Craftsman 358355070, 358355060 Owner’s Manual

[SearsI

operator's

manual

• Assembly

• Operation

• Maintenance

• Repair Parts

MODELNO.

358.355060-

2.3/16" AV

358.35507O

2.3/16" AV -PS

-- ......... i ,, , , ..

[RRFTSMRN

2.3/16" AV 2.3/16" PS.AV

GASOLINE CHAIN SAWS

THIS CHAIN SAW IS FOR OCCASIONAL USE ONLY.

i i ii, ,, ,, ,|,11, ,, , i , .. , ,,,

WARNING:

Carefully mad and follow

Safety Rules, Precautions

and Operating Instru¢,

tions. Failure to do so can

result in serious personal

injury.

, rl i

Sears, Roebuck and Cx_., Chiea_),Ill. 60684 U.S.A.

66378-1-12084-2-17884 PRINTEDIN U.S.A.

Record in the space provided below the Model No. and Serial No. of

your saw. These numbers are located on the starting instructions

decal.

Model No. Serial No,

Retain these numbers for future reference.

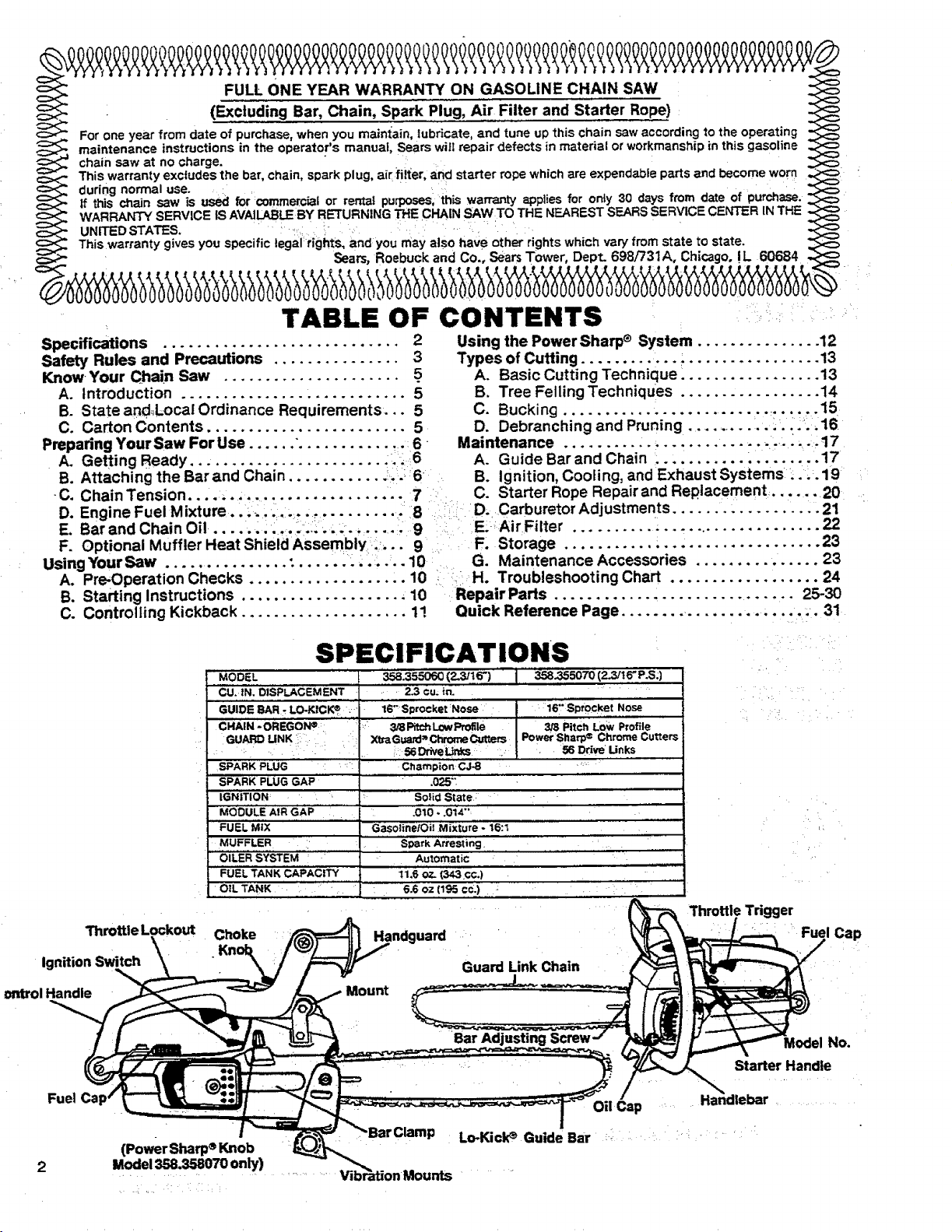

FULL ONE YEAR WARRANTY ON GASOLINE CHAIN SAW

(Excluding Bar, Chain, Spark Plug, Air Filter and Starter Rope)

For one year from date of purchase, when you maintain, Iubricate, and tune up this chain saw according to the operating

maintenance instructions in the operator's manual Sears will repair defects in material or workmanship in this gasoline

chain saw at no charge.

This warranty excludes the bar, chain, spark plug, air fiiter, and starter rope which are expendable parts and become worn

during normal use.

if thiSchainsaw is usedfor'commem_lor rentalpurposes_,this wan'antyappliesfor only30 daysfrom dateof purchase.

WARRANTY SERVICE IS AVA1LABLEBY RETURNING THE CHAIN SAW TOTHENEARESTSEARSSERVICE CENTER INTHE

UNITED STATES. ',_: :: _ ' • : '

Thiswarrantygivesyouspecificlegal:rightS,and:youmay alsohave otherrightswhichvaryfromstateto state.

Sears,Roebuckand Co., SearsTower,Dept. 698/731A, Chicago,IL 60684

TABLE OF CONTENTS

Specifications ............................ 2

Safety Rules and Precautions ............... 3

Know Your Chain Saw ..................... 5.

A. Introduction ........................... 5

B. State anti,Local Ordinance Requirements... 5

C. Carton Contents ........................ 5

Preparing Your Saw For Use ...... "............. 6

A. Getting Ready .......................... 6

B. Attaching the Barand Chain ............... 6

C. Chain Tension .......................... 7

D. Engine Fuel Mixture ..................... 8

E. Bar and Chain Oil ........................ 9

F. Optional Muffler Heat Shield Assembly ;... 9

Using Your Saw ............... - ............. 10

A. Pre.Operation Checks ................... 10

B. Starting Instructions .................... 10

C. Controlling Kickback .................... 11

Using the Power Sharp ® System ............... 12

Types of Cutting ............................. 13

A. Basic Cutting Technique ................. 13

B. Tree Felling Techniques ................. 14

C. Bucking ................................ 15

D. Debranching and Pruning ............. _.._16

Maintenance ............................... 17

A. Guide Bar and Chain ........... ; ........ 17

B. Ignition, Cooling, and Exhaust Systems .... 19

C. Starter Rope Repair and Replacement ....... 20

D. Carburetor Adjustments .................. 21

E:: Air Filter ............................... 22

F. Storage ............................... 23

G. Maintenance Accessories ............... 23

; H. Troubleshooting Chart .................. 24

Repair Parts ............................. 25-30

Quick Reference Page ........................ 31

Ignition Switch

ontrolHandle

Fuel Ca

Throttle Lockout

SPECIFICATIONS

MODEL _ ':_.355060(2.3/.1_.6")

CU. tN. DISPLACEMENT 2.3 cu. in.

GUIDE BAR- LO-KICK® 16" Sgrocket Nose

CHAIN -ORI=GON ¢ " " "" " ' 3t_PitchLowPro_le '

GUARD LINK : XtmG_rd_ChromeCut_srs

SPARK PLUG "" : Champio'n CJ-8

SPARK PLUG GAP .025":

IGNITION • Solid State:

MODULE AIR GAP .010 - .014""

FUEL MIX GasolinelOi| Mixture - 16:t

MUFFLER S_rk Arresting. , .

OILER SYSTEM ':' Automatic

FUEL TANK CAPACITY 11.6 OZ. (343 .cc.)

OIL TANK "' 6:6 oz (195 co:)

Choke

I 56D_eUnks

,, , ,,,

I. 3ss_SOTO(2_tEP.S:}

le'-sp,ocket

3/8 Pitch LoW P_ofile

Power Sltarp¢ Chrome Cutters

56 Drive Unks

Oil Cap ...... Handlebar .......

Throttle Trigger

Fuel Cap

No.

Starter Handle

(PowerSharp®Knob :

Lo-Kicke Guide Bar :: : _ " :_ '

2

SAFETY RULES AND PRECAUTIONS

WARNING!

Because a chain saw is a high-speed wood-cutting tool, special safety precautions

must be observed to reduce the risk of personal accidents. Careless or improper use

may cause serious injury,

A. KNOWYOUR SAW

14

Read your Operator's Manual carefully until

you completely understand and can follow all

safety.rules and operating instructions before

attempting to operatethe unit.

2.

Restrictthe use,of your saw to adult users

who understand and follow the safety rules,

precautions, and operating instructions

found in this manual.

B. PLAN AHEAD

personal protective gear. AI-

use steel-toed safety foot-

wear with non-stip soles; snug;

fitting clothing with reinforced

cutting resistant inserts; heavy-duty non-slip

gloves;appropriate eye protectionsuch as non-

fogging, vented goggles or face screen; an ap-

proved safety hard hat, and sound barriers meat

plugs or mufflers to protectyour headng. Regular

users should have hearing checked regularly as

chain saw noise may damage hearing.

,

Keep children, bystanders, and pets out of the

work area.Do not allow other people to be near

the chain saw when starting or operatingthe chain

SaW.

3.

Do not handle or operate a chain saw when. you D,

are fatigued, ill, or upset; or if you have taken -

alcohol,, drugs or medication. You must be in "

good physical condition and mentally alert. Chain

saw work is strenuous. If you have any condition

that might be aggravated by strenuous work,

checl_-W!_ your doctor before operating a chain

saw.

°

Do notlattempt to use your saw during bad

weather, conditions such as strong wind, rain,

snow,e_., or during darkness.

5.

Plan your sawing operations carefully in ad-

vance; :Do not start cuttinguntil you havea clear

work area; secure footing,, and if you are felling

trees_ a_planned retreat path.

To reduce the hazard of kickback:

1. Hold the saw firmly with both hands. Left hand

on front handle bar, right hand on rear handle

whether you are right-handed or/eft-handed.

Never use thesaw withone hand.

2. Do not overreach.

3. Do not let the tip of the guide bar contact the

ground, another log, branch, or any other

obstruction.

4. Begin and continuecutting atfuilthrottle.

5. Cut one log at atime.

6. Use extreme-caution when re,entering a pre-

viouscut.

7 Do not attempt plunge cuts.

8. Watch for shifting logs or other forces that

could close a cut and pinch the chain.

9. Do not out above shoulder heighL

10. Follow manufacturer's chain sharpening

and maintenance instructions. Keep the

chain properlytensioned. Check tensionat reg-

ular intervals with the engine stopped; never

with the,engine running. Make surethe bar

clamp nuts are securely tightened aiter tension-

ing the chain.

11. Use the Guard Link Chain and Lo-Kick ®

Guide Bar designedfor your saw to reduce the

hazard ofkickback.

AVOID REACTIVE FORCES

Pushback and Pull-in occur when the chain is

suddenly stopped by being pinched; caught, or.

by contacting a foreign object in the wood. This

results in a reversal of the chain force used to cut

wood andcauses the-saw to move inthe oppositedi-

rection of chain rotation,'resuiting-in loss of control

and possiblesenous personal injury.

To avoid Pushback:

1. Be extremely aware of situations or obstruc-

.... , tions that may cause material.to pinchthe top of..

, : • orotherwisestopthechain. , : . "

_ .... 2. Do not cut more than one log at a time. ......

3. Do not twist the saw as the baris withdrawn

'.... : from an under-cutwhenbucking. ,

C. GUARD AGAINST KICKBACK

Kickback can lead to dangerous loss of control of

the saw and possibly cause serious personal in-

jury. Kickback is the upwardand backward motion of

the guide bar that occurswhen the movingchain con-

tects an object at thetipofthe guide bar.

: _ • To avoid PulHn:

_ _ 1."Always begin cutting with the engine at full

throttle and the saw housing against the

wood.

2. Use wedges made of plastic, wood, or light

alloy (never of steel or iron) toholdthecut open.

3

E. HANDLE FUELWITH CAUTION

1. Eliminate all sources of sparks or flame in the

areas where fuel is mixed, poured, or stored.

There should be no smoking, open flames, orwork

that could cause sparks.

2. Mix, pour and store fuel in a well-ventilated

area, on bare ground, and in an approved,

marked container.

3. Wipe up all spilled fuel before starting your

SaW.

4. Move at least 10 feet (3 meters) away from fuel

and fueling site before startingthe engine.

5. Do not smoke while handling fuel or while

operating the saw.

6. Turn the engine off and let your saw cool be-

fore removing the fuel tank cap and refueling

the unit.

7. Let the saw cool in a non-combustible area, not

on dry leaves, straw,paper, etc.

F. OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled.

2. Do not operate the saw from a ladder or in a

tree.

3. Position all parts ofyour body away tothe side

of the saw chainr protrudingto the left ofcut when

the engine is running.

4. Cut wood only. Do not use to pryor shove away

limbs, rootsor other objects.

S_ Make sure the chain will not make contact be-

fore starting the engine. Never try to start the

saw when the guide bar isin acut orkerr.

6. Use extreme caution when cutting small size

brush and saplings. Slender matedai may catch

the saw chain and be whipped toward youor pull

you offbalance.

7. Be alert for springback when cuttinga limb that

is under tension so you will not be struck by the

limb or saw when the tension inthe wood fibersis

released.

8. Do not put pressure on the saw at the end of

a cut. This could cause you to lose control when

the cutis completed.

9. Stopthe engine before setUng the saw down.

'G. r MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

1. Have all chain saw service performed by your

authorized service dealer center, other than the

items listed in the maintenance section of this

manual.

2. Keep fuel and oil caps, screws and fasteners

securelytightened.

3. Keep the handles dry, clean, and free of oil or

fuel mixture.

4. Make certain the saw chain stops moving

when the throttle trigger is released, if it does

not,refer to page 21 for correct carburetoridle ad-

justment instructions.

5. Stop the saw if the chain strikes a foreign ob-=

ject. Inspectthe unitand repair or reptaceparts as

necessary. "

6. Disconnect the spark plug before performing

any maintenance except for carburetor adjust-

ments.

7. Never modify your saw in any way. Use only at-

tachments supplied or specificallyrecommended

bySears.

H. CARRY AND STORE YOUR SAW

SAFELY

1. Hand carry the unit with the engine stopped,

the Muffler away.from your body, andthe Guide

Bar and Chain to the rear covered preferably with

a scabard.

2. Before transporting in any vehicle orstodng in

any enclosure, allow your saw to cool com-

pistely, cover the bar and chain and properly se-

cureto avoid turnover, fuelspillageordamage.

3. Drain oiland fuel tank before storing for more ._

than 30 days.

4. Store in a dry area out of the reach of children

and away from where fuel vapors can reach an

open flame from hotwater heaters, furnaces, etc.

Exposure to vibrations through prolonged use of chain saws may produce Whitefinger disease (Raynaud's

phenomenon). This phenomenon reduces the hand's ability to feel and regulate temperature, produces

numbness and burning sensations and may cause nerve and circulation damage and tissue necrosis. An

anti-vibration system designed to reduce engine vibration is available on many Sears models and is

recommended for those using chain saws on a regular or sustained basis.

An anti-vibration system does not guarantee the avoidance of Whitefinger disease. Continual and regular

_ usersshould monitor closely their use of chain saws and physical condition.

4

KNOW YOUR CHAIN SAW

A. INTRODUCTION

The information found in this manual will help

you properly prepare your chain saw for use,

understand how to operate your saw safely, and

perform maintenance required to keep your unit

in top working condition

Your saw has been designed with safety in mindand

includes the following safety features as standard

equipment,

Spark Arrestor

Handguard

Counter-Vibe® Vibration System

Lo-KickcGuide Bar

Guard Link Chain

The chain saw should never be operated unless

these devices are properly instailed_on theunit.

The _-Kick_ Guide Bar and Guard Unk Chain have:

been designed to help reduce the hazard of

KICKBACK. You should thoroughly read and under-

stand the section, =CONTRO_ING KICKBACK" on

page 11 before operating the saw.

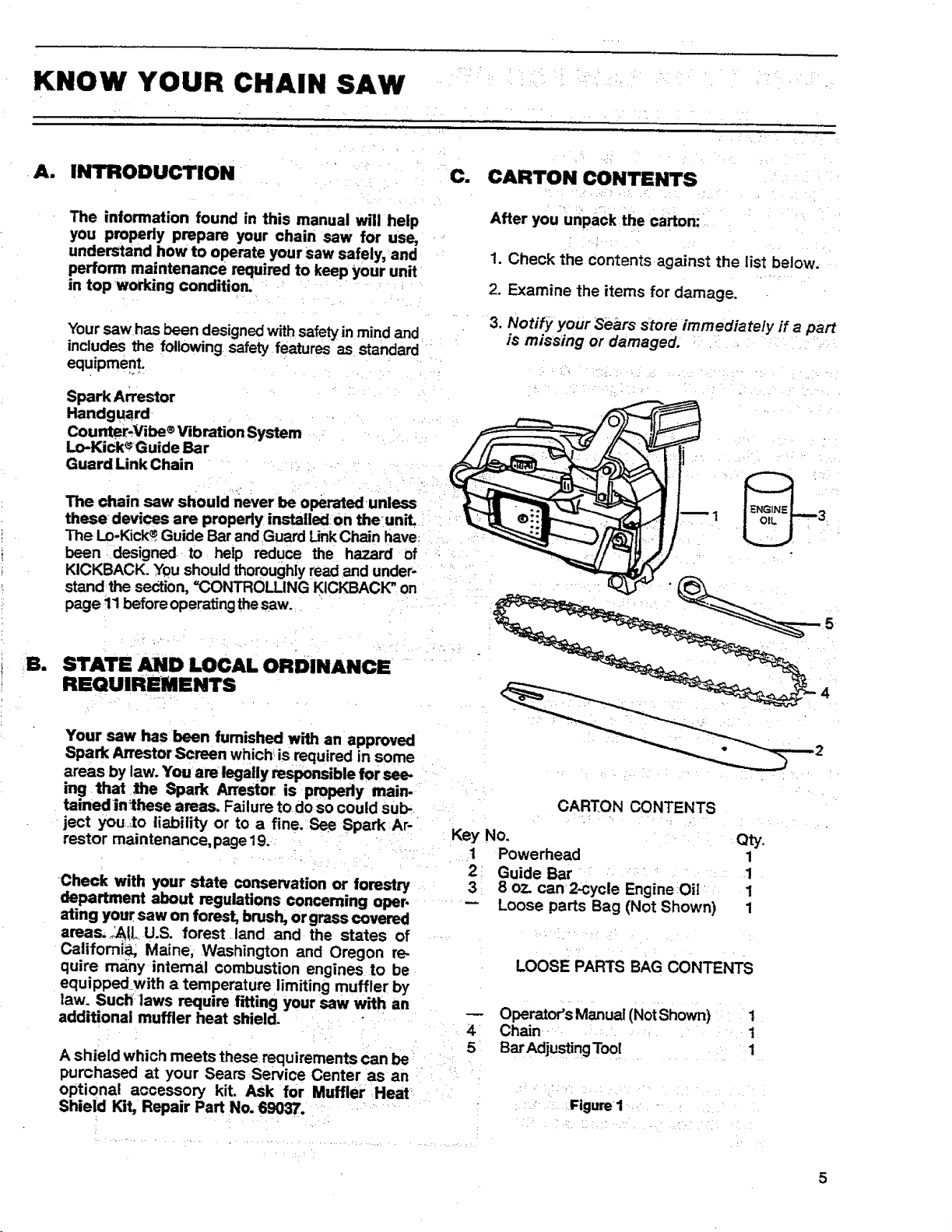

C. CARTON CONTENTS

After you unpack the carton:

1. Check the contents against the list below.

2. Examine the items for damage.

3. Notify your Sears store immediately ff a part

is missing or damaged.

Sm

STATE AND lOCAL ORDINANCE

REQUIREMENTS

Your saw has been furnished with an approved

Spark Arrestor Screen which is required in some

areas by law. You are legally responsible for see-

ing that the Spark Arrestor is propedy main-

tainedin_these areas. Failure todo so could sub,

ject you_to liability or to a fine. See Spark Ar-

restor maintenance, page 19.

Check with your state conservation or forestry

department about regulations concerning oper.

ating your saw on forest, brush, or grass covered

areas,_IL U.S. forest land and the states of

Califomi_ Maine, Washington and Oregon re-

quire many internal combustion engines to be

equippedwith a temperature limiting muffler by

law. Such laws require fitting your saw with an

additional muffler heat shield.

A shield which meets these requirements can be

purchased at your Sears Service Center as an

optional accessory kit. Ask for Muffler Heat

Shield Kit, Repair Part No. 69037.

• 0

CARTON CONTENTS

Key No. Qty.

1 Powerhead 1

2 Guide Bar 1

3 8 oz. can 2-cycle Engine.Oil 1

-- Loose parts Bag (Not Shown) 1

LOOSE PARTS BAG CONTENTS

Operator's Manual (Not Shown) 1

4 Chain 1

5 BarAdjustingTool 1

FigureI

5

PREPARING YOUR SAW FOR USE

A. GEl"rING READY ......... _ 2. HAVE THE FOLLOWING AVAILABLE:

1, READ YOUR OPERATOR'S a. Protective gloves

CAREFULLY.

Your Operator's Manual has been developed

to help you prepare your saw for use and to

understand its safe operation. It is important

that you read your manual completely to

become familiar with =the unit before you

begin assembly.

MANUAL

b. Approved, markedfuel container

.... c. One gallon regulargasoline

d. One-half pint, 2-cycle, air-cooled engine oil

provided withyour unit.

e. Barand Chain Lubricant (see page 9.)

f. Bar Adjusting Tool provided with your unit.

One end of the tool serves as a wrench; the

other can be used as a screwdriver. No other

too! isnecessary for assembly.

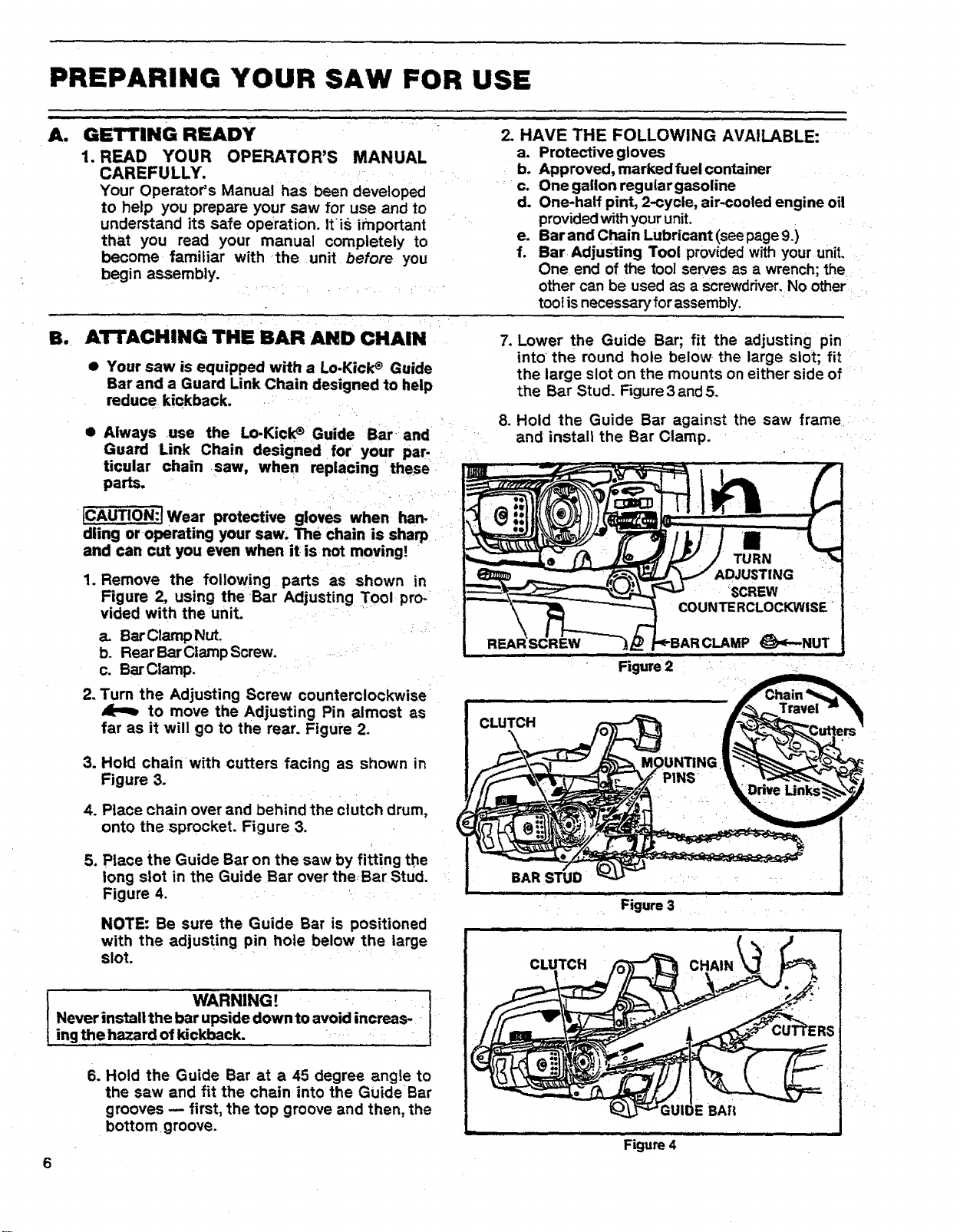

B. ATTACHING THE BAR AND CHAIN _

• Your saw is equipped with a Lo.Kick _ Guide

Bar and a Guard Link Chain designed to help

reduce kickback. ._

• Always use the Lo-Kick_ Guide Bar, and r _ ,

Guard Link Chain designed for your par. .

ticular chain .saw, when replacing these

parts.

tCAUT!ON:{ Wear protective gloves when harv'

dling or operating your saw; The chain is sharp _

and can cut you even when it isnot moving!

1. Remove the following parts as shown in

Figure 2, using the Bar Adjusting T0olpro-,

vided with the unit. _

a. BarClamp Nut.

b. Rear BarCtamp Screw.

c. Bar Clamp.

2. Turn the Adjusting Screw counterclockwise

to move the Adjusting Pin almost as

far as it will go to the rear. Figure 2.

3. Hold chain with cutters facing as shown in

Figure 3.

7, Lower the Guide Bar; fit the adjusting pin

into the round hole below the large slot; fit

the large slot on the mounts on either side of

the Bar Stud. Figure 3and 5,

8. Hold the Guide Bar against the saw frame

and install the Bar Clamp.

II

Figure2

4.PlacechainoverandbehindtheCtutchdrum,

onto the sprocket. Figure 3.

5. Place the Guide Bar on the saw by fitting the

long slot in the Guide Bar over the Bar Stud.

Figure 4.

NOTE: Be sure the Guide Bar is positioned

with the adjusting pin hole below the large

slot.

Never install the bar upside down to avoid increas-

I WARNING! _1

ing the hazard of kickback. =.......

6. Hold the Guide Bar at a 45 degree angle to

the saw and fit the chain into the Guide =Bar

grooves -- first, the top groove and then, the

bottom groove.

6

BARSTUD

. r!ll ,, i i

. Figure 3

Figure 4

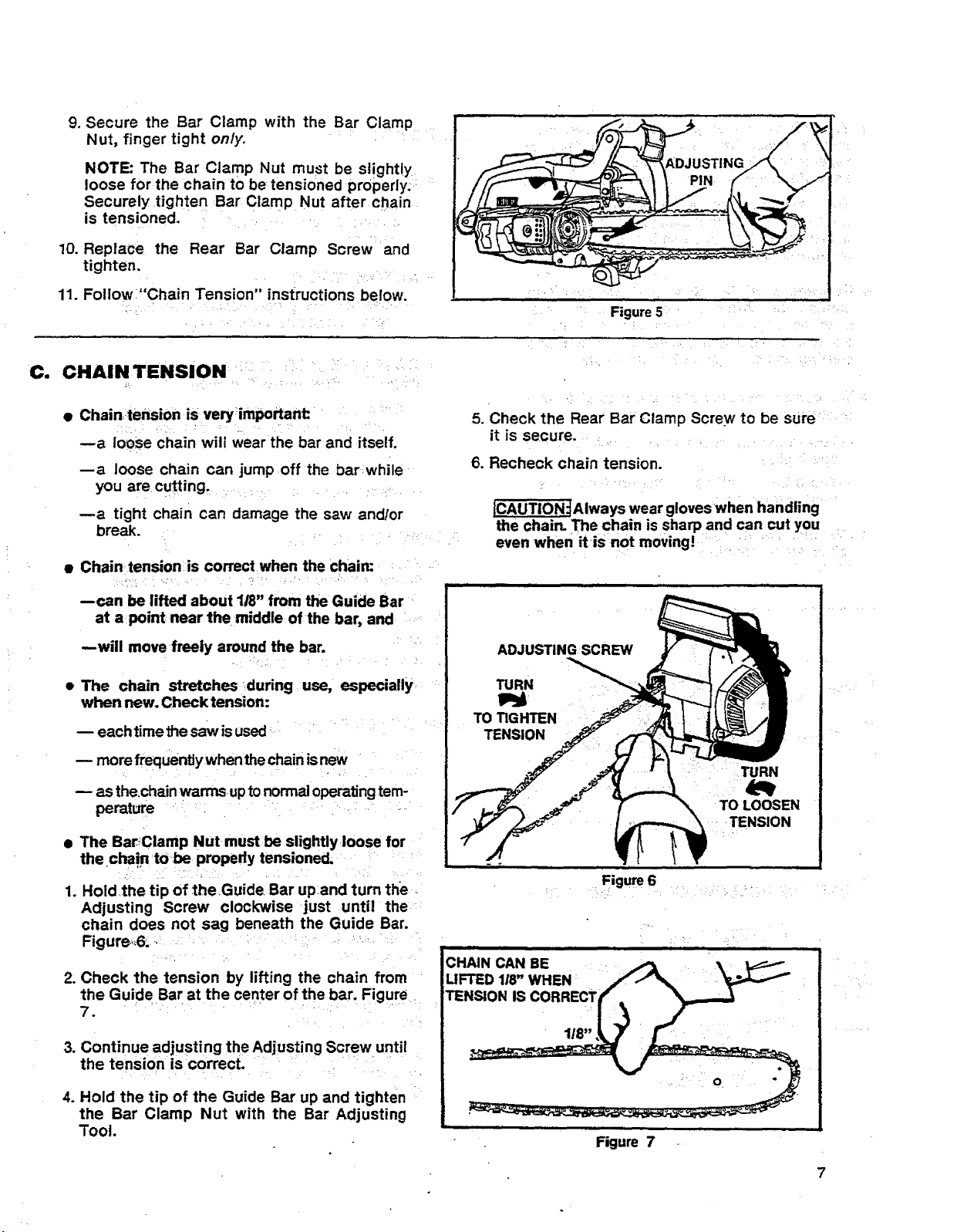

9. Secure the Bar Clamp with the Bar Clamp .....

Nut, finger tight only,

NOTE: The Bar Clamp Nut must be slightly

loose for the chain to be tensioned properly::

Securely tighte n Bar Clamp Nut after chain

is tensioned. . :.

10.

Replace. the Rear Bar Clamp Screw and

tighten.

11.

Follow:"Chain Tension" instructions below.

C.

Figure 5

• Chaintension is very important: _

loose chain will wear the bar and itself,

--a loose chain can jump off the barwhile

you are cu:tting. • , .1.

--a tight chain can damage the saw andlor

break.

• Chain tension is correct when the chain: :_

--can be lifted about 1/8" from the Guide Bar

at a point :near the middle of the bar, and ..... '

--will move-freely around the bar.

• The chain stretches during use, especially

when new. Checktension:

-- each time the saw is used, .... _

-- more frequentJywhen the chainis new

as the,chain warms upto normal operating tem-

perature " ' , .....' _ _._

• The Bar,Clamp Nut must be slightlyloose for

the chain to be propedy tensioned. _

1. Hold the tip of the Guide Bar upand turn the L

Adjusting Screw clockwise just until the

chain does not sag beneath the Guide Bar.

Figure_6._._ _ _ • ' __ •_

2. Check the tension by lifting the chain from '

the Guide Bar at the center of the bar. Figure

5. Check the Rear Bar Clamp Screw to be sure

it is secure.

6. Recheck chain tension.

JcAUTION__Always wear gloves when handling

the chain. The chain is sharp and can cut you

even when iris not moving!

TURN

TO LOOSEN

TENSION

Figure6

i

CHAIN CAN BE

LIFTED 118"WHEN

TENSION

3. Continue adjusting the Adjusting Screw until

the tension is correct, ...... = _

4. Hold the tip of the Guide Bar up and tighten :

the Bar Clamp Nut with the Bar Adjusting

Tool.

118"

o

illlllllqlllllllll fl

Figure 7 -

7

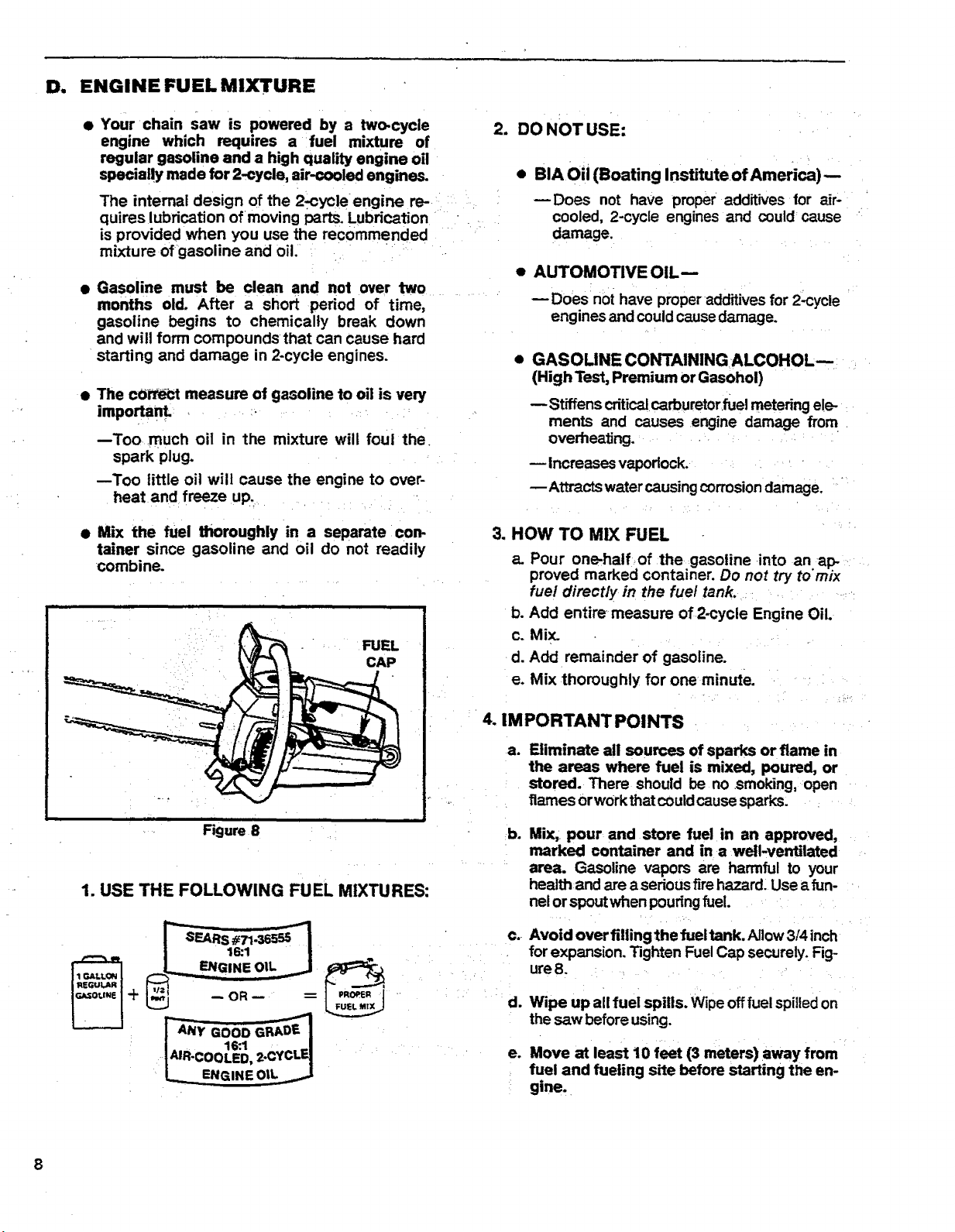

11 ENGINE FUEL MIX"rURE

• Your chain saw is powered by a two-cycle

engine which requires a fuel mixture of

regular gasoline and a high quality engine oil

specially made for 2,cycle, air-cooled engines.

The internal design of the 2_ycleengine re-•

quires lubrication of moving parts. Lubrication

is provided when you use the recommended

mixture of gasoline and oil.

• Gasoline must be clean and not over two

months old. After a short period of time,

gasoline begins to chemically break down

and will form compounds that can cause hard

starting and damage in 2-cycle engines.

The c0_t measure of gasoline to oil is very

importanL

--Too much oil in the mixture will foul the

spark plug.

--Too little oil wilt cause the engine to over-

heat and freeze up_

• Mix the fuel thoroughly in a separate con-

tainer since gas, line and oil do not readily

combine.

FUEL

CAP

2. DO NOT USE:

• BIA Oil (Boating InstituteofAmeHca)--

--Does not have proper additives for aiP

cooled, 2-cycle engines and could cause

damage.

• AUTOMOTIVE OIL--

k

-- Does not have properadditives for 2-cycle

engines and could causedamage.

• GASOLINE CONTAINING ALCOHOL--

(High Test, Premium or Gasohol)

Stiffens criticalcarburetorfuel metering ele-

ments and causes engine damage from

overhealJng.

Increases vaporiock.

_ Attracts water causingcorrosiondamage.

3. HOW TO MIX FUEL

a. Pour one-half of the gasoline into an ap-

proved marked container. Do not try tomix

fuel directly in the fuel tank.

b. Add entire measure of 2-cycle Engine Oil.

c. Mix.

d. Add remainder of gasoline.

e. Mix thoroughly for one minute.

Figure 8

1. USE THE FOLLOWING FUEL MIXTURES:

""_RS #,1._=ss_""1

ls:1 /

_ .__e_G,NEO,L ....J _

-}" __ --OR-- =

._ 16:1 .... I

R-coo o,2.cYcL !

ENGINE OIL_,.,,J

8

4. IMPORTANT POINTS

a.

Eliminate all sources of sparks or flame in

the areas where fuel is mixed, poured, or

stored. There should be no smoking, open

flames or workthat couldcause sparks.

b°

Mix, pour and store fuel in an approved,

marked container and in a well-ventilated

area. Gasoline vapors are harmful to your

health and are a serious firehazard. Use afun-

nel orspoutwhen pouringfuel.

c. Avoid over filling the fuel tank. Allow3/4 inch

for expansion. Tighten FuelCap securely. Fig-

ure8.

d.

Wipe up all fuel spills. Wipe offfuel spilledon

the saw before using.

e.

Move at least 10 feet (3 meters) away from

fuel and fueling site before starting the en-

gine.

E, BARAND CHAIN OIL

e The guide bar and cutting chain require con.

stant lubrication in order to remain in

operating condition. Lubrication is provided

by the automatic oiler system when,the oil

tank is kept filled.

--Lack of oil will quickly ruin the bar and

chain.

--Too little oil will cause overheating shown

by smoke coming from the chain and/or

discoloration Of the guide bar rails.

Use Sears Bar and Chain Lubricant #71-36554

or clean SAE 30W oil.

e

In freezing weather oil wiU thicken, making it

necessary to thin bar and chain oil.with a

smaflamount of Diesel Fuel #1 or Kerosene.

Bar and chain oil must be free flowing for the

oil system to pump enough oil for adequate

lubrication.

lo USE THE FOLLOWING:

30°F or above--Lubricant--undiluted.

30°F!-0°F --95% Lubricant to

5% Diesel Fuel #1

or Kerosene.

Below 0°F --90% Lubricant to

10% DieseiFuet #1

or Kerosene.

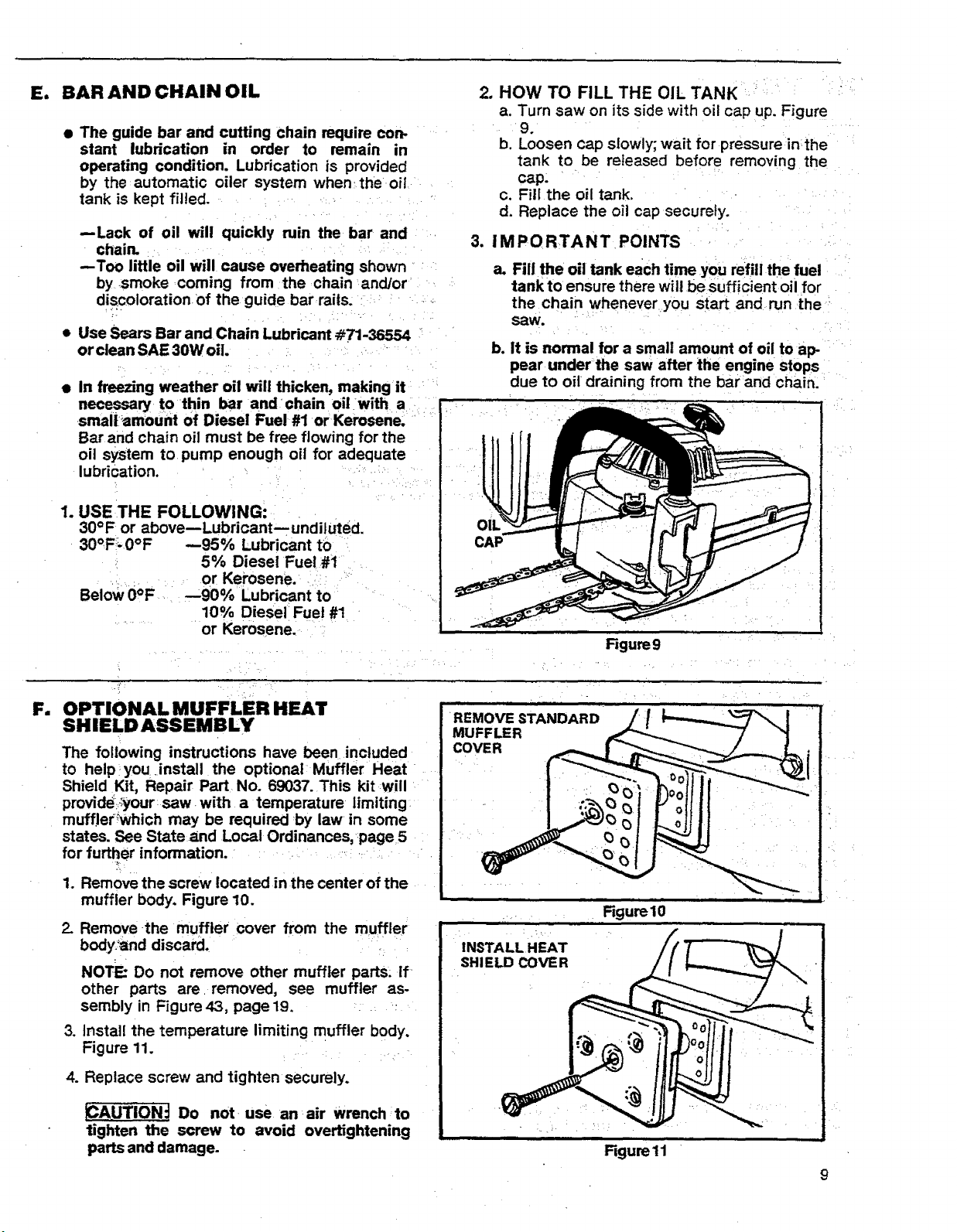

2. HOW TO FILL THE OIL TANK

a. Turn saw on its side with oil cap UP.Figure

9.

b. Loosen cap slowly; wait for pressure in the

tank to be released before removing the

cap.

c. Fill the oil tank.

d. Replace the oil cap securely.

3. IMPORTANT POINTS

a. Fill the oil tank each time you refill the fuel

tank to ensure there will be sufficient oil for

the chain whenever you start and run the

saw.

b. It is normal for a small amount of oil to ap-

pear under the saw after the engine stops

due to oil draining from the bar and chain.

CAP

Figure9

Fal OPTIONAL MUFFLER HEAT

SHIELDASSEMBLY

The following instructions have been included

to help you install the optional Muffler Heat

Shield Kit, Repair Part No. 69037. This kit will

provid_;your saw with a temperature limiting

mufflet'_which may be required by law in some

states. See State and Local Ordinances, page5

for furtl_er information.

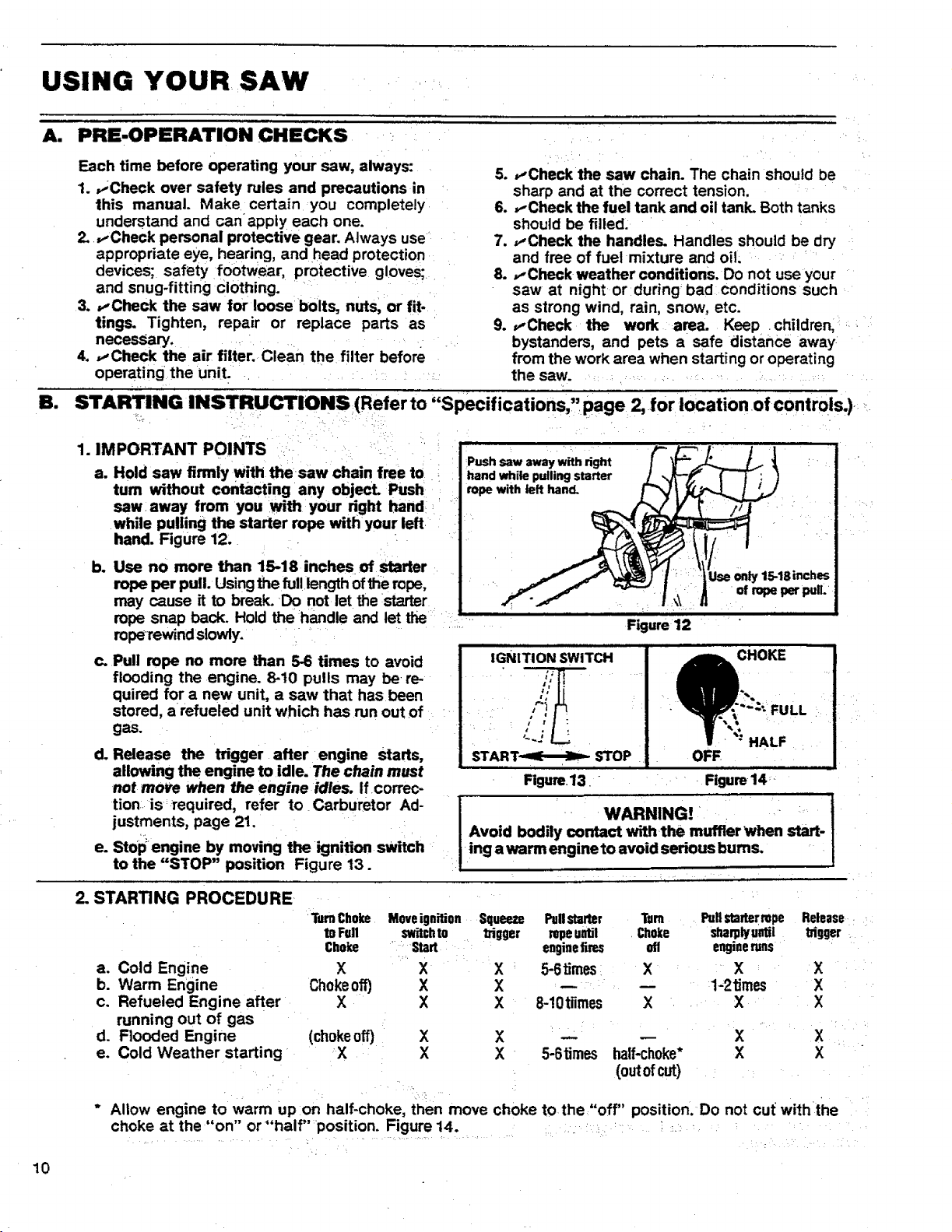

1. Remove the screw located in the center of the

muffler body. Figure 10.

2_3.Remove the muffler cover from the muffler

body/and discard.

NOTE: Do not remove other muffler parts, if

other parts are removed, see muffler as-

sembly in Figure 43, page 19.

install the temperature limiting muffler body.

Figure 11.

4. Replace screw and tighten securely.

_--AUTIO--O-N-_Do not use an air Wrench to

tighten the screw to avoid overtightening

parts and damage.

Figure11

USING YOUR SAW

Am

PRE-OPERATION CHECKS _=

Each time before operating your saw, always:

1. ,_Check over safety rules and precautions in

this manual. Make certain you completely

understand and can apply each one.

2. ,,,Check personal protective gear. Always use

appropriate eye, hearing, and head protection

devices; safety footwear, protective gloves;

and snug.fitting clothing.

3. ,,,Check the saw for loose bolts, nuts, or fit-

tings. Tighten, repair or replace parts as

4. ,,,Check the air filter. Clean the filter before

operating the unit.

am

STARTING INSTRUCTIONS (Refer to

1. IMPORTANT POINTS

a. Hold saw firmly with thesaw chain free to

turn without contacting any object. Push

saw away from you with your dght hand

while pulling the starter rope with your left

hand. Figure 12.

b.

Use no more than 15-18 inches of starter

rope per pull. Usingthe fulllength oflhe rope,

may cause it to break. Do not let the starter

rope snap back. Hold the handle and let the

roperewind slowly.

C.

Pull rope no more than 5-6 times to avoid

flooding the engine. 8-10 pulls may be re-

quired for a new unit, a saw that has been

stored, a refueled unit which has run out of

gas.

d.

Release the trigger after engine starts,

allowing the engine to idle. The chain must

not move when the engine idles. If correc-

tion is required, refer to Carburetor Ad-

justments, page 21.

e.

Stop engine by moving the ignition switch

to the "STOP" position Figure 13.

=

,_'Check the saw chain. The chain should be

• 6.

sharp and at the correct tension.

,,-Check the fuel tank and oil tank. Both tanks

should be filled.

7.

,,,Check the handles. Handles should be dry

and free of fuel mixture and oil.

8.

,,-Check weather conditions. Do not use your

saw at night or during bad conditions such

as strong wind, rain, snow, etc.

g°

,,'Check the work area. Keep children,

bystanders, and pets a safe distance away

from the work area when starting or operating

the saw.

"SpecificaUons,,' page 2, for location of controls.)

Use only 15-18 inches

of rope Per Pull.

Figure 12

I F"''

I !

START-_P_I=- STOP | OFF

Figure13 Figure14

WARNING!

Avoid bodily contact with the muffler When start-

ing a warm engine to avoid serious bums.

, ,. J

2. STARTING PROCEDURE

a. Cold Engine

b. Warm Engine

c. Refueled Engine after

running out of gas

d. Flooded Engine

e. Cold Weather starting

" Allow engine to warm up on half-choke, then move choke tothe "off" position. Do not cut with the

choke at the "on" or "'half" position. Figure 14.

10

TurnChoke Moveignition Squeeze Pullstarter Tam Pullstarterrope

toFull switchto trigger ropeuntil Choke sharplyuntil

Choke Start eaginefires off engineruns

X X X 5-6times X X

Chokeoff) X X 1-2times

X X X 8-!0tiimes X X

(chokeoff) X X -- -- X X

X X X 5-6times half-choke* X X

Release

trigger

(out0fcut)

X

X

X

Loading...

Loading...