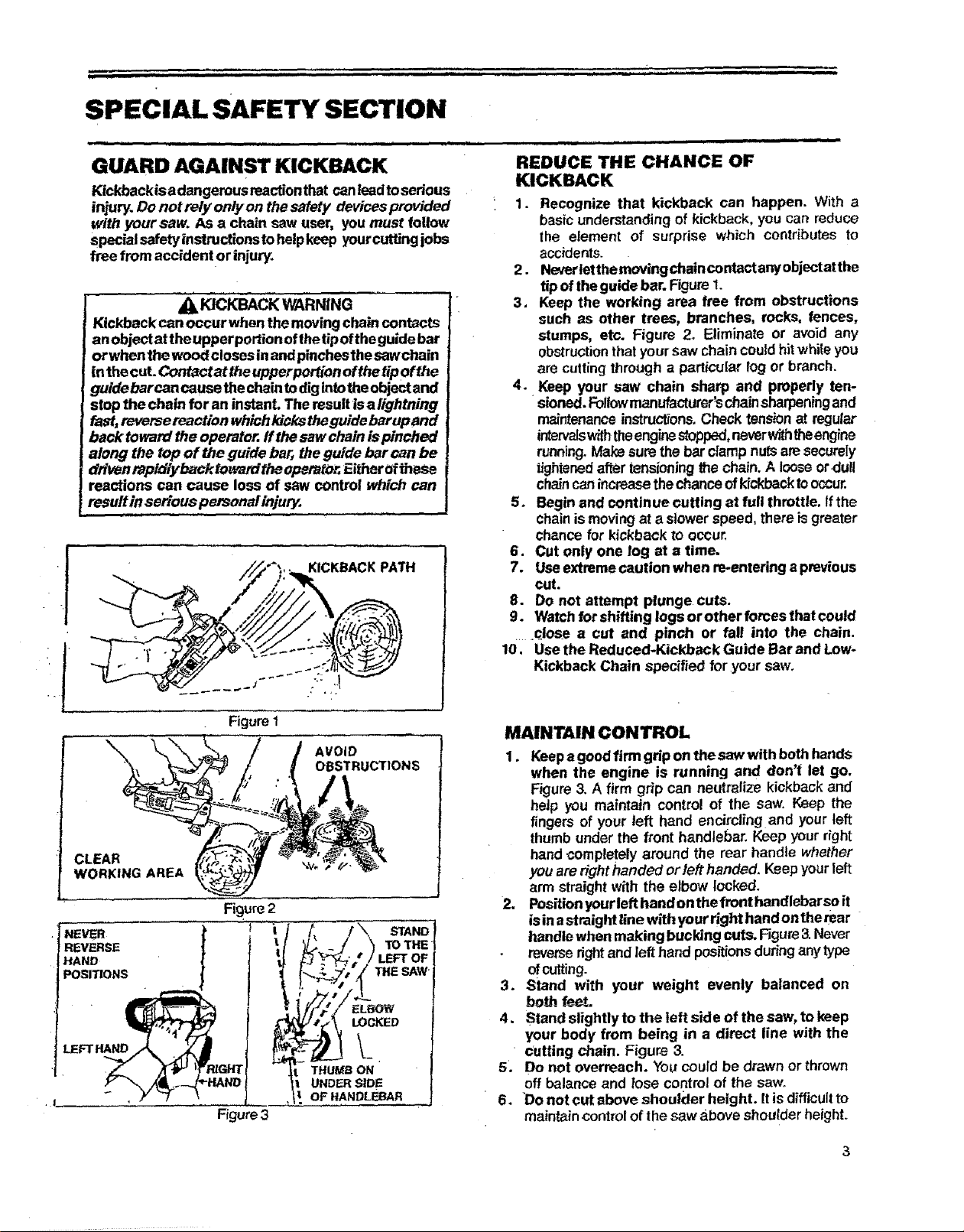

SPECIAL SAFETY SECTION

GUARD AGAINST KICKBACK

Kickbackisa dangerous reactionthat can/eadtosedous

injury. Do not rely only on the safety devices provided

with your saw. As a chain saw user, you must follow

special safetyinstructlonsto helpkeep yourcuttingjobs

free from accident or injury.

_ILKICKBACK WARNING

Kickback can occur when the moving chaincontacts

anobjectat the upperportion ofthetip ofthe guide bar

orwhen the wood closes inand pinchesthe sawchain

in the cut. Contactattheupperportionofthetipofthe

guidebarcan cause the chaintodigintotheobjectand

stop the chain for an instanL The result is a lightning

fast,reverse reaction whichIdckstheguide barupand

back toward the operator, ff the saw chain is pinched

along the top of the guide bar_the guide bar can be

driven rapldiyback towardthe operator.Either oTthese

reactions can cause loss of saw control which can

result in serious personal injury. ................

KICKBACKPATH

, =l, ii ill == ,,,,m,,= ,, =

REDUCE THE CHANCE OF

KICKBACK

1. Recognize that kickback can happen. With a

basicunderstandingof kickback, you can reduce

the element of surprise which contributes to

accidents.

2. Neverletthemovingchaincontact anyobjectatthe

tip of the guide bar. Figure1.

3. Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Figure 2. Eliminate or avoid any

obstructionthat your saw chain couldhitwhileyou

are cutting through a particula_ log or branch.

4. Keep your saw chain sharp and properly ten-

sioned. Followmanufacturer_chainsharpeningand

maintenanceinstru_ons. Check tensionat regular

intervalsw_ththeengines_opped,neverwiththeengine

running. Makesure the bar clampnutsaresecurely

tightenedafter tensioningthe chain. A looseor-dull

chaincanincrease thechanceofkickbacktooccur.

5. Beginand continue cutting at full throttle. Ifthe

chainis movingat a slower speed, there isgreater

chance for kickback to occur,

6. Cut only one log at a time.

7. Useextreme caution when re-entering a previous

cut.

8. Do not attempt plunge cuts.

g. Watch for shifting logs or other forces that could

.....close a cut and pinch or fall into the chain.

10. Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for .yoursaw.

CLEAR

WORKING AREA

LEFT _ND

,/

Figure 1

Figure3

AVOID

OBSTRUCTIONS

EL_

LOCKED

\_

ON

UNDER SID E

OF HANDLEBAR

MAINTAIN CONTROL

1. Keepa goodfirm grip on the saw with both hands

when the engine is running and don't let go.

Figure3. A firm grip can neutralize kickback and

help you maintain control of the saw. Keep the

fingers of your left hand encircling and your left

thumb under the front handlebar, Keep your right

handcompletely around the rear handle whether

you are righthanded or left handed. Keepyourleft

arm straight with the elbow locked.

2. Positionyourlefthandonthefronthandlebarsoit

isin astraightline with yourright handon the mar

handle when making bucking cuts. Figure& Never

reverseright and left hand positionsduringany type

ofcutting.

3. Stand with your weight evenly balanced on

both fe_.I.

4. Stand slightly to the left side of the saw, to keep

your body from being in a direct line with the

• Cutting chain. Figure 3.

5. Do not overreach. Youcould be drawn or thrown

off balance and/ose control of the saw.

6. Do not cut above shoulder height. It is difficultto

maintain control ofthe saw above shoulder height.

./ iii iiii iii . : i.. i_ iml lira,,,, ,,,, ,,, .... ,, UlmllllllHi I H i i I, ,I

.,J , ........... i i

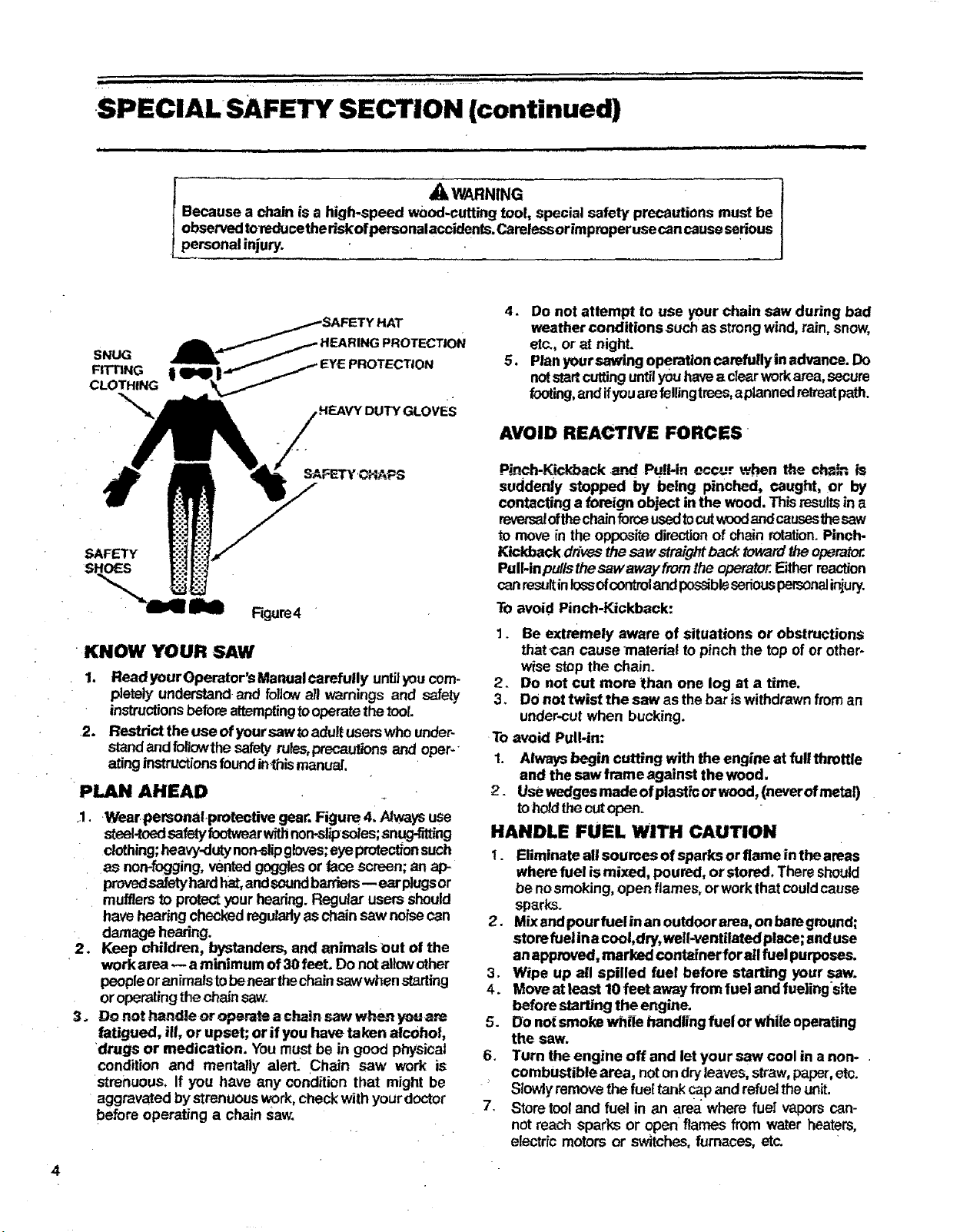

SPECIAL +SAFETY SECTION (continued)

iilll ill ,i ii

WARNING

Because a chain is a high-speed w0od-cutting tool, special safety precautions must be

observedtoreducethedskofpersonalaccidenls.Carelessorimpmper useean causesedous

personal injury.

4. Do not attempt to use your chain saw during bad

SAFETY HAT

SNUG

FITTING

CLOTHING

-.,,

SAFETY

EARING PROTECTION

,HEAVY DUTY GLovEs

SHOES

Figure4

KNOW YOUR SAW

1. Read your Operetor's Manual carefuily untJlyoucom-

pletely understandand followall warnings and safety

instructionsbeforeattemptingto operatethe tool.

2. Restdct the use of yoursaw toadult userswho under-

stand and followthesafety rules,precautions and oper.

atinginstructionsfoundin-thlsmanual

+PLAN AHEAD +

+1. Wear personalpmtective gear. Figure 4. Always use

steel-toedsafetyfo_wear withnon-slipsoles;snug-fitting

clothing;heavy-dutynon-slipgloves;eyeprotectionsuch

as non-fogging,vented gogglesorface screen; an ap-

pmvedsafetyhardhat,andsoundban_rs-- earplugsor

mufflers tOprotect your hearing.Regular users should

havehearing checkedregutadyas chainsaw no_secan

+ damage hearing.

2. Keep _hiidren, bystanders, and animals Out of the

work area -- a minimum of 30 feet. Do notallowother

peopleoranimalstobe nearthechainsawwhen starting

oroperatingthe chainsaw.

3 o Do .notha.md_eor operate a cha_ saw when _ m_

fatigued, ill, or upset; or if you have taken alcohol,

drugs or medication. You mustbe in good physical

condition and mentally alert: Chain saw work is

strenuous. If you have any condffion that might be

aggravated by strenuouswork,checkwith yourdoctor

before operating a chain saw.

.=

6. Turn the engine off and let your saw cool in a non-

7. Storetooland fuel in an area where fuel vapors can-

weather conditions such as strongwind,rain, snow,

etc., or at night.

5. Planyoursawing operation carefullytn advance. Do

notstartcuttinguntilyou havea ctearworkarea,secure

footing,and ifyouarefellingtrees,aplanned retreatpath.

AVOID REACTIVE FORCES

Pin0h-Kickback and Pu!!-in occur when the chain is

suddenly stopped by being pinched, caught, or by

contacting a foreign object in the wood. Thisresultsina

reversalofthechainforceusedtocutwoodandcausesthesaw

to movein the oppositedirectionof chain rotation.Pinch-

Kickback drives the saw straight back towardthe operator.

Pull-inpullsthe sawaway from the operator. Either reaction

canresultinlossofcontrolandpossiblesedouspersonalinjury.

TOavoid Pinch-Kickback:

1. Be extremely aware of situations or obstructions

that<:an cause matedal to pinch the top of or other-

wise stop the chain.

2. Do not cut more than one log at a time.

3. DOnot twist the saw as the bar is withdrawnfrom an

under-cutwhen bucking.

To avoid Pull-in:

1. Alwaysbegin cuffing with the engine at full thmffie

and the saw frame against the wood,

2. Use wedgesmade of plasticor wood, (neverof metal)

toholdthe cutopen.

HANDLE FUEL WITH CAUTION

I. Eliminate all soumes of sparks or flame in the areas

where fuel is mixed, poured, or stored, There should

be nosmoking,open flames, or workthat couldcause

sparks.

2. Mixandpour fuelin an outdoor area, onbare ground;

storefuel ina cool,dry, well-ventilated place; and use

anapproved, marked containerforatl fuel purposes.

3. Wipe up all spilled fuel before starling your saw.

4. Moveat least 10 feet away from fuel and fuelingslte

before starting the engine.

5. Do not smoke while handling fuelor while operating

the saw.

combustible area, notondryleaves, straw,paper,etc.

Slowly removethe fueltank ca.pandrefuelthe unit.

not reach sparks or open flames from water heaters,

electric motors or switches,furnaces, etc.

4

m i i,,i _ i ui, i • ,i,, i i [L I,l,I ,I

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw thst is damaged, im-

properly adjusted, or not completely and securely

assembled.

2. Operatethechainsawonlyinoutdoorareas.

3. Do not operate the saw from a ladder or in a tree.

4. Position all parts of your body to the left of cut and

away from the saw chain when the engine is

running.

5. Cutwoodonly. Donotcutmetal, plastics,masonry,non-

woodbuildingmaterials, et_ Do notuseyoursawtopryor

shoveawaylimbs,rootsorotherobjects.

6. Makesurethe _hain willnotmape contactwithanyc;b-

ject while slatting the engine. Nevertrytostartthesaw

whenthe guidebaris ina cutorPerf.

7. Use extreme caution when cutting small size brush

and saplings. Slender material can catch the saw

chain and be whipped toward you or pull you off

balance.

8. Be alert for springback when cutting a limb that is

under tensionso you willnot be struck by the limbor

saw when the tension in the wood fibers is released,

•9. Do not put pressure on the saw at the end of a cut.

This can cause you to lose control when the cut is

completed,

10. Stop the engine before setting the saw down.

Keep the vibration isolators in good condition.

Periodicallyinspectisolatorsfor tear,ripsorseparationof

the rubberportionfromthemetalmountings,Haveyour

Sears Service Center replace the isolatorsif worn or

damaged, ifvibra_onincreasesorifmountsdevelopanout

ofroundorswollenshapefromexposuretogasolineand!or

oil.itisrecommendedthatallisolatorsbereplacedwhen

a failure toone occurs.

CARRY AND STORE YOUR SAW SAFELY

1. Handcarrywith theengine stopped,theMuffler aw_

•from your body,andtheGuideBarandChaintotherear

coveredpreferablywithascabbard.

2, Before transporting in any vehicle orstoring in any

enclosure, allow your saw to cool completely, cover

the bar and chain and propedy secure to avoid

turnover,fuel spillage or damage,

3, Emptythe fuel tankbefore storing the tool, Use

up fuelleft in the carburetor by starting the eng-

ine and letting the engine run until it stops,

4. Store in a dry area out of the reach of children and

away from where fuel vaporscan reach sparks oran

open flame from hotwater heaters,furnaces, etc.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER .

1. Have all chain saw service performed by aqualified

service dealer with the exception of the items listed

in the maintenance section of this manual. For

example, if impropertoolsare used to removeor hold

the flywheeJ when servicing the clutch, structural

damage to the flywheel can occur and cause the

flywheel to burst.

2. Keep fuel and oil caps, screws and fasteners

securely tightened.

3. Keep the handles dry, clean, and free of oil or fuel

mixture.

4. Make certain the saw chain stops moving when the

throttle trigger is released. For correction,refer to

"Carburetor Adjustments:'

5_

Stop the saw if the chain strikes a foreign object.

Inspectthetoolandrepairorreplacepartsas necessary.

Disconnect the spark plug before performing any

maintenance except for carburetor adjustments.

Never modify your saw in any way. Use onlyatfach-

merits supplied or specifically recommended by the

manufacture[

8.

Always replace the handguard immediately if it

becomes damaged, or broken or is otherwise

removed ÷

THIS SAW IS 'FOR OCCASIONAL USE ONLY

NOTE: Exposure tovibrationsthrough prolonged useof

chain saws may produce Whitefinger disease

(Raynaud's phenomenon). This phenomenon

reduces the hand's ability to feel and regulate

temperature, produces numbness and burning

sensations andcan cause nerve and circulation

damage and tissue necrosis,

An anti-vibration system designed to reduce

enginevibrationis recommended for those using

chain saws ona regular orsustained basis and is

provided on this saw, An anti-vibration system

doesnotguaranteetheavoidanceofWhitefinger

disease, Continual and regular users must

monitor closely their use of chain saws and

physical condition.

Notice: Refer to the Code of Federal Regulations,Section

1910.266{5);2.5.1 of American National Standard

Safety Requirements for Pulpwood Logging, ANSI

•03.1-1978;and relevant state safety codes when

usinga chain saw for logging purposes.

5

KNOW YOUR CHAIN SAW

A. INTRODUCTION

Yoursaw has beendesigned withsafetyin mindand

includesthefoltowingfeaturesasstandardequipment:

--Reduced-Kickback Guide Bar (Lo-Kick®)

-- Low-KickbackChain(Xtra-Guard®)

Spark Arrestor

Muffler Shield

-- Handguard

-- Anti-Vibration System

_IL WARNING

The following feature,sam includedon yoursewto help

reduce the hazardofkickback, however,suchfeatures

will not totally eliminate thisdangerous reaction. As a

chainsaw user, donot relyonly onsafety devices.You

must follow all safety precautions, instructions and

maintenancein this manual to helpavoid kiekbackand

other forcaswhich can resultin serious personalinjury.

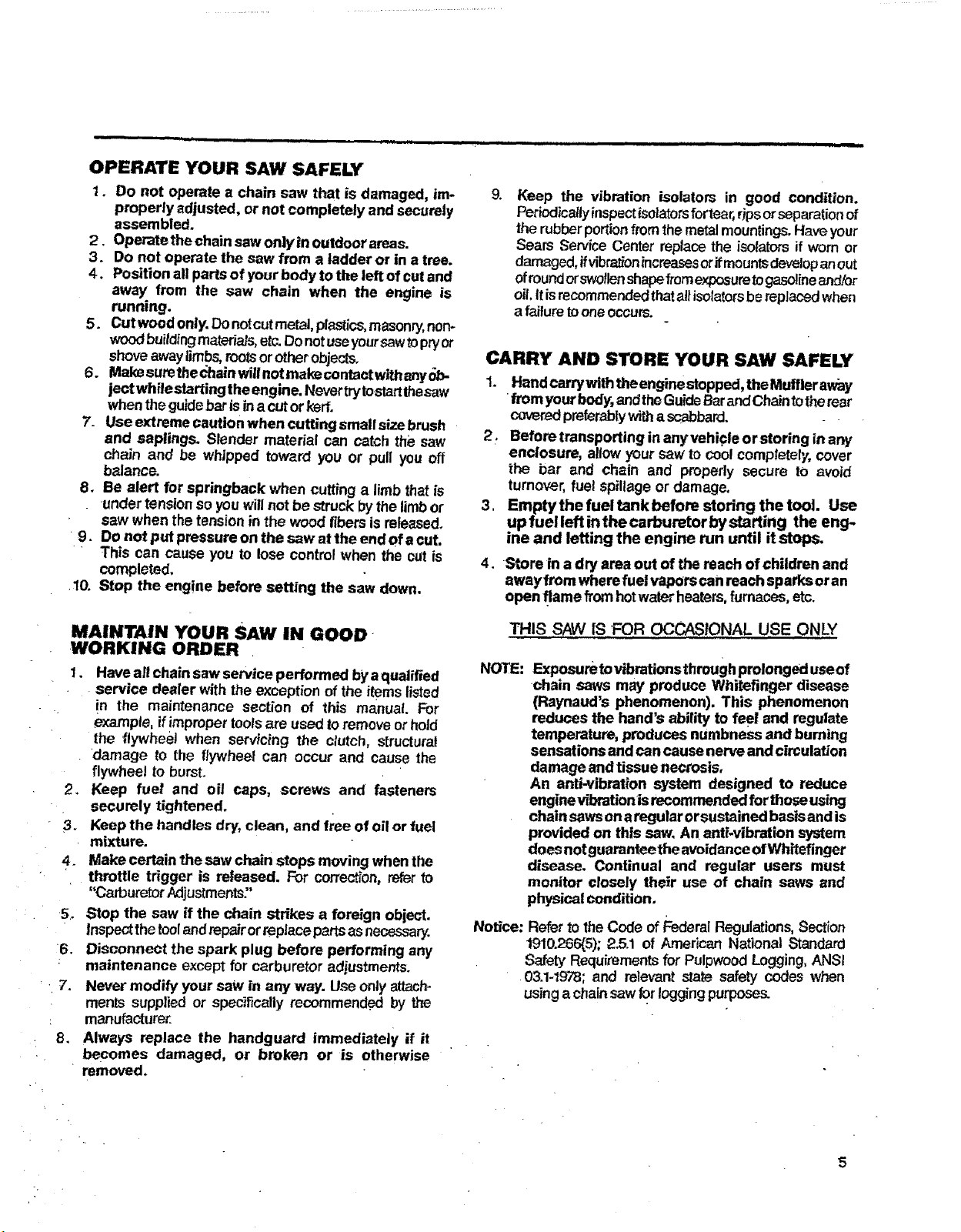

B. KICKBACK SAFETY FEATURES

Reduced-Kickback Guide Bar, designedwith a

small radiustipwhichreducesthe sizeofthekickback

danger zone on the bar tip. Figure 5. A Reduced-

KickbackGuide Bar isone whichhasbeendemon-

strated to significantly reduce the number and

seriousnessof kickbackswhentestedinaccordance

with the safety requirements for gasoline powered

chain sawsasset bythe American NationalStandards

Institute, Inc.,StandardBt75.1-t985_

-- Low.Kickback Chain, designed with a contured

depthgaugeandguard linkwhichdeflectthekickback

force and allow wood to gradualty rideintothecutter.

Figure5.Low-Kickback Saw Chainis chainwhichhas

rnetthe kickback performancerequirementsofANSI

B175.I when tested on a representative sample of

chain saws below 3,8 cubic inch displacement

specifiedin ANSI B175.1-1985.(American National

Standardfor Power Tools.-GasolinePoweredChain

Saves-Safety Requirements).

Handguard, designed to reducethe chance ofyour

left handcontactingthechain ifyourhandslips offthe

fronthandtebar.

Position of front and rear handlebars, designed

withd'_z_ce betweenhandles and"inline" witheach

other.Thespread and "in line"positionofthehandle-

barsworktogether togive balanceand resistancein

controllingthe saw if kickbackoccurs.

_I, WARNING

Do not operate ttie chain saw unless the safetydevices

or their specified replacements are properly installed

and maintained according to the instructions in this

manual. Donot use any otherguide barand chain com-

binationthatis not equivalent totheoriginalequipment

or not certified to comply with ANSI B175.1.Failure to

follow these instructions canresult inseriouspersonal

injury.

Figure5

C. STATE AND LOCAL REQUIREMENTS.

Yoursewis equippedwith atemperature limitingrnuf-

tier and spark arresting screen which meets the

-requirements of California Codes 4442 and 4443. All

Li.S.forest land and the _ of California, Maine,

WashingtonaridOregon requiremany internalcombus-

tionenginestobeequippedwitha sparkarrestorscreen

bylaw.Other statesare enacting similar taws.

If you operate a chain saw in a state or locale where

such regulationsexist, you arelegaliy responsib!efor

maintaining the operating condition of these parts.

'Failureto do so isa violation Of the law. Refer tothe

"Spark Arrestor"se_on for maintenance.I

D= CARTON CONTENTS

After you unpack the carton:

1. Check the contents against the tist below.

2. Examinethe itemsfordamage. Donot usedamaged

paris.

3. Notify your Sears store immediately if a part is

missing or damaged.

NOTE: it isnormaltohearthefuelfilterrattJeinanempty

fuel tank.

KeyNo. : Carton Contents: Qty.

1 Powerhead 1

2 GuideBar 1

3 8 oz_can2.cycle Engine Oil 1

Operator'sManual(notshown) t

-- LoosePartsBag(not shown) t

LooseParts Bag Contents:

4 /Chain "1

5 BarAdjusting Tool 1

6 FlexWrench(for fan housing 1

SCrews)

PREPARING YOUR SAW FOR USE

A. GETTING READY'

1. READ YOUROPERATOR'SMANUAL

CAREFULLY.

YourOperator'sManualhasbeendevelopedtohelp

youprepareyoursawforuseandtounderstandits

safe operation. It is important that you read your

manual completelytobecomefamiliar withthe saw

beforeyoubegin assemb}y.

.............. ,,,,, ,i

2. HAVETHE FOLLOWING AVAILABLE:

a. Protective gloves.

b. Approved, market fuel container

c. One gallon regular unleaded gasoline

d, 8oz. (1/2 pt.), 2-cycle, engine oil

e. Bar and Chain Lubricant.

f. BarM|usting Tool providedw_lhyoursaw.One

end ofthetoolserws asawrench;theothercanbe

usedas ascrewdriver.

L,

.11111

ATTACHING THE BAR AND CHAIN

B,

.._ ii ii "H ,.... HH,.HH I. I

, ,,,,. ,,,,,,,,,,,i

__CAUTION:t Wearprotectivegloves when handling

oropemting your saw.The ¢hainissharpand can cut

you even when it is not moving!

• Yoursaw is equipped with a Reduced.Kickback

Guide Bar and a Low-Kickback Chain.

• Use only the Reduced-Kickback Guide Barand

Low-Kickback Chain specified for your chain

saw model when replacing these parts. See

"Specifications"

,_WARNING

Do not start engine without guide bar and chain com-

pletelyassembled. Otherwise,theclutch cancomeoff

and Serious personal injury can result.

._AUTION:I Wear protective gloves when han-

dling or operating your saw. The chain is sharp

and can cut you even when it is not moving!

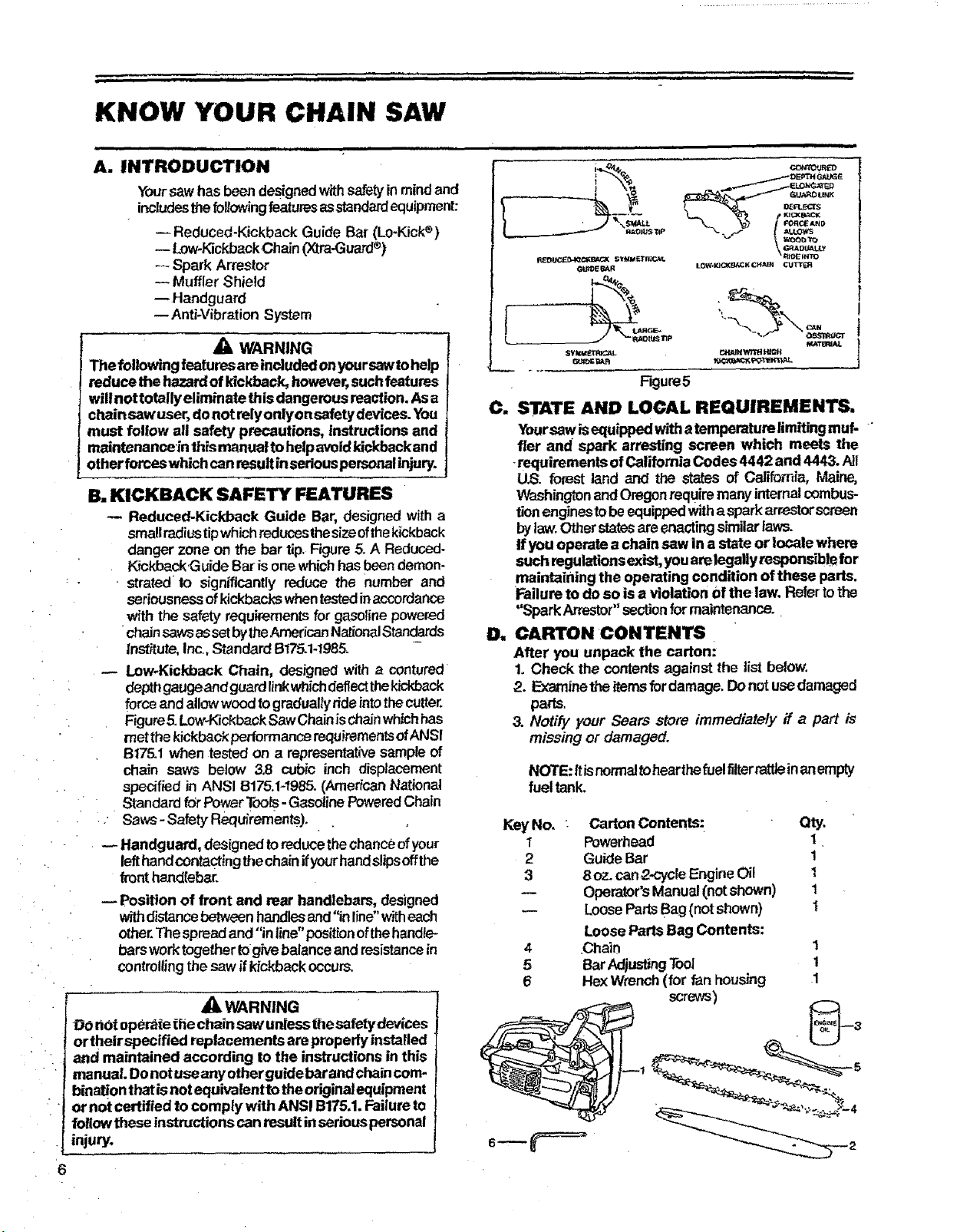

1. Remove the following partsas shownin Figure 6,

using the Bar AdjustingTooland HexWrench pro-

vided with the unit.

a. Bar Clamp Nut.

b. Rear Bar Clamp Screw.

c- Bar Clamp Housing.

2. Turn the Adjusting Screw counterclockwise

to move the Adjusting Pin almost as

far as it will go to the rear. Figure 6.

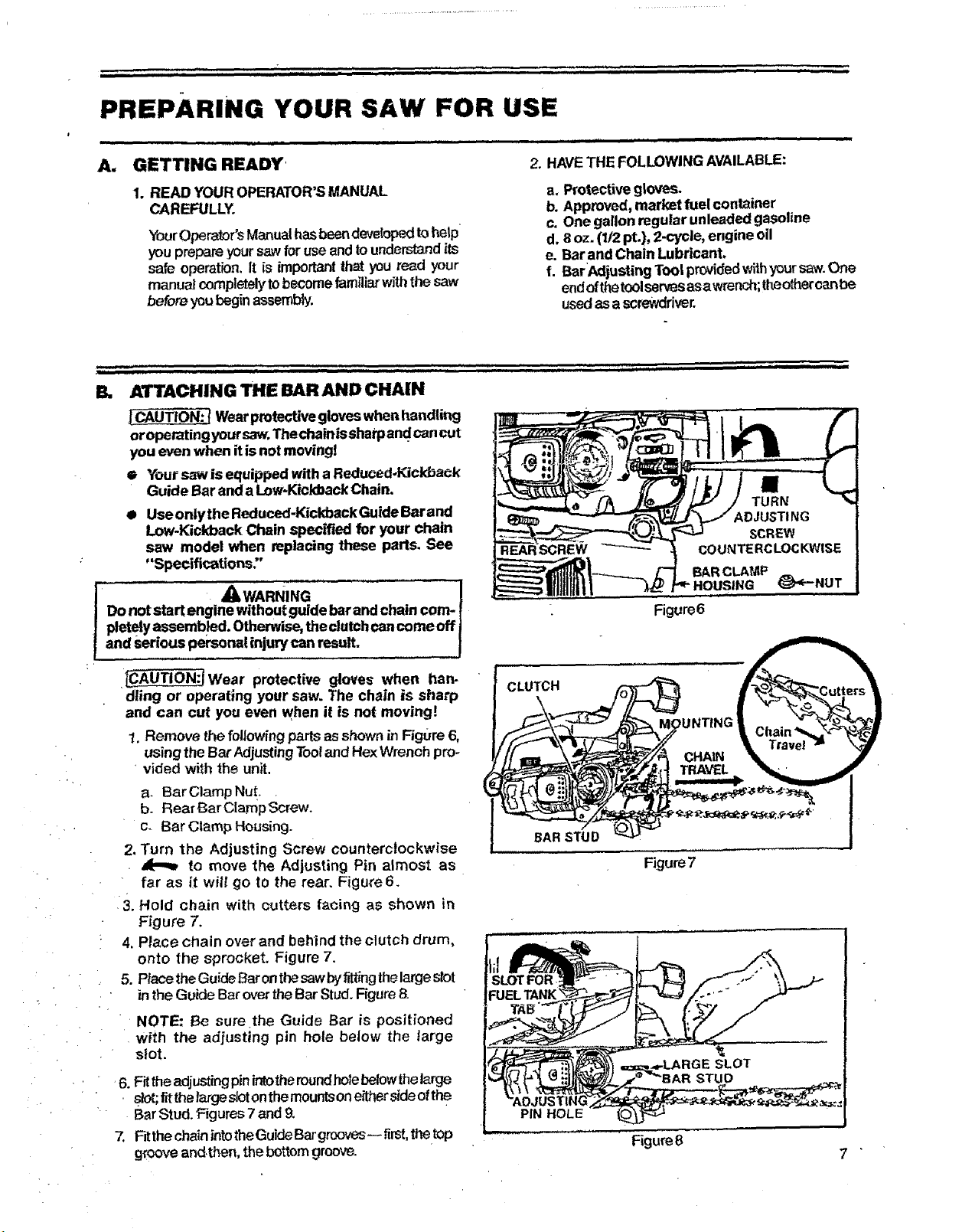

•3. Hold chain with cutters facing as shown in

Figure 7.

4. Place chain over and behind the clutch drum,

onto the sprocket. Figure 7.

5. Place the Guide Bar onthesawbyfittingthelarge stot

in the Guide Bar overthe Bar Stud.Figure 8.

NOTE: Be sure the Guide Bar is positioned

with the adjusting pin hole below the large

slot.

•6. Fit the adjusting pin intotheround holebelowthelarge

stot;fit the far_ sJotonthemountson e_d'tersideofthe

BarStud. Figures7 and 9.

7. Fitthe chainintotheGuideBar grooves-- first,thetop

grooveandthen, the bottom groove.

.11, ,,,,,,,,,,, , ,, i ii i H

!1

TURN

ADJUSTING

SCREW

SCREW

| /-.-HOUSZ G -NUT

Figure6

CLUTCH

BARSTUD

Figure7

STU

Figure 8

jCAUTION:JMakesure that the tabon thebottom ofthe

fuel tank isaligned inthe slotprovidedinthe fan housing.

See inset, Figure 8,

& HoldtheGuideBaragainstthesawframe andinstall

the BarClamp Housing.

9. Securethe Bar ClampHousing withtheBar Clamp

Nut, finger tight only.TightenBar Clamp Nut after

chainistensioned.

10. Replace the Rear Bar Clamp Screw and

tighten securely.

11. Follow "Chain Tension" instructions below.

• , ,=1¸ " iiiiiiii i i ii ¸ _'il i _ '" i

C. CHAIN TENSION

i i

Figure9

, iiii ii, i i,

-• Chain tension is very important:

--a loose chain wilt wear the bar and i_setf.

ma loose chain can jump off the bar while

you are cutting, : _ .:"

--a _ght chain can break or damage the saw b_

• The chain Stretches during use, especially

when new. Check tension:

-- each timethe_awis used.

more frequently whenthechainisnew•

as thelchainwarms up tonormaloperatingtem-

perature.

ICAUTION_Always wear gloves when handling

the chain. The chain is sharp and can cut you

.even When it is not moving!

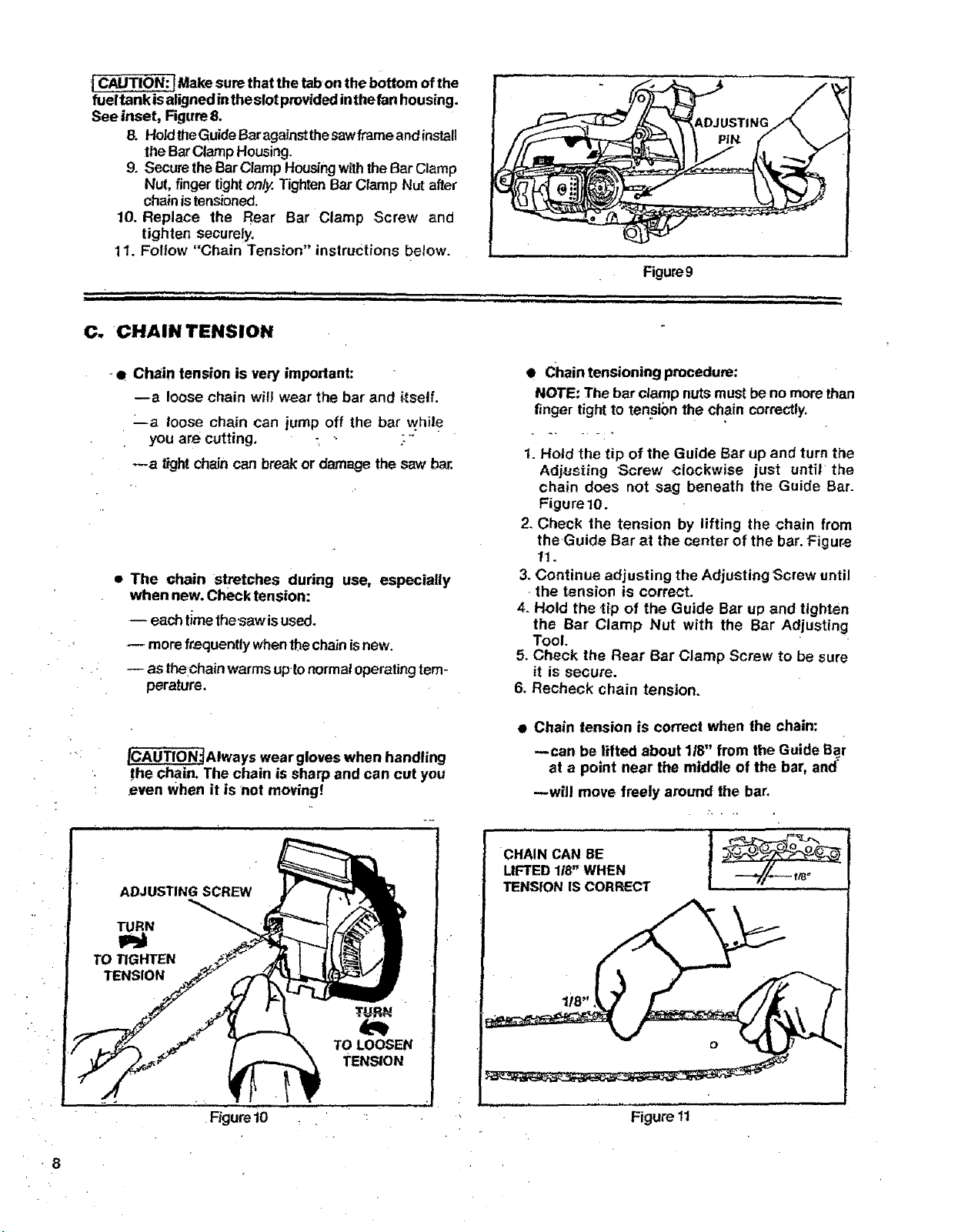

• Chain tensioning procedure:

NOTE: The bar clamp nutsmust be no more than

finger tight to tension the chain correctly.

1. Hold the tip of the Guide Bar up and turn the

Adjusting Screw clockwise just until the

chain does not sag beneath the Guide Bar.

Figure 10.

2. Check the tension by lifting the chain from

the Guide Bar at the center of the bar. Figure

11.

3. Continue adjusting the Adjusting Screw until

•the tension is correct.

4. Hold the tip of the Guide Bar up and tighten

the Bar Clamp Nut with the Bar Adjusting

Tool.

5. Check the Rear Bar Clamp Screw to be sure

it is secure.

6, Recheck chain tension.

Chain tension is correct when the chain:

--can be lifted about 118" from the Guide Bar

at a point near the middle of the bar, and"

_will move freely around the bar,

-8

.Figurei0

CHAIN CAN BE

LIFTED 118" WHEN

TENSION IS CORRECT

TURN

TO LOOSEN

TENSION

Figure 11

........ p.,,, ,..

D. I=UELING YOUR ENGINE

, , .J,,, .., ...,, ......,.,......i_,

=i=afii=liiii; = = ,,=,,=ii,ii" = =,1 ,,,,,,,,,,,,,,,,,,,,,,,,,

1. FUELSAFETY

a. Useonly recomreended fuelreixtures.

b. Mixand pourfueloutdoorsandwherethereare

no sparks or flames.

c_ Use a container approved forfuel

d. Donot smokeorallowsreokingnearfuelor the

tool Orwhlle using the tool.

e. Wipe up allfuel spills beforestarting engine.

f. Move at least 10 feet away from fueling site

before starting engine.

g. Stop engine before rereovingfuel cap.

h. Ereptythefuel tank before storingthetool, itis

recommendedthatthefuel tankbe emptiedafter

eachuse. Iffuel isleftintank,storesofuel wiltnot

leak. "

L Storetooi and fuelinan areawherefuelvapors

cannot reachsparksoropen flamesfrom water

heaters,electric motors orswit¢he_,furnaces,

etc. ,

2. FUEL MIXTURE

• Your tool is powered by a two-cycle engine

which i_=quiresa fuel mixture of regular un-

. leaded gasoline and a high quality engine

0il specially reade, for 2.cycle, air cooled

engines.The internaldesignoffife2-cycleengine

_ .. requireslubdcationofreovingparts.Lubricationis

provided when the recommended mixture

gasolineandoil is used. r

• Gasoline must be clean and not over two

• reonthsold, Gasolinewiflchereicaltybreakdown

andformcompoundsthatcausehardstartingand

damage in2-cycleengines.

• Thecorrectmeasureofgasolinetooilisvery

importanL Toomuchoilinthemixturewillfoulthe

spark plug.

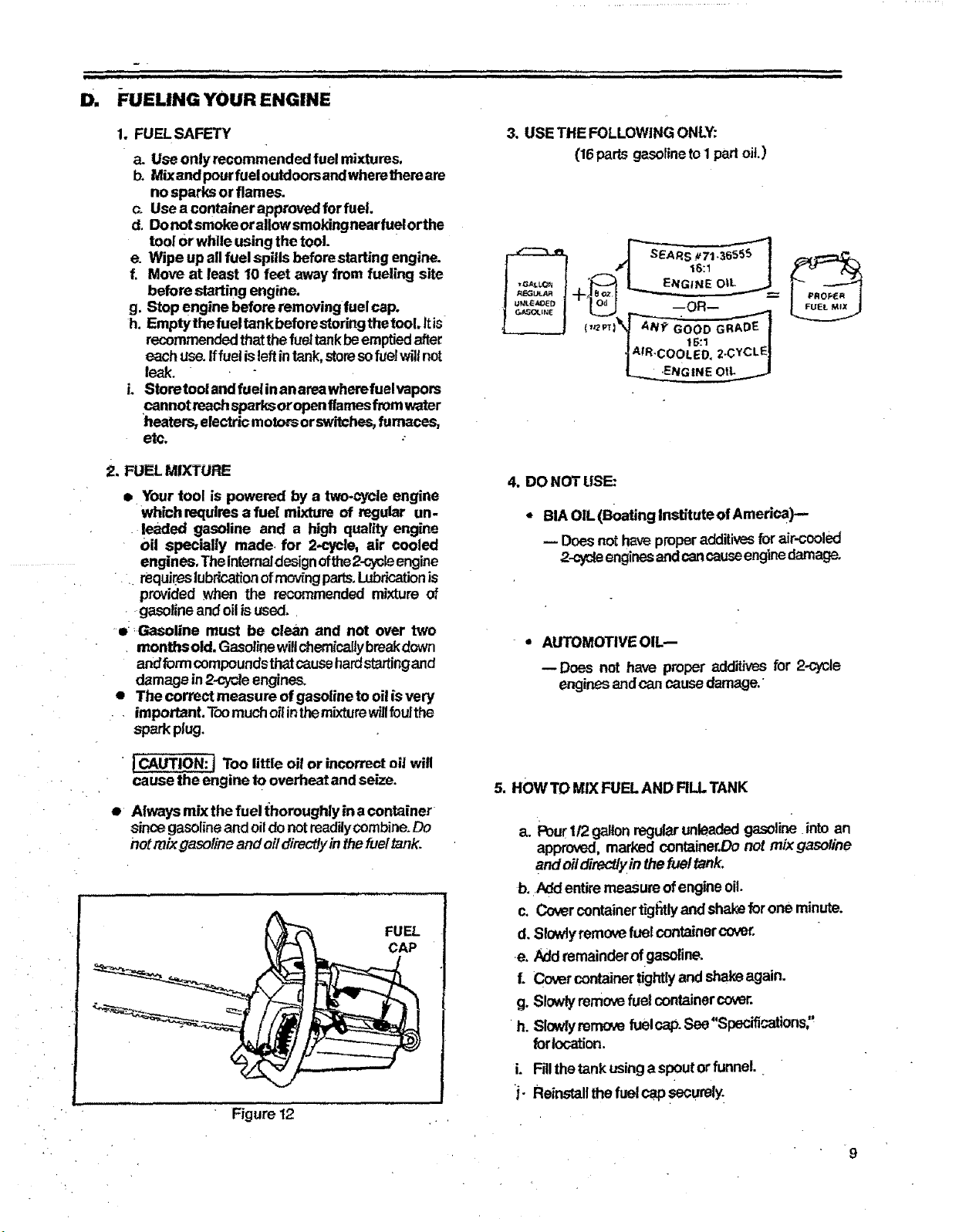

3, USE THE FOLLOWING ONLY:

{16parts gasolineto I partoil.)

RL_-G_

4. DO NOT USE:

• BIA OIL (Boating Institute of Amedca)--

-- Doesnot haveproperadditives for air-cooled

2-cyd,eengines andcancauseengine damage.

" " AUTOMOTIVE OIL-

--Does not have proper additives for 2-cycle

enginesandcan causedamage."

]CAUTION: j Too little oil or incorrect oil will

cause the engine to overheat and seize.

O ¸

Always mix the fuel thoroughly in acontainer

sincegasolineandoildo notreadilycornbine.Do

notmixgaso/ineand oildirectlyinthefue!tank.

Figure t2

FUEL

CAP

5. HOW TO MIX FUEL AND FILL TANK

a. Pour I/2 gallonregular unleaded gasoline intoan

approved, marked container.Donot mixgasoline

and oildimctl_ in thefuel tank.

b. Add entiremeasureof engineoil.

c_ Cover containertigi'_tlyandshakefor one minute.

d. Slowlyremovefuel containercover.

e. Addrernainderof gasoline.

f. Covercontainertightlyand shakeagain.

g. Slowlyremovefuel container cover.

h. Slowlyremovefuel cap.See"Specifications"

forlocation.

L Fillthetankusinga spoutorfunnel. •

j- Reinstallthe fuel capsecurely.

iiiiiiiiiiiiiiiiii = III.H III I

'1_-Ii i , ,,,,,,111ii , ii ii i i

E. BAR AND CHAIN LUBRICANT

• The guide bar and cutting chain require con-

stant lubrication in order to remain in

operating condition. Lubrication is provided

by the automatic oiler system when the oil

tank is kept fitled.

-- Lack of lubricant will quickly ruin the bar and

chain.

--Too little lubricant will cause overheating

shown bysmokecomingfrom thechainand/or

discolorationoftheguidebe#mi!_

• Use Sears Bar and Chain Lubricant (#71-36554--

I qt. or 71-36556 -- 1 gal.) or clean SAE 30W oil.

In freezing weather oil will thicken, making

it necessary to thin bar and chain oil with a

small amount of Diesel Fuel #1 or

Kerosene. Bar and chain oil must be free flow-

ingfor the oil system topump enoughoil for ad-

equate lubrication.

1. USE THE FOLLOWING:

30°F or above--Lubricant--undiluted.

• 30°F- 0°F --95% Lubricant to

5% Diesel Fuel #1

or Kerosene.

Below OOF _90% Lubricant to

10% Diesel Fuel #1

or Kerosene.

iiii iiiiiiii %111 i iii

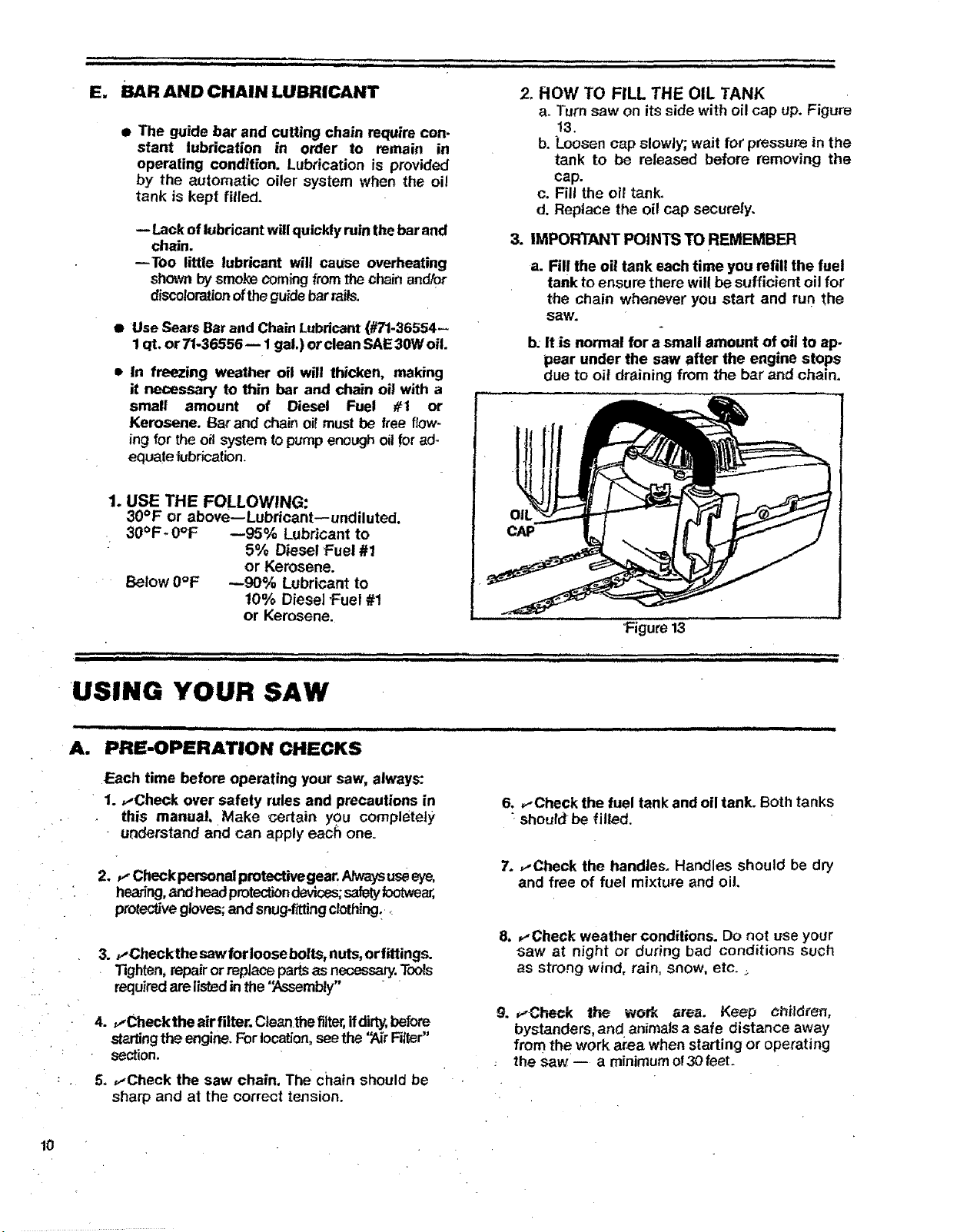

2. HOW TO FILL THE OIL TANK

a. Turn saw on its side with oil cap up. Figure

13.

b. Loosen cap slowly; wait for pressure in the

tank to be released before removing the

cap.

c. Fill the oil tank.

d. Reptace the oil cap securely.

3. IMPORTANT POINTS TO REMEMBER

a. Fill the oil tank each time you refill the fuel

tank to ensure there will be sufficient oil for

the chain whenever you start and run the

saw.

b. It is normal for a small amount of oil to ap-

pear under the saw after the engine stops

due to oft draining from the bar and chain,

CAP

Figure 13

i i i illl i i iiii i i iiiiiiiiii

, , ,,, ,

USING YOUR SAW

A. PRE-OPERATION CHECKS

Each time before operating your saw, always:

1. ,,-Check over safety rules and precautions in

this manual. Make certain YOu completely/

understand and can apply each one.

2. ,f Check personal protectivegear.Atwaysuseeye,

hearing,and headprotectiondevices;safetyfootwear;,

protecEvegloves;and snug-fittingclothing.._

3. ,,-Checkthe saw for loose bolts, nuts,orfitUngs.

Tighten,repair orreplaceparts as necessary.Too_s

requiredarelistedin the '_.ssembly"

4. _,,Check the air filter. Cleanthe filter,if dirty,before

startingthe engine.Forioca_on, see the '_'r Filter"

section.

5, ,,-Check the saw chain. The chain should be

sharp and at the correct tension.

i. ii ii iiii i • . iiii iiiiiiiii

6. ,_Check the fuel tank and oil tank. Both tanks

shoutd be filled.

7. ,--Check the handles. Handles should be dry

and free of fuel mixture and oil.

8. _.-Check weather conditions. Do not use your

saw at night or during bad conditions such

as strong wind, rain, snow, etc.

9. ,_Check the work area. Keep Children,

bystanders, and animats a safe distance away

from the work area when starting or operating

the saw -- a minimum of30 feet.

10

Loading...

Loading...